Page 1

JOHN DEERE

AG & TURF DIVISION

GX24537

G2

John Deere Tractors

100 Series

OMGX24537 G2

OPERATOR’S MANUAL

North American Ve rsion

Printed in U.S.A.

Page 2

INTRODUCTION

c WARNING: The Engine Exhaust

from this product conta ins chemicals kno wn

to the State of California to cause cancer,

birth defects or other reproductive harm.

California Proposition 65 Warning

T able of Contents

Introduction................................................................................................ 1

Product Identification.................................................................................1

Safety Labels............................................................................................. 3

Safety ........................................................................................................ 9

Machine Cleanout ................................................................................... 14

Assembly................................................................................................. 16

Operating Controls ..................................................................................18

Operating................................................................................................. 21

Service Intervals...................................................................................... 31

Service Lubrication.................................................................................. 32

Service Engine ........................................................................................33

Service Transmission .............................................................................39

Service Mower.........................................................................................39

Service Electrical..................................................................................... 44

Service Miscellaneous ............................................................................46

Troubleshooting .......................................................................................50

Storage....................................................................................................52

Specifications.......................................................................................... 53

Warranty..................................................................................................55

Index........................................................................................................ 57

Getting Quality Service ........................................................................... 58

Service Record........................................................................................59

Introduction

Thank Yo u for Purchasing a John Deere Product

We appreciate having you as a customer and wish you many years of safe

and sat is fie d us e of you r mac hi ne.

Using Your Operator’s Manual

This manual is an important part of your machine and should remain with

the machine when you sell it.

Reading your operator’s manual will help you and others avoid personal

injury or damage to the machine. Information given in this manual will

provide the operator with the safest and most effective use of the machine.

Knowing how to operate this machine safely and correctly will allow you to

train others who may operate this machine.

This ma nua l and safety si gn s on your mach in e may also be availa ble in

other languages (see your authorized dealer to order).

Sections in your operator’s manual are placed in a specific order to help

you understand all the safety messages and learn the control s so you can

operate this machine safely. You can also use this manual to answer any

specific operating or servicing ques tions.

The machine shown in this manual may differ slightly from your machine,

but will be similar enough to help you understand our instructions.

RIGHT-HAND and LEFT-HAND si des are determined by facing in the

direction the machine w ill travel when going forward. When you see a

broken line (------), the item referred to is hidden from view.

Before delivering this machine, your dealer performed a predelivery

inspection to ensure best performance.

Special Messages

Your manual contains special messages to bring attention to potential

safety concerns, machine damage as well as helpful operating and

servicin g information. Please read all the information carefully to avoid

injury and machine damage .

c CAUTION: Avoid injury! This symbol and text highlight

potential hazards or death to the operator or bystanders that may

occur if the hazards or procedures are ignored.

Original Instruction

All information, illustrations and

specifications in this manual are based on

the latest information at the time of

publicati on. The right is reserved to make

changes at any time without notice.

COPYRIGHT© 2012

John Deere Worldwide Commercial and

Consumer Equipment Division

COPYRIGHT© 2009, 2010, 2011

Deere & Co.

All rights reserved

Previous Editions

IMPORTANT: Avoid damage! This text is used to tell the operator

of actions or conditions that might result in damage to the

machine.

NOTE: General information is given throughout the manual that may

help the operator in the operation or service of the m achine.

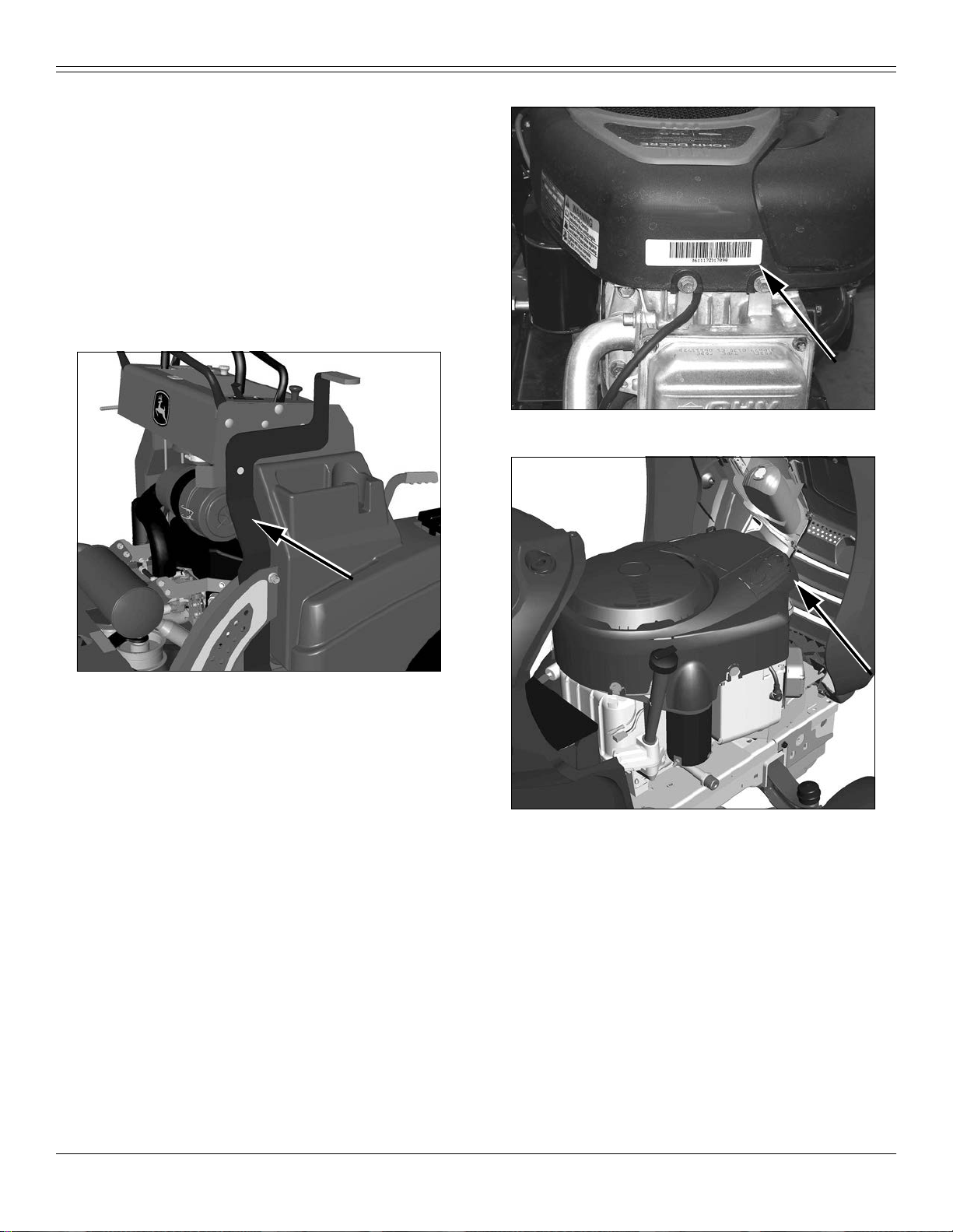

Product Identification

Record Identification Numbers

Lawn Tractors

D105, D110, D120, D130, D140, D160, D170

PIN (D400001-) 49 State

PIN (D040001-) California

PIN (D070001-) Australia, Canada , Mexico, ROW.

If you need to contact an Authoriz ed Service Center for information on

servicing, always provide the prod uct model and ide ntification numbers.

You will need to locate the product identification number (PIN) for the

Introduction - 1

Page 3

PRODUCT IDE NTIFICATION

machin e and engine serial number. Record the information in the spaces

prov ided below.

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

PRODUCT IDENTIFICATION NUMBER:

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER:

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

Machine Product Identification Number Location

Engine Seri al Num be r Loca tion

MX25599

Picture Note: Single Cylinder Engines

Picture Note: Located on left side of frame.

MX46486

MX49394

Picture Note: V-Twin Engines

Regist er Your Product and Warranty Onli ne

To register your product through the Internet, simply go to

www.JohnDeereWarrantyRegistration.com. Complet ing the information,

either online or with the product warranty card, will ensure the customer

that their product receives all post sales service and important product

infor mation.

Product Identification - 2

Page 4

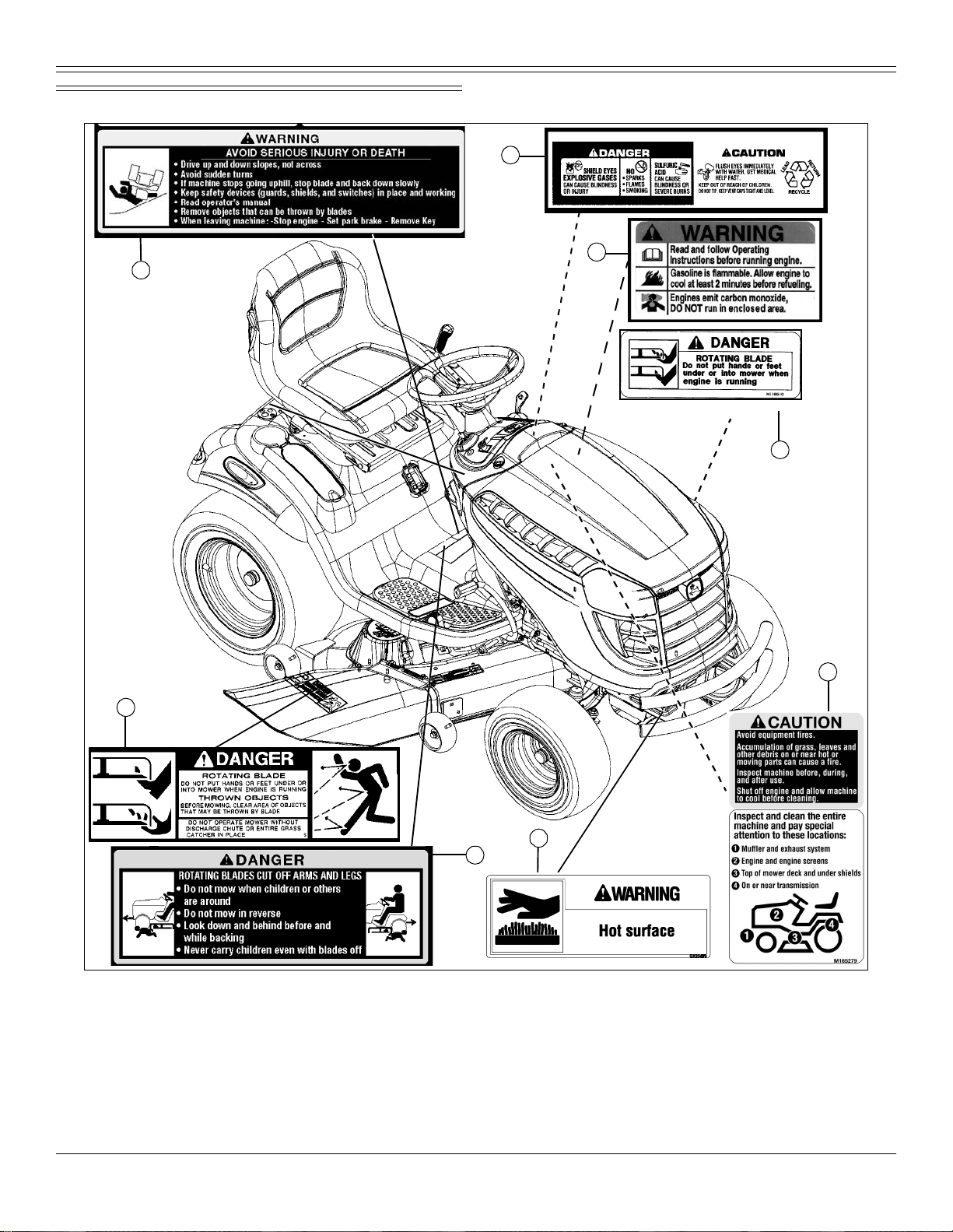

Safety Labels

A

SAFETY LABELS

Safety Label Location (Text)

B

C

D

H

MX46490

Picture Note: Use label number listed in table below to locate

complete text of safety label message following this illustration.

