Page 1

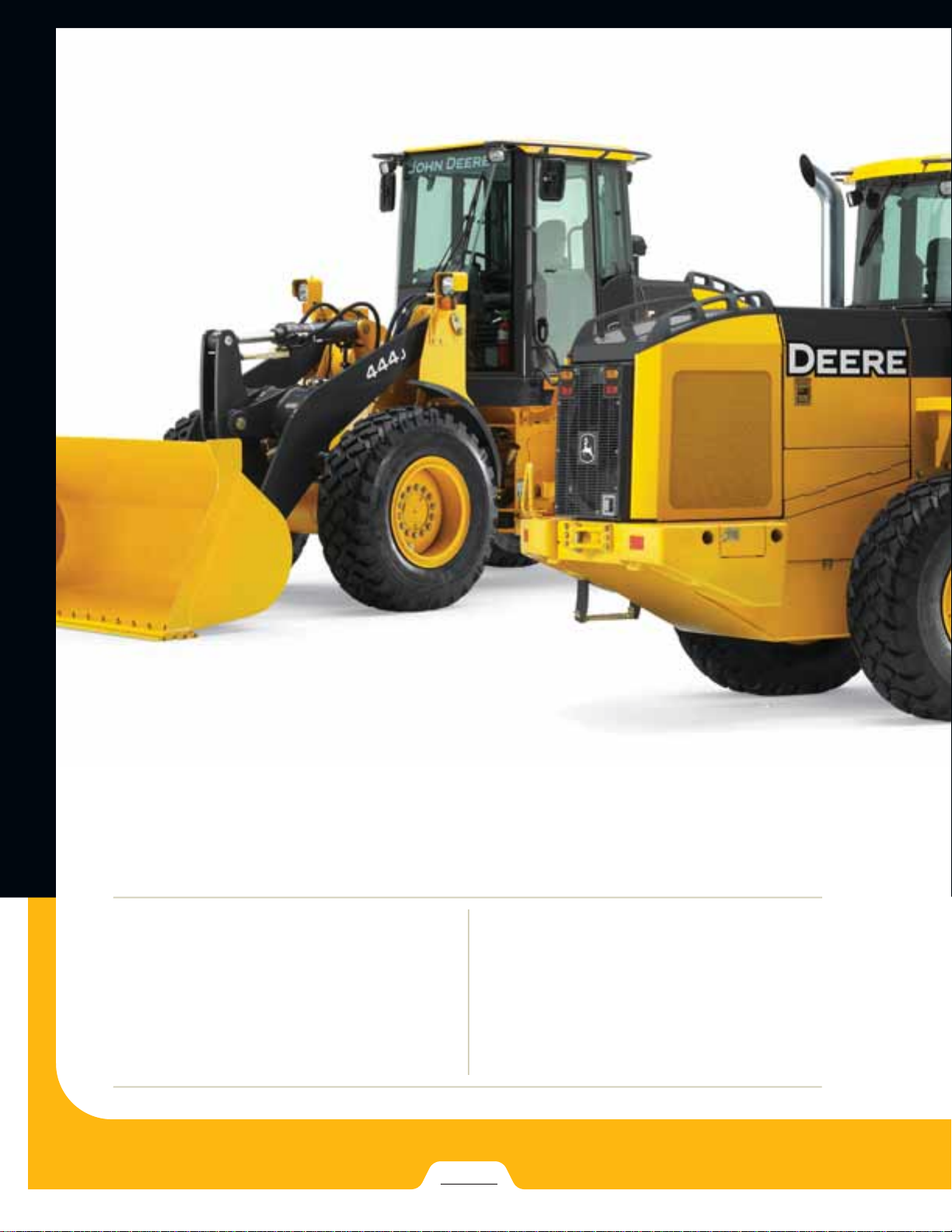

125–180 NET HORSEPOWER

J

444J | 544J | 624J

LOADERS

Z-BAR

LINKAGE

Page 2

LOADERS

444J | 544J | 624J

J

444J

125 hp

2.5-cu.-yd. bucket

18,340-lb. tipping load, straight

15,639-lb. tipping load,

40-degree full turn

18,104-lb. breakout

22,645-lb. operating weight

Take productivity

Take productivity

Take productivity

to a higher level.

to a higher level.

to a higher level.

Whether you’re shuttling sand, stockpiling

silage, placing pallets, or loading out trucks —

the J-Series Loaders will put you at the

top of your game. Each comes loaded with

production boosting advantages such as a state-

of-the-art multifunction monitor with advanced

diagnostics, durable solid-state electrical

distribution center, convenient sealed switch

module, and an innovative Quad-Cool

that keeps everything running cool. That’s just

for starters. Read on to learn all the ways the

J-Series Loaders will help maximize your efforts.

PAGES

2–3

™

system

Page 3

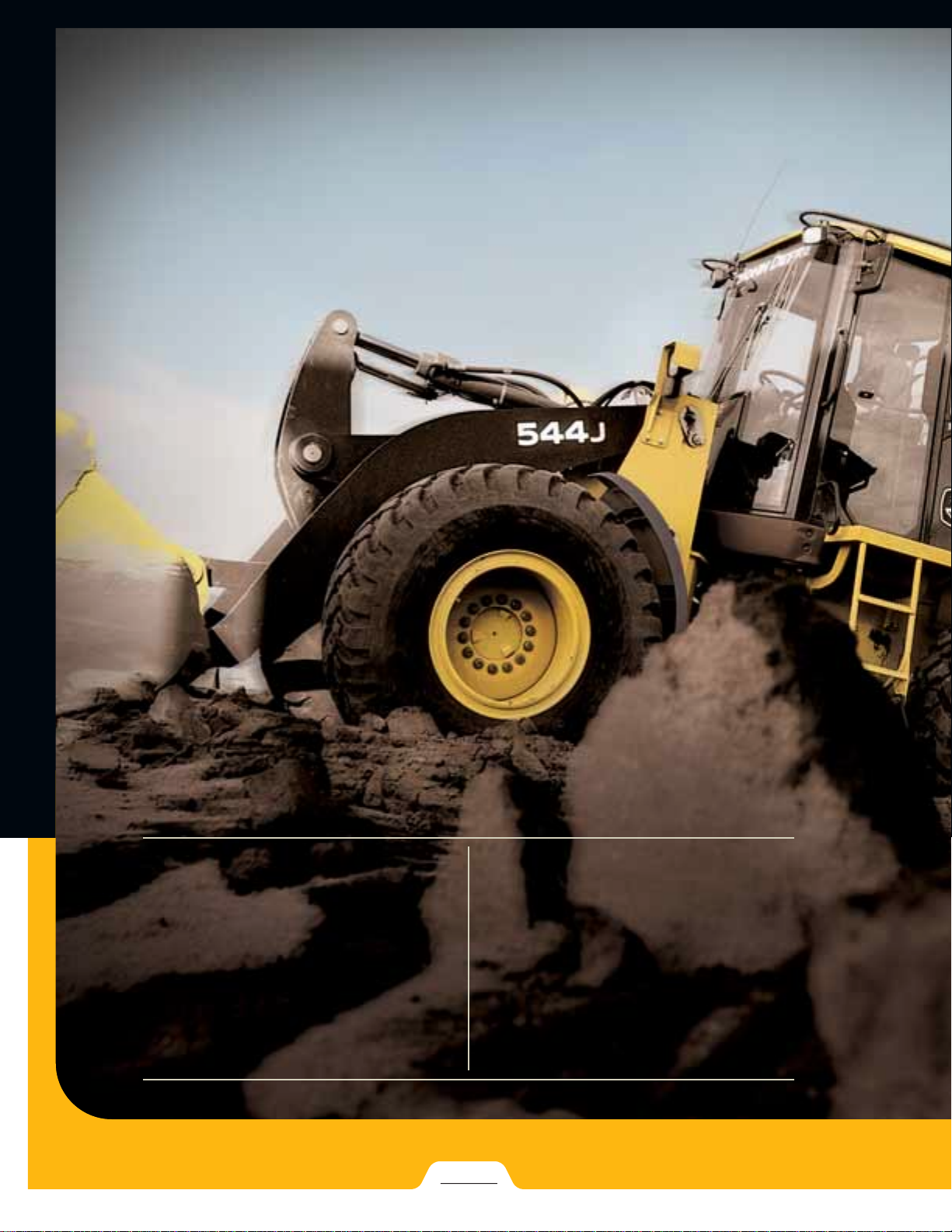

544J

160 hp

3.0-cu.-yd. bucket

22,801-lb. tipping load, straight

18,752-lb. tipping load,

40-degree full turn

22,672-lb. breakout

27,489-lb. operating weight

624J

180 hp

3.5-cu.-yd. bucket

25,639-lb. tipping load, straight

21,854-lb. tipping load,

40-degree full turn

28,483-lb. breakout

31,691-lb. operating weight

Refined PowerTech™diesels deliver an impressive

torque rise of 37, 41, and 54 percent in the 444J,

544J, and 624J, respectively.

444J, 544J, and 624J ride on a wider stance,

providing additional lateral stability for handling heavy

loads and work on rough terrain.

Extended service intervals and larger fuel tanks help

maximize uptime.

Same-side ground-level daily service access makes

routine tasks quick and easy.

