Page 1

OPERATOR'S MANUAL

W

DEBRIS BLO

BL1130

ER

OM 0400-A

01/11

Page 2

Page 3

TABLE OF CONTENT

SPECIFICATIONS ........................................................................................................................................... 3

INTRODUCTION – TO THE PURCHASER .................................................................................................... 4

SECURITY .................................................................................................................................................... 5-9

Before Operation .................................................................................................................................. 5

Notice .................................................................................................................................................. 6

Debris Blower ....................................................................................................................................... 6

Before Operation...................................................................................................................... 6

Debris blower Operation .......................................................................................................... 7

The Tractor ........................................................................................................................................... 8

General Information ................................................................................................................. 8

Operating the Tractor ............................................................................................................... 8

During Operation...................................................................................................................... 8

Maintenance ........................................................................................................................................ 9

Transportation ...................................................................................................................................... 9

Storage ................................................................................................................................................. 9

DECALS ......................................................................................................................................................... 10

ASSEMBLY ............................................................................................................................................... 11-18

Tractor Preparation .............................................................................................................................. 11

Debris Blower Assembly ...................................................................................................................... 11

Debris Blower removing front wooden crate ...................................................................... 11

Debris Blower Installation on a Three Point Hit ch .............................................................. 12

Installation of the Debris Blower with a Quick Hitch Cat. 1 ................................................ 13

Installation of the Debris Blower with a Quick Hitch Cat. 2 ................................................ 13

Driveline Preparation ........................................................................................................... 14

How To Determine Driveline Ang le s

................................................................ 14

Angles at Each End Of Driveline ........................................................................... 15

Determining Driveline Length ............................................................................ 15-16

Driveline Installation ............................................................................................................ 17

Removing Debris Blower from Tractor ............................................................................... 18

OM 0400-A

1

Page 4

TABLE OF CONTENT

OPERATION ............................................................................................................................................ 19-21

General Preparation ............................................................................................................................. 19

Roadway Transport ............................................................................................................................. 19

OPERATION ........................................................................................................................................ 20

Debris Blower Commands ................................................................................................. 20

Debris Blower Utilisation ..................................................................................................... 20

Nozzle air ejection Orientation ........................................................................................... 20

Adjustments ......................................................................................................................................... 21

Reduction Chain Tension Adjustment ............................................................................... 21

MAINTENANCE ........................................................................................................................................ 22-28

Maintenance ......................................................................................................................................... 22

Shear Bolt ............................................................................................................................ 22

Lubrication ............................................................................................................................................ 23

Periodic Checks ................................................................................................................................... 23

Belt Replacement ................................................................................................................................. 24

Impeller Removing and Reinstallation ................................................................................................. 25

Driveline Troubleshooting ............................................................................................................... 26-28

PARTS ..................................................................................................................................................... 29-35

Introduction ............................................................................................................................................... 29

Manual Holder ........................................................................................................................................... 29

Debris Blower – Housing .......................................................................................................................... 30

Debris Blower – Drum............................................................................................................................... 31

Debris Blower – Belt Drive ................................................................................................................... 32-33

Debris Blower – Hitch and Wheels ........................................................................................................... 34

Driveline 5RD4700159 ............................................................................................................................. 35

TORQUE SPECIFICATION TABLE .................................................................................................... ......... 36

OM 0400-A

2

Page 5

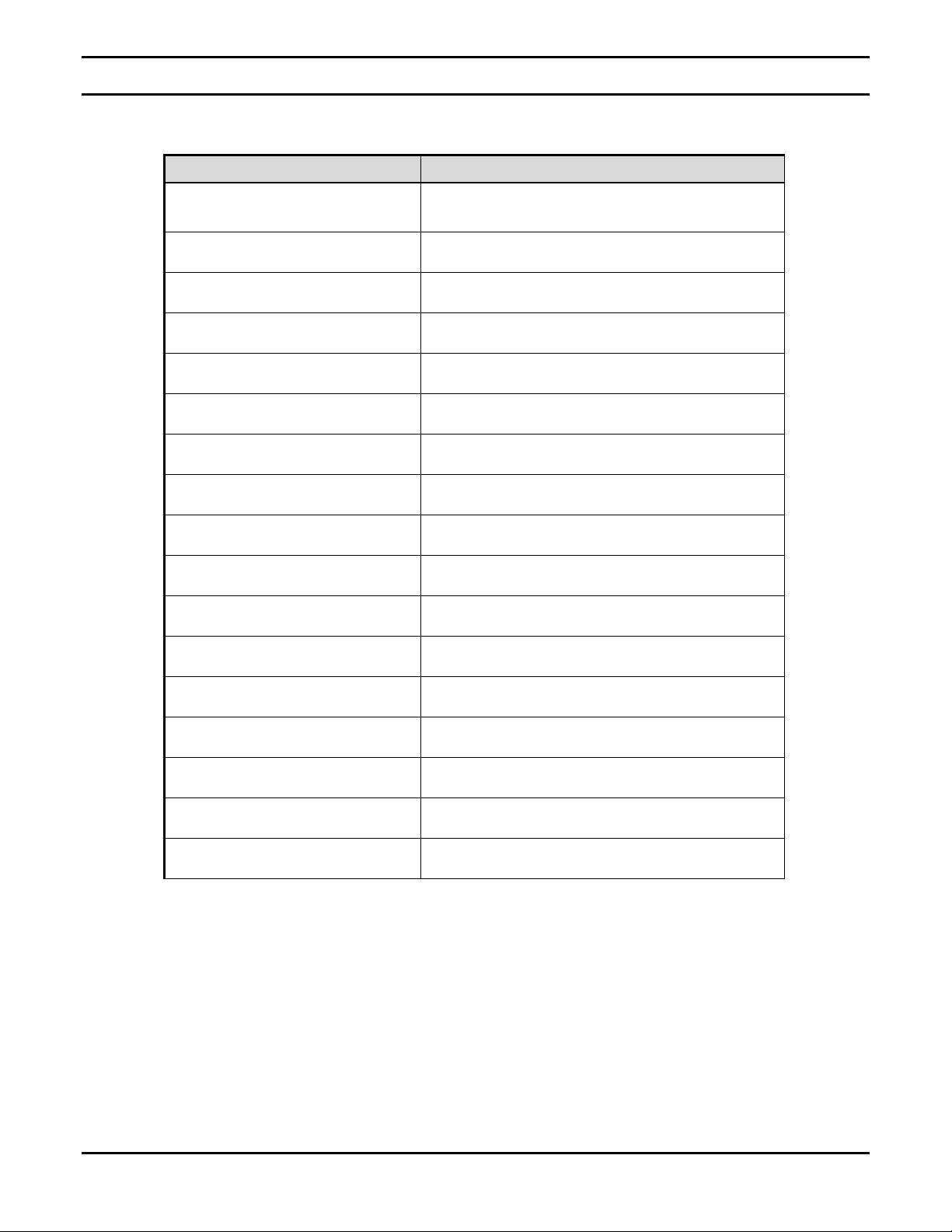

SPECIFICATION

Features and Specifications

Power source

Category Compatibility 3 point Standard cat.1 & cat.2

Quick Hitch Compatibility ASABE Compatible Cat. 1 & 2

Air flow 6061 cfm

Impeller dimension 29 3/4" x 10" – 12 blades

Impeller speed 1453 rpm to 540 rpm

Air velocity 141 m/h – 227 km/h

Outlet area 70.4 cu.in – 454.2 cu.cm

30HP tractor – PTO 540 rpm

BL1130

25 HP PTO

Drive Belt 4-5VX560 "power ban d"

Driveline 40 series

Directional control Manual Panel – left or right

Ground clearance 3 1/ 8"

Height adjustment Determined by tractor

Caster wheel 3 wheels – 12" dia. X 3" pn eumatic

Impeller housing

Dimension 46 1/2" length x 48 1/2" height x 49 1/4" width

Weight 655 lbs

Rear & front panel: 10ga

Housing edge : 12ga

OM 0400-A

3

Page 6

TO THE PURCHASER

INTRODUCTION

All products are designed to give safe, dependable

service if they are operated and maintained

according to instructions.

