Juki CP180 Parts Book

CP-180

校正用

取扱説明書

/パーツリスト

INSTRUCTION MANUAL / PARTS LIST

BETRIEBSANLEITUNG MANUEL D’UTILISATION

MANUAL DE INSTRUCCIONES

使用说明书

MANUALE D’ISTRUZIONI

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

KULLANMA KILAVUZU

注意: このたびは、当社の製品を、お買い上げいただきまして、有難うございました。

安全に使用していただくために、使用前に必ずこの取扱説明書をお読みください。

また、いつでもすぐに読めるように、この取扱説明書を保管してください。

NOTE : Read safety instructions carefully and understand them before using.

Retain this Instruction Manual for future reference.

HINWEIS : Lesen Sie die Sicherheitsanweisungen aufmerksam durch, um sich mit ihnen vertraut

zu machen, bevor Sie diese Maschine in Betrieb nehmen. Bewahren Sie diese

Bedienungsanleitung für spätere Bezugnahme auf.

NOTE : Avant d’utiliser la machine, lire attentivement toutes les consignes de sécurité.

Conserver ce manuel pour pouvior le consulter en cas de besoin.

NOTA : Antes de comenzar a usar esta máquina lea con detención hasta comprender todas las

instrucciones de sequridad. Conserve este Manual de instrucciones a mano para futuras

consultas.

NOTA : Leggere attentamente e compredere tutte le istruzioni per la sicurezza prima di inziare l’ uso

di questa macchina. Conservare questo Manuale d’Instruzioni per pronto riferimento.

注意 :

另外,请您注意保管本使用说明书,以便随时查阅。

ЗАМЕЧАНИЯ : Внимательно прочитайте и усвойте правила техники безопасности перед использованием швейной

NOT : Güvenlik talimatını dikkatle okuyun ve makineyi kullanmadan önce tümüyle öğrenin.

Gelecekte de yararlanmak için, bu kullanma kılavuzunu muhafaza edin.

为了安全地使用,请您在使用之前一定阅读本使用说明书。

машины. Сохраните эту инструкцию по эксплуатации для того, чтобы обращаться к ней и в будущем.

No.1528-00

40088353

校正用

日本語

校正用

日本語

目 次

校正用

1. コントロールパネルの取り付け....................................................................................... 1

2. コードの接続...................................................................................................................... 1

3. 各部の説明.......................................................................................................................... 2

4. 頭部設定方法...................................................................................................................... 2

5. 頭部調整(ダイレクトモータ方式のミシンのみ)........................................................... 3

6. 操作パネルの説明............................................................................................................... 4

7. 各種縫いパターンの操作方法........................................................................................... 5

8. ワンタッチ設定について................................................................................................... 9

9. 生産支援機能について....................................................................................................... 9

10. 下糸カウンタの使い方.................................................................................................... 12

11. 糸切りカウンタの使い方................................................................................................ 13

12. 半針補正スイッチについて............................................................................................ 13

13. キーロック機能について................................................................................................ 14

14. 布端センサ ON / OFF スイッチ

15. 自動糸切りスイッチ

16. ワンショット自動縫いスイッチ

17. 糸切り禁止スイッチ

18. 機能設定スイッチについて............................................................................................ 15

19. オプション入出力設定について.................................................................................... 16

20. ペダルセンサ中立自動補正............................................................................................ 18

21. 自動押え上げ機能選択方法............................................................................................ 18

22. 機能設定データの初期化方法........................................................................................ 19

23. エラーコードの確認方法................................................................................................ 19

について................................................................................. 14

について................................................................................. 15

