Page 1

FAA Approved Installation Manual for the EDM-960 Report No 909

Primary Engine Data Management System Page 1 of 46 Rev D

Date 2-6-2014

TABLE OF CONTENTS

Revisions_____________________________________________________________________________2

1.

2. Read This First ________________________________________________________________________2

3. Instrument Marking_____________________________________________________________________3

4. Primary TSO Label _____________________________________________________________________3

5. Operation and Abbreviations_____________________________________________________________4

6. Dimming______________________________________________________________________________5

7. Locating and Installing the Indicator and Remote Alarm Display, RAD __________________________6

8. EDM-960 Display Installation_____________________________________________________________7

9. EDM-960 Key Card Installation ___________________________________________________________8

10. EDM-960 in aircraft with wing-mounted engines_____________________________________________9

11. EDM-960 in aircraft with centerline thrust engines __________________________________________10

12. Wiring harness for 950_________________________________________________________________11

13. Wiring harness for Display _____________________________________________________________11

14. Pressurized Aircraft wire Routing________________________________________________________12

15. Power Connection ____________________________________________________________________12

16. Probe Wiring _________________________________________________________________________12

17. Wiring Markings ______________________________________________________________________13

18. Exhaust Gas Temperature Probe (EGT) Installation _________________________________________13

19. Turbine Inlet Temperature (TIT) Probe Installation (optional) _________________________________14

20. Cylinder Head Temperature (CHT) Probe Installation________________________________________14

21. Outside Air Temperature (OAT) Probe Installation __________________________________________15

22. Compressor Discharge Temp Probe Installation (optional) ___________________________________15

23. Carburetor Probe Installation (optional)___________________________________________________15

24. Oil Temperature Probe Installation _______________________________________________________15

25. Oil Pressure Sensor Installation _________________________________________________________15

26. Ammeter Shunt Installation_____________________________________________________________17

27. General Fuel Flow Transducer Installation_________________________________________________18

28. Fuel Level Interface Installation _________________________________________________________19

28.3 Fuel Tank Calibration __________________________________________________________________21

29. Capturing the sender reading at each calibration point: _____________________________________22

30. GPS Interface ________________________________________________________________________25

31. Manifold Pressure (MAP) Sensor ________________________________________________________26

32. RPM Sensor installation________________________________________________________________27

33. EDM-960 system Specifications and Limitations____________________________________________28

34. EMI Radio Test:_______________________________________________________________________29

35. Component Parts List__________________________________________________________________30

36. Weight and Balance Data_______________________________________________________________32

37. Pilot Programming ____________________________________________________________________32

38. Programming the K factor ______________________________________________________________35

39. Trouble Shooting _____________________________________________________________________36

40. Connector Pin Assignments EDM-950, J1 through J5 _______________________________________37

41. P8 Harness Display PN 790807 __________________________________________________________43

42. Interconnection between Display, DAU’s and GPS__________________________________________46

43. Instructions for Continued Airworthiness (ICA) ___________________________________________46

The Owner of the EDM-960 must keep this manual

J.P. INSTRUMENTS

PO BOX 7033

HUNTINGTON BEACH CA

Last printed 5/8/2014 1:08:00 PM

Page 2

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 2 of 46 Rev D

Date 2-6-2014

1. Revisions

REV Description Date Approval

A

B

C

D

2. Read This First

The following notes apply to a new installation. Read this section before proceeding.

The JPI warranty found in the back of the pilots guide clearly states that JPI will replace defective parts under

warranty, but does NOT cover labor to remove or install any parts.

The most common cause of probe problems is poor terminal crimps. Crimp ring terminals with AMP tool or

equivalent. Fold back the wire double before crimping terminals.

This installation will require some parts unique to your aircraft that are not supplied with the kit , (including but not

limited to tie-wraps, hoses and fittings). Acquire all the necessary parts prior to beginning the installation.

Do not use aluminum fittings or Teflon tape or pipe sealant with the FXT-201 or FXT-231 fuel flow transducer.

Write down the K-factor engraved on the side of the fuel flow transducer here ______ _. Once the transducer is

installed and covered with the fire sleeve, you will not be able to access this K factor.

Determine the locations of all holes before drilling to ensure that nothing interferes with the probe, clamp, clamp

screw or wire.

New diagrams added 2-10-2006 jfp

Added Revision box, new pictures of 900 and 930, page 6. Abbreviations page 4.

Revised how the

Added new Pictures of fuel pressure and oil pressure transducers 12-12-12 jfp

Added new ICA and Pressure bulkhead paragraph 2-6-2014 jfp

9-28-2011 jfp

Provide service loops at the instrument so that it can be moved for maintenance or trouble sho oting.

Thermocouple wire length is not critical. Trim to required length, allowing for service loops at the engine so that

probes can be swapped with probes on adjacent cylinders for troublesh ooting purposes.

Dress all wires away from high temperature components such as exhaust stacks.

Never splice thermocouple wire using copper wire. Use only K-type thermoco uple wire. Solder using zinc chloride

flux such as Nokorode brand – rosin flux alone won’t work.

Observe correct polarity on all probe wires. Connect like colors together (red to red, yellow to yellow).

The DAU EDM-950 must be grounded at the engine, not at the avionics ground.

Record the installation of the EDM-960 on a FAA form 337. Make an entry in the aircraft logbook.

Page 3

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 3 of 46 Rev D

Date 2-6-2014

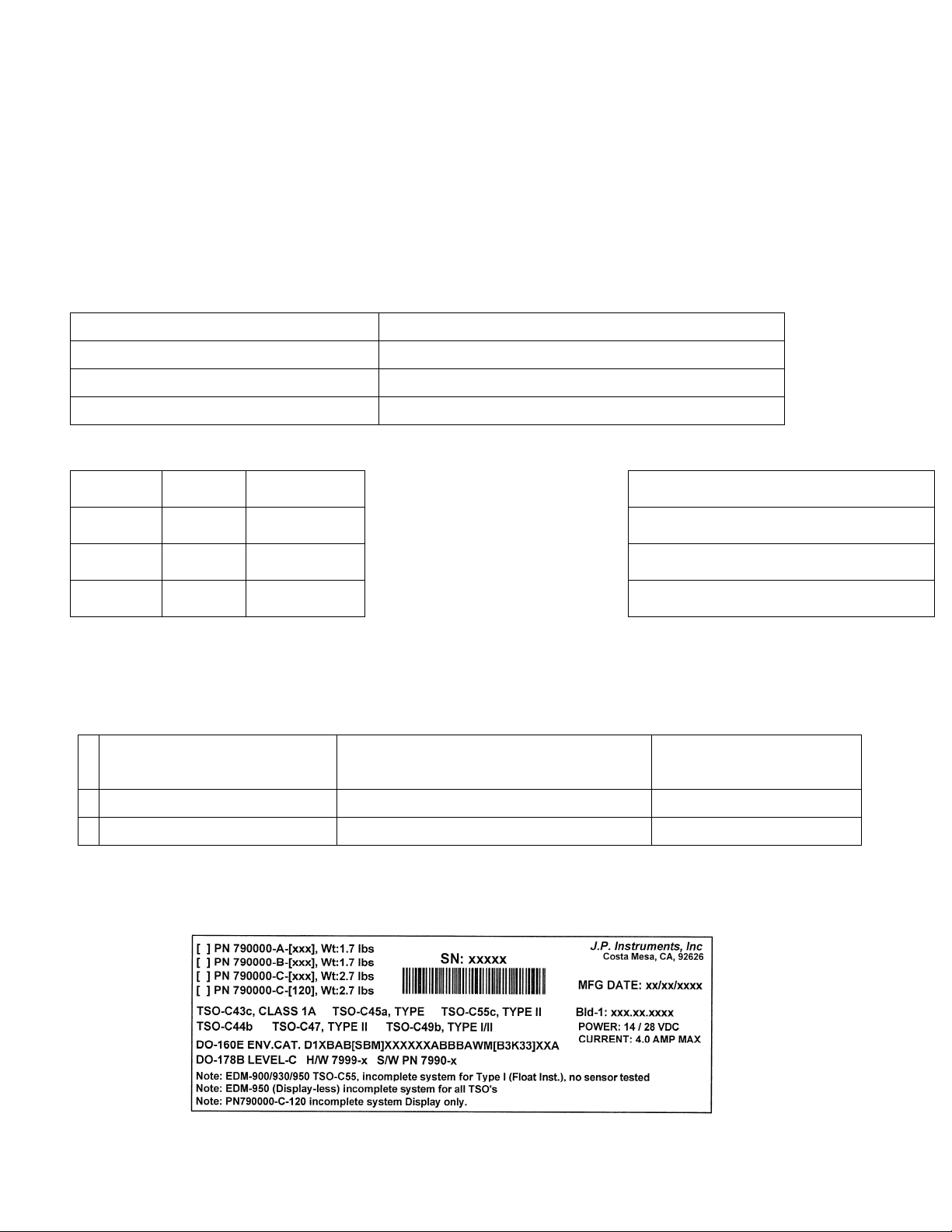

3. Instrument Marking

The TSO label on the instrument is marked as to the instrument’s configuration and DO-160 and DO-178 testing.

The EDM-960 system consists of one (1) EDM-930 Display P/N 790000-C-120, two (2) EDM-950’s P/N 790000-B(xxx), two RADs P/N-790749, and all related wiring and connectors.

Model Number / Part Number Description

EDM-930 PN 790000-C- [120] Display only with TFT (liquid crystal) Type

EDM-950 PN 790000-B- [XXX] DAU (Data Acquisition Unit)

PN 790749 RAD (Remote Alarm Display)

PRIMARY INSTRUMENTS NON-PRIMARY INSTRUMENTS

EGT

CHT

OIL TEMP RPM CDT Volts

OIL

PRESS

Example PN 790000-(X)-(XXX) (X) denotes EDM-900 or EDM-930, (XXX) denotes Part Number for a specific

aircraft with or without and engine STC. Each PN is specific to a Make and Model Aircraft with or without STC.

In which the information is gathered from the Aircraft POH or STC Data sheet.

