Joyce CDB3230 User Manual

Joyce/Dayton Corp

.

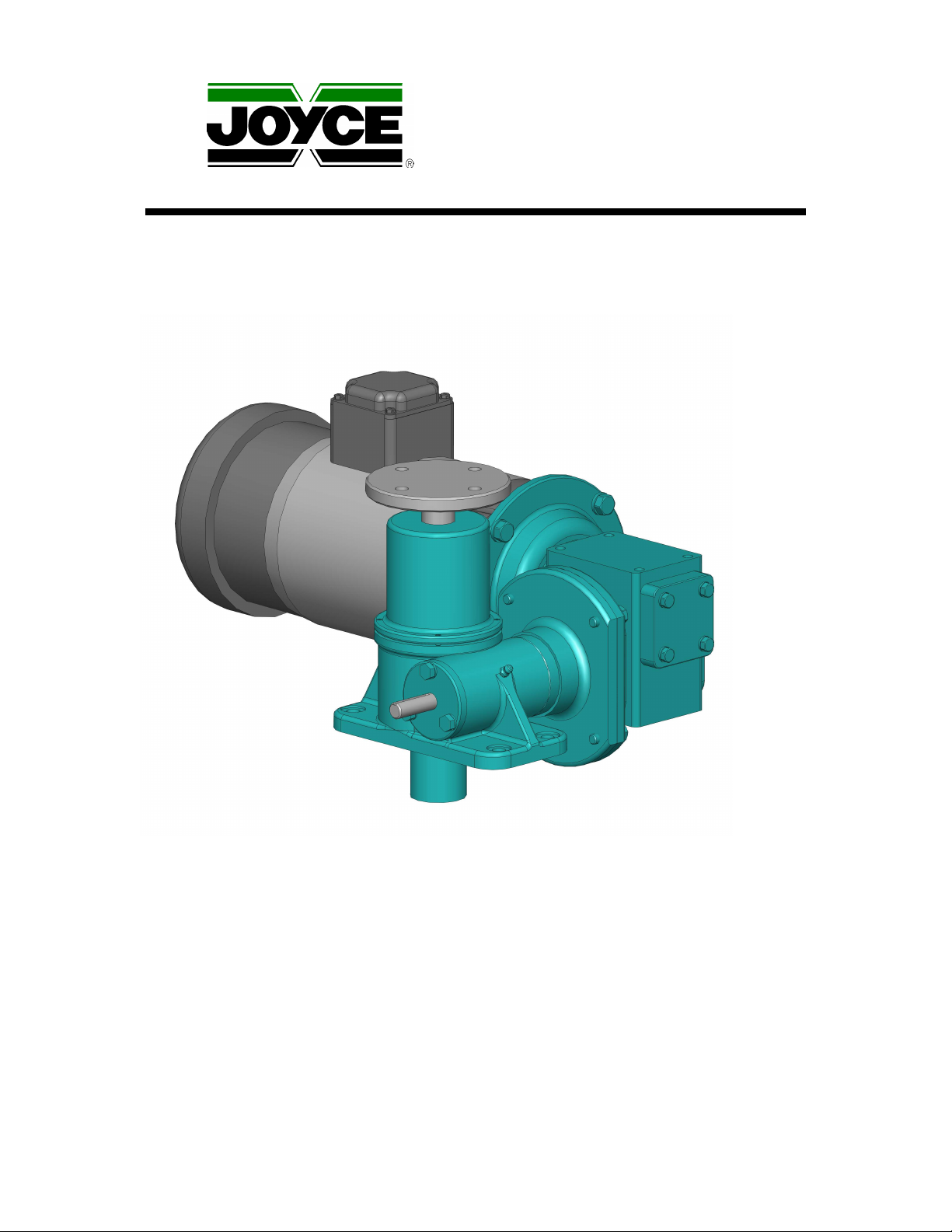

Operation and Maintenance Manual for Joyce/Dayton

Ball Screw ComDRIVE® Actuators

The recommendations in this manual for installation, operation and maintenance must be followed to ensure safe

use. All persons responsible for the installation and use of Joyce ball screw ComDRIVE® actuators must be familiar

with the contents of this manual.