Read and understand this manual before

operation.

This manual has been prepared to assist the

owner and operators in the safe operation and

suitable maintenance of the implements. The

information was applicable to products at the time

of manufacture and does not include modifications

made afterwards.

Read and understand this operator's manual

before attempting to put an implement into

service. Familiarize yourself with the operating

instructions and all the safety recommendations

contained in this manual and those labeled on the

implements and on the tractor. Follow the safety

recommendations and make sure that those with

whom you work follow them.

The Dealer is responsible for wa rran t y re gistra ti on of t he uni t y ou h ave pu rchas ed . T o assis t yo ur deal er i n

handling your needs, please record here after the mo del numb er and seri al number o f your imple ment and

tractor. It is also advisable to supply them to your insurance company. It will be helpful in the event that an

implement or tractor is lost or stolen.

Illustrations

The illustrations may not necessarily reproduce

the full detail and the exact sha pe of the parts or

depict the actual models, but are intended for

reference only.

Direction Reference

Right Hand and Left Hand are determined by

those seen by the conductor standing behi nd the

equipment.

TRACTOR DEBRIS BLOWER

MODEL :

SERIAL NUMBER :

DATE OF PURCHASE :

OM 0400-A

4

Page 7

SECURITY

SAFETY FIRST

This symbol, the industry's "Safety Alert Symbol", is used th roughout this manual and on labels

on the machine itself to warn of the possibility of personal injury. Read these instructions

carefully. It is essential that you read the instructions and safety regulations before yo u attempt

to assemble or use this unit.

DANGER : Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING : Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION : Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

IMPORTANT : Indicates that equipment or property damage could result if instructions

are not followed.

NOTE : Gives helpful information.

All products are designed to give saf e, dependable service if they are operated and maintained according

to instructions. Read and understand this man ual before operation

be certain anyone operating this product reads this manual, and all other applicable manuals , to become

familiar with this equipment and all safety precautions. Failure to do s o could result in serious personal

injury or equipment damage. If you have any questions, consult your dealer.

. It is the owner's responsibility to

BEFORE OPERATION

Children and Bystanders

Tragic accidents can occur if the operator is not

alert to the presence of children. Children are

generally attracted to machines and the work

being done. Never assume children will remain

where you last saw them.

1. Keep children out of the operating area and

under the watchful eye of another

responsible adult.

2. Be alert and turn machine off if children enter

the work area.

3. Before and when backing, look behind and

look for small children.

4. Never carry children while operating the

machine. They may fall off and be seriously

injured or interfere with safe operation of the

machine.

5. Never allow children to play on the machine

or attachment even when turned off.

6. Never allow children to operate the machine

even under adult supervision.

7. Use extra care when approaching blind

corners, shrubs, trees, or other obstructions

that might hide children from sight.

OM 0400-A

5

Page 8

SECURITY - continued

NOTICE

A safe operator is the best insuranc e against accidents. All operators, no matter how experienced t hey

may be, should read this Operator's Manual and all other related manuals before attempting to opera te

an implement. Please read the following section and pay particular attention to all safety recommendations contained in this manual and those labeled on the implements and on the tractor.

DEBRIS BLOWER

Before Operation

1. Read and understand this operator's

manual and tractor operator's manual.

Know how to operate all controls and how

to stop the unit and disengage the controls

quickly.

2. Never wear loose, torn, or bulky clothing

around the tractor and implement. It may

catch on moving parts or controls, leading

to the risk of accident.

3. Disengage clutch and shift into neutral

before starting the engine.

4. Do not operate equipment in wintertime

without wearing adequate winter garments.

5. Never attempt to make any adjustments

while engine is running. Read this manual

carefully to acquaint yourself with the

equipment as well as the tractor operator's

manual. Working with unfamiliar equipment

can lead to accidents. Be thoroughly

familiar with the controls and proper use of

the equipment. Know how to stop the unit

and disengage the controls quickly.

8. Replace all missing, illegible, or damaged

safety and warning decals. See list of

decals in the operator's manual.

9. Do not modify or alter this equipment or

any of its components, or any equipment

function without first consulting your dealer.

10. Keep safety decals clean of dirt and grime.

11. Make sure the tractor is counterweighted

as recommended by your dealer. Weights

provide the necessary balance to prevent

tip-over or loss of traction or steering

6. Keep all shields in place and properly

tighten all mounting hardware.

7. Periodically, inspect all moving parts for

wear and replace with authorized service

parts if an excessive amount of wear is

present.

OM 0400-A

6

Page 9

SECURITY - continued

Debris blower Operation

1. Before leaving the tractor/debris blower

unattended, take all possible precautions.

Park the tractor/debris blower on level

ground, set the parking brake, disengage

debris blower drive, lower the debris blower

to the ground, place all levers including

auxiliary control levers in neutral, shut off the

engine and remove the ignition key.

2. Prior to operation, clear work area of all

objects that can be picked up and thrown.

Mark all curbs, pipes, etc. that cannot be

moved.

3. Be sure the debris blower drive is in OFF

position before starting engine.

4. Exercise extreme caution when operating on

or crossing a gravel drive, walks, or roads.

Stay alert for hidden hazards or traffic.

5. Do not carry passengers.

6. Keep clear of all rotating parts. Do not put

hands or feet under, or into debris blower

with engine running. Be especially

observant of the debris blower areas of

discharge, intake or all other mechanical

motions.

7. Park the tractor/debris blower on level

ground, set the parking brake, disengage

the debris blower drive, lower the debris

blower to the ground, place all control levers

in neutral, shut off the engine, remove the

ignition key and allow the rotating parts to

stop BEFORE making any repairs,

adjustments or inspections.

8. If the debris blower starts to vibrate

abnormally, disengage the pulley, stop the

engine immediately and check for cause.

Excessive vibration is generally a sign of

trouble.

9. Do not ru n the engine indoors except when

starting engine and transporting attachment

in or out of building. Carbon monoxide gas

is colorless, odorless and deadly.

10. Do not attempt to operate on ste ep slopes. If

operating on slopes is necessary, exercise

extreme caution when changing direction.

11. Never operate debris blower without guards,

and other safety protective de vices in place.

All tractor and debris blower shields and

covers must be correctly installed at all times.

When necessary to remove these, th ey must

be reinstalled immediately.

12. Never operate debris blower near glass

enclosures, automobiles, window wells,

embankments, etc., without proper

adjustment of the angling deflector.

13. Never operate machine at high transport

speeds on a slippery surface.

14. Use extra caution when backing up.

15. Disengage power to debris blower when

transporting or when n ot in use.

16. Never operate the debris blower without good

visibility and lighting.

17. Prolonged exposure to loud noise c an cause

impairment or loss of hearing. Wear a

suitable hearing protective device such as

earmuffs or earplugs to protect against

objectionable or uncomfortable noises.

18. Never allow anyone near the work area.

19. Never allow anyone to operate the debris

blower until they have read the manual

completely and are thoroughly familiar with

basic tractor and debris blower operation.

