Page 1

GreenStar Equipment

for

7000 Series Forage

Harvesters

BZ13788, BZ100157

INSTALLATION INSTRUCTIONS

GreenStar Equipment for 7000

Series Forage Harvesters (BZ13788,

BZ100157)

Z103757 13DEC06 (ENGLISCH)

7000 Series Forage Harvesters

John Deere Werke Zweibru¨cken

Z103757 (13DEC06)

COPYRIGHT 2006

DEERE & COMPANY

European Office Mannheim

All rights reserved

A John Deere ILLUSTRUCTION

Z103757-19-13DEC06

Manual

Page 2

Page 3

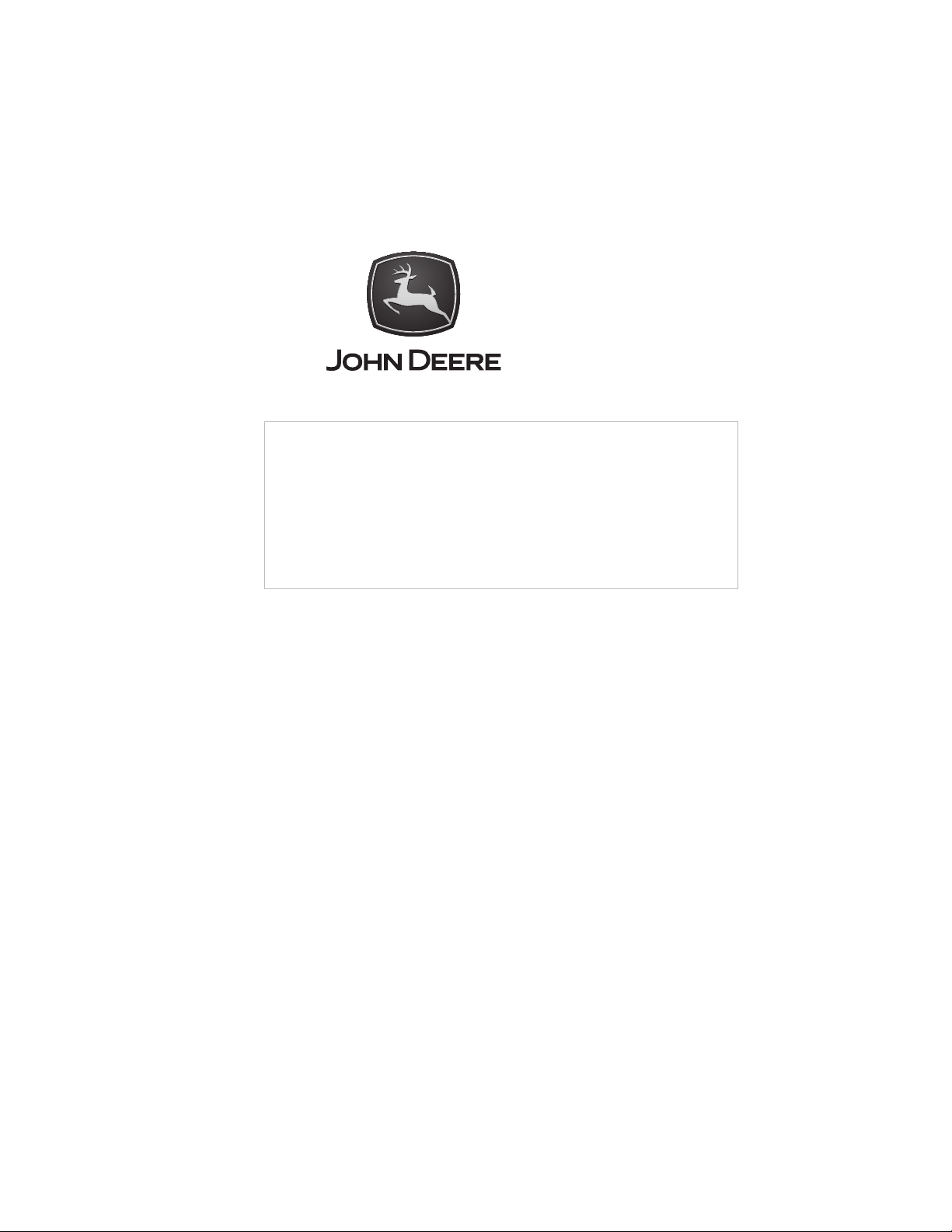

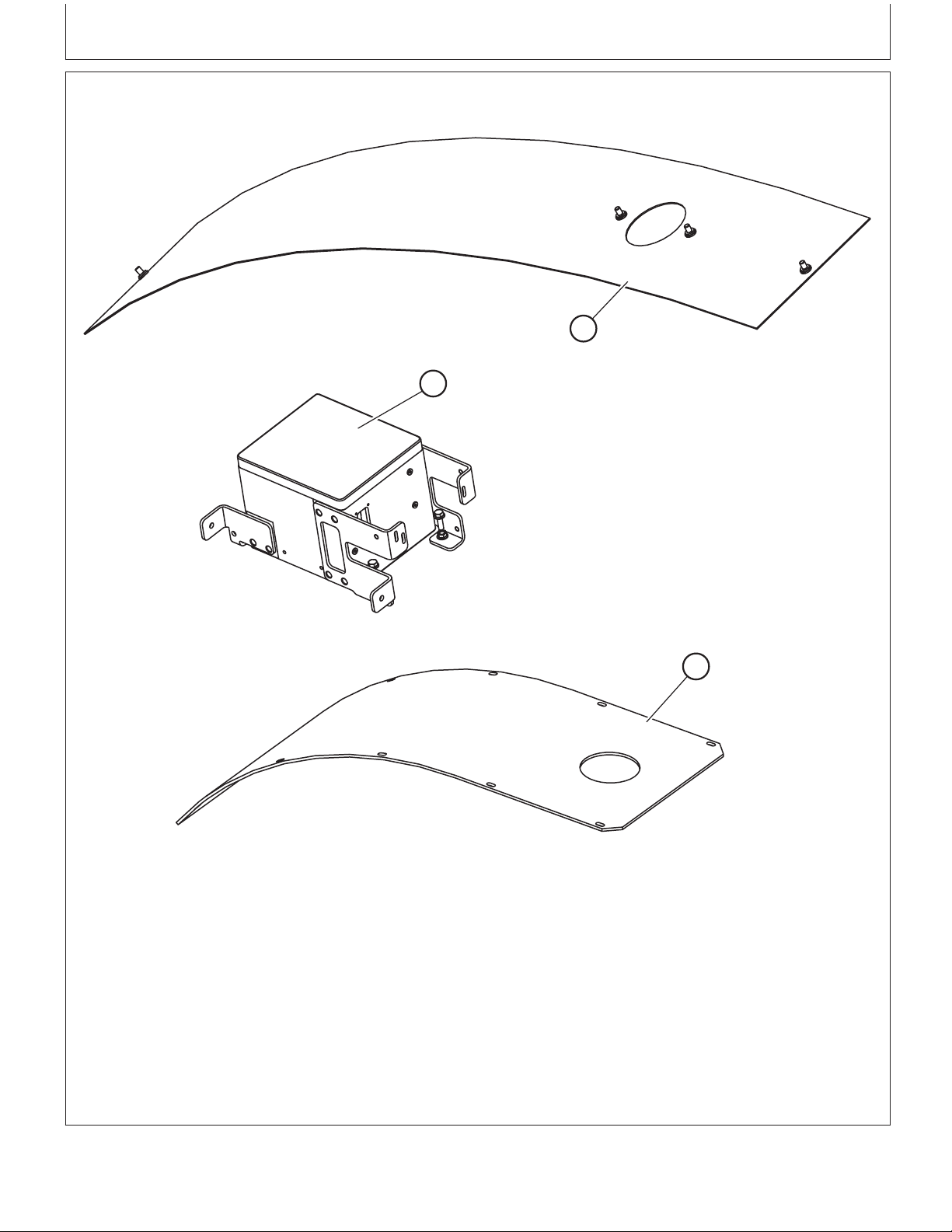

Contents of Bundle BZ13788

Installation Instructions

A—Z73362 Plate (1x) D—AZ59199 Job computer (1x) G—AZ101120 Wiring harness J—PF80209 Bracket (1x)

B—Z72204 Plate (1x) E—H204964 Decal (1x) (1x) K—AZ71569 Connector (1x)