Aircraft type

Cessna 182-P 534 790000-X-534

Cessna 182-P, STC12345NW 875 790000-X-875

4. Primary TSO Label

FUEL

FLOW

FUEL

PRESS

MAP FUEL

w/engine STC No. if

applicable

Remote

Display

TIT OAT

Quantity

IAT MPG Percent of HP

JPI assigned Data Base Part No. per

Limits found in the POH or engine STC

EGT

4-9

CARB

Amps

for a specific aircraft

Time to

empty

Required to

WP

Reserve at

WP

OAT, AMP, VOLTS, CARB, IAT

Shock Cooling

Differential EGT

Part No. Displayed on 930

RAD at Start-up or 900

message area

Lean Find

Page 4

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 4 of 46 Rev D

Date 2-6-2014

5. Operation and Abbreviations

Gauge Function

Primary Primary

Engine rotational speed RPM xxxx

Engine Manifold Pressure MAP xx.x in hg

Engine Cylinder Head Temp CHT2 xxx oF

Engine Oil Temperature O-T xxx oF

Engine Oil Pressure O-P xxx oF

Fuel Pressure F-P xx PSI

Fuel Flow to engine F-F xx.x GPH

Comp. Discharge Temp. CDT xxx oF

Turbine inlet Temp. Left side TIT-L xxxx oF

Turbine Inlet Temp. Right side TIT-R xxxx oF

Single Turbine Inlet Temp. TIT xxxx oF

Non-Primary Non-Primary

Exhaust Gas Temp. EGT2 xxxx oF

Shock Cooling of CHT CLD xx o/MIN

Differential Temp. of EGT DIF xx oF

Bus Voltage Volts xx.x

Amperage Load AMPS xx

Outside Air Temp. OAT xx oF

Estimated Time to Empty Est. T to E xx:xx H:M

Fuel used to date USED xx.x GAL

Estimated Remaining fuel Est. REM xx GAL

Message Area

Alarm Abbreviation

Estimated Fuel required to Waypoint Est. WP REQ xx GAL

Estimated Fuel Remaining at Waypoint Est. WP RES xx GAL

Nautical Miles per Gallon ECON xx.x MPG

Brightness, Dim control DIM/BRT

The EDM-960 is a combined electronic indicating system made up of one Display Unit and two Data Acquision Units

one mounted behind each engine. Which displays to the pilot powerplant parameters. It replaces all previous primary

digital and/or analog instruments: The display has a message area below the EGT/CHT”s Above are Abbreviation’s

used in the Message Area, the parenthesis. (X)* denotes cylinder No.

Remote Alarm Display Operation (RAD)

The RAD is composed of two (one per engine) red 0.2” high by 8 character displays. The RAD displays fla shin g alert

messages when any of the parameters reaches its preset trigger point, otherwise the RAD is dark. The RAD also

serves as an alert back-up if the main LCD display screen becomes inoperative. The RAD will extinguish when no

primary alarms exist or when the pilot acknowledges the alarm by tapping the STEP button on the EDM-960. On initial

startup or whenever power is turned on, the words ‘EDM-960 PRIMARY’ are displayed, followed by the make and

model of the aircraft for which the primary limits are set.

Page 5

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 5 of 46 Rev D

Date 2-6-2014

Alarm hierarchy

When a measurement limit is reached, the pilot can momentarily tap the STEP button on the EDM-960 instrument to

extinguish the particular flashing alarm acronyms. If another measurement has also reached its limit, that label will

then begin to flash. The pilot should continue to monitor the affected parameters (just as he would using a

conventional analog display that had reached a limit). The bar graph functions of CHT, EGT, and TIT remain displayed

for easy reference should one of these limits be reached.

1. OILP_LO.

2. FP_LO.

3. OILT_HI.

4. CHT.

5. TIT.

6. Dimming

Automatic dimming is provided to dim both the panel display and the remote alarm display, RAD. Dimming can also be

accomplished manually to change the Automatic setting. Tapping the third right button will bring up the Dim/Bright

menu making the 3 and 4

mode display.

th

button Dim or Bright in % Bright. Continuously holding this button increases brightness

6. FLVL.

7. REM.

8. FP_HI.

9. MAP.

10. DIF.

11. CLD.

12. RPM.

13. OILT_LO.

14. VOLTS.

15. OILP_HI.

16. AMPS.

17. CDT.

18. RES.

19. EGT.

20. Fuel Flow.

Each EDM-950 has four mounting holes to mount to the avionics equipment rack or to the cold side of the firewall.

The data ports are then connected to the display unit via a harness terminating at the EDM-930 display with a 25 pin

D-Sub connector.

Remote Alarm Display PN

790749

DAU EDM-950 P/N 790000-B

Page 6

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 6 of 46 Rev D

Date 2-6-2014

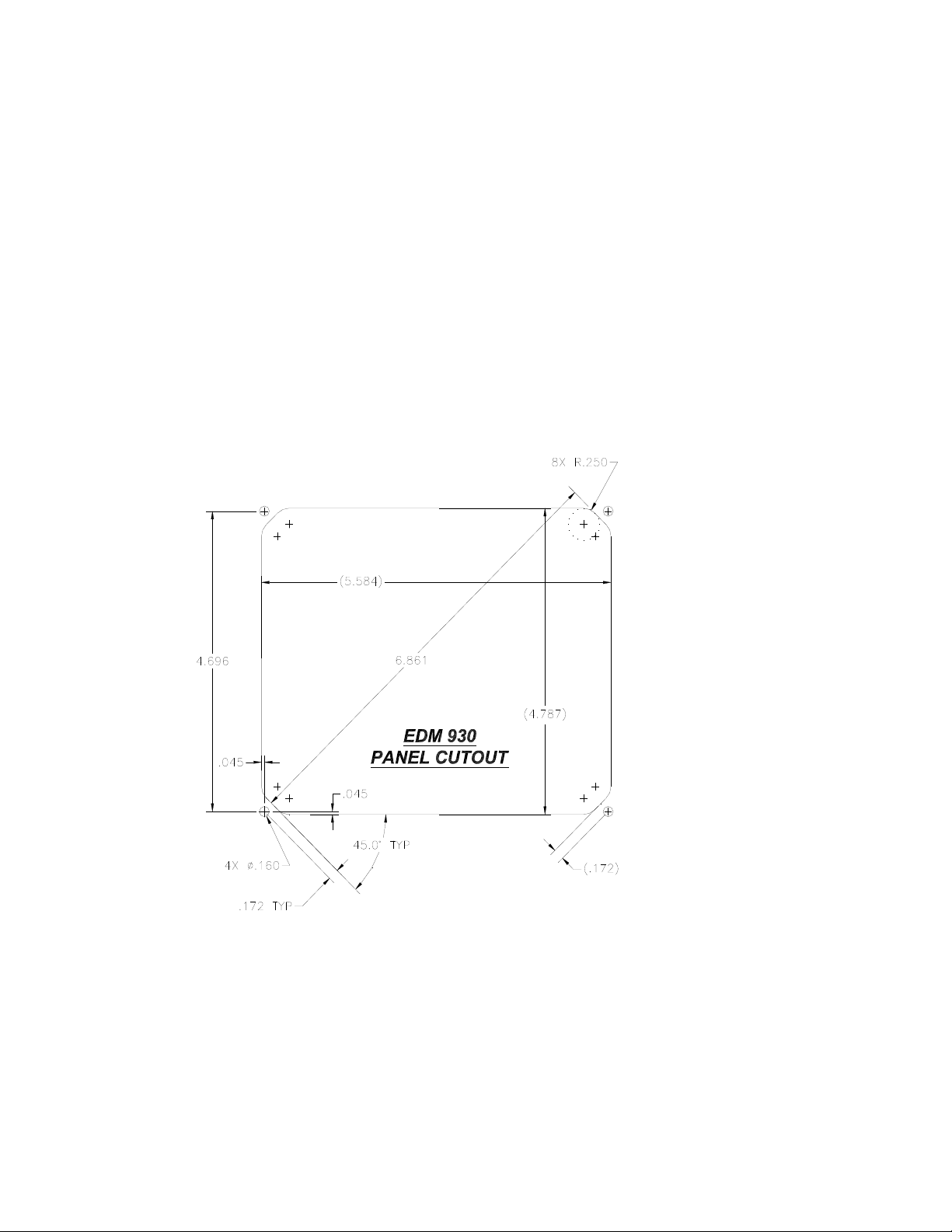

7. Locating and Installing the Indicator and Remote Alarm Display, RAD

A) The diagram below should be used as a guide for cutting and drilling the mounting and buttonholes in the

instrument panel. The dimensions shown are for the final cutouts. Allow extra clearance for any panel finish such as

powder coat. The plastic button caps are removable by grasping and pulling each off. The EDM-930 mounts in a 6x4.5

cutout. Mount the indicator using the figure below as a guide. If the panel has too many holes for a clean installation, it

is recommended that an .10” aluminum overlay panel be constructed and installed over the original instrument panel

and the EDM be installed into this overlay panel.

B) The Remote Alarm Display PN-790749 mounts in a 5/8 inch hole in the panel immediately above the Attitude Gyro

/ D.G. / HSI +/- 0.5 inches from their centerline directly in front of the pilot.

EDM-930/960 PANEL CUTOUT

Page 7

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 7 of 46 Rev D

Date 2-6-2014

Figure 2: EDM-960 Mounting Area

8. EDM-960 Display Installation

Choose the Proper Installation Location

The display is best located within the natural scan and easy reach of the pilot. The recommended mounting location is

defined as the distance from the vertical centerline of the Primary Flight Instruments to the outer edge of the further

most gage displayed on the EDM-930.

HORIZONTAL ORIENTATION:

The EDM-960 display may be mounted from the vertical centerline of the Primary Flight

Instrument “T” to a maximum of 21” to the further most gage of the EDM-930 display and to the left of the centerline as

much as needed. See fig 2

VERTICAL ORIENTATION:

The EDM-960 to be mounted within +/- 10” from the horizontal centerline of the Primary Flight

Instrument “T”. The installer should insure that the EDM-960 display is not obstructed by either

the glare shield or the control wheel.

The installing A&P and IA should decide that where the installation is to occur does not conflict with the viewing angle

requirements listed above.

Note: Any appliances that are installed under the original Type Certificate (TC) that require

relocation should be relocated in accordance with the guidance provided in AC.23.1311-1B,

Section 15.4 (presented below). Special care should be exercised to insure that proper pilot

visibility of displays and pilot access to controls in not interfered with, with respect to relocated

instruments and non-relocated instruments.

Page 8

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 8 of 46 Rev D

Date 2-6-2014

9. EDM-960 Key Card Installation

The EDM Key Card activates the primary engine instrument limits for you engine monitor. This key card contains the

primary engine POH markings data. After installation do not remove the Key Card from the instrument. The key card is

programmed with the serial number of your EDM and the make, model and year of your aircraft. Every time you power

up the EDM, the Remote Auxiliary Display (RAD) will show your aircraft make and model in the right engine RAD. The

Left RAD will display “EDM-960”

Each system is configured to a specific aircraft type. Therefore for example, a Cessna 310R would have a different

series Part number than a Cessna 310Q.

Installation

With the EDM removed from the aircraft, position it on a flat surface with the rear of the instrument facing you as

shown below. You do not have to remove any cables if you have sufficient service loop available. Follow the

appropriate instructions below.