Page 4

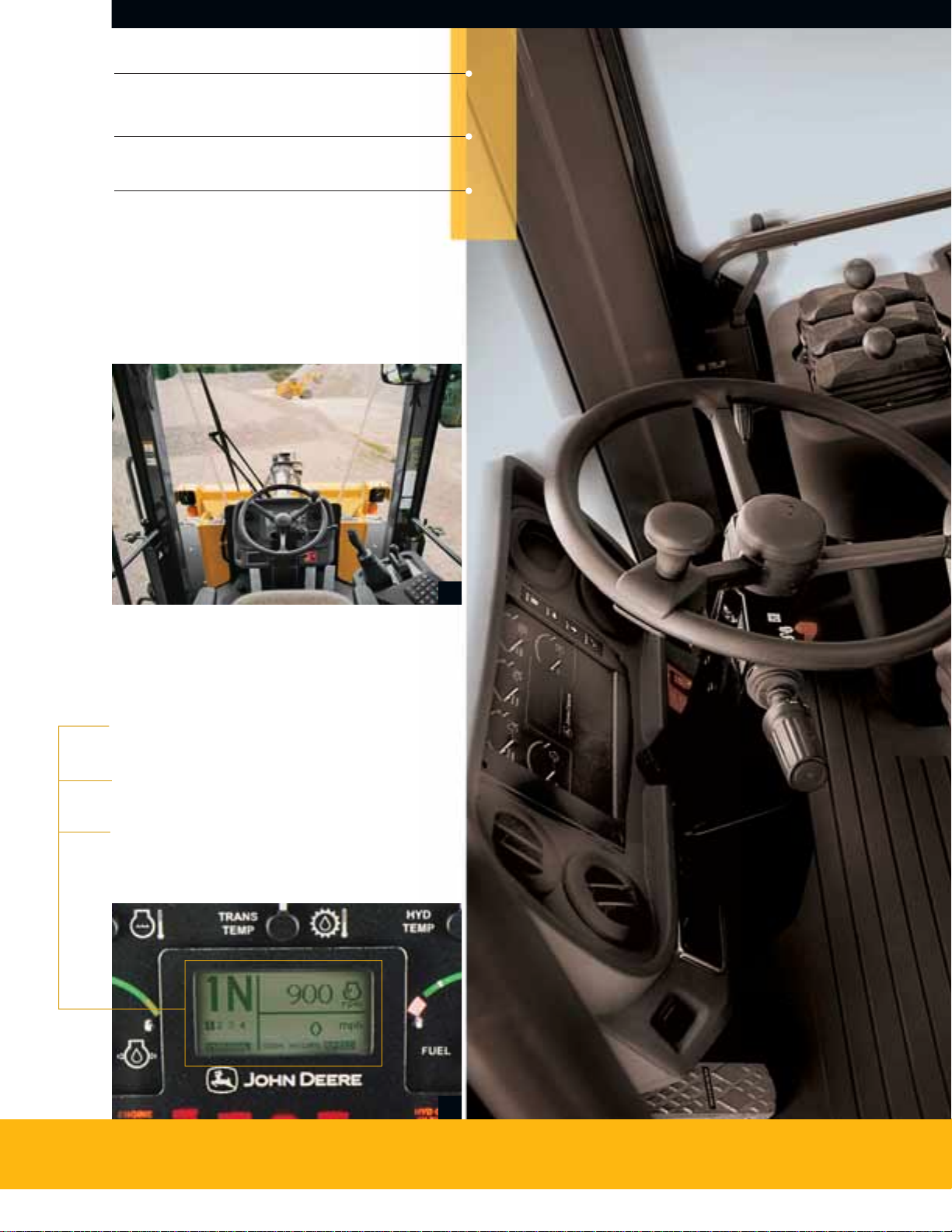

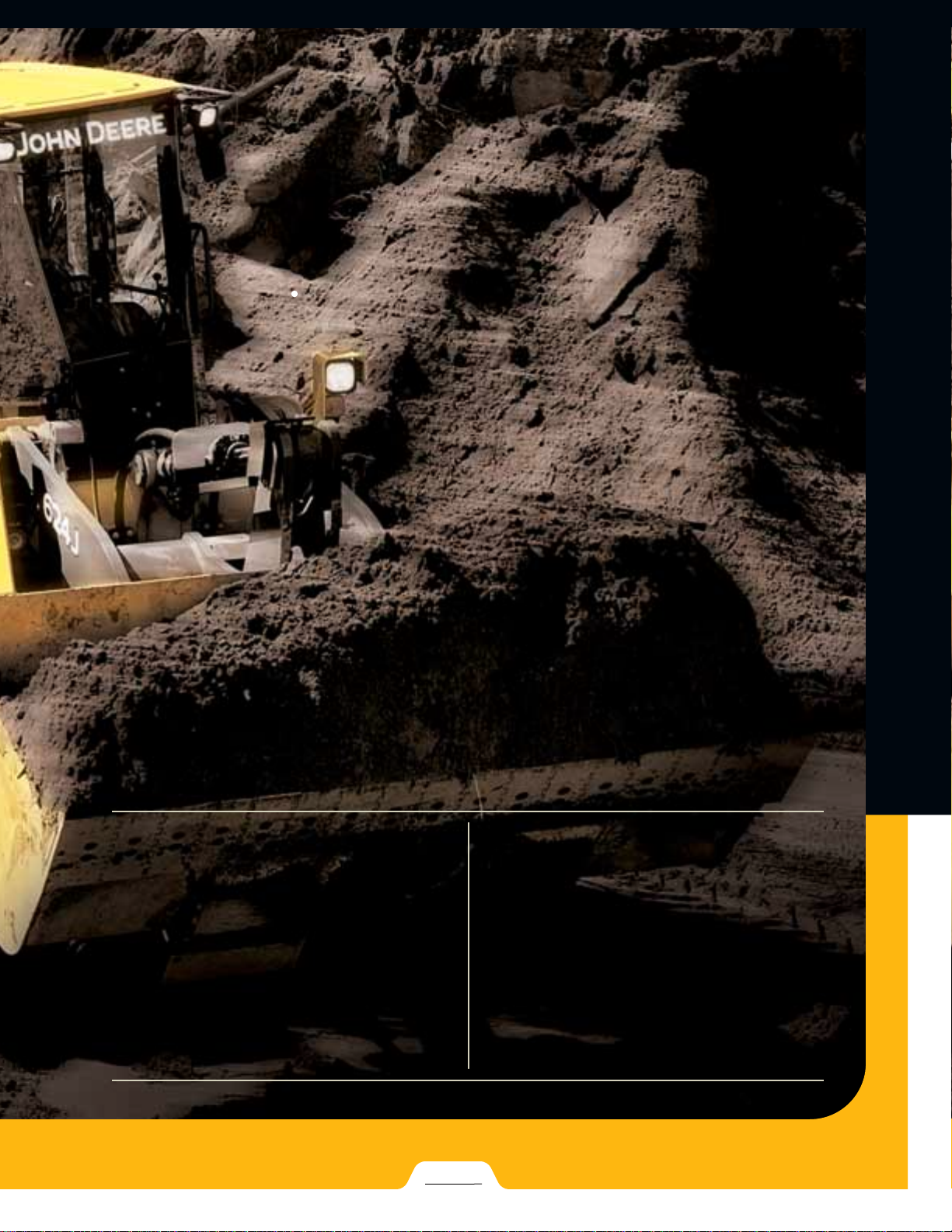

Conveniently positioned switch module helps reduce operator fatigue

with clearly visible backlit and sealed controls.

Standard air-ride armchair seat adjusts multiple ways for extra comfort.

Eleven automotive-style louvers including two directed at the pedals

and independently adjustable defrosters provide effective airflow to help

keep the glass clear and the pressurized cab comfortable.

1. Industry-leading 360-degree visibility gives a clear view of the work

ahead and the jobsite around you.

2. Advanced, multi-language monitor with analog gauges and LED

indicators provides:

Diagnostic readings of most sensors and switches, enabling

technicians to quickly troubleshoot problems.

Vital and general operating information including transmission

mode, gear, engine rpms, and ground speed.

Customized machine settings let you match operating

characteristics to specific applications by preselecting

transmission functions such as Quick-Shift and Auto-to-1st

for maximum productivity.

1

2

Page 5

Hard work

Hard work

Hard work

never felt

never felt

never felt

this easy.

this easy.

this easy.

From the convenient controls that customize

machine operation, to the comfortable, fully

adjustable air-ride armchair seat, the J-Series

Loaders have everything your operators

need to do their best. All-around visibility is

unobstructed, and an improved HVAC system

helps keep the view clear, the cab comfortable.

Your choice of single-lever joystick or two-lever

pilot-operated controls and an all-new sealed

switch module allow convenient control of

multiple machine operations. Up-front, a state-of-

the-art multifunction monitor with easy-to-read

messaging, large analog gauges, and LED warning

lights provides vital operating info at a glance.

PAGES

4–5

Page 6

More power and

More power and

More power and

control means

control means

control means

more productivity.

more productivity.

more productivity.

Want to increase productivity? Choose the

J-Series Loaders. It’s not just their impressive

torque reserves and Power Bulge advantage

that make them such powerful performers.

Excavator-style hydraulics sense the load and

deliver the power needed for smooth boom

and bucket functions and fast work cycles.

You won’t find a smoother shifting loader,

either. The powershift torque converter

transmission employs smart-shift tech-

nology to continuously evaluate speed and

load conditions, and adjusts clutch-

pack engagement to suit. For more

productivity without a lot of extra effort.

PAGES

6–7

Page 7

Since the hydraulic system provides only the power required, there’s no

wasted horsepower or fuel.

Responsive steering and full 80-degree articulation increase

maneuverability in tight quarters — for fast cycle times and fewer

“three-point” turns.

Smart-shift technology ensures that gear changes are smooth as silk

regardless of whether the bucket is empty or fully loaded.

When rpms drop below 2,200, the horsepower actually goes up. The

John Deere Power Bulge advantage helps maintain good boom and

bucket speed into the pile.