C—AZ57754 Holder (1x) F—N302284 Decal (1x) H—AZ63280 Potentiometer

(1x)

NOTE: The bundle contains a hardware bag.

OUZXMAG,0002081 –19–03AUG05–1/1

Z103757 (13DEC06)

1

Installation Instructions

ZX1037465 –UN–13SEP05

011507

PN=3

Page 4

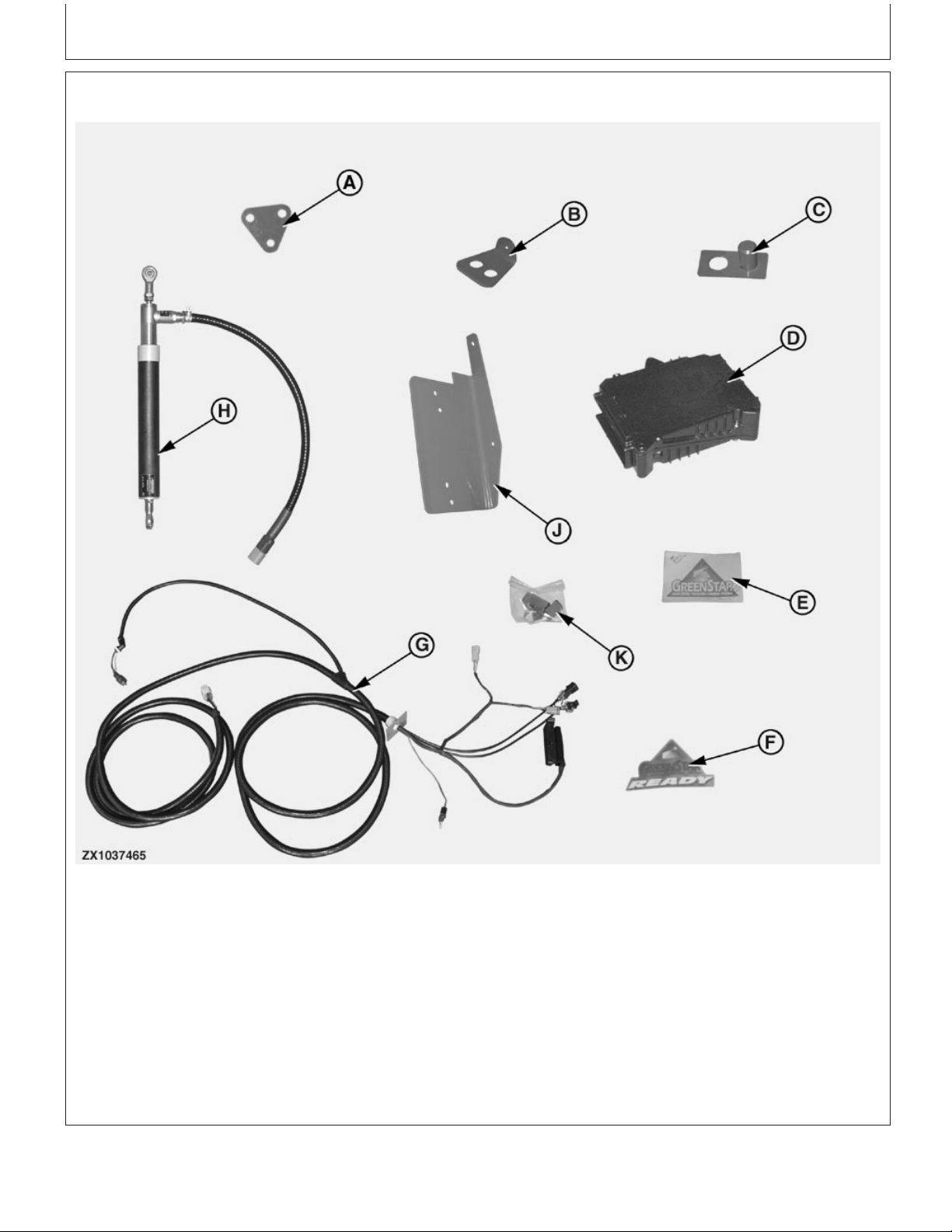

Contents of Bundle BZ100157

Installation Instructions

A

B

E

C

D

ZX1039590

A—Z102720 Support (1x) C—AZ102637 Cover Plate D—Z102760 Fixing Plate (1x) E—AZ102820 Sensor Support

B—Z101939 Shield (1x) (1x)

NOTE: The bundle contains a hardware bag including

(7x) 14M7298 M8 flange nuts, (2x) 14M7396

M8 self locking nuts, (10x) 19M7865 M8X16

Z103757 (13DEC06)

2

screws, (6x) 19M7867 M8X25 screws, (3x)

19M7897 M8X35 screws and (2x) 24M7207

8.4X24X2 washers.

