Page 1

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E

THE OWNER OF THIS EDM-700/800/730/830

MUST

TABLE OF CONTENTS

Page

1) INSTALLING THE INDICATOR 3

2) EXHAUST GAS TEMPERATURE PROBE 3

3) TURBINE INLET TEMPERATURE PROBE 3

4) CYLINDER HEAD TEMPERATURE PROBE 4

5) SPARK PLUG GASKET CHT PROBE 4

6) INDUCTION AIR TEMPERATURE PROBE 4

7) OIL TEMPERATURE PROBE 5

8) OIL PRESSURE TRANSDUCER 7

9) OUTSIDE AIR TEMPERATURE PROBE 7

10) FUEL FLOW OPTION 8

11) WIRING 9

12) EGT AND CHT PROBE WIRING 9

13) ROUTING THE WIRING HARNESS 11

14) MANIFOLD PRESSURE INSTALLATION & CALIBRATION 12

15) RPM SENSOR INSTALLATION 13

16) OPERATING INSTRUCTIONS 14

17) INDICATOR INSTALLATION & RECORD 16

18) ENGINE OPERATION 16

19) LIMITATIONS & OPERATION 16

20) COMPONENT PARTS LIST FOR EGT PROBE 17

21) COMPONENT PARTS LIST FOR CHT PROBE 17

22) COMPONENT PARTS LIST FOR OIL PROBE 17

23) COMPONENT PARTS LIST FOR OAT PROBE 17

24) COMPONENT PARTS LIST FOR MANIFOLD PRESSURE 17

25) COMPONENT PARTS LIST FOR RPM 17

26) COMPONENT PARTS LIST FOR SINGLE ENGINE EGT/CHT 17

27) WEIGHT AND BALANCE DATA 17

28) CHANGING PROGRAMMED LIMITS 18

29) TROUBLE-SHOOTING 20

FIG-1 INSTRUMENT BEZEL TEMPLATE 22

FIG-2 EGT/CHT/TIT PROBE PLACEMENT 23

FIG-3 EGT PROBE INSTALLATION 24

FIG-6 EGT/CHT PICTORIAL LAYOUT 25

FIG-7 WIRING DIAGRAM DRAWING 300701 26

FIG-9 DRAWING 700744 FUEL FLOW WIRING 27

INSTRUCTIONS FOR CONTINUED AIRWORTHINESS (ICA) 28

KEEP THIS MANUAL

J.P.INSTRUMENTS Inc.

PO BOX 7033

HUNTINGTON BEACH CA 92646

FAA APPROVED 10-28-09

Last printed 05/16/13

Page 2

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 2 of 30

READ THIS FIRST

The following notes apply to a new installation. Read this section before proceeding.

a) The JPI warranty found in the back of the pilots guide clearly states that JPI will replace defective parts

under warranty, but does NOT cover labor to remove or install any parts.

b) To prevent damage to the display it is essential that the four mounting screws not penetrate the

instrument more than 0.12 inches. Damage caused by screw penetration is not covered under

warranty.

c) You must be an FAA certified aircraft mechanic to install this instrument.

d) Check that any necessary FAA approvals (STC’s, etc) are available for the aircraft before beginning the

installation.

e) The most common cause of probe problems is poor terminal crimps. Crimp ring terminals with AMP part

45518 crimp tool or equivalent. Fold back the wire double before crimping terminals.

2 1/4"

yellow

Thermocouple wire harness

red

f) This installation will require some parts unique to your aircraft that are not supplied with the kit,

(including but not limited to tie-wraps, hoses and fittings). Acquire all the necessary parts prior to

beginning the installation.

1/4" 1 1/2"

Fold back wire

double before

crimping terminals

g) Do NOT use aluminum fittings with the FXT-201 or FXT-231 fuel flow transducer.

h) Write down the K-factor engraved on the side of the fuel flow transducer here _______. Once the

transducer is installed and covered with the fire sleeve, you will not be able to access this K factor.

i) Determine the locations of all holes before drilling to ensure that nothing interferes with the probe,

clamp, clamp screw or wire.

j) Provide service loops at the instrument.

k) Thermocouple wire length is not critical. Trim to required length, allowing for service loops at the engine

so that probes can be swapped with probes on adjacent cylinders for troubleshooting purposes.

l) Dress all wires away from high temperature components such as exhaust stacks.

m) Never splice thermocouple wire using copper wire. Use only K-type thermocouple wire. Solder using

zinc chloride flux such as Nokorode brand – rosin flux alone won’t work.

n) Observe correct polarity on all probe wires. Connect like colors together (red to red, yellow to yellow).

o) This instrument must be grounded at the engine, not at the avionics ground.

p) If a spark plug gasket probe is used, expect the CHT reading on that cylinder to be somewhat higher

than on the cylinders with bayonet probes. At additional cost an adapter probe (bayonet or screw-in) is

available that permits the factory CHT probe and the JPI probe to be placed in the same bayonet

location.

Page 3

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 3 of 30

1) INSTALLING THE INDICATOR

Should Be Done In Accordance With Advisory Circular AC43.13-1A. All Models have the same basic

Part No. EGT-701 ( ).

EDM-700/800 Model :A steel template supplied with the installation kit is used as a guide for drilling two button holes

in the instrument panel. Align and Mount the Template into the instrument panel hole. First drilling a 0.125 hole.

Remove the template and check the instrument alignment, if OK redrill with a 0.147 drill. Buttons can be removed by

pulling off. The EGT-701 mounts in a standard 2.25” or 3 1/8” instrument hole. The instrument configures itself

automatically for 4 to 9 cylinders, 14/28 volt aircraft. The instrument is 7.5” deep less connectors and is 2.6 square

behind the panel.

TO PREVENT DISPLAY DAMAGE IT IS ESSENTIAL THAT THE FOUR MOUNTING SCREWS NOT PENETRATE

THE INSTRUMENT MORE THAN .12 INCHES.

DAMAGE OF THIS NATURE IS NOT COVERED UNDER WARRANTY.

EDM-730/830 Model: Mounts in a standard 3.1/8” instrument hole. First place the mounting bracket on the

instrument and tighten the clamp hex screw until you can just remove the instrument from the bracket. The Mounting

bracket is then placed behind the instrument panel hole and screwed (6-32 x ½” screws) in place using the existing

holes. Three screws should be used leaving one hole vacant on either side of the hex screw. Locate the hex screw in

a location that you can easily get to from the rear of the panel. The body of the instrument is 3.0 inches and 2.0 inches

deep less connectors. The body of the instrument is 3.0 inches and 2.0 inches deep less connectors.

Installation

2) EXHAUST GAS TEMPERATURE PROBE (EGT)

The Model M-111 Probe will fit any existing holes in the exhaust stack in any engine having the diameter of 1/8" to

1/4". If no hole exists, it will require the drilling of a 1/8" diameter hole and ream to fit. It is important that each probe

be mounted a uniform distance from the exhaust stack flange. A nominal distance of 2 to 4 inches from the exhaust

flange is recommended. (See fig-2). If the recommended distance is impractical because of obstructions, slip joints or

bends in the exhaust system then position the probes a uniform distance from the flange as space permits. Be

certain to locate all holes BEFORE drilling to ensure that nothing interferes with the probe, clamp, clamp screw or wire.

Careful matching of probe position will provide best temperature readings. Insert the probe in the exhaust or

previously drilled hole (see fig-3) so that the tip of the probe is in the center of the exhaust stream. Tighten the

stainless steel clamp to a torque of 45 in/Lbs. Cut off the excess strap close to the screw. Probe warranty is void if

mounted in a slip-joint of any kind.

RADIAL ENGINES , EGT

Radial engine exhaust, require a larger EGT clamp (supplied) to fit the 2.5 inch exhaust pipe. The EGT probe is

installed in the same fashion as a Lycoming or Continental engine and should be placed between the exhaust pipe

flange and the accumulator at a distance of 2 to 3 inches form the engine exhaust flange. Cylinder head temperatures

are measured with a spark plug gasket type probe placed under the front sparkplugs. Refer to the engine

manufactures red line and set the EDM-700 appropriately. Front spark plugs will read 15 to 20 degrees cooler than

the rear plugs. Do not route the EGT/CHT harness in with the ignition harness. Do not extend the yellow

thermocouple leads with copper wire.

