Page 1

O P E R A T O R ’ S M A N U A L

DISC/MOWER CADDY

DC1000

5TIDC611125 (Rev. 12/22/2010)

Page 2

DEALER PREPARATION CHECK LIST

Frontier DC1000 Series Disc/Mower Caddy

THIS CHECKLIST IS TO REMAIN IN OWNER’S MANUAL

It is the responsibility of the dealer to complete the procedures listed below, then

review this checklist with the customer upon the delivery or the sale of this implement.

q 1. Implement is completely assembled.

q 2. All drivelines, bearings, and grease zerks are

properly lubricated. (See page 23)

q 3. All shields in place and in good condition.

q 4. Check PTO driveline. Make sure it is the

correct length to operate caddy with intended

tractor.

Dealer’s Signature ______________________________________________

Purchaser’s Signature ____________________________________________

IMPORTANT SAFETY MESSAGE FOR OWNERS/OPERATORS OF MOWER CADDIES

q 5. All decals in place and readable. (See page 8 - 9)

q 6. Overall condition good (i.e. paint, welds, hydraulic

hoses)

q 7 Operator’s manual has been given to owner and

the owner has been instructed on the safe and

proper use of the Disc/Mower Caddy.

Safety

Safety is a primary concern in the design, manufacture, sale, and use

of mower caddies. As manufacturers of mower caddies, we want to

conrm to you, our customers, our concern for safety. We also want to

remind you about the simple, basic, and common sense rules of safety

when using a mower caddy. Failure to follow these rules can result in

severe injury or death to operators or bystanders.

It is essential that everyone involved in the assembly, operation,

transport, maintenance, and storage of this equipment be aware,

concerned, prudent, and properly trained in safety. The majority of

accidents involve entanglement on the driveline or thrown objects.

These risks become greater when you do not use proper shielding

specied by the manufacturer.

Our current production machines include, as standard equipment,

guards or shields for drivelines and input shafts, safety signs and

operators manuals. If you have an older machine which does not have

current standard safety equipment, please contact your dealer about

bringing your machine up to the current level of safety.

Below are some of the most important safety rules to be understood

and followed by anyone who works with mower caddies:

Before operating a mower caddy, an operator must read and understand

all the information in the owner’s manual and in the safety signs

attached to the product. A person who has not read or understood the

owner’s manual and safety signs is not qualied to operate the unit.

Accidents occur often on machines that are loaned or rented to someone

who has not read the owner’s manual and is not familiar with the

equipment. If you do not have an owner’s manual or current production

safety signs, contact the manufacturer or your dealer immediately.

Mower caddies are designed for one-man operation. Never operate the

caddy with anyone near, or in contact with, any part of the implement or

PTO driveline. Be sure no one else, including bystanders, is near you

when you operate this product.

Following these simple, basic safety rules, as well as others identied

in the owner’s manual and in product safety signs, will help minimize

the possibility of accidents and increase your productivity in using this

product. Be careful and make sure that everyone who operates the caddy

knows and understands that it is a very powerful piece of machinery,

and if used improperly, serious injury or death may result. The nal

responsibility for safety rests with the operator of this machine.

2 Introduction

Page 3

TO THE DEALER:

Assembly and proper installation of this product is the responsibility of the Frontier dealer. Read manual

instructions and safety rules. Make sure all items on the Preparation Check List in the Operator’s Manual are

completed before releasing equipment to the owner.

The dealer must complete the Product Registration form, located on the Frontier web site. Failure to complete

and return the form does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your Frontier equipment. Keep this manual

handy for ready reference. Require all operators to read this manual carefully

and become acquainted with all adjustments and operating procedures before

attempting to operate the equipment. Replacement manuals can be obtained

from your selling dealer.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and satisfactory use. Like all mechanical

products, it will require cleaning and upkeep. Lubricate the unit as specied.

Please observe all safety information in this manual and safety decals on the

equipment.

For service, your authorized Frontier dealer has trained mechanics, genuine

Frontier service parts, and the necessary tools and equipment to handle all of

your service needs.

Use only genuine Frontier service parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure

to observe procedures can cause damage to equipment. The terms CAUTION,

WARNING and DANGER are used in conjunction with the Safety-Alert Symbol, (a triangle with an exclamation mark), to indicate the degree of hazard for items of personal safety.

This Safety-Alert Symbol indicates a hazard and means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could

WARNING

CAUTION

IMPORTANT

result in death or serious injury, and includes hazards that are exposed

when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

NOTE

Indicates helpful information.

Introduction 3

Page 4

TABLE OF CONTENTS

Introduction ......................................................................................................... 4

Safety ............................................................................................................... 5-9

Description ................................................................................................... 10-11

Hardware Check Sheet .................................................................................... 12

Assembly & Setup ....................................................................................... 13-16

Attaching ...................................................................................................... 17-20

Operation and Detaching ............................................................................. 21-22

Detaching ......................................................................................................... 22

Lubrication & Maintenance .............................................................................. 23

Parts ............................................................................................................ 24-29

Torque Specications ......................................................................................... 30

All information, illustrations and specications in this manual are based on

the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

General Information

The purpose of this manual is to assist you in operating and maintaining your disc/mower caddy for years of

service. Read it carefully. The information and instructions in this manual have been compiled from extensive

eld experience and engineering data. Some information may be general in nature due to unknown and varying

operating conditions. However, through experience and these instructions, you should be able to develop

procedures suitable to your particular situation.

The illustrations and data used in this manual were current at the time of printing, but due to possible inline

production changes, your machine may vary slightly in detail. We reserve the right to redesign and change the

machines as may be necessary without notication.

WARNING: Some illustrations in this manual may show the disc/mower caddy with safety shields

removed to provide a better view. The disc/mower caddy should never be operated with any safety

shielding removed.

Throughout this manual, references are made to right and left direction. These are determined by standing

behind the equipment facing the direction of forward travel.

4 Introduction

Page 5

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to provide safe

equipment can be wiped out by an operator’s single careless act.

In addition to the design and conguration of equipment, hazard control and accident prevention are dependent

upon the awareness, concern, judgment, and proper training of personnel involved in the operation, transport,

maintenance and storage of equipment.

It has been said “The best safety device is an informed, careful operator.” We ask you to be that kind of operator.

• Training

Safety instructions are important! Read all attachment

and power unit manuals; follow all safety rules

and safety decal information. (Replacement manuals and

safety decals are available from your dealer.) Failure

to follow instructions or safety rules can result in

serious injury or death.

