Page 1

A421 Series Standard Electronic

Temperature Controls Installation Guide

Applications

Important: Use this A421 Series Electronic Temperature Control only as an operating control.

Where failure or malfunction of the A421 Control could lead to personal injury or property

damage to the controlled equipment or other property, additional precautions must be

designed into the control system. Incorporate and maintain other devices, such as supervisory

or alarm systems or safety or limit controls, intended to warn of or protect against failure or

malfunction of the A421 Control.

Important: Utiliser ce A421 Series Electronic Temperature Control uniquement en tant que

dispositif de régulation. Lorsqu'une défaillance ou un dysfonctionnement du A421 Control

risque de provoquer des blessures ou d'endommager l'équipement contrôlé ou un autre

équipement, la conception du système de contrôle doit intégrer des dispositifs de protection

supplémentaires. Veiller dans ce cas à intégrer de façon permanente d'autres dispositifs,

tels que des systèmes de supervision ou d'alarme, ou des dispositifs de sécurité ou de

limitation, ayant une fonction d'avertissement ou de protection en cas de défaillance ou de

dysfonctionnement du A421 Control.

The A421 Series Electronic Temperature Controls are single-stage, electronic temperature controls

with a single-pole, double-throw (SPDT) output relay.

A421 Controls feature a backlit LCD with adjustable brightness and three-button touchpad interface

that you can set up to restrict user adjustments. An LED indicates the output relay's on and off

status.

A421 Controls have simple on and off temperature settings for heating or cooling, an adjustable

anti-short cycle delay, temperature setback, and sensor offset capability. The temperature control

range is -40°F to 212°F or -40°C to 100°C.

The A421 Controls are available either in Type 1 (NEMA), IP20 (CE), high-impact plastic enclosures

suitable for surface or DIN rail mounting (Figure 1), or in Type 4X (NEMA), IP66 (CE) watertight,

corrosion resistant surface mount enclosures (Figure 2).

Part No. 24-7664-3019 Rev E

2018-11-13

A421ABC-x, A421AEC-x, A421GBF-x, A421GEF-x

Page 2

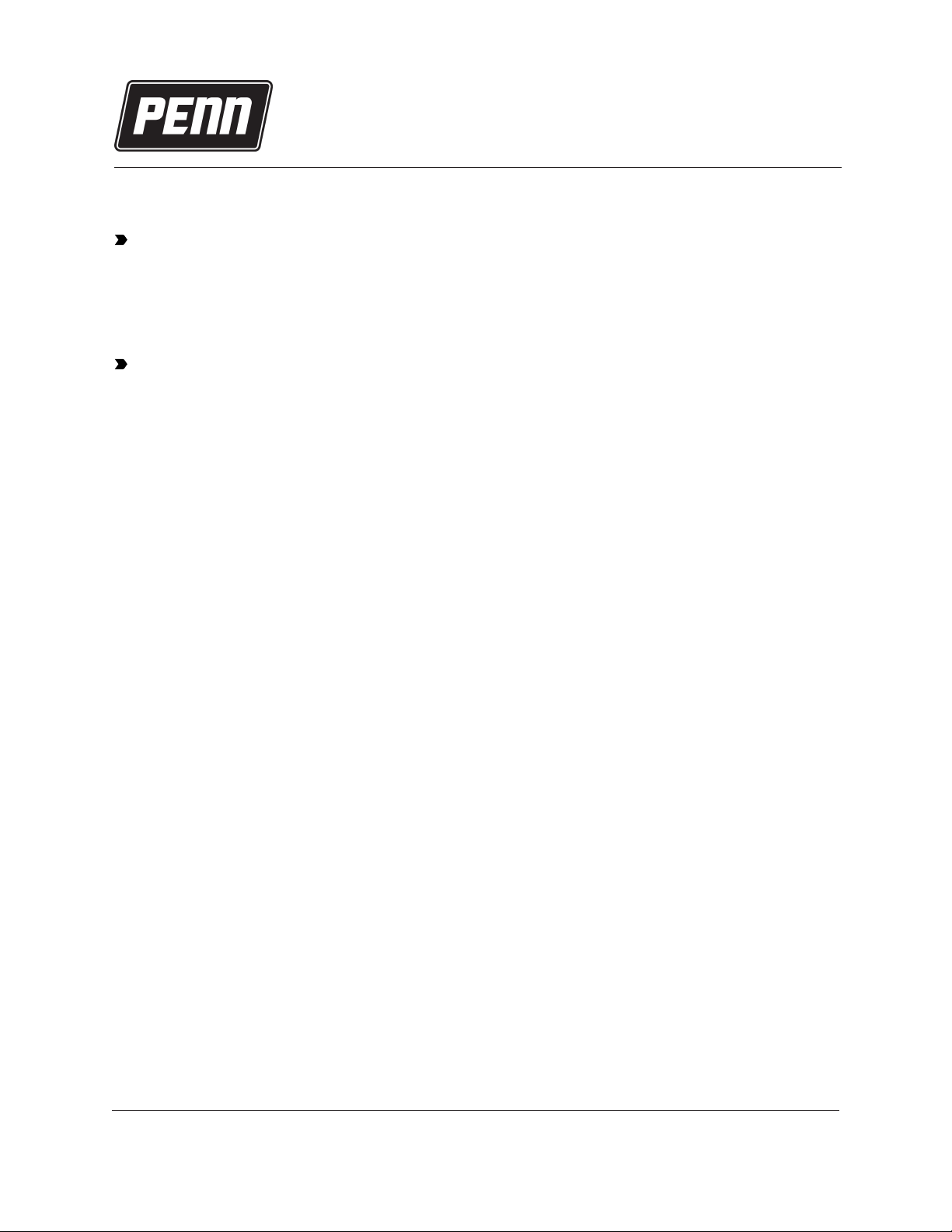

Dimensions

Figure 1: A421 Control with Type 1 (NEMA), IP20 enclosure dimensions, in. (mm)

Figure 2: A421 Control with Type 4X (NEMA), IP66 enclosure dimensions, in. (mm)

Parts included

Each A421 Control includes a Johnson Controls® or PENN® A99 Series temperature sensor. See A99

Series Temperature Sensors, Wiring, and Technical specifications for more information about A99

sensors.

A421 Series Standard Electronic Temperature Controls Installation Guide2

Page 3

A99 Series Temperature Sensors

The A421 Controls require an A99 sensor, and each A421 Control includes an A99 sensor. Any A99

Series sensor works with the A421 Series Controls. Do not replace an A99 Series sensor with any

other brand, series, or type of temperature sensor. See Ordering information for available A99

Series sensor models.

You can extend the sensor leads in the field. See Table 1 for information about wire sizes and

lengths. On long sensor cable runs, use shielded cable to reduce electromagnetic interference

(EMI). Observe EMI best practices when you route sensor leads.

Do not immerse the A99 Series sensors in water or any other liquid. The A99 sensors are moisture

tolerant and splash resistant but if you immerse the sensor, liquid can enter the sensor probe

where the steel tube meets the wire cable and result in sensor failure, which voids any warranty.

In applications where the sensor may be exposed to a lot of moisture, splashing, or rain, mount the

sensor in a vertical position with the cable at the bottom routed downward so that moisture can

drain away from the stainless steel probe. Use a suitable bulb well for complete fluid immersion

applications. See Ordering information for information about bulb wells.

The A99 Series sensors are positive temperature coefficient (PTC) sensors. To test an A99 sensor,

disconnect the sensor from the control and measure the resistance between the sensor leads in the

following situations:

• When the temperature at the sensor is 77°F (25°C), the resistance should be 1,035 ohms.