20. Always make sure all debris blower

components are properly installed and

securely fastened BEFORE operation.

21. Keep away from discharge. This debris

blower has the capacity to throw deb ris at far

distances.

22. Never direct discharge towards people or

animals. Thrown debris can cause serious

injury.

OM 0400-A

7

Page 10

THE TRACTOR

General Information

SECURITY - continued

1. Read the operator's manual carefully before

using tractor. Lack of operating knowledge

can lead to accidents.

Operating the Tractor

1. Never run the tractor engine in a closed

building without adequate ventilation, as

the exhaust fumes are very dangerous.

2. Never allow an open flame near the fuel

tank or battery.

3. Make sure the shield is installed when

using a PTO-driven equipment and always

replace the shield if damaged.

4. Always bring the tractor to a complete stop,

shut off the engine, lower the implement to

the ground and remove the ignition key

before leaving the tractor.

5. Never park the tractor on a steep slope.

6. Do not attempt to operate on steep slopes.

7. Use of tire chains for better traction and

stability is recommended.

8. Always drive the tractor at speeds

compatible with safety, especially when

operating over rough ground, crossing

ditches, or when turning.

9. Handle fuel with care, as it is highly

flammable.

10. Use approved fuel container.

11. Never add fuel to a running engine or a hot

engine.

12. Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors. Replace fuel

cap securely and wipe up spilled fuel.

13. Never allow anyone to operate the debris

blower until they are thoroughly familiar

with basic tractor and debris blower

operation.

2. Do not allow anyone but the operator to ride

on the tractor. There is no safe place for

extra riders

14. A minimum 20% of tractor and equipment

weight must be on the tractor front wheels

when attachments are in transport position.

Without this weight, tractor could tip over,

causing personal injury or death. The

weight may be attained with a loader, front

wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and

equipment. Do not estimate.

15. Always make sure all debris blower

components are properly installed and

securely fastened BEFORE operation.

During Operation

1. Do not allow anyone to ride on the tractor/

debris blower at any time. There is no safe

place for passengers on this equipment.

The operator MUST sit in the tractor seat.

2. Eye and hearing protection is

recommended when operating the debris

blower.

3. Operate only during daylight hours, or when

the area is well lit with bright artificial light.

4. Disengage the PTO (turn to “OFF”), place

the transmission in neutral, set the parking

brake, shut off the engine and remove the

key, and make sure rotating components

have stopped BEFORE leaving the

operator’s seat.

5. Inspect the debris blower after striking any

foreign object to assure that all debris

blower parts are safe and secure and not

damaged.

OM 0400-A

8

Page 11

SECURITY - continued

MAINTENANCE

1. Park the tractor/ debris blower on level

ground, set the parking brake, disengage

the PTO, shut off the engine, remove the

key, and lower the implement to the ground

BEFORE making any debris blower

adjustments.

2. To avoid injury, do not adjust or service the

debris blower with the tractor engine

running. Making sure rotating components

have completely stopped before leaving the

operator’s seat

3. Always wear eye protection when cleaning

or servicing the debris blower.

4. Do not work under any part of the tractor or

debris blower, unless it is securely

supported by safety stands.

5. Make sure all shields and guards are

securely in place following all service,

cleaning, or repair work.

6. Do not modify or alter this equipment or

any of its components or operating

functions. If you have questions concerning

modifications, consult with your dealer.

TRANSPORTATION

1. If the tractor/ debris blower is to be driven on

public roads, it must be equipped with an

SMV (Slow Moving Vehicle) sign. Check

local traffic codes that may apply to unit

usage on public roads and highways in your

area.

2. Be alert for all ot her traffic when driving the

tractor/ debris blower on public roads or

highways.

3. Reference the Roadway Transport section

on page 19.

STOR AGE

1. Before storing the debris blower, certain

precautions should be taken to protect it

from deterioration.

2. Clean the debris blower thoroughly.

3. Make all the necessary repairs.

4. Replace all Safety Signs that are

damaged, lost, or otherwise become

illegible. If a part to be replaced has a sign

on it, obtain a new safety sign from your

dealer and install it in the same place as on

the removed part.

OM 0400-A

5. Repaint all parts from which paint has worn

or peeled.

6. Lubricate the debris blower as instructed

under "Lubrication" section.

7. When the debris blower is dry, oil all

moving parts. Apply oil liberally to all

surfaces to protect against rust.

8. Attach driveline shield safety chain around

driveline by passing it over the upper hitch

9. Store in a dry place.

9

Page 12

5RD2500813

DECALS

Replace immediately if damaged

5RD2500786

5RD2500792

5RD2500793

5RD2500785

5RD2500624

5RD664391

5RD664391

5RD664391

5RD2500616

OM 0400-A

5RD2500820

5RD2500830

5RD2500827

5RD2500828

10

Page 13

ASSEMBLY

TRACTOR PREPARATION

See Dealer for Tractor Preparation information.

DEBRIS BLOWER ASSEMBLY

Use the present manual and lay out all parts for assembly. Separate bolts and nuts into various sizes. After

assembly, torque all the bolts according to the Torque Specification Table at the end of the manual.

Debris Blower removing front wooden crate (Fig. 1)

1. Remove the six 3/8"NC x 3/4" carriage bolt

and six 3/8"NC serrated flange nut to

remove the belt protector (item 1).

2. Keep the hardware for further use. Remove

the four screws (item 4) and 1/4" flat

washers (item 5) that maintain the Debris

Blower to the crate.

3. Reinstall the belt protector (item 1) with the

six 3/8"NC x 3/4" carriage bolt and six

3/8"NC serrated flange nut removed

previously.

4. Remove the three round wire lock pins

(item 6) from the wheel support pins and

attach them in the holes provided on the

side of the Debris Blower (item A).

5. You may use the two lifting holes (item 7) to

move the Debris Blower more easily.

OM 0400-A

A

Figure 1

11

Page 14

ASSEMBLY

Debris Blower Installation on a Three Point Hitch (Figures 2-3)

NOTE: To install on a Cat. 1 three point hitch,

the hitch pins (item 3) must be oriented tow ard

the inside. On a Cat. 2, they must be oriented

toward the outside.

NOTE

quick hitch, remove the

1 1/4" OD bushing from the

3/4" upper pin. If you install

the debris blower on a

Cat.2 tractor, you must

remove the two 1 1/2"OD

bushings attached to the

hitch pins with spring pins

(items 1-2-3).

1. Attach the upper and lower arms to the

: To install on a

tractor:

CATEGORY 1

A- Attach the tractor lower arms (item 1) to

debris blower pins (item 2) from the inside

and secure with linchpins (item 3).

B- Secure the tractor upper arm (item 4)

between the upper hitch plates (item 6)

with a pin (item 5) and a linchpin (item 3).

(Figure 2)

Before connecting debris blower

driveline to tractor drive shaft, make

sure driveline is not too long in raised,

lowered and middle position. If the

driveline is too long it must be

shortened, to avoid damaged to tractor.

See procedure on pages 14 to 16.

ATTENTION

CATEGORY 2

A- Attach the tractor lower arms (item 1) to

debris blower pins (item 2) from the

outside and secure with linchpins (item 3).

B- Secure the tractor upper arm (item 4)

between the upper hitch plates (item 6)

with a pin (item 5) and a 1"OD x 2" lg

bushing (5RD4600056) (item 7 – not

included) and a linchpin (item 3).

2. Lower the debris blower to the ground to

adjust the level, parallel to the ground, with

the tractor upper arm.

3. Adjust the tractor anti-sway arms (item 8) to

prevent back and forth movement of the

debris blower. Make sure there is no contact

with the tractor tires.