If you do not understand any part of this manual and

need assistance, see your dealer.

Know your controls and how to stop engine and

attachment quickly in an emergency.

Operators must be instructed in and be capable of the

safe operation of the equipment, its attachments, and all

controls. Do not allow anyone to operate this equipment

without proper instructions.

Never allow children or untrained persons to operate

equipment.

• Preparation

Check that all hardware is properly installed

and tightened.

Always wear relatively tight and belted clothing to avoid

getting caught in moving parts. Wear sturdy, rough-soled

work shoes and protective equipment for eyes, hair,

hands, hearing, and head; and respirator or lter mask

where appropriate.

Make sure attachment is properly secured, adjusted,

and in good operating condition.

Before putting equipment into service, check and adjust

driveline length. Driveline must not bottom out or pull

apart throughout the full range of the tractor hitch. Do

not operate until driveline length is correct.

Make sure driveline shield safety chain is attached as

shown in this manual. Replace if damaged or broken.

Check that driveline guards rotate freely on driveline

before putting equipment into service.

Before starting power unit, check all equipment

driveline guards for damage. Replace any damaged

guards. Make sure all guards rotate freely on all

drivelines. If guards do not rotate freely on drivelines,

repair and replace bearings before putting equipment

into service.

Remove accumulated debris from this equipment,

power unit, and engine to avoid re hazard.

Power unit must be equipped with cab and seat belt.

Keep seat belt securely fastened. Falling off power unit

can result in death from being run over or crushed.

A minimum 20% of tractor and equipment weight must

be on the tractor front wheels when attachments are in

transport position. Without this weight, tractor could tip

over, causing personal injury or death. The weight may

be attained with a loader, front wheel weights, ballast

in tires or front tractor weights. Weigh the tractor and

equipment. Do not estimate.

Make sure collar slides freely and is seated rmly in

tractor PTO spline groove.

(Safety Rules continued on next page)

Safety 5

Page 6

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

(Safety Rules continued from previous page)

Make sure all safety decals are installed. Replace if

damaged. (See Safety Decals section for location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Inspect and clear area of stones, branches, or other

hard objects that might be thrown, causing injury

or damage.

• Transportation

Power unit must be equipped with cab and seat belt.

Keep seat belt securely fastened. Falling off power unit

can result in death from being run over or crushed.

A minimum 20% of tractor and equipment weight

must be on the tractor front wheels when attachments

are in transport position. Without this weight,

tractor could tip over, causing personal injury or

death. The weight may be attained with a loader,

front wheel weights, ballast in tires or front tractor

weights. Weigh the tractor and equipment. Do not

estimate.

Always comply with all state and local lighting and

marking requirements.

Never allow riders on power unit or attachment.

Do not operate PTO during transport.

Watch for hidden hazards on the terrain.

Do not leave cutter bar in up position when parked.

Do not transport fully weighted caddy without a disc

mower installed.

Maximum Compatible Disc Mower Cutting Width =

10’ 2”.

• Operation

Do not allow bystanders in the area when operating,

attaching, removing, assembling, or servicing

equipment.

Never direct discharge toward people, animals, or

property.

Do not operate or transport equipment while under

the inuence of alcohol or drugs.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Operate only in daylight or good articial light.

Always comply with all state and local lighting and

marking requirements.

Never allow riders on power unit or attachment.

Power unit must be equipped with cab and seat

belt. Keep seat belt securely fastened. Falling off

power unit can result in death from being run over or

crushed.

Do not operate or transport on steep slopes.

Do not operate or transport equipment while under

the inuence of alcohol or drugs.

• Disc Mower Caddy Compatibility

The combined weight of disc mower and caddy should

not exceed 1.5 X weight of the tractor.

Base Disc Mower Caddy weight = 1750 Lbs.

Fully Ballasted Disc Mower weight = 2190 Lbs.

Maximum recommended Disc Mower weight to use with

caddy = 1421 Lbs.

Cab tractor is required when using Frontier Disc Mower

Caddy.

6 Safety

Page 7

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Always sit in power unit seat when operating

controls or starting engine. Securely fasten seat

belt, place transmission in neutral, engage brake,

and ensure all other controls are disengaged before

starting power unit engine.

Operate tractor PTO at 540 RPM. Do not exceed.

Do not operate PTO during transport.

Look down and to the rear and make sure area is

clear before operating in reverse.

Do not operate or transport on steep slopes.

Do not stop, start, or change directions suddenly

on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch for hidden hazards on the terrain during operation. Stop power unit and equipment immediately upon

striking an obstruction. Turn off engine, remove

key, inspect, and repair any damage before

resuming operation.

Leak down or failure of mechanical or hydraulic

system can cause equipment to drop.

• Maintenance

Before dismounting power unit or performing any

service or maintenance, follow these steps: disengage

power to equipment, lower the 3-point hitch and all

raised components to the ground, set parking brake,

stop engine, remove key, and unfasten seat belt.

Before performing any service or maintenance,

disconnect driveline from tractor PTO.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components

in any way.

Always wear relatively tight and belted clothing to

avoid getting caught in moving parts. Wear sturdy,

rough-soled work shoes and protective equipment

for eyes, hair, hands, hearing, and head; and respirator

or lter mask where appropriate.

Make sure attachment is properly secured, adjusted,

and in good operating condition.

Keep all persons away from operator control area

while performing adjustments, service, or

maintenance.

Never go underneath equipment (lowered to the

ground or raised) unless it is properly blocked and

secured. Never place any part of the body under

neath equipment or between moveable parts even

when the engine has been turned off. Hydraulic system

leak down, hydraulic system failures, mechanical

failures, or movement of control levers can cause

equipment to drop or rotate unexpectedly and cause

severe injury or death. Follow Operator’s Manual

instructions for working underneath and blocking

requirements or have work done by a qualied dealer.

Make certain all movement of equipment components has

stopped before approaching for service.

Tighten all bolts, nuts, and screws to torque chart

specications. Check that all cotter pins are installed

securely to ensure equipment is in a safe condition

before putting unit into service.

Make sure all safety decals are installed. Replace if

damaged. (See Safety Decals section for location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

• Storage

Block equipment securely for storage.

Keep children and bystanders away from storage area.

Follow manual instructions for storage.

Always use a tractor to position equipment for storage.

Never attempt to move equipment by hand.

