Page 1

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

Page 2

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

PAGES

2–3

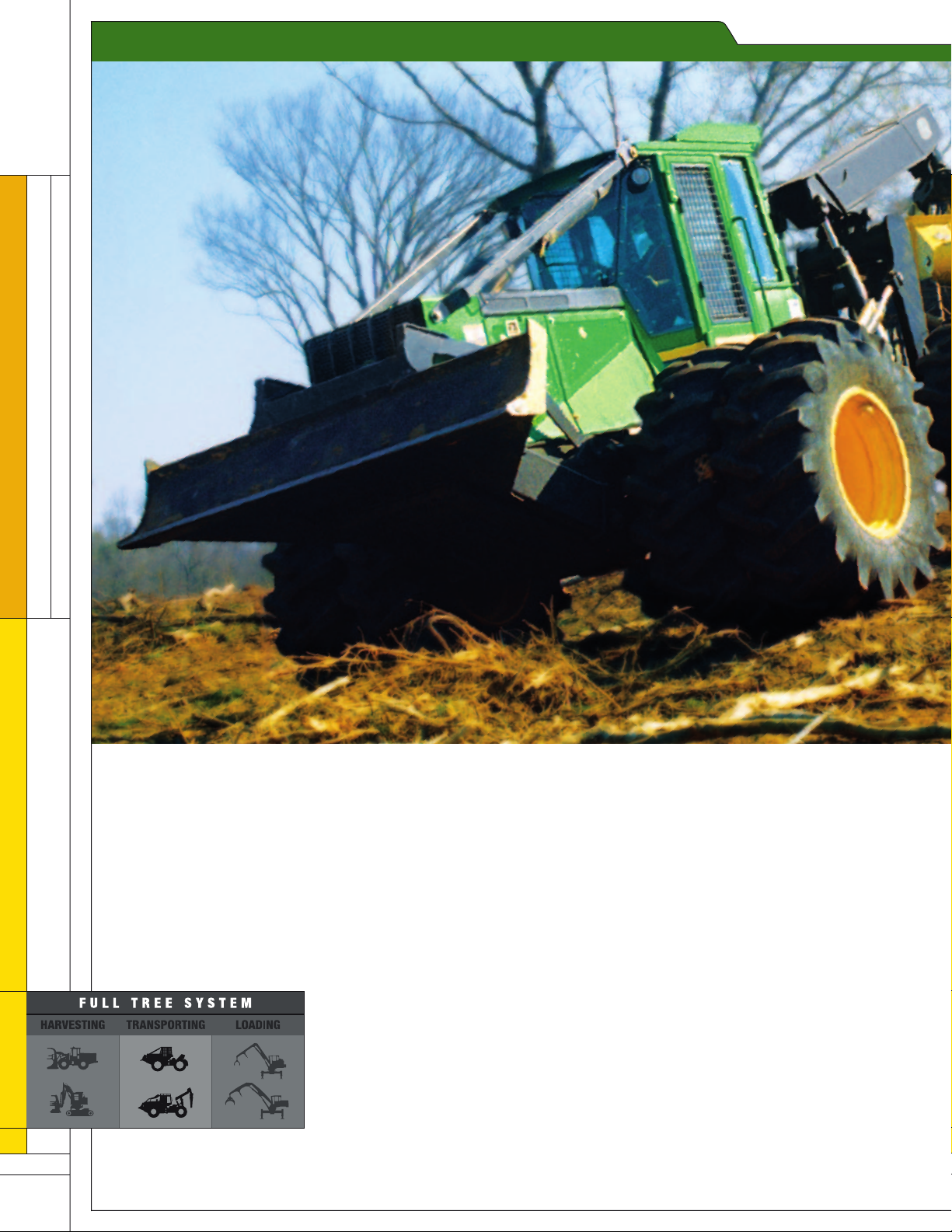

THE PERFECT SKIDDER

FOR YOUR IMPERFECT WORKING CONDITIONS.

Full Tree System—No one offers the

extensive product line, dealer network

and tough, purpose-built machines

like John Deere.

Page 3

GRAPPLE 548G-III/

CABLE 540G-III

Rated Power @ 2,200 rpm 129 SAE gross hp 96 kW 171 SAE gross hp 128 kW 177 SAE gross hp 132 kW

GRAPPLE 648G-III/

CABLE 640G-III

GRAPPLE 748G-III

Rated Power @ 2,200 rpm

with Torque Converter

Maximum Gross Torque

Maximum Gross Torque

with Torque Converter Option

Engine Type 6.8 L Deere PowerTech

N/A 185 SAE gross hp 138 kW N/A

32% @ 1,400 rpm/

407 lb-ft 552 Nm

N/A

28% @ 1,400 rpm/

521 lb-ft 706 Nm

40% @ 1,400 rpm/

618 lb-ft 838 Nm

™

6.8 L Deere PowerTech Plus™8.1 L Deere PowerTech

35% @ 1,400 rpm/

596 lb-ft 808 Nm

N/A

No matter what kind of terrain you work, there’s a John Deere G-III Series Skidder

that can be perfectly matched to your exact needs.

You know what you need out of your skidder. We can give it to you

with the widest range of models and options in the industry.

Choose the size, power, and options that best suit your job needs.

With a selection of engines, transmissions, axles, grapples, winches

and cab comforts, you can build the perfect skidder.

™

PRODUCTIVITY UPTIME LOW DAILY OPERATING COSTS

Page 4

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

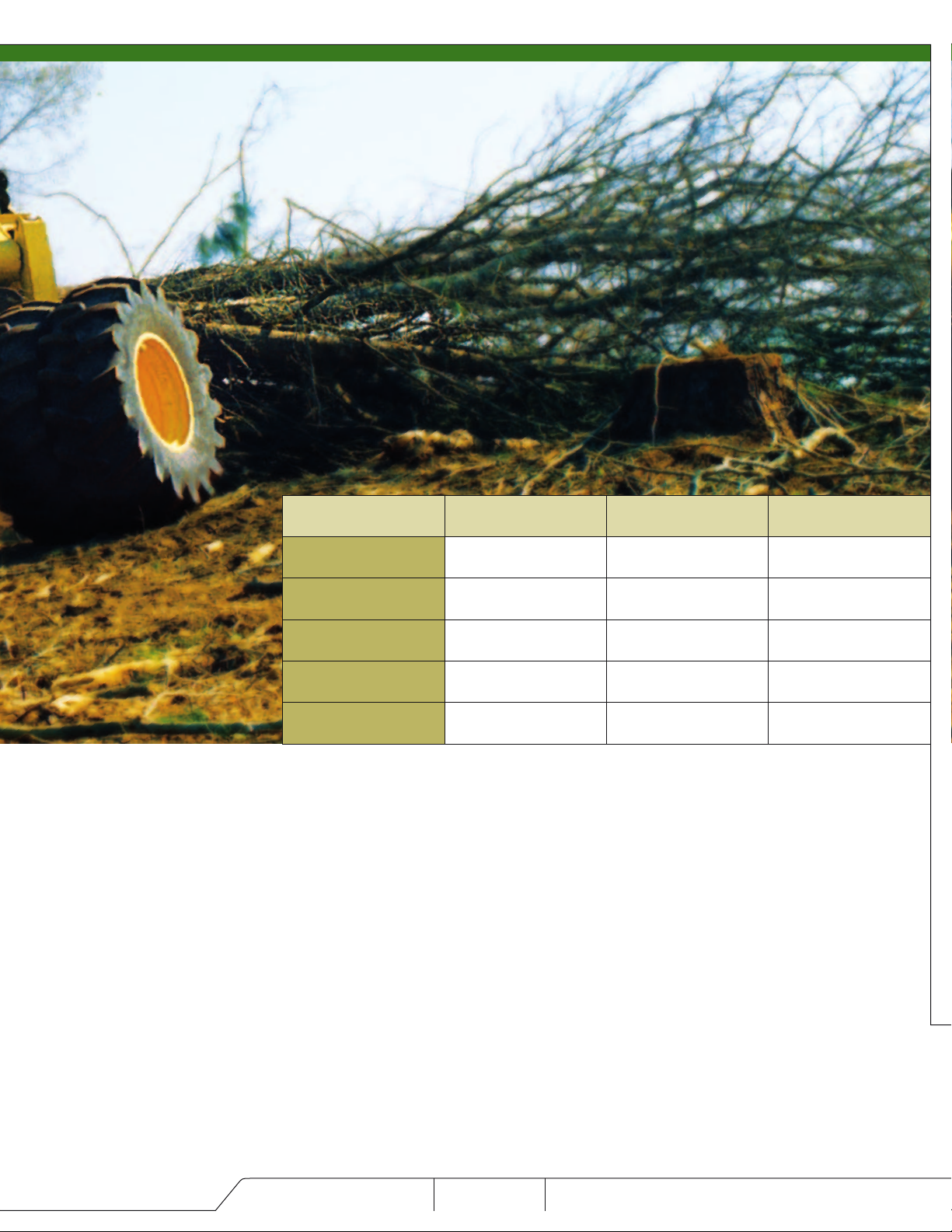

GRAPPLE SKIDDERS

IMPRESS THE GUYS BACK AT THE LANDING.