1

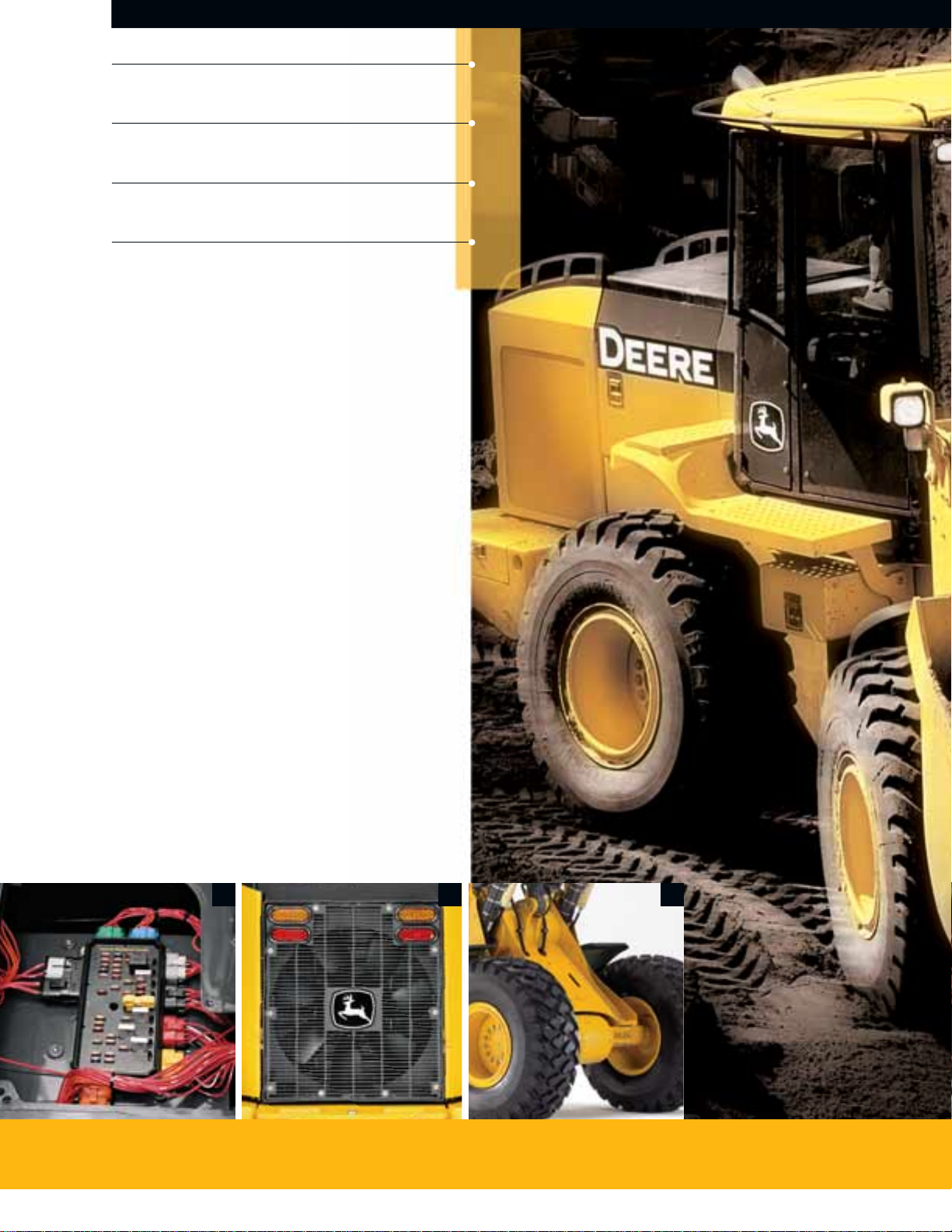

1. Choose from single-lever joystick or two-lever fingertip pilot-operated controls.

Single-lever control can also be equipped with an optional fingertip FNR selector

for convenient direction and full-range gear changes. Both controls also include

John Deere’s innovative Quick-Shift feature that allows pushbutton gear changes,

one gear at a time.

2. Convenient sealed switch module gives fingertip control of numerous functions:

A. Boom height kick-out sets maximum desired dump height, while return-to-

carry predetermines the lowered boom position. Use these two John Deere

advantages to speed production in repetitive loading applications.

B. Programmable clutch cutoff increases productivity in all kinds of terrain. Simply

select the slope at your dumpsite — level, small, or steep.When the brake

pedal is depressed, the transmission disconnects while keeping engine speed

high for fast boom cycles.

2

A

B

Page 8

Large-capacity fuel tanks let you run longer between fill-ups for more

uptime and productivity.

Wet-sleeve liners provide uniform engine cooling and longer durability

than cast-in-block designs.

Service intervals for engine oil, transmission oil, and hydraulic oil have

been extended to 500, 2,000, and 4,000 hours.

Standard features such as bypass-start protection, automatic park

brake, convenient handholds, and slip-resistant steps help keep the

operator out of harm’s way.

1. Electrical distribution center utilizes highly reliable circuit-board

technology and solid-state switches, eliminating numerous wiring

harnesses, fuses, relays, and connectors.

2. Optional reversible fan automatically reverses every 30 minutes,

ejecting debris from the radiator and coolers for more uptime and

productivity. Or just hit a button to choose your own cleaning cycles.

3. Four steel plates support the far end of the boom pivot, extending

the life of the pins and protecting the boom cylinder hoses.

1

2

3

Page 9

If only all your

If only all your

If only all your

workers were

workers were

workers were

this reliable.

this reliable.

this reliable.

If you’re looking for a highly dependable worker,

put a 444J, 544J, or 624J on the payroll. All

three come equipped with advantages that

help them survive, even thrive, in a hostile

world. New features such as a solid-state

electrical distribution center, highly efficient

Quad-Cool system, and extended service

intervals all help keep downtime to a minimum.

PAGES

Of course, not everything is new. You’ll

also benefit from traditional John Deere

durability features such as replaceable

wet-sleeve engine cylinder liners and

reinforced articulation joints with double

tapered roller bearings, to list just a couple.

When you know how they’re built, you’ll

run a Deere.

8–9

Page 10

Build one

Build one

Build one

your way.

your way.

your way.

Who says you have to “settle” for a

loader with the wrong axles, boom, bucket,

or whatever? The 444J, 544J, and 624J

are available with a wide variety of factory-

or field-installed options to fit a wide

variety of work. So you can equip a

loader with the features, tools, and attach-

ments you need to maximize your efforts.

PAGES

10–11

Page 11

Available sound-suppression packages make J-Series cabs even

quieter — some by as much as 5 dBa.

Axle options include front and rear locking differentials or front

locking differential with conventional rear.

Corrosion package shields electrical components and connections for

longer life.

Onboard weighing systems help you to load trucks to their full

legal payload, for maximum productivity.

1. Equip your loader with the bucket teeth or

edges that best suit your application. Easydigging Fanggs

edges, and special-duty Guardian Poly-Edges

™

teeth, interchangeable JAGZ

™

2

all deliver superior life and a host of other

advantages for a wide variety of work.

1

2. Choose either single-lever joystick or two-

lever fingertip control. Add up to five hydraulic

functions.

3. Need to go higher? The factory-installed high-lift

option extends lift height nearly a foot-and-ahalf and is ideal for efficiently moving materials

to new heights.

4. Ride-control option enables the hydraulic lift

cylinders to act as shock absorbers and lets

these loader navigate rough terrain more

quickly without losing the load. Auto-actuation

speed is adjustable between 2 and 15 mph.

5. Extra guarding and integrated “purpose-built”

features go into the J-Series Waste Handlers.

We’ve got what it takes for other heavy-duty

applications, too.

6. Optional hydraulically activated Worksite Pro

quick-coupler lets an operator switch attachments without leaving the cab.

6

3

4

™

5

Page 12

Hydraulically driven fan

runs only as needed —

for efficient cooling and

reduced fuel consumption.

Optional reversing fan

automatically back-blows

every 30 minutes to help

keep cooler cores clean.

Or hit the button to choose

your own cleaning cycles.

All daily service points

including fuel are on the

left side for quick and

convenient ground-level

access.

Quad-Cool system

keeps the radiator; airconditioner condenser;

intercooler; and hydraulic,

transmission, and optional

axle coolers isolated from

engine heat for increased

efficiency and durability.

Large service doors

swing open wide, providing quick entry to the

engine and Quad-Cool

system compartments.

Three-millimeter

perforations act as a

“first filter,” preventing

entry of most airborne

debris. Both sides of

all coolers are easily

accessible for quick

cleaning, if necessary.

Page 13

We made

We made

We made

ourselves even

ourselves even

ourselves even

more accessible.

more accessible.

more accessible.

When it comes to helping you control daily

operating costs, we’re open to new ideas —

and these loaders are packed with them.

Take the Quad-Cool system, for example.

It places major coolers in a unique boxed

configuration that eliminates stacked coolers,

for unsurpassed access and resistance to

1. Vertical spin-on oil filters allow quick,

no-spill changes. Extended transmission

filter and engine and hydraulic oil service

intervals contribute to low operating costs.

4. Conveniently located, easy-to-read sight gauges

let you check fluid levels at a glance.

1

2. Greasing is less messy with centralized lube

banks, providing easy access to difficult-toreach zerks.

5. Lockable compartment swings open, offering

convenient ground-level access to batteries and

electrical disconnect switch.

2

plugging. We didn’t stop there. Service intervals

have been extended, and ground-level same-

side service points help make quick work of

the daily routine. The list of J-Series features

that help minimize maintenance goes on and

on. And so will the owning and operating cost

savings you’ll enjoy.

3. If something goes wrong, the advanced monitor

gives diagnostic messages and even offers

possible troubleshooting solutions to help get

you back up and running more quickly.

6. Your John Deere dealer has the parts and service

you need to stay productive, and also offers a

wide variety of preventative maintenance and

support programs to help control costs.

3

4

5

PAGES

12–13

6

Page 14

Specifications

Specifications

Specifications

Engine 444J

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . John Deere PowerTechTM4045H; certified to EPA Tier 2 emissions

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Valves Per Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . 2

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276 cu. in. (4.5 L)

Net Peak Power . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 hp (90 kW) @ 2,000 rpm

Net Rated Power . . . . . . . . . . . . . . . . . . . . . . . . . . 115 hp (82 kW) @ 2,200 rpm

Net Peak Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . 375 lb.-ft. (505 Nm) @ 1,400 rpm

Net Torque Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . 37%

Net Power Bulge. . . . . . . . . . . . . . . . . . . . . . . . . . . 10%

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electronically controlled rotary pump-line-nozzle

Lube System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . full-flow spin-on filter and integral cooler

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . turbocharged, charge air cooled

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dual element dry type, restriction indicator in cab monitor for service

Fan Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulically driven, proportionally controlled, fan aft of coolers

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . 24 volt with 80-amp alternator

Batteries (two 12 volt) . . . . . . . . . . . . . . . . . . . . . . 950 CCA

Transmission

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . countershaft-type power shift

Torque Converter . . . . . . . . . . . . . . . . . . . . . . . . . . single stage, single phase

Shift Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electronically modulated, adaptive, load and speed dependent

Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . steering-column or joystick-mounted F-N-R and gear-select lever, kick-down button on hydraulic lever

Shift Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . auto/manual, auto to 1st or 2nd, kick down or kick up/down, three clutch cutoff settings adjustable on switch pad

Tra vel Speeds*

Gear 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 mph (7.2 km/h) 4.7 mph (7.5 km/h)

Gear 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.7 mph (12.4 km/h) 8.1 mph (13.1 km/h)

Gear 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.9 mph (24.0 km/h) 15.7 mph (25.3 km/h)

Gear 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.4 mph (37.7 km/h)

*Equipped with 17.5-25 tires.