3) TURBINE INLET TEMPERATURE PROBE (TIT)

The standard TIT probe P/N M-111-T with a special clamp is placed in the exhaust stack accumulator to a maximum

depth of 1/2 inch and approximately four (4) inches from the Turbine inlet if possible, on the wastgate side of the

turbine. TIT will appear as the seventh column “T “and the expression “1650 TIT” will be seen when the dot is in place

over it. The EDM-700 input is also compatible with the aircraft’s factory TIT and may be piggy backed.

The EDM-700 TIT cable may be connected in parallel (piggyback) at the TIT probe (preferred), or at the ship's TIT

gage. Check the TIT readings between the EDM and the ships TIT gage in flight, then do the following calibration

procedure. (This may be done in flight or on the ground.)

Page 4

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 4 of 30

Press & hold 'STEP' and 'LF' keys simultaneously until you see

'PROGRAM' and 'RATE 4'. (Note: Bargraph disappears)

Now press & hold 'STEP' and 'LF' simultaneously again until you see

'ORIG. TIT' and 'ORIG. T-N'.

Tap 'LF' once to change to

'ORIG. T-Y'.

Tap 'STEP' once to display

'CAL TIT' and 'TIT+ 0'.

This is the correction added to (+), or subtracted from (-) the EDM reading for TIT (at high temperatures).

Hold in 'LF' to raise the correction, or tap 'LF' to lower it.

For example, if the EDM read 100 less than the ship's TIT,

Then hold in 'LF' until you see

'TIT+100'.

Adjust the correction slightly if a difference between the EDM

and the ship's gage still exists.

Now tap 'STEP' once to complete setup.

4) CYLINDER HEAD TEMPERATURE PROBE (CHT), BAYONET

The Bayonet probe 5050-T has the 3/8-24 adaptor boss as part of the probe and is screwed into the base of the

cylinder (See fig-2). The bayonet probe has a screwdriver slot to facilitate tightening.

NOTE: Required original equipment that has a Red Line may not be replaced by the EGT-701 TIT or CHT installation.

This includes but is not limited to all aircraft with adjustable cowl flaps and on aircraft with placards on the instrument

panel showing a climb air speed, for cooling, different from the best rate of climb air speed.

If a previously installed TIT, CHT or EGT is listed on the aircraft equipment list as Optional Equipment or not listed at

all, it may be replaced by the EGT/CHT SCANNER.

5) CYLINDER HEAD TEMPERATURE PROBE (CHT) SPARK PLUG GASKET

Most factory installed cylinder head temperature gauges utilize a bayonet or screw-in resistive type probe that

occupies one of the bayonet sockets. This probe is not compatible with the thermocouple probes required for the

EGT-701.

The spark plug gasket probe, P/N M-113, replaces the standard copper spark plug gasket on one spark plug. The

plug chosen, upper or lower, should be the one that provides the best correlation with the other temperature probes.

Due to the spark plug location, the gasket probe may read 25

o

F higher or lower than the factory probe. The probe is

usually placed on the plug that receives the most direct cooling air. After many removals the probe may be annealed

for re-use. Heat and quench in water. At additional cost an adapter probe P/N M-113-3/8 is available that permits the

factory CHT probe and a JPI probe to fit the same bayonet location.

6) INDUCTION AIR TEMPERATURE PROBE (IAT) / CARB TEMP.

Induction Air temperature probe, IAT, is installed just after the inter-cooler (OUT) and the Compressor Discharge

Temp (CDT) just before the inter-cooler (IN). The probe is an EGT probe and installed the same way as an EGT

probe. A large clamp is supplied to fit around the airport leaving the inter-cooler or a 1/8 NPT is available. IAT option

is displayed as an independent digital temperature like "125 IAT". On non-turbo engines the IAT in reality is the

Carburetor temperature and displayed as “34 CRB”.

Page 5

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 5 of 30

7) OIL TEMPERATURE PROBE

The Oil Temperature Probe PN 400505-C or 400505-L is installed as a supplemental oil temperature indicator.

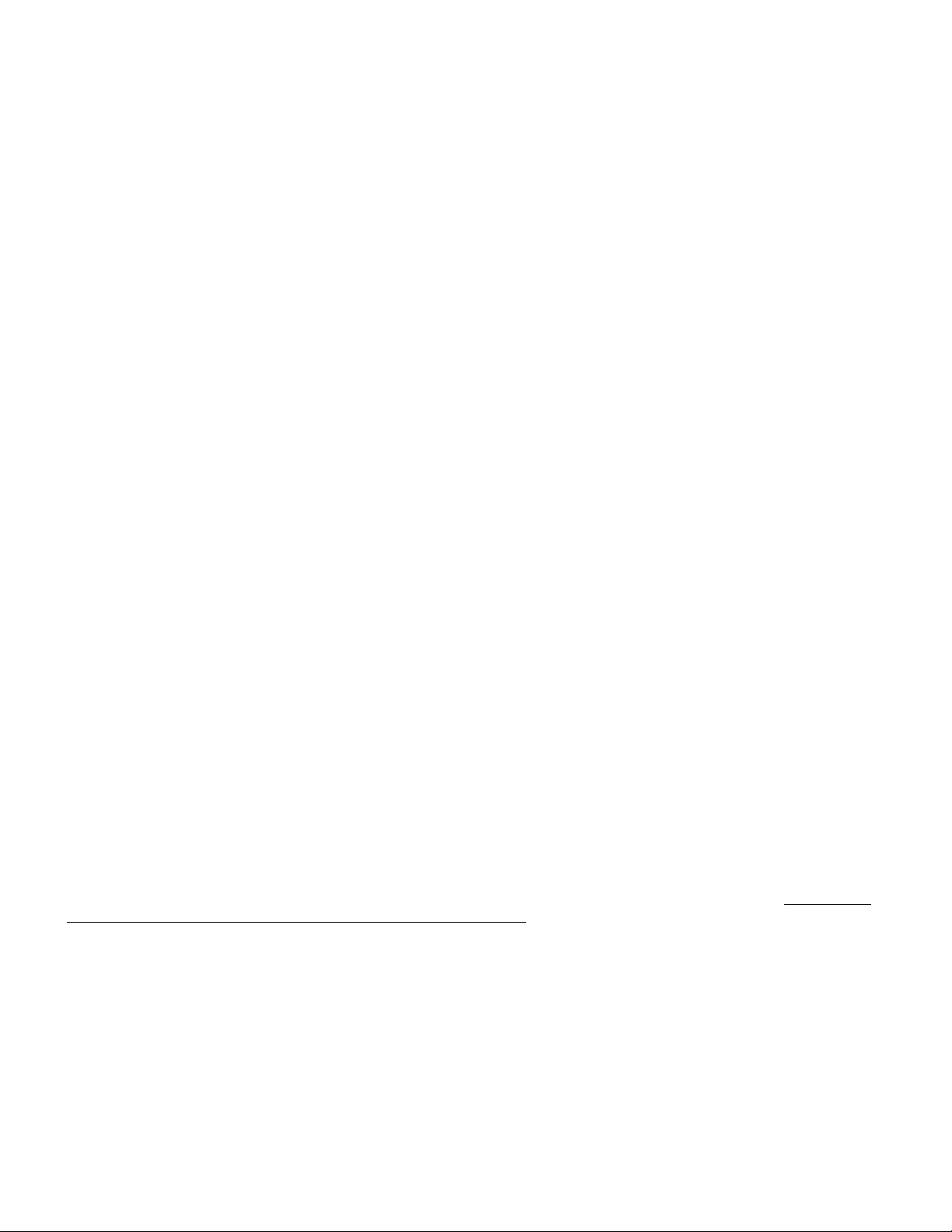

Lycoming Engines: The -L part number is for all Lycoming direct drive engines and is installed in the right (passenger

side) front oil galley by removing the existing 1/8 NPT plug on the passenger side of the engine and inserting the

optional JPI oil probe supplied with the kit. Oil temperature will be displayed as an independent temperature like "230

OIL" and will be displayed In the seventh column automatically if TIT is not available. The original oil temperature

gauge and sensor must remain. Check for oil leaks and safety wire before first flight.