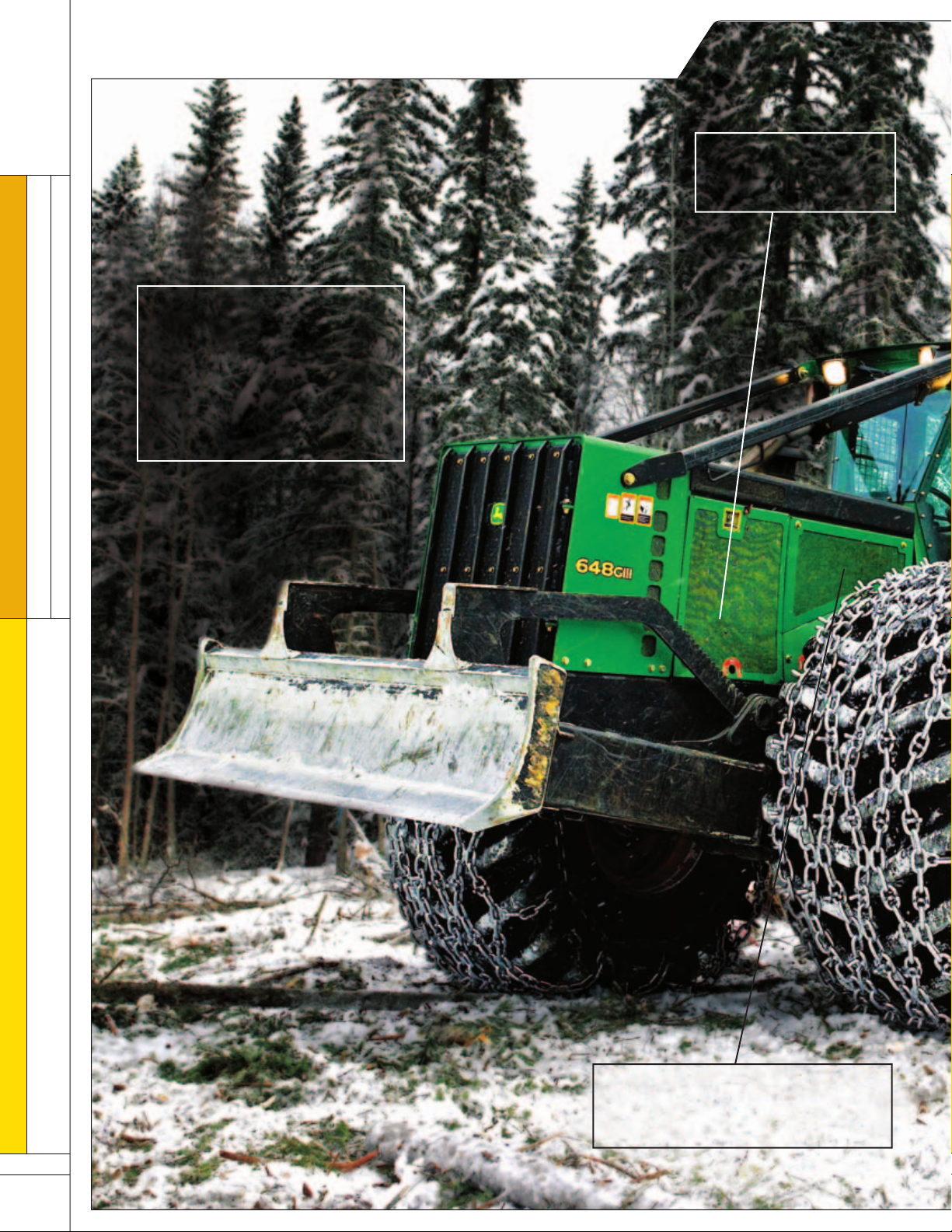

Standard decking blade has a

replaceable, weld-on cutting

edge of high-carbon material

for longer life.

A heavy-duty blade (optional on

the 648G-III, standard on the

748G-III) is wider at 9-ft 8-in

(2,95 m) with a heavier weldon cutting edge for more tire

protection and improved weight

distribution.

PAGES

4–5

You can count on John Deere Grapples to pick up a load the fi rst try.

The innovative G-III Series Grapples are designed with

two hydraulic cylinders, one for each tong, so they adjust

to each load with a secure grip. Closed-center, load-sensing

hydraulics maintain constant pressure on the tongs from

start to fi nish. Box construction with three internal ribs

on each tong makes them stronger without adding weight.

Choose from four single-function grapples

or three dual-function grapple versions.

A high torque motor drives the grapple

through 360-degree continuous rotation.

The single-function arch simply lowers and raises the

grapple head. It’s most productive working where it can pick up

tightly bunched piles in a single pass. Dual-arch geometry

uses four cylinders to reach out as well as lift. It pulls the load

over the rear for the best weight distribution and heavy load

control over longer hauls.

Page 5

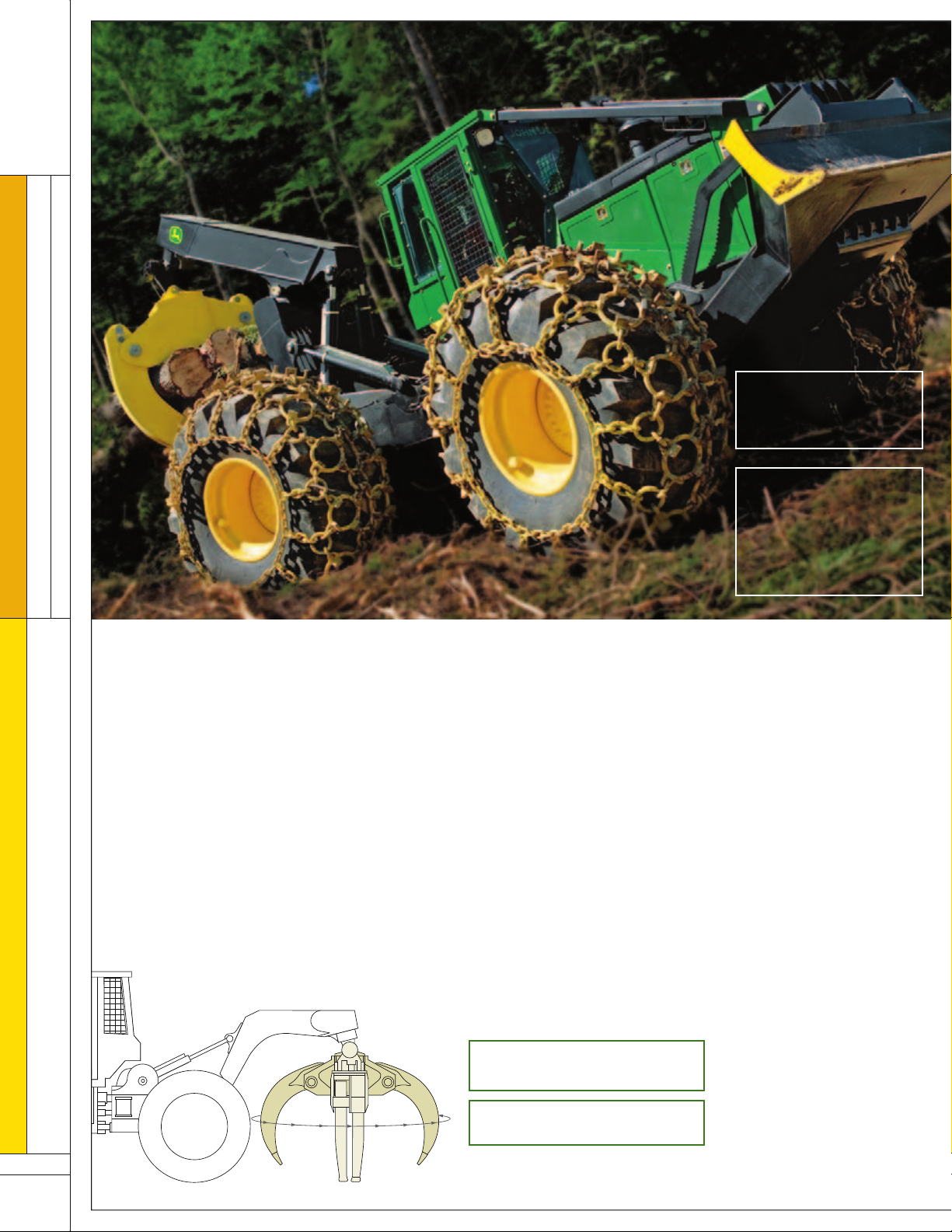

John Deere winches provide the power and

confi dence you need to skid big loads.

CABLE SKIDDERS

MAKE THE MOST OF EVERY LOAD.

G-III Series Cable Skidders have the power to skid big loads.

John Deere winches give you the power and reliability you need.

They are easy to operate with a single lever, and feature powerful

line pull, sealed wet-disc clutches, and spring-applied, hydraulically

activated brakes for extreme durability.

The rear assembly is built forest-tough to withstand the heavy

buffering they endure. The adjustable fairlead, heavy butt pan,

see-through ramguard screen, and strong fenders protect the tires,

rear frame, winch, and more importantly—the operator.

The fenders are shaped

to guide butts into the best

position for load control

during skidding.

Page 6

LET’S KICK THE TIRES.

6.8 L and 8.1 L Deere engines

feature high torque rise, heavyduty engine blocks, proven

durability and fuel effi ciency.

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

The standard 4000 winch on cable skidders

boosts a bare drum line pull up to 47,697 lbf

(212 kN), while the optional 6000, only

available on the 640G-III, pulls a massive

50,517 lbf (225 kN). They are both easily

operated with a single lever and feature

sealed, wet-disc clutches and springapplied, hydraulically activated brakes

for extreme durability.

PAGES

6–7

Industry-leading Deere diesel engines feature

Powershift transmissions, with seven forward

and six reverse gears, which are controlled with

a bump shifter for ease of operation.

Page 7

Industry-leading cab design utilizes isolation

mounts for reduced noise, vibration, and driver

fatigue. Operator comforts include a seat that

swivels up to 30 degrees, ergonomically located

controls, a tilt/telescopic steering wheel, and

climate control for all-season comfort.

Grapples are designed with

two hydraulic cylinders that adjust

to each load. Closed-center,

load-sensing hydraulics maintain

constant pressure on the tongs.

Three internal ribs on each tong

make them stronger without

adding weight, and tong tips are

constructed of wear-resistant

cast steel for a reliable grip.

Inboard planetary axles feature

wet disc brakes sealed and

immersed in cooling oil bath.

They are self-equalizing and

self-adjusting to decrease wear

with on-the-fl y diff locks.

Page 8

648G-III / 640G-III

THE 600 SERIES SKIDDERS

SKIDDERS

RUN CLEAN WITHOUT COMPROMISE.

The muscle behind the 600 Series Skidders is the powerful PowerTech Plus™

6.8 L engine that runs clean without sacrifi cing power.

All John Deere skidder engines meet EPA and CARB

emission non-road regulations, while maintaining the

legendary John Deere power.