The customer is responsible for travel stops, guards and other protective devices and ensuring that ComDRIVE®

usage conforms with local and national operating and safety codes appropriate to the class of equipment into which

the Ball Screw ComDRIVE® is installed. Series CDB, CDBL, CDHB, and CDHBL ComDRIVEs® are not selflocking. A brake motor or other external locking device must be provided.

Adjustable extending stop collars are included on standard ComDRIVE® actuators. The customer is responsible for

providing travel limits.

©2011 Joyce/Dayton Corp. All rights reserved FB0196-8/11

Table of Contents

Section I – General Information

1-1 Contact Joyce Dayton Corp...................................................................................................2

1-2 Purpose and Scope.................................................................................................................2

1-3 Receipt of Product...................................................................................................................2

1-4 Warranty....................................................................................................................................2

1-5 Precautions of Use and Installation......................................................................................3

1-6 General Installation Instructions...........................................................................................3

Section II – Maintenance

2-1 Lubrication................................................................................................................................4

2-2 Repair Parts...............................................................................................................................5

2-3 Disassembly of ComDRIVE® jacks.......................................................................................6

2-4 Inspection of Components.....................................................................................................7

2-5 Assembly of ComD Assembly of ComDRIVE® jacks .......................................................8

2-6 Ball Nut disassembly and rebuild .........................................................................................8

Section III – Views &Parts list

3-1 Exploded View ...........................................................................................................................9

3-2 Parts List forTranslating & KFTN ComDRIVEs® .................................................................10

3-3 Maintenance Log and Serial Number.....................................................................................11

Section I

General Information

1-1

Contact Joyce Dayton Corp.

Joyce Dayton Corp.

P.O. Box 1630

Dayton, OH 45401

(800) 523-5204 (US and Canada)

(937) 294-6261 (937) 297-7173 Fax

Email: sales@joycedayton.com

Website: www.joycedayton.com

1-2

Purpose and Scope

This manual provides installation, operation and maintenance instruction for standard

Joyce/Dayton ball screw ComDRIVE® actuators. Although this manual covers the

standard ball screw ComDRIVE® and most variations of the ball screw ComDRIVE®, there

may be some that vary significantly from this manual. For special units not covered please

contact Joyce/Dayton Corp. for assistance.

1-3

Receipt of Product

All equipment should be immediately inspected upon receipt for any damage and to verify

correct product and quantities. Any problems should be reported to Joyce/Dayton Corp.

and the freight carrier as soon as possible. Products returned without a Return Goods

Authorization (RGA) form will not be accepted.

1-4

Warranty

Seller warrants its products to be free from defects in material and workmanship under

normal and proper use in accordance with instruction of seller for a period of one year

from the date of shipment to buyer. Seller's liability under such warranty or in connection

with any other claim relating to the products shall be limited to the repair, or at seller’s

2

option, the replacement or refund of the purchase price, of any products or parts or

components thereof which are returned to seller freight prepaid and which are defective in

material or workmanship. Products or parts or components thereof, which are repaired or

replaced by seller, will be returned to buyer freight collect. This warranty is not intended to

cover consumer products, as defined in the Magnuson-Moss Warranty-Federal Trade

Commission Improvement Act, 15 U. S. C. Sections 2301-12, which are purchased by

buyer for purposes other than resale. If buyer is not intending to resell the products, and if

the products are consumer products as defined in the Magnuson-Moss Act, the foregoing

warranty, but not the limitation of seller's liability, shall be null and void. EXCEPT AS

EXPRESSLY STATED ABOVE, SELLER MAKES NO WARRANTY, EXPRESS OR

IMPLIED, WHETHER OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE OR USE OR OTHERWISE, ON THE PRODUCTS, OR ON ANY PARTS OR

LABOR FURNISHED DURING THE SALE, DELIVERY OR SERVICING OF THE

PRODUCTS.

1-5

Precautions of Use and Installation

1. Side loading of the lifting screw is not permitted in the dynamic operation of the jack.

A limited side load is allowable in the static condition. Contact Joyce/Dayton for the

allowable side load for a specific application.

