Page 1

Pilot’s Guide

Engine Data Management

EDM-900

Primary

TSO/STC

Copyright 2011 J.P. Instruments, Inc.

All Rights Reserved

J.P. INSTRUMENTS INC.

Information: P. O. Box 7033

Huntington Beach, CA 92646

Factory: 3185 B Airway

Costa Mesa, CA 92626

(714) 557-5434 Fax (714) 557-9840

www.jpinstruments.com

www.JPITech.com

www.buyJPI.com

Printed in the United States of America Rev A

Last printed

For Your Safe Flight Page 1

Page 2

Table of Contents

Section-1 Getting Started 4

View Angle 4

Rotation 6

Fuel Flow Computer Basics (independent of fuel quantity) 6

Display Screen Basics 7

Horizontal Display Mode 7

Vertical Display Mode 8

Remote Annunciate Light Basics 8

RPM and MAP Display Basics 9

Linear Bar Graph Display Basics 9

Scanner® Information Area 10

LeanFind Basics 11

Section 2 - Interpreting Data 12

Operation for each Phase of Flight 12

Typical Normal Measurements 14

Section 3 - Displays and Controls 17

Control Buttons 17

Scanner Displays 19

Additional Displays Hobbs, Revisions, and Alarm Limits 21

Dimming the Display 22

Section 4 - Operating Modes 22

Automatic Mode 22

Manual Mode 23

Section 5 - LeanFind 24

LeanFind Procedure—General Explanation 28

Expanded Leaning Procedures 31

Common Misapplications 32

Section 6 - Fuel Flow Operation 33

Fuel Management 33

Start Up Fuel 34

Resetting ‘USD’ 35

Trip Mode (Accumulate Trip Totalizer) 35

Scanner Fuel Flow Display Select 35

Section 7 - Alarms 36

Section 8 - Memory and Data Download 37

Downloading Data from the EDM 37

Transferring data from the USB Flash Drive to a PC 38

Section 9 - First Time Setup and Customization 38

Section 10 - Adjusting Manifold Pressure & %HP 41

Adjusting the HP Constant for Rich of Peak Operation 41

Adjusting the MAP 41

Adjusting the HP Value 42

Section 11 - Programming the Fuel Flow 42

Page 2 Engine Data Management

Page 3

Fuel Flow K factor 43

Programming Trip Mode 45

Setting the GPS Com Format 45

Troubleshooting the EDM 47

Diagnostic Testing on Startup and During Flight 47

Diagnostic Messages 47

Section 12 - Appendices 48

Shock Cooling (CLD) 48

List of ALL messages in EDM-900 49

Navigation Data Formats 50

Navigation Data Ports for GPS Comm 50

Interface connections to selected GPS models 50

Section 13 - Technical Support 51

For Your Safe Flight Page 3

Page 4

Section-1 Getting Started

This is a summary of basic operation. Detailed descriptions of all

operations appear later in this Pilot’s Guide.

EDM-900 primary instrument has preset alarm limits and

cautionary ranges per the POH (user cannot change them)

typically for the following measurements of: oil temperature, oil

pressure, fuel pressure, fuel quantity, cylinder head temperature,

turbine inlet temperature, manifold pressure, and RPM.

Note: Fuel quantity gauges must be calibrated to the aircraft and

will not be functional until the fuel calibration process has been

performed.

View Angle

The best view angle for the pilot is in the horizontal mode with the

buttons on the bottom. The best Portrait mode is with the buttons

on the right.

View angles are per the table below:

Horizontal Left 65 Degrees

Viewing Right 65 Degrees

angle Vertical Left 60 Degrees

Right 50 Degrees

Page 4 Engine Data Management

Page 5

List of abbreviations and acronyms

Message Area

Alarm

Abbreviation

Engine Oil Temperature

Gauge Function

Primary Primary

Engine rotational speed RPM xxxx

Engine Manifold Pressure MAP xx.x in hg

Engine Cylinder Head Temp CHT2 xxxoF

O-T xxxoF

Engine Oil Pressure O-P xxxoF

Fuel Pressure F-P xx PSI

Fuel Flow to engine F-F xx.x GPH

Comp. Discharge Temp. CDT xxxoF

Turbine inlet Temp. Left side TIT-L xxxxoF

Turbine Inlet Temp. Right side TIT-R xxxxoF

Single Turbine Inlet Temp. TIT xxxxoF

Non-Primary Non-Primary

Exhaust Gas Temp. EGT2 xxxxoF

Shock Cooling of CHT CLD xxo/MIN

Differential Temp. of EGT DIF xxoF

Bus Voltage Volts xx.x

Amperage Load AMPS xx

Outside Air Temp. OAT xxoF

Estimated Time to Empty Est. T to E xx:xx H:M

Fuel used to date USED xx.x GAL

Estimated Remaining fuel Est. REM xxGAL

Estimated Fuel required to Waypoint Est. WP REQ xx GAL

Estimated Fuel Remaining at

Waypoint

Nautical Miles per Gallon ECON xx.x MPG

Brightness, Dim control DIM/BRT

Est. WP RES xx GAL

For Your Safe Flight Page 5

Page 6

Rotation

Holding the step button in for 5 seconds, with the engine OFF, will

produce the gray arrow. This arrow can be rotated to a new up position

by tapping the LF button and then the STEP button. If for some reason

you chose the one bad angle (Landscape looking up from the

buttons), return the instrument to JPI and JPI will rotate the

screen.

Fuel Flow Computer Basics (independent of fuel quantity)

The fuel flow computer tracks the fuel flowing to the engine and

computes various values based on this. At installation, then each time

you refuel the aircraft, you must inform the EDM about how much

useable fuel is onboard. This is done via the REFUEL function.

See page 33 for detailed information

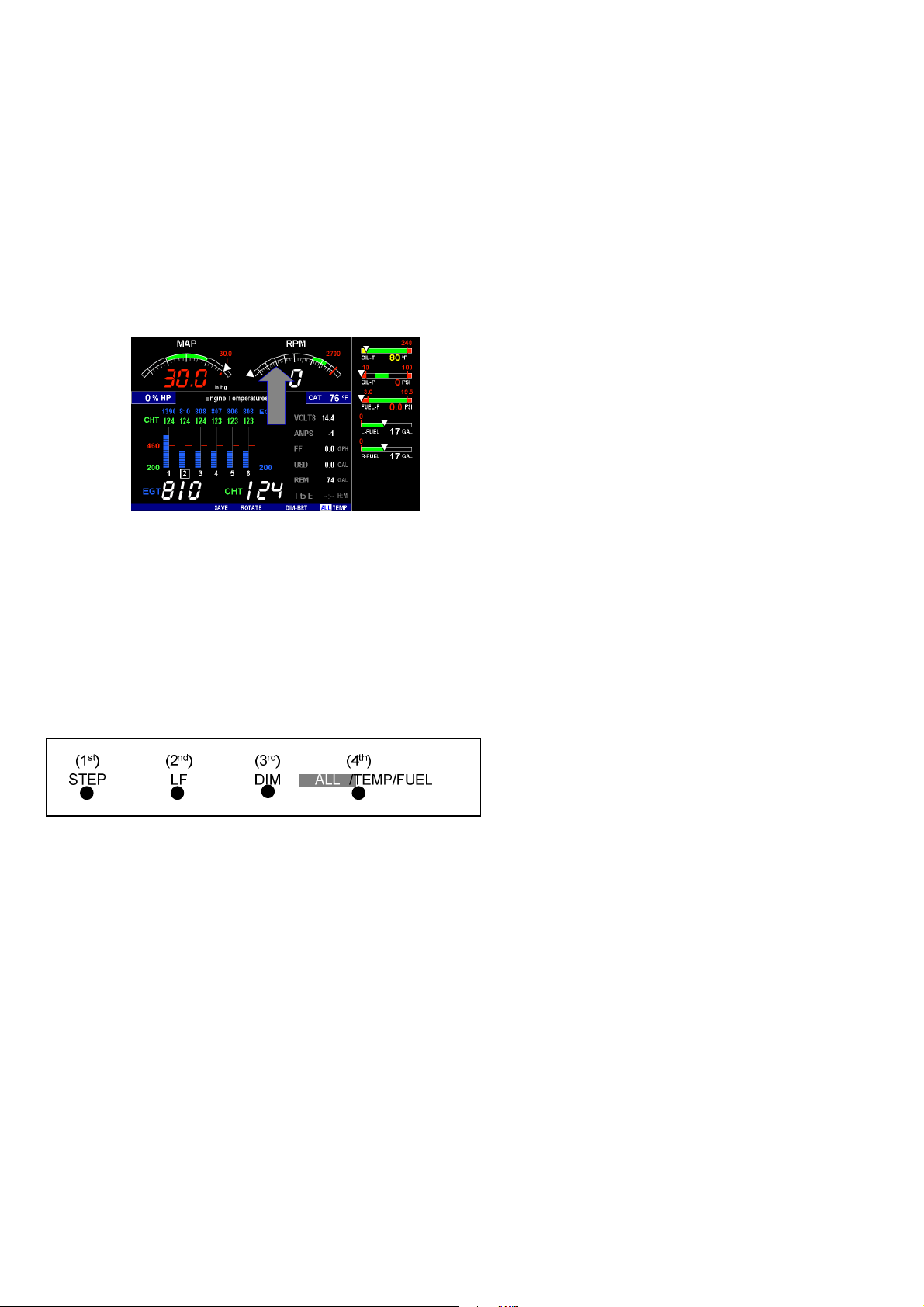

Control Button Basics

Four operating buttons control all functions of the EDM. These buttons

change labels depending on the current state of the EDM.

