Page 1

ET -3403-J 10-INCH

COMPOUND MITER SA W

CAUTION

RISK OF INJURY!

READ MANUAL BEFORE OPERATING!

THIS MANUAL IS AN IMPORTANT PART OF THE MITER SAW

AND SHOULD REMAIN WITH THIS UNIT WHEN YOU SELL OR RENT IT.

10-Inch Compound Miter Saw Operator's Manual 1

Page 2

Introduction

Congratulations on the purchase of your new Compound Miter Saw! You can be assured your compound miter saw

was constructed and designed with quality and performance in mind. Each component has been rigorously tested to

ensure the highest level of acceptance.

This operator's manual was compiled for your benefit. By reading and following the simple safety, installation, operation, maintenance and troubleshooting steps described in this manual, you will receive years of trouble-free operation

from your new heavy duty impact wrench. The contents of this manual are based on the latest product information

available at the time of publication. The manufacturer reserves the right to make changes in price, color, materials,

equipment, specifications or models at any time without notice.

Once the unit has been removed from the box, immediately write in the serial number of your unit in the space provided

below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim with the transportation company

immediately. Be sure that all damaged parts are replaced and that the mechanical problems are corrected prior to operation

of the unit. If you require service, contact your Customer Service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Please have the following information available for all service calls:

1. Model Number

2. Serial Number

3. Date and Place of Purchase

WARNING

WEAR RESPIRA TOR Y PROTECTION

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contain chemicals

known to the State of California to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-base paints,

• Crystalline Silica from bricks, cement and other masonry products, and

• Arsenic and Chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure

to these chemicals, work in a well ventilated area and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

2 10-Inch Compound Miter Saw Operator's Manual

Page 3

Table of Content

SAFETY ....................................................................................................................................................... 4-9

GENERAL SAFETY RULES............................................................................................................ 4-9

FUNCTIONAL DESCRIPTION..................................................................................................................... 10-11

MODEL............................................................................................................................................ 10

NAME OF PARTS ........................................................................................................................... 10

SPECIFICATIONS........................................................................................................................... 11

PREPARATION ........................................................................................................................................... 12

OPERATION ................................................................................................................................................ 13-21

APPLICATIONS .............................................................................................................................. 13

PRE-OPERATION........................................................................................................................... 13-15

OPERATION ................................................................................................................................... 16-20

SAW BLADE MOUNTING AND DISMOUNTING ............................................................................ 21

MAINTENANCE AND INSPECTION............................................................................................................ 22-23

MAINTENANCE AND INSPECTION ............................................................................................... 22

STORAGE....................................................................................................................................... 23

LUBRICATION ................................................................................................................................ 23

CLEANING ...................................................................................................................................... 23

SERVICE AND REPAIRS................................................................................................................ 23

STANDARD ACCESSORIES .......................................................................................................... 23

FRENCH ...................................................................................................................................................... 24-45

SPANISH ..................................................................................................................................................... 46-67

10-Inch Compound Miter Saw Operator's Manual 3

Page 4

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on your tool or in

this manual, be alert to the potential for personal injury.

Follow recommended precautions and safe operating practices.

UNDERSTAND SIGNAL WORDS

A "DANGER, WARNING or CAUTION" safety warning will be surrounded by a

"SAFETY ALERT BOX." This box is used to designate and emphasize Safety

Warnings that must be followed when operating this tool.

Accompanying the Safety Warnings are "signal words" which designate the degree

or level of hazard seriousness. The "signal words" used in this manual are as

follows:

DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

WARNING:Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided MAY result in minor or moderate injury.

GENERAL SAFETY RULES

WARNING: Read and understand all instructions.

Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

4 10-Inch Compound Miter Saw Operator's Manual

Page 5

WARNING

ALWAYS KEEP GUARDS IN PLACE and in working order.

ALWAYS KEEP WORK AREA CLEAN

Avoid injuries by not cluttering the work areas and work benches.

NEVER USE TOOL IN HAZARDOUS

ENVIRONMENTS

Never use the power tool in damp or wet places and never expose it to rain.

Always keep the work area well lighted.

NEVER PERMIT CHILDREN OR OTHERS TO LOITER NEAR THE WORK

AREA

Keep all people (especially children) away from the work area. Always unplug

unattended tools and keep the work place tamper-proof by installing locks on the

doors and on the master switches.

ALWAYS WEAR PROPER APPAREL WHEN WORKING WITH THE TOOL

Never wear loose clothing, gloves, neckties, rings, bracelets or other jewelry

which may get caught in the moving parts. Always wear nonslip footwear,

preferably with steel toes. Wear protective hair covering to contain long hair.

ALWAYS USE EYE PROTECTION WHEN WORKING WITH THE TOOL TO

PREVENT EYE INJURY

Ordinary eyeglasses do not provide adequate protection because they have only

impact resistant lenses, they are NOT safety glasses. Also, use a face mask for

additional safety and wear a dust mask if the cutting operation produces dust.

ALWAYS SECURE THE WORKPIECE TO THE FENCE OR THE TABLE

Use clamps or a vise to hold the workpiece in place. It is safer than using your

hand and it frees both hands to operate the tool.

NEVER OVERREACH

Always keep proper footing and balance when working with the tool.

ALWAYS DISCONNECT THE TOOL

before servicing and before changing blades or other accessories.

NEVER RISK UNINTENTIONAL STARTING WHEN PLUGGING IN THE TOOL

Always confirm that the switch is in the OFF position before inserting the power

plug into the receptacle.

NEVER STAND ON THE TOOL

Serious injury could occur if the tool is tipped or if unintentional contact with the

saw blade is made.

NEVER LEAVE THE TOOL RUNNING WHILE UNATTENDED. TURN POWER

OFF

Do not leave tool until it comes to a complete stop. Always turn the power off

when the tool is not in use. Always unplug the power cord when the tool is not in

use.

10-Inch Compound Miter Saw Operator's Manual 5

Page 6

WARNING

FOR YOUR OWN SAFETY READ THIS INSTRUCTION MANUAL BEFORE OPERATING THE COMPOUND

MITER SAW

1. Always wear eye protection when using the compound miter saw.

2. Always keep hands out of the path of the saw blade.

3. Never operate the saw without the guards in place.

4. Never perform any freehand operation with the compound miter saw.

5. Never reach around the saw blade.

6. Always turn off tool and wait for saw blade to stop before moving workpiece or changing settings.

7. Always disconnect power before changing blade or servicing.

8. Saw blade diameter is 10" (255mm).

9. No load speed is 4900 min-1.

CAUTION

ALWAYS REMOVE ADJUSTING KEYS AND WRENCHES BEFORE STARTING TOOL

Always confirm that all keys and adjusting wrenches have been removed from the tool before it is turned on.

NEVER FORCE THE TOOL

It will do the job better and more safely if it is operated at the rate for which it was designed.

ALWAYS USE THE RIGHT TOOLS

Never force a tool or an attachment to do a job for which it was not designed.

ALWAYS MAINTAIN TOOLS WITH CARE

Always keep tools sharp and clean for the best and safest performance. Always follow instructions for lubricating

the tool and for changing accessories.

ALWAYS USE RECOMMENDED ACCESSORIES ONLY WHEN OPERATING THIS TOOL

Consult this instruction manual for descriptions of recommended accessories. To avoid personal injuries, use only

recommended accessories in conjunction with this tool.

ALWAYS CHECK FOR DAMAGED PARTS BEFORE USING THE TOOL

Always check the guard and all other components for damage before using the tool to assure that they will function

properly. Check all moving parts for proper alignment, free from binding and other conditions that might affect

proper operation. Always repair or replace any damaged guards or other damaged components before using the

tool.

ALWAYS CONFIRM THE ROTATION DIRECTION OF THE BLADE BEFORE USING THE TOOL

Always feed work into the tool against the rotation direction of the blade in order to prevent possible injury.

This tool was not designed to be used for mass-production applications and should not be used in mass-produc-

tion environments.

When servicing this tool, use only authorized replacement parts.

Apply 115 volts AC only to this tool. Applying the wrong voltage or applying DC power can cause the POWER

TOOL to operate improperly and cause serious personal injury or damage the tool.

Never raise the saw blade from the workpiece until it has first come to a complete stop.

Always use outboard stands to provide support for long workpieces that overhang the table of the compound saw.

6 10-Inch Compound Miter Saw Operator's Manual

Page 7

CAUTION

POLARIZED PLUGS

To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to install the proper outlet. Do not change the plug in any way.

EXTENSION CORD

Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. Table shows the correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

Table 1

MINIMUM GAGE FOR CORD SETS

Total Length of Code in Feet (Meter)

0-25 26-50 51-100 101-150

(0-7.6) (7.9-15.2) (15.5-30.5) (30.8-45.7)

Ampere Rating AWG Size of Cord

More Not More

Than Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not recommended

DOUBLE INSULATION SYSTEM ENHANCES SAFE OPERATION

DOUBLE INSULATION

To enhance safe operation of this electric power tool, JOHN DEERE has adopted a double insulation system. The

term "double insulation" used here denotes an insulation systems with two insulations physically separated and

arranged between the electrically conductive material connected to the power supply and outer frame subject to

contact by the operator.

Thus, the power tool is termed double insulated and both the mark and " " double insulation", or either one is

indicated on the name plate.

While no external grounding is required with this system, normal safety precautions as outlined in this manual must

still be followed.

To maintain the effectiveness of the double insulation system, follow the precautions described below:

1. Always contact your John Deere Dealer when assembling, disassembling or replacing parts other than

accessories or carbon brushes. Improper assembly and/or replacement with wrong parts may result in

eliminating the double insulation-feature.

2. Clean the exterior of the tool with a soft cloth moistened with soapy water, and dry thoroughly. Choleric

solvent, gasoline, and thinner will cause plastic components to dissolve.

WARNING: AVOID ELECTRICAL SHOCK HAZARD. NEVER USE THIS TOOL

WITH A DAMAGED OR FRAYED ELECTRICAL CORD OR

EXTENSION CORD. INSPECT ALL ELECTRICAL CORDS

REGULARLY. NEVER USE IN OR NEAR WATER OR IN ANY

ENVIRONMENT WHERE ELECTRIC SHOCK IS POSSIBLE.

10-Inch Compound Miter Saw Operator's Manual 7

Page 8

IMPORTANT

SPECIFIC SAFETY RULES FOR USE OF THIS POWER TOOL

WARNING: THE FOLLOWING SPECIFIC OPERATING INSTRUCTIONS MUST BE OBSERVED WHEN

USING THIS POWER TOOL IN ORDER TO AVOID INJURY.

DO's:

ALWAYS OBSERVE THE FOLLOWING RULES TO ASSURE SAFE USE OF THIS TOOL:

1. Review the Manual and familiarize yourself with the safety rules and operatinginstructions for this POWER

TOOL before attempting to use it.

2. Always confirm that the POWER TOOL is clean before using it.

3. Always wear snug-fitting clothing, nonskid footwear (preferably with steel toes) and eye protection when

operating the POWER TOOL.

4. Always handle the POWER TOOL carefully. If the POWER TOOL falls or strikes against a hard object, it might

become deformed or cracked or sustain other damage.

5. Always cease operating the saw at once, if you notice any abnormality what so ever.

6. Always confirm that all components are mounted properly and securely before using the tool.

7. When replacing the saw blade, always confirm that the rating of the new blade is correct for use on this tool.

8. Always shut off the power and wait for the saw blade to completely stop rotating before doing any maintenance

or adjustments.

9. Always clamp or otherwise secure the workpiece to the fence; otherwise the workpiece might be thrust from the

table and cause bodily harm.

10. During miter or bevel cutting, always wait for the rotation of the blade to stop completely before lifting the saw

blade.

11. Always make a trial run first before attempting any new use of the saw.

12. Always handle the saw blade with care when dismounting and mounting it.

13. Always confirm that the workpiece is free of nails or other foreign objects before beginning a cut.

14. Always keep your hands out of the path of the saw blade.

15. Always confirm that the safety cover is in the proper place before using the saw.

16. Inspect the tool's power cord periodically.

17. Always confirm that the proper lengths and types of extension cords are being utilized, if necessary, before

starting the tool.

18. Always confirm that the motor air vents are fully open before using the tool.

19. Always wait until the motor has reached full speed before starting a cut.

20. Always keep the handles dry, clean and free of oil and grease. Hold the tool firmly when in use.

21. Always use outboard stands to provide support for long workpieces that overhang the table of the compound

miter saw.

22. Always operate the tool after ensuring the workpiece is fixed properly with a vise assembly.

23. The operating instructions provided with the tool shall direct the user to secure the tool to supporting structure if,

during normal operation, there is a tendency for the tool to tip over, slide, or walk on the supporting surface.

8 10-Inch Compound Miter Saw Operator's Manual

Page 9

IMPORTANT

SPECIFIC SAFETY RULES FOR USE OF THIS POWER TOOL

WARNING: THE FOLLOWING SPECIFIC OPERATING INSTRUCTIONS MUST BE OBSERVED WHEN

USING THIS POWER TOOL IN ORDER TO AVOID INJURY.

DON'Ts:

NEVER VIOLATE THE FOLLOWING RULES TO ASSURE SAFE USE OF THIS TOOL:

1. Never operate the POWER TOOL unless you fully understand the operating instructions contained in this

Manual.

2. Never leave the POWER TOOL unattended without first unplugging the power cord.

3. Never operate the POWER TOOL when you are tired, after you have taken any medications, or have

consumed any alcoholic beverages.

4. Never use the POWER TOOL for applications not specified in the instruction manual.

5. Never operate the tool while wearing loose clothing, a necktie or jewelry, or while your hair is uncovered, to

protect against getting caught in the moving machinery.

6. Never reach around the saw blade.

7. Never touch any moving parts, including the blade, while the saw is in use.

8. Never remove any safety devices or blade guards; use of the tool without them would be hazardous.

9. Never lock the safety cover; always confirm that it slides smoothly before using the tool.

10. Never damage the power cord of the tool.

11. Never attempt to move a plugged-in POWER TOOL while your finger is on the starting switch.

12. Never use the POWER TOOL if the starting switch does not turn on and off properly.

13. Never use the POWER TOOL if the plastic housing or the handle is cracked or deformed.

14. Never use the POWER TOOL near flammable liquids or gases because sparking can cause an explosion.

15. Never clean plastic components with solvents because the plastic may dissolve.

16. Never operate the saw unless all the blade guards are in place.

17. Never raise the saw blade from the workpiece until it has first come to a complete stop.

18. Never cut ferrous metals or masonry.

19. Never place your limbs inside of the line next to warning sign " " while the tool is being operated. This may

cause hazardous conditions.

