JUKI APW-895N/IP-420 Instruction Manual

APW-895N/IP-420

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

CONTENTS |

|

I. CAUTIONS BEFORE OPERATION.................................................................................. |

1 |

II. CONFIGURATION OF THE MACHINE............................................................................ |

2 |

III. SPECIFICATIONS........................................................................................................... |

3 |

1. MECHANICAL SPECIFICATIONS........................................................................................................... |

3 |

2. ELECTRICAL SPECIFICATIONS............................................................................................................ |

3 |

IV. INSTALLATION............................................................................................................... |

4 |

1. REMOVING PACKING MATERIALS....................................................................................................... |

4 |

2. SECURING THE MACHINE..................................................................................................................... |

4 |

3. CONNECTING THE FOOT PEDAL.......................................................................................................... |

5 |

4. CONNECTING THE AIR COUPLER ....................................................................................................... |

5 |

5. CONNECTING THE POWER PLUG ....................................................................................................... |

6 |

6. ASSEMBLING THE THREAD STAND AND ATTACHING IT TO THE MACHINE................................... |

7 |

7. INSTALLING SP-46N (CLAMP BAR STACKER) (OPTIONAL PART NO. : 40149301)......................... |

8 |

8. INSTALLING SP-47N (ROLLER STACKER) (OPTIONAL PART NO. : 40149302)................................ |

9 |

9. REMOVING THE HEAD FIXING PLATE................................................................................................ |

10 |

10. INSTALLING THE SUB-TABLE........................................................................................................... |

10 |

11. INSTALLING OPERATION PANEL IP-420.......................................................................................... |

10 |

12. LUBRICATING THE OIL TANK............................................................................................................ |

11 |

13. INSTALLING SA-120N (INTERLINING SUPPLYING DEVICE) |

|

(OPTIONAL PART NO. : 40149798)...................................................................................................... |

12 |

14. ADJUSTMENT OF SA-120N (INTERLINING SUPPLYING DEVICE) |

|

(OPTIONAL PART NO. : 40149798)...................................................................................................... |

13 |

V. PREPARATION OF THE SEWING MACHINE............................................................... |

14 |

1. HOW TO OPERATE THE SEWING MACHINE HEAD.......................................................................... |

14 |

(1) How to attach the needles................................................................................................................ |

14 |

(2) Thread used..................................................................................................................................... |

14 |

(3) How to pass the needle thread......................................................................................................... |

15 |

2. HOW TO REMOVE THE SEWING TABLE............................................................................................ |

16 |

(1) When replacing the bobbin thread.................................................................................................... |

16 |

(2) Cautions to be taken when the sewing tables are removed............................................................. |

17 |

3. HOW TO WIND THE BOBBINS............................................................................................................. |

18 |

4. HOW TO THREAD THE BOBBIN CASE............................................................................................... |

19 |

5. HOW TO INSTALL THE BOBBIN CASE............................................................................................... |

19 |

6. HOW TO ADJUST THE THREAD TENSION......................................................................................... |

20 |

7. SETTING THE MATERIAL TO BE SEWN............................................................................................. |

21 |

8. ADJUSTING THE MATERIAL GUIDE.................................................................................................... |

21 |

VI. HOW TO USE THE OPERATION PANEL.................................................................... |

22 |

1. PREFACE............................................................................................................................................... |

22 |

2. BASIC OPERATION OF THE OPERATION PANEL (IP-420)................................................................ |

25 |

(1) Configuration of IP-420..................................................................................................................... |

25 |

(2) Buttons used in common.................................................................................................................. |

26 |

(3) Basic operation................................................................................................................................. |

26 |

3. EXPLANATION OF THE BASIC SCREEN............................................................................................ |

29 |

(1) Input screen (Independent sewing mode)........................................................................................ |

29 |

(2) Sewing screen (Independent sewing mode) ................................................................................... |

30 |

i |

|

(3) |

Input screen (Alternate sewing mode).............................................................................................. |

31 |

(4) |

Sewing screen (Alternate sewing mode).......................................................................................... |

32 |

(5) |

Input screen (Cycle sewing mode)................................................................................................... |

33 |

(6) |

Sewing screen (Cycle sewing mode) .............................................................................................. |

34 |

4. USING THE COUNTER.......................................................................................................................... |

35 |

|

(1) |

Setting procedure of the counter...................................................................................................... |

35 |

(2) |

Releasing procedure of count-up..................................................................................................... |

38 |

(3) |

Counter value changing procedure during sewing........................................................................... |

38 |

5. USING THE BOBBIN THREAD AMOUNT ADJUSTMENT COUNTER................................................ |

39 |

|

(1) |

Setting procedure of the bobbin thread remaining amount adjustment counter............................... |

39 |

(2) |

Releasing procedure of the bobbin thread remaining amount detection count-up........................... |

41 |

6. CHANGING THE SEWING MODE......................................................................................................... |

42 |

|

7. USING THE SEWING PATTERN........................................................................................................... |

43 |

|

(1) |

Performing the selection of pattern................................................................................................... |

43 |

(2) |

Performing the new creation of pattern............................................................................................ |

44 |

(3) |

Copying the pattern.......................................................................................................................... |

45 |

(4) |

Erasing the pattern........................................................................................................................... |

47 |

(5) |

Naming the pattern........................................................................................................................... |

48 |

(6) |

Editing procedure of the cycle sewing data...................................................................................... |

49 |

8. CHANGING THE SEWING DATA.......................................................................................................... |

51 |

|

(1) |

Changing procedure of the sewing data........................................................................................... |

51 |

(2) |

Sewing data list................................................................................................................................ |

52 |

9. CHANGING THE MEMORY SWITCH DATA.......................................................................................... |

60 |

|

(1) |

Changing procedure of the memory switch data.............................................................................. |

60 |

(2) |

Memory switch data list.................................................................................................................... |