Page 6 Engine Data Management

Page 7

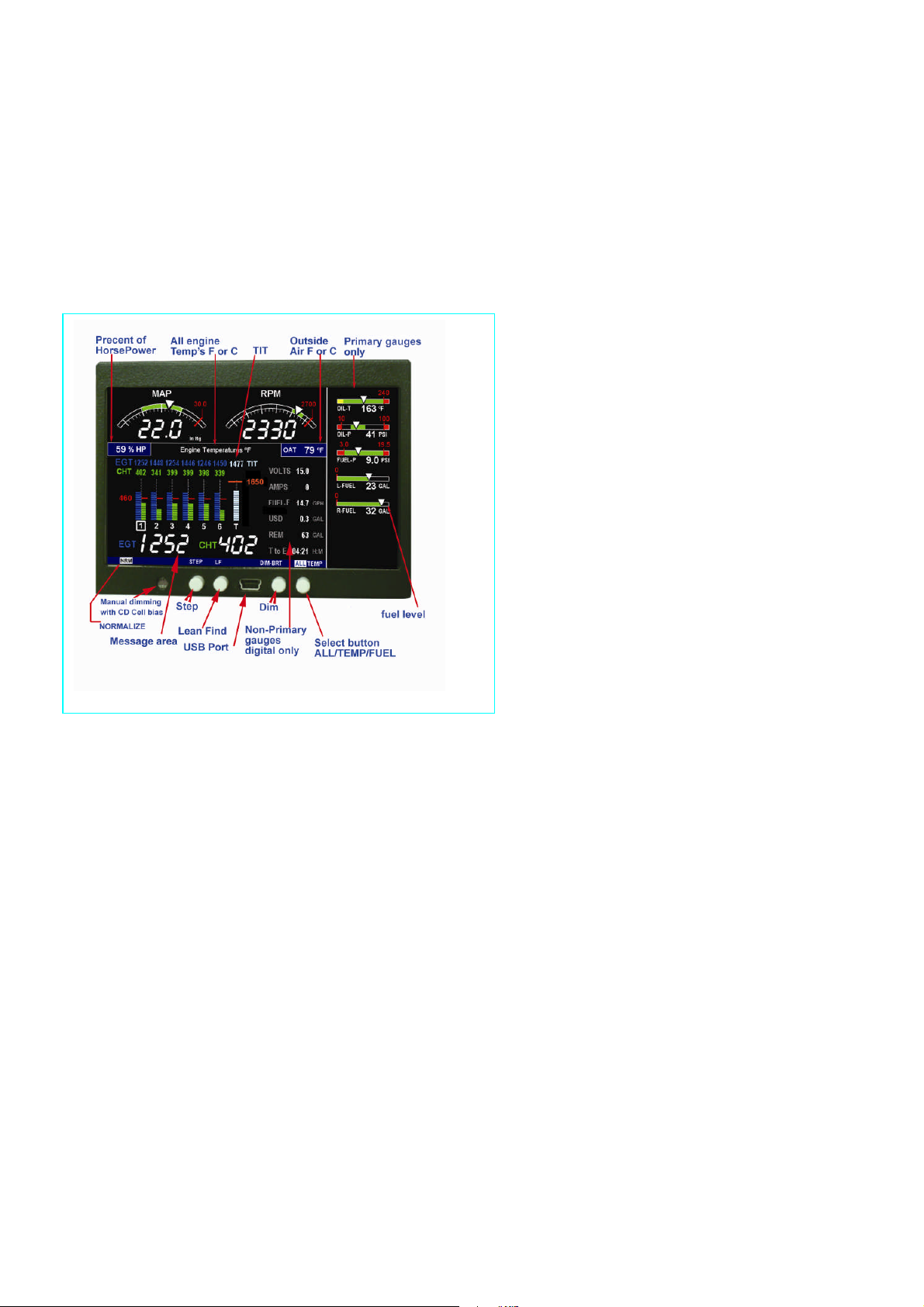

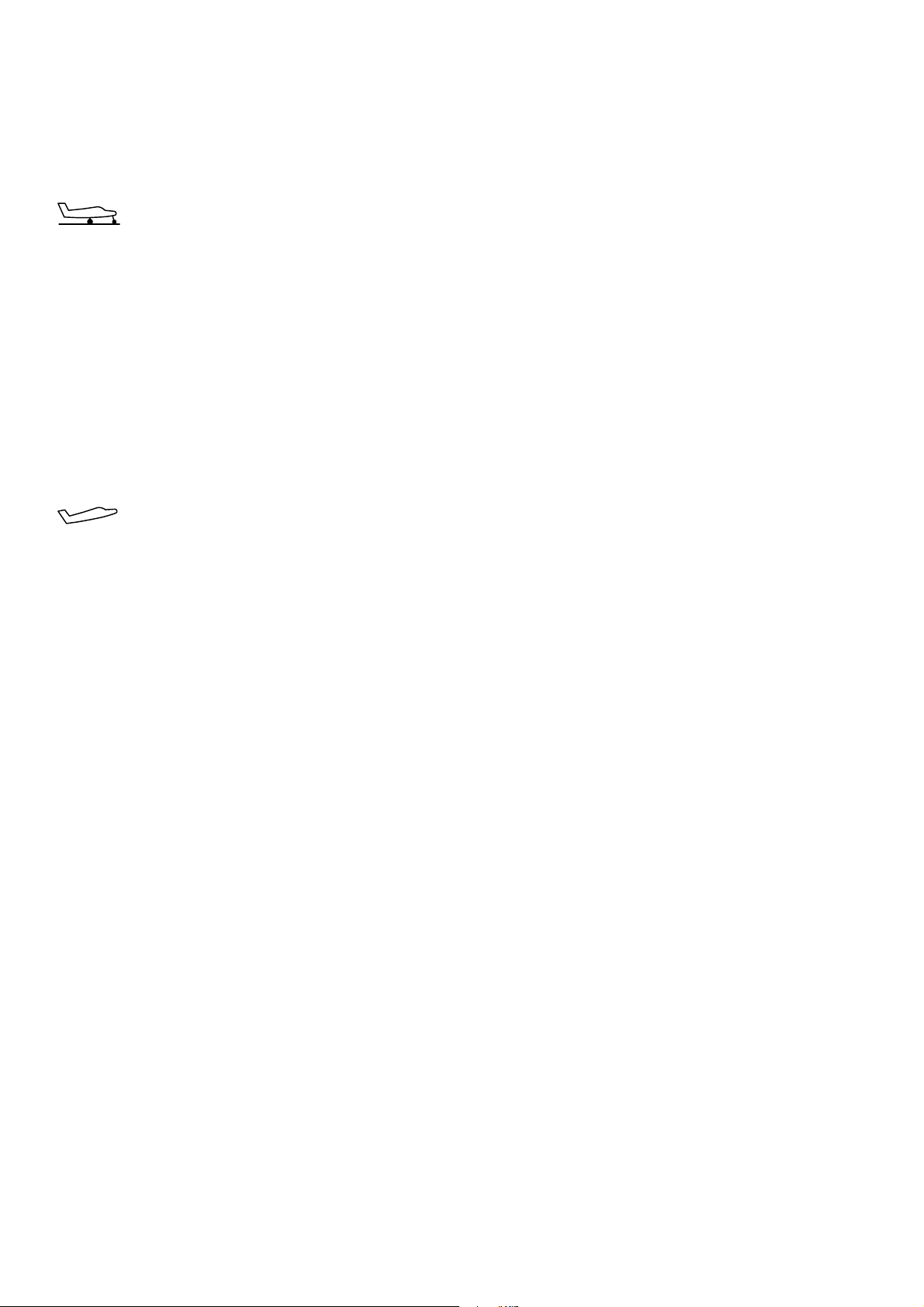

Display Screen Basics

The display screen is arranged into three sections. The top left is the

MAP and RPM section. The bottom left is the Scanner® section or

message area. On the right side are the horizontal primary strip gauges.

Non-Primary gauges have a digital read out only. The instrument ranges

and alarm limits are configured to match those of your aircraft POH when

the EDM is set up as a Primary instrument. TIT column is to the right

of the last EGT/CHT when applicable.

Horizontal Display Mode

For Your Safe Flight Page 7

Page 8

Vertical Display Mode

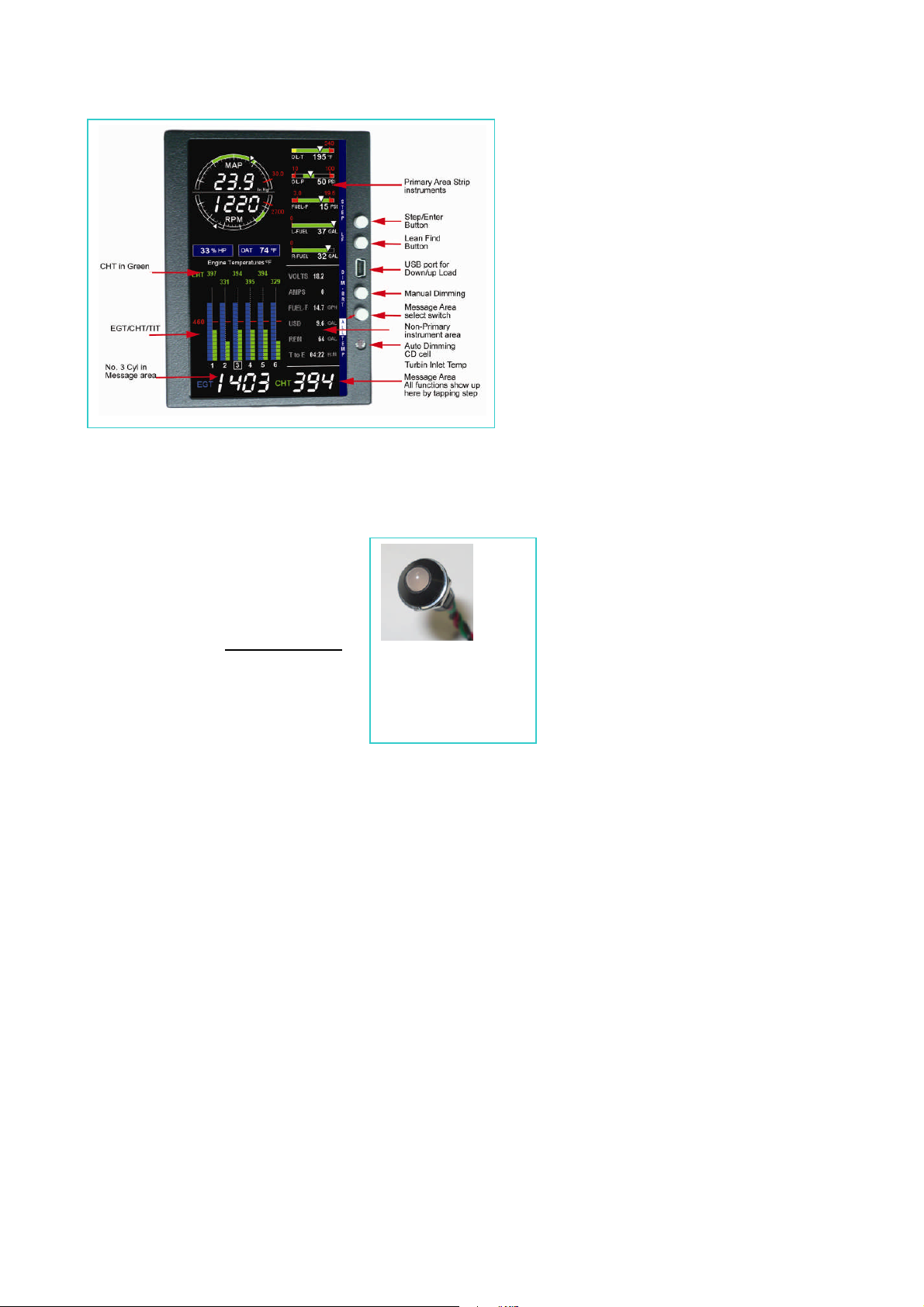

Remote Annunciate Light Basics

The Remote Annunciator Light ‘RAL’

provides notification that an alarm is present

in the display, for all Primary gauges. Upon

power up, the RAL shows Red and yellow

indicating it is functional. Before each flight,

confirm that it is functional. Non-functioning

RAL must be repaired before flight.

Remote

Annunciator Light

(RAL)

Page 8 Engine Data Management

Page 9

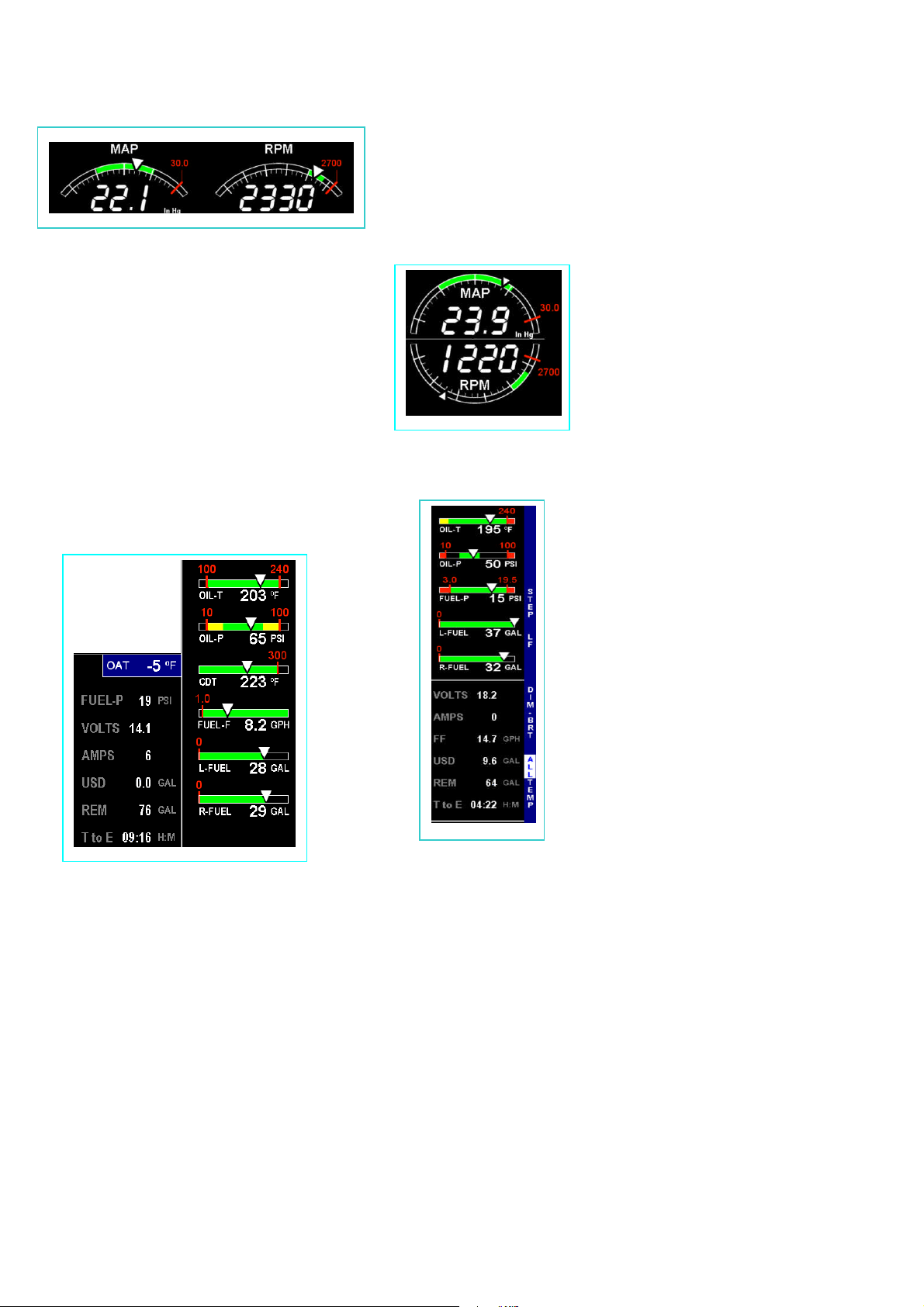

Horizontal mode Vertical mode

RPM and MAP Display Basics

In the vertical mode to the right and the

Horizontal mode above MAP (Manifold Pressure)

and RPM (Revolutions per Minute) are shown.

Operations exceeding red line cause the digital

value to turn red or yellowwith the RAL coming

on and a digital value in the Scanner message

area.