2. Extending mechanical stops are provided on the actuator lifting screw. It is the

customer’s responsibility to provide travel limit devices on all ball screw

ComDRIVEs®. The mechanical stop is only an auxiliary device to limit the travel of the

lifting screw. Engaging a mechanical stop during operation can cause damage to the

internal jack mechanism.

3. In most applications, factory or manufacturer-assisted installation is not required.

However, it is necessary that appropriate, qualified personnel perform the installation

of Joyce/Dayton products.

4. Joyce/Dayton ball screw ComDRIVE® actuators are not rated for shock-loading,

extreme vibration or critical speed conditions (high speed or long-length screw.) It is

the responsibility of the user to ensure these conditions are not imposed on the

actuator or the power transmission equipment. Contact Joyce/Dayton for technical

assistance.

5. In the event that service or maintenance is required, the load must be secured or

removed before any work can begin.

6. Ball screw ComDRIVE® actuators can be mounted and operated in any orientation.

When used with the lifting screw in a horizontal position, the worm should be mounted

parallel with the horizon and below the gear to ensure proper lubrication. Standard ball

screw ComDRIVE® actuators are shipped with all holes plugged. The user must insert

the vent in the highest location at final installation.

7. Never allow the actuator to retract beyond the minimum closed position, as damage to

the jack can occur.

8. Boots or protective bellows covers should be used to protect and keep the lifting

screw clean in dusty or abrasive environments.

9. For continuous or high-duty cycles inquire with your local sales representative or

consult Joyce/Dayton Corp. regarding Bevel Ball actuators.

1-6

General Installation instructions

1. Ensure that all personnel who will service or operate equipment are familiar with its

use and limitations.

2. Secure or remove the load before any installation procedures begin.

3. Be certain the rating of the ball screw ComDRIVE® meets or exceeds the load.

4. Ball screw ComDRIVEs® must be mounted on a structure sufficient to support the

maximum possible load. The structure must be rigid. An under-designed structure

could lead to bending of the lifting screw causing premature wear or failure.

5. In a system with shafts, miter boxes, etc., confirm that the shafts and actuators

operate without binding or excessive force before powered drive devices are engaged.

3

Drive shaft alignment is critical. Mis-alignment will cause reversing stresses in rotating

members and will lead to fatigue failure. Correct coupling specification is important.

6. When fastening the load to a ball screw actuator, make sure the actuator is in the

retracted position. This positions the load accurately with respect to the lifting screw

centerline. Never pull the screw to one side to make connection with your structure.

Fully extend the actuator to make sure the load is aligned with the lifting screw.

7. All ball screw ComDRIVE® actuators are designed to be mounted with S.A.E. Grade 8

bolts or equivalent.

8. Torque all mounting bolts in a symmetric pattern to avoid damage to the sleeve.

9. Shaft and coupling guards are the responsibility of the user.

10. Optional limit switches furnished with the actuator are NOT preset and require field

adjustment before use.

Section II

Maintenance

2-1

Lubrication

Jacks

1. Ball screw ComDRIVE® actuators are lubricated before leaving the factory.

2. For normal operation, jacks should be greased at least once per month. Under

extended use, grease twice monthly or as conditions dictate. Grease thru the fittings

on the jack with hand or power operated equipment. Grease with No. 1 Consistency

Grease. Do not allow jacks to operate without lubrication. It is the responsibility of the

user to maintain sufficient lubrication of the jack and to the lifting screw.

3. The products listed below are recommended by the lubricant manufacturers to meet

the requirements for normal operation. The listing of brand names is solely for the

convenience of users of Joyce equipment and their lubricant suppliers; it does not

constitute any endorsement. Joyce/Dayton assumes no responsibilities for the quality,

performance or availability of any listed products

COMPANY BRAND NAME

Mobil Grease…………………….XHP 461

Mobil Grease…………………….XHP 221

Mobilith……………….…………..SHC221

Mobilith……………………………SHC 460

4. For operation above 250° F or extreme loading, consult the Engineering Department of

Joyce/Dayton Corp.

5. Ball screw and ball nut (on KFTN models) should be lubricated with a spindle or 10weight oil applied to the ball screw.