について........................................................... 14

について............................................................. 14

- i -

本取扱説明書はコントロールパネル CP-180 についての説明書です。

校正用

事前にコントロールボックス取扱説明書の「安全についての注意事項」を読み、十分理解の

注意

上でご使用ください。

また、本製品は精密機器のため、水や油をかけたり、落下させるなどの衝撃を与えないよう

に取扱いには十分注意をお願いします。

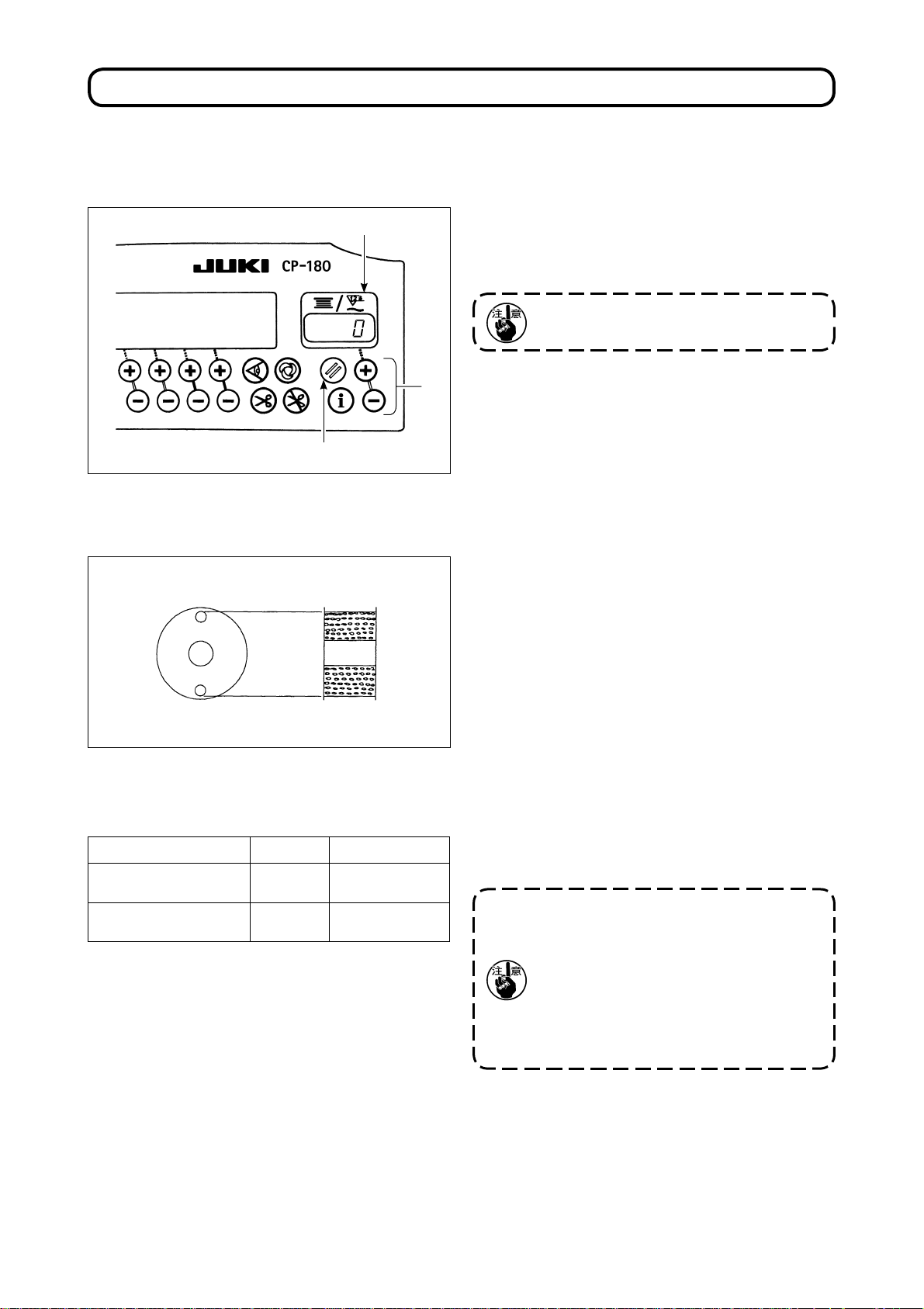

1.コントロールパネルの取り付け

日本語

注意

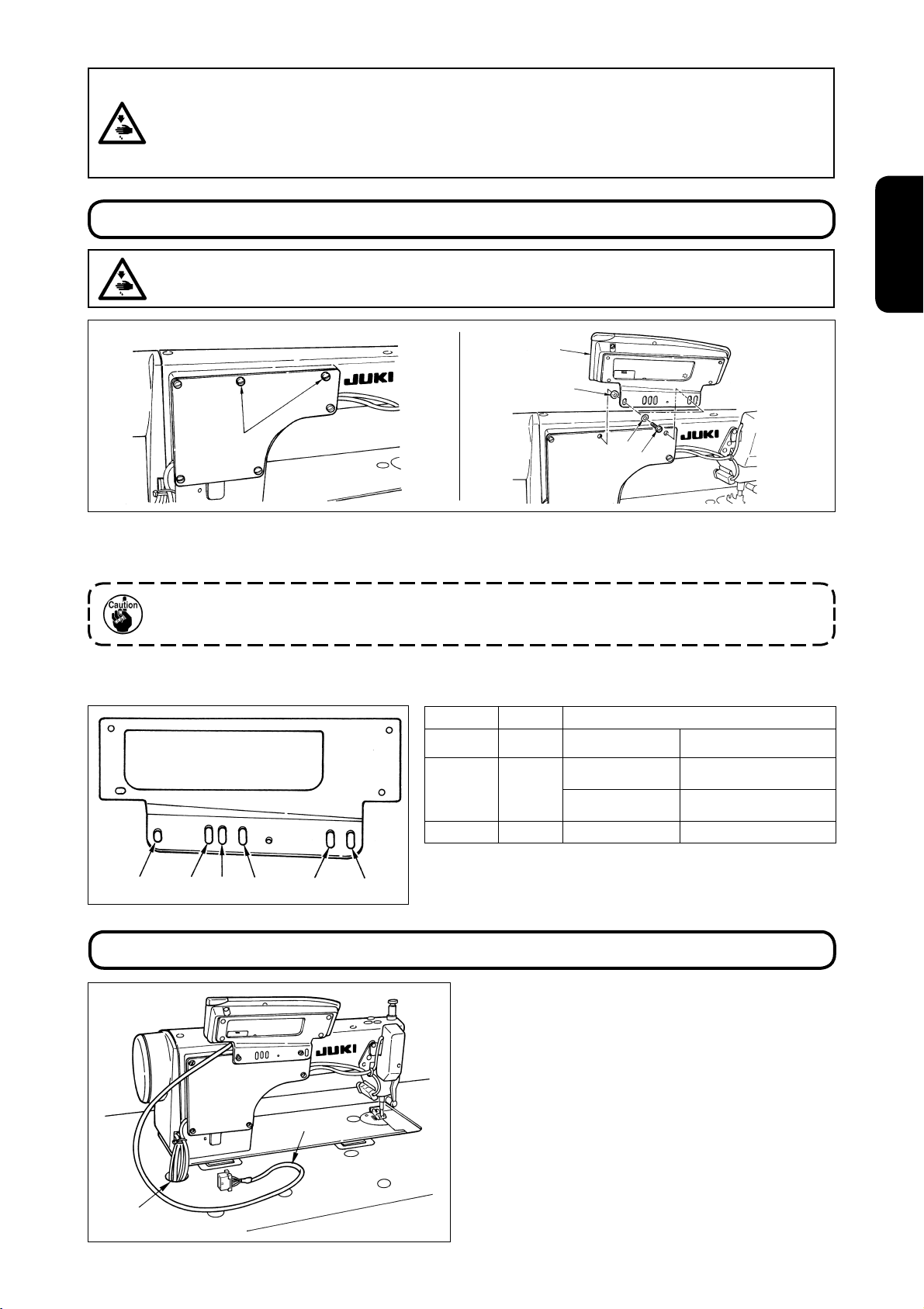

1) 窓板止めねじ1を窓板より取り外します。

2) コントロールパネル2を、パネル付属のねじ5・平座金3・およびゴム座4を使用して頭部に取り

付けます。

1.取付け方法は DDL-9000B(AK 無し)を例にしています。

2.頭部によってパネル取付けのねじが変わります。表 1 を参照し、ねじの種類を確認してください。

<各頭部とブラケット取り付け穴位置>

不意の起動による事故を防ぐため、電源を切ってから行ってください。

2

4

1

表1

DDL-9000A

DDL-9000B

LH-3500A

取り付け穴 ねじ

-

1

-

1

-

2

3

5

5

5

5

M5 × 12 パネル付属ねじ

AK 付き M5 × 14 窓板ねじ

