Page 1

D

HARVESTERS

770D | 1070D | 1270D | 1470D

Page 2

Work harder and smarter.

Whether it’s thinning or regeneration harvesting, each D-Series Harvester packs a powerful, intelligent

punch. With features like a durable, fuel-effi cient John Deere engine, a rotating and leveling cab, and

the Timbermatic 300 management system with Total Machine Control (TMC

are a smart choice for any application.

™

), these nimble workhorses

2

3

Page 3

The rotating and leveling cab provides operator comfort and

increased visibility to the cut.

The John Deere PowerTech

™

Plus Tier 3 engine boasts excellent

fuel economy with high torque at low rpms.

The fi eld-tested, parallel boom and balanced bogie axles have

become industry legends for boosting productivity.

PowerTech Plus Tier 3 Engine Power

Reach (With Harvester Head)

Harvesting Head

Operating Weight

Maximum Tractive Effort

Best Applications Per Model

770D

115 gross hp 86 kW

25 ft. 11 in. 7.9 m

745 or H754

23,810 lb. 10 800 kg

22,481 lbf 100 kN

First thinning applications and

for processing trees with small

diameters.

1070D

182 gross hp 136 kW

32 ft. 10 in. 10 m or 28 ft. 3 in.

8 6 m optional

745 or H754

31,306 lb. 14 200 kg

29,225 lbf 130 kN

Applications where an effi cient,

versatile harvester is required,

from thinning to regeneration

harvesting.

1270D

215 gross hp 160 kW

30 ft. 6 in. 9 3 m

H270, H290, 758HD, H480

38,580 lb. 17 500 kg

35,970 lbf 160 kN

Both thinning and regeneration

felling.

1470D

241 gross hp 180 kW

27 ft. 3 in. 8 3 m / 31 ft. 10 in.

9 7 m / 35 ft. 1 in. 10 7 m

H270, 758HD, H290, H480

43,580 lb. 19 770 kg

40,466 lbf 180 kN

Best for the most extreme

conditions.