(Figure 3)

Figure 2

CATEGORY 1

Figure 3

OM 0400-A

CATEGORY 2

12

Page 15

ASSEMBLY

Installation of the Debris Blower

with a Quick Hitch Cat. 1

Figure 4: Place the Debris Blower (item 1) on

flat hard ground. Unlock the lower locks of the

quick hitch (item 2) by lifting the two hitch

levers. Back up the tractor slowly aligning the

three quick hitch hooks (item 4) with the three

bushings (item 3) of the debris blower and

lock the quick hitch lower locks.

IMPORTANT: To install on a Cat. 1 three

point hitch with a Quick Hitch, the pins with 1

1/2"OD bushings must be oriented toward

the inside. On a Cat. 2 quick hitch, they mus t

be oriented toward t he o ut sid e.

Installation of the Debris Blower

with a Quick Hitch Cat. 2

1. Figure 5a: Remove the linchpins (item 1),

lockwashers (item 3), nuts (item 2) and pins

(item 4). Use a round wood stalk to block the

cat.1 and 2 pin during the loosening and the

tightening of the nut.

2. Figure 5b: Install the pins (item 1) in the

position illustrated and reinstall the

lockwashers (item 3), nuts (item 2), and

linchpins (item 4).

3. Figure 5c: Place the debris blower (item 1) on

flat hard ground. Unlock the lower locks of the

quick hitch (item 2) by lifting the two hitch

levers. Back up the tractor slowly aligning the

three quick hitch hooks (item 4) with the three

bushings (item 3) of the debris blower and lock

the quick hitch lower locks.

Figure 4

CATEGORY 1

OM 0400-A

Figure 5a

CATEGORY 2

13

Figure 5b

Figure 5c

Page 16

Driveline Preparation

ASSEMBLY

IMPORTANT:

A proper initial installation w ill give you years

of satisfactory service on your equipment.

Please read carefully following instructions

that have been specially included to help you

and ensure you are satisfied with your

purchase.

HOW TO DETERMINE DRIVELINE ANGLES

IMPORTANT: To obtain the proper universal

joint angles, it is recommended to adjust the

three point hitch at the furthest point from the

tractor recommended by the manufacturer

Danger: Tractors Too Big

It is dangerous to use a tractor that is too big an d

powerful. The tractor will always be able to

overload the blower, even if the machine is

already at maximum capacity. Furthermore,

tractors being very high, the driveline angles will

be excessive which means the universal joints

will be very vulnerable and the life of the driveline

will be dramatically reduced.

The universal joint angle is directly related with

the life of driveline. In order to reduce the angle, it

is necessary to increase the distance between

the debris blower and the tractor .

Angles of Driveline Joints Too Large Reasonable Angles of Driveline Joints

Avoid Acceptable

Unequal Angles at Driveline Joints Equal Angles at Driveline Joints

Avoid

OM 0400-A

Recommended

14

Page 17

ASSEMBLY

ANGLES AT EACH END OF DRIVELINE

To avoid damages to the driveline or the

debris blower, it is recommended to always

keep tractor driveline and debris blower input

shaft parallel.

DETERMINING DRI VELINE LENGTH

IMPORTANT: Before using the equipment,

make sure the driveline is not too long. At

working position, the two half drivelines

must intersect each other sufficiently to

insure maximum efficiency but there must

not be any interference.

1. To determine the "L" length for your tractor

model first find the "X" factor by measuring

the horizontal distance between the end of

the tractor's drive shaft and the end of the

debris blower's driven shaft when the

debris blower is in transport position as

shown on Figure A.

2. Choose in the table below the "Y" factor

according to the tractor category and

deduct that number from "X" to determine

"L" which is the center-to-center length

between the universal joints.

L = X – Y

3 PTS HITCH

CATEGORY

Figure A

Y

OM 0400-A

Cat. 1 4 1/2"

Cat. 2 5 1/2"

15

Page 18

ASSEMBLY

T

A

NOTE:

Before cutting, make sure the two sha fts

intersect by at least 7 3/4" when in working

position that is when the debris blower rests on

the ground.

3. Hold the two half-shaft side by side and

locate the "L" length between the two centerto-center half-shaft universal joints. Mark off

the zone to be cut on both halves opposite

each half-shaft guard as show n on Figure B.

4. Cut off inner and outer guard tubes as well as

the inner and outer telescopic sections.

SECTION TO CU

5. Cut the guard a second time leaving the

same distance between the end of the guard

and the end of the shaft as existed before.

To obtain the proper distance "A" shown on

Figure C, cut the guard according to the

following table:

DISTANCE A

Male PTO Female PTO

1 3/4" 1 1/4"

6. File down tubes and remove chips.

7. Apply grease to inside of outer telescopic

section.

IMPORTANT

: Work with fully guarded s hafts

only!

Figure B Figure C

MARK OFF THE ZONE TO BE CUT ON BOTH HALVES

OPPOSITE EACH HALF-SHAFT GUARD

SECTION TO CUT

OM 0400-A

16

Page 19

ASSEMBLY

Driveline Installation

(Figure 6)

1. Separate the debris blower from the three

point or quick hitch.

2. Grease driveline sliding surfaces and yoke

(item 1).

3. Remove t he bolts (items 2) from the driveline

yoke ( (item 1) and connecter to the debris

blower shaft. Make sure the driveline is

well secured to the shaft by reinstalling the

bolts and nuts (item 2-3) in the order shown.

Tighten the bolts according to the Torque

Specification Table at the end of the manual.

4. Attac h safety chain (item 4) around the upper

link to prevent the guard from spinning.

Figure 6

OM 0400-A

17

Page 20

ASSEMBLY

Removing Debris Blower from Tractor (Figure 7)

1. Set parking brake and turn engine off.

2. Direct the wheel supports (item 2) along the

housing support tube (as illustrated) and lock in

position with three round wire lock pins (ite m 1),

that are attached to the debris blower housing

(item A).

3. 3 point Hitch only: Detach upper arm by

removing linchpin and pin.

4. Disconnect driveline (item 3) from tractor and

attach the driveline safety chain (item 4) to the

housing support with the chain spring hook.

5. 3 point Hitch only: Carefully detach lo wer arms

from hitch pins by removing linchpins and loosen

anti-sway turnbuckles.

6. Quick Hitch only: Lift the two levers to release

lower hooks.

7. Lower the tractor 3 point system and slowly back

tractor away from the Debr is Bl ower.

IMPORTANT

blower, retorque all bolts after the first 10

hours of operation.

: To avoid damages to the debris

A

Figure 7

OM 0400-A

18

Page 21

OPERATION

GENERAL PREPARATION

1. Read the operator’s manual

carefully before using the tractor

and debris blower. Be thoroughly

familiar with the controls and proper

use of the equipment. Know how to

stop the unit and disengage the

controls quickly.

2. Make sure the impeller operates

freely.

3. Check the s hear bolt on the PTO, fo r

proper tightness.

4. Wear adequate winter outer

garments while operating equipment.

ATTENTION

To avoid personal injury, be sure the

tractor engine is off, the drive shaft

disengaged, and all movement has

stopped before making any

adjustments.

Roadway Transport (Figures 8a-8b-8c)

1. Position the tractor and the debris blower on a level

surface.

2. Adjust the 3 point height to maximum.

3. Figure 8a: Go to the front of the debris blower at

approximate distance of 15 feet fro m it, in the middle

and at the same level than the tractor.