A- WARNING GX22477

B- DANGER/CAUTION M128699

C- W ARNING MX4878

D- DANGER M118610

E- CAUTION M165279

E

F

G

F- WARNING GX23479

G- DANGER GX22477

H- DANGER M89504

Safety Labels - 3

Page 5

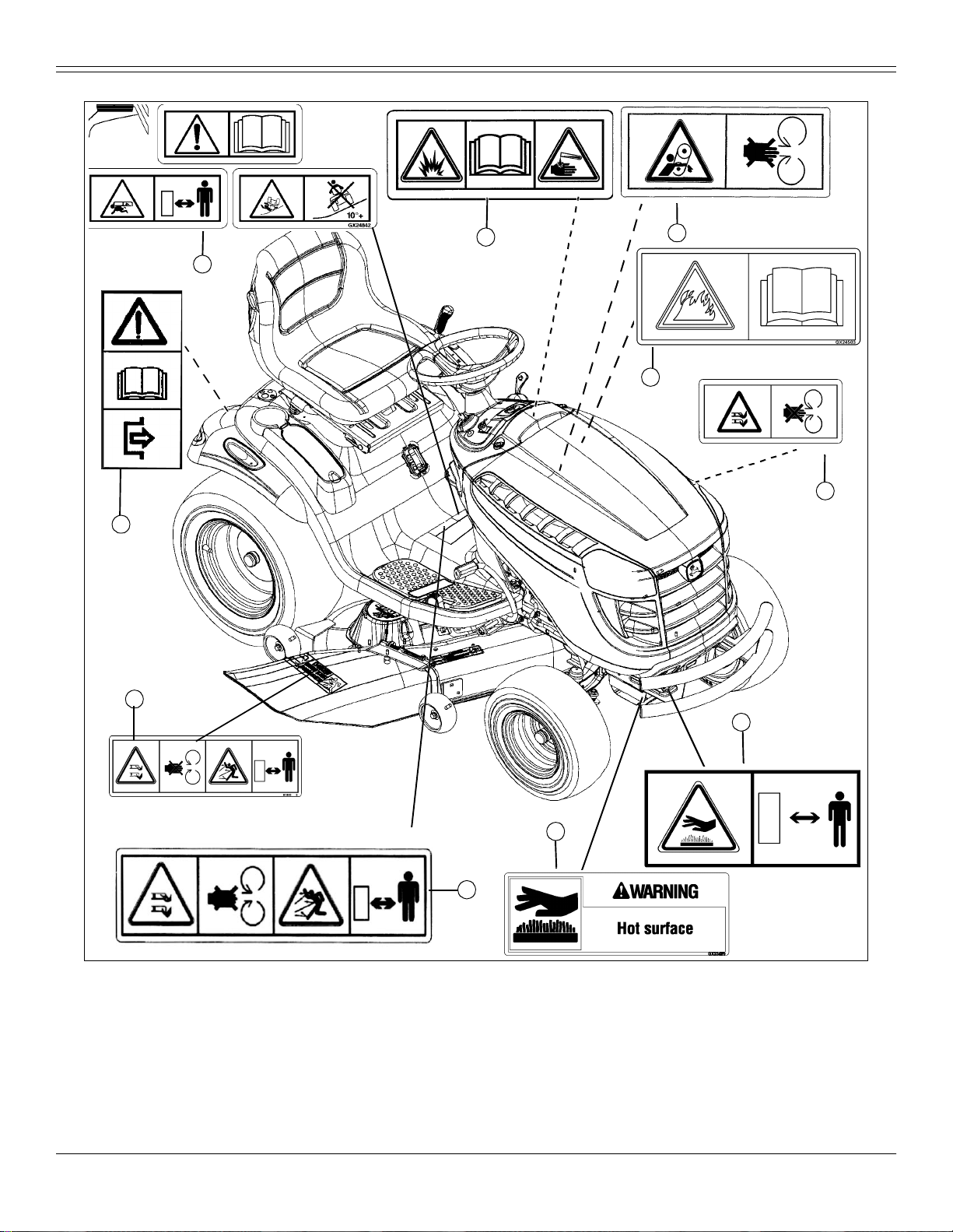

Safety Label Loc a tion (No Text)

SAFETY LABELS

B

A

J

C

D

E

I

MX46490

Picture Note: Non-text labels are required for certain regions of the

world. Your machine may not be equipped with th ese labels. Use

label number listed in table below to locate complete text of safety

label message following this illustration.

A- WARNING GX24842

B- W ARNING M128484

C- W ARNING M136436

D- WARNING GX24503

F

G

H

E- DANGER M118041

F- WARNING GX21121

G- WARNING GX23479

H- DANGER M148522

I - DAN GER M118040

J- WARNING (Bypass Rod) GX21086

Safety Labels - 4

Page 6

SAFETY LABELS

Understanding The Machine Safety Labels

The machine safety labels shown in this section are placed

in impo rtant areas on your machine to draw atte ntion to

potential safety hazards.

On your machine safety labels, the words DANGER,

WARNING, and CA UTION are used with this safety-alert symbol.

DANGER identifies the most serious hazards.

The operator’s manual also explains any potential safety hazards

whenever necessary in special safety messages that are identified with

the word, CAUTION, and the safety-alert symbol.

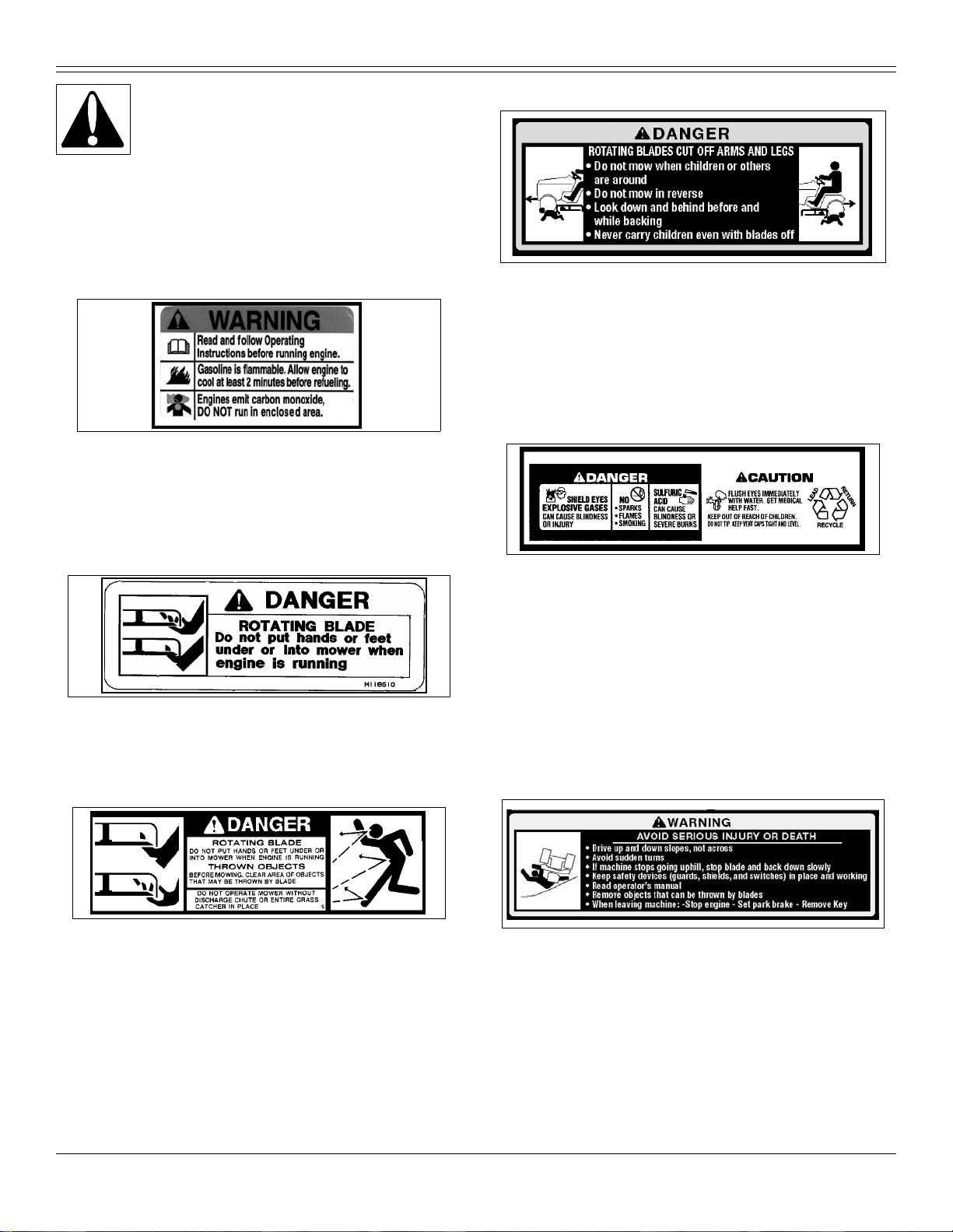

Warning MX4878

MX4878

• Read and follow Operating Instructions before running engine.

• Gasoline is flammable. Allow engine to cool at l east 2 minutes before

refueling.

• Engines em it carbon mo nox id e, DO NOT ru n in enclosed area.

DANGER

GX22477

ROTATING BLADES CUT OFF ARMS AND LEGS

• Do not mow when children or others are around.

• Do not mow in reverse.

• Look down and behind before and wh ile backing.

• Never carry childr en even with blad es off.

DANGER M128699

DANGER

M118610

ROTA TING BL ADE

• Do not put ha nd s or feet und er or into mowe r wh en eng ine is runn in g.

DANGER - M89504

M89504

ROTA TING BL ADE

• Do not put ha nd s or feet und er or into mowe r wh en eng ine is runn in g.

THROWN OB JECTS

• Before mowing, clear area of objects that may be thrown by blade.

• Do not operate mower without discharge chute or entire grass catcher in

place.

M128699

Picture Note: Located on battery

• Shield eyes, explosive gases can cause blindness or injury.

• No sparks, flames, smoking.

• Sulfuric acid can cause blindness or severe burns.

• Flush eyes immediately with water. Get medical help fast.

• Kee p out of reach of children.

• Do not tip.

• Keep vent caps tight and level.

WARNING

GX22477

AVOID SERIOUS INJURY OR DEATH

• Drive up and down slopes, not across.

• Avoid sudden turns.

• If machine stops going u phill, stop blades and back d own slowly.

• Keep safety devices (guards, shields, and switches) in place and

working.

• Remove objects that could be thrown by blades.

• Read operator’s manual.

Safety Labels - 5

Page 7

SAFETY LABELS

• Remove objects th at can be thrown by blades

• When leaving machine:

–Stop engine

–Set par k brake

–Remove key

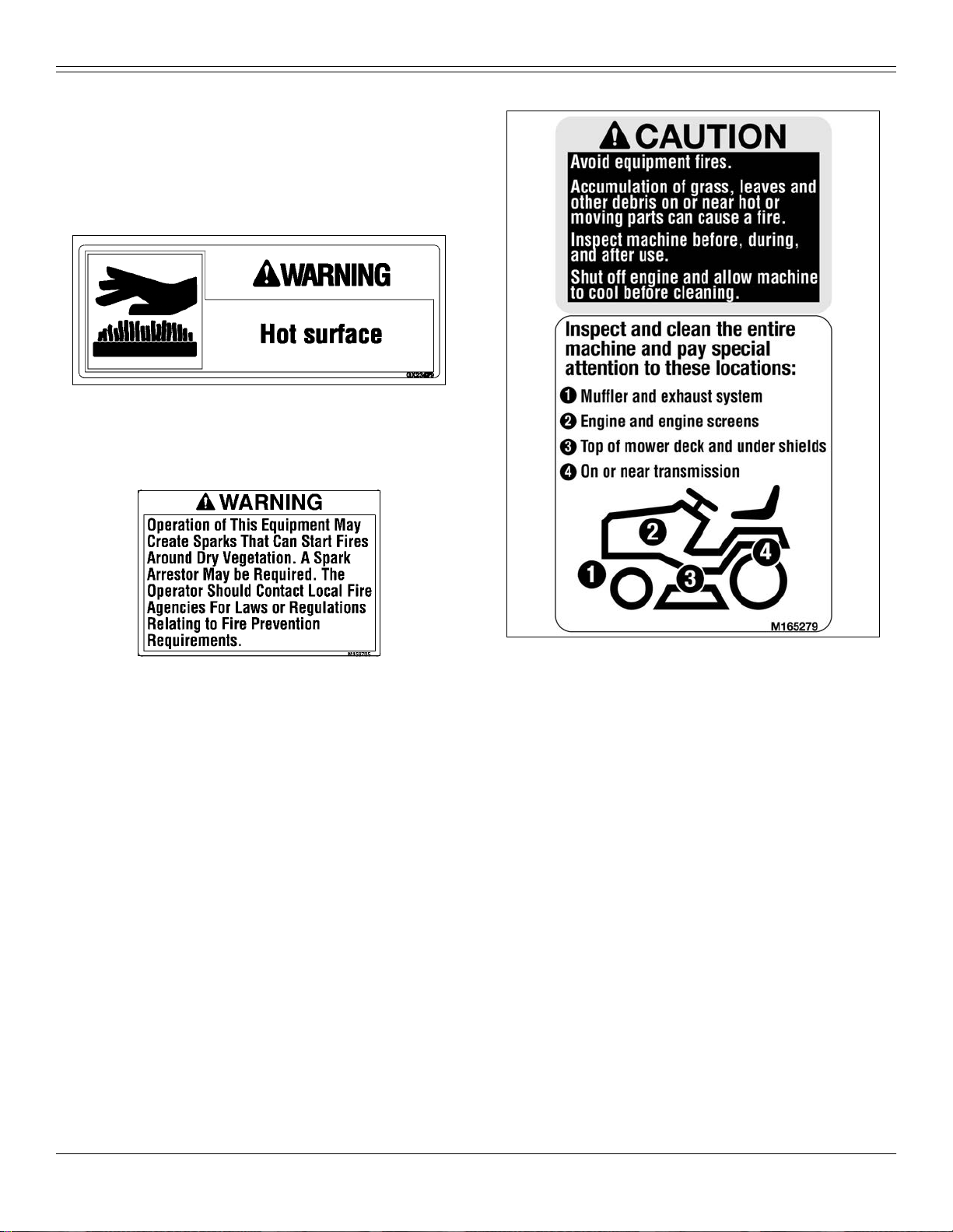

DANGER GX23479

WARNING

• Hot sur face

Warning M159705

Prevent Equipment Fires

GX23479

M159705

Picture Note: This label is required and installed on machines sold

in California. This label may also be installed on machines sold in

other locations.

Oper ation of This Equipment May Create Sparks that Can Start Fires

Around Dry Vegetatio n. A Spark Arrestor May be Requ ired. The Operator

Should Contact Local Fire Agencies For La ws or Regulations Relating to

Fire Prevention Requirements.