20. Never use abrasive type blades on this saw.

21. Never expose to rain or use in damp locations.

22. When you cut the workpiece, avoid any cut off thinner than the clearance between the cutting edge and the saw

blade. Otherwise, the cut off material can enter the clearance between the cutting edge and the saw blade and

scatter around you, resulting in injury.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

Repairs should be conducted only by a JOHN DEERE authorized dealer.

SAVE THESE INSTRUCTIONS

AND MAKE THEM AVAILABLE TO OTHER USERS OF THIS TOOL!!

10-Inch Compound Miter Saw Operator's Manual 9

Page 10

Functional Description

MODEL:

ET-3403-J 10-INCH COMPOUND MITER SAW

NOTE: The information contained in this Instruction Manual is designed to assist you in the safe operation and

maintenance of the power tool.

NEVER operate, or attempt any maintenance on the tool unless you have first read and understood all safety

instructions contained in this manual.

Some illustrations in this Instruction Manual may show details or attachments that differ from those on your own

power tool.

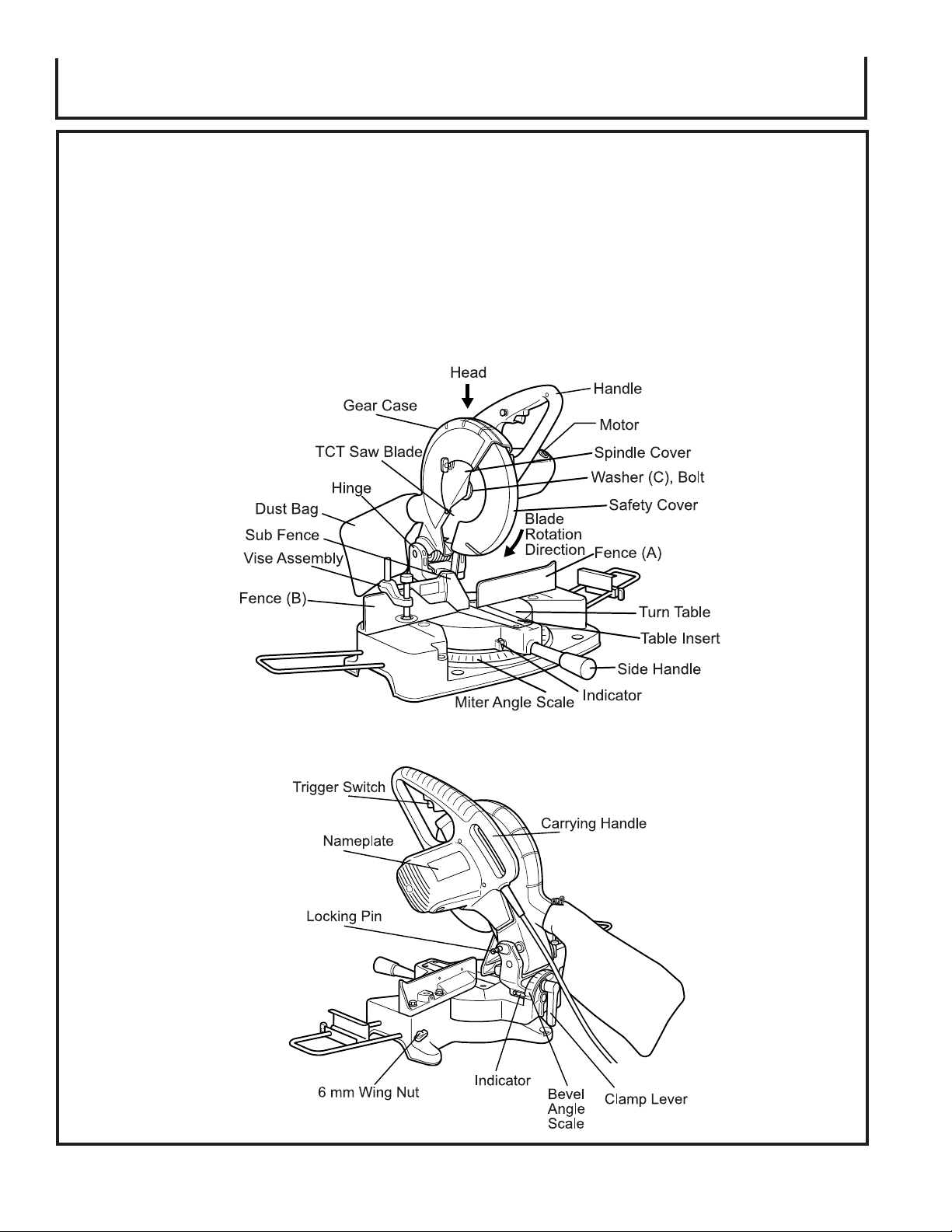

NAME OF PARTS:

(Fig. 1)

(Fig. 2)

10 10-Inch Compound Miter Saw Operator's Manual

Page 11

Functional Description

SPECIFICATIONS:

COMPOUND MITER SAW ET-3403-J:

Motor Series Commutator Motor

Power Source Single-Phase AC 60Hz

Voltage (Volts) 11 5

Full-load Current (Amp) 15

Applicable saw blade Outside Dia. 10" (255 mm)

Hole Dia. 5/8" (15.9 mm)

No load speed 4900 min

Max. sawing deminsions:

Bevel 0°:

Miter 0° Max. Height 2-1/4" (59 mm) (Max. Height 3-1/2" (89 mm)

Max. Width 5-5/8" (144 mm) (Max. Width 3-7/8" (101 mm)

Miter 45° Max. Height 2-1/4" (59 mm) (Max. Height 3-1/2" (89 mm)

Max. Width 4" (102 mm) (Max. Width 2-3/4" (70 mm)

Miter 60° Max. Height 2-1/4" (59 mm) (Max. Height 3-1/2" (89 mm)

Max. Width 2-3/4" (72 mm) (Max. Width 2" (55 mm)

Bevel 45°

Miter 0° Max. Height 1-5/8" (41 mm)

Max. Width 5-5/8" (144 mm)

Miter 45° Max. Height 1-5/8" (41 mm) (Max. Height 1-3/4" (44 mm)

Max. Width 4" (102 mm) (Max. Width 3-1/2" (89 mm)

Miter sawing range Left 0° - 45°, Right 0° - 60°

Bevel sewing range Left 0° - 45°

Net Weight 31 lbs (14 kg)

-1

Cord 2 Conductor type cabtire cable 7.2 ft (2.2 m)

10-Inch Compound Miter Saw Operator's Manual 11

Page 12

Preparation

PREPARATION:

Make the following preparations before operating the power tool:

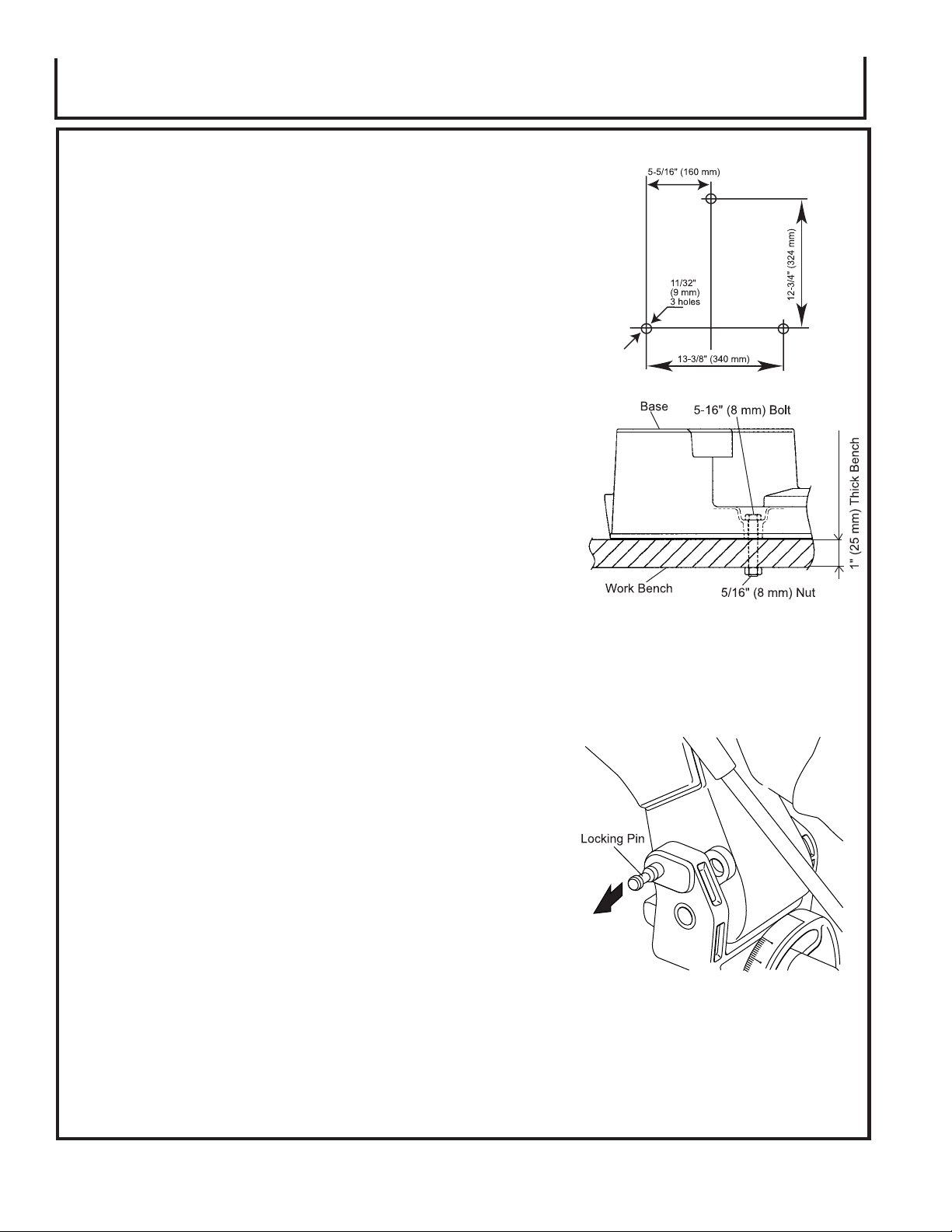

1. Installation:

Attach the power tool to a level, horizontal work bench in

accordance with Fig. 3. Select 5/16" (8 mm) diameter

bolts suitable in length for the thickness of the work bench.

For example, use 2" (50 mm) or larger bolts for 1"

(25 mm) thick work bench. The holder attached to the rear of

the base helps stabilize the power tool.

2. Releasing the locking pin:

When the power tool is prepared for shipping, its main parts

are secured by a locking pin. Move the handle

(see Fig. 4) slightly so that the locking pin can be disengaged.

During transport, lock the locking pin into the gear case.

NOTE: Lowering the handle (See Fig. 1) slightly will enable you to

disengage the locking pin easily and safely. The lock

position of the locking pin is for carrying and storage only.

3. Installing the dust bag, holder and vises:

Attach the dust bag, holder, and vises as indicated in Fig. 1.

(Fig. 3)

(Fig. 4)

12 10-Inch Compound Miter Saw Operator's Manual

Page 13

Operation

APPLICATIONS:

Wood, plywood, color board, soft fabric board, hard board similar materials and aluminum sash.

PRE-OPERATION:

1. Make sure that the power source is appropriate for the tool.

WARNING: NEVER CONNECT THE POWER TOOL UNLESS THE AVAILABLE AC POWER

SOURCE IS OF THE SAME VOLTAGE IS THAT SPECIFIED ON THE NAMEPLATE OF

THE TOOL. NEVER CONNECT THIS POWER TOOL TO A DC POWER SOURCE.

2. Make sure the trigger switch is turned OFF.

WARNING: IF THE POWER CORD IS CONNECTED TO THE POWER SOURCE WITH THE

TRIGGER SWITCH TURNED ON THE POWER TOOL WILL START SUDDENLY AND

CAN CAUSE A SERIOUS ACCIDENT.

3. Check the saw blade for visible defects:

Confirm that the saw blade is free of cracks or other visible damage.

4. Confirm that the saw blade is attached securely to the power tool:

Using the supplied wrench, tighten the bolt on the arbor shaft to secure the

saw blade. For details, see Fig. 25-a and Fig. 25-b in the section on

"SAW BLADE MOUNTING AND DISMOUNTING."

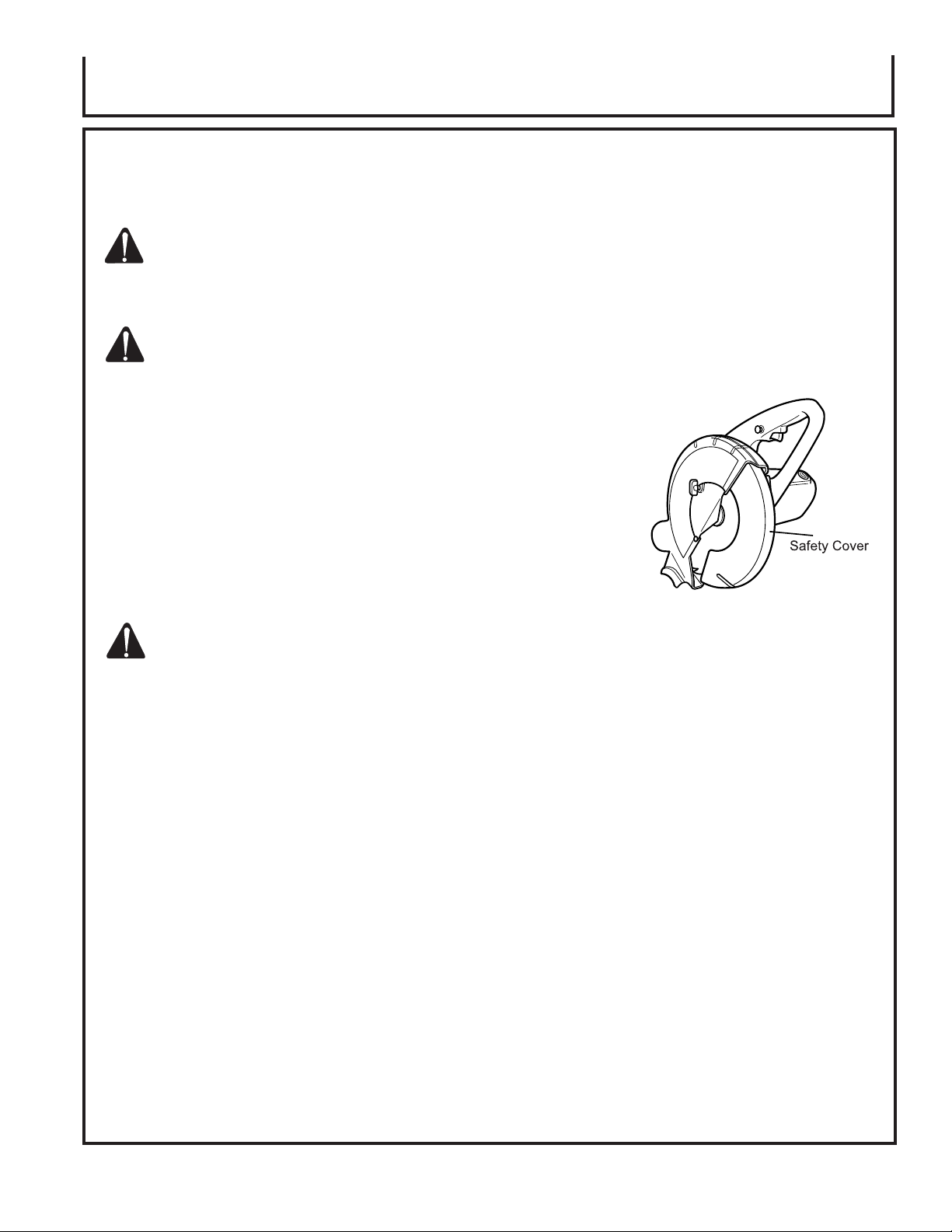

5. Check the safety cover for proper operation:

Safety cover is designed to protect the operator from coming into

contact with the saw blade during operation of the tool. Always

check that the safety cover moves smoothly and covers the saw

blade properly.

