Page 1

AD-1272 Advanced Thermal Dispersion Probe Airflow

Measuring System

Technical Bulletin

AD-1272

Refer to the QuickLIT website for the most up-to-date version of this document.

Code No. LIT-12012477

Issued December 2017

Document Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Navigating the Start-Up Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Membrane Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Navigating the Menu Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Navigating the Operator Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Enable, Disable, and Change the Operator PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flow Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Display Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Updating Display Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Selecting Custom Text. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Analog Output 1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Updating Analog Output 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Analog Output 2 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Updating Analog Output 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Temperature Output LPF (Low Pass Filter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Updating Temperature Output LPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Flow Output LPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Updating Low Output LPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Analog Output Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuring the Analog Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Temperature Balance Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

K-Factor Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuring the K-Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System

Technical Bulletin

1

Page 2

Menu Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

BACnet Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

BACnet Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Hardware Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

BACnet Flow Alarm Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

BACnet Temperature Alarm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Navigating the Supervisor Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Enable, Disable, and Change the Supervisor PIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Sensor Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Reset Sensor Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Factory Default Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

2

Page 3

AD-1272 Advanced Thermal Dispersion Probe Airflow

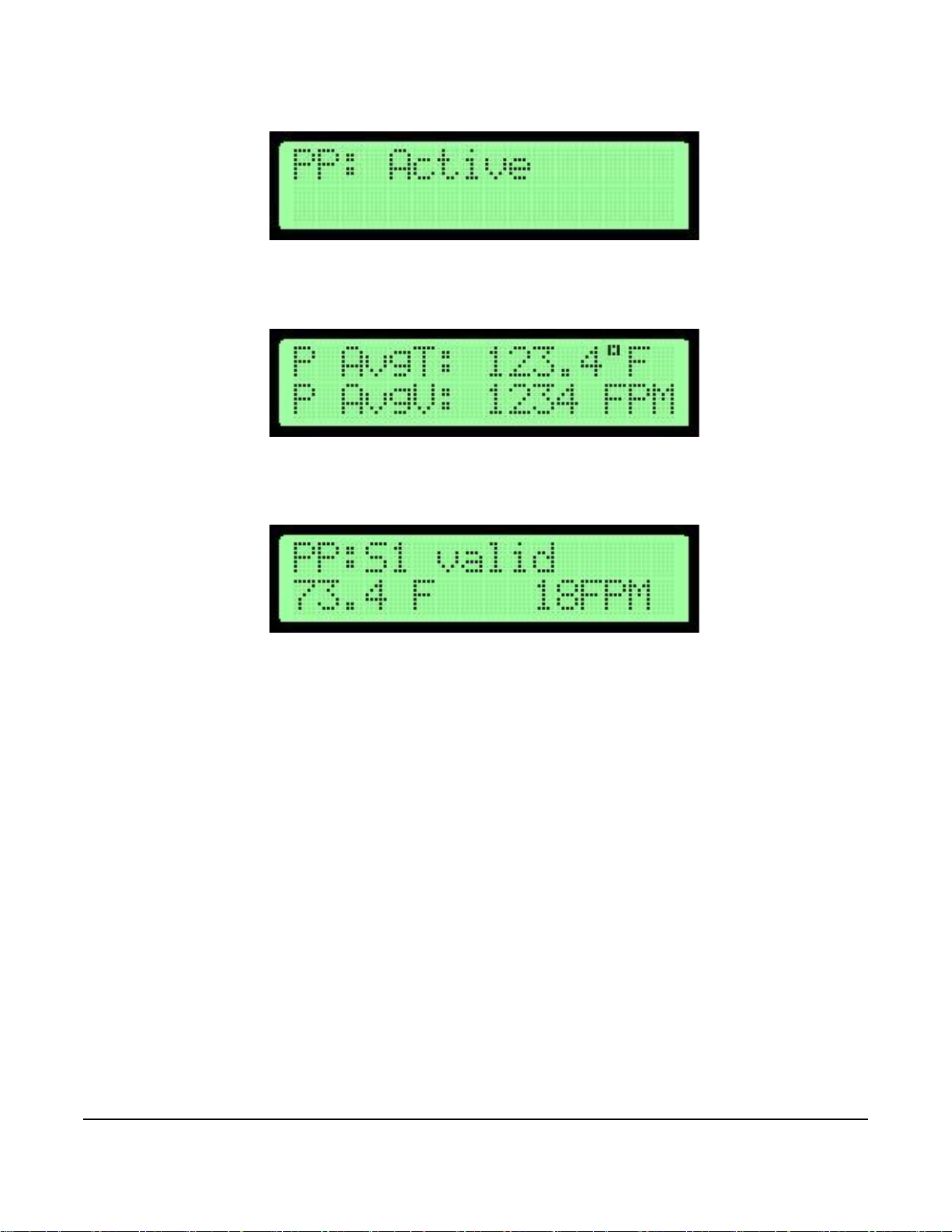

Figure 1: Front Panel LCD Display of Primary and Wired Remote AD-1272 Transmitter

(Left) and Wireless Remote Display (Right)

Figure 2: Firmware Version

Measuring System

Technical Bulletin

Document Introduction

This document describes the AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System’s features

and functions. It also provides guidelines and instructions for setting up and troubleshooting these devices used in

plenum and duct applications.

Navigating the Start-Up Menu

After installing the AD-1272 Airflow Measuring System, power on the unit. Menu options appear on the front panel

LCD display of the primary transmitter and are replicated on the Remote Display (see Figure 1). The LCD display

has a 16-character per line, 2-line display.

When the device is first powered on, the display boot screen indicates the firmware version.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

3

Page 4

After 5 seconds, the display indicates the number of active probes and sensors. This example indicates one active

Figure 3: Active Probes and Sensors Screen

Figure 4: Unit is Warming Up Screen

Figure 5: Average Temperature and Velocity Screen

Figure 6: Imperial Temperature and Volume Screen

probe and four total sensors.

Note: When the Primary Transmitter with Display is located remotely, the AD-1272 count the Primary Transmitter

as an additional probe. This will cause the number of probes to be shown as one greater than the number

of ancillary probes.

After another 5 seconds, the display indicates that the unit is warming up.

Normal Operation

The normal operation screens display the average temperature and average velocity or volume in the units

selected.

When the display is configured for the International System of Units (SI), the display shows the temperature in

Celsius and the average velocity in meters per second or the volume as liters per minute. See Table 3 for the

available units.

When the display is configured for Imperial, the display shows the temperature in Fahrenheit and the average

velocity in Actual Cubic Feet per Minute. See Table 3 for the available units.

Note: An asterisk (*) appears on the top left corner of the display if the number of sensors has changed during

normal operation mode.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

4

Page 5

Configuration

Figure 7: Membrane Pushbuttons

Figure 8: Menu Option Selection Screen

Figure 9: Adjusting Digits Screen

The onboard microprocessor in the AD-1272 primary transmitter allows for system configuration, operating

parameter selection, analog output configuration, and display filtering.

Note: Each primary and ancillary probe automatically reports temperature and flow based on the number of

installed sensors (1 through 8) per probe.

Verify configuration and change editable parameters, within defined ranges, in the configuration mode.

Membrane Pushbuttons

You can use the five membrane pushbuttons (MENU, ESC, UP, DOWN, and ENTER) on the front panel display

cover to interface with the AD-1272 primary transmitter.

Note: When in Normal Operation Display Mode the second line can be too long to display everything at once.

When this occurs, the display will flash between the value and the unit.

Navigating the Menu Options

The left arrow (→) symbol appears on the left side of the currently selected menu, submenu, or option. Press

ENTER to access the selected option.

The up and down arrow (↕) symbol on line two of the display indicates that the selected digit or character can be

changed one character or digit at a time. The character or digit blinks when selected.

Press the UP or DOWN buttons to scroll through the available menu and submenu options.

Press ESC to return to the previous menu without making updates to the currently selected option. Press ESC from

the Operator or Supervisor Menu to return to normal operation mode.

Press MENU at any time to return to the normal operation mode.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

5

Page 6

To enter numerical values into a submenu selection option, enter the digits one at a time beginning with the

Figure 10: Selecting Operator Menu Screen

Figure 11: Ente ri n g Ope ra tin g PIN Scre en

leftmost digit. Press UP or DOWN to scroll through the numbers 0 through 9. When the correct value is displayed,

press ENTER. The cursor automatically moves to the next position. If an error is made after pressing ENTER,

press ESC to return to the previous digit.

Navigating the Operator Menu

The Operator Menu allows you to view, set, or change system parameters. System configuration setup in the

Operator Menu may be required when connected to a building automation system.

1. During normal operation when the LCD screen displays the average temperature and average velocity or

volume, press MENU and UP or DOWN until the arrow is next to Operator Menu.

2. Press ENTER to enter the Operator Menu submenu options.

a. If the Operator PIN is enabled, the LCD screen displays the following message:

(1) Enter the 4-digit PIN to access the Operator Menu. PIN entry is made one digit at a time beginning with

the leftmost digit. Press UP or DOWN to scroll through the numbers 0 through 9.

(2) When the correct number is displayed, press ENTER to select the digit. The cursor automatically

moves to the next position. If an error is made after you press ENTER, press ESC to go back and

change the digit.

Note: If the PIN is not correctly entered, the display returns to normal operation.

Note: If you misplace your pin, contact JCI technical support.

b. If the Operator PIN is not enabled, the Operator Menu selections display.

Note: See Enable, Disable, and Change the Operator PIN

for more information about enabling the PIN.

3. Press UP or DOWN to scroll through the available menu selections. See Table 1 for a list of Operator Menu

submenus and their descriptions.

Note: Each Operator Menu submenu has submenu selections to access the configurable options.

Table 1: Operator Menu Submenus

Operator Menu

Submenu Description

Submenus (Actual

Display Name)

Enable Operator PIN

(Enable Oper PIN)

Change Operator PIN

(Change Oper PIN)

Allows user to select a PIN to access the Operator Menu and prevents unauthorized access

of the Operator Menu.