M165279

• Avoid equipment fires.

• Accumulation of grass, leaves and other debris on or n ear hot or moving

parts can cause a fire.

• Inspect machine before, during, and after use.

• Shut off engine and allow machine to cool before cleaning.

Inspect and clean the entire machine and pay special attention to these lo c ations:

1. Muffler and exhaust system

2. Engine and engine screens

3. Top of mower deck and un der shields

4. On or near transmission

Emission Control System Certification Label

NOTE: Tampering with emission controls and components by

unauthorized personnel may result in severe fines or penalties.

Emission controls and components can only be adjusted by EPA

and/or CARB authorized service centers. Contact your John Deere

Retailer concerning emission controls and component questions.

The presence of an emissions label signifies that the engine has been

certified with the United States Environmental Protection Agency (EPA)

and/or California Air Resources Board (CARB).

The emis sions warranty applies only to those engines marketed by John

Deere that have been certified by the EPA and/or CARB; and used in the

United States and Can ada in off-road mobil e equipment.

Safety Labels - 6

Page 8

SAFETY LABELS

Emission Compliance Period

If your engine has the emission compliance category listed on the

emissio n control sy s tem ce rtific a tion or air index la be l, thi s in dic a t es the

number of operating hours for which the engine has been certified to meet

EPA and/or CARB emission requirements. The following table provides

the engine compliance period in hours associated with the category found

on the cer tifica tio n label.

Agency Category Hours

EPA C 250

EPA B 500

EPA A 1000

CARB Moderate 125

CARB Intermediate 250

CARB Extended 500

Certification

Your mo wer has been certified for compliance with American National

Standards Institute B-71.1-2003, “Safety Specifications” for Power Lawn

Mowers, Lawn and Garden Tractors, and Lawn Tractors.

Canadian Electromagnetic Compatibility (EMC) Compliance

This spark ignition system complies with Canadian ICES-002.

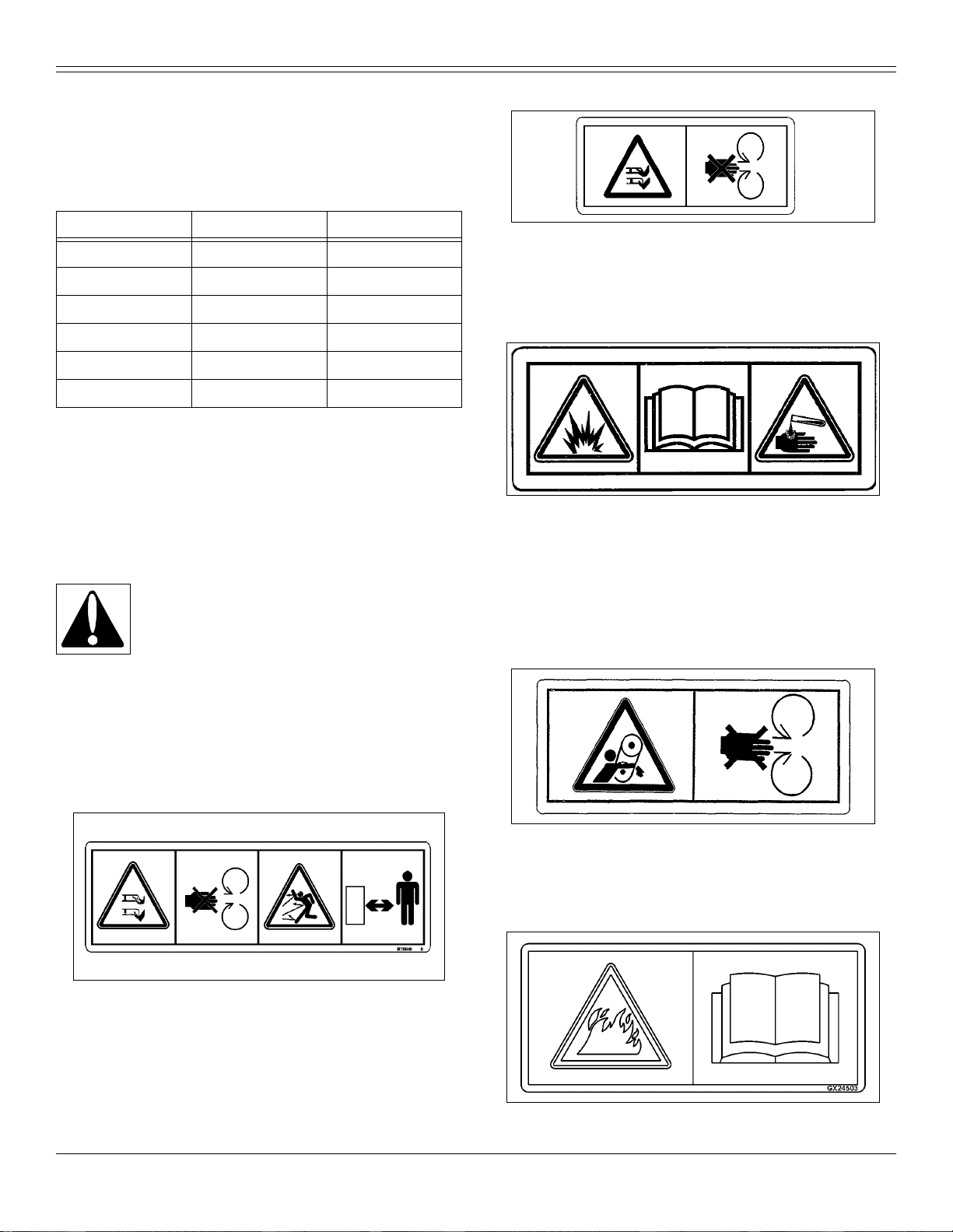

Pictoria l Safety Signs

At several imp ortan t pl a c es on t hi s ma ch ine safety signs

are affixed intended to signify potential danger. The hazard

is iden tif i ed b y a pi ctor ia l in a w a rnin g tria ng l e. An ad ja ce nt

pictorial provides information how to avoid personal injury.

These sa fety signs, the ir pl ac em e nt on the ma ch ine and a bri ef

explanatory text are shown in this Safety section.

There can be additional safety information contained on parts and

components sourced from suppliers that is not reproduced in this

operator’s manual.

Avoid In jury From Rotating Blades - M118041

M118041

• Do not put hands or feet under or into mower when eng ine is running.

• Do not operate mower without discharge chute or entire grass catcher in

place.

WARNING M128484

M128484

Avoid Injury From Battery Gases and Acids

• Batteri es conta in e xp losi v e ga se s an d sulf ur ic acid. Us e ex tr em e caut i on

when handling battery.

• Read operator’s manual for all safety informa tion before handling battery.

• Use extreme caution when handling battery.

Avoid In jury From Getting Caught in Belt - M136436

Av oi d Inju ry Fr om Rot ati ng Bl ades and Thr own Objec ts

- M118040

M118040

• Do not put ha nd s or feet und er or into mowe r wh en eng ine is runn in g.

• Do not operate mower without discharge chute or entire grass catcher in

place.

• Before mowing, clear area of objects that may be thrown by blade.

• Stay clear wh ile engine is runn in g.

Safety Labels - 7

M136436

• Stay clear of belts.

• Do not oper at e mow e r wit ho ut sh ields in plac e.

WARNING GX24503

GX24503

Page 9

SAFETY LABELS

Clean and inspect the entire machine.

Carefully read Operator’s Manual Machine Cleanout section for details.

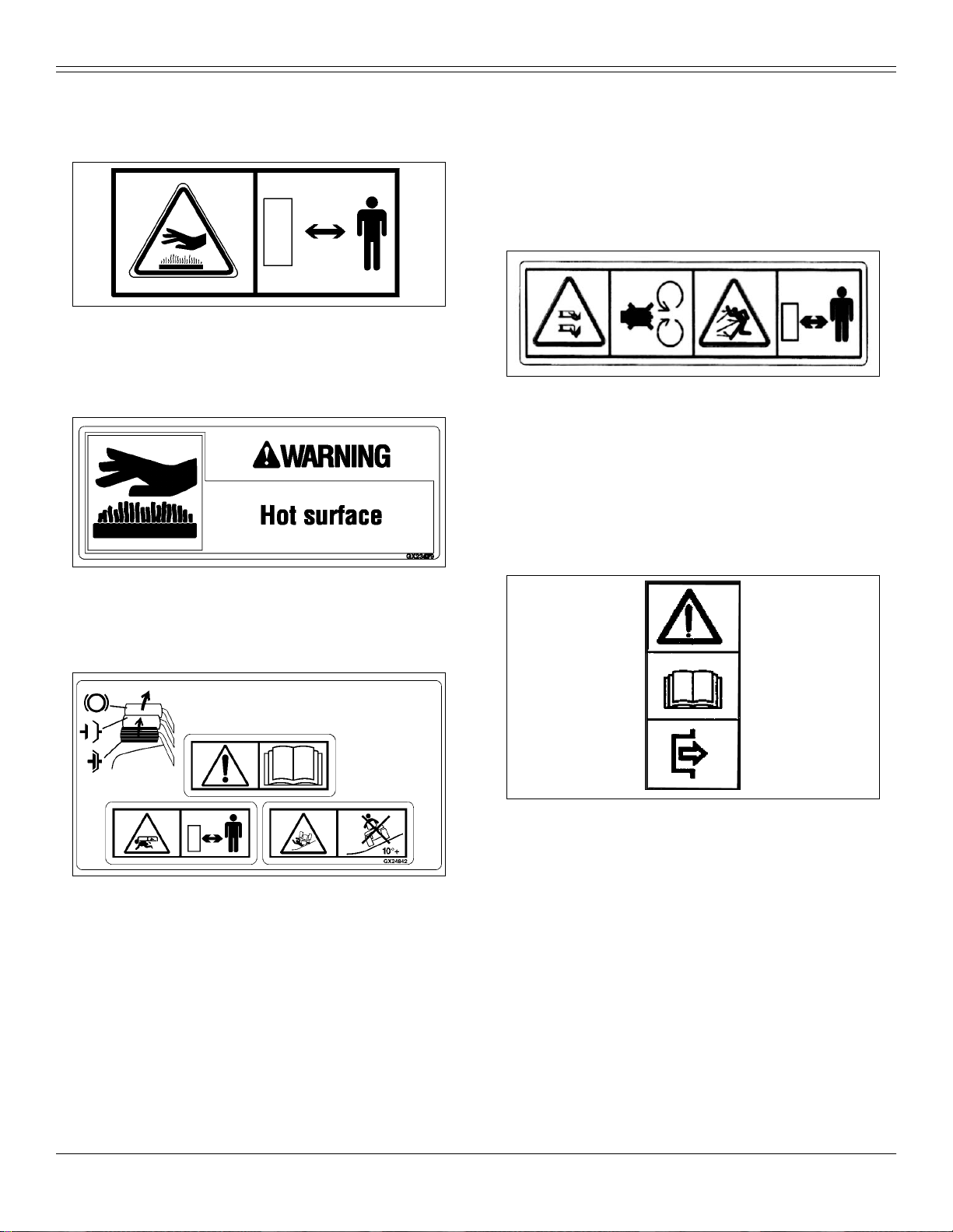

WARNING GX21121

GX21121

Warning - Hot Surfaces

• Ke ep away from hot surfaces.

WARNING - GX23479

Avoid Injury From Tipping

• In some co nfigurations, do not drive or operate on a slope of more than

10 degree s.

• Refer to the Operating on Slopes section for more information.

• Drive up and down slopes, not across.

• Avoid sudden turns.

Avoid Injury From Rotating Blades and Thrown Objects

M148522

• Do not put hands or feet under or into mower when eng ine is running.

• Keep away from rotating parts. Do not open or remove safety shields

while engine is runnin g.

• Thrown O bjects - Before mowing, clear area of objects t hat may be

thrown by blade. Do not operate mower without discharge chute or entire

grass catcher in place.

• Stay a safe distance from machine.

GX23479

WARNING

• Hot sur face

Avoid Inju ry

GX24842

Picture Note: Located on fenderdeck in front of seat.

Read Operators Manual

• This operator’s manual contains important information necessary for safe

machine operation. Observe all safety warnings to avoid accidents.

Keep Children Away From Mower

• Do not mow when children or others are around.

• Do not mow in reverse.

• Look down and behind before and while backing.

• Never carry children even with blades off.

Avoid Injury: Use Transmission Bypass Rod Safely

GX21086

• Carefully read operator’s manual for safe operation of transmission

bypass rod.

Safety Labels - 8

Page 10

SAFETY

Safety

Operating Safely

This cutting machine is capable of amp utating hands and

feet and throwing objects. Failure to observe the following

safety instructions could result in serious injury or death.

• Read, understand and follow all instructions on the

machine and in manuals provided, and view safety video, before starting.

Be thoroughly familiar with the controls and the proper use of the machine

before starting.

• Do not put hands or feet near rotating parts or under the machine. Keep

clear of the discharge opening at all times.

• Only allow responsible adults, who are familiar with the instructions, to

operate this machine. Local regulations may restrict the age of the

operator.

• Clear the area of objects such as rocks, wire and toys which could be

thrown by the blades.

• Be sure the area is clear of bystanders befor e operating. Stop machine if

anyone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary. Always look down

and behi nd befor e an d wh il e ba cki ng.

• Never direct discharged material toward anyone. Avoid discharging

material against a wall or obstruction. Material may ricochet back toward

the operator. Stop the blades when crossing gravel surfaces.