OUCC002,00021C8 –19–26SEP06–1/1

Installation Instructions

ZX1039590 –UN–06SEP06

011507

PN=4

Page 5

Installation Instructions

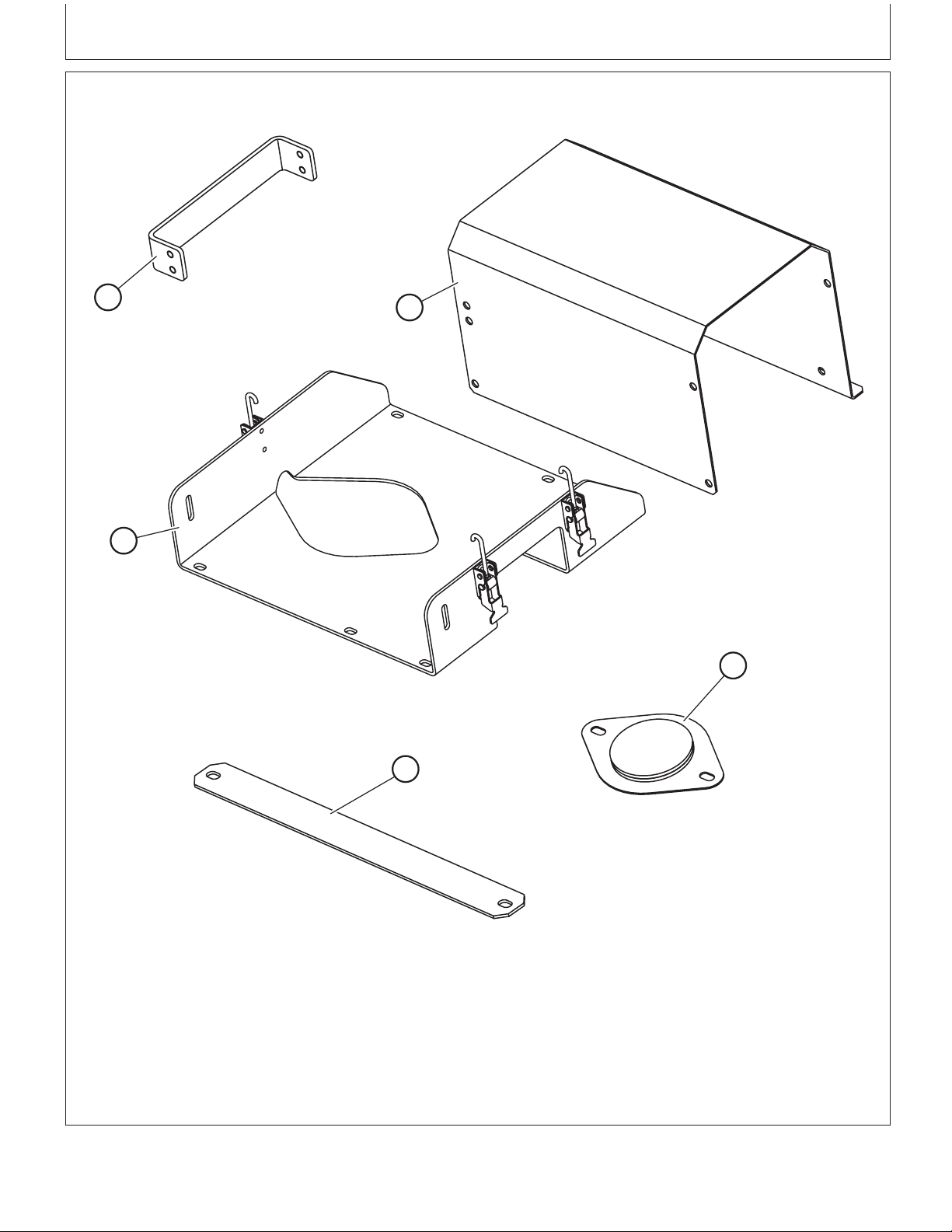

Contents of Bundle BZ100157—Continued

A—Z103667 Bracket (2x) B—Z103666 Template (1x) C—19M7865 Cap Screw M8X16 D—14M7298 Flange Nut M8

Z103757 (13DEC06)

(4x) (4x)