• When the temperature at the sensor is 32°F (0°C), the resistance should be 855 ohms.

See Troubleshooting for more information.

When you connect an A99 sensor to a standard A421 Control, the control restricts the range of

usable values from -40°F to 212°F or -40°C to 100°C.

See Wiring, Technical specifications, and refer to the A99B Series Temperature Sensors Product/

Technical Bulletin (LIT-125186) for more information about A99 Series sensors.

Mounting

Observe the following guidelines when you locate and mount an A421 Control:

• Make sure that the mounting surface can support the control, DIN rail, mounting hardware, and

any user-supplied panel or enclosure.

• Mount the control in a vertical, upright orientation wherever possible. It is best practice to use

DIN rail mounting for type 1 controls.

• In direct-mount applications, mount the control on a flat and even surface.

Mount the control in a location free of corrosive vapors and observe the ambient operating

conditions listed in Technical specifications for the A421 Control and the A99 sensor.

• Allow sufficient space to connect and route wires, view the LCD, and use the touchpad.

• Do not mount the control on surfaces that are prone to vibration or in a location where highvoltage relays, motor starters, other sources of electromagnetic emissions, or strong radio

frequency may cause interference.

• Do not install the control in an airtight enclosure.

• Do not install heat generating devices with the control in an enclosure that may cause the

ambient temperature to exceed 150°F (66°C).

3A421 Series Standard Electronic Temperature Controls Installation Guide

Page 4

Mounting a Type 1/IP20 control on DIN rail

1. Provide a section of 35 mm DIN rail that is longer than the control width. Mount the DIN rail in

a suitable location and use appropriate mounting hardware.

2. Clip the control module on the rail, position the module’s upper DIN rail clips on the top rail,

and gently snap the lower clips on to the bottom of the rail.

Direct-mounting a Type 1/IP20 control to a wall or other flat surface using the four keyhole slots

1. Disconnect the power and remove the enclosure cover. Place the control vertically against

the wall surface in a suitable location, and mark the keyhole slot locations on the mounting

surface.

2. Install appropriate screws or fasteners and leave the screw heads approximately one or two

turns away from flush to the mounting surface.

3. Position the control mounting slots over the screw heads, and then tighten the mounting

screws to secure the control to the surface.

Note: When you mount the control on an uneven surface, use shims to mount the control

evenly.

Additional guidelines for mounting Type 4X/IP66 controls

You can mount the Type 4X models to flat vertical surfaces using the four holes at the enclosure

corners. Place the control against a flat wall surface in a suitable location, and mark the mounting

screw hole locations on the mounting surface. Use appropriate screws and shims to mount the

control evenly on the surface.

On Type 4X models, select the knockout for removal. Place a screwdriver blade on the knockout

near the edge. Apply a sharp blow to the screwdriver handle to loosen the knockout. Be careful not

to damage the control’s interior components.

The A421 Control's temperature setback (BI) function requires an additional low-voltage, two-wire

cable for operation. On Type 4X/IP66 enclosures, you must install a suitable watertight fitting in an

available knockout to pass the two-wire cable through the enclosure wall.

You can rotate the control enclosure base on the Type 4X/IP66 models 180º relative to the control

enclosure cover and LCD, to bring the electrical connection to the top or bottom of the mounted

control.

Note: Do not twist the wiring harness between the enclosure base and cover more than 180º.

A421 Series Standard Electronic Temperature Controls Installation Guide4

Page 5

Wiring

WARNING

Risk of Electric Shock

Disconnect or isolate all power supplies before making electrical connections. More than one

disconnection or isolation may be required to completely de-energize equipment. Contact with

components carrying hazardous voltage can cause electric shock and may result in severe personal

injury or death.

Avertissement

Risque de décharge électrique

Débrancher ou isoler toute alimentation avant de réaliser un raccordement électrique. Plusieurs

isolations et débranchements sont peut-être nécessaires pour -couper entièrement l'alimentation de

l'équipement. Tout contact avec des composants porteurs de tensions dangereuses risque d'entraîner

une décharge électrique et de provoquer des blessures graves, voire mortelles.

Important: Use copper conductors only. Make all wiring in accordance with local, national,

and regional regulations.

Important: Do not exceed the A421 Control’s electrical ratings. Exceeding the electrical ratings

can result in permanent damage to the control and void any warranty.

Important: Run all low-voltage wiring and cables separate from all high-voltage wiring.

It is best practice to use shielded cable for input (sensor) cables that are exposed to high

electromagnetic or radio frequency noise.

Important: Electrostatic discharge (ESD) can damage A421 Controls. Use proper electrostatic

discharge precautions during installation and servicing to avoid damaging A421 Controls.

Important: Do not connect supply power to the A421 Controls before checking all wire

connections. Short circuits or improperly connected wires can result in damage to the modules

and void any warranty.

Important: When you connect an A99 sensor with a shielded cable to an A421 Control,

connect the cable shield drain lead to the common (COM) terminal on the sensor and binary

input terminal block (TB3). Do not connect the shield at any other point along the cable, and

isolate and insulate the shield along the entire length of the sensor cable. If you connect a

cable shield at more than one point, transient currents can flow through the sensor cable

shield and cause erratic control operation.

Observe the wire size restrictions listed in Table 2 and the electrical ratings listed in Technical

specifications.

Observe the following guidelines, procedures, and illustrations when you wire an A421 Series

Control and A99 Series sensor.

• Select the appropriate A99 sensors for the ambient operating range that the A421 Control

monitors and controls, as shown in Table 7. See Technical specifications for more information.

• Keep the sensor leads as short as possible in your application. The additional resistance in long

5A421 Series Standard Electronic Temperature Controls Installation Guide

Page 6

sensor cables creates an offset between the actual temperature and the displayed temperature.

See Table 1 when you extend sensor leads.

• A99 sensors are not polarity specific. You can connect either lead to the SEN or COM terminals.

• It is best practice to use 22 AWG, stranded, twisted-pair cable with a shield to extend sensor cable

runs.

Table 1: Maximum sensor cable lengths and wire sizes

Wire gauge

1

Maximum sensor cable length

1

16 AWG 500 ft (150 m)

18 AWG 300 ft (100 m)

20 AWG 200 ft (60 m)

22 AWG 125 ft (40 m)

1 The maximum sensor cable lengths have less than 1°F (0.6°C) error between the temperature sensed at the A99 sensor

and the temperature displayed on the LCD.