Oil Probe Location

Alternate Oil Probe

Location

front view

Lycoming Engines

Continental Engines: The -C part number is for all Continental direct drive engines and is installed in the left (pilot

side) front oil galley by removing the existing 3/8 or 1/8 inch NPT plug (see figure below) located on the front, pilots

side of the engine. Insert the optional JPI oil probe supplied in the kit. For 3/8 inch NPT installations, use the supplied

brass adapter. An alternate location is on the top, front of the engine on the pilot’s side, where the probe is inserted

vertically. There are two 1/8 NPT plugs close together. Install the probe in the position that is above and to the rear of

the nearby position.

Alternate Oil Probe

front view

Location

Alternate Oil Probe

Location

Oil Probe Location

Continental Engines

Page 6

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

A

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 6 of 30

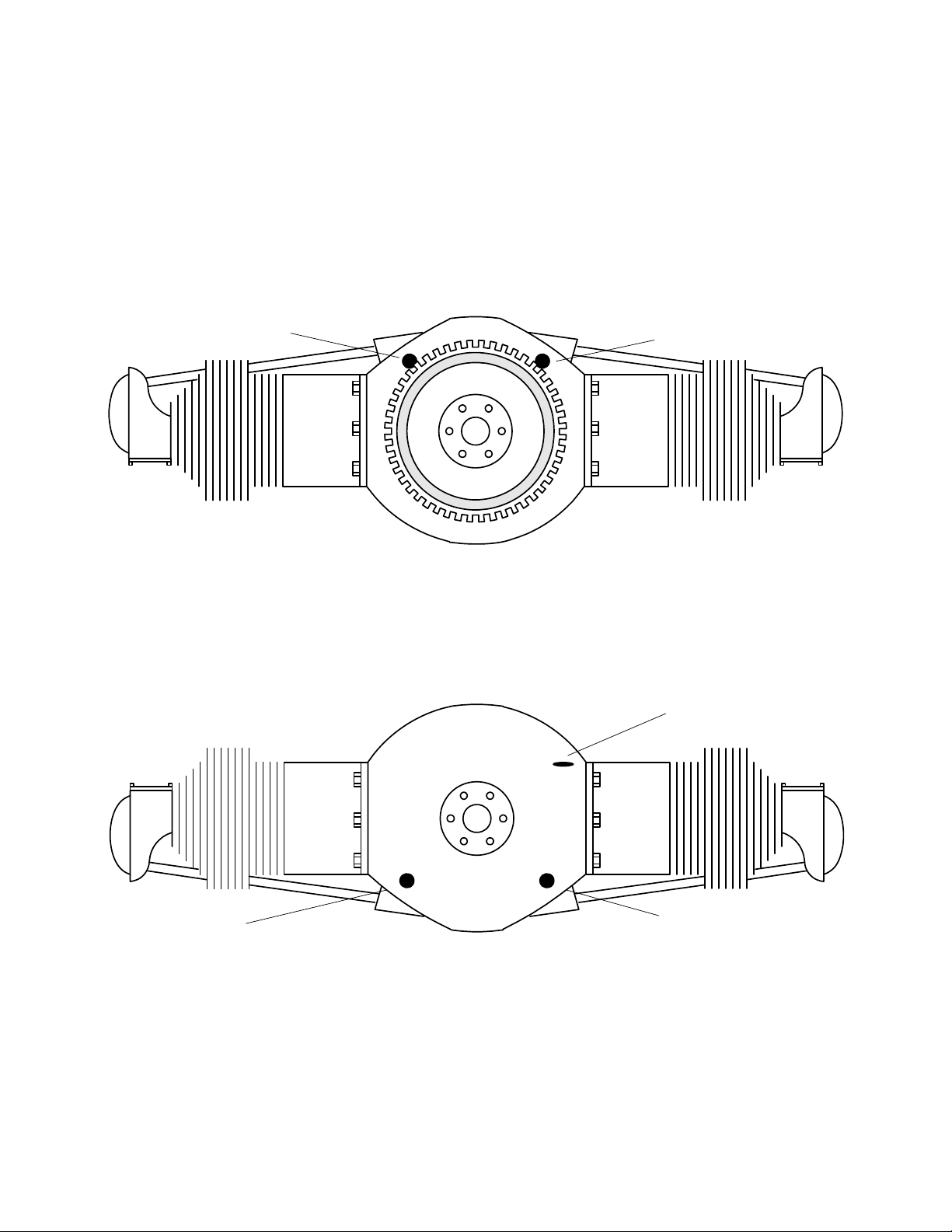

Continental Engines Oil probe location

lt location IO-520/550

Std oil IO-360

IO-360

O-470

Requires ¼ NPT to 1/8 NPT reducer Oil reports after thermostat opens

Alternate Oil

Location

IO-520/550

IO-520/550

The oil probe P/N 400505-C is installed by removing the 3/8 or 1/8 pipe plug located on the front of the engine inline

with the push rods. This oil galley feeds the valve lifters. Insert the JPI 1/8 NPT probe supplied with the kit. Check for

leaks after installation. Due to cowling restrictions the alternate oil location may be chosen. The probe leads are

routed back to the cockpit along with the EGT wires. Do not install the Oil Probe in the rear of the engine near the

vernatherm (oil temperature regulator).

Page 7

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 7 of 30

8) Oil Pressure Sensor Installation

Use the J3 connector harness 790420 labeled OIL-P for a VDO pressure sensor (shown in diagram below). Oil

pressure sensor mounts using an aluminum clamp MS21919. Mount to firewall or tie wrap to existing wiring bundle.

Mount the pressure sensor to the pressure line using a flexible hose and fittings (not supplied) as depicted in the

drawing below. Use aluminum clamp to mount the pressure sensor to firewall. Do not mount the sensor directly to

the engine. Connect the other end of the hose to the engine manufacturer’s recommended location for engine oil

pressure. An alternate method of installation is to install a T-fitting (not supplied) in the aircraft’s oil pressure gage line

in the cockpit near the oil pressure gage. Their is no polarity on the oil pressure transducer wires.