AK 無し M5 × 12 パネル付属ねじ

M5 × 14 窓板ねじ

1

23

4

2.コードの接続

A

56

1

1) コントロールパネルのコード1をテーブル穴

を通して、テーブルの下に通します。

A

2) コネクタの接続については、コントロールボッ

クスの取扱説明書を参照してください。

- 1 -

3.各部の説明

校正用

2

電源表示 LED:電源スイッチを ON すると点灯します。

1

最高速度制限ボリューム:左方向 ( ) へ動かすと最高速度が制限されます。

2

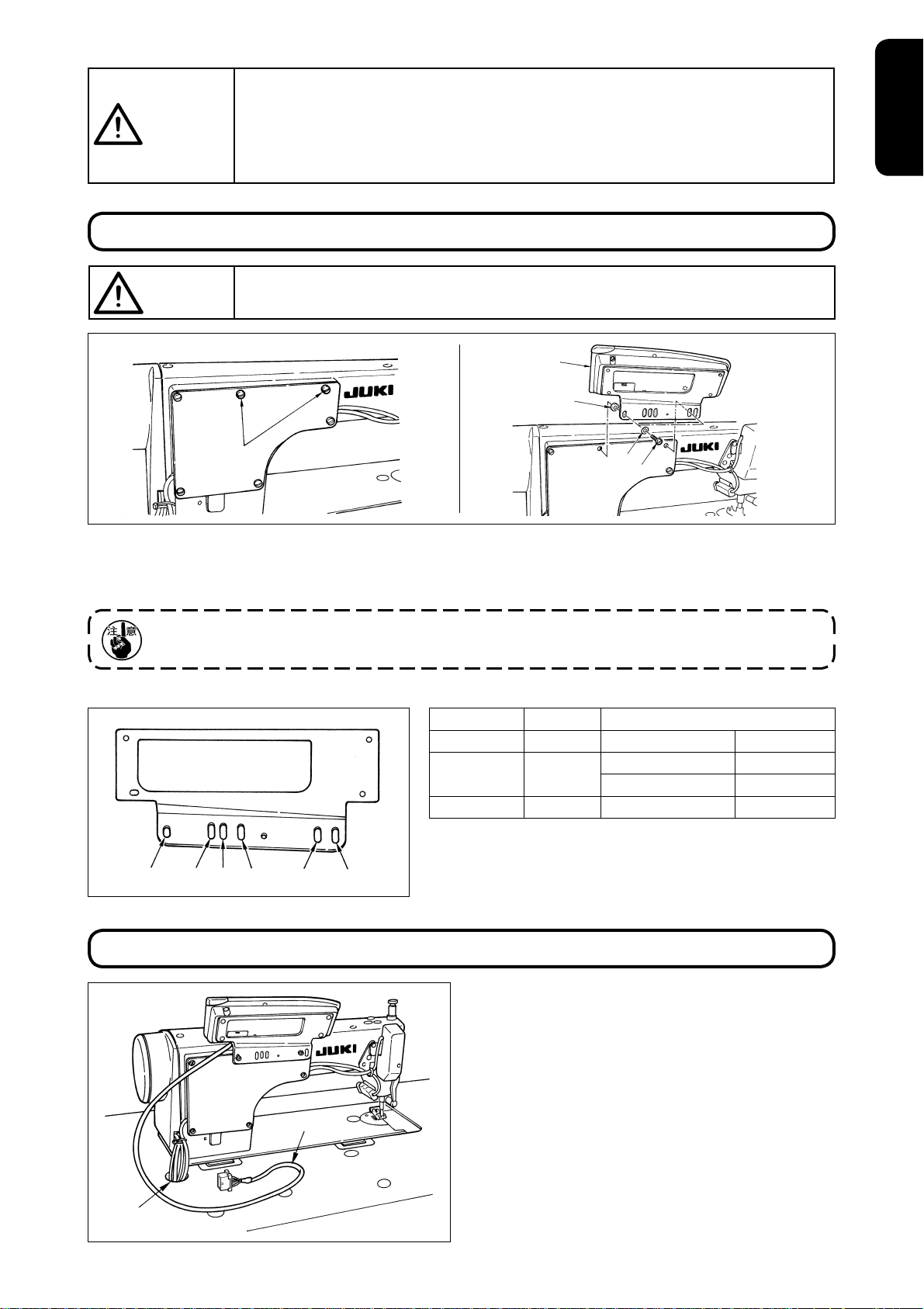

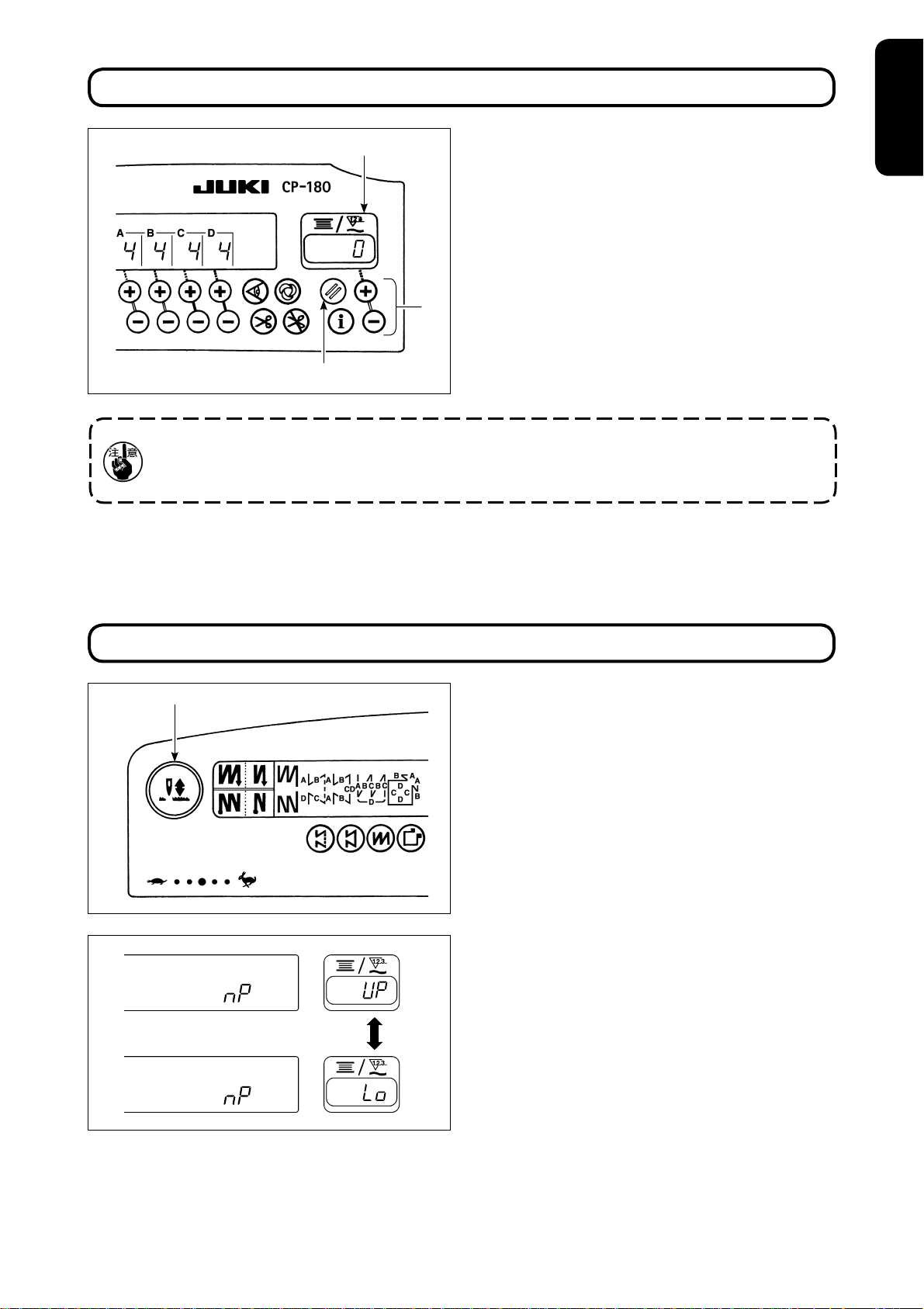

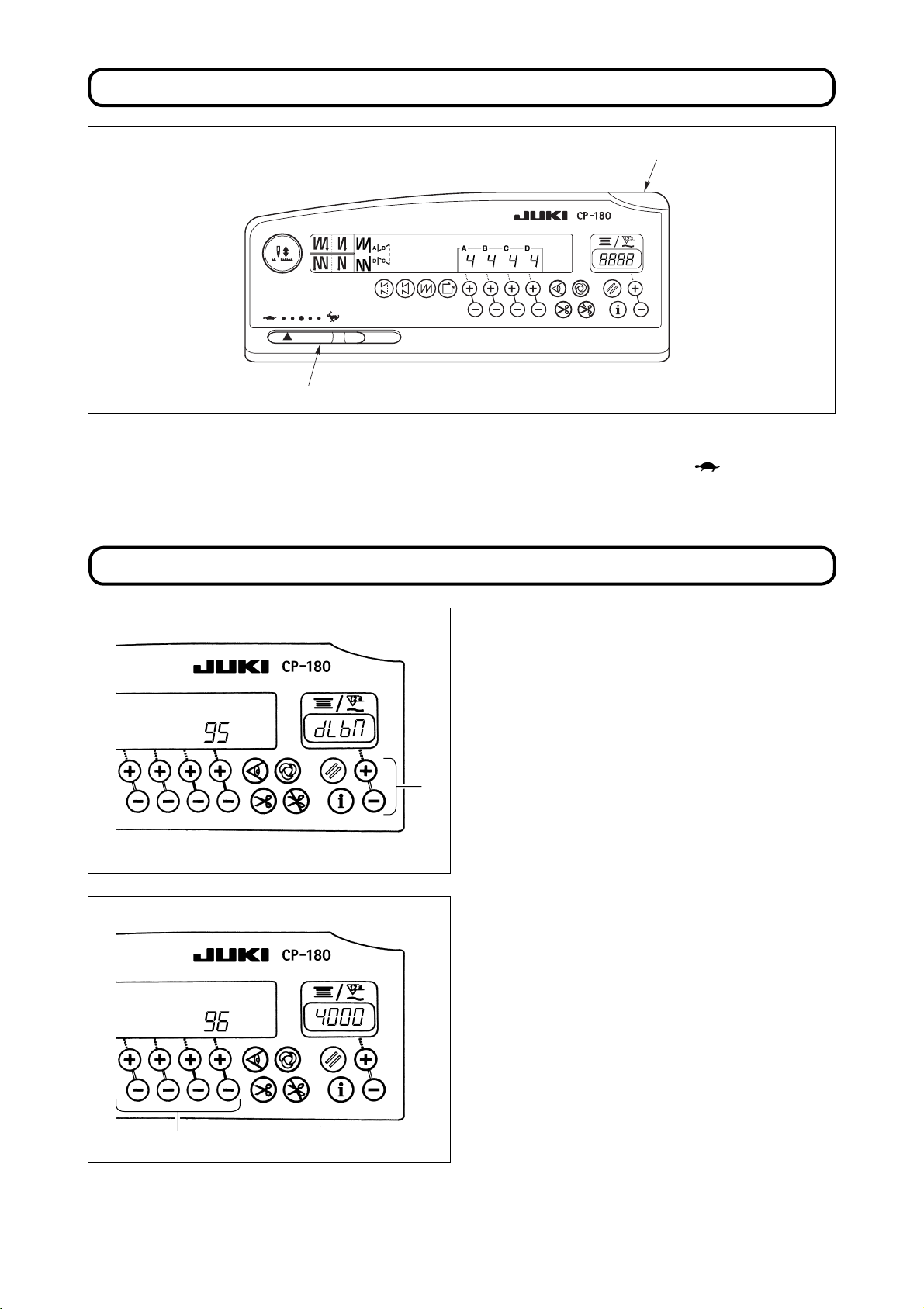

4.頭部設定方法

1

1

1)18.機能設定スイッチについてp.15 を参照

して機能設定 No.95 を呼び出します。

2) スイッチ1を押すことにより、頭部のタイプを

選択することができます。

※ 頭部のタイプは、別紙の「ミシンセットアップ

上の注意」または「頭部一覧表」を参照して下

さい。

3) 頭部タイプを選択後、スイッチ2を押すことに

よりステップが「96」または「94」に進み、

頭部タイプにあわせて設定内容が自動的に初期

化されます。

2

- 2 -

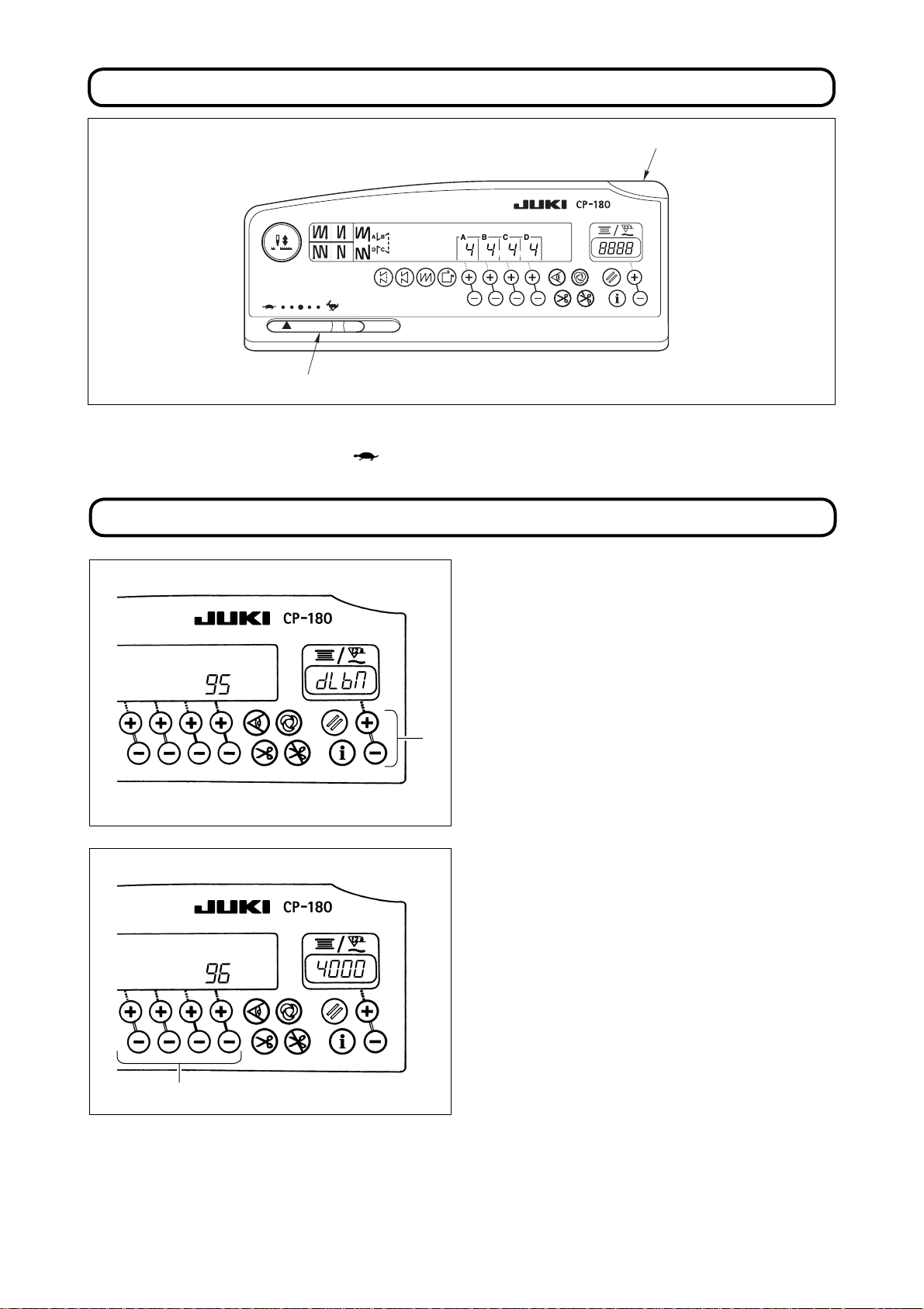

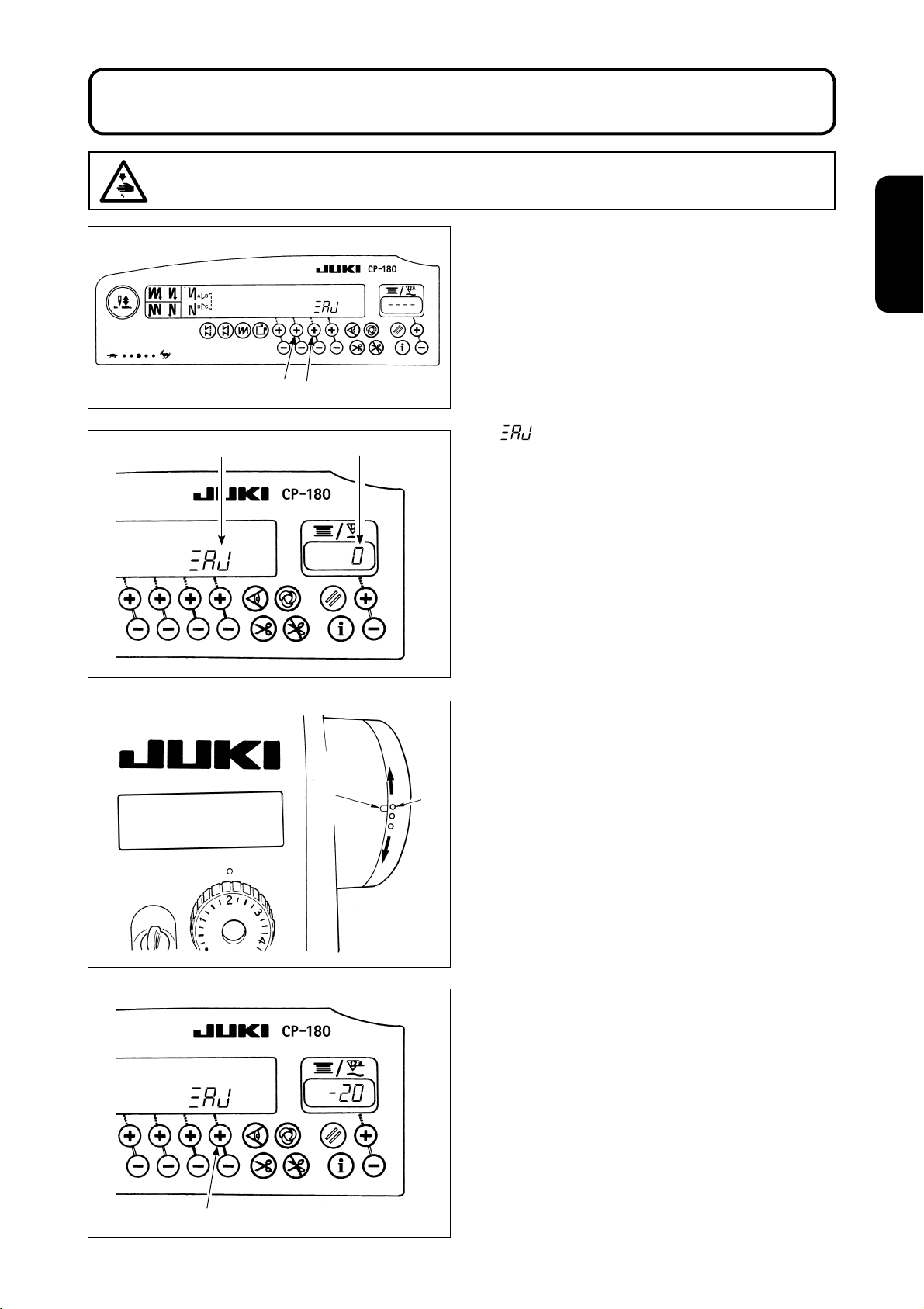

5.頭部調整(ダイレクトモータ方式のミシンのみ)