Open the small access door on the side of the

EDM-930/960 Display using the appropriate tool.

UP

KEY

CARD

Hold the Key Card so that the UP arrow is facing

up and in insertion arrow is facing to the right.

Insert the Key Card in the guide rails until you feel it snap into place. Secure the access door.

Power up the EDM and confirm that your aircraft make and model is initially shown in the RAD upon power up. Install

the EDM back into the aircraft. Your installation of the Key Card is complete.

If your EDM should ever have to be replaced with a unit with a different serial number, the factory will reprogram your

Key Card to match the new serial number. You should always retain your fuel quantity calibration records, as these

may need to be manually re-entered in a different or serviced unit.

Page 9

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 9 of 46 Rev D

Date 2-6-2014

10. EDM-960 in aircraft with wing-mounted engines

Figure 1

RAD: Left/Right engine

Cockpit Display unit

Back of Display unit

Page 10

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 10 of 46 Rev D

Date 2-6-2014

11. EDM-960 in aircraft with centerline thrust engines

FRONT/REAR engine RAD’s must be oriented top to bottom as shown below.

FRONT

REAR

EDM-960 centerline thrust display

Page 11

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 11 of 46 Rev D

Date 2-6-2014

12. Wiring harness for 950

Five connectors are protruding from each of the two EDM-950 DAU’s, one for each engine. Connect the five wiring

harnesses to the rear of the 950 DAU mounted on the cold side of the firewall and run the cables thro ugh the firewall

into the engine compartment. Allow sufficient service loop to facilitate removal of the connectors for servicing. These

wiring harnesses are labeled as follows:

EDM-950

DAU

P1

P2

P3

P4

P5

P6

P7

P8

Route the wires from the connectors through the firewall using fireproof rubber grommets and flame retarding sili cone.

Use an existing hole if possible. All wires must be routed away from high temperature areas (exhaust stacks,

turbochargers, etc.). Secure probe and sensor leads to a convenient location on the engine a pproximately 8 to 12

inches from the probe or sensor, being sure there is sufficient slack to absorb engine torque. It is essential in routing

the probe wire that this wire not be allowed to touch metal parts of the air-frame or engine since abrasion will destroy

this high temperature wire. Secure wires along the route to the indicator. Secure wire using original clamps, tape or tie

wrap if possible.

13. Wiring harness for Display

Harness PN

790200 Oil temperature, Induction temperature, Carburetor temperature, Outside air

temperature, Turbine inlet temperature, Turbine inlet temperature 2, Engine ground.

700700

700702

790422 RPM, MAP, Oil pressure

700708 Fuel flow transducers FX-201, GPS

790723 Fuel pressure , amperes, Voltage, and fuel level.

790827 Part of fuel qty sensor interface. Connects with J6 and P5

790811 FQ, interface to Fuel tank.

790807 Power for, GPS , Aux Light to display on cockpit display

CHT, EGT 6 cylinder 10 feet

CHT, EGT 4 cylinder 10 feet

EDM-930 Display Harness PN Description

LEFT/FRONT RAD

RIGHT/REAR RAD

P8

LEFT/FRONT ENGINE (P9)

RIGHT/REAR ENGINE (P10)

P9/P10

P11

P12

CAUTION: Be sure any wiring does not obstruct the control movement under the instrument panel.

The probe wires must not be tied in with ignition, alternator or engine cabin heater ignition wires because of potential

interference with readings.

The temperature probe wiring harness is made of Chromel-Alumel alloy wire s that must not be substituted or extended

with copper wire. The power and ground wire are normal copper. Temperature probe leads may be spliced with

additional Chromel-Alumel wire using copper butt splices.

790749 Category 5 jack and cable for RAD Right engine

790749 Category 5 jack and cable for RAD Left engine

790807 25 pin D-Sub - GPS RS232, GND, Aux Tank Intfc.

790808 Canon Plug (Installer wired) - Power, RS232 MFD data

790808 Canon Plug (Installer wired) - Power, RS232 MFD data

174203 Connector Lft/Rt Data (field installed to P11)

790808 Power DAU, Data for DAU

790810 Optional—Aux Light interface cable to J12 on P8

Page 12

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 12 of 46 Rev D

Date 2-6-2014

When the installation is complete all wires should be secured using ties and carefully checked for interference, rubbing

or chafing with flight control cables or other moving parts.

14. Pressurized Aircraft wire Routing

Pressurized twin Engine Aircraft have a factory installed pressure bulkhead pass thru boot or connector at each wing

root where all electrical wires from the engine pass through to the cockpit. If you can not find the opening follow the

wires from the engine to the pressure vessel. If a boot with sealant is used remove the sealant, pass the three RS232 signal wires from the Data Acquisition Unit mounted in the engine compartment to the Display. Upon

accomplishing this reseal the hole with factory recommended sealant.

An alternate method for a cannon connector is to use existing wires in the aircraft going thru the pressure bulkhead.

The EDM-960 replaces

the pressure bulkhead. Any combination of three wires can be used to transmit signal to the cockpit display. Making a

new hole in the pressure bulkhead is beyond the scope of this document and will require a DER or other FAA

approval

.

15. Power Connection

The EDM-960 automatically accommodates either a 14 or a 28-volt electrical system. Master Bus po wer must be

individually provided, via three 5 amp circuit breakers, to the two DAU units and the EDM-960 head.

the RPM, MAP, Oil Temperature, Oil Pressure and TIT gauges which have wires going thru

IMPORTANT: Insure the DAU ground wires are connected to the engine block. Any wiring extension s or additions

beyond JPI supplied wiring must be MIL-W-32759/16 or equivalent. The EDM-960 has a 8-second warm-up. No

connection to the aircraft dimmer system is required because the instrument dims automaticall y with reductions in

ambient light. The instrument is designed to reset at less than 10 vdc bus power, therefore the instrument may reset

on engine start (typical for 14 vdc systems). This is normal due to the starter loading down the battery outp ut to below

10 vdc.

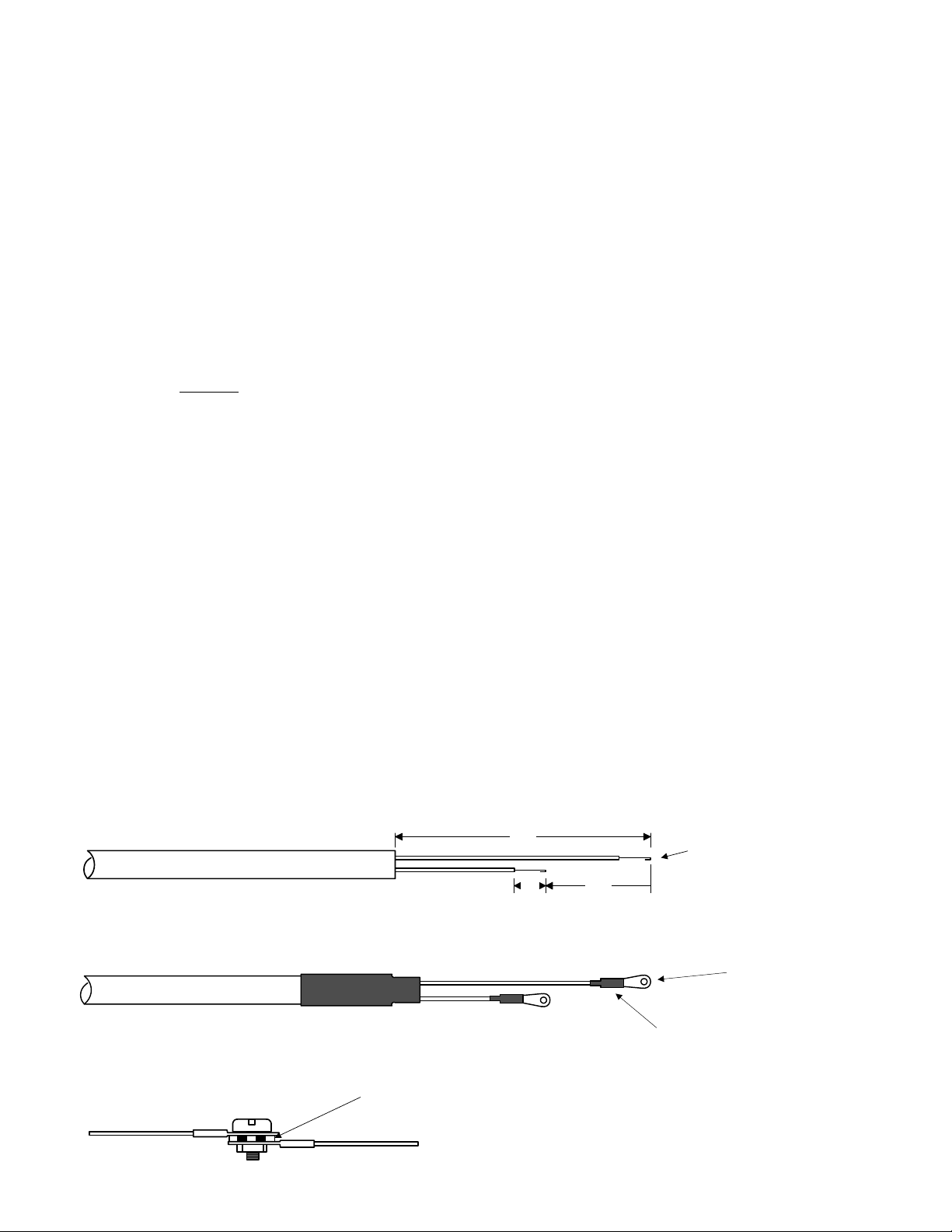

16. Probe Wiring

When cutting the pair of leads to the proper length to connect to the probes, leave enough slack in the wiring so that

probe may be interchanged to an adjacent cylinder if necessary for trouble-shooting and servicing. Thermocouple wire

length is not critical and should be trimmed to any length as required for a clean installation.

The Temperature probe must be wired with the correct polarity. The temperature probe connects to its temperature

indicator with yellow jacket Teflon Chromel-Alumel wire supplied. Strip the wires as shown below—ob servin g colorcoding.

2 1/4"

Thermocouple wire harness

red

yellow

1/4" 1 1/2"

Fold back wire

double before

crimping terminals

Terminate each wire with a crimp-on ring terminal, provided. The ring terminals may be crimped with a “service-type”

tool, however AMP part number 48518 crimp tool is recommended. Verify the quality of each crimp with a sharp tug on

the wire. The terminal should be impossible to pull off when crimped correctly.

ring terminal

shrink tubing

Place a ¼ x 4-inch sleeve over each pair of wires in the wiring. Connect the wire ring lug to the probe ring lug using the

supplied number 4 screws and nuts, placing the star washer between the ring lugs, not ag ainst the nut.