Forward Reverse

Axles/Brakes

Final Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . heavy-duty mid-board planetary

Differentials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic locking front, conventional rear — standard; dual locking front and rear — optional

Rear Axle Oscillation, Stop to Stop* . . . . . . . . . . . . 24 deg.

Brakes (conform to SAE J1473, ISO3450)

Service Brakes . . . . . . . . . . . . . . . . . . . . . . . . hydraulically actuated, mid-board, self adjusting, wet multi-disc

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . automatic spring applied, hydraulically released, oil cooled, multi-disc

*Equipped with 17.5-25 tires.

Tires

Choice of (with three-piece rims)

17.5R25 L-3 . . . . . . . . . . . . . . . . . . . . . . . . . . 74.8 in. (1900 mm) 92.3 in. (2345 mm) 0 in. (0 mm)

17.5R25 L-2 . . . . . . . . . . . . . . . . . . . . . . . . . . 74.8 in. (1900 mm) 92.9 in. (2359 mm) – 0.5 in. (– 13 mm)

17.5-25 L-2* . . . . . . . . . . . . . . . . . . . . . . . . . . 74.8 in. (1900 mm) 92.9 in. (2359 mm) – 0.4 in. (– 10 mm)

17.5-25 L-2. . . . . . . . . . . . . . . . . . . . . . . . . . . 74.8 in. (1900 mm) 92.8 in. (2357 mm) – 0.4 in. (– 10 mm)

17.5-25 L-3. . . . . . . . . . . . . . . . . . . . . . . . . . . 74.8 in. (1900 mm) 92.8 in. (2357 mm) – 0.3 in. (– 8 mm)

20.5R25 L-2 . . . . . . . . . . . . . . . . . . . . . . . . . . 76.8 in. (1950 mm) 97.7 in. (2482 mm) + 2.8 in. (+ 70 mm)

20.5-25 L-2. . . . . . . . . . . . . . . . . . . . . . . . . . . 76.8 in. (1950 mm) 98.6 in. (2504 mm) + 2.6 in. (+ 67 mm)

550/65R25 L-3 . . . . . . . . . . . . . . . . . . . . . . . . 76.8 in. (1950 mm) 100.2 in. (2544 mm) + 1.8 in. (+ 47 mm)

*Equipped with one-piece rims.

Refill Capacities (U.S.)

Fuel Tank (with ground-level fueling) . . . . . . . . . . . 65 gal. (246 L)

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 qt. (21 L)

Engine Lubrication, Including Full-Flow Spin-

On Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.5 qt. (17.5 L)

Powershift Transmission, Including Filter . . . . . . . . 19.5 qt. (18.5 L)

Tread Width Width Over Tires Change In Vertical Height

PAGES

14–15

Page 15

Refill Capacities (U.S.)

A

B

C

J

E

45˚

I

Cab and Canopy

F

H

G

D

K

L

M

Differential (each axle)

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 qt. (17 L)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 qt. (17 L)

Loader Hydraulic Reservoir and Filters . . . . . . . . . . 25.5 gal. (96.5 L)

Wet-Disc Parking Brake . . . . . . . . . . . . . . . . . . . . . 10 oz. (0.3 L)

(continued)

444J

Hydraulic System/Steering

Pump (loader and steering). . . . . . . . . . . . . . . . . . . variable-displacement, axial-piston pump; closed-center, pressure-compensating system

Maximum Flow @ 2,350 rpm . . . . . . . . . . . . . 37 gpm (140 L/m) @ 1,000 psi (6895 kPa)

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . loader and steering relief 3,600 psi (24 850 kPa)

Loader Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . two-function valve; single- or dual-lever controls; control lever lockout feature; optional third- and fourth-function valve with auxiliary lever

Steering (conforms to SAE J1511)

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . power, fully hydraulic

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,600 psi (24 850 kPa) relief

Articulation Angle . . . . . . . . . . . . . . . . . . . . . . 80-deg. arc (40 deg. each direction)

Hydraulic Cycle Times

Raise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.6 sec. 5.6 sec.

Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 sec. 1.7 sec.

Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4 sec. (float down) / 3.4 sec. (power down) 2.4 sec. (float down) / 3.4 sec. (power down)

Total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 sec. 9.7 sec.

Maximum Lift Capacity (with 2.0-cu.-yd.

Turning Radius (measured to centerline of

3

] bucket with bolt-on edge)

[1.5 m

Lift at Ground Level . . . . . . . . . . . . . . . . . . . . . 22,403 lb. (10 160 kg) 18,912 lb. (8577 kg)

Lift at Maximum Height . . . . . . . . . . . . . . . . . . 10,719 lb. (4861 kg) 10,575 lb. (4796 kg)

outside tire) . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 ft. 5 in. (4703 mm) 15 ft. 5 in. (4703 mm)

Standard Z-Bar High-Lift Z-Bar

Dimensions with Pin-On Bucket

Standard Z-Bar High-Lift Z-Bar

A Height to Top of Cab and Canopy. . . . . . . . . . . . 10 ft. 4.2 in. (3154 mm) 10 ft. 4.2 in. (3154 mm)

B Height to Top of Exhaust . . . . . . . . . . . . . . . . . . 10 ft. 3.6 in. (3140 mm) 10 ft. 3.6 in. (3140 mm)

C Ground Clearance . . . . . . . . . . . . . . . . . . . . . . . 15.6 in. (395.5 mm) 15.6 in. (395.5 mm)

D Length from Centerline to Front Axle . . . . . . . . . 54.1 in. (1375 mm) 54.1 in. (1375 mm)

E Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108.3 in. (2750 mm) 108.3 in. (2750 mm)

F Dump Clearance . . . . . . . . . . . . . . . . . . . . . . . . (see page 17) (see page 18)

G Height to Hinge Pin, Fully Raised. . . . . . . . . . . . 11 ft. 10 in. (3597 mm) 13 ft. 0 in. (3975 mm)

H Dump Reach . . . . . . . . . . . . . . . . . . . . . . . . . . . (see page 17) (see page 18)

I Maximum Digging Depth . . . . . . . . . . . . . . . . . . 3.4 in. (85 mm) 4.1 in. (105 mm)

J Overall Length. . . . . . . . . . . . . . . . . . . . . . . . . . (see page 17) (see page 18)

K Maximum Rollback at Ground Level . . . . . . . . . 39 deg. 39.5 deg.

L Maximum Rollback, Boom Fully Raised . . . . . . . 55 deg. 55 deg.

M Maximum Bucket Angle, Fully Raised . . . . . . . . 50 deg. 50 deg.

Page 16

Dimensions with Quick-

E

45˚

C

A

B

H

D

F

G

H

A

C

E

D

B

G

F

Coupler and Bucket 444J

Standard Z-Bar High-Lift Z-Bar

A Dump Clearance . . . . . . . . . . . . . . . . . . . . . . . . (see page 17) (see page 18)

B Dump Reach . . . . . . . . . . . . . . . . . . . . . . . . . . . (see page 17) (see page 18)

C Maximum Digging Depth . . . . . . . . . . . . . . . . . . 3.9 in. (99 mm) 4.7 in. (119 mm)

D Height to Hinge Pin, Fully Raised . . . . . . . . . . . . 11 ft. 10 in. (3597 mm) 13 ft. 0 in. (3975 mm)

E Overall Length. . . . . . . . . . . . . . . . . . . . . . . . . . (see page 17) (see page 18)

F Maximum Rollback, Boom Fully Raised . . . . . . . 57 deg. 48 deg.

G Maximum Bucket Discharge Angle, Fully

Raised. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 deg. 49 deg.

H Maximum Rollback at Ground Level . . . . . . . . . 38 deg. 38 deg.

444J LOADER WITH QUICK-COUPLER AND BUCKET

Dimensions with Quick-Coupler

and Construction Fork 444J

Standard Z-Bar High-Lift Z-Bar

A Reach, Fully Raised . . . . . . . . . . . . . . . . . . . . . 2 ft. 10 in. (874 mm) 2 ft. 11 in. (880 mm)

B Fork Height, Fully Raised . . . . . . . . . . . . . . . . . 11 ft. 0 in. (3356 mm) 12 ft. 2 in. (3713 mm)

C Maximum Reach, Fork Level . . . . . . . . . . . . . . 5 ft. 2 in. (1585 mm) 6 ft. 1 in. (1851 mm)

D Fork Height, Maximum Reach . . . . . . . . . . . . . 5 ft. 4 in. (1624 mm) 5 ft. 4 in. (1624 mm)

E Reach, Ground Level . . . . . . . . . . . . . . . . . . . . 3 ft. 2 in. (974 mm) 4 ft. 4 in. (1316 mm)

F Depth Below Ground . . . . . . . . . . . . . . . . . . . . 4 in. (100 mm) 4 in. (100 mm)

G Tine Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . (see page 18) (see page 19)

H Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . (see page 18) (see page 19)

444J LOADER WITH QUICK-COUPLER

AND CONSTRUCTION FORK

PAGES

16–17

Page 17

Standard Z-Bar Information

with Pin-On-Type Bucket 444J

Bucket Type/Size

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . . . 2.5 cu. yd. (1.9 m3) 2.0 cu. yd. (1.5 m3) 2.0 cu. yd. (1.5 m3)

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . . 2.1 cu. yd. (1.6 m3) 1.6 cu. yd. (1.2 m3) 1.6 cu. yd. (1.2 m3)