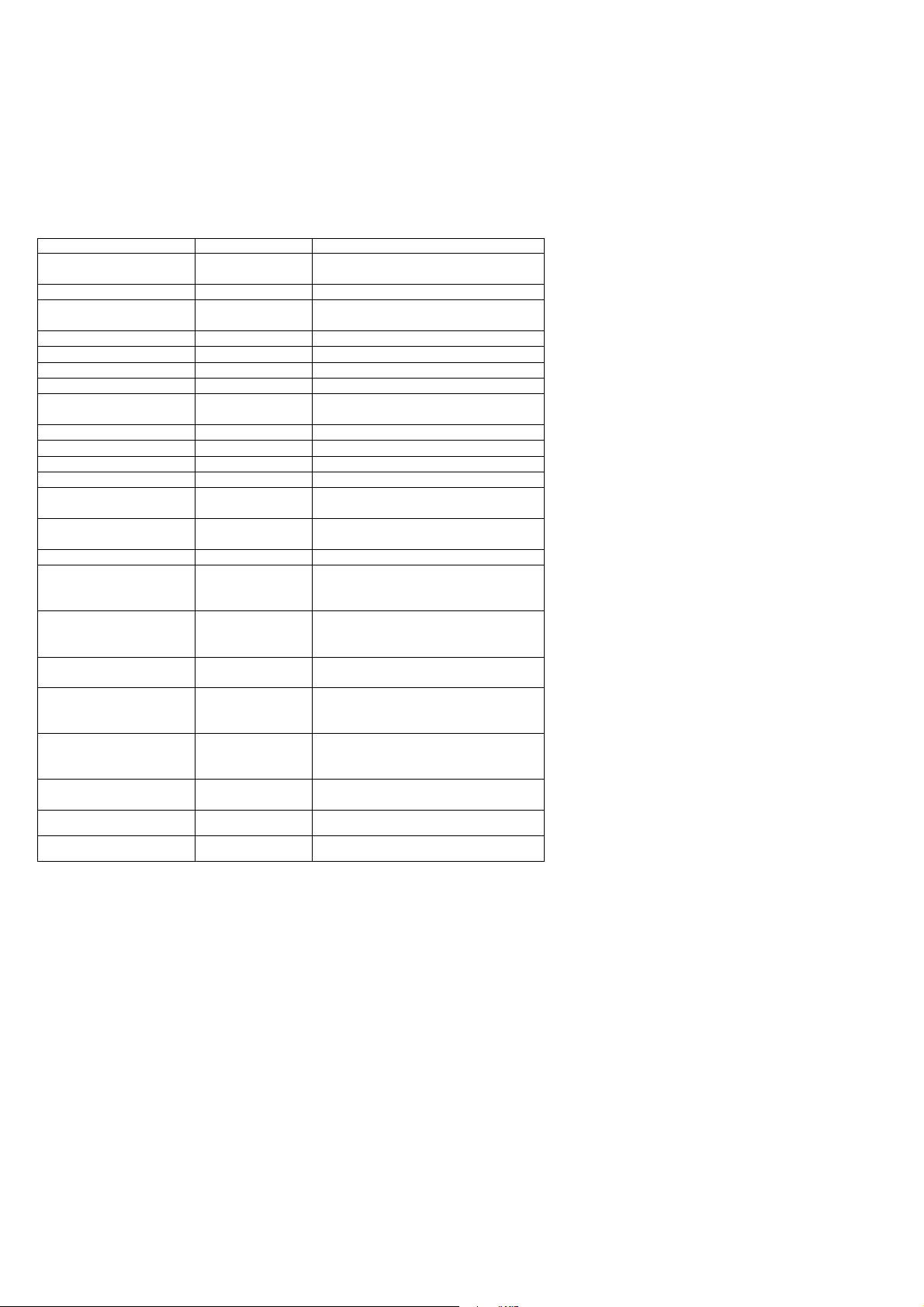

Linear Bar Graph Display Basics

The Bar Graphs section contains dedicated bar graphs with digital

display. An example is shown here. Pointers move horizontal left to right

showing value changes and digital readouts turn red

when primary exceedances occur. Non primary

functions flash white.

Horizontal mode Vertical mode

For Your Safe Flight Page 9

Page 10

Scanner® Information Area

The Scanner® Information Area provides expanded information in the form of

alpha-numeric messages, parameters and calculations. In Auto-Scan,

parameters will ‘scan by’ once every 4 seconds (default). This rate can be

changed in Pilot Programming Mode. Tap the STEP button for ‘Manual’ selection

of any parameter. Parameters for the installed options will be displayed. To start

the automatic scan tap LF and then STEP.

DISPLAY PARAMETER DESCRIPTION

EGT 1436 CHT 382 EGT/CHT

TIT 1580oF TIT Single Turbine Inlet Temp.

TIT-L and -R 1490

o

F

Oil-T 204oF OIL TEMP Oil temperature in degrees F

Oil-P 64 PSI OIL PRES Oil pressure in psi

F-P16 PSI FUEL PRES. Fuel pressure in psi

F-F 2.7GPH FUEL FLOW Fuel flow in GPH

CLD 75oF

VOLTS 13.9 BATTERY Battery/Bus voltage

AMPS -6 Amperage Set up per the specific aircaraft

OAT 23oF OAT Outside air temperature F or C

DIF 40oF DIF Hottest minus coldest EGT

CRB 56oF CRB

CDT 145oF CDT

IAT 105oF IAT Induction Air Temp

Est. REM 68.0GAL

WP REQ 12.7 GAL

Est. WP REM 63 GAL

ECON 9.8 MPG

EST. T to E 04:32

H:M

GPH 15.0 GPH

USD 7.2 GAL FUEL USED Actual fuel used by the engine

FUEL-P 64 PSI FUEL PRES Fuel pressure in PSI

TIT-L, TIT -R

SHOCK

COOL

FUEL

REMAINING

FUEL

REQUIRED

FUEL

RESERVE

Nautical

MILES PER

GALLON

Estimated

Time to

Empty

FUEL FLOW

RATE

Shows successive pairs of EGT &

CHT per STEP tap.

Two Turbine Inlet Temp. Left and

Right engine side

CHT cooling rate (deg/min)

Carburetor Air Temp (only allowed if

IAT not present)

Compressor Discharge Temp (only

allowed if CRB not present)

Calculated fuel remaining on board

based on what the pilot put in as

maximum.

Calculated fuel required to reach

waypoint or destination (GPS

interface must be corrected)

Calculated fuel reserve at waypoint

(GPS interface must be correct)

Calculated fuel miles per units

(GPS interface required)

Calculated time remaining to fuel

exhaustion in Hours and Minutes at

present power.

Actual fuel flow rate in Gallons per

hour

Page 10 Engine Data Management

Page 11

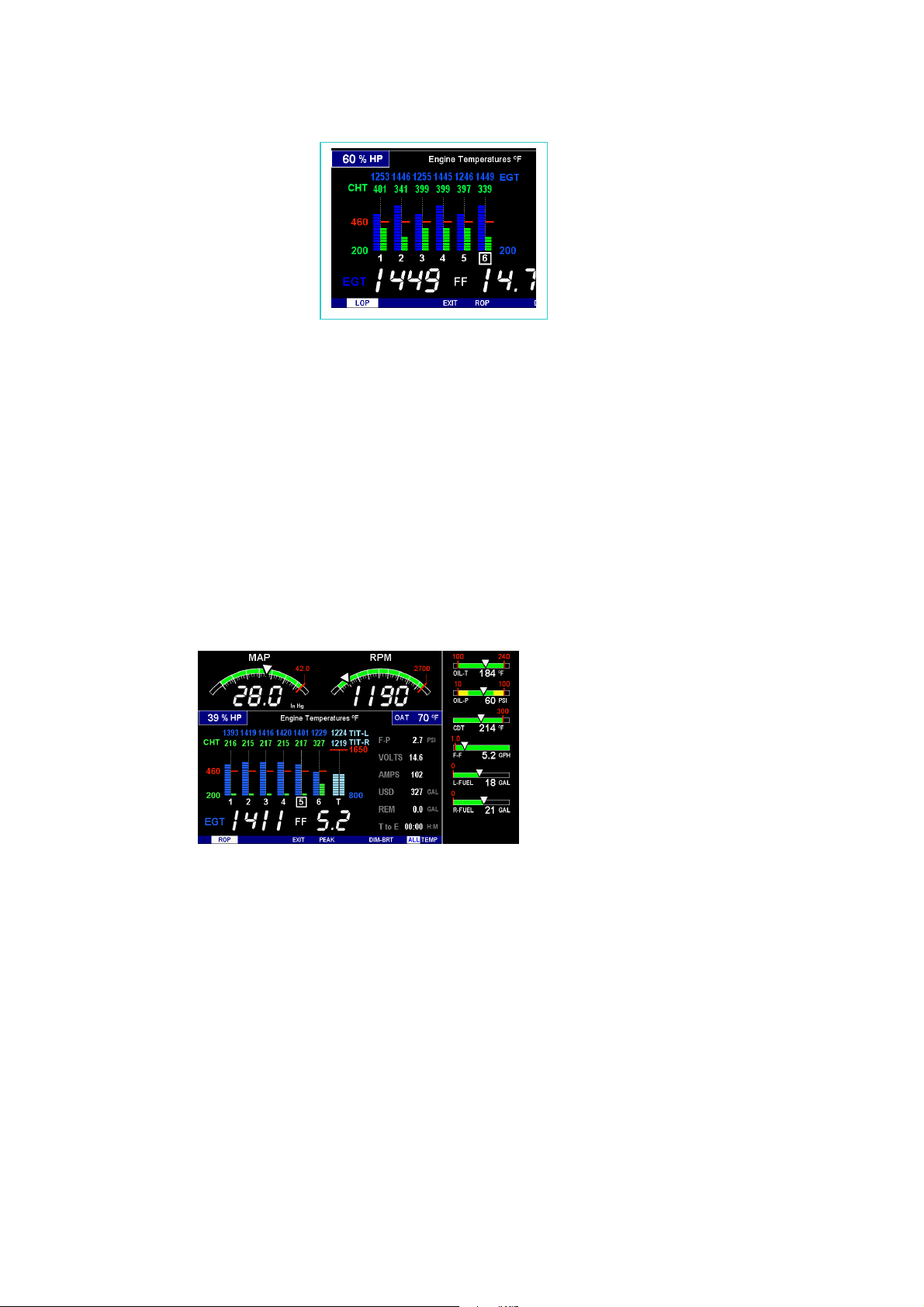

LeanFind Basics

Simply pre-lean, tap the LF button

(Lean Find) and begin leaning. The

EDM will assist you in finding the first

cylinder to peak. This example is for

Rich of Peak, ROP. See page 24 for

a more detailed description of

leaning. Press LOP to exit the ROP

mode and enter the LOP mode.

1. Establish cruise at approximately 65 to 75% power and pre-lean the

mixture to 50°F estimated rich of peak EGT on any cylinder.

2. Wait about 30 seconds, then tap the LF button.

3. Begin leaning the mixture smoothly without stopping. Turn a vernier

about ¼ turn per second; retract a non-vernier or quadrant lever so

that EGT rises about 10°F per second.

4. Stop leaning when you see LEANEST for two seconds, followed by—

for example—

temperature of the first EGT to peak and the right number is the

current fuel flow.

5. Now tap the PEAK button to display the EGT difference from peak

which is very useful for setting desired degrees below peak.

6. Slowly enrich the mixture noting that the EGT difference diminishes

as EGT climbs back to peak, followed by it going minus again. Stop

enriching at the desired EGT difference (such as ‘EGT -75’).

7. You can also see what the peak EGT was by holding the PEAK

button.

8. Tap STEP to

exit the Lean

Find Mode.

EGT

1449FF14.7 The left number is the current

For Your Safe Flight Page 11

Page 12

Section 2 - Interpreting Data

Operation for each Phase of Flight

(Worth adding to your run-up checklist)

Suggested setup:

Setengine to run-up RPM

Engine

Run-Up

Take-Off,

Climb, and

Full

Throttle

Operations

Normalize view:

Manual mode

Verify:

Uniform rise of about 50°F in all EGTs in single

magneto operation.

Uniform rise of EGTs with application of the mixture

control.

Be alert for:

unusually low voltage (less than nominal battery

voltage)

cold OIL and normal oil pressure

abnormally high CHT

Large drop in EGT on one cylinder in single magneto

operation—may be fouled spark plug.

Suggested setup:

Standard view

Automatic mode

Verify:

EGTs and CHTs consistent with past climbs. EGTs

should be in the 1100 to 1300°F range (100° to 300°F

cooler than cruise) due to fuel cooling.

Be alert for:

High EGT in one cylinder, 300°F above the others may

indicate plugged injector or leaking manifold gasket on

a carbureted engine. At high density altitude an overly

rich mixture can significantly reduce engine power.

If all EGT columns go off scale to the top of the

column, be sure you are not in Normalize view, as

indicated by the symbol NRM above the Scanner®

section.

Page 12 Engine Data Management

Page 13

Cruise

Descent

After the engine is warmed up, use LeanFind to lean the

mixture.

Suggested setup:

Normalize view

Automatic mode

Be alert for:

Uneven EGTs (injected engines). Make fine

adjustments to throttle, then RPM, then mixture to

level the display columns.

Abnormal patterns of EGTs and CHT. (see Engine

Diagnosis Chart on page 15).

Suggested setup:

Standard view

Manual mode

Be alert for:

CLD: shock cooling alarm is set to -60°F. Average

cool rates of -40°F/minute to -50°F/minute are normal,

depending on the engine size.

For Your Safe Flight Page 13

Page 14

Typical Normal Measurements

The following chart lists typical normal measurement values that you will

observe for most general aircraft engines. Your particular engine’s

ranges may not fall within these values.