Safety 7

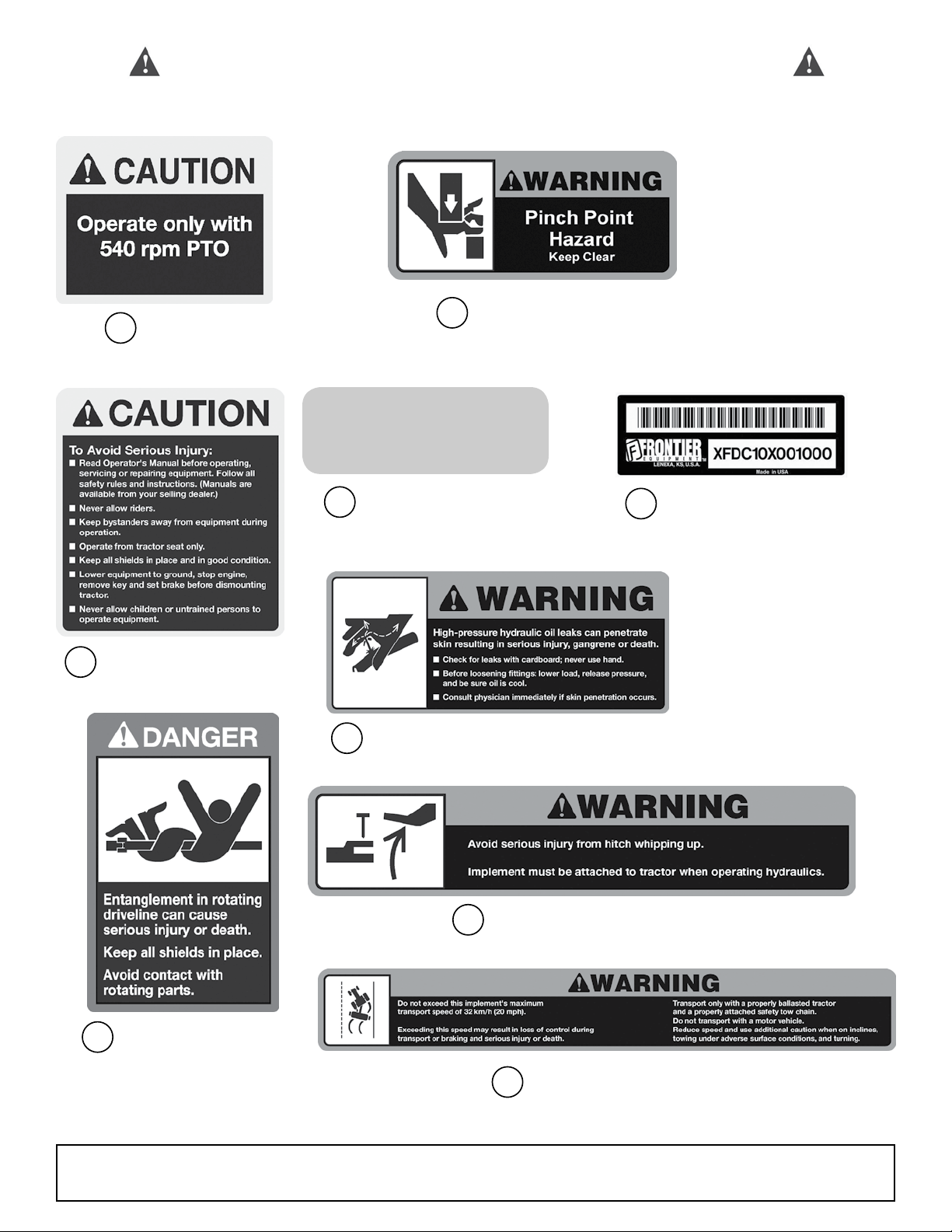

Page 8

SAFETY and INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately if Damaged!

5

4

3

1

7

8

2

3

4

5

6

8 Safety and Instruction Decals

9

Page 9

1

540 RPM

SAFETY and INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately if Damaged!

4

PINCH POINT

RED REFLECTOR

2 Needed

1 Extra Supplied in Manual

Holder for Rear of Disc Mower

2

CAUTION INJURY

RED REFLECTOR

5

TIFC711207

6

HIGH PRESSURE HYDRAULICS

HITCH WARNING

7

SERIAL NUMBER

9

ENTANGLEMENT

3

Warning Label Sheet

Part Number 5TIDC611124

(Contains Label #s 1, 2, 3, 4, 6, 7 & 8)

TRANSPORT SPEED

8

Safety and Instruction Decals 9

Page 10

GENERAL DESCRIPTION

Your Frontier DC1000 Disc/Mower Caddy has been carefully designed for easily moving your disc mower. This

manual is provided to give you the necessary operation and maintenance instructions for keeping your caddy in

excellent operating condition. Please read this manual thoroughly. Understand the purpose of the controls and

how to use them. Observe all safety precautions on the machine and as noted throughout this manual. If any

assistance or additional information is needed, contact your authorized Frontier dealer.