Page 4

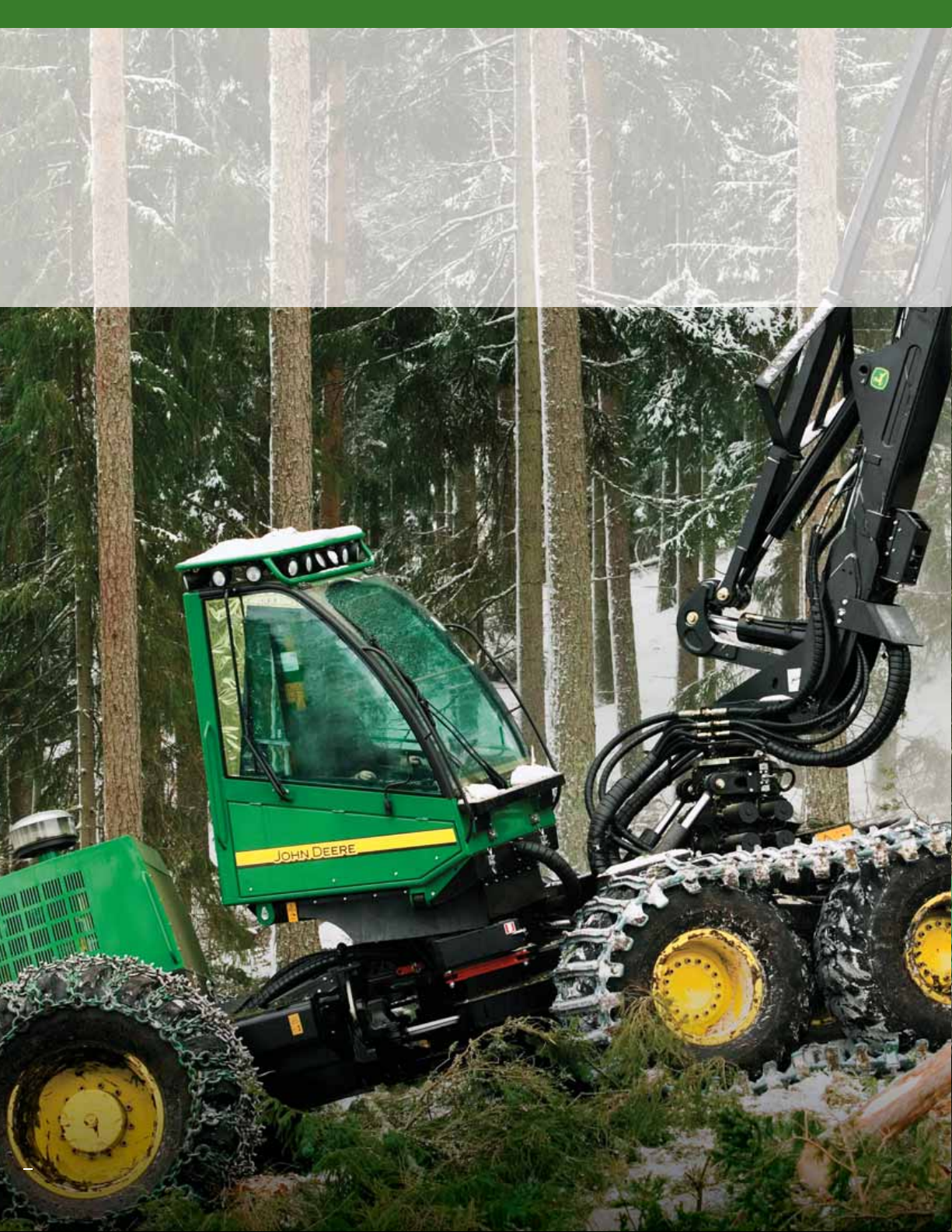

Productivity follows wherever you go.

With a D-Series Harvester, you’re sure to make the most out of every hour spent in the woods. The boom,

head, cab, and overall structure are tough enough to stand up to anything you or nature dishes out. That means

big-time mobility and unbeatable productivity in dense stands, fi nal fellings and even steep terrain hillsides.

3

4

4

5

Page 5

Boom: The fast and accurate parallel

1

boom is easy to control thanks to its

logical motion. Four different boom

reach lengths are available. These

durable booms will reduce service time.

1

2

Rotating and Leveling Cab: The cab

2

offers excellent operator visibility and

maximum operator comfort.

Engine: John Deere PowerTech Plus

3

Tier 3 engines are the largest of the

PowerTech family. They are designed

for low emissions, improved engine

performance and fuel effi ciency across

the board.

Hydraulics: The effi cient hydraulic

4

system makes processing wood easy.

The large diameter hoses and piping

reduce pressure loss.

Rear Axles: Reliable rear axles offer

5

generous ground clearance with high

tractive effort for the toughest terrain.

Bogie Axles: Industry-exclusive, front-

6

balanced bogie axles provide maximum

tractive effort in all terrains as well as

high and wide ground clearance.