Measurement Normal range Comments

EGTs in Cruise 1350°F

1550°F

EGT span (DIF) 70 to 90°F

120 to 150°F

TIT 1600°F average

CHTs 350°F (OAT 60°F)

410°F

CHT span 50 to 70°F

OIL T 200°F

OIL P 30 to 60 psi

FUEL P (injected) 14 to 18 psi

FUEL P (carbureted) 0.5 to 8 psi

Shock cooling* -40°/minute

-55°/minute

-200°/minute

under 200 HP engines

high performance engines

(EGT should drop 200°F when

full throttle is applied)

fuel injected engines

carbureted engines

100° higher than EGT

normally aspirated engines

Turbocharged engines

100° with gasket probes

oil cooler thermostat typically

opens at 180°F

varies with aircraft type

varies with aircraft type

tightly cowled engines

Bonanza

helicopter

* Maintain a cooling rate magnitude of less than -50°/minute. You will find

that the cylinder with the greatest shock cooling may shift from front

cylinders (during climb out) to the rear cylinders (during descent ).

Page 14 Engine Data Management

Page 15

Engine Diagnosis Chart

The following chart will help you diagnose engine problems in your

aircraft.

Display Symptom Probable

Cause

TIT ~100°

higher than

EGTs

75° to 100°

EGT rise for

one cylinder

during flight

EGT Increase

or decrease

after ignition

maintenance

Loss of EGT

for one

cylinder.

Engine rough

Loss of EGT

for one

cylinder; no

digital EGT

Decrease in

EGT for one

cylinder

This is normal

Spark plug not

firing due to fouling,

faulty plug, wire or

distributor.

Improper timing:

high EGT

retarded ignition;

low EGT

advanced ignition.

Stuck valve. Other

cylinders are okay.

Failed probe

or

failed wire harness.

Intake valve not

opening fully; faulty

valve lifter.

Recommende

d Action

Enrich mixture to

return EGT to

normal. Have

plugs checked.

Check EGT for

each magneto to

determine any

uneven timing.

Have valve train

checked.

Swap probes to

determine if probe

or wire harness is

bad.

Have valve lifter or

rocker arm

checked.

Increase in

DIF at low

RPM

EGT and

CHT not

uniform

Decrease in

EGT for all

cylinders

Low compression

(blow by) in

cylinder

Normal for

carbureted

engines. Dirty fuel

injectors or fouled

plugs.

Decrease in airflow

into the induction

system. Carb or

induction ice.

Check

compression.

Check injectors

and plugs.

Check for change

in manifold

pressure.

For Your Safe Flight Page 15

Page 16

Display

(no picture)

(no picture)

Symptom Probable

Cause

Slow rise in

EGT. Low

CHT

High CHT on

cylinders on

one side of

engine

Rapid rise in

CHT of one

cylinder

Sudden off

scale rise for

any or all

cylinders

Loss of peak

EGT

Decrease in

peak or flat

EGT

response to

leaning

process

Below 10,000

ft. full throttle

causes EGTs

to rise

CHT more

than 500°,

EGT normal.

Adjacent EGT

may be low

Burned exhaust

valve. CHT is low

due to low power

output.

Obstruction under

cowling.

Detonation. Reduce power.

Pre-ignition

Normalize view

or failed probe

Poor ignition or

vapor in fuel

injection system.

Detonation.

Usually the result

of 80 Octane fuel

in 100 Octane

engine.

Weak or defective

mechanical fuel

pump.

Leaking exhaust

gasket blowing on

CHT probe.

Recommended

Action

Have compression

checked.

Check for improper

installed baffling,

cowl flap

misalignment or bird

nests.

Full rich and reduce

power.

Change to Standard

view

Check probe

Have magneto

tested.

Enrich mixture,

reduce power and

relean mixture.

Repeat to find power

setting where normal

peak is obtained or

run rich.

Apply booster pump.

If EGTs drop,

replace fuel pump.

Look for white

powder around

cylinder to determine

leak area.

Page 16 Engine Data Management

Page 17

Section 3 - Displays and Controls

The EDM monitors engine temperatures, pressures and voltages, assists

in adjusting the fuel/air mixture, and helps diagnose engine malfunctions.

There are multiple components of the user interface:

Four front panel operating buttons below the bottom of the display.

RPM and MAP display in the upper left corner of the display

Scanner analog display including cylinder number and index square

in the lower left corner of the display

Scanner digital display for numeric readouts and messages at the

bottom left

Bar graph displays on the right half of the display

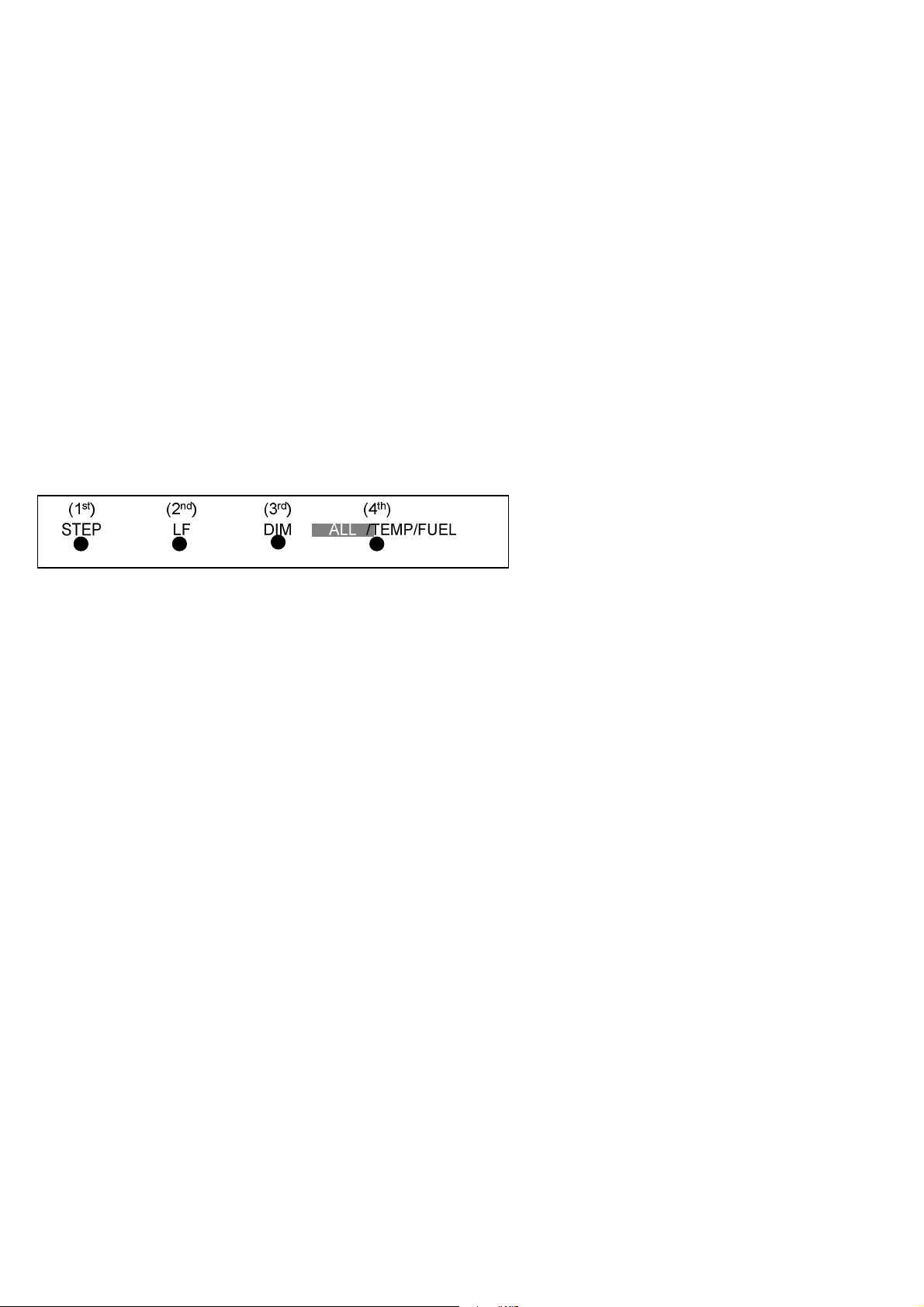

Control Buttons

Four operating buttons control all functions of the EDM. These buttons

may change labels depending on the current operating mode of the EDM.

The term tap is used to denote pressing a button momentarily. The term

hold is used to denote pressing and holding a button for five seconds or

longer. Button layout is shown below:

1st Button

In the Automatic mode, tapping the STEP button stops Scanner auto-

sequencing and changes to Manual mode. Each tap of the STEP

button then displays the next measurement in the sequence. Holding

the STEP button sequences in reverse order.

In the LeanFind mode tapping the EXIT button will terminate the

LeanFind mode and change to the Automatic mode.

In the Program mode tapping the NEXT button will advance to the

next item.

2ndButton

In Automatic or Manual modes, tapping the LF button will activate the

LeanFind mode.

For Your Safe Flight Page 17

Page 18

In the LF mode holding the LF button after peak EGT is found will

display the peak EGT.

In Automatic or Manual modes holding the LF button for three

seconds will toggle between Standard and Normalize (NRM) views.

In the programming mode, tapping the PLUS or MINUS button will

allow you to edit a parameter value.

Holding LF during power up will display the primary alarm limits after

the self-test is complete.

1stand 2ndButtons

Holding both the STEP and LF buttons simultaneously for five

seconds will enter the pilot programming mode.

Just after entering Lean Find Mode (but before any EGT has risen),

holding both First and Second buttons for five seconds will toggle

between LOP or ROP leaning modes.

Tapping both the STEP and LF buttons simultaneously in Manual

mode toggles to ‘include’ or ‘exclude’ the displayed non-primary

measurement from the Automatic mode only. The excluded

measurement will show up in the manual mode.

3rdButton

Tapping DIM (brightness decreases) or holding DIM (brightness

increases) allows decrease or increase brightness respectively.

2ndand 3rdButtons

Holding both the LF and DIM buttons simultaneously will display the

Hobbs readings. Tap button labeled NEXT to see additional

information screens.

4thButton ( ALL/TEMP/FUEL )

Select what is shown during Scanner auto-sequence. Choices are

ALL, TEMP or FUEL. Highlighted one is what is active.

Page 18 Engine Data Management

Page 19

Scanner Displays

Scanner EGT and CHT Analog Bar Graph

The height of each column represents a EGT or CHT or TIT (if installed)

temperature. Note: when in certain modes, such as leaning or normalize,

the EGT resolution will temporarily be finer.

Cylinder Numbers and Index

Just below the bar graph columns are numbers identifying the respective

cylinder. If TIT is installed, it is labeled by the letter T underneath. A

square ‘Cylinder I.D. Index’ surrounding a number indicates what cylinder

is currently selected and relates to the digital display.

Scanner Digital Display

Located under the Scanner bar graph area is the alphanumeric display. It

displays alphanumeric values for different parameters as well as status

and alarm messages.

Normalize / Standard View

To toggle between Standard and the Normalize views, hold the LF button

for three seconds until the NRM icon toggles on or off. Note: Normalize

cannot be activated while in Lean Find mode.

Standard view (when the NRM icon is not lit): the EGT top of the

columns represent absolute temperature.

Normalize view (when the NRM icon is lighted): When you change

to the Normalize view, all EGT columns are initiallynormalized to the

mid-point for deviation trend analysis. Any changes are shown as an

increase or decrease relative to the mid-point, thus giving an

instantaneous indication that an EGT has deviated. You normally use

normalize in level cruise, but it is also useful during steady state runups. Note: A common misapplication is to be in the Normalize view

and then change power setting. This causes all columns to go off

scale, high or low. Select Standard view before changing power or

altitude.

Temperature Units (°F or °C)

The EDM can display engine temps in either °F or °C (Fahrenheit or

Celsius). In Primary configurations, this is set to the same units as the

configuration the aircraft was originally certified to.