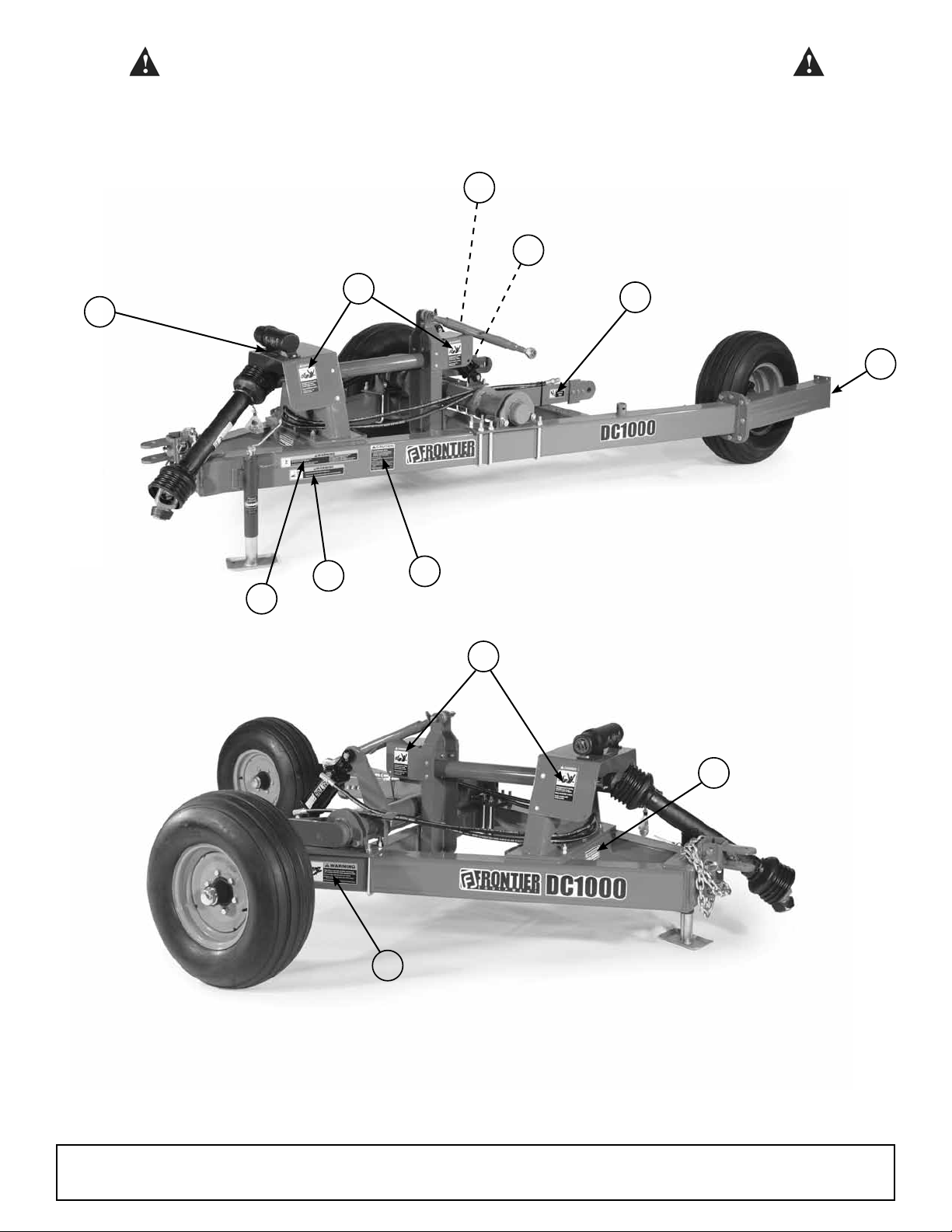

Major components

Front Tower

PTO Shield

Manual Tube

Hydraulic Cylinder

Rear Tower

PTO Shield

Driveline

Tire & Wheel Assembly

Top Link

A-Frame

Rear PTO

Tower

Adjustable

Tongue Clevis

Front PTO

Tower

Safety Chain

Jack

10 Description

Lift Arms

Page 11

TECHNICAL DESCRIPTION

Model DC1000

Frame

Construction 4” x 6” tubing

Ballasting

Internal Internally weighted and counterbalanced

External Up to 5 tongue and 5 side weights as needed

Hitch

Type Adjustable Clevis Tongue

Operating Dimensions

Overall Length, in. (mm) 140 (3556)

Overall Width, in. (mm) 83 (2108.2)

Overall Height, in. (mm) 44 (1117.6)

Approx. Weight, lb. (kg) without suitcase weights 1750 (795.5)

Approx. Weight, lb. (kg) with suitcase weights 2190 (995.5)

Hydraulic Lift 3-point hitch

Category 2

Cylinder Stroke 6”

Hoses All hydraulic hoses (3) and tips included

Tires

Size 11L x 15SL ribbed implement tires

PTO

Type Equal angle Cat IV 540rpm

(20 spline double locking collar)

Jack

Type Screw Type

Shipping Dimensions

Overall Length, in. (mm) 85.75 (2178.05)

Overall Width, in. (mm) 90 (2286)

Overall Height, in. (mm) 21 (533.4)

Approx. Weight, lb. (kg) without suitcase weights 1975 (897.7)

Description 11

Page 12

HARDWARE CHECK SHEET

Ref # Qty. Part # Description Picture

1 1 5TIDC611154 44” Double Splined Shaft

2 10 5TIDC611112 PTO HOUSING BOLTS

5/8” x 2” Grade 5 hex bolt with nylon

lock nut

3 1 5TIDC611101 Manual Holder with Hardware (1/46”

x 1” Grade 5 hex bolt with hardware),

Manual and red reector inside

4 1 5TIDC611132 Clevis Tongue

5 1 5TIDC611108 Cat 2 Pin with Lynch Pin

6 8 5TIDC611122 FLANGE BOLTS

5/8” x 2” Grade 5 with nylon lock nut

7 4 5TIDC611113 CROSSBAR BOLTS

3/4” x 2 1/2” Grade 2 with lock washer

and nut

8 8 5TIDC611115 PTO SHIELD BOLTS

1/4” x 1” Grade 5 with at washer, lock

washer and hex nut

9 1 5TIDC611146 Top Link Adjustment Handle (Included

for replacement with Top Link Only)

10 2 5TIDC611109 Cat 1 Pins with Lynch Pins

11 1 5TIDC611136 Safety Chain with 1/2” x 2” Grade 2 with

two washers and nylon lock nut

12 1 5TIDC611103 Hydraulic Cylinder

13 2 5TIDC611102 Eccentric Locking Collars w/ Bearings

14 1 5TIDC611118 Hydraulic Cylinder Safety Stop with

Locking Pin

15 2 5TIDC611120 Hydraulic Hoses with 90° Connecting

Tips

16 1 5TIDC611137 Hydraulic Hose with Straight Connector

17 2 5TIDC611148 &

5TIDC611149

18 1 5TIDC611114 Hose Clamp with 3/8” x 2” Grade 2 Hex

Front & Rear PTO Shields

Bolt and anged nylon lock nut

12 Hardware Check Sheet

Page 13

ASSEMBLY & SET UP

TOOLS REQUIRED: rubber hammer, impact wrench, 1 1/8” socket & wrench, adj. wrench, 3/4” socket

& wrench, regular hammer, 1/2” socket, socket wrench, 15/16” socket, 9/16” socket, allen wrenches, 7/8”

socket, grease gun, and Teon tape or pipe compound.

Note: Ref # refers to the DC1000 Hardware Check

Sheet included at the end of this manual (pg. 12) and in

the hardware box that ships with caddy.

• Removing caddy from pallet

5. Cut weight retaining strap on end of frame

and rear wheel assembly.

1. Place pallet in open area to begin

assembly.

2. Remove box of

hardware and set

aside.

3. Remove tires and wheels from pallet

and set in assembly area.

