Page 1

ENGLISH

CP-180

INSTRUCTION MANUAL

No.02

40088353

Page 2

CONTENTS

1. INSTALLING THE CONTROL PANEL ..........................................................................1

2. CONNECTING THE CORD ............................................................................................1

3. CONFIGURATION .........................................................................................................2

4. S

ETTING PROCEDURE OF THE MACHINE HEAD .....................................................2

5.

ADJUSTING THE MACHINE HEAD(direct-drive motor type sewing machine only)

6. EXPLANATION OF THE CONTROL PANREL ..............................................................4

7.

HOW TO OPERATE THE CONTROL PANEL FOR SEWING STITCHING PATTERNS

8. O

NE-TOUCH SETTING .................................................................................................9

9. P

RODUCTION SUPPORT FUNCTION .........................................................................9

10. HOW TO USE THE BOBBIN THREAD COUNTER ....................................................12

11. HOW TO USE THE THREAD TRIMMING COUNTER ................................................13

...3

...5

12. NEEDLE UP/DOWN COMPENSATION SWITCH .......................................................13

13. KEY LOCK FUNCTION ...............................................................................................14

14. ON/OFF SWITCH

15. AUTOMATIC THREAD TRIMMING SWITCH

16. ONE-SHOT AUTOMATIC STITCHING SWITCH

17. THREAD TRIMMING PROHIBITION SWITCH

18. FUNCTION SETTING SWITCH ...................................................................................15

19. O

PTIONAL INPUT/OUTPUT SETTINGS ....................................................................16

20. A

UTOMATIC COMPENSATION OF NEUTRAL POINT OF THE PEDAL SENSOR ...18

21. S

ETTING OF THE AUTO LIFTER FUNCTION ............................................................18

22. I

NITIALIZATION OF THE SETTING DATA ..................................................................19

23. C

HECKING PROCEDURE OF THE ERROR CODE ...................................................19

OF THE MATERIAL EDGE SENSOR ......................................14

.........................................................14

...................................................14

......................................................15

i

Page 3

WARNING :

This Instruction Manual is for the control panel, CP-180.

Read "Safety Instructions" of the Instruction Manual for the control box carefully beforehand and

understand them before using CP-180.

In addition, be careful not to splash water or oil on it, or shock such as dropping and the like since

this product is a precision instrument.

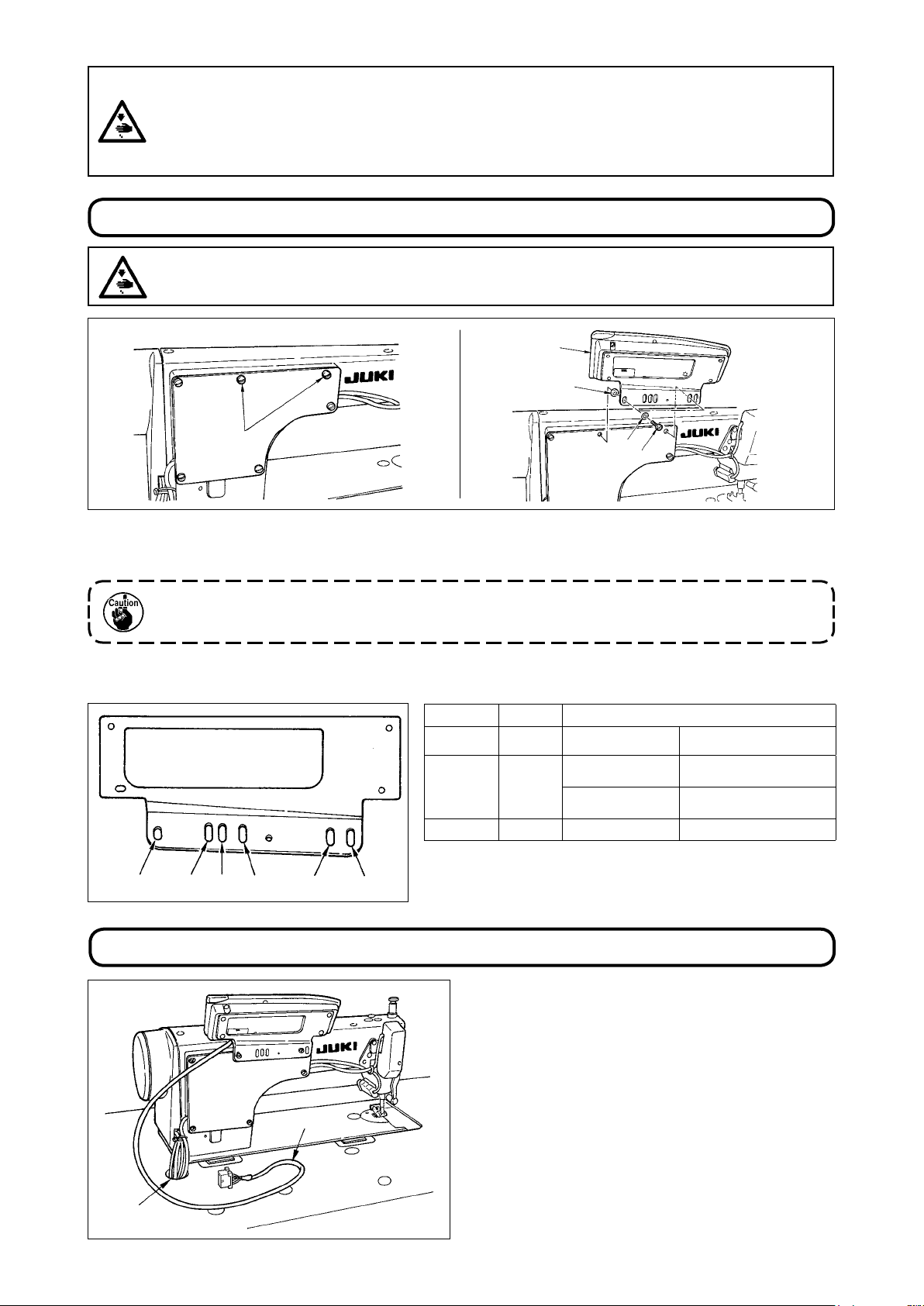

1. INSTALLING THE CONTROL PANEL

WARNING :

To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after

turning OFF the power switch and ascertaining that the motor has completely stopped.

2

4

1

3

5

1) Remove side plate setscrews 1 from the s

ide plate.

2) Install control panel 2 on the machine head using screws 5, at washers 3 and rubber seat 4 suppl

ied with the control panel as the accessories.

1. DDL-9000B (Not provided with AK) is given as an example of installing procedure.

2. Screw to install the panel changes according to the machine head used. Refer to Table 1 and

conrm the kind of screw.