Important: place star waster between two ring

terminals and tighten nut and bolt as

to instrument

necessary

to probe

Page 13

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 13 of 46 Rev D

Date 2-6-2014

Slide the sleeve over the joint and secure with three tie-wraps.

tie-wrap 3 places

1/4 x 4" sleeve

The most common installation problems are related to poor quality terminations.

17. Wiring Markings

The EDM-960 is supplied with special Teflon insulated Chromel Alumel factory assembled wiring ha rness configured

for the correct number of cylinders. The wire harness is marked E1= EGT-1, C1= CHT-1, etc.

NOTE: Unlike most other EGT & CHT installations the probe wire length is not critical and should be trimmed to any

length as required for a clean installation. Do not extend the thermocouple wire with copper wire.

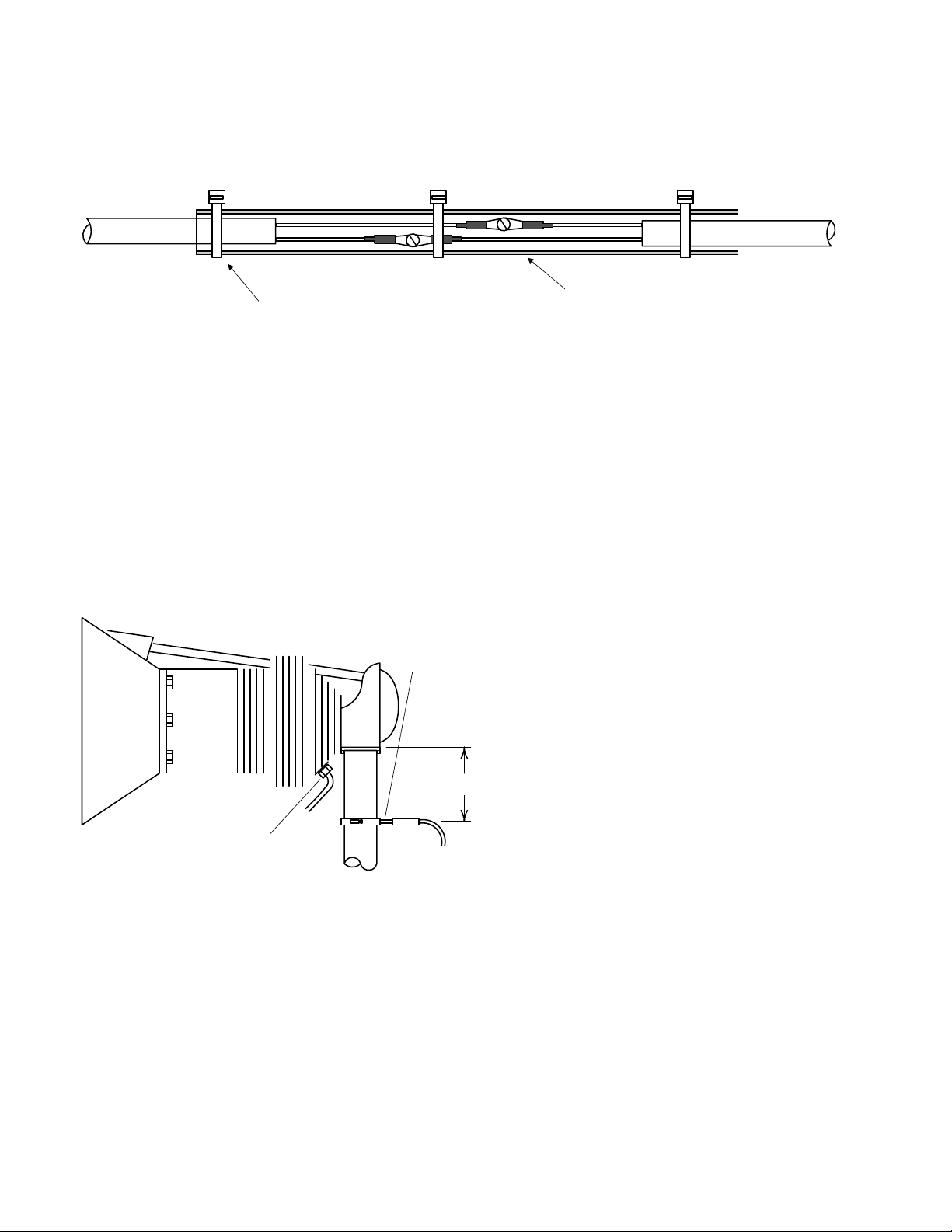

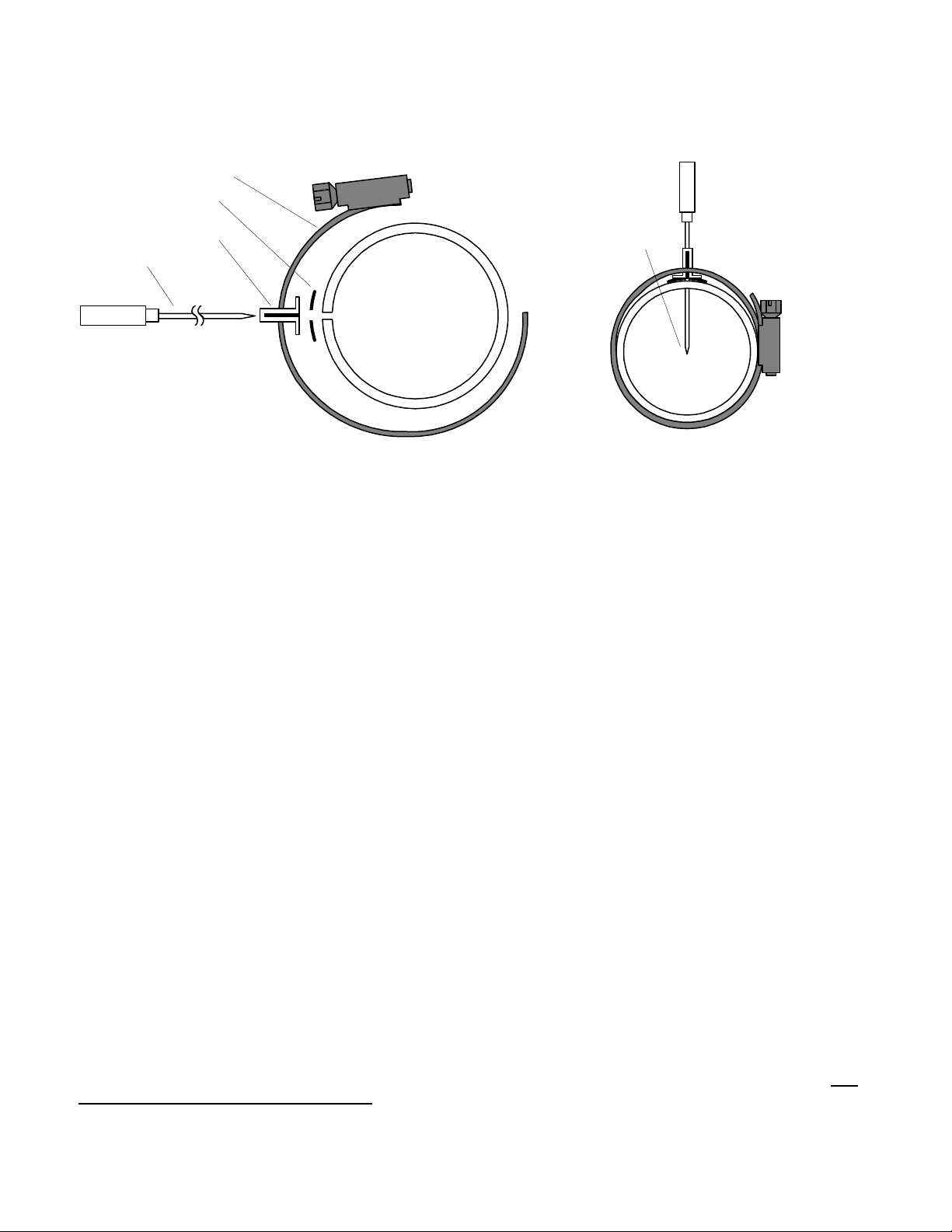

18. Exhaust Gas Temperature Probe (EGT) Installation

Use the J2 connector harness 700700 or 700702 labeled E1 through E4 or E6. Remove the existing EGT ga ge and

Probe. Replace with JPI probe M-111 in all exhaust stacks.

The Model M-111 Probe will fit any engines where the

existing holes in the exhaust stack are 1/8" to 1/4" in

EGT probe

Drill no. 40

pilot hole,

then no. 30

hole.

diameter. If no hole exists, it will require the drilling of a

1/8" diameter hole and ream to fit. It is important that

each probe be mounted the same distance from its

exhaust stack flange. A nominal distance of 2 to 4

inches from the exhaust flange is recommended. If the

recommended distance is impractical because of

exhaust stack

obstructions, slip joints or bends in the exhaust system

then position the probes a uniform distance from the

2" to 4"

flange as space permits. Do not mount probes in slip

joints. Be certain to locate all holes BEFORE drilling to

CHT probe

ensure that nothing interferes with the probe, clamp,

screw or wire. Careful matching of probe position will

provide best temperature readings.

Insert the probe in the exhaust or previously drilled

hole so that the tip of the probe is in the center of the exhaust stream. Tighten the stainless steel clamp to a torque of

45 in/Lbs. Cut off the excess strap close to the screw.

Page 14

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 14 of 46 Rev D

Date 2-6-2014

Clamp

Seal Washer

note orientation of

Probe

Thimble

slot

RADIAL ENGINE EGT

Radial engine exhaust, require a larger EGT clamp (supplied) to fit the 2.5 inch exhaust pipe. The EGT probe is

installed in the same fashion as a Lycoming or Continental engine and should be placed between the exhaust pipe

flange and the accumulator at a distance of 2 to 3 inches form the engine exhaust flange. Cylinder head temperatures

are measured with a spark plug gasket type probe placed under the front sparkplugs. Front spark plug s will read 15 to

20 degrees cooler than the rear plugs. Refer to the engine manufactures recommended location. Do not route the

EGT/CHT harness in with the ignition harness. Do not extend the yellow thermocouple leads with copper wire.

Position probe

in approximate

center of

exhaust

19. Turbine Inlet Temperature (TIT) Probe Installation (optional)

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 16 and the red wire into pin 17.

The standard TIT probe PN M111-T with a #48 clamp is placed in the exhaust stack ac cumulator to a maximum depth

of 1/2 inch and approximately 4 inches from the turbine inlet if possible, on the waste-gate side of the turbine.

19.1 Using the Factory original TIT Probe

The factory installed TIT probe (K-calibration) is compatible with the JPI EDM-960 System. Connect the JPI wire

marked TIT. Replacement probes should be purchased per part number from the aircraft manufacturer.