6. Do not operate jack without lubrication.

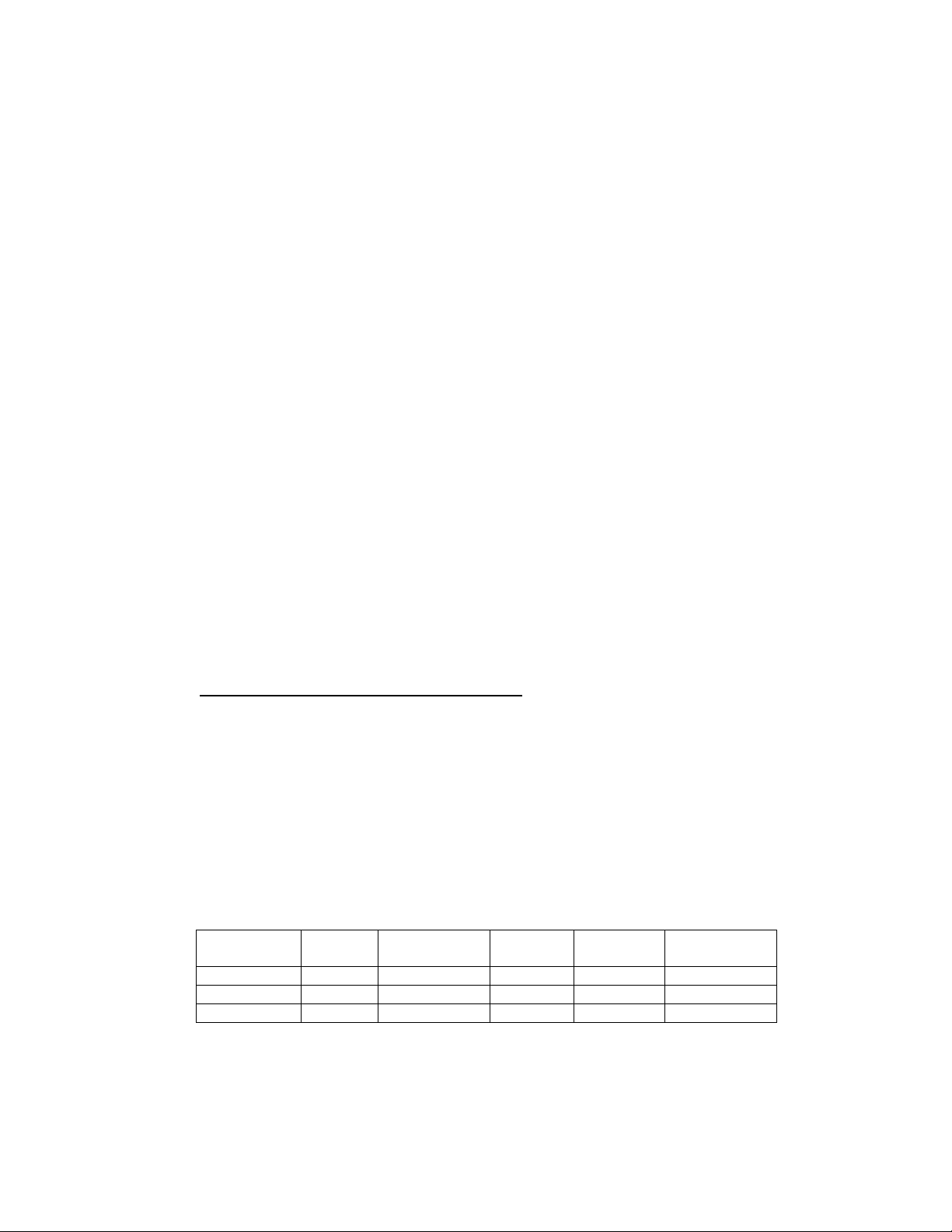

7. Total grease capacity by jack type:

Jack

Capacity

2 ton 13 4.5 oz 20 ton 95 33 oz.

5 ton 26 9 oz. 30 ton 135 47 oz.

10 ton 50 17 oz

Number

of Shots

Approximate

Weight

Jack

Capacity

Number

of Shots

Approximate

Weight

4

Loading...

Loading...