Exhaust gas recirculation (EGR) cools and mixes measured

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

amounts of exhaust gas with incoming fresh air to lower

peak combustion temperatures and reduce emissions.

And the engine’s four-valve design, with high-pressure

common rail fuel injection, provides greater low-speed

torque and better transient response.

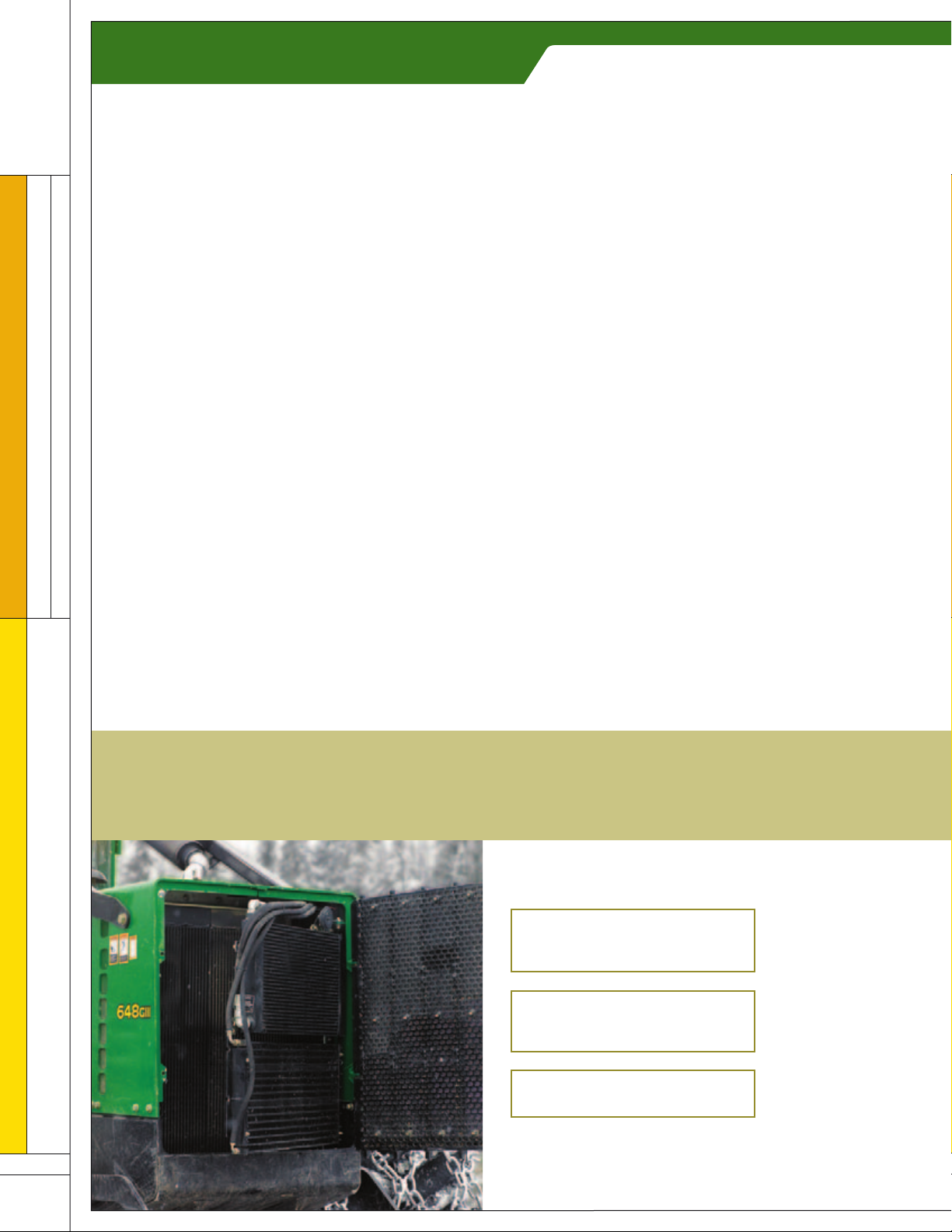

The 600 Series Skidders feature an enhanced cooling system

with a new, more effi cient sucker fan design, which draws

air in the front, through the cooling package and out the

sides. The hydraulically driven cooling fan is temperature

controlled, so it runs only as needed, minimizing horsepower

use and drag. The fan is fully reversible to automatically

blow debris off the grill screen, optimizing air fl ow.

PAGES

8–9

The hydraulic reversible fan maximizes

debris management, and productivity,

by automatically blowing off the screen.

The new sucker fan design on the cooling

package pulls air in through the front

and out the sides.

The hinged door optimizes serviceability

with easy access to the cooling package.

Page 9

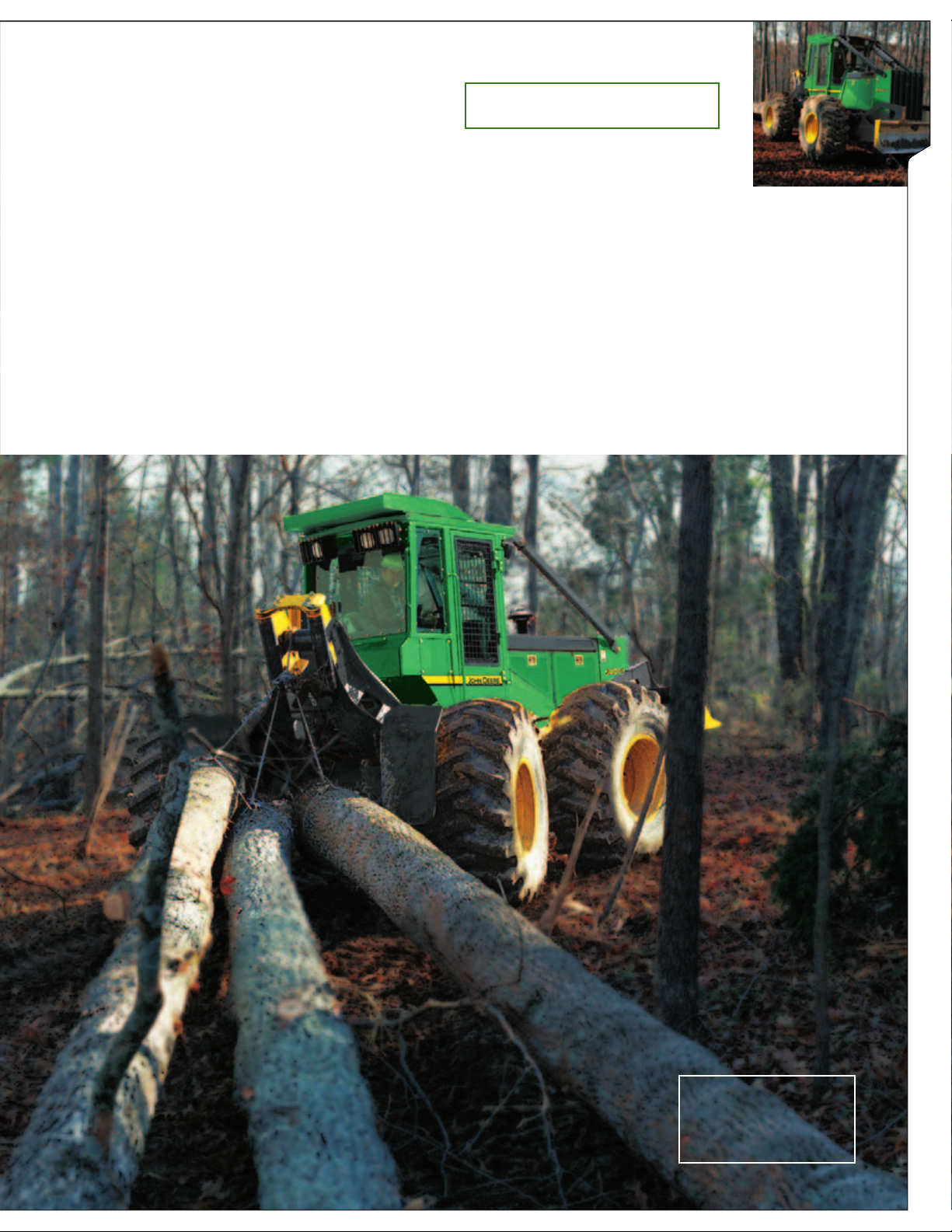

Southern Thinning Special

Designed specifi cally to make fi rst thinnings more profi table, the optional 648G-III Single Arch Grapple Skidder can pull larger loads each turn

to increase the amount of wood to the landing every shift. It has a large 123-in (312 cm) grapple and an extended 145-in (368 cm) wheelbase

for better balance and stability to handle larger loads. The wider stance improves traction when reversing uphill or backing up to a gate delimber.

• New bulkhead fi ttings in the cab

improve the electrical system’s

reliability and simplifi es serviceability.

• The dual-arch 648G-III features a new

125-inch grapple, with 12.5 square

feet of carrying capacity, a 6.8%

increase over the previous model.

And added wear plating to the tongs

improves its durability.

• The fuel tank on the single- and

dual-arch 648G-III Skidders has

been increased by 10 gallons,

increasing the machine’s productivity

by minimizing fuel-ups.

• Torque converter transmission, with

six forward and three reverse gears,

available in the 648G-III Grapple

Skidder and 640G-III Cable Skidder.

Page 10

MORE POWER. MORE COMFORT.

MORE DONE.

The G-III Series Skidder engines deliver high torque-on-demand power

and best-in-class cabs that will keep your operator happy and your landing busy.

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

PAGES

10 –11

Page 11

All John Deere engines use an advanced, electronically controlled

fuel injection system that produces more torque for quick

turnaround and faster cycles. The common rail fuel injection system

controls the big power bulge programmed into the torque curve.

Power automatically adjusts as the load increases, optimizing

performance and productivity.

The quiet, isolation-mounted cabin on the G-III Series Skidders

will keep the operator working effortlessly without sacrifi cing

control or production effi ciency. The seat is fully adjustable

for individual height and weight, and it swivels so the operator

doesn’t have to. The steering wheel with spinner knob is adjustable

as well. And the soft-touch levers are positioned to give easy control

with the least amount of effort.