校正用

糸切り後にプーリの白点とカバーの凹みが大きくズレている場合は、下記の操作により頭部

注意

の角度調整を行ってください。

21

BA

1) スイッチ1とスイッチ2を同時に押しながら

電源スイッチをONします。

2) 表示部Aに と表示され頭部調整モードに

なります。

3) 頭部プーリを手で回して主軸基準信号を検出す

ると、表示部Bに主軸基準信号からの角度が表

示されます。

(値は参考値です。)

日本語

3

4) この状態でプーリの白点2とプーリカバーの凹

み3を図のように一致させます。

2

5) スイッチ4を押して調整作業は終了です。

(値は参考値です。)

4

- 3 -

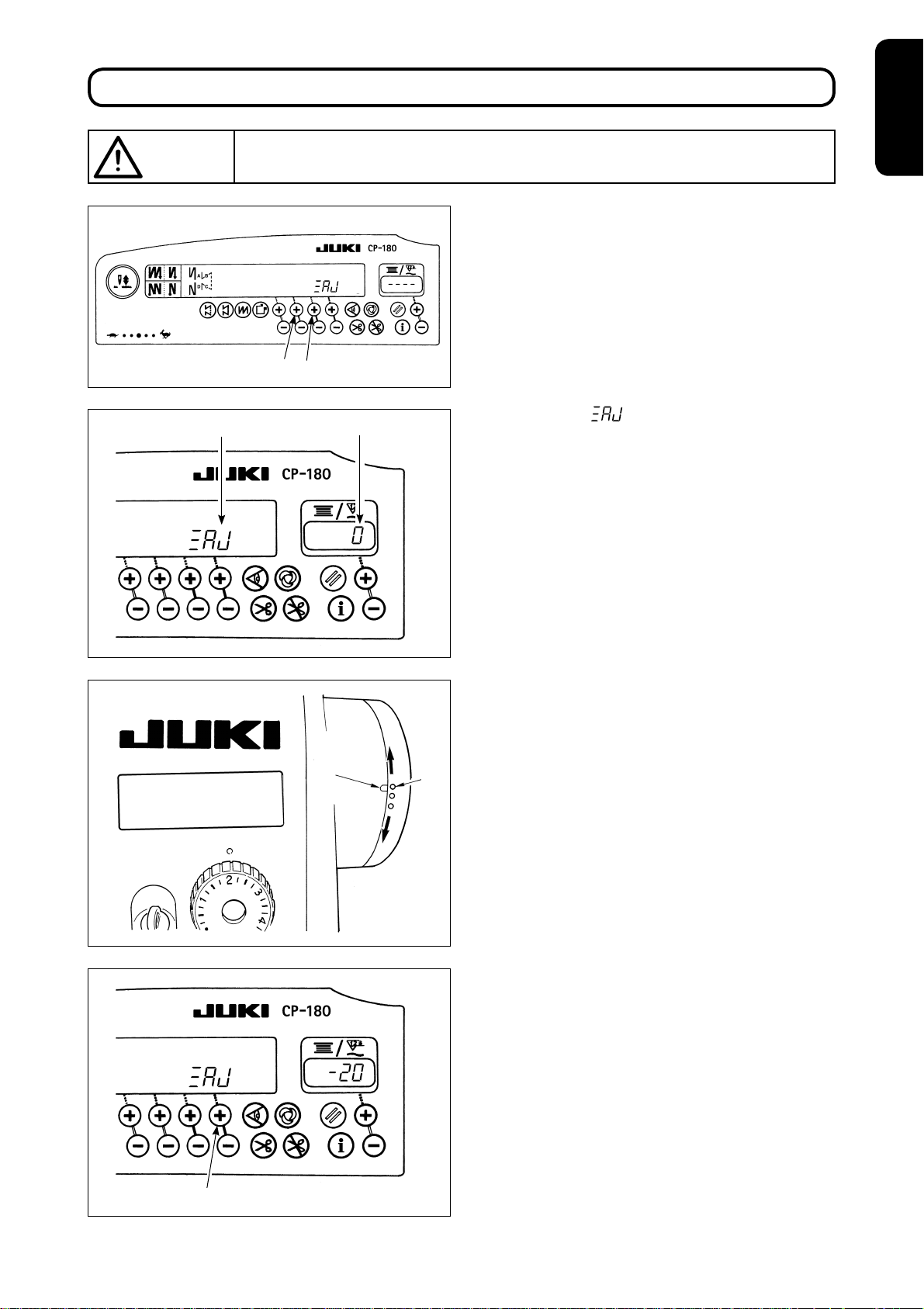

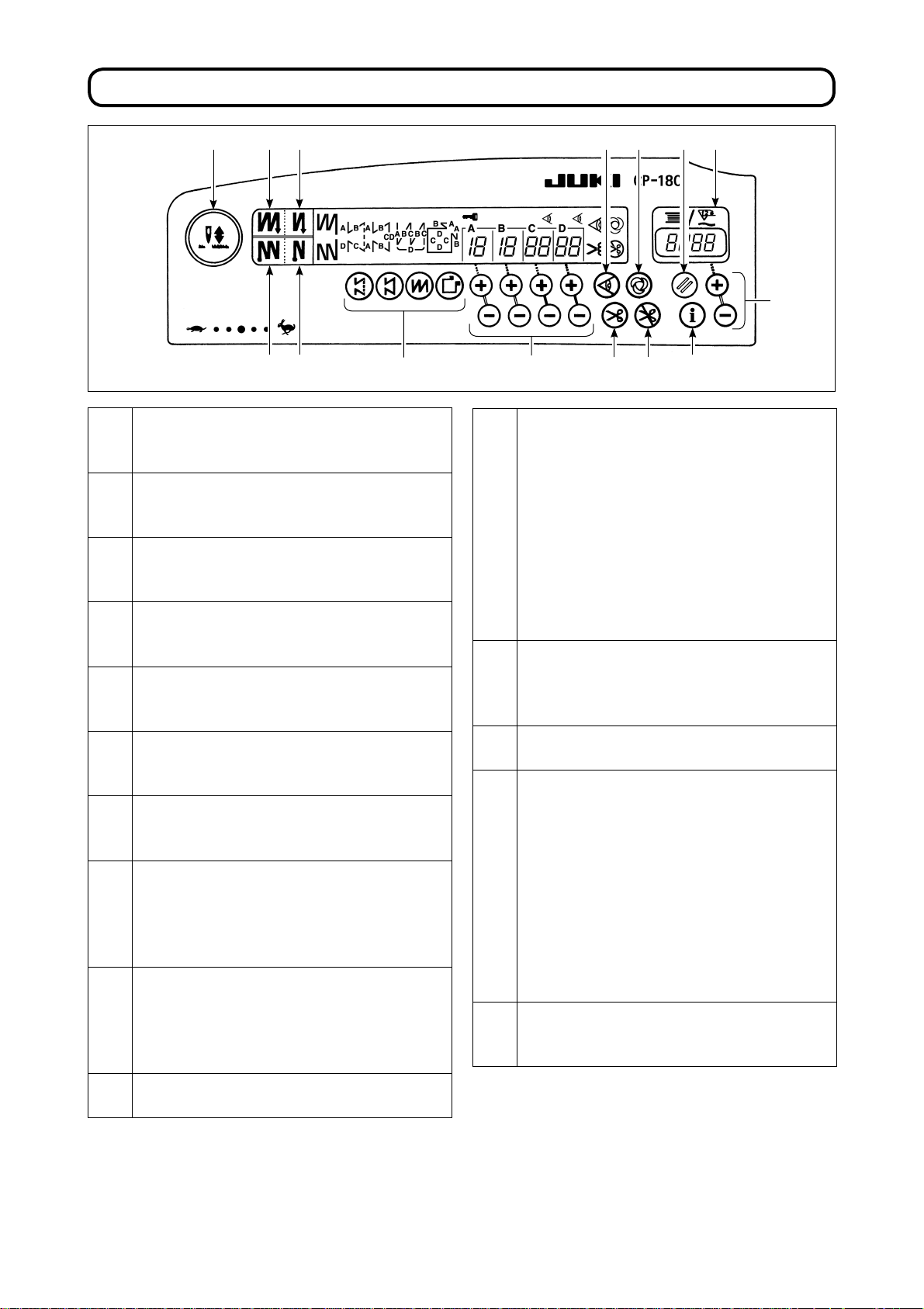

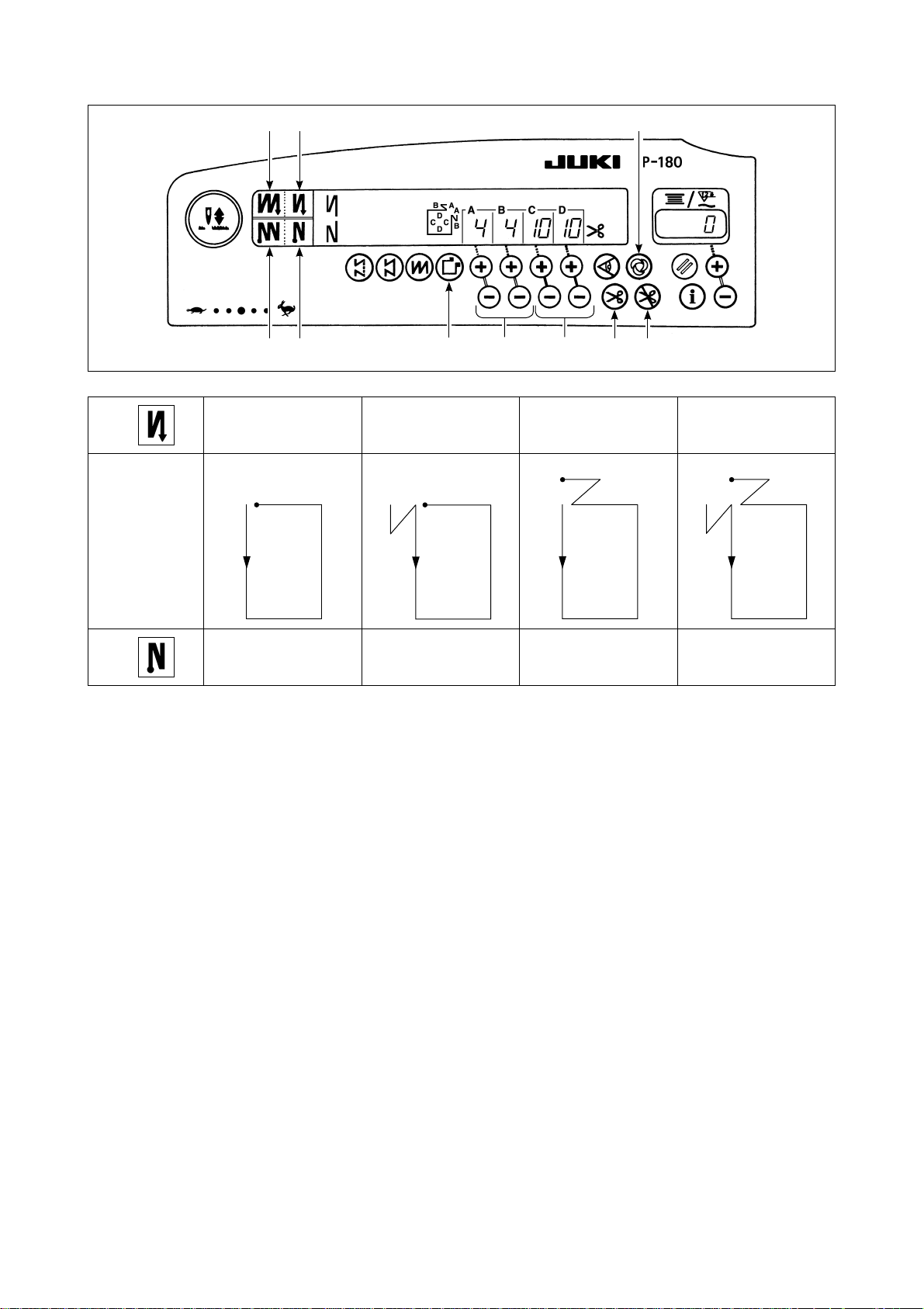

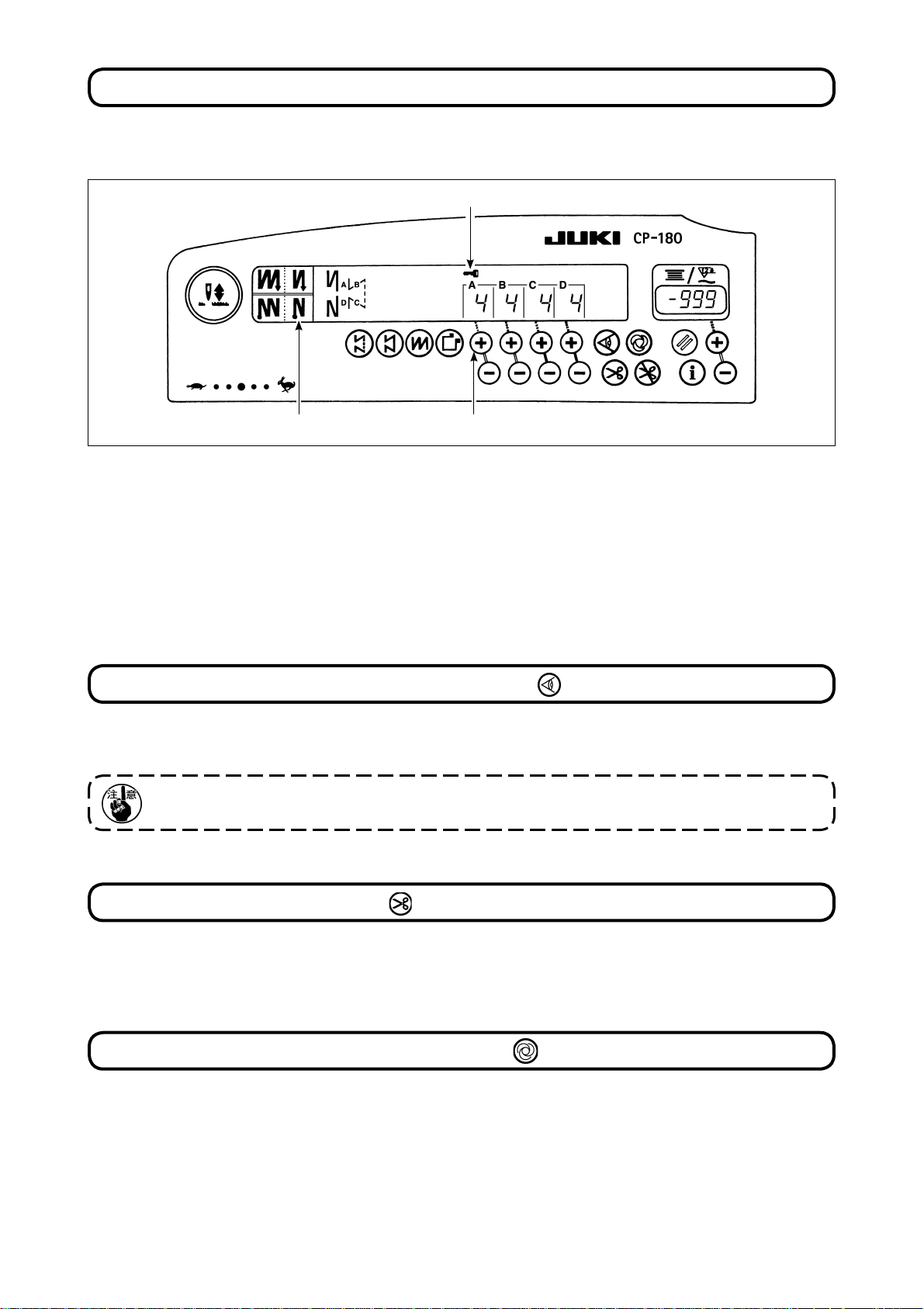

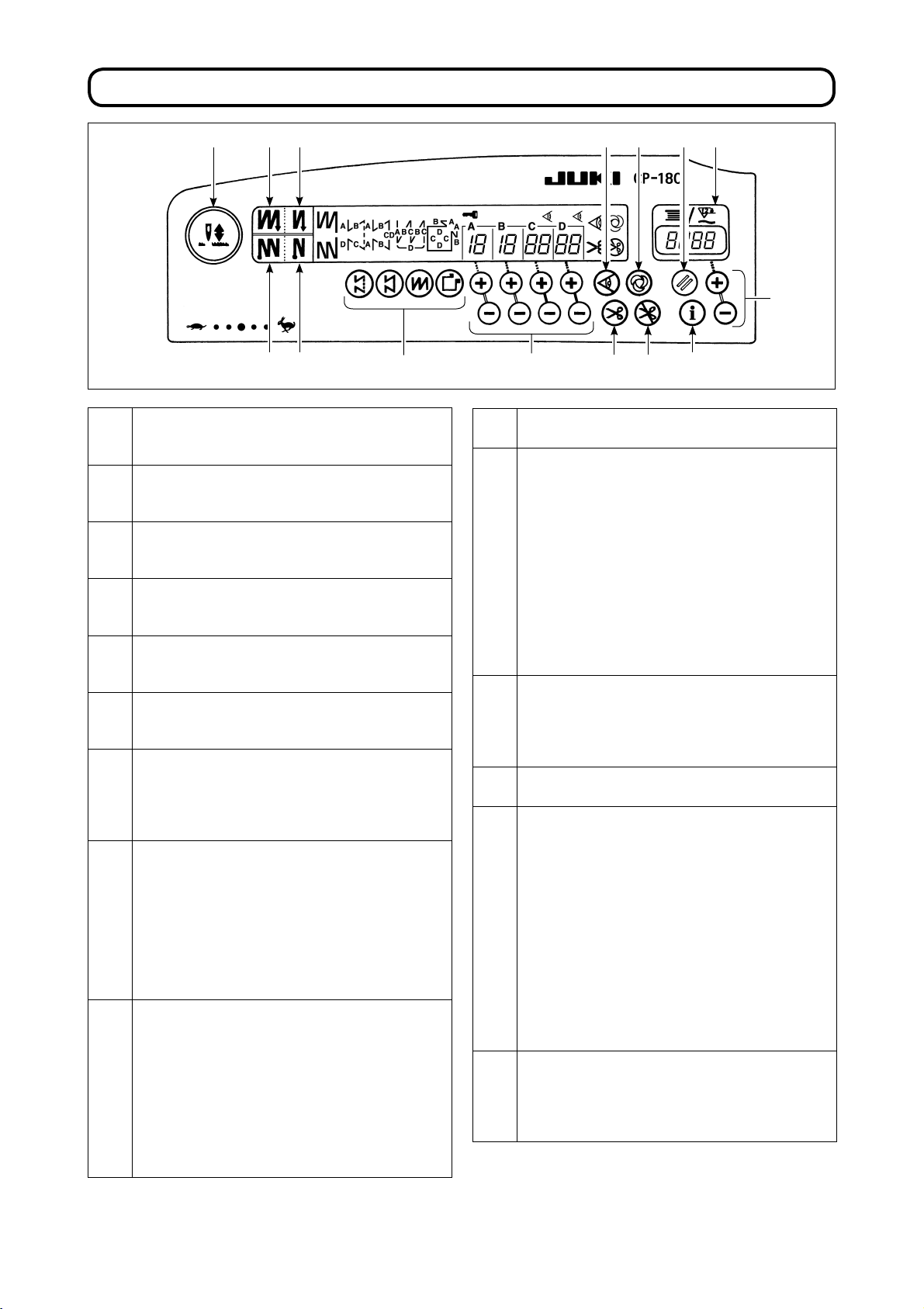

6.操作パネルの説明

校正用

!4

24 8

35

パターンの選択スイッチ

1

・4 種類のパターンを選択するためのスイッチ

です。

始め二重返し縫いスイッチ

2

・縫い始めの二重返し縫いを ON/OFF するため

のスイッチです。

終わり二重返し縫いスイッチ

3

・縫い終わりの二重返し縫いを ON/OFF するた

めのスイッチです。

始め自動返し縫いスイッチ

4

・縫い始めの自動返し縫いを ON/OFF するため

のスイッチです。

終わり自動返し縫いスイッチ

5

・縫い終わりの自動返し縫いを ON/OFF するた

めのスイッチです。

針数設定スイッチ

6

・A 〜 D の各工程の針数を設定するためのス

イッチです。

布端センサ ON/OFF スイッチ

7

・布端センサ取り付け時、有効となります。

・布端センサを使用する、しないを選択します。

ワンショット自動縫いスイッチ

8

・布端センサ取り付け時、定寸縫い時に有効と

なります。

・縫製をスタートすると布端検知、または、設

定針数までミシンを自動で動かします。

自動糸切りスイッチ

9

・布端センサ使用時、定寸縫い時に有効となり

ます。

・ペダル前踏みのままでも布端検知、または、

定寸縫いが終了すると糸切り工程に移ります。

!0 糸切り禁止スイッチ

・全ての糸切りを禁止します。

!1

!0

!2

!5

7

61

!1 下糸カウンタ / 糸切りカウンタ

・コントロールボックス本体の機能により、下

糸カウンタ / 糸切りカウンタを切替えること

が出来ます。

下糸カウンタ :

・下糸量の設定値を減算し表示します。

・下糸残量検知装置取り付け時は、検知回数を

設定します。

糸切りカウンタ :

・糸切りを行うごとに、カウンタ値が加算され

ます。

!2 カウンタリセットスイッチ

・下糸カウンタの値を初期の設定値に戻します。

・糸切りカウンタ選択時は「0」にリセットさ

れます。

!3 下糸量設定スイッチ

・下糸量の設定をするためのスイッチです。

!4 半針補正スイッチ

・半針ごとの補正縫いを行うためのスイッチで

す。

[ ペダル中立時の針棒停止位置の切替え選択 ]

・半針補正スイッチを押しながら電源を ON す

ると、ペダル中立時の針棒停止位置が、下位

置 / 上位置と切替わります。

・コントロールボックス前面カバーにて、停止

位置の確認を行うことが出来ます。

上位置停止選択時:"nPUP"

下位置停止選択時:"nPLo"

!5 インフォメーションスイッチ

・生産支援機能の呼び出しとワンタッチ設定の

呼び出し(1 秒間長押し)に使用します。

9

!3

- 4 -

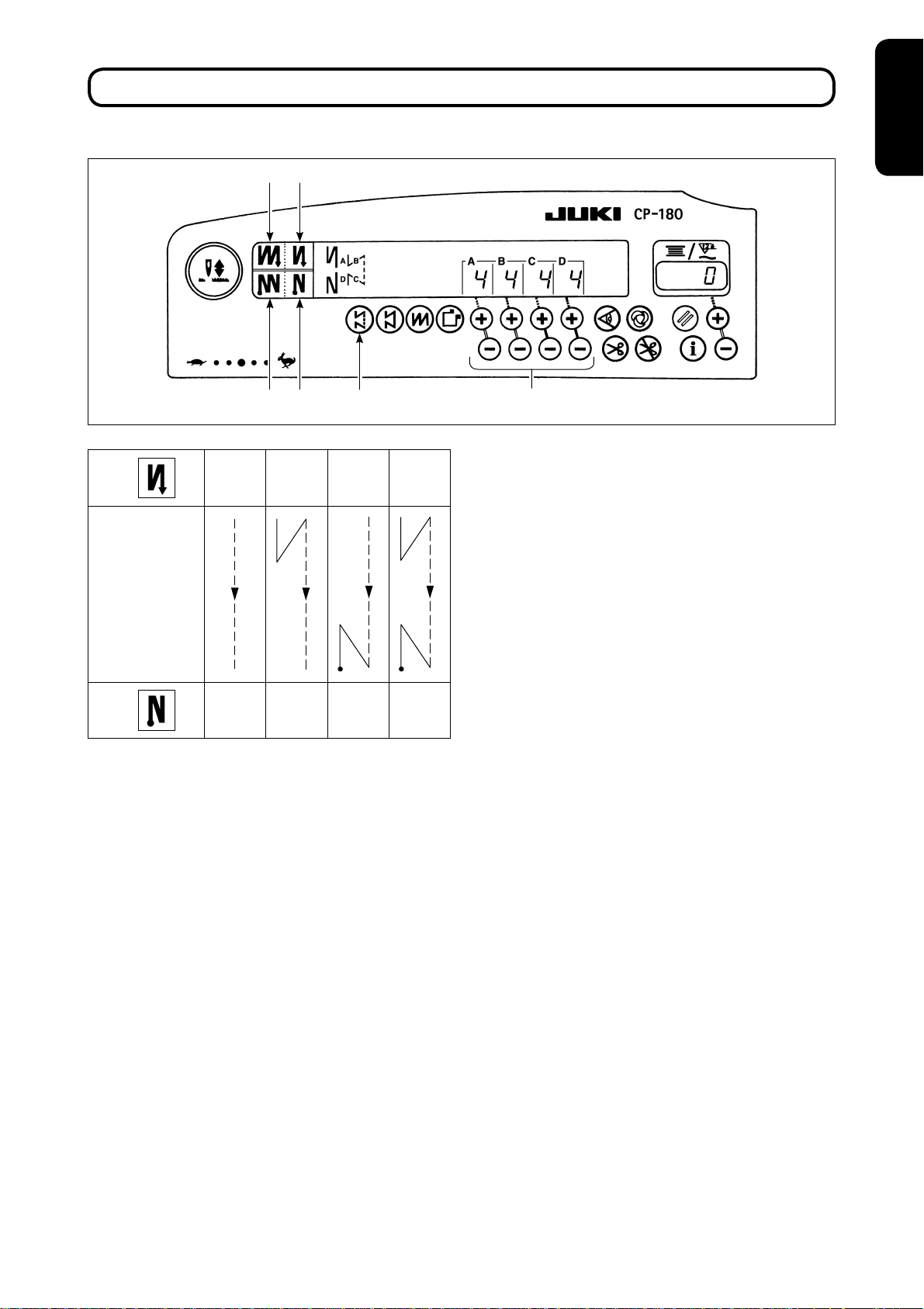

7.各種縫いパターンの操作方法

校正用

(1)返し縫いパターン

52

日本語

2

縫いパターン

3

63

OFF ON OFF ON

A

B

C

D

OFF OFF ON ON

A

B

C

D

41

1) 返し縫いパターンスイッチ1を押して、返し縫

いパターンを選択します。

2) 返し縫いパターンが選択され、すでに設定して

ある針数と返し縫いの状態が表示されます。

3) 針数を変更するときは、A 〜 D の各針数設定ス

イッチ4の+または−スイッチにより変更して

ください。

(変更範囲 0 〜 19 針)

