Page 1

EN (2-18)

IT (19-35)

GR (36-53)

SI (54-70)

PA 1100

Operator ′ s manual

Istruzioni per l’uso

√‰ËÁ›Â˜ ¯Ú‹Ûˆ˜

Navodila za uporabo

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Prima di usare la macchina, leggere per intero le istruzioni per l’uso e accertarsi di averne compreso il contenuto.

¢И·Я¿ЫЩВ ЪФЫВОЩИО¿ ЩИ˜ √‰ЛБ›В˜ ¯Ъ‹ЫВˆ˜ О·И О·Щ·УФ‹ЫЩВ ЩФ ВЪИВ¯fiМВУФ ЪИУ ¯ЪЛЫИМФФИ‹ЫВЩВ ЩФ МЛ¯¿УЛМ·.

Natanãno preberite navodila za uporabo in se prepriãajte, da ste jih razumeli, predno zaãnete z uporabo stroja.

Page 2

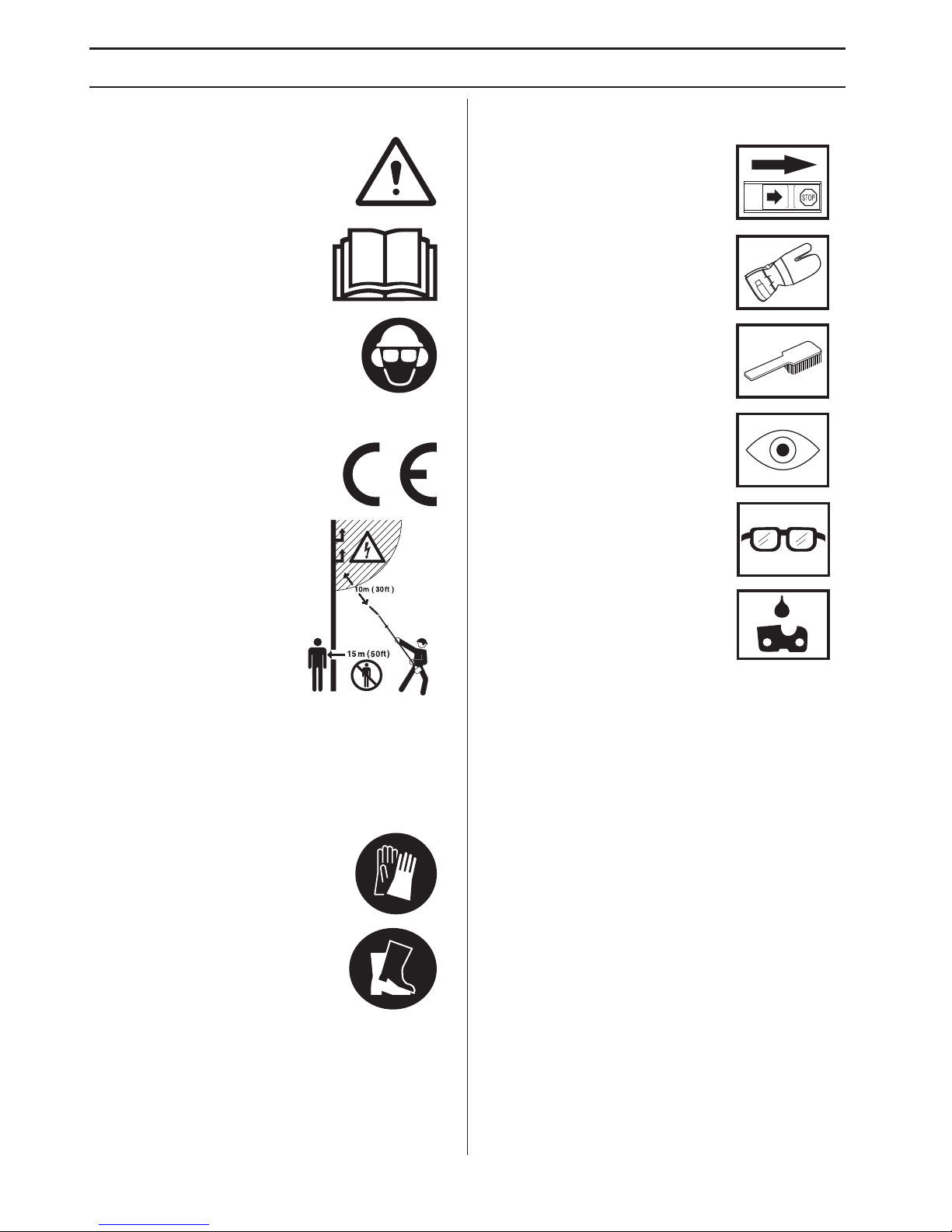

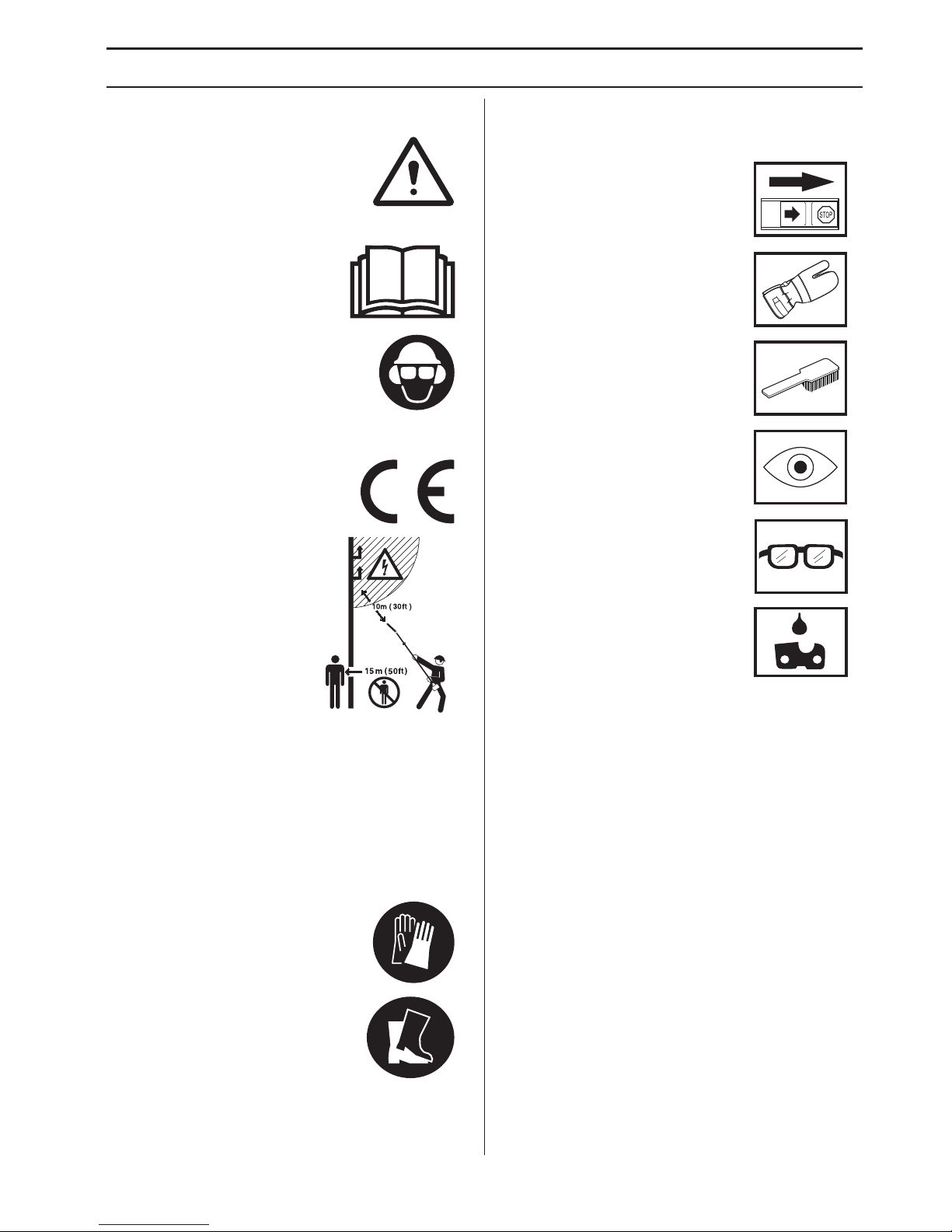

KEY T O SYMBOLS

2

– English

Symbols

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

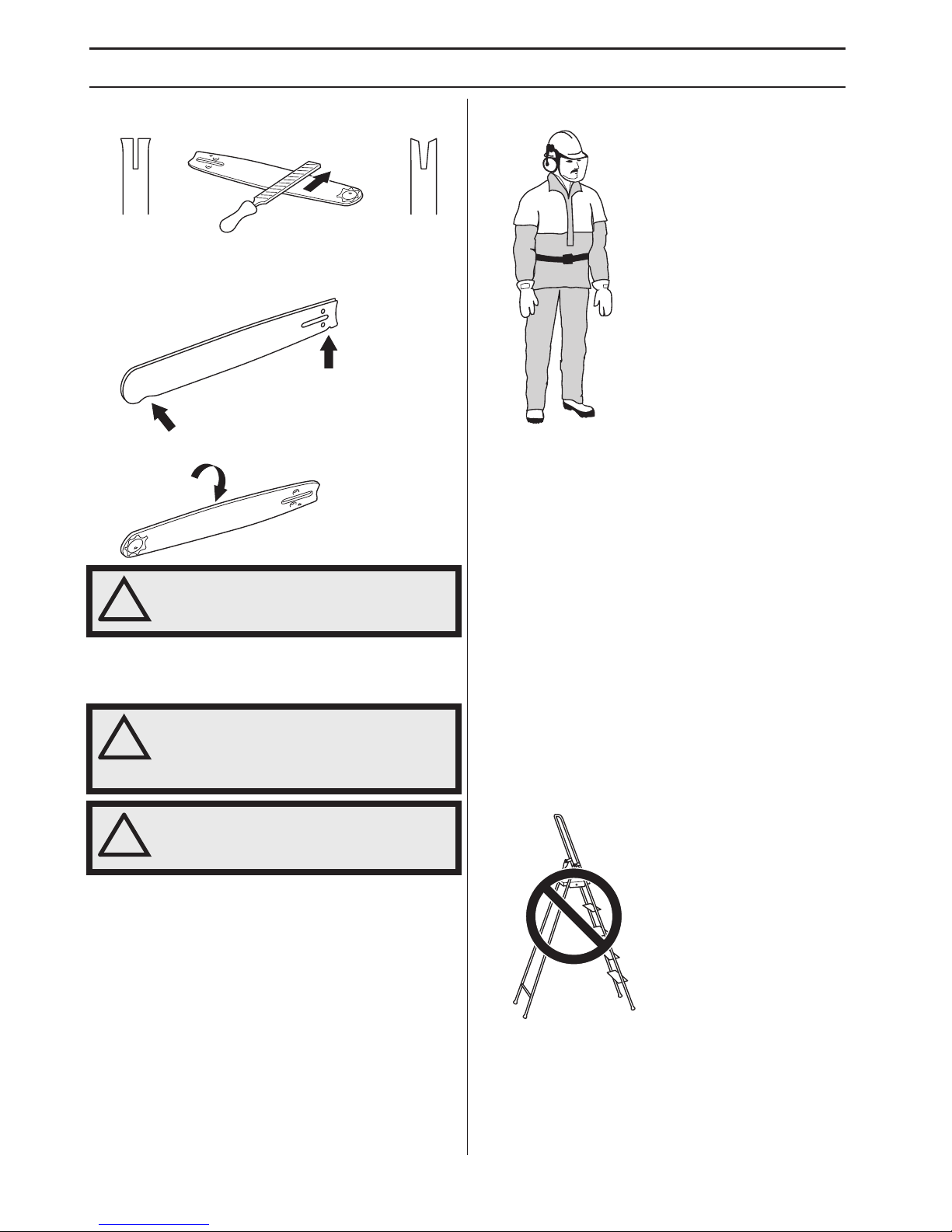

Always wear:

• A protective helmet where there is a

risk of falling objects

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with

applicable EC directives.

This machine is not electrically

insulated. If the machine

touches or comes close to highvoltage power lines it could lead

to death or serious bodily injury.

Electricity can jump from one

point to another by arcing. The

higher the voltage, the greater

the distance electricity can

jump. Electricity can also travel

through branches and other

objects, especially if they are wet. Always keep a distance

of at least 10 m between the machine and high-voltage

power lines and/or any objects that are touching them. If

have to work within this safe distance you should always

contact the relevant power company to make sure the

power is switched off before you start work.

Always wear approved protective

gloves.

Wear sturdy, non-slip boots.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

Switch off the engine by moving the

stop switch to the STOP position

before carrying out any checks or

maintenance.

Always wear approved protective

gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be

worn.

Filling with chain oil and adjusting oil

flow

Page 3

CONTENTS

English

–

3

Contents

Note the f ollowing before

starting:

Husqv arna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

Long-term exposure to noise can result in permanent

hearing impairment. So always use approved hearing

protection.

Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

These instructions supplement the instructions that were

included with the machine. For other procedures, please

refer to the operating instructions for the machine.

The machine is only designed for cutting branches and

twigs.

KEY TO SYMBOLS

Symbols ................................................................ 2

CONTENTS

Contents ............................................................... 3

Note the following before starting: ........................ 3

INTR ODUCTION

Dear Customer , .................................................... 4

WHA T IS WHAT?

What is what on the sa w attachment? .................. 5

SAFETY INSTR UCTIONS

Cutting equipment ................................................ 6

Specification of bar and saw chain ....................... 6

Sharpening your chain and adjusting raker

clearance ..............................................................

7

Tensioning the chain ............................................. 9

Lubricating cutting equipment .............................. 10

Checking wear on cutting equipment ................... 11

Safety instructions for using a pruning saw .......... 12

ASSEMBL Y

Fitting the cutting head ......................................... 15

Fitting the bar and chain ....................................... 15

Fitting the suspension ring ................................... 15

Adjusting the harness ........................................... 15

Filling with oil ........................................................ 16

Check before starting ........................................... 16

TECHNICAL D ATA

T

echnical data ...................................................... 17

Guide bar and saw chain combinations ............... 17

EC Declaration of Conformity ............................... 18

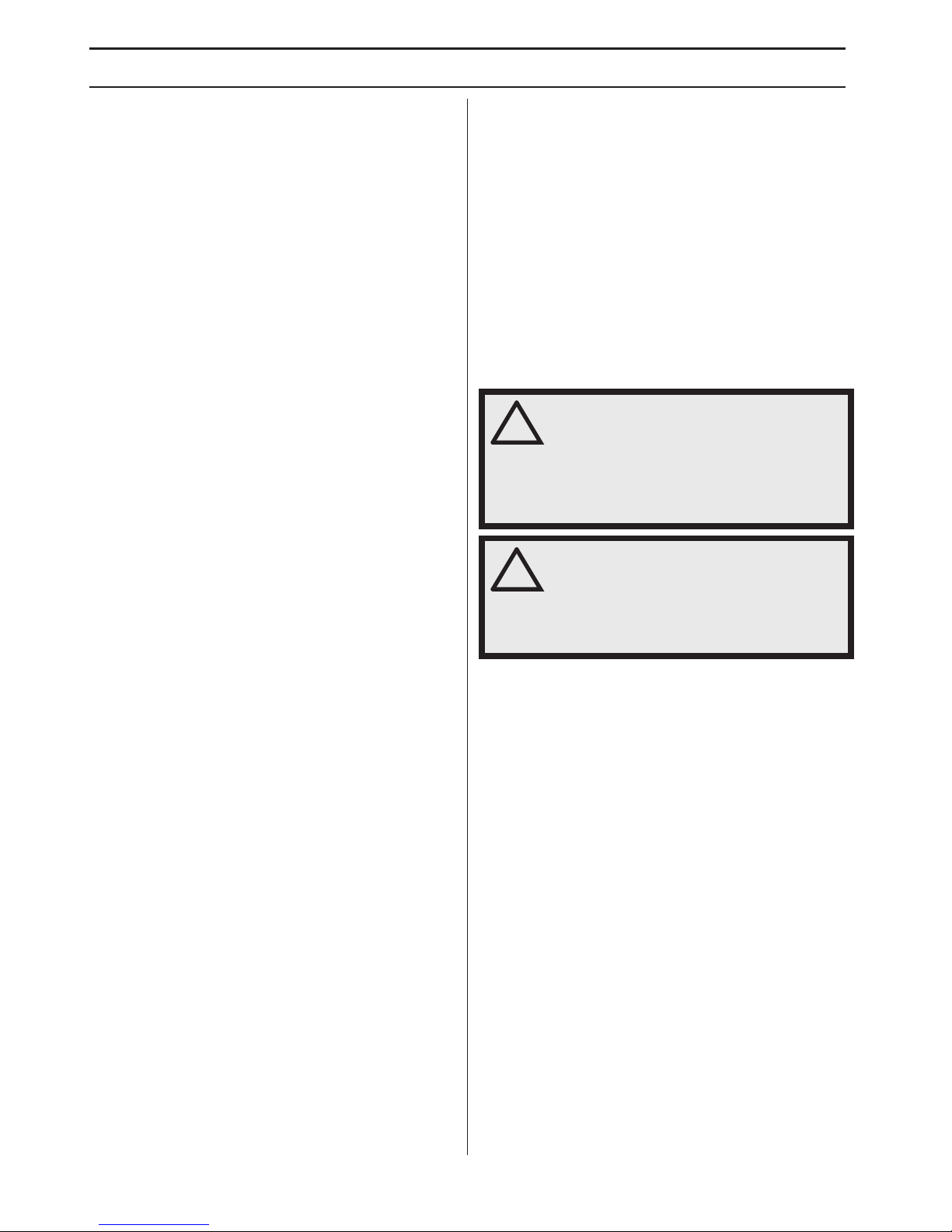

!

W

ARNING! Under no circumstances may

the design of the machine be modified

without the permission of the

manufacturer. Always use original

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

!

W

ARNING! This accessory may only be

used together with the intended brush

cutter/trimmer, see under heading

”Approved accessories” in chapter

Technical data in the machine’s

Operator’s Manual.

Page 4

4

– English

INTR ODUCTION

Dear Customer ,

Cong ratulations on your choice to buy a Jonsered product!

We are convinced that you will appreciate with great satisfaction the quality and performance of our product for a very

long time to come. The purchase of one of our products gives you access to professional help with repairs and service

whenever this may be necessary. If the retailer who sells your machine is not one of our authorised dealers, ask for the

address of your nearest service workshop.