• Do not operate the machine without the entire grasscatcher, discharge

guard, or other safety devic es in place and wo rking. Never operate with

the discharge deflector raised, removed, or altered, unless using a

grasscatcher.

• Slow down before t u rn ing.

• Never leave a running machine unattended. Always turn off blades, lock

park brake, stop engine and remove key before dismounting.

• Disengage blades when not mowing. Shut off engine and wait for all

parts to com e to a complete stop before cleaning the machine, removing

the grasscatcher, or unclogging the discharge chute.

• Operate machine only in daylight or good artificial light.

• Do not operate the machine while under the influence of alcohol or

drugs.

• Watch for traffic when operating near or crossing roadways. Stop blades

before crossing ro ads or sidewal k s.

• Use extra care whe n loading or unloading the machine into a trailer or

truck.

• Always wear safety goggles or safety glasses with side shields when

operating machin e.

• Data indicates operators 60 year s and above ar e involved in a large

percentage of riding mower-related injuries. These operators should

evaluate their ability to operate the riding mower safely enough to protect

themselves and others from serious injury.

• Follow the manufacturer’s recommendation for wheel weights or

counterweights.

• Inspect machine before you operate. Be sure hardware is tight. Repair or

replace damaged, badly worn, or missing parts. Be sure guards and

shields are in good condition and fastened in place. Make any necessary

adjust me nts before yo u op erate.

• Before using, always visually inspect to see that the blades, blade bolts

and the m ower assembly are not worn and damaged. Replace worn and

damaged blades and bolts in sets to preserve balance.

• Make sure spark plug, m uffler, fu el cap and air cleaner are in place

before starting the engine.

• Be sure all drives are in neutral and parking brake is locked before

starting engine. Only st art engine from the operator’s position.

• Do not change the engine governor settings or overspeed the engine.

Operating the engine at excessive speed can increase the hazard of

person al injury.

• If y ou hit an object or if abnormal vibration occurs, stop the machine and

inspect it. Make repairs before you operate.

• Use only accessories and attachments approved by the manufacturer of

the machine. Keep safety labels visible when installing accessories and

attachments.

• Do not wear radio or music head ph on es. Safe service and operation

requires your full attention.

• When machine is left unattended, stored, or parked, lower the mower

deck unless a positive mechanical lock is used.

Using a Spark Arrestor

The California Public Resources Code, section 4442.5 provides as

follows:

No person shall sell, offer for sale, lease, or rent to any person any internal

combustion engine subject to Section 4442 or 4443, and not subject to

Section 13005 of the Health and Safety Code, unless the person provides

a written n ot ic e to t he pu rcha se r o r bai l ee , at th e tim e of sa le or at the t i me

of entering into the lease or rental contract, stating that it is a violation of

Section 4442 or 4443 to use or operate the en gine on any f orest-covered,

brush-covered, or grass-cov ered land unless the engine is eq uipped with

a spark arrestor, as defined in Section 4442, maintained in effective

working order or the engine is constructed, equipped, and maintained for

the prevention of fire pursuant to Section 4443. Cal. Pub. Res. Code

4442.5.

Other states or jurisdictions may have similar laws. A spark arre stor for

your m achine may be available from your auth orized dealer. An installed

spark arrestor must be maintained in good working order by the operator.

Checking Mowing Area

• Clear mowing area of objects that might be

throw n. Keep people and pets out of mowing

area.

• Low-hanging branches and similar obstacles

can injure the operator or interfere with

mowing operation. Before mowing, identify potential obstacles such as

low-hanging branch es, and trim or r emove those obstacles.

• Study mowing area. Set up a safe mowing pattern. Do not mow where

traction or stability is doubtful.

• Test drive area with mower lowered but not running. Slow down when

you travel over rough ground.

Parking Safely

1. Stop machine on a level surface, not on a slope.

2. Disengage mower blades or any other attachments.

3. Lower attachments to the ground.

4. Lock the park brake.

5. Stop the engine.

6. Remove the key.

Safety - 9

Page 11

SAFETY

7. Wait for engine and all moving parts to stop before you leave the

operator’s seat.

8. Close fuel shut-of f valve, if your machine is equipped.

9. Disconnect the negative battery cable or remove the spark plug wire(s)

(for gasoline engines) before servicing the mac hine.

Rotating Blades are Dangerous

HELP PREVENT SERIOU S OR FATAL ACCIDENTS:

• Rotating blades can cut off arms and legs,

and throw objects. Failure to observe safety

instructions could result in serious injury or

death.

• Keep hands, feet and clothing away from mower deck when engine is

running.

• Be alert at all times, drive forward and in reverse carefully. People,

especially children can move quickly into the mowing area before you

know it.

• Before backing up, stop mower blades or attachments and look down

and behind the machine carefully, especially for children.

• Do not mow in reverse.

• Shut off blades when you are not m owing.

• Park machi ne safely before leaving the operator’s station for any reason

including emptying the grasscatchers or unplugging the chute.

• The mo wer blades should stop in appr oximately f ive seconds when the

mower is disengaged. If you believe that your blades may not be stopping

in that period of time, take your machine to your authorized dealer where

they can safely check and service yo ur machine.

Protect Children

• Death or se rious injury ca n

occur when young children

associate having fun with a lawn

mowing machine simply because

someone has given them a ride

on a machine.

• Children are attracted to lawn mowing machines and mowing act ivities.

They don’t understand the dangers of rotating blades or the fact that the

operator is unaware of their presence.

• Children who have been given rides in the past may su ddenly appear in

the mo wing area for another ride and be run over or backed over by the

machine.

• Tragic accidents with children can occur if the operator is not alert to the

presence of children, especially when a child approaches a machine from

behind . B efore and while ba cking up, stop mo we r blades and look down

and behind the machine carefully, especially for children.

• Never carry children on a machine or attachment, even with the blades

off. Do no t t ow c hi ldr en in a cart or t r a ile r. They ca n f al l of f an d b e s er ious ly

injured or interfere with safe machine operation.

• Never use the machine as a recreational vehicle or to entertain children.

• Never allow chil dr e n or an untraine d pe r so n op er a te the machin e.

Instruct all operat ors not to give children a ride on the machine or in an

attachment.

• Ke ep chi l dr en in do or s , out of the mo w ing ar ea , and in t he wat ch ful e y e of

a responsible adult, other than the operator, when a mower is being

operated.

• Stay alert to the presence of children. Never assume that children will

remain where you last saw them. Turn the machine off if a child enters the

work area.

• Use ex treme care when approaching b lind corners, shrubs, trees, or

other objects that may block your view of a child.

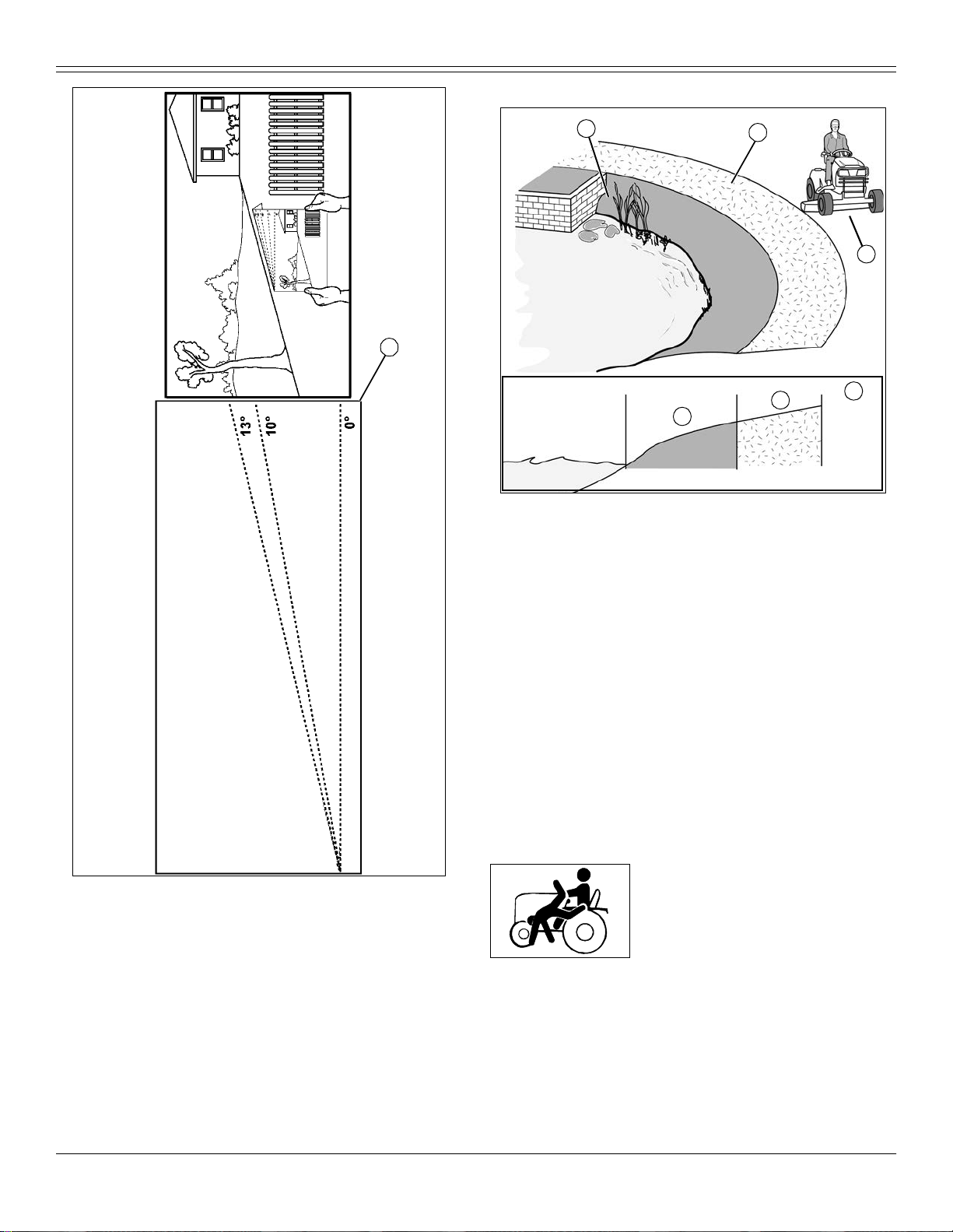

Operating on Slopes

NOTE: Make a photocopy of this page and cut out angle chart (A) to

use for measuring slope angle.

• Slopes ar e a maj or factor relate d t o l oss -of -co nt rol an d t ipo v er ac cide nt s ,

which can result in severe injury or death. Operation on all slopes requires

extra caution.

Identify Slopes for Safe Operation

• Follow safe procedures for operation on slopes. Measure slopes of all

moving sites to determine which slopes are safe for mowing with a ride-on

mower. Always use common sense and good judgement when performing

this survey.

Measuring Slopes

• Sugges ted Method 1: Lay a straight piece of sturdy lumber 1.2 m (4 ft)

long on the slope and measu re the angle of the slope with an angle

indica tor or protract or level.

• Suggested Method 2: Refer to the slope gauge provided with this

manual.

Operate Safely on Slopes

• Exceeding the recommended maximum slope angle increases the risk of

rollover accidents that can result in serious injury or death.

• Nev er mow or operate ride-on mower on slope angles greater than 13°

with the lawn ride-on mower in its basic configuration. The basic

configuration is the ride-on mower with mower deck and not other

attachments. (A 13° slope is a slope tha t rises 1.4 m (4.6 ft) over a

horizontal distance of 6.1 m (20 ft).)

• When us in g att a c hm en ts, never mow or operate the rid e -o n mow e r on

slope ang le s grea t e r th an 10° . Th e ad di tio n of a weather enc lo su re,

material collection system, or other attachments will increase the risk of a

rollover. (A 10° slope is a slop e that rises 1 m (3.5 ft) over a horizontal

distance of 6.1 m (20 ft).)

• On slope angles of 10° or less, the risk of rollover is low, but as the slope

angle increases to the recommended maxim um, the risk increases to a

medium level.

• Always consider potential turf conditions and slope angles when

determining the risk of loss-of-control and tip-ov er accidents.

• Drive slowly when mowing or operating on slopes.

• If you feel uneasy on a hillside, do not mow or operate on it.

• Mow up and down slopes, not across.

• Watch for holes, ruts, bumps, rocks, or other hidden objects. Uneven

terrain could overturn the ride-on mower. Tall grass can hide obstacles.

• Drive slowly so you will not have to stop while on a slope.

• Do not mow on wet grass. Tires may lose traction. Tires may slip on

slopes even though the brakes are func tioning properly.

• Avoid starting, stopping or turning on a slope. If the tires lose traction,

diseng age the PTO and proceed slowly, straight down the slope.

• Keep all movement on slopes slow and gradual. Do not make sudden

changes in spee d or dir e ctio n, whi ch co ul d caus e t he ride - on mo w er to r ol l

over.

Safe ty - 10

Page 12

SAFETY

Operating Near Hazards

A

A

A

Picture Note: Example side view of slope and hazards, showing

areas (A), (B), and (C).

• Do not mow or operate ma chine in areas adjacent to haza r d s that may

cause the machine to roll over. The machine could suddenly lose traction,

slide, and/or roll over if a wheel goes over the edge or if the edge breaks

away.

• Hazards (A) include but are not limited to:

• Drop-offs, ditches, embankments, or bodies of water.

• Areas of unsafe slope, soft ground, edges along bodies of water, or

area with holes, ruts, bumps, or other hidden objects.