< The relation between the respective machine heads and the positions of installing hole of the bracket are as described in the table. >

Table 1

1 2

3 4 5

6

DDL-9000A

DDL-9000B

LH-3500A

Installing hole

-

1

5

-

1

5

-

2

5

12

M5 X

(Prov

ided with AK)

M5 X 14

(Not provided with AK)

M5 X 12

14 Side plate setscrew

M5 X

Screw

Screw supplied with panel

as accessories

Side plate setscrew

Screw supplied with panel

as accessories

2. CONNECTING THE CORD

1

A

1) Pass cord 1 of the control panel through hole A

in the machine table route it to the underside of

the table.

2) As for the connection of the connector, refer to

the Instruction Manual for the control box.

- 1 -

Page 4

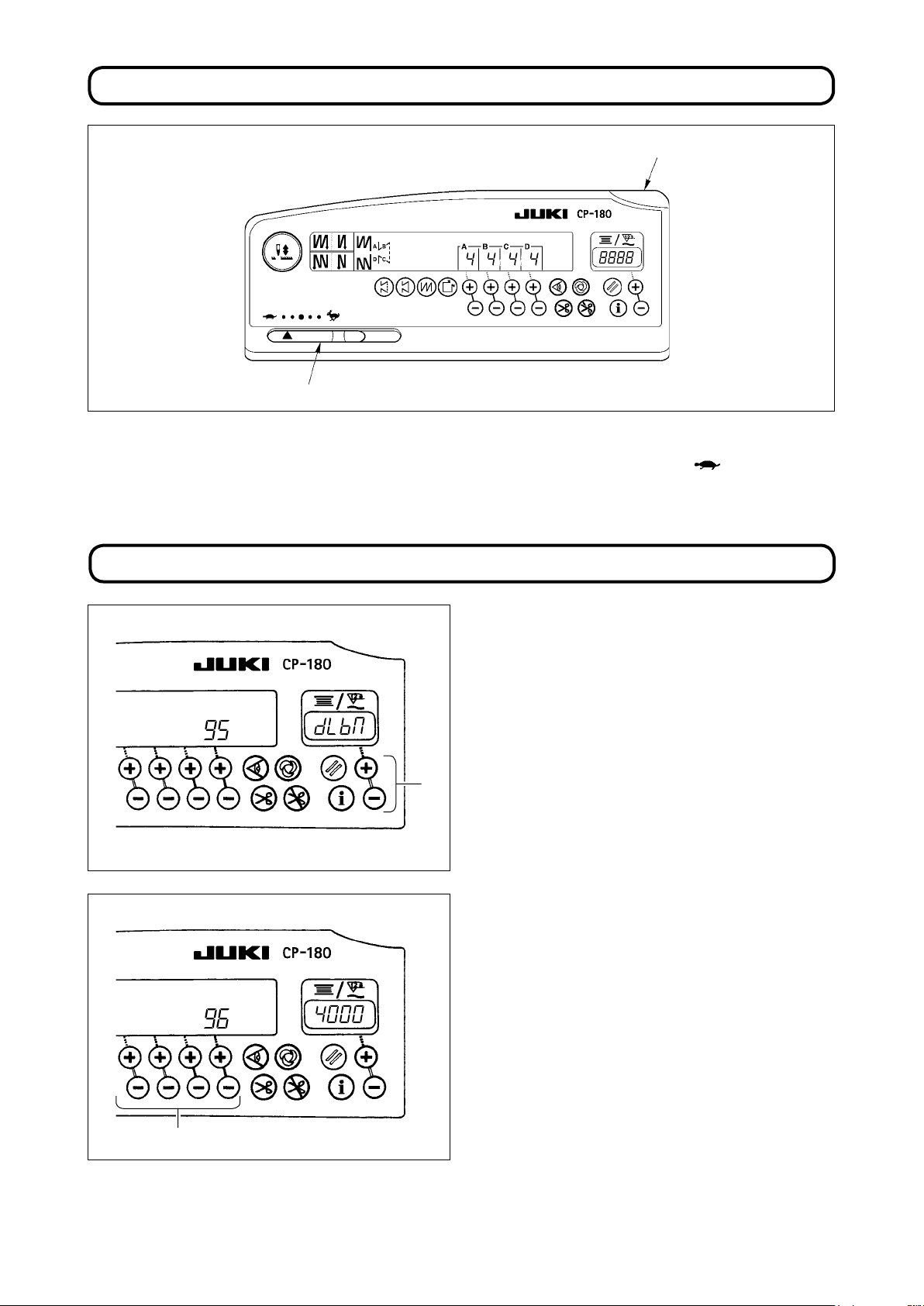

3. CONFIGURATION

1

2

Power indicator lamp (LED) : Lights up when the power switch is turned ON.

1

Max. speed limitation variable resistor : Limits the speed when it is moved to the left ( ).

2

4. SETTING PROCEDURE OF THE MACHINE HEAD

1) Refer to "18. FUNCTION SETTING SWITCH

p.15, and call the function setting No. 95.

2) The type of machine head can be selected by

pressing switch 1.

* Refer to "CAUTIONS WHEN SETTING UP THE

SEWING MACHINE" or "Machine head list"

on the separate sheet for the types of machine

1

heads.

3) After selecting the type of machine head, by

pressing switch 2, the step proceeds to 96 or

94, and the display automatically initializes to the

contents of the setting corresponding with the

type of machine head.

"