Allows user to change the Operator Menu PIN.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

6

Page 7

Table 1: Operator Menu Submenus

Operator Menu

Submenu Description

Submenus (Actual

Display Name)

Flow Configuration

(Flow Config)

Display Configuration

(Display Config)

Analog Output 1

Parameters

(Output 1 Param)

Analog Output 2

Parameters

(Output 2 Param)

Temperature Low Pass

Filter

(Temp LPF)

Flow Low Pass Filter

(Flow LPF)

Analog Output Calibration

(Output Cal Menu)

Temperature Balance

Menu

(Temp Bal Config)

K-Factor Configuration

(K-Factor Config)

Menu Inactivity Timeout

(Menu Timeout)

BACnet Configuration

(Network Cfg)

BACnet Flow Alarm

Configuration

(Flow Alarm Cfg)

BACnet Temperature

Alarm Configuration

(T emp Alarm Cfg)

Exit Operator Menu

(Exit Oper Menu)

Configures system variables including duct size and shape, elevation, process type, and

process maximum/units.

Selects LCD display parameters.

Selects Analog Output 1 parameters including temperature, flow, or none.

Selects Analog Output 2 parameters including temperature, flow, or none.

Selects the amount of filtering applied to the analog output for temperature.

Selects the amount of filtering applied to the analog output for flow.

Adjusts the span for the analog outputs.

Selects an offset to apply to the reported average temperature including front panel display,

BACnet®, and Analog Outputs 1 and 2.

Turns the K-Factor on and off and allows for the calculation or selection of gain and offset

values.

Selects a time period after which the backlight on the front panel display turns off when no

menu activity is detected and automatically returns to normal operation.

Configures BACnet settings and turns BACnet on and off.

Configures high and low setpoints, deadband, and alarm delay settings and turns the BACnet

flow high and low alarms on and off.

Configures high and low setpoints, deadband, and alarm delay settings and turns the BACnet

temperature high and low alarms on and off.

Returns the display to normal operation.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

7

Page 8

Enable, Disable, and Change the Operator PIN

Figure 12: Operator PIN Flowchart

Selected Submenu

*Default value s s hown

Normal Disp lay

Enable Operator

PIN

Change Operator

PIN

MENU

ENTER

ESC or ENTER

ENTER

ESC or ENTER

DOWN

UP

y

The Enable Operator PIN and Change Operator PIN menu options enable or disable the Operator Menu PIN and

change the current PIN.

Note: The PIN is not set or enabled on a device with factory-default settings.

Submenu Selection Displa

Note: If the Enable Operator PIN option is selected, the Operator Menu can only be accessed with a PIN.

To enable or disable the PIN:

1. Enter the Enable Operator PIN submenu.

2. Press UP or DOWN to choose Yes to enable the PIN or No to disable the PIN.

3. Press ENTER to confirm your selection.

To update the PIN:

1. Enter the Change Operator PIN submenu.

2. Press UP or DOWN to scroll through the numbers 0 through 9.

3. When the correct number is displayed, press ENTER to select the digit. The cursor automatically moves to the

next position. If an error is made after pressing ENTER, press ESC to return to the previous digit.

4. Enter the last digit and press ENTER to store the PIN number. The display returns to the Operator Menu

submenu display. Alternatively, press ESC to return to the Operator Menu without updating the PIN.

Note: If the PIN settings are enabled, the PIN number must be entered each time the Operator Menu is entered.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

8

Page 9

Flow Configuration

Figure 13: Flow Configuration Flowchart

1. Duct Area controls area input when the Other duct shape is selected.

2. Range is set in Feet per Minute (FPM), but should be converted to

Cubic Feet Per Minute (CFM) to correspond to the output.

ENTER

ESC

Site Elevation

Relative Humidity

Flow Units

Output Lockout

Exit this Menu

Flow Con?guration

Display

Con?guration Menu

Selected Submenu

Submenu Selec tio ns

Output Lockout

Exit this Menu

Duct Setup

Duct Diameter

010.0 in

Duct Minor Axis

010.0 in

Duct Width

010.0 in

Duct Area

000.69 in

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ESC

ESC

ESC

ESC

ESC or Enter

ESC or Enter

ESC or Enter

ESC or Enter

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

UP

UP

UP

UP

UP

UP

Other

Round

Oval

The Flow Configuration submenu stores the application-specific data for unique applications. The typical data

includes units of measure, duct type and size, flow units, site elevation, system ranges, and output lockout.

Submenu Selection Display

ENTER

ENTER

ESC

ENTER

Duct Major Axis

010.0 in

Duct Height

010.0 in

ENTER

ESC

Calc’dDuctArea

0.69 sq ft

ENTER

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

9

Page 10

Table 2: Flow Configuration Submenu Selections and Configurable Options

Figure 14: Flow Configuration Selection Screen

Flow Configuration

Submenu

Selections

Duct Shape Select between rectangle, round, oval, or other duct shapes.

Duct Width

Duct Height

Duct Diameter

Duct Area Scroll between 0 to 100 square feet or 0 to 9.3 square meters. A value not stored or an out of range

Site Elevation Select between 0 to 15,000 feet or 0 to 4,572 meters. The units are previously determined.

Relative Humidity Select between 0 and 99% relative humidity 1% at a time. Holding the button increases the speed at

Flow Units Select between the units listed in Table 3.

Output Lockout Enter three digits with two decimal places. Units are in ft/min or m/sec.

1. For oval ducts, width equals major axis and hight equals minor axis. For round ducts, width and height are not used.

2. For rectangular ducts, oval, or other duct types, diameter is not used.

1

1

2

Configurable Options

Select between 0 to 120 in. or 0 to 304.8 cm.

Select between 0 to 120 in. or 0 to 304.8 cm.

Select between 0 to 120 in. or 0 to 304.8 cm.

error displays if the entry exceeds the design range. The units are previously determined.

which the value changes.

1. In the Operator Menu, press UP or DOWN to scroll to the Flow Configuration submenu.

2. Press ENTER.

3. Scroll through the submenu options and make any necessary updates. See Table 2 for a description of the

Flow Configuration submenu selection options and their configurable options.

See Table 3 and Table 4 for the available selections for units appropriate for the flow type.

Table 3: Volumetric Units of Measurement from Flow Unit Selection and Display Units

1

Actual Flow Units

Actual/Sec ACFS ALPS Standard/Sec SCFS SLPS

Actual/Min ACFM ALPM Standard/Min SCFM SLPM

Actual/Hour ACFH ACMH Standard/Hour SCFH SCMH

1. Actual Flow Units is the default setting.

Imperial Units SI Units

Standard Flow

Units

Imperial Units SI Units

Table 4: Volumetric Units of Measurement (Part 1 of 2)

Volumetric Units of Measurement Display

Actual Cubic Feet Per Second ACFS

Actual Cubic Feet Per Minute ACFM

Actual Cubic Feet Per Hour ACFH

Actual Liters Per Second ALPS

Actual Liters Per Minute ALPM

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

10

Page 11

Table 4: Volumetric Units of Measurement (Part 2 of 2)

Volumetric Units of Measurement Display

Actual Cubic Meters Per Hour ACMH

Standard Cubic Feet Per Second SCFS

Standard Cubic Feet Per Minute

Standard Cubic Feet Per Hour SCFH

Standard Liters Per Second SLPS

Standard Liters Per Minute SLPM

Standard Cubic Meters Per Hour SCMH

1. The standard conditions for Standard Cubic Feet Per Minute airflow measurements are as follows: 14.696 pounds per

square inch (psi) equals 101.325 kPa at sea level. 70 degrees Fahrenheit equals 21.1 degrees Celsius. 50% relative

humidity (RH).

1

SCFM

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

11

Page 12

Display Configuration

Figure 15: Display Configuration Flowchart

Selected Submenu

Submenu Selec ti ons

Submenu Sele ction Display

Display Units

Display

UP

DOWN

ENTER

ENTER

ESC or ENTER

ESC

ENTER

ESC or

ENTER

Display Flow

Type

ENTER

ESC or ENTER

UP

DOWN

Line 2 Parameter

ENTER

UP

DOWN

ESC or ENTER

Line 2 Custom

Text

ENTER

UP

DOWN

ESC or ENTER

Exit this Menu

Returns to

Operator Menu

UP DOWN

ENTER

*Default va lues shown

Display Filter

UP

DOWN

F

I

G

:

f

l

o

w

c

h

a

r

t

_

d

i

s

p

l

a

y

Con iguration

f

The Display Configuration submenu is used to configure display units, parameters, and line 2 customization. The

level of display from 0 to 4 (0 is off, 4 is 80%) is also configurable.

Table 5: Display Configuration Submenu Selections and Configurable Options

Display

Configuration

Submenu

Selections

Display Filter Select between 0 and 4 where 0 is off. Filtering is equal to the value times 20%. A value of 2 is equal

Display Units Select between SI and Imperial.

Display Flow Type Select between velocity and volume.

Line 2 Parameters Select between System Flow and Custom Text for text appearing in line 2 of the display.

Line 2 Custom Select up to seven ASCII characters to display in line 2 of the display. See Selecting Custom Text

Configurable Options

to 40% filtering.

more information.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

12

for

Page 13

Updating Display Configuration

Figure 16: Display Configuration Selection Screen

1. In the Operator Menu, press UP or DOWN to scroll to the Display Configuration submenu.

2. Press ENTER.

3. Scroll through the submenu options and make any necessary updates. See Table 5 for a description of the

Display Configuration submenu selection options and their configurable options.

Selecting Custom Text

1. Scroll to the Line 2 Custom submenu and press ENTER.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

13

Page 14

2. Press UP or DOWN to scroll through the available character set. See Figure 17 for a list of available

Figure 17: Custom Text Character Chart

characters.

3. Press ENTER to choose a character when it is displayed. The character is stored and the cursor advances one

position to the right. Press ESC to return to the previous character.

4. Fill the line with characters for the remaining positions. After the seventh character is entered, the custom text

is stored in memory and the display returns to the Display Configuration submenu.

Analog Output 1 Parameters

The Analog Output 1 Parameters submenu is used to select the process variables that Output 1 represents.