Bucket Weight . . . . . . . . . . . . . . . . . . . . . . . . . 1,973 lb. (895 kg) 1,827 lb. (829 kg) 1,940 lb. (880 kg)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . . . 100.4 in. (2550 mm) 100.4 in. (2550 mm) 100.4 in. (2550 mm)

Breakout Force, SAE J732C . . . . . . . . . . . . . . . 18,104 lb. (8212 kg) 20,531 lb. (9313 kg) 18,437 lb. (8363 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . . . 18,340 lb. (8319 kg) 18,719 lb. (8491 kg) 18,613 lb. (8443 kg)

Tipping Load, 40-Degree Full Turn, SAE. . . . . . 15,639 lb. (7094 kg) 15,983 lb. (7250 kg) 15,880 lb. (7203 kg)

Reach, 45-Degree Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 56.1 in. (1478 mm) 54.6 in. (1388 mm) 56.4 in. (1433 mm)

Reach, 45-Degree Dump, Full Height. . . . . . . . 40.3 in. (1024 mm) 37.2 in. (945 mm) 40.3 in. (1023 mm)

Dump Clearance, 45 Degree, Full Height . . . . . 105.3 in. (2674 mm) 108.0 in. (2752 mm) 105.8 in. (2688 mm)

Overall Length, Bucket on Ground . . . . . . . . . . 22 ft. 2 in. (6752 mm) 21 ft. 9 in. (6633 mm) 22 ft. 1 in. (6734 mm)

Loader Clearance Circle, Bucket In Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . . 36 ft. 3 in. (11 053 mm) 36 ft. 0 in. (10 972 mm) 36 ft. 2 in. (11 029 mm)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 22,645 lb. (10 272 kg) 22,500 lb. (10 206 kg) 22,612 lb. (10 257 kg)

Loader operating information is based on machine with standard equipment; cab; rear cast bumper/counterweight; 20.5R25 tires; ROPS cab; 175-lb. (79 kg) operator; and full fuel tank. This

information is affected by tire size, ballast, and different attachments.

General Purpose General Purpose General Purpose

w/Bolt-On Edge w/Bolt-On Edge w/Teeth and Segments

Adjustments to Operating Weights for Standard Z-Bar with Pin-On-Type Buckets or Quick-Coupler and Hook-On-Type Buckets

Adjustments to operating weights and tipping loads for 2.5-cu.-yd. (1.9 m3) general-purpose bucket with bolt-on cutting edge

Add (+) or deduct (–) lb. (kg) as indicated for

loaders with three-piece rims and

17.5R25 L-3 tires . . . . . . . . . . . . . . . . . . . . . . 0 lb. (0 kg) 0 lb. (0 kg) 0 lb. (0 kg)

17.5R25 L-2 tires . . . . . . . . . . . . . . . . . . . . . . – 228 lb. (– 104 kg) – 150 lb. (– 68 kg) – 131 lb. (– 60 kg)

17.5-25 L-2 tires* . . . . . . . . . . . . . . . . . . . . . . – 544 lb. (– 247 kg) – 357 lb. (– 162 kg) – 310 lb. (– 140 kg)

17.5-25 L-2 tires. . . . . . . . . . . . . . . . . . . . . . . – 496 lb. (– 225 kg) – 325 lb. (– 148 kg) – 284 lb. (– 129 kg)

17.5-25 L-3 tires. . . . . . . . . . . . . . . . . . . . . . . – 460 lb. (– 209 kg) – 302 lb. (– 137 kg) – 262 lb. (– 119 kg)

20.5R25 L-2 tires** . . . . . . . . . . . . . . . . . . . . . + 412 lb. (+ 187 kg) + 270 lb. (+ 123 kg) + 235 lb. (+ 107 kg)

20.5-25 L-2 tires** . . . . . . . . . . . . . . . . . . . . . + 92 lb. (+ 42 kg) + 61 lb. (+ 28 kg) + 53 lb. (+ 24 kg)

550/65R25 L-3 tires** . . . . . . . . . . . . . . . . . . . + 1,316 lb. (+ 598 kg) + 863 lb. (+ 392 kg) + 752 lb. (+ 341 kg)

CaCl2in 17.5-25 rear tires** . . . . . . . . . . . . . . + 1,179 lb. (+ 535 kg) + 1,546 lb. (+ 701 kg) + 1,344 lb. (+610 kg)

Optional rear cast bumper/counterweight

(removed) . . . . . . . . . . . . . . . . . . . . . . . . . N/A N/A N/A

Operating Weight Tipping Load, Straight Degree Full Turn, SAE

*Equipped with one-piece rims.

**CaCl2not recommended with 20.5R25, 20.5-25, and 550/65R25 tires.

Tipping Load, 40-

Standard Z-Bar Information with Quick-Coupler and Bucket

Bucket Type/Size

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . . . 2.5 cu. yd. (1.9 m3) 2.0 cu. yd. (1.5 m3)

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . . 2.1 cu. yd. (1.6 m

Bucket Weight with Coupler. . . . . . . . . . . . . . . 2,806 lb. (1273 kg) 2,643 lb. (1199 kg)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . . . 100.4 in. (2550 mm) 100.4 in. (2550 mm)

Breakout Force, SAE J732C . . . . . . . . . . . . . . . 14,762 lb. (6696 kg) 15,765 lb. (7151 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . . . 17,108 lb. (7760 kg) 17,310 lb. (7852 kg)

Tipping Load, 40-Degree Full Turn, SAE. . . . . . 14,296 lb. (6485 kg) 14,680 lb. (6659 kg)

Reach, 45-Degree Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 58.5 in. (1485 mm) 57.5 in. (1461 mm)

Reach, 45-Degree Dump, Full Height. . . . . . . . 45.7 in. (1160 mm) 43.8 in. (1112 mm)

Dump Clearance, 45 Degree, Full Height . . . . . 100.0 in. (2542 mm) 101.6 in. (2581 mm)

Overall Length, Bucket on Ground . . . . . . . . . . 22 ft. 10 in. (6955 mm) 22 ft. 7 in. (6887 mm)

Loader Clearance Circle, Bucket In Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . . 36 ft. 9 in. (11 192 mm) 36 ft. 6 in. (11 134 mm)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 23,481 lb. (10 651 kg) 23,316 lb. (10 576 kg)

Loader operating information is based on machine with standard equipment; cab; rear cast bumper/counterweight; 20.5R25 tires; ROPS cab; 175-lb. (79 kg) operator; and full fuel tank. This

information is affected by tire size, ballast, and different attachments.

General Purpose General Purpose

w/Bolt-On Edge w/Bolt-On Edge

3

) 1.6 cu. yd. (1.2 m3)

Page 18

Standard Z-Bar Information with

Quick-Coupler and Construction Fork 444J

Tine Length

Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . 24 ft. 4 in. (7407 mm) 25 ft. 4 in. (7710 mm)

Tipping Load, Straight (fork level, load

centered forward 24 in. [610 mm]

on 48-in. [1220 mm] tine and 30 in.

[762 mm] on 60-in. [1525 mm] tine) . . . . . 11,449 lb. (5193 kg) 10,759 lb. (4880 kg)

Tipping Load, 40-Degree Full Turn (fork

level, load centered forward 24 in.

[610 mm] on 48-in. [1220 mm]

and 30 in. [762 mm] on 60-in. tine

[1525 mm] tine) . . . . . . . . . . . . . . . . . . . . 9,739 lb. (4418 kg) 9,136 lb. (4144 kg)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 22,626 lb. (10 261 kg) 22,727 lb. (10 307 kg)

48 in. (1220 mm) 60 in. (1525 mm)

High-Lift Z-Bar Information with Pin-On-Type Bucket

Bucket Type/Size

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . . . 2.5 cu. yd. (1.9 m3) 2.0 cu. yd. (1.5 m3)

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . . 2.1 cu. yd. (1.6 m3) 1.6 cu. yd. (1.2 m3)

Bucket Weight . . . . . . . . . . . . . . . . . . . . . . . . . 1,973 lb. (895 kg) 1,827 lb. (829 kg)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . . . 100.4 in. (2550 mm) 100.4 in. (2550 mm)

Breakout Force, SAE J732C . . . . . . . . . . . . . . . 16,655 lb. (7555 kg) 18,946 lb. (8594 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . . . 14,995 lb. (6802 kg) 15,346 lb. (6961 kg)

Tipping Load, 40-Degree Full Turn, SAE. . . . . . 12,736 lb. (5777 kg) 13,055 lb. (5922 kg)

Reach, 45-Degree Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 69.3 in. (1759 mm) 67.6 in. (1715 mm)

Reach, 45-Degree Dump, Full Height. . . . . . . . 41.3 in. (1050 mm) 38.3 in. (972 mm)

Dump Clearance, 45 Degree, Full Height . . . . . 120.1 in. (3052 mm) 123.3 in. (3130 mm)

Overall Length, Bucket on Ground . . . . . . . . . . 23 ft. 5 in. (7133 mm) 23 ft. 0 in. (7015 mm)

Loader Clearance Circle, Bucket In Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . . 37 ft. 5 in. (11 401 mm) 37 ft. 1 in. (11 306 mm)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 22,877 lb. (10 377 kg) 22,731 lb. (10 311 kg)

Loader operating information is based on machine with standard equipment; cab; rear cast bumper/counterweight; 20.5R25 tires; ROPS cab; 175-lb. (79 kg) operator; and full fuel tank. This

information is affected by tire size, ballast, and different attachments.