3

OUCC002,000233A –19–31JUL06–1/1

Installation Instructions

ZX1039634 –UN–31JUL06

011507

PN=5

Page 6

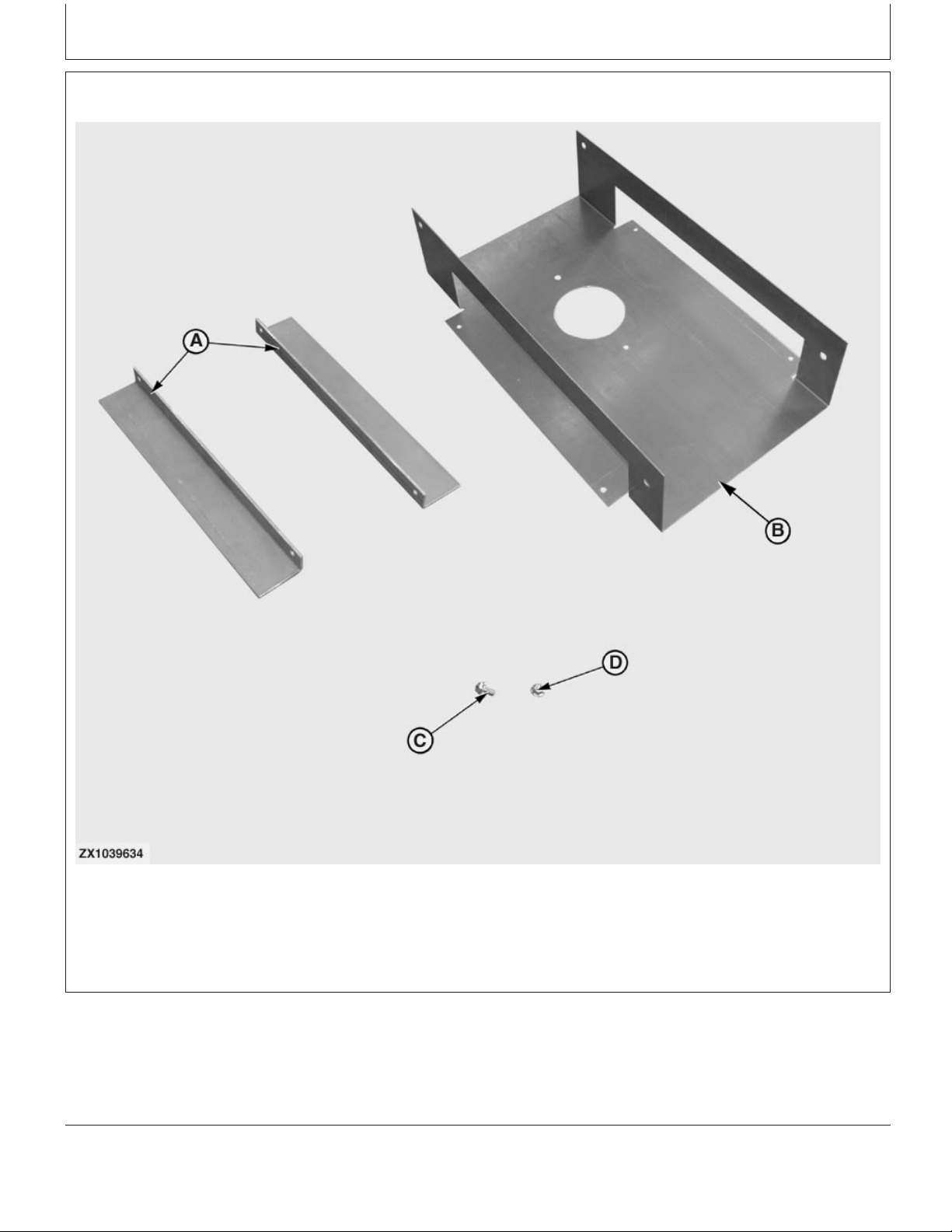

Parts to Order

Installation Instructions

B

A

ZX1039591

A—BZ100165 NIR Sensor (1x) B—AZ101740 Wear Plate for C—Z101953 Wear Plate for Flat

To complete the bundle BZ100157 installation the

parts or bundles above illustrated must be ordered

separately.

Z103757 (13DEC06)

High arc Spout (1x) Spout (1x)

4

C

OUCC002,00021C9 –19–04AUG06–1/1

Installation Instructions

ZX1039591 –UN–12JUL06

011507

PN=6

Page 7

Installation Instructions

Mount and Dismount Safely With the Moisture Sensor

Hold handrail with one hand and carry the moisture

sensor with the other.

Maintain Stability

Keep work surfaces dry and clean. Maintain balance while

transporting and installing the moisture sensor onto the

forage harvester’s spout.

Care should also be observed while servicing the sensor.

ZX1039668

OUCC002,0002373 –19–06SEP06–1/1

ZX1039921 –UN–06SEP06

ZX1039668 –UN–29AUG06

OUCC002,0002374 –19–06SEP06–1/1

Z103757 (13DEC06)