• The standard cab is isolation-mounted

for quiet operation, with tinted front

windshield, sun visor, and heavy screens

to secure the sides and back.

• The optional cab is fully enclosed with

polycarbonate windows on all openings

and screens on the door windows

only. This well-sealed cab keeps dust

out and helps the air conditioning,

venting, and heating systems operate

at peak effi ciency.

• Optional AM/FM stereo, located in

the contoured headliner with remote

speakers, has a CD or cassette option.

• An electronic hand throttle option with

three pre-set speeds lets the operator

free up his throttle pedal foot.

• The little things that mean a lot—

a dome light, storage under the armrest

with cell phone hookup, a beverage

holder, door bins, and easy-to-read

gauges, indicators and switches.

• Controls for heating, venting,

air conditioning, and windshield wipers

are handy without obstructing visibility.

• A quick glance tells you engine

temperature, transmission oil temperature,

and fuel level. The select button to the

left calls up digital readouts for hour

meter, gear selection, battery voltage,

engine rpm, and hydraulic oil temperature,

along with fault codes for the engine and

transmission. The warning indicators

across the bottom are accompanied by

audible alarm beeps, either critical for

immediate shut-down or cautionary to

warn of less critical malfunction.

• For really soft going, steep slopes

or severe ground, the smooth, steady

traction of the torque converter

powershift can make all the difference.

Some features differ from model to model.

Fast maneuvering with 90-degree stop-to-stop

articulation and differential locks front and rear.

John Deere turbocharged engines have the steep torque

rise for easier load starting, better low-speed driveability

and superior lugging power.

45˚

45˚

Page 12

SKIDDERS

The hydraulic wet-disc

brakes are completely

sealed and immersed

in an oil cooling bath.

They are self-equalizing

and self-adjusting for

wear, extending their

service intervals.

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

PAGES

12–13

AS RELIABLE AS THE WORKDAY IS LONG.

Building reliability into the transmissions and axles sets the G-III Series Skidders

apart from the competition load after load.

Not only are John Deere transmissions built to work effi ciently,

but the internal oil fl ow for the bearing to the front housing

gives a more consistent fl ow, eliminating external lines to

avoid damage and extending the transmission’s life cycle.

The engines have heavy-duty blocks, high-capacity oil and

water pumps, and hardened, replaceable wet cylinder liners

that make them as durable as they are productive.

With a choice of tires and axles, you can build a skidder

to your working conditions. The powerful, dependable

driveline gives you the rim pull to skid heavy loads shift

after shift. It all adds up to a skidder you can count on

no matter what the terrain.

Page 13

Direct drive or torque converter powershift—choose

the one that’s right for your job. The standard direct

drive powershift transmission puts the most power

to the axles on mostly fi rm ground and for short-tomedium skidding distances.

The 100-inch (254 cm) SWEDA axles, for fl otation

tires or duals, has a massive housing, large axle and

fl ange, plus its own dipstick for fast oil check.

Page 14

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

PAGES

14–15

STRETCH YOUR DAILY

OPERATING COSTS FURTHER.

When it comes to servicing, it’s good to know your skidder

will make it as quick and painless as possible.

There’s nothing to compare with the simple service access these skidders offer. The cab

can be released and hydraulically tilted in a few minutes, providing unrestricted access

to all critical components. Daily servicing points are easy to get at as well, making routine

maintenance less of a chore.

Page 15

• Quick-release fuel fi lters and separators, spin-on oil fi lters,

and oil drain shut-off for spill-free oil changes make daily

maintenance a snap.

• The panel door behind the cab can be lowered for easy

access to HVAC’s fi lers, evaporators, blower motor, and

optional precleaner.

• Extended Coverage Warranty lets you custom fi t coverage

to your specifi c needs, giving you a fi xed cost for machine

repairs over a given period of time. Whether you work in a

severe-service operation or just want to spread the risk of

doing business, Extended Coverage Warranty is a great way

to protect your cash fl ow.

Rest assured that your purpose-built John Deere Forestry equipment is

supported by the most extensive dealer network in the industry and

unsurpassed parts availability. That’s our promise.

Page 16

TECHNICAL DATA 548G-III 648G-III 748G-III GRAPPLE SKIDDERS

ENGINE 548G-III 648G-III 748G-III

Type ................................................ John Deere 6068T, 6-cylinder, .............................John Deere 6068H, 6-cylinder, ............................John Deere 6081H, 6-cylinder,

meets EPA and CARB emission meets EPA and CARB emission meets EPA and CARB emission

non-road regulations, non-road regulations, non-road regulations,

with altitude compensating with altitude compensating with altitude compensating

spark-arresting turbocharger spark-arresting turbocharger spark-arresting turbocharger

Rated Power @ 2,200 rpm .............. 129 SAE gross hp 96 kW ....................................171 SAE gross hp 128 kW ...................................177 SAE gross hp 132 kW

With Torque-Converter Option .................................................................................185 SAE gross hp 138 kW

Displacement .................................. 414 cu-in 6,8 L ...................................................414 cu-in 6,8 L ...................................................494 cu-in 8,1 L

Maximum Gross Torque ................... 32% @ 1,400 rpm / 407 lb-ft 552 Nm ................28% @ 1,400 rpm / 521 lb-ft 706 Nm ................35% @ 1,400 rpm / 596 lb-ft 808 Nm

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

With Torque-Converter Option .................................................................................40% @ 1,400 rpm / 618 lb-ft 838 Nm

Air Cleaner ....................................... Dual stage with safety element ...........................Dual stage with safety element ...........................Dual stage with safety element

and dust unloader valve and dust unloader valve and dust unloader valve

Cooling System ................................ Heavy-duty radiator with in-line ..........................Heavy-duty radiator with in-line ..........................Heavy-duty radiator with in-line

core coolant recovery reservoir core coolant recovery reservoir core coolant recovery reservoir

Cooling Fan...................................... Blower ................................................................Sucker ................................................................Blower

Lubrication ...................................... Pressure system with oil cooler ...........................Pressure system with oil cooler ...........................Pressure system with oil cooler

Oil Filter ........................................... Vertically mounted spin-on ..................................Vertically mounted spin-on ..................................Vertically mounted spin-on

Electrical System ............................. 12 volt with 120-amp alternator..........................12 volt with 120-amp alternator ..........................12 volt with 120-amp alternator

Battery (two 12 volt) ........................ Reserve capacity: 360 min, 1,850 CCA ...............Reserve capacity: 360 min, 1,850 CCA ................Reserve capacity: 360 min, 1,850 CCA

TRANSMISSION

Type ................................................ Direct-drive power shift* .....................................Direct-drive power shift* .....................................Direct-drive power shift*

Oil Filtration ..................................... 10 micron pressure side with bypass ..................10 micron pressure side with bypass ..................10 micron pressure side with bypass

*Power shift with torque converter optional on 648G-III only

AXLES

Final Drives ...................................... Heavy-duty planetary, mounted inboard ................Heavy-duty planetary, mounted inboard ................Heavy-duty planetary, mounted inboard

Differentials ..................................... Hydraulic locking, operated on the go .................Hydraulic locking, operated on the go ..................Hydraulic locking, operated on the go

Front Axle Oscillation ....................... 30 degrees, stop to stop .....................................30 degrees, stop to stop ......................................30 degrees, stop to stop

BRAKES

Service Brakes ................................ Long-life, inboard-mounted wet disc oil cooled, self-adjusting and self-equalizing front and rear axles

Parking Brake .................................. Automatically spring-applied, hydraulically released, sealed and lubricated, wet multi-disc, integrally mounted in transmission

STEERING

Frame Articulation............................ 90 degrees total, stop to stop ..............................90 degrees total, stop to stop ..............................90 degrees total, stop to stop

Steering Wheel With Orbitrol™ Valve

POWER TRAIN

PERFORMANCE 548G-III 648G-III DIRECT DRIVE 748G-III

with 28L-26 tires with 30.5-32 tires with 30.5-32 tires

No Tire Slip ........................Maximum Speed ........... Maximum Drawbar ........Maximum Speed ...........Maximum Drawbar ....... Maximum Speed ........... Maximum Drawbar

@ 2,200 rpm @ peak torque @ 2,200 rpm @ peak torque @ 2,200 rpm @ peak torque

Forward

Gear 1 ...........................1.4 mph 2,3 km/hr ........31,143 lb 139 kN ..........1.7 mph 2,7 km/hr ........36,139 lb 161 kN.......... 1.7 mph 2,7 km/hr ........ 37,812 lb 168 kN

Gear 2 ...........................1.9 mph 3,0 km/hr ........23,465 lb 104 kN ..........2.2 mph 3,5 km/hr ........27,229 lb 121 kN.......... 2.2 mph 3,5 km/hr ........ 28,490 lb 127 kN

Gear 3 ...........................2.5 mph 4,0 km/hr ........17,628 lb 78 kN ............2.9 mph 4,7 km/hr ........20,479 lb 91 kN............ 2.9 mph 4,7 km/hr ........ 21,739 lb 97 kN

Gear 4 ...........................3.3 mph 5,3 km/hr ........13,280 lb 59 kN ............3.9 mph 6,3 km/hr ........15,428 lb 69 kN............ 3.9 mph 6,3 km/hr ........ 16,377 lb 73 kN

Gear 5 ...........................4.4 mph 7,1 km/hr ........9,950 lb 44 kN .............. 5.2 mph 8,4 km/hr ........11,559 lb 51 kN............ 5.8 mph 9,3 km/hr ........ 11,979 lb 53 kN

Gear 6 ...........................5.9 mph 9,5 km/hr ........7,482 lb 33 kN .............. 6.9 mph 11,1 km/hr ......8,692 lb 39 kN.............. 7.7 mph 12,4 km/hr ...... 9,008 lb 40 kN

Gear 7 ...........................8.7 mph 14,0 km/hr ......5,053 lb 22 kN ..............10.2 mph 16,4 km/hr ....5,864 lb 26 kN.............. 11.4 mph 18,3 km/hr .... 6,084 lb 27 kN

