Page 1

ET -3504-J

1/2-INCH DRILL

CAUTION

RISK OF INJURY!

AND SHOULD REMAIN WITH THIS UNIT WHEN YOU SELL OR RENT IT.

THIS MANUAL IS AN IMPORTANT PART OF THE DRILL

1/2-Inch Drill Operator's Manual 1

READ MANUAL BEFORE OPERATING!

Page 2

Introduction

Congratulations on the purchase of your new drill! You can be assured your drill was

constructed and designed with quality and performance in mind. Each component has

been rigorously tested to ensure the highest level of acceptance.

This operator's manual was compiled for your benefit. By reading and following the simple

safety, installation, operation, maintenance and troubleshooting steps described in this

manual, you will receive years of trouble-free operation from your new tool. The contents

of this manual are based on the latest product information available at the time of

publication. The manufacturer reserves the right to make changes in price, color, materials, equipment, specifications or models at any time without notice.

Once the unit has been removed from the box, immediately write in the serial number of your

unit in the space provided below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim

with the transportation company immediately. Be sure that all damaged parts are replaced and

that the mechanical problems are corrected prior to operation of the unit. If you require service,

contact your Customer Service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Please have the following information available for all service calls:

1. Model Number

2. Serial Number

3. Date and Place of Purchase

WARNING

WEAR RESPIRAT ORY PROTECTION

Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contain chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-base paints,

• Crystalline Silica from bricks, cement and other masonry products, and

• Arsenic and Chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals, work in a well ventilated area and work

with approved safety equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

2 1/2-Inch Drill Operator's Manual

Page 3

Table of Content

SAFETY .................................................................................................................. 4-9

FUNCTIONAL DESCRIPTION............................................................................... 10

PREPARATION ...................................................................................................... 10

OPERATION........................................................................................................... 11-12

MAINTENANCE AND INSPECTION ..................................................................... 12-13

NOTES ................................................................................................................... 14-15

GENERAL SAFETY RULES.................................................................. 4-9

MODEL................................................................................................... 10

NAME OF PARTS.................................................................................. 10

SPECIFICATIONS ................................................................................. 10

APPLICATIONS ..................................................................................... 11

PRE-OPERATION ................................................................................. 11-12

OPERATION .......................................................................................... 12

STANDARD ACCESSORIES ................................................................ 12

MAINTENANCE AND INSPECTION ..................................................... 13

SERVICE AND REPAIRS...................................................................... 13

REPLACEMENT PARTS ....................................................................... 13

1/2-Inch Drill Operator's Manual 3

Page 4

W

ARNIN

G

W

A

R

N

I

NG

SIN

T

HEM

A

NUA

LS

.

W

A

RN

I

NG

SIN

T

HEMA

NUA

LS

.

CA

U

T

I

ON

OCAUT

I

ON

S

IN

O

T

H

E

M

A

N

UA

L

S

OC

AUT

I

ON

S

IN

O

T

H

E

M

A

N

UA

L

S

OC

AUT

I

ON

S

IN

O

T

H

E

M

A

N

UA

L

S

OCAUT

I

ON

S

IN

O

T

H

E

M

A

N

UA

L

S

DANGER

WARNING

CAUTION

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on

your tool or in this manual, be alert to the potential for

personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A "DANGER, WARNING or CAUTION" safety warning will be

surrounded by a "SAFETY ALERT BOX." This box is used to

designate and emphasize Safety Warnings that must be

followed when operating this tool.

Accompanying the Safety Warnings are "signal words" which

designate the degree or level of hazard seriousness. The

"signal words" used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided MAY result in minor or

moderate injury.

GENERAL SAFETY RULES

WARNING: Read and understand all

instructions.

Failure to follow all

instructions listed below, may

result in electric shock, fire and/

or serious personal injury.

SAVE THESE INSTRUCTIONS

4 1/2-Inch Drill Operator's Manual

Page 5

WARNING

KEEP WORK AREA CLEAN AND WELL LIT.

Cluttered areas and benches invite injuries.

CONSIDER WORK AREA ENVIRONMENT.

Don't expose power tools to rain. Don't use power

tools in damp or wet locations. Keep work area well

lit. Don't use tool in presence of flammable liquids

or gases. Power tools produce sparks during

operation. They also spark when switching ON/

OFF. Never use power tools in dangerous sites

containing lacquer, paint, benzine, thinner, gasoline,

gases, adhesive agents, and other materials which

are combustible or explosive.

GUARD AGAINST ELECTRIC SHOCK

Prevent body contact with grounded surfaces. For

example, pipes, radiators, ranges, refrigerator

enclosures.

KEEP CHILDREN AWAY

Do not let visitors contact tool or extension cord. All

visitors should be kept away from work area.

STORE IDLE TOOLS

When not in use, tools should be stored in dry, and

high or locked location - out of reach of children.

DRESS PROPERLY

Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and nonskid

footwear are recommended when working outdoors.

USE SAFETY GLASSES

Also use face or dust mask if cutting operation is

dusty. All persons in the area where power tools re

being operated should also wear safety eye

protectors and face or dust masks.

SECURE WORK

Use clamps or a vise to hold work. It's safer than

using your hand and it frees both hands to operate

tool.

1/2-Inch Drill Operator's Manual 5

Page 6

WARNING

DON'T OVERREACH

Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for better and safer performance. Follow instructions for

lubricating and changing accessories. Inspect tool cords periodically and replace if

damaged, have repaired by authorized service facility. Inspect extension cords

periodically and replace if damaged. Keep handles dry, clean, and free from oil and

grease.

DISCONNECT TOOLS

When not in use, before servicing, and when changing accessories, such as blades,

bits, cutters.

AVOID UNINTENTIONAL STARTING

Don't carry plugged-in tool with finger on switch. Be sure switch is off when plugged

in.

SECURELY MOUNT ACCESSORIES AND BLADES TO THE TOOL MAIN BODY

Extra care must be taken when using tools on elevated location (such as a roof

ladder, scaffold, or the like) to prevent injury to someone on a lower level in the event

the tool and/or accessory should drop.

NEVER TOUCH THE MOVING PARTS

Never touch the moving parts such as blades, bits, cutters and others.

CAUTION

DON'T FORCE TOOL

It will do the job better and safer at the rate from which it was intended.

USE RIGHT TOOL

Don't force small tool or attachment to do the job of a heavy-duty tool. Don't use tool for

purpose not intended - for example - don't use circular saw for cutting tree limbs or logs.

DON'T ABUSE CORD

Never carry tool by cord or yank it to disconnect from receptacles. Keep cord from heat,

oil and sharp edges.

REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking to see that keys and adjusting wrenches are removed from tool

before turning it on.

6 1/2-Inch Drill Operator's Manual

Page 7

CAUTION

OUTDOOR USE EXTENSION CORDS

When tool is used outdoors, use only extension cords intended for use outdoors and

so marked.

STAY ALERT

Watch what you are doing. Use common sense. Do not operate tool when you are

tired.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that may affect its operation. A guard or

other part that is damaged should be properly repaired or replaced by a John Deere

Dealer unless otherwise indicated elsewhere in this instruction manual. Have

defective switched replaced by a John Deere Dealer. Do not use tool if switch does

not turn it on and off.

AVOID USING A POWER TOOL FOR APPLICATIONS OTHER THAN THOSE

SPECIFIED

Never use a power tool for applications other than those specified in the instruction

manual.

ENSURE SAFE OPERATION THROUGH CORRECT HANDLING

Secure safe operation through correct handling by observing the instructions described herein. Do not employ accessories other than those specified herein;

otherwise, a hazardous condition may be created. Never allow a power tool to be

used by persons not familiar with correct handling (such as children) or by those who

cannot handle the tool correctly.

CONFIRM THAT NO ITEMS SUCH AS AN ELECTRIC CABLE OR CONDUIT ARE

BURIED INSIDE

In places where live wiring may be hidden behind a wall, floor, ceiling, etc. do not hold

or contact any metal parts of the tool. In such cases, metal parts could become

electrically live and present a serious shock hazard.

KEEP THE RIGHT PARTS IN THE RIGHT POSITION

Do not remove covers and screws which have been factory-mounted. They perform

important respective roles. Keep them in the right positions.

SHOULD THE PLASTIC HOUSING OR HANDLE OF A POWER TOOL BE

CRACKED OR DEFORMED, DO NOT USE IT

Since cracked or deformed parts may lead to an operator receiving an electric shock,

do not use such a power tool. Immediately have it repaired.

1/2-Inch Drill Operator's Manual 7

Page 8

CAUTION

ALWAYS KEEP THE MOTOR AIR VENT FULLY OPENED

A constantly open motor air vent is necessary to allow air to come in and out for cooling

the motor. Do not allow it to become clogged up, even if dust is blown through it.

OPERATE POWER TOOLS AT THE RATED VOLTAGE

Operate power tools at voltages specified on the nameplates.

STOP OPERATION IMMEDIATELY IF ANY ABNORMALITY IS DETECTED

Should a power tool be detected as out of order or should other abnormalities be

observed during operation, stop using the tool immediately.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF.

Don't leave tool until it comes to a complete stop.

CAREFULLY HANDLE POWER TOOLS

Should a power tool be dropped or struck against hard materials inadvertently, it may be

deformed, cracked, or damaged.

DO NOT WIPE PLASTIC PARTS WITH SOLVENT

Solvents such as gasoline, thinner, benzine, carbon tetrachloride, and alcohol may

damage and crack plastic parts. Do not wipe them with such solvents. Wipe plastic

parts with a soft cloth lightly dampened with soapy water.

WHEN REPLACING A COMPONENT PART, ADOPT THE SAME TYPE

When replacing a component part with a new one, adopt the same type of new part.

Also, never attempt to repair a power tool yourself.

POLARIZED PLUGS

To reduce the risk of electric shock, this equipment has a polarized plug (one blade is

wider than the other).

This plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to install the proper outlet.

Do not change the plug any way.

PRECAUTIONS ON USING DRILL

1. Attach the side handle and hold the drill firmly while using.

2. Do not wear gloves when operating.

3. Take care of downward direction in the high position.

8 1/2-Inch Drill Operator's Manual

Page 9

CAUTION

EXTENSION CORD

Make sure your extension cord is in good condition. When using an extension cord, be

sure to use one heavy enough to carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of power and overheating. Table

shows the correct size to use depending on cord length and nameplate ampere rating. If

in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

MINIMUM GAGE FOR CORD SETS

Total Length of Code in Feet (Meter)

0-25 26-50 51-100 101-150

(0-7.6) (7.9-15.2)(15.5-30.05) (30.8-45.7)

Ampere Rating AWG Size of Cord

More Not More

Than Than

0 6 18 16 16 14

6 10181614 12

10 12 16 16 14 12

12 16 14 12 Not recommended

WARNING: AVOID ELECTRICAL SHOCK HAZARD. NEVER USE THIS TOOL

WITH A DAMAGED OR FRAYED ELECTRICAL CORD OR

EXTENSION CORD. INSPECT ALL ELECTRICAL CORDS

REGULARLY. NEVER USE IN OR NEAR WATER OR IN ANY

ENVIRONMENT WHERE ELECTRIC SHOCK IS POSSIBLE.

DOUBLE INSULATION SYSTEM ENHANCES SAFE OPERATION

To enhance safe operation of this electric power tool, JOHN DEERE has adopted a

double insulation system. The term "double insulation" used here denotes an insulation

systems with two insulations physically separated and arranged between the electrically

conductive material connected to the power supply and outer frame subject to contact by

the operator.

Thus, the power tool is termed double insulated and both the mark and " " double

insulation", or either one is indicated on the name plate.

While no external grounding is required with this system, normal safety precautions as

outlined in this manual must still be followed.

To maintain the effectiveness of the double insulation system, follow the precautions

described below:

1. Always contact your John Deere Dealer when assembling, disassembling or

replacing parts other than accessories or carbon brushes. Improper assembly

and/or replacement with wrong parts may result in eliminating the double

insulation-feature.

2. Clean the exterior of the tool with a soft cloth moistened with soapy water, and

dry thoroughly. Choleric solvent, gasoline, and thinner will cause plastic compo

nents to dissolve.

SAVE THESE INSTRUCTIONS AND MAKE THEM AVAILABLE TO

OTHER USERS AND OWNERS OF THIS TOOL!

1/2-Inch Drill Operator's Manual 9

Table 1

DOUBLE INSULATION

Page 10

Functional Description

MODEL:

ET-3504-J 1/2-INCH DRILL

NOTE: The information contained in this Instruction Manual is designed to assist you in

NEVER operate, or attempt any maintenance on the tool unless you have first read and

understood all safety instructions contained in this manual.

Some illustrations in this Instruction Manual may show details or attachments

that differ from those on your own power tool

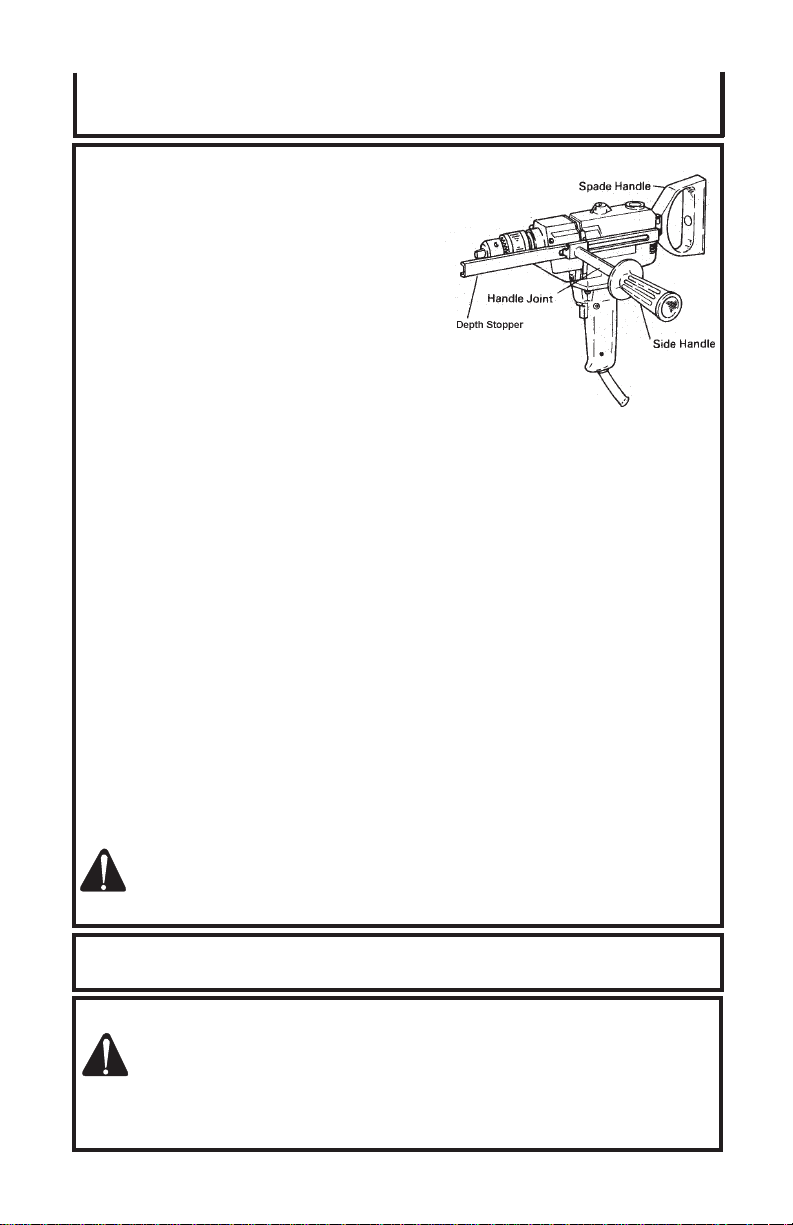

NAME OF PARTS:

SPECIFICATIONS:

1/2-INCH DRILL ET-3504-J:

Motor Single-Phase, Series: Wound Commutator Motor

Power Source Single-Phase 115V AC/DC 60Hz

Current 6.2A

Capacity 1/2” (13mm) (Steel) 1-5/8” (40mm) (Wood)

No-Load Speed 550 rpm

Weight 6.6 lbs. (3kg)

the safe operation and maintenance of the power tool.

(Fig. 1)

Preparation

PREPARATION PRIOR TO OPERATION:

Before using the Electric Power Tool, complete the following preparations.

1. Extension cord:

When the work area is far away from the power source,use an extension cord of

sufficient thickness and rated capacity. The extension cord should be kept as short

as possible.

CAUTION: DAMAGED CORD MUST BE REPLACED OR REPAIRED.

2. Confirming condition of the environment:

Confirm that the work site is placed under appropriate conditions conforming to

prescribed precautions.

10 1/2-Inch Drill Operator's Manual

Page 11

Operation

APPLICATIONS:

Drilling in various metal, lumber, and plastics.

PRE-OPERATION:

CAUTION: CONFIRM THE FOLLOWING POINTS

PRIOR TO CONNECTING THE PLUG

TO THE POWER RECEPTACLE.

1. Confirm the applied power source:

Be sure to operate the Electric Power Tool in the voltage

specified on the name plate.

2. Confirm that the power switch is turned "OFF":

If the plug is connected to the power receptacle while the

power switch is turned ON, the machine starts operating

unexpectedly, inviting serious accidents. Prior to using

the Electric Power Tool, be sure to confirm that the power

switch is turned "OFF".

3. Confirm the direction of bit rotation (Fig. 2):

The drill bit rotates clockwise (when viewed from the rear)

when the lever of the reversing switch is set to the “R”

position, and rotates in the reverse direction when the

lever of the reversing switch is set to the “L” position.

4. Mounting drill bits:

Tighten drill bits with the chuck wrench. There are three

holes in which the chuck wrench should be inserted.

Tighten them equally in turn at three holes, without

tightening them only at one hole. The drill bits can be

removed in the opposite method as mentioned above.

5. How to select drill bits:

a. When drilling holes in metals or plastics:

Use ordinary metalworking drill bits, applicable drill

sizes range from min 3/64” (1.2mm) to drill chuck

capacity.

(Fig. 2)

b. When drilling holes in lumber:

Use woodworking drill bits. For small holes of 1/4”

(6.5mm) diam. or below, use metalworking drill bits.

6. Installing spade handle:

The spade handle can be installed on the back of the

drill. Insert the bolt through the hole in the spade handle,

locate the spade handle in the desired position and

tighten the bolt firmly.

1/2-Inch Drill Operator's Manual 11

Page 12

Operation

PRE-OPERATION (CONTINUED):

7. Installing the side handle:

The side handle screws into the housing

and two sides of the gear cover. For safe

operation, use of the side handle is

necessary. Especially in heavy duty drilling,

use handle joint and side handle (Fig. 3).

8. Confirm the power receptacle:

If the power receptacle only loosely accepts

the plug, the receptacle must be repaired.

Contact the nearest electric store for repair

service. If such a faulty receptacle is

used, it may cause overheating, resulting in

a serious hazard.

OPERATION:

1. Pressing force of drill:

You can not get holes quickly even if pressing it by strong force more than

necessary. It not only damages the tip of the drill bits and decreases the efficiency

of operation, but also shortens the life of the drill.

2. In case of penetrating holes:

Drill bits are subject to break when penetrating. It is important to decrease

pressing force when penetrating.

3. Operation of switch:

a. Trigger switch:

By pulling the trigger switch, the switch is turned "ON". By pulling the trigger

again and the trigger is released, the switch is turned "OFF".

(Fig. 3)

b. Reversing switch:

This drill can rotate both clockwise (for drilling) and counterclockwise (for

releasing the drill bit) by operating the reversing switch.

CAUTION: NEVER CHANGE THE DIRECTION OF ROTATION WHILE THE

MOTOR IS ROTATING. TURN THE POWER SWITCH OFF

BEFORE CHANGING THE DIRECTION OF ROTATION.

Maintenance and Inspection

STANDARD ACCESSORIES:

CAUTION: RECOMMENDED ACCESSORIES FOR THE ELECTRIC POWER

TOOL ARE MENTIONED IN THIS MANUAL. THE USE OF ANY OTHER

1. Chuck Wrench 1

2. Side Handle 1

12 1/2-Inch Drill Operator's Manual

ATTACHMENT OR ACCESSORY IS HAZARDOUS.

Page 13

Maintenance and Inspection

MAINTENANCE AND INSPECTION:

CAUTION: BE SURE TO SWITCH POWER OFF AND DISCONNECT THE

1. Inspecting the drill bit:

Since use of an abraded drill bit will cause motor malfunctioning and degraded

efficiency, replace the drill bit with a new one or resharpen without delay when

abrasion is noted.

2. Inspecting tightness of various screws:

Periodically inspect screw tightness of individual components. If any screws are

loosened, securely retighten them. Loosened screws, if unheeded, may cause a

hazardous situation.

3. Keeping after use:

When not in use, the Electric Drill should be kept in a dry place out of the reach of

children.

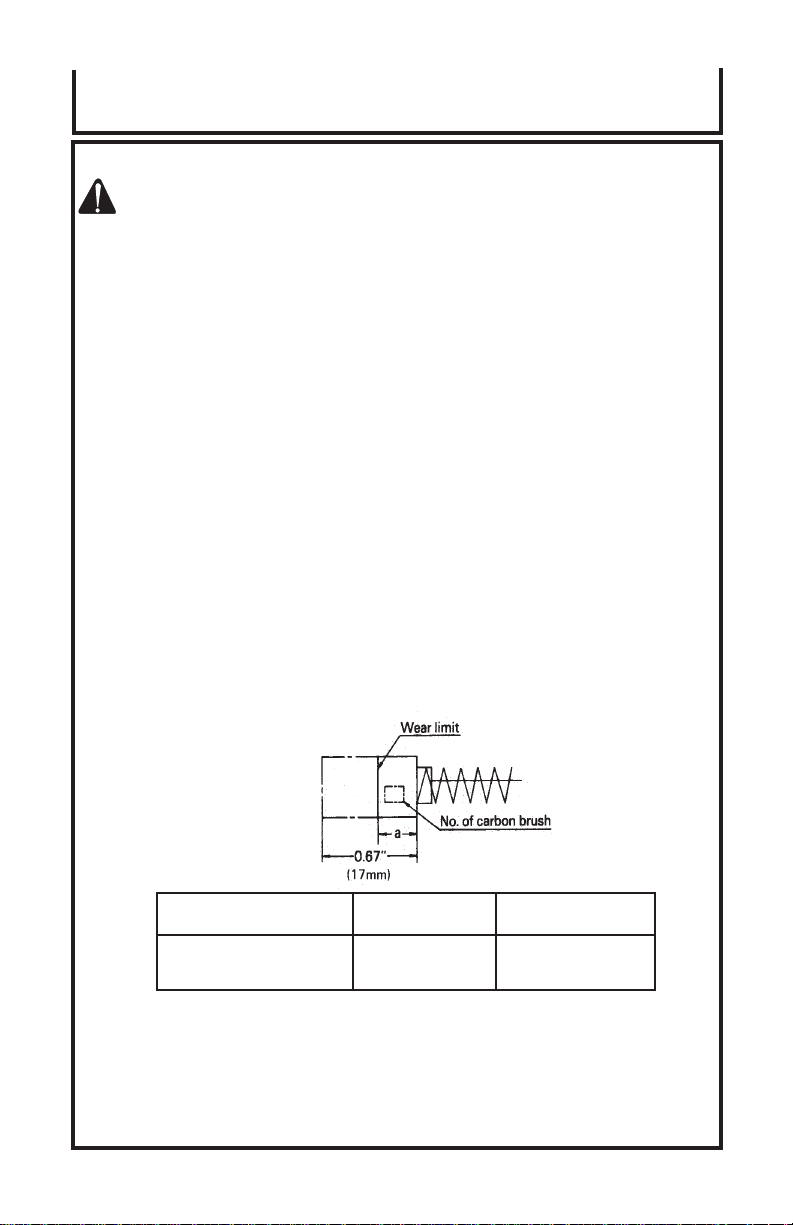

4. Inspecting the carbon brushes:

The motor employs carbon brushes which are consumable parts. When the

brushes are worn down, motor trouble may result. When the brushes are worn

down to the limit line, replace the brushes with new ones. Keep the brushes clean,

so that they smoothly slide into the brush holders.

When replacing the brushes with new ones, be sure to use a pair of brushes for

JOHN DEERE ELECTRIC DRILL ET-3504-J corresponding to the illustrated

number.

Auto-stop carbon brushes automatically cut off the electric circuit, when worn down

to the wear limit. This indicates the replacement time of the brush and prevents

damage of the commutator.

PLUG DURING MAINTENANCE AND INSPECTION.

(Fig. 4)

Usual carbon brush 0.24” (6mm) 43

a carbon brush

Auto-stop carbon brush 0.28” (7mm) 73

SERVICE AND REPAIRS

All quality tools will eventually require servicing or replacement of parts due to wear from

normal use. These operations should ONLY be performed by a John Deere Dealer.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

NOTE: Due to JOHN DEERE’s continuing program of research and development, the

specifications herein are subject to change without prior notice.

No. of

1/2-Inch Drill Operator's Manual 13

Page 14

Notes

14 1/2-Inch Drill Operator's Manual

Page 15

Notes

1/2-Inch Drill Operator's Manual 15

Page 16

#37-0689-090403

16 1/2-Inch Drill Operator's Manual

©

Copyright 2003. John Deere

Manufactured for Deere & Company,

Moline, Illinois 61265

1/2" Drill Operator's Manual

111 Code No. C99110561 N

Loading...

Loading...