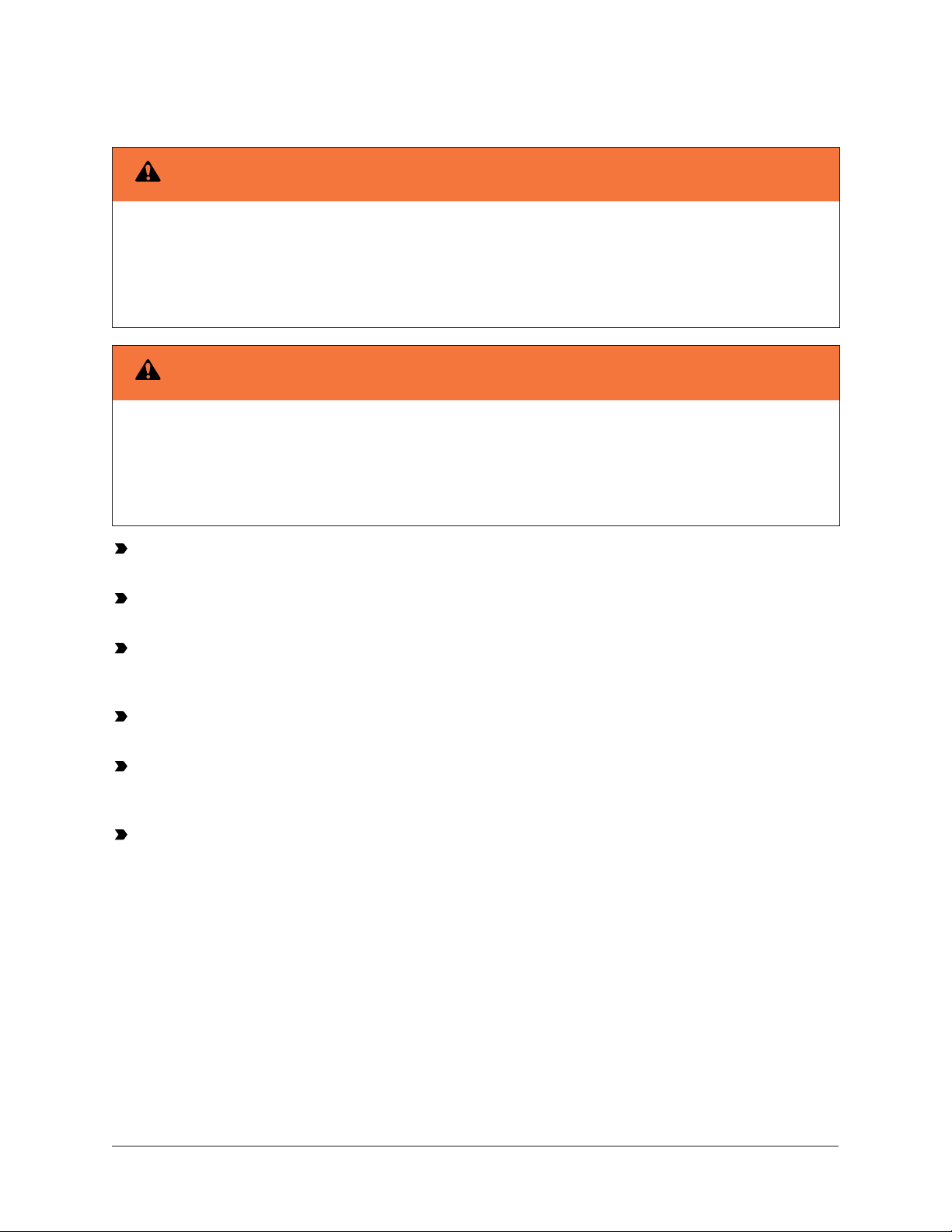

TB2 Terminal Block and SPDT relay output

The terminals LC, LNO, and LNC on the TB2 terminal block connect to an SPDT dry-contact relay in

the A421 Control (Figure 3). The control does not provide any internal power to the TB2 terminals

or relay contacts. The A421 Control energizes and de-energizes the relay to open and close the

contacts based on the On/OFF temperature values.

• Relay De-energized (Off) = LC open to LNO as shown in Figure 3, and the relay status LED is off

• Relay Energized (On) = LC closed to LNO and the relay status LED is on

Figure 3: TB2 Terminal Block showing connections to the internal SPDT relay

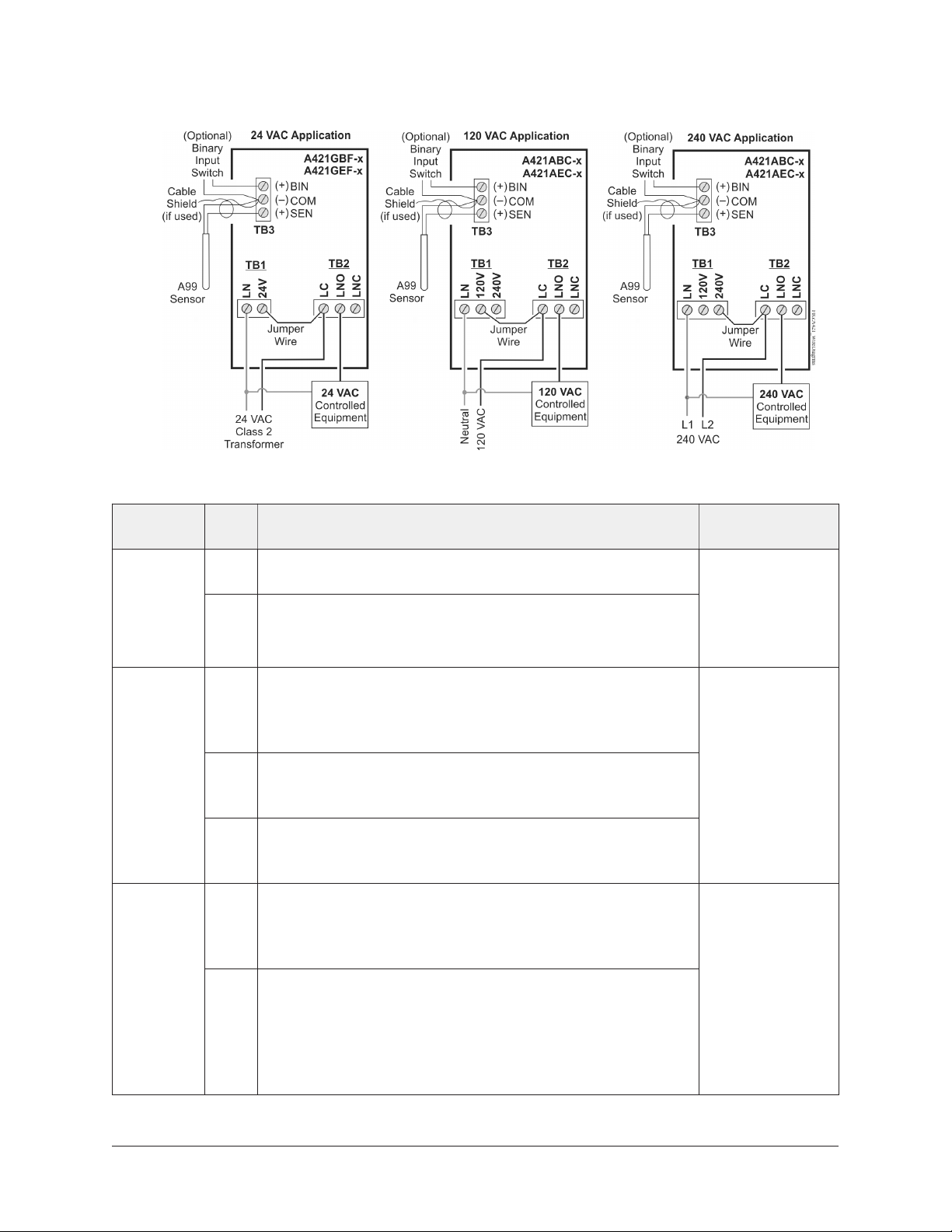

Figure 4 shows how to wire the A421 Control to use the same power source that powers the

controlled equipment to also power the A421 Control.

You can also provide an independent power source for the A421 Control on the TB1 terminals and

then wire the TB2 relay terminals to a separate power source to switch and power the controlled

equipment circuit.