Gear 8 ...........................11.6 mph 18,7 km/hr .... 3,792 lb 17 kN ..............13.6 mph 21,9 km/hr ....4,400 lb 19 kN.............. 15.2 mph 24,5 km/hr .... 4,565 lb 20 kN

Reverse

Gear 1 ...........................1.4 mph 2,3 km/hr ........31,143 lb 139 kN ..........1.7 mph 2,7 km/hr ........36,139 lb 161 kN.......... 1.7 mph 2,7 km/hr ........ 37,812 lb 168 kN

Gear 2 ...........................1.9 mph 3,0 km/hr ........23,465 lb 104 kN ..........2.2 mph 3,5 km/hr ........27,229 lb 121 kN.......... 2.2 mph 3,5 km/hr ........ 28,490 lb 127 kN

Gear 3 ...........................2.5 mph 4,0 km/hr ........17,628 lb 78 kN ............2.9 mph 4,7 km/hr ........20,479 lb 91 kN............ 2.9 mph 4,7 km/hr ........ 21,374 lb 95 kN

Gear 4 ...........................3.3 mph 5,3 km/hr ........13,280 lb 59 kN ............3.9 mph 6,3 km/hr ........15,428 lb 69 kN............ 3.9 mph 6,3 km/hr ........ 16,124 lb 72 kN

Gear 5 ...........................4.4 mph 7,1 km/hr ........9,950 lb 44 kN .............. 5.2 mph 8,4 km/hr ........11,559 lb 51 kN............ 5.2 mph 8,4 km/hr ........ 12,081 lb 54 kN

Gear 6 ...........................5.9 mph 9,5 km/hr ........7,482 lb 33 kN .............. 6.9 mph 11,1 km/hr ......8,692 lb 36 kN.............. 6.9 mph 11,1 km/hr ...... 9,084 lb 40 kN

Gear 7 ...........................8.7 mph 14,0 km/hr ......5,053 lb 22 kN ..............10.2 mph 16,4 km/hr ....5,864 lb 26 kN.............. 10.2 mph 16,4 km/hr .... 6,136 lb 27 kN

PAGES

16–17

™

Orbitrol is a registered trademark of Eaton Corp.

Page 17

HYDRAULIC SYSTEM 548G-III 648G-III DIRECT DRIVE 748G-III

Pump .........................................................Variable-displacement axial piston ..................... Variable-displacement axial piston ...................... Variable-displacement axial piston

Maximum Rated Flow ...........................27 gpm 102 L/min @ 2,200 rpm ........................ 42 gpm 159 L/min @ 2,200 rpm ........................42 gpm 159 L/min @ 2,200 rpm

Pressure ...............................................3,000 psi 20 684 kPa ......................................... 3,000 psi 20 684 kPa..........................................3,000 psi 20 684 kPa

Oil Filtration ...............................................One 10 micron return oil with bypass ................. One 10 micron return oil with bypass .................. One 10 micron return oil with bypass

WINCH (OPTIONAL)

Type ..........................................................Sealed, wet multi-disc clutch and brake ............. Sealed, wet multi-disc clutch and brake .............. Sealed, wet multi-disc clutch and brake

pressurized lubrication single lever control pressurized lubrication single lever control pressurized lubrication single lever control

Cable Capacity 4000 (8-in drum) 4000 (10-in drum) 4000 (8-in drum) 4000 (10-in drum) 4000 (8-in drum)

0.625-in 15,8 mm cable ....................... 254-ft 77,4 m ...........199-ft 60,6 m .................... 254-ft 77,4 m .......... 199-ft 60,6 m ....................254-ft 77,4 m

0.75-in 19,1 mm cable .........................179-ft 54,6 m ...........141-ft 43 m ....................... 179-ft 54,6 m .......... 141-ft 43 m ....................... 179-ft 54,6 m

0.875-in 22,2 mm cable ....................... 129-ft 39,3 m ...........101-ft 30,8 m .................... 129-ft 39,3 m .......... 101-ft 30,8 m ....................129-ft 39,3 m

1-in 25,4 mm cable ..............................100-ft 30,5 m ........... 78-ft 23,8 m ...................... 100-ft 30,5 m .......... 78-ft 23,8 m ......................100-ft 30,5 m

0.625-in 15,8 mm cable Bare Drum Full Drum Bare Drum Full Drum Bare Drum Full Drum

4000 (8-in drum high speed) ................30,068 lb 134 kN .....18,150 lb 81 kN ................ 37,296 lb 166 kN ..... 22,377 lb 100 kN ...............43,313 lb 193 kN .....25,988 lb 116 kN

4000 (8-in drum standard speed)..........35,029 lb 156 kN .....21,145 lb 94 kN ................ 43,449 lb 193 kN ..... 26,069 lb 116 kN ...............50,458 lb 224 kN .....30,275 lb 135 kN

4000 (10-in drum high speed) ..............28,435 lb 127 kN .....21,145 lb 94 kN ................ 35,270 lb 157 kN ..... 26,069 lb 116 kN

Line Speed @ 2,200 rpm,

0.625-in 15,8 mm cable Bare Drum Full Drum Bare Drum Full Drum Bare Drum Full Drum

4000 (8-in drum high speed) ................142 fpm ...................236 fpm ............................ 142 fpm ................... 236 fpm ............................. 142 fpm ................... 236 fpm

43,2 m/min 72,0 m/min 43,2 m/min 72,0 m/min 43,2 m/min 72,0 m/min

4000 (8-in drum standard speed) 122 fpm 203 fpm 122 fpm 203 fpm 122 fpm 203 fpm

37,1 m/min 61,8 m/min 37,1 m/min 61,8 m/min 37,1 m/min 61,8 m/min

4000 (10-in drum high speed) ..............150 fpm ...................203 fpm ............................ 150 fpm ................... 203 fpm ............................. 150 fpm ...................203 fpm

45,7 m/min 61,8 m/min 45,7 m/min 61,8 m/min 45,7 m/min 61,8 m/min

GROUND PRESSURE DATA [BASED ON 3-INCH GROUND PENETRATION]

Tires Single Function Single Function Dual Function Dual Function

Short Frame

23.1-26 ................................................8.4 psi 57,9 kPa

28L-26 .................................................7.0 psi 48,3 kPa ................................................. 6.0 psi 41,4 kPa

24.5-32 ................................................7.4 psi 51,0 kPa ................................................. 8.6 psi 60,3 kPa ....... 8.9 psi 61,4 kPa ................................................. 9.5 psi 65,5 kPa

30.5-32 ................................................6.2 psi 42,7 kPa ................................................. 7.2 psi 49,9 kPa ....... 7.4 psi 51,0 kPa ................................................. 7.9 psi 54,5 kPa

67/34-25 or 26 .....................................6.3 psi 43,4 kPa ................................................. 7.3 psi 50,3 kPa ....... 7.5 psi 51,7 kPa ................................................. 8.0 psi 55,2 kPa

66/43-25 or 26 .....................................5.6 psi 38,6 kPa ................................................. 6.4 psi 44,1 kPa ....... 6.5 psi 44,8 kPa ................................................. 7.0 psi 48,3 kPa

68/50-32 .......................................................................................................................................................... 5.0 psi 34,5 kPa .................................................5.3 psi 36,5 kPa

73/44-32 ...................................................................................................................................................................................................................................... 6.0 psi 41,4 kPa

30.5/24.5 Duals ............................................................................................................................................................................................................................ 5.6 psi 38,6 kPa

CAPACITIES [U.S.]

Single Function Dual Function

Fuel Tank ...................................................50 gal 189 L ....................................................... 73 gal 276,3 L ......... 83 gal 313 L .......................................................83 gal 313 L

Cooling System ..........................................26 qt 24,6 L ....................................................... 36 qt 34 L ................ 36 qt 34 L ........................................................... 30 qt 28,4 L

Engine Lubrication, Including Filter ............20 qt 18,9 L ....................................................... 20 qt 18,9 L ............. 20 qt 18,9 L ........................................................ 25 qt 23,7 L

Transmission .............................................7.75 gal 29,3 L ................................................... 7.75 gal 29,3 L ........ 7.75 gal 29,3 L ...................................................7.75 gal 29,3 L

Differentials

Front .....................................................4.5 gal 17 L ........................................................ 4.5 gal 17 L ............. 7.5 gal 28,4 L .....................................................7.5 gal 28,4 L

Rear ......................................................4.5 gal 17 L ........................................................ 7.5 gal 28,4 L .......... 7.5 gal 28,4 L .....................................................7.5 gal 28,4 L

Winch ........................................................9.3 gal 35,2 L ..................................................... 9.3 gal 35,2 L .......... 9.3 gal 35,2 L .....................................................9.3 gal 35,2 L

Hydraulic Reservoir ....................................8 gal 30,3 L ........................................................ 14.3 gal 54 L ........... 14.3 gal 54 L ......................................................11 gal 41,6 L

OPERATING WEIGHTS

Single Function Single Function Dual Function Dual Function

Short Frame

Standard Equipment ..................................23,690 lb............................................................ 30,655 lb ................. 31,975 lb ............................................................34,310 lb

10 768 kg 13 934 kg 14 534 kg 15 595 kg

(23.1x26 tires) (30.5x32 tires) (30.5x32 tires) (30.5x32 tires)

Page 18

TECHNICAL DATA 548G-III 648G-III 748G-III GRAPPLE SKIDDERS

JOHN DEERE G-III SERIES GRAPPLE SKIDDERS

DIMENSIONS 548G-III 648G-III DIRECT DRIVE 648G-III TORQUE CONVERTER 748G-III

Tire Size ......................................28L-26, 14 PR LS2 ..........................28L-26, 14 PR LS2 .........................30.5-32, 16 PR LS2 ................................ 30.5-32, 16 PR LS2

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

A Overall Height* .....................9-ft 10.5-in 3,01 m ..........................9-ft 11-in 3,03 m ...........................10-ft 3.1-in 3,13 m ................................ 10-ft 3.1-in 3,13 m