General Purpose General Purpose

w/Bolt-On Edge w/Bolt-On Edge

Adjustments to Operating Weights for High-Lift Z-Bar with Pin-On-Type Buckets or Quick-Coupler and Hook-On-Type Buckets

Adjustments to operating weights and tipping loads for 2.5-cu.-yd. (1.9 m3) general-purpose bucket with bolt-on cutting edge

Add (+) or deduct (–) lb. (kg) as indicated for

loaders with three-piece rims and

17.5R25 L-3 tires . . . . . . . . . . . . . . . . . . . . . . 0 lb. (0 kg) 0 lb. (0 kg) 0 lb. (0 kg)

17.5R25 L-2 tires . . . . . . . . . . . . . . . . . . . . . . – 228 lb. (– 104 kg) – 131 lb. (– 60 kg) – 112 lb. (– 51 kg)

17.5-25 L-2 tires* . . . . . . . . . . . . . . . . . . . . . . – 544 lb. (– 247 kg) – 313 lb. (– 142 kg) – 267 lb. (– 121 kg)

17.5-25 L-2 tires. . . . . . . . . . . . . . . . . . . . . . . – 496 lb. (– 225 kg) – 285 lb. (– 129 kg) – 243 lb. (– 110 kg)

17.5-25 L-3 tires. . . . . . . . . . . . . . . . . . . . . . . – 460 lb. (– 209 kg) – 265 lb. (– 120 kg) – 225 lb. (– 102 kg)

20.5R25 L-2 tires** . . . . . . . . . . . . . . . . . . . . . + 412 lb. (+ 187 kg) + 237 lb. (+ 108 kg) + 202 lb. (+ 92 kg)

20.5-25 L-2 tires** . . . . . . . . . . . . . . . . . . . . . + 92 lb. (+ 42 kg) + 53 lb. (+ 24 kg) + 45 lb. (+ 21 kg)

550/65R25 L-3 tires** . . . . . . . . . . . . . . . . . . . + 1,316 lb. (+ 598 kg) + 757 lb. (+ 344 kg) + 645 lb. (+ 293 kg)

CaCl2in 17.5-25 rear tires** . . . . . . . . . . . . . . + 1,179 lb. (+ 535 kg) + 1,356 lb. (+ 615 kg) + 1,155 lb. (+ 524 kg)

Optional rear cast bumper/counterweight

(removed) . . . . . . . . . . . . . . . . . . . . . . . . . N/A N/A N/A

Operating Weight Tipping Load, Straight Degree Full Turn, SAE

*Equipped with one-piece rims.

**CaCl2not recommended with 20.5R25, 20.5-25, and 550/65R25 tires.

Tipping Load, 40-

PAGES

18–19

Page 19

High-Lift Z-Bar Information with

5.00

(3.8)

4.00

(3.0)

3.00

(2.3)

2.00

(1.5)

2,000 2,500 3,000 3,500

2100

180015001200

lb./cu. yd.

kg/m

3

This guide, representing bucket sizes not necessarily manufactured by Deere, will help you in selecting proper bucket size for material density, loader configuration, and operating conditions. Optimum bucket size is determined

after adding or subtracting all tipping load changes due to optional equipment. The “conservative load” line on this guide is recommended when operating in conditions such as soft ground and unlevel surfaces. The “maximum

load” condition on this guide is sometimes utilized when operating on firm ground and level surfaces.

*

BUCKET SIZE cu. yd. (m

3

)

900

1,500

600

MATERIAL (Loose weight)

Caliche

Cinders

Clay and gravel, dry

Clay and gravel, wet

Clay, dry

Clay, natural bed

Clay, wet

Coal, anthracite, broken

Coal, bituminous, broken

Earth, dry, packed

Earth, loam

Earth, wet, excavated

Granite, broken or large crushed

Gravel, dry

Gravel, dry 1/2" to 2" (13 to 50 mm)

Gravel, pit run (graveled sand)

Gravel, wet 1/2" to 2" (13 to 50 mm)

Gypsum, crushed

Limestone, broken or crushed

Magnetite, iron ore

Phosphate rock

Pyrite, iron ore

Sand and gravel, dry

Sand and gravel, wet

Sand, dry

Sand, wet

Sandstone, broken

Shale

Slag, broken

Stone, crushed

Tops oi l

lb./cu. yd.

2,100

1,000

2,400

2,600

2,500

2,800

2,800

1,850

1,400

2,550

2,100

2,700

2,800

2,550

2,850

3,250

3,400

2,700

2,600

4,700

2,160

4,350

2,900

3,400

2,400

3,100

2,550

2,100

2,950

2,700

1,600

kg/m

3

1250

590

1420

1540

1480

1660

1660

1100

830

1510

1250

1600

1660

1510

1690

1930

2020

1600

1540

2790

1280

2580

1720

2020

1420

1840

1510

1250

1750

1600

950

M

a

x

i

m

u

m

L

o

a

d

N

o

r

m

a

l

L

o

a

d

C

o

n

s

e

r

v

a

t

i

v

e

L

o

a

d

Deere 2.5-cu.-yd. (1.9 m3)

General-Purpose Bucket

Deere 2.0-cu.-yd. (1.5 m3)

General-Purpose Bucket

Quick-Coupler and Bucket 444J

Bucket Type/Size

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . . . 2.5 cu. yd. (1.9 m3) 2.0 cu. yd. (1.5 m3)

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . . 2.1 cu. yd. (1.6 m

Bucket Weight with Coupler. . . . . . . . . . . . . . . 2,806 lb. (1273 kg) 2,643 lb. (1199 kg)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . . . 100.4 in. (2550 mm) 100.4 in. (2550 mm)

Breakout Force, SAE J732C . . . . . . . . . . . . . . . 13,552 lb. (6146 kg) 14,502 lb. (6577 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . . . 13,717 lb. (6221 kg) 14,094 lb. (6392 kg)

Tipping Load, 40-Degree Full Turn, SAE. . . . . . 11,545 lb. (5236 kg) 11,889 lb. (5392 kg)

Reach, 45-Degree Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 71.5 in. (1817 mm) 70.9 in. (1801 mm)

Reach, 45-Degree Dump, Full Height. . . . . . . . 46.4 in. (1179 mm) 44.8 in. (1139 mm)

Dump Clearance, 45 Degree, Full Height . . . . . 114.7 in. (2914 mm) 116.5 in. (2959 mm)

Overall Length, Bucket on Ground . . . . . . . . . . 24 ft. 1 in. (7333 mm) 23 ft. 10 in. (7267 mm)

Loader Clearance Circle, Bucket In Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . . 37 ft. 11 in. (11 553 mm) 37 ft. 8 in. (11 486 mm)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 23,717 lb. (10 756 kg) 23,951 lb. (10 682 kg)

Loader operating information is based on machine with standard equipment; cab; rear cast bumper/counterweight; 20.5R25 tires; ROPS cab; 175-lb. (79 kg) operator; and full fuel tank. This

information is affected by tire size, ballast, and different attachments.

General Purpose General Purpose

w/Bolt-On Edge w/Bolt-On Edge

3

) 1.6 cu. yd. (1.2 m3)

High-Lift Z-Bar Information with Quick-Coupler and Construction Fork

Tine Length

Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . 25 ft. 5 in. (7749 mm) 26 ft. 5 in. (8052 mm)

Tipping Load, Straight (fork level, load

centered forward 24 in. [610 mm]

on 48-in. [1220 mm] tine and 30 in.

[762 mm] on 60-in. [1525 mm] tine) . . . . . 11,674 lb. (5295 kg) 10,950 lb. (4967 kg)

Tipping Load, 40-Degree Full Turn (fork

level, load centered forward 24 in.

[610 mm] on 48-in. [1220 mm]

tine and 30 in. [762 mm] on 60-in.

[1525 mm] tine) . . . . . . . . . . . . . . . . . . . . 9,898 lb. (4490 kg) 9,267 lb. (4203 kg)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 22,857 lb. (10 366 kg) 22,959 lb. (10 412 kg)

48 in. (1220 mm) 60 in. (1525 mm)

Standard Z-Bar Pin-On Bucket Selection Guide*

Page 20

Specifications

Specifications

Specifications

Engine 544J

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . John Deere PowerTech 6068H; certified to EPA Tier 2 emissions

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valves Per Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . 2

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414 cu. in. (6.8 L)

Net Peak Power . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 hp (116 kW) @ 1,900 rpm

Net Rated Power . . . . . . . . . . . . . . . . . . . . . . . . . . 145 hp (100 kW) @ 2,200 rpm

Net Peak Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . 485 lb.-ft. (650 Nm) @ 1,400 rpm

Net Torque Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . 41%

Net Power Bulge. . . . . . . . . . . . . . . . . . . . . . . . . . . 11%

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electronically controlled rotary pump-line-nozzle

Lube System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . full-flow spin-on filter and integral cooler

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . turbocharged, charge air cooled

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dual element dry type, restriction indicator in cab monitor for service

Fan Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulically driven, proportionally controlled, fan aft of coolers

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . 24 volt with 80-amp alternator

Batteries (two 12 volt) . . . . . . . . . . . . . . . . . . . . . . 950 CCA

Transmission

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . countershaft-type power shift

Torque Converter . . . . . . . . . . . . . . . . . . . . . . . . . . single stage, single phase

Shift Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electronically modulated, adaptive, load and speed dependent

Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . steering-column or joystick-mounted F-N-R and gear-select lever, kick-down button on hydraulic lever

Shift Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . auto/manual, auto to 1st or 2nd, kick down or kick up/down, three clutch cutoff settings adjustable on switch pad

Tra vel Speeds*

Gear 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3 mph (6.9 km/h) 4.5 mph (7.3 km/h)

Gear 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4 mph (11.9 km/h) 7.8 mph (12.6 km/h)

Gear 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.2 mph (22.8 km/h) 15.0 mph (24.1 km/h)

Gear 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.8 mph (38.4 km/h)

*Equipped with 20.5-25 tires.

Forward Reverse

Axles/Brakes

Final Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . heavy-duty inboard planetary

Differentials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic locking front, conventional rear — standard; dual locking front and rear — optional

Rear Axle Oscillation, Stop to Stop* . . . . . . . . . . . . 24 deg.

Brakes (conform to SAE J1473, ISO3450)

Service Brakes . . . . . . . . . . . . . . . . . . . . . . . . hydraulically actuated, inboard, carrier mounted, pressure oil cooled, self adjusting, multi-disc

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . automatic spring applied, hydraulically released, oil cooled, multi-disc

*Equipped with 20.5-25 tires.