5

Installation Instructions

011507

PN=7

Page 8

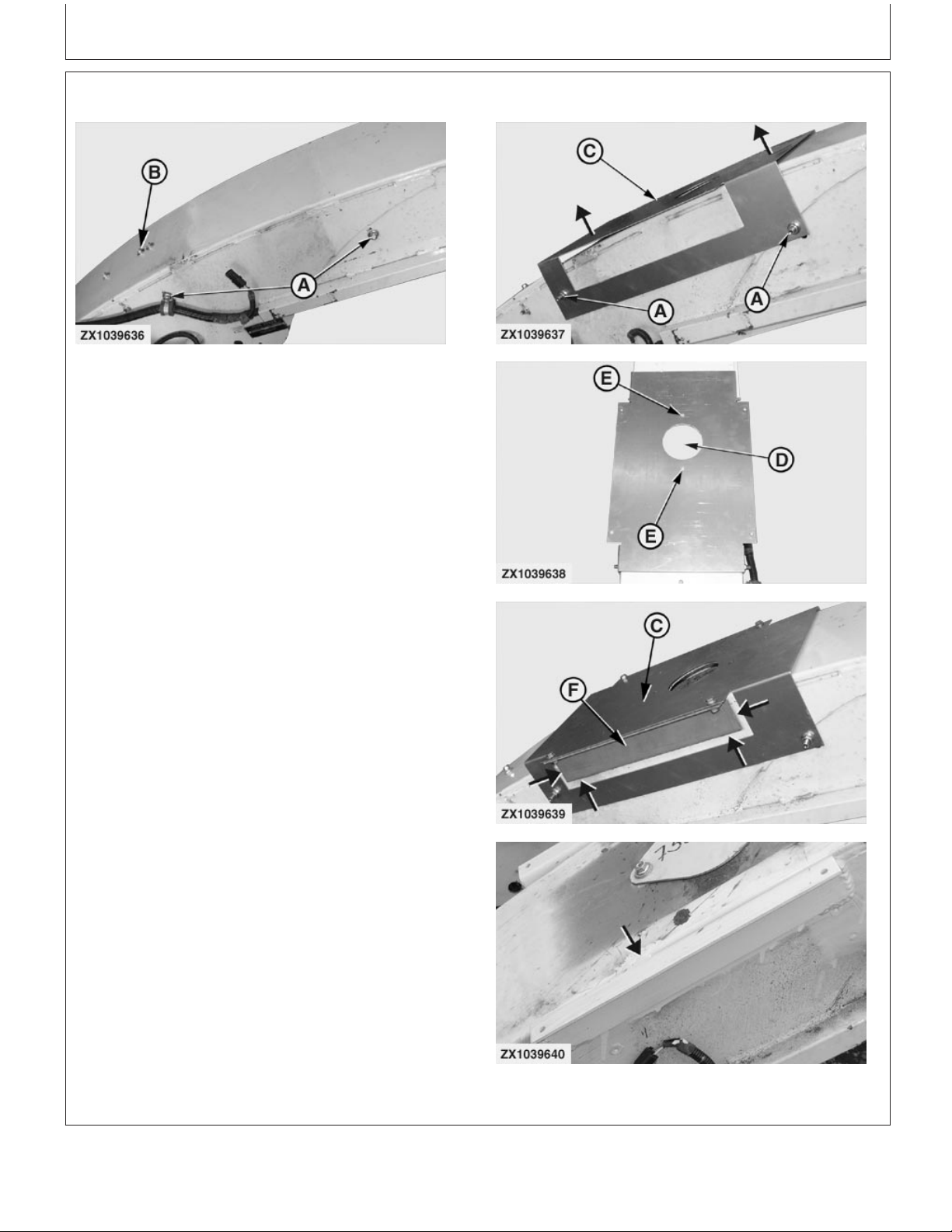

Modify High Arc Spout

Installation Instructions

ZX1039636 –UN–12JUL06

On machines with old high arc type spout, proceed as

follows to install NIR sensor brackets:

1. On both sides of the spout, release the side wear plate

fixing screws (A) and rear wear plate fixing screws (B).

Remove and discard rear wear plate. Remove both

side wear plates.

2. Install template Z103666 (C) over spout as shown

using original hardware (A). Pull up template Z103666

(C) to set it correctly in position then tighten fixing

screws (A).

3. Mark area (D) to cut a hole 102 mm (4.01 in.) diameter

then drill two holes 11x20 mm (0.43x0.78 in.) at

locations (E).

4. Install brackets Z103667 (F) on template Z103666 (C)

with four screws 19M7865 M8X16 and flange nuts

14M7298. Make sure brackets (F) are in contact with

spout sides then weld at front and rear of the brackets

(F) (see arrows) on spout.

IMPORTANT: Grind spout sides at locations where

weld will be carried out.

ZX1039637 –UN–12JUL06ZX1039638 –UN–12JUL06ZX1039639 –UN–12JUL06ZX1039640 –UN–12JUL06

5. Remove template Z103666 (C) then finalize welding

process on top of brackets Z103667 (F) (see arrow).

A—Fixing Screws

B—Fixing Screws

C—Template Z103666

D—Area to Cut

E—Drilling Holes

F—Brackets Z103667

Z103757 (13DEC06)

Continued on next page

6

OUCC002,000233C –19–12OCT06–1/2

Installation Instructions

011507

PN=8

Page 9

Installation Instructions

IMPORTANT: Grind weld at top of brackets Z103667

(F) so that weld surface is flush with the

bracket surface.

6. Cut out previously marked area (D).

OUCC002,000233C –19–12OCT06–2/2

Z103757 (13DEC06)

7

Installation Instructions

011507

PN=9

Page 10

Replace Spout Wear Plate

Installation Instructions

A

B

ZX1039595

Using original hardware, install wear plate AZ101740 (A)

on high arc type spout or wear plate Z101953 (B) on flat

spout.

On new high arc type spout, use a hammer to remove

pre-cut part (C) of spout as shown.

A—Wear plate—AZ101740—High arc spout

B—Wear plate—Z101953—Flat spout

C—Part to remove

ZX1039594

ZX1039595 –UN–10APR06

C

ZX1039594 –UN–10APR06

OUCC002,00021CE –19–12OCT06–1/1

Z103757 (13DEC06)

8

Installation Instructions

011507

PN=10

Page 11

Installation Instructions

Install NIR Sensor BZ100165

1. Pre-assemble NIR sensor BZ100165 (A) with the

shield Z101939 (B) using 6 flange screws M8X16 (C).

2. Install support Z101720 (D) using 4 flange screws

M8X16 (C).

3. Place three screws M8X35 (E) and three flange nuts

(F) on sensor support as shown.

4. Insert sealing ring Z101944 (G) on glass adapter of

sensor BZ100165 (A).

IMPORTANT: To install the sealing ring (G) correctly,

align its centering protrusion with the

groove of glass adapter.

5. Install support AZ102820 (H) on spout using four

flange screws M8X25 (I) and flange nuts.

A—NIR sensor—BZ100165

B—Shield—Z101939

C—Flange screws M8X16

D—Support Z101720

E—Flange screws M8X35

F—Flange nut

G—Sealing ring—Z101944

H—Support—AZ102820

I—Flange screws M8X25

ZX1039596 –UN–10APR06ZX1039597 –UN–10APR06ZX1039598 –UN–26SEP06

Z103757 (13DEC06)

Continued on next page

9

OUCC002,00021CD –19–18NOV06–1/4

Installation Instructions

011507

PN=11

Page 12

Installation Instructions

6. Attach sensor assembly (A) to support AZ102820 (B)

using two flange screws M8X25 (C), two washers

8.4X24X2 (D) and two self-locking nuts (E) as shown.

IMPORTANT: To ease sensor assembly fold/unfold,

place washers (D) between support (B)

and sensor assembly brackets. Do not

overtighten self-locking nuts (E). Sensor

assembly (A) must remain easily

foldable.

The NIR sensor (A) is delivered with a dedicated wave

length standard (F). To avoid NIR sensor and non

dedicated wave length standard mix up, it is strongly

recommended to report the NIR sensor serial number

on its relevant wave length standard cover (G).

IMPORTANT: Prior to operating the NIR sensor (A),

carry out an initial wave length standard

measurement as described in Harvest

Monitor System Operator’s Manual.