A421 Series Standard Electronic Temperature Controls Installation Guide6

Page 7

Figure 4: Wiring the A421 Series Controls using the same power source

to power the control operation and power the controlled equipment

Table 2: A421 Control wiring terminals and wire size information

Terminal

block

TB1

24 VAC

Models

TB1

120/240

VAC

Models

TB2

Label Description, function, and requirements Wire sizes

LN Low-voltage 24 VAC control power (common): Connect the

24 VAC supply power to operate the control.

28 AWG to

12 AWG

24 V Low-voltage 24 VAC control power (hot): Connect 24 VAC

supply power to operate the control (via jumper from LC in

Figure 4).

LN Line-voltage power source (common): Connect the neutral

wire for 120 VAC supply power applications. Connect the

L1 supply power lead for all 208/240 VAC supply power

applications.

120 V Line-voltage 120 VAC control power (hot): Connect the

0.08 mm² to

4.0 mm²

28 AWG to

12 AWG

0.08 mm² to

4.0 mm²

120 VAC supply power (hot) for 120 VAC supply power

applications through the jumper from LC. (Figure 4).

240 V Line-voltage 240 VAC control power (L2) terminal: Connect

the L2 supply power connection for 208/240 VAC supply

power applications through the jumper from LC. (Figure 4).

LC Line-voltage SPDT relay common contact: Connects power

supply to power the controlled load. Connect 24 VAC

(hot) for 24 VAC applications; 120 VAC (hot) for 120 VAC

applications’ and L2 for 208/240 VAC applications.

LNO Line-voltage SPDT relay normally open contact: Connects

28 AWG to

12 AWG

0.08 mm² to

4.0 mm²

controlled equipment to the line-voltage normally open

(LNO) contact on the SPDT relay. When LC is closed to

LNO, the relay is energized and the green LED is on. The

LNO terminal typically provides power to the controlled

equipment in cooling and heating applications.

7A421 Series Standard Electronic Temperature Controls Installation Guide

Page 8

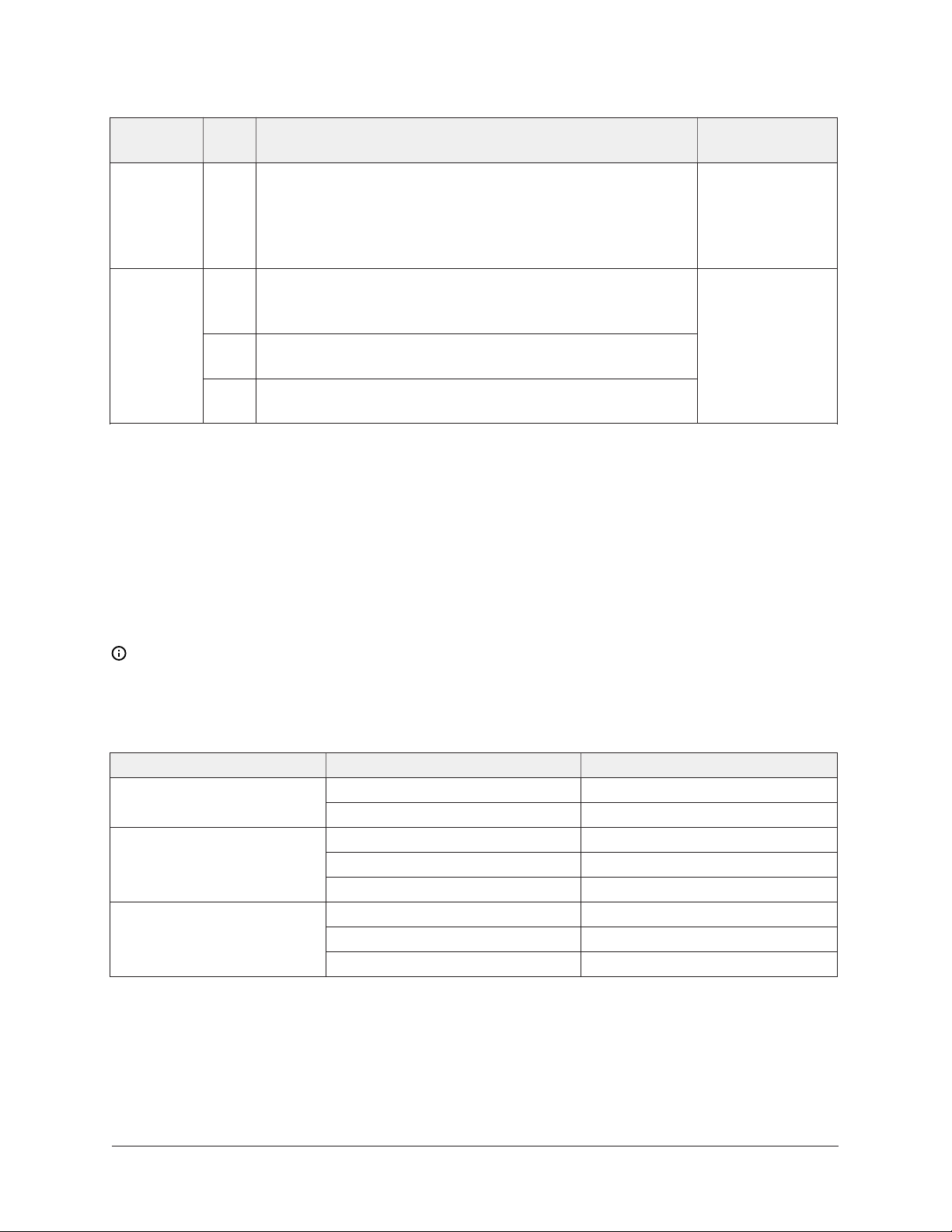

Table 2: A421 Control wiring terminals and wire size information

Terminal

block

TB3

Label Description, function, and requirements Wire sizes

LNC Line-voltage SPDT relay normally closed contact: Connects

controlled equipment to the line-voltage normally closed

(LNC) contact on the SPDT relay. When LC is closed to LNC,

the relay is de-energized and the green LED is off. The LNC

terminal is not typically wired to the controlled equipment.

BIN Detects a switch closure between the BIN and COM

terminals and enables the selected temperature setback

(tSb) value.

COM Connects the low-voltage common from the sensor and

binary input.

SEN Connects the low-voltage input signal wire from control

sensors.

22 AWG (0.34

mm²) stranded,

shielded cable

Replacing an A419 Control with an A421 Control: Terminal locations and labels

The A421 Series Electronic Temperature Controls are the next generation of the A419 Series

Electronic Temperature Controls.

If you need to replace an A419 Control with an A421 Control, be sure to note that wiring terminals

on the TB1 and TB2 terminal blocks on A421 Controls are in different positions and have different

terminal labels from the wiring terminals on the A419 Controls. Table 3 provides a cross-reference

for matching the terminal labels on A419 Controls to the terminal labels on A421 Controls.

Note: The low-voltage signal terminals on the TB3 terminal block are labeled the same on both

A419 Controls and A421 Controls.

See Figure 4 for terminal block and terminal positions on the A421 Control.

Table 3: A419 and A421 wiring terminal labels

Terminal block A419 Terminal label A421 Terminal label

(24 VAC)

TB1

(120/240 VAC)

TB2

(All Voltages)

T1 LNTB1

T2 24V

120 120V

240 240V

AC COM LN

C LC

NO LNO

NC LNC

Setup and adjustments

The front panel of the A421 Series Electronic Temperature Control has an LCD and a three-button UI

(Figure 5).

A421 Series Standard Electronic Temperature Controls Installation Guide8

Page 9

Figure 5: A421 Control front panel with LCD and three-button UI

LCD

The A421 Series Control has a backlit LCD screen (Figure 5). You can adjust the LCD brightness.