• Maint ain a buffer area (B) at least as wid e as the machine between

hazards ( A) an d the mo win g a rea (C) . D o not mo w or o per ate th e ma ch ine

in the hazard area or buffer area.

• Only mow or operate the machine in the mowing area (C). Do not exceed

the recommended slope operating angle. Refer to the "Operate Safely on

Slopes" section.

• Use a walk-behind mower or string trimmer in and around areas (A) and

(B).

B

C

B

C

MX51888

MX51667

Keep Riders Off

• Only allo w the op er ator on the mach ine . Ke ep

riders off.

• Riders on the machine or attachment may be

struck by foreign objects or thrown off the

mach in e ca us in g seriou s in jury.

• Riders obstruct the operator’s view resulting in the machine being

operated in an unsafe manne r.

Tow ing Loads S afely

• Stopping distance increases with speed and weight of towed load. Travel

slowly and allow extra time and distance to stop.

• T otal towed weight must not exceed combined weight of pulling machine,

ballas t an d o pe rat o r . Use co un ter we ig ht s or whe el we ig ht s as de scr ibed i n

Safe ty - 11

Page 13

SAFETY

the attachment or pulling machine operator’s manual.

• Excessive towed load can cause loss of traction an d loss of control on

slopes. Reduce towed weight when operating on slopes.

• Never allow children or others in or on tow ed equipment.

• Use on ly approved hitches. Tow only with a machine that has a hitch

designed for towing. Do not attach towed equipment except at the

approved hi t ch poi nt.

• Follow the manufacturer’s recommendations for weight limits for towed

equipment and towing on slopes.

• Towed attachments will increase the risk of rollover. Refer to the

“Operating on Slopes” section for more information.

• Do not turn sharply. Use additional caution when turning or operating

under adverse surface conditions. Use care when reversing.

• Do not shift to neutral and coast downhill.

Wear Appropriate Clothing

• Always wear eye protection when operating

the machine.

• Wear close fitting cl oth in g and safety

equipment appropriate for the job.

• Whil e oper a tin g t hi s mac hi ne, al ways wear subs ta nti al f oot we ar an d l ong

trousers. Do not ope rate the equipment when barefoot or wearing open

sandals.

• Wea r a suitable protective device such as earplugs. Loud noise can

cause impairment or loss of hearing.

Driving Safely on Public Roads

Avoid personal injury or death resulting from a

collision with another vehicle on public roads:

• Use safety lights and devices. S low moving

machin es when driven on public roads are

hard to see, especially at night.

• Whenever driving on public roads, use flashing warning lights and turn

signals according to local regulations. Extra flashing warning lights may

need to be installed.

Practice Safe Maintenance

• Only qualified, trained adults should service

this machine. Understand service procedure

before doing work.

• Never operate machine in a closed area

where dangerous carbon monox ide fumes can collect.

• Keep all nuts and bolts tight, especially blade attachment bolts, to be

sure the equipment is in safe working condition.

• Never tamper wit h safety devices. Check their proper operation r egularly.

• Keep machine free of grass, leaves or other debris build-up. Clean up oil

or fuel spillage and remove any fuel-soaked debris. Allow the machine to

cool before storing.

• If you strike a foreign object, stop and inspect the machine. Repair, if

necessary, before restarting.

• Never make any adjustments or repairs with the engine running. Wait for

all mo vement to stop on machine bef ore adjusting, cleaning or r epairing.

• Check grasscatcher components and the discharge guard frequently and

replace with manuf acturer’s recommended parts, when necessary.

Grass ca tche r co mpo nent s ar e subjec t to wea r , dam ag e , and de te rioration

which could expose moving parts or allow objects to be thrown.

• Mower blades are sharp. Wrap the blade or wear gloves, and use extra

care when servicing them. Only replace blades. Never straighten or weld

them.

• Chec k brake operation frequently. Adjust and servic e as required.

• Maintain or replace safety and instruction labels, as necessary.

• On multi-bladed machines, take care as rotating one blade can cause

other blades to rotate.

• Keep hands, feet, clothing, jewelry, and long hair away from any moving

parts, to prevent them from getting caught.

• Lower any attachments to the ground before cleaning or servicing

machine. Disengage all power and stop th e engine. Lock park brake and

remove the key. Let machine cool.

• Securely support any machine elements that must be raised for service

work. Use jack stands or lock service latches to support components

when needed.

• Disconnect battery or remove spark plug wire (for gasoline engines)

before making any repairs. Disconnect negative terminal first and positive

last. Install positive terminal first and negative last.

• Before servicing machine or attachment, carefully release pressure from

any components with stored energy, such as hydraulic components or

springs.

• Keep all parts in good condition and properly installed. Fix damage

immediately. Replace wo rn or broken parts.

• Charge batteri es i n an op en , we ll-ventila te d area, away from sparks.

Unplug battery charger be fore connecting or disconnecting from the

battery. Wear protectiv e clothing and u s e insulated tools.

• Do not str ike the flywheel with a hammer or hard object be cause the

flywheel may later shatter during operation.

• If equipped with hydraulic lift - release hydraulic pressure by lowering

attachment or cutting units to the ground or to a mechanical stop and

move hydraulic control levers back and forth.

Avoid High Pressure Fluids

• Hydraulic hoses and lines can fail due to

physi cal damage, kinks, age, and exposure.

Check hoses and lines regularly. Replace

damaged hoses and line s.

• Hydraulic fluid connections can loosen due to physical damage and

vibration. Check connections regularly. Tighten loose connections.

• Escaping fluid under pr essure can penetrate the skin causing serious

injury. Avoid the hazard by relieving pressure before disconne cting

hydraulic or other lines. Tighten all connections before applying pressure.

• Search for leaks with a piece of cardboard. Protect hands a nd body from

high pressure fluids.

• If an accident occurs, see a doctor immediately. Any fluid injected into

the skin must be surgically removed within a few hours or gangrene may

result. Doctors unfamiliar with this type of injury s hould refere nce a

knowled g ea ble me dical sourc e. S uc h inform a tion is available from D ee r e

& Company Medical Department in Moline, Illinois, U.S.A. Information may

be obta ined in the United States and Canada only by calling 1-800-822-

8262.

Safe ty - 12

Page 14

SAFETY

Prevent Fires

• Besides routine maintenance, one of the best

ways to keep your John Deere equipment

running efficiently and to reduce fire risk is to

regularly remove debris buildup from the

machine.

• Please review these recommendations with all

operators. See your John Deere dealer with

questions.

• Always follow all safety procedures posted on the machine and in this

operator manual. Before carrying out any inspection or cleaning, always

shut off engine, set parking brak e and remove ignition key.

• After op era ti n g, all o w mac hi ne to coo l in an ope n ar ea be fore cleanin g or

storing. Do not park machine near flammable materials such as wood,

cloth or chemicals.

• Empty any grasscatcher bags or containers completely before storing.

• Frequency of thes e inspect i on s an d cleanin g will vary de pe nd ing on a

number of factors incl ud in g operatin g co nd it i on s, ma chine configurat ion,

operating speeds and weather con ditions particularly dry, hot and windy

conditions. When you are operating in these conditions, inspect and cl ean

these areas frequently throughout the day.

• Wind direction, terrain type and moisture content of surrounding

vegetation can effect where and how much debris accumulates.

• Debris can accumulate anywhere on the machine, especially on

horizontal surfaces.

• Ke eping engine ar ea clean will provide the greatest impact on fire

prevention. Other are as re qu iring reg ul ar ins p ec t io n an d cl eaning include

behind wheel rims, wire harness, hose/line routings, mowing attachments,

etc. Compressed air, leaf blowers or high pressured water can assist

keeping these areas clean.

• Excess lubrication or fuel/oil leaks or spills on the machine can also

serve as collection sites for debris. Prompt machine repair and oil/fuel

cleanup will minimize the potential for debris collection and reduced

cooling throughout machine life.

• Bearing failures or overheating can result in a fire. To reduc e this risk,

always follow the instructions in the machine operator’s manual regarding

lubrication intervals and locations. Washing the machine while warm may

also reduce bearing life and increase potential for premature bearing

failure.

• Always shut off fuel when storing or transpo rting machine, if the machine

has a fuel sh utoff.

Handling Fuel Safely

To avoid personal injury or property

dama ge, use extre me care in handling fuel.

Fuel is extremely flam m able and fue l

vapors are explosive:

• Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

• Use only an approved fuel co nt ainer. Use

only non-metal, portable fuel containers

approved by the Underwriter’s Laboratory

(U.L.) or the American Society for Testing &

Materials (ASTM). If using a funnel, make sure

it is plastic and has no screen or filter.

• Never remove the fuel tank cap or add fuel with the engine running. Allow

engine to cool before refueling.

• Never add fuel to or drain fuel from the machine indoors. Move machine

outdoo rs and provid e adequate ventilation.

• Clean up spilled fuel immediately. If fuel is spilled on clothing, change

clothing immediately. If fuel is spilled near machine, do not attempt to start

the engine but move the machine away from the area of spillage. Avoid

creating any source of ignition until fuel vapors have dissipated.

• Nev er store the machine or fuel container where there is an open flame ,

spark, or pilot light such as on a water heater or other appliance.

• Prevent fire and explosion caused by static electric di scharge. Static

electric discharge can ignite fuel v apors in an ung rounded fuel c ontainer.

• Nev er fill containers inside a vehicle or on a truck or tra iler bed with a

plasti c liner. Always place containers on the ground away from your

vehicle before fueling.

• Remove fuel-powered equipment from the truck or trailer and refuel it on

the ground. If this is not possible, then refuel such equipment with a

portable container, rather than from a fuel dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel tank or container

opening at all times until the fuel ing is complete. Do not use a nozzle lockopen devi ce.

• Never overfill fuel tank. Replace fuel tank cap and tighten securely.

• Replace all fuel container caps securely after use.

• For gasoline engines, do not use gas with methanol. Methanol is harmful

to your health and to the en vi ronment .

Tire Safety

Explos ive separation of a tire and rim parts

can cause serious injury or death:

• Do not attempt to mount a tire without the

proper equipment and experience to perform

the job.

• Always maintain the correct tire pressure. Do not inflate the tires above

the recommended pressure. Never weld or heat a wheel and tire

assembly. The heat can cause an increase in air pressure resulting in a

tire explosion. Welding can structurally weaken or deform the wheel.

• When i nfl at i ng ti r es, u se a cl i p-o n c huc k an d e xt e nsi on hose l on g e noug h

to allow you to stand to one side and NOT in front of or over the tire

assembly.

• Check tires for low pressure, cuts, bubbles, damaged rims or missing lug

bolts and nuts.

Checking Wheel Hardware

• A serious accident could occur causing serious injury if wheel hardware

is not tight.

• Check wheel hardware tightness often during the first 100 hours of

operation.

• Wheel hardware must be tightened to specified torque using the proper

procedure anytime i t is loosened.

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries,

can harm the environment and people:

• Do not use beverage containers for waste fluids - someone may drink

from them.

• See your local Recycling Center or authorized dealer to learn how to

recycle or get rid of waste products.

• A Material Safety Data Sheet (MSDS) provides specific details on

chemical products: physical and health hazards, safety procedures, and

Safe ty - 13

Page 15

MAC HINE CLEANOUT

emergency response techniques. The seller of the chemical products

used with you r mac h in e is res ponsible for prov iding the MSDS for that

product.

A

Machine Cleanout

Prevent Fires

• Besides routine maintenance, one of the best ways to keep your John

Deere equipment running efficiently and to reduce fire risk is to regularly

remove debris buildup from the machine.

• Please review these recommendations with all operators. See your John

Deere de al er wit h que st ions.

• Always follow all safety procedures posted on the machine and in this

operator manual. Before carrying out any inspection or cleaning, always

shut off engine, set parking brak e and remove ignition key.

• After op era ti n g, all o w mac hi ne to coo l in an ope n ar ea be fore cleanin g or

storing. Do not park machine near flammable materials such as wood,

cloth or chemicals.

• Empty any grasscatcher bags or containers completely before storing.

• Frequency of thes e inspect i on s an d cleanin g will vary de pe nd ing on a

number of factors incl ud in g operatin g co nd it i on s, ma chine configurat ion,

operating speeds and weather con ditions particularly dry, hot and windy

conditions. When you are operating in these conditions, inspect and cl ean

these areas frequently throughout the day.

• Wind direction, terrain type and moisture content of surrounding

vegetation can effect where and how much debris accumulates.

• Debris can accumulate anywhere on the machine, especially on

horizontal surfaces.

• Ke eping engine ar ea clean will provide the greatest impact on fire

prevention. Other are as re qu iring reg ul ar ins p ec t io n an d cl eaning include

behind wheel rims, wire harness, hose/line routings, mowing attachments,

etc. Compressed air, leaf blowers or high pressured water can assist

keeping these areas clean.