2

- 2 -

Page 5

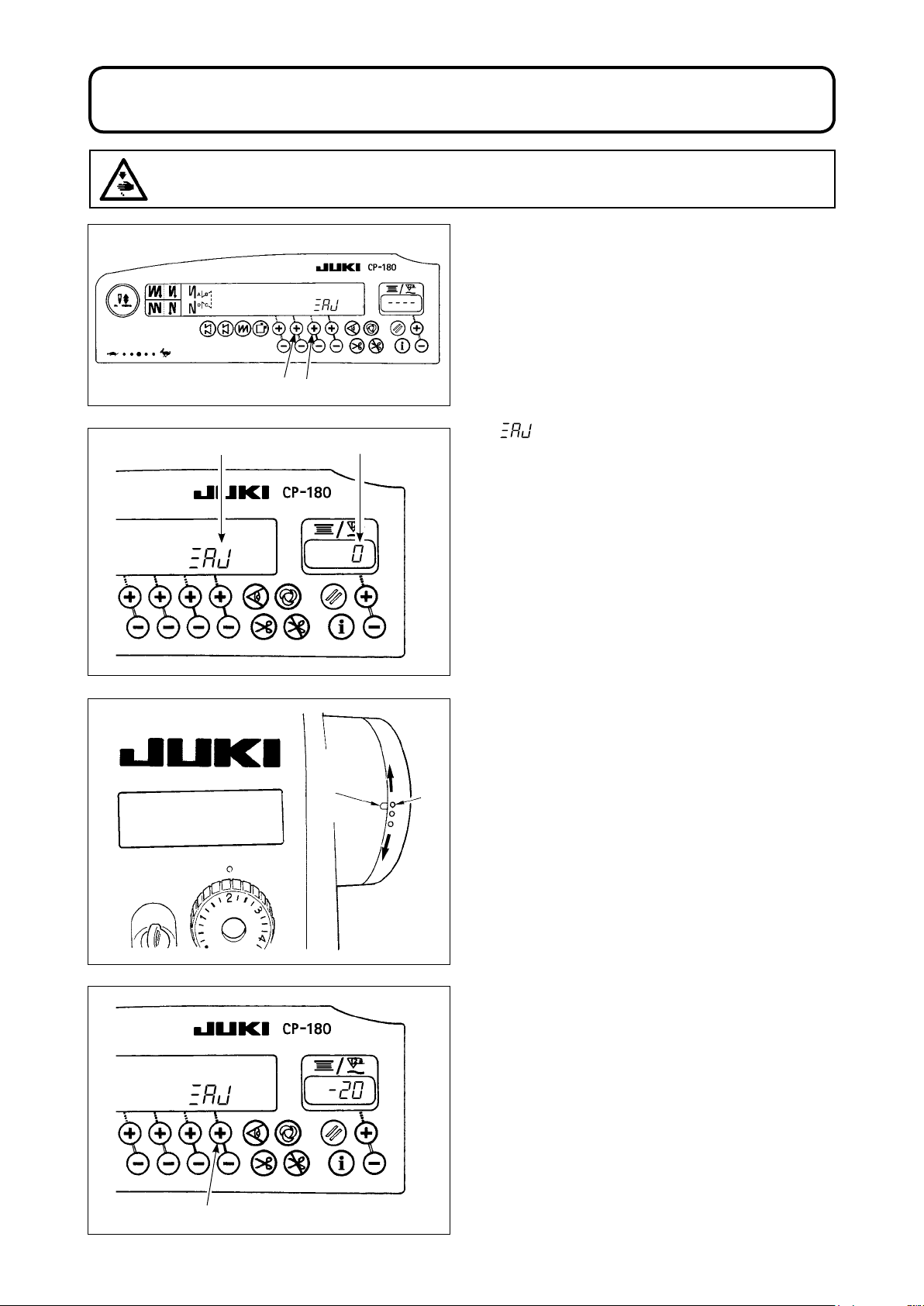

5. ADJUSTING THE MACHINE HEAD (DIRECT-DRIVE MOTOR TYPE SEWING MACHINE ONLY)

WARNING :

Be sure to perform the angle adjustment of the machine head by the operation below before using

the machine head.

1) Simultaneously pressing switch 1

turn ON the power sw

21

2) is displayed A

BA

mode is changed over to the adjustment mode.

3) Turn the handwheel by hand and angle B is dis-

played

has been detected.

(The value

in the indicator when the reference signal

is the reference value.)

itch.

in the indicator and the

and switch 2,

3

4) In this state, align the white dot 2 of the hand-

wheel with the concave 3 of the handwheel

cover as shown in the gure.

2

5) Press switch 4 to nish the adjustment work.

(The value is the reference value.)

4

- 3 -

Page 6

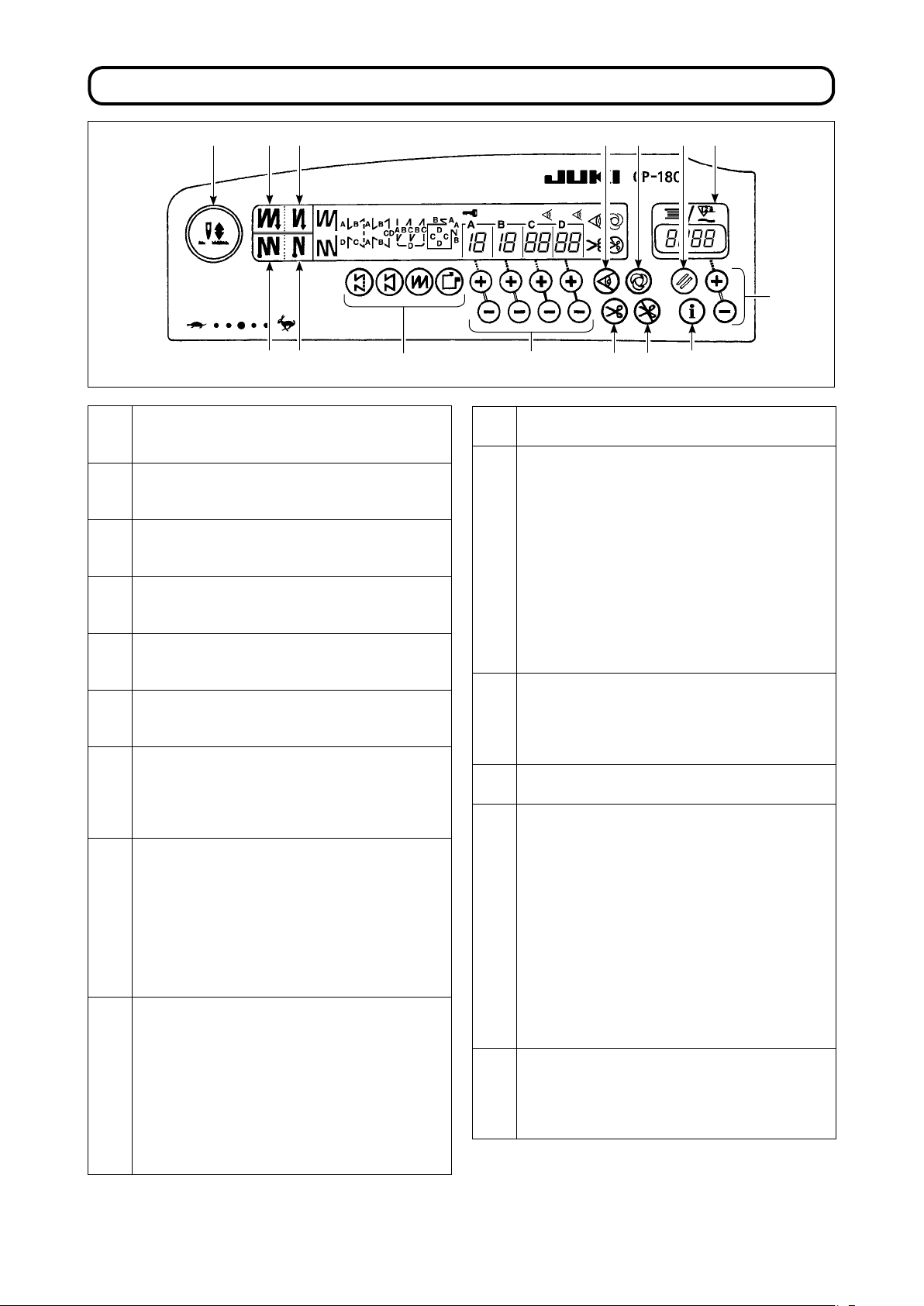

6. EXPLANATION OF THE CONTROL PANEL

!4

2 4 8

3 5

Pattern selector switch

1

• Used for selecting a pattern from among the

four different patterns.