Tires

Choice of (with three-piece rims)

20.5R25 L-3 . . . . . . . . . . . . . . . . . . . . . . . . . . 76.8 in. (1950 mm) 97.7 in. (2482 mm) 0 in. (0 mm)

20.5R25 L-2 . . . . . . . . . . . . . . . . . . . . . . . . . . 76.8 in. (1950 mm) 97.7 in. (2482 mm) + 1.45 in. (+ 37 mm)

20.5-25 L-2. . . . . . . . . . . . . . . . . . . . . . . . . . . 76.8 in. (1950 mm) 97.7 in. (2483 mm) – 0.27 in. (– 7 mm)

20.5-25 L-3. . . . . . . . . . . . . . . . . . . . . . . . . . . 76.8 in. (1950 mm) 97.9 in. (2488 mm) – 0.04 in. (– 1 mm)

600/65R25 L-3 . . . . . . . . . . . . . . . . . . . . . . . . 76.8 in. (1950 mm) 100.2 in. (2544 mm) – 0.83 in. (– 21 mm)

23.1-26 Logger* . . . . . . . . . . . . . . . . . . . . . . . 84.0 in. (2136 mm) 107.2 in. (2723 mm) + 1.9 in. (+ 48 mm)

*Equipped with one-piece rims.

Refill Capacities (U.S.)

Fuel Tank (with ground-level fueling) . . . . . . . . . . . 85 gal. (322 L)

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 qt. (21 L)

Engine Lubrication, Including Full-Flow Spin-

On Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.5 qt. (18.5 L)

Powershift Transmission, Including Filter . . . . . . . . 19.5 qt. (18.5 L)

Tread Width Width Over Tires Change In Vertical Height

PAGES

20–21

Page 21

Refill Capacities (U.S.)

A

B

C

J

E

45˚

I

Cab and Canopy

F

H

G

D

K

L

M

Differential (each axle)

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 qt. (18 L)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 qt. (18 L)

Loader Hydraulic Reservoir and Filters . . . . . . . . . . 25.5 gal. (96.5 L)

Wet-Disc Parking Brake . . . . . . . . . . . . . . . . . . . . . 10 oz. (0.3 L)

(continued)

544J

Hydraulic System/Steering

Pump (loader and steering). . . . . . . . . . . . . . . . . . . variable-displacement, axial-piston pump; closed-center, pressure-compensating system

Maximum Flow @ 2,350 rpm . . . . . . . . . . . . . 50 gpm (189 L/m) @ 1,000 psi (6895 kPa)

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . loader and steering relief 3,650 psi (25 167 kPa)

Loader Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . two-function valve; single- or dual-lever controls; control lever lockout feature; optional third- and fourth-function valve with auxiliary lever

Steering (conforms to SAE J1511)

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . power, fully hydraulic

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,650 psi (25 167 kPa) relief

Articulation Angle . . . . . . . . . . . . . . . . . . . . . . 80-deg. arc (40 deg. each direction)

Hydraulic Cycle Times

Raise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.7 sec. 5.7 sec.

Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 sec. 1.2 sec.

Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2 sec. (float down) / 3.3 sec. (power down) 3.2 sec. (float down) / 3.3 sec. (power down)

Total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.1 sec. 10.1 sec.

Maximum Lift Capacity (with 2.5-cu.-yd.

[1.9 m3] bucket with bolt-on edge)

Lift at Ground Level . . . . . . . . . . . . . . . . . . . . . 29,596 lb. (13 422 kg) 26,074 lb. (11 835 kg)

Lift at Maximum Height . . . . . . . . . . . . . . . . . . 14,904 lb. (6759 kg) 12,996 lb. (5894 kg)

Turning Radius (measured to centerline of

outside tire) . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 ft. 3 in. (4959 mm) 16 ft. 3 in. (4959 mm)

Standard Z-Bar High-Lift Z-Bar

Dimensions with Pin-On Bucket

Standard Z-Bar High-Lift Z-Bar

A Height to Top of Cab and Canopy. . . . . . . . . . . . 10 ft. 7.6 in. (3241 mm) 10 ft. 7.6 in. (3241 mm)

B Height to Top of Exhaust . . . . . . . . . . . . . . . . . . 10 ft. 7.0 in. (3227 mm) 10 ft. 7.0 in. (3227 mm)

C Ground Clearance . . . . . . . . . . . . . . . . . . . . . . . 17.7 in. (450.5 mm) 17.7 in. (450.5 mm)

D Length from Centerline to Front Axle . . . . . . . . . 57.1 in. (1450 mm) 57.1 in. (1450 mm)

E Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114.2 in. (2900 mm) 114.2 in. (2900 mm)

F Dump Clearance . . . . . . . . . . . . . . . . . . . . . . . . (see page 23) (see page 24)

G Height to Hinge Pin, Fully Raised. . . . . . . . . . . . 12 ft. 7 in. (3836 mm) 13 ft. 9 in. (4188 mm)

H Dump Reach . . . . . . . . . . . . . . . . . . . . . . . . . . . (see page 23) (see page 24)

I Maximum Digging Depth . . . . . . . . . . . . . . . . . . 3.25 in. (83 mm) 6.5 in. (165 mm)

J Overall Length. . . . . . . . . . . . . . . . . . . . . . . . . . (see page 23) (see page 24)

K Maximum Rollback at Ground Level . . . . . . . . . 41 deg. 41 deg.

L Maximum Rollback, Boom Fully Raised . . . . . . . 55 deg. 55 deg.

M Maximum Bucket Angle, Fully Raised . . . . . . . . 50 deg. 50 deg.

Page 22

Dimensions with Quick-

E

45˚

C

A

B

H

D

F

G

H

A

C

E

D

B

G

F

Coupler and Bucket 544J

Standard Z-Bar High-Lift Z-Bar

A Dump Clearance . . . . . . . . . . . . . . . . . . . . . . . . (see page 23) (see page 24)

B Dump Reach . . . . . . . . . . . . . . . . . . . . . . . . . . . (see page 23) (see page 24)

C Maximum Digging Depth . . . . . . . . . . . . . . . . . . 5.5 in. (139 mm) 8.7 in. (221 mm)

D Height to Hinge Pin, Fully Raised . . . . . . . . . . . . 12 ft. 7 in. (3836 mm) 13 ft. 9 in. (4188 mm)

E Overall Length. . . . . . . . . . . . . . . . . . . . . . . . . . (see page 23) (see page 24)

F Maximum Rollback, Boom Fully Raised . . . . . . . 55 deg. 49 deg.

G Maximum Bucket Discharge Angle, Fully

Raised. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 deg. 51 deg.

H Maximum Rollback at Ground Level . . . . . . . . . 42 deg. 41 deg.

544J LOADER WITH QUICK-COUPLER AND BUCKET

Dimensions with Quick-Coupler

and Construction Fork 544J

Standard Z-Bar High-Lift Z-Bar

A Reach, Fully Raised . . . . . . . . . . . . . . . . . . . . . 2 ft. 6 in. (758 mm) 2 ft. 6 in. (760 mm)

B Fork Height, Fully Raised . . . . . . . . . . . . . . . . . 11 ft. 9 in. (3574 mm) 12 ft. 11 in. (3926 mm)

C Maximum Reach, Fork Level . . . . . . . . . . . . . . 5 ft. 1 in. (1546 mm) 5 ft. 11 in. (1810 mm)

D Fork Height, Maximum Reach . . . . . . . . . . . . . 5 ft. 7 in. (1705 mm) 5 ft. 7 in. (1705 mm)

E Reach, Ground Level . . . . . . . . . . . . . . . . . . . . 3 ft. 0 in. (912 mm) 4 ft. 1 in. (1249 mm)

F Depth Below Ground . . . . . . . . . . . . . . . . . . . . 1.2 in. (30 mm) 1.2 in. (30 mm)

G Tine Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . (see page 24) (see page 25)

H Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . (see page 24) (see page 25)

544J LOADER WITH QUICK-COUPLER

AND CONSTRUCTION FORK

PAGES

22–23

Page 23

Standard Z-Bar Information

with Pin-On-Type Bucket 544J

Bucket Type/Size

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . . . 3.0 cu. yd. (2.3 m3) 3.0 cu. yd. (2.3 m3) 2.5 cu. yd. (1.9 m3) 2.5 cu. yd. (1.9 m3)

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . . 2.6 cu. yd. (2.0 m3) 2.6 cu. yd. (2.0 m3) 2.1 cu. yd. (1.6 m3) 2.1 cu. yd. (1.6 m3)

Bucket Weight . . . . . . . . . . . . . . . . . . . . . . . . . 2,400 lb. (1089 kg) 2,617 lb. (1187 kg) 2,061 lb. (935 kg) 2,173 lb. (986 kg)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . . . 100.4 in. (2550 mm) 105.9 in. (2690 mm) 100.4 in. (2550 mm) 100.4 in. (2550 mm)

Breakout Force, SAE J732C . . . . . . . . . . . . . . . 22,672 lb. (10 284 kg) 24,250 lb. (11 000 kg) 26,770 lb. (12 143 kg) 24,292 lb. (11 019 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . . . 22,801 lb. (10 016 kg) 21,993 lb. (9976 kg) 22,798 lb. (10 341 kg) 22,698 lb. (10 296 kg)

Tipping Load, 40-Degree Full Turn, SAE . . . . . . 18,752 lb. (8506 kg) 18,653 lb. (8461 kg) 19,422 lb. (8810 kg) 19,325 lb. (8766 kg)

Reach, 45-Degree Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 58.5 in. (1486 mm) 57.2 in. (1453 mm) 56.22 in. (1428 mm) 58.0 in. (1475 mm)

Reach, 45-Degree Dump, Full Height. . . . . . . . 39.3 in. (997 mm) 37.0 in. (939 mm) 34.7 in. (882 mm) 37.8 in. (959 mm)

Dump Clearance, 45 Degree, Full Height . . . . . 110 in. (2787 mm) 111 in. (2837 mm) 114 in. (2904 mm) 112 in. (2840 mm)

Overall Length, Bucket on Ground . . . . . . . . . . 24 ft. 3 in. (7385 mm) 23 ft. 11 in. (7281 mm) 23 ft. 7 in. (7184 mm) 23 ft. 10 in. (7283 mm)

Loader Clearance Circle, Bucket In Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . . 37 ft. 10 in. (11 547 mm) 38 ft. 2 in. (11 630 mm) 37 ft. 7 in. (11 445 mm) 37 ft. 9 in. (11 502 mm)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 27,489 lb. (12 469 kg) 27,703 lb. (12 566 kg) 27,149 lb. (12 315 kg) 27,260 lb. (12 365 kg)

Loader operating information is based on machine with standard equipment; cab; rear cast bumper/counterweight; 20.5R25 tires; ROPS cab; 175-lb. (79 kg) operator; and full fuel tank. This

information is affected by tire size, ballast, and different attachments.