WARNING: NEVER OPERATE THE POWER TOOL IS THE

SAFETY COVER DOES NOT FUNCTION SMOOTHLY.

(Fig. 5)

6. Confirm the position of the spindle lock before using the tool:

After installing the saw blade, confirm that the spindle lock has been returned to the retract position before

using the power tool (see Fig. 25-a).

7. Check the lower limit position of the Saw Blade:

Although it was adjusted before shipment, carefully check the height of the saw blade. Confirm that the saw

blade can be lowered 1-5/8" tp 1-21/32" (41 mm or 42 mm) below the table insert. For details, see the section

on "Checking the saw blade lower limit position".

8. Check the Power Receptacle:

To prevent overheating, accidental stopping or intermittent operation, confirm that the power cord plug fits

properly in the electrical receptacle and does not fall out after it is inserted. Repair and replace the receptacle if

it is faulty.

9. Confirm the tool's power cord is not damaged:

Repair or replace the power cord if an inspection indicates that it is damaged.

AFTER CONNECTING THE POWER PLUG TO AN APPROPRIATE AC POWER SOURCE, CHECK THE

OPERATION OF THE TOOL AS FOLLOWS:

10. Trial Run:

After confirming that no one is standing behind the power tool, start and confirm that no operating abnormalities

exist before attempting a cutting operation.

11. Inspect the rotating stability of the saw blade:

For precise cutting, rotate the saw blade and check for deflection to confirm that the blade is not noticeably

unstable; otherwise, vibrations might occur and cause an accident.

10-Inch Compound Miter Saw Operator's Manual 13

Page 14

Operation

PRE-OPERATION (CONTINUED):

BEFORE CUTTING:

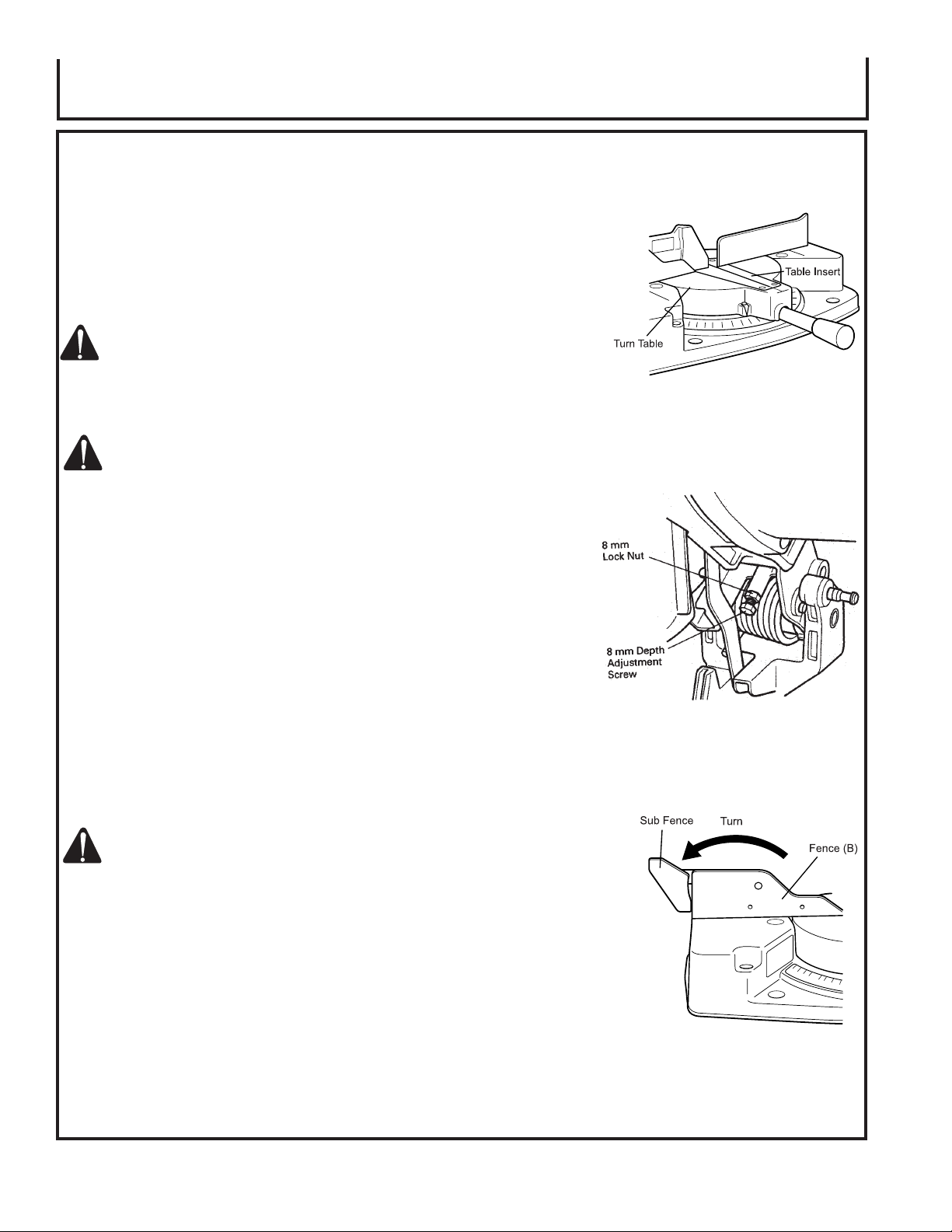

1. Cutting groove on the table insert:

A groove has to be cut in the table insert, before starting operation.

Secure a piece of wood about 5-1/2" (140 mm) wide to the table with the

vise assembly, to prevent the breakage of the table insert. After the switch

hasbeen turned on and the saw blade has reached maximum speed,

slowly lower the handle to cut a groove on the table insert.

CAUTION: DO NOT CUT THE GROOVE TOO QUICKLY,

OTHERWISE THE TABLE INSERT MIGHT BECOME

DAMAGED.

2. Checking the saw blade lower limit position:

WARNING: TO PREVENT AN ACCIDENT OR PERSONAL

INJURY, ALWAYS TURN OFF THE TRIGGER SWITCH

AND DISCONNECT THE POWER PLUG FROM THE

RECEPTACLE BEFORE ADJUSTMENT.

Check that the saw blade can be lowered 1-5/8" to 1-21/32"

(41 mm to 42 mm) below the table insert. If necessary, adjust as follows:

a. Loosen the 8 mm lock nut on the 8 mm depth

adjustment screw.

b. Turn the 8 mm depth adjustment screw as necessary to set the lower

limit position. The saw blade goes up when the 8 mm depth

adjustment screw is turned counterclockwise and down when it is

turned clockwise.

c. Once the adjustment is complete, fully tighten the 8 mm lock nut.

NOTE: Before tightening the 8 mm lock nut, confirm that the saw blade is

adjusted so that it will not cut into the table.

3. Confirmation for use of sub fence:

WARNING: IN THE CASE OF LEFT BEVEL CUTTING, TURN THE SUB

FENCE COUNTERCLOCKWISE. UNLESS IT IS TURNED

COUNTERCLOCKWISE, THE MAIN BODY OR SAW

BLADE MAY CONTACT THE SUB FENCE, RESULTING IN

AN INJURY.

(Fig. 6)

(Fig. 7)

This power tool is equipped with a sub fence. (See Fig. 1) In the case of

direct angel cutting and angle cutting, use the sub fence.

In the case of left bevel cutting, raise the sub fence up as illustrated in

Fig. 8 and then turn it counterclockwise.

(Fig. 8)

14 10-Inch Compound Miter Saw Operator's Manual

Page 15

Operation

PRE-OPERATION (CONTINUED):

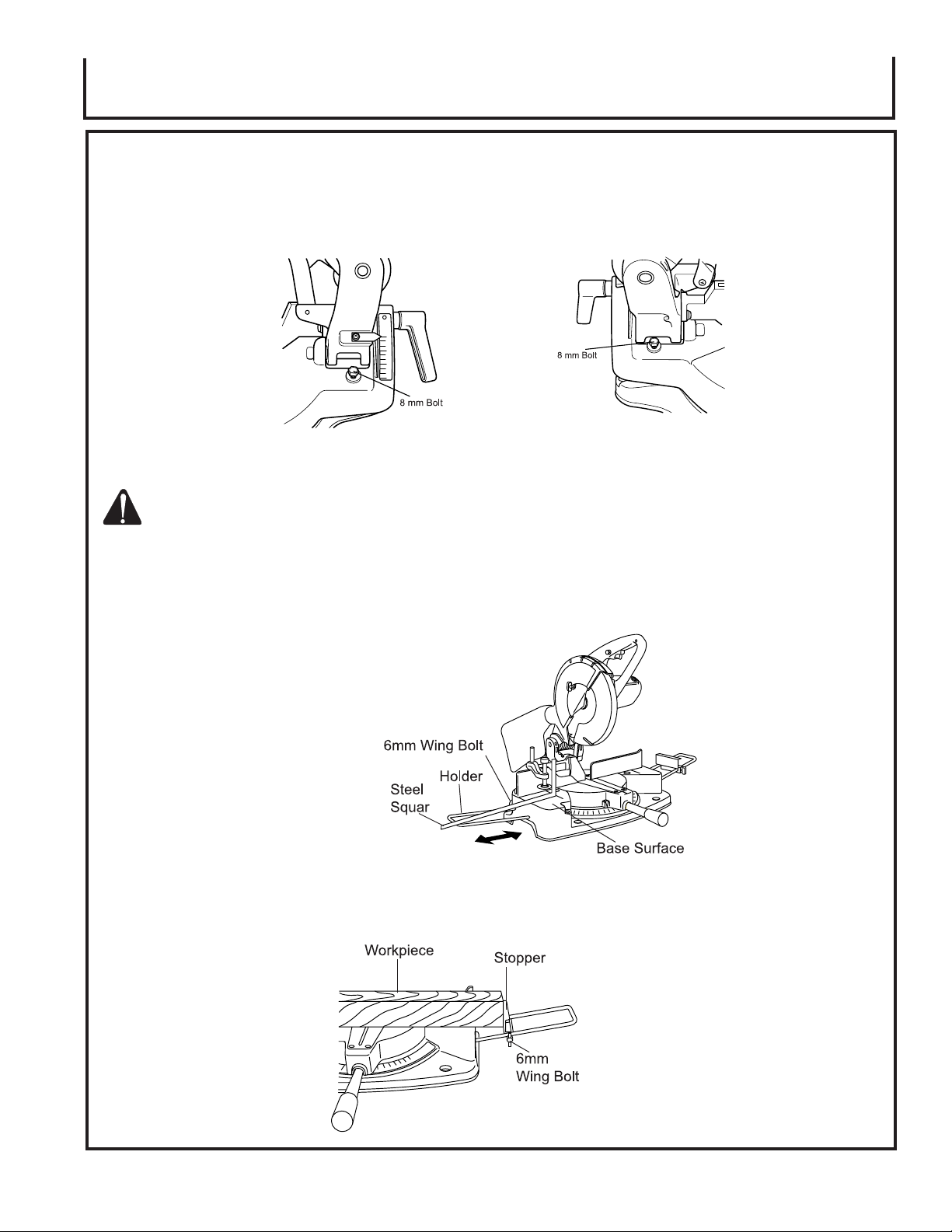

4. Oblique angle:

Before the power tool is shipped from the factory, it is adjusted for 0° and left 45° bevel cutting angles. The

positioning and bevel cutting angle can be adjusted by changing the height of the 8 mm bolt. (Maximum bevel

cutting angle is 45°).

(Fig. 9)

5. Securing the workpiece:

WARNING: ALWAYS CLAMP OR VISE, TO SECURE THE WORKPIECE TO THE FENCE;

OTHERWISE THE WORKPIECE MIGHT BE THRUST FROM THE TABLE

AND CAUSE BODILY HARM.

6. Installing the holders:

The holders help keep longer workpieces stable and in place during the cutting operation.

a. As indicated in Fig.11, use a steel square for aligning the upper edge of the holders with the base surface.

b. After aligning, secure the holders with the 6mm wing bolts.

7. Stopper for precision cutting:

The stopper facilitates continuous precision cutting in lengths of 10" to 16-1/2" (255mm to 420mm). To install

the stopper, attach it to the holder with the 6mm wing bolt as shown in Fig. 12.