4) 始め自動返し縫いスイッチ2と、終わり自動返

し縫いスイッチ3の ON / OFF の組合せによ

り、4 つの縫いパターンが行えます。

5) さらに始め二重返し縫いスイッチ5と、終わり

二重返し縫いスイッチ6により、二重返し縫い

を選択できます。

- 5 -

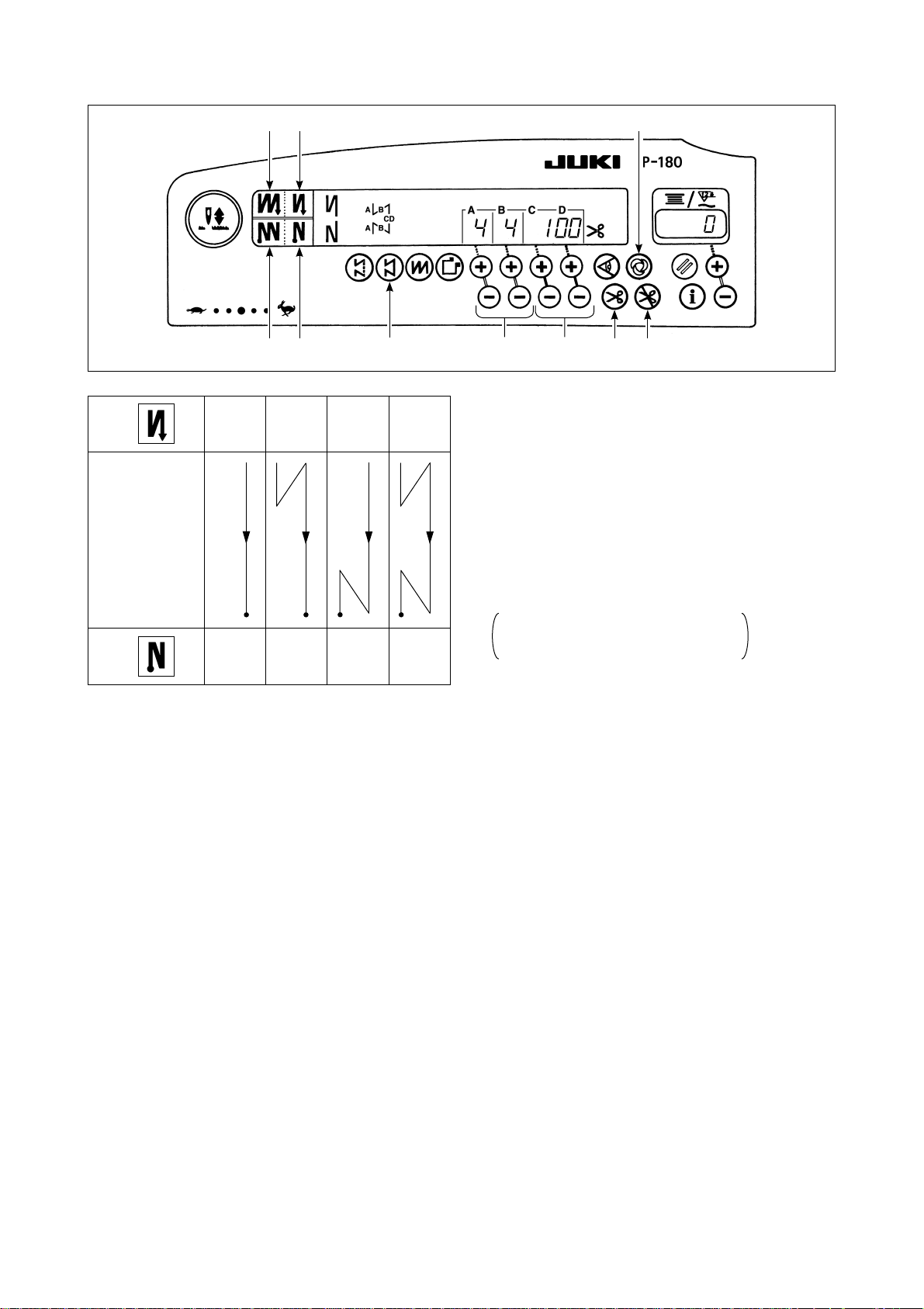

(2)定寸縫いパターン

校正用

2

縫いパターン

3

72

83

OFF ON OFF ON

A

B

CD

OFF OFF ON ON

CD

CD

B

A

A

B

CD

B

A

!0

41 5

1) 定寸縫いパターンスイッチ

69

を押して、定寸縫

1

いパターンを選択します。

2) 定寸縫いパターンが選択され、すでに設定して

ある針数と、返し縫い等の状態が表示されます。

3) 定寸縫いパターンの針数を変更するときは、C、

D の針数設定スイッチ5で針数を変更してくだ

さい。また、返し縫いを合わせて選択し、その

針数を変更するときは、A、B の針数設定スイッ

チ4で変更してください。

変更範囲 A、B=0〜19針

C、D=0〜500針

4) 始め自動返し縫いスイッチ2と、終わり自動返し縫いスイッチ3の ON、OFF の組み合わせにより、

4 つの縫いパターンが行えます。

5) さらに始め二重返し縫いスイッチ7と、終わり二重返し縫いスイッチ8により、二重返し縫いを選択

できます。

6) 自動糸切りスイッチ6が選択されている場合は、 CD 区間設定値分縫製すると、自動的に糸切りを

行います。(終わり自動返し縫いが選択されているときは、自動糸切りスイッチが選択されていなくて

も、終わり自動返し縫い後、自動糸切りします。)

自動糸切りスイッチ6が選択されていない場合は、CD 工程終了後、タッチバックスイッチを操作する

とミシンは低速で回転(補正縫い動作)します。また、ペダルを中立まで戻し再度前踏みすると針数設

定とは無関係に縫いを続行できます。

7) 糸切り禁止9を選択されたときは糸切りせず上停止します。

8) ワンショット縫い!0が選択されている時は、ペダル前踏みによって、一気に設定されたスピードで自

動縫いを行います。

- 6 -

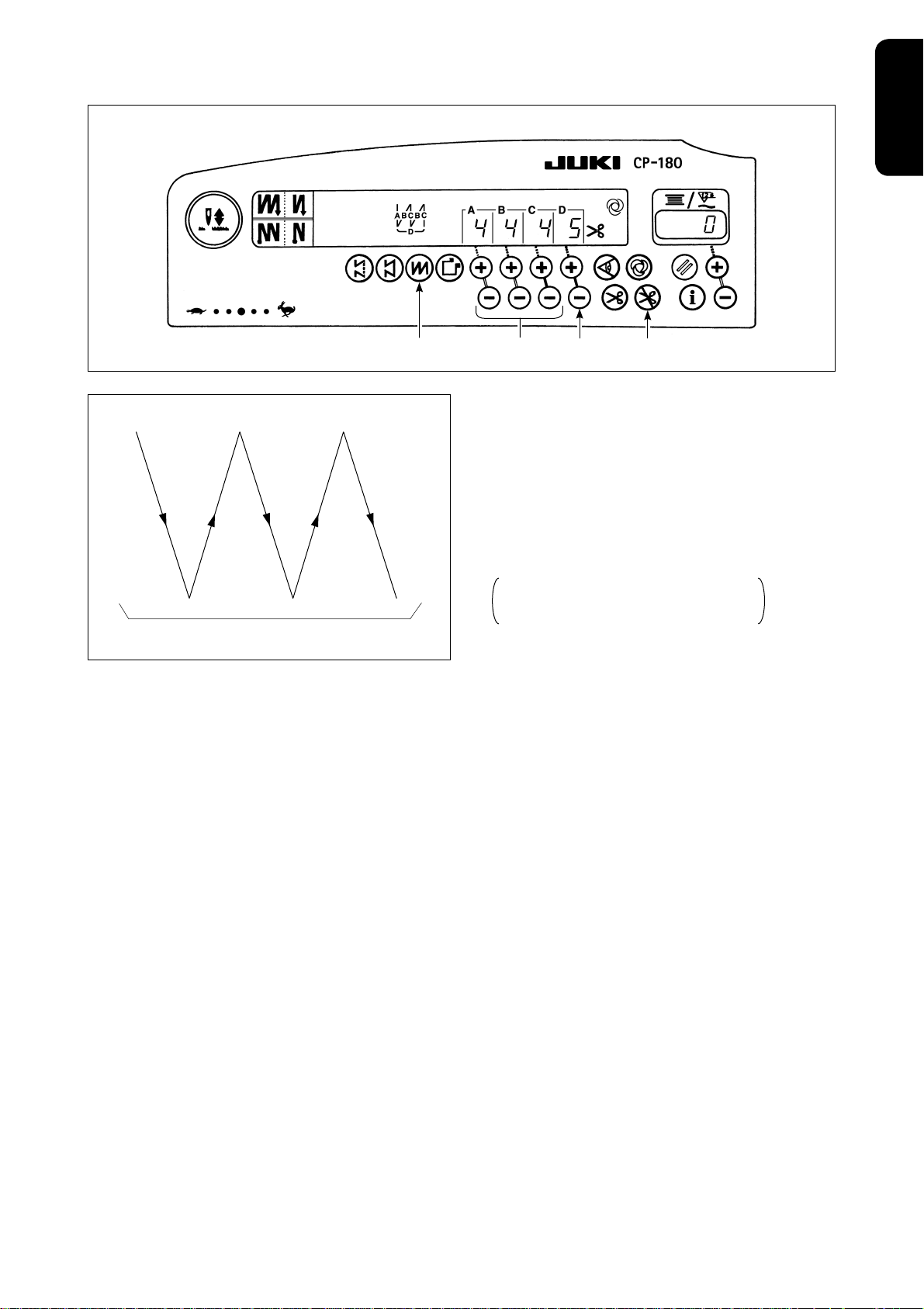

(3)重ね縫いパターン

校正用

A

B

CC

B

D

日本語

2 31 4

1) 重ね縫いパターンスイッチ1を押して、重ね縫

いを選択します。

2) 重ね縫いパターンが選択され、すでに設定して

ある針数等の状態が表示されます。

3) 針数の変更は、A 〜 C の各針数設定スイッチ2、

繰り返し工程数の変更は D の工程数設定スイッ

チ3の+または一スイッチにより変更してくだ

さい。

変更範囲 A、B、C =0〜19針、

D=0〜9回

4) ペダル前踏みを一度行うことにより、正逆縫い

を指定回数繰り返し縫製し、自動糸切りを行っ

て終了します。

(ワンショット縫いの OFF はできません。)

5) 糸切り禁止4を選択したときは、全工程終了し

ても糸切りを行わず上停止します。

- 7 -

(4)四角縫いパターン

A

B

校正用

1

縫いパターン

62

73

OFF ON OFF ON

A

B

D

C

C

A

A

B

D

B

C

41 5

C

A

C

!0

89

B

D

C

A

B

A

B

C

D

C

D

1

OFF OFF ON ON

1) 四角縫いパターンスイッチ

D

を押して、四角縫いパターンを選択します。

1

D

D

2) 四角縫いパターンが選択され、すでに設定してある針数等の状態が表示されます。

3) 四角縫いパターンの針数を変更するときは、C、D の針数設定スイッチ5で C 工程 D 工程各々の針数

を変更してください。また、返し縫いを合わせて選択し、その針数を変更するときは A、B の針数設定

スイッチ4で変更してください。

(変更範囲 A、B =0〜19針、C、D =0〜99針)

4) 始め自動返し縫いスイッチ2と終わり自動返し縫いスイッチ3の ON、OFF の組合せにより、4 つの

縫いパターンが行えます。

5) さらに、始め二重返し縫いスイッチ6と、終わり二重返し縫いスイッチ7により、二重返し縫いを選

択できます。ステップ毎に設定針数縫製後、自動停止します。

このときタッチバックスイッチを操作するとミシンは低速で回転(補正縫い動作)します。また、最終

行程では、ペダルを中立まで戻し再度前踏みをすると針数設定とは無関係に縫いを続行できます。

6) 自動糸切りスイッチ8が選択されている場合は、最終工程終了後、自動糸切りします。(終わり自動返

し縫いが選択されているときは、終わり自動返し縫い後、自動糸切りします。)

7) 糸切り禁止9を選択されたときは、糸切りせず上停止します。

8) ワンショット縫い!0が選択されているときは、C および D の工程で一度前踏みを行うと、設定されて

いる針数だけ縫製し停止します。最終工程は糸切り工程まで入ります。

9) 自動押え上げ仕様の場合は、各工程終了後、自動的に押えが上がります。

- 8 -

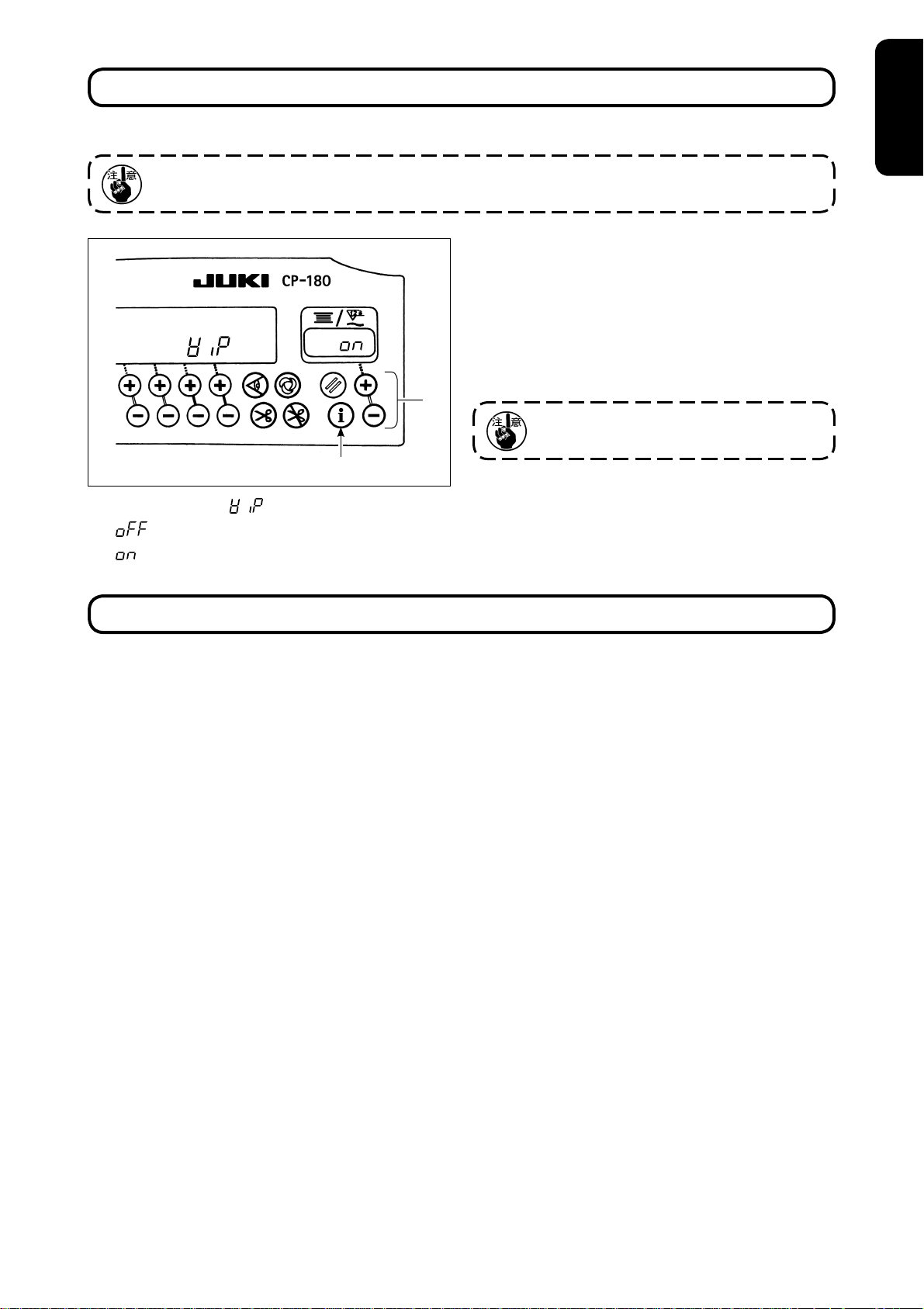

8.ワンタッチ設定について

校正用

通常の縫製状態から一部の機能設定項目を簡単に変更することができます。

その他の機能設定は、SC-920 の取扱説明書を参照してください。

[ ワンタッチ設定方法 ]

1) スイッチ1を 1 秒間長押しすると、機能設定

モードになります。

2) スイッチ2によって、設定値を変更することが

できます。

3) 通常の縫製状態へ戻る場合は、スイッチ1を押

してください。

2

スイッチ1を押すと設定が確定されます。

1

※ワイパー機能( )