4. Figure 8b: Look toward the tractor and check if the

rear tractor lights are all visible, specially the lower

ones. (item 1). If some are hidden, lower the 3 point

until the lights become visible.

5. Figure 8c: When the height is set, take note of the

adjustment on the lever graduation (item 1) fo r futures

utilization with the same tractor. Then adjust the lock

(item 2) to the position found previously to make sure

to not exceed the prescribed he ight for security.

6. If you use another equipment and modify the lock

adjustment, make sure to reset the lock to the good

position to make the tractor lower rear lights always

visible.

Figure 8b

OM 0400-A

1

19

1

1

Figure 8a

2

Figure 8c

Page 22

OPERATING CONTROLS

OPERATION

Debris Blower Commands

1. Use the PTO button to start and stop the

impeller. Start the engine and put the

throttle lever at low engine speed.

Engage the PTO lever and maintain

engaged. Make sure the debris blower is

turning in the right direction. If not, switch

the quick couplers. To stop the rotation,

disengage the PTO button.

2. Raise and lower the debris blower using

the hydraulic lift lever located on the

tractor. Pulling the lever backward raises

the debris blower, pushing the lever

forward lowers the debris blower.

3. Control brush speed with the RPM that

controls the debris ejection power.

Debris Blower Utilisation

1. A debris blower purpose s to displace rather light

debris to a variable distance according to the

impeller speed. For heavy debris, it is

recommended using some other equipmen t type

such as a rotary broom. For an optimum

performance, lower the debris blower as the 3

wheels touch the ground. Make sure th e loader

control lever is in floating position to allow the

equipment to follow the ground variation and so

more debris to be blown.

2. For light debris, use a higher vehicle ground

speed. For heavier debris, use a reduced vehicle

ground speed. For small area, lowe r the tractor

motor speed to eject debris on a short dis tance.

For wider area, use higher speed.

Nozzle air ejection Orientation

Equipment air ejection can be don e to the right or

the left. To change direction, move the orientation

arms on the debris blower. See decal on equipment

to check arm positions for right orientation.

WARNING: To avoid serious injuries:

never move the orientation arm when th e debris

blower is running.

OM 0400-A

20

Page 23

ADJUSTMENTS

Belt Tension Adjustment (Figure 9)

OPERATION

1. Remove the belt protector (item 5) by

removing the six 3/8"NC x 3/4" carriage

bolts and six serrated flange nuts (items 6-

7).

2. Loosen the eight 1/2"NC nylon insert

locknut (item 1).

3. Tighten eyebolt nuts (item 2). With a belt

tension gauge check for a 35lbs tension

and a 3/16" displacement in the cent er in all

belt axis (item 3).

4. Realign the driv ing pulle y assembl y (item 4)

by pressing the support against the bolted

guides. Tighten loosely the eight 1/2"NC

nylon insert locknuts (item 2) loosen

previously. With a long ruler t hat may cove r

the distance between pulleys, check the

pulleys alignment, If alignment is good,

tighten the eight 1/2"NC nylon insert

locknuts (item 2). If not, follow next step.

5. If the b elts are not well aligned, loosen the guide

nuts and the eyebolt nuts. Align the two pulleys,

slightly tighten the eight 1/2"NC nylon insert

locknuts (item 2). Press the guides against the

driving pulley assembly (item 4) and t ighten guide

nuts. Redo step 2. Check the pulleys alignment

and if the driving pulley assembly is well pressed

on guides. If so, tighten firmly the eight 1/2"NC

nylon insert locknuts. If not , repeat proced ure.

6. Reinstall the belt protector (item 5) with the six

3/8"NC x 3/4" carriage bolts and six serrated

flange nuts (items 6-7).

Figure 9

OM 0400-A

21

Page 24

MAINTENANCE

MAINTENANCE

Shearbolt

Check the shearbolt indicated on th e figure below

at frequent intervals for prop er tig ht ness to be sure

the debris blower is in safe working condition. If

the shearbolt needs replacement, use the

following part only

Driveline

Shearbolt M8 x 1.25 x 50mm gr. 6.6 with nut. Part

# 5RD4700060.

SHEAR

BOLT

WARNING

Provide adequate blocking before working

under the debris blower when in the raised

position.

Driveline

IMPORTANT: When the debris blower is not

used for more than two weeks, perform

driveline maintenance and alw ays store it in a

dry place, away from bad weather conditions.

OM 0400-A

22

Page 25

MAINTENANCE

LUBRICATION

Use oil or a grease gun and lubricate as follows:

DESCRIPTION INTERVAL LUBRICATION REQUIRED

Driveline

Bearing

8 hours

16 hours Oil the push pins

24 hours of

operation

Grease each universal joint. Separate the sliding parts and

cover each one of them with grease

Grease each bearing of the impeller shaft, the driving shaft, the

wheel support pins and the wheels.

PERIODIC CHECKS

DESCRIPTION TIME INTERVAL

Belt Each lubrication Check for damages

Housing, hitches, impeller

wheel supports

Hardware 24 hours of use Check a n d ti g h t e n i f n e e d e d

Tires Each utilization Check pressure

OM 0400-A

REQUIRED CHECKS

100 hours of use Repair if needed

23

Page 26

MAINTENANCE

Belt Replacement (figures 10a-10b-10c)

1. Figure 10a: Remove the belt guard (item 1) and

the six 3/8"NC x 3/4" carriage bolts (item 2) and

six 3/8"NC serrated flange nuts (item 3).

2. Figure 10a: Remove the 1/2"NC x 2 1/2" bolt

hex (item 4) and the 1/2" lockwasher (item 5),

the 1/2" flat washer (item 6), the spacer (item 7)

and the 1/2" nylon insert locknut (item 8).

3. Figure 10a: Remove the 3/8" x 5" eyebolt

(item 9), the flat washer (item 10) and the nylon

insert locknut (item 11).

4. Figure 10a: Perform the 2 and 3 steps for the

second eyebolt.

5. Figure 10a: Remove the eight 1/2"NC nylon

insert locknuts (item 12), the eight 1/2"

lockwashers (item 13), the eight 1/2" (9/16" int.)

flat washers (item 14) and the eight 1/2"NC x 1

3/4" carriage bolts (item 15).

6. Figure 10b: With a hoist, raise the drive pulley

assembly (item 2) with a two hook chain (item 1)

to well balance the weight. (This assembly

weights approximately 75 pounds).

7. Put the drive pulley assembly to the ground and

move forward the debris blower.

8. Figure 10c: Remove the two set screws of the

bearing (item 1).

9. Figure 10c: Clean up the shaft behind the

bearing to remove the rear support plate

more easily (item 2).

10. Figure 10c: Place the new belt (item 3) over

the drive pulley (item 4).

11. Figure 10c: Reinstall the rear support plate

(item 2) and the two set screws on the

bearing (item 1) without tightening.

12. Figure 10c: Align the four notches with the

ones on the drive pulley assembly (item 4).

13. Place the drive pulley assembly to the ground

and back up the debris blower over it.

14. Raise the drive pulley assembly with the hoist

and reinstall the eight 1/2"NC x 1 3/4"

carriage bolts with the flat washers,

lockwashers and nylon insert locknuts. Do

not tighten.

15. Reinstall the two 3/8" x 5" eyebolts with the

1/2"NC x 2 1/2" hex bolts, the 1/2"

lockwashers, the 1/2" flat washers, the

spacers and the 1/2" nylon insert locknuts.

16. Go to «BELT TENSION ADJUSTMENT »

section.