AN-910-1D

1/8 NPT coupling

pressure

sensor

PN 30601

mount using

MS21919 -DG24

1.5 inch clamp

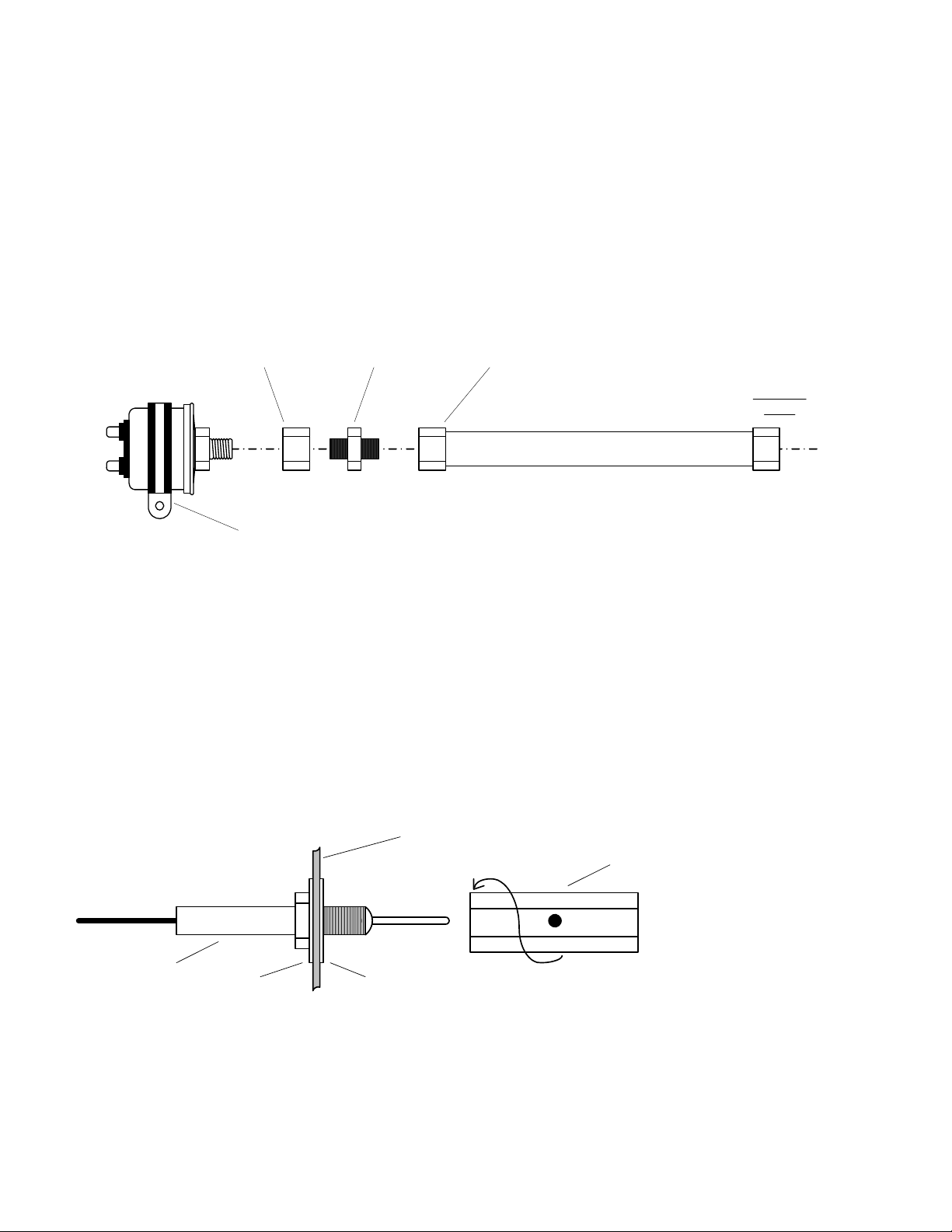

9) OUTSIDE AIR TEMPERATURE PROBE, OAT

Install the OAT probe, P/N 400510 in the airframe manufactures recommended location. If this is not possible, it is

recommended that the OAT probe be placed in clean airflow such as in a cabin air scoop or below the underside of

the wing away from engine heat or exhaust. In this case it is recommended that the installation be done similar to the

antenna installation instructions of AC 43.12-2a "Acceptable Methods, Techniques and Practices". The outside

aluminum tube is used to both hold the probe in place and shield it from radiated heat. OAT option is displayed as an

independent digital temperature like "75 OAT". Be sure that when testing the OAT it is not in direct sun and the engine

is running.

AN-816-4D

1/8 NPT to flared

MIL-H-8794 hose

MS-24587 fitting (AEROQUIP 491, 2 req'd)

to engine

fitting

flexible tube 6 inch (AEROQUIP 303)

DO NOT MOUNT SENSOR DIRECTLY TO ENGINE

Transducer supplied by JPI, all other hardware supplied by

installer.

aircraft sheet metal

shield tube

used to secure

probe

probe

washer

washer

Page 8

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 8 of 30

10) FUEL FLOW OPTION

The EGT-701 receives signal from any installed Flowscan Transducer of the following Flowscan P/N’s embossed on to

the top of the transducer. The K-Factor is engraved on the side of the Transducer. Wire per drawing 700744, Route

the JPI wires along the existing wiring bundle lacing every foot.

Flowscan Instruments, Seattle WA 98106

FlowScan PN Shadin equivalent

PN

201-A

201-B 680501/680600

201-C

231 680503

Install the function switch in the panel per drawing 700124.

Select the appropriate installation configuration from the three following fuel system categories:

For gravity feed systems without a fuel pump

For pump feed or fuel injected systems without

vapor return lines

For all fuel injected engines with vapor return

lines to the fuel tank before the servo/throttle.

use transducer FXT-231 (yellow plastic top). Connect the

transducer between the fuel tank and carburetor.

use transducer FXT-201 (black plastic top). Connect the

transducer between the engine driven pump and

servo/throttle body or carburetor.

use transducer FXT-201 (black plastic top). Connect the

transducer between the throttle body and the fuel flow divider.

The transducer output port should be mounted lower or level with the carburetor inlet port (or fuel servo on a fuel

injected engine). If this is not possible, an anti-siphon loop should be put in the fuel line between the fuel flow

transducer and the carburetor or fuel servo.

Find a convenient location within 8 inches of a

hose support or fitting to suspend the fuel flow

transducer. Mount it away from any hot exhaust

pipes. The hose support or fitting may be on the

input or output line of the fuel flow transducer.

Secure the end of the transducer to any

convenient point on the engine with MS21919

clamps or equivalent.

Do not place an

angled elbow joint immediately

If the transducer is higher than the

carburetor or fuel servo, put a loop

between the transducer and carburetor

or servo

OUT

IN

transducer

SIDE VIEW

carburetor

or servo

prior to the input port of the fuel

flow transducer.

inches of straight flow immediately before the transducer input port.

For a carbureted engine: remove the fuel hose which connects the carburetor to the fuel tank. Purchase two new

hoses — one to connect the carburetor to the fuel flow transducer, and the other to connect the fuel flow transducer to

the fuel tank. Before connecting the fuel hose to the carburetor, verify that the boost pump delivers at least 125

percent of takeoff fuel flow at minimum fuel pressure as marked on the fuel pressure gage.

For a pump-fed carbureted or fuel injected engine without vapor return lines: remove the fuel hose which

connects the engine-driven pump and the servo/throttle body or the carburetor. Purchase two new hoses one to

connect the engine-driven pump to the fuel flow transducer, and the other to connect the fuel flow transducer to the

servo/throttle body or the carburetor.

For a fuel injected engine with vapor return lines before the servo/throttle: remove the fuel hose which connects the

throttle body and the flow divider. Purchase two new hoses one to connect the throttle body to the fuel flow transducer,

and the other to connect the fuel flow transducer to the flow divider. For Continental fuel injected engines adjust the

fuel pressure to account for the pressure drop across the transducer per Continental Service Bulletin M89-10.

There should be two

Page 9

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 9 of 30

There must be flexible hose into and out of the fuel flow transducer. The hoses must meet TSO-C53a type C or D FAA

specification. The new hoses must be the same size as the current hose in the aircraft. The fuel flow transducer must

be wrapped with fire sleeving. Cut a 1 inch slit in the center of the fire sleeve and pass the transducer connector and

cable through it. Seal with high temperature silicone RTV sealant.

The placard “Do not rely on fuel flow instrument to determine fuel levels in tanks” must be mounted on the

aircraft instrument panel near the EGT-701. If the aircraft is equipped with a primary fuel flow instrument, the following

placard must be mounted on the aircraft instrument panel near the EGT-701 “Refer to original fuel flow

instrumentation for primary information.”

11) WIRING (12 / 24 volt)

The EGT-701 automatically accommodates both 14 and 28 volt electrical systems. Connect the power lead (red) to a

separate 5 amp circuit breaker (or 2 amp slow blow in-line fuse) connected to the avionics power buss. The avionics

master switch will then be used to turn off the instrument during engine start-up. The EDM-700 has a 10-second

warm-up. If the panel lacks an avionics master switch we recommend that one be installed or a circuit breaker switch

be provided to turn off the EGT-701 during engine start-up. If the voltage fall below 9.8 vdc the instrument will turn off

automatically. The Instrument should be grounded at the engine. No connection to the aircraft dimmer system is

required because the instrument dims automatically with reductions in ambient light.

12) EGT and CHT Probe Wiring

The EGT-701 is supplied with special Teflon insulated Chromel Alumel factory assembled wiring harness configured

for the correct number of cylinders. The wire harness is marked E-1= EGT-1, C-1= CHT-1, etc. TIT is marked “T”,

Oil I = “O” and OAT = “A”. For retrofits of the EGT-100 SCANNER or bar graph instruments, where only the

indicators are being exchanged, the old harness wires need to be pinned with AMP P/N 665049 and fitted into AMP

D-SUB connector P/N 205207-1 with hood per drawing 300701 fig-6 or connected directly via an adapter connector.

NOTE: Unlike most other EGT & CHT installations the probe wire length is not critical and should be trimmed to any

length as required for a clean installation.

The Temperature probes must be wired with the correct polarity. Each wire is marked with the cylinder number. The

EGT and CHT probes connect to the temperature indicator with yellow jacket Teflon Chromel Alumel wire supplied.

Strip the wires according to drawing 5057 and terminate with the crimp-on ring terminals provided. Verify the quality of

each crimp with a sharp pull on the wire. The terminal should be almost impossible to pull off when crimped correctly.

With in a few inches of the instrument terminal strip a connector may be installed.