:糸切り後ワイパー動作なし

:糸切り後ワイパー動作あり

日本語

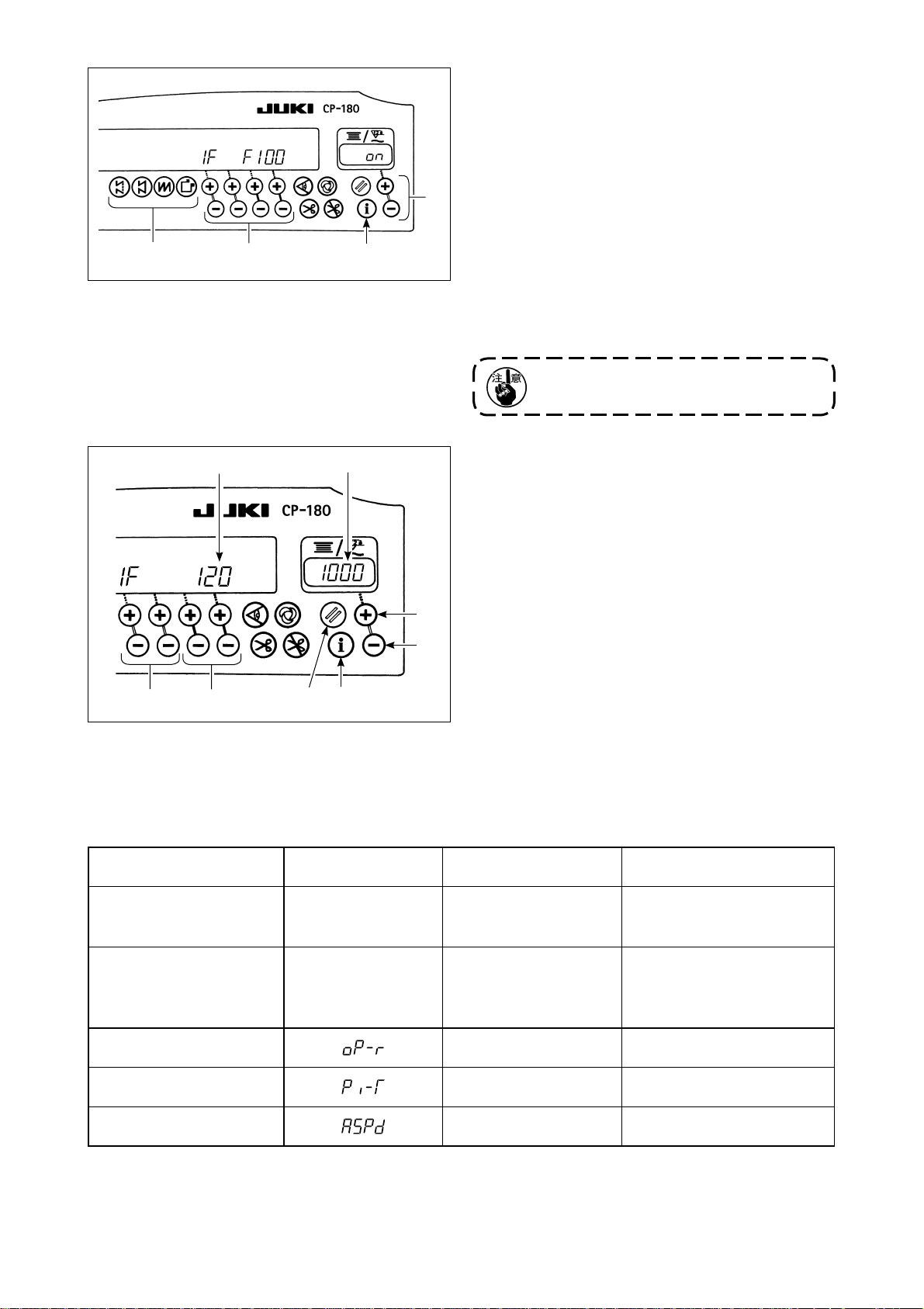

9.生産支援機能について

生産支援機能には、出来高管理機能と稼動計測機能の 2 つの機能(5 つのモード)があり、それぞれ異

なる支援効果があります。必要に応じて機能(モード)を選択してご使用ください。

[ 出来高管理機能 ]

・目標生産枚数表示モード [F100]

・目標生産枚数と実生産枚数との差異表示モード [F200]

作業時間に応じた目標生産枚数、実生産枚数、目標生産枚数と実生産枚数との差異を表示して縫製作業

の遅れ、進みをリアルタイムに通知します。縫製作業者は常に自分の作業ペースを確認しながら作業が

できるため、達成意識が高まり生産性アップにつながります。また、作業の遅れを早期に発見すること

につながり、早期の問題発見と対策が可能となります。

[ 稼動計測機能 ]

・ミシン稼働率表示モード [F300]

・ピッチタイム表示モード [F400]

・平均回転数表示モード [F500]

ミシン稼動状況を自動的に計測してパネルに表示します。工程分析、ライン編成、設備効率確認などを

行うための基礎データとして利用できます。

- 9 -

2

校正用

3

1

4

[ 各生産支援モードを表示するには ]

1) 通常の縫製状態からスイッチ1を長押し (1 秒

間 ) して、ワンタッチ設定画面にします。

2) さらにワンタッチ設定画面からスイッチ2を押

すことにより、各生産支援モードの表示/非表

示を設定できます。

3) スイッチ3を押すことにより、表示/非表示を

設定するモードを選択します。

4) スイッチ4を押すことにより、表示のON/O

FFを切り替えることができます。

5) 通常の縫製状態に戻る場合は、スイッチ1を押

してください。

出荷状態では F100 〜 F500 のモードは非

表示に設定されています。

2

3

表1「各モードの表示」

モード名 表示部

目標生産枚数表示モード

(F 100)

目標生産枚数と実生産枚数

との差異表示モード

(F 200)

ミシン稼働率表示モード

(F 300)

ピッチタイム表示モード

(F 400)

平均回転数表示モード

(F 500)

BA

6

1

A

実生産枚数

[ 単位:枚数 ]

(※ 1)

目標生産枚数と

実生産枚数との差異

[ 単位:枚数 ]

(※ 1)

[ 各生産支援モードの基本操作 ]

各種生産支援データを表示させながら、縫製を行う

ことができます。

1) 通常の縫製状態でスイッチ1を押すと、生産支

援モードになります。

2)

スイッチ2を押す事により、生産支援機能(F

100 〜F 500)を切り替えることができます。

5

4

3) 表1「各モードの表示」の(※ 1)マークのデー

タはスイッチ3で変更可能です。(※ 2)マー

クのデータはスイッチ4またはスイッチ5で

変更可能です。

4) 各データのリセット操作は、表 2「各モードの

リセット操作」を参照してください。

5) 通常の縫製状態へ戻る場合は、スイッチ1を押

してください。

表示部

目標生産枚数

[ 単位:枚数 ]

(※ 2)

目標ピッチタイム

[ 単位:100msec]

(※ 2)

前回縫製のミシン稼働率

[ 単位:% ]

前回縫製のピッチタイム

[ 単位:1sec]

前回縫製の平均回転数

[ 単位:sti/min]

B

表示部

B

( スイッチ4または6押下時 )

―

―

平均ミシン稼働率表示

[ 単位:% ]

平均ピッチタイム表示

[ 単位:100msec]

平均回転数表示

[ 単位:sti/min]

- 10 -

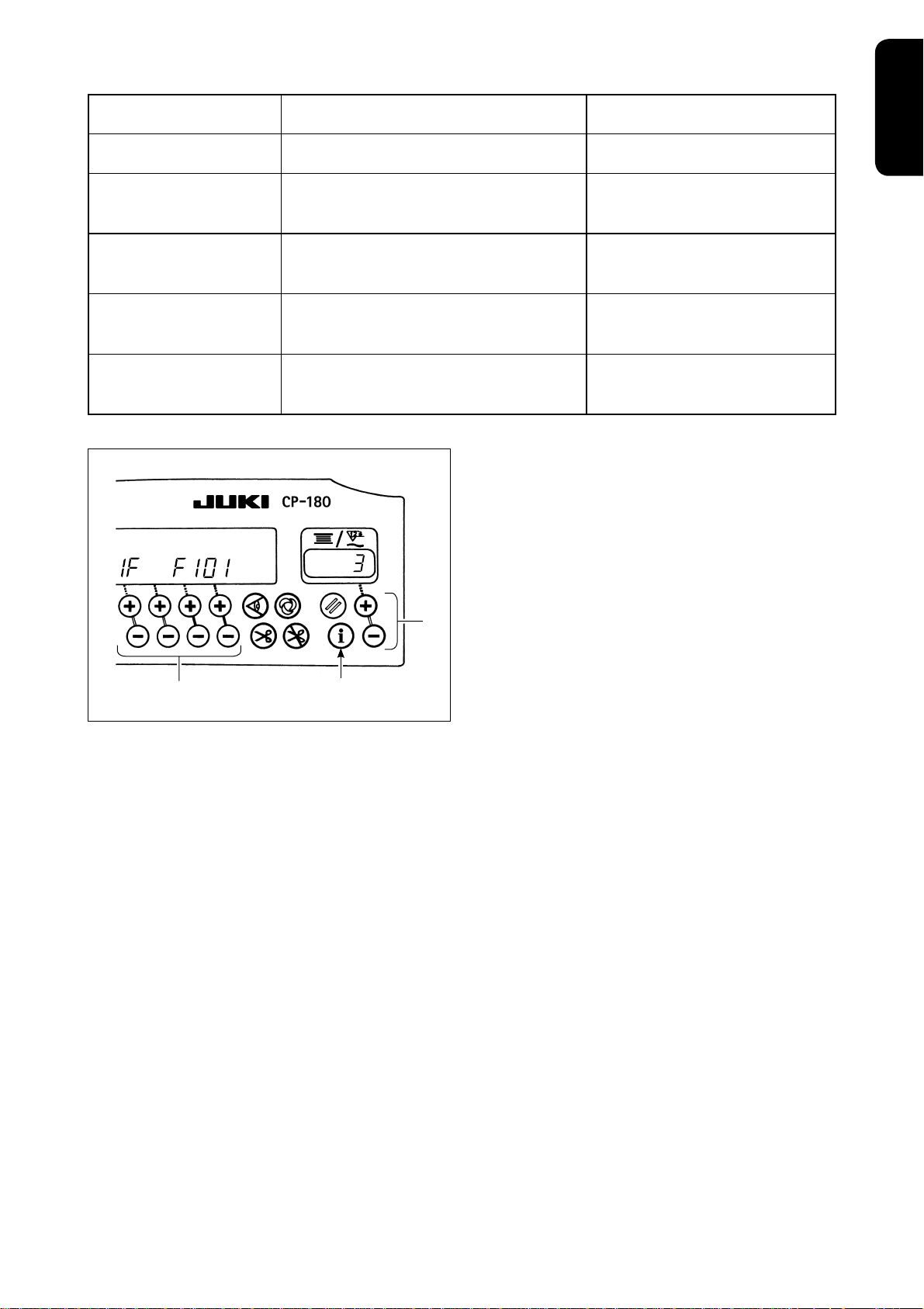

表 2「各モードのリセット操作」

校正用

日本語

モード名

目標生産枚数表示モード

(F 100)

目標生産枚数と実生産枚数

との差異表示モード

(F 200)

ミシン稼働率表示モード

(F 300)

ピッチタイム表示モード

(F 400)

平均回転数表示モード

(F 500)

2

スイッチ

(2 秒長押し)

実生産枚数リセット

目標生産枚数と実生産枚数との差異リセット

実生産枚数リセット

目標生産枚数と実生産枚数との差異リセット

平均ミシン稼働率リセット

平均ピッチタイムリセット

平均回転数リセット

6

[ 出来高管理機能の詳細設定(F 101、F 102)]

・目標生産枚数表示モード(F 100)または目標

生産枚数と実生産枚数との差異表示モード(F

200)中にスイッチ1を長押し(3 秒間)すると、

出来高管理機能の詳細設定が行えます。

・スイッチ2を押すことにより、糸切り回数設定

状態(F 101)と目標達成ブザー設定状態(F

3

102)を切り替えることができます。

・糸切り回数設定状態(F 101)でスイッチ

を押す事により、1 着分の糸切り回数を設定す

1

る事ができます。

・目標達成ブザー設定状態(F 102)でスイッチ

を押す事により、実生産枚数が目標生産枚数

3

に達した時にブザーを鳴らすかどうかを設定す

る事ができます。

スイッチ

(4 秒長押し)

平均ミシン稼働率リセット

平均ピッチタイムリセット

平均回転数リセット

平均ミシン稼働率リセット

平均ピッチタイムリセット

平均回転数リセット

平均ミシン稼働率リセット

平均ピッチタイムリセット

平均回転数リセット

6

―

―

3

- 11 -

10.下糸カウンタの使い方

校正用

ミシンの針数を検出し、その針数により、あらかじめ設定した値から減算(機能設定 No.7、下糸カウント

ダウン単位の設定に従い減算します)してゆき、カウンタの値がマイナス(‥・…→1→0→ー1)になっ

たときに、ブザー(ピピッ、ピピッ、ピピッ)にて報知し、下糸の交換時期を促します。

2

3

1

く下糸カウンタ初期設定参考値>

上図のように、ボビンケースの外側に空いている小

穴の上郡まで巻かれた状態での、初期設定参考値が

下表となります。

使用糸 糸巻長さ 下糸カウント値

ポリエステルスパン糸 #50

綿糸 #50 31m

36m

1200

(ピッチ 3mm)

1000

(ピッチ 3mm)

糸締り率 100%

※ 実際には布厚、縫いスピードにより変化します

ので、使用条件に合わせて調整してください。

1)下糸カウンタリセットスイッチ

を押して、下

1

糸カウンタ2の表示を初期設定値(出荷時設定

値は 0)に戻します。

縫製途中ではリセットしませんので、−度糸

切りを行ってください。

2)下糸量設定スイッチ3で、初期値を設定します。

スイッチを押しつづけると、切替え速度が速く

なります。

3)初期値の設定ができたら、縫製を始めます。

4)下糸カウンタ値がマイナスになり、ブザー(ピ

ピッ、ピピッ、ピピッ)が鳴りましたら下糸を

交摸します。

5)下糸の交換が終わりましたら、下糸カウンタリ

セットスイッチ1を押して、初期値に戻してか

ら縫製を再開します。

6)糸残り量が多かったり、下糸カウンタがマイナ

スになる前に下糸が無くなった場合には、初期

設定値を下糸調整スイッチ3の+または−ス

イッチにより調整してください。

糸残り量が多い場合‥‥‥‥+スイッチで増加

糸残り量が足りない場合‥‥−スイッチで減少

1.糸の巻き方や布厚によっては、バラツキが

発生する恐れがあるので、糸切り量は若干

余裕のある設定が必要です。

2.下糸残量検知装置と組み合わせて使用する

場合には、下糸カウンタは下糸残量検知装

置の検知回数の設定にかわりますので、下

糸残量検知装置の取扱説明書をよく読んで

こ使用ください。

- 12 -

11.糸切りカウンタの使い方

校正用

日本語

2

3

1

各項目の選択後、必ず機能設定 No. の更新を行ってください。

更新を行わず、電源を OFF すると、設定内容は変更されません。

更新方法は18.機能設定スイッチについてp.15 を参照してください。

4) リセットスイッチ1を押すと、表示2の内容は「0」にリセットされます。

5) カウント値を修正する場合は、設定スイッチ3で増減してください。

下記操作により、下糸カウンタ表示を糸切りカウン

タ(簡易縫製カウンタ)表示に切替えることが出来

ます。

1)機能設定 No.6、下糸カウンタ機能の設定を off

にしてください。

(0:off/1:on)

2)機能設定 No.14、縫製カウンタ機能の設定を

on にしてください。

(0:off/1:on)

3) 次の電源 on より、カウンタ表示は糸切りカウ

ンタとして動作します。糸切りを行うごとに、

カウンタ表示がアップします。

12.半針補正スイッチについて

1

半針補正スイッチ1を押すごとに針が上→下、下

→上に動き、半針分の補正縫いが行えます。

ただし、スイッチを押し続けても、連続的に低速で

運転はしません。

また、手回し後は半針補正スイッチは無効となります。

半針補正操作の縫製では、糸切り操作は有効となり

ません。

半針補正スイッチ1を押しながら電源を on すると、

その都度、ペダル中立時の停止位置を切替えること

が出来ます。

また、そのときに選択された状態は、パネルにて確

認することが出来ます。

(表示される内容は、次回以降の電源 on 時に反映さ

れます。)

- 13 -

13.キーロック機能について

校正用

一度設定した針数や、工程(A、B、C、D)の内容を誤ってかえられたりしないようにするため、設定スイッ

チにロックをかけることができます。(パターンの変更や、下糸カウンタの変更は行えます。)