Double reverse stitching (for start) switch

2

• U

sed for turning ON/OFF the double reverse

stitching for start.

Double reverse stitching (for end) switch

3

• U

sed for turning ON/OFF the double reverse

stitching for end.

Automatic reverse stitching (for start) switch

4

• U

sed for t u r n i n g O N / O FF the autom a t i c

reverse stitching for start.

Automatic reverse stitching (for end) switch

5

• U

sed for t u r n i n g O N / O FF the autom a t i c

reverse stitching for end.

Switches for setting the number of stitches

6

• Used

Material edge sensor ON/OFF switch

7

• R

• Used for setting whether or not the material

One-shot automatic stitching switch

8

• R

• Start the sewing machine with this switch, and

Automatic thread trimming switch

9

• R

• Even keep depressing the front part of the

for setting the number of stitches to be

sewn in processes A through D.

endered effective when the material edge

sensor is installed on the machine.

edge sensor is used during sewing.

endered effective when the material edge

sensor is installed on the machine or when

the sewing machin e is operated under the

constant-dimension stitching mode.

the sewing machine will run automatically until

the material edge is detected or the end of a

constant-dimension stitching is reached.

endered effective when the material edge

sensor is installed on the machine or when

the sewing machin e is operated under the

constant-dimension stitching mode.

pe dal, the sensor can det ect the m ater ial

edge, or after the completion of the constantdimension stitching mode, the machine will

automatically perform thread trimming.

!1

!0

!2

!5

7

61

Thread trimming prohibition switch

!0

•

Used for prohibiting thread trimming at any occasion.

Bobbin thread counter/thread trimming counter

!1

• Bobbin thread counter/thread trimming counter

can be changed over by the function of the control

box main body.

Bobbin thread counter :

icates the amount of bobbin thread while

• Ind

counting it by subtracting from the set value.

• When the bobbin thread remaining amount

detecting device is installed on the machine, the

counter indicates the number of times of detecting.

Thread trimming counter :

• Every t

counter value is added.

Bobbin counter reset switch

!2

sed for returning the value shown on the

• U

bobbin thread counter to the initial value.

• When the thread trimming counter is selected,

it is reset to [0].

Bobbin thread amount setting switch

!3

• Used for sett

Needle up/down compensation switch

!4

• Used for performing needle up/down

compensation stitching.

[Changeover selection of needle bar stop position

when the pedal is in its neutral position]

• Pressing the needle up/down compensation

switch, turn ON the power to the machine, and

the needle bar stop position when the pedal is

in its neutral position is changed over to down

position/up position.

• Conrmation of the stop position can be

performed at the front cover of the control box.

When up position stop is specied : " nP UP

When down stop position is specied : " nP Lo "

Information switch

!5

sed f o r ca l l i ng th e pr o d u c tion s u p p o r t

• U

function and callin g th e on e-t ouc h se tti ng

(by keeping the switch held pressed for one

second.)

9

ime thread trimming is performed, the

ing the amount of bobbin thread.

!3

"