For Your Safe Flight Page 19

Page 20

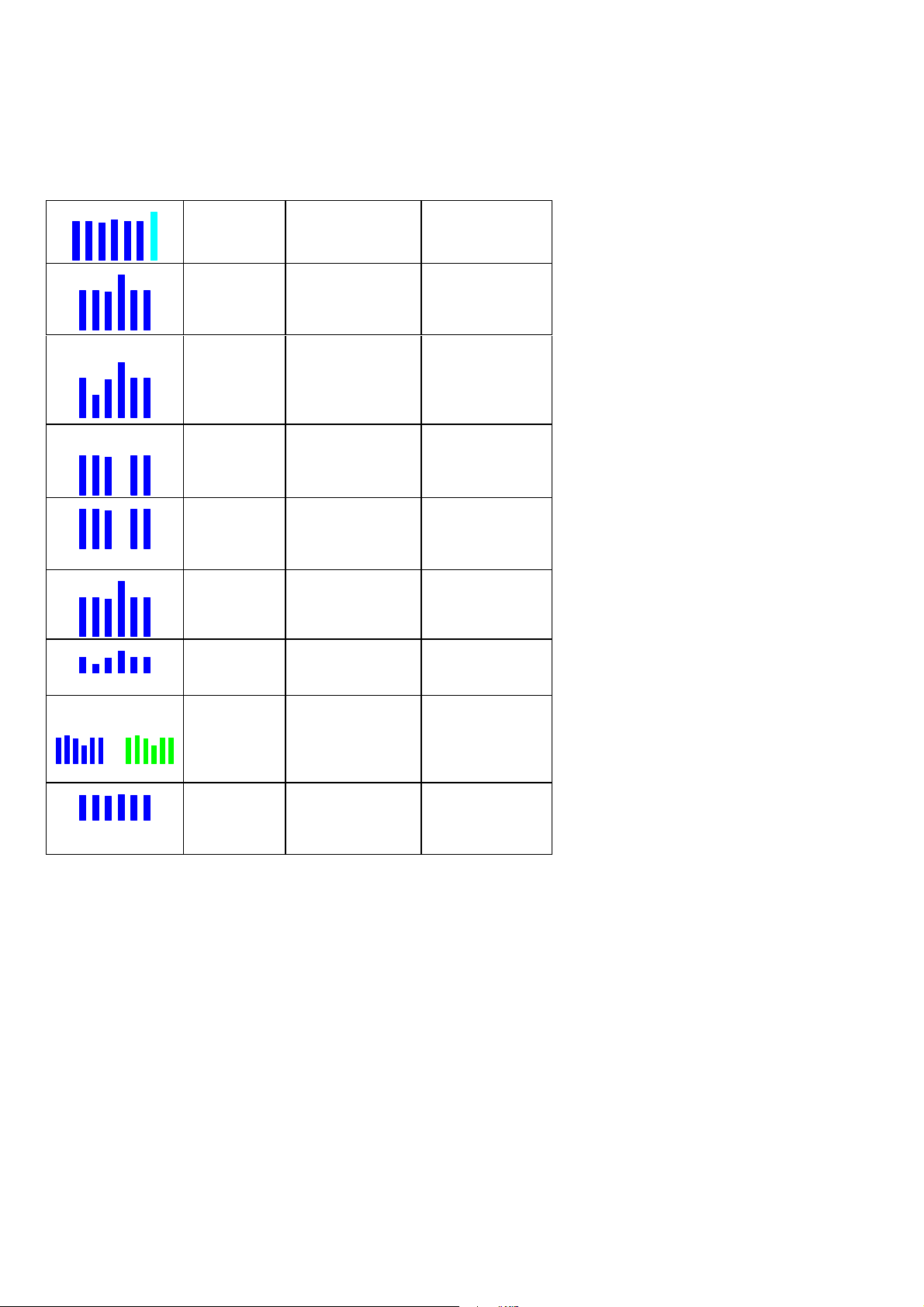

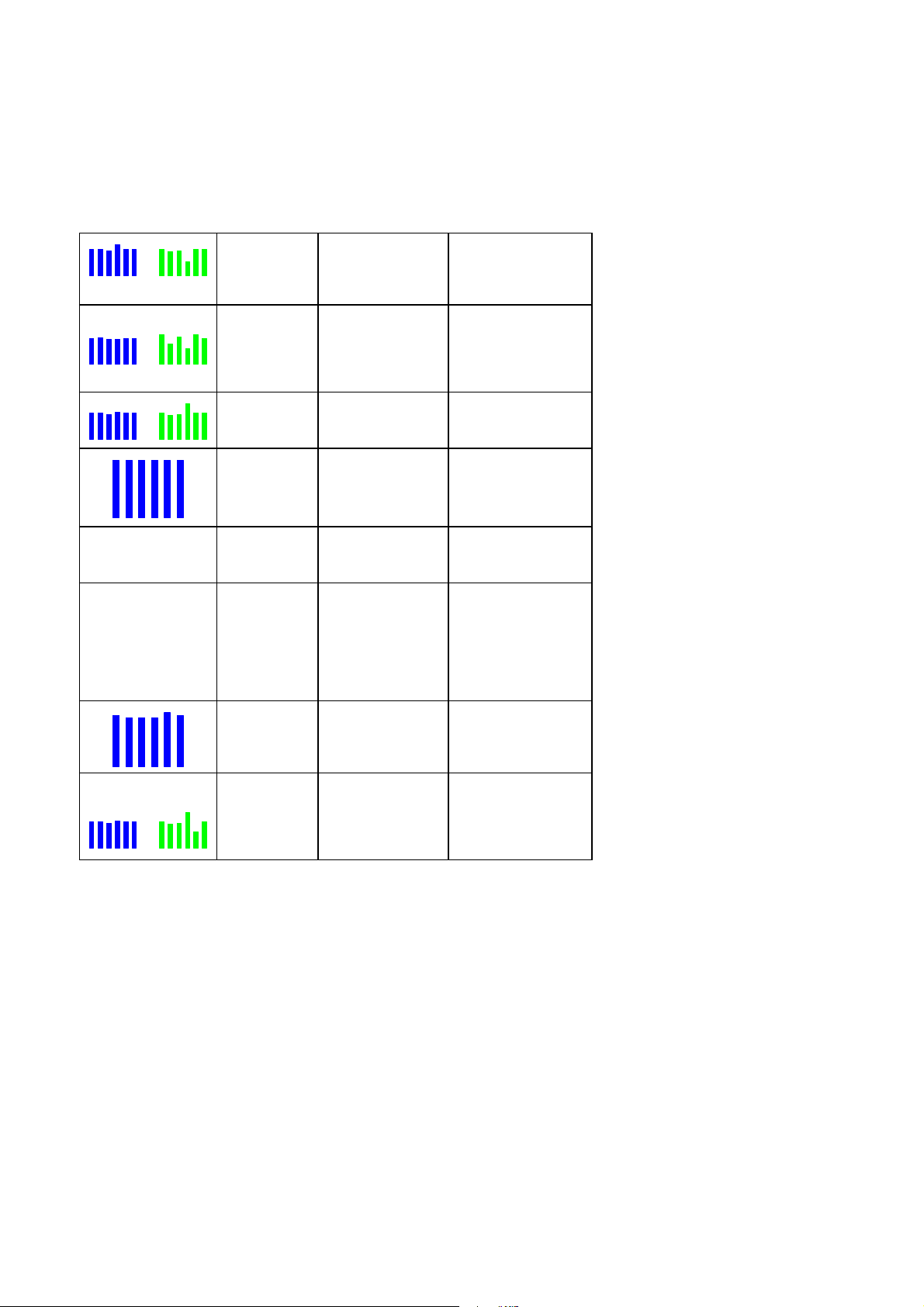

Linear Bar Graph Displays

The linear bar graphs are

arranged on the right half of the

display. A typical layout is

depicted here (Note: your actual

configuration may vary). Typical

functions that can be displayed

are:

Primary gauges

Oil temperature

Oil pressure

Compressor Discharge

temp

Fuel Flow.

Left tank fuel quantity

Right tank fuel quantity

Non Primary gauges

Fuel pressure

Volts

Amps

Fuel USED Estimated

Fuel REM Estimated

Time to Empty Estimated

Outside Air Tem.

The range of the bar graphs depends on the programming. Range,

redlines and/or limits are typically set to match the original aircrafts gauge

markings. These are locked for Primary installations, however nonprimary gauges can be user modified.

Non Primary Primary

Page 20 Engine Data Management

Page 21

See ‘Section 9 - First Time Setup and Customization’.

Note: Amps can operate either as a (Amps Charge) charge/discharge or

(Amps Load) load meter, depending on programming.

Remote Annunciate Light

The remote auxiliary ‘ALERT LIGHT’ provides redundancy. Upon power

up the Remote Annunciate Light displays Red and Yellow. If the RAL is

not working abort the flight. While the EDM’s programmed configuration

(aircraft make and model and primary status) is shown in the display.

Mentally Confirm that it matches your aircraft configuration before using

the instrument. If it does not match the aircraft configuration abort the

flight.

Additional Displays Hobbs, Revisions, and Alarm Limits

Holding both the LF and DIM buttons simultaneously will display the

Hobbs times similar to the example below:

or Revisions

For Your Safe Flight Page 21

Page 22

or Programmed Limits in this Instrument.

Dimming the Display

Automatic dimming is provided to the panel display. You can manually

adjust brightness by tapping the DIM button. You will see DIM BRT.

Holding DIM lowers brightness or holding BRT increase brightness. The

percentage of brightness is displayed in the message area.

Section 4 - Operating Modes

The EDM has four basic operating modes: Automatic, Manual, Program

and LeanFind. LeanFind is described in the next section; Program mode

is described on page 38, ‘. When you first turn on the power the EDM

starts in the Manual mode, but will enter the Automatic mode after a few

minutes. The Automatic mode provides you with engine monitoring

information for the majority of flight conditions. To optimize the mixture,

use the LeanFind mode. To display specific parameters, use the Manual

mode. In either Automatic or Manual modes, the display always shows

the Scanner bar graphs for EGT and CHT for each cylinder and TIT (if so

equipped) with the temperatures above the columns except in the vertical

mode only the CHT temperatures are shown.

Automatic Mode

To activate Automatic Scanner Mode, just tap the LF button, then

tap the STEP button. In the Automatic mode the EDM changes which

measurement is displayedevery four seconds (factory default is ‘Auto

Scan Rate 4’), however you can change this rate in the Program Mode.

A setting of zero disables auto scanning altogether.

Page 22 Engine Data Management

Page 23

The order of automatic scan if the switch is in the ALL MODE: EGT/CHT,

TIT, CLD, DIFF, CDT,OIL-T, REM, T to E, GPH, USD,AMP,Volts,OIL-P,

and Fuel-P.

Some non-primary measurements can be excluded from the Automatic

mode: tap STEP to enter the Manual mode. Tap STEP repeatedly to

index to the measurement you want to exclude. Then tap both the STEP

and LF buttons simultaneously. Excluded measurements display a

decimal point before the measurement name. For example:

Included: 1540 CDT Excluded: 1540 ●CDT

Tapping the STEP and LF buttons simultaneously will toggle back and

forth between include and exclude. Note: All measurements are always

checked for alarm conditions every second.

Every time you turn on the EDM, all measurements are reset to be

included.

All installed measurements are always displayed in the Manual

mode. Exclusion only applies to the Automatic mode.

Manual Mode

To activate Manual Mode, just tap the STEP button. Use the Manual

mode when you want to lock on one specific measurement such as

shock cooling during descent, or your hottest CHT during climbs. To

select the desired parameter, tap the STEP button until it appears. To

return to the Automatic mode, tap the LF button and then tap the STEP

button. You may completely disable the Automatic mode by setting zero

for ‘Auto Scan Rate 4’. See Pilot Programming.

Scan Sequence Example

Measurement EXAMPLE COMMENTS

EGT, CHT EGT 1354 CHT 335

TIT 1370 TIT

Shock Cooling -30 CLD

Compressor Discharge

Temperature

Induction Air

Temperature

Carburetor Temperature -22 CRB

Difference between

hottest and coldest EGT

300 CDT

125 IAT

80 DIF

Square indicates the

cylinder being viewed

Turbine Inlet

Temperature # 1

Square indicates

fastest cooling cylinder

Temperature into

intercooler

Temperature out of the

intercooler

(Not available when

CDT is installed)

Square indicates most

widely deviating

cylinder

For Your Safe Flight Page 23

Page 24

Fuel Remaining Est. REM XX GAL

Fuel required to next

GPS WP or Destination

at present power

Fuel Reserve at next

GPS WP or Destination Est. WP REM XX GAL

Nautical Miles per Gal ECON XX.X MPG

Time to Empty

Total Fuel Used USD X.X GAL

WP REQ XX GAL

Est. T to E XX:XX H:M

In gallons, liters,

pounds or kilograms

Present with GPS

interface, valid signal

and way point

Present with GPS

interface, valid signal

and way point

Present with GPS

interface and valid

signal. MPK, MPL,

MPP for dif units

Hours: minutes

calculated remaining

at current fuel burn.

Since last refueling or

trip total.

Section 5 - LeanFind

The EDM supports two methods of leaning; ROP (Rich Of Peak) and

LOP (Lean Of Peak). Note: on power-up, the unit defaults to

Rich Of Peak mode, but is easily changed to Lean Of Peak mode. During

Rich Of Peak leaning, you’ll finalize the mixture to about 20° to 80° rich of

peak (depending on engine operating requirements). However, with the

advent of closely balanced injectors (such as GAMI), it is possible to set

the mixture lean of peak—thus saving fuel and running the engine cooler.

Both Rich Of Peak and Lean Of Peak processes are described in detail in

this manual.

Upon reaching cruise configuration, use the LeanFind mode to identify

the correct cylinder to reach peak EGT (for Rich Of Peak this is the

FIRST to peak, for Lean Of Peak this is the LAST to peak). To change

from one method to the other, right after activating LeanFind, hold STEP

and LF and the other method will be momentarily shown: ROP (Rich Of

Peak) or LOP (Lean Of Peak). Release buttons after other method

appears.

Page 24 Engine Data Management

Page 25

The following depicts the power, mixture and temperature relationships.

Best

n

i

f

t

Power

i

c

o

p

Peak

f

u

e

Best

economy

power

range

range

GAMI

spread

r

e

w

l

c

o

n

s

u

m

p

t

i

o

n

Last cylinder to

peak. Use Lean of

Peak leaning with

GAMI injectors

20

0

-20

-40

-60

-80

best power

CHT °F change from

-100

-200

EGT °F below peakPercent of best power

-300

100

First cylind er

to peak. U se

Rich of P eak

leaning

0

T

G

E

T

H

C

e

c

r

e

95

90

85

80

P

S

p

e

c

Full Rich

(Take-off)

LeanRich

Leaner Mixture

Over

lean

The following pages provide step by step guidelines in leaning your

engine, for both rich of peak and lean of peak modes:

As the mixture is leaned, EGT rises to a peak temperature, and then

drops as the mixture is further leaned. Peak power occurs at a mixture

using more fuel than at peak EGT. Best economy occurs at peak EGT.