If the wave length standard

measurement is not successful then a

black and white calibration of the NIR

sensor is required. Proceed as

described in the forage harvester

Technical Manual.

The wave length standard (F) must be kept in good

condition for future measurement. In this way, special

attention must be paid so that the wave length

standard (F) doesn’t come in contact with chemical

products such as:

• Diesel

• Gasoline (Leaded or unleaded)

• Thinners

• Engine cleaner

• Cavity sealing

• After cleaning

• Finishing paint

• Blackboard lacquer

• Freeze protection

ZX1039599 –UN–10APR06ZX1040034 –UN–18NOV06

A—Sensor assembly

B—Support—AZ102820

C—Flange screws M8X25

D—Washers 8.4X24X2

E—Self-locking nuts

F—Wave length standard

G—Cover

Z103757 (13DEC06)

Continued on next page

10

OUCC002,00021CD –19–18NOV06–2/4

Installation Instructions

011507

PN=12

Page 13

Installation Instructions

NOTE: Do not disconnect sensor (A) from machine wiring

harness until sensor shuts down completely.

Before disconnecting sensor turn forage harvester

ignition off. Wait at least 30 seconds before

disconnecting the sensor.

Continued on next page

OUCC002,00021CD –19–18NOV06–3/4

Z103757 (13DEC06)

11

Installation Instructions

011507

PN=13

Page 14

F

Installation Instructions

E

E

A

B

ZX1039600

A—Adapter glass C—Front point setting E—Flange screw F—Flange nut

B—Wear plate D—Rear point setting

7. Place sensor into working position but do not latch

it. Adjust sensor assembly position so that tip of

adapter glass (A) is flush with wear plate (B) at

C

IMPORTANT: To allow a proper adapter glass

self-cleaning process, make sure

that sensor position is correctly set.

front point (C) and about 1 mm (0.08 in.) below

surface of wear plate (B) at rear point (D) as

NOTE: Arrow is showing the crop flow direction.

shown. Use the three flange screws (E) to adjust

then secure with flange nuts (F).

D

F

ZX1039600 –UN–10APR06

Z103757 (13DEC06)

12

OUCC002,00021CD –19–18NOV06–4/4

Installation Instructions

011507

PN=14

Page 15

Installation Instructions

Install Feed Roll Potentiometer AZ63280

Install Upper Plate Z72204 and Holder AZ57754

1. Remove right-hand feed roll spring (A) by loosening

eye-bolt (B).

2. Install plate Z72204 (C) and holder AZ57754 (D) in the

free holes.

3. Put the eye-bolt (B) back in place and tighten the

spring to its original setting.

A—Feed roll spring

B—Eye-bolt

C—Plate Z72204

D—Holder AZ57754

Continued on next page

OUZXMAG,0001BEF –19–13NOV03–1/3

ZX1034539 –UN–16NOV03

Z103757 (13DEC06)

13

Installation Instructions

011507

PN=15

Page 16

Installation Instructions

Install Lower Plate Z73362

1. Drill two 9 mm (0.35 in.) diameter holes on cutterhead

frame (A) as shown.

2. Install plate Z73362 (D) on frame (A) with two cap

screws M8x40 (E) and nuts, as shown.

A—Cutterhead frame

B—75 mm (2.95 in.)

C—34 mm (1.34 in.)

D—Plate Z73362

E—Cap screws M8x40

F—15 mm (0.59 in.)

Continued on next page

ZX1034541 –UN–18NOV03ZX1031222 –UN–02NOV02

OUZXMAG,0001BEF –19–13NOV03–2/3

Z103757 (13DEC06)

14

Installation Instructions

011507

PN=16

Page 17

Installation Instructions

Install Feed Roll Potentiometer AZ63280

1. Install potentiometer AZ63280 (A) between plate

Z72204 (B) and plate Z73362 (C) with screws (D)

M12x35, flange nuts and lock nuts as shown.

2. Connect potentiometer AZ63280 (A) to free connector

(E) of machine wiring harness.

IMPORTANT: The potentiometer (A) should be

mounted so that the wiring harness

connector is in top position.

A—Potentiometer AZ63280

B—Plate Z72204

C—Plate Z73362

D—Screws M12x35

E—Connector

OUZXMAG,0001BEF –19–13NOV03–3/3

ZX1034542 –UN–16NOV03

Z103757 (13DEC06)

15

Installation Instructions

011507

PN=17

Page 18

Installation Instructions

Install Job Computer AZ59199 and Wiring Harness AZ101120

1. Install job computer AZ59199 (A) as shown on the

bottom left side of load center with three screws M8x60

(B) using existing nuts in the wall.

2. Connect main connector (C) of wiring harness

AZ101120 (D) to job computer (A).

3. Disconnect A7-CAN bus terminator (E) located near

the board A3. Connect CAN bus terminator (E) to

relevant connector (F) of wiring harness AZ101120 (D),

then connect wiring harness AZ101120 to terminator

(E) original connector as shown.

4. Locate free connectors X27 (G) and X30 (H), then

connect them to the relevant machine wiring harness

free connections using parts of connector AZ71569 (I)

and following tables:

X27 Connector AZ71569 Pin Connections

Pin Number Wire

Pin #1 .......................................... 552C

Pin #2 .......................................... 974

Pin #3 .......................................... 975

Pin #4 .......................................... 050B

Pin #5 .......................................... not used

Pin #6 .......................................... not used

ZX1037466 –UN–13SEP05

ZX1037467 –UN–13SEP05ZX1037468 –UN–13SEP05ZX1037469 –UN–13SEP05

A—Job computer AZ59199

B—Screws M8x60

C—Main connector

D—Wiring harness AZ101120

E—A7 CAN bus terminator

F—Connector

G—X27 Connector

H—X30 Connector

I—AZ71569 Connector

Z103757 (13DEC06)

Continued on next page

16

OUCC002,00021CA –19–18NOV06–1/8

Installation Instructions

011507

PN=18

Page 19

X30 Connector AZ71569 Pin Connections

Pin Number Wire

Pin #1 .......................................... 584

Pin #2 .......................................... 586

Pin #3 .......................................... 585

Pin #4 .......................................... 571

Pin #5 .......................................... not used

Pin #6 .......................................... not used

Installation Instructions

OUCC002,00021CA –19–18NOV06–2/8

5. Connect part of wiring harness AZ101120 with

15A-fuse (A) to connecting point 002 (B) located on

board A3 as shown.

6. Remove closing plate from bottom of load center (not

illustrated) and pass wiring harness AZ101120 (C)

through the opening until guide plate (D) can be

installed using original hardware previously removed.

A—Fuse

B—Connecting point

C—Wiring harness AZ101120

D—Guide plate

ZX1037470 –UN–13SEP05ZX1037471 –UN–13SEP05

Z103757 (13DEC06)

Continued on next page

17

OUCC002,00021CA –19–18NOV06–3/8

Installation Instructions

011507

PN=19

Page 20

Installation Instructions

A—Inoculant dosing device B—NIR sensor connector C—Wiring harness AZ101120 D—Connection box

connector

7. Using above illustration, route connectors (A) and

(B) of wiring harness AZ101120 (C) underneath the

Z103757 (13DEC06)

18

connection box (D), alongside the left-hand side of

machine frame then behind the cab.

Continued on next page

OUCC002,00021CA –19–18NOV06–4/8

Installation Instructions

ZX1037472 –UN–13SEP05

011507

PN=20

Page 21

Installation Instructions

IMPORTANT: Route wiring harness AZ101120 (C)

alongside machine wiring harness

and secure with tie bands.

NOTE: Connector (A) shall be used for inoculant

dosing device connection.

Connector (B) shall be stored in a safe place if

NIR sensor is not installed on spout.

8. Route inoculant dosing device connector (A) outside

the rear right-hand side of the cab as shown.

9. Drill a suitable hole near the cab closing plate (B) so

that connector sleeve (C) can be inserted and fixed to

the cab wall as shown.

IMPORTANT: Open plate (B) and check that no wiring

harness is being damaged while drilling

the hole!

NOTE: Use the existing machine wiring harnesses

and/or hydraulic hoses to fix the wiring

harness AZ101120 (C) with plastic clamps so

that it will not be left loose in a way it can be

caught by any moving part.

OUCC002,00021CA –19–18NOV06–5/8

-If an inoculant dosing device is used, route dosing

device connecting wires through opening of closing

plate and refer to “Connecting Inoculant Dosing

Device” for proper device connection.

-If no inoculant dosing device is used, keep connector

(A) protected behind closing plate (B).

A—Connector for inoculant dosing device

B—Closing plate

C—Connector sleeve

10. In Case Bundles BZ100157 and BZ100165 are Not

Installed on Spout:

Route and store NIR sensor connector (A) near the

spout motor (B). Make sure to store the cable so that

it will not be caught by any moving part.

ZX1037996 –UN–13SEP05ZX1037997 –UN–13SEP05

OUCC002,00021CA –19–18NOV06–6/8

A—NIR sensor connector

B—Spout motor

Z103757 (13DEC06)

Continued on next page

19

OUCC002,00021CA –19–18NOV06–7/8

Installation Instructions

011507

PN=21

ZX1037998 –UN–13SEP05

Page 22

Installation Instructions

11. In Case Bundles BZ100157 and BZ100165 are

Installed on Spout:

Route NIR sensor connector (A) to the right-hand side

of the spout motor (B) then alongside the spout wiring

harness (C) up to the NIR sensor BZ100165 (D) as

shown. Secure cable with tie bands.

Make sure to route the cable so that it will not be

caught by any moving part.

12. Connect NIR sensor connector (A) to NIR sensor

BZ100165 (D) then engage the three latches (E) to

maintain NIR sensor BZ100165 (D) in working

position as shown.

IMPORTANT: Route cable as shown on illustration

and make sure to keep sufficient play to

cable so that NIR sensor assembly can

be folded/unfolded without

disconnecting connector (A).

NOTE: If connection box BZ100168 has been installed on

NIR sensor BZ100165 then connect NIR

connector (A) to the connection box (not

illustrated).

NOTE: Do not disconnect sensor (D) from spout wiring

harness until sensor shuts down completely.

Before disconnecting sensor turn forage harvester

ignition off. Wait at least 30 seconds prior to

disconnecting the sensor.

A—NIR sensor connector

B—Spout motor

C—Spout wiring harness

D—NIR sensor—BZ100165

E—Latch (3 used)

ZX1037998 –UN–13SEP05ZX1039592 –UN–10APR06

Z103757 (13DEC06)

20

OUCC002,00021CA –19–18NOV06–8/8

Installation Instructions

011507

PN=22

Page 23

Installation Instructions

Connecting Inoculant Dosing Device

To enable the dosing device system, the connector (A)

MUST be connected to the relevant connector of inoculant

dosing device control unit in the following manner (refer to

table for connector (A) pin connections).

• Tx wire1of dosing device connector to Rx wire2of

wiring harness AZ101120 connector (A).

• GND wire3of dosing device connector to GND wire of

wiring harness AZ101120 connector (A).

ZX1037996 –UN–13SEP05

• Rx wire of dosing device connector to Tx wire of wiring

harness AZ101120 connector (A).

Connector (A) Pin Connections

Pin Number Wire

Pin #A .......................................... 589—Tx

Pin #B .......................................... 590—GND

Pin #C ......................................... 591—Rx

1

Tx wire: Means wire that transmits the signal

2

Rx wire: Means wire that receives the signal

A—Connector for inoculant dosing device

3

GND wire: Means ground wire

Z103757 (13DEC06)

21

OUZXMAG,00020A0 –19–13SEP05–1/1

Installation Instructions

011507

PN=23

Page 24

Installation Instructions

Install Bracket PF80209 in Cab

1. Install monitor bracket PF80209 (A) on right-hand

corner post as shown using corner post fixing screws

(B).

2. Pull down cab roof trim (C) and look for monitor wiring

harness (D). Extract it from cab roof and route it up to

the bracket PF80209 as shown. Keep the wiring

harness (D) connectors free for further monitor

installation.