- 4 -

Page 7

7. HOW TO OPERATE THE CONTROL PANEL FOR SEWING STITCHING PATTERNS

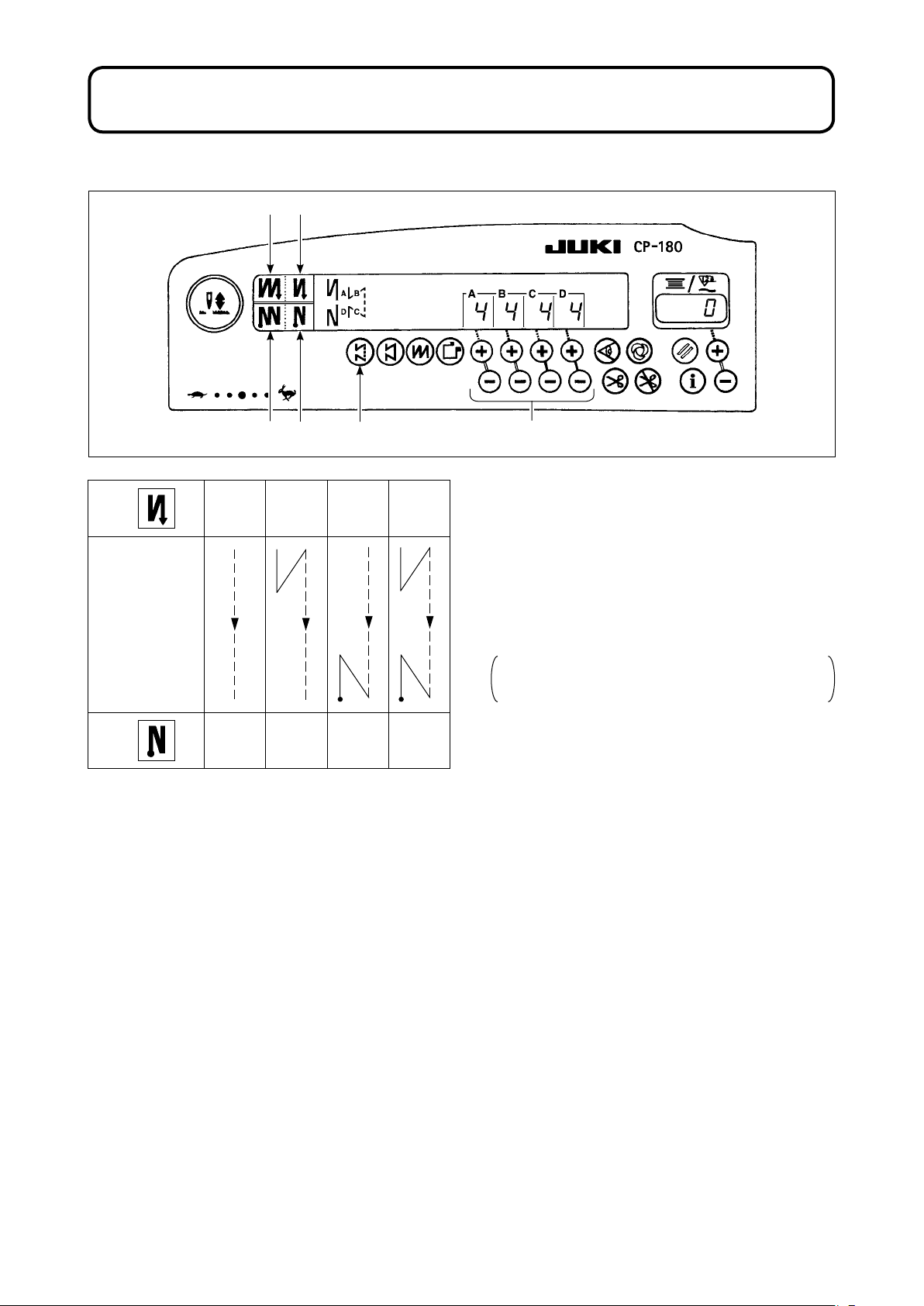

(1) Reverse stitching pattern

5 2

2

Sewing pattern

3

6 3

OFF ON OFF ON

A

B

C

D

OFF OFF ON ON

A

B

C

D

41

1) Press reverse stitching pattern switch 1 to

specify the reverse stitching pattern.

2) The reverse stitching pattern is selected, and the

number of stitches and data on reverse stitching

which have already been specied are shown on

the panel.

3) If you want to change the number of stitches,

operate the " + " or " - " switch of switches 4 for

setting the number of stitches A through D.

The range of the number of stitches that can be

changed : 0 to 19 stitches

4)

Four different stitching patterns can be performed

by matching the ON and OFF settings of automatic reverse stitching (for start) switch 2 and

automatic reverse stitching (for end) switch 3.

5) Furthermore, the double reverse stitching can be

selected by operating double reverse stitching

(for start) switch 5 and double reverse stitching

(for end) switch 6.

- 5 -

Page 8

(2) Constant-dimension stitching pattern

2

Sewing pattern

3

7 2

8 3

OFF ON OFF ON

A

B

CD

OFF OFF ON ON

CD

CD

B

A

A

B

CD

B

A

!0

41 5

6 9

1) Press constant-dimension stitching pattern

switch

on the control panel to select the

1

constant-dimension stitching pattern.

2) The constant-dimension stitching pattern is

selected. Now, the predetermined number of

stitches and the state of reverse stitching function are shown on the control panel.

3) To change the number of stitches of the process-

in the constant-dimension stitching pattern,

es

change the number of stitches for processes C

and D by operating switches 5 for setting the

number of stitches for processes C and D. Select

the reverse feed stitching accordingly. To change

the number of reverse-feed stitches, operate

switches 4 for setting the number of stitches for

processes A and B.

Adjusting range : A, B = to 19 stitches

C, D = 5 to 500 stitches

4) Four different kinds of stitching patterns can be performed according to the combination of ON/OFF setgs of automatic reverse stitching (for start) switch 2 and automatic reverse stitching (for end) switch 3.

tin

5) Furthermore, the double reverse stitching mode can be specied by operating double reverse stitching (for

start) switch 7 and double reverse stitching (for end) switch 8.

6) If automatic thread trimming switch 6 is turned ON, the sewing machine will automatically perform

thread trimming after it nishes the predetermined number of stitches between C and D. (If the automatic

reverse feed stitching (for end) is selected, the sewing machine will automatically perform thread trim-

ming after it nishes the automatic reverse stitching (for end) even when the automatic thread trimming

switch is not selected.)

If automatic thread trimming switch 6 is turned OFF, operate the touch-back switch after the completion

of processes C and D. Then the machine runs at a low speed (stitch compensation operation).

Also, if the pedal is returned to its neutral position and depressed its front part again, the sewing can be

continued regardless of the setting of number of stitches.

7) If thread trimming prohibiting function 9 is chosen, the machine will stop with the needle up without per-

forming thread trimming.

8) If one-shot automatic stitching function !0 is chosen, the machine will automatically perform sewing at a

stretch, at the specied speed by depressing the front part of the pedal.

- 6 -

Page 9

(3) Overlapped stitching pattern

2 31 4

1) Press overlapped stitching pattern switch

1

to

specify the overlapped stitching pattern.

A

C C

2) The overlapped stitching pattern is selected, and

the number of stitches and data on overlapped

stitching which have already been specied are

shown on the panel.

If you want to change the number of stitches,

3)

operate number of stitches setting switches 2

B

B

for processes A through C, and to change the

number of repeated processes, operate the " + "

D

or " - " switch of switch 3 for setting the number

of processes D.

The range of the number of stitches A, B and C

that can be changed : 0 to 19 stitches.

The range of the number of processes D that

can be changed : 0 to 9 times.

4) Depress the front part of the pedal once, and the sewing machine will repeat the normal stitching and re-

verse stitching by the predetermined times. Then, the sewing machine will automatically make the thread

trimmer actuate and will stop to complete the overlapped stitching procedure. (The one-shot automatic

stitching cannot be turned OFF.)

5) If thread trimming prohibiting function 4 is chosen, the machine will stop with the needle up upon com-

pletion of the overlapped stitching procedure without performing thread trimming.

- 7 -

Page 10

(4) Rectangular stitching pattern

1

Sewing pattern

6 2

7 3

OFF ON OFF ON

A

B

D

C

C

A

A

B

D

B

C

41 5

C

A

C

!0

8 9

B

D

C

A

B

A

B

C

D

C

1

D

OFF OFF ON ON

D

1) Press rectangular stitching pattern switch 1 on the control panel to select the rectangular st

D

D

itching pattern.

2) The rectangular stitching pattern is selected. Now, the predetermined number of stitches and other sewing

data are shown on the control panel.

3) To change the number of stitches of the processes in the rectangular stitching pattern, operate switches 5

(for processes C and D) to change the number of stitches for processes C and D.

Select the reverse feed stitching accordingly. To change the number of reverse-feed stitches, operate

switches 4 for setting the number of stitches for processes A and B.

(Adjustable range : A, B = 0 to 19 stitches, C, D = 0 to 99 stitches)

4) Four different kinds of stitching patterns can be performed according to the combination of ON/OFF set-

tings of automatic reverse stitching (for start) switch 2 and automatic reverse stitching (for end) switch 3.

5) Furthermore, the double reverse stitching mode can be specied by operating double reverse stitching (for

start) switch 6 and double reverse stitching (for end) switch 7.

At each step the sewing machine automatically stops after sewing the predetermined number of stitches.

At this time, if the touch-back switch is operated, the sewing machine runs at a low speed (stitch compen-

sation operation). Also, at the last process, if the pedal is returned to its neutral position and depressed its

front part again, the sewing can be continued regardless of the setting of number of stitches.