4. Cut weight retaining

strap on end of the

main A-frame.

6. Remove bands from frame and rear wheel

assembly.

7. Using forklift, move frame and rear wheel

assembly and line up bolt holes with main

frame. Make sure wheel is to the inside. Use

caution as assembly is extremely heavy.

8. Using 15/16” socket, install eight 5/8” x

2” bolts and nylon locknuts into frame and

tighten. (Ref #6)

(continued on next page)

Assembly & Set Up 13

Page 14

ASSEMBLY & SET UP

(continued from previous page)

9. Using forklift, remove large A-frame from

pallet and place in assembly area.

CAUTION: A-frame is extremely heavy and has

signicantly unbalanced weight. Use Extreme

Caution!

10. Remove all lugs from both hubs.

13. Your A-frame is now ready to have components

added to the frame.

• Crossbar Lift Arm Assembly

11. Install wheels and tires on both hubs.

12. Once tires and wheels are

in place, place chocks in

front and behind each wheel.

Using forklift or front end

loader, lift front of caddy and

swing front jack into down

position and lower A-frame

onto jack.

14. Using two people to lift the crossbar assembly,

place onto A-frame. Make sure that lift arms face

rear of caddy.

15. Install four 3/4” x 2 1/2” Grade 2 bolts with lock

washers and nuts from hardware box (Ref #7)

and tighten. Install all four bolts with nuts facing

toward outside of caddy.

Note: When installing the bolt in the right rear side,

with assistance, lift the arm to access the hole and

install the head of the bolt on the inside.

12. Cut zip-ties to remove top link from

A-Frame of caddy

14 Assembly & Set Up

(continued on next page)

Page 15

ASSEMBLY & SET UP

• Installing PTO Shaft Shields and

Manual Holder

Note: There

are two PTO

shaft shields

to install.

(Ref #17)

16. Install the smaller PTO guard on the rear

bearing tower and the larger on the front

bearing tower using four (4) 1/4” x 1” hex

bolts, eight (8) 1/4” at washers, four (4) 1/4”

lock washers, and four (4) 1/4” hex nuts from

hardware box. (Ref #8) Use a 7/16” wrench to

secure all nuts and bolts.

19. Install hydraulic cylinder to frame and

crossbar lift assembly.

Port

17. Install manual holder on front PTO shield

using 1/4” x 1” bolts and nuts. (Ref #3)

Note: Manual Holder contains manual and a red

reector for installation on the rear of disc

mower, IF the mower obscures the view of the

red reector on the back, right-hand side of the

caddy cart. Install this red reector on the back

of the disc mower as close to the right-hand

outermost portion as practical.

• Installing Hydraulic Cylinder Assembly

Note: Be sure that hose hookup ports on

hydraulic cylinder face outside of caddy.

20. Install two hydraulic hoses with elbows to the

hydraulic cylinder. Be sure to use Teon tape

or pipe compound on these ttings. (Ref #15)

Note: The third hydraulic hose with straight

connector in the hardware box is extension

hose that will be used later on the disc mower

cylinder. (Ref #16)

18. Remove pin clips from hydraulic cylinder

pins and remove pins on both ends of

cylinder. (Ref #12)

21. Thread hydraulic lines through hole in base of

front bearing mount tower.

(continued on next page)

Assembly & Set Up 15

Page 16

ASSEMBLY & SET UP

(continued from previous page)

22. Place hydraulic

lines into

hydraulic hose

clamp and

tighten.

23. Using Category 2 pin, install top link

adjustment arm on top of rear bearing

mount tower. (Ref #5)

24. Install top link adjustment

handle (Ref #9) into shaft

body on top link. Line

the handle up directly

over hole in top link. Use

hammer to drive handle

through top link.

27. Install safety chain on

tongue in bottom hole

of hitch. If tractor hitch

height requires hitch to

be in bottom hole, attach

safety chain to top hole.

(Ref #11)

28. Remove red Hydraulic Cylinder Safety Stop with

Locking Pin and install through hole on rear of

PTO shield. (Ref #14)

25. Using two pins and clevis

tongue, install tongue

assembly on front of

A-frame. (Ref #4 & Ref

#10)

PTO Shaft

26. Install PTO shaft on front bearing

mount tower.

16 Assembly & Set Up

29. Your caddy is now ready for your disc

mower.

Page 17

• Attaching Caddy to Tractor

CAUTION: To avoid bodily injury or machine

damage whenever an implement is attached,

put transmission in PARK position and check

the full range of hitch for interference, binding,

or PTO separation. Do not stand between

tractor and implement.

1. Ensure that disc mower caddy is on level

surface with wheels rmly blocked.

2. Back tractor up slowly until hitch is near

caddy tongue.

ATTACHING

5. Attach safety chain to tractor.

6. Slowly lower jack to let weight of caddy

down onto tractor.

3. Use caddy jack to adjust caddy tongue to

correct height.

4. Slowly back tractor hitch onto tongue and

align holes. Insert pin into hitch and secure

with R-pin in bottom of hitch pin.

7. Remove jack completely and store on rear of

caddy near rear tire.

8. Attach two hydraulic cylinder hoses on caddy

to rear of tractor.

9. Your caddy is now ready to have a disc

mower attached.

Attaching 17

Page 18

ATTACHING

• Attaching Disc Mower to Caddy

1. Ensure that mower is on level surface and

stabilized.

Note: Inside measurements of caddy lift arm are

32 3/4”. If necessary, adjust hitch pins on disc

mower to accommodate caddy arm width.

2. Remove mounting brackets from caddy lift

arms.

7. Install top link on caddy to top of disc mower.

Note: Top link may have to be adjusted with

adjustment handle in order to t.

3. Position caddy arms under mower hitch pins

so that they are just below mower hitch pins.

4. Using hydraulic controls on tractor, slowly

raise the lift arms on caddy to “seat” mower

hitch pins in caddy arms.

8. Once adjusted, tighten lock ring on top link.

9. Install PTO shaft from the front of mower to

the rear bearing mount tower.

10. Install PTO driveline

safety chain to mower.

5. Reinstall mounting brackets and bolts,

tighten bolts.

6. Install lynch pins in end of each hitch pin.

18 Attaching

11. Remove quick coupler

hydraulic nipple from end of

mower disc cylinder line.

(continued on next page)

Page 19

ATTACHING

(continued from previous page)

12. Attach teon tape or pipe compound to thread

ttings on hydraulic line.