Available process variables include flow, temperature, and none. If flow is selected, the output represents the

defined flow design range.

Note: Default flow is in FPM. See BACnet Network Configuration

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

14

for CFM configuration.

Page 15

Note: The factory-default setting for Analog Output 1 is airflow velocity. However, Output 1 or Output 2 can be

Figure 18: Analog Output 1 Parameters Flowchart

Analog Output 1

Parameters

ENTER

ESC or ENTER

*Default values shown

?

Selected Submenu

Submenu Selection Display

Figure 19: Outp u t 1 Parameter Selection Screen

configured for either airflow or temperature.

Table 6: Analog Output 1 Submenu Selection and Configurable Option

Analog Output 1

Submenu

Selection

Output 1

Parameters

Configurable Option

Select between none, flow, and temperature.

Updating Analog Output 1

1. In the Operator Menu, press UP or DOWN to scroll to the Analog Output 1 submenu.

2. Press ENTER.

3. Make any necessary updates to the submenu selection. See Table 6 for a description of the Analog Output 1

submenu selection option and its configurable option.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

15

Page 16

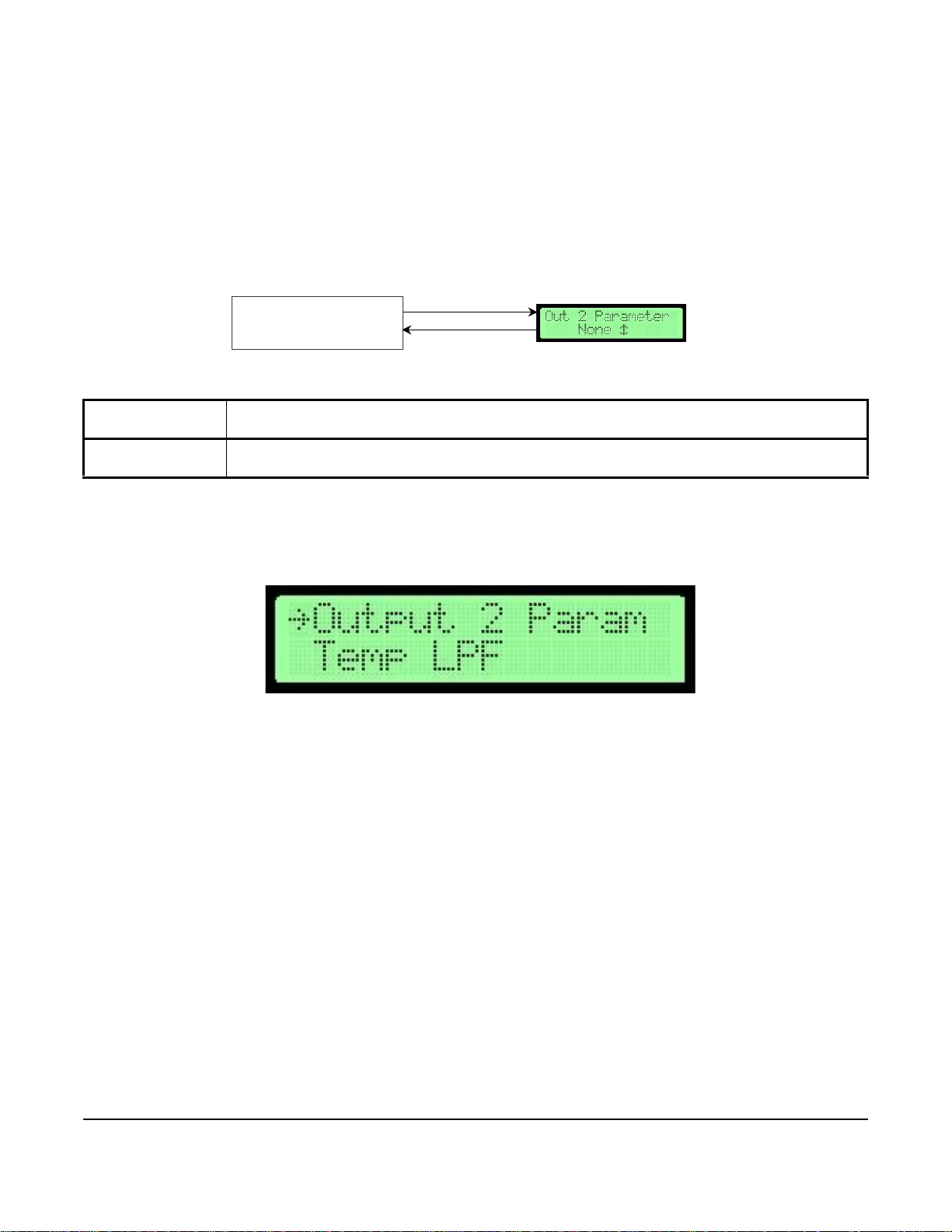

Analog Output 2 Parameters

Figure 20: Analog Output 2 Parameters Flowchart

Analog Output 2

Parameters

ENTER

ESC or ENTER

*Default values shown

?

Selected Submenu

Submenu Selection Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

a

n

a

l

o

g

2

Figure 21: Outp u t 2 Parameter Selection Screen

The Analog Output 2 Parameters menu allows you to select the process variables that Output 2 represents.

Available process variables include flow, temperature, and none. If flow is selected, the output represents the

defined flow design range. If temperature is selected, the default output span for temperature is -25.6 to 120.2°F

(-32°C to 49°C).

Note: The factory-default setting for Analog Output 2 is temperature.

Table 7: Analog Output 2 Submenu and Configurable Options

Analog Output 2

Submenu

Output 2

Parameters

Updating Analog Output 2

1. In the Operator Menu, press UP or DOWN to scroll to the Analog Output 2 submenu.

Configurable Option

Select between none, flow, and temperature.

2. Press ENTER.

3. Make any necessary updates to the submenu selection. See Table 7 for a description of the Analog Output 2

submenu selection option and its configurable option.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

16

Page 17

Temperature Output LPF (Low Pass Filter)

Figure 22: Temperature Output LPF Flowchar t

Temperature Output LPF

ENTER

ESC or ENTER

*Default values shown

Selected Submenu

Submenu Selection Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

t

e

m

p

Figure 23: Temperature Output LPF Selection

The Temperature Output LPF (Low Pass Filter) submenu is used to select the level of process filtering applied to

the temperature outputs. The levels are 0 to 9, with 0 indicating the filter is off and 9 indicating maximum filtering.

The filtering affects the reported temperature values and analog channels configured for temperature. Display Filter

is an additional filter selection applied only to the display.

Note: Each unit of filtering is equal to 10% filtering. For example, 2 is equal to 20%.

Table 8: Temperature Output LPF Submenu Selection and Configurable Option

Temperature Output

LPF Submenu

Selection

Temperature Output

LPF

Updating Temperature Output LPF

Configurable Option

Select between 0 to 9 (9 equals 90% filtering).

1. In the Operator Menu, press UP or DOWN to scroll to the Temperature Output LPF submenu.

2. Press ENTER.

3. Make any necessary updates to the submenu selection. See Table 8 for a description of the Temperature

Output LPF submenu selection option and its configurable option.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

17

Page 18

Flow Output LPF

Figure 24: Flow Output LPF Flowchart

Flow Output LPF

ENTER

ESC or ENTER

*Default values shown

Selected Submenu

Submenu Selection Display

F

I

G

:

f

?

l

o

w

c

h

a

r

t

_

w

o

Figure 25: Flow Output LPF Selection Screen

The Flow Output LPF submenu allows the selection of the level of process filtering applied to the flow outputs. The

levels are 0 to 9, with 0 indicating the filter is off and 9 indicating maximum filtering. The filtering affects the reported

flow values and analog channels configured for flow. Display Filter is an additional filter selection applied only to the

display.

Note: Each unit of filtering is equal to 10% filtering. For example, 2 is equal to 20%.

Table 9: Flow Output LFP Submenu Selection and Configurable Option

Flow Output LPF

Submenu

Selection

Flow LPF Selection Select between 0 to 9 (9 equals 90% filtering).

Updating Low Output LPF

1. In the Operator Menu, press UP or DOWN to scroll to the Flow Output LPF submenu.

Configurable Option

2. Press ENTER.

3. Make any necessary updates to the submenu selection option. See Table 9 for a description of the Flow Output

LPF submenu selection option and its configurable option.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

18

Page 19

Analog Output Calibration

Figure 26: Analog Output Calibration Flowchart

Output 1 Low

Span

UP

DOWN

ESC or ENTER

ESC

ENTER

Output 2 Offset

ESC or ENTER

UP

DOWN

Output 2 Low

Span

UP

DOWN

ESC or ENTER

UP

Low

ESC

DOWN

UP

Output 1 High

Span

ESC or ENTER

ENTER

Output 2 High

Span

ESC or ENTER

ENTER

UP

Design Range

High

ESC

UP

Output 1 Offset

Temperature

Range Low

ESC

UP

ESC

UP

Exit this Menu

UP

Output Calibration

DOWN

UP

?

?

Temperature

Range High

f

i

:

f

g

l

o

w

c

h

a

r

t

_

a

n

a

l

o

g

Analog

Used to adjust the Analog Output Calibration submenu is used to configure the offset and span of Analog Outputs

1 and 2. Span is used to obtain the greatest resolution over the expected or design operating range.

Selected Submenu

ENTER

Submenu Selections Submenu Selection Display

Design Range

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

19

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

ENTER

ENTER

ESC or

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

*Default values shown

Temp Range Hi

Exit this Menu

Page 20

.

Figure 27: Output 1 mA Offset Selection Screen

Figure 28: Anal o g Outp u t 1 Disp la y Scre en

Table 10: Analog Output Calibration Submenu Selections and Configurable Options

Analog Output Calibration

Submenu Selections

Output 1 mA Offset Select between -2 to 2 mA adjustment range.

Output 1 mA Low Span Select between 1 to 4 mA.

Output 1 mA High Span Select between 1 to 20 mA. This value must be higher than the low span value of Output 1.