(Fig. 11)

(Fig. 10)

(Fig. 12)

10-Inch Compound Miter Saw Operator's Manual 15

Page 16

Operation

OPERATION:

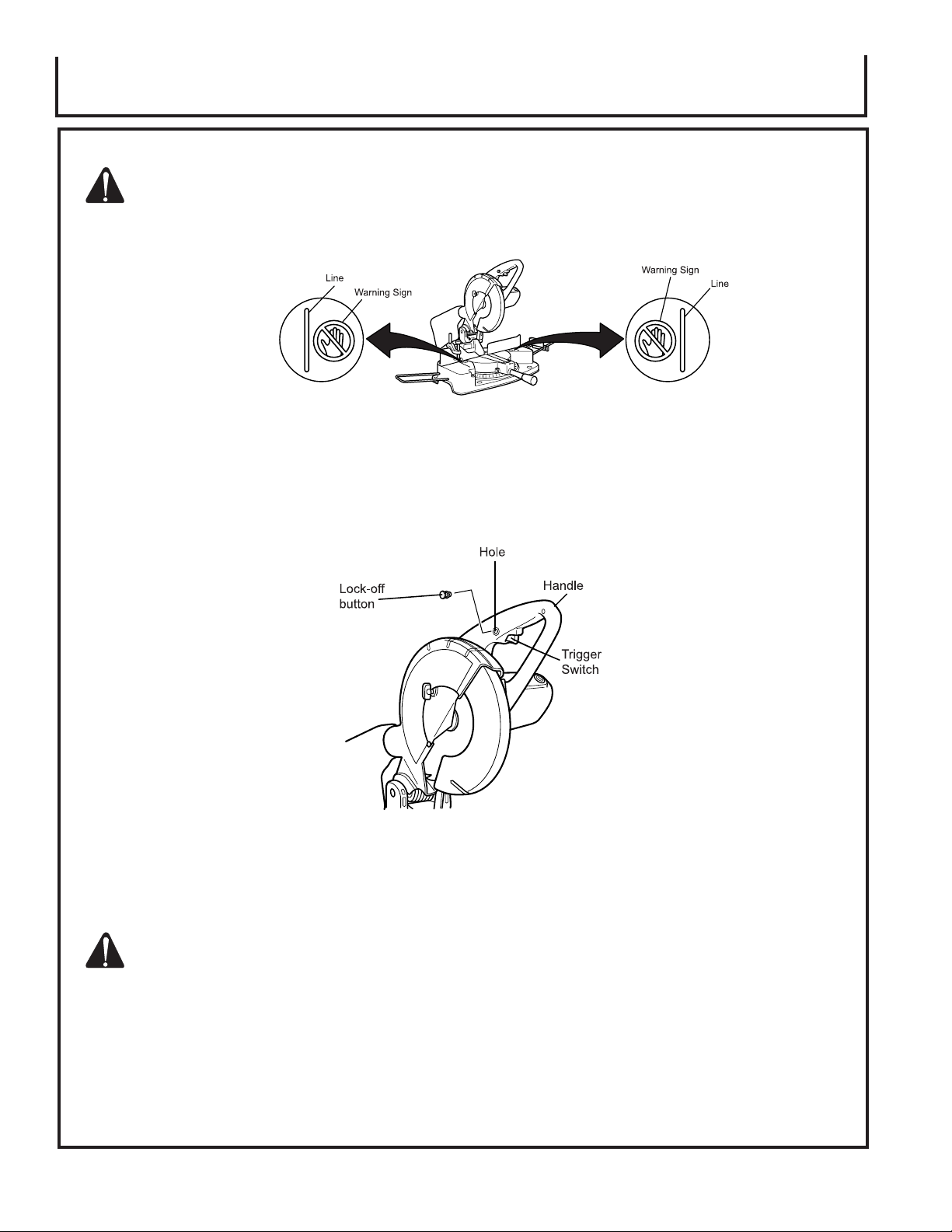

WARNING: TO AVOID PERSONAL INJURY, NEVER REMOVE OR PLACE A WORKPIECE ON

THE TABLE WHILE THE TOOL IS BEING OPERATED. NEVER PLACE YOUR

LIMBS INSIDE OF THE LINE NEXT TO WARNING SIGN WHILE THE TOOL IS BEING

OPERATED. THIS MAY CAUSE HAZARDOUS CONDITIONS (SEE FIG. 13).

(Fig. 13)

1. Switch operation:

The trigger switch lock-off button is designed to prevent inadvertent operation of the power tool. To operate

the power tool, it is necessary to first fully insert the lock-off button into the hole on the handle as shown in

Fig. 14.

(Fig. 14)

The trigger switch will not operate unless the lock-off button has beenpushed in. When the trigger switch is

released, the power goes off and the lock-off button automatically returns to its initial position, locking the

trigger switch.

WARNING: ALWAYS REMOVE THE LOCK-OFF BUTTON FROM THE HANDLE WHEN THE

POWER TOOL IS NOT IN USE. THIS WILL ENSURE THAT THE POWER TOOL

CANNOT BE TURNED ON ACCIDENTALLY OR BY SOMEONE (ESPECIALLY A

CHILD) WHO IS NOT QUALIFIED TO USE THE POWER TOOL. IF THE LOCK-OFF

BUTTON IS LEFT IN THE HANDLE, SERIOUS PERSONAL INJURY CAN RESULT.

SINCE THE LOCK-OFF BUTTON FITS RATHER TIGHTLY, IT MAY BE NECESSARY `

TO TURN IT TO THE LEFT AND RIGHT DURING MOUNTING AND REMOVING.

16 10-Inch Compound Miter Saw Operator's Manual

Page 17

Operation

OPERATION (CONTINUED):

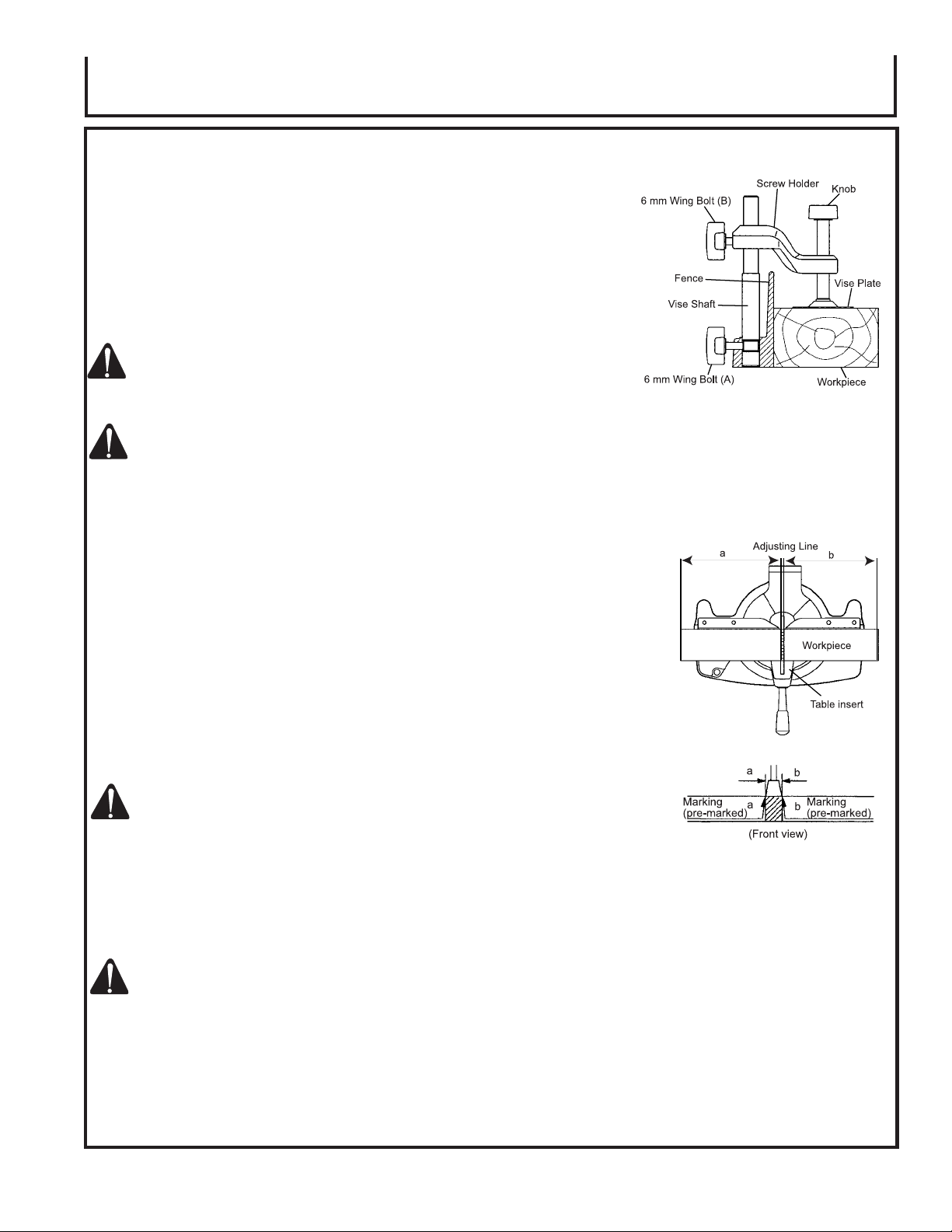

2. Using the vise assembly (Standard accessory):

a. The vise assembly can be mounted on either the left fence {Fence

(B)} or the right fence {Fence (A)} by loosening the 6 mm wing

bolt (A).

b. The screw holder can be raised or lowered according to the height of

the workpiece by loosening the 6 mm wing bolt (B). After the

adjustment, firmly tighten the 6 mm wing bolt (B) and fix the screw

holder.

c. Turn the upper knob and securely fix the workpiece in position

(Fig. 15).

WARNING: ALWAYS FIRMLY CLAMP OR VISE, TO SECURE THE

WORKPIECE TO THE FENCE; OTHERWISE THE

WORKPIECE MIGHT BE THRUST FROM THE TABLE AND

CAUSE BODILY HARM.

CAUTION: ALWAYS CONFIRM THAT THE MOTOR HEAD

(SEE FIG. 1) DOES NOT CONTACT THE VISE ASSEMBLY

WHEN IT IS LOWERED FOR CUTTING. IF THERE IS ANY

DANGER THAT IT MAY DO SO, LOOSEN THE 6 MM WING

BOLT (B) AND MOVE THE VISE ASSEMBLY TO A

POSITION WHERE IT WILL NOT CONTACT THE SAW

BLADE.

(Fig. 15)

3. Cutting Operation:

a. As shown in Fig. 16 the width of the saw blade is the width of the cut.

Therefore, slide the workpiece to the right (viewed from the

operator's position) when length (b) is desired, or to the left when

length (a) is desired.

b. Once the saw blade reaches maximum speed, push the handle down

carefully until the saw blade approaches the workpiece.

c. Once the saw blade contacts the workpiece, push the handle down

gradually to cut into the workpiece.

d. After cutting the workpiece to the desired depth, turn the power tool

OFF and let the saw blade stop completely before raising the handle

from the workpiece to return it to the full retract position.

WARNING: CONFIRM THAT THE TRIGGER SWITCH IS TURNED OFF

AND THE POWER PLUG HAS BEEN REMOVED FROM

THE RECEPTACLE WHENEVER THE TOOL IS NOT IN

USE. WHEN YOU CUT THE WORKPIECE, AVOID ANY

CUTOFF THINNER THAN THE CLEARANCE BETWEEN

THE CUTTING EDGE AND THE SAW BLADE.

OTHERWISE, THE CUTOFF MATERIAL CAN ENTER THE

CLEARANCE BETWEEN THE CUTTING EDGE AND THE

SAW BLADE AND SCATTER AROUND YOU, RESULTING

IN AN INJURY.

CAUTION: INCREASED PRESSURE ON THE HANDLE WILL NOT

INCREASE THE CUTTING SPEED. ON THE CONTRARY,

TOO MUCH PRESSURE MAY RESULT IN OVERLOAD OF

THE MOTOR AND/OR DECREASED CUTTING

EFFICIENCY. IF THE HANDLE IS PRESSED DOWN WITH

EXCESSIVE OR LATERAL FORCE, THE SAW BLADE

MAY VIBRATE DURING THE CUTTING OPERATION AND

CAUSEUNWANTED CUTTING MARKS ON THE

WORKPIECE, THUS REDUCING THE QUALITY OF THE

CUT. ACCORDINGLY, PRESS THE HANDLE DOWN

GENTLY AND CAREFULLY.

10-Inch Compound Miter Saw Operator's Manual 17

(Fig. 16)

Page 18

Operation

OPERATION (CONTINUED):

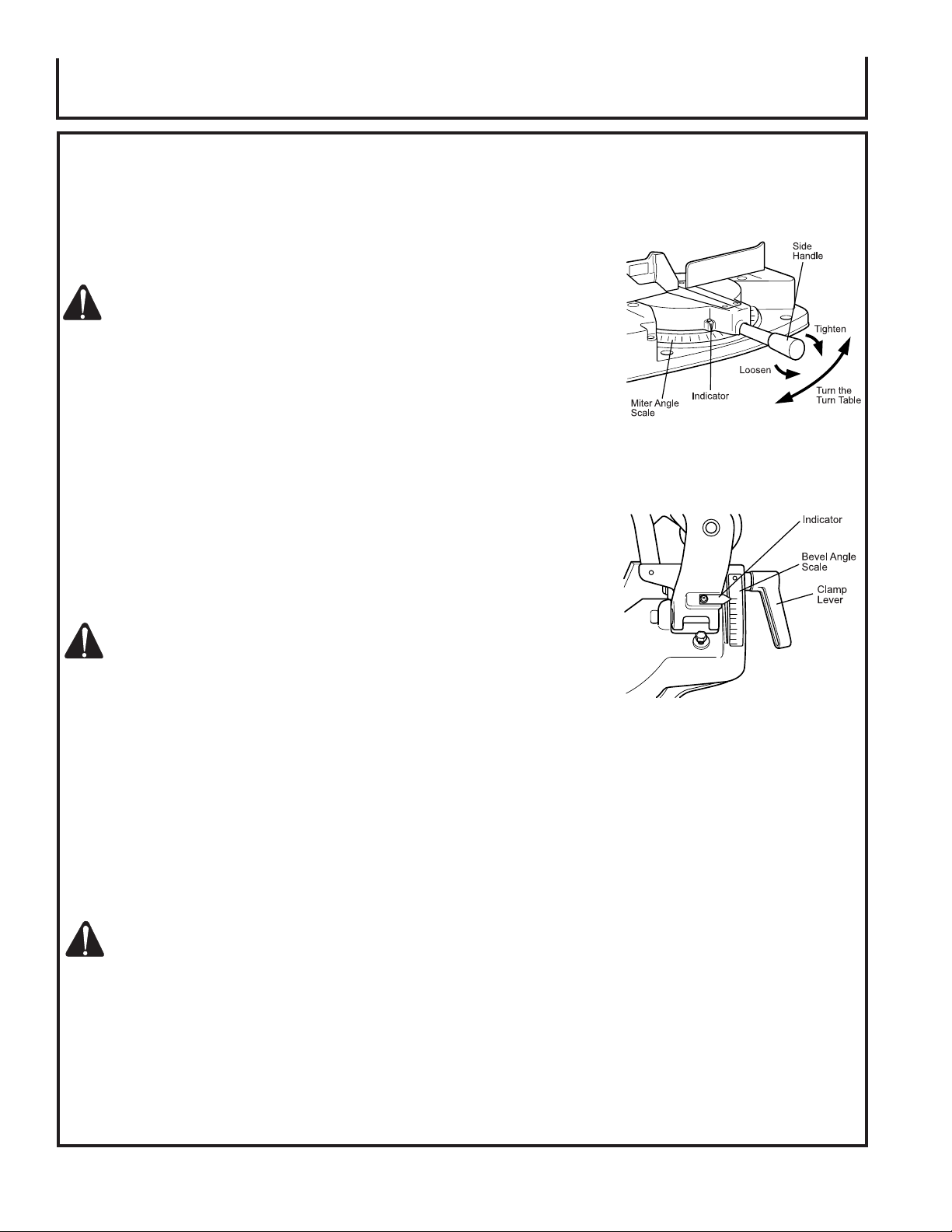

4. Miter cutting procedures:

a. Loosen the side handle.

b. Adjust the table until the indicator aligns with the desired setting on the

miter angle scale as shown in Fig. 17.

c. Retighten the side handle to secure the table in the desired position.