WARNING: Cutter bar guard/cover must

be folded back into transport position before

attempting to raise mower blade.

16. Start tractor and slowly raise caddy lift arms.

17. If mower is equipped with it’s own stand,

raise or release stand on mower at this time.

18. Slowly raise cutter bar to full upright position using

hydraulic cylinder on mower.

13. Attach 9’ hydraulic line extension to end of

mower hydraulic cylinder hose to increase overall

length and tighten.

14. Reattach hydraulic nipple coupler to end of

lengthened hydraulic line. Be sure to use teon

tape or pipe compound on all ttings.

19. Remove hydraulic cylinder safety stop and place

stop in storage location.

15. Thread extended hydraulic line through opposite

hole in base of PTO housing tower and attach to

rear of tractor.

20. Install PTO shaft from front PTO housing

tower to rear of tractor.

(continued on next page)

Attaching 19

Page 20

(continued from previous page)

21. If equipped, install mower blade release

handle and rope to tractor within easy and

safe reach of operator.

ATTACHING

Note: Please contact your John Deere Dealer

for assistance with ballasting your caddy cart. If

you are able to ballast your caddy cart without

assistance from your dealer, please follow the

proceeding ballasting procedure:

To ensure safe operation of your mower, ballast

your mower caddy to have positive tongue

weight and a maximum side-to-side weight

distribution ratio of 3.2. Side-to-side weight

distribution ratio should be calculated by

dividing the righthand caddy tire weight by the

lefthand caddy tire weight (RH tire wt./LH tire

wt.) when the mower is fully raised on the cart

and with the cutter bar lowered to the side but

not touching the ground.

22. If needed, install approved suitcase

weights for ballast on front and rear

weight racks of disc mower caddy to

achieve proper weight balance.

IMPORTANT: Unit must be properly

ballasted before operation. See

“Ballasting” in next section before use.

• Ballasting Disc Mower Caddy

Note: All references to RH/LH side of machine

are made with the operator facing the operating

direction of the machine.

Note: The R66949 John Deere suitcase weight

is the approved suitcase weight to use when

ballasting your Frontier Mower Caddy Cart.

Mower

blade

in down

position

but not

touching

ground.

Caddy arms

fully up.

20 Attaching

Scales under each

tire and jack.

Page 21

OPERATION and DETACHING

• Disc Mower Operation

1. Before mowing, ensure that all mower guards

and covers are in place and are in good condition. Replace if necessary. (Consult your

mower’s operating manual.)

2. Raise caddy arm to full upright position and

remove hydraulic cylinder safety stop.

6. Lower disc mower safety guard/cover.

7. Slowly engage tractor PTO. Let mower run to

make sure all parts are working properly.

3. Slowly lower disc mower blade to fully down

position.

4. Slowly lower caddy arms until cutter bar is in its

working position.

5. Adjust top link on caddy to ensure that disc mower

blade is at desired operating level.

8. Put tractor in gear to mow at recommended speed

for your tractor and terrain. (Consult your disc

mower manual.)

• Detaching Caddy from Tractor

(with mower attached)

1. Ensure that disc mower caddy is on level surface

with wheels chocked. (Disc mower cutter bar

should be in full upright position at this point.)

2. With tractor in park, raise disc mower caddy

arms to full upright position.

(continued on next page)

Operation and Detaching 21

Page 22

DETACHING

(continued from previous page)

3. Remove hydraulic cylinder safety stop from

hydraulic cylinder.

Note: The safety stop should be loose on the

cylinder arm with no pressure on the stop.

7. Turn tractor off.

8. Remove jack from rear

position on frame and place

on tongue of mower caddy.

Raise jack until weight of

caddy is resting on jack

rather than tractor tongue.

9. Remove

hydraulic lines

from tractor.

4. Place safety stop in storage location on PTO shield.

5. Slowly lower cutter bar of disc mower to side to

be parallel with ground.

10. Remove

PTO shaft

from

tractor.

11. Remove rope for blade arm release if so

equipped.

12. Remove pin from hitch.

13. Remove

safety chain

from tractor.

6. Then, slowly lower the disc mower caddy arms

down until cutter bar rests on ground.

22 Detaching

14. Slowly pull tractor away from caddy.

Page 23

LUBRICATION and MAINTENANCE

• Lubrication Before Each Use

1. Driveline Universal Joints

a. Apply multi-purpose grease with a grease gun.

2. Driveline Guard

b. Apply 2-3 shots of multipurpose grease with

grease gun to plastic tting.

3. Driveline Prole

c. Disconnect PTO Driveline.

d. Pull the two sections about half way apart and

rotate until the holes in the plastic guards align

with the exposed spline in the shaft.

e. Apply thin coat of multi-purpose grease to the

spline section in several locations around the

spline. Contract and expand the shaft several

times to distribute the grease.

f. Reconnect the PTO Driveline.

Note: Pull each driveline section to be sure driveline

and shields are securely connected. Make certain

PTO shielding is in good condition. Do not grease

outer or inner plastic shields.

4. PTO Housing Bearings

g. Apply multi-purpose grease with a grease gun.

5. Crossbar Lift Arm Assembly

h. Apply multi-purpose grease with a grease gun.

6. Wheel Bearings

i. Check monthly and repack as necessary.

(4) PTO Housing Bearings - On Each Tower,

Before Each Use

(1) Before Each Use

(2) Before

Each Use

(1) Before Each Use

(6) Monthly

(5) On Each Side,

Before Each Use

(3) Before Each Use

Lubrication and Maintenance 23

Page 24

PARTS

Back Front

9

18

10

4

5

13*

3

1

11

2

17

* For complete Safety Decals listing and

locations refer to pages 8 and 9 of Disc/

Mower Caddy Operator’s Manual.

Item Number Qty.