3

21

1)針数等の設定終了後、いったん電源を OFF にします。

2)パネル上の終わり自動返し縫いスイッチ1と A 工程針数設定スイッチ2の+スイッチを同時に指で押

しながら電源スイッチを ON します。

3) パネル上にキーマーク3が表示されれば、キーロック完了です。

(キーマークが表示されない場合は、再度 1)からやり直してください。)

※ キーロックの解除は、再度 1)、2)の操作を行います。

(キーマーク表示が消え、解除されます。)

14.布端センサ ON / OFF スイッチ について

・オプションの布端センサが接続されている場合に有効となります。

・布端センサ選択時は布端を検知すると自動的に停止または糸切り処理を行います。

布端センサを組み合わせて使用する場合は、布端センサの取扱説明書をよく読んでご使用ください。

15.自動糸切りスイッチ

・自動停止する工程または布端センサ使用時において、自動的に糸切りを実行させるスイッチです。

(終わり自動返し縫いが選択されている場合は、終わり自動返し縫いを行ってから糸切りを行います。)

16.ワンショット自動縫いスイッチ

・定寸縫い、四角縫いまたは布端センサ使用時において、いったんミシンを駆動すると、その工程を最後

まで設定スピードにて自動縫いを行わせるためのスイッチです。

について

について

- 14 -

17.糸切り禁止スイッチ について

校正用

・糸切り機能を、一時的に禁止させるためのスイッチです。

糸切りをしない他は、通常の糸切り動作とかわりません。

(終わり自動返し縫いを選択時は、終わり自動返し縫いを行います。)

日本語

・

と が同時に設定されている場合は、糸切り動作をせず上停止となります。

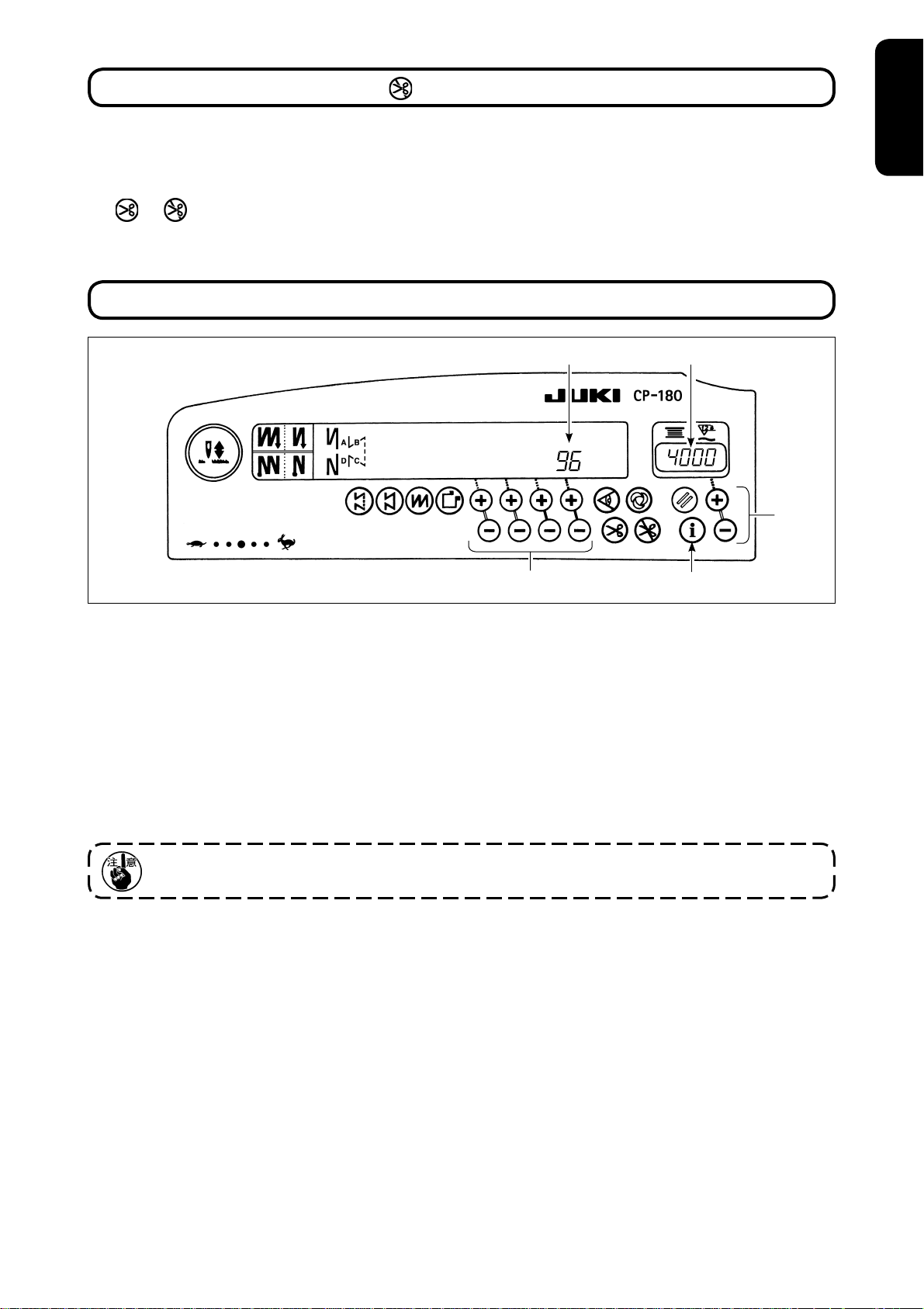

18.機能設定スイッチについて

A

2 1

1) 機能設定スイッチ1を押しながら電源を on します。

2) 操作パネル上の表示は、機能設定表示モードに切替わります。

※ 表示される内容は、前回設定された内容により異なります。

3)スイッチ2を操作することにより、機能設定 No. が切替わります。

4)スイッチ3を操作することにより、機能設定値(on/off の場合は設定状態)を切り替えることが出

5)設定完了後、スイッチ2を操作することにより、変更内容は記憶され次回より反映されます。

6)機能設定内容の詳細は、コントロールボックス付属の取扱説明書を参照願います。

部に、機能設定 No. カウンタ表示部B部に設定値が表示されます。

A

来ます。

B

3

機能設定一覧と機能設定詳細とオプション入出力コネクタについては、SC− 920 取扱説明書をご覧くだ

さい。

- 15 -

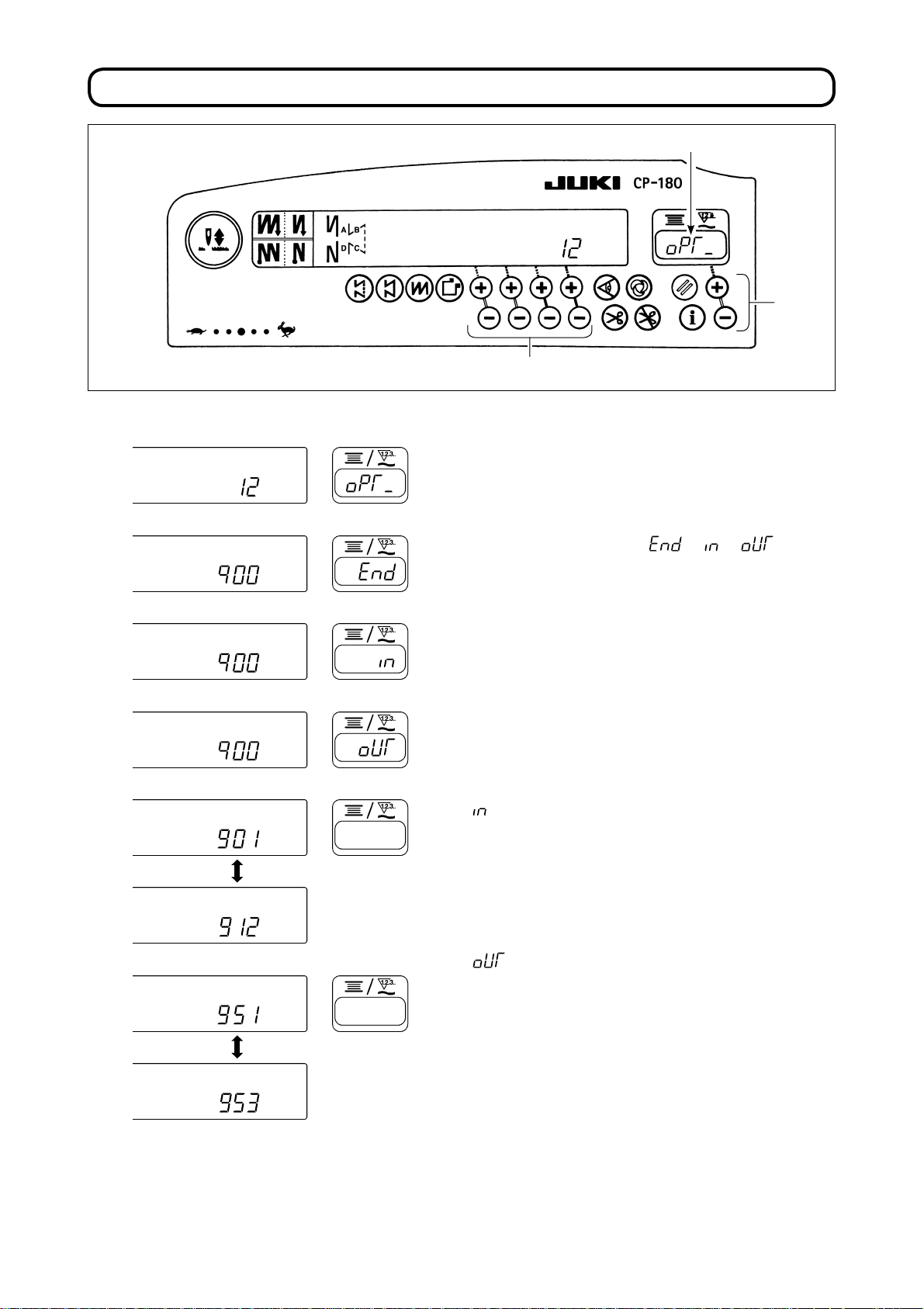

19.オプション入出力設定について

校正用

1)機能番号No.12 を選択します。

1

3

2

※※※※

オプション名が表示されます。

※※※※

オプション名が表示されます。

2) スイッチ3によって、 の項目

を選択します。

[ を選択した場合 ]

スイッチ2で入力ポートを指定し、スイッチ3で入

力ポートの機能を指定します。

に機能コードと略字が交互に表示されます。

1

(信号入力番号とコネクタのピン配列との関係はSC−

920 取扱説明書を参照願います。)

[ を選択した場合 ]

スイッチ2で出力ポートを指定し、スイッチ3で出

力ポートの機能を指定します。

に機能コードと略字が交互に表示されます。

1

(信号入力番号とコネクタのピン配列との関係はSC−

920 取扱説明書を参照願います。)

- 16 -

例)入力オプションポートに糸切り機能を設定

校正用

日本語

1) 機能設定方法にて機能番号No.12 を選択します。

交互に点灯します。

交互に点灯します。

2) スイッチ3にて

3) スイッチ2にて 901 のポートを選択します。

4) スイッチ3にて 糸切り機能を選択します。

5) スイッチ2にて 糸切り機能を確定します。

6) スイッチ3にて信号のアクティブを設定します。

信号がLowで糸切り動作なら表示を に、H

ighで糸切り動作なら表示を に設定します。

の項目を選択します。

7) スイッチ2にて上記機能を確定します

8) スイッチ2にてオプション入力を終了します。

9) スイッチ3にての項目を選択し機能設定

モードへ戻ります。

- 17 -

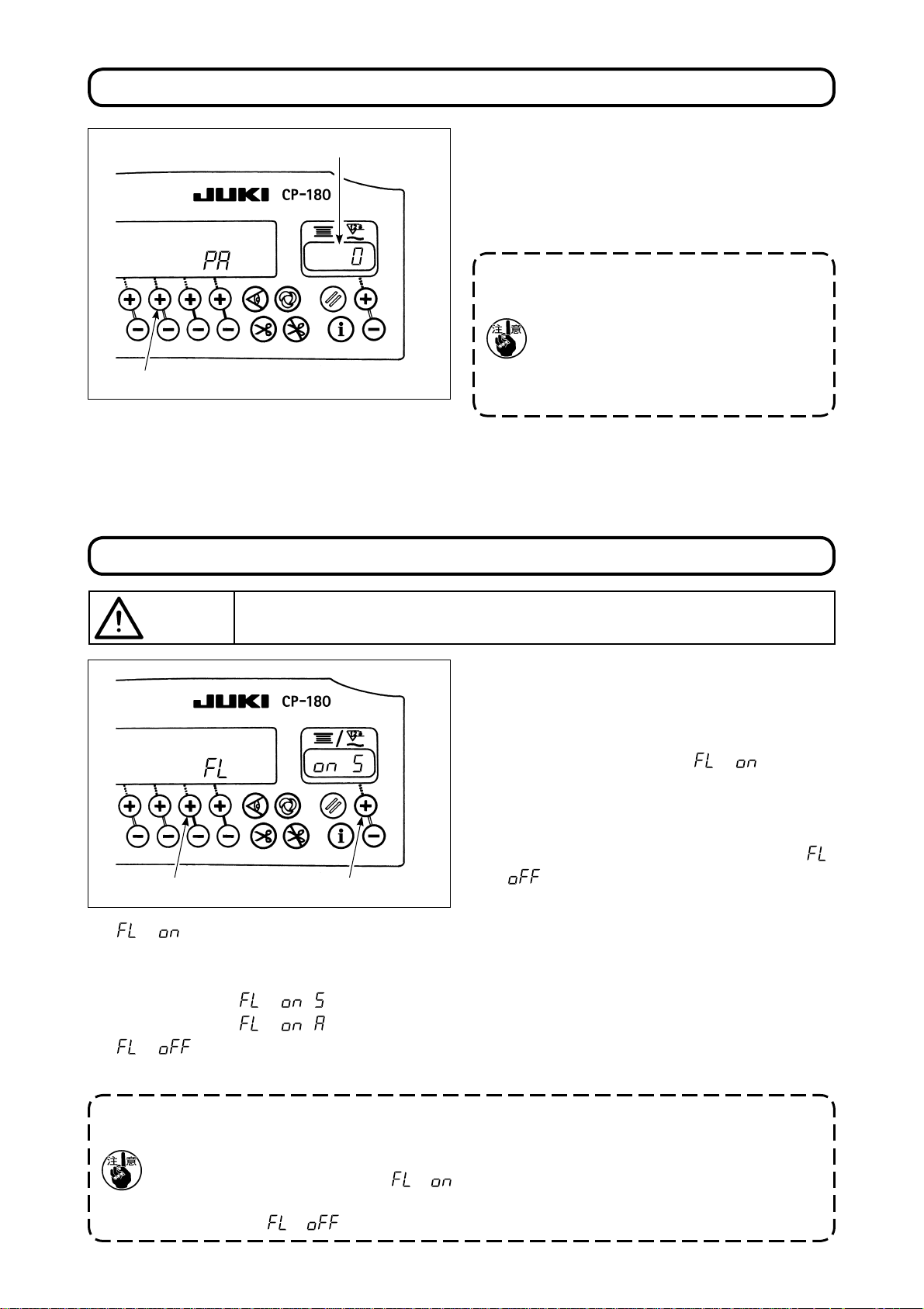

20.ペダルセンサ中立自動補正

校正用

補正値

1

21.自動押え上げ機能選択方法

ペダルセンサやばね等を交換した時は、必ず以下の

操作を実施してください。

1) スイッチ1を押しながら電源スイッチを ON し

ます。

2) 図のように補正値が表示されます。

1.この時、ペダルが踏まれていたりすると正

しく動作しません。ペダルの上には足や物

をのせないでください。警告音がピピッ

となり、補正値は表示されません。

2.補正値ではなく数値以外の表示がされた場

合は、サービスマニュアルを参照してくだ

さい。

3) 電源スイッチを OFF し、再度電源スイッチを

ON してください。通常動作に戻ります。

ソレノイドをエアー駆動設定で使用するとソレノイドが焼損する恐れがありますので、間違

注意

1

: 自動押え上げ装置が有効となります。スイッチ2で押え上げ装置をソレノイド駆動(+

(CN37 の駆動電源が+ 33V または+ 24V に切り替わります。)