NOTE: The ring terminals may be crimped with a “service type” tool, however AMP part number 48518 tool is

recommended. Be sure to test each crimp by pulling on the wire to assure it will not come out.

The most common installation problems are poor quality terminations.

The EGT-701 must be grounded to the engine block, not at a ground point under the instrument panel. No

connection to the aircraft dimmer system is required or permitted because the instrument dims automatically with

reductions in ambient light.

Install the data port connector in the instrument panel. This is the 2.5 mm ID, 5.5 mm OD on the

twisted white and black wires on J1. See Installing the Instrument section earlier in this manual.

Page 10

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 10 of 30

+12/24 avionic bus

(alarm wire not supplied)

15

8

8

7

6

5

11

9

4

3

2

RS-232 input to EDM-700

1

1

9

RS-232

output from

EDM-700

Cut red lead if

transducer is

also connected

to another fuel

flow instrument

GPS output

GPS input

(some KLN series only)

FF

COM

EGT

WHT

BLK

RED

Alarm lamp or enunciator

(customer supplied option)

EGT

ALL

FF

1

fuel flow option

connector

GPS

panel

mounted

switch

WHT

BLK

RED

OUT

Fuel Flow Transducer

FloScan 201 -A, -B, -C, or 231

IN

Before you begin, note that the most common cause of probe problems is poor

terminal crimps.

When cutting each pair of leads in the wiring harness to the proper length to connect to the probes, leave enough

slack in the harness so that probes from adjacent cylinders may be interchanged if necessary for trouble-shooting and

servicing. Thermocouple wire length is not critical and should be trimmed to any length as required for a clean

installation.

The Temperature probes must be wired with the correct polarity. Each wire is marked with the cylinder number. The

EGT and CHT probes connect to the temperature indicator with yellow jacket Teflon Chromel Alumel wire supplied.

Strip the wires as shown below, observing color codes.

crimping terminals.

Thermocouple wire harness

Terminate each wire with a crimp-on ring terminal, provided. The ring terminals may be crimped with a “service-type”

tool, however AMP part number 48518 crimp tool is recommended. Verify the quality of each crimp with a sharp tug on

the wire. The terminal should be impossible to pull off when crimped correctly.

Important: fold back the wire double before

red

2 1/4"

yellow

1/4" 1 1/2"

Fold back wire

double before

crimping terminals

ring terminal

shrink tubing

shrink tubing

Place a ¼ x 4 inch sleeve over each pair of wires in the harness. Connect the harness ring terminal to the probe ring

terminal using the supplied number 4 screws and nuts, placing the star washer between the ring terminals, not against

the nut.

Important: place star waster between two ring

terminals and tighten nut and bolt as

to instrument

necessary

to probe

Slide the sleeve over the joint and secure with three tie-wraps.

tie-wrap 3 places

1/4 x 4" sleeve

Page 11

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 11 of 30

13) ROUTING THE WIRING HARNESS

Route the wires from the probes and sensors through the firewall using fireproof rubber grommets and flame retarding

silicone. Use an existing hole if possible. Following the existing wiring harness and connect to the indicator marking

each lead with the cylinder number. All wires must be routed away from high temperature areas (exhaust stacks,

turbochargers, etc.). Secure Probe leads to a convenient location on the engine approximately 8 to 12 inches from the

probe, being sure there is sufficient slack to absorb engine torque. It is essential in routing the probe wire that this

wire not be allowed to touch metal parts of the airframe or engine since abrasion will destroy this high temperature

wire.

Connect the JPI RPM sensor to the wiring harness using the 3-pin connector supplied.

Secure thermocouple wires along the route to the indicator. Secure wire using original clamps, tie wrap if possible.

CAUTION: Be sure the wiring does not obstruct the controls under the panel.

The probe wires must not be tied in with ignition, alternator or twin engine cabin heater ignition wires because of

potential interference with temperature readings.

Temperature probe wiring harness is made of Chromel-Alumel alloy wire (yellow) that must not be substituted or

extended with normal copper wire. The power and ground wire are normal copper. Leads may be spliced with

additional Chromel-Alumel wire using copper butt splices.

When the installation is complete all wires should be secured using ties and carefully checked for interference,

rubbing or chaffing with flight control cables or other moving parts.

Page 12

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 12 of 30

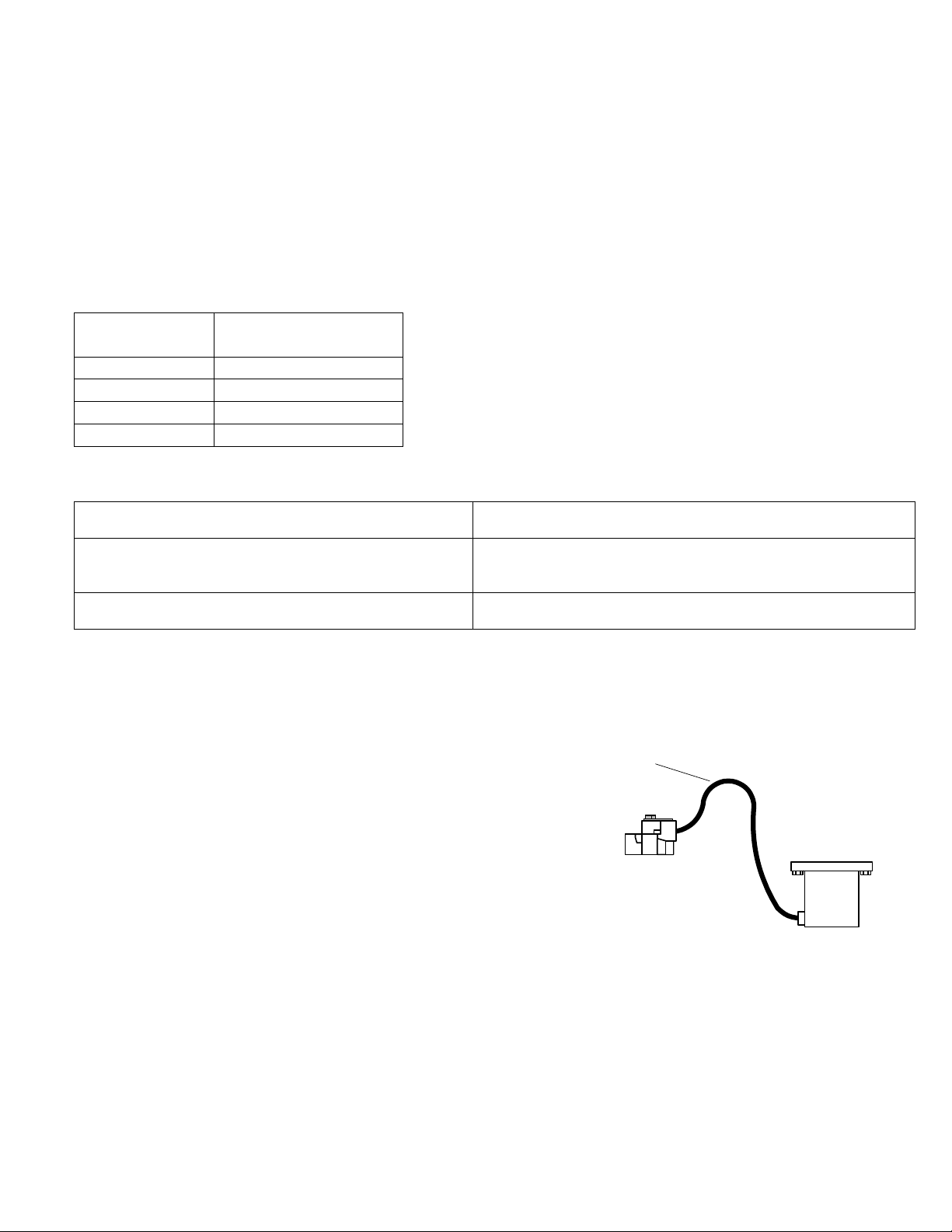

14) Manifold Pressure (MP) Sensor

Install a T-fitting (not supplied) in the aircraft’s MP gage line in the cockpit near the MP gage. Install the JPI MAP

sensor

P/N 604010 on the T-fitting. Connect the JPI MP sensor to the wiring harness using the 4-pin connector supplied. The

MAP sensor uses a 1/8 NPT fitting. Note: this is eligible for installation on all 4 & 6 cylinder engines only. There are

no alarm limits.