61 |

10. PERFORMING OPTIONAL SETTING.................................................................................................. |

69 |

|

(1) |

Changing procedure of the optional setting...................................................................................... |

69 |

(2) |

Optional setting list........................................................................................................................... |

70 |

11. CHANGING THE DEVICE SETTING.................................................................................................... |

71 |

|

(1) |

Changing procedure of the device setting........................................................................................ |

71 |

(2) |

Device setting list.............................................................................................................................. |

72 |

12. CUSTOMIZING THE PEDAL OPERATION.......................................................................................... |

73 |

|

(1) |

Method to select and use the customized data................................................................................ |

73 |

(2) |

Customizing the pedal operation data.............................................................................................. |

74 |

13. CUSTOMIZING THE DATA INPUT SCREEN....................................................................................... |

76 |

|

14. PERFORMING THE CUSTOMIZING SETTING OF THE SEWING SCREEN....................................................... |

78 |

|

15. USING THE INFORMATION................................................................................................................ |

80 |

|

(1) |

Observing the maintenance inspection information.......................................................................... |

81 |

(2) |

Releasing procedure of the warning................................................................................................. |

82 |

(3) |

Observing the production control information................................................................................... |

83 |

(4) |

Performing setting of the production control information.................................................................. |

85 |

(5) |

Observing the operation measurement information......................................................................... |

87 |

16. USING THE COMMUNICATION FUNCTION....................................................................................... |

89 |

|

(1) |

Handling possible data .................................................................................................................... |

89 |

(2) |

Performing communication by using the media................................................................................ |

89 |

(3) |

Performing communication by using USB........................................................................................ |

89 |

(4) |

Take-in of the data............................................................................................................................ |

90 |

(5) |

Take-in of plural data together.......................................................................................................... |

91 |

17. PERFORMING FORMATTING OF THE MEDIA.................................................................................. |

93 |

|

ii

VII. MAINTENANCE........................................................................................................... |

94 |

|

1. INSPECTION.......................................................................................................................................... |

94 |

|

(1) |

Maintenance and inspection of the pneumatic device...................................................................... |

94 |

(2) |

Maintenance and inspection related to the sewing machine............................................................ |

94 |

(3) |

With regard to the waste oil of the hook oil....................................................................................... |

95 |

(4) |

With regard to the cleaning of the hook shaft base.......................................................................... |

95 |

2. MARKING LIGHT................................................................................................................................... |

96 |

|

(1) |

Fixed marking (standard).................................................................................................................. |

96 |

(2) |

Movable marking (optional).............................................................................................................. |

96 |

(3) Adjusting the marking light irradiation position................................................................................. |

97 |

|

3. REPLENISHING GREASE TO THE DESIGNATED PLACE................................................................. |

98 |

|

4. CONSUMABLE REPLACEMENT COMPONENTS............................................................................. |

100 |

|

5. TILTING THE MACHINE...................................................................................................................... |

102 |

|

6. STANDARD OF REPLACING TIME OF THE GAS SPRING............................................................... |

103 |

|

7. REPLACING PROCEDURE BETWEEN DOUBLE-WELT AND SINGLE-WELT......................................................... |

104 |

|

(1) |

Replacing procedure between double-welt and single-welt........................................................... |

104 |

(2) |

Fine adjustment of the position of garment body clamp................................................................. |

104 |

(3) |

Replacing the binder....................................................................................................................... |

105 |

8. ADJUSTING THE CORNER KNIFE..................................................................................................... |

106 |

|

9. ADJUSTING THE POSITION OF THE SENSOR FOR DETECTING FLAPS..................................................... |

107 |

|

10. CAUSES AND CORRECTIVE MEASURES AGAINST TROUBLES WITH THE BOBBIN THREAD REMAIN- |

|

|

ING AMOUNT DETECTING DEVICE..................................................................................................................... |

108 |

|

11. HOW TO ADJUST THE FOOT PEDAL.............................................................................................. |

109 |

|

12. ERROR CODE LIST........................................................................................................................... |

111 |

|

13. INPUT NUMBER TABLE.................................................................................................................... |

121 |

|

iii

I. CAUTIONS BEFORE OPERATION

Following items have to be checked every working day before the operation of the machine and before the start of work hours.

1.Ascertain that the sewing machine is filled with the predetermined amount of oil.

2.Never operate the machine unless the lubricating part in the hook has been filled up with oil.

3.Ascertain that the pressure gauge indicates the designated air pressure of 0.5 MPa.

*(This is necessary particularly when the compressor is stopped for a lunch break or the like.)

If the compressed air pressure is equal to or less than the designated value, troubles such as interference between the parts can occur. It is therefore necessary to carefully check the compressed air pressure.

4.Check whether the needle thread/bobbin thread need to be replenished.

5.To perform sewing immediately after turning ON the power switch, perform trial stitching first, then proceed with sewing of actual products after the test sewing.

6.In order to prevent the optical fiber sensor of the bobbin thread remaining amount detecting device from showing a detecting failure, be sure to clean thread waste around the hook using an air gun once or more times a day.

7.In order to protect the flap sensor from showing a detecting failure, be sure to clean dust on the reflecting tape of the folding plate using an air gun once or more times a day.

− 1 −

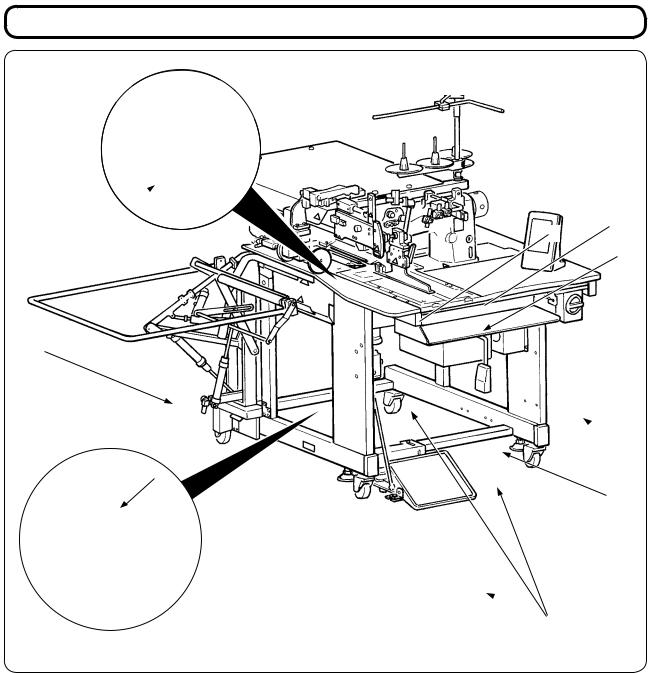

II. CONFIGURATION OF THE MACHINE

E

D  K

K

G

B

I F

I F

J

J

C

H

A

A

The APW-895N consists mainly of the following units.

A Frame and structural components (Framesewing table, covers, foot switch, etc.) B Clamp foot unit and feed mechanism

CCorner knife unit

D Binder unit (Binder components and its driving components)

E Pneumatic control unit (Pneumatic control devices and pipings)

F Stacker unit (Optional)

GSewing machine head

H Electric control unit (Control panel)

IOperation panel

J Power switch (Also used as the emergency stop switch)

KTemporary stop switch

With this machine consisting of the aforementioned 11 units, you can do desired welting work simply by setting materials (garment body, interlining piece, welting patch, etc.) in place and operating the switches on the operation panel.

In addition, when temporary stop switch K is pressed during operation of the device, the device stops.

− 2 −

III. SPECIFICATIONS

1. MECHANICAL SPECIFICATIONS

1 |

Sewing machine |

LH-895N model of 2-needle, lockstitch machine with a center knife |

|||||

|

|

|

|

|

|

|

|

2 |

Sewing speed |

3,000 sti/min (max.) |

|

|

|

||

|

|

|

|

|

|||

3 |

Stitch length |

Lockstitch : 2.0 to 3.4 mm (standard : 2.5 mm) |

|||||

|

|

|

Condensation stitch : 0.5 to 1.5 mm (standard : 1.0 mm) |

||||

|

|

|

Back tack stitch : 0.5 to 3.0 mm (standard : 2.0 mm) |

||||

|

|

|

Condensation/Back tack stitch selectable |

||||

4 |

Types of welt |

Parallel double welt, |

|

Each with flap or without flap |

|||

|

|

|

parallel single welt |

|

|||

|

|

|

|

|

|

||

5 |

Pocket lip length |

Standard type : Possible to set in increments of 1 mm within the range of min. 18 to |

|||||

|

(Welt lenght) |

max. 220 mm |

|

||||

|

|

|

Note that the pocket length is min. 35 mm when using the corner knife. |

||||

|

|

|

(Min. 50 mm in case of 14 mm gauge or more, and min. 21 mm by adding a solenoid valve) |

||||

|

|

|

For the long and wide type : Possible to set in increments of 1 mm within the range of |

||||

|

|

|

|

|

min. 18 to max. 250 mm |

||

|

|

|

Note that the pocket length is min. 70 mm when using the corner knife. (Min. 56 mm by add- |

||||

|

|

|

ing a solenoid valve) |

|

|

|

|

|

|

|

Possible to set max. 300 mm without entering corner knife. |

||||

6 |

Welting width |

8, 10, 12, 14, 16, 18 and 20 mm ( |

Long and wide type : 22, 24, 26, 28, 30 and 32 mm) |

||||

|

(Needle gauge) |

* However, for |

with dart stretcher, 8, 10, and 12 mm |

||||

|

|

|

For |

with zipper attachment, 16 mm, 18 mm, 20 mm |

|||

|

|

|

|

|

|||

7 |

Needles |

ORGAN DP X 17 #14 to #18 (standard #16) |

|||||

|

|

|

|

|

|

||

8 |

Thread |

Spun thread #60 (Recommended) |

|

||||

|

|

|

|

|

|||

9 |

Hook |

Full rotary, vertical-axis, self-lubrication hook |

|||||

|

|

|

|

|

|

||

10 |

Thread take-up lever |

Slide thread take-up lever |

|

|

|||

|

|

|

|

|

|

|

|

11 |

Needle bar stroke |

33.3mm |

|

|

|

||

|

|

|

|

|

|

||

12 |

Cloth feed mechanism |

Driven by stepping motor |

|

|

|||

|

|

|

|

|

|

|

|

13 |

Control |

By a micro-computer |

|

|

|

||

|

|

|

|

|

|||

14 |

Safety mechanism |

Machine operation is automatically stopped if the cloth feed mechanism error detector, |

|||||

the needle thread breakage detector or any of the various safety devices is actuated. |

|||||||

|

|

|

|||||

15 |

Lubricating oil |

JUKI New Defrix Oil No. 1 |

|

|

|||

|

|

|

|

|

|

|

|

16 |

Operating air pressure |

0.5 MPa |

|

|

|

||

|

|

|

|

|

|

|

|

17 |

Air consumption |

Approx. 40 Nℓ/min |

|

|

|

||

|

|

|

|

|

|||

18 |

Dimensions of machine |

Width : 1,095 mm (1,580 mm - when including the stacker) |

|||||

|

|

|

Length : 1,500 mm |

|

|

|

|

|

|

|

Height : 1,165 mm (1,800 mm - when including the thread stand) |

||||

19 |

Weight |

238.5kg |

|

|

|

||

|

|

|

|

|

|||

20 |

Noise |

- Equivalent continuous emission sound pressure level (LpA) at the workstation : |

|||||

|

|

|

A-weighted value of 78.5 dB; (Includes KpA = 2.5 dB); according to ISO 10821- C.6.3 |

||||

|

|

|

-ISO 11204 GR2 at 3,000 sti/min for the sewing cycle, 4.5s ON. |

||||

|

|

|

(Pattern : No.1, Jump feed speed of clamp foot : Max speed). |

||||

2. ELECTRICAL SPECIFICATIONS |

|

||||||

|

|

|

|

|

|

||

1 |

The number of independent sewing patterns that |

|

99 (1 to 99) |

|

|||

can be stored in memory |

|

|

|

||||

2 |

The number of alternate sewing patterns that can be |

20 (1 to 20) |

|

||||

stored in memory |

|

|

|

||||

|

|

|

|

||||

3 |

The number of cycles that can be stored in memory |

20 (1 to 20) |

|

||||

|

|

|

|

|

|||

4 |

Input power : |

|

|

Single phase : 220 to 240V 50/60 Hz |

|||

|

|

|

|

|

3-phase : 200 to 240V 50/60 Hz (Optional 380V) |

||

|

|

|

|

|

Voltage fluctuation : Within + 10% of the rated voltage |

||

5 |

Power consumption |

|

|

270VA |

|

||

|

|

|

|

|

|

|

|

− 3 −

IV. INSTALLATION

1. REMOVING PACKING MATERIALS

Remove the upper cover and remove the string and packing materials that have fixed the clamp foot.

Remove the string and packing materials that have fixed the clamp bar stacker.

Draw out the corner knife unit and remove the string that has fixed the unit.

Remove the string that has fixed the binder unit.

Wooden table

Frame

Cut and remove the clip band that has fixed the needle bar.

When lifting the machine, hold the frame without holding the wooden table.

When lifting the machine, hold the frame without holding the wooden table.

2. SECURING THE MACHINE

CAUTION :

To prevent a fatal accident, lower and fix adjust bolts (4 places) located at the side of caster after moving the machine to the level and stabilized place.

− 4 −

3. CONNECTING THE FOOT PEDAL

CAUTION :

When installing the pedal, perform the work paying attention to the overhead table.

|

|

|

Install the pedal base to the machine frame with |

|

|

|

screws . |

|

|

|

Connect pedal bases A and B with two screws |

|

|

|

|

|

|

|

. |

|

|

B |

|

|

|

|

Position of the pedal can be optionally |

|

|

|

adjusted within the range of the slot. |

|

|

|

|

|

|

A |

|

|

|

|

Connect the connecting rods with fixing screw |

|

|

|

. |

|

|

|

1. When connecting, do not connect the |

|

|

C |

rods with connecting rod C on the |

|

|

sensor side pulled downward, |

|

|

|

|

|

|

|

|

2. Install so that connecting rod on the |

|

|

pedal side D and the caster do not |

|

D |

|

||

|

interfere with each other within the |

||

|

|

|

range of pedal operation. |

4.CONNECTING THE AIR COUPLER

|

|

Connect one end of air coupler A supplied with |

|

|

the machine as an accessory to air hose . Then |

|

|

connect the other end to coupler on the main unit |

|

|

side. |

|

|

|

|

|

• Connect coupler A to the main unit |

|

|

with air cock closed, then carefully |

|

|

open air cock to allow the com- |

|

A |

pressed air to be supplied. |

|

• Make sure that the pressure gauge of |

|

|

|

|

|

|

the regulator reads 0.5 MPa. |

|

|

− 5 −

5. CONNECTING THE POWER PLUG

CAUTION :

To prevent possible accidents caused by leakage or dielectric strength, an appropriate power plug shall be installed by a person who has an expert knowledge of electricity. Be sure to connect the power plug to the receptacle that is well grounded.

Connection of the power plug to the power depends on the specifications of the product. Adjust the power plug to the power specifications to connect.

In case of the product of single-phase, 220 to 240V specifications :

Connect the sky-blue and brown wires of the power cord to the power terminal (AC220 to 240V) and the yellow/green wire to the ground (earth) terminal respectively.

In case of the product of 3-phase, 200 to 240V specifications :

Connect the red, white and black wires of the power cord to the power terminal (AC200 to 240V) and the yellow/green wire to the ground (earth) terminal respectively.

In case of the product with the optional high voltage transformer (with SA-128) :

Connect the black wires (3 pieces) of the power cord to the power terminal (AC380 to 415V) and the yellow/green wire to the ground (earth) terminal respectively.

It is possible to connect to 380/400/415V by setting of the input tap of transformer (standard setting at the time of delivery : 380V).

This product performs operation by the single-phase connection for 3-phasse 380/400/415V.

This product performs operation by the single-phase connection for 3-phasse 380/400/415V.

[ Caution when changing the power source of the high voltage optional transformer ]

|

When using high voltage optional transformer with |

|

|

the input voltage of 400V or 415V, it is necessary to |

|

replace input power source cord of high voltage |

||

|

||

|

optional transformer . Change power source input |

|

|

cord (sky blue) that is connected to 380V to the |

|

|

connection of 400V or 415V. |

|

|

To prevent accidents, perform the work |

|

|

after leaving the sewing machine alone |

|

|

more than 4 minutes in the state that |

|

|

the power switch is turned OFF and the |

|

|

power cord is drawn out. |

High voltage optional transformer is set on the

rear side of the table.

When performing changeover of voltage, remove transformer box after removing top cover .

− 6 −

6.ASSEMBLING THE THREAD STAND AND ATTACHING IT TO THE MACHINE

Putting nut and washer between main unit frame and fix the thread stand as illustrated in the left-hand figure.

|

Washer |

|

Spring washer |

|

|

|

Nut |

− 7 −

7.INSTALLING SP-46N (CLAMP BAR STACKER) (OPTIONAL PART NO. : 40149301)

Clamp bar stacker is delivered in the state that it is fixed in the frame at the time of delivery with the clamp bar stacker mounted. It is necessary to change the installing position to the normal using position.

|

|

Remove stacker fixing plate . |

|

|

|

|

|

Turn the whole stacker in the direction of the |

|

|

arrow and take it out from inside of the frame. |

|

|

Change stacker turning shaft A section to |

B |

|

stacker base hole B. |

A

At this time, take care to prevent the stacker cord, the air piping, etc. from being caught.

In addition, insert the stacker rotating shaft into the hole in the stacker base until the bottom of the base is reached.

Stacker in the operation state (with the air supply)

C

Stacker in the setup state (without the air supply)

Lock the whole stacker with hinge .

Insert safety bar in direction C as illustrated in the figure. Fix the safety bar at the position where it is in parallel with the floor surface.

At this time, confirm that air is being supplied.

In the case of power interruption due to a power failure, etc., the folding operation of the stacker can get out of order.

Be aware that this can give rise to a risk that the hand is caught in the stacker. Do not put hands in the area surrounded by the safety bar.

If the aforementioned situation occurs, stop the air supply to bring the stacker back to the state shown in the left figure "Stacker in the setup state (without the air supply)".

Then, start supplying the air after checking to make sure that the stacker is in the setup state.

− 8 −

8.INSTALLING SP-47N (ROLLER STACKER) (OPTIONAL PART NO. : 40149302)

(1)Adjusting the position

Confirming parallelism

|

|

|

Make sure that stacker |

|

|

|

table and rubber roller |

|

|

are installed parallel |

|

|

|

|

|

|

|

|

with each other. |

|

|

|

If not, loosen four set- |

|

|

screws to adjust. |

|

|

|

|

|

|

|

|

Confirming the clearance |

|

|

|

|

|

|

|

Make sure that the clear- |

|

|

|

ance between stacker ta- |

|

|

|

ble and rubber roller |

|

|

|

is approximately 0.5 mm. |

|

0.5mm |

|

If it is not approximately |

|

|

0.5 mm, loosen nut to |

|

|

|

|

|

|

|

|

adjust. |

|

|

|

|

(2) Maintenance

(Working |

When the roller stacker is not used or adjusting the |

|||

corner knife, the roller stacker can be turned upward |

||||

|

|

|

||

|

|

with the procedure below. |

||

|

|

|

Pull release lever . Lift up the roller section to |

|

|

|

|

thrust pin into fixing spring , then bring them |

|

|

into locked state (see Fig. 1). This puts the sewing |

|||

machine in standby state. |

||||

|

|

|

||

|

|

|

(Waiting |

|

|

|

|

|

|

|

|

|

|

|

Fig. 1

− 9 −

9. REMOVING THE HEAD FIXING PLATE

Remove fixing screws of head fixing plate .

Be sure to fix the machine and the frame when performing re-transportation.

10. INSTALLING THE SUB-TABLE

Install the sub-table with four screws as shown in the figure.

At this time, fix the sub-table so as to be flush with the main table.

|

|

11. INSTALLING OPERATION PANEL IP-420

B

Tape

Connector

As shown in the figure above, open the lid on the right-hand section B of IP-420 and connect the connector which is fixed with tape to the right-hand top surface A of the table.

To prevent malfunction due to static electricity, install operation panel IP-420 on the panel base to use and do not change the position of the panel base.

− 10 −

12. LUBRICATING THE OIL TANK

CAUTION :

1.To prevent accidents caused by abrupt start of the sewing machine, do not connect the power plug until lubrication has been completed.

2.To prevent inflammation or rash, immediately wash the part when oil has stuck to your eyes or body.

3.If oil has been swallowed, diarrhea or vomiting may occur. Put oil to the place where children cannot reach.

Lower engraved marker line

A

Upper engraved marker line

A

Fill the oil tank with the oil for hook lubrication before operating the sewing machine.

Remove oil cap and fill the oil tank with JUKI MACHINE OIL No. 1 (Part No. : MDFRX1600C0) using the oiler supplied with the machine as accessories.

To prevent entering of dust, be sure to attach the cap for use.

Fill the oil tank with the oil until the top end of oil amount indicating rod comes between the upper engraved marker line and the lower

engraved marker line of oil amount indicating window .

When oil amount is excessively large, oil leaks from the air hole or adequate lubrication cannot be performed. So, be careful.

When operating the sewing machine and the top of oil amount indicating rod has lowered up to oil amount indicating window , start lubricating.

•At the time of initial filling, fill the oil tank with oil of 200cc as the standard and confirm that the oil amount indicating rod is working.

•When operating a newly installed machine or a machine which has not been used for a relatively long period of time, make the machine run at 2,000 sti/min or less for the purpose of

break-in. In addition, use the machine after applying oil to races A of the right/left hooks.

•For the oil for hook, purchase JUKI

MACHINE OIL No. 1 (Part No. : MDFRX1600C0).

•Be sure to fill the oil tank with clean oil.

•Never fill the oil tank with dirty oil.

− 11 −

13. INSTALLING SA-120N (INTERLINING SUPPLYING DEVICE) (OPTIONAL PART NO. : 40149798)

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

Guide plate

*It cannot be used for the long and wide type.

Fix interlining installing plate to the machine frame with two screws .

Sewing table |

Roller |

Notch

|

|

Guide A |

|

|

Guide B |

Guide B |

||

|

|

|

Spring |

|

|

Set collar |

|

|

Side plate

Interlining

Set interlining as shown in the figure above.

The roll core that can be used is 40 to 70 mm wide and 200 mm in roller diameter (max.).

Pass the interlining between guide B and guide A and roller, and route it up above the table.

Feed the interlining up to the roller section using the notch of the guide plate.

Feed the interlining up to the roller section using the notch of the guide plate.

Adjust the lateral position of two guides, two guide pins and side plate (on the right) to allow the interlining to be fed straight up above the sewing table.

Position the set collar on the left-hand side to allow the side plate to lightly hold the interlining by spring. Then fix the set collar there.

−12 −

14. ADJUSTMENT OF SA-120N (INTERLINING SUPPLYING DEVICE) (OPTIONAL PART NO. : 40149798)

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

|

Adjustment of the interlining feeding amount |

|

|

is performed with memory switch ( |

). |

|

However, perform further fine adjustment with |

|

|

the speed controller of the interlining feeding |

|

|

cylinder . |

|

|

(When tightening the speed controller , the |

|

|

amount is decreased and when loosening it, the |

|

|

amount is increased.) |

|

|

|

|

When a new interlining is mounted, press

interlining supply button , perform feeding of the trial sewing several times and use the device after confirming the feeding amount and the parallel feeding of the interlining.

|

(Caution when operating) |

|

|

When using the interlining supplying device with |

|

|

rear reference , the interlining at the sewing |

|

|

start remains long since it is away from interlin- |

|

ing outlet . So, use the device with front refer- |

||

|

||

|

ence . |

|

|

For handling the sewing tables, refer to |

|

|

"V-2.(2) Cautions to be taken when the |

|

|

sewing tables are removed" p. 17. |

− 13 −

V. PREPARATION OF THE SEWING MACHINE

1.HOW TO OPERATE THE SEWING MACHINE HEAD

(1)How to attach the needles

CAUTION :

•Turn OFF the power before starting the work so as to prevents accidents caused by abrupt start of the sewing machine.

•When replacing the needle, be careful not to allow your fingers to touch the blade section of the center knife.

Needles used are DP X 17 #14 to #18 (standard #16). Use the specified needle.

Insert leftand right-hand sides needles as far asthey will go pointing their long grooves at each

other and tighten needle clamp screws .

(2) Thread used

• Use the left hand twist thread for the needle thread.

• Either twist thread will do for the bobbin thread.

Right hand twist thread |

Use a new thread which is uniformly |

|

twisted. |

Left hand twist thread

− 14 −

(3) How to pass the needle thread

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

Lift binder in the direction A, Hold section B by hand and turn the whole binder in the direction C.

Be sure to press section B since welt- B ing width may become improper when the binder is pressed and turned in the

direction C.

A |

|

|

Binder is locked with the ball plunger. |

|

|

C |

Rather strongly turn the binder in the |

||

|

||||

|

|

direction C to release the lock. |

||

|

|

|

Then pass needle thread in the order as shown in the figure below.

AB

B

A

A

C

B

B

A

A B

AB

Periodically replace thread guide felt C. Sewing trouble due to rough motion of thread during sewing can be prevented.

Pass the needle thread in the illustrated order. |

|

A |

Left-hand side needle thread toward the sewing machine |

|

|

|

||

Right-hand side needle thread toward the sewing machine |

|

B |

|

||

− 15 − |

|

|

2. HOW TO REMOVE THE SEWING TABLE

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

(1) When replacing the bobbin thread

|

|

Pin

A

Move the clamp foot to the rear end of its stroke.

Insert your fingers into notches A in the bottom of rightand left-hand sewing tables and , and push up the sewing tables.

Move the tables in the direction of the arrow keeping the above state, and you can see the bobbin case.

At this time, move the sewing tables so as not to allow the sewing tables to come in contact with the needles.

After replacing the bobbin thread, return the sewing tables in place by following the above-mentioned steps of procedure in the

reverse order. Now, firmly set the sewing tables on the throat plates and the pins.

− 16 −

(2) Cautions to be taken when the sewing tables are removed

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

When you remove the sewing tables and , be sure to accurately set them by following the points below.

Pins, rear |

Securely fit the pins, rear (left) (right) over the |

|

pin holes. |

||

|

||

|

Securely fit pin holes, front (left) (right) over the |

|

|

pins. |

|

|

Pin holes, front |

|

|

|

|

Plate spring |

|

1.In case of the machine provided with

SA-120N (automatic interlining supplying device), return the sewing tables

to their home positions while lifting the sewing tables and so that the plate spring section is not bent.

Outlet of interlining supply

2.In case of removing the sewing tables and with the types below, take care not to bend pocket bag clamping device and interlining clamping device.

Pocket bag clamping device (standard)

Pocket bag clamping device (for interlining supply)

− 17 −

3. HOW TO WIND THE BOBBINS

CAUTION :

To prevent damage, avoid contact with bobbins while the machine is in operation.

|

|

|

|

Put bobbin into the thread winder |

|

|

|

|

shaft until it will go no further. |

|

|

|

|

Pass thread through thread guide |

|

|

|

|

plate , open thread tension disk |

|

|

|

|

and put the thread into the slit of |

|

|

|

|

thread tension rod . |

|

|

|

Pass thread in the order as shown in |

|

|

|

|

the figure, and wind the thread onto |

|

|

|

|

|

|

Direction of |

|

|

||

|

|

bobbin by four or five turns. (The |

||

|

rotation |

|

|

|

|

|

|

direction of the arrow corresponds to |

|

|

|

|

|

|

|

|

|

|

the direction of rotation of the bobbin.) |

|

|

|

|

Press bobbin thread guide and |

|

|

|

|

the bobbin rotates. |

|

|

|

|

The thread winder will automatically |

|

|

|

|

stop as soon as it has wound up the |

|

|

|

|

bobbin to a predetermined amount. |

1.If you want to wind a bobbin, start winding it from recess as illustrated in the figure above. If you start to wind a bobbin from portion , the detection of run-out of bobbin thread will fail to be performed normally.

2.To ensure the appropriate remaining amount of bobbin thread, it is important to wind the bobbin uniformly. Be sure to check that the bobbin is uniformly wound particularly at the start of bobbin winding.

If the bobbin fails to be uniformly wound with thread, properly adjust the lateral position of tension post socket .

3.It is most suitable to wind the bobbin with thread to approximately 80% of the outer diameter of the bobbin. The winding amount can be adjusted with winding amount adjustment screw .

4.Do not press lever except when winding bobbin thread. Motor continues to run and trouble will be caused.

5.When abnormalities such as overload of the thread winding motor, etc. are delected, thermal switch is shut off. When thermal switch is shut off, turn ON thermal switch again after turning OFF it to return.

− 18 −

4.HOW TO THREAD THE BOBBIN CASE

Hold in hand a bobbin in the way that it spins clockwise and put it into the bobbin case.

Bobbin case |

Pass the thread through slot in the bobbin |

|

case. |

|

Pull the thread to pass it under the tension |

|

spring. |

Bobbin

5. HOW TO INSTALL THE BOBBIN CASE

CAUTION :

Turn OFF the power before starting the work so as to prevent accident caused by abrupt start of the sewing machine.

|

Raise hook levers and take out the bobbin |

|

cases together with the bobbins. |

|

When fitting, fit the bobbin cases into the hook |

|

driving shaft and tilt levers . |

|

When bobbin cases, left and right, are |

|

replaced, make sure that the clearance |

|

between the opener which is extremely |

|

receded and the bobbin case is 0.2 to 0.3 |

|

mm. If the clearance is not 0.2 to 0.3 mm, |

|

loosen setscrew and adjust it. |

|

|

|

|

|

.3mm |

|

|

0 |

|

|

to |

|

|

.2 |

|

|

|

0 |

|

|

|

− 19 −

6. HOW TO ADJUST THE THREAD TENSION

Bobbin case |

Adjusting bobbin thread tension |

|

Turn bobbin thread tension adjustment screw |

||

|

||

|

clockwise to increase the bobbin thread tension |

|

|

or turn the screw counterclockwise to decrease it. |

Bobbin

thread tension adjustment screw

As shown in the left-hand figure, standard bobbin thread tension is 0.25 to 0.35N when measuring with the tension gauge.

Adjusting needle thread tension

First, adjust the rightand left-hands bobbin thread tension.

Then in accordance with the bobbin thread tension obtained, adjust the rightand left-hand sides needle threads tension appropriately by turning thread tension adjustments nuts andrespectively. Turning the nuts clockwise will increase the thread tension or turning them counterclockwise to decrease it.

− 20 −

7. SETTING THE MATERIAL TO BE SEWN

Garment body |

Garment body |

clamp (left) |

clamp (right) |

Garment body |

Garment body |

|

clamp rubber |

Use a garment body that is larger than the garment body clamp rubber piece adhered under the right and left garment body clamps.

If a garment body of which size is smaller than the garment body clamp rubber piece, the rubber piece can come off or the machine can malfunction.

If it is necessary to use a small material, mount a shim type gauge

(optional) on the machine.

8. ADJUSTING THE MATERIAL GUIDE

Material guide functions to stabilize the welt patch at the edge of the machine needle.

Adjust the height and the presser pressure of material guide in accordance with the thickness of material.

|

|

|

|

|

|

The height of material guide can be adjusted by |

|

Material guide |

|

loosening nut and screw . |

|||

|

|

|

||||

|

spring |

|

|

|

(Clearance between material guide and welt |

|

Material guide arm |

|

|

|

patch scale has been adjusted to 0.5 to 1.0 mm |

||

|

|

at the time of delivery.) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

Presser pressure can be adjusted with spring |

|

|

|

|

|

|

|

pressure adjust screw . |

|

|

|

|

|

|

(Adjust the pressure so that there is no exces- |

|

|

|

|

|

|

sive resistance when the material passes.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 to 1.0 mm |

|

|

|

|

|

− 21 −

VI. HOW TO USE THE OPERATION PANEL

1.PREFACE

1)To use the data for APW-895N/896N (EPD data) on APW-895N

To use the EPD data on the APW-895N, read the data into the IP-420.

Insert the relevant medium into the IP-420. Select pattern number xxx from EPD data.

2)Folder structure of the media

Store each file in the directories below of the media.

Media drive |

APW-895N |

APW××× .EPD |

|

|

|

|

|

APW××× .EPD |

|

|

APW××× .EPD |

Data that are not stored in the directories above cannot be read. So, be careful.

3)CompactFlash (TM)

■Inserting the CompactFlash (TM)

Media

1)Turn the label side of the CompactFlash(TM) to this side (place the notch of the edge to the rear.

) and insert the part that has a small hole into the panel.

2)After completion of setting of the media, close the cover. By closing the cover, it is possible to access. If the media and the cover come in contact with each other and the cover is not closed, check the following matters.

•Check that the media is securely pressed until it goes no further.

•Check that the inserting direction of the media is proper.

1.When the inserting direction is wrong, panel or media may be damaged.

2.Do not insert any item other than the CompactFlash (TM).

3.The media slot in the IP-420 accommodates to the CompactFlash (TM) of 2 GB or less.

4.The media slot in the IP-420 supports the FAT16 which is the format of the CompactFlash (TM). FAT32 is not supported.

5.Be sure to use the CompactFlash (TM) which is formatted with IP-420. For the formatting procedure of the CompactFlash (TM), see "VI-17. PERFORMING FORMATTING OF THE MEDIA" p. 93.

−22 −

■ Removing the CompactFlash (TM)

4)USB port

■ Inserting a device into the USB port

1)Hold the panel by hand, open the cover, and press the media removing lever . The media is eject.

When the lever is strongly pressed, the media may be broken by protruding and falling.

2)When the media is drawn out as it is, removing is completed.

Slide the top cover and insert the USB device into the USB port. Then, copy data to be used from the USB device onto the main body.

After completion of copying the data, remove the USB device.

■ Disconnecting a device from the USB port

Remove the USB device. Put the cover back in place.

Cautions when using the media

•Do not wet or touch it with wet hands. Fire or electric shock will be caused.

•Do not bend, or apply strong force or shock to it.

•Never perform disassembling or remodeling of it.

•Do not put the metal to the contact part of it. Data may be disappeared.

•Avoid storing or using it in the places below.

Place of high temperature or humidity / Place of dew condensation /

Place with much dust / Place where static electricity or electrical noise is likely to occur

− 23 −

Precautions to be taken when handling USB devices

•Do not leave the USB device or USB cable connected to the USB port while the sewing machine is in operation. The machine vibration can damage the port section resulting in loss of data stored on the USB device or breakage of the USB device or sewing machine.

•Do not insert/remove a USB device during reading/writing a program or sewing data. It may cause data breakage or malfunction.

•When the storage space of a USB device is partitioned, only one partition is accessible.

•Some type of the USB device may not be properly recognized by this sewing machine.

•JUKI does not compensate for loss of data stored on the USB device caused by using it with this sewing machine.

•When the panel displays the communication screen or pattern data list, the USB drive is not recognized even if you insert a medium into the slot.

•For USB devices and media such as CF(TM) cards, only one device/medium should be basically connected/inserted to/into the sewing machine. When two or more devices/media are connected/inserted, the machine will only recognize one of them. Refer to the USB specifications.

•Insert the USB connector into the USB terminal on the IP panel until it will go no further.

•Do not turn the power OFF while the data on the USB flash drive is being accessed.

USB specifications

•Conform to USB 1.1 standard

•Applicable devices *1 Storage devices such as USB memory, USB hub, FDD and card reader

•Not-applicable devices CD drive, DVD drive, MO drive, tape drive, etc.

•Format supported FD (floppy disk) FAT 12

Others (USB memory, etc.), FAT 12, FAT 16, FAT 32

• Applicable medium size FD (floppy disk) 1.44MB, 720kB

Others (USB memory, etc.), 4.1MB ~ (2TB)

• Recognition of drives For external devices such as a USB device, the device which is recognized first is accessed. However, when a medium is connected to the builtin media slot, the access to that medium will be given the highest priority. (Example : If a medium is inserted into the media slot even when the USB memory has already been connected to the USB port, the medium will be accessed.)

• Restriction on connection Max. 10 devices (When the number of storage devices connected to the sewing machine has exceeded the maximum number, the 11th storage device and beyond will not be recognized unless they are once disconnected and re-connected. )

• Consumption current The rated consumption current of the applicable USB devices is 500 mA at the maximum.

*1 : JUKI does not guarantee operation of all applicable devices. Some device may not operate due to a compatibility problem.

− 24 −

2.BASIC OPERATION OF THE OPERATION PANEL (IP-420)

(1)Configuration of IP-420

[ Front ] |

[ Right side ] |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

||

|

|

|

|

|

Symbol |

Name |

|

Description |

|

|

|

|

|

|

|

TOUCH PANEL, LCD display section |

|

|

|

|

|

|

||

|

READY key |

Change-over of the data input screen and the sewing screen is |

||

performed. |

|

|||

|

|

|

||

|

|

|

||

|

INFORMATION key |

Change-over of the data input screen and the information screen is |

||

performed. |

|

|||

|

|

|

||

|

|

|

||

|

COMMUNICATION key |

Change-over of the data input screen and the communication |

||

screen is performed. |

|

|||

|

|

|

||

|

|

|

||

|

MODE CHANGEOVER key |

Change-over of the data input screen and the mode change-over |

||

screen which performs |

various details setting. |

|||

|

|

|||

|

|

|

|

|

|

Contrast control |

|

|

|

|

|

|

|

|

|

Brightness control |

|

|

|

|

|

|

|

|

|

CompactFlash (TM) eject button |

|

|

|

|

|

|

|

|

|

CompactFlash (TM) slot |

|

|

|

|

|

|

|

|

|

Cover detection switch |

|

|

|

|

|

|

|

|

|

Connector for external switch |

|

|

|

|

|

|

|

|

|

Connector for control-box connection |

|

|

|

|

|

|

|

|

1.Lightly press the target key on the touch panel with a fingertip to operate the IP-420. If you operate with any means other than your fingertip, the IP-420 can malfunction or the glass surface of the touch panel can be scratched or break.

2.When READY key is pressed first after turning ON the power, origin retrieval of the clamp foot is performed. At this time, the clamp foot moves. So, be careful.

−25 −

(2) Buttons used in common

Buttons that perform common operation in the respective screens of IP-420 are as described below.

Pictograph |

Name |

Description |

|

|

|

|

CANCEL button |

Pop-up screen is closed. In case of the data change screen, the data during |

|

changing can be cancelled. |

|

|

|

|

|

|

|

|

ENTER button |

Data changed are determined. |

|

|

|

|

UP SCROLL button |

This button scrolls button or display upward. |

|

|

|

|

DOWN SCROLL button |

This button scrolls button or display downward. |

|

|

|

|

RESET button |

This button releases error and the like. |

|

|

|

|

NUMBER INPUT button |

Ten keys are displayed and input of number can be performed. |

|

|

|

|

CHARACTER INPUT button |

Character input screen is displayed. |

|

|

|

(3) Basic operation

Turn ON the power switch.

First, turn ON the power switch.

Reset pop-up screen is displayed after displaying WELCOME screen. Press RESET button  A.

A.

When RESET button is pressed, the binder goes up. So, be careful.

A

A

Next, language selection pop-up screen is displayed. After selecting the language you desire to display, press ENTER button

B. Then the independent sewing input screen (screen A) of the figure below is displayed.

|

|

When ending the selection screen with CANCEL button |

|

|

|

or ENTER button |

without performing the lan- |

|

|

guage selection, the language selection screen is dis- |

|

|

B |

played whenever the power is turned ON. |

|

|

|||

− 26 −

Loading...

Loading...