:ソレノイド駆動表示(+ 33V)

:エアー駆動表示(+ 24V)

: 自動押え上げ機能は働きません。(標準出荷状態)

(プログラム縫い完了時も押え上げは自動上昇しません。)

わないように設定してください。

自動押え上げ装置(AK)を取り付けたとき、自動

押え上げ機能を働かせます。

1) スイッチ1を押しながら電源スイッチをO N

します。

2)ピッと音ともに表示が になり、

自動押え上げ機能が有効になります。

3) 電源スイッチをOFFし、再度電源スイッチを

ONにしてください。通常動作に戻ります。

4) 1)〜 3)の動作を再度くり返すと表示が

2

33V)かエアー駆動(+ 24V)に選択できます。

となり、自動押え上げ機能が働かなくな

ります。

1.電源の入れ直しは、必ず1秒以上経過してから行ってください。

(電源の ON / OFF 動作が早すぎると、設定がうまく切り換わらない場合があります。)

2.本機能を正しく選択しないと、自動押え上げは正しく動作しません。

3.自動押え上げ装置を取り付けずに

また、タッチバックスイッチが動作しなくなることがありますので、自動押え上げ装置を取り付けていな

い時は、必ず

を選択してください。

を選択すると、縫い始めに一瞬起動が遅れます。

- 18 -

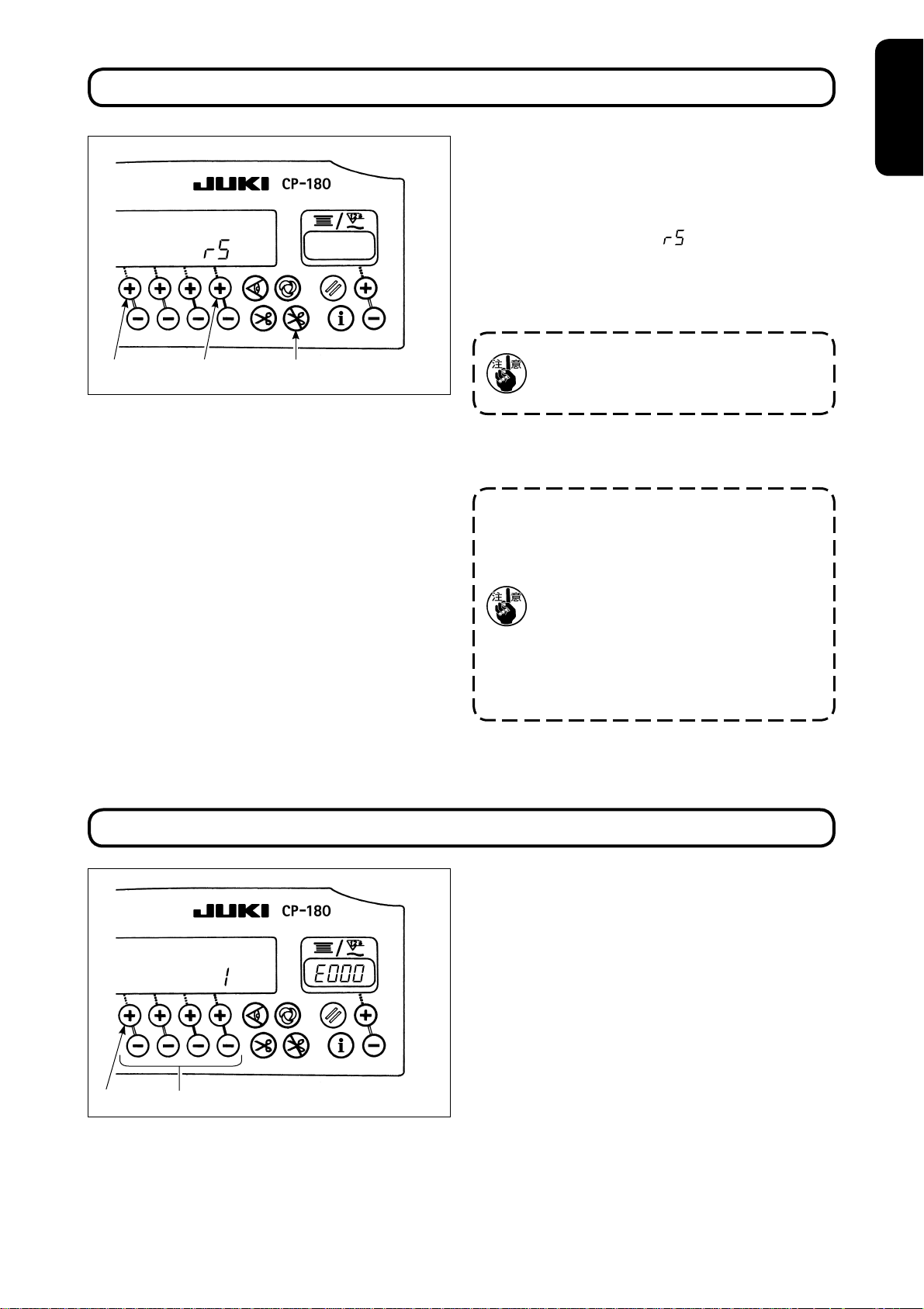

22.機能設定データの初期化方法

校正用

機能設定内容をすべて標準設定値に戻すことができ

ます。

1)スイッチ1、2、3をすべてを押しながら電源

スイッチをO N します。

2)ピッと音とともに

が始まります。

3) 約 1 秒後にブザーが鳴り(単音3回ピ、ピ、

ピ)標準設定値に戻ります。

が表示され初期化

日本語

1 2

3

初期化作業の途中で電源を OFF しないでく

ださい。本体のプログラムを破損する危険が

あります。

4) 電源スイッチを OFF し、再度電源スイッチを

ON にしてください。通常動作に戻ります。

1.

2.この操作を行うと頭部調整値も初期化され

(

3.この操作をしても操作パネルで設定した縫

この操作を行うとペダルセンサの中立補正値

も初期化されるため、使用前に必ずペダルセ

ンサ中立自動補正操作を行ってください。

(20.ペダルセンサ中立自動補正p.18参照)

るため、使用前に必ず頭部調整操作を行っ

てください。

5.頭部調整p.3参照)

製データは初期化されません。

23.エラーコードの確認方法

1

2

1)スイッチ1を押しながら電源スイッチをO N

します。

2)ピッと音とともに、最新のエラー番号が表示

されます。

3)スイッチ2を押すことにより、以前のエラー内

容の確認が行えます。

(最後まで進むと単音で2回ピッ、ピッと

警告音が鳴ります。)

- 19 -

校正用

ENGLISH

校正用

ENGLISH

CONTENTS

校正用

1. INSTALLING THE CONTROL PANEL ............................................................................1

2. CONNECTING THE CORD .............................................................................................1

3. CONFIGURATION ...........................................................................................................2

4. SETTING PROCEDURE OF THE MACHINE HEAD ......................................................2

5. A

DJUSTING THE MACHINE HEAD (DIRECT-DRIVE MOTOR TYPE SEWING MACHINE ONLY)

6. EXPLANATION OF THE CONTROL PANREL ...............................................................4

7.

HOW TO OPERATE THE CONTROL PANEL FOR SEWING STITCHING PATTERNS

8. ONE-TOUCH SETTING ...................................................................................................9

9. PRODUCTION SUPPORT FUNCTION ...........................................................................9

10. HOW TO USE THE BOBBIN THREAD COUNTER ....................................................12

11. HOW TO USE THE THREAD TRIMMING COUNTER ................................................13

.....3

.......5

12. NEEDLE UP/DOWN COMPENSATION SWITCH .......................................................13

13. KEY LOCK FUNCTION ...............................................................................................14

14. ON/OFF SWITCH

15. AUTOMATIC THREAD TRIMMING SWITCH

16. ONE-SHOT AUTOMATIC STITCHING SWITCH

17. THREAD TRIMMING PROHIBITION SWITCH

18. FUNCTION SETTING SWITCH ...................................................................................15

19. OPTIONAL INPUT/OUTPUT SETTINGS ....................................................................16

20.

AUTOMATIC COMPENSATION OF NEUTRAL POINT OF THE PEDAL SENSOR

21. SETTING OF THE AUTO LIFTER FUNCTION ............................................................18

22. INITIALIZATION OF THE SETTING DATA ..................................................................19

23. CHECKING PROCEDURE OF THE ERROR CODE ...................................................19

OF THE MATERIAL EDGE SENSOR ......................................14

......................................................... 14

...................................................14

......................................................15

......18

i

WARNING :

校正用

This Instruction Manual is for the control panel, CP-180.

Read "Safety Instructions" of the Instruction Manual for the control box carefully beforehand and

understand them before using CP-180.

In addition, be careful not to splash water or oil on it, or shock such as dropping and the like since

this product is a precision instrument.

1. INSTALLING THE CONTROL PANEL

WARNING :

To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after

turning OFF the power switch and ascertaining that the motor has completely stopped.

ENGLISH

2

4

1

3

5

1) Remove side plate setscrews 1 from the side plate.

2) Install control panel 2 on the machine head using screws 5, fl at washers 3 and rubber seat 4 supplied with the control panel as the accessories.

1. DDL-9000B (Not provided with AK) is given as an example of installing procedure.

2. Screw to install the panel changes according to the machine head used. Refer to Table 1 and

confi rm the kind of screw.

< The relation between the respective machine heads and the positions of installing hole of the bracket are as described in the table. >

Table 1

12

34 5

6

DDL-9000A

DDL-9000B

LH-3500A

Installing hole

-

1

5

-

1

5

-

2

5

M5 X 12

(Provided with AK)

M5 X 14

(Not provided with AK)

M5 X 12

M5 X 14 Side plate setscrew

Screw

Screw supplied with panel

as accessories

Side plate setscrew

Screw supplied with panel

as accessories

2. CONNECTING THE CORD

1) Pass cord 1 of the control panel through hole A

in the machine table route it to the underside of

the table.

2) As for the connection of the connector, refer to

the Instruction Manual for the control box.

1

A

- 1 -

3. CONFIGURATION

校正用

1

2

Power indicator lamp (LED) : Lights up when the power switch is turned ON.

1

Max. speed limitation variable resistor : Limits the speed when it is moved to the left ( ).

2

4. SETTING PROCEDURE OF THE MACHINE HEAD

1) Refer to "18. FUNCTION SETTING SWITCH

p.15, and call the function setting No. 95.

2) The type of machine head can be selected by

pressing switch 1.

* Refer to "CAUTIONS WHEN SETTING UP THE

SEWING MACHINE" or "Machine head list"

on the separate sheet for the types of machine

1

heads.

3) After selecting the type of machine head, by

pressing switch 2, the step proceeds to 96 or

94, and the display automatically initializes to the

contents of the setting corresponding with the

type of machine head.

"

2

- 2 -

5. ADJUSTING THE MACHINE HEAD

校正用

(DIRECT-DRIVE MOTOR TYPE SEWING MACHINE ONLY)

WARNING :

Be sure to perform the angle adjustment of the machine head by the operation below before using

the machine head.

1) Simultaneously pressing switch 1 and switch 2,

turn ON the power switch.

21

2) is displayed A in the indicator and the

BA

mode is changed over to the adjustment mode.

3) Turn the handwheel by hand and angle B is displayed in the indicator when the reference signal

has been detected.

(The value is the reference value.)

ENGLISH

3

4) In this state, align the white dot 2 of the handwheel with the concave 3 of the handwheel

cover as shown in the fi gure.

2

5) Press switch 4 to fi nish the adjustment work.

(The value is the reference value.)

4

- 3 -

6. EXPLANATION OF THE CONTROL PANREL

校正用

!4

24 8

35

Pattern selector switch

1

• Used for selecting a pattern from among the

four different patterns.

Double reverse stitching (for start) switch

2

• Used for turning ON/OFF the double reverse

stitching for start.

Double reverse stitching (for end) switch

3

• Used for turning ON/OFF the double reverse

stitching for end.

Automatic reverse stitching (for start) switch

4

• Used for turning ON/OFF the automatic

reverse stitching for start.

Automatic reverse stitching (for end) switch

5

• Used for turning ON/OFF the automatic

reverse stitching for end.

Switches for setting the number of stitches

6

• Used for setting the number of stitches to be

sewn in processes A through D.

Material edge sensor ON/OFF switch

7

• Rendered effective when the material edge

sensor is installed on the machine.

• Used for setting whether or not the material

edge sensor is used during sewing.

One-shot automatic stitching switch

8

• Rendered effective when the material edge

sensor is installed on the machine or when

the sewing machine is operated under the

constant-dimension stitching mode.

• Start the sewing machine with this switch, and

the sewing machine will run automatically until

the material edge is detected or the end of a

constant-dimension stitching is reached.

Automatic thread trimming switch

9

• Rendered effective when the material edge

sensor is installed on the machine or when

the sewing machine is operated under the

constant-dimension stitching mode.

• Even keep depressing the front part of the

pedal, the sensor can detect the material

edge, or after the completion of the constantdimension stitching mode, the machine will

automatically perform thread trimming.

!1

7

!2

!3

!0

!5

61

Thread trimming prohibition switch

!0

•

Used for prohibiting thread trimming at any occasion.

Bobbin thread counter/thread trimming counter

!1

• Bobbin thread counter/thread trimming counter

can be changed over by the function of the control

box main body.

Bobbin thread counter :

• Indicates the amount of bobbin thread while

counting it by subtracting from the set value.

• When the bobbin thread remaining amount

detecting device is installed on the machine, the

counter indicates the number of times of detecting.

Thread trimming counter :

• Every time thread trimming is performed, the

counter value is added.

Bobbin counter reset switch

!2

• Used for returning the value shown on the

bobbin thread counter to the initial value.

• When the thread trimming counter is selected,

it is reset to [0].

Bobbin thread amount setting switch

!3

• Used for setting the amount of bobbin thread.

Needle up/down compensation switch

!4

• Used for performing needle up/down

compensation stitching.

[Changeover selection of needle bar stop position

when the pedal is in its neutral position]

• Pressing the needle up/down compensation

switch, turn ON the power to the machine, and

the needle bar stop position when the pedal is

in its neutral position is changed over to down

position/up position.

• Confi rmation of the stop position can be

performed at the front cover of the control box.

When up position stop is specifi ed : " nP UP "

When down stop position is specifi ed : " nP Lo "

Information switch

!5

• Used for calling the production support

function and calling the one-touch setting

(by keeping the switch held pressed for one

second.)

9

- 4 -

Loading...

Loading...