During normal operation, the LCD displays the Main screen, which provides the following

information:

• Temperature sensed at the A99 sensor

• Selected temperature units (°F or °C)

• Mode of operation (Flame = Heating mode, Snowflake = Cooling mode)

• Binary Input status (BIN) when a user-supplied binary input (switch) is connected and closed to

enable the temperature setback feature.

During setup and adjustment, the LCD displays the parameter code screens and the parameter

value screens. See the A421 Control parameter setup menus for more information.

Three-button touchpad

The touchpad has three buttons for setup and adjustment of the A421 Control (Figure 5). See

Navigating the Basic and Advanced menus for more information about the three-button touchpad.

Relay status LED

The green LED on the front panel illuminates when the SPDT output relay is energized and the LC

and LNO contacts are closed. See Figure 5.

Parameter codes and modes of operation

Relay Off temperature (OFF)

Select the temperature at which the output relay de-energizes, the LC to LNO relay contacts

open (cutout), and the green LED goes off. The range of usable temperature values is -40°F

to 212°F (-40°C to 100°C) in 1° increments.

9A421 Series Standard Electronic Temperature Controls Installation Guide

Page 10

Relay On temperature (On)

Select the temperature at which the output relay energizes, the LC to LNO relay contacts

close (cut in), and the green LED lights. The range of usable temperature values is -40°F to

212°F (-40°C to 100°C) in 1° increments.

Heating or Cooling mode of operation

When you select your required On and OFF values, the control automatically determines the

mode of operation and displays the proper mode icon on the Main screen.

Note: The A421 Series controls do not have jumpers for setting up the heating or cooling

mode.

The heating or cooling mode is determined by the On and OFF value relationship as follows:

• OFF > On = Heating mode = Flame icon

• OFF < On = Cooling mode = Snowflake icon

Important: During normal operation, adjusting just the On value or just the OFF

value on the A421 control changes the differential between On and OFF, and can

potentially change the mode of operation from heating to cooling or cooling to heating.

To maintain a constant differential between on and off, you must adjust both the on

and off values by an equal number of degrees, or set up the control in the Restricted

Adjustment mode. See Restricting User Adjustment.

Anti-short cycle delay (ASd)

Select the minimum time that the output relay remains off (de-energized) before the next

on-cycle can start. The ASd interval overrides any load demand (On) and does not allow the

output relay to go on until the selected ASd interval has elapsed. See the following figure.

Figure 6: Anti-short cycle delay

Anti-short cycle delay is typically used for refrigeration applications so that the system

pressure can equalize before restarting the compressor.

Note: When the ASd value is greater than 0, the delay interval initiates every time that the

A421 Control is powers on and every time that an off-cycle begins. When the ASd interval

is activated, the temperature sensed at the A99 sensor and the parameter code ASd flash

alternately on the LCD. You can set the ASd interval from from 0 minutes to 12 minutes, in 1

minute increments.

Sensor Failure mode (SF)

Select whether the control’s output relay operates as energized or de-energized in the event

of a sensor or sensor wiring failure. When the control detects a sensor circuit failure, the

A421 Series Standard Electronic Temperature Controls Installation Guide10

Page 11

output relay operates in the selected sensor failure mode. The LCD flashes SF and OP if the

sensor circuit is open or SF and SH if the sensor circuit is shorted.

Temperature Units (Un)

Select the preferred temperature scale for your application. Select either the Fahrenheit (°F)

or Celsius (°C) temperature scale.

Note: After you change the temperature units value (Un), confirm that the temperature values

for the other parameter codes are still correct for your application.

Low Temperature Stop (LtS)

Select the lowest temperature value that the On/OFF control band can be adjusted to when

control adjustment is restricted.

High Temperature Stop (HtS)

Select the highest temperature value that the On/OFF control band can be adjusted to when

control adjustment is restricted.

Restricted Adjustment mode

The HtS and LtS values define the restricted adjustment temperature range and are

enforced only when the A421 control is set to the restricted adjustment mode (Figure 9). See

Restricting user adjustment.

Note: It is best practice to leave HtS and LtS at their default values, unless you intend to use

the restricted adjustment mode.

Note: If you use the Temperature Setback feature in the Restricted Adjustment Mode, the

effective On and OFF setback values (On + tBs and OFF + tBs) can be greater than the selected

HtS value or less than the selected LtS value.

Temperature Setback (tSb)

Select a temperature value for setting back the On and OFF temperature values. When

a user-supplied switch between the BIN and COM terminals closes, note the following

changes:

• The Main screen displays BIN in the upper-right corner of the LCD.

• The temperature setback feature is enabled and the control uses the effective On and OFF

setback values (On + tSb and OFF + tSb) to control the relay.

Note: The control displays only the original On and OFF values in both the normal and setback

modes. The effective setback On and OFF values (On + tSb and OFF + tSb) never display on the

control LCD.

The temperature setback adjustment range is from -50°F to 50°F (-30°C to 30°C). Typically,

heating applications require a negative temperature setback (tSb) value, and cooling

applications require a positive value.

Sensor Offset Adjustment (So)

Sensor offset allows you to compensate for any difference between the displayed

temperature value and the temperature sensed at the A99 sensor. Select a temperature

value to offset the temperature displayed on the LCD from the temperature sensed at the

sensor. The sensor offset adjustment range is from -5°F to 5°F (-3°C to 3°C) in 1° increments.

11A421 Series Standard Electronic Temperature Controls Installation Guide

Page 12

Backlight Brightness Level (bLL)

The backlight brightness level feature allows you to adjust the LCD backlight intensity. At

level 0 the backlight is off. Level 10 is the brightest backlight setting and the system default.

The selected backlight brightness level is applied to the LCD during normal operation.

When you enter the programming menus to set up the control or press any key, the LCD

automatically goes to the brightest level. If you do not press a key for 30 seconds, the main

screen displays and the backlight setting reverts to the selected brightness level.

Table 4: Standard parameter setup codes, descriptions, range of values, and default values

Parameter

code

Parameter description (menu) Range of usable values1Factory default

value

Un Temperature Units (Advanced only) ºF or ºC ºF

OFF Relay Off Temperature (Basic,

Advanced, and Restricted)

On Relay On Temperature (Basic and

Advanced)

ASd Anti-Short Cycle Delay (Basic and

-40ºF to 212ºF

25ºF

(-40ºC to 100ºC)

-40ºF to 212ºF

30ºF

(-40ºC to 100ºC)

0 minutes to 12 minutes 1 minute

Advanced)

tSb Temperature Setback (Advanced

only)

So Sensor Offset Adjustment (Advanced

only)

HtS High Temperature Stop (Advanced

only)

LtS Low Temperature Stop (Advanced

only)

SF Sensor Failure Action (Basic and

Advanced)

-50ºF to 50ºF

(-30ºC to 30ºC)

-5ºF to 5ºF

(-3ºC to 3ºC)

-40ºF to 212ºF

(-40ºC to 100ºC)

-40ºF to 212ºF

(-40ºC to 100ºC)

0 = output relay de-

energized

0ºF

0ºF

212ºF

-40ºF

1 output relay

energized

1 = output relay

energized

1

bLL LCD Backlight Brightness Level

Adjustment (Advanced only)

0 to 10; 0 = backlight off,

10 = brightest backlight

10 (brightest

backlight)

setting

1 The default values for general application A421 models are shown. OEM A421 models may have different default values.

A421 Control parameter setup menus

The A421 Temperature Controls have a Basic and an Advanced setup menu. You can scroll through

the parameter setup codes, view and edit parameter values, and set up your control for your

application requirement. The control also has a Restricted adjustment menu. See Restricting user

adjustment for more information.