CAUTION: NEVER REMOVE THE SIDE HANDLE; USE OF THE TOOL

WITHOUT IT WOULD BE HAZARDOUS. TO PREVENT AN

ACCIDENT OR PERSONAL INJURY ALWAYS FIRMLY

TIGHTEN THE MITER HANDLE.

NOTE: Positive stops are provided at the right and left of the 0° center

setting, at 15°, 22.5°, 31.6°, 35.3°, 45° and 60° right and 15°,

22.5°, 31.6°, 35.3°, and 45° left settings. Check that the miter

angle scale and the tip of the indicator are properly aligned.

*Operation of the power tool with the miter angle scale and

indicator out of alignment, or with the miter handle not

properly tightened, will result in poor cutting precision.

5. Bevel cutting procedures:

a. Loosen the clamp lever and bevel the saw blade to the left.

b. Adjust the bevel angle to the desired setting while watching the bevel

angle scale and indicator, then secure the clamp lever (Fig. 18).

(Fig. 17)

WARNING: WHEN THE WORKPIECE IS SECURED ON THE LEFT SIDE

OF THE BLADE, THE SHORT CUTOFF PORTION WILL

COME TO REST ON THE RIGHT SIDE OF THE SAW

BLADE. ALWAYS TURN THE POWER OFF AND LET THE

SAW BLADE STOP COMPLETELY BEFORE RAISING THE

HANDLE FROM THE WORKPIECE. IF THE HANDLE IS

RAISED WHILE THE SAW BLADE IS STILL ROTATING, THE

CUTOFF PIECE MAY BECOME JAMMED AGAINST THE

SAW BLADE CAUSING FRAGMENTS TO SCATTER ABOUT

DANGEROUSLY.

6. Compound cutting procedures:

For compound cutting, follow the instructions in paragraphs 4 and 5 above.

At a bevel angle of 45° and a miter angle of 45°, a workpiece of 1-5/8"

(41 mm) in height and up to 4" (102 mm) in width can be cut.

CAUTION: ALWAYS SECURE THE WORKPIECE WITH THE RIGHT

HAND SIDE FOR COMPOUND CUTTING. NEVER ROTATE

THE TABLE TO THE RIGHT FOR COMPOUND CUTTING,

BECAUSE THE SAW BLADE MIGHT THEN CONTACT

THE CLAMP OR VISE THAT SECURES THE WORKPIECE,

AND CAUSE PERSONAL INJURY OR DAMAGE.

(Fig. 18)

18 10-Inch Compound Miter Saw Operator's Manual

Page 19

Operation

OPERATION (CONTINUED):

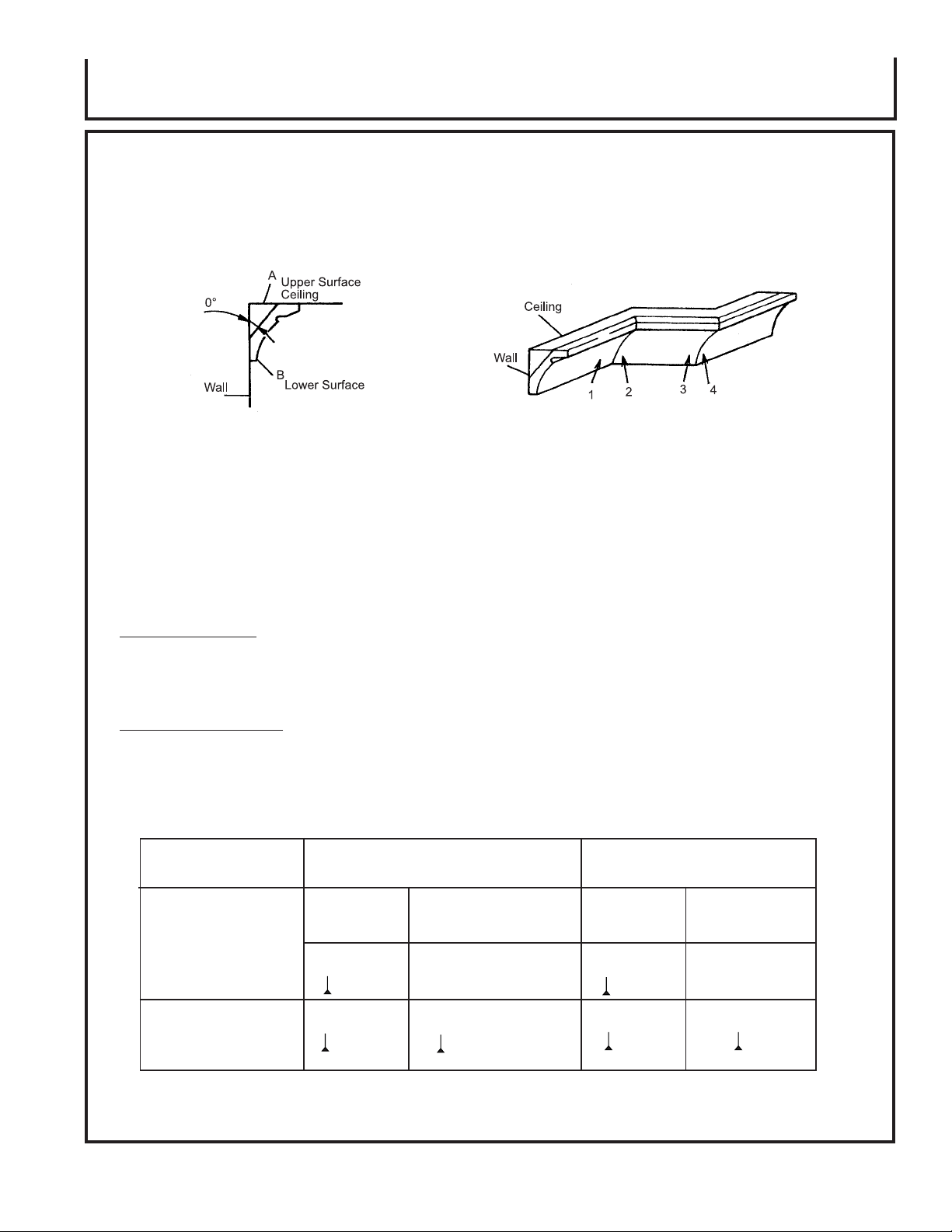

7. Crown molding cutting procedures:

Fig. 20 shows two common crown molding types having angles of (0) 38° and45°. For the typical crown molding

fittings, see Fig. 20.

(Fig. 19) (Fig. 20)

The table below shows the miter angle and the bevel angle settings that are ideal for the two crown molding

types.

NOTE: For convenience, positive stops are provided for the miter setting (left and right 31.6°, 35.3°)

positions.

For miter cut setting

If the table has been set to either of the angles described, move the table adjusting miter handle a little to the

right and left to stabilize the position and to properly align the miter angle scale and the tip of the indicator before

the operation starts.

For bevel cutting setting

Move handle on bevel section to the right and left and check that the position is stable and that the bevel angle

scale and the tip of the indicator are properly aligned. Then tighten the clamp lever.

Type of To process crown molding at To process crown molding at

Crown Molding positions (1) and (4) in Fig. 20 positions (2) and (3) in Fig. 20

Miter angle Bevel angle Miter angle Bevel angle

Setting Setting Setting Setting

45° Type right 35.3° 30° left 35.3° 30°

( mark) ( mark)

38° Type right 31.6° 33.9° left 31.6° 33.9°

( mark) ( mark) ( mark) ( mark)

10-Inch Compound Miter Saw Operator's Manual 19

Page 20

Operation

OPERATION (CONTINUED):

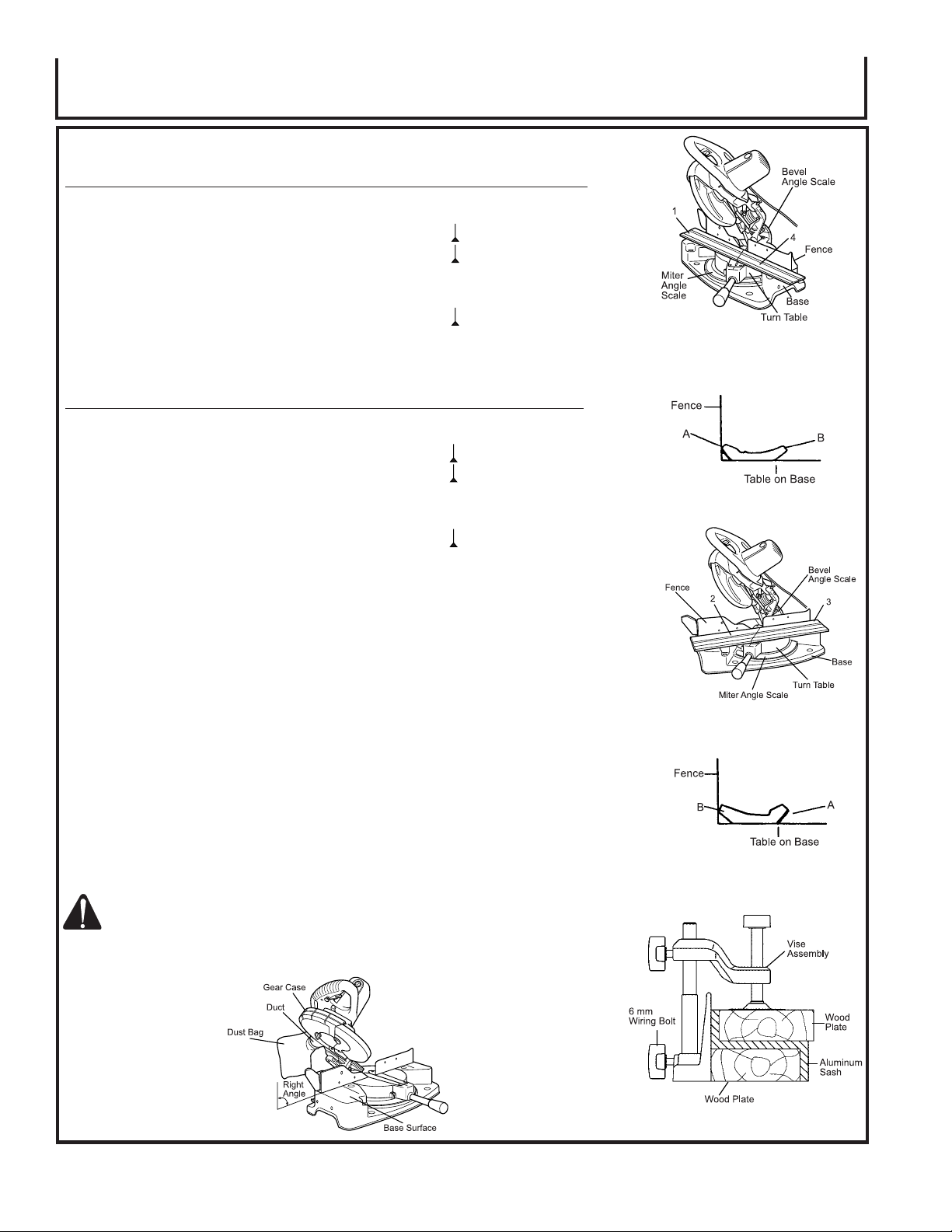

Setting to cut crown moldings at positions (1) and (4) in Fig. 20 (see Fig. 21):

1. Turn the table to the right and set the Miter Angle as follows:

*For 45° type crown moldings: 35.3° ( mark)

*For 38° type crown moldings: 31.6° ( mark)

2. Tilt the head to the left and set the Bevel Angle as follows:

*For 45° type crown moldings: 30°

*For 38° type crown moldings: 33.9° ( mark)

3. Position the crown molding so that the upper surface ((A) in Fig. 19)

contacts the fence as indicated in Fig. 25.

Setting to cut crown moldings at positions (2) and (3) in Fig. 20 (see Fig.23):

1. Turn the table to the left and set the Miter Angle as follows:

*For 45° type crown moldings: 35.3° ( mark)

*For 38° type crown moldings: 31.6° ( mark)

2. Tilt the head to the left and set the Bevel Angle as follows:

*For 45° type crown moldings: 30°

*For 38° type crown moldings: 33.9° ( mark)

3. Position the crown molding so that the lower surface (B) in Fig. 19)

contacts the fence as in Fig. 25.

8. Cutting easily-deformed materials, such as aluminum sash:

Materials such as aluminum sash can easily deform when tightened too

much in a vise assembly. This will cause inefficient cutting and possible

overload of the motor. When cutting such materials, use a wood plate to

protect the workpiece as shown in Fig. 25. When cutting aluminum

materials, coat the saw blade with cutting oil (noncombustible) to achieve

smooth cutting and a fine finish.