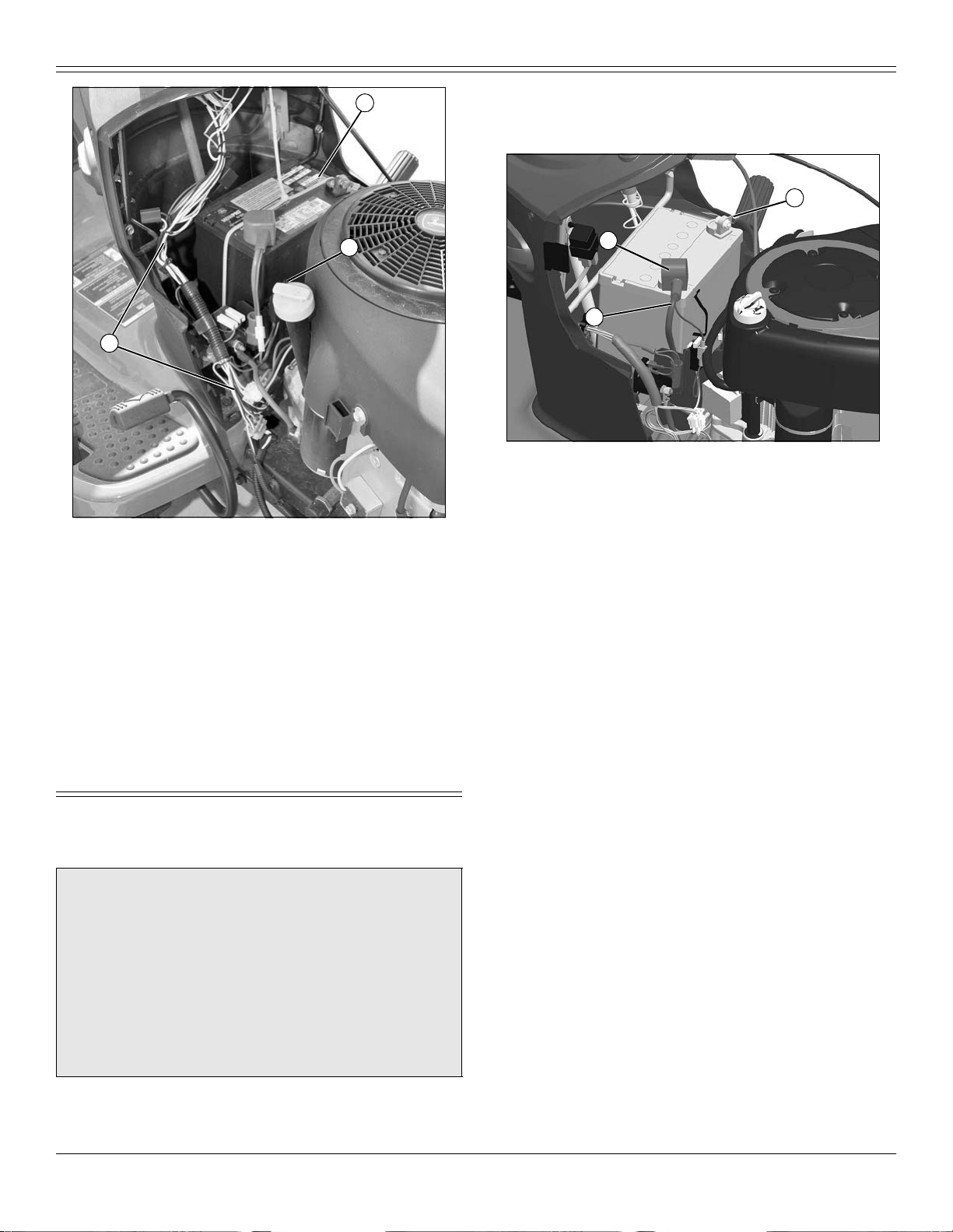

• Primary area s th at mu st be in s pe ct ed an d cl ea ne d on the mach in e

include (See Safety Label Section):

B

D

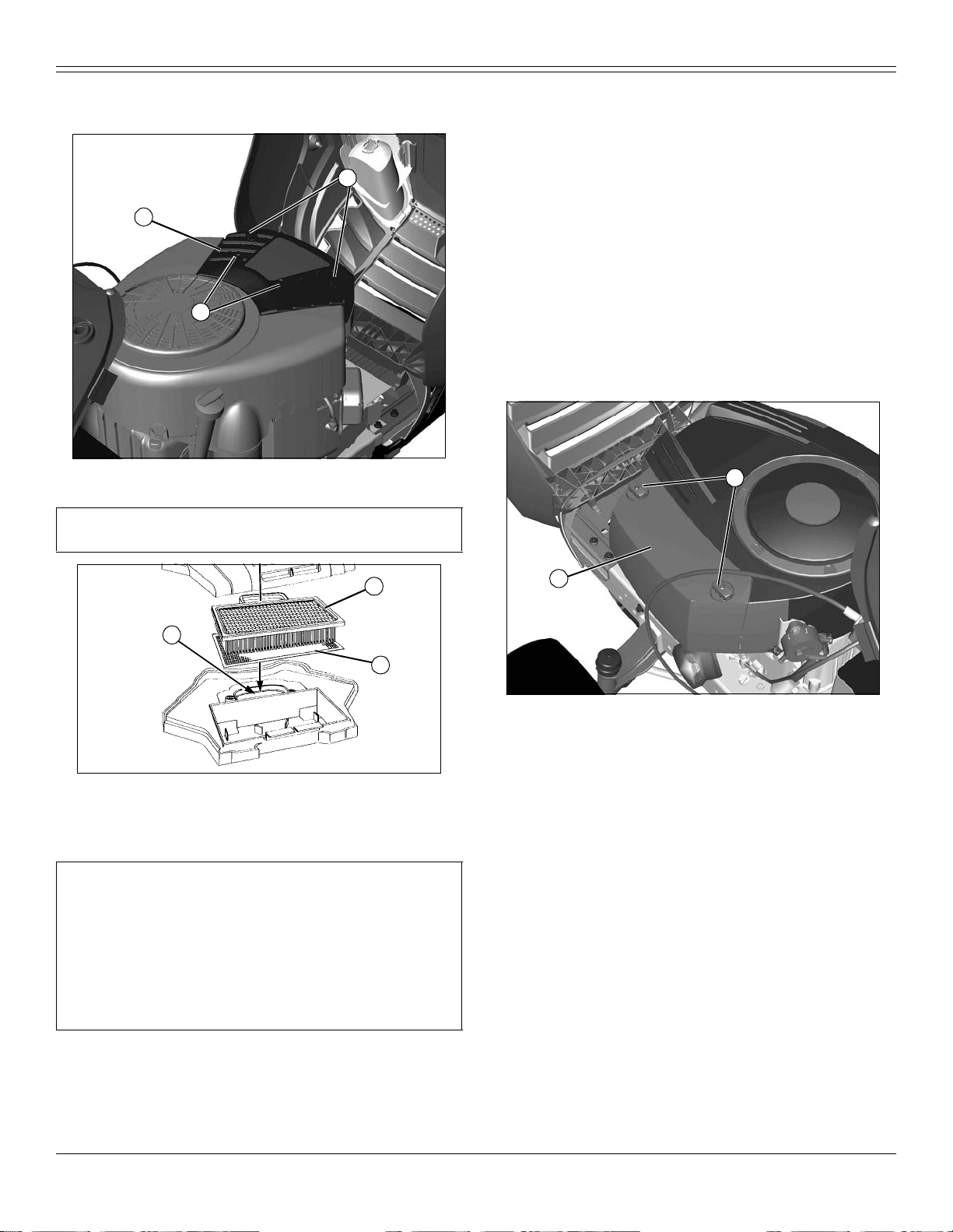

Picture Note: Single cylinder shown.

A

B

D

Picture Note: Twin cylinder shown.

a.Exhaust manifold (A), muffler pipe (B), muffler (C) and muffler shield

(D).

C

MX48341

A

B

C

MX48340

Machine Cleanout - 14

Page 16

MAC HINE CLEANOUT

Picture Note: Single cylinder shown.

E

G

F

c.Top of mower d eck, under shields (G), including spindle (H) and belt

areas.

MX49847

E

H

MX49849

F

MX49848

Picture Note: Twin cylinder shown.

b.Engine intake screens (E), cooling fins (F), and oil cooler (if equipped).

I

J

MX38694

Picture Note: Shown with wheel removed.

d.On or near transmission (I) and driveline (J).

Machine Cleanout - 15

Page 17

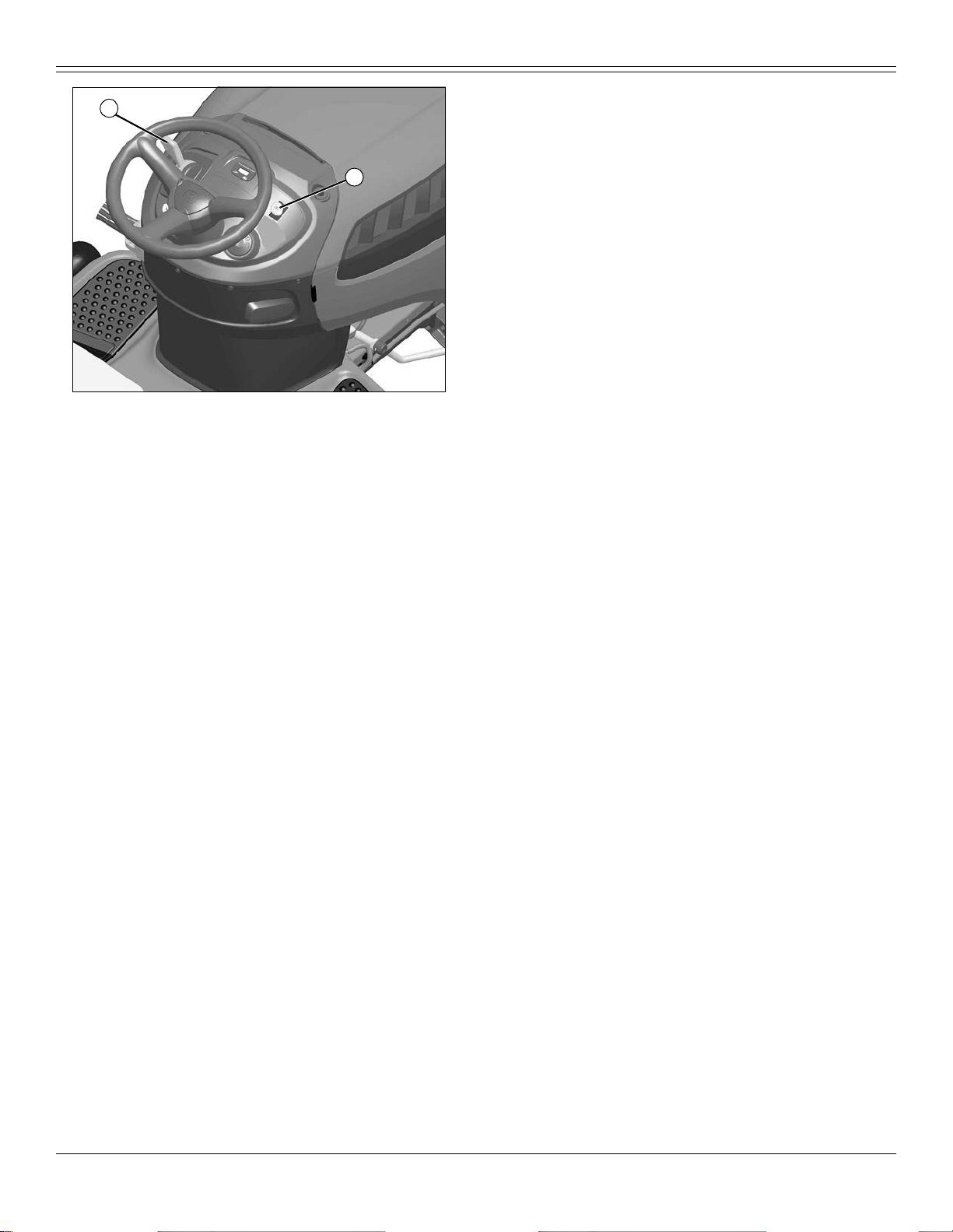

ASSEMBLY

L

K

M

MX49850

e.Under left side panel near fuse block (K), and all wiring, including the

battery (L) and related wiring harnesses (M).

• Excess lubrication or fuel/oil leaks or spills on the machine can also

serve as collection sites for debris. Prompt machine repair and oil/fuel

cleanup will minimize the potential for debris collection and reduced

cooling throughout machine life.

• Bearing failures or overheating can result in a fire. To reduc e this risk,

always follow the instructions in the machine operator’s manual regarding

lubrication intervals and locations. Washing the machine while warm may

also reduce bearing life and increase potential for premature bearing

failure.

• Always shut off fuel when storing or transpo rting machine, if the machine

has a fuel sh utoff.

battery terminal.

3. Charge the battery.

• Battery is fully charged at 12.6 volts.

B

C

A

MX46480

4. Connect positive (+) battery cable (A) to battery.

5. Connect negative (–) battery cable (B).

6. Apply general purpose grease or silicone spray to t erminal to help

prevent corrosion.

7. Slide red cover (C) over positive battery cable.

Check Tire Pressure

Check tire pressure. (See Checking Tire Pressure in the SERVICE

MISCELLANEOUS section.)

Adjust Mower Deck Level

Adjust mower deck level. (See Adjusting Mower Level in the OPERATING

section.)

Check Engine Oil Level

Check engine oil level. (See Checking Engine Oil Level in the SERVICE

ENGINE secti on.)

Assembly

Charge and Connect Battery

c CAUTION: Avoid injury! The battery produces a flammable

and explosive gas. The battery may explode:

• Do not smoke or have open flame near battery.

• Wear eye protection and gloves.

• Never check battery charge by placing a metal object across

the posts. Use a voltmete r or hydrome ter.

• Do not jump start or charge a frozen battery. Warm battery to

16°C (60°F).