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. Think of this

operator

′ s manual as a valuable document. By following its content (usage, service, maintenance, etc), the life span and

the second-hand value of the machine can be extended. If you sell this machine, make sure that the operator

′ s manual

is passed on to the buyer.

Good luck on using your Jonsered machine!

Jonsered has a policy of continuous product development and therefore reserves the right to modify the design and

appearance of products without prior notice.

Page 5

English – 5

WHA T IS WHA T?

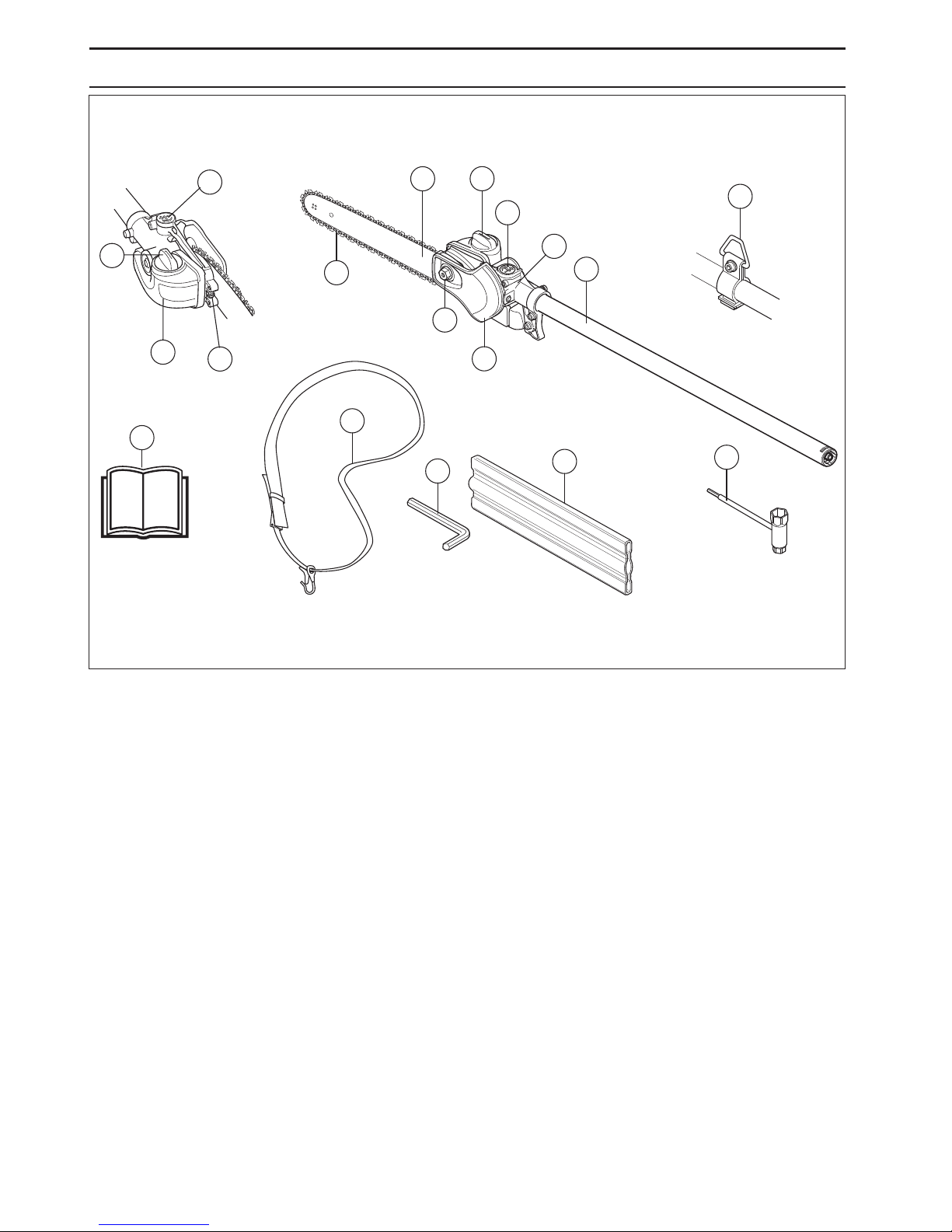

What is what on the sa w attachment? (Saw attachment with shaft PA 1100)

4

13

12

14

15

10

11

2

7

11

9

1

2

8

6

5

3

16

1

Bevel gear

2 Chain lubrication adjustment screw

3 Shaft (1100 mm)

4 Harness support hook

5 Protective guard for saw chain

6 Bar nut

7 Chain tensioning screw

8 Saw chain

9 Guide bar

10 Chain oil tank

11 Filling with chain oil

12 Operator ′ s manual

13 Transport guard

14 Combination spanner

15 Harness

16 Torx wrench

Page 6

SAFETY INSTR UCTIONS

6

– English

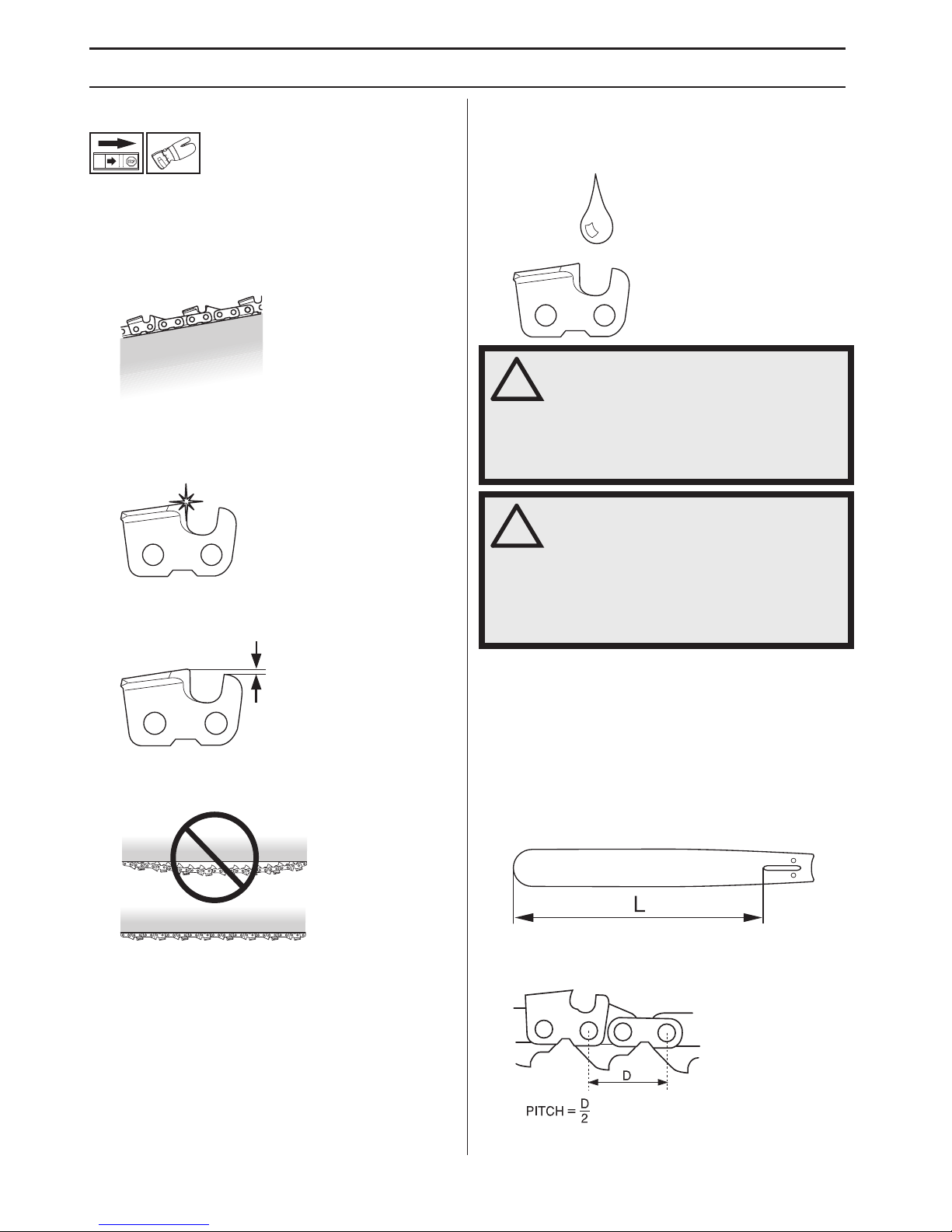

Cutting equipment

This section descr ibes how you can achieve maximum

clearing capacity and extend the life of the cutting

attachment through correct maintenance and using the

right type of cutting attachment.

Onl y use cutting equipment recommended by us!

See the Technical data section.

K

eep the chain’s cutting teeth properly sharpened!

Follow our instructions and use the recommended

file gauge.

A damaged or badly sharpened chain

increases the risk of accidents.

Maintain the correct raker c learance! Follow our

instructions and use the recommended raker gauge.

Too large a clearance increases the risk of kickback.

K

eep the chain properly tensioned! If the chain is slack

it is more likely to jump off and lead to increased wear on

the bar, chain and drive sprocket.

K

eep cutting equipment well lubricated and properly

maintained!

A poorly lubricated chain is more likely to

break and lead to increased wear on the bar, chain and

drive sprocket.

Specifi cation of bar and saw

chain

When the cutting attachment supplied with y our machine

has to be replaced, because it is worn out or damaged,

you must only fit the types of bar and saw chain

recommended by us.

Guide bar

•

Length (inches/cm)

• Chain pitch (inches). The spacing between the drive

links of the chain must match the spacing of the teeth

on the bar tip sprocket and drive sprocket.

!

W

ARNING! Never use a machine with

faulty safety equipment. The machine's

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

!

W

ARNING! Always stop the engine

before doing any work on the cutting

attachment. This continues to rotate even

after the throttle has been released.

Ensure that the cutting attachment has

stopped completely and disconnect the

spark plug cap before you start to work

on it.

Page 7

SAFETY INSTR UCTIONS

English

–

7 •

Number of drive links. The number of drive links is

determined by the length of the bar, the chain pitch

and the number of teeth on the bar tip sprocket.

• Bar groove width (inches/mm). The groove in the bar

must match the width of the chain drive links.

• Saw chain oil hole and hole for chain tensioner pin.

Sa

w chain

•

Saw chain pitch (inches). (The distance between

three drive links, divided by two.)

• Drive link width (mm/inches)

• Number of drive links.

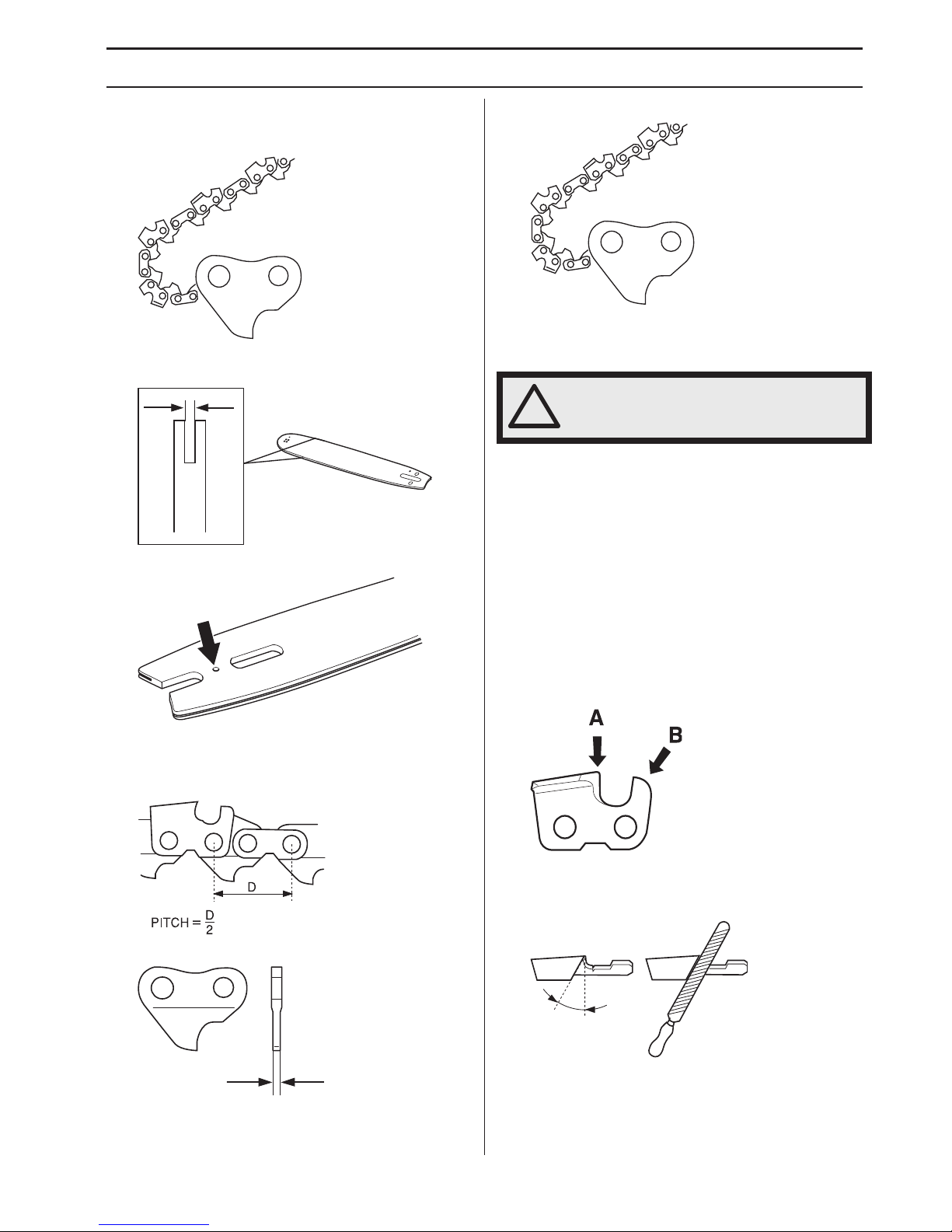

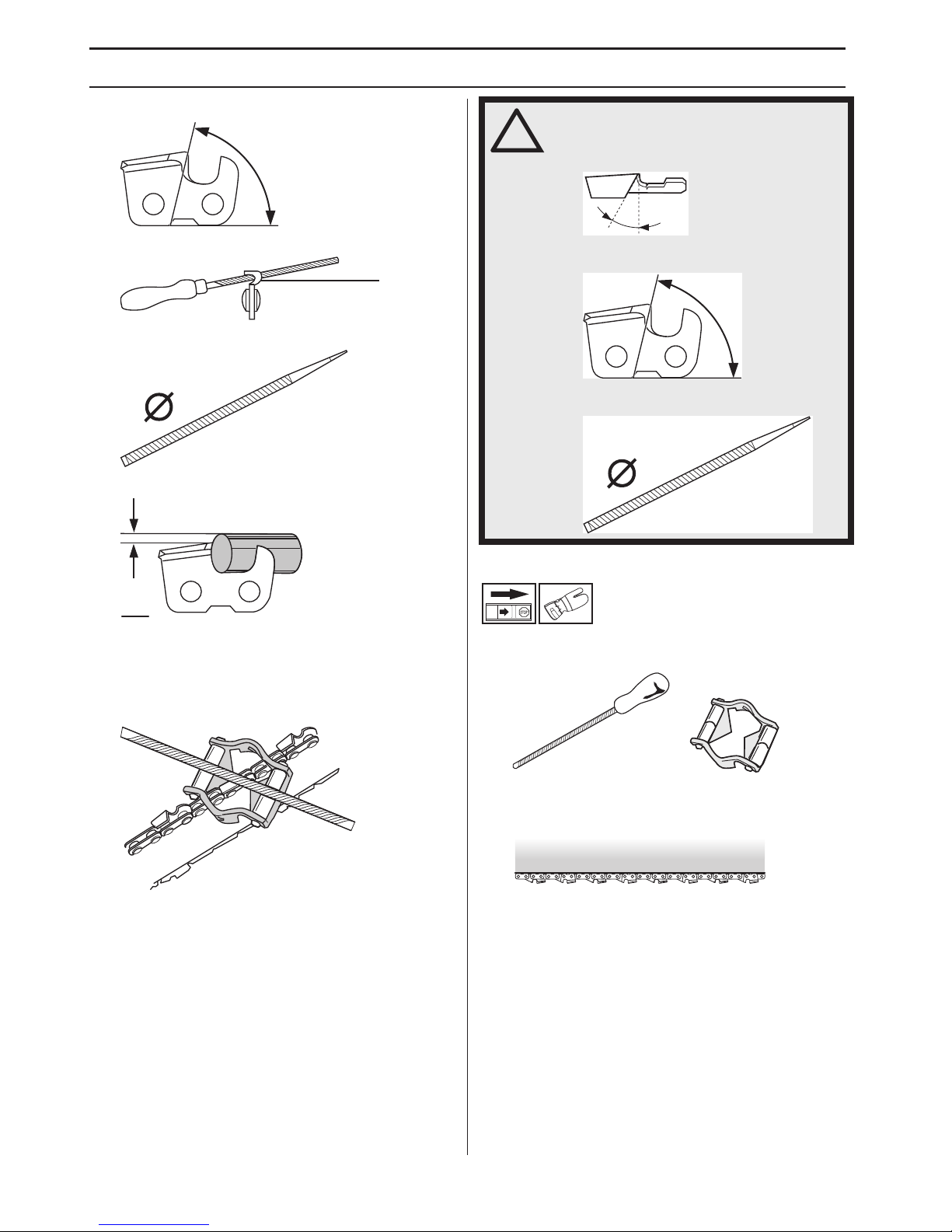

Sharpening y our chain and

adjusting raker clearance

General inf ormation on sharpening

cutting teeth

•

Never use a blunt chain. When the chain is blunt you

have to exert more pressure to force the bar through

the wood and the cuttings will be very small. If the

chain is very blunt it will not produce any cuttings at all.

Wood powder would be the only result.

• A sharp chain eats its way through the wood and

produces long, thick cuttings. The cutting part of the

chain is called the cutting link and this consists of a

cutting tooth (A) and the raker lip (B). The cutting

depth is determined by the difference in height

between the two.

• When you sharpen a cutting tooth there are five

important factors to remember.

1 Filing angle

!

W

ARNING! The risk of kickback is

increased with a badly sharpened chain!

Page 8

SAFETY INSTR UCTIONS

8

– English

2

Cutting angle

3 File position

4 Round file diameter

5 File depth

It is very difficult to sharpen a chain correctly without the

right equipment. We recommend that you use our file

gauge. This will help you obtain the maximum kickback

reduction and cutting performance from your chain.