B Maximum Blade Lift

Above Ground .......................3-ft 11.6-in 1,21 m ..........................4-ft 3.5-in 1,31 m ..........................4-ft 11-in 1,50 m ................................... 4-ft 11-in 1,50 m

C Maximum Blade Dig

Below Ground .......................11.3-in 288 mm .............................. 14.5-in 367 mm ............................. 14.2-in 360 mm ..................................... 14.2-in 360 mm

C-1 Dozer Blade Width ................7-ft 2-in 2 184 mm ..........................7-ft 2-in 2 184 mm ........................9-ft 8-in 2 964 mm ................................ 9-ft 8-in 2 964 mm

Optional ........................................................................................9-ft 8-in 2 964 mm ........................9-ft 8-in 2 964 mm

D Front Axle

To Front Of Machine .............4-ft 11.3-in 1 507 mm.....................5-ft 6.3-in 1 685 mm .....................5-ft 10-in 1 777 mm .............................. 5-ft 10-in 1 777 mm

E Front Axle

To Blade Cutting Edge Arc ....6-ft 11.2-in 2 112 mm..................... 7-ft 6.2-in 2 292 mm .....................8-ft 1.4-in 2 474 mm ............................. 8-ft 1.4-in 2 474 mm

F Front Axle

To Articulation Joint ..............5-ft 2-in 1 575 mm ..........................5-ft 8-in 1 727 mm ........................5-ft 10-in 1 778 mm .............................. 5-ft 8-in 1 727 mm

G Wheelbase ............................9-ft 7-in 2 920 mm ..........................11-ft 3-in 3 430 mm

*Add 6.3-in 160 mm when equipped with water tank

†For Long Frame Single Arch and for Dual-function machines add 10-in 254 mm

†

.....................11-ft 5-in 3 481 mm† ............................. 12-ft 1-in 3 680 mm

GRAPPLE

Single Function Single Function Dual Function Dual Function

H Height Of Grapple

From Ground Level .................34-in ............................................... 31-in .............................................. 4-ft 6-in ................................................. 4-ft 4.4-in

864 mm 908 mm 1 376 mm 1 331 mm

I Reach Of Grapple

At Ground Level......................6-ft 5.6-in ........................................7-ft 4.3-in ......................................5-ft 1-in ................................................. 5-ft 1-in

1 970 mm 2 243 mm 1 536 mm 1 547 mm

J Reach Of Grapple

At Full Reach ..........................7-ft 1-in ........................................... 7-ft 11.8-in ....................................9-ft 8.9-in .............................................. 9-ft 8.9-in

2 158 mm 2 433 mm 2 968 mm 2 968 mm

K Maximum Height

Of Boom .................................9-ft 10-in .........................................10-ft 6-in ....................................... 12-ft 1-in ............................................... 12-ft 4.9-in

2 991 mm 3 195 mm 3 680 mm 3 781 mm

L Below Ground Reach

Of Grapple At Full Reach ........34-in ...............................................37-in ..............................................42.2-in ................................................... 44-in

872 mm 942 mm 1 072 mm 1 117 mm

†

M Overall Length ........................20-ft 9-in .........................................23-ft 8.6-in

6 330 mm 7 230 mm 7 814 mm 7 763 mm

†For Long Frame Single Arch machine, add 10-in 254 mm

...................................25-ft 7.6-in ............................................ 25-ft 5.6-in

PAGES

18–19

548G-III / 648G-III / 748G-III WITH SINGLE-FUNCTION GRAPPLE

648G-III / 748G-III WITH DUAL-FUNCTION GRAPPLE

Page 19

JOHN DEERE G-III SERIES GRAPPLE SKIDDERS

548G-III DIMENSIONS WITH TIRES

Tire Size 23.1-26 28L-26 24.5-32 23.1-26 28L-26 24.5-32

(narrow gauge) (narrow gauge) (narrow gauge)

N Ground Clearance ..................19.6-in 498 mm .........20.2-in 514 mm ........ 23.5-in 598 mm .........19.6-in 498 mm ......... 20.2-in 514 mm ........ 23.5-in 598 mm

O Wheel Tread ...........................7-ft 3-in 2,21 m ..........7-ft 6-in 2,29 m ........8-ft 2-in 2,49 m .........6-ft 8.9-in 2,06 m ....... 7-ft 2-in 2,18 m ......... 7-ft 5-in 2,26 m

P Overall Width ..........................9-ft 2-in 2,79 m ..........9-ft 10-in 3,0 m ........10-ft 2.5-in 3,11 m ....8-ft 8-in 2,64 m .......... 9-ft 6-in 2,90 m ......... 9-ft 5.5-in 2,88 m

Tur ning Radius Over Tires ......17-ft 11-in 5,474 m ....18-ft 1-in 5,512 m .......................................17-ft 6-in 5,398 m ...... 17-ft 6-in 5,460 m

648G-III DIMENSIONS WITH TIRES

Tire Size 28L-26 24.5-32 30.5-32 28L-26 24.5-32

(narrow gauge) (narrow gauge)

N Ground Clearance ..................20.2-in 514 mm .........23.5-in 598 mm ........ 24.2-in 615 mm .........20.2-in 514 mm ......... 23.5-in 598 mm

O Wheel Tread ...........................7-ft 10.5-in 2,40 m .....8-ft 2-in 2,49 m ........8-ft 1-in 2,46 m .........7-ft 6.5-in 2,29 m ....... 7-ft 5-in 2,26 m

P Overall Width ..........................10-ft 2.5-in 3,11 m .....10-ft 2.5-in 3,11 m ...10-ft 7.5-in 3,23 m ....9-ft 10.5-in 3,01 m .... 9-ft 5.5-in 2,88 m

Tur ning Radius Over Tires ...............................................DD: 18-ft 9-in 5,7 m / TC: 19-ft 0-in 5,8 m .............................................................

748G-III DIMENSIONS WITH TIRES

Tire Size 24.5-32 30.5-32

N Ground Clearance ..................22.9-in 582 mm .........23.6-in 599 mm

O Wheel Tread ...........................8-ft 2-in 2,49 m ..........8-ft 1-in 2,46 m

P Overall Width ..........................10-ft 2.5-in 3,11 m .....10-ft 7.5-in 3,23 m

Tur ning Radius Over Tires ......19-ft 10-in 6,04 m

C-1

DIMENSIONS WITH GRAPPLE 548G-III 648G-III 748G-III

STANDARD GRAPPLE HEAD

Q Tong Opening At Tips .........................................7-ft 1-in 2 160 mm ........... 9-ft 7-in 2 921 mm ....... 10-ft 5-in 3 175 mm

R Enclosure Area,

Tongs Tip To Tip ..................................................8 sq-ft 0,75 m2 .................. 10.4 sq-ft 0,97 m2 ........ 12.5 sq-ft 1,16 m

S Minimum Diameter

Of Stem .............................................................. 5-in 24 mm ....................... 5.5-in 140 mm ............. 5.2-in 132 mm

2

HIGH-CAPACITY GRAPPLE HEAD

Q Tong Opening At Tips ................................................................................... 10-ft 5-in 3 175 mm ..... 10-ft 7-in 3 226 mm

R Enclosure Area,

Tongs Tip To Tip ............................................................................................ 12.5 sq-ft 1,16 m2 ........ 14.9 sq-ft 1,38 m

S Minimum Diameter

Of Stem ........................................................................................................ 5.2-in 132 mm ............. 6.0-in 152 mm

2

Page 20

TECHNICAL DATA 540G-III 640G-III CABLE SKIDDERS

ENGINE 540G-III 640G-III

Type ................................................ John Deere 6068T, 6 cylinder, ................................................................... John Deere 6068H, 6-cylinder,

meets EPA and CARB emission non-road regulations, meets EPA and CARB emission non-road regulations,

with altitude compensating spark-arresting turbocharger with altitude compensating spark-arresting turbocharger

Rated Power @ 2,200 rpm .............. 129 SAE gross hp 96 kW ..........................................................................171 SAE gross hp 128 kW

With Torque-Converter Option .......................................................................................................................185 SAE gross hp 138 kW

Displacement .................................. 414 cu-in 6,8 L .........................................................................................414 cu-in 6,8 L

Maximum Gross Torque ................... 32% @ 1,400 rpm / 407 lb-ft 552 Nm ......................................................28% @ 1,400 rpm / 521 lb-ft 706 Nm

With Torque-Converter Option .......................................................................................................................40% @ 1,400 rpm / 618 lb-ft 838 Nm

Air Cleaner ....................................... Dual stage with safety element and dust unloader valve ...........................Dual stage with safety element and dust unloader valve

SKIDDERS

Cooling System ................................ Heavy-duty radiator with in-line ................................................................Heavy-duty radiator with in-line

core coolant recovery reservoir core coolant recovery reservoir

Cooling Fan...................................... Blower ......................................................................................................Sucker

Lubrication ...................................... Pressure system with oil cooler .................................................................Pressure system with oil cooler

Oil Filter ........................................... Vertically mounted spin-on ........................................................................Vertically mounted spin-on

Electrical System ............................. 12 volt with 90-amp alternator .................................................................. 12 volt with 90-amp alternator

Battery (two 12 volt) ........................ Reserve capacity: 360 min, 1,850 CCA .....................................................Reserve capacity: 360 min, 1,850 CCA

TRANSMISSION

Type ................................................ Direct-drive power shift* ........................................................................... Direct-drive power shift *

Oil Filtration ..................................... 10 micron pressure side with bypass ........................................................10 micron pressure side with bypass

*Power shift with torque converter optional on 640G-III only

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

AXLES

Final Drives ...................................... Heavy-duty planetary, mounted inboard ....................................................Heavy-duty planetary, mounted inboard

Differentials ..................................... Hydraulic locking, operated on the go .......................................................Hydraulic locking, operated on the go

Front Axle Oscillation ....................... 30 degrees, stop to stop ...........................................................................30 degrees, stop to stop

BRAKES

Service Brakes ................................ Long-life, inboard-mounted wet disc oil cooled, self-adjusting and self-equalizing front and rear axles

Parking Brake .................................. Automatically spring-applied, hydraulically released, sealed and lubricated, wet multi-disc, integrally mounted in transmission