1. Remove and discard the tie strap from the positive (+) battery terminal.

2. Remove and discard the black protective cap from the negative (–)

Assembly - 16

Check Machine Safety System

Perform safety system check to make sure the electronic safety interlock

circuit is functioning properly. Perform all tests. (See Testing Safety

System in t he OPERATING section.)

Break In Electric Engagement Clutch (If Equipped)

1. Start engine and move ma chine to flat level surface.

Page 18

ASSEMBLY

A

B

MX49386

2. Push throttle lever (A) up to full thro tt le po sitio n.

3. Engage attachment engagement switch (B) and allow mower to run for

10 seconds.

4. Disengage attachment engagement switch and wait 10 seconds.

5. Repeat steps 3 and 4 for 12-15 cycles.

NOTE: Clutch is now properly burnished.

Assembly - 17

Page 19

Operating Controls

A

L

OPERATING CONTROLS

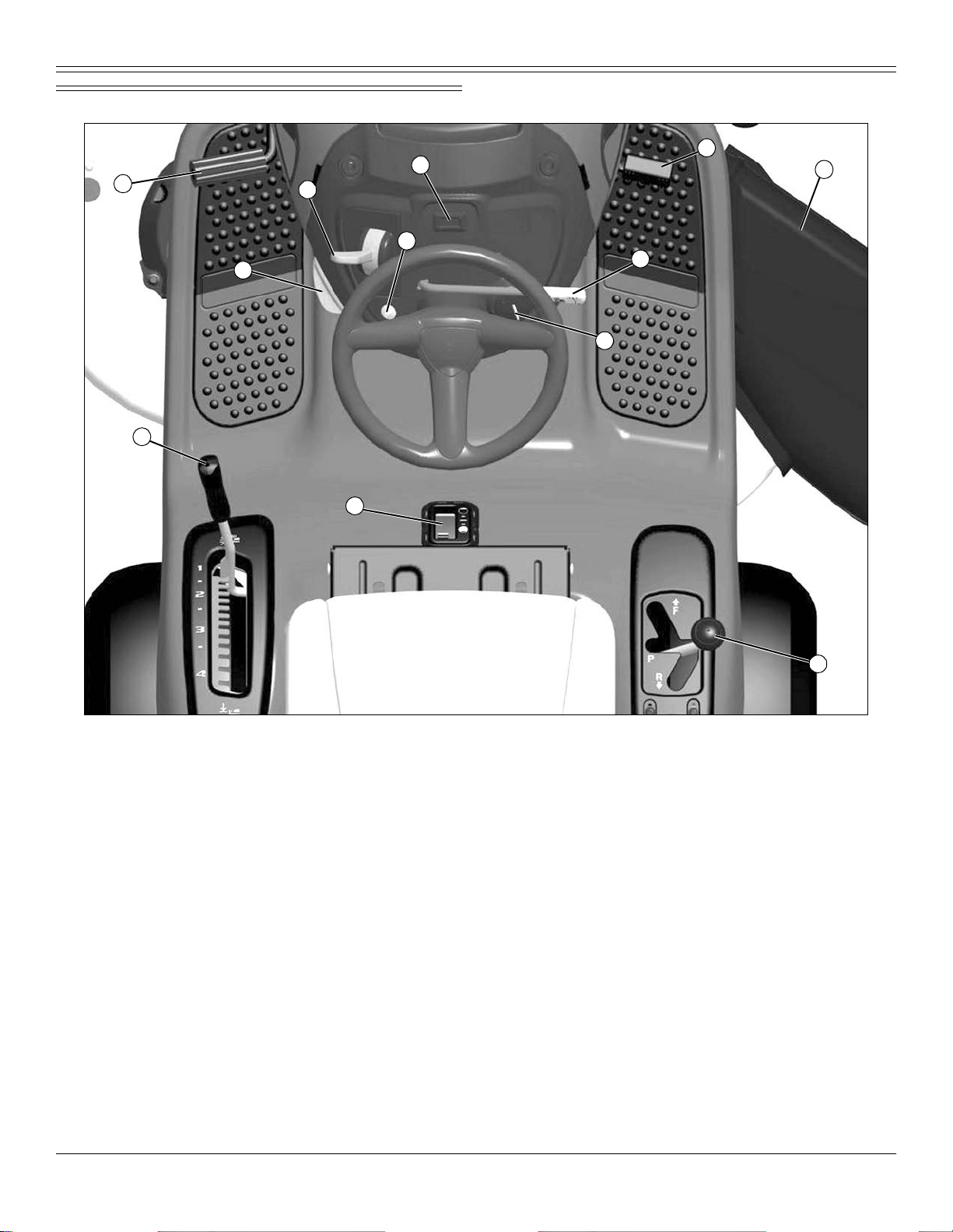

Operator Station Controls (D105)

H

E

C

D

B

G

F

I

ABrake Pedal

B Park Brake Lo ck Lever

C Throttle/Choke Lever

D Reverse Implement Option (RIO) Switch

E Service Reminder/Hourmeter

FKey Switch

G Attachment Engagement Lever

H Motio n Pedal

I Deflector Shield

J Transmissi on Shift Lever

K Fuel Level Window

L Attachment Lift Lever

K

J

MX51677

Operating Controls - 18

Page 20

OPERATING CONTROLS

Operator Station Controls (D110, D120, D130)

C

D

I

A

B

L

M

H

G

J

K

F

E

ABrake Pedal

B Park Brake Lock Lev er

C Throttle/Choke Lever

D Service Reminder/Hourmeter

EKey Switch

F Cruise Control Lever (D120 and D 130)

G Attachm e nt Eng ag em ent Lever

H Rev erse Implement Option (RIO) Switch

I Forward Travel Pedal

J Rev erse Travel Pedal

K Deflector Shield

L Fuel Level Window

M Att ac hm e nt Lift Lever

MX49390

Operating Controls - 19

Page 21

OPERATING CONTROLS

Operator Station Controls (D140, D160, D170)

D

A

B

C

G

E

L

H

F

I

J

K

M

ABrake Pedal

B Park Brake Lock Lever

C Throttle/Choke Lever

D Service Reminder/Hourmeter

EKey Switch

F Cruise Control Lever

G Reverse Implement Option (RIO) Switch

H Attach ment Engagement Switch

I Forward Travel Pedal

J Reverse Travel Pedal

K Deflector Shield

L Fuel Level Window

M Attachment Lift Lever

MX49389

Operating Controls - 20

Page 22

OPERATING

Operating

Daily Operating Checklist

❏ Test saf ety systems.

❏ Check tire pressure.

IMPORTANT: Avoid damage! Usin g stale, contaminated or

improper fuel can result in engine and fuel system damage.

Repairs caused by stale, contaminated or improper fuel are not

covered by warranty.

❏ Chec k fu el le vel. (See SER V IC E MISCE LLA NE OUS se ct ion, Us ing

Proper Fuel and Stabilizer)

4. Release seat adjustment lever to lock in position.

Lumbar Seat Adjustment (D160, D170)

• Turn lumbar seat adjustment dials (B) on either side of seat to adjust

firmness of seat.

Adjusting Cutting Height

Cutting height can be adjusted from approximately 25 - 100 mm (1 - 4 in.)

in 6.4 mm (1/4 in.) increments. When mower deck is in transport position,

cuttin g he ight is app roxim a tely 100 mm (4 in.) .

Detents allow the adjustment lever to be positioned at each indicated

mower s etting, as wel l as the mid-point between each s etting.

Mower Setting Approximate Cutti ng H eig ht

1 25 mm (1 in.)

❏ Check engine oil level.

❏ Remove grass and debris from engine compartment and muffler

area, and on top of mower deck, before and after operating machine.

❏ Clea n air intake screen.

❏ Check area below machine for leaks.

Avoid Damage to Plastic and Painted Surfaces

• Do not wipe pl astic parts unless rinsed first. Using a dry cloth may cause

scratches.

• Insect repellent spray may damage plastic and painted surfaces. Do not

spray insect repel lent near machine.

• Be careful not to spill fuel on machine. Fuel may damage surface. Wipe

up spille d fu el im m ed ia t el y.

• Prolonged exposu re to sunlight w ill damage hood s urfaces.

Adjusting Seat

1. Sit in seat.

B

A

– 38 mm (1 1/2 in.)

2 50 mm (2 in.)

– 65 mm (2 1/2 in.)

3 75 mm (3 in.)

– 90 mm (3 1/2 in.)

4 (Transport) 100 mm (4 in.)

1. Put attachment lift lever into the slot adjacent to desired cutting height.

2. Adjust mower deck wheels.

Transporting or Getting On and Off Machine

• Pull attachment lift lever all the way back to transport position or 100 mm

(4 in.) cutting height.

Checking and Adjusting Mower Deck Level

c CAUTION: Avoid injury! Rotating blades are dangerous.

Before adjusting or servicing mower:

• Disconnect spark plug wire(s) or battery negative (-) cable to

prevent engine from starting accidently.

• Always wear gloves when handling mower blades or working

near bl ades.

NOTE: Mower deck wheels should not contact the ground when

leveling the mower deck.

Method One

1. Make sure machine is on a flat, level surface.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

3. Check that tires are inflated to correct tire pressure. Tire pressure is

marked on the side of the tire.

MX46483

2. Lift up on seat adjustment lever (A) on right side of seat.

3. Lean forward and slide seat forward or rearward to desired position. Do

not lean back on top of seat to push rearward.

Operating - 21

Page 23

OPERATING

A

A

A

M17687a

Picture Note: 107 cm (42 in.) mower deck shown

4. Place three short 51 mm (2 in.) blocks of wood under the edges (A) of

the mower deck.

5. Lower mower deck to the 65 mm (2.5 in.) cutting height position.

6. Check that the mower deck is level and lightly touching each of the

three wooden blocks.

C

MX51678

Picture Note: 107 cm (42 in.) mower deck shown

• If the front of the mower deck is not lightly touching the front block,

adjust the front draft arm by turning the nut (C).

7. Raise the cutting height to the next highe st position and remove the

three wooden blocks.

8. Turn the nut (C) on the front draft arm counterclockwise 1-2 full turns so

that the front of the deck is 3-6 mm (1/8-1/4 in.) lower than the rear. This

adjustment prevents “double cutting,” which wastes horsepower and

causes brown gras s tip s.

B

C

MX16561

• If the rear of the mower deck is not touching the rear blocks, or is

sitting heavily on the blocks, adjust the rear lift links by turning the

leveling nut (B) on each lift link. The blocks should be able to easily slide

in and out beneath the mo wer deck when the mower deck is correctly

adjusted.

Method Two

NOTE: An optional mower deck leveling gauge (AM130907) is

available from your John Deere dealer. It allows for precision mower

deck leveling by measuring mower deck level at the blade tips.

1. Make sure machine is on a flat, level surface.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

3. Inflate tires to the correct pressure.

4. Move mower lift handle to preferred cutting height.

5. Measu re mower deck level (side-to-side).

B

A

MX4871

Picture Note: A convenient leveling gauge (A) (AM130907) is

available from your dealer.

a.Position mower blades as follows and me asure from each outside

blade tip (B) to the level surface.

Operating - 22

Page 24

OPERATING

C

b.Turn left b l ad e (C) a s s ho w n. H o ld drive belt and turn ri ght b la de (D ) as

shown. Take measurement for both blades.

The difference between blade measurements must not be more than 3

mm (1/8 in.).

E

c.Adjust mower deck le vel, if necessary, by turning rear nuts (E)

clockwise to raise the side of the mow er deck, or counterclockwise to

lower the mower deck.

6. Measure mower level (front-to-rear).

D

MX4896

MX16561

G

MX51678

Picture Note: 107 cm (42 in.) mower deck shown

c.Adjust mower deck level, if necessary, by turning the nut (G)

counterc lockw i se to lower the fro nt of deck or cl ockwis e to rais e front of

deck.

Adjusting Mower Deck Wheels

IMPORTANT: Avoid damage! The mower deck can be damaged if

mower wheels are adjusted wrong:

• Wheels must not ride on ground supporting mower weight.

• Check wheel adjustment each time cutting height is changed.

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Inflate tires to the correct pressure.

3. Lower mower dec k to the desired mowing position.

NOTE: Bottom of wheels should be approximately 3-13 mm (1/8-1/2

in.) from the ground.

A

B

F

MX4896a

a.Turn right blade (F) so blade tip points straight forward.

b.Measure from blade t ip to the surface. Take measurement for both

blades.

The front blade tip must be 3–6 mm (1/8 -1/4 in.) lower than rear blade

tip.

Operating - 23

MX10509a

4. Check each mower wheel position. Remove nut (A) and bolt (B), and

move mower wheel to proper hole.

Page 25

A

B

C

D

A- 38 mm (1.5-In.)

B- 51 mm (2-In.)

C- 64 mm (2.5-In.)

D- 76 mm (3-In.) and above

OPERATING

3. Unlock the park brake.

4. Try to start engine.

Result: Engine must not start. If engine starts, there is a problem with

your safety interlock circuit.

Testing Park Brake

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

2. Lock the park brake.

3. Put transmission in park. Engage bypass ro d located at rear of

machine.

4. Try to push machine manually.

MIF

Result: Park brake must prevent machine from moving. If machine moves,

parking brake needs to be adjusted.

Testing Attachment Engagement Switch or Lever

5. Install bolts and nuts to lock wheels in position. Tighten nuts to 34 N•m

(25 lb-ft).

Testin g Safety Systems

c CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Do not run an engine in an enclosed area, such as a garage, even

with doors or windows open ed.

Move the machine to an outsid e area before r unn ing the engi ne .