Sharpening cutting teeth

•

To sharpen cutting teeth you will need a round file and

a file gauge.

• Check that the chain is correctly tensioned. A slack

chain will move sideways, making it more difficult to

sharpen correctly.

1

5

!

W

ARNING! The following faults will

increase the risk of kickback

considerably: File angle too large

Cutting angle too small

File diameter too small

Page 9

SAFETY INSTR UCTIONS

English – 9

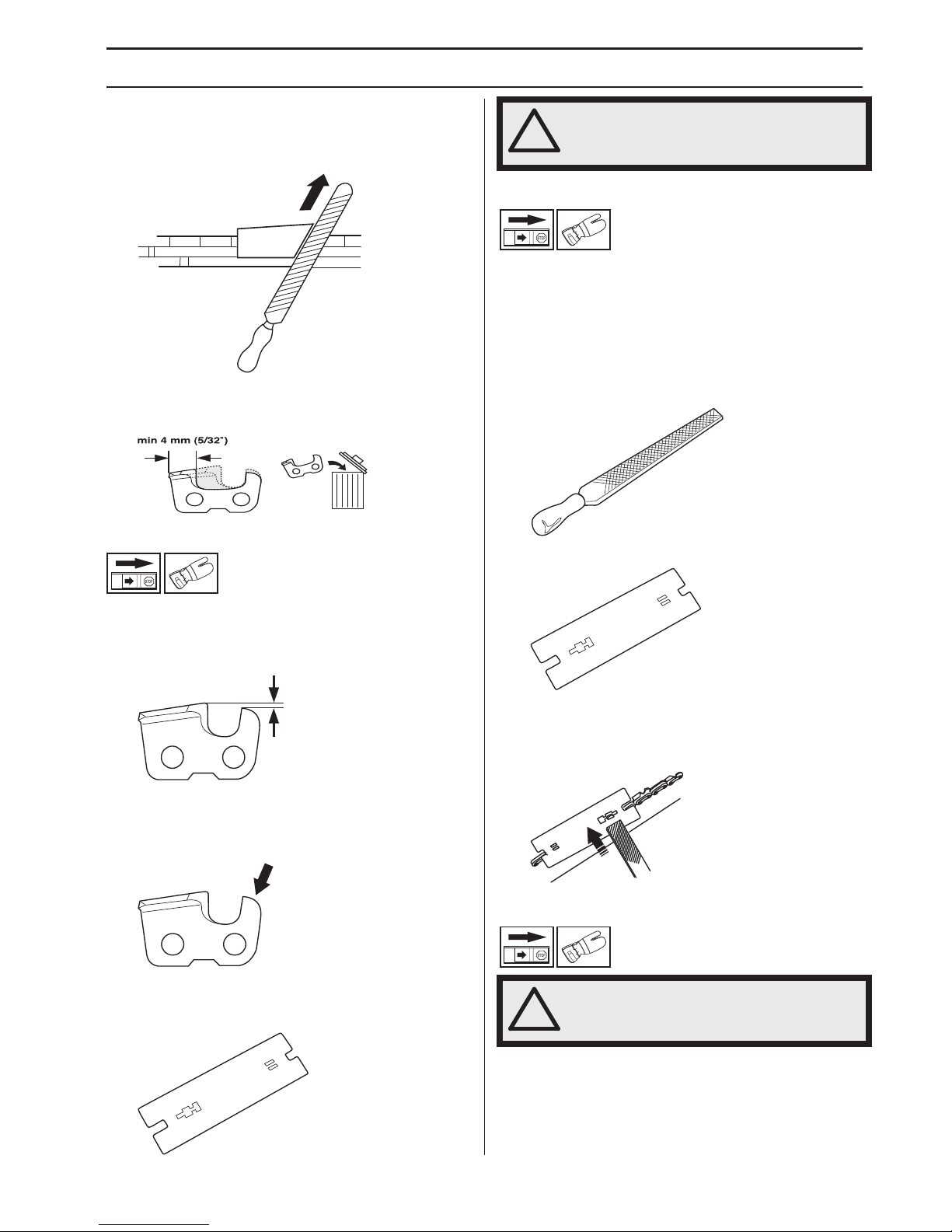

• Always file cutting teeth from the inside face outwards.

Reduce the pressure on the return stroke. File all the

teeth on one side of the bar first. Then turn the saw

over and file the remaining teeth from the other side.

• File all the teeth to the same length. When the length

of the cutting teeth is reduced to 4 mm (5/32") the

chain is worn out and should be replaced.

General advice on setting raker clearance

• When you sharpen the cutting teeth you reduce the

raker clearance (=cutting depth). To maintain optimal

cutting performance you must file back the raker lip to

the recommended height.

• On a low-kickback cutting link the front edge of the

raker lip is rounded. It is very important that you

maintain this radius or bevel when you adjust the raker

clearance.

• We recommend that you use our raker gauge to

achieve the correct clearance and bevel on the raker

lip.

Setting the raker clearance

• Before setting the raker clearance the cutting teeth

should be newly sharpened. We recommend that you

adjust the raker clearance every third time you

sharpen the chain. NOTE! This recommendation

assumes that the length of the cutting teeth is not

reduced excessively.

• To adjust the raker clearance you will need a flat file

and a raker gauge.

• Place the gauge over the raker lip.

• Place the file over the part of the lip that protrudes

through the gauge and file off the excess. The

clearance is correct when you no longer feel any

resistance as you draw the file over the gauge.

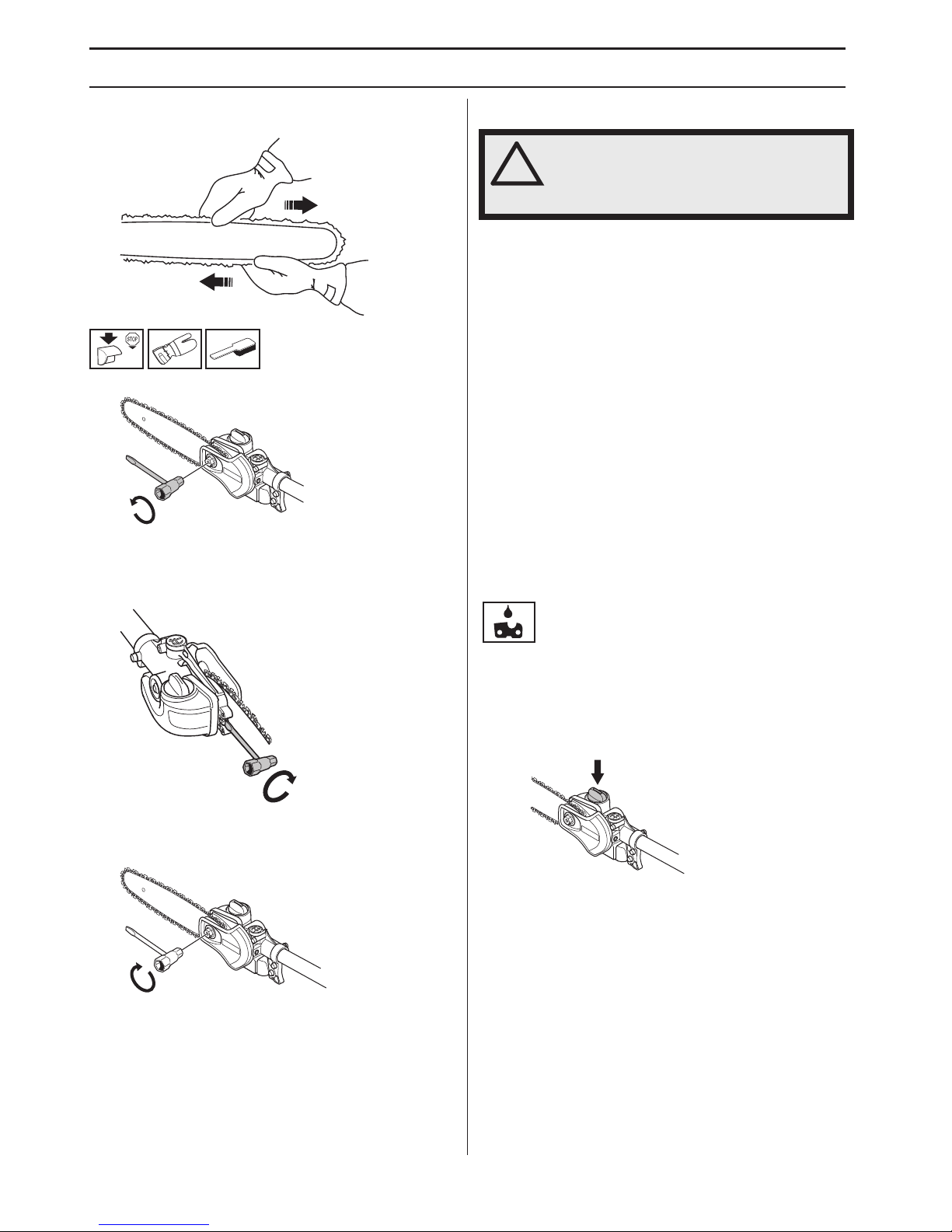

Tensioning the chain

• The more you use a chain the longer it becomes. It is

therefore important to adjust the chain regularly to

take up the slack.

• Check the chain tension every time you refuel. NOTE!

A new chain has a running-in period during which you

should check the tension more frequently.

!

WARNING! The risk of kickback is

increased if the raker clearance is too

large!

!

WARNING! A slack chain may jump off

and cause serious or even fatal injury.

Page 10

SAFETY INSTRUCTIONS

10 – English

• Tension the chain as tightly as possible, but not so

tight that you cannot pull it round freely by hand.

1 Undo the bar nut.

2 Raise the tip of the bar and stretch the chain by

tightening the chain tensioning screw using the

combination spanner. Tighten the chain until it does

not sag from the underside of the bar.

3 Use the combination spanner to tighten the blade nut

while holding up the tip of the bar. Check that you can

pull the saw chain round freely by hand.

Lubricating cutting equipment

Chain oil

• Chain oil must demonstrate good adhesion to the

chain and also maintain its flow characteristics

regardless of whether it is warm summer or cold

winter weather.

• As a chain saw manufacturer we have developed an

optimal chain oil which, with its vegetable oil base, is

also biodegradable. We recommend the use of our

own oil for both maximum chain life and to minimise

environmental damage.

• If our own chain oil is not available, standard chain oil

is recommended.

• In areas where oil specifically for lubrication of saw

chains is unavailable, ordinary EP 90 transmission oil

may be used.

• Never use waste oil! This is dangerous for yourself,

the machine and the environment.

Filling with chain oil

The oil pump is preset at the factory to meet most

lubrication requirements. A full oil tank will last about half

as long as a full tank of fuel. You should therefore check

the level of oil in the oil tank regularly to avoid damage to

the saw chain and bar that could occur due to lack of

lubrication.

!

WARNING! Poor lubrication of cutting

equipment may cause the chain to snap,

which could lead to serious, even fatal

injuries.

Page 11

SAFETY INSTRUCTIONS

English – 11

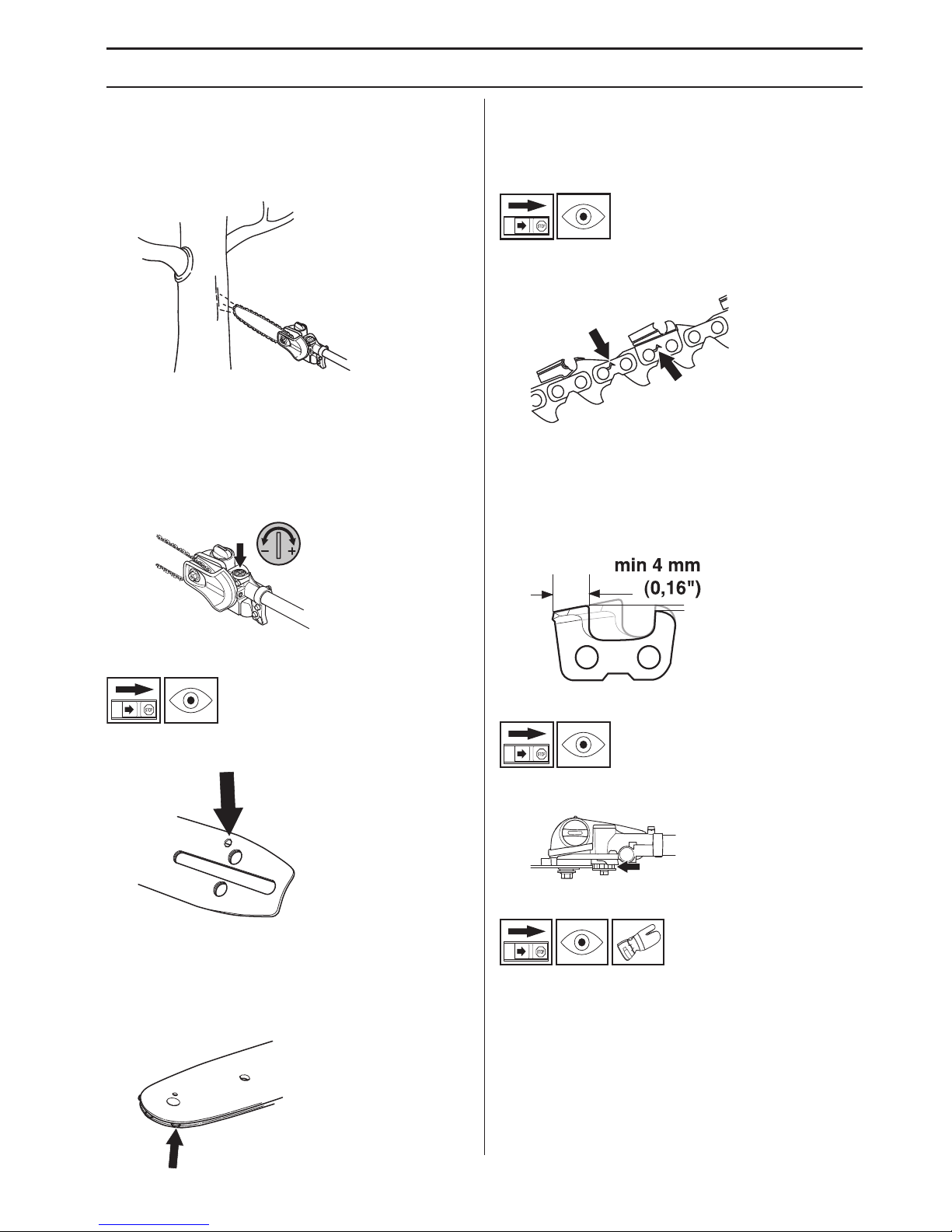

Checking chain lubrication

Check the chain lubrication each time you refuel. Aim the

tip of the bar at a light coloured surface about 20 cm (8

inches) away. After 1 minute running at 3/4 throttle you

should see a distinct line of oil on the light surface.

Adjusting chain lubrication

When cutting dry or hard species of wood it may be

necessary to increase lubrication. Turn the adjuster screw

anticlockwise to increase the oil flow. Remember that this

will increase oil consumption, check the level in the oil

tank regularly. Turn the adjuster screw clockwise to

decrease the oil flow.

What to do if lubrication does not work:

1 Check that the oil channel in the bar is not obstructed.

Clean if necessary.

2 Check that the oil channel in the gear housing is

clean. Clean if necessary.

3 Check that the bar tip sprocket turns freely. If the chain

lubrication system is still not working after carrying out

the above checks you should contact your service

workshop.

Checking wear on cutting

equipment

Saw chain

Check the chain daily for:

• Visible cracks in rivets and links.

• Whether the chain is stiff.

• Whether rivets and links are badly worn.

We recommend you compare the existing chain with a

new chain to decide how badly the existing chain is worn.

When the length of the cutting teeth has worn down to

only 4 mm the chain must be replaced.

Chain drive sprocket

Regularly check the degree of wear on the drive sprocket.

Replace if wear is excessive.

Guide bar

Check regularly:

• Whether there are burrs on the edges of the bar.

Remove these with a file if necessary.

Page 12

SAFETY INSTRUCTIONS

12 – English

• Whether the groove in the bar has become badly

worn. Replace the bar if necessary.

• Whether the tip of the bar is uneven or badly worn. If

a hollow forms on the underside of the bar tip this is

due to running with a slack chain.

To prolong the life of the bar you should turn it over daily.

Safety instructions for using a

pruning saw

CAUTION! Please read the operator’s manual carefully

and make sure you understand the instructions before

using the machine.

Personal protection

• Always wear boots and other equipment described

under the heading Personal protective equipment in

the machine’s Operator’s Manual.

• Always wear working clothes and heavy-duty long

trousers.

• Never wear loose clothing or jewellery.

• Make sure your hair does not hang below shoulder

level.

Safety instructions regarding the

surroundings

• Never allow children to use the machine.

• Ensure that no-one comes closer than 15 metres

while you are working.

• Never allow anyone else to use the machine without

first ensuring that they have read and understood the

contents of the operator’s manual.

• Never work from a ladder, stool or any other raised

position that is not fully secured.

!

WARNING! A faulty cutting attachment

may increase the risk of accidents.

!

WARNING! The machine can cause

serious personal injury. Read the safety

instructions carefully. Learn how to use

the machine.

!

WARNING! Cutting tool. Do not touch the

tool without first switching off the

engine.