STEERING

Frame Articulation............................ 90 degrees total, stop to stop ....................................................................90 degrees total, stop to stop

Steering Wheel With Orbitrol™ Valve

POWER TRAIN

PERFORMANCE 540G-III 640G-III DIRECT DRIVE

with 28L-26 tires with 30.5-32 tires

No Tire Slip ...................................... Maximum Speed .....................Maximum Drawbar ....................................Maximum Speed ....................Maximum Drawbar

@ 2,200 rpm @ peak torque @ 2,200 rpm @ peak torque

Forward

Gear 1 ......................................... 1.4 mph 2,3 km/hr ..................31,143 lb 139 kN.......................................1.7 mph 2,7 km/hr .................36,139 lb 161 kN

Gear 2 ......................................... 1.9 mph 3,0 km/hr ..................23,465 lb 104 kN.......................................2.2 mph 3,5 km/hr .................27,229 lb 121 kN

Gear 3 ......................................... 2.5 mph 4,0 km/hr ..................17,628 lb 78 kN.........................................2.9 mph 4,7 km/hr .................20,479 lb 91 kN

Gear 4 ......................................... 3.3 mph 5,3 km/hr ..................13,280 lb 59 kN.........................................3.9 mph 6,3 km/hr .................15,428 lb 69 kN

Gear 5 ......................................... 4.4 mph 7,1 km/hr ..................9,950 lb 44 kN...........................................5.2 mph 8,4 km/hr .................11,559 lb 51 kN

Gear 6 ......................................... 5.9 mph 9,5 km/hr ..................7,482 lb 33 kN...........................................6.9 mph 11,1 km/hr ...............8,692 lb 39 kN

Gear 7 ......................................... 8.7 mph 14,0 km/hr ................5,053 lb 22 kN...........................................10.2 mph 16,4 km/hr .............5,864 lb 26 kN

Gear 8 ......................................... 11.6 mph 18,7 km/hr ..............3,792 lb 17 kN...........................................13.6 mph 21,9 km/hr .............4,400 lb 19 kN

Reverse

Gear 1 ......................................... 1.4 mph 2,3 km/hr ..................31,143 lb 139 kN.......................................1.7 mph 2,7 km/hr .................36,139 lb 161 kN

Gear 2 ......................................... 1.9 mph 3,0 km/hr ..................23,465 lb 104 kN.......................................2.2 mph 3,5 km/hr .................27,229 lb 121 kN

Gear 3 ......................................... 2.5 mph 4,0 km/hr ..................17,628 lb 78 kN.........................................2.9 mph 4,7 km/hr .................20,479 lb 91 kN

Gear 4 ......................................... 3.3 mph 5,3 km/hr ..................13,280 lb 59 kN.........................................3.9 mph 6,3 km/hr .................15,428 lb 69 kN

Gear 5 ......................................... 4.4 mph 7,1 km/hr ..................9,950 lb 44 kN...........................................5.2 mph 8,4 km/hr .................11,559 lb 51 kN

Gear 6 ......................................... 5.9 mph 9,5 km/hr ..................7,482 lb 33 kN...........................................6.9 mph 11,1 km/hr ...............8,692 lb 39 kN

Gear 7 ......................................... 8.7 mph 14,0 km/hr ................5,053 lb 22 kN...........................................10.2 mph 16,4 km/hr .............5,864 lb 26 kN

PAGES

20–21

Page 21

HYDRAULIC SYSTEM 540G-III 640G-III DIRECT DRIVE

Pump .........................................................Variable-displacement axial piston .................................................Variable-displacement axial piston

Maximum Rated Flow ...........................27 gpm 102 L/min @ 2,200 rpm .....................................................27 gpm 102 L/min @ 2,200 rpm

Pressure ...............................................3,000 psi 20 684 kPa ......................................................................3,000 psi 20 684 kPa

Oil Filtration ...............................................One 10 micron return oil with bypass ..............................................One 10 micron return oil with bypass

WINCH

Type ..........................................................Sealed, wet multi-disc clutch and brake ..........................................Sealed, wet multi-disc clutch and brake

pressurized lubrication single lever control pressurized lubrication single lever control

Cable Capacity 4000 (8-in drum) 4000 (10-in drum) 4000 (8-in drum) 4000 (10-in drum) 6000 (11-in drum)

0.625-in 15,8 mm cable ....................... 254-ft 77,4 m ...........199-ft 60,6 m .................................................254-ft 77,4 m ...........199-ft 60,6 m ................373-ft 114 m

0.75-in 19,1 mm cable .........................179-ft 54,6 m ...........141-ft 43 m ....................................................179-ft 54,6 m ...........141-ft 43 m ...................263-ft 80,2 m

0.875-in 22,2 mm cable ....................... 129-ft 39,3 m ...........101-ft 30,8 m .................................................129-ft 39,3 m ...........101-ft 30,8 m ................189-ft 58 m

1-in 25,4 mm cable ..............................100-ft 30,5 m ........... 78-ft 23,8 m ...................................................100-ft 30,5 m ...........78-ft 23,8 m ..................147-ft 45 m

Linepull @ Peak Engine,

0.625-in 15,8 mm cable Bare Drum Full Drum Bare Drum Full Drum

4000 (8-in drum high speed) ................30,068 lb 134 kN .....18,150 lb 81 kN .............................................37,296 lb 166 kN .....22,377 lb 100 kN

4000 (8-in drum standard speed)..........35,029 lb 156 kN .....21,145 lb 94 kN .............................................43,449 lb 193 kN .....26,069 lb 116 kN

4000 (10-in drum high speed) ..............28,435 lb 127 kN .....21,145 lb 99 kN .............................................35,270 lb 157 kN .....26,069 lb 116 kN

6000 (11-in drum high speed) ......................................................................................................................37,839 lb 168 kN .....23,615 lb 105 kN

Line Speed @ 2,200 rpm,

0.625-in 15,8 mm cable Bare Drum Full Drum Bare Drum Full Drum

4000 (8-in drum high speed) ................142 fpm ...................236 fpm .........................................................142 fpm ...................236 fpm

43,2 m/min 72,0 m/min 43,2 m/min 72,0 m/min

4000 (8-in drum standard speed)..........122 fpm ...................203 fpm .........................................................122 fpm ...................203 fpm

37,1 m/min 61,8 m/min 37,1 m/min 61,8 m/min

4000 (10-in drum high speed) ..............150 fpm ...................203 fpm .........................................................150 fpm ...................203 fpm

45,7 m/min 61,8 m/min 45,7 m/min 61,8 m/min

6000 (11-in drum high speed) ......................................................................................................................128 fpm ...................205 fpm

39,0 m/min 62,5 m/min

GROUND PRESSURE DATA

Tires

23.1-26 ................................................8.3 psi 57,1 kPa

28L-26 .................................................6.8 psi 46,9 kPa ..............................................................................8.4 psi 57,9 kPa

24.5-32 ................................................7.3 psi 50,3 kPa ..............................................................................9.0 psi 62,0 kPa

30.5-32 ................................................6.1 psi 42,0 kPa ..............................................................................7.5 psi 51,7 kPa

67/34-25 or 26 .....................................6.3 psi 43,4 kPa ..............................................................................7.6 psi 52,4 kPa

66/43-25 or 26 .....................................5.5 psi 37,9 kPa ..............................................................................6.6 psi 45,5 kPa

68/50-32 ......................................................................................................................................................5.1 psi 35,1 kPa

CAPACITIES [U.S.]

Fuel Tank ...................................................42.0 gal 159,0 L ..............................................................................42.0 gal 159,0 L

Cooling System ..........................................30 qt 24,6 L ....................................................................................36 qt 34,4 L

Engine Lubrication, Including Filter ............20 qt 18,9 L ....................................................................................20 qt 18,9 L

Transmission .............................................7.8 gal 29,3 L .................................................................................. 7.8 gal 29,3 L

Differentials

Front .....................................................4.5 gal 17 L .....................................................................................4.5 gal 17 L

Rear ......................................................4.5 gal 17 L .....................................................................................7.5 gal 28,4 L

Winch ........................................................9.3 gal 35,2 L ..................................................................................9.3 gal 35,2 L

Hydraulic Reservoir ....................................8 gal 30,3 L .....................................................................................14.3 gal 54 L

OPERATING WEIGHTS

Standard Equipment ..................................22,780 lb 10 355 kg .......................................................................30,025 lb 13 648 kg

(23.1 x 26 tires) (30.5 x 32 tires)

Page 22

TECHNICAL DATA 540G-III 640G-III CABLE SKIDDERS

JOHN DEERE G-III SERIES CABLE SKIDDERS

DIMENSIONS 540G-III 640G-III DD

Tire Size ......................................28L-26 ......................... 28L-26

A Overall Height* ......................9-ft 10.5-in ................... 9-ft 11-in

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

3,01 m 3,03 m

B Maximum Blade Lift

Above Ground .......................3-ft 11.6-in ................... 4-ft 3.5-in

1,21 m 1,31 m

C Maximum Blade Dig

Below Ground .......................11.3-in ......................... 14.5-in

288 mm 367 mm

C-1 Dozer Blade Width ................7-ft 2-in ........................ 7-ft 2-in

2184 mm 2184 mm

Optional...................................................................... 9-ft 8-in

2964 mm

D Front Axle

To Front Of Machine ..............4-ft 11.3-in ................... 5-ft 6.3-in

1 507 mm 1 685 mm

E Front Axle

To Blade Cutting Edge Arc .....6-ft 11.2-in ................... 7-ft 6.2-in

2 112 mm 2 292 mm

F Front Axle

To Articulation Joint ..............5-ft 2-in ........................ 5-ft 8-in

1 575 mm 1 727 mm

G Wheelbase ............................9-ft 7-in ........................ 11-ft 3-in

2 920 mm 3 430 mm

H Overall Length .......................20-ft 9.0-in ................... 23-ft 8.6-in