Accurate leaning yields optimal engine temperatures. By being able to

precisely adjust the mixture, your engine can produce either the best fuel

economy or maximum power, whichever you choose.

A single EGT gauge merely gives you an average of a few

cylinder’s temperature: some cylinders can be too rich, while others too

lean. Variations produced by differences in fuel distribution, ignition, and

compression will cause each cylinder to peak at a different temperature.

In some cases the coldest cylinder will peak first. TIT will run up to 100

degrees hotter than the hottest EGT.

For Your Safe Flight Page 25

Page 26

Rich of Peak leaning is as simple as:

A. Pre-lean your mixture.

B. Tap the LF button (verify ROP appears).

C. Lean mixture until LEANEST flashes (peak found).

D. Enrichen to the desired value ‘Rich Of Peak’.

R Procedure Scanner

Comments

Example

Establish cruise at 65

1

to 75% power.

Pre-lean the mixture

2

to 50°F estimated

rich of peak on any

EGT: _________°F.

Wait one minute Let engine stabilize.

3

Tap the LF button

4

Lean the mixture at

5

approx. 10°/second

without pausing.

Stop leaning when

6

a column begins

flashing. You will see

LEANEST for one

second, followed by:

If you hold PEAK, the

7

values of EGT and

FF when peak was

found are displayed.

If you tap PEAK, the

8

difference from peak

EGT is shown. Tap

again to return to the

peaked EGT value.

Slowly enrich the

9

mixture noting that

EGT is returning to

peak. Stop enriching

at the desired EGT.

‘Peak’: best Econ.

‘ROP’ target: best

power.

EGT 1490

CHT 370

ROP

EGT 1520

FF 13.8

EGT 1545

FF 12.4

EGT ↑1560

FF 12.9

EGT∆ -90

FF 13.4

EGT 1560

FF 12.9

EGT 1460

FF 13.6

(100º RICH OF PEAK)

*See ‘Pre-leaning’

Start LeanFind (if LOP

appears hold STEP & LF until

ROP appears)

Flashing cylinder I.D. box

identifies that EGT increased

at least 15°F. EDM is now

looking for first EGT to peak.

Flashing cylinder I.D. box

AND its column indicates

leanest cylinder. Due to

thermal inertia this will usually

be about -15°F down the lean

side of peak.

Captured peak EGT value and

peak FF are displayed.

A useful mode for setting

mixture the desired degrees

rich of peak - no math

required! NOTE: Unit

remembers view last used.

Page 26 Engine Data Management

Page 27

Lean of Peak leaning is as simple as:

A. Pre-lean your mixture.

B. Tap the LF button (verify LOP appears).

C. Lean mixture until RICHEST flashes (peak found).

D. Enrichen to the desired value ‘Lean Of Peak’.

L Procedure Scanner

Comments

Example

Establish cruise at 65

1

to 75% power.

Pre-lean the mixture to

2

50°F estimated rich of

peak on any EGT:

_________°F.

Wait one minute Let engine stabilize.

3

Tap the LF button

4

Lean the mixture at

5

approx. 10°/second

without pausing.

(cylinder I.D. box

flashes when a EGT

rises 15°F)

After the first EGT

6

peaks, you will see

LEANEST for one

second and bars

coming from the top

down. Continue

leaning.

When RICHEST

7

appears, fine tune the

delta EGT to the

desired degrees below

‘Peak’ (Lean of peak).

EGT 1490

CHT 370

LOP

EGT 1520

FF 13.8

EGT∆ -17

FF 12.4

EGT∆ -45

FF 11.6

*See ‘Pre-leaning’

Start LeanFind (if ROP

appears, hold STEP & LF

until LOP appears)

Flashing cylinder I.D. box

identifies the hottest EGT

and that an EGT has

increased at least 15°F

which arms the EDM to

now look for first EGT to

peak.

When bars come from the

top down, the cylinder I.D.

box identifies the first EGT

that peaked (leanest).

Continue leaning.

If you hold PEAK, the

8

peak EGT recorded

will be displayed along

with FF spread.

EGT↑ 1560

FF∆ 0.6

Captured peak EGT value

and the FF spread between

richest and leanest

cylinders.

For Your Safe Flight Page 27

Page 28

LeanFind Procedure—General Explanation

Lycoming and Continental established specific restrictions on leaning

that must be followed, such as percent power, climb leaning, and TIT

limits. Lycoming recommends operation at peak of EGT at 75% or

less power only. Continental recommends operation at peak EGT at

65% or less power only. This guide does not supersede specific

recommendations of the engine or airframe manufacturer. It is your

responsibility to know your aircraft’s limitations.

Pre-leaning: The leaning process typically begins with ‘pre-leaning’ to

insure all cylinders are operating rich of peak EGT (note: you can

optionally activate ‘Normalize’ - hold LF until NRM appears - making it

easier to confirm all EGTs decrease). Now enriched the mixture to

achieve a 50° drop on the hottest EGT. Insure that all EGTs decrease.

Wait one minute to allow temperatures to stabilize.

Lean Find-Initiation: Initiate the EDM leaning mode by tapping the LF

button. Note that the EDM displays its current leaning mode

momentarily: ‘ROP’ for operating Rich of Peak or ‘LOP’ for operating

Lean of Peak. Then the current mode will show up in the message bar

white on black, also you will see the alternate mode over the LF button.

You have 10 seconds to chose the alternate mode which will disappear

indicating your chosen mode white on black. To change, simply exit the

mode you are in and re-tap the LF button. The EDM is now waiting for a

15° rise on any EGT (this feature significantly reduces false peaks). Lean

the mixture without pausing to achieve about a 10 deg per second

change. With a vernier mixture control, turn the knob about a quarter turn

every second. With a non-vernier or quadrant mixture control, lean slowly

and smoothly about 1/16 inch every five seconds (note: leaning

accurately with a quadrant system is difficult due to its mechanical

linkage).

Lean Find-Activation: When a 15° EGT rise occurs, LeanFind

activates (indicated by a cylinder I.D. box flashing over the number of the

hottest EGT). Remember: The LeanFind mode is not active until a

cylinder I.D. box is flashing. To show the progress of the leaning

process, the EDM now displays the hottest EGT in the left side of the

digital display and the fuel flow in the right side. This information allows

you to observe the EGT behavior throughout the leaning process.

Page 28 Engine Data Management

Page 29

Column of Leanest

cylinder flashes

indicating the first

EGT to peak.

Fuel Flow will

go down then

up as one

enriches

You are leaning

to Rich of Peak

If you want to

lean Lean of

Peak press

button.

mixture

Leaning Rich Of Peak (ROP) Detection: Eventually, one cylinder

will reach peak before any of the other cylinders. The EDM will determine

this automatically. The EDM will indicate success in finding a peak by

displaying the word LEANEST for two seconds and flashing its

corresponding Cylinder column. The Scanner® Information Area will also

display the current value for the EGT on the left, and the fuel flow value

on the right, for final adjustment of the mixture, do not exit until the

leaning process is complete. The peak EGT value and Fuel Flow value

encountered during leaning is remembered by the EDM and can be

displayed by holding the PEAK button during Lean Find Mode.

Finalizing the Rich Of Peak Mixture: You may now enrichen the

mixture to operate at peak or continue enriching to a value of your choice

(typicallybetween 50 to 100° rich of peak for best power), consistent with

the procedures defined in your aircraft and/or engine manual. Because

during the leaning process the mixture control was not stopped at the

exact time the column flashed the value shown will be 5 to 10 degrees on

the lean side. So as the mixture is enriched the temperature will go up to

peak and then down as the mixture is enriched further. Note: tap PEAK to

see the current difference from the peak temperature. This is handy for

finalizing mixture. Tapping EXIT exits the lean find mode and automatic

scanning resumes.

For Your Safe Flight Page 29

Page 30

Leaning Lean Of Peak (LOP) Detection: Note: This mode should

only be used when your engine is equipped with balanced fuel injectors

or you have a DIF value of around 80 degrees. When using the Lean of

Peak mode, you lean until all EGTs decrease slightly below their

respective peaks. The EDM has automatic peak detection and will

sequentially indicate leaning progress. When the first EGT peaks, the

word LEANEST appears and the cylinder I.D. box highlights the cylinder

number. Each column successively drops as leaning continues. When

the last column drops (last EGT peaks), RICHEST appears and its

respective column flashes momentarily. The last EGT to peak is the one

you will use when setting the final mixture.

Finalizing the Lean Of Peak Mixture: The Scanner® Information

Area displays the degrees below peak for the last (or richest) EGT to

peak, giving you precise information necessary in setting the final

mixture. Adjust the mixture to achieve the desired value below peak

(using the digital EGT readout) or before engine roughness occurs.

Caution: do not lean to the point where the engine runs rough. Note: the

peak EGT value encountered during leaning can be recalled by holding

the PEAK button. Do not exit until finished or all values will be lost.

Tapping STEP exits the lean find mode and automatic scanning

resumes.

Peak Detected - Lean Of Peak Mode LOP

Page 30 Engine Data Management

Page 31

Expanded Leaning Procedures

Lean Of Peak, LOP mode: During the ‘lean of peak’ process, the

EDM hunts for the last cylinder to peak. Ultimately, you want to have ALL

cylinders operating on the lean side of peak. You will final adjust your

mixture to this cylinder. To provide a unique graphical depiction during

lean of peak operation, the columns become inverted after the first EGT

goes just beyond peak. Each EGT column then originates from the top of

the display and drops downward. As each subsequent EGT goes past

peak, its column will begin falling. The columns length depicts how far the

EGT has dropped below its original peak. In this mode, each segment is

5° F. You will continue to lean until the last EGT peaks (note: never lean

to the point where the engine is running rough). When the last EGT

peaks, its column will flash and RICHEST appears. The digital readout

will show the current temperature difference from where peak EGT

occurred and the current fuel flow (if so equipped). Note: holding the

PEAK button will show the captured peak value of the ‘last EGT to peak’

and also the difference in fuel flow between the first and last to peak

(known as the GAMI Spread). This is a good indication of injector

balance (the smaller the FF difference, the better the balance). Tapping

STEP exits the lean find mode and automatic scanning resumes.

Leaning Turbocharged Engines: The leaning process for

turbocharged engines is by reference to the first EGT or TIT to reach

peak. Therefore you should use the Rich Of Peak mode. The factory TIT

red line (typically 1650°F to 1750°F) may limit the leaning process,

depending on flight conditions. If TIT exceeds red line (but not by more

than 99°), the EDM will allow you to continue leaning for one minute

before a TIT alarm activates. NOTE: TIT can read approximately 100°F

hotter than the hottest EGT due to unburned fuel in the exhaust igniting

and is not necessarily abnormal behavior. The reduced size of the JPI

Hastaloy-X-tip probes produce faster response and are more accurate

than the massive factory installed probes. Therefore a JPI probe may

read as much as 100°F higher than a factory installed probe.

For Your Safe Flight Page 31

Page 32

Common Misapplications

Some of the more common misapplications made by first-time

EDM users are presented here in an attempt to help you avoid

similar problems.

Problem Situation Corrective action

LeanFind finds a

‘peak’ too soon.

Peak not found

Off-scale EGT bars,

too high or low

First cylinder to

peak is not the

hottest

EGT rises during

single magneto

check

EGT not uniform

during low power

operation

No display of %HP

Failure to pre-lean before

performing LeanFind or

you stopped leaning.

Leaning too slowly.

Lean Find not activated or

you stopped leaning.

You forgot that you set the

EDM in the Normalize

view and later notice that

the EGT bars go off-scale.

This is normal. The first

cylinder to peak is not

necessarily the hottest.

This is normal, due to

incomplete combustion

persisting longer.

This is normal. Fuel and

air distribution is not

optimal at low power

settings.

FF, MAP, RPM, OAT not

reading or not equipped

Follow the pre-lean

procedure in ‘Error!

Reference source

not found.’ section

(pg 24).

Lean more quickly.

Lean at the speed of

approximately 10°F per

second.

The higher sensitivity

(10° per segment) of

the Normalize view can

quickly go too high or

low off-scale with only

small changes in EGT.

None

None

None

FF, RPM, OAT, MAP

required for %HP

Page 32 Engine Data Management

Page 33

Section 6 - Fuel Flow Operation

Fuel Management

Without a means of measuring accurate fuel flow, you must rely on the

aircraft fuel gauges or total time of flight. Aircraft fuel gauges are

notoriously inaccurate (they are only required by the FAA to read

accurately when displaying empty). Determining fuel consumption by

multiplying time of flight by estimated flow rate is, at best, an

approximation, and assumes a constant fuel flow rate for each phase of

flight. However, the EDM Fuel Flow Option uses a small, turbine

transducer that measures the fuel flowing into the engine. Higher fuel

flow causes the transducer turbine to rotate faster which generates a

faster pulse rate. Because the transducer turbine generates thousands of

pulses per gallon of fuel, it can measure with high resolution the amount

of fuel that flows into the engine. Prior to engine start you inform the EDM

Fuel Flow Computer system of the known quantity of fuel onboard, it then

subsequently tracks all fuel delivered to the engine.