A421 Series Standard Electronic Temperature Controls Installation Guide12

Page 13

Note: The A421 Control retains a copy of the saved parameter values in memory. When you

change and save a new value, the new value immediately overwrites the previous value and

saves to memory. In the event of a power failure, brown out, or when you disconnect power

from the control, all of the current parameter values in memory are retained. Reconnecting

power to the control restores all of the saved values.

Navigating the Basic and Advanced menus

The A421 Control buttons and display operate the same way in Basic and Advanced menus. You can

observe the following behavior in any parameter code screen:

The parameter code flashes on and off.

• To navigate through all of the parameter code screens, press Down or Up.

• To exit either menu and return to the Main screen, press Down and Up simultaneously.

You can perform the following actions in any parameter code screen:

The parameter value flashes on and off.

• To scroll through all of the available parameter values for the associated parameter code, press

Down or Up.

• With the preferred parameter value displayed, press MENU to save the value and go to the next

parameter code screen.

Note: If you do not press MENU to save a new value, the control reverts to the last saved

value.

After 30 seconds of inactivity while in any screen, the control reverts to the Main screen.

Basic menu

Use the Basic menu to quickly edit the On and OFF temperature values, as well as the Sensor Failure

Mode (SF) and the Anti-Short Cycle Delay (ASd) value.

See Parameter codes and modes of operation and Table 4 for more information about parameter

codes, usable parameter values, and default values.

13A421 Series Standard Electronic Temperature Controls Installation Guide

Page 14

Figure 7: Navigating the Basic menu

Viewing and changing values in the Basic menu

To access the Basic menu and view and change the Basic parameter values, complete the following

steps:

1. On the Main screen, press MENU. The LCD displays OFF, which is the first parameter code

screen displayed in the Basic menu.

2. To scroll through all of the basic parameter codes and display the preferred code, press Down

or Up.

3. With the preferred parameter code displayed, press MENU to display the current parameter

value for the code.

4. With the current parameter value displayed, press Down or Up to scroll through all of the

parameter’s usable values and display the preferred value.

5. With the preferred parameter value displayed, press MENU to save the displayed value and go

to the next parameter code.

6. To exit the Basic menu and go to the Advanced menu, simultaneously press and hold Down or

Up for 5 seconds.

Advanced menu

You can use the Advanced menu to change the parameter values in the Basic menu and the

parameter values for the following advanced parameter codes:

• Temperature Units (Un)

• Temperature Setback (tSb)

A421 Series Standard Electronic Temperature Controls Installation Guide14

Page 15

• Sensor Offset (So)

• High Temperature Setpoint Stop (HtS)

• Low Temperature Setpoint Stop (LtS)

• Backlight Level (bLL)

See Parameter codes and modes of operation and Table 4 for more information about parameter

codes, usable parameter values, and default values.

Figure 8: Navigating the Advanced menu

Viewing and changing values in the Advanced menu

To access the Advanced menu and view and change the parameter values, complete the following

steps:

1. On the Main screen, press and hold Down or Up simultaneously for 5 seconds. Un displays on

the LCD, which is the first parameter code screen displayed in the Advanced menu.

2. To scroll through all of the advanced parameter codes and display the preferred code, press

Down or Up

3. With the preferred parameter code displayed, press MENU to display the current parameter

value for the code.

15A421 Series Standard Electronic Temperature Controls Installation Guide

Page 16

4. With the current parameter value displayed, press Down or Up to scroll through all of the

parameter code’s usable values and display the preferred value.

5. With the preferred parameter value displayed, press MENU to save the displayed value and go

to the next parameter code.

Restricting user adjustment

You can restrict user adjustment of the A421 Control to the OFF value control band only and limit

the range of this value (Figure 9).

To set the A421 Control the restricted adjustment mode, position the jumper located on the circuit

board next to the TB3 terminal block. See Setting the control to Restricted Adjustment mode.

Note: Setting the A421 Control up in the Restricted mode prevents casual users from overadjusting the control in your application, or from inadvertently changing the mode of

operation from cooling to heating or heating to cooling by over-adjusting the On value or OFF

value.

When the A421 Control is set up in the restricted adjustment mode, the controller enforces the

following behavior:

• The selected HtS and LtS values define the restricted temperature adjustment range.

• The On and OFF values define the control band differential, and the control band between On

and OFF remains fixed and not adjustable.

• Only the OFF value can be adjusted, the control band remains fixed, and the On value

automatically shifts equal to the OFF value adjustment.

• The OFF value can only be adjusted to values that maintain the entire control band within the

restricted temperature adjustment range defined by HtS and LtS. See Figure 9.

• The basic and advanced menus are not available. Only the Restricted Adjustment mode menu is

available and only the OFF value can be adjusted. See Figure 11.

Figure 9: Adjustment behavior in Restricted Adjustment mode

Setting the control to Restricted Adjustment mode

To set up the restricted adjustment feature, complete the following steps:

1. To make sure that the A421 is not in restricted mode, position the jumper on both pins. See

Figure 10.

2. Select the OFF and On values that define the application’s required control band (Figure 9).

A421 Series Standard Electronic Temperature Controls Installation Guide16

Page 17

3. Change the HtS and LtS temperature values to define the restricted adjustment range (Figure

9).

4. Disconnect power to the control and reposition the jumper to one pin (Figure 10). Reconnect

power.

Figure 10: Repositioning the jumper to restrict control adjustment

Control adjustment is now restricted to changing only the OFF value, which shifts the On and OFF

control band within the restricted adjustment range defined by HtS and LtS (Figure 9).

Note: To completely restrict and lockout all user adjustment on the control, set the HtS value

equal to the On or OFF value and the LtS value equal to the OFF or On value. Then the (On to

OFF) control band is equal to the restricted adjustment range, LtS to HtS, and the OFF value

cannot be adjusted in the restricted mode.

Adjusting the control in Restricted mode

To adjust the OFF value and shift the On and OFF control band within the restricted adjustment

range, when the control is in the restricted adjustment mode, complete the following steps:

1. On the Main screen, press MENU to go to the Restricted Adjustment mode menu and display

the OFF parameter code screen (Figure 11).

2. To go to the OFF value screen, press MENU again.

3. On the OFF value screen, press Down or Up to change the OFF value within the restricted

adjustment range.

4. To save the selected OFF value and return to the OFF code screen, press MENU.

5. To return to the Main screen, press Down or Up simultaneously.

17A421 Series Standard Electronic Temperature Controls Installation Guide

Page 18

Figure 11: Adjusting temperature in the Restricted menu

Troubleshooting

A421 Series Controls display fault codes on the LCD as described in the following table.

Table 5: Fault codes

Fault code Definition System status Solution

SF flashing

alternately

with OP

SF flashing

alternately

with SH

EE Program failure Output is off To reset the control, press

Open temperature

sensor or sensor wiring

Shorted temperature

sensor or sensor wiring

Output functions

according to the

selected SF mode

Output functions

according to the

selected SF mode

See Troubleshooting procedure.

Cycle power to reset the control.

See Troubleshooting procedure.

Cycle power to reset the control.

MENU. If problems persist,

replace the control.

Troubleshooting procedure

1. Check for proper voltage to the A421 Control.

a. To remove the cover, loosen the two captive cover screws.

b. Use an AC voltmeter to check the voltage between the COM and 120 V or 240 V terminals

on line-voltage models and the two 24 V terminals on low-voltage models. See Figure 4.