6 330 mm 7 230 mm

*Add 6.3 in 160 mm when equipped with water tank

†

Add 2.0 in 50,8 mm for machines equipped with a torque converter

‡

Add 7.2 in 182,9 mm for machines equipped with a torque converter

C-1

‡

†

†

‡

PAGES

22–23

540G-III DIMENSIONS WITH TIRES

Tire Size 23.1-26 28L-26 24.5-32 23.1-26 28L-26 24.5-32

(narrow gauge) (narrow gauge) (narrow gauge)

I Ground Clearance ........................ 19.6-in..................... 20.2-in ................23.5-in .....................19.6-in .....................20.2-in ..........................23.5-in

498 mm 514 mm 598 mm 498 mm 514 mm 598 mm

J Wheel Tread ................................. 7-ft 3-in ................... 7-ft 6-in ...............7-ft 9.5-in ................6-ft 9-in ...................7-ft 2-in ........................7-ft 0.5-in

2,21 m 2,29 m 2,38 m 2,06 m 2,18 m 2,15 m

K Overall Width ...............................9-ft 2-in ................... 9-ft 10-in .............9-ft 10-in .................8-ft 8-in ...................9-ft 6-in ........................9-ft 1-in

2,79 m 3,00 m 3,00 m 2,64 m 2,90 m 2,77 m

640G-III DIMENSIONS WITH TIRES

Tire Size 23.1-26 28L-26 24.5-32 30.5-32 23.1-26 28L-26 24.5-32

(narrow gauge) (narrow gauge) (narrow gauge)

I Ground Clearance ........................ 19.6-in................. 20.2-in................ 23.5-in ................ 24.2-in ...............19.6-in .................. 20.2-in .....................23.5-in

498 mm 514 mm 598 mm 615 mm 498 mm 514 mm 598 mm

J Wheel Tread ................................. 7-ft 3-in ............... 7-ft 6-in ..............7-ft 9.5-in ........... 7-ft 8.5-in ...........6-ft 9-in.................7-ft 2-in ...................7-ft 0.5-in

2,21 m 2,28 m 2,38 m 2,35 m 2,06 m 2,18 m 2,15 m

K Overall Width ...............................9-ft 2-in ............... 9-ft 10-in ............9-ft 10-in ............ 10-ft 3-in ............8-ft 8-in.................9-ft 6-in ...................9-ft 1-in

2,79 m 3,00 m 3,00 m 3,12 m 2,64 m 2,90 m 2,77 m

Page 23

OPERATOR’S STATION GRAPPLE SKIDDER OPTIONAL FEATURES CABLE SKIDDER OPTIONAL FEATURES

GRAPPLE AND CABLE SKIDDERS

Accessory power ports (2),

12-volt/15-amp fuse

Beverage holder

Cab hydraulic tilt for service

Canopy with tinted polycarbonate

front windows and screens on all other

openings / Heater, 40,000 Btu/hr 11.8 kW

Cell-phone storage compartment

and power port in right-hand armrest

Deluxe interior trim package

Dome light

Door storage bins

Fire extinguisher, 5 lb

Floormat

Foot throttle

Front wiper with washer

Full Function Monitor Instrumentation:

Illuminated Gauges: Fuel level, Engine Coolant

Temperature, Transmission Oil Temperature;

Audible Warning Alarm for: Transmission Oil

Temperature High, Engine Coolant High, Engine Oil

Pressure Low, Hydraulic Oil Temperature High;

Indicator lights for: Check Service Code, Engine Air

Filter Restriction, Transmission Oil Filter Restriction,

Hydraulic Oil Filter Restriction, Engine Oil Pressure,

Differential Lock, Engine Alternator Volts, Fasten Seat

Belt/Park Brake; and Selectable digital readout for:

Hourmeter, Gear Selection, Battery Voltage,

Engine PRM, Hydraulic Oil Temperature, Transmission

and Engine fault codes

Full heating and ventilation ducting

Lockable doors with start switch key

Meets noise regulation: SAE J1166

(OSHA and BC)

Mirror, interior rearview

Operator manual with storage compartment

Operator protection withtegral ROPS, FOPS,

and OPS structure

Seat belt, 2-in 51 mm retractable

Sunscreen (front and rear)

Sunvisor (front)

Swivel seat with 15-, 22.5-, and

30-degree positions

Tilt-telescopic steering wheel with spinner knob

Vinyl cushion/mechanical suspension seat with:

Fore/aft adjustment / Height, weight adjustment /

Adjustable backrest angle / Armrests, two position

ENGINE

Electric ether starting aid (548 and 748 only)

ELECTRICAL

Work lights (halogen, 2 front, 2 rear)

Work lights (halogen, 4 front, 4 rear)

TRANSMISSION

Power shift with torque converter with six forward

and three reverse speeds (648 only)

Transmission disconnect, for cold weather starting

(648 and 748 only)

OPERATOR’S STATION

Cab, fully enclosed, with polycarbonate windows

on all openings with screens on the door windows only;

also includes: Air conditioner, R134a refrigerant /

Heater, 40,000 Btu/hr 11,8 kW / Pressurizer

Fire extinguisher, 10 lb

Hand throttle

Rear wiper with washer

Seat belt, 3-in 76 mm, anti-cinch retractable

Vinyl cushion/air suspension seat with:

Fore/aft adjustment / Height, weight adjustment /

Adjustable backrest angle / Armrests, two position

Fabric cushion/air suspension seat with:

Fore/aft adjustment / Height, weight adjustment /

Adjustable backrest angle / Armrests, two position

Fabric cushion/mechanical suspension seat with:

Fore/aft adjustment / Height, weight adjustment /

Adjustable backrest angle / Armrests, two position

AM/FM stereo sound system

AM/FM cassette stereo sound system

Cab fresh-air precleaner

Window glazing kit (canopy to cab fi eld conversion)*

AXLES

1400 HD SWEDA (648 and 748 only)

TIRES

23.1-26, 14 ply rating, narrow gauge (548 only)

28L-26, 14 ply rating (548 and 648 only)

24.5-32, 12 ply rating, narrow gauge (548 and 648 only)

24.5-32, 16 ply rating (548 and 648 only)

30.5-32, 16 ply rating

30.5-32 and 24.5-32, 16 ply rating Duals (648 and 748 only)

HYDRAULIC SYSTEM

Single-lever “pilot” grapple control

(optional on single- and dual-function grapples)

GRAPPLE

Dual function with 115-in tong opening (648 only)

Dual function with 125-in tong opening (648 and 748 only)

Dual function with 127-in tong opening (748 only)

WINCH

Model 4000 (8-in drum high speed) (548 and 648 only)

Model 4000 (8-in drum standard speed) (548 and 648 only)

Model 4000 (10-in drum high speed) (548 and 648 only)

ENGINE

Electric ether starting aid (540 only)

ELECTRICAL

Alternator, 120 amp

Work lights (halogen, 2 front, 2 rear)

Work lights (halogen, 4 front, 4 rear)

TRANSMISSION

Power shift with torque converter with six forward

and three reverse speeds (640 only)

Transmission disconnect,

for cold weather starting (640 DD only)

OPERATOR’S STATION

Cab, fully enclosed, with polycarbonate windows

on all openings with screens on the door windows only;

also includes: Air conditioner, R134a refrigerant /

Heater, 40,000 Btu/hr 11,8 kW / Pressurizer

Fire extinguisher, 10 lb

Hand throttle

Rear wiper with washer

Seat belt, 3-in 76 mm, anti-cinch retractable

Vinyl cushion/air suspension seat with:

Fore/aft adjustment / Height, weight adjustment /

Adjustable backrest angle / Armrests, two position

Fabric cushion/air suspension seat with:

Fore/ aft adjustment / Height, weight adjustment /

Adjustable backrest angle / Armrests, two position

Fabric cushion/mechanical suspension seat with:

Fore/aft adjustment / Height, weight adjustment /

Adjustable backrest angle / Armrests, two position

AM/FM stereo sound system

AM/FM cassette stereo sound system

Premium AM/FM//CD stereo sound system (fi eld installed)*

Cab fresh-air precleaner

Window glazing kit (canopy to cab fi eld conversion)*

TIRES

23.1-26, 14 ply rating, narrow gauge

28L-26, 12 ply rating

28L-26, 12 ply rating, narrow gauge

28L-26, 14 ply rating

24.5-32, 16 ply rating

30.5-32, 16 ply rating (640 only)

WINCH

Model 4000 (8-in drum high speed)

Model 4000 (10-in drum high speed)

Model 6000 (11-in drum) (640 only)

Engine power is with standard equipment including air

cleaner, exhaust system, alternator, and cooling fan, at

standard conditions per SAE J1349 and DIN 70 020, using

No. 2-D fuel at 35 API gravity. No derating is required up to

10,000 ft. (3050 m) altitude. Gross power is without cooling fan.

Specifi cations and design subject to change without notice.

Wherever applicable, specifi cations are in accordance with

SAE standards. Except where otherwise noted, these

specifi cations are based on units with full fuel tanks,

175-lb. (79 kg) operators, and standard equipment: 548-III

and 648-III units with 28L-26, 14 PR LS2 tires; and 748G-III

unit with 30.5-32, 16 PR LS2 tires.

Photos may show features or options not available

in all markets.

Page 24

SKIDDERS

GRAPPLE 548G-III 648G-III 748G-III CABLE 540G-III 640G-III

NOTHING RUNS LIKE A DEERE.

Maybe those words are the reason why almost every

other professional logger is a John Deere customer.

They’re just fi ve simple words. Yet they have profound

impact on your company. Because at their heart they

mean equipment that is built forest tough, with greater

productivity, more uptime, and lower daily operating

costs. They mean a dealer network over 380 locations

strong, with immediate access to parts and experts that

understand your industry. They mean a dedicated lender

Your world is logging. So is ours. John Deere Forestry. Leading the way, worldwide.

in John Deere Credit, committed to helping loggers succeed

with competitive fi nancing to enhance cash fl ow. And they

mean a global forestry equipment leader that invests more

in research and development than any other manufacturer.

But most of all, these words represent the confi dence that

comes with over 168 years of experience.

www.JohnDeere.com

www.JohnDeere.com

DKA648GIII Litho in U.S.A. (06-05)

Loading...

Loading...