OM 0400-A

Figure 10a

Figure 10b

Figure 10c

24

Page 27

MAINTENANCE

Impeller Removing and Reinstallation (figures 11a-11b)

TO REMOVE THE IMPELLER:

1. Figure 11a: If the debris blower is in

storage, remove the round wire lockpin

(item 1). Then remove the 1/4" cotter pin

(item 2), the flat washer (item 3) and the

wheel assembly (item 4). Place the arm

on a small wood block as a temporary

support.

2. Figure 11a: Attach the housing (item 7)

to a hoist with the hook provided on the

housing (item 5). Remove the twelve 3/8"

NC serrated flange nuts (item 6) and

move the housing to the front to take it

out from the impeller.

3. Figure 11b: Remove the 1/2"NC x 1" hex

bolt, the lockwasher and the flat washer

(items 2, 3 and 4) in front of the impeller

(item 1).

4. Figure 11b: Then remove the 1/2"NC x

3 1/2" hex bolt (item 5) and the 1/2"NC

nylon insert locknut (item 6).

5. Figure 11b: The impeller is provided with

an ejection device, so just screw a

3/4"NC x +/- 2 1/2" hex bolt (item 7) that

pushes against the shaft end and ejects

the impeller (item 1).

T

O REINSTALL THE IMPELLER:

1. Figure 11b: Remove the 3/4" x +/- 2 1/2" hex bolt

(item7).

2. Figure 11b: Apply grease on the shaft to

facilitate the reinstallation. Make sure to align the

hole in the impeller with the hole on the shaft,

where the 1/2"NC x 3 1/2" hex bolt was installed

(item 5). A light punch on the impeller should be

enough to insert it on the shaft.

3. Figure 11b: Attach with the 1/2"NC x 1" hex bolt,

the lockwasher and the flat washer (items 2, 3

and 4) in front of the impeller.

4. Figure 11b: Then attach the impeller with the

1/2"NC x 3 1/2" hex bolt (item 5) and the 1/2"NC

nylon insert locknut (item 6).

5. Figure 11a: Reinstall the front housing and the

wheels (follow the preceding procedure in

reverse).

Figure 11b

OM 0400-A

Figure 11a

25

Page 28

MAINTENANCE

DRIVELINE TROUBLESHOOTING

QUICK-DISCONNECT YOKE

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

Quick-disconnect pin tight or

completely seized.

Quick-disconnect pin

damaged (broken or bent)

Quick-disconnect pin

damaged in the locking

portion.

Quick-disconnect pin dirty

(insufficient maintenance).

Quick-disconnect pin

defective (forced

engagement, incorrect

handling)

Excessive shaft length.

Axial loads too high.

Note: Quick-disconnect pins must be cleaned and greased every 16 hours.

YOKE

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

Yoke ears deformation

Excessive shaft length.

Axial loads too high.

Excessive working angle

and torque.

Clean, oil and follow service

instructions.

Replace quick-disconnect pin.

Shorten shaft length (cut both

telescopic tubes as well as

shield and remove burrs).

Replace quick-disconnect pin.

Clean and grease telescopic

tubes, and replace both tubes,

if necessary.

Replace quick-disconnect pin.

Shorten shaft length (cut both

telescopic tubes as well as

shields and remove burrs).

Replace defective yokes.

Clean and grease telescopic

tubes, and replace bot h tubes,

if necessary.

Replace defective yokes.

Verify compatibility between

shaft and working conditions

(torque vs. angle).

Disengage tractor driveline

during cornering or when lifting

or lowering the implement.

Change to a larger driveline

size.

Replace defective yokes.

OM 0400-A

Yoke ears distorted. Overload caused by high

starting and peak torques.

Yoke ears worn or pounded.

Excessive working angle. Avoid excessive working

26

Engage driveline more

carefully.

Use appropriate safety

devices.

Replace defective yokes.

angle.

Disengage tractor driveline

during cornering.

Replace defective yokes.

Page 29

MAINTENANCE

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

CROSS KIT

Cross arms broken.

Bearing caps turning in their

cross journal.

Overheated bearing caps.

Accelerated wear of cross kit.

Extreme torque peak or

shock load.

Axial loads too high.

Excessive continuous

torque and/or excessive

working angle.

Inadequate greasing.

Excessive continuous

torque and/or excessive

working angle.

Inadequate greasing.

Use appropriate safety device.

Change to a larger driveline

size.

Shorten driveline shaft.

Replace defective cross

bearings.

Verify compatibility between

shaft and working conditions.

Carefully follow greasing

instructions.

Replace defective cross

bearings.

Verify compatibility between

shaft and working conditions.

Carefully follow greasing

instructions.

Replace defective cross

bearings.

Note: Cross bearings must be greased every 8 working hours.

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

TELESCOPIC TUBES

Telescopic tubes failure or

twisting.

Extreme torque peak or

shock load.

Short tube engagement.

Use appropriate safety device.

Change to a larger driveline

size.

Replace the driveline drive

shaft with one having

adequate length.

Replace defective tubes.

Note: Telescopic tubes must be cleaned and greased every 8 working hours.

Accelerated wear of telescopic

tubes.

Extreme load when sliding.

Short tube engagement.

Inadequate greasing.

Dirt

Change to a driveline with

rilsan coated inner tube.

Replace the driveline with one

having adequate length.

Carefully follow greasing

instructions.

Replace defective tubes.

OM 0400-A

27

Page 30

MAINTENANCE

SHIELD

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

Excessive wear of shield

bearings.

Chain moving or failure.

Shield cone damaged.

Shield tubes damaged

(deformed and split at one

side).

Insufficient lubrication.

Incorrect chain mounting.

Shield interfering with

implement.

Shield interfering with

implement.

Incorrect chain mounting.

Shield cone in contact with

components on the tractor

and/or implement.

Excessive angularity.

Shields in con tact with

components on the tractor

and/or implement.

Shield tubes ove rlap too

short or no overlap at all

with extended driveline.

Follow lubrication instructions.

Mount chain to allow

maximum angularity.

Avoid contact of the shields

with fixed parts of the machine

or tractor.

Replace shield bearings.

Avoid contact of the shields

with fixed parts of the machine

or tractor.

Mount chain to allow

maximum angularity.

Replace defective parts.

Eliminate interference

between Shield cones and any

part on the tractor and/or

implement.

Avoid excessive angle during

cornering or when lifting or

lowering the implement.

Replace damaged Shield

cones.

Eliminate interference

between Shield cones and

any part on the tractor and/or

implement.

Replace damaged tubes.

Adjust Shield tube s length

with longer tubes.

Note: Shield bearings must be greased every 8 working hours.

OM 0400-A

28

Page 31

PARTS

I

NTRODUCTION

All parts are illustrated in "exploded views" which show the individual parts in their normal relationship to

each other. Reference numbers are used in the illustrations . These numbers correspond to those in the

"Reference Number" (REF) column, and are followed by the description and quantity required.

Right Hand and Left Hand are determined by those seen by the conductor standing behind the equipment.

The manufacturer reserves the rights to change , modify, or eliminate from time to time, for technical or

other reasons, certain or all data, specifications, or the product or products themselves, without any liability

or obligation.

The parts listed here are available through your local dealer.