The voltage must be between:

- 20 VAC and 30 VAC for 24 VAC applications

- 102 VAC and 132 VAC for 120 VAC applications

A421 Series Standard Electronic Temperature Controls Installation Guide18

Page 19

- 177 VAC and 264 VAC for 208/240 VAC applications

c. If the voltage reading is not within the required range, check the power source and input

power wires for problems.

2. Check for proper sensor operation.

a. Disconnect all power sources to the control.

b. Use an accurate thermometer to take a temperature reading at the sensor location.

c. Disconnect the sensor from the control.

d. Use an ohmmeter to measure the resistance across the two sensor leads while the

sensor is at the temperature taken in Step 2b.

e. See Figure 12 to verify that the measured temperature and resistance conform to

established temperature and resistance values.

f. If the measured values conform to the values in Figure 12, proceed to Step 3.

g. If the sensor’s measured resistance value is substantially different from the expected

value for that temperature, check the sensor wiring. If sensor wiring is correct, replace

the sensor.

Figure 12: Temperature versus sensor resistance

3. Check the A421 for proper operation.

Note: Perform troubleshooting Steps 1 and 2 before you perform this step.

a. Disconnect the load from the output relay terminals.

b. Make sure that you install the Parameter Adjustments jumper so that you have

unrestricted access to adjust parameters.

c. Reconnect the sensor leads and supply power to the control.

d. Replace the cover.

e. Check the control settings for proper values.

f. Press MENU until On appears. Press MENU again to display the On value.

19A421 Series Standard Electronic Temperature Controls Installation Guide

Page 20

g. Press Down or Up to change the On temperature above and below the sensor

temperature until the relay energizes and de-energizes.

Note: If the anti-short cycle delay is set to a value other than 0 minutes, when the

control is powered On, on the relay does not energize until the time delay elapses.

h. If the output relay does not perform as expected, replace the A421 Control.

i. If proper operation of the A421 Control is verified, reconnect the load and consult the

equipment manufacturer’s instructions for troubleshooting the controlled equipment.

Repair information

Do not attempt to repair or recalibrate the A421 Temperature Control. In case of a defective or

improperly functioning control, contact your nearest authorized Johnson Controls/PENN distributor

or sales representative.

When you contact your Johnson Controls/PENN distributor, have the model number of the control

available. You can find this number on the label inside the cover of the control.

Ordering information

See Table 6 for information about a standard A421 Series Electronic Temperature Control. See Table

7 and Table 8 to order A99 sensors, mounting hardware, and other accessories you use to install

A421 Controls. Contact your nearest Johnson Controls or PENN distributor or sales representative to

order these products.

Table 6: A421 Series Standard Electronic Temperature Controls selection chart

Product type Description

A421ABC-02C Line-voltage Type 1 Electronic Temperature Control: Type 1 (NEMA), IP20

standard enclosure for DIN rail and surface-mount applications. Rated for

120/240 VAC. Includes an A99BB-200C temperature sensor with 6.6 ft (2.0 m)

cable.

A421ABC-03C Line-voltage Type 1 Electronic Temperature Control: Type 1 (NEMA), IP20

standard enclosure for DIN rail and surface-mount applications. Rated for

120/240 VAC. Includes an A99BB-300C temperature sensor with 9.75 ft (3.0 m)

cable.

A421ABC-04C Line-voltage Type 1 Electronic Temperature Control: Type 1 (NEMA), IP20

standard enclosure for DIN rail and surface-mount applications. Rated for

120/240 VAC. Includes an A99BB-400C temperature sensor with 13.1 ft (4.0 m)

cable.

A421ABC-06C Line-voltage Type 1 Electronic Temperature Control: Type 1 (NEMA), IP20

standard enclosure for DIN rail and surface-mount applications. Rated for

120/240 VAC. Includes an A99BB-600C temperature sensor with 19.5 ft (6.0 m)

cable.

A421AEC-01C Line-voltage Type 4X Electronic Temperature Control: Type 4X (NEMA), IP66

watertight enclosure for surface-mount applications. Rated for 120/240 VAC.

Includes an A99BB-25C temperature sensor with 9 7/8 in. (0.25 m) cable.

A421 Series Standard Electronic Temperature Controls Installation Guide20

Page 21

Table 6: A421 Series Standard Electronic Temperature Controls selection chart

Product type Description

A421AEC-02C Line-voltage Type 4X Electronic Temperature Control: Type 4X (NEMA), IP66

watertight enclosure for surface-mount applications. Rated for 120/240 VAC.

Includes an A99BB-200C temperature sensor with 6.6 ft (2.0 m) cable.

A421GBF-02C Low-voltage Type 1 Electronic Temperature Control: Type 1 (NEMA), IP20 standard

enclosure for DIN rail and surface-mount applications. Rated for 24 VAC Class 2,

safety extra low voltage. Includes an A99BB-200C temperature sensor with 6.6 ft

(2.0 m) cable.

A421GEF-01C Low-voltage Type 4X Electronic Temperature Control: Type 4X (NEMA), IP66

watertight enclosure for surface-mount applications. Rated for 24 VAC Class 2,

safety extra low voltage. Includes an A99BB-25C temperature sensor with 9 7/8 in.

(0.25 m) cable.

A421GEF-02C Low-voltage Type 4X Electronic Temperature Control: Type 4X (NEMA), IP66

watertight enclosure for surface-mount applications. Rated for 24 VAC Class 2,

safety extra low voltage. Includes an A99BB-200C temperature sensor with 6.6 ft

(2.0 m) cable.

Table 7: A99 Temperature Sensors selection chart

1

Product code Description

A99BA-200C Positive temperature coefficient (PTC) Temperature Sensor: Standard probe 2

in. (5.1 cm) with 6.6 ft (2.0 m) shielded polyvinyl chloride (PVC) cable; ambient

operating temperature range: -40ºF to 212ºF (-40ºC to 100ºC)

A99BB-25C PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 9-7/8 in. (0.25 m) PVC

cable; ambient operating temperature range: -40ºF to 212ºF (-40ºC to 100ºC)

A99BB-200C PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 6.6 ft (2.0 m) PVC

cable; ambient operating temperature range: -40ºF to 212ºF (-40ºC to 100ºC)

A99BB-300C PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 9.8 ft (3.0 m) PVC

cable; ambient operating temperature range: -40ºF to 212ºF (-40ºC to 100ºC)

A99BB-400C PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 13.1 ft (4.0 m) PVC

cable; ambient operating temperature range: -40ºF to 212ºF (-40ºC to 100ºC)

A99BB-600C PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 19.7 ft (6.0 m) PVC

cable; ambient operating temperature range: -40ºF to 212ºF (-40ºC to 100ºC)

11

A99BC-25C

PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 9 7/8 in. (0.25 m)

high-temperature silicon cable; ambient operating temperature range: -40ºF to

248ºF (-40ºC to 100ºC)

1

A99BC-100C

PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 3.3 ft (1.0 m) hightemperature silicon cable; ambient operating temperature range: -40ºF to 248ºF

(-40ºC to 120ºC)

1

A99BC-300C

PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 9.8 ft (3.0 m) hightemperature silicon cable; ambient operating temperature range: -40ºF to 248ºF

(-40ºC to 120ºC)

1

A99BC-500C

PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 16.4 ft (5.0 m) hightemperature silicon cable; ambient operating temperature range: -40ºF to 248ºF

(-40ºC to 120ºC)

21A421 Series Standard Electronic Temperature Controls Installation Guide

Page 22

Table 7: A99 Temperature Sensors selection chart

1

Product code Description

1

A99BC-1500C

PTC Temperature Sensor: Standard probe 2 in. (5.1 cm) with 49.2 ft (15.0 m) hightemperature silicon cable; ambient operating temperature range: -40ºF to 248ºF

(-40ºC to 120ºC)

A99CB-200C PTC Temperature Sensor: Extended probe 6 in. (15.2 cm) with 6.6 ft (2.0 m) PVC

cable; ambient operating temperature range: -40ºF to 212ºF (-40ºC to 100ºC)

A99CB-600C PTC Temperature Sensor: Extended probe 6 in. (15.2 cm) with 19.7 ft (6.0 m) PVC

cable; ambient operating temperature range: -40ºF to 212ºF (-40ºC to 100ºC)

1 When any A99 Series Temperature Sensor is connected to a standard A421 Control model, the range of displayed

temperature values is restricted to -40ºF to 212ºF or -40ºC to 100ºC.