9. How to use the dust bag:

a. When the dust bag has become full of sawdust, dust will be blown out

of the dust bag when the saw blade rotates. Check the dust bag

periodically and empty it before it becomes full.

b. During bevel and compound cutting, attach the dust bag at a right angle

to the base surface as shown in Fig. 26.

(Fig. 21)

(Fig. 22)

(Fig. 23)

(Fig. 24)

CAUTION: EMPTY THE DUST BAG FREQUENTLY TO PREVENT THE

DUCT AND THE GEAR CASE FROM BECOMING

CLOGGED. SAWDUST WILL ACCUMULATE MORE

QUICKLY THEN NORMAL DURING BEVEL CUTTING.

(Fig. 26)

20 10-Inch Compound Miter Saw Operator's Manual

(Fig. 25)

Page 21

Operation

OPERATION (CONTINUED):

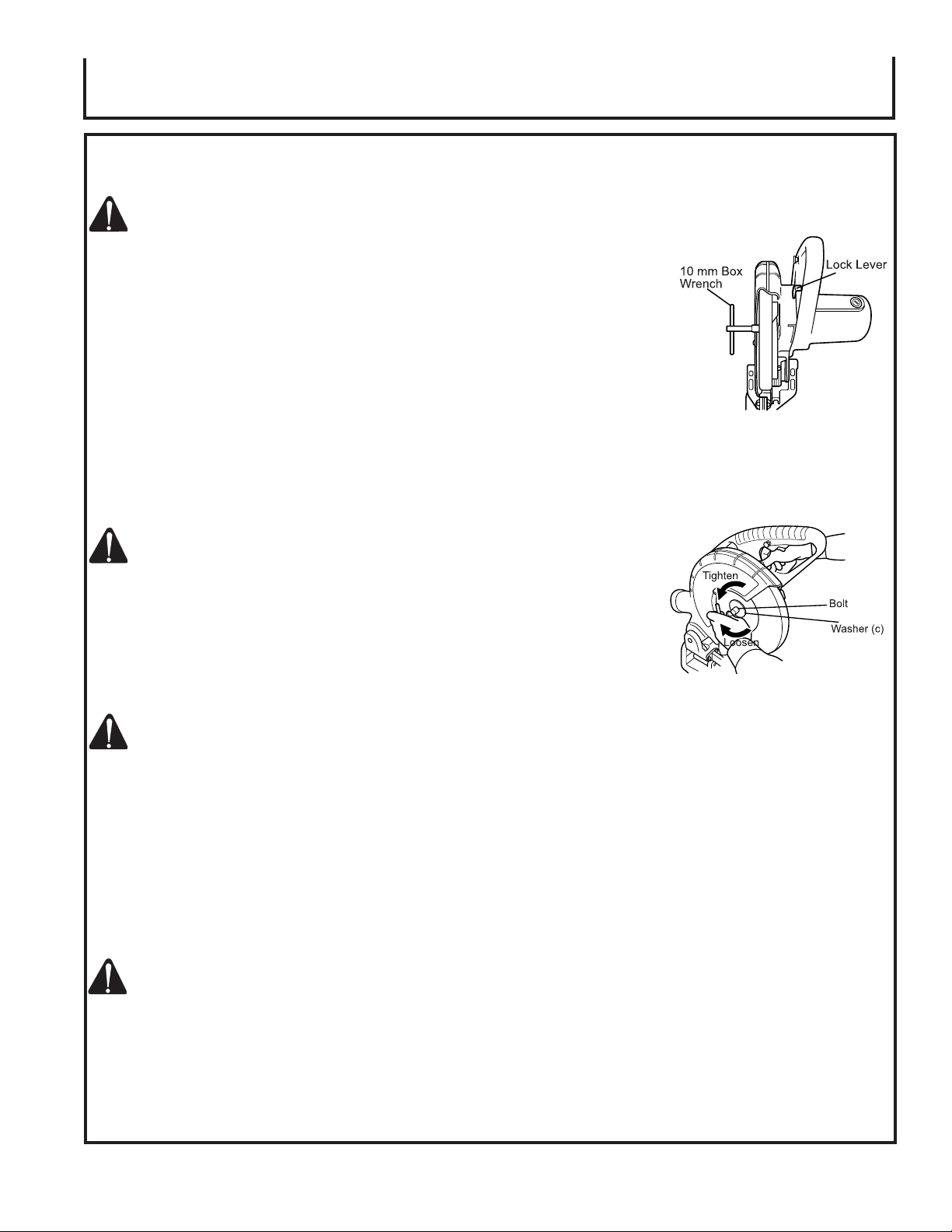

SAW BLADE MOUNTING AND DISMOUNTING:

WARNING: TO PREVENT AN ACCIDENT OR PERSONAL INJURY, AL

WAYS TURN OFF THE TRIGGER SWITCH AND DISCONNECT

THE POWER PLUG FROM THE RECEPTACLE BEFORE

REMOVING OR INSTALLING A SAW BLADE.

1. Mounting the saw blade (Fig. 27-a and Fig. 27-b)

a. Press in lock lever and loosen bolt with 10 mm box wrench. Since the bolt

is left-hand threaded, loosen by turning it to the right as shown in

Fig. 27-b.

NOTE: If the lock lever cannot be easily pressed in to lock the spindle,

turn the bolt with 10 mm box wrench while applying pressure on

the lock lever. The saw blade spindle is locked when the lock

lever is pressed inward.

b. Remove the bolt and washer (C)

c. Lift the safety cover and mount the saw blade.

WARNING: WHEN MOUNTING THE SAW BLADE, CONFIRM THAT

THE ROTATION INDICATOR MARK ON THE SAW BLADE

AND THE ROTATION DIRECTION OF THE GEAR CASE (SEE

FIG. 1) ARE PROPERLY MATCHED.

(Fig. 27-a)

d. Thoroughly clean washer (C) and the bolt, and install them onto the saw

blade spindle.

e. Press in the lock lever and tighten the bolt by turning it to the left by

10 mm box wrench as indicated in Fig. 27-b.

CAUTION: CONFIRM THAT THE SPINDLE LOCK HAS RETURNED TO

THE RETRACT POSITION AFTER INSTALLING OR

REMOVING THE SAW BLADE.

TIGHTEN THE BOLT SO IT DOES NOT COME LOOSE

DURING OPERATION. CONFIRM THE BOLT HAS BEEN

PROPERLY TIGHTENED BEFORE THE POWER TOOL IS

STARTED.

2. Dismounting the saw blade:

Dismount the saw blade by reversing the mounting procedures described in

paragraph 1 above. The saw blade can easily be removed after lifting the

safety cover.

CAUTION: NEVER ATTEMPT TO INSTALL SAW BLADES LARGER THAN

10" (255 MM) IN DIAMETER. ALWAYS INSTALL SAW

BLADES THAT ARE 10" (255 MM) IN DIAMETER OR LESS.

(Fig. 27-b)

10-Inch Compound Miter Saw Operator's Manual 21

Page 22

Maintenance and Inspection

MAINTENANCE AND INSPECTION:

WARNING: TO AVOID AN ACCIDENT OR PERSONAL INJURY, ALWAYS CONFIRM THAT THE

TRIGGER SWITCH IS TURNED OFF AND THE POWER PLUG HAS BEEN

DISCONNECTED FROM THE RECEPTACLE BEFORE PERFORMING ANY

MAINTENANCE OR INSPECTION OF THIS TOOL.

1. Inspecting the saw blade:

Always replace the saw blade immediately upon the first sign of deterioration or damage. A damaged saw

blade can cause personal injury and a worn saw blade can cause ineffective operation and possible overload

to the motor.

CAUTION: NEVER USE A DULL SAW BLADE. WHEN A SAW BLADE IS DULL, ITS

RESISTANCE TO THE HAND PRESSURE APPLIED BY THE TOOL HANDLE TENDS

TO INCREASE, MAKING IT UNSAFE TO OPERATE THE POWER TOOL.

2. Inspecting the carbon brushes (Fig. 28 and Fig. 29):

The carbon brushes in the motor are expendable parts. If the carbon brushes become excessively worn,

motor trouble might occur. Therefore, inspect the carbon brushes periodically and replace them when they

have become worn to the wear limit line as shown in Fig. 28. Also, keep the carbon brushes clean so that they

will slide smoothly within the brush holders. The carbon brushes can easily be removed after removal of the

brush caps (see Fig. 29) with a slotted (minus) screwdriver.

(Fig. 28) (Fig. 29)

3. Inspecting the mounting screws:

Regularly inspect each component of the power tool for looseness. Retighten mounting screws on any loose

part.

WARNING: TO PREVENT PERSONAL INJURY, NEVER OPERATE THE POWER TOOL IF ANY

COMPONENTS ARE LOOSE.

4. Inspecting the safety cover for proper operation:

Before each use of the tool, test the safety cover (see Fig. 5) to assure that they are in good condition and that

they move smoothly. Never use the tool unless the safety cover operates properly and unless they are in good

mechanical condition.

22 10-Inch Compound Miter Saw Operator's Manual

Page 23

Maintenance and Inspection

MAINTENANCE AND INSPECTION (CONTINUED):

STORAGE:

After operation of the tool has been completed, check that the following has been performed:

a. Trigger switch is in the OFF position.

b. Power plug has been removed from the receptacle.

c. Stored in a secure place.

When the tool is not in use, keep it stored in a dry place out of the reach of children.

LUBRICATION:

Lubricate the following sliding surfaces once a month to keep the power tool in good operating condition for a long

time. (see Fig. 1). Use of machine oil is recommended.

Oil Supply Points:

-Rotary portion of hinge

-Rotary portion of vise assembly

-Rotary portion of sub fence

CLEANING:

Periodically remove chips, dust and other waste material from the surface of the power tool, especially from the inside

of the safety cover with a damp, soapy cloth. To avoid a malfunction of the motor, protect it from contact with oil or

water.

SERVICE AND REPAIRS:

All quality power tools will eventually require servicing or replacement of parts because of wear form normal use. To

assure that only authorized replacement parts will be used and that the double insulation system will be protected, all

service (other than routine maintenance) must be performed by an AUTHORIZED JOHN DEERE DEALER.

NOTE: Specifications are subject to change without any obligation on the part of JOHN DEERE.

WARNING: ACCESSORIES FOR THIS POWER TOOL ARE MENTIONED IN THIS INSTRUCTION

STANDARD ACCESSORIES:

1. 10" (255 mm) TCT Saw Blade 1 5. Holder 2

2. Dust Bag 1 6. Stopper 1

3. Vise Assembly 1

4. 10 mm Box Wrench 1

NOTE: Accessories are subject to change without any obligation on the part of JOHN DEERE.

MANUAL. THE USE OF ANY OTHER ATTACHMENT OR ACCESSORY CAN BE

DANGEROUS AND COULD CAUSE INJURY OR MECHANICAL DAMAGE.

10-Inch Compound Miter Saw Operator's Manual 23

Page 24

Introduction

Félicitations de l'achat de votre nouveau la clé à outil! Vous pouvez être assuré que votre nouveau la outil a été construit

avec le plus haut niveau de précision et de fiabilité. Chaque composant a été rigoureusement testé par des techniciens

pour assurer la qualité, la durabilité et la performance de ce outil.

Ce manuel opérateur a été dressé pour que vous en retiriez le meilleur parti. Par la lecture et l'application des

mesures simples de sécurité, d'installation et d'opération, d'entretien et de dépannage décrites dans ce manuel, votre

nouveau outil. Fonctionnera sans faille pendant de nombreuses années. Le contenu de ce manuel est basé sur la

dernière information disponible du produit au moment de la publication. Félicitations se réserve le droit d'effectuer

des changements de prix, de couleur, de matériaux, d'équipement, de caractéristiques ou de modèles à tout moment

sans communication préalable.

Une fois l'appareil déballé, écrivez immédiatement le numéro de série de votre appareil dans l'espace çidessous.

NUMÉRO DE SÉRIE_________________________________

Assurez vous qu'il n'y a pas de signes de dommages évidents ou cachés suite au transport. En cas de dommage,

remplissez immédiatement une réclamation avec la compagnie de transport. Assurez vous que toutes les pièces

endommagées sont remplacees et les problémes mécaniques et électriques corrigés avant l'utilisation de l'appareil.

Si vous avez besoin d'assistance, entrez en contact avec votre service clientèle.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068-0050

Tél.: JD-KLEEN (1-877-535-5336) Fax 563-556-1235

du lundi au vendredi de 8h00 à 17h, CST (heure centrale)

Veuillez avoir les informations suivantes disponibles pour toute intervention:

1. Numéro de modèle

2. Numéro de série

3. Date et lieu d'achat

ADVERTISSEMENT

LE PORT D’UNE PROTECTION RESPIRATOIRE EST RECOMMANDÉ

Certaines poussières produites par le sablage, le sciage, le broyage, le perçage, et autres activités de construction

contiennent des produits chimiques connus par l'Etat de Californie pour cause de cancer, de défauts de naissance

ou de problèmes de reproduction. Des exemples de ces produits chimiques sont:

• Du plomb provenant de peintures à base de plomb.

• De la silice de Crystalline provenant de briques, de ciment et d’autres produits de maçonnerie.

• De l’arsenic et du chrome provenant de bois de charpente traité chimiquement.

Votre risque de ces contacts varie selon le temps passé à faire ce genre de travail. Pour réduire votre exposition à

ces produits chimiques, travailler dans un endroit bien aéré et avec un équipement de sécurité approuvé tels que

les masques de poussière conçus spécialement pour filtrer les particules microscopiques.

24 Manuel opérateur

Page 25

Table Des Matieres

SÉCURITÉ ................................................................................................................................................... 26-31

SIGNIFICATION DES MOTS D’AVERTISSEMENT ........................................................................ 26-31

DESCRIPTION FONCTIONNELLE ............................................................................................................. 32-33

MAQUETTE .................................................................................................................................... 32

NOM DES PARTIES ....................................................................................................................... 32

SPECIFICATIONS........................................................................................................................... 33

PRÉPARATION ........................................................................................................................................... 34

UTILISATION............................................................................................................................................... 35-43

APPLICATIONS .............................................................................................................................. 35

AVANT L'UTILISATION................................................................................................................... 35-37

UTILISATION .................................................................................................................................. 38-43

ENTRETIEN ET INSPECTIONS .................................................................................................................. 44-45

ENTRETIEN ET INSPECTIONS ..................................................................................................... 44

REMISAGE...................................................................................................................................... 45

GRAISSAGE ................................................................................................................................... 45

NETTOYAGE .................................................................................................................................. 45

APRÉS-VENTE ET RÉPARATIONS ............................................................................................... 45

ACCESSOIRIES STANDARD ......................................................................................................... 45

Manuel opérateur 25

Page 26

Sécurité

DANGER

AVERTISSEMENT

ATTENTION

RECONNAÎTRE LES SYMBOLES DE MISE EN GARDE

Voici le symbole de mise en garde. Lorsqu'il apparaît sur la outil ou dans

la présente publication, c'est pour prévenir d'un risque potentiel de

blessure.