The EDM-960 permits you to remove the factory installed TIT indicator and leave the TIT probe installed. Connect the

JPI wire marked TIT directly to the probe noting color polarity. The TIT probe should now have only the JPI leads

attached to it. No calibration of the EDM-960 is necessary.

20. Cylinder Head Temperature (CHT) Probe Installation

Use the J2 connector harness 700700 or 700702 labeled C1 through C4 or C6. The JPI probe is a bayonet probe P/N

5050-T that has a captive 3/8-24 boss that is screwed into the head of each cylinder.

For Indicator replacement, replace your existing CHT probe and adapter, a bayonet or screw in type with one supplied

by JPI. Install the probe on the same cylinder from which you removed the original equipment probe. Your current CHT

probe is installed in the hottest cylinder as determined by the airframe manufacturer.

RADIAL ENGINE (CHT) SPARK PLUG GASKET

The spark plug gasket probe, P/N M-113, replaces the standard copper spark plug gasket on one spark plug. The

probe is usually placed on the Rear plugs. After many removals the probe may be annealed for re-use. Heat to 1100

o

F and quench in water.

Page 15

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 15 of 46 Rev D

Date 2-6-2014

21. Outside Air Temperature (OAT) Probe Installation

Connect the OAT probe to the

LEFT ENGINE DAU J1 connector

harness 790200 labeled OAT. All

wiring must be type K

thermocouple wire. Do not splice

ordinary copper wire in any

temperature probe circuits.

probe

washer

Install the OAT probe, PN 400510

in the airframe manufacturer’s recommended location. If this information is not available, place the OAT probe in clean

airflow such as in a cabin air scoop or below the underside of the wing away from engine heat or exhaust. In this ca se

it is recommended that the installation be done similar to the antenna installation. The outside aluminum shield tube is

used to both hold the probe in place and shield it from radiated heat from the sun it can be replaced with a 5/16 nut.

The OAT option is typically displayed as digital gauge and has no associated alarms.

22. Compressor Discharge Temp Probe Installation (optional)

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 3 and the red wire into pin 4. All

wiring must be type K thermocouple wire. The Induction Air Temperature probe, (IAT), is installed just after the

inter-cooler and the Compressor Discharge Temperature (CDT) just before the inter-cooler. Th e probe is the same as

an EGT probe and installed similarly to an EGT probe. A large clamp is supplied to fit around the air duct leaving the

inter-cooler. Alternately a 1/8 NPT fitting is available. IAT option is displayed as an independent digital temperature like

"125 IAT". On non-turbo engines the IAT in reality is the Carburetor temperature and displayed as “34 CRB.”

aircraft sheet metal

washer

shield tube

used to secure

probe

23. Carburetor Probe Installation (optional)

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 5 and the red wire into pin 6. All

wiring must be type K thermocouple wire. Do not splice ordinary copper wire in any temperature probe circuits. Locate

the access hole (1/4-24 thread) in the carburetor near the butterfly valve. Remove the screw plug now in that hole and

screw the CRB probe into the carburetor throat. No drilling or machining of the carburetor is nece ssary.

24. Oil Temperature Probe Installation

The sensor port is a standard 5/8-18 thread for both the Continental and Lycoming engines. Probe PN 4 00509 is a

complete assembly using type K thermocouple wire (red/yellow). Connect the wire marked oil temperature observing

polarity. Wire length has no effect on the readings. Oil temperature will be displayed as an independent temperature

digital and bar-graph. Check with engine manufactures proper location for oil temperature. Check for oil leaks before

first flight.

5/8-18 Thd

Oil Temp PN 400509

25. Oil Pressure Sensor Installation

Use the J3 connector harness 790422 labeled OIL-P

Oil pressure sensor mount using an aluminum clamp MS21919. Mount to firewall.

Mount the pressure sensor to the pressure line using a flexible hose and fittings (not supplied) as depicted in the

drawing below. Use aluminum clamp to mount the pressure sensor to firewall. Do not mount the sensor directly to the

engine

Page 16

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 16 of 46 Rev D

Date 2-6-2014

Connect the other end of the hose to the engine manufacturer’s recommended location for engine oil pressure.

Page 17

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 17 of 46 Rev D

Date 2-6-2014

25.1 Fuel Pressure Sensor Installation

Use the J5 connector harness 790723.

Mount the pressure sensor to the pressure line using a flexible hose and fittings (not supplied) as depicted in the

drawing below. Use Aluminum Clamps MS21919WDG25, or WDG16 to mount the pressure sensor to engine mount

structure or firewall. Do not mount the sensor’s directly to the engine. Connect the other end of the hose to the existing

pressure line. Later, you will connect the pressure sensor to the three pressure sensor wires through the su pplied 3-pin

connector. i2s sensor PN 159935A Carbureted or PN 159938 for turbocharged. Fuel pressure se nsors are only

supplied if the POH requires it. Fuel pressure can be supplied at additional cost.

26. Ammeter Shunt Installation

Use the J5 connector harness 790719-X labeled AMP+ and AMP-. Connect the harness lead s using ring terminals to

the smaller terminal screws on the side of the shunt. The information will be displayed as Amp-1 and Amp-2 on the

display.Typical charging circuit for a Cessna 310 (reference only)

Page 18

FAA Approved Installation Manual for the EDM-960 system Report No 909

pump

Primary Engine Data Management System Page 18 of 46 Rev D

Date 2-6-2014

26.1 Volt Meter reading is derived from the bus location that the EDM Display is wired to. A second voltage input

is also available.

26.2 Load Meter Configuration. The shunt must be installed in the main bus where it will be the load meter

configuration showing alternator load (positive only). Be sure that the negative side of the shunt is connected to the

main bus in the load meter configuration. There are no alarms for the load meter configuration.

27. General Fuel Flow Transducer Installation

Use the J4 connector harness 700708 labeled FFSIG (white), FFPWR (red), and FFGND (black). If no previous fuel

flow transducer is installed, install transducer per Report 503, Rev B, 03/14/97, FUEL FLOW TRANS DUCER

INSTALLATION . The EDM-960 receives signal from any installed FloScan Transducer with the following FloScan

P/N’s embossed on to the top of the transducer. The K-Factor is marked on the side of the Transducer and on an

attached white ticket. Route the JPI wires along the existing wiring bundle lacing every foot. The EDM is ap proved to

work with the following Shadin equivalent PN.

FloScan PN Shadin equivalent PN

201-A

201-B 680501/680600

231 680503

Before connecting any hoses to the transducer, thoroughly clean them and insure they are free of any loose material.

Never pass air pressure through the transducer or use Teflon tape/pipe cement; damage will occur. Use only steel

fittings never use aluminum fittings on transducer. Aluminum will gaul. Remove the transducer cap plugs only when

ready to install the hoses. Note the direction of fuel flow marked on the transducer. Fuel must flow in this direction.

Reverse flow installations will read ½ the required flow. Mount the transducer with the three wires pointing up. The

K-factor is printed on the side of the transducer and on a tag. Write down the K-factor here for future reference .

Aeroquip

900591B Clamp

Cut slit in fire sleeve

up

Fittings 1/4 NPT. Do NOT

MS 21919

Clamp as required

Transducer

use alumi num fittings

Aeroquip

303 hose

OUT

IN

to carburetor, flow

divider, or fuel

injector

The EDM-960 fuel flow transducer receives signal from any installed 201 transducer with part numbe rs imprinted on to

the top of the transducer. For specific engine installations see Report 503

6 inches maximum from

support

Aeroquip Fire Sleeve

AE102/62-24

from fuel tank,

throttle body or

engine driven fuel

.

Page 19

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 19 of 46 Rev D

Date 2-6-2014

28. Fuel Level Interface Installation

The EDM-960 has the capability to interface to 4 tanks in the aircraft’s fuel level system. This is done by connecting

the DAU directly to the senders or in some cases to the aircraft’s fuel sender signal conditioner, for example the

Pennycap system which converts capacitance (frequency) to a voltage output, typically found in Cessn a Twin s. The

DAU has the capability to process signals from two types of sender signals: Resistive output, Voltage output. JPI

provides the appropriate interface hardware (the P5 harness and any associated signal conditioners) based on

information you provided when your order was placed. Once installation is completed, you will perform a fuel level

calibration. The EDM-960 stores this calibration internally. NOTE: The fuel quantity function will not be available until

this calibration has been performed successfully.

28.1 Resistive Output Type Sender System

Locate the wires that run between the existing ships fuel gauges and the senders and disconnect them at the senders.

For tanks that have more than one sender, the wiring between

do not have voltage on them before connecting to the EDM. Connect the EDM to the senders using the wire pairs

coming from the signal conditioner (PN 790802) P7 as shown below. Note that one pair is for MAIN and the other is for

AUX. Connect the ‘SIG’ wire to the senders signal terminal (typically the center stud) and the ‘GND’ wire to the closest

ground terminal near or on that sender.

the senders must be retained. Make sure the senders

28.2 Voltage Output Type Sender System

Voltage output type systems usually have a convertor box. This is typical with the ‘Pennycap’ brand capacitive sender

system. The Pennycap convertor box measures sender capacitance and converts it to a DC voltage output signal for

the aircrafts fuel level gauge. Connect the EDM to the Pennycap converter box using the wire pairs coming from the

signal conditioner (PN 791802). In some cases the Pennycap convertor box alternately monitors two tanks per wing

controlled by cockpit selector switch positions. This is typical for Cessna twins having 4 selectable tanks. The EDM can

interface to this system with the addition of the dashed interface hardware (PN 790810) shown below. NOTE: This

drawing is accurate for most models of the Pennycap system; however it is the installer’s responsibility to verify proper

connections to the Pennycap output signal. Note: The original ships gauge and all gauge selector switches and related

annunciate lights must remain in the aircraft. The gauge could be mounted behind the panel if desired.

Page 20

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 20 of 46 Rev D

Date 2-6-2014

Page 21

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 21 of 46 Rev D

Date 2-6-2014

28.3 Fuel Tank Calibration Setting Fuel Calibration Points

The EDM interfaces to various fuel level sensor types to facilitate direct reading of the fuel level in the

aircraft fuel tanks. The EDM has a multi-point fuel calibration table that you must enter. This table contains

calibration values (stored in non-volatile memory) used to translate sensor readings into the displayed fuel

quantity values. The calibration information is collected and recorded on paper for later entry into the EDM.

NOTE: Fuel quantity gauges will not be functional until the fuel calibration information has been entered

into the EDM. You will use the EDM instrument itself as the measuring device to collect calibration data.

The following describes the basic procedures necessary for collection and entry of data into the fuel level

calibration table. Note: Any changes to fuel table data will be temporary until you execute the ’SAVE’

function (available after last cell of the last tank table is entered).