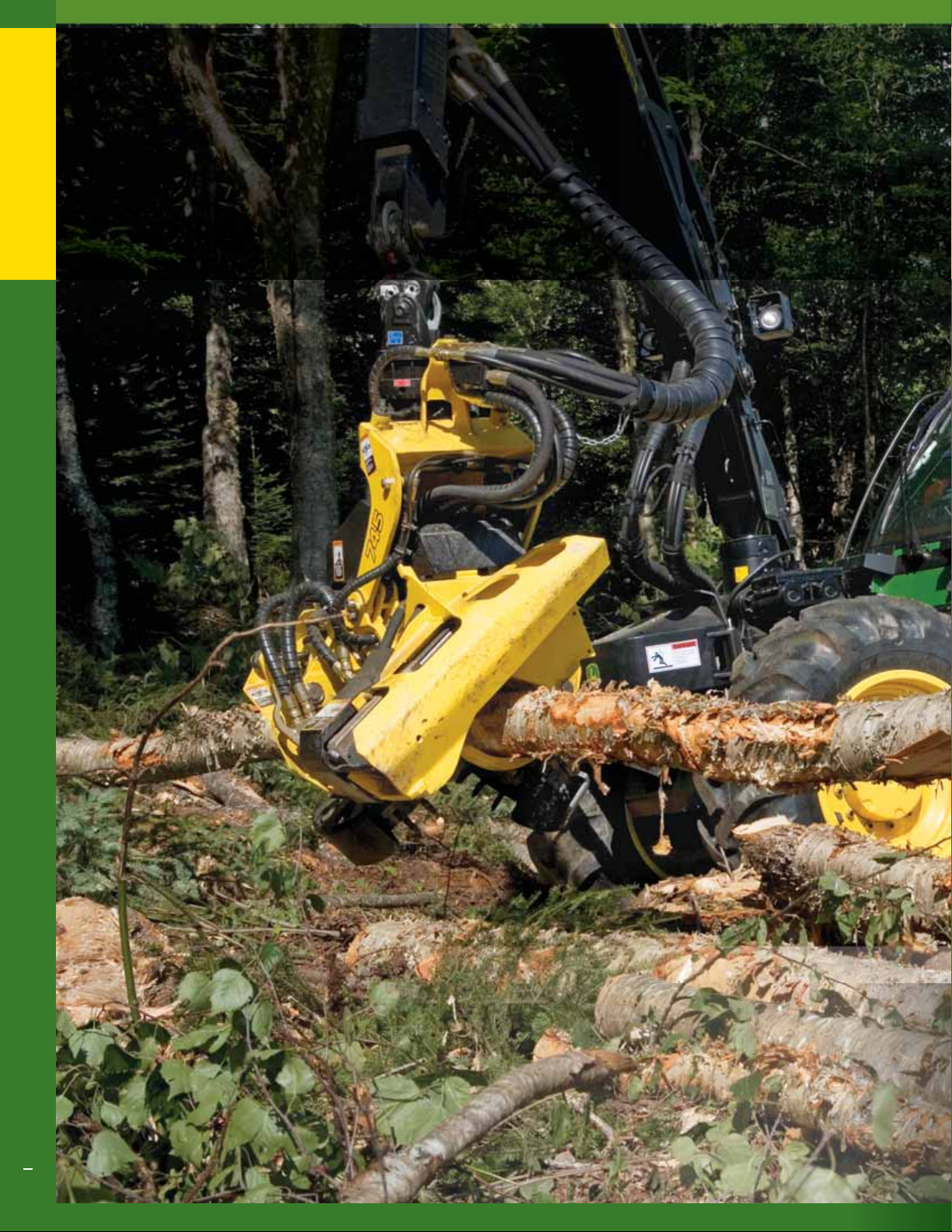

Harvesting Heads: Tested and true

7

harvesting heads are available in twoor four-roller driven, with optional feed

rollers and motors available.

6

5 7

Page 6

The smartest thing in the forest.

At John Deere we’re passionate about operator comfort. Every harvester cab comes with features designed

to keep your crew comfortable and productive for long periods. Try out the smartest machine in the woods.

And watch your production go up.

6

7

Page 7

Measuring and Control System: Allows the operator to automate

1

the entire tree processing cycle with the touch of a button. Set your

log size and length to get the maximum volume and quality out of

each and every log.

Timbermatic 300 System: Effi cient and easy to use, this system

2

has been designed with the latest forestry company requirements

and operators in mind.

Comfort: Effi cient air conditioning, sound insulation and fully

3

adjustable seat.

Tilt and turn: The cab can turn by +/- 50 degrees and tilt in all

4

directions either automatically through the Timbermatic 300 system

or by manual control.

1 2

3

Visibility: Visibility is maximized with large, tinted polycarbonate

windows, well-guarded sunlight, and climate-controlled interiors.

Total Machine Control: Industry-leading Total Machine Control system

enables the operator to match application, terrain, and capabilities.

It automatically adjusts travel speed and braking to ground conditions.

Cab and Boom Sync: When set on automatic control, the turning of

the cab follows the turning of the boom at the speed or angle that the

operator has programmed into the system. The tilt function of the cab

works similarly, following the slopes of the terrain.

Rotating and Leveling Cab: The rotating and leveling cab provides

operator comfort and increased visibility to every cut.

4

Page 8

A machine that stands up to any stand.

Designed with durability in mind, D-Series Harvesters are built to last in a variety of terrains and working conditions.

Each machine houses charge-air-cooled John Deere engines, high-walker axles, which are stronger with more ground

clearance, and industry-exclusive, front-balanced bogie axles for maximum tractive effort—no matter the terrain. It’s

8

9

strong components combined in one smart design.