Respecter tous les conseil de sécurité ainsi que les consignes générales

de prévention des accidents.

COMPRENDRE LES TERMES DE MISE EN GARDE

Les avertissements de sécurité "DANGER, AVERTISSEMENT ou

ATTENTION" seront entourés par un "ENCADRE ALERTE SECURITE".Cet

encadré est utilisé pour indiquer et souligner les avertissements de sécurité qui

doivent être suivis en actionnant d'outils. En plus des avertissements de

sécurité, des "mots d'alerte" sont utilisés pour indiquer le degré ou niveau de

risque. Les "mots d'alerte" utilisés dans ce manuel sont comme suit:

DANGER: Indique une situation au danger

imminent qui, si elle n'est pas évitée,

ENTRAINERA

AVERTISSEMENT: Indique une situation

potentiellement dangereuse qui, si elle n'est pas évitée,POURRAIT

entraîner la mort ou des blessures graves.

la mort ou des blessures graves.

ATTENTION: Indique une situation

potentiellement dangereuse, qui, si elle n'est pas évitée, PEUT

entraîner des blessures mineures ou peu graves et des

dégats au compresseur.

REGLES GENERALE DE SECURITE

AVERTISSEMENT: Lire et coxmprendre toutes les

instructions. Un non respect de toutes les

instructions ci-dessous peut entraîner une

électrocution, un incedie et/ou de

sérieuses blessures personnelles.

CONSERVER CES INSTRUCTIONS

26 Manuel opérateur

Page 27

ADVERTISSEMENT

TOUJOURS LAISSER LES PROTECTIONS EN PLACE ET LES MAINTENIR

EN BON ORDRE DE MARCHE.

TOUJOURS MAINTENIR L’AIRE DE TRAVAIL PROPRE. Pour éviter tout risque

de blessure, ne pas encombrer l’aire de travail ni l’établi.

NE JAMAIS UTILISER L’OUTIL DANS UN ENVIRONNEMENT DANGEREUX.

Ne jamais utiliser l’outil électrique dans un endroit humide ou mouillé, et ne

jamais l’exposer à la pluie. Toujours veiller à ce que l’aire de travail soit

suffisamment éclairée.

NE JAMAIS LAISSER LES ENFANTS NI AUCUNE AUTRE PERSONNE

APPROCHER DE L’AIRE DE TRAVAIL. Interdire l’accès de l’aire de travail à

tout le monde (en particulier aux enfants). Toujours débrancher l’outil quand on

s’en éloigne et veiller à ce que personne ne puisse pénétrer dans l’aire de travail

en mettant des verrous aux portes et aux interrupteurs principaux.

PORTER DES VÊTEMENTS APPROPRIÉS PENDANT LE TRAVAIL. Ne jamais

porter de vêtements lâches ni de gants, cravate, bagues, bracelets ni aucun

autre bijou. Ils pourraient se coincer dans les pièces en rotation. Toujours porter

des chaussures anti-dérapantes, en particulier avec des doigts de pied en acier.

Porter un couvre-chef qui recouvre les cheveux longs.

TOUJOURS PORTER DES LUNETTES DE PROTECTION PENDANT LE

TRAVAIL POUR ÉVITER TOUT RISQUE DE BLESSURE DES YEUX. Les

lunettes ordinaires n’assurent pas une protection suffisante parce que leurs

verres sont uniquement résistants aux chocs, ce NE sont PAS des verres de

sécurité. Par ailleurs, porter un masque sur le visage pour accroître la sécurité, et

un masque anti-poussière si le travail doit dégager de la poussière.

TOUJOURS FIXER LA PIÈCE À LA GARDE OU À LA TABLE. Utiliser des

dispositifs de serrage ou un étau pour tenir la pièce. Cela sera plus sûr que de

tenir la pièce à la main et libérera les deux mains pour le travail.

NE JAMAIS TROP SE PENCHER. Toujours garder une bonne assise et un bon

équilibre pendant le travail.

TOUJOURS DÈBRANCHER L’OUTIL avant un entretien et lors du

remplacement des lames ou de tout autre accessoire.

NE JAMAIS RISQUER UNE MISE EN MARCHE INOPINÉE LORSQU’ON

BRANCHE L’OUTIL. Toujours vérifier que l’interrupteur est en position OFF

avant de brancher la fiche d’alimentation dans la prise secteur.

NE JAMAIS MONTER SUR L’OUTIL. Il y a risque de blessure grave en cas de

renversement de l’outil ou en cas de contact accidentel avec la lame de scie.

NE JAMAIS S’ÉLOIGNER DE L’OUTIL QUAND IL FONCTIONNE. LE METTRE

HORS TENSION. Ne pas s’éloigner de l’outil tant qu’il n’est pas complètement

arrêté. Toujours mettre l’outil hors tension quand on ne s’en sert pas. Toujours

débrancher le cordon d’alimentation quand on ne se sert pas de l’outil.

Manuel opérateur 27

Page 28

ADVERTISSEMENT

POUR VOTRE PROPRE SÉCURITÉ, LISEZ ATTENTIVEMENT CE MODE D’EMPLOI AVANT

D’UTILISER LA SCIE À ONGLET INCLINABLE.

1. Toujours porter des lunettes de protection lorsqu’on utilise la scie à onglet inclinable.

2. Toujours éloigner les mains du trajet de lame.

3. Ne jamais faire fonctionner la scie si les protections ne sont pas en place.

4. Ne jamais effectuer d’opération à la volée avec la scie à onglet inclinable.

5. Ne jamais s’approcher de la lame.

6. Toujours mettre la scie hors tension et attendre que la lame ait complètement cessé de tourner avant de

déplacer la pièce ou de modifier les réglages.

7. Toujours débrancher l’alimentation avant de remplacer la lame ou d’entretenir l’outil.

8. Le diamètre de la lame est de 255 mm (10").

9. La vitesse à vide est de 4900 min-1.

ATTENTION

TOUJOURS RETIRER LES CLAVETTES DE RÉGLAGE ET LES CLÉS AVANT DE METTRE L’OUTIL EN

MARCHE. Toujours vérifier que les clés et les clavettes de réglage sont bien toutes retirées de l’outil avant de le

mettre en marche.

NE JAMAIS FORCER L’OUTIL. Il effectuera le travail le meilleur et avec la sécurité maximale au régime pour

lequel il a été conçu.

TOUJOURS UTILISER LES OUTILS APPROPRIÉS. Ne jamais utiliser un outil ou un accessoire pour un travail

pour lequel il n’est pas conçu.

TOUJOURS ENTRETENIR LES OUTILS AVEC SOIN. Maintenir les outils aiguisés et propres pour optimiser le

travail et la sécurité. Toujours suivre les instructions de graissage et de remplacement des accessoires.

TOUJOURS UTILISER EXCLUSIVEMENT LES ACCESSOIRES RECOMMANDÈS POUR L’OUTIL. Consulter le

mode d’emploi pour la description des outils recommandés. Pour éviter tout risque de blessure, utiliser

exclusivement les accessoires recommandés pour cet outil.

TOUJOURS VÉRIFIER SI L’OUTIL A DES PIÈCES ENDOMMAGÉES AVANT DE L’UTILISER. Toujours vérifier

si la protection et les autres composants sont endommagés avant d’utiliser l’outil pour s’assurer qu’ils

fonctionneront correctement. Vérifier si toutes les pièces mobiles sont bien alignées, non voilées, ou toute autre

condition qui pourrait entraver leur bon fonctionnement. Toujours réparer ou remplacer les protections ou les

autres pièces endommagées avant d’utiliser l’outil.

TOUJOURS VÉRIFIER LE SENS DE ROTATION DE LA LAME AVANT D’UTILISER L’OUTIL. Toujours avancer

la pièce dans l’outil contre le sens de rotation de la lame pour éviter tout risque de blessure.

L’outil n’est pas conçu pour des applications de fabrication en série, et il ne devra donc pas être utilisé dans un

environnement de fabrication en série.

Pour les réparations, utiliser exclusivement des pièces de rechange agréées.

Alimenter l’outil exclusivement sur un courant alternatif de 115 volts. Une tension ou une alimentation incorrectes

pourraient provoquer un mauvais fonctionnement de l’OUTIL ELECTRIQUE et provoquer des blessures physiques

ou des dommages matériels graves.

Ne jamais relever la lame de la pièce tant qu’elle n’est pas complètement arrêtée.

Toujours utiliser des supports extérieurs pour assurer la stabilité des longues pièces qui dépassent de la table de

la scie à onglet radiale.

28 Manuel opérateur

Page 29

ATTENTION

FICHES POLARISÉES Pour réduire tout risque de choc électrique, l’appareil possède une fiche polarisée (l’une des

lames est plus large que l’autre). Cette fiche ne rentrera dans une prise polarisée que dans un sens. Si la fiche ne

rentre pas dans la prise, l’inverser. Si elle ne rentre toujours pas, faire installer une prise appropriée par un

électricien qualifié. Ne pas modifier la fiche de quelque façon que ce soit.

UTILISATION D’UN CORDON DE RALLONGE

Utiliser exclusivement un cordon de rallonge en bon état. Lorsqu’on utilise un cordon de rallonge, veiller à ce qu’il

soit suffisamment lourd pour supporter le courant dont l’appareil aura besoin. Un cordon trop petit provoquera une

chute de la tension de ligne, ce qui entraînera une perte de puissance et une surchauffe. Le tableau indique le

calibre à utiliser en fonction de la longueur du cordon et de l’intensité nominale indiquée sur la plaque signalétique.

En cas de doute, utiliser un calibre supérieur. Plus le numéro du calibre est petit, plus le cordon est lourd.

CALIBRE MINIMUM DES CORDONS

Longueur totale de cordon en pieds (mètres)

0 – 25 26 – 50 51 – 100 101 – 150

(0 – 7,6) (7,9 – 15,2) (15,5 – 30,5) (30,8 – 45,7)

Intensité nominale CALIBRE

Supérieure Non supérieure

0 – 6 18161614

6 – 10 18 16 14 12

10 – 12 16 16 14 12

12 – 16 14 12 Non recommandé

DOUBLE ISOLATION POUR UN FONCTIONNEMENT PLUS SUR

Pour assurer un fonctionnement plus sûr de cet outil électrique, JOHN DEERE a adopté une conception à double

isolation. “Double isolation” signifie que deux systèmes d’isolation physiquement séparés ont été utilisés pour isoler

les matériaux conducteurs d’ électrique connectés à l’outil électrique à partir du cadre extérieur manipulé par

l’utilisateur. C’est pourquoi, le symbole “ ” ou les mots “Double insulation” (double isolation) apparaissent sur

l’outil électrique ou sur la plaque signalétique.

Bien que ce système n’ait pas de mise à la terre extérieure, il est quand même nécessaire de suivre les précautions

de sécurité électrique données dans ce mode d’emploi, y compris de ne pas utiliser l’outil électrique dans un

environnement humide.

Pour garder le système de double isolation effectif, suivre ces précautions:

1. Seuls les CENTRES DE SERVICE AUTORISES JOHN DEERE peuvent démonter et remonter cet outil

électrique et uniquement des pièces de rechange JOHN DEERE garanties d’origine doivent être utilisées.

2. Nettoyer l’extérieur de l’outil électrique uniquement avec un chiffon doux légèrement imbibé d’une solution

savonneuse et essuyer minutieusement. Ne jamais utiliser de solvants, d’essence ou de diluants sur les parties

en plastique; sinon le plastique risquerait de se dissoudre.

AVERTISSEMENT: EVITER TOUT RISQUE DE CHOC ÉLECTRIQUE. NE JAMAIS UTILISER L’OUTIL AVEC

UN CORDON ÉLECTRIQUE OU UN CORDON DE RALLONGE ENDOMMAGÉ OU

DÉNUDÉ. INSPECTER RÉGULIÈREMENT LES CORDONS ÉLECTRIQUES. NE

JAMAIS UTILISER DANS L’EAU OU À PROXIMITÉ D’EAU, NI DANS UN

ENVIRONNEMENT SUSCEPTIBLE DE PROVOQUER UN CHOC ÉLECTRIQUE.

Manuel opérateur 29

Page 30

IMPORTANT

CONSIGNES DE SÉCURITÉ SPÉCIALES POUR CET OUTIL ÉLECTRIQUE:

AVERTISSEMENT: POUR ÉVITER TOUT RISQUE DE BLESSURE, LES CONSIGNES DE SÉCURITÉ

SPÉCIALES SUIVANTES DEVRONT ÊTRE RESPECTÉES LORS DE L’UTILISATION DE

L’OUTIL.

CHOSES A FAIRE

TOUJOURS OBSERVER LES CONSIGNES SUIVANTES POUR GARANTIR UNE UTILISATION EN TOUTE

SÉCURITÉ:

1. Bien lire le manuel et se familiariser avec les consignes de sécurité et les instructions d’utilisation de l’OUTIL

ELECTRIQUE avant de l’utiliser.

2. Toujours vérifier que l’OUTIL ELECTRIQUE est propre avant de l’utiliser.

3. Toujours porter des vêtements bien ajustés et des chaussures anti-dérapantes (de préférence avec des doigts

de pied en acier) et des lunettes de protection lorsqu’on utilise l’OUTIL ELECTRIQUE.

4. Toujours manier l’OUTIL ELECTRIQUE avec soin. Si l’OUTIL ELECTRIQUE tombe ou qu’il heurte un objet dur,

il risque de se déformer, de se fendiller ou autre dommage.

5. Toujours cesser immédiatement d’utiliser la scie si l’on remarque quelque chose d’anormal.

6. Toujours vérifier que les pièces sont toutes correctement montées et fixées avant d’utiliser l’outil.

7. Pour le remplacement de la lame, toujours vérifier que le min-1 nominal de la nouvelle lame convient pour l’outil.

8. Toujours mettre l’outil hors tension et attendre que la lame ait complètement cessé de tourner avant tout

remplacement ou tout réglage.

9. Toujours visser ou fixer la pièce sur la garde, pour qu’elle ne risque pas d’être éjectée de la table et de

provoquer des blessures.

10. Pendant une coupe d’onglet ou de biseau, toujours attendre que la lame ait complètement cessé de tourner

avant de la relever.

11. Toujours faire un essai avant d’utiliser la scie pour un nouvel usage.

12. Toujours manipuler la scie avec soin lorsqu’on la démonte ou qu’on la monte.

13. Toujours vérifier qu’il n’y a ni clou ni aucun autre corps étranger dans la pièce avant de commencer une coupe.

14. Toujours éloigner les mains du trajet de lame.

15. Toujours vérifier que les carters de sécurité sont en place avant d’utiliser la scie.

16. Inspecter périodiquement les cordons d’alimentation.

17. Le cas échéant, toujours vérifier que l’on utilise des cordons et des rallonges du type et de la longueur voulus

avant de mettre l’outil en marche.

18. Toujours vérifier que les évents d’aération du moteur sont complètement dégagés avant d’utiliser l’outil.

19. Toujours attendre que le moteur ait atteint sa vitesse de régime avant d’entamer une coupe.

20. Toujours maintenir les poignées sèches, propres et sans huile ni graisse. Tenir l’outil fermement pendant le

travail.

21. Toujours utiliser des supports extérieurs pour soutenir les pièces longues qui dépassent de la table de la scie à

coupe d’onglet.

22. Toujours commencer par s’assurer que la pièce est correctement fixée dans un étau.

23. Le mode d’emploi fourni avec l’outil explique à l’utilisateur comment fixer l’outil sur sa structure de support si, en

fonctionnement normal, il a tendance à se renverser, à glisser ou à bouger le long de la surface de support.

30 Manuel opérateur

Page 31

IMPORTANT

CONSIGNES DE SÉCURITÉ SPÉCIALES POUR CET OUTIL ÉLECTRIQUE:

AVERTISSEMENT: POUR ÉVITER TOUT RISQUE DE BLESSURE, LES CONSIGNES DE SÉCURITÉ

SPÉCIALES SUIVANTES DEVRONT ÊTRE RESPECTÉES LORS DE L’UTILISATION DE

L’OUTIL.

CHOSES A NE PAS FAIRE

POUR GARANTIR UNE UTILISATION EN TOUTE SÉCURITÉ, NE JAMAIS VIOLER LES

CONSIGNES SUIVANTES:

1. Ne jamais utiliser l’OUTIL ELECTRIQUE si l’on ne comprend pas bien les instructions de ce manuel.

2. Ne jamais s’éloigner de l’OUTIL ELECTRIQUE sans débrancher auparavant son cordon d’alimentation.

3. Ne jamais utiliser l’OUTIL ELECTRIQUE quand on est fatigué, après avoir pris des médicaments ou

consommé des boissons alcoolisées.

4. Ne jamais utiliser l’OUTIL ELECTRIQUE pour des applications non spécifiées dans ce mode d’emploi.

5. Ne jamais faire fonctionner l’outil si l’on porte des vêtements lâches, une cravate ou des bijoux, ou sans se

couvrir les cheveux, pour éviter qu’ils ne se prennent dans les pièces mobiles.

6. Ne jamais approcher les mains de la lame.

7. Ne jamais toucher les pièces en mouvement, y compris la lame, pendant le fonctionnement de la scie.

8. Ne jamais retirer les dispositifs de sécurité ni les protections de lame ; l’utilisation de l’outil serait dangereuse

sans ces pièces.

9. Ne jamais verrouiller le carter de sécurité ; toujours vérifier qu’il glisse régulièrement avant d’utiliser l’outil.

10. Ne jamais endommager le cordon d’alimentation de l’outil.

11. Quand l’OUTIL ELECTRIQUE est branché, ne jamais tenter de le déplacer avec le doigt sur l’interrupteur de

marche.

12. Ne jamais utiliser l’OUTIL ELECTRIQUE si l’interrupteur de marche ne fonctionne pas correctement.

13. Ne jamais utiliser l’OUTIL ELECTRIQUE si le logement en plastique ou la poignée sont déformés ou fendillés.

14. Ne jamais utiliser l’OUTIL ELECTRIQUE à proximité d’un liquide ou d’un gaz inflammable, car les étincelles

pourraient provoquer une explosion.

15. Ne jamais nettoyer les composants en plastique avec des solvants car cela risquerait de dissoudre le plastique.

16. Ne jamais faire fonctionner la scie si les protections de lame ne sont pas toutes en place.

17. Ne jamais relever la lame de la pièce tant que la lame n’est pas complètement arrêtée.

18. Ne jamais couper de métaux ferreux ni de maçonnerie.

19. Ne jamais amener les membres à l’intérieur de la ligne à côté du signe d’avertissement “ ” quand l’outil

fonctionne. Cela pourrait être dangereux.

20. Ne jamais utiliser de lames de type abrasif avec cette scie.

21. Ne jamais exposer à la pluie ni utiliser dans un endroit humide.

22. Lorsqu’on coupe la pièce, éviter de couper des morceaux plus minces que l’espace entre le bord de coupe et la

lame de scie. Sinon, le matériau coupé risque de pénétrer entre le bord de coupe et la lame de scie, de

s’éparpiller et de blesser l’opérateur.

PIECES DE RECHANGE

Pour les réparations, utiliser exclusivement des pièces de rechange identiques.

Les réparations devront être effectuées exclusivement par un centre de service après-vente JOHN DEERE agréé.

CONSERVER CES INSTRUCTIONS ET LES METTRE A LA DISPOSITION

DES AUTRES UTILISATEURS DE L’OUTIL!

Manuel opérateur 31

Page 32

Description Fonctionnelle

MAQUETTE:

ET-3403-J

NOTE: Les informations contenues dans ce mode d’emploi sont conçues pour assister

l’utilisateur dans une utilisation sans danger et un entretien de l’outil motorisé.

NE JAMAIS utiliser ni entreprendre une révision de l’outil sans avoir d’abord lu et compris toutes les instructions de

sécurité contenues dans ce manuel.

Certaines illustrations dans ce mode d’emploi peuvent montrer des détails ou des accessoires différents de ceux

de l’outil motorisé utilisé.

NOM DES PARTIES:

(Fig. 1)

(Fig. 2)

32 Manuel opérateur

Page 33

Description Fonctionnelle

SPÉCIFICATIONS:

ET-3403-J:

Moteur:

Type Moteur à commutateur série

Alimentation Courant alternatif monophasé 60 Hz

Tension (volts) 115

Courant à pleine charge (Amp) 15

Lame applicable Diámetro exterior: 255 mm (10")

Dia. d’orifice 15,9 mm (5/8")

Vitesse à vide 4900 min

Dimension de coupe max.

Biseau 0°

Onglet 0° Hauteur max. 59 mm (2-1/4") Hauteur max. 89 mm (3-1/2")

Largeur max. 144 mm (5-5/8") (Largeur max. 101 mm (3-7/8"))

Onglet 45° Hauteur max. 59 mm (2-1/4") Hauteur max. 89 mm (3-1/2")

Largeur max. 102 mm (4") (Largeur max. 70 mm (2-3/4"))

Onglet 60° Hauteur max. 59 mm (2-1/4") Hauteur max. 89 mm (3-1/2")

Largeur max. 72 mm (2-3/4") (Largeur max. 50 mm (2"))

Biseau 45°

à droite

Onglet 0° Hauteur max. 41 mm (1-5/8")

Largeur max. 144 mm (5-5/8")

Onglet 45° Hauteur max. 41 mm (1-5/8") Hauteur max. 44 mm (1-3/4")

Largeur max. 102 mm (4") (Largeur max. 89 mm (3-1/2"))

Plage de coupe d’onglet Gauche 0° – 45° Droite 0° – 60°

Plage de coupe en biseau Gauche 0° – 45°

Poids net 14 kg (31 lbs.)

-1

Cordon Câble sous gaine de caoutchouc à 2 conducteurs, 2,2 m (7,2 ft)

Manuel opérateur 33

Page 34

Préparation

PRÉPARATION:

Avant de mettre l’outil électrique en service, effectuer les

préparations suivantes :

1. Installation:

Fixer l’outil électrique sur un établi horizontal et de niveau

conformément à la Fig. 3.

Sélectionner des boulons d’un diamètre 8 mm (5/16") dont la

longueur convient pour l’épaisseur de l’établi.

La longueur des boulons devra être d’au moins 25 mm (1")

plus l’épaisseur de l’établi.

Par exemple, utiliser des boulons de 50 mm (2") ou plus avec

un établi de 25 mm (1") d’épaisseur.

Le support fixé à l’arrière du socle aide à stabiliser l’outil

électrique.

2. Libérer la goupille de verrouillage:

Quand l’outil électrique quitte nos usines, ses pièces

principales sont fixées à l’aide d’une goupille de verrouillage.

Déplacer légèrement la poignée (voir Fig. 4) de façon à

dégager la goupille de verrouillage.

NOTE: La goupille de verrouillage se dégagera plus facilement et

plus sûrement si l’on abaisse légèrement la poignée (voir

Fig. 1). La position verrouillée de la goupille de verrouillage

ne doit servir que pour le transport et le remisage.

3. Installation du sac à poussière, poignée d’onglet, servante,

butée de matériau et de l’étau:

Fixer le sac à poussière, la servante et les étaux comme

indiqué à la Fig. 1.

(Fig. 3)

(Fig. 4)

34 Manuel opérateur

Page 35

Utilisation

APPLICATIONS:

Bois, contreplaqué, planches à tissu souple, planches dures et autres matériaux semblables et cadres d’aluminium.

AVANT L’UTILISATION:

1. S’assurer que la source d’alimentation convient pour l’outil.

AVERTISSEMENT: NE JAMAIS RACCORDER L’OUTIL ÉLECTRIQUE SI L’ALIMENTATION SECTEUR

N’EST PAS DE LA TENSION SPÉCIFIÉE SUR LA PLAQUE SIGNALÉTIQUE DE

L’OUTIL NE JAMAIS RACCORDER L’OUTIL À UNE SOURCE DE COURANT

CONTINU.

2. Vérifier que la gâchette est sur OFF.

AVERTISSEMENT: SI L’ON RACCORDE LE CORDON D’ALIMENTATION ALORS QUE LA GÂCHETTE

EST ENCLENCHÉE, L’OUTIL SE METTRA BRUSQUEMENT EN MARCHE, CE QUI

PEUT PROVOQUER UN GRAVE ACCIDENT.

3. Vérifier s’il y a des défauts visibles sur la lame.

S’assurer qu’il n’y a ni fissures ni dommages visibles sur la lame.

4. Vérifier que la lame est solidement fixée sur l’outil électrique.

A l’aide de la clé fournie, serrer le boulon de l’arbre pour fixer la lame.

Pour les détails, voir les Fig. 25-a et 25-b de la section relative au

“MONTAGE ET DEMONTAGE DE LA LAME DE SCIE”.

5. Vérifier le fonctionnement des carters de sécurité.

Les carters de sécurité sont conçus pour protéger l’opérateur de

tout contact avec la lame pendant le travail.

Toujours vérifier que le carter de sécurité (en plastique) se déplace

en douceur et qu’il recouvre bien la lame.

AVERTISSEMENT: NE JAMAIS FAIRE FONCTIONNER L’OUTIL SI LE CARTER DE SÉCURITÉ (EN

PLASTIQUE) NE FONCTIONNE PAS EN DOUCEUR.

6. Vérifier la position du verrou d’axe avant d’utiliser l’outil.

Avant d’installer la lame, vérifier que le verrou d’axe est revenu sur sa position rentrée avant d’utiliser l’outil

électrique (voir Fig. 25-a).

7. Vérifier la position de limite inférieure de la lame.

Bien que la lame ait été réglée en usine, vérifier soigneusement sa hauteur. S’assurer que la lame peut être

abaissée de 41 mm à 42 mm (1" à 1-21/32") en-dessous de la plaque d’insertion. Pour les détails, voir la

section “Vérification de la limite de position inférieure de la lame”.

8. Vérifier la prise d’alimentation.

Pour éviter toute surchauffe, arrêt accidentel ou fonctionnement intermittent, vérifier que la fiche du cordon

d’alimentation rentre à fond dans la prise secteur et qu’elle ne ressort pas après l’insertion. Réparer ou

remplacer la fiche si elle est défectueuse.

9. Vérifier que le cordon d’alimentation de l’outil n’est pas endommagé.

Réparer ou remplacer le cordon si l’on constate un dommage.

Après avoir branché la fiche d’alimentation dans une source d’alimentation appropriée, vérifier le

fonctionnement de l’outil comme suit :

(Fig. 5)

10. Marche d’essai

Après avoir vérifié qu’il n’y a personne derrière, mettre l’outil électrique en marche et vérifier qu’il n’y a pas

d’anomalie de fonctionnement avant d’effectuer une coupe.

11. Vérifier la stabilité de rotation de la lame.

Pour assurer des coupes précises, faire tourner la lame et vérifier qu’il n’y a pas de flèche pour s’assurer que la

lame ne présente pas d’instabilité évidente ; sinon, cela risque de provoquer des vibrations et un accident.

Manuel opérateur 35

Page 36

Utilisation

AVANT L’UTILISATION:

AVANT LA COUPE:

1. Coupe d’une encoche dans la plaque d’insertion:

Avant de mettre l’outil en service, il faudra découper une encoche dans la

plaque d’insertion. Fixer un morceau de bois d’environ 140 mm (5-1/2") de

large sur la table avec l’ensemble d’étau pour éviter que la plaque

d’insertion ne se rompe. Mettre l’outil en marche et, lorsque la lame a

atteint sa vitesse maximale, abaisser doucement la poignée pour couper

une encoche dans la plaque d’insertion.

ATEENTION: NE PAS COUPER L’ENCOCHE TROP RAPIDEMENT ;

L’ON POURRAIT ENDOMMAGER LA PLAQUE

D’INSERTION.

2. Vérification de la position de limite inférieure de la lame:

AVERTISSEMENT: POUR ÉVITER TOUT RISQUE DE BLESSURES,

TOUJOURS COUPER L’INTERRUPTEUR À GÂCHETTE ET

DÉBRANCHER LA FICHE D’ALIMENTATION DE LA PRISE

AVANT TOUT RÉGLAGE.

Vérifier que la lame de scie s’abaisse de 41 mm à 42 mm