IMPORTANT !

For EDM fuel calculations to be accurate, it is mandatory that

you inform the EDM of the correct amount of usable fuel

onboard the aircraft and confirm proper operation of the fuel

flow transducer prior to and during flight. Do not rely on fuel

flow instruments to determine fuel levels in tanks. Refer to

original fuel flow instrumentation for primary fuel

management information.

For Your Safe Flight Page 33

Page 34

Start Up Fuel

On power-up, you will be prompted to enter any fuel you might have

added to the aircraft (this process updates the REM and USD values).

The EDM will flash REFUEL? . If you didn’t add any fuel, simply tap NO

to quit, otherwise tap YES to pick one of the three quickset choices

below:

If you say YES then you will see Fuel onboard, if you have Aux tanks

you will see TWO chooses like in the example 76 GAL Main and Main +

Aux = 96GAL. You pick the one you want to enter.

Upon making a choice you will see your choice as Initial Fuel

If you tap ADD SUBTRACT then you can add say 10 gallons

NOTE: If you forgot to perform your EDM REFUEL before starting

the engine, it can still be performed. The EDM will automatically

subtract any burned fuel from the value you choose. Go to Program

mode and the first item is REFUEL

You are responsible for insuring that your usage of the REFUEL

feature results in the EDM’s REM parameter showing the correct

amount of usable fuel remaining onboard the aircraft.

Page 34 Engine Data Management

Page 35

Resetting ‘USD’

USD is automatically reset whenever you perform REFUEL on your EDM

(except if TRIP mode = yes).

After filling your tanks and prior to engine start you should inform the

EDM that the aircraft has been filled. In this case USD is automatically

set to zero.

To manually zero the amount of fuel USD at any time, manuallySTEP

to display USD and then hold both DIM (button 3) and EGT/FF (button 4)

until the display shows ‘USD 0.0 GAL ’ (this normally takes about five

seconds).

Trip Mode (Accumulate Trip Totalizer)

Trip mode is typically used if you want to track the total fuel used over a

multi-stop cross country. To have the USD parameter continuously

accumulate total consumed fuel, set TRIP? Y. ‘Trip Mode’ is described in

the ‘Program Mode section’. Note: typically, TRIP? is set to ‘N’ so that

USD will be reset every time you fuel the aircraft.

Scanner Fuel Flow Display Select

Button four selects three different Scanner filters - ALL, EGT or Fuel.

Tapping this button will select the next choice (shown after the ‘/’ symbol):

ALL/TEMP: all installed parameters are shown in Scanner (and

battery voltage).

TEMP/Fuel: only the installed temperature parameters are

shown in Scanner.

Fuel/ALL: only fuel flow parameters are shown in Scanner.

For Your Safe Flight Page 35

Page 36

Section 7 - Alarms

Whenever a primary measured parameter falls outside of the

normal allowed operating limits, i.e. goes beyond redline, the main

display will blink an alert icon. This consists of the current digital value

and a flashing red label in the Scanner area and the REDRemote

Annunciate Light. For example, if CHT 2 is at 480, and redline is 460, the

alert would be displayed as CHT2 480oF.

Tapping the CLEAR button extinguishes the alert

Primary alarm limits for each specific aircraft model are set by JPI

in accordance with the POH and are not programmable by the pilot.

These typicallyinclude some or all of the following measurements: CHT,

CDT, Oil-T, Oil-P, Fuel-P, GAL LEFT, GAL RIGHT, MAP, RPM, Fuel

Flow, and TIT. To view the alarm limits screen, hold button 2 during

power up (or hold both buttons 2 & 3 during normal operation), tap NEXT

until the list is displayed.

The primary functions for your installation are shown on the Primary label

on the back of the instrument and are identical to those specified in the

FAA Approved Airplane Flight Manual/Pilot’s Operating Handbook.

Alarm Priority Hierarchy

1. OILP_LO

2. FP_LO

3. OILT_HI

4. CHT

5. TIT

6. FLVL

7. REM

8. FP_HI

9. MAP

10. DIF

11. CLD

12. RPM

13. OILT

14. BUS

15. OILP_HI

16. AMPS

17. CDT

18. BAL

19. FUEL_END

20. FUEL_RES

21. EGT

22. Fuel Flow

Page 36 Engine Data Management

Page 37

Section 8 - Memory and Data Download

The EDM compresses and records all displayed parameters once every

six seconds (default) in Long Term Data Memory (note: you can

change this rate to be 1 to 500 seconds). This data is retrievable by

inserting a USB Drive into the jack on the front of the instrument and

following the prompts. You can choose to retrieve ‘ALL’ the data stored in

the EDM, or only the ‘NEW’ data recorded since your last retrieval. In

either case, the selected data in the EDM is not erased. The data can

later be viewed on EZTrends, a PC program available from JPI or over

the internet.

RPM is greater than 500. The amount of data that the EDM can store will

vary depending on how rapidly parameters change. The typical storage

capacity is greater than 300 hours at a 6 second recording interval, but

can vary depending on configuration. When the memory becomes full,

the oldest data will be discarded to make room for the newest. All data

are time-stamped. The EDM contains a real-time clock that may be set

when you initially program your instrument. You may change the

recording interval from 1 to 500 seconds, even in flight (when you change

the interval in flight, the current flight file is closed and a new flight file is

started at the new interval).

Downloading Data from the EDM

Downloading is a simple process. Follow the steps below:

a. With the EDM powered up, plug the USB flash drive adaptor and

flash drive into the EDM USB port.

b. Wait for the EDM display to show DOWNLOAD: NEW.

c. To download only the new data since the last download, tap the

STEP button.

d. To download all data in the EDM, tap the CHANGE button to see

DOWNLOAD: ALL, then tap STEP.

e. You will see a ‘progress indicator’ as the data is copied to the

USB flash drive. DO NOT INTERRUPT THIS PROCESS. When

the download is complete the display on the EDM will show

DONE and then return to normal operation.

f. Wait until the process is complete then remove the USB flash

drive from the USB connector.

For Your Safe Flight Page 37

Page 38

Transferring data from the USB Flash Drive to a PC

To transfer your data from the USB flash drive to your PC, follow these

easy steps.

1. On your PC, start the EzTrends program.

2. Plug in the USB flash drive into an available USB port.

3. In EzTrends, select the Move and Plot Data from Memory Stick

option.

4. In the displayed list, find the USB flash drive and double click it.

5. Select the file you wish to plot and then select the flight in that file.

Refer to the EzTrends manual for details on how to use EzTrends.

Section 9 - First Time Setup and Customization

Your EDM comes with most settings programmed. However some

settings you will fine tune to your installation and/or preferences. We

recommend you perform the following minimum set up:

1. Pilot Programming Mode:

Set the GPS Communications format to match your type of GPS.

Fine tuning of fuel flow K-factor is important as it affects your fuel

computer parameter accuracies.

Set the Engine HP equal to your engines rated horsepower.

Perform the HP Constants set up for best accuracy of the

Percent Horsepower readout.

Optionally fine tune other parameters such as MAP, OAT.

Page 38 Engine Data Management

Page 39

Pilot Programming Mode

to proceed to

To start Pilot Program Mode, hold both STEP and LF buttons until you

see PROGRAM for two seconds. Then tap the NEXT button to advance

to the desired item in the list. Hold the NEXT button to back up in the list.

Either tap NEXT until you see END. Yes and then tap EXIT or hold both

NEXT and LF to save changes.

First button advances

to NEXT item

Program Mode Stays on for two seconds.

Refuel?

Auto Scan Rate 4

Trip Used? No

EGT Display in 1’s 1’s

OAT Display ºF

OAT Adjustment 0

HP Constants

HP Constant= 125

Engine Constant = 14.9

Second

button

selects

values

0 9

NO YES

10’s

F C

-10 10

10 999

1 99.9

Comments

Tap REFUEL to change fuel status.

Exits program mode when done.

Scan rate (seconds between

parameters) in the Automatic Mode.

0 disables the Automatic Mode.

NO: When Refuel mode used on EDM,

total fuel used is reset to 0.

YES: accumulate total fuel used rather

than reset to 0 at each refueling. See

page 41.

Tapping 1’s sets the digital display to

one-degree resolution; tapping 10’s

sets 10°. (10° resolution is easier to

interpret the EGTs.)

Tap C to display OAT in Celsius, F to

display in Fahrenheit. Hold STEP and LF

for 5 seconds to ADJUST the OAT

calibration.

Adjust the indicated temperature up or

down by up to 10° using PLUS or MINUS.

For example, OAT3 adjust the OAT 3°

higher.

Hold NEXT and button 2 for 5 seconds

until you see ADJUST rich of peak or lean

of peak constants. Tap ROP

Rich of Peak ‘HP Constant’ setting. Tap

LOP to proceed to Lean of Peak ‘Engine

Constant’ setting.

Hold NEXT and button 2 until you see

ADJUST. Tap PLUS or MINUS to adjust

(%HP display will reflect changes). Hold

NEXT and button 2 to save changes.

Hold NEXT and button until you see

ADJUST. Tap PLUS or MINUS to adjust.

Hold NEXT and button 2 to save changes.

For Your Safe Flight Page 39

Page 40

Engine HP = 225

to skip to next

Map Adjustment +0.0

K-Factor 1 29.90

GPS Format = 6

Time: 18:23:59

Date: 05/14/09

END? Yes END? Yes

10999

-3.0 +3.0

00.10 99.99

0 8

00:00:00

23:59:59

01/01/00

12/31/99

Set the nominal horsepower of your

engine. This value will is used with FF to

calculate LOP %HP. Hold NEXT and

button 2 for 5 seconds until you see

ADJUST. Use PLUS or MINUS to adjust.

Tap SAVE to save changes. Tap NEXT to

skip to next item.

Correct the MAP to the altimeter setting at

a sea level airport ±3.0 inHg. Hold NEXT

and button 2 for 5 seconds until you see

ADJUST. Use PLUS or MINUS to adjust.

Tap SAVE to save changes. Tap NEXT to

skip to next item.

Set the instrument’s K-factor to match the

fuel flow transducer K-factor and

performance. Hold DIGIT and button 2 for

5 seconds until you see ADJUST. Use

DIGIT, PLUS or MINUS to adjust. Hold

NEXT and button 2 to save changes.

Adjust to set the GPS Communications

format. Hold NEXT and button 2 for 5

seconds until you see ADJUST. Use

PLUS or MINUS to adjust. Tap SAVE to

save changes. Tap NEXT to skip to next

item. See page 45.

Hold NEXT and button 2 for 5 seconds

until you see ADJUST. Use Hours,

Minutes, Seconds to adjust. Tap SAVE

to save changes. Tap NEXT

item.

Hold NEXT and button 2 for 5 seconds

until you see ADJUST. Use Month, Day,

Year to adjust. Tap SAVE to save

changes. Tap NEXT to skip to next item.

Yes exits the pilot program mode.

No reenters pilot program mode.

Page 40 Engine Data Management

Page 41

Section 10 - Adjusting Manifold Pressure & %HP

Adjusting the HP Constant for Rich of Peak Operation

To fine tune the %HP readout, follow this procedure airborne between

5,000 and 8,000 feet MSL. (note: Verify that the MAP adjustment has

been perform prior to this process).

1. Enter the pilot program mode by simultaneously holding the STEP

and LF buttons for five seconds.

2. Tap STEP repeatedly until you see HP Constants. Hold both NEXT

and Button 2 until you see ROP and LOP appear in status bar. Tap

ROP. Now HP Constant 125 should appear. Hold both NEXT and

Button 2 until you see ADJUST momentarily. Adjustment range for

the HP Constant is 45 to 180.

3. Set the MP and RPM per your POH to 70 percent power. Let

conditions stabilize.

4. Adjust the HP Constant value PLUS or MINUS so that the %HP

reading on the display equals ‘70 %HP’. Note: this is the percent of

maximum horsepower.

5. Hold both NEXT and Button 2 until you see SET.

Adjusting the MAP

This procedure allows you to adjust the MAP to the altimeter setting at a

sea level airport. NOTE: If airport is not at sea level, use the

correction table to derive corrected sea level altimeter setting).

1. Enter the pilot program mode by simultaneously holding the STEP and

LF buttons for five seconds.

2. Tap NEXT repeatedly until you see MAP ADJUSTMENT +0.0. Then

hold both the NEXT and Button 2 until you see ADJUST

momentarily.

3. Adjust the value using the PLUS or MINUS until the value equals the

altimeter setting (sea level airport). The adjustment range for the

MAP is ±3.0 inHg.

4. Hold both NEXT and Button 2 until you see SET.

For Your Safe Flight Page 41

Page 42

Adjusting the HP Value

You must set the nominal horsepower of your engine. This value

is used to calculate the percent horsepower display.

1. Enter the pilot program mode by simultaneously holding the

STEP and LF buttons for five seconds.

2. Tap NEXT repeatedly until you see Engine HP 200. Then hold

both the NEXT and Button 2 until you see ADJUST

momentarily.

3. Adjust the value PLUS or MINUS to equal your engines HP.

4. Hold both NEXT and Button 2 until you see SET.

Section 11 - Programming the Fuel Flow

Fuel Flow Parameters

Three additional parameters may be set by the pilot when the Fuel Flow

Option is installed:

K Factor—the fuel flow transducer calibration constant.