6) If automatic thread trimming switch 8 is turned ON, the sewing machine will automatically perform thread

trimming after the completion of the last process. (If the automatic reverse stitching (for end) is selected,

the sewing machine will automatically perform thread trimming after it nishes the automatic reverse stitch-

ing (for end).)

7) If thread trimming prohibiting function 9 is chosen, the machine will stop with the needle up without per-

forming thread trimming.

8) If one-shot automatic stitching function !0

stretch until the number of stitches specied is reached, at the predetermined sewing speed by depr

is chosen, the machine will automatically perform sewing at a

essing

the pedal while the sewing machine is engaged in the sewing of process C or D. The machine performs

thread trimming in the last process of one-shot automatic stitching pattern.

9) For the sewing machine equipped with an auto-lifter, the presser foot will automatically go up after the com-

pletion of each sewing process.

- 8 -

Page 11

8. ONE-TOUCH SETTING

A part of function setting items can be easily changed in the normal sewing state.

WARNING :

For the setting of functions other than those covered in this part, refer to "Instruction manual for the

SC-920".

< One-touch setting procedure >

1

) Keep switch 1 held pressed one second to en-

ter the funct

2) The set value can be changed by using switch 2.

3) To return to the normal sewing state, press

switch 1.

ion setting mode.

2

1

* Wiper function ( )

: Wiper does not operate after thread trimming

: Wiper operates after thread trimming

Th e setting is confirmed by pressing

switch 1.

9. PRODUCTION SUPPORT FUNCTION

The production support function consists of two different functions (five different modes) such as the

production volume management function, operation measuring function. Each of them has its own production

support effect. Select the appropriate function (mode) as required.

< Production volume management function >

•

Target No. of pcs. display mode [F100]

• Target/actual No. of pcs difference display mode [F200]

The target number of pieces, actual number of pieces and the difference between the target and actual

number of pieces along with the operation time are displayed to notify the operators of a delay and advance

in real time. Sewing machine operators are allowed to engage sewing while constantly checking his/her

work pace. This helps raise target awareness, thereby increasing productivity. In addition, a delay in work

can

be found at an early stage to enable early detection of problems and early implementation of corrective

measures.

< Operation measuring function >

Sewing machine availability rate display mode [F300]

•

• Pitch time display mode [F400]

• Average number of revolutions display mode [F500]

Sewing machine availability status is automatically measured and displayed on the control panel. The data

obtained can be used as basic data to perform process analyses, line arrangement and equipment efciency

checkup.

- 9 -

Page 12

2

2

3

3

6

1

< To display the production support modes >

1) Keep switch 1 held pressed (for one second)

in

the normal sewing state to call up the one-touch

setting screen.

4

2)

Then, press switch 2 on the one-touch sett

screen to display/hide the production support modes.

ing

3) Select the mode to be displayed/hidden by

1

pressing switch 3.

4) ON/OFF of the display can be changed over by

pressing switch 4.

5) To return to the normal sewing state, press

switch 1.

F100 to F500 modes have been factory-set

to HIDE at the time of delivery.

< Basic operation of the production support modes >

BA

Sewing can be perfor m e d w i t h t he production

support data displayed on the control panel.

1) When switch 1

is pressed in the normal sewing

state to enter the production support mode.

2) Production support function (F100 to F500) can

be changed over by pressing switch 2.

5

4

3) The data with an asterisk mark (*1) in Table 1

"

Display of modes" can be changed by pressing

switch 3. The data with an asterisk mark (*2)

can be changed by switch 4 or switch 5.

4) Refer to the Table 2 "Mode resetting operation"

for the resetting procedure of data.

5) To return to the normal sewing state, press

switch 1.

Table 1: Display of modes

Mode name Indicator

Target No. of pcs. display mode

(F100)

Target/actual No. of pcs.

ifference display mode

d

(F200)

Sewing machine availability

rate display mode

(F300)

Pitch time display mode

(F400)

A v e r a g e n u m b e r o f

ions display mode

revolut

(F500)

A

Actual No. of pcs.

(Unit : Piece)

(*1)

Difference between target No.

of pcs and actual No. of pcs

(Unit : Piece)

(*1)

icator

Ind

Target No. of pcs.

(Unit : Piece)

(*2)

Target pitch time

(Unit : 100 msec)

(*2)

S e w i n g m a c h i n e

av a i la b i li t y r a t e in th e

previous sewing

(Unit : %)

Pitch time in the previous

sewing

(Unit : 1 sec)

Average number of revolutions

in the previous sewing

(Unit : sti/min)

- 10 -

B

Indicator

(when switch 4

is pressed)

D i s p l a y o f a v e r a g e

availability rate of sewing

machine

(Unit : %)

Display of average pitch

time

(Unit : 100 msec)

Display of average number

of revolutions

(Unit : sti/min)

B

or switch

-

-

6

Page 13

Table 2: Mode resetting operation

Mode name

Target No. of pcs. display mode

(F100)

arget/actual No. of pcs. difference

T

display mode

[F200]

Se wing machine ava ilab ilit y rat e

display mode

(F300)

Pitch time display mode

(F400)

Averag e nu m b er of re v o l u tions

display mode

(F500)

Switch

6

(held pressed for 2 seconds)

Resets the actual number of pieces.

Resets the difference between target

number of pieces and actual number

of pieces.

Resets the actual number of p

Resets the difference between target

number of pieces and actual number

of pieces.

esets average availability rate of

R

sewing machine

Resets average p

R e s e t s a v e r a g e n u m b e r o f

ions of sewing machine

revolut

itch time

ieces.

Switch

6

(held pressed for 4 seconds)

-

-

Resets average availability rate of

sewing machine.

Resets average pitch time.

R e s e t s a v e r a g e n u m b e r o f

revolutions of sewing machine.

Resets average availability rate of

sewing machine.

Resets average pitch time.

R e s e t s a v e r a g e n u m b e r o f

revolutions of sewing machine.

Resets average availability rate of

sewing machine.

Resets average pitch time.

R e s e t s a v e r a g e n u m b e r o f

revolutions of sewing machine.

2

1

3

< Detailed setting of production volume manage-

ment function (F101, F102) >

• When switch 1 is held pressed (for three sec-

onds) under the target No. of pcs. d

isplay mode

(F100) or the target/actual No. of pcs. difference

display mode (F200), the detailed setting of the

production volume management function can be

carried out.

• The setting state of the number of times of

thread trimming (F101) and that of the target

achievement buzzer (F102) can be changed

over by pressing switch 2.

• The number of times of thread trimming for sew-

ing one piece of garment can be set by pressing

switch 3

in the setting state of the number of

times of thread trimming (F101).