Before beginning the fuel table entry/edit process, you must have properly installed and tested for correct

functionality of the fuel sensors.

WARNING:

Never add or remove fuel from the aircraft when the

master switch is turned on.

Fuel quantity gauge performance is affected by many

factors, such as the integrity of the sensor performance, the

accuracy of the calibration data you collected and entered

and most importantly your validation that the EDM fuel

quantity gauge is accurate and repeatable after installation

and calibration. You should not use the fuel quantity gauge

system for any flight related operations until this validation

criteria has been met.

Page 22

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 22 of 46 Rev D

Date 2-6-2014

29. Capturing the sender reading at each calibration point:

Getting Started…Collecting Fuel Level Calibration Data using the EDM as a meter.

1. For each EDM monitored tank, create a paper table with the desired number of calibration points (2 to 5) and at what

volume each will be. Number of calibration points to be entered into the system later. The zero gallon point reading is

always taken with unusable fuel in the tank. Example of a completed 3 point table for LEFT tank:

F 39.0 GAL 1907

2 19.5 GAL 1154

E 0.0 GAL 685

2. This screen provides real-time readings of all active fuel level sensors. Verify readings look normal. Reading are arbitrary

whole numbers

3. Now add fuel as needed to match the required volume for a particular point. Allow this to settle, then take a reading and

record it on paper adjacent to that point.

4. Repeat this process until all points have been recorded for each tank.

LEFT

Readings

Actual Screen Shot

29.1 After you have collected your data

After you have collected your data…Entering / Editing Fuel Level Calibration Data

The Fuel Table Editor is a spreadsheet type format allowing you to easily see the volume and related calibration values side by

side. You can easily navigate through the cells to enter values.

1. With power off, hold in Button 3 (Button 1 being far left) and then turn on power. Wait until you see ‘Do you agree

with the disclaimer?’. Tap YES if you agree and wish to continue.

Page 23

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 23 of 46 Rev D

Date 2-6-2014

2. Tap YES when you see ‘Do you have table data?’.

Page 24

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 24 of 46 Rev D

Date 2-6-2014

3. Tap USER when you see ‘Do you want to restore user table?’ (Note: tapping FACTORY causes the fuel table

stored on the Key Card to over-write any previous user entries in the fuel table. Use FACTORY if you want to start from

the original factory default).

4. Tap POINTS when you see ‘Do you want to edit the table?’.

5. You see ‘Points in LEFT’, the current calibration points for the LEFT tank.

6. Tap/hold VALUE to change to the desired number of calibration points for this tank (2 to 5). Each Tank can have a

different set of calibration points. So 5 points for Main and 2 points for Aux.

7. Tap TANK to select the next active tank and repeat previous step. Continue until all tanks ‘points’ have been set.

Page 25

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 25 of 46 Rev D

Date 2-6-2014

8. Tap TABLE. You see ‘Fuel Table Data’ ( White at top of screen) with a table. You may change any of the fuel levels

in the left column except for empty. You will enter the readings taken previously on paper into the right column.

9. Tap/hold STEP to select the cell you want to edit. Tap EDIT to change the value. Tap or hold Modify to change digit.

Tap digit to change another part of the number.

10. Tap SAVE to record it. Follow the on-screen menus to edit the value. Repeat previous step until all tanks data have been

entered.

11. You see ‘Save fuel tank data?’. Answer SAVE to store all final data values or CANCEL to return to table editing. To

complete the process, tap SAVE a second time.

30. GPS Interface

The GPS is wired to the EDM-960 head. Refer to the Manufactures GPS manual for the required pin connections on

the GPS.

Page 26

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 26 of 46 Rev D

Date 2-6-2014

31. Manifold Pressure (MAP) Sensor

Screw an AN816-4D (flared to pipe thread) into the Aeroquip 303 hose to and from the bulkhe ad fitting an 832-4 as

shown below if not already installed from the aircraft factory MAP gage.

P-2 GRN FP-Sig +

P-3 RED-FP PWR+5

P-1 BLK FP GND

Manifold Air-pressure

PN 159934A

0-30 PSIA

7/16 UNJF

#4 fitting

MS-24587 FITTING

AEROQUIP 303 Flex hose

DO NOT MOUNT SENSOR DIRECTLY TO ENGINE

Page 27

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 27 of 46 Rev D

Date 2-6-2014

32. RPM Sensor installation

There are four types of magnetos commonly in use. You must have the correct RPM sensor for the

magneto installed in the aircraft. The following part numbers apply: Slick – pressurized 4000, -6000

series use JPI P/N 420809. For the Bendix pressurized -1200 series use P/N 420807. Dual

magnetos use JPI PN 420808. For the Bendix -20 series and Slick 600 use JPI P/N 420806.

Mount the sensor as shown in the appropriate diagram below. Note: this is eligible for installation

on all 4 & 6 cylinder engines only.

Bendix Magnetos Slick Magnetos

engine

Connector to harness

Bendix -20, -21, -200, 1200 series

non-pressurized

JPI 420815-2

Mount sensor side of bracket towards

magneto body, positioned over the magnet

armature

position lim it

P

O

T

engine

position lim it

Connector to harness

Alternate bracket locations

Bendix 1200 series

pressurized

JPI 420807

Mount sensor side of bracket towards

magneto body

engine

engine

engine

engine

TOP

Alternate bracket location

Vent plug

Spacer ring

Sensor ring bracket

Magneto body

Connector to har ne ss

Slick 6000, 4000 series

non-pressurized

JPI 420815-1

Mount sensor side of bracket towards

magneto body

Sensor ring munted under vent plug.

Stem at right angles to magneto center line

Connector to har ne ss

Slick 6000, 4000 series

pressurized

JPI 420809

Sensor must be over

moving magnet armatu re

Remove this sc rew

to mount sensor

bracket

Bendix Dual Magneto

JPI PN 420808

non-pressurized

rev Dec 2010

Slick 600 series

JPI PN 420806

non-pressurized

Page 28

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 28 of 46 Rev D

Date 2-6-2014

33. EDM-960 system Specifications and Limitations

The following parameters must be customized for the aircraft into which the EDM-960 system is installed.

Factory set limits or default values for EDM-960

1. TIT 1650 F TSO-C43

2. CHT 450 F TSO-C43

3. Oil Temp Low 90 F TSO-C43

4. Oil Temp HI 230F TSO-C43

5. Oil Press low 15 psi TSO-47

6. Oil Press Hi 100 psi TSO-47

7. Vacuum 0- 15”hg TSO-47

8. RPM 2700 Limit and range TSO-C49

9. RPM set to cyl 6 TSO-C49

10. Map 32 In hg HI TSO-C45

11. Map setting 29.90 In Hg TSO-C45

12. Fuel Pressure Hi 35 psi Injected TSO-47

13. Fuel Pressure Lo 15 psi Injected TSO-47

14. Fuel Pressure Hi 8 psi Carb TSO-47

15. Fuel Pressure Lo .5 psi Carb TSO-47

16. Fuel Flow 24 GPH TSO-C44

17. K-factor 29.99

18. Carburetor filter smoothing 1

19. Ammeter configuration (load or charge-discharge). Load NON TSO

20. HC-120 (% of HP) NON TSO

21. Fuel Level Resistive/Capacitive TSO-55

22. Low fuel 10 Gal

23. Low time 45 Min

24. Main tank 75 gallons

25. Aux tank 0

26. GPS set at GARMIN

27. Diff 500 degrees TSO-C43

28. CLD 60 degrees per minute TSO-C43

29. Amps limit 100 amps NON TSO

30. Record time, 6 sec intervals NON TSO

31. Tach Time based on cruise RPM setting of 2400 true NON TSO

During start-up the EDM may reset (typical on 14 vdc systems). This is normal due to extremely low battery voltage

due to starter amperage draw. The conditions and test required for TSO approval of this article are minimum

performance standards. It is the responsibility of those desiring to install this article either on or within a specific type or

class of aircraft to determine that the aircraft installation conditions are within the TSO standards. The article may be

installed only if installation of the article is approved by the Administrator. The functions of Volts, Amps, and Horse

Power were tested to DO-160D and DO-178B, but not TSO’d since no TSO exist for these functions. Deviation granted

for TSO-C49b to include digital display and sensor. All TSO required probes, transmitters and sensors al so tested to

DO-160D.

Page 29

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 29 of 46 Rev D

Date 2-6-2014

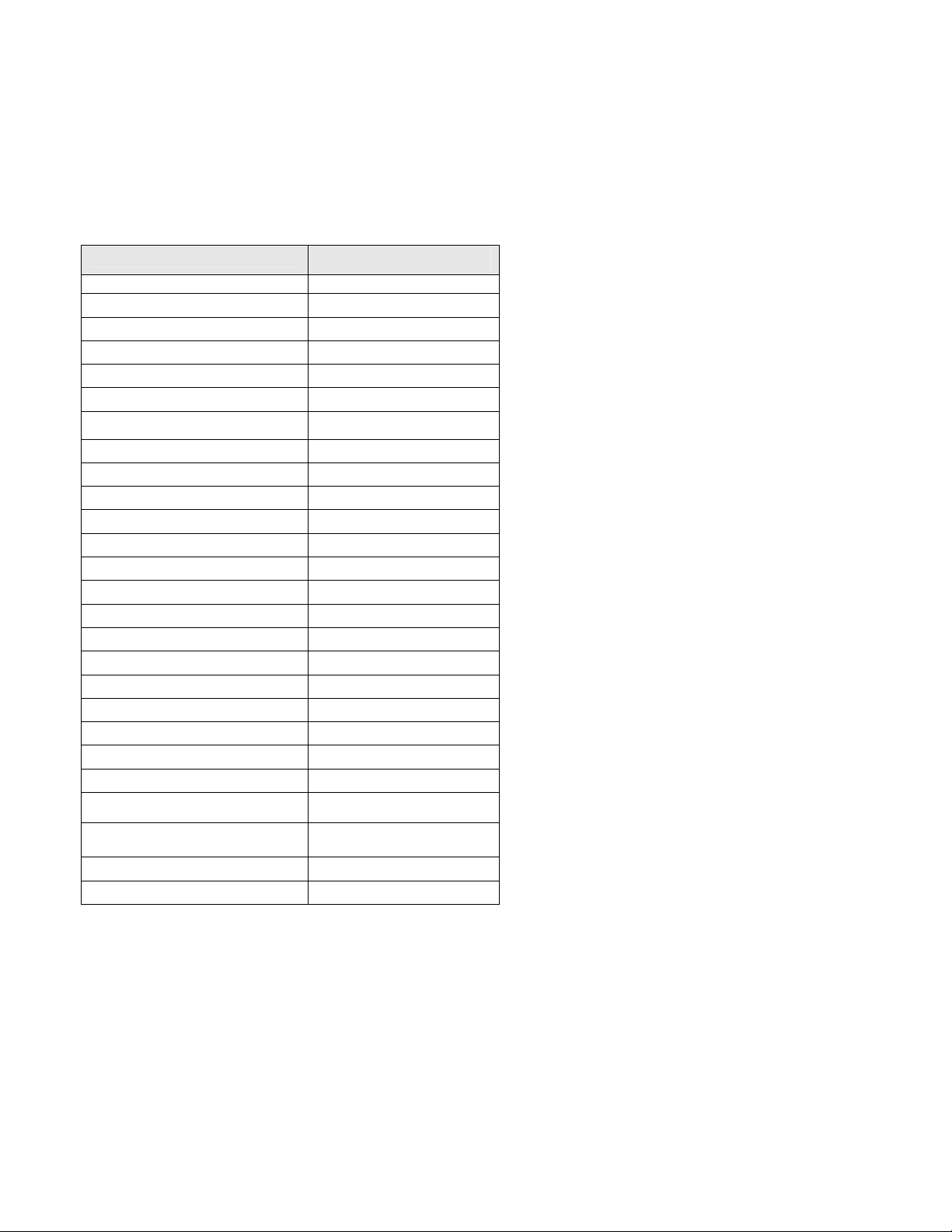

34. EMI Radio Test:

Even through the EDM-960 has been tested to DO-160E Section 20 (EMI) the installation itself could creates radio

interference on specific frequencies. The following test is to insure that this does not exist