MP Sensor

connector

from engine

T-fitting

MP gage

Manifold Pressure Calibration

The manifold pressure must be calibrated to the ambient air pressure. Enter the current ambient barometric pressure. The engine

must not be running. This setting is not the same as the altimeter setting that you receive from ATIS or unicom. It will vary with

field elevation. Use the chart below to calculate the MP FACTOR. Multiply this MP FACTOR by the altimeter setting that you

receive from ATIS or unicom. For example if the field elevation is 1700 ft and the altimeter setting is 30.1, the MP FACTOR is

0.9400 from the table. Multiply 30.1 x 0.9400 to get the ambient MP of 28.29.

Field Elev MP FACTOR

-500 1.0182

-400 1.0145

-300 1.0109

-200 1.0073

-100 1.0036

0 1.0000

100 0.9964

200 0.9928

300 0.9892

400 0.9856

500 0.9821

600 0.9785

700 0.9750

800 0.9714

900 0.9679

1000 0.9644

1100 0.9609

1200 0.9574

1300 0.9539

1400 0.9504

1500 0.9469

1600 0.9435

1700 0.9400

1800 0.9366

1900 0.9332

2000 0.9298

2100 0.9264

2200 0.9230

2300 0.9196

2400 0.9162

2500 0.9129

2600 0.9095

2700 0.9062

2800 0.9028

2900 0.8995

3000 0.8962

3100 0.8929

3200 0.8896

3300 0.8863

3400 0.8830

3500 0.8798

3600 0.8765

3700 0.8733

3800 0.8700

3900 0.8668

4000 0.8636

4100 0.8604

4200 0.8572

4300 0.8540

4400 0.8508

4500 0.8477

4600 0.8445

4700 0.8414

4800 0.8382

4900 0.8351

5000 0.8320

5100 0.8289

5200 0.8258

5300 0.8227

5400 0.8196

5500 0.8165

5600 0.8135

5700 0.8104

5800 0.8074

5900 0.8043

6000 0.8013

6100 0.7983

6200 0.7953

6300 0.7923

6400 0.7893

6500 0.7863

6600 0.7833

6700 0.7804

Page 13

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 13 of 30

15) RPM Sensor installation

There are four types of magnetos commonly in use. You must have the correct RPM sensor for the magneto installed

in the aircraft. The following part numbers apply: Slick – pressurized 4000, -6000 series use JPI P/N 420809. For the

Bendix pressurized -1200 series use P/N 420807. Dual magnetos use JPI PN 420808. For the Bendix -20 series and

Slick 600 use JPI P/N 420806. Mount the sensor as shown in the appropriate diagram below. Note: this is eligible for

installation on all 4 & 6 cylinder engines only.

Bendix Magnetos Slick Magnetos

engine

Connector to harness

Bendix -20, -21, -200, 1200 series

non-pressurized

JPI 420815-2

Mount sensor side of bracket towards

magneto body, positioned over the magnet

armature

position limit

P

O

T

engine

Connector to harness

Slick 6000, 4000 series

non-pressurized

JPI 420815-1

Mount sensor side of bracket towards

magneto body

Sensor ring munted under vent plug.

Stem at right angles to magneto ce nter line

TOP

engine

position limit

Alternate bracket locations

Connector to harness

Bendix 1200 series

pressurized

JPI 420807

Mount senso r s ide o f b rac ke t to wards

magneto body

engine

Alternate bracket location

Vent plug

Spacer ring

Sensor ring bracket

Magneto body

Connector to harness

Slick 6000, 4000 series

pressurized

JPI 420809

Sensor must be over

moving magnet armature

Remove this screw

to mount sensor

bracket

engine

engine

Bendix Dual Magneto

JPI PN 420808

non-pressurized

rev Dec 2010

Slick 600 series

JPI PN 420806

non-pressurized

Page 14

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 14 of 30

16) DESCRIPTION / OPERATING INSTRUCTIONS

The EGT-701 temperature indicator displays temperature digitally and in analog format. The EGT as displayed is

based on probes located near the exhaust outlet for each cylinder and the TIT probe, if installed, is adjacent to the

turbo charger. These probes are not necessarily collocated with the primary probes therefore; EGT-701 may not

indicate the same as the aircraft primary instruments. The analog display is an electronic bar graph (vertical columns,

one per cylinder) of EGT & TIT temperatures presented as a percentage of 1650

specific value for EGT and CHT are displayed digitally. The dot over the column indicates which cylinder’s digital

information is presently displayed. The missing bars at the base of the columns indicate the hottest and coldest

Cylinder Head temperature trend. During Lean Find mode the leanest cylinder is displayed along with the fuel flow

(optional) at that time. Depressing the LF and STEP button simultaneously brings up the adjustable scan rate

function, OAT in

Depressing STEP.

If the EGT-701 buttons are not depressed for 10 minutes the system will start scanning automatically. Depressing the

STEP button will stop the automatic scan and index through all the functions available. During constant power cruise,

if the LF button is depressed for five seconds the Bargraph will level at mid scale. The leveled bars represent the

peaks of each column. Each bar represents 10

increase or decrease in temperature. Depress again to return to normal; nothing else is affected. With the fuel flow

option there is a three position toggle switch. The positions are: 1) EGT, digital and Bargraph display of temperatures,

2) FF, digital display of GPH, REM and USED Fuel. Temperature Bargraph remains. 3) Both, cycles through

everything installed. The data port output sends RS232 serial data every 6-sec.

o

C or oF. Depress the LF button will change the value of the rate or Oat in oC or oF. Exit by

o

F and now acts as an EGT & TIT trend monitor, quickly showing an

o

F. Below the vertical columns the

Options of Fuel Flow, TIT, OAT, IAT (induction air temp.), OIL, BAT (voltage) and are displayed digitally with headlines

after the number, as “230 OIL” or “14 GPH”. A large value (50 +) of “CLD” indicates shock cooling usually associated

with rapid descents at low power. Optional functions not installed will not display. The same acronyms are

incorporated in the TFT flat panel display.

RPM 2700

switc

EGT 1340 F

CH 376 F

EDM-800 Plasma display

Page 15

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 15 of 30

EDM-830 TFT Flat panel display

Portrait

switc

EDM-830 TFT Flat panel display

Landscape

EDM-830 system mounts in a 3.125 inch instrument panel hole in either a portrait or landscape position

depending on panel hole location.

By holding the Step button (white) for approx. 10 seconds and arrow will appear on the display showing

which way is up. Use the LF button to index the arrow. When the proper position is achieved, press the

step button and the system will reboot in the direction chosen.

switc

Page 16

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 16 of 30

17)Installation Record

The indicator and probes FAA TSO approved, as a temperature indicator under TSO-C43b. Record the

installation of the EGT-701 per STC# SA 2586NM. Make an appropriate entry in the aircraft log book. FAA form 337

may be required.

18)Operation

Airplane flight manual limitations based on primary instrument indication take precedence over those of the EGT-701.

CAUTION: Comply with manufacturer’s airplane/rotorcraft flight manual leaning procedure. Do not exceed

applicable engine or aircraft limitations.

CAUTION

Comply with manufacturer’s Airplane/Rotor craft

Flight Manual leaning procedure.

Do not exceed applicable engine

or aircraft limitations.

After establishing desired cruise power depress the LF button to activate the Lean Find Mode. As the mixture is

leaned, the column display on the EGT-701 for one cylinder will begin blinking; indicating the exhaust gas temperature

for that cylinder has peaked. Continue with the leaning procedure as recommended by the aircraft manufacturer while

monitoring the primary engine instruments and the EGT-701 display. Once the leaning procedure has been

completed, depress the Step button briefly to exit the Lean Find Mode and enter the Monitor Mode.

ENGINE OPERATION: Operate and lean the engine in accordance with the manufacturers’ recommendations

for different power settings. Lycoming recommends running peak EGT only at 75% power or less. Continental recommends

running peak EGT at 65% power or less.