Output 2 mA Offset Select between -2 to 2 mA adjustment range.

Output 2 mA Low Span Select between 1 to 4 mA.

Output 2 mA High Span Select between 1 to 20 mA. This value must be higher than the low span value of Output 2.

Design Range Low Selects the low range of output flow spanning.

Design Range High Selects the maximum range of output flow spanning.

Temperature Range Low Select between -34.6 to 129.2°F (-37 to 54°C) for low range of output temperature spanning.

Temperature Range High Select between -34.6 to 129.2°F (-37 to 54°C) for maximum range of output temperature

Configurable Options

spanning.

Note: By default, the AD-1272 Airflow Measuring System is factory calibrated.

Configuring the Analog Output

To configure the analog output:

1. Set the Analog Output 1 parameter to None to keep the output from changing with flow or temperature. See

Analog Output 1 Parameters

2. In the Operator Menu, press UP or DOWN to scroll to the Output Calibration submenu.

for instructions.

3. Press ENTER. Scroll to the Output 1 mA Offset submenu selection and press ENTE R.

4. The display indicates the current Analog Output 1 offset.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

20

Page 21

5. Connect a digital multi-meter set to scale Analog Output 1 across terminals plus and minus on the AD-1272

Figure 29: AD-1272 Airflow Measuring System—Terminals 1 and 2

Figure 30: Output 1 mA Low Selection Screen

Figure 31: Output 1 Low Span Display Screen

Airflow Measuring System. See Figure 29 for terminal locations.

Note: The output value should be between 1 and 20 mA. To align the load resistance with the digital multi-meter,

connect the actual process load or a resistor of similar value to the actual process load (250 ohm/

minimum). The digital multi-meter should read a minimum value of 4.00 ± 0.01 mA as determined in Output

1 Span.

6. Press UP or DOWN to adjust the output. Once the last digit is entered, the digital multi-meter reflects the

adjusted Output 1 offset value.

7. Press UP or DOWN in the Output Calibration submenu to scroll to the Output 1 mA Low Span submenu

selection.

8. Press ENTER. The display indicates the current Output 1 low span value.

9. Press UP and DOWN to scroll between 1 and 4 mA to set the low span value.

Note: The low span value must be set lower than the high span value.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

21

Page 22

10. Once the low span is set, press ENTER. In the Output Calibration submenu, scroll to the Output 1 mA High

Figure 32: Output 1 mA High Span Selection Screen

Figure 33: Output 1 High Span Display Screen

Figure 34: Output Calibration Menu Selection

Span submenu selection and press ENTER.

11. The display indicates the current Analog Output 1 high span value. Press UP or DOWN to set the high span by

scrolling between 1 and 20 mA. The high span value must be higher than the low span value.

12. Once the high span is set, press ENTER to confirm the setting.

13. Set the parameter for Analog Output 1 to its previous value before the calibration process. See

Analog Output 1 Parameters

14. Repeat Steps 1 through 13 for Analog Output 2. In Step 5, connect the digital multi-meter across terminals

A02 plus and minus.

for instructions.

15. After both outputs are configured, as necessary, configure the Design Range Low, Design Range High,

Temperature Range Low, and Temperature Range High submenu selections.

16. In the Operator Menu, press UP and DOWN to scroll to the Analog Output Calibration submenu. Press

ENTER.

17. Scroll through the submenu options and make any necessary updates. See Table 10 for a description of the

Analog Output Calibration submenu selection options and their configurable options.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

22

Page 23

Temperature Balance Configuration

Figure 35: Temperature Balance Flowchart

Temperature Balance

Temperature

Balance Enable

ENTER

ENTER

ESC or ENTER

ESC

*Default values shown

Temperature

ESC or ENTER

ENTER

DOWN

UP

Exit this Menu

DOWN

UP

ENTER

DOWN

UP

Returns to

Operator Menu

Returns to

Operator Menu

Selected Su bme n u

Submenu Selections

Submenu Sele ction Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

t

e

m

p

_

b

a

l

Offset

Con iguration

f

Figure 36: Temperature Balance Configuration Selection Screen

The Temperature Balance Configuration submenu applies a temperature offset to the displayed and reported

temperature and the temperature used for analog outputs.

Table 11: Temperature Balance Configuration Submenu Selections and Configurable Options

Temperature

Balance

Configuration

Submenu

Selections

Temperature

Balance Enable

Temperature Offset

Selection

Configurable Options

Select On or Off.

Enter the currently selected value. The temperature displayed on the left side of line 2 is the offset and

the value on the right side of line 2 is a live view of the current temperature with the last confirmed

offset value.The offset range is ±5.4°F (±3°C).

1. In the Operator Menu, press UP or DOWN to scroll to the Temperature Balance Configuration submenu.

2. Press ENTER.

Temperature Balance Configuration submenu selection options and their configurable options.

3. Scroll through the submenu options and make any necessary updates. See Table 11 for a description of the

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

23

Page 24

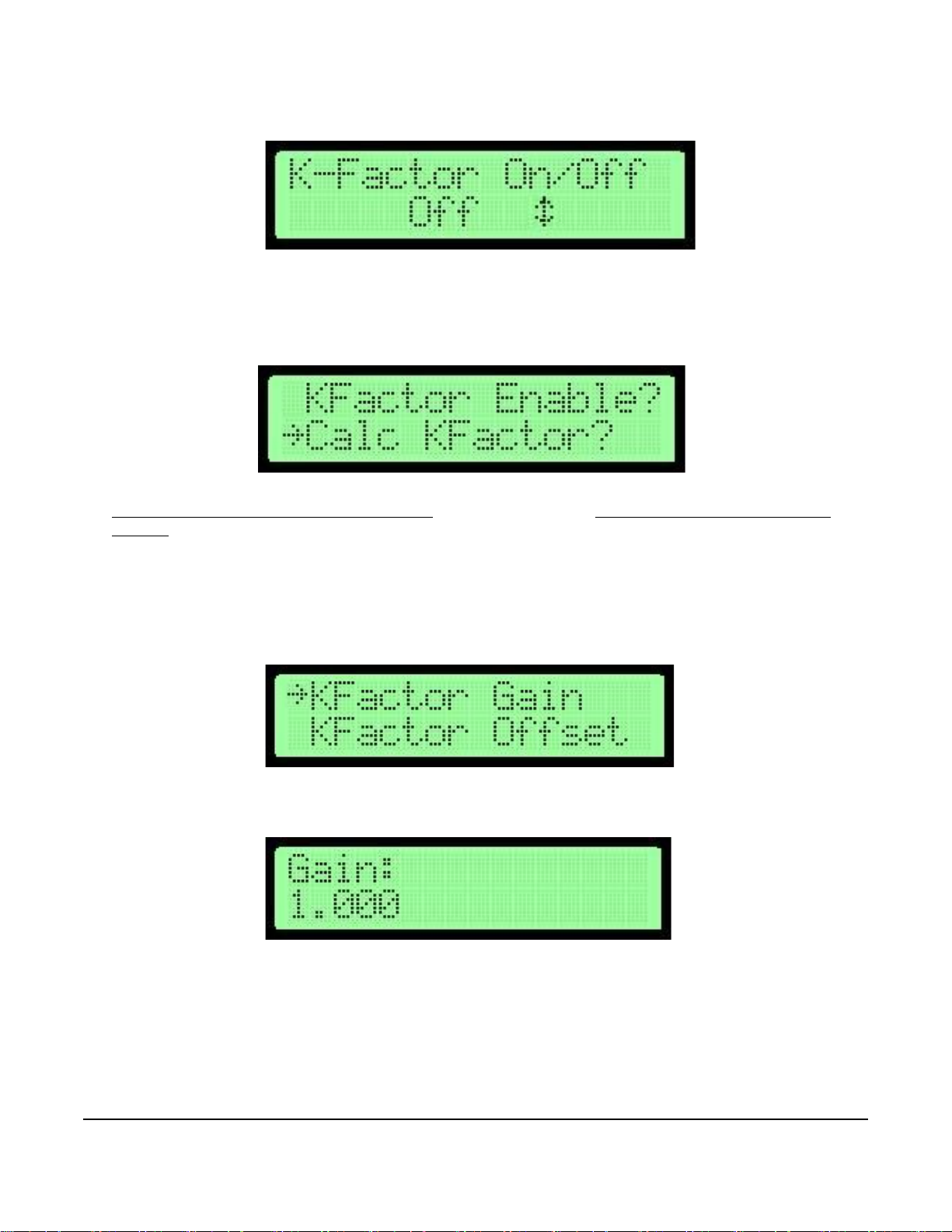

K-Factor Configuration

Figure 37: K-Factor Configuration Flowchart

Calculate

K-Factor

K-Factor Enable?

UP

DOWN

ENTER

ESC or ENTER

*Default values shown

ESC

ENTER

Note:

1

Only when

Calculate K-Factor

is set to

No

.

2

Only when Calculat e K- Fac tor is set to

Yes

3

Only when # of Data Points is set to

1

or higher

4

Only when # of Data Points is set to

2

or higher.

5

Only when # of Data Points is set to

3

.

ENTER

ESC

K-Factor Gain

1

UP

DOWN

ESC

ENTER

K-Factor Offset

1

UP

DOWN

ESC

ENTER

of Data Points

2

UP

DOWN

ESC

ENTER

System at

UP

DOWN

3 seconds

Veloc ity

UP

DOWN

ESC

ENTER

System at

UP

DOWN

3 Seconds

UP

DOWN

ESC

ENTER

System at

3

2,5

UP

DOWN

3

Seconds

3

2,5

UP

DOWN

ESC

ENTER

Generate K-Factor

2

UP

DOWN

Exit this Menu

UP

DOWN

DOWN

UP

.

.

Returns to

Operator Menu

Selected Submenu

Submenu Selections

Submenu Selection Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

K

f

a

c

t

o

r

Point

Point

2

2,4

Point

2

2,4

Point

1

2,3

Point

1

2,3

Point

K-Factor?

Number

Con iguration

f

Veloc ity

Veloc ity

The K-Factor Configuration submenu turns K-Factor on and calculates a K-Factor gain and offset from measured

and reference data. The K-Factor gain and offset values can also be manually configured.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

24

Page 25

Table 12: K-Factor Configuration Submenu Selections and Configurable Options

Figure 38: K-Factor Configuration Selection Screen

Figure 39: K-Factor Enable Selection Screen

K-Factor

Configuration

Submenu

Selections

K-Factor Enable? Select On or Off.

Calculate K-Factor Select between Yes or No.

Manual Gain

Manual Offset

1

1

Number of Data

2

Points

System at Point 1

Point 1 Velocity

System at Point 2

Point 2 Velocity

System at Point 3

Point 3 Velocity

Generate K-Factor

Configurable Options

Update the currently selected value.

Update the currently selected value.

Select between one to three points for calculating the K-Factor.

2

Record the current velocity over the sensors as reference point 1.

2

Update the currently selected value. Reference point 1 is displayed on the right side and the

measured value is entered on the left.

2

Record the current velocity over the sensors as reference point 2.

2

Update the currently selected value. Reference point 2 is displayed on the right side and the

measured value is entered on the left.

2

Record the current velocity over the sensors as reference point 3.

2

Update the currently selected value. Reference point 3 is displayed on the right side and the

measured value is entered on the left.

2

Calculate and update the K-Factor values used then display the calculated values.

1. This submenu selection only appears when Calculate K-Factor is set to No.

2. This submenu selection only appears when Calculate K-Factor is set to Yes.

Configuring the K-Factor

1. In the Operator Menu, press UP or DOWN to scroll to the K-Factor Configuration submenu.

2. Press ENTER to view the K-Factor Configuration submenu. Scroll to the K-Factor Enable? submenu

selection.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

25

Page 26

3. Press ENTER. The display indicates the current K-Factor setting (Off or On).

Figure 40: K-Factor Settings Screen

Figure 41: Calculate K-Factor Selection Screen

Figure 42: K-Factor Gain Selection Screen

Figure 43: K-Factor Gain Screen

4. Press UP or DOWN to change the setting and ENTER to confirm the setting. The new setting is stored in

memory and the display returns to the K-Factor Configuration submenu.

5. Press UP or DOWN to scroll to the Calculate K-Factor submenu selection and press ENTER.

6. Press UP or DOWN to scroll between Yes or No. Press EN TER to make a selection. If No is selected, see

Automatic Calculation of K-Factor Not Enabled

Enabled.

. If Yes is selected, see Automatic Calculation of K-Factor

Automatic Calculation of K-Factor Not Enabled

1. When K-Factor is not enabled, the K-Factor Configuration submenu formats itself for manual K-Factor entry

mode. Scroll to the K-Factor Gain submenu selection and press ENTER.

2. Press ENTER to adjust the manual K-Factor gain. Press UP or DOWN to modify the currently selected value.

3. Press ENTER to confirm the value and return to the K-Factor Configuration submenu.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

26

Page 27

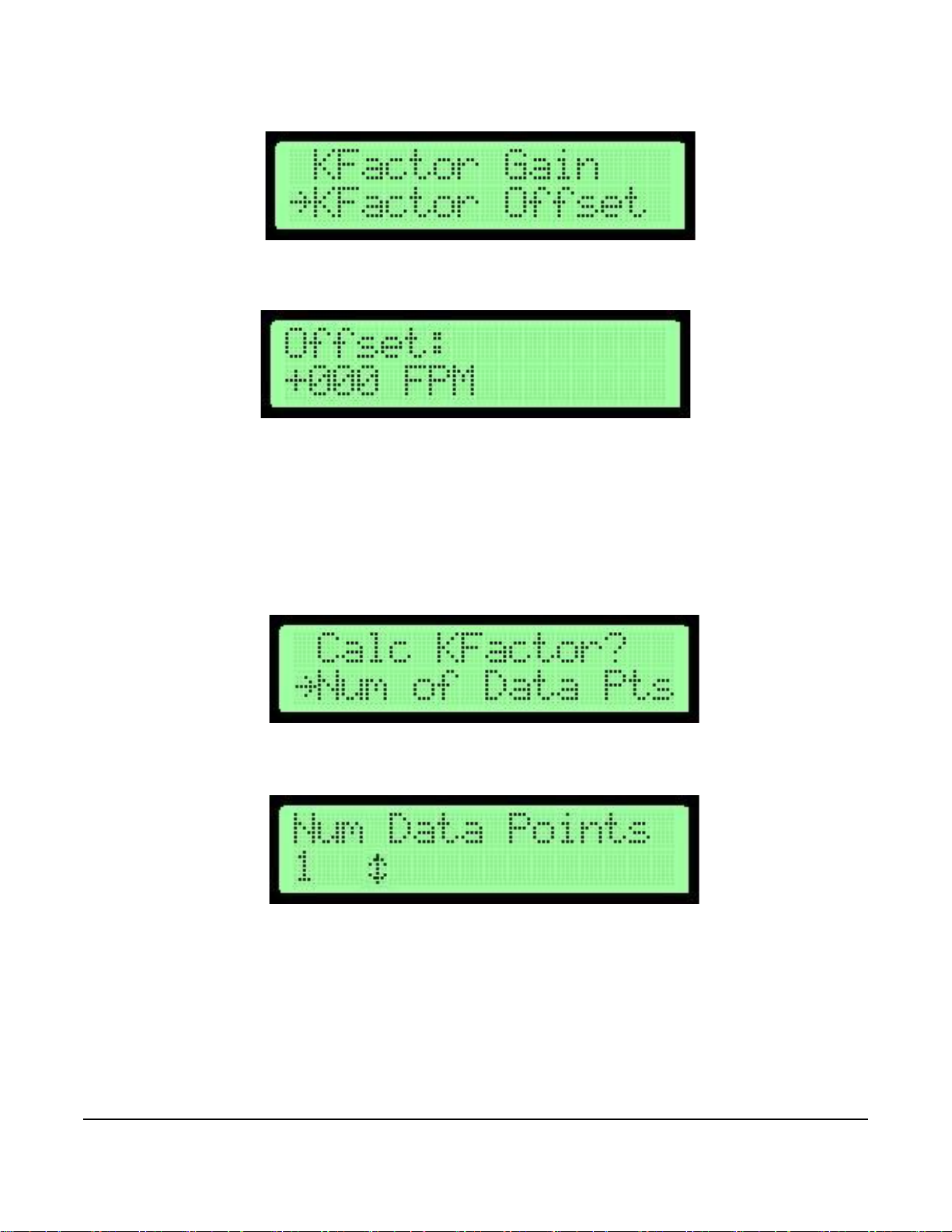

4. Scroll to the K-Factor Offset submenu selection.

Figure 44: K-Factor Offset Selection Screen

Figure 45: K-Factor Gain Screen

Figure 46: Number of Data Point Selection Screen

Figure 47: Number Data Points Adjustment Screen

5. Press ENTER to adjust the manual K-Factor offset. Press UP or DOWN to modify the currently selected value.

6. Press ENTER to confirm the value and return to the K-Factor Configuration submenu.

Automatic Calculation of K-Factor Enabled

Automatic K-Factor calculations can be adjusted to use up to three data points in the calculation. One data point

calculates and uses one offset. Two data points calculate and use one offset and one gain in one equation. Three

data points calculate and use two offsets and two gains in two equations that meet at the middle point.

1. In the K-Factor Configuration submenu, scroll to the Number of Data Points submenu selection.

2. Press ENTER. Press UP or DOWN to select the number of points to use in the K-Factor calculation.

3. Press ENTER to confirm the value and return to the K-Factor Configuration submenu.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

27

Page 28

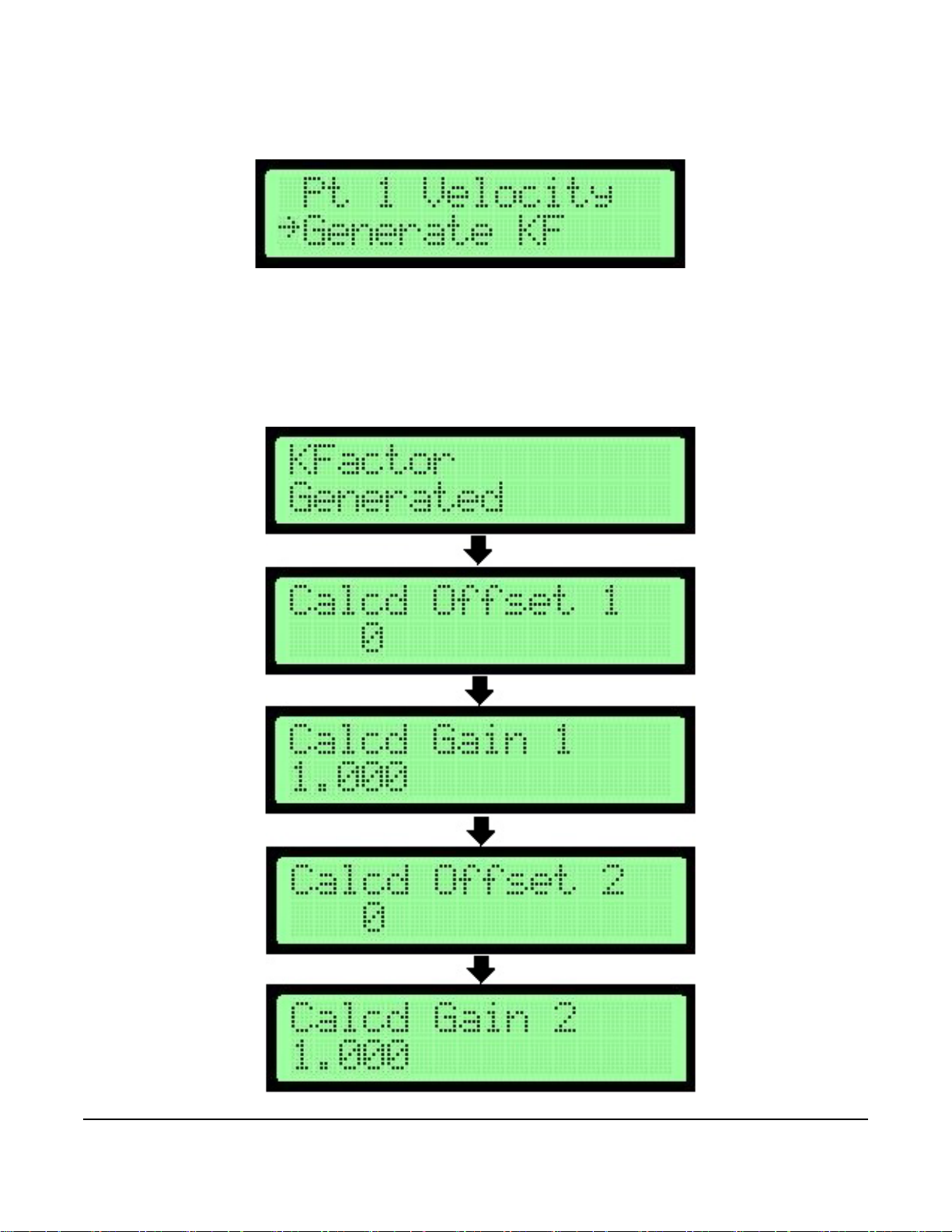

4. Scroll to the System at Point 1 submenu selection.

Figure 48: System at Point 1 Selection Screen

Figure 49: Point 1 Recorded Velocity Screen

Figure 50: Point 1 Velocity Selection Screen

Figure 51: K-Factor Setpoint Screen

5. Press ENTER. Run the air handling system unit to the first K-Factor setpoint. Once the appropriate velocity is

displayed on the external device, press ENTER to store the sensor data and measured velocity in FPM as the

reference value for calculating the K-Factor equation. The display indicates the value is stored and displays the

value for 3 seconds.

Note: Allow the system at least 60 seconds after a velocity state change to balance the displayed readings.

6. The display returns to the K-Factor Configuration submenu. Scroll to the Point 1 Velocity submenu selection.

7. Press ENTER to enter the first measured K-Factor setpoint that is acquired from an external device. Press UP

or DOWN to modify the currently selected digit.

Note: The left side of the display indicates the measured value and the right side shows the corresponding

reference value that was recorded for that point.

8. Press ENTER on the last digit to confirm the value and return to the K-Factor Configuration submenu.

9. If the number of data points from Step 2 was set for more than one, repeat Steps 4 through 8 for each point.

Point 2 must be higher than point 1 and point 3 must be higher than point 2. When all points are recorded,

continue to Step 10.

10. Press UP or DOWN to scroll to the Generate K-Factor submenu selection.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

28

Page 29

Note: The line above Generate K-Factor may display a different number depending on the number of data points

Figure 52: Generate KF Selection Screen

Figure 53: K-Factor Equation Value Generator Screens

selected.

11. Press ENTER to generate the K-Factor equation values.

Note: When one data point is selected, the display indicates the K-Factor Generated and Calculated Offset 1

screens. When two data points are selected, the display indicates the K-Factor Generated, Calculated

Offset 1, and Calculated Gain 1 screens. When three data points are selected, all five screens display.

.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

29

Page 30

12. In the Operator Menu, press UP or DOWN to scroll to the K-Factor Configuration submenu.

Figure 54: K-Factor Configuration Selection Screen

Figure 55: Menu Timeout Flowchart

Menu Timeout

ENTER

ESC or ENTER

*Default values shown

Selected Submenu

Submenu Selection Display

Figure 56: Menu Timeout Selection Screen

13. Press ENTER.

14. Press UP or DOWN to scroll through the submenu options and make any necessary updates. See Table 12 for

a description of the K-Factor Configuration submenu selection options and their configurable options.

Menu Timeout

The Menu Timeout submenu is used to select a time in minutes after which the device backlight dims and the

device returns to normal operation mode if no activity is detected in the Operator Menu.

Table 13: Menu Timeout Submenu Selection and Configurable Option

Menu Timeout

Submenu

Selection

Menu Timeout Select from 0 to 30 minutes. A value of 0 indicates that the display never times out and the backlight is

Configurable Option

always on.

1. In the Operator Menu, press UP or DOWN to scroll to the Menu Timeout submenu.

2. Press ENTER.

3. Make any necessary updates to the submenu selection. See Table 13 for a description of the Menu Timeout

submenu selection option and its configurable option.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

30

Page 31

BACnet Network Configuration

Figure 57: BACnet Configuration Flowchart

BACNet Instance

BACNet Network BACNet On/Off

UP

DOWN

ENTER

ENTER

ESC or ENTER

ESC

ENTER

ESC or ENTER

BACNet Address

ENTER

ESC or ENTER

UP DOWN

BACNet Max

Masters

ENTER

UP

DOWN

ESC or ENTER

BACNet Baud

Rate

ENTER

UP

DOWN

ESC or ENTER

Exit this Menu

UP

DOWN

ENTER

*Default values shown

UP

DOWN

Returns to

Operator Menu

Con iguration

f

Selected Submenu

Submenu Selecti ons

Submenu Selection Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

b

a

c

n

e

t

_

n

e

t

w

o

r

k

The BACnet Network Configuration submenu turns BACnet on or off and configures parameters based on the

BACnet type.

Table 14: BACnet Network Configuration Submenu Selections and Configurable Options

BACnet Network

Configuration

Submenu

Selections

BACnet On/Off Select On or Off.

BACnet Instance Update the currently selected value. The instance number must be unique from all BACnet devices on

BACnet Address Select a value between 4 and 127. Holding down the button increases the rate the value updates.

BACnet Max Mast Select a value between 1 and 127. Holding down the button increases the rate the value updates.

BACnet Baud Rate Select the 9,600, 19,200, 38,400 (default), or 76,800 baud rate.

Configurable Options

the entire system. The range of values is 1 to 4,194,302.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

31

Page 32

1. In the Operator Menu, press UP or DOWN to scroll to the BACnet Network Configuration submenu.

Figure 58: BACnet Network Configuration Selection Screen

2. Press ENTER.

3. Scroll through the submenu options and make any necessary updates. See Table 14 for a description of the

BACnet Network Configuration submenu selection options and their configurable options.

Note: If any changes are made to the BACnet Network Configuration parameters after turning on BACnet, you

must change the BACnet On/Off setting off and back on again to get the changes to take effect.

BACnet Objects

If BACnet communications is enabled on the AD-1272 and all parameters are correctly set (see Figure 57) the

BACnet objects listed below will be available to the Building Automation System (BAS). The units for the BACnet

objects will be the same as the units the display is configured for. For example, if the display is setup to show flow

on CFM, the units for the BACnet Flow objects will also be in CFM. The Flow and Temperature alarms must be

enabled in the AD-1272 (see Figure 59 through Figure 61) for the points to be map able to the BAS.

•Flow

• Temperature

• Low Flow Alarm (if enabled)

• High Flow Alarm (if enabled)

• Low Temperature Flow (if enabled)

• High Temperature Flow (if enabled)

Hardware Objects

If the Analog Outputs on the AD-1272 are wired directly to a field controller on the BAS it is important to note that

the high and low values for the Flow Output are configured in Feet per Minute (FPM) and the Temperature high and

low values are in Deg F when imperial units are selected and Meters per Second (MPS) with Deg C when SI units

are selected. If there is a need to convert the BAS to a different unit, calculate the corresponding values for the

units of measure and program the input’s high and low values with the calculated values. For example, if you have

a 24 x 24 in. (4 square feet) duct and the High Flow Output in the transmitter is set to 5000 FPM (default), the

corresponding high CFM value will be 20,000 CFM, see equation below.

[(24 in. x 24 in.)/144 square inches per square foot] x 5000 FPM = 20,000 CFM

The scaling for the input receiving the signal should be configured from 0 to 20,000 CFM.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

32

Page 33

BACnet Flow Alarm Configuration

Figure 59: BACnet Flow Alarm Configuration Flowchart

UP

DOWN

Alarm High On/Off

BACNet Flow Alarm

Alarm Low On/Off

UP

DOWN

ENTER

ENTER

ESC or ENTER

ESC

ENTER

ESC or ENTER

Alarm Low

Setpoint

ENTER

ESC or ENTER

UP DOWN

Alarm High

Setpoint

ENTER

UP

DOWN

ESC or ENTER

Alarm Deadband

ENTER

ESC or ENTER

Alarm Delay

ENTER

UP

DOWN

ESC

*Default values shown

UP

DOWN

Exit this Menu

ENTER

DOWN

UP

Returns to

Operator Menu

Selected Submenu

Submenu Selec tions

Submenu Selection Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

b

a

c

n

e

t

_

?

o

w

The BACnet Flow Alarm Configuration submenu is only available when BACnet is on (see BACnet Network

Configuration). Alarm parameters can be configured including high and low alarms, setpoints, and alarm delay.

Table 15: BACnet Flow Alarm Configuration Submenu Selection and Configurable Options

BACnet Flow Alarm

Configuration

Submenu Selections

Alarm Low On/Off Select On or Off.

Alarm High On/Off Select On or Off.

Alarm Low Setpoint Choose a value the flow must go below for an alarm condition to exist.

Alarm High Setpoint Choose a value the flow must surpass for an alarm condition to exist.

Alarm Deadband

Setpoint

Alarm Delay Select the amount of time between any alarm condition and the BACnet Flow Alarm Low and High

Configurable Options

Choose a value of flow the controller must reach above the Alarm Low Setpoint for Alarm Low or

below the Alarm High Setpoint for Alarm High before an activated alarm resets. The display units

are the same as those chosen in the Display Configuration

activation. This value is adjustable between 0 and 10 minutes.

submenu and flow configuration.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

33

Page 34

1. In the Operator Menu, press UP or DOWN to scroll to the BACnet Flow Alarm Configuration submenu.

Figure 60: BACnet Flow Alarm Configuration Selection Screen

2. Press ENTER.

3. Scroll through the submenu options and make any necessary updates. See Table 15 for a description of the

BACnet Flow Alarm Configuration submenu selection options and their configurable options.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

34

Page 35

BACnet Temperature Alarm Configuration

Figure 61: BACnet Temperature Alarm Configuration Flowchart

UP

DOWN

Alarm High On/Off

BACNet Temperature

Alarm Low On/Off

UP

DOWN

ENTER

ENTER

ESC or ENTER

ESC

ENTER

ESC or ENTER

Alarm Low

Setpoint

ENTER

ESC or ENTER

UP DOWN

Alarm High

Setpoint

ENTER

UP

DOWN

ESC or ENTER

Alarm Deadband

ENTER

ESC or ENTER

Alarm Delay

ENTER

UP

DOWN

ESC

*Default values shown

UP

DOWN

Exit this Menu

ENTER

DOWN

UP

Returns to

Operator Menu

Selected Submenu

Submenu Selec tions

Submenu Selection Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

b

a

c

n

e

t

_

t

e

m

p

Alarm

The BACnet Temperature Alarm Configuration submenu is only available when BACnet is on (see BACnet Network

Configuration). In this submenu, you can configure temperature parameters including high and low alarms,

setpoints, and alarm delay.

Table 16: BACnet Temperature Alarm Configuration Submenu Selections and Configurable Options (Part 1

of 2)

BACnet Temperature

Alarm Configuration

Submenu Selections

Alarm Low On/Off Select On or Off.

Alarm High On/Off Select On or Off.

Alarm Low Setpoint Choose a value the temperature must go below for an alarm condition to exist.

Alarm High Setpoint Choose a value the temperature must surpass for an alarm condition to exist.

Configurable Options

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

35

Page 36

Table 16: BACnet Temperature Alarm Configuration Submenu Selections and Configurable Options (Part 2

Figure 62: BACnet Temperature Alarm Configuration Selection Menu

of 2)

BACnet Temperature

Alarm Configuration

Submenu Selections

Alarm Deadband

Setpoint

Alarm Delay Select the amount of time between any alarm condition and the BACnet Temperature Alarm Low

Configurable Options

Choose a value of temperature the controller must reach above the Alarm Low Setpoint for Alarm

Low or below the Alarm High Setpoint for Alarm High before an activated alarm resets. The

display units are the same as those chosen in the Display Configuration

and High activation. This value is adjustable between 0 and 10 minutes.

submenu.

1. In the Operator Menu, press UP or DOWN to scroll to the BACnet Temperature Alarm Configuration submenu.

2. Press ENTER.

3. Scroll through the submenu options and make any necessary updates. See Table 16 for a description of the

BACnet Temperature Alarm Configuration submenu selection options and their configurable options.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

36

Page 37

Navigating the Supervisor Menu

Figure 63: Supervisor Menu Selection Screen

Figure 64: Supervisor PIN Selection Screen

The Supervisor Menu is used to enable or disable probes and individual sensors, scan all sensors for status

updates, and perform diagnostics on alert conditions. It is also used to restore the device to a pre-installation state.

1. When the AD-1272 Airflow Measuring System’s LCD screen displays the average temperature and average

velocity or volume, press MENU and UP or DOWN until the arrow is next to the Supervisor Menu.

2. Press ENTER to access the Supervisor Menu settings.

a. If the Supervisor PIN is enabled, the LCD screen displays the following message.

(1) Enter the 4-digit PIN to access the Supervisor Menu. PIN entry is made one digit at a time beginning

with the leftmost digit. Press UP or DOWN to scroll through the numbers 0 through 9.

(2) When the correct number is displayed, press ENTER to select the digit. The cursor automatically

moves to the next position. If an error is made after pressing ENTER, press ESC to go back and

change the digit.

Note: If the PIN is not correctly entered, the display returns to normal operation.

b. If the Supervisor PIN is not enabled, the Supervisor Menu selections display.

Note: See Enable, Disable, and Change the Supervisor PIN

for more information about enabling the PIN.

3. Press UP or DOWN to scroll through the available menu selections. See Table 17 for a list of Supervisor Menu

selections and their descriptions.

Note: Use any Supervisor Menu to access configurable options.

Table 17: Supervisor Menu Submenus (Part 1 of 2)

Supervisor Menu

Description

Submenus (Actual

Display Name)

Enable Supervisor PIN

(Enable Supv PIN)

Change Supervisor PIN

(Change Supv PIN)

Sensor Management

(Sensor Mgmt)

Reset Sensors

(Reset Sensors)

When enabled, prevents unauthorized access to the Supervisor Menu.

Set or change the Supervisor Menu PIN.

Scans the probe network for active and enabled sensors and enables or disables individual

sensors. It also displays the probe status and each sensor’s velocity and temperature

reading.

Allows the cycle of power to the sensors.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

37

Page 38

Table 17: Supervisor Menu Submenus (Part 2 of 2)

Figure 65: Supervisor PIN Flowchart

Selected Submenu

*Default value s s hown

Normal Disp lay

Enable Supervisor

PIN

Change Supervisor

PIN

MENU

ENTER

ESC or ENTER

ENTER

ESC or ENTER

DOWN

UP

Submenu Selection Display

Supervisor Menu

Description

Submenus (Actual

Display Name)

Factory Default

(Factory Default)

Exit Supervisor Menu

(Exit Supv Menu)

Restores the device to the factory-default settings. Any previous settings made in the

Operator and Supervisor Menus are reset including dimensions, the Operator PIN, and

custom text.

Returns the display to normal operation.

Enable, Disable, and Change the Supervisor PIN

The Enable Supervisor PIN and Change Supervisor PIN menu options are used to enable or disable the

Supervisor Menu PIN and change the current PIN.

Note: The PIN is not set or enabled on a device with factory-default settings.

Note: If the Enable Supervisor PIN option is selected, the Supervisor Menu can only be accessed with a PIN.

To enable or disable the PIN:

1. Enter the Enable Supervisor PIN submenu.

2. Press UP or DOWN to choose Yes to enable the PIN or No to disable the PIN.

3. Press ENTER to confirm the selection.

To update the PIN:

1. Enter the Change Supervisor PIN submenu.

2. Press UP or DOWN to scroll to display the numbers 0 through 9.

3. When the correct number is displayed, press ENTER to select the digit. The cursor automatically moves to the

4. Enter the last digit and press ENTER to store the PIN number. The display returns to the Supervisor Menu

next position. If an error is made after pressing ENTER, press ESC to return to the previous digit.

submenu display. Alternatively, press ESC to return to the Supervisor Menu without updating the PIN.

Note: If the PIN settings are enabled, the PIN number must be entered each time the Supervisor Menu is

entered.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

38

Page 39

Sensor Management

Figure 66: Sensor Management Flowchart

UP

DOWN

Scan for Sensors

Sensor

Management

UP

DOWN

ENTER

ENTER

ESC or ENTER

ESC

ENTER

Display Sensor

Status

ENTER

ESC

UP

DOWN

Enable Sensors

ENTER

UP DOWN

ESC

Disable Sensors

ENTER

ESC

Display Probe

Status

ENTER

UP

DOWN

ESC

*Default values shown

UP

DOWN

Display Probe

Data

ENTER

ESC

Exit this Menu

UP

DOWN

ENTER

DOWN

Display Active

Sensors

UP

Selected Submenu

Submenu Selections

Submenu Selection Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

s

e

n

s

o

r

_

m

g

m

t

Returns to

Operator Menu

The Sensor Management submenu is used to scan the sensor network for active sensors and enable or disable

individual sensors. This also displays each sensor’s velocity and temperature reading.

Probes are numbered with P=Primary, 0=First Achillary, 1=Second Anchillary, and so on. Sensor information is

displayed on the left-most sensor in the enclosure at the end of the probe.

Note: When the Primary Transmitter with Display is located remotely the AD-1272 count the Primary Transmitter

as an additional probe. This will cause the number of probes to be shown as one greater than the number

of ancillary probes.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

39

Page 40

Table 18: Sensor Management Submenu Selections and Configurable Options or Display Screens

Figure 67: Sensor Management Selection Screen

Figure 68: Display Active Sensor Selection Screen

Figure 69: Probe and Sensor Display Screen

Sensor

Management

Submenu

Selections

Display Active

Sensor

Scan for Sensor Scan for sensors and restart all devices on the network. The primary probe restarts last. After

Display Sensor

Status

Enable Sensors

Disable Sensors

Display Probe

Status

Display Probe Data

1. The primary probe (P) is displayed first. Ancillary probes use hexadecimal (base 16) numbering. The hexadecimal number

corresponds to the setting on the probe’s rotary switch.

Configurable Options or Display Screen

Display screen indicates the number of active and total probes and sensors.

restarting, the primary probe returns to normal operation.

1

Select the probe addresses on the probe network (P, 0 through F)

indicates a disabled address.

1

Select between probes (P, 0 through F)

(1 through 8) to enable.

Select between probes (P, 0 through F)

(1 through 8) to disable.

Select between probes (P, 0 through F)

the probe’s average temperature and velocity (FPM) from the probe data screen.

Select between probes (P, 0 through F)

sensors (1 through 8).

then select between sensors. Choose the sensor

1

then select between sensors. Choose the sensor

1

to choose the probe on line 2 of the screen. Display indicates

1

. Display shows the individual sensor data. Select between

. V indicates a valid address and D

1. In the Supervisor Menu, press UP or DOWN to scroll to the Sensor Management submenu. Press ENTER.

2. Press UP or DOWN to scroll to Display Active Sensor.

3. Press ENTER. The display indicates the number of active probes and sensors. In this example, one probe is

active and enabled and two out of two sensors are valid and enabled.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

40

Page 41

4. Press ESC or ENTER to return to the Sensor Management submenu.

Figure 70: Scan for Sensor Selection Screen

Figure 71: Scanning for Sensors Display Screen

Figure 72: Display Sensor Status Selection Screen

Figure 73: Sensor Status Display Screen

5. Press UP or DOWN to scroll to the Scan for Sensors submenu selection. Press ENTER. When this option is

selected, the primary probe sends scan and restart commands to all ancillary probes on the wired probe

network. The primary probe then restarts to detect all probes and sensors and updates the inventory.

6. Press ENTER to scan for sensors.The primary probe provides scan and restart commands to the network.

7. Once the scan is complete, the display returns to the normal operation mode. Press MENU.

8. Press UP or DOWN to scroll to the Supervisor Menu. Press ENTER.

9. Press UP or DOWN to scroll to the Display Sensor Status submenu.

10. Press ENTER. The display indicates the following message:

11. Press UP or DOWN to scroll to the probe to display on line 1 of the display.

12. Press ESC. The display returns to the Sensor Management submenu.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

41

Page 42

13. Press UP or DOWN to scroll to the Enable Sensors submenu selection. Press ENTER.

Figure 74: Enable Sensors Selection Screen

Figure 75: Probe Selection Display Screen

Figure 76: Probe Selection Display Screen

Figure 77: Disable Sensors Selection Screen

Figure 78: Disable Probe Status Selection Screen

14. Scroll to display the correct probe number on line 2 and press ENTER.

15. Press UP or DOWN to display the sensor numbers that are enabled by selecting this option and press ENTER.

16. Press ESC. The display returns to the Sensor Management submenu.

17. Scroll to the Disable Sensors submenu selection and press ENTER.

18. Follow Steps 14 and 15 to disable the sensors.

19. Press UP or DOWN to scroll to the Display Probe Status submenu selection.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

42

Page 43

20. Press ENTER. The display indicates:

Figure 79: Active Sensors Display Screen

Figure 80: Probe Data Display Screen

Figure 81: Individual Sensor Information Screen

21. Press UP or DOWN to scroll to the probe that are displayed on line 1 of the display with this selection. Press

ENTER. The display shows the probe data.

22. Press ENTER to view the status and values of individual sensors on the selected probe. Press UP or DOWN to

scroll through the sensors (1 through 8). Press ESC to return to the Probe Data screen.

23. Press UP or DOWN to scroll the menu display to the remaining probes, or press ESC to return to the Sensor

Management menu.

Note: In the Sensor Management submenu, press UP or DOWN to scroll to the Display Probe Data submenu

selection and press ENTER to display the probe data without going through the Probe Status submenu

selection.

24. Press UP or DOWN to scroll to Exit this Menu and press ENTER to return to the Supervisor Menu.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

43

Page 44

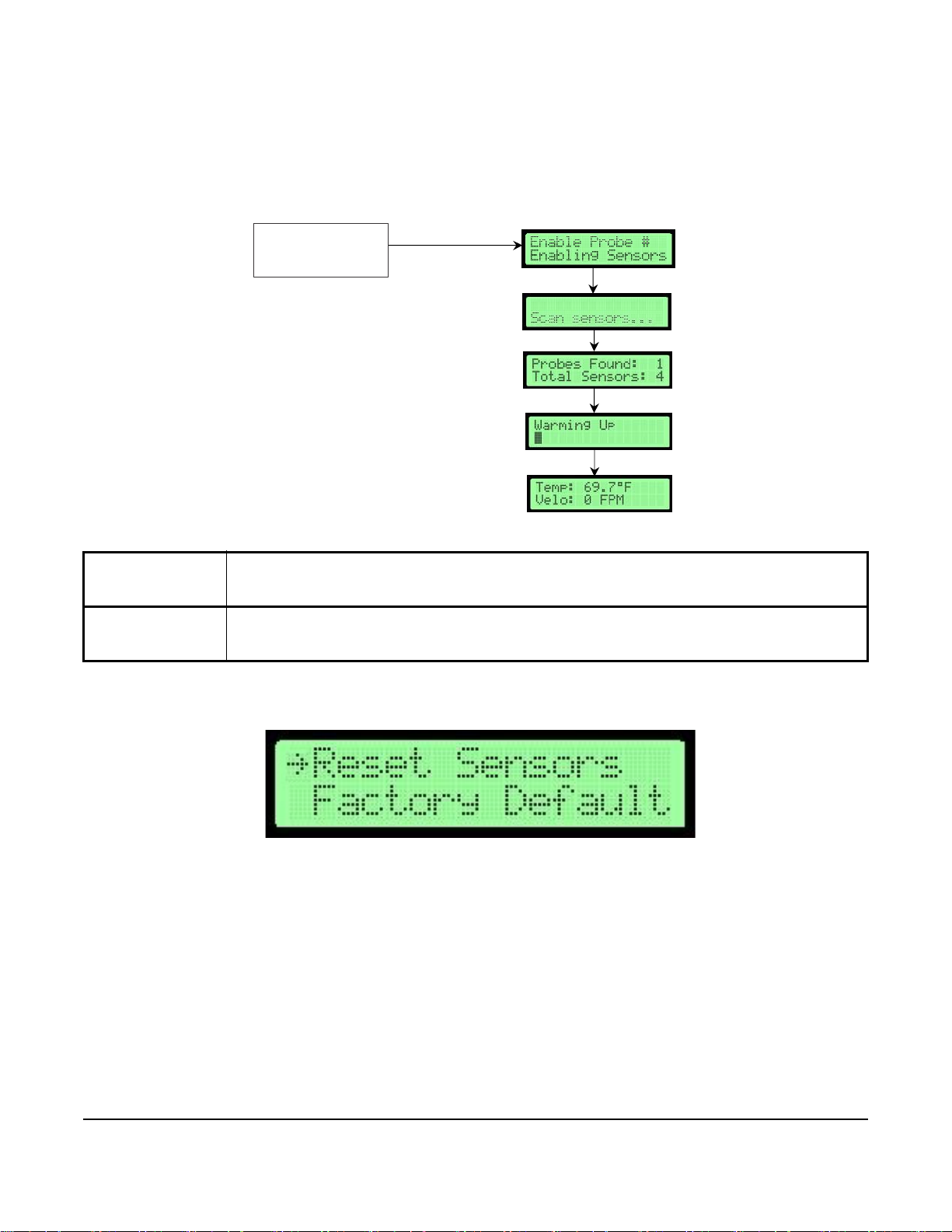

Reset Sensor Network

Figure 82: Rese t Sen s or Net w ork Flowc h a rt

Reset Sensors

*Default values shown

Selected Submenu

Submenu Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

r

e

s

e

t

ENTER

Figure 83: Reset Sensors Selection Screen

The Reset Sensor Network submenu is used to reset all the sensors on the network and cycle power to the devices

for an inventory. It also re-enables any disabled probes or sensors on the network

Table 19: Reset Sensor Network Submenu Selections and Display Screens

Reset Sensor

Network Submenu

Selection

Reset Sensors Primary probe commands all probes to re enable all sensors and to restart. Primary probe performs a

Display Screens

sensor scan and re-enables sensors to get an inventory from the probe network. Primary probe

returns to normal operation.

.

1. In the Supervisor Menu, press UP or DOWN to scroll to the Reset Sensors submenu.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

44

Page 45

2. Press ENTER. The display appears as follows:

Figure 84: Enable Probes Display Screens

The primary probe automatically resets all the sensors and devices and then restarts. After warming up, the

primary probe returns to the normal operation mode.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

45

Page 46

Factory Default Reset

Figure 85: Factory Default Reset Flowchart

Factory Default

*Default values shown

Selected Submenu

Submenu Display

F

I

G

:

f

l

o

w

c

h

a

r

t

_

d

e

f

a

u

l

t

ENTER

Figure 86: Factory Default Selection Screen

The Factory Default Reset submenu is used to reset all settings to the original factory-default settings.

Note: After a Factory Default Reset, any unique configuration settings must be re-entered if they are different

from the default settings

.

Table 20: Factory Default Reset Submenu Selection and Display Screens

Factory Default

Reset Submenu

Selection

Factory Default Cycle power from probe to re-enable all sensors and restart the auxiliary devices.

1. In the Supervisor Menu, press UP or DOWN to scroll to the Factory Default submenu.

Actions and Display Screens

Perform a local sensor scan and re-enable local sensors to get an inventory from the probe network.

Display returns to normal operation and factory-default settings are restored.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

46

Page 47

2. Press ENTER. The display indicates:

Figure 87: Enable Probes Display Screens

The primary probe automatically resets all the sensors and devices and then restarts. After warming up, it

returns to the normal operation mode. All settings are restored to their factory-default state.

Troubleshooting

Use Table 21 to troubleshoot problems with the AD-1272 Airflow Measuring System.

Table 21: AD-1272 System Troubleshooting (Part 1 of 2)

Problem Possible Cause Corrective Action

Airflow readings do not match what

T&B is reporting

Turbulent or non-uniform airflow across

the air measurement station.

Use Automatic K-factor Configuration

and use 1 point calibration if only gain is

required. If flow is non-linear use two or

three-point calibration feature.

Install additional probes to provide more

sensing points.

Move probes to a better location in

accordance with the minimum

placement guide.

Check for leaks in the duct.

AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

47

Page 48

Table 21: AD-1272 System Troubleshooting (Part 2 of 2)

Problem Possible Cause Corrective Action

No display No power Verify 24 VAC power at power terminal.

Make sure the ribbon cable is fully

seated in the board’s socket.

Visually check to make sure membrane

is plugged in to the display board in lid.

Incorrect number of PROBES shown

when the power is applied.

No BACnet communication with the

BAS

Probe network is not wired correctly or

the plug is plugged into the wrong port.

Duplicate addresses on Probe Network Verify each ancillary probe has a unique

Network wires terminated to the

incorrect point or the wrong connector.

The device is not configured properly. Verify configuration parameters in the

Verify wiring using the probe network

wiring information in the AD-1272

Thermal Dispersion Probe Airflow

Measuring Station Installation

Instructions (LIT-12012552).

Look at the drawings and make sure

the left and the right terminals are not

swapped. AO, Probe Network and

BACnet ports on the primary fit into any

of the plugs so make sure connections

are correct on the board.

address by checking the rotary dial

position.

Verify wiring using the BACnet wiring

information in the AD-1272 Thermal

Dispersion Probe Airflow Measuring