Accumulate—default is OFF: resets the fuel used to 0 every time you

inform the EDM that the aircraft was refueled. With accumulate ON,

fuel used will continue to accumulate for all subsequent flights.

GPS Communications fuel data format.

K Factor

The K factor is shown on the fuel flow transducer as a four-digit number,

which is the number of pulses generated per tenth gallon of fuel flow.

Before installing the transducer, write down the K factor here

_________. To enter the number into the EDM, place a decimal point two

places from the right of the number. For example if the K factor written on

the fuel flow transducer is ‘2912’ enter 29.12 in the EDM K factor

parameter field.

The K factor can be changed in the pilot programming procedure. When

the K factor is changed during a trip, calculations of fuel used, fuel

remaining and time to empty are not retroactively recalculated.

Page 42 Engine Data Management

Page 43

Fuel Flow K factor

The K factor is shown on the fuel flow transducer as a hand written fourdigit number, which represents the number of pulses per tenth gallon of

fuel flow. Before installing the transducer, record its K factor here

_________. The EDM stores the K Factor in the form 29.12, i.e. if the

transducer K factor is 2912, you would enter 29.12 in the EDM’s K factor

field.

Fine Tuning the K Factor

The K factor shown on the fuel flow transducer does not take into

account your aircraft’s particular installation. Fuel hose diameters and

lengths, elbows, fittings and routing can cause the true K factor to be

different from that shown on the fuel flow transducer.

You must use the following procedure to fine tune the K factor.

1. Make at least three flights of about two to three hours each. Note

the actual fuel used (as determined by topping the tanks) and the

EDM calculation of the fuel consumed for each flight = USD.

Fuel USED shown by EDM

Flight

(total tank - REM) Actual fuel used by topping

tanks

1

2

3

Total

2. Total the EDM fuel used and the actual fuel used.

3. Record the current K factor here ____________________

and in the table below.

4. Calculate the New K Factor as follows:

New K Factor = (EDM fuel used) x (Current K factor)

(actual fuel used)

New K Factor = ( ) x ( )

( )

Every time you fine tune the K factor, record the measurements

here:

EDM

actual

Current New K Pilot’s

For Your Safe Flight Page 43

Page 44

Date fuel used fuel used K factor factor

=x/

Setting the K factor

This procedure differs somewhat from setting other parameters. If you

haven’t already done so, start the pilot programming procedure by

simultaneously holding the STEP and LF buttons for a few seconds until

you see the word PROGRAM appear.

1. Tap STEP button to advance to the KF-SET screen KF=29.90 .

2. Hold both the STEP and LF buttons for a few seconds until the first

digit flashes (shown here as a larger digit for illustration purposes):

29.00

3. Tap or hold the LF button to change flashing digit: 19.00

4. Tap STEP button to move to next digit: 19.00

5. Tap or hold the LF button to change flashing digit: 18.00

6. Tap STEP button for next digit: 18.00

7. Repeat items 5 and 6 for the remaining two digits.

8. Hold STEP and LF buttons until the parameter is saved.

initials

Fine Tuning the K factor

The K factor shown on the fuel flow transducer does not take into

account your aircraft’s particular installation. Fuel hose diameters and

lengths, elbows, fittings and routing can cause the true K factor to be

different from that shown on the fuel flow transducer. Fine tuning is

accomplished over multiple flights of sufficient duration and repeatable

conditions. Use the process below to calculate and correct the K Factor

to achieve maximum performance. Note: This process adjusts the K.

factor only half of the correction. We recommend this because it

minimizes ‘chasing’ a correction target back and forth

Page 44 Engine Data Management

Page 45

Programming Trip Mode

Trip Mode keeps a running total of fuel used (USD) for all flights. If Trip

Mode = No, fuel ‘USD’ is zeroed after updating the EDM’s fuel computer

via Refuel modes. NOTE: to clear the fuel used display at any time, tap

STEP until you see USD. Hold both DIM and ALL/EGT/FF buttons until

the display shows ‘.0 USD’.

1. Enter the pilot program mode by simultaneously holding the STEP

and LF buttons for five seconds.

2. Tap NEXT repeatedly until you see TRIP Used? No .

3. Tap YES to select the trip mode or NO to deselect mode.

4. Tap NEXT to accept your choice.

Setting the GPS Com Format

This process allows you to select what GPS communication format the

EDM should use when sending fuel flow data to the GPS. See table

below with the numeric GPS-C values and their corresponding formats.

1. Enter the pilot program mode by simultaneously holding the STEP

and LF buttons for five seconds.

2. Tap NEXT repeatedly until you see GPS FORMAT .

3. Hold DIGIT and Button 2 until ADJUST appears

4. Select desired code value using PLUS or MINUS.

5. Hold both NEXT and Button 2 until you see SET.

GPS-C Type of GPS Format

0 No fuel data output

1 Garmin (Shadin Miniflow format)

2 Allied Signal (format B) “To waypoint only”

4 Arnav/EI fuel flow data

4 Allied Signal (format C) *

5 (Not used)

6 Garmin 430/530 GNX-80/GX-60 “To waypoint only”

7 Garmin 430/530 GNX-80/GX-60 “To Destination only”

8 Bendix(B) - DEST

For Your Safe Flight Page 45

Page 46

Factory Limits (Hold Step and LF at end of Pilot Program

Mode).

Factory Next

MAIN = 76 Plus Minus

Aux = 0.0 Plus Minus

AMPS ADJ. +0 Plus Minus Hold Step and LF to enter or

FUEL PRESSURE

FP=30PSI 2W

CUSTOMIZE

DISPLAY

END Yes No

Plus Minus Hold Step and LF to enter or

Plus Minus Hold Step and LF to enter or

exit

exit

exit

Page 46 Engine Data Management

Page 47

Troubleshooting the EDM

Diagnostic Testing on Startup and During Flight

When your EDM is first turned on, it tests internal components,

calibration and integrity of the probes. Most alarms are disabled until the

engine has been started.

During flight, probes are constantly checked for inconsistent or

intermittent signals. A faulty channel or probe encountered during start-up

or during flight will be deleted from the sequence, producing a missing

column or blank digital data.

Diagnostic Messages

The following displays indicate malfunctions in the system:

Startup and Operational Diagnostics

0.0 GPH

--- GPH

--- H.M

OPEN PRB

BAD-PRB

Red ‘X’ drawn

through a gauge

CAL ERR

DSP XXX

COMM ERR

NO I 5 MV

NO 50MV

NO 2.5V

PWR DWN

WARNCAL,

WARNCFG

Zero’s indicate Fuel flow is too low to register

Dashes indicate No fuel flow transducer signals

Dashes indicate No fuel flow transducer signals

Open probe. Wiring to probe is open circuit. Check

wiring and crimps. Swap probes to troubleshoot.

Bad probe. Erratic reading. May be poor electrical

connection. Swap probes to troubleshoot.

Gauge is non functional.

Calibration error. Return unit to factory.

Internal communication error. Return unit to factory.

Internal communication error. Return unit to factory.

Calibration error. Return unit to factory.

Calibration error. Return unit to factory.

Calibration error. Return unit to factory.

Power down the instrument and power up again.

Transient warning messages. If they persistently

occur, return the unit to JPI for repair.

For Your Safe Flight Page 47

Page 48

HOBSERR

The time of the most recent flight may not be

reflected in the HOBBS meter.

HOBSBAD

HANGCFG,

HANGCAL

The HOBBS data has been corrupted. The HOBBS

meter will be cleared.

Internal system errors. Return unit to factory.

GPS Interface Diagnostics

Measurements ‘xxx REQ’,

‘xxx RES’ and ‘xxx MPG’ are all

missing from the scan.

NO - COM message and

‘xxx REQ’, ‘xxx RES’ and

‘xxx MPG’ are all missing from

the scan.

No communications from GPS

receiver to EDM. Possibly no

connection or aircraft GPS is off.

Communications are received by

EDM and the Auto-Protocol setup is

in process. Verify correct output

format setup in GPS receiver; check

GPS connections.

NO - SIG message and

‘xxx REQ’, ‘xxx RES’ and

‘xxx MPG’ are all missing from

GPS receiver has insufficient signal

for valid data.

the scan.

NO - WPT message and

‘xxx REQ’, ‘xxx RES’ are all

No waypoints are programmed into

the aircraft GPS receiver.

missing from the scan.

Section 12 - Appendices

Shock Cooling (CLD)

Cooling the cylinders too fast can result in cracking and eventual failure.

Lycoming Service Instruction 1094D (March 25, 1994) on Fuel Mixture

Leaning Procedures states:

“At all times, caution must be taken not to shock cool the cylinders. The

maximum recommended temperature change from Lycoming should

not exceed 50°F per minute cooling rate.”

JPI checks shock cooling (CLD) on all cylinders displaying the

fastest cooling cylinder in degrees per minute cool rate.

Page 48 Engine Data Management

Page 49

List of ALL messages in EDM-900

Startup Banner Messages

=====================

EDM900

PRIMARY FOR

182P-SA000152WI 550

Refuel Messages

=====================

REFUEL?

TOP OFF? MAIN 74.0 GAL

CHANGE FUEL QTY? + X.X

GAL

Adjusted by + 0.5 GAL

Initial Fuel 71.6 GAL

LeanFind Messages (ROP)

=====================

ROP

EGT 1494 FF 17.7

NOPEAK

EGT 1494 FF 17.7

LEANEST

ROP -90 FF 12.5

LeanFind Messages (LOP)

====================

ROP

EGT 1494 FF 17.7

NOPEAK

LOP

EGT 1494 FF 17.7

LEANEST

RICHEST

LOP -55 FF 11.5

LCD Brightness Messages

=====================

LCD BRIGHTNESS: 2%

'Normal' Scanner

Messages

====================

EGT 1494 CHT 332

OIL-T 195 °F

VOLTS 27.4

T to E 00:04 H:M

CLD 0 ° / Min

DIF 8 °F

Est. REM 74.0 GAL

WP REQ 12.5 GAL

Est. RES 61.5 GAL

ECON 9.9 MPG

F-F 14.7 GPH

AMPS 0

VOLTS 27.4

FUEL-P 13 PSI

Primary Alert Messages

(All RED text, channel

name flashing)

====================

L-FUEL 0 GAL

R-FUEL 0 GAL

CHT1 476 °F

OIL-T 245 °F

DIF 1382 °F

BAD PROBE CHT5

REM 1.1 GAL

RPM 2760

MP 37.7 In. Hg

Non-Primary Alert

Messages

(All WHITE text, channel

name flashing)

====================

T to E 00:04 H:M

CLD 87 ° / Min

Est. REM 74.0 GAL

BAD PROBE EGT3

VOLTS 21.4

AMPS -5

Data Download Messages

======================

DOWNLOAD: NEW

DOWNLOAD: ALL

DOWNLOAD: EXIT

Pilot Program Messages

=====================

PROGRAM

REFUEL?

Auto Scan Rate 4

Trip Used? No

Trip Used? Yes

EGT Display In 1's

EGT Display In 10's

OAT Display :F

OAT Display :C

HP Constants

Engine HP 300

MAP ADJUSTMENT +0.0

K-Factor 1 30.45

CARB? No

CARB? Yes

CARB=2

GPS Format

#0: No Output

#1: Shadin

#2: Bendix(B)-WP

#3: Arnav/EI fuel data

#4: Bendix(C)

#5: No Output

#6: GNS 430/530-WP

#7: GNS 430/530-DEST

#8 Bendix(B)-DEST

Time: 13:17:45

Date: 07/11/11

End?

Please wait...Saving

changes.

For Your Safe Flight Page 49

Page 50

Navigation Data Formats

Output of GPS; input to EDM. The EDM automatically configures itself for

one of three industry standard data formats:

Format Baud

NMEA-183

(Marine Nav

Data Format)

4,800

This is the format for most handheld GPS receivers. Loran

must have sentences RMA & RMB. GPS must have

sentences RMB & RMC.

Aviation Data

Format

Northstar

(Northstar

binary)

9,600

1,200 M1 setup select “NO EXTENDED”, “NAV ONLY”

“Output sentence type 1” Required sentences are: A, B, C,

D, E, I and L first character identifier byte. Sentence

terminator may be either <CR><LF> or <CR> alone.

Navigation Data Ports for GPS Comm

(These ports are independent of the EDM serial data output port.)

Navigation Data (output from GPS; input to EDM)

Compatible with RS-232, TTL, RS-423, RS-422 SDA.

Serial format: 8 data, 1 start, no parity. Baud 1200, 4800, or 9600,

depending on the GPS data output format. The EDM automatically

detects the GPS data output format and is independent of the GPS-C

setting.

Fuel Data (input to GPS; output from EDM)

RS-232 Serial format: 8 data, 1 start, no parity. Baud 9600. Output

format is determined by the GPS-C setting, but may be over-ridden

by the GPS navigation format: If the EDM senses Northstar or

NMEA-183 navigation data input, there will be no fuel data output.

Interface connections to selected GPS models

EDM P4 - Pin 1 to: EDM P4 - Pin 2 to:

Arnav 5000 Pin 4 Pin 5

Garmin 195 (nc) Pin 4

Garmin 430 / 430 Pin 57 Pin 56