MANUAL HOLDER

EF. DESCRIPTION QTY PART #

R

1 Manual holder 1 5RD4200030

2 Bolt hex. 5/16" NC x 1" lg gr. 5, PTD 2 5RD0100019

3 Nylon insert locknut 5/16" NC, PTD 2 5RD10000 05

OM 0400-A

29

Page 32

PARTS

DEBRIS BLOWER – HOUSING

R

EF. DESCRIPTION QTY PART #

1 Housing 1 5RD669547

2 Belt shield 1 5RD669556

3 Lateral bracket 1 5RD669573

4 Carriage bolt ø3/8"NC x 3/4" Gr.5 PTD 6 5RD0300007

5 Carriage bolt ø1/2"NC x 1 3/4" Gr.5 PTD 10 5RD0300025

6 Serrated flange nut ø3/8"NC PTD 6 5RD0900035

7 Nylon insert locknut 1/2"NC, PTD 10 5RD10000 11

8 Lockwasher 1/2", PTD 10 5RD1200006

9 Flat washer ø9/16" int., PTD 6 5RD1400006

OM 0400-A

30

Page 33

PARTS

DEBRIS BLOWER – DRUM

R

EF. DESCRIPTION QTY PART #

1 Impeller housing 1 5RD669548

2 Intake cover 1 5RD669550

3 Orientation deflector 1 5RD669553

4 Angling arm 1 5RD669554

5 SMV reflective sign 1 5RD4200029

6 Bolt serrated flange ø3/8"NC x 3/4" Gr.5 PTD 3 5RD0200066

7 Bolt hex. Ø1/4"NC x 1" Gr.5 PTD 2 5RD0100004

8 Flat washer ø5/16" int., PTD 4 5RD1400002

9 Nylon insert locknut 1/4"NC, PTD 2 5RD1000003

10 Serrated flange nut ø3/8"NC PTD 12 5RD0900035

11 Cotter pin 3/16" x 1 1/4" 1 5RD1500012

OM 0400-A

31

Page 34

DEBRIS BLOWER – BELT DRIVE

PARTS

OM 0400-A

32

Page 35

PARTS

DEBRIS BLOWER – BELT DRIVE

REF. DESCRIPTION QTY PART #

1 CCW impeller 1 5RD669549

2 Rear bearing support 1 5RD669551

3 Front bearing support 1 5RD669552

4 Tension guide 2 5RD669576

5 Spacer ring - Upper shaft 1 5RD669571

6 Bushing - Tensioner 2 5RD669572

7 Key 5/16" x 5/16" x 1 3/4" 1 5RD661166

8 Driven shaft 1 3/8" 1 5RD669559

9 Drive shaft 1 3/8" 6 splines 1 5RD669558

10 Bearing 1 3/8" with setscrew 4 5RD4300019

11 Eye bolt 3/8" NC x 5" (Hex. nut 3/8" NC included) 2 5RD661426

12 Pulley 14" diam., "4V", TYPE "5V" 1 5RD480 0020

13 Hub Type E-1 3/8" dia. 1 5RD4800021

Including: Hex bolt 1/2"NC x 2 3/4" Gr.5 "full thread"

Lockwasher ø1/2" PTD

Set screw 3/8"NC x 3/8"

14 Pulley 5.2" diam., "4V", TYPE "5V" 1 5RD4 8000 22

15 Hub Type SD-1 3/8" dia. 1 5RD4800023

Including: Hex bolt 1/4"NC x 2" Gr.5 "full thread "

Lock washer ø1/4" PTD

Set screw 1/4"NC x 1/4"

16 Belt "Power Band" 4-R5VX560 1 5RD4800024

17 Bolt hex. 1/2"NC x 1 3/4" Gr.5 PTD 9 5RD0100071

18 Carriage bolt ø1/2"NC x 1 3/4" Gr.5 PTD 8 5RD0300025

19 Nylon insert locknut 1/2"NC, PTD 19 5RD1000011

20 Lockwasher 1/2", PTD 20 5RD1200006

21 Flat washer ø9/16" int., PTD 20 5RD1400006

22 Bolt hex. 1/2"NC x 3 1/2" Gr.5 PTD 1 5RD0100079

23 Key 5/16" x 5/16" x 2 1/8" 1 5RD669582

24 Carriage bolt ø3/8"NC x 1 1/4" Gr.5 PTD 4 5RD0300009

25 Lockwasher 3/8", PTD 4 5RD1200004

26 Nylon insert locknut 3/8"NC, PTD 6 5RD10000 06

27 Flat washer ø7/16" int., PTD 6 5RD1400004

28 Retaining ring 1 5RD4300068

29 Bolt hex. 1/2"NC x 2 1/2" Gr.5 PTD 2 5RD0100076

30 Protective rubber 2 5RD669348

31 Bolt hex. 1/2"NC x 1" Gr.5 PTD 1 5RD0100068

32 Driveline 1 5RD4700159

3 3 1 -

3 3 1 -

OM 0400-A

33

Page 36

PARTS

DEBRIS BLOWER – HITCH AND WHEELS

R

EF. DESCRIPTION QTY PART #

1 Hitch and wheels support 1 5RD669557

2 Wheels support 3 5RD669555

3 Chain 35" lg. with springhook 1 5RD669210

4 Spacer 1.015" ID x 1" lg. 6 5RD661119

5 Wheel bushing 3 5RD669560

6 Wheel and rim 3 5RD660658

7 Hitch pin cat. 1 & 2, PTD 2 5RD654204

8 Pin 3/4" x 5 7/16", PTD 1 5RD4600051

9 Bushing 1 1/4 " ext. x 2-13/32" lg x .770" int. PTD 1 5RD669211

10 Bushing 1.135" int. x 1 1/2" ext. x 2 15/16" lg 2 5RD668379

11 Linchpin 7/16", PTD 3 5RD1900003

12 Round wire lock pin 1/4" x 1 3/4" 3 5RD1900006

13 Spring pin 3/8" x 1 1/2" , bla ck 2 5RD1600022

14 Cotter pin 1/4" x 2" 3 5RD1500022

15 Flat washer ø1 1/4" int., PTD 3 5RD1400014

16 Bolt hex. Ø5/8"NC x 7" Gr.5 PTD 3 5RD0100109

17 Nylon insert locknut 5/8"NC, PTD 3 5RD1000012

18 Flat washer ø11/16" int., PTD 3 5RD1400008

19 Grease fitting 1/4NF 3 5RD654106

OM 0400-A

34

Page 37

PARTS

DRIVELINE 5RD4700159

EF. DESCRIPTION QTY PART #

R

Yoke ass'y

1

Journal cross

2

Yoke for female tube

3

Female tube

4

Male tube

5

Yoke for male tube

6

Yoke ass'y

7

Shear bolt M12 x 1.25 x 70 with nut

8

Grease fitting

9

10

11

12

13

14

Ball Ø1/4"