Page 9

Frame Structure and Middle Joint: Durability is built into the frame structure

and the middle joint resulting in a well-balanced unit with a powerful frame brake.

Parallel Boom: The parallel boom is proven to be heads above the competition

when it comes to reliability.

Engines: John Deere turbocharged diesel engines are number one in power

and high torque-on-demand at low rpms, with Deere reliability and no-surge

starts are built in.

Hydraulics: For sawing or at the start of feeding, the power-controlled,

load-sensing hydraulics increase oil fl ow to improve function speeds in

peak performance situations and increase the hydraulic system’s lifespan.

Page 10

Easy Safe Maintenance Access: For easy maintenance, the

engine hood is comprised of two sections and is operated by

an electrical motor for easy access.

John Deere PowerTech

TM

Engines (cooling and hydraulics):

The Tier 3-certifi ed engines include engine and powertrain

management enhancements (Eco III) to improve productivity and

fuel economy. The cooling system for the engine and hydraulics

remains effi cient in any conditions nature can throw at it.

Software: EcoPull optimizes the engine’s RPMs with a hydrostatic

transmission ratio, so you can run at the right speed at the

lowest possible RPMs. EcoPull automatically engages in slow

driving in the forest, and can also be engaged during fast driving

on level, easy terrain, helping to reduce fuel consumption and

lower daily operating costs.

10

11

Page 11

Less expense. More productivity.

One smart choice.

Each D-Series Harvester features a super-effi cient, Tier 3-certifi ed engine with advanced software features that help

you get the most out of every drop of costly fuel. You get the most out of your machine’s performance while keeping

maintenance at a minimum and uptime at a maximum. Reap the benefi ts of a smart and productive machine.

Page 12

Wheeled Harvesters

770D, 1070D, 1270D, 1470D

770D 1070D 1270D 1470D

ENGINE John Deere 4045HTJ John Deere 6068HTJ John Deere 6090HTJ John Deere 6090HTJ

Cylinders 4 6 6 6

Displacement 275 cu.-in. 4.5 L 414 cu.-in. 6.8 L 552 cu.-in. 9.0 L 552 cu.-in. 9.0 L

Rated power 115 SAE gross hp 182 SAE gross hp 215 SAE gross hp 241 SAE gross hp

86 kW 136 kW 160 kW 180 kW

@ 2,000 rpm @ 1,900 rpm @ 1,400–2,000 rpm @ 1,200–2,000 rpm

Maximum net torque ? lb. ft. 498 Nm 575 lb. ft. 780 Nm 811 lb. ft. 1100 Nm 922 lb. ft. 1250 Nm

@ 1,300–1,400 rpm @ 1,400 rpm @ 1,400 rpm @ 1,400 rpm

Additional features Aspiration: turbocharged, air-to-air charge air cooler

Engine mount: isolation-mounted diesel with TMC

Air cleaner: two stage with safety element and dust unloader valve

Cooling: heavy-duty radiator, oil-to-water engine cooler

POWERTRAIN Hydrostatic-mechanical, two-speed gearbox

Travel speeds:

High

0–15.5 mph 0–25 km/h 0–14.9 mph 0–24 km/h 0–15.5 mph 0–25 km/h 0–13.7 mph 0–22 km/h

Low 0–0 mph 0–8 km/h 0–4.3 mph 0–7 km/h 0–5 mph 0–8 km/h 0–5 mph 0–8 km/h

Maximum tractive effort 22,480 lb. ft. 100 kN 29,225 lb. ft. 130 kN 35,969 lb. ft. 160 kN 40,466 lb. ft. 180 kN

™

ELECTRICAL

Standard features

Alternator: 140 amp

Batteries: dual, heavy duty, low maintenance

Work lights: 14 twin power and 4 single lamps on the boom; 30 lux in the working area of the boom;

Xenon lights also available

AXLES Hydro-mechanical differential lock at the front and the rear

Front Rigid Balanced gear bogie Balanced gear bogie Balanced gear bogie

Rear Rigid Rigid Rigid Rigid

BRAKES

Standard features

Parking and emergency: spring-actuated

Frame articulation brake: automatic

STEERING Articulated frame steering with two hydraulic cylinders

Frame articulation (stop to stop) ±40 degrees ±40 degrees ±42 degrees ±42 degrees

Lever steering Proportional, electrical mini-joystick over hydraulics, armrest mounted

HYDRAULIC SYSTEM Load-sensing, pressure compensated

Working hydraulics Variable-displacement pump

Rated fl ow @ 1,600 rpm 55 gpm 208 L/min 61.3 gpm 232 L/min 80 gpm 304 L/min 88.8 gpm 336 L/min

Pressure 3,480 psi 24 MPa 3,480 psi 24 MPa 3,480 psi 24 MPa 3,480 psi 24 MPa

4,060 psi 28 MPa 4,060 psi 28 MPa 4,060 psi 28 MPa

Powertrain hydraulics Variable-displacement pump/motor

Rated fl ow @ 1,600 rpm 30 gpm 114 L/min 42.3 gpm 144 L/min 52.8 gpm 200 L/min 52.8 gpm 200 L/min

Type: 24 volt

Service and working: hydraulically actuated, oil-immersed multi-disc brakes

12

13

Page 13

770D 1070D 1270D 1470D

CAPACITIES

Fuel reservoir

(located in the rear bumper)

Cooling system 8.2 gal. 31 L 8.2 gal. 31 L 7.4 gal. 27 L 7.4 gal. 27 L

Hydraulic oil system (includes

hydraulic oil reservoir)

TIRES

Front:

Standard 650 x 26.5, 12 PR TRS NK 600 x 22.5, 16 PR ELS NK 600 x 26.5, 20 PR 650 x 26.5, 20 PR

Forest King F NK Forest King ELS NK

Optional 600 x 34, 14 PR TRS NK 710 x 22.5, 16 PR 710 x 26.5, 16 PR 750 x 26.5, 20 PR

Forest King F NK Forest King F NK Forest King F NK

700 x 34, 14 PR TRS NK 710 x 26.5, 20 PR 750 x 26.5, 20 PR

Forest Rider NK Forest King TRS NK

Rear:

Standard 650 x 26.5, 12 PR TRS NK 750 x 26.5, 20 PR TRS NK 600 x 34, 14 PR TRS NK 700 x 34, 14 PR TRS NK

Optional 600 x 34, 14 PR TRS NK 650 x 26.5, 12 PR TRS NK 700 x 34, 14 PR TRS NK

700 x 34, 14 PR TRS NK

GROUND PRESSURE Front / Rear Front / Rear Front / Rear Front / Rear

Standard tires 8.1 psi 56 kPa / 9.7 psi 67 kPa / 10.1 psi 70 kPa / 9.7 psi 67 kPa /

6.7 psi 46 kPa 6.1 psi 42 kPa 8.7 psi 60 kPa 7.1 psi 49 kPa

66 gal. 250 L 79.3 gal. 300 L 127 gal. 480 L 127 gal. 480 L

44.9 gal. 170 L 76.6 gal. 290 L 76.6 gal. 290 L 76.6 gal. 290 L

CAB Safe and in conformity with ISO standards

Standard Fixed Fixed Fixed Fixed

Optional Sideways leveling Sideways leveling Rotating and leveling Rotating and leveling

Sideways tilt 10 deg. 10 deg. 15 deg. 15 deg.

Forward/backward tilt N/A N/A 11 deg. 11 deg.

Turning angle N/A N/A ±50 deg. ±50 deg.

MEASURING AND CONTROL

SYSTEM

PC/Windows-based Timbermatic 300

HARVESTER HEADS 745 745, H754 758HD, H270, H480 758HD, H270, H480,

H290

OPERATING WEIGHT

Standard (minimum depending

on equipment) 25,460 lb. 11 550 kg 31,085 lb. 14 100 kg 38,580 lb. 17 500 kg 43,431 lb. 19 700 kg

Page 14

DIMENSIONS 770D

A Length 19 ft. 4 in. 5.9 m

B Width

650 x 26.5 tires 7 ft. 10 in. 2.40 m

600 x 34 tires 8 ft. 0 in. 2.45 m

700 x 34 tires 8 ft. 8 in. 2.63 m

C1 Transport height with fi xed cab 11 ft. 10 in. 3.62 m

C2 With side-leveling cab option 12 ft. 1 in. 3.69 m

D Ground clearance 22.4 in. 57 cm

E Wheelbase 11 ft. 6 in. 3.50 m

F Reach (with harvester head) 25 ft. 11 in. 7.9 m

G Rear section 11 ft. 2 in. 3.4 m

770D Wheeled Harvester

C2

C1

E

A

F

G

DIMENSIONS 1070D

A Length 22 ft. 2 in. 6.75 m

B Width (front)

600 x 26.5 tires 8 ft. 4 in. 2.53 m

710 x 26.5 tires 8 ft. 9 in. 2.68 m

Width (rear)

650 x 26.5 tires 8 ft. 7 in. 2.62 m

750 x 26.5 tires 8 ft. 10 in. 2.70 m

C1 Transport height with fi xed cab 11 ft. 10 in. 3.62 m

C2 With side-leveling cab option 12 ft. 1 in. 3.69 m

D Ground clearance 22.6 in. 57.5 cm

E Wheelbase 11 ft. 6 in. 3.5 m

F Reach (with harvester head) 32 ft. 10 in. 10 m

Optional 28 ft. 3 in. 8.6 m

G Rear section 12 ft. 5 in. 3.77 m

1070D Wheeled Harvester

F

D

C2

E

A

G

A

C1

14

15

D

Machine not exactly as shown. Illustrations for dimensioning purposes only.

A

Page 15

DIMENSIONS 1270D 1470D

A Length 24 ft. 10 in. 7.58 m 25 ft. 4 in. 7.72 m

B Width (front)

600 x 26.5 tires 9 ft. 1 in. 2.77 m N/A

710 x 26.5 tires 9 ft. 8 in. 2.96 m N/A

650 x 26.5 tires N/A 9 ft. 10 in. 3.0 m

750 x 26.5 tires N/A 10 ft. 0 in. 3.05 m

(optional) 750 x 26.5 tires N/A 9 ft. 10 in. 2.99 m / 10 ft. 5 in. 3.17 m

Width (rear)

600 x 34 tires 8 ft. 9 in. 2.68 m N/A

700 x 34 tires 9 ft. 5 in. 2.86 m 9 ft. 8 in. 2.96 m

C1 Transport height with fi xed cab 12 ft. 2 in. 3.70 m 12 ft. 6 in. 3.8 m

C2 With rotating/leveling cab option 12 ft. 8 in. 3.85 m 13 ft. 0 in. 3.95 m

C3 With rotating/leveling cab option

in raked back position

12 ft. 3 in. 3.74 m 12 ft. 8 in. 3.85 m

D Ground clearance 24.6 in. 62.5 cm 27.9 in. 71 cm

E Wheelbase 13 ft. 3 in. 4.05 m 13 ft. 3 in. 4.05 m

F Reach (with harvester head) 30 ft. 6 in. 9.3 m 28 ft. 3 in. 8.6 m

Optional 32 ft. 10 in. 10.0 m 32 ft. 10 in. 10.0 m / 36 ft. 1 in. 11.0 m

G Rear section 12 ft. 10 in. 3.9 m 12 ft. 10 in. 3.9 m

1270D / 1470D Wheeled Harvester

F

C1

E

A

D

G

C3

C2

B

Machine not exactly as shown. Illustrations for dimensioning purposes only.

Page 16

770D 1070D 1270D 1470D

BOOM 140H 180S 210H CH8

Gross lifi ting torque 70 lb. ft. 95 kN 105,471 lb. ft. 143 kNm 131,285 lb. ft. 178 kNm 154,888 lb. ft. 210 kNm

Gross swing torque 17,700 lb. ft. 24 kN 28,027 lb. ft. 38 kNm 32,160 lb. ft. 43.6 kNm 40,566 lb. ft. 55 kNm

Maximum reach (without

harvester head) 24 ft. 11 in. 7.6 m 31 ft. 10 in. 9.7 m 29 ft. 6 in. 9.0 m 27 ft. 3 in. 8.3 m

Optional N/A 27 ft. 3 in. 8.3 m 31 ft. 10 in. 9.7 m 31 ft. 10 in. 9.7 m

Tilt boom base ±15 deg. –13/+18 deg. –13/+25 deg. –13/+25 deg.

Swing angle 220 deg. 220 deg. 220 deg. 220 deg.

Rotator AV 12S AV 12S BBR 15 HD BBR 15 HD

Optional BBR 15 HD, H172 H172 BBR 16 HD, H172

Link double dampened double dampened double dampened double dampened

Optional dual dampened dual dampened dual dampened

MPB2-1, MPB2-2 MPB2-1, MPB2-2 MPB2-1, MPB2-2

Additional features Dedicated boom lubrication system

Guarding for boom hydraulic valve

770D / 1070D 745 Harvester Head 4WD H754 Harvester Head 4WD

Maximum cutting diameter 24.4 in. 62 cm 24.4 in. 62 cm

Weight from (excludes rotator and

link, depending on equipment) 1,720 lb. 780 kg 1,809 lb. 820 kg

Feed motors (4): Max feed force / speed Max feed force / speed

Standard 4,429 lb. ft. 19.7 kN / 18.7 ft./sec. 5.7 m/sec 4,968 lb. ft. 22.1 kN / 18.7 ft./sec. 5.7 m/sec

Optional 5,598 lb. ft. 24.9 kN / 15.1 ft./sec. 4.6 m/sec 6,250 lb. ft. 27.8 kN / 15.1 ft./sec. 4.6 m/sec

Feed rollers (4) synchronized:

Fixed (2) Steel thumb-type Steel thumb-type

Movable (2) Steel thumb-type Steel thumb-type

Optional Accumulator arms and rollers for multi-tree handling, N/A

debarking rollers

Delimbing knives Three moving (2 upper, 1 lower), hydraulically Four moving (2 upper, 2 lower), hydraulically

operated, one fi xed top knife operated, one fi xed top knife and one welded

bottom knife

Maximum reach 745 Head 745 Head

32 ft. 10 in. 10.0 m 32 ft. 10 in. 10.0 m

Additional features Automatic chain tensioner and lubrication system Automatic chain tensioner and lubrication system

16

17

Machine not exactly as shown. Illustrations for dimensioning purposes only.

Page 17

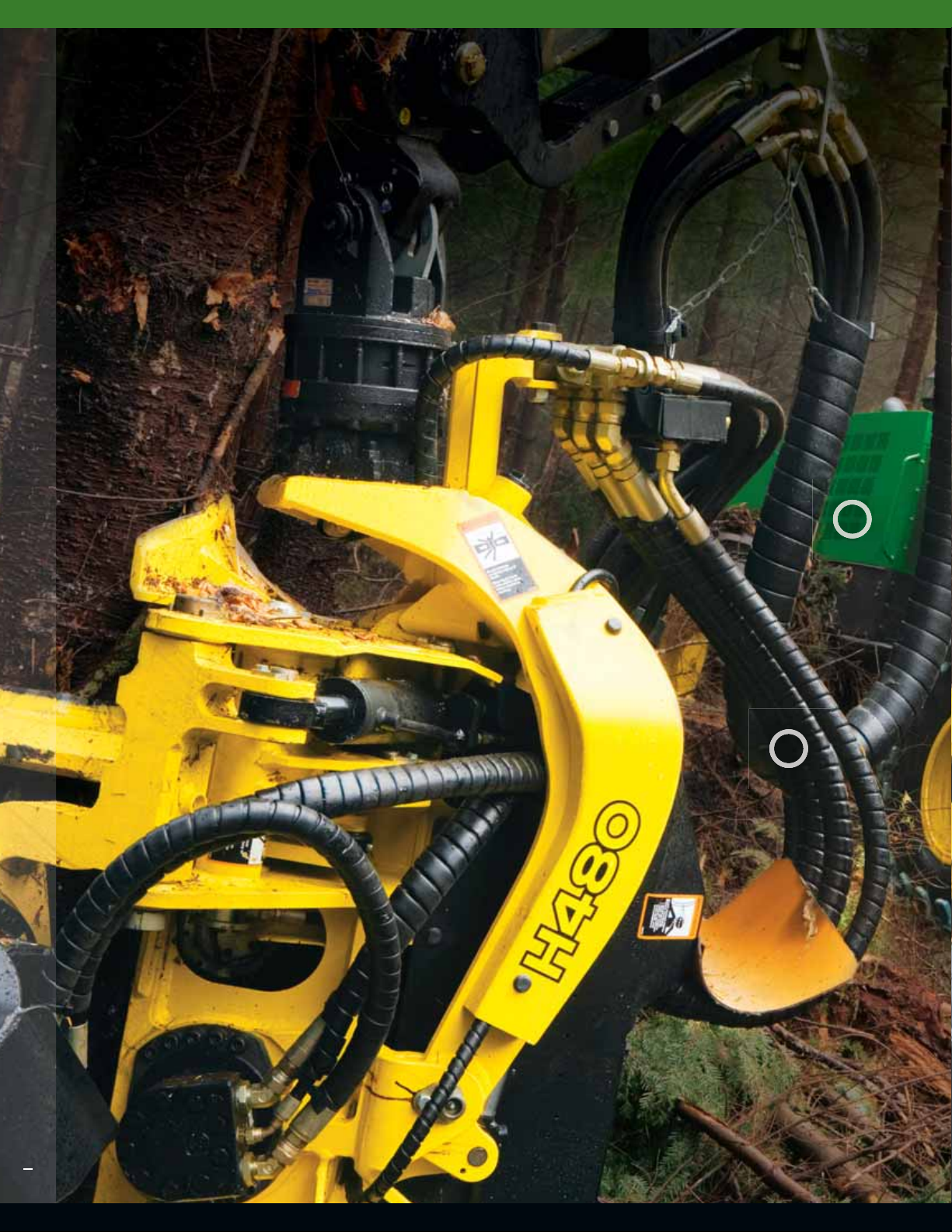

1270D / 1470D H270 Harvester 758HD Harvester H290 Harvester H480 Harvester

Head 2WD Head 4WD Head 2WD Head 4WD

Maximum cutting diameter 25.6 in. 65 cm 28.3 in. 72 cm 29.5 in. 75 cm 28.3 in. 72 cm

Weight from (excludes rotator and link) 2,888 lb. 1310 kg 2,513 lb. 1140 kg 4,079 lb. 1850 kg 2,645 lb. 1200 kg

Feed motors (2): Max feed force / speed Max feed force / speed Max feed force / speed Max feed force / speed

Standard 5,265 lb. ft. 23.4 kN / N/A 8,385 lb. ft. 37.3 kN / N/A

14.8 ft./sec. 4.5 m/sec 19.7 ft./sec. 6.0 m/sec

Optional 5,783 lb. ft. 25.7 kN / N/A 9,352 lb. ft. 41.6 kN / N/A

14.0 ft./sec. 4.3 m/sec 19.7 ft./sec. 6.0 m/sec

Optional 6,300 lb. ft. 28.0 kN / N/A N/A N/A

13.1 ft./sec. 4.0 m/sec

Feed motors (4):

Standard N/A 5,328 lb. ft. 23.7 kN / N/A 5,328 lb. ft. 23.7 kN /

15.4 ft./sec. 4.7 m/sec 15.4 ft./sec. 4.7 m/sec

Optional N/A 6,789 lb. ft. 30.2 kN / N/A 6,789 lb. ft. 30.2 kN /

13.8 ft./sec. 4.2 m/sec 13.8 ft./sec. 4.2 m/sec

Feed rollers (2):

Standard Rubber, with chains or N/A Mense steel thumb-type N/A

Optional Steel thumb-type N/A Steel thumb-type N/A

Feed rollers (4) synchronized:

Fixed (2) N/A Steel thumb-type N/A Steel thumb-type

Movable (2) N/A Steel thumb-type N/A Steel thumb-type

Optional N/A Accumulator arms and N/A Accumulator arms and

rollers for multi-tree rollers for multi-tree

handling handling

Maximum reach H270 Head 758 Head H290 Head H480 Head

32 ft. 10 in. 10.0 m 32 ft. 10 in. 10.0 m 27 ft. 3 in. 8.3 m 32 ft. 10 in. 10.0 m

Page 18

John Deere is the world’s leading designer,

manufacturer, and distributor of forest machines.

Our range of purpose-built forestry equipment

is without equal in the industry.

From thinning to regeneration harvesting,

for both cut-to-length and full-tree applications,

John Deere builds woods-tough equipment

with the logger in mind.

DKA1070WH Litho in U.S.A. (07-10)

www.JohnDeere.com

Loading...

Loading...