A—Bracket PF80209

B—Screws

C—Cab roof trim

D—Monitor wiring harness

ZX1034544 –UN–16NOV03ZX1034545 –UN–16NOV03

OUZXMAG,0001BF0 –19–16NOV03–1/1

Z103757 (13DEC06)

22

Installation Instructions

011507

PN=24

Page 25

Installation Instructions

Attach GreenStar Decals

• Attach decal H204964 (A) to left hand side of the

harvester as indicated.

• Attach decal N302284 (B) as indicated in front of the

display (C), on inside of cab.

A—Decal H204964

B—Decal N302284

C—Display

OUZXMAG,00020A1 –19–14SEP05–1/1

ZX1031229 –UN–02NOV02ZX1031230 –UN–02NOV02

Z103757 (13DEC06)

23

Installation Instructions

011507

PN=25

Page 26

Installation Instructions

Load Software

Load Display Software

To load new software:

1. Install PC Card containing NEW software in card slot A

of mapping processor.

2. Turn ignition key to RUN position.

3. Press “INFO” key to enter INFO mode.

4. Press key B in “INFO” to select “Keycard”.

5. Press key A to select “Devices on CAN Bus”. Actual

Version Display Software and Version Harvest Mon

are then displayed.

6. Press key G once to go back.

7. Press key C to select “Program Target”.

8. Press key A to select “GreenStar Display”.

9. Press relevant key to choose “PF303182B” software

version, or higher.

10. While programming (about 30 seconds):

- DO NOT REMOVE PC CARD

- DO NOT REMOVE POWER

11. When programming is complete, the

PROGRAMMING COMPLETE screen will appear.

CYCLE POWER will be displayed in lower left

corner.

Turn ignition switch OFF.

Load Job Computer Software

To load new software:

1. Install PC Card containing NEW software in card slot A

of mapping processor.

2. Turn ignition key to RUN position.

Z103757 (13DEC06)

Continued on next page

24

OUZXMAG,0002083 –19–04AUG05–1/2

Installation Instructions

011507

PN=26

Page 27

Installation Instructions

3. Press “INFO” key to enter INFO mode.

4. Press key B in “INFO” to select “Keycard”.

5. Press key A to select “Devices on CAN Bus”. Actual

Version Display Software and Version Harvest Mon

are then displayed.

6. Press key G once to go back.

7. Press key C to select “Program Target”.

8. Press key A to select “Harvest Mon”.

9. Press relevant key to choose “PF311135C” software

version, or higher.

10. While programming (about 30 seconds):

- DO NOT REMOVE PC CARD

- DO NOT REMOVE POWER

11. When programming is complete, the

PROGRAMMING COMPLETE screen will appear.

CYCLE POWER will be displayed in lower left

corner.

Turn ignition switch OFF.

OUZXMAG,0002083 –19–04AUG05–2/2

Z103757 (13DEC06)

25

Installation Instructions

011507

PN=27

Page 28

Installation Instructions

Check Yield Monitoring Functionality

Calibrate Mass-Flow Sensor

1. Turn ignition key to RUN position.

2. Press “SETUP” key to enter SETUP mode.

3. Press key C in “SETUP” to select “GreenStar

Display”.

4. Select your native language and units then press key

G once to go back.

5. Press key A to select “Harvest Mon”.

6. Make sure that “Recording ON/OFF By:” is set on

“HEADER” then press key G once to go back.

7. Press key D to select “Yield Calibration”.

8. Press key A to start calibration. Wait until feedroll

height is 10 mm (0.4 in.).

9. Press RUN key.

Check Monitoring Functions

1. Turn ignition key to start harvester engine.

2. Press “INFO” key to enter INFO mode.

3. Press key A in “INFO” to select “Harvest Mon”.

4. Press key F to select “Diagnostics”.

5. Press key B to select “Mass-Flow System”. Engage

main clutch and harvesting unit then check the

following points:

• Height right—should be between 0.2 and 0.6 V.

• Vref—Should be between 4.8 and 5.1 V.

If any of these points are not OK, contact your John

Deere dealer.

Press key G once to go back.

Z103757 (13DEC06)

Continued on next page

26

OUZXMAG,0001BF6 –19–18NOV03–1/2

Installation Instructions

011507

PN=28

Page 29

Installation Instructions

6. Press key C to select “SPFH Network” and check

communication between SPFH and Harvest Monitor.

7. Press RUN key.

Check Inoculant Dosing Functionality

1. Turn ignition key to start harvester engine.

2. Press “SETUP” key to enter SETUP mode.

3. Press key A in “SETUP” to select “Harvest Mon”.

4. Press “PAGE” key to go to “SETUP - Harv Mon PAGE 2” screen then press key “F” to toggle inoculant

dosing support state from OFF to ON or vice versa.

5. Press RUN key.

6. The inoculant dosing device can be engaged if:

OUZXMAG,0001BF6 –19–18NOV03–2/2

ZX1035268 –UN–26JUL04

• The road safety switch is in field operating mode

• The forage harvester is travelling forward

• The ground speed is greater than 2 km/h (1.24 mph)

• The feedrolls are turning in forward direction

• The header is in harvesting position

7. Press once the liquid injection pump switch (A). Carry

out a test to make sure that inoculant device is

properly connected to the wiring harness AZ101120.

If this is not the case check wiring harness connection

or contact your John Deere dealer.

NOTE: For a proper use of the liquid injection pump

switch (A), refer to the forage harvester Operator’s

Manual.

Z103757 (13DEC06)

27

OUZXMAG,0002084 –19–04AUG05–1/1

Installation Instructions

011507

PN=29

Page 30

Installation Instructions

Use of Cover Plate AZ102637

In case the spout is operated without the NIR sensor it is

necessary to install cover plate AZ102637 (A) to close

opening in wear plate AZ101740 or Z101953.

NOTE: The illustration shows the cover plate AZ102637

(A) installed on a high arc type spout. In case of

flat spout, it is necessary to use the supplied

fixing plate Z102760 to maintain cover plate

AZ102637 in place using original spout wear plate

fixing hardware—Not illustrated.

A—Cover Plate—AZ102637

ZX1039593 –UN–10APR06

OUCC002,00021CF –19–18JUL06–1/1

Z103757 (13DEC06)

28

Installation Instructions

011507

PN=30

Loading...

Loading...