The safety systems installed on your machine should be checked before

each machine use. Be su re you have read the machine operator manu al

and are completely familiar with the operation of the machine before

performing these safety system checks.

Use the following checkout procedures to check for normal operation of

machine.

If there is a malfunction during one of these procedures, do not operate

machine. See your authorized dealer for service.

Perform these tests in a clear open area. Keep bystanders a way.

Testin g Park Brake Switch

1. Park machine safely . (See Parking Safely in the SAFETY Section.)

2. Sit on seat.

c CAUTION: Avoid injury! The mower blades should stop in

approximately five seconds when the mower or PTO is

disengaged.

If you believe that your blades may not be stopping in that period

of time, take your machine to your authorized dealer where they

can safely check and service your machine.

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

2. Sit on seat.

3. Lock the park brake.

4. Engage mower:

• On models with electric attachment engagement switch, pull switch

up.

• On models wi th mechanical attachment en gagement le ver, pu sh lever

forward.

5. Try to start engine.

Result: Engine must not start. If engine starts, there is a problem with

your safety interlock circuit.

Te sting Seat Switch

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

2. First test:

a.Start engi ne.

b.Move throttle lever up to maximum engine speed.

c.Unlock park brake.

d.Engage mower .

e.Raise up off seat. Do not get off machine.

Result: Engine and mower blades should stop. If engine and mower

blades do not stop, there is a problem with your safety interlock circuit.

3. Second test:

a.Lock pa r k brake.

b.Disengage mower.

c. St a rt engi ne.

d.Unlock park brake.

Operating - 24

Page 26

OPERATING

e.Rais e up off seat. D o no t get off machine.

Result: Engine should stop . If engine does not stop, there is a problem

with your safety interlock circuit.

4. Third test:

a.Di se ng ag e mow e r.

b.Start en gine.

c.Lock park brake.

d.Rais e up off seat. D o no t get off machine.

Result: Engine should continue to run. If engine stops, there is a problem

with your safety interlock circuit.

Testi ng Reverse Implement Option (RIO)

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Start engine.

3. Engage attachment engagement switch or lever to start attachment.

c CAUTION: Avoid injury! Rotating blades are dangerous.

Children or bystanders may be injured by runover and rotating

blades.

Before backing up, carefully check the area around the machine.

4. Look behind the vehicle to be sure there are no bystanders.

5. Begin reverse travel by depressing reverse pedal for hydrostatic

transmissio n or mov in g auto ma tic sh ift lever to R (reverse) posi tio n for

automatic transmission and depressing pedal.

Result: Attachment and engine should stop operation. If attachment or

engine continues to operate as machine begins travel in reverse, do not

continu e to operate ma c hine.

Using the Park Brake

Using the Hourmeter and Service Reminder

A

D

B

• The hou rmeter (A) shows the number of hours the engine has run. The

service reminder will indicate that a g eneral lubrication (B) or mow er/

engine (C) service interval has been reached. When service is required,

the service “SVC” arrows (D) will periodically flash for two hours. Follow

the service timetable on the maintenance schedule located under the

seat. For specific service procedures, see the Servi ce section of this

manual.

• Hourmeter cannot be reset.

• The hourmeter display will always be on.

• The decimal point will flash while the hourmeter is accumulating time.

D

C

MX49388

Using Key Switch and Headlights

B

C

c CAUTION: Avoid injury! Children or bystanders may

attempt to move or operate an unattended machine.

Always lock the park brake and remove the key before leaving the

machine unattended.

Locking park brake:

1. Push and hold brake pedal down.

2. Pull park brake lever up to lock park brake.

3. Release brake pedal. Pedal should stay down and park brake lever

should stay locked.

Unlocking pa rk brake:

1. Push and hold brake pedal down.

2. Push park brake lever down to unlock park brake.

3. Release brake p edal.

Operating - 25

A

D

M94336a

A- STOP Position

B- Headlights On Position

C- Run Position

D- Start Position

Engine Off

NOTE: Headlights will drain the battery rapidly if key switch is left in

headlights on position (B) with the engine off.

• To turn headlights on, turn key switch to headlights on position (B).

• To turn headlights off, turn key switch to STOP position (A).

Engine On

• T o turn headlights on, start engine, then turn key switch from run position

(C) to headlights on position (B).

Page 27

OPERATING

• To turn headlights off, turn key switch from headlights on position (B) to

run position (C).

Starting the Engine

IMPORTANT: Avoid damage! Hydrostatic transmission might be

damaged if the bypass rod is not pushed back to operating

position before attempting to start the engine. Do not start or

operate the machine with the bypass rod in the pulled-out

position.

1. Make sure bypass rod is pushed in.

c CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Do not run an engine in an enclosed area, such as a garage, even

with doors or windows open ed.

Move the machine to an outsid e area before r unn ing the engi ne .

2. Sit in seat.

3. Make sure mower is disengaged. (See Engaging and Disengaging

Mower in the OPERATING s ection.)

4. Lock the park brake.

5. For automatic models, put transmission in park.

6. Check starting conditions:

A

• Repeat procedure if necessary.

IMPORTANT: Avoid damage! Unnecessary engine idling may

cause engine damage. Excessive idling can cause engine

overheating, carbon build-up, and poor performance.

9. Let engine run at high idle for a couple of minutes to warm-up before

operating machine.

Idling the Engine

IMPORTANT: Avoid damage!

Unnecessary engine idl ing may cause engine or transmission

damage. Excessive idling can cause engine overheating, carbon

build-up, and poor performance.

Idling or low throttle operation while mowing, climbing hills, or

towing could result in transmission overheating. always operate

at full throttle on ce the engine is warm.

Do not operate machine with hood open. Hood must be closed for

proper engine cooling and exhaust.

• Engine is air cooled and needs a large volume of air to keep cool. K eep

air intake screen on top of engine clean.

• Keep hood closed when engine is idling.

Stopping the Engine

IMPORTANT: Avoid damage! Do not stop the engine by moving

choke control to the choke position. Backfire, fire or engine

damage can occur. Follow recommended procedure for stopping

engine.

MX49386

• If engine is co ld: Mo v e thr ot tl e/ ch ok e le v e r (A ) up to the cho k e po si tion .

• If engine is warm: Move throttle/choke lever (A) to the half-speed

position.

IMPO R TANT : A v o i d da ma ge ! Sta rter ma y be da m a ge d if sta rt e r is

operated for more th an 20 seconds at a time:

• Wait two minutes before trying again if engine does not start.

7. Turn key to start position for no more than five seconds.

8. Release key to run position when engine starts, and gradually move

choke lever down to the off position.

• If engine does not start, wait 10 seconds.

• Turn key to start position again for no longer than 5 seconds.

1. Let engine run at high throttle without load for a few seconds.

2. Turn key to STOP position. Engine will stop and headlights will turn off.

3. Remove key.

4. Lock the park brake.

Using Travel Controls on Automatic Transmission

c CAUTION: Avoid injury! Children or bystanders may be

injured by runover and rotating blades. Before traveling forward or

rearward:

• Careful ly check the area around the machine.

• Disengage the mower before backing up.

IMPORTANT: Avoid damage! Stop machine movement before

shifting between reverse and forward to prevent transmission

damage.

Operating - 26

Page 28

OPERATING

T ravel Forward

B

1. Completely remove foot from travel pedal (A).

2. Push brake pedal (B) all the way down to stop machine.

3. Move transmission shift lever to forward (C).

4. Release brake p edal.

5. Slowly apply foot to travel pedal.

T ravel in Reverse

1. Completely remove foot from travel pedal (A).

NOTE: Any operating attachment and the engine will stop as the

transm is si o n shift lever is moved to R (reve rse) wi th attachmen t

engaged.

2. It may be required to push brake pedal to stop machine when on a

slope.

3. Move transmission shift lever to reverse (D).

4. Look behind the machi ne to be sure there are no bystan ders nearby.

5. Release brake p edal.

6. Slowly apply foot to trvael pedal.

Emergency Stopping

Push brake pedal all the way down to stop machine.

A

C

D

MX51677

Using Travel Controls on Hydrostatic Tran sm ission

c CAUTION: Avoid injury! Children or bystanders may be

injured by runover and rotating blades. Before traveling forward or

rearward:

• Carefully check the area around the machine.

• Disengage the mower before backing up.

Travel Forward

C

B

• Push down the forward travel pedal (A).

Travel in Reverse

NOTE: Any operating attachment and the engine will stop as the

reverse motion pedal is pressed with attachment engaged.

1. Disengage attachment:

• On models with mechanical attachment engagement lever (B), pull

lever back to the off position.

• On models with electric attachment engagement switch, push switch

in loca tion (C) (not sh own above) down to the off position.

2. Look behind the machine to be sure there are no bystanders nearby.

3. Touch the r everse travel pedal (D) with front of foot and slide foot over

pedal f rom front to rear.

Emergency Stopping

• Push brake pedal all the way down to stop machine.

A

D

MX46484

Using The Reverse Implement Option (RIO)

c CAUTION: Avoid injury! Children or bystanders may be

injured by runover and rotating blades. Before traveling forward or

rearward:

• Careful ly check the area around the machine.

• Disengage the mower before backing up.

NOTE: Backing up while the mower is engaged is strongly

discouraged. The Reverse Implement Option should be used only

when operating another attachment or when the operator deems it

necess ary to repositi on the machine with the mowe r engaged.

1. Stop forward travel.

2. Look behind the machine to be sure there are no bystanders.

Operating - 27

Page 29

OPERATING

• On models with electric attachment engagement switch: Pull switch

up.

• On models with mechanical attachment engagement lever: Push lever

forward.

NOTE: The mower and engine will stop as the reverse foot pedal is

pressed for hydrostatic transmission or when the automatic shift

lever is moved to the R (reverse) position for automatic transmission

with mower engaged.

5. Disengage mower blades before moving in revers e or stopping engine.

• Machines with mechanical attachment engagement lever: Pull lever

A

back.

• Machines with electric attachment engagement switch : Push switch

down.

MX46484

3. Push and hold in the reverse implement switch (A) while depressing

reverse pedal slightly for hydrostatic transmission or moving the automatic

shift lever to the R (reverse) position for automatic transmission.

NOTE: If the engine and mower stop while repositioning the

machine, return the attachment engagement lever/switch to the off

position. Start engine and engage mower. Begin again with Step 2.

4. Release the reverse impleme nt switch and reposition the machine as

the machine begins to move rearward.

5. Resume forward travel. The mower should continue operating.

6. Repeat procedure to position the machine again.

Using Cruise Control (D120, D130, D140, D160, D170)

c CAUTION: Avoid injury! Do not use cruise control when

going down hills. Machine speed will increase. Operate machine in

a large, open ar e a t o lea rn how t he cr u ise co ntr ol wor k s.

Use cruise control when you want to maintain travel speed without having

to hold the forward travel pedal down. Cruise control operates only for

forward travel.

Engage Cruise Control

1. Push forward pedal down until you reach desired travel speed.

2. Pull cruise control lever up and release forward pedal to lock the cruise

control.

Disengage Cruise Control

• Depress brake pedal, tap on forward pedal or push cruise control lever

down to the off position.

Engaging and Disengaging Mower

NOTE: Put attachment lift lever in transport position to transport

machine or when parking machine.

1. Start engine and run at half speed for a couple of minutes to warm up.

2. Lower mower deck to desired cutting height position.

NOTE: Throttle lever should be at full throttle position before

engaging mower to avoid stalling engine.

3. Push throttle lever up to the full throttle position.

4. Engage mower.

Using Wash Por t to Clea n Mower Deck

NOTE: Follow this procedure after each use to prevent buildup and

remove corrosive lawn chemic als.

1. Park machine safely. (See Parking Safely in the Safety section).

A

MX38397

2. Attach quick-coupler to garden hose.

3. Attach garden hose with quick-coupler to wash port (A) on the mower

deck.

4. Turn on water.

5. Start engine.

6. Run at full throttle.

7. Engage mower blades.

8. Flush water under deck for approximately one mi nute.

9. Disengage mower blades.

10. Stop engine.

11. Turn off water and remove garden hose and quick-coupler from wash

port.

12. Remove quick-coupler from garden hose and store for future use.

Operating - 28

Page 30

OPERATING

Unplugging Mower, Bagger, or Material Collection System

c CAUTION: Avoid injury! Do not attempt to unplug

attachment with machine running.

• Rotating blades are dangerous. Shut off the engine and

remove the key before getting off the seat to inspect the

machine and attachment.

• Thrown objects can cause serious injury. Make sure all

machine parts are stopped before raising hopper top or

removing chutes.

Checking For Plugging While Driving

If grass builds up in front of mower discharge chute, check for plugged

chute or problems with blower assembly (if equipped).

If there is a trail of clippings behind mower or clippings blow to the side,

check for plugged chute, full collector bags, or problems with blower

assembly.

Removing Debris From Inspection Points:

c CAUTION: Avoid injury! Do not use hands or feet to clear

plugged mower deck or blower assembly. Stored energy can cause

blades to rotate.

1. Park machine safely. Wait for all moving parts to stop before getting off

to inspect machine.

2. Open ho pp er cove r. Che ck ch ute ou t le t .

3. Remove chut e fr om mow er deck or blower as se m bl y. Check chut e inl et.

4. Check under mower deck for debris.

Moving Machine by Hand

c CAUTION: Avoid injury! When the bypass valve is open, the

machine will have unrestricted motion.

• Do not open the bypass valve when the machine is stopped

on an incline to prevent it from going downhill out of control.

IMPORTANT: Avoid damage! Transmission damage m ay occur i f

the machine is towed or moved incorrectly: