Page 1

FANs 125, 121, 930, 930.5

Product/Technical Bulletin A99

Issue Date 0615

A99B Series Temperature Sensors

The A99B Series Temperature Sensors are passive

PTC (Positive Temperature Coefficient) sensors.

The A99B sensors are splashproof and are

designed to measure temperature in a variety of

refrigeration applications. Several accessories allow

easy tailoring of the temperature sensor to various

mounting configurations.

Applications include temperature sensing for

freezers and coolers, as well as in defrost

termination sensing, space and return air

temperature sensing, and condenser fan cycling.

Figure 1: A99B Temperature Sensors

Features and Benefits

Variety of Lead Lengths Encompasses most application requirements

and simplifies wiring sensors

Assortment of Mounting

Hardware Available

Very Accurate Sensing

Element

Stainless Steel Sensor Bulb Allows use in more applications than other

Provides configuration for many

applications—customizable

Provides excellent performance in a wide

variety of control applications

types of bulbs; no corrosion

© 2015 Johnson Controls, Inc. 1

Part No. 24-7664-1636, Rev. A www.johnsoncontrols.com

Code No. LIT-125186

Page 2

pplication Overview

A

IMPORTANT: All A99B Series Sensors are

designed for use only with

operating controls. Where an

operating control failure would

result in personal injury and/or

loss of property, it is the

responsibility of the installer to

add devices (safety, limit controls)

or systems (alarm, supervisory)

that protect against, or warn of,

control failure.

The A99B temperature sensor line offers an

economical solution for a wide variety of

temperature sensing needs in refrigeration and

HVAC applications. Typical temperature sensing

applications and environments include:

Sensor

Sensor

Sensor

Sensor

To Controller

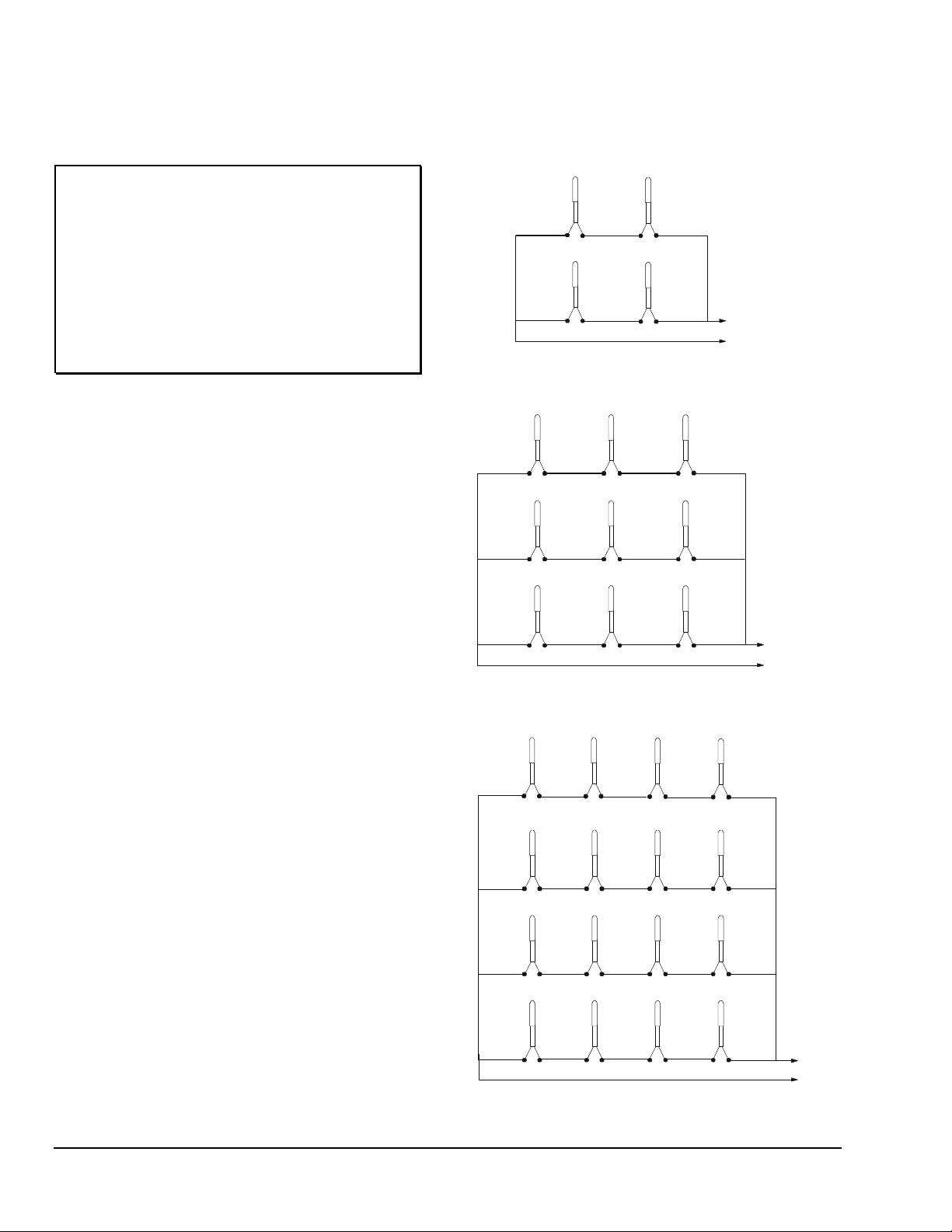

Figure 2: 4-Sensor Averaging Wiring

SensorSensorSensor

freezers

display cases

walk-in coolers

reach-in coolers

defrost termination temperature sensing

condenser fan cycling

space and return air temperature sensing

outdoor air sensing

process cooling and heating

ensor Temperature Averaging

S

Multiple sensors may be wired in a series parallel

arrangement to provide an average temperature

reading in an area when one sensor cannot provide

a representative temperature reading. This can be

accomplished with 4, 9, 16, etc., (2

2

, 32, 42, etc.)

sensors.

In a series parallel arrangement, there must always

be the same number of parallel-connected sensors

as there are series connected sensors.

In Figures 2-4, each parallel leg is represented as a

column of sensors and each series leg as a row of

sensors.

Sensor Sensor Sensor

SensorSensorSensor

To Controller

Figure 3: 9-Sensor Averaging Wiring

Sensor

Senso

Sensor

Sensor

Sensor

Senso

r

Sensor

Sensor

Sensor

Senso

r

Sensor

Sensor

Sensor

Senso

r

r

Sensor

Sensor

2 A99B Series Temperature Sensors Product/Technical Bulletin

To Controller

Figure 4: 16-Sensor Averaging Wiring

Page 3

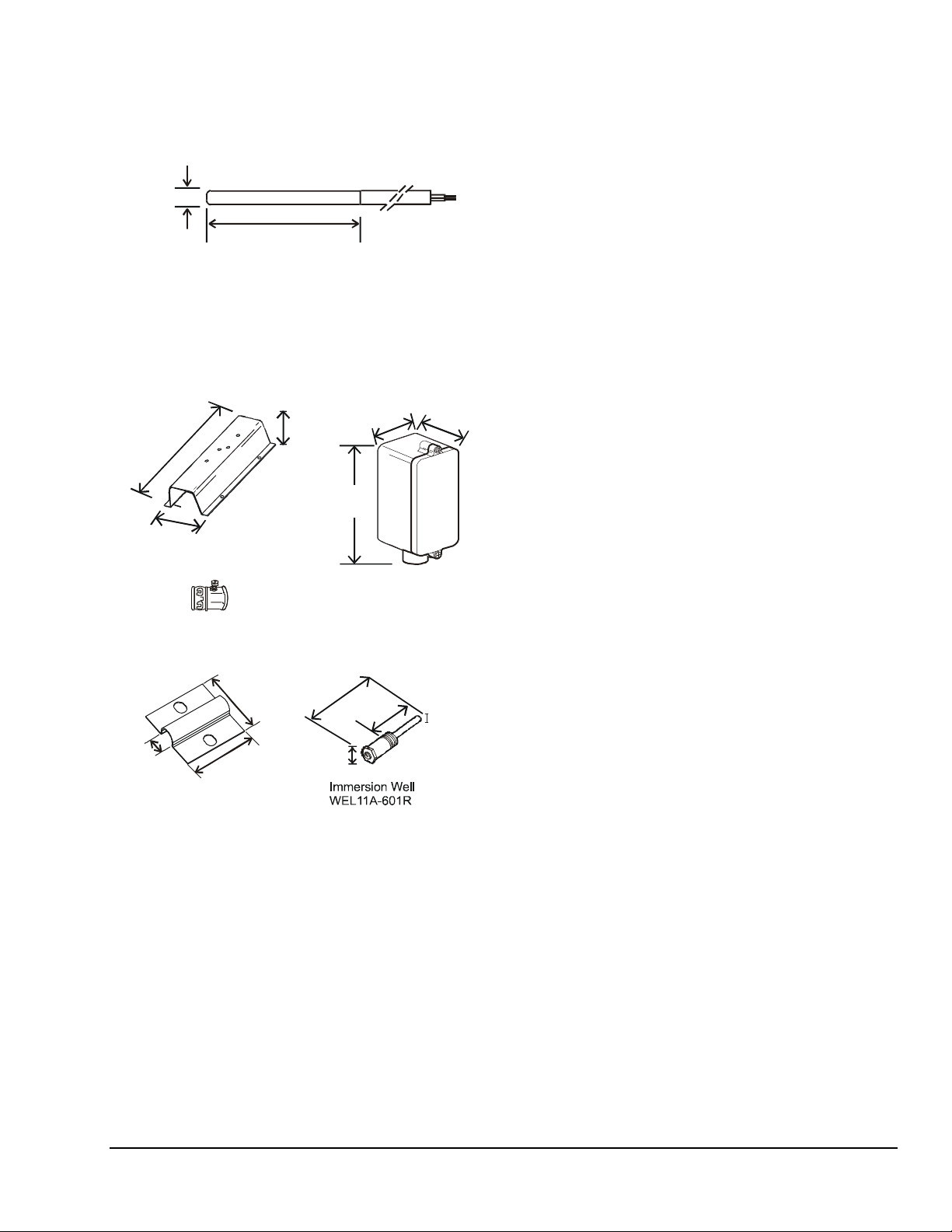

imensions

D

1/4 (6)

2 (50)

Figure 5: A99B Sensor, in. (mm)

Accessories

A99B series accessories include the following:

1 1 1/16

9 1/8

(229)

4 5/16

(110)

1/4 (6)

Surface M ount Clip

1/2

(13)

(25.4)

A99-CLP-1

Sun Shield

SHL10A-603R

ADP11A-600R

(25.4)

1

EMT

Conduit

Adapter

1

1 3/4

(44)

4 3/4

(119)

7/8

(23)

Figure 6: Available Accessories, in. (mm)

(42)

4 1/2

(113.5)

PVC Enclosure

BOX10A-600R

3

(76)

1 3/8

(35)

Dia.

3/8

(9.3)

peration

O

The A99B sensor incorporates a PTC silicon sensing

element whose resistance increases with an increase in

temperature. The sensor has a reference resistance of

1,035 ohms at 77F (25C). Each element is calibrated

according to a standard graph, as shown in Table 2.

The A99B series sensors are typically used with

Johnson Controls/PENN System 450™ controls,

MR Defrost controls, MS Multi-Stage controls, and

A421 Electronic Temperature Controls.

The A99B sensors can also be used with

Johnson Controls System 27 NOVA; A255 fan speed

control modules; and R78, DX-9100, XP-9102, XPA-4x1,

System 350™ controls, A419 Electronic Temperature

controls, and XPA-8x1 products.

ounting

M

Mounting Considerations

The A99B sensor may be mounted in virtually any

position. To ensure proper operation of the A99B Series

sensors, observe the following guidelines:

Mount sensors in areas where they are exposed to

representative temperature conditions and sufficient

air mixing. Avoid mounting the sensors where air

stratification exists.

Avoid areas subject to excessive mechanical

vibration or electrical noise.

For outdoor applications, avoid areas where the

sensor will be exposed to direct sunlight because

this causes the sensor to read a higher temperature.

The north side of the building is preferred for outdoor

sensors. If not possible, install a sun shield.

Use a thermally conductive paste where appropriate

to improve the thermal contact with the sensor.

Do not subject silicon cable (A99BC) to any

silicon-based fluids, as this will degrade the cable.

A99B Series Temperature Sensors Product/Technical Bulletin 3

Page 4

r

Mounting Using an Immersion Well

1. Select the mounting location in the pipe line.

A 1/2 in., 14 NPT, opening is required to

properly install the immersion well (WEL11A601R). The pipe’s diameter must be greater

than the length of the well probe.

2. Insert an appropriate amount of thermally

conductive paste in the well.

3. Install the immersion well. Tighten hex nut

securely using a wrench.

Tighten

with Wrench

1/2 inch 14 NP T

Opening

Mounting with a PVC Enclosure

The PVC enclosure can be mounted in a variety of

ways. See Figure 6 for mounting dimensions. When

mounting the PVC enclosure, refer to the Mounting

Considerations section, as well as the following:

To minimize false readings caused by air movement

through the conduit hole, seal that part of the

enclosure after the sensor has been inserted.

If a conduit connection is required, snap the conduit

adapter into the bottom opening of the enclosure

and tighten the adapter’s set screw.

1. Loosen the two PVC enclosure screws and remove

the front plate.

Sensor

Clip

Front

Plate

PVC Enclosure

Screws

Figure 7: Installing the Immersion Well

4. Using a straight slot screwdriver, loosen the set

screw at top of the immersion well.

5. Thread the spring, then the bushing, onto the

sensor lead.

Figure 8: Insert Sensor, Spring, and Bushing

6. Insert sensor, spring, and bushing into well, so

that at least one-half of the bushing is inserted

into the well, as shown in Figure 8 (bushing will

compress spring).

7. Tighten the set screw against the bushing.

Senso

Figure 9: PVC Enclosure

2. Thread the sensor through the bottom opening and

snap the sensor in the sensor clip inside the PVC

enclosure.

3. Replace the front plate on the PVC enclosure and

firmly tighten the screws.

4 A99B Series Temperature Sensors Product/Technical Bulletin

Page 5

iring

W

!

WARNING: Shock Hazard. Disconnect all

power to the controller that the

sensor is connected to before

wiring or servicing.

For wiring, follow the instructions below:

Make sure all wiring conforms to the National

Electric Code and local regulations.

Run high and low voltage wiring in separate

conduits. For applications in critical industrial

environments, use a sensor with a shielded

cable (A99BA).

If wire is added to the sensor leads, additional

resistance may affect the sensor reading.

Longer wires increase resistance, which causes

a shift in the sensor temperature reading.

Note: At the wire lengths listed in Table 1, the

error in the sensed temperature is less

than 1F (0.5C).

Table 1: Maximum Sensor Wire Lengths

(for less than 1°F error)

Wire Gauge Wire Length

AWG Feet Meters

14 AWG

16 AWG)

18 AWG

20 AWG

22 AWG

800 244

500 152

310 94

200 61

124 38

heckout Procedure

C

Before applying power, make sure installation and wiring

connections are according to job specifications. After

necessary adjustments and electrical connections have

been made, operate the system and observe at least

three complete cycles before leaving the installation.

roubleshooting

T

Check the sensor for proper resistance:

1. Disconnect the sensor from the control.

2. Take a temperature reading at the sensor location.

Be sure to let the thermometer stabilize before

taking a reading.

3. Use the temperature reading from Step 2 to

determine the expected sensor resistance from

Table 2.

4. Using an ohmmeter, measure the actual resistance

across the two sensor leads.

5. Compare the expected resistance to the actual

resistance.

6. If the sensor's actual resistance deviates

substantially from the expected resistance found in

Table 2, replace the sensor.

Shielded Cable Models (A99BA) Only: For all

controls, including the Johnson Controls/PENN

System 350, MR, MS, and A419, connect the

sensor cable shield to the controller per the

controller’s instructions.

A99B Series Temperature Sensors Product/Technical Bulletin 5

Page 6

r

r

r

r

N

F

° (C

°

260

240

220

200

180

160

140

120

100

80

60

40

Temperature (°F)

20

0

-20

-40

500 700 900 1100 1300 1500 1700 1900 2100

Resistance in Ohms

Figure 10: Resistance Scale for

Fahrenheit Temperatures

120

100

80

60

40

20

0

T emp er at u re (°C )

-20

-40

500 700 900 1100 1300 1500 1700 1900 2100

Resistance in Ohms

Table 2: Resistance vs. Temperature

°F (°C) Resistance

in Ohms

-40 (-40) 613 113 (45) 1195

-31 (-35) 640 122 (50) 1237

-22 (-30) 668 131 (55) 1279

-13 (-25) 697 140 (60) 1323

-4 (-20) 727 149 (65) 1368

5 (-15) 758 158 (70) 1413

14 (-10) 789 167 (75) 1459

23 (-5) 822 176 (80) 1506

32 (0) 855 185 (85) 1554

41 (5) 889 194 (90) 1602

50 (10) 924 203 (95) 1652

59 (15) 960 212 (100) 1702

68 (20) 997 221 (105) 1753

77 (25) 1035 230 (110) 1804

86 (30) 1074 239 (115) 1856

95 (35) 1113 248 (120) 1908

104 (40) 1153

Sensor accuracy is within 0.9F° (0.5C°) between

5 and 167°F (-15 and 75°C). Tolerance increases at

temperatures outside this range, as shown in Figure 12.

°F (°C) Resistance

in Ohms

Figure 11: Resistance Scale for

Celsius Temperatures

)

ominal

-0.9 (-0.50)

om

f

o

-1.8 (-1.00)

E

-2.7 (-1.50)

2.7 (1.50)

1.8 (1.00)

0.9 (0.50)

0.00

-40

(-40)

-4

(-20)

32

(0)

68

(20)

(40)

(60)

140

104

Temperature °F (°C)

Figure 12: Sensor Accuracy

176

(80)

212

(100)

248

(120)

6 A99B Series Temperature Sensors Product/Technical Bulletin

Page 7

epairs and Replacement

R

Field repairs or calibration must not be made.

For replacement sensors, contact your nearest

Johnson Controls/PENN representative.

rdering Information

O

Table 3: Sensors

Product

Code Number

A99BA-200C

A99BB-25C

A99BB-200C

A99BB-200D

A99BB-300C

A99BB-500C

A99BB-600C

A99BC-25C

A99BC-300C

A99BC-1500C

PTC Silicon Sensor with Shielded Cable; Cable length 6-1/2 ft (2 m); Range: -40 to 212°F (-40 to 100°C)

PTC Silicon Sensor with PVC Cable; Cable length 9-3/4 in. (0.25 m); Range: -40 to 212°F (-40 to 100°C)

PTC Silicon Sensor with PVC Cable; Cable length 6-1/2 ft (2 m); Range: -40 to 212°F (-40 to 100°C)

PTC Silicon Sensor with PVC Cable Bulk Pack; contains 100 A99BB-200 sensors.

Individual sensor cable length 6-1/2 ft (2 m); Range: -40 to 212°F (-40 to 100°C)

PTC Silicon Sensor with PVC Cable; Cable length 9-3/4 ft (3 m); Range: -40 to 212°F (-40 to 100°C)

PTC Silicon Sensor with PVC Cable; Cable length 16-3/8 ft (5 m); Range: -40 to 212°F (-40 to 100°C)

PTC Silicon Sensor with PVC Cable; Cable length 19-1/2 ft (6 m); Range: -40 to 212°F (-40 to 100°C)

PTC Silicon Sensor with High Temperature Silicon Cable

Cable length 9-3/4 in. (0.25 m); Range: -40 to 248°F (-40 to 120°C)

PTC Silicon Sensor with High Temperature Silicon Cable

Cable length 9-3/4 ft (3 m); Range: -40 to 248°F (-40 to 120°C)

PTC Silicon Sensor with High Temperature Silicon Cable

Cable length 49 ft (15 m); Range: -40 to 248°F (-40 to 120°C)

When contacting the supplier, state the model number of

the sensor. The sensor model is printed on the yellow

label wrapped around the sensor cable.

Description

Table 4: Accessories (See Figure 6 for illustration of accessories.)

Product

Code Number

A99-CLP-1

ADP11A-600R

BOX10A-600R

SHL10A-603R

WEL11A-601R

Surface Mounting Clip for the A99B Temperature Sensor

1/2 in. diameter EMT Conduit Adapter (box of 10) for use with BOX10A-600R

PVC Enclosure

Sun Shield

Immersion Well

A99B Series Temperature Sensors Product/Technical Bulletin 7

Description

Page 8

pecifications

S

Product A99B Series Silicon Temperature Sensors

Sensing Range Model A99BA and A99BB: -40 to 212F (-40 to 100C)

Model A99BC: -40 to 248F (-40 to 120C)

Reference Resistance 1,035 ohms at 77F (25C)

Accuracy 0.9°F (0.5°C) between 5 and 167°F (-15 and 75°C). See Figure 12 for accuracy outside of

this range.

Sensor Construction Probe: Stainless Steel

Sensor Lead Wire

Insulation

Lead Wire Gauge 22 AWG

Ambient Operating

Conditions

Ambient Storage

Conditions

Shipping Weight 1.4 oz (41 g) for 6 1/2 ft (2 m) sensor

Accessories

Model A99BA: Shielded PVC Cable

Model A99BB: PVC Cable

Model A99BC: High Temperature Silicon Cable

Model A99BA and A99BB: -40 to 212°F (-40 to 100°C); 0 to 100% RH, Condensing

Model A99BC: -40 to 248°F (-40 to 120°C); 0 to 100% RH, Condensing

Model A99BA and A99BB: -40 to 221°F (-40 to 105°C); 0 to 100% RH, Condensing

Model A99BC: -40 to 266°F (-40 to 130°C); 0 to 100% RH, Condensing

See Table 4.

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult Johnson Controls/Penn Application Engineering at (414) 274-5535. Johnson Controls, Inc. shall not be liable for

damages resulting from misapplication or misuse of its products.

Controls Group

507 E. Michigan Street

P.O. Box 423 www.johnsoncontrols.com

Milwaukee, WI 53201 Printed in U.S.A.

8 A99B Series Temperature Sensors Product/Technical Bulletin

Loading...

Loading...