19) EGT-701 SPECIFICATIONS and LIMITATIONS

OUTPUT FUNCTIONS (ALL OPTIONS): FACTORY LIMITS

EGT (Exhaust Gas Temp.,K ,Max. limit 2500

CHT (Cylinder Head Temp., J/K Max. limit 600

TIT (Turbine Inlet Temperature, K, Max. limit 2500

OIL (Oil temperature, K, Max. limit 600

OAT (Outside Air Temp., K, Limit -40 to 300

IAT (Induction Air Temp., K, Max. Limit 600

o

F) 1650

o

F) 450

o

o

F) (Hi/Lo) 230/90oF

o

o

F.)

F) 1650

F)

CLD (Rate of change of CHT) -60

DIF (Maximum EGT differential) 500

LFM (Lean Find Mode, detects first EGT peak)

BAT (Voltage, 0 to 40 volts.) Not FAA Approved under TSO-C43b 15.5/11.0 or 31.0/22.0 Hi/Lo

RPM Tested under TSO-C43b (Does not comply with TSO-C49a)

MAP Tested under TSO-C43b ( Does not comply with TSO-C45)

The conditions and test required for TSO approval of this article are minimum performance standards. It is the

responsibility of those desiring to install this article either on or within a specific type or class of aircraft to determine

that the aircraft installation conditions are within the TSO standards.

An alarm causes the digital function to flash when the particular limit is exceeded. Factory set alarm limits for CHT

o

(450

F) and OIL (230oF) are lower than the actual aircraft limits. The values may be adjusted to suit individual

preference by pressing the reset button. Other factory set alarm limits are: “BAT” Voltage 15.5/11.0 or 31.0/22.0 Hi/Lo

as appropriate; “DIF” (differential Hi/Lo EGT) 500

o

F; “TIT” 1650oF Hi; “OIL” Lo 90oF; “CLD” (Rate of change of

cylinder head temperature in degrees per minute) -60 degrees/minute. The pilot should be aware of the setting of each

alarm for his particular aircraft. An alarm is “Canceled” by holding the step button in for 5 seconds and seeing

the word “OFF”. Then, only that particular alarm is canceled. Canceled alarms will not appear again until the power

o

F

o

F

o

F

o

/minute

o

F

Page 17

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 17 of 30

has been removed and reapplied to the EGT-701. The entire display dims automatically depending on the ambient

lighting.

20) Component Parts List for EGT PN-1280, TIT PN-1200, IAT PN-1300 Probe in polybag

1 Thermocouple probe PN M-111

1 Stainless Steel Clamp Thimble

1 Stainless Steel Exhaust Seal Washer

1 Stainless Steel Screw Type Clamp

2 Ring Terminals

2 Screws and nuts 6-32 X 1/4

1Fiberglass tube 1/2” X 4”

21) Component Parts list for CHT probe PN 1260

1 Bayonet Probe Spring loaded PN-5050

1 Or Gasket thermocouple probe PN M-113

2 Ring Terminals

2 Screws and Nuts 6-32 X 1/4”

1 Fiberglass tube 1/2” X 4”

22) Components Parts list for OIL probe PN 1240

1 P/N 400505 –C or –L, OIL probe

2 Ring Terminals

2 Screws and Nuts 6-32 X 1/4”

1 Fiberglass tube 1/2” X 4”

22) Components Parts list for OIL pressure PN 306018

1 P/N 306018 OIL pressure transducer

2 Ring Terminals

23) Components Parts list for OAT probe PN 1220

1 P/N 400509, OAT probe

2 Ring Terminals

2 Screws and Nuts 6-32 X1/4”

1 Fiberglass tube 1/2” X 4”

24) Components Parts list for Manifold pressure sensor probe P/N 604010

1 P/N 604010, Manifold pressure sensor with 1/8 NAP termination.

25) Components Parts list for RPM sensor P/N depends on Magneto make and model.

1) Bendix magneto series 20,21………………….…P/N 420806

2) Bendix magneto series 1200,………………..…...P/N 420807

3) Bendix magneto Plug Std and Dual ……………...P/N 420815-1

4) Slick magneto series 4000 or 6000 P/N 420809 or Plug PN 420815-2

26) Component Parts list for Single Engine, EGT and CHT

P.N. EGT-701 -4C -6C -7C -8C -9C

Temperature Indicator 1 1 1 1 1

EGT probe KIT PN 1280 4 6 7 8 9

CHT probe KIT PN 1260 3 5 6 7

CHT Gasket probe KIT PN 1260 1 1 1 1 9

Oil probe with option O KIT 1240 1 1 1 1 1

TIT probe with option T KIT 1200 1 1 1 1

OAT probe with option A KIT 1220 1 1 1 1 1

IAT probe with option I KIT 1300 1 1 1 1 1

Oil pressure transducer PN 306018 1 1 1 1 1

MAP P/N 604010 1 1 1 1 1

RPM one of P/N 420806, 7, 9, 15-1,-2 1 1

TC Harness PN 700702 1 0 0 0 0

TC Harness PN 700700 0 1 1 1 1

TC Harness PN 700200 1 1 1 1 1

TC Option wire PN 700201 0 0 2 4 6

Page 18

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 18 of 30

27) Weight and Balance Data

TSO C43b, Temperature Indicator EGT-701 30 oz. / 1.9 lbs

EGT probe MM-111 2.0 oz. Each / 0.125 lbs

CHT probe 5050 1.5 oz. each / 0.094 lbs

Wire P.N. WK.-24 Harness 8 ft. 14.0 oz. each / 0.88 lbs

RPM, MAP, and Oil pressure 1.5 oz each / .094 lbs

CHANGING THE PROGRAMMED LIMITS

40

Setting the K-factor (Fuel Flow Option)

You must set the K factor before using the EGT-701 with fuel flow. Note the K-factor that was engraved on the fuel flow

transducer.

1. Turn on the EGT-701 and after self-test, press STEP until the instrument is cycling normally.

2. Place the select toggle switch in the FF position.

3. Start the Pilot Programming Procedure by simultaneously holding the STEP and LF buttons for five seconds. You

will see the word PROGRAM for two seconds.

4. Tap the STEP button repeatedly until you see KF-SET.

5. Hold STEP and LF for five seconds. First digit blinks: 29.00

6. Tap or Hold LF to change flashing digit (for example): I9.00

7. Tap STEP for next digit: I9.00

8. Tap or Hold LF to change flashing digit: I8.00

9. Tap STEP for next digit: I8.00

10. Repeat steps 7 and 8 for the remaining two digits.

11. Verify the K-factor that was engraved on the fuel flow transducer is now displayed.

12. Hold STEP and LF for five seconds to exit.

13. Tap STEP

Setting the Data Recording Option Parameters

(Data Recording Option only)

If you haven’t already done so, start the pilot programming procedure; simultaneously hold the STEP and LF buttons

for five seconds. You will see the word PROGRAM for two seconds. To change the date, time and user id for the Data

Recording Option, tap the STEP button until the display shows DUMP? N. Next, simultaneously hold the STEP and

LF buttons for five seconds. Then set the date and time as show below

Tap STEP to

next item

MNTH

DAY

YEAR

HOUR

MIN

LF sequences

through these values

I I2

I 3I

80 79

OO 23

OO 59

USER ID N I2345

Month

Day

1980 through 2079

24 hour time. We suggest you set Zulu time.

Tapping the step will also zero the seconds (not shown)

Hold both STEP and LF buttons simultaneously until the first character flashes.

Use LF to select the first character. STEP moves to the next character.

Hold both STEP and LF to exit.

Comments

Page 19

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

M

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 19 of 30

Setting the Alarm Limits

Turn on the EGT-701 and after self-test, press STEP until the instrument is cycling normally.

To start the Alarm Limit Procedure, with the EGT-701 powered up, do the following:

Hold both

buttons for 5

seconds until

the word

Tap STEP

button until

the words

PROGRAM

END Y

Hold both

buttons for 5

seconds until

the words

FAC LI

Tap the STEP button to advance to the next item in the list. Tap the LF button to select alternate values of that item. Hold the LF

button to rapidly back up. Prompts listed in the first column are displayed for only two seconds.

Changing the Alarm Limits:

STEP to next

item

FAC LIM

REV X.XX

TYPE K

EGT-CHT

BATTERY

EGT DIF

CHT HI

COOL CHT

TIT HI

OIL TEMP

OIL PRESS

FUEL FLW

MAIN TK

AUX TNK

LO TIME

LO FUEL

RECRD?