Page 13

SAFETY INSTRUCTIONS

English – 13

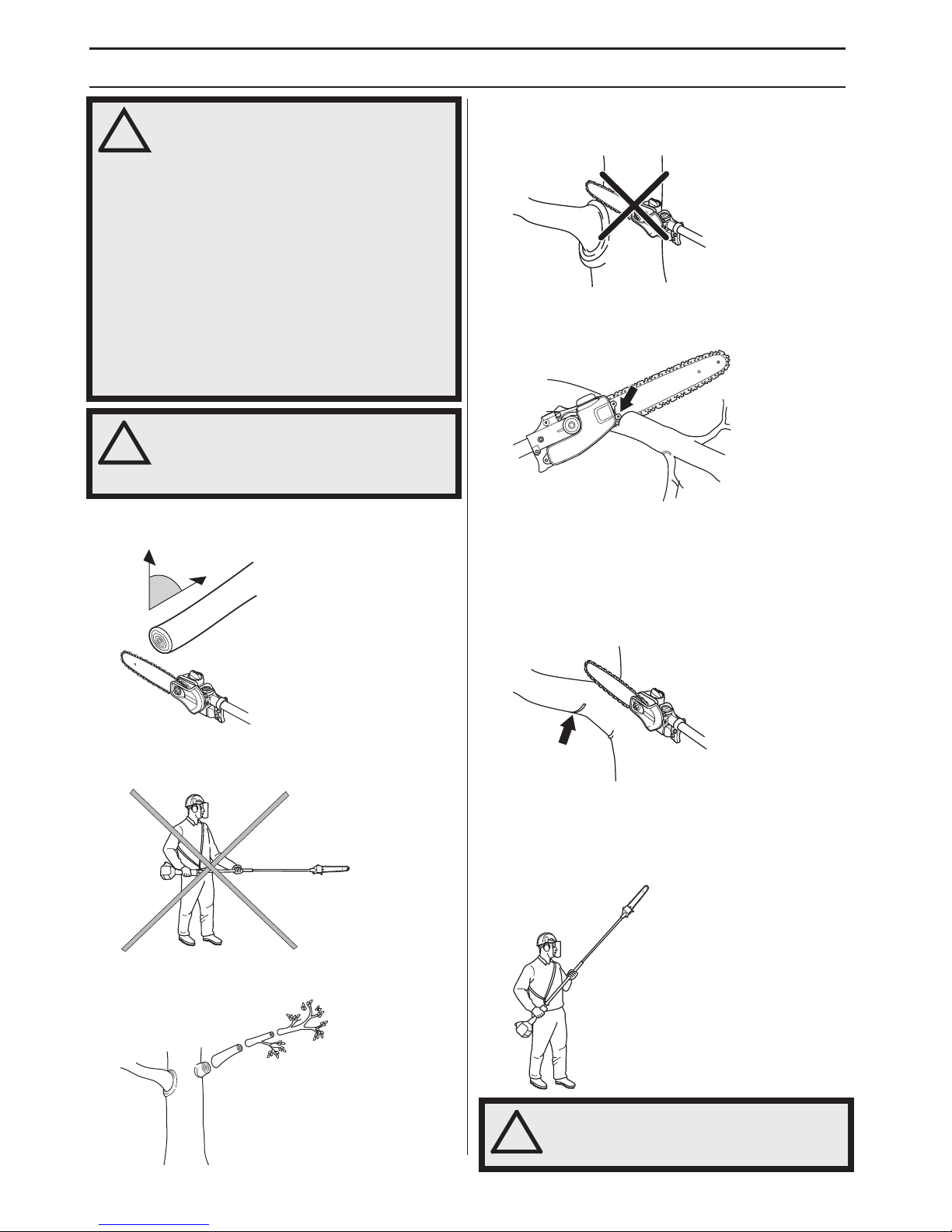

Safety instructions while working

• Always ensure you have a safe and stable working

position.

• Always use both hands to hold the machine. Hold the

machine at the side of your body.

• Use your right hand to control the throttle setting.

• Make sure that your hands and feet do not come near

the cutting attachment when the engine is running.

• When the engine is switched off, keep your hands and

feet away from the cutting attachment until it has

stopped completely.

• Watch out for stumps of branches that can be thrown

out during cutting.

• Always lay the machine on the ground when you are

not using it.

• Check the working area for foreign objects such as

electricity cables, insects and animals, etc, or other

objects that could damage the cutting attachment,

such as metal items.

• If any foreign object is hit or if vibrations occur stop the

machine immediately. Disconnect the HT lead from

the spark plug. Check that the machine is not

damaged. Repair any damage.

• If anything gets caught up in the cutting attachment

while you are working, switch off the engine and let it

stop completely before cleaning the cutting

attachment.

Safety instructions after completing work

• The transport guard should always be fitted to the

cutting attachment when the machine is not in use.

• Make sure the cutting attachment has stopped before

cleaning, carrying out repairs or an inspection.

Disconnect the spark plug cap from the spark plug.

• Always wear heavy-duty gloves when repairing the

cutting attachment. This is extremely sharp and can

easily cause cuts.

• Store the machine out of reach of children.

• Use only original spare parts for repairs.

Basic working techniques

• Hold the machine as close to your body as possible to

get the best balance.

• Make sure that the tip does not touch the ground.

• Do not rush the work, but work steadily until all the

branches have been cut back cleanly.

• Always slow the engine to idle speed after each

working operation. Long periods at full throttle without

any load on the engine can lead to serious engine

damage.

• Always work at full throttle.

Observe great care when working close to overhead

power lines. Falling branches can result in short-circuiting.

!

WARNING! Never stand directly

underneath a branch that is being cut.

This could lead to serious or even fatal

personal injury.

!

WARNING! Observe the applicable safety

regulations for work in the vicinity of

overhead power lines.

Page 14

SAFETY INSTRUCTIONS

14 – English

• Whenever possible position yourself so that you can

make the cut at right angles to the branch.

• Do not work with the shaft held straight out in front of

you (like a fishing rod) as this increases the apparent

weight of the cutting attachment.

• Cut large branches in sections so that you have better

control over where they fall.

• Never cut through the swelling at the root of the

branch as this will slow down healing and increase the

risk of fungal attack!

• Use the stop at the base of the cutting head to provide

support during cutting. This will help prevent the

cutting attachment from ”jumping” on the branch.

• Make an initial cut on the underside of the branch

before cutting through the branch. This will prevent

tearing of the bark, which could lead to slow healing

and cause permanent damage to the tree. The cut

should not be deeper than 1/3 of the branch thickness

to prevent jamming. Keep the chain running while you

withdraw the cutting attachment from the branch to

prevent it jamming.

• Use the harness to support the weight of the machine

and make it easier to handle.

• Make sure you have a firm footing and that you can

work without being hampered by branches, stones

and trees.

!

WARNING! This machine is not electrically

insulated. If the machine touches or

comes close to high-voltage power lines it

could lead to death or serious bodily

injury. Electricity can jump from one point

to another by arcing. The higher the

voltage, the greater the distance

electricity can jump. Electricity can also

travel through branches and other

objects, especially if they are wet. Always

keep a distance of at least 10 m between

the machine and high-voltage power lines

and/or any objects that are touching them.

If have to work within this safe distance

you should always contact the relevant

power company to make sure the power is

switched off before you start work.

!

WARNING! This machine has a long

reach. Make sure that no people or

animals come closer than 15 m when the

machine is running.

90°

!

WARNING! Never activate the throttle

without having the cutting attachment in

full view.

Page 15

ASSEMBLY

English – 15

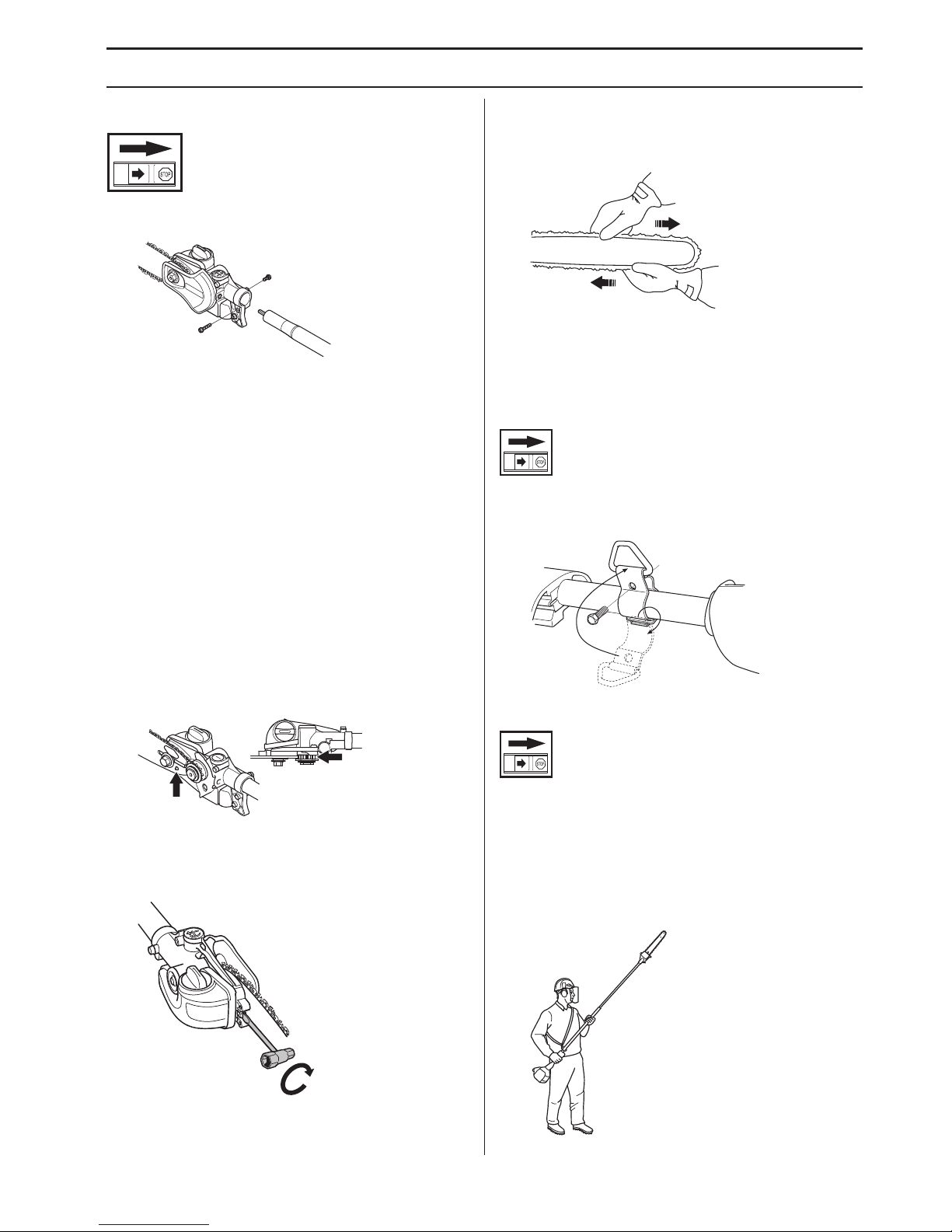

Fitting the cutting head

• Fit the cutting head on the shaft so that the screw (A)

is aligned with the hole in the shaft as shown.

• Tighten screw A.

• Tighten screw B.

CAUTION! Make sure that the drive shaft inside the shaft

engages with the cut-out in the cutting head.

Fitting the bar and chain

• Unscrew the bar nut and remove the protective cover.

• Fit the bar over the bar bolt. Place the bar in its

rearmost position. Place the chain over the drive

sprocket and in the groove on the bar. Begin on the top

side of the bar.

• Make sure that the edges of the cutting links are facing

forward on the top edge of the bar.

• Fit the cover and locate the chain adjuster pin (A) in

the hole in the bar. Check that the drive links of the

chain fit correctly on the drive sprocket (B) and that the

chain is in the groove in the bar (C). Tighten the bar

nut finger-tight.

• Tension the chain by turning the chain tensioning

screw clockwise using the combination spanner. The

chain should be tensioned until it does not sag from

the underside of the bar.

• The chain is correctly tensioned when it does not sag

from the underside of the bar, but can still be turned

easily by hand. Hold up the bar tip and tighten the bar

nuts with the combination spanner.

• When fitting a new chain, the chain tension has to be

checked frequently until the chain is run-in. Check the

chain tension regularly. A correctly tensioned chain

ensures good cutting performance and long life.

Fitting the suspension ring

Fit the suspension ring between the rear handle and the

loop handle. Position the hanging ring so that the machine

is balanced and comfortable to work with.

Adjusting the harness

You should always use the harness with the machine to

give maximum control over the machine and reduce the

risk of fatigue in your arms and back.

• Put on the harness.

• Hook the machine onto the harness support hook.

• Adjust the length of the harness so that the support

hook is roughly level with your right hip.

A

B

A

B

Page 16

ASSEMBLY

16 – English

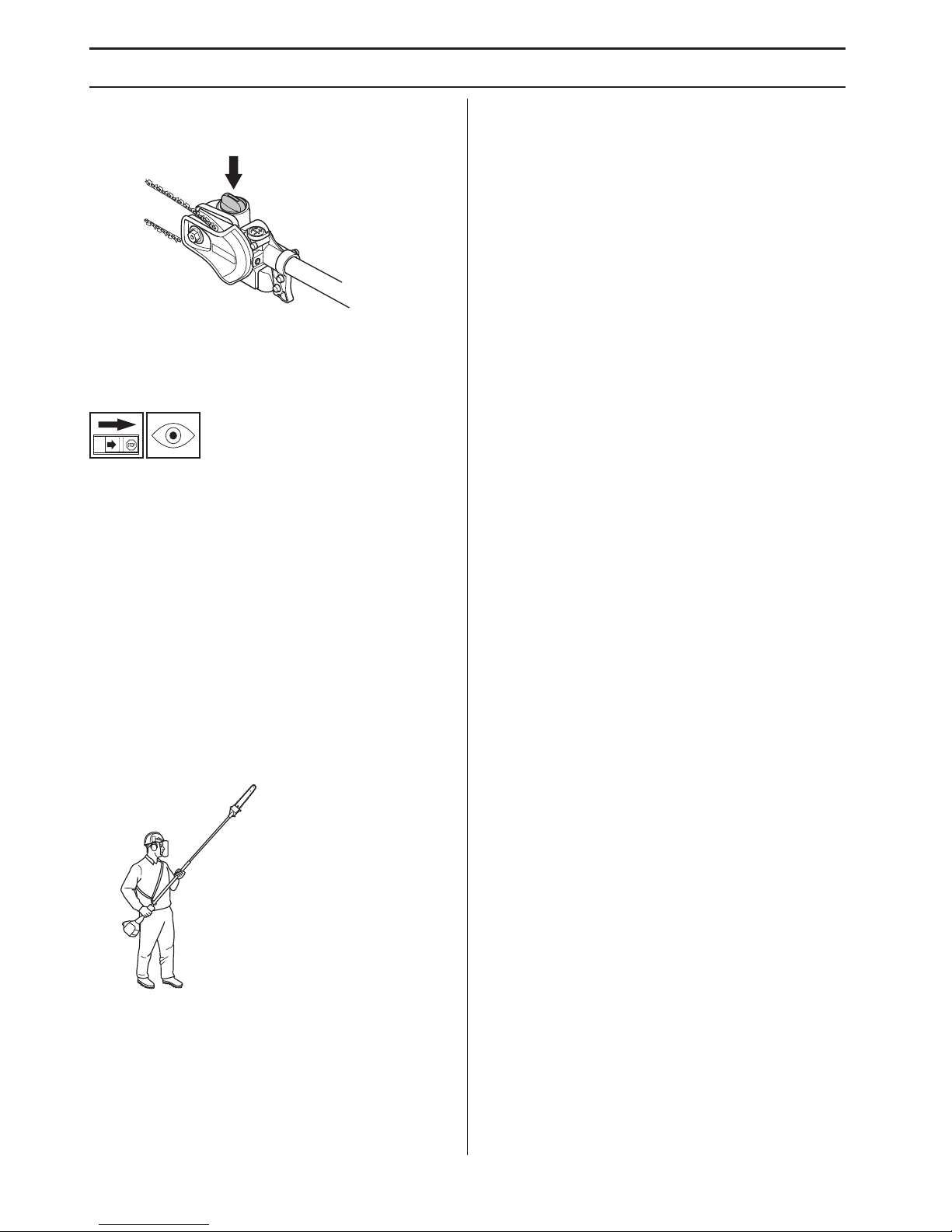

Filling with oil

• Open the cap on top of the bar head

• Fill with Husqvarna saw chain oil.

•Refit the cap.

Check before starting

• Inspect the working area. Remove any objects that

could be thrown out.

• Check the cutting attachment. Never use blunt,

cracked or damaged equipment.

• Check that the machine is in perfect working order.

Check that all nuts and screws are tight.

• Make sure the chain is adequately lubricated. See

instructions under the heading Lubricating the cutting

attachment.

• Check that the cutting attachment always stops when

the engine is idling.

• Only use the machine for the purpose it was intended

for.

• Make sure the handle and safety features are in order.

Never use a machine that has any parts missing or

has been modified in relation to the specification.

Page 17

English – 17

TECHNICAL DATA

Technical data

Note 1 Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/

EC. Reported sound power level for the machine has been measured with the original cutting attachment that gives the

highest level. The difference between guaranteed and measured sound power is that the guaranteed sound power also

includes dispersion in the measurement result and the variations between different machines of the same model

according to Directive 2000/14/EC.

Note 2: Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard

deviation) of 1 dB (A).

Note 3: Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s2.

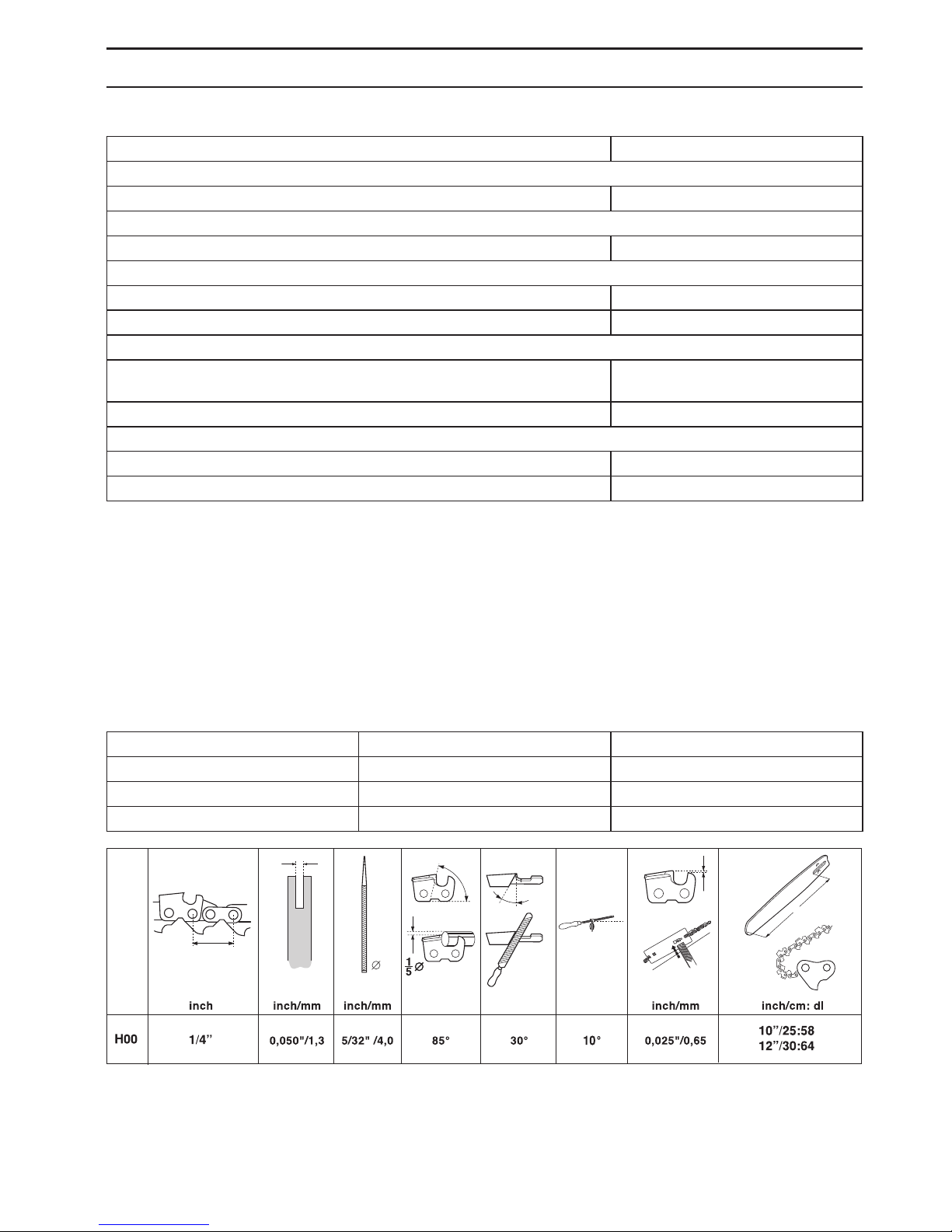

Guide bar and saw chain combinations

The following combinations are CE approved.

Technical data Saw attachment with shaft PA 1100

Lubrication system

Oil tank capacity, litre 0,15

Weight

Weight without fuel, cutting attachment and guard, kg 1,4

Noise emissions (see note 1)

Sound power level, measured dB (A) 110

Sound power level, guaranteed LWA dB (A) 111

Sound levels (see note 2)

Equivalent sound pressure level at the operator’s ear, measured according to

EN ISO 11806 and ISO 22868, dB(A):

Equipped with approved accessory (original) 94

Vibration levels (see note 3)

Vibration levels at handles, measured according to EN ISO 22867, m/s

2

Equipped with approved accessory (original), left/right 3,5/4,6

Guide bar Saw chain

Length, inch Pitch, inch

10 1/4 Husqvarna H00

12 1/4

D

2

L

_

D

PITCH =

Page 18

18 – English

TECHNICAL DATA

EC Declaration of Conformity (Applies to Europe only)

We, Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel +46-36-146500, declare that this saw attachment from 2014’s

serial numbers and onwards (the year is clearly stated in plain text on the type plate, with subsequent serial number),

complies with the requirements of the COUNCIL’S DIRECTIVE:

of May 17, 2006 ”relating to machinery” 2006/42/EC.

The following standards have been applied: EN ISO 12100:2010, ISO 11680-1:2011

Notified body: 0404, SMP Svensk Maskinprovning AB, Box 7035, SE-750 07 Uppsala, Sweden, has carried out EC

type examination in accordance with the machinery directive’s (2006/42/EC) article 12, point 3b. The certificates for EC

type examination in accordance with annex VI, have the numbers:

0404/14/2394

Huskvarna 13 March, 2014

Per Gustafsson, Development manager

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

Page 19

SIMBOLOGIA

Italian – 19

Simboli

AVVERTENZA! Se utilizzata in modo

improprio o non corretto, la macchina

può essere un attrezzo pericoloso in

grado di provocare gravi lesioni o morte

dell’operatore , o di altre persone.

Prima di usare la macchina,

leggere per intero le istruzioni per

l’uso e accertarsi di averne

compreso il contenuto.

Usare sempre:

• Casco di protezione laddove

sussiste il rischio di caduta di oggetti

• Protezioni acustiche omologate

• Occhiali o visiera di protezione

Il presente prodotto è conforme alle

vigenti direttive CEE.

Questa macchina non è isolata

elettricamente. Se la macchina

viene a trovarsi a contatto o

nelle vicinanze di cavi

conduttori di tensione si può

incorrere in lesioni gravi o

mortali. L’elettricità può essere

condotta da un punto all’altro

tramite un cosiddetto arco di

tensione. Più la tensione è alta,

maggiore è lo spazio attraverso

il quale è possibile condurre l’elettricità. L’elettricità può

anche essere condotta tramite rami o altri oggetti,

particolarmente se bagnati. Mantenere sempre una

distanza di almeno 10 m fra la macchina e il cavo

conduttore di tensione e/o l’oggetto che si trova a contatto

con esso. Se siete obbligati a lavorare con una distanza di

sicurezza inferiore, contattare sempre l’azienda

distributrice dell’energia per assicurarvi che la tensione

sia staccata al momento in cui date inizio al lavoro.

Utilizzare sempre guanti protettivi

omologati.

Usare stivali robusti e antisdrucciolo.

I restanti simboli/decalcomanie riguardano

particolari requisiti necessari per ottenere la

certificazione in alcuni mercati.

Il controllo e/o la manutenzione

vanno eseguiti a motore spento, con

il pulsante di arresto in posizione

STOP.

Utilizzare sempre guanti protettivi

omologati.

E’ necessario pulire con regolarità.

Controllo visivo.

Usare sempre occhiali o visiera di

protezione.

Rifornimento e regolazione del flusso

dell’olio

Page 20

INDICE

20 – Italian

Indice Prima dell’avviamento osservare

quanto segue:

La Husqvarna AB procede costantemente allo sviluppo

dei propri prodotti e si riserva quindi il diritto di apportare,

senza alcun preavviso, modifiche riguardanti fra l’altro la

forma e l’aspetto esteriore.

Una lunga esposizione al rumore può comportare lesioni

permanenti all'udito. Usare quindi sempre cuffie di

protezione omologate.

Prima di usare la macchina, leggere per intero le istruzioni

per l’uso e accertarsi di averne compreso il contenuto.

Il presente libretto integra le istruzioni per l’uso allegate

alla macchina. Per le altre funzioni, vedere il libretto di

istruzioni per l’uso della macchina.

La macchina è costruita esclusivamente per il taglio di

rami e ramoscelli.

SIMBOLOGIA

Simboli .................................................................. 19

INDICE

Indice .................................................................... 20

Prima dell’avviamento osservare quanto segue: .. 20

INTRODUZIONE

Alla gentile clientela .............................................. 21

CHE COSA C’È?

Cosa c’è nell’accessorio motosega? .................... 22

NORME DI SICUREZZA

Attrezzatura di taglio ............................................. 23

Specifiche relative a lama e catena ...................... 23

Affilatura della catena e controllo della profondità

di taglio .................................................................

24

Tensionamento della catena ................................. 26

Lubrificazione dell’attrezzatura di taglio ................ 27

Controllo dell’usura dell’attrezzatura di taglio ....... 28

Norme di sicurezza per l’uso di motosega ad asta 29

MONTAGGIO

Montaggio testina di taglio .................................... 32

Montaggio di lama e catena .................................. 32

Montaggio del gancio di sospensione ................... 32

Impostazione dell’imbracatura .............................. 33

Rabbocco dell’olio ................................................. 33

Controlli prima dell’avviamento ............................. 33

CARATTERISTICHE TECNICHE

Caratteristiche tecniche ........................................ 34

Combinazioni di lama e catena ............................. 34

Dichiarazione di conformità CE ............................ 35

!

AVVERTENZA! Evitare assolutamente di

modificare la versione originale della

macchina senza l’autorizzazione del

fabbricante. Usare sempre accessori

originali. Modifiche e/o accessori non

autorizzati possono causare lesioni gravi

o mortali all’operatore o a terzi.

!

AVVERTENZA! Questo accessorio può

essere usato solo con alcuni tipi di

decespugliatori/bordatori appositamente

studiati (vedere alla voce ”Accessori

omologati”, al capitolo Dati Tecnici, nel

manuale delle istruzioni della macchina).

Page 21

Italian – 21

INTRODUZIONE

Alla gentile clientela

Congratulazioni per aver scelto di acquistare un prodotto Jonsered!

Siamo convinti che sarete pienamente soddisfatti della qualità e delle prestazioni del nostro prodotto per un lungo tempo

a venire. L'acquisto di uno dei nostri prodotti vi garantisce l'accesso alla competenza di personale qualificato per

l'assistenza e le riparazioni in caso di necessità. Se non avete acquistato la macchina presso uno dei nostri rivenditori

autorizzati, rivolgetevi alla più vicina officina di assistenza.

Ci auguriamo che rimarrete soddisfatti della vostra macchina e speriamo di potervi servire per molto tempo in futuro.

Non dimenticate che questo manuale delle istruzioni è un documento di valore. Seguendone il contenuto (uso,

assistenza, manutenzione ecc.) potrete aumentare notevolmente la durata della vostra macchina e anche il suo valore

di usato. Se vendete la macchina, ricordate di consegnare il manuale delle istruzioni al nuovo proprietario.

Buona fortuna nell’uso del vostro prodotto Jonsered!

La Jonsered procede costantemente allo sviluppo dei propri prodotti e si riserva quindi il diritto di apportare, senza alcun

preavviso, modifiche riguardanti fra l’altro la forma e l’aspetto esteriore.

Page 22

22 – Italian

CHE COSA C’È?

Cosa c’è nell’accessorio motosega? (Accessorio motosega con albero cavo PA 1100)

4

13

12

14

15

10

11

2

7

11

9

1

2

8

6

5

3

16

1 Riduttore angolare

2 Vite di regolazione lubrificazione catena

3 Albero cavo (1100 mm)

4 Gancio di sospensione imbracatura

5 Coperchio di protezione catena

6 Dado della lama

7 Vite tendicatena

8 Catena

9 Lama

10 Contenitore olio per catena

11 Rifornimento dell’olio per catena

12 Istruzioni per l’uso

13 Protezione per trasporto

14 Chiave combinata

15 Imbracatura

16 Chiave Torx

Page 23

NORME DI SICUREZZA

Italian – 23

Attrezzatura di taglio

Questo capitolo descrive come, eseguendo una

manutenzione corretta ed usando il giusto tipo di gruppo

di taglio, è possibile ottenere la massima capacità di

abbattimento e prolungare la durata del gruppo di taglio.

Usare solo attrezzatura di taglio da noi consigliata!

Vedi istruzioni alla voce Caratteristiche tecniche.

Tenere sempre ben affilati i denti della catena!

Seguire le istruzioni e usare i riscontri raccomandati.

Se la catena non è ben affilata, aumenta il rischio di

incidenti.

Mantenere una corretta profondità di taglio! Seguire

le istruzioni e usare la dima di riscontro

raccomandata.

Una profondità di taglio eccessiva

aumenta il rischio di contraccolpo.

Controllare la tensione della catena! Una catena

troppo lenta salta facilmente e aumenta l’usura di ruota di

rinvio, lama e catena.

Curare la lubrificazione e la manutenzione

dell’attrezzatura di taglio!

Una lubrificazione

insufficiente aumenta il rischio di rottura della catena e di

usura di ruota di rinvio, lama e catena.

Specifiche relative a lama e

catena

Quando il gruppo di taglio in dotazione alla vostra

macchina è usurato o danneggiato e dev’essere

sostituito, usare esclusivamente i tipi di lama e catena da

noi raccomandati.

Lama

• Lunghezza (pollici/cm)

!

AVVERTENZA! Non usare mai una

macchina con dispositivi di sicurezza

guasti. Questi dispositivi vanno

controllati e sottoposti a manutenzione

secondo quanto descritto in questo

capitolo. Se la macchina non supera tutti

i controlli, contattare un’officina per le

necessarie riparazioni.

!

AVVERTENZA! Spegnere sempre il

motore prima di eseguire qualsiasi

operazione sul gruppo di taglio. Questo

infatti continua a ruotare anche quando

l’acceleratore viene rilasciato. Accertarsi

che il gruppo di taglio sia completamente

fermo e staccare il cavo dalla candela

prima d’iniziare qualunque operazione.

Page 24

NORME DI SICUREZZA

24 – Italian

• Partitura della catena (pollici). La rotella di punta della

lama e l’ingranaggio di trascinamento della catena

devono essere adeguati alla distanza tra le maglie di

trascinamento.

• Numero di maglie di trascinamento (pz). Ogni

lunghezza di lama, unita alla partitura della catena e

ai denti della rotella di punta, risulta in un preciso

numero di maglie di trascinamento.

• Larghezza della guida della lama (pollici/mm). La

larghezza della guida della lama deve essere

adeguata alla larghezza delle maglie di

trascinamento.

• Foro di lubrificazione della catena e foro del perno

tendicatena.

Catena

•

Partitura (pollici). (Distanza tra tre maglie divisa per due.)

• Larghezza della maglia di trascinamento (mm/pollici)

• Numero di maglie di trascinamento (pz)

Affilatura della catena e controllo

della profondità di taglio

Generalità sull’affilatura della catena

• La catena deve essere sempre ben affilata. Se la

catena non taglia senza dover premere la lama contro

il legno e produce segatura molto fine, è segno che

non è affilata bene. Se il taglio non produce segatura,

la catena ha perso completamente il filo e nel tagliare

polverizza il legno.

• Se la catena è affilata, avanza da sola nel legno e

produce trucioli grossi e lunghi. La parte tagliente

della catena è costituita dalla maglia di taglio, con un

dente (A) e una punta per la profondità di taglio (B). Il

dislivello tra questi determina la profondità di taglio.

!

AVVERTENZA! Se la catena non è affilata

aumenta il rischio di contraccolpo!

Page 25

NORME DI SICUREZZA

Italian – 25

• Per l’affilatura del dente di taglio vanno considerate 5

misure.

1 Angolo di affilatura

2 Angolo di appoggio

3 Posizione della lima

4 Diametro della lima tonda

5 Profondità di affilatura

E’ difficile affilare correttamente una catena senza gli

strumenti necessari. Raccomandiamo perciò l’uso dei

nostri blocchetti di riscontro. Essi garantiscono

un’affilatura che riduce al minimo il contraccolpo e

permette la massima capacità di taglio.

Affilatura dei denti

• Per ottenere una buona affilatura della catena

servono un riscontro e una lima tonda.

• Controllare che la catena sia ben tesa. In caso

contrario la catena si muove lateralmente ed è più

difficile ottenere una corretta affilatura.

•Affilare sempre il dente di taglio dall’interno verso

l’esterno. Allentare la pressione sulla lima in fase di

1

5

!

AVVERTENZA! Le seguenti deviazioni

dalle istruzioni per l’affilatura aumentano

considerevolmente la tendenza al

contraccolpo della motosega: Angolo di

affilatura eccessivo

Angolo di affilatura insufficiente

Diametro della lima insufficiente

Page 26

NORME DI SICUREZZA

26 – Italian

ritorno. Affilare prima tutti i denti di un lato della lama.

Girare ed affilare poi i denti restanti sull’altro lato.

•Affilare facendo in modo che tutti i denti siano di

uguale lunghezza. Quando il dente di taglio è di soli 4

mm (5/32"), la catena è usurata e va rottamata.

Generalità sulla profondità di taglio

• Con l’affilatura dei denti diminuisce la profondità di

taglio. Per mantenere la massima capacità di taglio è

necessario abbassare il bordo del raschiatoio al livello

consigliato.

• Su un dente di taglio con riduzione del contraccolpo la

parte anteriore della punta della profondità di taglio è

stondata. È indispensabile mantenere questa

configurazione dopo aver regolato la profondità di

taglio.

• Si consiglia di usare la nostra dima di riscontro che

fornisce la corretta profondità di taglio e permette di

regolare anche la smussatura della punta.

Regolazione della profondità di taglio

• Prima di controllare la profondità di taglio, la catena

deve essere affilata. Si consiglia di effettuare questo

controllo ogni tre affilature della catena. N.B! Questa

raccomandazione presuppone che i denti siano stati

sottoposti ad una affilatura normale.

• La regolazione della profondità di taglio viene

effettuata con una lima piatta e una dima di riscontro.

• Porre la dima sulla punta.

• Appoggiare la lima piatta sulla parte in eccesso della

punta ed eliminare l’eccesso. L’operazione è conclusa

quando la lima passa sulla dima senza incontrare

resistenza.

Tensionamento della catena

• La lunghezza della catena aumenta con l’uso. È

importante quindi regolare l’attrezzatura di taglio in

seguito a cambiamenti del genere.

!

AVVERTENZA! Una profondità di taglio

eccessiva aumenta la propensione della

catena al contraccolpo!

!

AVVERTENZA! Una catena troppo lente

salta facilmente, e rappresenta motivo di

pericolo in quanto può provocare lesioni

gravi o mortali.

Page 27

NORME DI SICUREZZA

Italian – 27

• Controllare spesso la tensione della catena, meglio se

ad ogni occasione di rifornimento. N.B! Se la catena è

nuova, richiede un periodo di rodaggio durante il

quale va controllata più spesso.

• Tendere la catena il più possibile, ma in modo che

possa essere facilmente fatta girare con la mano.

1 Allentare il dado della lama.

2 Sollevare la punta della lama e tirare la catena

avvitando la vite del tendicatena con l’utensile

combinato. Tendere la catena fino a quando non

rimane nella scanalatura intorno alla lama.

3 Stringere il dado della lama con la chiave combinata

tenendo sollevata la punta della lama. Controllare che

la catena possa essere fatta girare manualmente con

facilità.

Lubrificazione dell’attrezzatura di

taglio

Olio per catena

• L’olio per catena deve presentare una buona

aderenza e buone proprietà di scorrimento, sia

d’estate che d’inverno.

• In qualità di produttori di motoseghe abbiamo messo

a punto un olio per catena ottimale e, grazie alla base

vegetale, biodegradabile. Consigliamo l’utilizzo del

nostro olio per assicurare la massima durata della

motosega e tutelare l’ambiente.

• Qualora il nostro olio per catena non fosse disponibile,

utilizzare un comune olio per catene.

• Nelle zone in cui non sono disponibili oli studiati

appositamente per la lubrificazione della catena è

possibile utilizzare olio per trasmissioni EP 90.

• Non utilizzare mai oli esausti! Questi oli sono nocivi

per voi, la macchina e l’ambiente.

Rifornimento dell’olio per catena

La pompa dell’olio è registrata in fabbrica per far fronte

alla maggior parte delle necessità di lubrificazione. Un

rifornimento d’olio completo ha una durata pari a circa la

metà della durata di un rifornimento di benzina.

Controllare quindi regolarmente la quantità d’olio nel

serbatoio per evitare danni alla catena e alla lama che

potrebbero venir causati da una mancata lubrificazione.

!

AVVERTENZA! Una lubrificazione

insufficiente dell’attrezzatura di taglio

provoca la rottura della catena con gravi

rischi di lesioni personali anche mortali.

Page 28

NORME DI SICUREZZA

28 – Italian

Controllo della lubrificazione della catena

Controllare il funzionamento della lubrificazione ad ogni

rifornimento. Puntare la lama contro una superficie

chiara, da una ventina di centimetri (8 pollici) di distanza.

Dopo un minuto circa, a 3/4 di gas, la superficie dovrà

presentare evidenti tracce d’olio.

Regolazione della lubrificazione della catena

In caso di operazioni su legname duro e secco può

essere necessario aumentare la lubrificazione. Il flusso

d'olio aumenta girando la vite di regolazione in senso

antiorario. Ricordare che in questo modo il flusso d'olio

aumenta, controllare quindi regolarmente la quantità

d'olio nel serbatoio. Il flusso d'olio diminuisce girando la

vite di regolazione in senso orario.

Misure in caso di mancato funzionamento

della lubrificazione:

1 Controllare che il canale di lubrificazione della lama

non sia ostruito. Pulire se necessario.

2 Controllare che il canale di lubrificazione della scatola

del cambio sia pulito. Pulire se necessario.

3 Controllare che la rotella di punta della lama giri

liberamente. Se la lubrificazione della catena non

funziona nonostante gli interventi summenzionati

contattare l’officina per l’assistenza.

Controllo dell’usura

dell’attrezzatura di taglio

Catena

Controllare giornalmente la catena, ed in particolare:

• Presenza di fratture o lesioni sui perni o sulle maglie.

• Elasticità della catena.

• Usura inconsueta di maglie e denti.

Per riferimento usare una catena nuova.

Quando la lunghezza del dente di taglio è di soli 4 mm,

sostituire la catena con una nuova.

Rotella di trascinamento della catena

Controllare regolarmente il livello di usura della rotella di

trascinamento. Sostituire se necessario.

Lama

Controllare con regolarità:

• La presenza di graffi sui lati della lama. Eliminare con

una lima se necessario.

• Se la scanalatura della lama è usurata oltre il normale.

Sostituire la lama se necessario.

Page 29

NORME DI SICUREZZA

Italian – 29

• Se la punta della lama è usurata irregolarmente. In

caso di formazione di un ”affossamento” alla fine della

curvatura della punta, la catena non è correttamente

tesa.

Per la massima durata girare la lama giornalmente.

Norme di sicurezza per l’uso di

motosega ad asta

N.B! Prima di usare la macchina, leggere per intero le

istruzioni per l’uso e accertarsi di averne compreso il

contenuto.

Protezione personale

• Indossare sempre stivali e l’attrezzatura descritta alla

voce Abbigliamento protettivo personale nel manuale

delle istruzioni della macchina.

• Utilizzare sempre abiti da lavoro e pantaloni robusti.

• Non indossare mai abiti troppo ampi o gioielli.

• I capelli non devono scendere al di sotto delle spalle.

Norme di sicurezza per l’ambiente

circostante

• Non permettere che la macchina sia utilizzata da

bambini.

• Accertarsi che nessuno si avvicini ad una distanza

inferiore a 15 m durante il lavoro.

• Non consentire mai ad altri l’utilizzo della macchina

senza accertarsi che abbiano capito il contenuto del

manuale di istruzioni.

• Non lavorare mai su una scala, uno sgabello o in altra

posizione sollevata da terra che non sia ben fissata.

Norme di sicurezza durante il lavoro

• Lavorare sempre in posizione sicura e stabile.

• Tenere sempre la macchina con entrambe le mani.

Tenere la macchina lateralmente rispetto al corpo.

• Usare la mano destra per manovrare l’acceleratore.

• Accertarsi che mani e piedi non tocchino il gruppo di

taglio a motore acceso.

• Una volta spento il motore, tenere mani e piedi lontani

dal gruppo di taglio fino al suo completo arresto.

• Fare attenzione ad eventuali ramoscelli che

potrebbero venir lanciati in aria durante l’operazione.

• Appoggiare sempre la macchina a terra durante le

pause.

!

AVVERTENZA! Un gruppo di taglio

inadeguato può aumentare il rischio

d’infortuni.

!

AVVERTENZA! La macchina può

provocare gravi lesioni personali.

Leggere attentamente le norme di

sicurezza. Apprendete l’uso corretto

della macchina.

!

AVVERTENZA! Attrezzo tagliente. Non

toccare l’attrezzo senza aver prima

spento il motore.

Page 30

NORME DI SICUREZZA

30 – Italian

• Esaminare l’oggetto di taglio per escludere la

presenza di corpi estranei, quali cavi elettrici, insetti,

animali ecc., oppure di elementi che potrebbero

danneggiare il gruppo di taglio, ad esempio gli oggetti

metallici.

• In caso di collisione con un oggetto o all’insorgere di

vibrazioni fermare la macchina. Togliere il cavo di

accensione dalla candela. Controllare che la

macchina non presenti danni. Riparare

eventualmente ogni danno riscontrato.

• Nel caso in cui un oggetto dovesse incastrarsi nel

gruppo di taglio durante l’operazione spegnere il

motore e arrestare la macchina completamente fino

all’avvenuta pulizia del gruppo di taglio.

Norme di sicurezza dopo il lavoro

• Quando la macchina non viene usata coprire sempre

il gruppo di taglio con la protezione per il trasporto.

• Accertarsi sempre che il gruppo di taglio si sia fermato

prima di eseguire pulizia, riparazioni o controlli.

Staccare il cavo di accensione dalla candela.

• Usare sempre dei guanti robusti durante la

riparazione del gruppo di taglio. Questo è molto

tagliente e ci si può ferire molto facilmente.

• Conservare la macchina fuori dalla portata dei

bambini.

• Utilizzare esclusivamente ricambi originali per le

riparazioni.

Tecnica fondamentale di lavoro

• Per ottenere un equilibrio ottimale, tenere la macchina

il più possibile vicina al corpo.

• Assicuratevi che la punta non tocchi il terreno.

• Non forzare l’operazione, procedere a velocità

moderata, facendo in modo che tutti i rami vengano

tagliati lasciando una superficie uniforme.

• Dopo ciascuna fase di lavoro decelerare il motore fino

al regime minimo. Un esercizio prolungato a pieno

regime senza carico può causare gravi danni al

motore.

• Lavorare sempre a pieno gas.

Osservare la massima prudenza se si lavora in prossimità

di linee elettriche aeree. I rami che cadono potrebbero

causare un corto circuito.

!

AVVERTENZA! Non sostare mai sotto un

ramo che sta per essere tagliato. Esiste il

rischio di lesioni personali gravi, anche

mortali.

!

AVVERTENZA! In caso di lavori in

prossimità di linee aeree elettriche

osservare le norme di sicurezza vigenti.

!

AVVERTENZA! Questa macchina non è

isolata elettricamente. Se la macchina

viene a trovarsi a contatto o nelle

vicinanze di cavi conduttori di tensione

si può incorrere in lesioni gravi o mortali.

L’elettricità può essere condotta da un

punto all’altro tramite un cosiddetto arco

di tensione. Più la tensione è alta,

maggiore è lo spazio attraverso il quale è

possibile condurre l’elettricità.

L’elettricità può anche essere condotta

tramite rami o altri oggetti,

particolarmente se bagnati. Mantenere

sempre una distanza di almeno 10 m fra

la macchina e il cavo conduttore di

tensione e/o l’oggetto che si trova a

contatto con esso. Se siete obbligati a

lavorare con una distanza di sicurezza

inferiore, contattare sempre l’azienda

distributrice dell’energia per assicurarvi

che la tensione sia staccata al momento

in cui date inizio al lavoro.

!

AVVERTENZA! La macchina ha un raggio

di azione lungo. Accertarsi che non ci

siano persone o animali in un raggio di

15 metri quando la macchina è in

funzione.

Page 31

NORME DI SICUREZZA

Italian – 31

• Cercare la giusta posizione in relazione al ramo di

modo che l’angolo di taglio sia possibilmente di 90º.

• Evitare di lavorare tenendo l’attrezzo diritto davanti a

voi (come una canna da pesca) poiché in questo

modo si avverte maggiormente il peso del gruppo di

taglio.

• Tagliare i rami più spessi in diverse sezioni per avere

un maggior controllo sul luogo in cui andranno a

cadere.

• Non tagliare mai la protuberanza vicina al fusto poiché

essa accelera la cicatrizzazione e ostacola

l’imputridimento!

• Usare la faccia della testina di taglio per appoggiarvi

al ramo durante l’operazione. In questo modo si evita

che il gruppo di taglio ”rimbalzi” sul ramo.

• Praticare un’incisione nella sezione inferiore del ramo

prima di tagliarlo. In questo modo si evitano

sbucciature della corteccia, che potrebbero

danneggiare l’albero in modo permanente o

difficilmente riparabile. L’incisione non deve avere una

profondità superiore ad 1/3 dello spessore del ramo

per evitare inceppature durante il taglio. Staccare

sempre il gruppo di taglio dal ramo con la catena in

movimento per evitare che il gruppo di taglio rimanga

incastrato.

• Usare l’imbracatura per manovrare la macchina più

facilmente e per distribuirne meglio il peso.

• Accertarsi di mantenere una posizione stabile e di

poter lavorare senza venir disturbati da rami, pietre e

alberi.

90°

!

AVVERTENZA! Non accelerare mai senza

avere una visione totale del gruppo di

taglio.

Page 32

MONTAGGIO

32 – Italian

Montaggio testina di taglio

• Montare la testina di taglio sull’albero cavo di modo

che la vite (A) venga a trovarsi al centro rispetto al foro

presente sull’albero cavo, come mostrato nella figura.

• Serrare la vite A.

• Serrare la vite B.

N.B! Accertarsi che l’albero di trasmissione sull’albero

cavo combaci con l’incavo sulla testina.

Montaggio di lama e catena

• Svitare il dado della lama e togliere il coperchio di

protezione.

• Montare la lama sul relativo bullone. Situare la lama il

più indietro possibile. Situare la catena sopra la ruota

motrice e nella scanalatura della lama. Cominciare

dalla parte superiore della lama.

• Controllare che il taglio dei denti sia rivolto in avanti,

sul lato superiore della lama.

• Montare il coperchio e situare il perno tendicatena (A)

nell’incavo della lama. Controllare che le maglie della

catena prendano nella ruota motrice (B) e che la

catena sia al posto giusto nella scanalatura della lama

(C). Serrare con le dita il dado della lama.

• Tendere la catena con la vite apposita e la chiave

combinata avvitandola in senso orario. La tensione è

corretta quando la catena rimane nella scanalatura

intorno alla lama.

• La tensione è corretta quando la catena rimane nella

scanalatura intorno alla lama ed è possibile farla

scorrere con le dita, senza sforzo. Serrare a fondo i

dadi con la chiave combinata tenendo sollevata la

punta della lama.

• Controllare spesso la tensione di una nuova catena

fino al termine del rodaggio. Eseguire il controllo

regolarmente. Una catena correttamente tesa

significa migliori caratteristiche di taglio e lunga

durata.

Montaggio del gancio di

sospensione

Il gancio di sospensione viene montato fra l’impugnatura

posteriore e l’impugnatura ad anello. Situare il gancio in

modo che la macchina sia ben bilanciata e risulti facile da

manovrare.

A

B

A

B

Page 33

MONTAGGIO

Italian – 33

Impostazione dell’imbracatura

Lavorando con la macchina usare sempre l’imbracatura

per ottenere il massimo controllo sulla macchina e per

ridurre il rischio di stanchezza alle braccia e alla schiena.

• Indossare l’imbracatura.

• Fissare la macchina al gancio di sospensione

dell’imbracatura.

• Regolare la lunghezza dell’imbracatura facendo in

modo che il gancio venga a trovarsi all’incirca

all’altezza del fianco destro dell’operatore.

Rabbocco dell’olio

• Aprire il tappo sulla sezione superiore della testina di

taglio

• Rabboccare con olio per catena Husqvarna.

• Richiudere il tappo.

Controlli prima dell’avviamento

• Ispezionare l’area di lavoro. Rimuovere gli oggetti che

potrebbero venir lanciati in aria.

• Controllare il gruppo di taglio. Non usare mai un

gruppo di taglio smussato, rotto o danneggiato.

• Controllare che la macchina sia in perfette condizioni.

Controllare che tutti i dadi e le viti siano ben serrati.

• Verificare che la catena sia lubrificata a sufficienza.

Vedi istruzioni alla voce Lubrificazione del gruppo di

taglio.

• Controllare che il gruppo di taglio si arresti sempre

con il motore al minimo.

• Non utilizzare la macchina per scopi diversi da quelli

previsti.

• Accertarsi che le impugnature ed i dispositivi di

sicurezza siano in ordine. Non utilizzare mai la

macchina se qualche parte manca oppure è stata

sottoposta a modifiche non previste dalle specifiche

tecniche.

Page 34

34 – Italian

CARATTERISTICHE TECNICHE

Caratteristiche tecniche

Osserv. 1 Emissione di rumore nell’ambiente misurato come potenza acustica (LWA) in base alla direttiva CE 2000/14/

CE. Il livello di potenza acustica riportato per la macchina è stato misurato con il gruppo di taglio originale che emette il

livello massimo. La differenza tra potenza acustica misurata e garantita è che la potenza acustica garantita comprende

anche la dispersione nel risultato di misurazione e le variazioni tra le diverse macchine dello stesso modello come da

Direttiva 2000/14/CE.

Nota 2: I dati riportati per il livello di pressione acustica equivalente della macchina hanno una dispersione statistica

tipica (deviazione standard) di 1 dB (A).

Nota 3: I dati riportati per il livello di vibrazione equivalente hanno una dispersione statistica tipica (deviazione standard)

di 1 m/s

2

.

Combinazioni di lama e catena

Combinazioni omologate CE.

Caratteristiche tecniche

Accessorio motosega con albero

cavo PA 1100

Sistema di lubrificazione

Capacità serbatoio olio, litri 0,15

Peso

Peso, escluso carburante, gruppo di taglio e protezione, kg 1,4

Emissioni di rumore (vedere annot. 1)

Livello potenza acustica, misurato dB(A) 110

Livello potenza acustica, garantito LWAdB(A) 111

Livelli di rumorosità (vedi nota 2)

Livello di pressione acustica equivalente rispetto all’udito dell’operatore,

misurato in base alle norme EN ISO 11806 e ISO 22868, dB(A):

Accessorio approvato (originale) in dotazione 94

Livelli di vibrazioni (vedi nota 3)

Livelli di vibrazioni dell'impugnatura, misurati in base alle norme EN ISO

22867, m/s

2

Accessorio approvato (originale) in dotazione, sinistra/destra 3,5/4,6

Lama Catena

Lunghezza, pollici Partitura, pollici

10 1/4 Husqvarna H00

12 1/4

D

2

L

_

D

PITCH =

Page 35

Italian – 35

CARATTERISTICHE TECNICHE

Dichiarazione di conformità CE (Solo per l’Europa)

La Husqvarna AB, SE-561 82 Huskvarna, Svezia, tel +46-36-146500, dichiara con la presente che questo accessorio

motosega a partire dai numeri di serie del 2014 in poi (l’anno viene evidenziato nel marchio di fabbrica ed è seguito da

un numero di serie), è conforme alle disposizioni della DIRETTIVA DEL CONSIGLIO:

del 17 maggio 2006 "sulle macchine" 2006/42/CE.

Sono state applicate le seguenti norme: EN ISO 12100:2010, ISO 11680-1:2011

Organo competente: 0404, l’SMP Svensk Maskinprovning AB, Box 7035, SE-750 07 Uppsala, Svezia, ha eseguito il

controllo-tipo CE in base alla direttiva sulle macchine (2006/42/CE) articolo 12, punto 3b. I certificati-tipo CE in base

all’allegato VI, portano i numeri:

0404/14/2394

Huskvarna 13 marzo 2014

Per Gustafsson, Responsabile ricerca e sviluppo

(Rappresentante autorizzato per Husqvarna AB e responsabile della documentazione tecnica.)

Page 36

∂¶∂•∏°∏™∏ ™ÀMμ√§ø¡

36 – Greek

™‡ÌßÔÏ·

¶ƒ√∂π¢√¶√π∏™∏! ΔÔ Ì˯¿ÓËÌ·

ÌÔÚ› Ó· Á›ÓÂÈ ÂÈΛӉ˘ÓÔ. ∏

·ЪfiЫВ¯ЩЛ ‹ П·Уı·ЫМ¤УЛ ¯Ъ‹ЫЛ

МФЪВ› У· ¤¯ВИ ˆ˜ ·ФЩ¤ПВЫМ·

ЫФЯ·Ъfi ‹ ı·У¿ЫИМФ ЩЪ·˘М·ЩИЫМfi ЩФ˘

¯ВИЪИЫЩ‹ ‹ ¿ППˆУ ·ЩfiМˆУ.

¢И·Я¿ЫЩВ ЪФЫВОЩИО¿ ЩИ˜ √‰ЛБ›В˜

¯Ъ‹ЫВˆ˜ О·И О·Щ·УФ‹ЫЩВ ЩФ

ВЪИВ¯fiМВУФ ЪИУ

¯ЪЛЫИМФФИ‹ЫВЩВ ЩФ МЛ¯¿УЛМ·.

ГЪЛЫИМФФИВ›ЩВ ¿УЩФЩВ:

•

¶ЪФЫЩ·ЩВ˘ЩИОfi ОЪ¿УФ˜ ЫЩИ˜

ВЪИЩТЫВИ˜ fiФ˘ ˘¿Ъ¯ВИ

О›У‰˘УФ˜ ЩТЫЛ˜ ·УЩИОВИМ¤УˆУ

•

∂БОВОЪИМ¤У· ЪФЫЩ·ЩВ˘ЩИО¿ М¤Ы·

·ÎÔ‹˜

•

¶ÚÔÛٷ٢ÙÈο Á˘·ÏÈ¿ ‹ ‰ÈÎÙ˘ˆÙ‹ Ì¿Ûη

∞˘Ùfi ÙÔ ÚÔ˚fiÓ Â›Ó·È Û‡ÌʈÓÔ ÌÂ

ÙȘ ÈÛ¯‡Ô˘Û˜ Ô‰ËÁ›Â˜ Ù˘ ∂K.

∞˘Щfi ЩФ МЛ¯¿УЛМ· ‰ВУ В›У·И

ЛПВОЩЪИО¿ МФУˆМ¤УФ. ∞У ЩФ

МЛ¯¿УЛМ· ¤ЪıВИ ЫВ В·К‹ ‹

ПЛЫИ¿ЫВИ ЫВ ЛПВОЩЪФКfiЪФ

·БˆБfi МФЪВ› У· ЪФОПЛıВ›

ı·У·ЩЛКfiЪФ ·Щ‡¯ЛМ· ‹

ЫФЯ·ЪfiЩ·ЩФ˜ ЩЪ·˘М·ЩИЫМfi˜.

√ ЛПВОЩЪИЫМfi˜ МФЪВ› У·

МВЩ·‰ФıВ› ·fi ¤У· ЫЛМВ›Ф ЫВ

¿ППФ МВ ЩФ ПВБfiМВУФ

ЛПВОЩЪИОfi ЩfiНФ. √ЫФ

˘„ЛПfiЩВЪЛ В›У·И Л Щ¿ЫЛ, ЩfiЫФ М·ОЪ‡ЩВЪ· МФЪВ› У·

МВЩ·‰ФıВ› ЩФ ЪВ‡М·. √ ЛПВОЩЪИЫМfi˜ МФЪВ› В›ЫЛ˜ У·

МВЩ·‰ФıВ› МВ ОП·‰И¿ О·И ¿ПП· ·УЩИОВ›МВУ·, И‰›ˆ˜ ·У

В›У·И ˘БЪ¿. ¢И·ЩЛЪВ›ЩВ ¿УЩ· ·fiЫЩ·ЫЛ ·ЫК·ПВ›·˜

ЩФ˘П¿¯ИЫЩФУ 10 М¤ЩЪˆУ ·У¿МВЫ· ЫЩФ МЛ¯¿УЛМ· О·И

ЩФ˘˜ ЛПВОЩЪФКfiЪФ˘˜ ·БˆБФ‡˜ О·И/‹ Щ· ·УЩИОВ›МВУ· Щ·

ФФ›· ЯЪ›ЫОФУЩ·И ЫВ В·К‹ МВ ЩФ˘˜ ·БˆБФ‡˜. ∞У В›ЫЩВ

˘Ф¯ЪВˆМ¤УФИ У· ВЪБ·ЫЩВ›ЩВ ЫВ МИОЪfiЩВЪЛ ·fiЫЩ·ЫЛ

·fi ЩЛУ ·fiЫЩ·ЫЛ ·ЫК·ПВ›·˜, У· ВИОФИУˆУ‹ЫВЩВ

ЪТЩ· МВ ЩЛУ ЛПВОЩЪИО‹ ВЩ·ИЪ›· О·И У· ЯВЯ·ИˆıВ›ЩВ fiЩИ

ЩФ ЪВ‡М· В›У·И ОФММ¤УФ ЪИУ У· ·Ъ¯›ЫВЩВ ЩЛУ ВЪБ·Ы›·.

ГЪЛЫИМФФИВ›ЩВ ¿УЩФЩВ ВБОВОЪИМ¤У·

ЪФЫЩ·ЩВ˘ЩИО¿ Б¿УЩИ·.

ºФЪ¿ЩВ ЫЩ·ıВЪ¤˜, ·УЩИФПИЫıЛЩИО¤˜

МfiЩВ˜.

Δ· ˘fiÏÔÈ· Û‡ÌßÔÏ·/ÂÈÁڷʤ˜ ÙÔ˘ Ì˯·Ó‹Ì·ÙÔ˜

·У·К¤ЪФУЩ·И ЫВ ВИ‰ИО¤˜ ··ИЩ‹ЫВИ˜ БИ· ВОП‹ЪˆЫЛ

ЪФ‰И·БЪ·КТУ ¤БОЪИЫЛ˜ ЫВ ФЪИЫМ¤УВ˜ ·БФЪ¤˜.

√ ¤ПВБ¯Ф˜ О·И/‹ Ы˘УЩ‹ЪЛЫЛ Ъ¤ВИ

У· Б›УФУЩ·И МВ ЩФ ОИУЛЩ‹Ъ·

ЫЩ·М·ЩЛМ¤УФ, МВ ЩФ ‰И·ОfiЩЛ ™ЩФ

ЫЩЛ ı¤ЫЛ ™Δ√¶.

ГЪЛЫИМФФИВ›ЩВ ¿УЩФЩВ

ВБОВОЪИМ¤У· ЪФЫЩ·ЩВ˘ЩИО¿ Б¿УЩИ·.

∞·ÈÙÂ›Ù·È Ù·ÎÙÈÎfi˜ ηı·ÚÈÛÌfi˜.

√ÙÈÎfi˜ ¤ÏÂÁ¯Ô˜.

ГЪЛЫИМФФИВ›ЩВ ЪФЫЩ·ЩВ˘ЩИО¿

Б˘·ПИ¿ ‹ ‰ИОЩ˘ˆЩ‹ М¿ЫО·.

™˘ÌÏ‹ÚˆÛË Ï·‰ÈÒÓ ·Ï˘Û›‰·˜ ηÈ

Ú‡ıÌÈÛË Ï›·ÓÛ˘

Page 37

¶∂ƒπ∂Ã√M∂¡∞

Greek

–

37

¶ÂÚȯfiÌÂÓ· ¶ÚÈÓ ÙËÓ ÂÎΛÓËÛË Ú¤ÂÈ Ó·

ÚÔÛ¤ÍÂÙ ٷ ·ÎfiÏÔ˘ı·:

H Husqvarna AB ·Ó·Ù‡ÛÛÂÈ Û˘Ó¯Ҙ Ù· ÚÔ˚fiÓÙ· Ù˘

Î·È ÁÈ· ÙÔ ÏfiÁÔ ·˘Ùfi ÂÈÊ˘Ï¿ÛÛÂÈ ÛÙÔÓ Â·˘Ùfi Ù˘ ÙÔ

‰Èη›ˆÌ· ÙÚÔÔÔÈ‹ÛÂˆÓ ¯. ˆ˜ ÚÔ˜ ÙÔ Û¯Â‰È·ÛÌfi ηÈ

ÙËÓ ÂÌÊ¿ÓÈÛË, ¯ˆÚ›˜ ÚÔÂȉÔÔ›ËÛË.

∏ Ì·ÎÚfi¯ÚÔÓË ¤ÎıÂÛË Û ıfiÚ˘‚Ô ÌÔÚ› Ó· ÚÔηϤÛÂÈ

ÌfiÓÈÌË ‚Ï¿‚Ë ÛÙËÓ ·ÎÔ‹. £· Ú¤ÂÈ ¿ÓÙ· Ó·

Ï·Ì‚¿ÓÂÙ ̤ÙÚ· ÚÔÛÙ·Û›·˜ Ù˘ ·ÎÔ‹˜ Û·˜.

¢И·Я¿ЫЩВ ЪФЫВОЩИО¿ ЩИ˜ √‰ЛБ›В˜ ¯Ъ‹ЫВˆ˜ О·И

О·Щ·УФ‹ЫЩВ ЩФ ВЪИВ¯fiМВУФ ЪИУ ¯ЪЛЫИМФФИ‹ЫВЩВ ЩФ

МЛ¯¿УЛМ·.

∞˘Щ¤˜ ФИ Ф‰ЛБ›В˜ ¯Ъ‹ЫВˆ˜ ·ФЩВПФ‡У Ы˘МП‹ЪˆМ· ЩФ˘

ЯИЯП›Ф˘ Ф‰ЛБИТУ ¯Ъ‹ЫВˆ˜ Ф˘ Ы˘УФ‰В‡ВИ ЩФ МЛ¯¿УЛМ·.

°И· ¿ППВ˜ Ф‰ЛБ›В˜ Ы˘МЯФ˘ПВ˘ЩВ›ЩВ ЩФ ЯИЯП›Ф Ф‰ЛБИТУ

¯Ъ‹ЫВˆ˜ ЩФ˘ МЛ¯·У‹М·ЩФ˜.

ΔФ МЛ¯¿УЛМ· В›У·И ·ФОПВИЫЩИО¿ Ы¯В‰И·ЫМ¤УФ БИ· У·

ОfiЯВИ ОП·‰И¿ О·И ОП·‰¿ОИ·.

∂¶∂•∏°∏™∏ ™ÀMμ√§ø¡

™‡ÌßÔÏ· ............................................................... 36

¶∂ƒπ∂Ã√M∂¡∞

¶ÂÚȯfiÌÂÓ· ........................................................ 37

¶ÚÈÓ ÙËÓ ÂÎΛÓËÛË Ú¤ÂÈ Ó· ÚÔÛ¤ÍÂÙ ٷ

·ÎfiÏÔ˘ı·: ............................................................ 37

∂π™∞°ø°∏

∞Á·ËÙ¤ ÂÏ¿ÙË! ................................................. 38

Δπ ∂π¡∞π Δπ;

∞УЩ·ПП·ОЩИО¿ ЪfiЫıВЩФ˘ ВН·ЪЩ‹М·ЩФ˜ ЪИФУИФ‡ 39

√¢∏°π∂™ ∞™º∞§∂π∞™

∫ÔÙÈÎfi˜ ÂÍÔÏÈÛÌfi˜ ........................................... 40

¶ЪФ‰И·БЪ·К¤˜ П¿М·˜ О·И ·П˘Ы›‰·˜ ЪИФУИФ‡ ..... 40

∞ОfiУИЫМ· О·И Ъ‡ıМИЫЛ ‰И¿ОВУФ˘ ‰ФУЩИТУ

·Ï˘Û›‰·˜ ÚÈÔÓ›ÛÌ·ÙÔ˜ ....................................... 41

Δ¤Óو̷ ·Ï˘Û›‰·˜ ............................................... 43

§¿‰ˆМ· ОФЩИОФ‡ ВНФПИЫМФ‡ ............................ 44

∂ПВБ¯Ф˜ КıФЪ¿˜ ОФЩИОФ‡ ВНФПИЫМФ‡ .............. 45

√‰ЛБ›В˜ ·ЫК¿ПВИ·˜ БИ· ЩЛ ¯Ъ‹ЫЛ ЩЛПВЫОФИОФ‡

ЪИФУИФ‡ ............................................................... 46

™À¡∞ƒM√§√°∏™∏

MÔÓÙ¿ÚÈÛÌ· ÎÔÙÈ΋˜ ÎÂÊ·Ï‹˜ ........................... 50

MÔÓÙ¿ÚÈÛÌ· Ô‰ËÁÔ‡ Î·È ·Ï˘Û›‰·˜ ...................... 50

ªФУЩ¿ЪИЫМ· ОЪ›ОФ˘ ·У¿ЪЩЛЫЛ˜ .......................... 50

ƒ‡ıМИЫЛ ВН¿ЪЩЛЫЛ˜ ............................................. 51

°¤ÌÈÛÌ· Ï·‰ÈÔ‡ .................................................... 51

∂ÏÂÁ¯Ô˜ ÚÈÓ ·fi ÙËÓ ÂÎΛÓËÛË .......................... 51

Δ∂áπ∫∞ ™Δ√πÃ∂π∞

Δ¯ÓÈο ÛÙÔȯ›· .................................................. 52

™˘Ó‰˘·ÛÌÔ› Ô‰ËÁÔ‡ Î·È ·Ï˘Û›‰·˜ ....................... 52

∂K–μÂß·›ˆÛË Û˘Ìʈӛ·˜ ................................... 53

!

¶ƒ√∂π¢√¶√π∏™∏! ГˆЪ›˜ ¿‰ВИ· ЩФ˘

О·Щ·ЫОВ˘·ЫЩ‹, ЫВ О·МИ¿ ВЪ›ЩˆЫЛ ‰ВУ

ВИЩЪ¤ВЩ·И МВЩ·ЩЪФ‹ ЩФ˘ МЛ¯·У‹М·ЩФ˜

ЫВ Ы¯¤ЫЛ МВ ЩЛУ ·Ъ¯ИО‹ ЩФ˘ О·Щ·ЫОВ˘‹.

ГЪЛЫИМФФИВ›ЩВ ¿УЩФЩВ БУ‹ЫИ·

·УЩ·ПП·ОЩИО¿. MЛ ВБОВОЪИМ¤УВ˜

МВЩ·ЩЪФ¤˜ О·И/‹ ·УЩ·ПП·ОЩИО¿ МФЪВ› У·

¤¯Ф˘У ˆ˜ Ы˘У¤ВИ· ЫФЯ·Ъfi ‹ ı·У·ЩЛКfiЪФ

ЩЪ·˘М·ЩИЫМfi ЩФ˘ ¯ВИЪИЫЩ‹ ‹ ¿ППˆУ

·ÙfïÓ.

!

¶ƒ√∂π¢√¶√π∏™∏! ∞˘Щfi ЩФ ВН¿ЪЩЛМ·

ВИЩЪ¤ВЩ·И У· ¯ЪЛЫИМФФИЛıВ› МfiУФ МВ Щ·

ЪФЯПВfiМВУ· ı·МУФОФЩИО¿/

¯ПФФОФЩИО¿, ‰В›ЩВ ЫЩЛУ ·Ъ¿БЪ·КФ МВ

Щ›ЩПФ “∂БОВОЪИМ¤У· ·НВЫФ˘¿Ъ“ ЩФ˘

ОВК·П·›Ф˘ “ΔВ¯УИО¿ ¯·Ъ·ОЩЛЪИЫЩИО¿“ ЩФ˘

ЯИЯП›Ф˘ Ф‰ЛБИТУ ЩФ˘ МЛ¯·У‹М·ЩФ˜.

Page 38

38 – Greek

∂π™∞°ø°∏

∞Á·ËÙ¤ ÂÏ¿ÙË!

™˘Á¯·ÚËÙ‹ÚÈ· ÁÈ· ÙËÓ ÂÈÏÔÁ‹ Û·˜ Ó· ·ÁÔÚ¿ÛÂÙ ¤Ó· ÚÔ˚fiÓ Ù˘ Jonsered!

∂›М·ЫЩВ ‚¤‚·ИФИ fiЩИ ı· ВОЩИМ‹ЫВЩВ О·И ı· ИО·УФФИЛıВ›ЩВ ·fi ЩЛУ ФИfiЩЛЩ· О·И ЩЛУ ·fi‰ФЫЛ ЩФ˘ ЪФ˚fiУЩФ˜ М·˜ БИ·

МВБ¿ПФ ¯ЪФУИОfi ‰И¿ЫЩЛМ·. ªВ ЩЛУ ·БФЪ¿ ВУfi˜ ·fi Щ· ЪФ˚fiУЩ· М·˜ ЪФЫК¤ЪВЩ·И Л ‰˘У·ЩfiЩЛЩ· ·ЪФ¯‹˜

ВНВИ‰ИОВ˘М¤УЛ˜ ‚Ф‹ıВИ·˜ ЫВ ВЪ›ЩˆЫЛ ‚П·‚ТУ О·И БИ· ЩЛУ ВИЫОВ˘‹ ЩФ˘˜. ∞У Л ·УЩИЪФЫˆВ›· Ф˘ ·БФЪ¿Ы·ЩВ ЩФ

МЛ¯¿УЛМ· ‰ВУ ‰И·ı¤ЩВИ ВНФ˘ЫИФ‰ФЩЛМ¤УФ Ы˘УВЪБВ›Ф, ЩfiЩВ ЪˆЩ‹ЫЩВ ЩЛ Ф‡ ı· ‚ЪВ›ЩВ ЩФ ПЛЫИ¤ЫЩВЪФ Ы˘УВЪБВ›Ф

ВН˘ЛЪ¤ЩЛЫЛ˜.

∂П›˙Ф˘МВ У· МВ›УВЩВ ИО·УФФИЛМ¤УФИ ·fi ЩФ МЛ¯¿УЛМ¿ Ы·˜ О·И fiЩИ ı· Б›УВИ Ф ‚ФЛıfi˜ Ы·˜ Ф˘ ı· Ы·˜ Ы˘УФ‰В‡ВИ БИ·

МВБ¿ПФ ¯ЪФУИОfi ‰И¿ЫЩЛМ·. £ВˆЪ‹ЫЩВ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ Ф‰ЛБИТУ Ы·У ¤У· ФП‡ЩИМФ ‚Ф‹ıЛМ·. ΔЛЪТУЩ·˜ fiЫ·

·У·К¤ЪФУЩ·И ЫВ ·˘Щfi (¯Ъ‹ЫЛ, ВИЫОВ˘‹, Ы˘УЩ‹ЪЛЫЛ, ОП.) МФЪВ›ЩВ ·ИЫıЛЩ¿ У· ВИМЛО‡УВЩВ ЩЛ ˙ˆ‹ ЩФ˘ О·ıТ˜ О·И

ЩЛУ МВЩ·ˆПЛЩИО‹ ЩФ˘ ·Н›·. ∞У Ф˘П‹ЫВЩВ ЩФ МЛ¯¿УЛМ¿ Ы·˜, КЪФУЩ›ЫЩВ У· ‰ТЫВЩВ ЫЩФУ У¤Ф О¿ЩФ¯Ф О·И ЩФ

ВБ¯ВИЪ›‰ИФ Ф‰ЛБИТУ.

∫·Ï‹ ÂÈÙ˘¯›· Ì Ù ¯Ú‹Û ÙÔ˘ Ó¤Ô˘ Û·˜ ÚÔ˚fiÓÙÔ˜ Ù˜ Jonsered!

H Jonsered ·Ó·Ù‡ÛÛÂÈ Û˘Ó¯Ҙ Ù· ÚÔ˚fiÓÙ· Ù˜ Î·È ÁÈ· ÙÔ ÏfiÁÔ ·˘Ùfi ÂÈÊ˘Ï¿ÛÛÂÈ ÛÙÔÓ Â·˘Ùfi Ù˜ ÙÔ ‰Èη›ˆÌ·

ÙÚÔÔÔÈ‹ÛÂˆÓ ¯. ˆ˜ ÚÔ˜ ÙÔ Û¯Â‰È·ÛÌfi Î·È ÙÂÓ ÂÌÊ¿ÓÈÛÂ, ¯ˆÚ›˜ ÚÔÂȉÔÔ›ÂÛÂ.

Page 39

39 – Greek

Δπ ∂π¡∞π Δπ;

∞УЩ·ПП·ОЩИО¿ ЪfiЫıВЩФ˘ ВН·ЪЩ‹М·ЩФ˜ ЪИФУИФ‡ (¶ЪfiЫıВЩФ ВН¿ЪЩЛМ· ЪИФУИФ‡ МВ ЫˆП‹У· ¿НФУ· О›УЛЫЛ˜ PA 1100)

4

13

12

14

15

10

11

2

7

11

9

1

2

8

6

5

3

16

1 °ˆÓÈ·Îfi˜ Ì˯·ÓÈÛÌfi˜ ÌÂÙ¿‰ÔÛ˘

2 ƒ˘ıМИЫЩИО‹ Я›‰· П·‰ТМ·ЩФ˜ ·П˘Ы›‰·˜

3 ∞ÍÔÓ·˜ (1100 mm)

4 ХБОИЫЩЪФ ·У¿ЪЩЛЫЛ˜

5 £‹ÎË ÚÔÛÙ·Û›·˜ ·Ï˘Û›‰·˜

6 MÔ˘ÏfiÓÈ Û˘ÁÎÚ¿ÙËÛ˘ Ô‰ËÁÔ‡

7 웉· ЩВУЩТМ·ЩФ˜ ·П˘Ы›‰·˜

8 ∞Ï˘Û›‰· ÚÈÔÓ›ÛÌ·ÙÔ˜

9 §¿Ì·

10 ƒÂ˙ÂÚßÔ˘¿Ú Ï·‰ÈÔ‡ ·Ï˘Û›‰·˜

11 °¤ÌÈÛÌ· Ï·‰ÈÔ‡ ·Ï˘Û›‰·˜

12 √‰ËÁ›Â˜ ¯Ú‹Ûˆ˜

13 ¶ÚÔÊ˘Ï·ÎÙ‹Ú·˜ ÌÂÙ·ÊÔÚ¿˜

14 ™‡ÓıÂÙÔ ÎÏÂȉ›

15 ∂Н¿ЪЩИЫЛ

16 ∫ÏÂȉ› Torx

Page 40

√¢∏°π∂™ ∞™º∞§∂π∞™

40 – Greek

∫ÔÙÈÎfi˜ ÂÍÔÏÈÛÌfi˜

™В ·˘Щ‹ ЩЛУ ВУfiЩЛЩ· ВЪИБЪ¿КВЩ·И Т˜ МВ ЫˆЫЩ‹

Ы˘УЩ‹ЪЛЫЛ О·И МВ ¯Ъ‹ЫЛ ЩФ˘ ЫˆЫЩФ‡ Щ‡Ф˘

ВН·ЪЩ‹М·ЩФ˜ ОФ‹˜ МФЪВ›ЩВ У· ВН·ЫК·П›ЫВЩВ М¤БИЫЩЛ

·fi‰ÔÛË ÎÔ‹˜ Î·È Ó· ·˘Í‹ÛÂÙ ÙË ‰È¿ÚÎÂÈ· ˙ˆ‹˜ ÙÔ˘

ÂÍ·ÚÙ‹Ì·ÙÔ˜ ÎÔ‹˜.

ГЪЛЫИМФФИВ›ЩВ МfiУФ ЩФУ ОФЩИОfi ВНФПИЫМfi Ф˘

Ы˘УИЫЩФ‡МВ! μÏ. ÎÂÊ¿Ï·ÈÔ Δ¯ÓÈο ÛÙÔȯ›·.

Δ· ‰fiУЩИ· ЩЛ˜ ·П˘Ы›‰·˜ У· В›У·И ¿УЩФЩВ О·П¿ О·И

ЫˆЫЩ¿ ·ОФУИЫМ¤У·! AОoПo˘ıВ›ЩВ ЩИ˜ Ф‰ЛБ›В˜ М·˜ О·И

¯ЪЛЫИМФФИВ›ЩВ ЫˆЫЩfi Щ‡Ф П›М·˜. §¿ıФ˜ ·ОФУИЫМ¤УЛ ‹

¯·Ï·Ṳ̂ÓË ·Ï˘Û›‰· ·˘Í¿ÓÂÈ ÙÔÓ Î›Ó‰˘ÓÔ ·Ù˘¯ËÌ¿ÙˆÓ.

¢И·ЩЛЪВ›ЩВ ЫˆЫЩfi ‰И¿ОВУФ ‰ФУЩИФ‡! ∞ОФПФ˘ıВ›ЩВ ЩИ˜

Ф‰ЛБ›В˜ М·˜ О·И ¯ЪЛЫИМФФИВ›ЩВ ЫˆЫЩfi МВЩЪЛЩ‹

‰И·О¤УФ˘. ∞Ó ÙÔ ‰È¿ÎÂÓÔ Â›Ó·È ÌÂÁ·Ï‡ÙÂÚÔ ·’ ÙÔ

О·УФУИОfi, МВБ·ПТУВИ О·И Ф О›У‰˘УФ˜ ЩИУ¿БМ·ЩФ˜.

∏ ·Ï˘Û›‰· Ó· Â›Ó·È ÙÂÓو̤ÓË! ª›· ¯·Ï·Ú‹ ·Ï˘Û›‰·

ÍÂʇÁÂÈ Â˘ÎÔÏfiÙÂÚ· Î·È Ë ÊıÔÚ¿ Ù˘ Ï¿Ì·˜, Ù˘ ›‰È·˜

Ù˘ ·Ï˘Û›‰·˜ Î·È ÙÔ˘ ÙÚÔ¯Ô‡ ÌÂÙ¿‰ÔÛ˘ ΛÓËÛ˘ ÛÙËÓ

·Ï˘Û›‰· Á›ÓÂÙ·È ÌÂÁ·Ï‡ÙÂÚË.

¡· ¤¯ВЩВ ЩЛУ ·П˘Ы›‰· О·П¿ П·‰ˆМ¤УЛ О·И ЫˆЫЩ¿

Ы˘УЩЛЪЛМ¤УЛ! ∞Ó·ÚΤ˜ Ï¿‰ˆÌ· Ù˘ ·Ï˘Û›‰·˜

·˘Í¿ÓÂÈ ÙÔÓ Î›Ó‰˘ÓÔ Û·Û›Ì·Ùfi˜ Ù˘ Î·È ÂÈϤÔÓ Ë

ÊıÔÚ¿ ÙÔ˘ Ô‰ËÁÔ‡, Ù˘ ›‰È·˜ Ù˘ ·Ï˘Û›‰·˜ Î·È ÙÔ˘

ÙÚÔ¯Ô‡ ÌÂÙ¿‰ÔÛ˘ ΛÓËÛ˘ ÛÙËÓ ·Ï˘Û›‰· Á›ÓÂÙ·È

ÌÂÁ·Ï‡ÙÂÚË.

¶ЪФ‰И·БЪ·К¤˜ П¿М·˜ О·И ·П˘Ы›‰·˜

ЪИФУИФ‡

ŸЩ·У ЩФ ·ЪВПОfiМВУФ ОФ‹˜ Ф˘ ·Ъ¤¯ВЩ·И МВ ЩФ

МЛ¯¿УЛМ· Ы·˜ Ъ¤ВИ У· ·УЩИО·Щ·ЫЩ·ıВ› ПfiБˆ КıФЪ¿˜

‹ ˙ЛМИ¿˜, Ъ¤ВИ У· ЩФФıВЩВ›ЩВ МfiУФ ЩФ˘˜ Щ‡Ф˘˜

П¿М·˜ ‹ ·П˘Ы›‰·˜ ЪИФУИФ‡ Ф˘ Ы·˜ Ы˘УИЫЩФ‡МВ.

§¿Ì·

•

M‹ÎÔ˜ (›ÓÙÛ˜/cm)

•

μ‹М· ·П˘Ы›‰·˜ (›УЩЫВ˜). ∏ ·fiЫЩ·ЫЛ МВЩ·Н‡ ЩˆУ

‰ФУЩИТУ О›УЛЫЛ˜ Ъ¤ВИ У· В›У·И ›‰И· МВ ЩЛУ

·fiЫЩ·ЫЛ ЩˆУ ‰ФУЩИТУ ЩФ˘ ЩЪФ¯Ф‡ ЩФ˘ ¿ОЪФ˘ ЩФ˘

Ф‰ЛБФ‡ О·И ЩФ˘ ОИУЛЩ‹ЪИФ˘ ЩЪФ¯Ф‡.

!

¶ƒ√∂π¢√¶√π∏™∏! ¶ФЩ¤ МЛУ ¯ЪЛЫИМФФИВ›ЩВ

¤У· МЛ¯¿УЛМ· МВ ВП·ЩЩˆМ·ЩИОfi ВНФПИЫМfi

·ЫК¿ПВИ·˜. √ ВНФПИЫМfi˜ ·ЫК¿ПВИ·˜ ЩФ˘

МЛ¯·У‹М·ЩФ˜ Ъ¤ВИ У· ВП¤Б¯ВЩ·И О·И У·

Ы˘УЩЛЪВ›Щ·И fiˆ˜ ВЪИБЪ¿КВЩ·И ЫВ ·˘Щfi ЩФ

ОВК¿П·ИФ. ∂¿У ЩФ МЛ¯¿УЛМ¿ Ы·˜ ‰ВУ ПЛЪВ›

ЩФ˘˜ ··ИЩФ‡МВУФ˘˜ ВП¤Б¯Ф˘˜,

·Â˘ı˘Óı›Ù ÛÙÔÓ ·ÓÙÈÚfiÛˆÔ ÙÔ˘

Û¤ÚßȘ ÁÈ· ÂȉÈfiÚıˆÛË.

!

¶ƒ√∂π¢√¶√π∏™∏! ¢И·ОfiЩВЩВ ¿УЩ· ЩЛ

ПВИЩФ˘ЪБ›· ЩФ˘ ОИУЛЩ‹Ъ· ЪИУ

ЪФ¯ˆЪ‹ЫВЩВ ЫВ ФФИ·‰‹ФЩВ ВЪБ·Ы›·

ЫЩФ ВН¿ЪЩЛМ· ОФ‹˜. ∞˘Щfi Ы˘УВ¯›˙ВИ У·

ВЪИЫЩЪ¤КВЩ·И ·ОfiМ· О·И МВЩ¿ ·fi ЩЛУ

·ВПВ˘ı¤ЪˆЫЛ ЩФ˘ БО·˙ИФ‡. μВЯ·ИˆıВ›ЩВ

fiЩИ ЩФ ВН¿ЪЩЛМ· ОФ‹˜ ¤¯ВИ ЫЩ·М·Щ‹ЫВИ

ВУЩВПТ˜ О·И ·К·ИЪ¤ЫЩВ ЩФ О·ПТ‰ИФ ·fi ЩФ

МФ˘˙› ЪИУ ·Ъ¯›ЫВЩВ У· ВЪБ¿˙ВЫЩВ ЫВ

·˘Ùfi.

Page 41

√¢∏°π∂™ ∞™º∞§∂π∞™

Greek

–

41

• ∞ЪИıМfi˜ ‰ФУЩИТУ О›УЛЫЛ˜. √ ·ЪИıМfi˜ ЩˆУ ‰ФУЩИТУ

О›УЛЫЛ˜ ЪФО‡ЩВИ ·fi ЩФ М‹ОФ˜ ЩЛ˜ П¿М·˜, ЩФ Я‹М·

ЩЛ˜ ·П˘Ы›‰·˜ О·И ЩФУ ·ЪИıМfi ЩˆУ ‰ФУЩИТУ ЩФ˘

·ÎÚ·›Ô˘ ÁÚ·Ó·˙ÈÔ‡ Ù˘ Ï¿Ì·˜.

•

¶Ï¿ÙÔ˜ ·˘Ï¿ÎˆÛ˘ Ô‰ËÁÔ‡ (›ÓÙÛ˘/mm). ΔÔ Ï¿ÙÔ˜

·˘П¿ОˆЫЛ˜ ЩЛ˜ П¿М·˜ ı· Ъ¤ВИ У· Щ·ИЪИ¿˙ВИ МВ ЩФ

П¿ЩФ˜ ЩФ˘ ‰ФУЩИФ‡ О›УЛЫЛ˜.

•

√‹ П›·УЫЛ˜ О·И Ф‹ ЩВУЩТМ·ЩФ˜ ·П˘Ы›‰·˜.

∞Ï˘Û›‰· ÚÈÔÓ›ÛÌ·ÙÔ˜

•

μ‹М· ·П˘Ы›‰·˜ (›УЩЫВ˜). (∏ ·fiЫЩ·ЫЛ МВЩ·Н‡ ЩЪИТУ

ОЪ›ОˆУ О›УЛЫЛ˜, ‰И·ИЪВМ¤УЛ ‰И· ‰‡Ф.)

•

¶П¿ЩФ˜ ‰ФУЩИТУ О›УЛЫЛ˜ (mm/›УЩЫВ˜)

•

∞ЪИıМfi˜ ‰ФУЩИТУ О›УЛЫЛ˜

∞ОfiУИЫМ· О·И Ъ‡ıМИЫЛ ‰И¿ОВУФ˘

‰ФУЩИТУ ·П˘Ы›‰·˜ ЪИФУ›ЫМ·ЩФ˜

°ВУИО¿ БИ· ЩФ ·ОfiУИЫМ· ‰ФУЩИФ‡ ·П˘Ы›‰·˜

•

¶ÔÙ¤ ÌËÓ ÚÈÔÓ›˙ÂÙ Ì ÛÙÔ̤̈ÓË ·Ï˘Û›‰·. ∏

·Ï˘Û›‰· Â›Ó·È ÛÙÔ̤̈ÓË fiÙ·Ó ¯ÚÂÈ¿˙ÂÙ·È Ó·

ȤÛÂÙ ÙÔ ÚÈfiÓÈ ÁÈ· Ó· Îfi„ÂÙ ÙÔ Í‡ÏÔ Î·È Ù·

ÚÈÔÓ›‰È· Â›Ó·È Ôχ ÌÈÎÚ¿. MÈ· Ôχ ÛÙÔ̤̈ÓË

·Ï˘Û›‰· ‰ÂÓ ·Ú¿ÁÂÈ Î·ıfiÏÔ˘ ÚÈÔÓ›‰È·. ΔÔ ÌfiÓÔ

·ФЩ¤ПВЫМ· В›У·И Н˘ПfiЫОФУЛ.

•

MИ· О·ПФ·ОФУИЫМ¤УЛ ·П˘Ы›‰· МfiУЛ ЩЛ˜ Я˘ı›˙ВЩ·И

ЪИФУ›˙ФУЩ·˜ ¤Ъ· БИ· ¤Ъ· ЩФ Н‡ПФ О·И ‰ЛМИФ˘ЪБВ›

М·ОЪИ¿ О·И К·Ъ‰И¿ ЪИФУ›‰И·. ΔФ ЩМ‹М· ЩФ˘ ЪИФУИФ‡

Ф˘ ОfiЯВИ ФУФМ¿˙ВЩ·И ОФЩИО‹ ВИК¿УВИ· О·И

·ФЩВПВ›Щ·И ·fi ¤У· ‰fiУЩИ ОФ‹˜ (∞) О·И ¤У· Ф‰ЛБfi

Я¿ıФ˘˜ (μ). ∏ ‰И·КФЪ¿ ‡„Ф˘˜ ·˘ЩТУ ЩˆУ ЫЛМВ›ˆУ

О·ıФЪ›˙ВИ ЩФ Я¿ıФ˜ ЪИФУ›ЫМ·ЩФ˜.

•

°И· ЩФ ·ОfiУИЫМ· ВУfi˜ ‰ФУЩИФ‡ ОФ‹˜ Ъ¤ВИ У·

ПЛКıФ‡У ˘fi„Л 5 МВБ¤ıЛ.

1 ∏ ÁˆÓ›· ·ÎÔÓ›ÛÌ·ÙÔ˜

!

¶ƒ√∂π¢√¶√π∏™∏! §·ıВМ¤У· ·ОФУИЫМ¤УЛ

·Ï˘Û›‰· ·˘Í¿ÓÂÈ ÙÔÓ Î›Ó‰˘ÓÔ ÙÈÓ¿ÁÌ·ÙÔ˜!

Page 42

√¢∏°π∂™ ∞™º∞§∂π∞™

42 – Greek

2 ∏ ÁˆÓ›· ÎÔ‹˜

3 ∏ ı¤ÛË Ù˘ ϛ̷˜

4 ∏ ‰И¿МВЩЪФ˜ ЩЛ˜ ЫЩЪФББ˘П‹˜ П›М·˜

5 ΔÔ ß¿ıÔ˜ ·ÎÔÓ›ÛÌ·ÙÔ˜

∂›У·И ФП‡ ‰‡ЫОФПФ У· ·ОФУИЫЩВ› МИ· ·П˘Ы›‰· ¯ˆЪ›˜

¯Ъ‹ЫЛ ВИ‰ИОТУ ВЪБ·ПВ›ˆУ. °И’ ·˘Щfi Ы·˜ Ы˘УИЫЩФ‡МВ У·

¯ЪЛЫИМФФИВ›ЩВ ЩФ˘˜ ВИ‰ИОФ‡˜ МВЩЪЛЩ¤˜ БˆУ›·˜

ПИМ·Ъ›ЫМ·ЩФ˜ Ф˘ ‰И·ı¤ЩФ˘МВ. MВ ·˘ЩФ‡˜

ВН·ЫК·П›˙ВЩВ О·ПФ·ОФУИЫМ¤УЛ ·П˘Ы›‰· МВ

ВП·¯ИЫЩФФИЛМ¤УЛ Щ¿ЫЛ ЩИУ¿БМ·ЩФ˜ О·И О·П‹ ·fi‰ФЫЛ

ОФ‹˜ ЩЛ˜ ·П˘Ы›‰·˜ Ы·˜.

∞ОfiУИЫМ· ‰ФУЩИФ‡ ОФ‹˜

•

°И· ЩФ ·ОfiУИЫМ· ВУfi˜ ‰ФУЩИФ‡ ¯ЪВИ¿˙ВЫЩВ МИ·

™Δƒ√°°А§∏ §πM∞ О·И ¤У·У M∂Δƒ∏Δ∏ °ш¡π∞™

§πM∞ƒπ™M∞Δ√™.

•

μВЯ·ИˆıВ›ЩВ fiЩИ Л ·П˘Ы›‰· В›У·И ЩВУЩˆМ¤УЛ. MИ·

¯·П·ЪˆМ¤УЛ ·П˘Ы›‰· ‰˘ЫОФПВ‡ВИ ЩФ ЫˆЫЩfi

·ÎfiÓÈÛÌ·.

1

5

!

¶ƒ√∂π¢√¶√π∏™∏! √И ·Ъ·О¿Щˆ

ВУ¤ЪБВИВ˜, ‰ВУ В›У·И Ы‡МКˆУВ˜ МВ ЩИ˜

Ф‰ЛБ›В˜ М·˜ О·И ·˘Н¿УФ˘У ЫЛМ·УЩИО¿ ЩЛУ

Щ¿ЫЛ ЩИУ¿БМ·ЩФ˜ ЩЛ˜ ·П˘Ы›‰·˜:

MВБ·П‡ЩВЪЛ ЩФ˘ О·УФУИОФ‡ БˆУ›·

·ÎÔÓ›ÛÌ·ÙÔ˜

MИОЪfiЩВЪЛ ЩФ˘ О·УФУИОФ‡ БˆУ›· ОФ‹˜