Shear bolt 8mm x 1.25 x 50 gr.5.8 and nut

Protector and chain

Pin for outer tube

Pin for inner tube

1 5RD660764

2 5RD660765

1 5RD663189

1 5RD4700160

1 5RD4700161

1 5RD663193

1 5RD4700058

2 5RD662199

1 5RD663129

23 5RD663163

1 5RD4700060

1 5RD4700164

1 5RD4700061

1 5RD4700062

OM 0400-A

35

Page 38

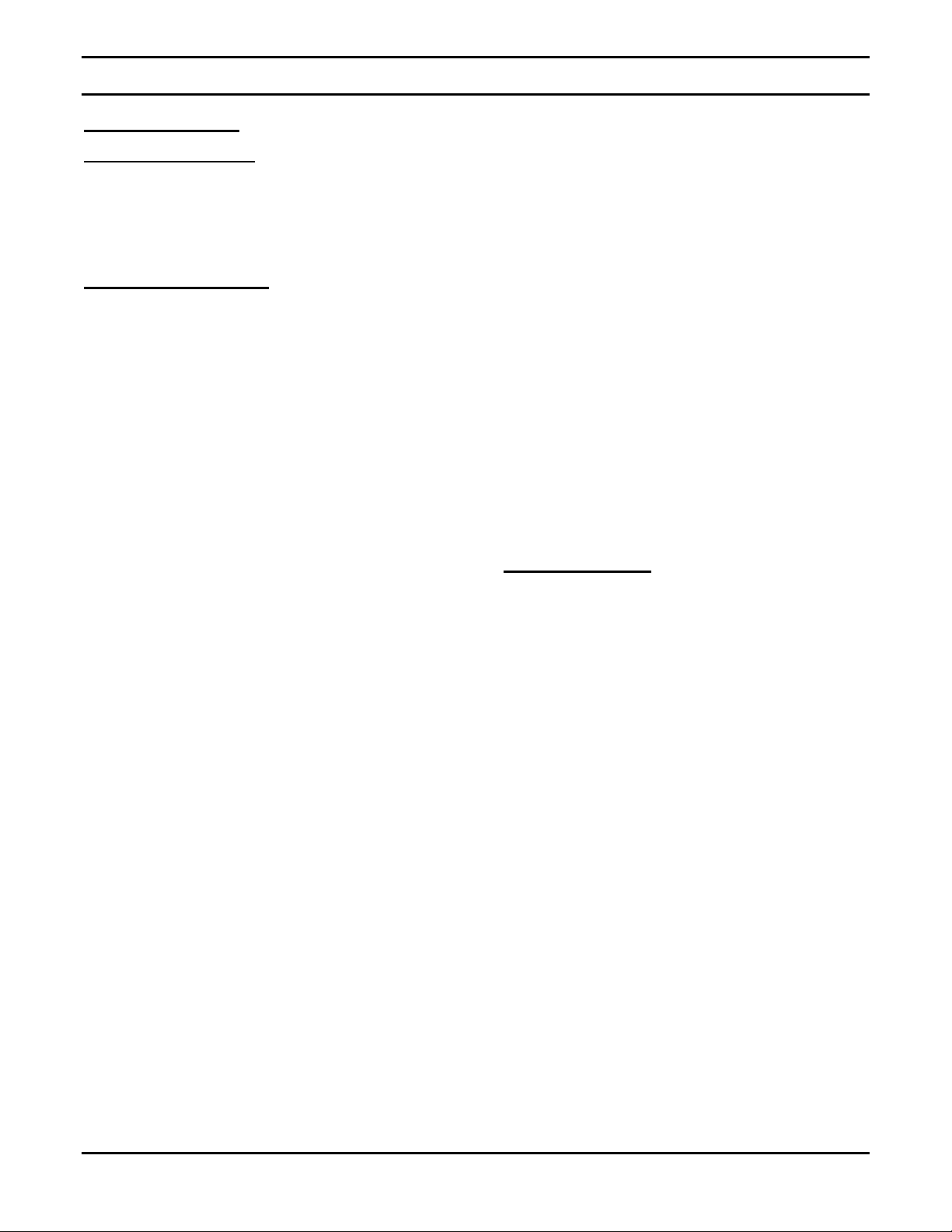

TORQUE SPECIFICATION TABLE

NOTE: These values apply to fasteners as received from supplier, dry, or when lubricated wi th normal engine oil. They do not a pply if special

graphited or moly sidulphide greases or other extreme pressure lubricants are used. This applies to both UNF and UNC threads.

SEE Grade No. 2 5 8

BOLT HEAD IDENTIFICATION

MARKS AS PER GRADE

NOTE: MANUFACTURING MARKS

WILL VARY.

Torque Torque Torque

BOLT SIZES Pounds-Foot Newtons-Meter Pounds-Foot Newtons -Meter Pounds-Foot Newtons-Meter

Inches Millimeters MIN. MAX. MIN. MAX. MIN. MAX. MIN. MAX. MIN. MAX. MIN. MAX.

1/4 6.35 5 6 6.8 8.13 9 11.0 12.2 14.9 12 15 16.3 30.3

5/16 7.94 10 12 13.6 16.3 17 20.5 23.1 27.8 24 29 32.5 39.3

3/8 9.53 20 23 27.1 31.2 35 42.0 47.5 57.0 45 54 61.0 73.2

7/16 11.11 25 30 40.7 47.4 54 64.0 73.2 86.8 70 84 94.9 113.9

1/2 12.70 45 52 61.0 70.5 80 96.0 108.5 130.2 110 132 149.2 179.0

9/16 14.29 65 75 88.1 101.6 110 132.0 149.2 179.0 160 192 217.0 260.4

5/8 15.88 95 105 128.7 142.3 150 180 203.4 244.1 220 264 298.3 358.0

3/4 19.05 150 185 203.3 250.7 270 324 366.1 439.3 380 456 515.3 618.3

7/8 22.23 160 200 216.8 271.0 400 480 542.4 650.9 600 720 813.6 976.3

1 25.40 250 300 338.8 406.5 580 696 786.5 943.8 900 1080 1220.4 1464.5

1 1/8 25.58 - - - - 800 880 1084.8 1193.3 1280 1440 1735.7 1952.6

1 1/4 31.75 - - - - 1120 1240 1518.7 1681.4 1820 2000 2467.9 2712.0

1 3/8 34.93 - - - - 1460 1680 1979.8 2278.1 2380 2720 3227.3 3688.3

1 1/2 38.10 - - - - 1940 2200 2630.6 2983.2 3160 3560 4285.0 4827.4

Coarse thread Fine Thread

Size of

screw

Grade No.

Pitch

mm

Use the following torques when specia l torque s are not given

Pounds-Foot Newtons-Meter

MIN. MAX. MIN. MAX. MIN. MAX. MIN. MAX.

GENERAL SPECIFICATION TABLE

METRIC BOLT TORQUE SPECIFICATIONS

Pitch mm

Pounds-Foot Newtons-Meter

M6

M8

M10

M12

M14

M16

M18

M20

4T

7T

8T

1.0

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

4T

7T

8T

1.25

1.5

1.75

2.0

2.0

2.0

2.5

3.6

5.8

7.2

7.2

17

20

20

34

38

28

51

57

49

81

96

67

116

129

88

150

175

108

186

213

5.8

9.4

10

14

22

26

25

40

46

34

59

66

56

93

109

77

130

145

100

168

194

130

205

249

4.9

7.9

9.8

9.8

23

27.1

27.1

46.1

51.5

37.9

69.1

77.2

66.4

109.8

130.1

90.8

157.2

174.8

119.2

203.3

237.1

146.3

252

288.6

7.9

12.7

13.6

19.0

29.8

35.2

33.9

54.2

62.3

46.1

79.9

89.4

75.9

126

147.7

104.3

176.2

196.5

136

227.6

262.9

176.2

277.8

337.4

-

1.0

1.25

1.25

1.5

1.5

1.5

1.5

-

-

-

12

19

22

20

35

40

31

56

62

52

90

107

69

120

140

100

177

202

132

206

246

-

-

-

17

27

31

29

47

52

41

68

75

64

106

124

83

138

158

117

199

231

150

242

289

-

-

-

16.3

25.7

29.8

27.1

47.4

54.2

42

75.9

84

70.5

122

145

93.5

162.6

189.7

136

239.8

273.7

178.9

279.1

333.3

-

-

-

23.0

36.6

42

39.3

63.7

70.5

55.6

92.1

101.6

86.7

143.6

168

112.5

187

214.1

158.5

269.6

313

203.3

327.9

391.6

OM 0400-A

36

Page 39

Page 40

PART NO.

5RDBL1130A

All Rights Reserved

Loading...

Loading...