• It is possible to set whether the buzzer sounds

or not when the actual number of pieces has

reached the target volume by pressing switch

in the setting state of the target achievement

3

buzzer.

- 11 -

Page 14

10. HOW TO USE THE BOBBIN THREAD COUNTER

The machine detects the number of stitches. The preset value on the bobbin thread counter is subtracted in

accordance with the number of stitches detected.

setting No. 7, bobbin thread count down unit.)

0 → -1 ", the buzzer peeps three times to warn the operator that the time to change the bobbin thread has come.

(Subtraction is made according to the setting of function

When the value on the counter becomes a minus value as " 1 →

2

to return the value indicated on bobbin thread

counter 2 to the initial value (it has been factory-set to "0" at the time of delivery).

1) Press bobbin thread counter reset switch 1

The bobbin thread counter cannot be reset

3

2) Specify an initial value using bobbin thread

amount setting switch 3.

When keeping pressing the switch, the change-

1

over speed is increased.

< Initial value on the bobbin thread counter for reference >

3) Once the initial value is specied properly, start

the sewing machine.

4)

When a minus value is shown on the counter and the

buzzer peeps three times, replace the bobbin thread.

5) After the bobbin thread has been properly replaced, press bobbin thread counter reset switch

1

ter to the initial value. Now, re-start the sewing

machine.

6) If the remaining amount of bobbin thread is excessive or the bobbin thread runs out before the

The table below gives the initial setting values for

reference when the bobbin is wound with thread

to the extent that the pinhole in the outside of the

bobbin case is reached as shown in the gure given

bobbin thread counter indicates a minus value,

adjust the initial value appropriately using the “+”

or “-“ switch of bobbin thread adjustment switch

3

above.

If the remaining amount of bobbin thread is excessive

Thread used

Polyester spun

thread #50

Cotton thread

#50

Length of thread wound

round the bobb

36m

31m

in

Thread tension rate 100 %

Value on bobbin

thread counter

1200 (stitch

length : 3 mm)

1000 (stitch

length : 3 mm)

If the remaining amount of bobbin thread is insufcient

… Decrease the initial value using the “-“ switch.

1. Uneven performance may occur in

※ Actually, the bobbin thread counter is affected

by the material thickness and the sewing speed.

So, adjust the

initial value of the bobbin

counter in accordance with the operating conditions.

thread

2.

So, be sure to use the device after carefully

during sewing. In this case, make the

thread trimmer actuate once.

to return the value on the bobbin thread coun-

.

… Increase the initial value using the “+” switch.

accordance with the winding way of

thread or the thickness of materials and

it is necessary to set the thread trimming

amount with some surplus.

If the bobbin thread counter is used

in combination with the bobbin thread

remaining amount detecting device, the

bobbin thread counter indicates the number

of detections of the bobbin thread remaining

amount detecting device.

reading the Instruction Manual for the

bobbin thread remaining amount detecting

device.

- 12 -

Page 15

11. HOW TO USE THE THREAD TRIMMING COUNTER

2

3

1

After selecting each item, be sure to perform updating of the function setting No.

When turning OFF the power without performing updating, the set contents are not changed.

For the updating procedure, refer to "18. FUNCTION SETTING SWITCH" p.15.

4) When reset switch 1 is pressed, the contents of indication 2 will be reset to " 0 ".

5) When modifying the count value, increase/decrease the value with setting switch 3.

Bobbin thread counter indication can be changed

over to thread trimming counter (simplified sewing

counter) indication by the operation below.

1) Function setting No. 6 Turn OFF the setting of

bobbin thread counter function. .

( 0 : off / 1 : on )

2) Function setting No. 14 Turn ON the setting of

sewing counter function.

( 0 : off / 1 : on )

3) From turning ON the power next, the counter

indication works as the thread trimming counter.

Every time thread trimming is performed, the

counter indication is upped.

12. NEEDLE UP/DOWN COMPENSATION SWITCH

Ev ery time needle u p/down com pensation switch

1

is pressed, the needle goes up when it is in its

1

lowest position or comes down when it is in its highest

position. This compensates the stitch by a half of the

predetermined stitch length. However, note that the

machine does not run continuously at a low speed even

if you keep the switch held pressed. Also, note that the

needle up/down compensation switch is inoperative

after turning the handwheel by hand. Sewing of needle

up/down compensation operation does not make the

thread trimming operation operative.

W h e n e v er p r e s s in g t h e n e e d l e u p / d o w n

compensation switch 1 and turning ON the power to

the machine, the stop position when the pedal is in

its neutral position can be changed over.

Al s o, th e s p ec i fi e d s tat e a t t h is ti me ca n b e

conrmed at the panel.

(The contents shown there will be reflected when

turning ON the power after next time.)

- 13 -

Page 16

13. KEY LOCK FUNCTION

In order to prevent the specied data on the number of stitches or the processes (A, B, C and D) to be

changed by mistake, the setting switch can be locked. (Even with the setting keys locked, the pattern to be

sewn and the value on the bobbin thread counter can be changed.)

3

21

1) After the completion of the setting of data on the number of stitches, etc., turn OFF the power to the machine once.

2) Turn ON the power switch while simultaneously pressing automatic reverse stitching (for end) switch 1

and the " + " switch of number of stitches setting switch 2 for process A with ngers.

3) Key mark 3 is shown on the control panel. This completes the locking of keys.

(If the key mark is not shown on the control panel, carry out the aforementioned steps 1) through 3) again.)

* To release the keys from the locked state, perform again the steps 1) and 2).

(Once the key mark goes out, the keys are released from the locked state.)

14. ON/OFF SWITCH OF THE MATERIAL EDGE SENSOR

• When the material edge sensor, which is optionally available, is connected to the control panel, the ON/

OFF switch of the material edge sensor becomes effective.

• If the material edge sensor is specied, the sewing machine will automatically stop running or perform

thread trimming when the sensor detects the material edge.

If the material edge sensor is used in combination with the control panel, carefully read the Instruc-

tion Manual for the material edge sensor beforehand.

15. AUTOMATIC THREAD TRIMMING SWITCH

• This switch is used to automatically actuate the thread trimmer in a process where the sewing machine

automatically stops or when the material edge sensor is used.

(If the automatic reverse stitching (for end) is specied, the thread trimmer will actuate after the sewing

machine completes the automatic reverse stitching (for end).)

16. ONE-SHOT AUTOMATIC STITCHING SWITCH

• This switch is used, in the constant-dimension stitching mode, rectangular stitching mode, or in the

process where the material edge sensor is specied, to make the sewing machine automatically perform

sewing at the specied speed until the end of the process is reached only by driving the sewing machine

mode.

- 14 -

Page 17

17. THREAD TRIMMING PROHIBITION SWITCH

• This switch is used to temporarily make the thread trimming function inoperative.

The other performance of sewing machine is not affected by this switch.

(If the automatic reverse stitching (for end) is specied, the sewing machine will perform the automatic

reverse stitching at the end of sewing.)

• If the automatic thread trimming switch

ed, the machine will not perform thread trimming but stop with its needle up.

and the thread trimming prohibition switch are both speci-

18. FUNCTION SETTING SWITCH

A

2

1) Pressing function setting switch 1, turn ON the power to the machine.

2) The indication on the control panel is changed over to the function setting indication mode.

Function setting No. is shown at section A and the set value is shown at section B of counter indication section.

* The contents to be shown will be different according to the contents that were set in the last time.

3) Function setting No. can be changed over by operating switch 2.

4) Function set value (setting state in case of on/off) can be changed over by operating switch 3.

5) After completion of setting, by operating switch 2 the changed contents are stored in memory and re-

ected from the next time.

6)

For the details of the contents of function setting, refer to the Instruction Manual supplied with the control box.

B

3

1

Refer to SC-920 instruction manual for the function setting list, details of the function setting and the

optional input/output connector.

- 15 -

Page 18

19. OPTIONAL INPUT/OUTPUT SETTINGS

2

1) Select function number 12.

1

3

※※※※

※※※※

2) Select the items of " ", " " and " " using

switch 3.

[When "

Specify the displayed number of the input func-

tion setting connector by means of switch 2. Then,

specify the connector pin function corresponding to

the displayed number by means of switch 3.

Function code and abbreviation are displayed alter-

nately in 1.

[When " " is selected.]

Specify the displayed number of the output func-

tion setting connector by means of switch 2. Then,

specify the connector pin function corresponding to

the displayed number by means of switch 3.

Function code and abbreviation are displayed alter-

nately in 1.

* Refer to the Instruction Manual for the control

" is selected]

box for the displayed numbers of the function

setting connectors and the function codes.

- 16 -

Page 19

Example) The thread trimming function is assigned to the displayed number "

setting connector.

1) Select function number 12 according to the function

setting method.

" of the input function

ENGLISH

The lamps will light up alternately.

2) Select the item of

3) Select the displayed number "

by switch 3.

"

"

" by means of

switch 2.

4) Se

5) Fix

lect

" "

"

thread trimming function by switch 3.

"

thread trimming function by switch 2.

6) Set activation of signal by switch 3. If the thread

trimming is performed by

play to

by

"

High" signal, set the display to

, and if the thread trimming is performed

"

"

"

Low" signal, set the dis-

.

"

"

7) The above function is xed by switch 2.

8) The option input is ended by switch 2.

9) Select the item of

" "

by switch 3, and return to

the function setting mode.

- 17 -

Page 20

20. AUTOMATIC COMPENSATION OF NEUTRAL POINT OF THE PEDAL SENSOR

Compensation value

Whe n eve r th e pe d al s ens o r, spr ing , et c . a r e

replaced, be sure to perform following operation.

1)

Pressing the switch 1,

2) Compensation value is displayed in the indicator

as illustrated.

1. At this time, the pedal sensor does not

work properly if the pedal is depressed.

Do not place the foot or any object on

the pedal. Warning sound "blip" and the

compensation value is not displayed.

1

2. When any thing other than number is

displayed in the indicator, refer to the

Engineer’s Manual.

3) Turn OFF the power switch, and turn ON the

power switch again to return to the normal mode.

21. SETTING OF THE AUTO LIFTER FUNCTION

turn ON the power switch.

WARNING :

When the solenoid is used with the air drive setting, the solenoid may be burned out. So, do not

mistake the setting.

When the auto-lifter device (AK) is attached, this

function makes the function of auto-lifter work.

1)

Turn ON the power switch while pressing switch 1.

2)

LED display is turned to " " " " with "blip",

and the function of auto-lifter becomes effective.

3) Turn OFF the power switch and turn ON the

power switch again. The machine returns to the

normal motion.

4) Repeat the operation 1) to 3), and LED display

1

" " " " : Auto-lifter device becomes effective. Selection of the auto-lifter device of solenoid drive

(+33V) or of air drive (+24V) can be performed with switch 2.

(Changeover is performed to drive power +33V or +24V of CN37.)

" " " " : Solenoid drive display (+33V)

" " " " : Air drive display (+24V)

" " " " : Auto-lifter function does not work. (Standard at the time of delivery)

(Similarly, the presser foot is not automatically lifted when programmed stitching is completed.)

is turned to " " " ". Then, the function of

auto-lifter does not work.

1.

(If ON/OFF operation of the power is performed quickly, setting may be not changed over well.)

2. Auto-lifter is not actuated unless this function is properly selected.

3. When

To perform re-turning ON of the power, be sure to perform after the time of one second or more has passed.

" " " "

delayed at the start of sewing. In addition, be sure to select

not installed since the touch-back switch may not work.

is selected without installing the auto-lifter device, starting is momentarily

" " "

- 18 -

when the auto-lifter is

"

Page 21

22. INITIALIZATION OF THE SETTING DATA

All contents of function setting can be returned to the

standard set values.

1) Pressing all switches 1, 2 and 3, turn ON the

power switch.

2) " " is displayed on indicator with a "blip" to

start initialization.

3) The buzzer sounds after approximately one

second (single sound three times, "blip", "blip",

and "blip"), and the setting data returns to the

1 2

1. When you carry out the aforementioned operation, the neutral position correction value for the

pedal sensor is also initialized. It is therefore necessary to carry out automatic correction of the

pedal sensor neutral position before using the sewing machine.

(Refer "20. AUTOMATIC COMPENSATION OF NEUTRAL POINT OF THE PEDAL SENSOR" p.18.)

2. When you carry out the aforementioned operation, the machine-head adjustment values are also

initialized. It is therefore necessary to carry out adjustment of the machine head before using the

sewing machine.

(Refer "5.

3. Even when this operation is performed, the sewing data set by the operation panel cannot be

initialized.

ADJUSTING THE MACHINE HEAD

3

standard setting value.

Do not turn OFF the power on the way of

initializing operation. Program of the main

unit may be broken.

4) Turn OFF the power switch and turn ON the

power switch again to return to the normal mode.

" p.3.)

23. CHECKING PROCEDURE OF THE ERROR CODE

1) Turn ON the power switch with switch 1 held

pressed.

2) The latest error number is displayed on indicator

with blip.

3) Contents of previous errors can be checked by

pressing switch 2.

(When the procedure has reached the end, two alarm

sounds in single tone will be heard, "blip" "blip".)

1

2

- 19 -

Loading...

Loading...