*CHT will read incorrectly if the wrong probe type is selected. Type K probes generally have red and yellow wires; type J probes

have black and white wires.

LF sequences through these values

Description

Factory Limits.

FAC? N FAC? Y

TYPE K TYPE J

Hold STEP and LF for five seconds to toggle

ENG F ENG C

I0.0 H BAT 35.0 H BAT

8.5 L BAT 30.0 L BAT

30 DIF 990 DIF

90 H CHT 500 H CHT

-5 CLD -200 CLD

650 TIT 2000 TIT

40 H OIL 500 H OIL

I0 L OIL 250 L OIL

FUEL GALFUEL KGSFUEL

LTRFUEL LBS

MAIN=50 Main tank capacity, in units selected

AUX? NAUX? Y

AUX=0 Au xiliary tank capacity

MIN =45 Alarm limit in minutes for low time in tanks

REM =I0 Alarm limit for low fuel quantity in tanks, in units selected

CARB? N CARB? Y

RECRD? YRECRD? N

END Y END N

Restore factory defaults

Firmware rev. number.

Type K or Type J CHT probes. USE THIS WITH CAUTION.*

Select F or C degrees for all engine temps.

Battery high voltage limit, set in 0.5 volt increments.

Battery low voltage limit.

EGT difference limit set in 10° increments.

CHT high limit set in 5° increments.

Cooling limit set in 5°/min. increments.

Both EGT and TIT hi limits are the same.

Oil temperature high limit, set in 5° increments.

Oil temperature low limit set in 5° increments

Oil pressure low limit

Selects the units in all parameters where fuel quantity or

fuel rate is displayed

Y - Yes - aircraft has auxiliary tanks

Y - Yes: carbureted engine

Data Recording Option Y-only data recording. N – Only realtime data output.

Y - Yes to exit; N - No to review list again

Page 20

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 20 of 30

Fuel Flow Units (Fuel Flow Option)

Selects the units in all parameters where fuel quantity or fuel rate is displayed. If you change this parameter, it does not change the

numerical value of the fuel tank capacity. You must do this manually. For example if you change from Gal. to Lbs., the tank

capacity will be interpreted as 50 Lbs. rather than 50 gallons; the EGT-701 will not convert 50 Gal to equivalent pounds.

Main Tank Capacity (Fuel Flow Option)

Enter the total capacity of the main tanks in the fuel flow units selected. If you hav e tank tabs (but no auxiliary tanks) and

sometimes fill only to the tabs, set the main tank capacity to the capacity up to the tabs.

Auxiliary Tanks (Fuel Flow Option)

If you do not have auxiliary tanks or tank tabs, answer “No.” If you answer yes, you will be asked to input the capacity of the

auxiliary tanks in the fuel flow units selected. If you have tank tabs and sometimes fill only to the tabs, set the auxiliary tank

capacity to the difference between full tank capacity and tab capacity.

Low Time Alarm Limit (Fuel Flow Option)

Select the value of the time remaining, in minutes, that triggers the alarm. Time remaining is calculated at the current fuel flow

rate.

Low Fuel Alarm Limit (Fuel Flow Option)

Select the value of the fuel remaining, in the selected fuel flow units, that triggers the alarm. Fuel remaining is calculated at the

current fuel flow rate.

Carburetor? (Fuel Flow Option)

Different response filters are used depending on whether your engine is carbureted or fuel injected. The filter for a carbureted

engine has a slower response time to reduce sudden fluctuations in readings.

29) Troubleshooting

a) A missing column in the display on start up indicates that the diagnostic routine has found an open

wire or probe with a poor connection. The error message will indicate which channel to examine.

b) A missing column in the display during flight indicates a widely varying or erroneous temperature

value. The probe is deleted from the indexing to prevent false alarms.

c) Start up OPEN PRB message. If one of the temperature probe circuits is open, the display indicates

OPEN PRB followed by one of these messages: EGT 1, EGT 2, EGT 3, EGT 4, EGT 5, EGT 6, EGT 7,

EGT 8, EGT 9, CHT 1, CHT 2 , CHT 3, CHT 4, CHT 5, CHT 6, CHT 7, CHT 8, CHT 9, OIL, IND, OAT,

TIT. Check the connector at the instrument and verify that a female pin is not recessed in the connector.

Check the crimps where the probe is connected to the wiring harness.

d) A negative reading (- in front of the number) indicates reverse polarity on the red and yellow

thermocouple wire to probe.

e) Ohmmeter check. Remove the connector from the rear of the instrument and measure the resistance

of the probe lead pairs. The reading should be about 10 ohms. At the connections between the probe

and the wiring harness in the engine compartment, the resistance should read about 2 ohms.

f) All readings varying rapidly. Verify that the Instrument is grounded at the engine block for single

engine installations. If an adapter probe is being used insure that it is screwed in tightly and grounded.

Remove the factory original probe that is in the adapter and note if problem is resolved. If so an ohm

ground exists between the engine and the adapter probe.

Page 21

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 21 of 30

g) One CHT reads higher or lower than the others. It is most likely that this is the cylinder that has the

spark plug gasket probe installed. Choose the upper or lower spark plug, the one that provides the best

correlation with the other temperature probes. Due to the spark plug location, the gasket probe may

read higher or lower than the factory probe. Place the probe on the plug that receives the most direct

cooling air

h) One cylinder seems to read erroneously. Physically swap the suspected probe with a probe from a

correctly reading cylinder. If the problem moves to the correctly reading cylinder (stays in the same

column on the instrument) check the crimps between the probe and the wiring harness. Check the pins

on the connector that plugs into the instrument. If those check okay, then the probe should be replaced.

If the problem moves to the other probe’s column on the instrument, the temperature readings are

correct and there is probably a problem with the original cylinder.

i) Large EGT span. Normally aspirated (carburetor) engines at normal cruise display a “DIF” of 125 to

o

175

F spread between cylinders. Injected engines at normal cruise display a “DIF” 50 to 90oF spread

between cylinders. All cylinders are measured by common circuitry. It is unlikely that the calibration is in

error on only one channel.

j) Temperature reading varies more than 500°F in one second. Check for a poor quality crimp between

the probe and harness.

k) All EGT or CHT readings seem too high or low or unsteady. Verify that the Instrument is grounded

at the engine block for single engine installations. Use a DVM (digital voltmeter) to measure the

difference between instrument ground and the engine block ground. If the difference is greater than 0.5

volts with the alternator charging, the ground to the instrument is faulty.

l) All EGT and CHT readings seem too low. The instrument may be set to display engine temperatures

in Celsius when you are used to seeing Fahrenheit. See Pilot’s Guide under Pilot Programming.

m) OAT readings in error more than 10°, but oil and CHT readings are okay. Look for copper wire spliced

in line to the OAT probe. The OAT reading can be adjusted 10°. See Pilot’s Guide under Pilot

Programming.

n) All CHTs read high (100F) EGT-701 calibrated for Gem installation “J” calibration. Change to “K”

calibration using the procedure to set alarm limits described earlier.

Page 22

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 22 of 30

FIG-1

Page 23

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 23 of 30

Mounting bracket for the EDM-730/830

EDM-730/830 Model: Mounts in a standard 3.1/8” instrument hole. First place the mounting bracket on the

instrument and tighten the clamp hex screw until you can just remove the instrument from the bracket. The Mounting

bracket is then placed behind the instrument panel hole and screwed (6-32 x ½” screws) in place using the existing

holes. Three screws should be used leaving one hole vacant on either side of the hex screw. Locate the hex screw in

a location that you can easily get to from the rear of the panel. The body of the instrument is 3.0 inches and 2.0 inches

deep less connectors.

Page 24

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 24 of 30

EDM-730/830 Layout

Page 25

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 25 of 30

Page 26

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 26 of 30

Page 27

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 27 of 30

FIG - 6

Page 28

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 28 of 30

Fig 7

Page 29

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 29 of 30

Fig - 9

Page 30

FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 30 of 30

Instructions for Continued Airworthiness (ICA)

There are no field adjustments and or calibration requirements for the EDM-700/730 series

instrument after initial installation. ICA is not required. Maintenance of nonfunctioning or

malfunctioning components is limited to removal and replacement of JPI factory supplied new or

repaired components as described in the troubleshooting section of the installation instructions

Loading...

Loading...