EMI/RFI TESTS: perform tests, in accordance to the table below, to insure wire routing and connectivity has not

compromised the signal integrity of the NAV/COM receivers. Power up the aircraft bus (or buses) in accordance with

normal engine prestart procedures (see Aircraft Pilot Operating Handbook). Verify that the EDM-960 is operating

normally. Set the frequency and audio panel to listen to that radio. Loud buzzing/humming is considered ‘unusual

noise’ in the context of these tests also the OBS needle should not move. Should any EMI noise be found that is

attributed to the EDM-960 system, it must be corrected by shielding and/or rerouting wiring to eliminate the noise. If

unusual noise is heard, remove power from the EDM-960 system to check if it is the source of this noise. If the EDM960 system is not the source of ‘unusual noise’ then mark the table with a ‘PASS’.

Frequency NAV/COM 1

(PASS/FAIL)

108.00

112.00

115.00

117.00

120.00

121.00

122.00

123.00

124.00

125.00

126.00

127.00

128.00

129.00

130.00

132.00

NAV/COM 2

(PASS/FAIL)

Comments

Page 30

FAA Approved Installation Manual for the EDM-960 system Report No 909

A

A

A

Primary Engine Data Management System Page 30 of 46 Rev D

Date 2-6-2014

35. Component Parts List

Twin engine

-4

Cyl

-6

Display EDM-930 P/N

DAU EDM-950 P/N

EGT probe KIT PN

TIT probe w ith opt ion KIT

CHT probe KIT PN

OAT probe with optio n KIT

IAT probe with option KIT

Carb temp probe KIT

Oil Temp probe w it h option KI T 1250 PN

Oil pressure sender KIT 1460 PN

Fuel pressure sender KIT 1450 PN

Fuel pressure differential se nder Kit 1480 PN

mmeter shunt PN

Fuel Flow transducer PN

Fuel Level sender

MAP KIT 1440 PN

RPM one of P/N 420815-1

RAD

P/N-790749

790000-C-120 1 1 1

790000-B-(xxx)

1280

1200

1260

1220

1300

1190

159920

700900-1

option

159934A

or,-2

400409 2 2 2

159936

159935

159938 2 2 2

2 2 2

8 12 14

2 2 2

8 12 14

1 1 1

2 2 2

2 2 2

2 2 2

2 2 2

2 2 2

2 2 2

2 2 2

2 2 2

2 2 2

2 2 2

Cyl

-7

Cyl

-8

Cyl

-9

1 1

2 2

16 18

2 2

16 18

1 1

2 2

2 2

2 2

2 2

2 2

2 2

2 2

2 2

2 2

2 2

2 2

2 2

Cyl

35.1 Component Parts List

1 Thermocouple type K probe PN

1 Stainless St eel Clamp

1 Stainless St eel Exhaust Seal

1 Stainless St eel Screw Type

2 Ring

2 Screws and nuts 6-32 X

1 Fiberglass tube 3/8” x

35.2 Component Parts

1 Bayonet Pro be Thermocouple type K Spring loaded PN

1 Or Gasket t hermocouple probe type K PN

2 Ring

2 Screws and Nuts 6-32 X

1 Fiberglass tube 3/8” x

35.3 Component Parts list for OAT (PN 1220) probe

1 P/N 400510, OAT

2 Ring

2 Screws and Nuts 6-32

Fiberglass tube 3/8” x 5”

35.4 Component Parts list for IAT (PN 1140) probe

Terminals

Terminals

Terminals

for EGT (KI T 128 0), TI T (KIT 120 0) Probe

M-111

Thimble

5”

list for CHT KIT

5”

probe

X1/4"

1/4

1/4"

Washer

Clamp

1260

MM-113

5050-T

1 Thermocouple type K probe PN

1 Stainless St eel Clamp

&Thimble

M-111

Page 31

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 31 of 46 Rev D

Date 2-6-2014

1 Stai nless St eel Ex ha ust Se a l

Component Parts list for CARB (KIT 1190)

Washer

probe

1 P/N 400128, CARB

2 Ring

2 Screws and Nuts 6-32

1 Fiberglass tube 3/8” x

Terminals

35.5 Component Parts list for

1 P/N 400509 OIL

1 AN900-10 c rush

2 Ring

2 Screws and Nuts 6-32 X

1 Fiberglass tube 3/8” x

Terminals

probe

washer

probe

X1/4"

5”

5”

OIL Temperatur e probe (K IT

1/4"

1250

)

35.6 Component Parts list for Oil Pressure sensor KIT 1240

1 P/N 159936A Oil Pressure

1 P/N 159961 Clamp, Loop

1 P/N 174402 Connector Pack 3 Pin and

sensor

Cushioned

Terminals

35.7 Component Parts list for Fuel Pressure Sensor KIT 1450 (only if required by POH)

1 P/N 159935A Fuel pressure

1 P/N 159961 Clamp, Loop

1 P/N 174402 Connector Pack 3 Pin and

35.8 Component Parts list for

sensor

Cushioned

Terminals

Kit 1480 Differential Fuel Pr essure (only if required b y

POH)

1 P/N 159938 Fuel pr essure

1 P/N 159961 Clamp, Loop

1 P/N 174204 Connector MS

sensor

Cushioned

3116F8-4S

35.9 Component Parts list for Kit 1300 ampere shunt

1 P/N 159920 100 amp shunt

2 Ring Terminals

35.10 Component Parts list for Fuel Flow Transducer

1 fuel flow transducer, 201 or 231 PN 700900-1,-2

8 inches of 1.5” dia. fire sleeve

1 3-pin connector housing

3 female pins

2 AN816-4-4 fittings (Continental) or AN816-4-6 (Lycoming)

35.11 Component Parts MAP sensor KIT 1440

1 P/N 159934A Manif old pr es sur e

1 P/N 159961 Clamp, Loop

1 P/N 174402 Connector Pack 3 Pin and

sensor

Cushioned

Terminals

35.12 Components Parts list for pressurized RPM sensor

Slick 6000………………………….….P/N 420809

Bendix magneto 20, slick 600………P/N 420806

Bendix Dual ………………………….P/N 420808

Page 32

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 32 of 46 Rev D

Date 2-6-2014

Bendix 1200………………………….P/N 420807

35.13 Components Parts list for RPM sensor P/N depends on Magneto make and model

Bendix magneto -20,120…………..P/N 420815-2

Slick magneto 4000 or 6000………P/N 420815-1

Bendix dual ………………………...P/N 420808

36. Weight and Balance Data

1.8

Lbs

Lbs

Lbs

lbs

lbs

lbs

lbs

lbs

lbs

DAU PN 790000-B EDM-950

Indicator PN 790000-C-120, EDM-930 incl. 2 RADs

EGT / TIT / CDT / IAT / OAT probe

CHT / Oil Temperature probe

4/6 Cylinder Harness 8 ft.

RPM and MAP

Fuel Pressure Sender

Oil Pressure Sender

Harness each

2.0

2.0 oz. each / 0.125

1.5 oz. each / 0.094

14.0 oz. each / 0.88

5.0 oz / 0.42

5.0 oz / 0.42

5.0 oz / 0.42

1.0

37. Pilot Programming

Refer to the Pilots Guide for specific Pilot Programming details. Basically to start the Pilot Program procedure,

simultaneously hold the STEP and LF buttons for five seconds. You will see the word PROGRAM for two seconds and

then the example sequence shown in the chart below.

Tap the STEP button to advance to the next item in the list. Hold the STEP button to step back to the previous item.

Tap the LF button to select alternate values of that item. Simultaneously hold both STEP and LF to exit.

STEP

advances

next item

PROGRAM

FUEL N FILL? N Tap LF to change fuel status. Exits program mode when done.

RATE 4 0 … 9 Index rate (pause time in seconds) in the Automatic Mode. 0 disables the Automatic

OAT F OAT

OAT0

LF

sequen

ces

through

these

values

F

OAT

C

OAT-I0

…

OATI0

Comments

Stays on for two seconds.

Mode.

To calibrate the OAT 10°, hold both the STEP and LF buttons simultaneously for five

seconds, which will proceed to the next step. Otherwise the next step will be skipped.

This step will be normally be skipped.

Adjust the indicated temperature up or down by up to 10°. For example, OAT3 adjust

the OAT 3° higher.

EGT I?N EGT

I?N

EGT

ICY

Y—Yes—sets the digital display to one-degree resolution; N—No—sets 10°. (10°

resolution is easier to interpret the Get’s.)

Page 33

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 33 of 46 Rev D

Date 2-6-2014

HIP I25 70 HP

HIP=

I25

%HP display will change when HP constant is adjusted. Hold STEP and LF for 5 seconds

until you see ADJUST to set the HP calibration. Tap STEP to continue to the next step.

See page 26

To adjust the MAP, hold both the STEP and LF buttons simultaneously for five seconds,

which will proceed to the next step. Otherwise the next step will be skipped.

MAP 29.9 MAP 20

32

KF 29.90 Adjust the instrument’s K-factor to match the fuel flow transducer K-factor. See page 33

TR IP? N TR IP?

N

TR IP?

Y

HOBS VAL 2424

ENG

25

EDM

3567

FRM

END? Y END?