Qty. Shipped

1 1 1 5TIDC611101 Black Manual Holder w/ Hardware

2 1 1 5TIDC611145 610MM 20 Spline PTO Shaft

3 1 1 5TIDC611151 PTO Tube Guard

4 1 1 5TIDC611146 29” Top Link

5 2 1 5TIDC611106 Wheel & Tire Combo

6 2 1 5TIDC611109 Cat #1 Hitch Pin w/ Lynch Pin

7 6 6 5TIDC611112 PTO Housing Mount Assembly Hardware

8 7 1 5TIDC611116 5/8” U-Bolts w/ Nylon Lock Nuts

9 2 1 5TIDC611148 Front PTO Shild Plate

10 1 1 5TIDC611149 Rear PTO Shield Plate

11 1 1 5TIDC611154 44” Double Spline Shaft

12 2 1 5TIDC611123 Model Number Decal Label

13 1 1 5TIDC611124 Warning Decal Sheet (see pages 8 & 9)*

14 2 1 TIFC711172 Frontier Logo Decal

15 1 1 5TIDC611136 Disc Caddy Safety Chain w/ Hook & Latch

16 2 1 5TIDC611120 9’ Hydraulic Hoses w/ 90° Ends

17 2 1

18 1 1 5TIDC611114 Hydraulic Line Holder w/ Hardware Kit

19 1 1 5TIDC611103 Hydraulic Cylinder

19

8

16

14

12

7

15

6

Parts Overall View

Double Tower Style

Part Number Description

5TIDC611139 Hub Kit (Hub, Lug Bolts, Dust Cap & Bearings)

19

Use this parts list if serial number is XFDC10X001400 or greater.

24 Parts

Page 25

PARTS

BackFront Front

8

5

3

1

14

7

12

2

11

13

19

9

4

6

15

18

1

10

Parts Overall View

Double Tower Style

Item Number Qty.

1 2 1 5TIDC611102 Eccentric Locking Collar Bearings (hardware not included)

2 1 1 5TIDC611107 Jack

3 1 1 5TIDC611108 Cat #2 Top Link Pin w/ Lynch Pin

4 4 2 5TIDC611110 Hitch Tab Hardware

5 4 4 5TIDC611150 Bearing Hardware

6 4 2 5TIDC611113 Disc Caddy Hitch Adjustment Beam Hardware

7 8 4 5TIDC611115 PTO Shield Hardware

8 1 1 5TIDC611118 Hydraulic Cylinder Safety Stop w/ Clinch Pin

9 2 1 5TIDC611138 Disc Caddy Hydraulic Hose End Attachment

10 8 8 5TIDC611122 Frame Plate Hardware

11 1 1 5TIDC611147 Disc Caddy Frame

12 1 1 5TIDC611152 Front Bearing Mount Tower

13 1 1 5TIDC611153 Rear Bearing Mount Tower

14 1 1 5TIDC611132 Disc Caddy Hitch Clevis Tongue

15 2 1 5TIDC611134 Disc Caddy Hitch Tab

16 1 1 5TIDC611135 Rear Frame and Axle Attachment (Frame & Spindle Only)

17 3 1 TIFC711207 Red Reector Decal

18 2 1 5TIDC611119 Weight Retaining Bar w/ R-Pin

19 1 1 5TIDC611133 Disc Caddy Hitch Adjustment Beam

20 2 1 5TIDC611137 (Not Shown) Disc Caddy Hydraulic Extension Hose w/

Qty. Shipped

Part Number Description

Straight End

17

16

Use this parts list if serial number is XFDC10X001400 or greater.

Parts 25

Page 26

PARTS

9

8

16

3

4

11*

2

1

15

* For complete Safety Decals listing and

locations refer to pages 8 and 9.

Item Number Qty.

Qty. Shipped

1 1 1 5TIDC611101 Black Manual Holder w/ Hardware

2 1 1 5TIDC611104 60” PTO Shaft

3 1 1 5TIDC611105 50” Top Link

4 2 1 5TIDC611106 Wheel & Tire Combo

5 2 1 5TIDC611109 Cat #1 Hitch Pin w/ Lynch Pin

6 6 6 5TIDC611112 PTO Housing Mount Assembly Hardware

7 7 1 5TIDC611116 5/8” U-Bolts w/ Nylon Lock Nuts

8 2 1 5TIDC611117 PTO Shield Plate (Rev A)

8 2 1 5TIDC611142 Single Tower PTO Shield Plate (Rev B) (For DC1000 with

9 1 1 5TIDC611121 15” Six-Spine PTO Adapter Shaft

10 2 1 5TIDC611123 Model Number Decal Label

11 1 1 5TIDC611124 Warning Decal Sheet (see pages 8 & 9)*

12 2 1 TIFC711172 Frontier Logo Decal

13 1 1 5TIDC611136 Disc Caddy Safety Chain w/ Hook & Latch

14 1 1 5TIDC611120 9’ Hydraulic Hoses w/ 90° Ends

15 2 1

16 1 1 5TIDC611114 Hydraulic Line Holder w/ Hardware Kit

17 2 1 5TIDC611137 (Not Shown) Disc Caddy Hydraulic Extension Hose w/

15

7

12

Parts Overall View

10

6

14

5

13

Single Tower Style

Part Number Description

serial number XFDC10X001234 or after)

5TIDC611139 Hub Kit (Hub, Lug Bolts, Dust Cap & Bearings)

Straight End

Use this parts list if serial number is before XFDC10X001400.

26 Parts

Page 27

PARTS

14

4

19

2

5

7

15

11

16

18

8

2

9

13

10

3

18

12

9

1

6

17

Parts Overall View

Single Tower Style

Item Number Qty.

1 2 1 5TIDC611102 Eccentric Locking Collar Bearings (hardware not included)

2 1 1 5TIDC611103 Hydraulic Cylinder

3 1 1 5TIDC611107 Jack

4 1 1 5TIDC611108 Cat #2 Top Link Pin w/ Lynch Pin

5 4 2 5TIDC611110 Hitch Tab Hardware

6 4 4 5TIDC611111 Bearing Hardware

7 4 2 5TIDC611113 Disc Caddy Hitch Adjustment Beam Hardware

8 8 4 5TIDC611115 PTO Shield Hardware

9 1 1 5TIDC611118 Hydraulic Cylinder Safety Stop w/ Clinch Pin

10 2 1 5TIDC611138 Disc Caddy Hydraulic Hose End Attachment

11 8 8 5TIDC611122 Frame Plate Hardware

12 1 1 5TIDC611130 Disc Caddy Frame

13 1 1 5TIDC611141 Single Tower Disc Caddy Mount Assy w/PTO Shield

14 1 1 5TIDC611132 Disc Caddy Hitch Clevis Tongue

15 2 1 5TIDC611134 Disc Caddy Hitch Tab

16 1 1 5TIDC611135 Rear Frame and Axle Attachment (Frame & Spindle Only)

17 3 1 TIFC711207 Red Reector Decal

18 2 1 5TIDC611119 Weight Retaining Bar w/ R-Pin

19 1 1 5TIDC611133 Disc Caddy Hitch Adjustment Beam

Qty. Shipped

Part Number Description

Plates (Rev B)

Use this parts list if serial number is before XFDC10X001400.