Table 8: Accessories

Product code Description

BKT287-1R 12 in. (305 mm) long DIN rail section

BKT287-2R 36 in. (914 mm) long DIN rail section

PLT344-1R Two end clamps for DIN rail sections

A99-CLP-1 Surface mounting clip for A99B and A99C Series Temperature Sensors

SHL10-603R Sun shield for A99B and A99C Series Temperature Sensors

BOX10A-603R PVC enclosure for A99B and A99C Series Temperature Sensors

WEL11A-601R Copper and brass immersion well for applying sensor in fluid applications

TE-6300W-102 Stainless steel immersion well for applying A99 sensors in fluid applications.

A99CB Type sensors with extended probe with this immersion well.

Technical specifications

Table 9: A421 Series Electronic Temperature Controls

Power consumption 1.8 VA maximum

Supply power Low-Voltage models: 24 VAC (20 to 30 VAC), 50/60 Hz, Class 2 or Safety

extra-low voltage

Line-voltage models: 110/120 or 208/230/240 VAC, 50/60 Hz

Ambient conditions Operating: Type 1 models: -40°F to 150°F (-40°C to 66°C), 0% to 95% RH

noncondensing

Type 4X models: -40°F to 140°F (-40°C to 60°C), 0% to 95% RH

noncondensing

Shipping and storage: All models: -40°F to 185°F (-40°C to 85°C), 0% to

95% RH noncondensing

Temperature control

range

Input signal 1,035 ohm at 77°F (25°C) for A99 PTC Temperature Sensors

A421 Series Standard Electronic Temperature Controls Installation Guide22

-40°F to 212°F or -40°C to 100°C

Page 23

Table 9: A421 Series Electronic Temperature Controls

Accuracy Combined accuracy of A421 Control and A99 sensor: ±2°F (±1°C) between

5°F and 167°F (-15°C and 75°C); diverging to ±3°F (±2°C) at -40°F (-40°C)

and ±3°F (±2°C) at 212°F (100°C)

Sensor offset range ±5ºF or ±3ºC

Enclosure material Type 1, IP20 high-impact thermoplastic or

Type 4X, IP66 watertight, corrosion-resistant, high-impact thermoplastic

Compliance North America: cULus Listed; UL 60730, File E27734, Vol. 1; FCC Compliant

to CFR47, Part 15, Subpart B, Class BIndustry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares that this product is in

compliance with the essential requirements and other relevant provisions

of the EMC Directive; Low Voltage Directive.

Australia and New Zealand: RCM, Australia/NZ Emissions Compliant

Table 10: A421 Temperature Control Output Relay Contacts electrical ratings

Agency and file UL 60730 and EN 60730

Applied AC voltage at 50/60 Hz 24 VAC 120 VAC 208 VAC 240 VAC

Horsepower LC/LNO (LC/LNC) -- 1 (0.25) 1 (0.3) 1 (0.5)

Full load amperes LC/LNO (LC/

-- 16 (5.8) 9.2 (4) 8 (4.9)

LNC)

Locked rotor amperes LC/LNO (LC/

-- 96 (34.8) 55.2 (24) 48 (29.4)

LNC)

Resistive amperes LC/LNO (LC/

15 (10) 15 (10) 10 (10) 10 (10)

LNC)

Pilot duty VA LC/LNO (LC/LNC) 125 (50) 125 (125) 125 (125) 125 (125)

Table 11: UL conformity declaration information

Information Description

Purpose of control Sensing control / operating control

Construction of control Electronic independently mounted control

Number of cycles 30,000 cycles

Method of mounting control Mounting screws or DIN rail

Type 1 or type 2 action Type 1.B (Micro-disconnection)

External pollution situation All models: A421 [ ] B: Pollution degree 3

All models: A421 [ ] E: Pollution degree 4

Internal pollution situation Pollution degree 2

Heat and fire resistance category D

Rated impulse voltage 4,000 V

Ball pressure temperature 128°C

Cover screw torque requirements

instruction

All models: A421 [ ] E: To maintain type 4X / IP66 rating,

tighten enclosure screws to: 10–12 in·lb

23A421 Series Standard Electronic Temperature Controls Installation Guide

Page 24

Table 12: A99B Series Positive Temperature Coefficient Sensors

1

Sensing range

1

Type A99BA and A99BB: -40°F to 212°F (-40°C to 100°C)

Type A99BC: -40°F to 248°F (-40°C to 120°C)

Reference resistance 1,035 ohms at 77°F (25°C) and 855 ohms at 32°F (0°C)

Accuracy 0.9°F (0.5°C) between 5°F and 167°F (-15°C and 57°C). Refer to the

A99B Series Temperature Sensors Product/Technical Bulletin (LIT-125186)

for accuracy rating outside of this temperature range.

Sensor construction Probe: Stainless steel

Sensor cable sheath Type A99BA: Shielded PVC cable

Type A99BB: PVC cable

Type A99BC: High temperature silicon cable

Wire gauge 22 AWG

Ambient operating

conditions

Type A99BA and A99BB: -40°F to 212°F (-40°C to 100°C); 0% to 100%

RH, condensing

Type A99BC: -40°F to 248°F (-40°C to 120°C); 0% to 100% RH,

condensing

Ambient storage

conditions

Type A99BA and A99BB: -40°F to 221°F (-40°C to 105°C); 0% to 100%

RH, condensing

Type A99BC: -40°F to 266°F (-40°C to 130°C); 0% to 100% RH,

condensing

Shipping weight 1.4 oz (41 g) for 6 1/2 ft (2 m) sensor

Accessories See Table 8

1 When any A99 Series Temperature Sensor is connected to a standard A421 Control model, the range of displayed

temperature values is -40ºF to 212ºF or -40ºC to 100ºC.

The performance specifications are nominal and conform to acceptable industry standards. For

application at conditions beyond these specifications Johnson Controls shall not be liable for damages

resulting from misapplication or misuse of its products.

A421 Series Standard Electronic Temperature Controls Installation Guide24

Page 25

North American emissions compliance

United States

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

Canada

This Class (B) digital apparatus meets all the requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (B) respecte toutes les exigences du Règlement sur le

matériel brouilleur du Canada.

Points of Single Contact

APAC Europe NA/SA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO. 32 CHANGJIJANG RD NEW DISTRICT

WUXI JIANGSU PROVINCE 214028

CHINA

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

25A421 Series Standard Electronic Temperature Controls Installation Guide

Page 26

© 2018 Johnson Controls. All rights reserved. All specifications and other information shown were current as of

document revision and are subject to change without notice.

Loading...

Loading...