Joyce RC-204 User Manual

Corporate Fax: (937) 297

-

7173

JACKS AND ACTUATORS

Installation and Lubrication Instructions for Miter Boxes

RC-6, RC-9, RC-12, RC-15, RC-18, RC-38, RC-99

Installation:

Check relative rotation of shafts to suit application before installing.

Remove plastic protective plugs (where applicable) from threaded mounting holes. Mount drive securely on a flat, rigid surface.

Shafts should be accurately aligned with connecting devices. Components assembled to the projecting shafts should be installed as

close to housing as possible and not so tightly fitted that assembly forces would damage the drive. Install vented filler plug (with

sintered bronze insert) into pipe tapped hole at top surface of housing and solid plug in remaining tapped holes. Contact factory for

other mounting configurations.

Lubrication:

RC-6, RC-9, and RC-12 are lifetime lubricated at the factory.

RC-15, RC-18, RC-38, and RC-99 are to be lubricated per the guidelines below.

Remove the vent filler plug and level plug (where applicable) at horizontal shaft centerline. Fill drive with AGMA 5EP oil (CitGO

Permagear, Amoco Permagear EP20, or equivalent) until lubricant flows out the level plug hole. Other lubricants may be applied with

application testing and the customer assuming the associated risk. Drives that are not supplied with oil level plug should be filled with

the specified quantity of recommended lubricant.

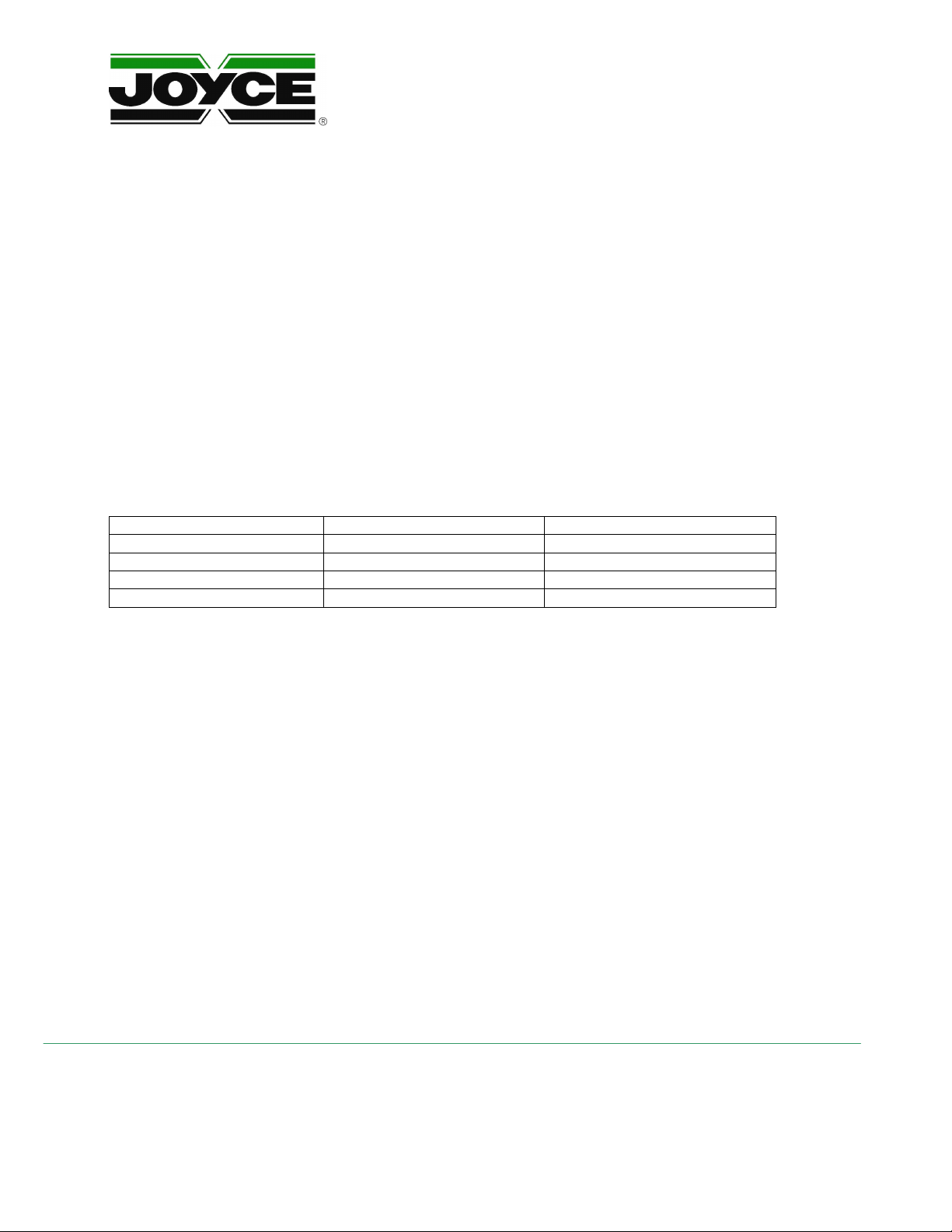

Miter Box Lubricant Quantity

RC-15 EP-90 gear oil 6 oz.

RC-18 EP-90 gear oil 16 oz. (1 pint)

RC-38 EP-90 gear oil 24 oz (1 ½ pints)

RC-99 EP-90 gear oil 72 oz. (4 ½ pints)

Re-lubrication:

Service life and efficiency of gears and bearings will be affected by oxidation or contamination of the lubrication oil. Improved

performance will be obtained by periodic re-lubrication in accordance with the following recommendations:

1. After an initial operation period of approximately 500 hours, or three months, the housing should be completely drained, preferably

while warm. Refill housing to proper level with new lubricant.

2. Under normal conditions, the drive should be re-lubricated at 6-month intervals. Note, if the unit has a grease zerk, it should be regreased at these times in addition to more frequent intervals.

Caution:

Re-lubricate more frequently if the unit is operated in abnormally high ambient temperatures or in an unusually contaminated

atmosphere. Note for slow speed operation, check the condition of the lubricant whenever other fluids in other system components are

checked.

Maintenance:

Backlash, endplay, and seals should be checked every time the unit is re-lubricated. Contact Joyce/Dayton for factory replacement

components.

Operating Temperatures:

During initial break in period, the operating temperature of the unit should not exceed 250 degrees F. After break in period, the normal

operating temperature should not exceed 220 degrees

JOYCE/DAYTON CORP.

P.O. Box 1630

Dayton, OH 45401-1630

Phone: ((937) 294-6261

Toll Free: (800) 523-5204

Designers and Builders of Screw Jacks and Actuators

Since 1873

www.joycedayton.com

FB0301 10/2012

Loading...

Loading...