Y

37.1.1 Programming the Horsepower Constant

You must adjust the HP Constant once for your aircraft. You must perform this adjustment in the air while the aircraft is

in flight between 5,000 and 8,000 feet MSL.

1. Enter the pilot program mode by simultaneously holding the STEP and LF buttons for five seconds.

2. Tap STEP repeatedly until you see—for example— HIP = I25. Then hold both the STEP and LF buttons display

until you see ADJUST, followed by HIP= I25. The adjustment range for the HP Constant is 45 to 180.

Adjust the MAP. See page Error! Bookmark not defined.

N—No—Upon informing the EDM that you refueled the aircraft, reset total fuel used to 0.

Y—Yes—accumulate total fuel used rather than reset to 0 at each refueling. See page

33

Displays the engine hours and airframe hours.

STEP exits the pilot programming mode.

LF reenters pilot programming mode.

3. Set the MP and RPM per your POH to 70 percent power. Let conditions stabilize.

4. Change the HP reading on the EDM-960 to 70 percent by adjusting the HP constant in the lower display by holding

or tapping the LF button. Percent HP should be close to 100 percent during takeoff at sea level or you can set it at

take-off ,100 ft into the roll.

5. Tap the STEP button to proceed to the next step.

Fine tuning the MAP gauge

Sets the manifold pressure calibration .

You may need to correct the MAP based on the altimeter setting at a sea level airport.

1. Enter the pilot program mode by simultaneously holding the Step and LF buttons for five seconds.

2. Tap Step/OK repeatedly until you see—for example— HPConstant=125. Then hold both the first two buttons

Step/OK and Change buttons display until you see Adjust, followed by HP Constant=125.

3. Again, Hold both the two buttons, Step/OK and Change buttons display until you see ADJUST, followed by

MAP+0. The adjustment range for the MAP is ±2.0 in Hg. As you adjust the MAP up or down you will see a

change in the MAP gage under RPM. When you see the correct setting stop.

4. Tap the Step/OK button to proceed to the next step or hold both buttons again to exit setup.

Do this one time and only if the MAP on your manifold pressure gauge doesn't match the MAP shown on the EDM-960

You must do this on the ground with the engine turned off.

Page 34

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 34 of 46 Rev D

Date 2-6-2014

37.1.2 K factor

The K factor is shown on the fuel flow transducer as a four-digit number, which is the number of pulses generated per

gallon of fuel flow. Before installing the transducer, write down the K factor here _________. To enter the number,

move the decimal point three places to the left. For example if the K factor on the fuel flow transducer is 29,123, enter

29.12 in the K factor parameter.

If the K factor is increased, the indicated fuel flow will decrease, and vice-versa. When the K factor is changed during a

trip, calculations of fuel used, fuel remaining and time to empty are not retroactively recalculated.

37.1.2.1.1 Fine Tuning the K factor

The K factor shown on the fuel flow transducer does not take into account your aircraft’s particular installation. Fuel

hose diameters and lengths, elbows, fittings and routing can cause the true K factor to be different from that shown on

the fuel flow transducer.

You must use the following procedure to fine tune the K factor.

1. Make at least three flights of about two to three hours each. Note the actual fuel used (as determined by topping

the tanks) and the EDM-960 calculation of the fuel used for each flight USD.

Flight

1

2

3

Total

2. Total the EDM-960 calculated fuel used and the actual fuel used.

3. Record the current K factor here ____________________ and in the table below.

4. Calculate the New K factor as follows:

New K factor = (EDM fuel used) x (Current K factor)

(actual fuel used)

New K factor = ( ) x ( )

( )

Every time you fine tune the K factor, change it by only half of the amount calculated above, and record the

measurements here:

Date

Fuel USED shown by EDM

(total tank - REM)

EDM fuel

used

actual fuel

used

Actual fuel used by topping

tanks

Current

K factor

New K factor

=

x/

Pilot’s initials

Page 35

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 35 of 46 Rev D

Date 2-6-2014

38. Programming the K factor

This procedure is different than for setting other parameters.

1. If you haven’t already done so, start the Pilot Program procedure; by simultaneously hold the STEP and LF buttons

for five seconds. You will see the word PROGRAM, followed by FUEL N.

2. Tap STEP button to advance to the FFLW? N screen.

3. Tap LF to enter the fuel flow submenu.

4. Tap STEP repeatedly until you see KF = 29.90 (for example)

5. Hold both the STEP and LF buttons simultaneously for five seconds. The first digit flashes (shown here as a larger

digit only for illustration purposes): 29.90

6. Tap or hold the LF button to change flashing digit: I 9.90

7. Tap STEP button for next digit (hold STEP for previous digit): I 9.90

8. Tap or hold the LF button to change flashing digit: I 8.90

9. Tap STEP button for next digit (hold STEP for previous digit): I8.90

10. Repeat items 9 and 10 for the remaining two digits.

11. Hold STEP and LF buttons simultaneously for five seconds to exit the K factor parameter setup.

12. Tap STEP repeatedly until you see END? Y, then Tap STEP once more to exit the factory setup mode.

Page 36

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 36 of 46 Rev D

Date 2-6-2014

39. Trouble Shooting

1. A missing column in the display upon start up indicates the continuity check diagnostic routine has found an open

line or probe with no connection. An error message will indicate which cylinder to look at.

2. A missing column in the display during flight indicates a reading that is jumping around or incorrect. The probe is

removed from the line up to prevent false alarms.

3. A negative reading (-) in front of the number indicates reverse polarity on the red/yellow wire to probe.

4. Using an ohmmeter or continuity checker measure across the probe output leads. A good probe should be around

2- ohms and at the connector to the probe around 20 ohms.

5. Erroneous or erratic readings on one cylinder reading. Swap the suspected probe with a pro be from a good

cylinder. If the problem goes to the good cylinder the probe should be replaced. If the problem remains the same, it

is in the Thermocouple hook-up wiring from the probe to the instrument or it can be in the ring terminals cri mped to

the wire. Remember to double back on the wire going into the ring terminal.

6. EGT, large span. Normally aspirated (carburetor) engines at normal cruise display a “DIFF” of 125 to 175

spread between cylinders. Injected engines at normal cruise display a “DIFF” 50 to 90

cylinders. All cylinders are measured by a common circuitry. It is almost impossible not to have identical calibration

on all channels.

o

F spread between

o

F

7. If the temperature reading is changing more than 500°F in one second it should be questioned and a loose wire

crimp or probe should be suspected. A malfunctioning probe will automatically be removed from the scan.

8. All EGT or CHT readings seem to high or low or unsteady. Use a DVM (digital voltmeter) to measure the difference

between 950 ground and the engine block ground. If the difference is greater than 0.5 volts with the alternator

charging. Then remove the EDM-960 ground (Black wire) from the instrument panel and connect it directly to the

ENGINE BLOCK for GROUND.

9. OAT readings off by 25 degrees, but oil and CHT readings OK, look for copper wire spliced in line to OAT probe.

OAT reading can be fine tuned +/- 5 degrees, see reset procedure. Engine heat could also be the cause.

10. The instrument configures itself automatically for 14 or 28 volt electrical systems.

Page 37

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 37 of 46 Rev D

Date 2-6-2014

40. Connector Pin Assignments EDM-950, J1 through J5

Top View of EDM-950 [DAU]

Showing Connector Locations

RS232 & Power

J11

RPM / MAP / OP

FP / FQ / Amps

FF

Options

EGT / C HT

J3

J5

J4

J1

J2

9

5

15

8

9

1

female c onn ector

25

13

25

13

6

1

9

1

15

8

14

1

14

1

Fac dip sw

18

Page 38

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 38 of 46 Rev D

Date 2-6-2014

J1 FOR 7, 8, and 9 cylinder installations

yel 1

red 2

yel 3

red 4

yel 5

red 6

yel 7

red 8

yel 9

red 10

yel 14

red 15

yel 18

red 19

yel 20

red 21

yel 22

red 23

gray 12

OIL temperature sensor

Carb temperature sensor

+

+

+

Remote temperature/voltage alarm light

(option)

CHT-7

CHT-8

CHT-9

OAT

EGT-7

EGT-8

EGT-9

yel 16

red 17

red 13

black 25

wht 11 DATA IN

wht 24

DATA OUT

TIT 1 sensor

No connection

Aircraft engine ground lead

Page 39

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 39 of 46 Rev D

Date 2-6-2014

Page 40

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 40 of 46 Rev D

Date 2-6-2014

6. J3 Oil-P, MAP, RPM

Page 41

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 41 of 46 Rev D

Date 2-6-2014

J4 (FF, AMPS2)

1.

Page 42

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 42 of 46 Rev D

Date 2-6-2014

J5 PN 790723 (Tanks, Fuel Press, Amps)

Main Tanks Voltage to Resistance

interface box for MAIN & AUX tank

J5

1 White

2 Green

12 Red

3 Blk

4 Green

5 White

6 red

7 black

PN 790802, Pennycap and Gull require

PN 791802

Sig-1

Sig-2

+5vdc

Gnd

Fuel Press Sig+

Power

Ground

PN 790802

MAIN

Differential port for upper deck pressure

PN 159938

FQ (resistive senders)

MAIN & AUX tanks

White Sig-1

White sig-2

Blk x2

Ground at Sender

PN 159935A

or 159938

Fuel-P

i2s Fuel Pressure 0-50 PSIG

PN 159935A

or

0-100 PSID PN 159938 (Differential

Pressure)

Electrical Connections are the same for

both

9 white

10 Green

12 red

3 black

13 white

14 White+

15 Gray8 White

7 Black

Signal AMP +

Aux Pwr IN optional

+

Blk x2

Ground at Sender

AMPS-1

Signal

FUEL TANK CONFIGURATION

SINGLE

Sig-1

Sig-2

Sig-4

Sig-3

L-MAIN

R-MAIN

L-AUX

R-AUX

L-MAIN

L-AUX R-AUX

NC

NC

TWIN

R-MAIN

NC

NC

Page 43

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 43 of 46 Rev D

Date 2-6-2014

41. P8 Harness Display PN 790807

Page 44

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 44 of 46 Rev D

Date 2-6-2014

Overall Installation Wiring Diagram

Page 45

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 45 of 46 Rev D

Date 2-6-2014

Page 46

FAA Approved Installation Manual for the EDM-960 system Report No 909

Primary Engine Data Management System Page 46 of 46 Rev D

Date 2-6-2014

42. Interconnection between Display, DAU’s and GPS

The DAU’s must be interfaced to the panel mounted Display. For certain aircraft the Display must

be interfaced to the aircraft’s fuel gauge system switches and signal conditioners (typical on

43. Instructions for Continued Airworthiness (ICA)

Refer to:

Supplement No: 960-01 Revision: A

Loading...

Loading...