Parts 27

Page 28

PARTS

5

4

3

1

2

3

8

9

7

10

6

1

2

PTO Driveline Assembly

Double Tower Style

Item Number Qty. Qty. Shipped Part Number Description

1 1 1 5TIDC611155 Yoke ASGE

2 1 1 TIFC711178 ASGE Collar Kit

3 2 2 5TIDC611156 Cross & Bearing Kit (2pk)

4 1 1 5TIDC611157 Inner Pinned Assembly

5 1 1 5TIDC611158 Outer Shield Kit

6 1 1 TIFC711179 Decal Outer

7 1 1 5TIDC611159 Inner Shield Kit

8 1 1 5TIDC611160 Outer Pinned Assembly

9 1 1 TIFC711180 Decal Inner

10 1 1 5TIDC611145 610MM 20 Spline PTO Shaft

28 Parts

Page 29

PARTS

5

4

3

1

2

8

7

9

10

3

6

1

2

PTO Driveline Assembly

Single Tower Style

Item Number Qty. Qty. Shipped Part Number Description

1 1 1 5TIFC711233 Yoke ASGE

2 1 1 TIFC711178 ASGE Collar Kit

3 2 2 5TIFC711234 Cross and Bearing Kit

4 1 1 5TIDC611126 Inner Pinned Assembly

5 1 1 5TIDC611127 Outer Shield Kit

6 1 1 TIFC711179 Decal Outer

7 1 1 5TIDC611128 Inner Shield Kit

8 1 1 5TIDC611129 Outer Pinned Assembly

9 1 1 TIFC711180 Decal Inner

10 1 1 5TIDC611104 60” PTO Shaft

Parts 29

Page 30

AMERICAN

Bolt Head Markings

Wrench

Size “A”

SAE Grade 2

(No Dashes)

SAE Grade 5

(3 Dashes)

Diameter “B”

SAE Grade 8

(6 Dashes)

Bolt

TORQUE SPECIFICATIONS

Proper torque for American fasteners used on manufactured implement.

Recommended Torque in Foot Pounds (Newton Meters).*

WRENCH

SIZE(IN.)”A”

7/16 1/4 -20 UNC 6 (7) 8 (11) 12 (16)

7/16 1/4 - 24 UNF 6 (8) 10 (13) 14 (18)

1/2 5/16 -18 UNC 11 (15) 17 (23) 25 (33)

1/2 5/16 - 24 UNF 13 (17) 19 (26) 27 (37)

9/16 3/8 - 16 UNC 20 (27) 31 (42) 44 (60)

9/16 3/8 -24 UNF 23 (31) 35 (47) 49 (66)

5/8 7/16 -14 UNC 32 (43) 49 (66) 70 (95)

5/8 7/16 - 20 UNF 36 (49) 55 (75) 78 (106)

3/4 1/2 - 13 UNC 49 (66) 76 (103) 106 (144)

3/4 1/2 - 20 UNF 55 (75) 85 (115) 120 (163)

7/8 9/16 -12 UNC 70 (95) 109 (148) 153 (207)

7/8 9/16 - 18 UNF 79 (107) 122 (165) 172 (233)

15/16 5/8 - 11 UNC 97 (131) 150 (203) 212 (287)

15/16 5/8 - 18 UNF 110 (149) 170 (230) 240 (325)

1-1/8 3/4 - 10 UNC 144(195) 266 (360) 376 (509)

1-1/8 3/4 - 16 UNF 192 (260) 297 (406) 420 (569)

1-5/16 7/8 - 9 UNC 166 (225) 430 (583) 606 (821)

1-5/16 7/8 - 14 UNF 184 (249) 474 (642) 668 (905)

1-1/2 1-8 UNC 250 (339) 644 (873) 909 (1232)

1-1/2 1 - 12 UNF 274 (371) 705 (955) 995 (1348)

1-1/2 1-14 UNF 280 (379) 721 (977) 1019 (1381)

1-11/16 1-1/8 - 7 UNC 354 (480) 795 (1077) 1288 (1745)

1-11/16 1-1/8 -12 UNF 397 (538) 890 (1206) 1444 (1957)

1-7/8 1-1/4 - 7 UNC 500 (678) 1120 (1518) 1817 (2462)

1-7/8 1-1/4 - 12 UNF 553 (749) 1241 (1682) 2013 (2728)

2-1/16 1-3/8 - 6 UNC 655 (887) 1470 (1992) 2382 (3228)

2-1/16 1-3/8 -12 UNF 746 (1011) 1672 (2266) 2712 (3675)

2-1/4

2-1/4

BOLT DIAMETER

(IN.)”B” AND

THREAD SIZE

1-1/2 - 6 UNC

1-1/2 - 12 UNF

SAE

GRADE 2

870 (1179)

979 (1327)

SAE

GRADE 5

1950 (2642)

2194 (2973)

SAE

GRADE 8

3161 (4283)

3557 (4820)

Proper torque for metric fasteners used on manufacturer implement.

METRIC

Bolt

Diameter “B”

Wrench

Size “A”

Numbers appearing on bolt heads

indicate ASTM classes.

*Use 75% of the specied torque value for

plated fasteners. Use 85% of the specied

torque values for lubricated fasteners.

WRENCH SIZE

(mm) “A”

8 5 1.8 (2.4) 5.1 (6.9) 6.5 (8.8)

10 6 3 (4) 8.7 (12) 11.1 (15)

13 8 7.3 (10) 21.1 (29) 27 (37)

16 10 14.5 (20) 42 (57) 53 (72)

18 12 25 (34) 74 (100) 73 (99) 93 (126)

21 14 40 (54) 118 (160) 116 (157) 148 (201)

24 16 62 (84) 167 (226) 181 (245) 230 (312)

30 20 122 (165) 325 (440) 449 (608)

33 22 443 (600) 611 (828)

36 24 211 (286) 563 (763) 778 (1054)

31 27 821 (1112) 138(1542)

46 30 418 (566) 1119 (1516) 1547(2096)

30 Torque Specications

Recommended Torque in Foot Pounds (Newton Meters).*

BOLT DIA.

(mm) ”B”

ASTM

4.6

ASTM

8.8

ASTM

9.8

ASTM

10.9

Page 31

NOTES

Notes 31

Page 32

PART NUMBER

5TIDC611125

Loading...

Loading...