Narrow General Wide General Purpose General Purpose General Purpose w/

Purpose w/Bolt-On Edge w/Bolt-On Edge w/Bolt-On Edge Teeth and Segments

Adjustments to Operating Weights for Standard Z-Bar with Pin-On-Type Buckets or Quick-Coupler and Hook-On-Type Buckets

Adjustments to operating weights and tipping loads for 3.0-cu.-yd. (2.3 m3) general-purpose bucket with bolt-on cutting edge

Add (+) or deduct (–) lb. (kg) as indicated for

loaders with three-piece rims and

20.5R25 L-3 tires . . . . . . . . . . . . . . . . . . . . . . 0 lb. (0 kg) 0 lb. (0 kg) 0 lb. (0 kg)

20.5R25 L-2 tires . . . . . . . . . . . . . . . . . . . . . . – 228 lb. (– 104 kg) – 154 lb. (– 70 kg) – 133 lb. (– 60 kg)

20.5-25 L-2 tires. . . . . . . . . . . . . . . . . . . . . . . – 548 lb. (– 249 kg) – 368 lb. (– 167 kg) – 318 lb. (– 144 kg)

20.5-25 L-3 tires. . . . . . . . . . . . . . . . . . . . . . . – 416 lb. (– 189 kg) – 279 lb. (– 127 kg) – 162 lb. (– 74 kg)

600/65 R 25 L-3 tires**. . . . . . . . . . . . . . . . . . + 676 lb. (+ 307 kg) + 453 lb. (+ 206 kg) + 393 lb. (+ 178 kg)

23.1-26 Logger* . . . . . . . . . . . . . . . . . . . . . . . + 44 lb. (+ 20 kg) + 30 lb. (+ 13.4 kg) + 26 lb. (+ 12 kg)

CaCl2in 20.5-25 rear tires . . . . . . . . . . . . . . . . + 1,821 lb. (+ 826 kg) + 2,440 lb. (+ 1107 kg) + 2,112 lb. (+ 958 kg)

Optional rear cast bumper/counterweight

(removed) . . . . . . . . . . . . . . . . . . . . . . . . . N/A N/A N/A

Operating Weight Tipping Load, Straight Degree Full Turn, SAE

*Equipped with one-piece rims.

**CaCl2not recommended with 600/65R25 tires.

Tipping Load, 40-

Standard Z-Bar Information with Quick-Coupler and Bucket

Bucket Type/Size

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . . . 3.0 cu. yd. (2.3 m3) 2.5 cu. yd. (1.9 m3)

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . . 2.6 cu. yd. (2.0 m3) 2.1 cu. yd. (1.6 m3)

Bucket Weight with Coupler. . . . . . . . . . . . . . . 3,206 lb. (1454 kg) 2,879 lb. (1306 kg)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . . . 105.9 in. (2690 mm) 100.4 in. (2550 mm)

Breakout Force, SAE J732C . . . . . . . . . . . . . . . 19,039 lb. (8636 kg) 18,937 lb. (8590 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . . . 18,163 lb. (8237 kg) 20,741 lb. (9408 kg)

Tipping Load, 40-Degree Full Turn, SAE. . . . . . 15,314 lb. (6945 kg) 17,548 lb. (7960 kg)

Reach, 45-Degree Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 59.0 in. (1499 mm) 61.4 in. (1560 mm)

Reach, 45-Degree Dump, Full Height. . . . . . . . 40.3 in. (1099 mm) 43.7 in. (1109 mm)

Dump Clearance, 45 Degree, Full Height . . . . . 103.6 in. (2632 mm) 107.0 in. (2718 mm)

Overall Length, Bucket on Ground . . . . . . . . . . 24 ft. 10 in. (7581 mm) 23 ft. 1 in. (7475 mm)

Loader Clearance Circle, Bucket In Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . . 37 ft. 10 in. (11 575 mm) 38 ft. 3 in. (11 669 mm)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 28,299 lb. (12 834 kg) 27,967 lb. (12 686 kg)

Loader operating information is based on machine with standard equipment; cab; rear cast bumper/counterweight; 20.5R25 tires; ROPS cab; 175-lb. (79 kg) operator; and full fuel tank. This

information is affected by tire size, ballast, and different attachments.

General Purpose General Purpose

(Wide) w/Bolt-On Edge w/Bolt-On Edge

Page 24

Standard Z-Bar Information with

Quick-Coupler and Construction Fork 544J

Tine Length

Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . 25 ft. 7 in. (7802 mm) 26 ft. 7 in. (8106 mm)

Tipping Load, Straight (fork level, load

centered forward 24 in. [610 mm]

on 48-in. [1220 mm] tine and 30 in.

[762 mm] on 60-in. [1525 mm] tine) . . . . . 14,859 lb. (6740 kg) 14,002 lb. (6351 kg)

Tipping Load, 40-Degree Full Turn (fork

level, load centered forward 24 in.

[610 mm] on 48-in. [1220 mm]

tine and 30 in. [762 mm] on 60-in.

[1525 mm] tine) . . . . . . . . . . . . . . . . . . . . 12,632 lb. (5730 kg) 11,887 lb. (5392 kg)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 27,097 lb. (12 289 kg) 27,199 lb. (12 335 kg)

48 in. (1220 mm) 60 in. (1525 mm)

High-Lift Z-Bar Information with Pin-On-Type Bucket

Bucket Type/Size

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . . . 3.0 cu. yd. (2.3 m3) 3.0 cu. yd. (2.3 m3) 2.5 cu. yd. (1.9 m3)

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . . 2.6 cu. yd. (2.0 m3) 2.6 cu. yd. (2.0 m3) 2.1 cu. yd. (1.6 m3)

Bucket Weight . . . . . . . . . . . . . . . . . . . . . . . . . 2,400 lb. (1089 kg) 2,396 lb. (1087 kg) 2,061 lb. (935 kg)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . . . 100.4 in. (2550 mm) 105.9 in. (2690 mm) 100.4 in. (2550 mm)

Breakout Force, SAE J732C . . . . . . . . . . . . . . . 20,939 lb. (9498 kg) 22,394 lb. (10 158 kg) 24,671 lb. (11 191 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . . . 18,816 lb. (8535 kg) 18,713 lb. (8488 kg) 19,380 lb. (8791 kg)

Tipping Load, 40-Degree Full Turn, SAE. . . . . . 15,928 lb. (7225 kg) 15,815 lb. (7174 kg) 16,455 lb. (7464 kg)

Reach, 45-Degree Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 70.0 in. (1779 mm) 68.7 in. (1744 mm) 67.1 in. (1705 mm)

Reach, 45-Degree Dump, Full Height. . . . . . . . 39.3 in. (999 mm) 37.0 in. (941 mm) 34.5 in. (876 mm)

Dump Clearance, 45 Degree, Full Height . . . . . 123.6 in. (3139 mm) 125.6 in. (3189 mm) 128.0 in. (3249 mm)

Overall Length, Bucket on Ground . . . . . . . . . . 25 ft. 3 in. (7689 mm) 24 ft. 11 in. (7612 mm) 24 ft. 8 in. (7516 mm)

Loader Clearance Circle, Bucket In Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . . 38 ft. 11 in. (11 865 mm) 39 ft. 2 in. (11 942 mm) 38 ft. 7 in. (11 751 mm)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 27,641 lb. (12 538 kg) 27,855 lb. (12 635 kg) 27,302 lb. (12 384 kg)

Loader operating information is based on machine with standard equipment; cab; rear cast bumper/counterweight; 20.5R25 tires; ROPS cab; 175-lb. (79 kg) operator; and full fuel tank. This

information is affected by tire size, ballast, and different attachments.

Narrow General Wide General Purpose General Purpose

Purpose w/Bolt-On Edge w/Bolt-On Edge w/Bolt-On Edge

Adjustments to Operating Weights for High-Lift Z-Bar with Pin-On-Type Buckets or Quick-Coupler and Hook-On-Type Buckets

Adjustments to operating weights and tipping loads for 3.0-cu.-yd. (2.3 m3) general-purpose bucket with bolt-on cutting edge

Add (+) or deduct (–) lb. (kg) as indicated for

loaders with three-piece rims and

20.5R25 L-3 tires . . . . . . . . . . . . . . . . . . . . . . 0 lb. (0 kg) 0 lb. (0 kg) 0 lb. (0 kg)

20.5R25 L-2 tires . . . . . . . . . . . . . . . . . . . . . . – 228 lb. (– 104 kg) – 139 lb. (– 63 kg) – 120 lb. (– 55 kg)

20.5-25 L-2 tires. . . . . . . . . . . . . . . . . . . . . . . – 548 lb. (– 249 kg) – 332 lb. (– 150 kg) – 287 lb. (– 130 kg)

20.5-25 L-3 tires. . . . . . . . . . . . . . . . . . . . . . . – 416 lb. (– 189 kg) – 233 lb. (– 106 kg) – 219 lb. (– 99 kg)

600/65R25 L-3 tires** . . . . . . . . . . . . . . . . . . . + 676 lb. (+ 307 kg) + 409 lb. (+ 186 kg) + 355 lb. (+ 161 kg)

23.1-26 Logger* . . . . . . . . . . . . . . . . . . . . . . . + 44 lb. (+ 20 kg) + 27 lb. (+ 12 kg) + 23 lb. (+ 11 kg)

CaCl2in 20.5-25 rear tires . . . . . . . . . . . . . . . . + 1,821 lb. (+ 826 kg) + 2,203 lb. (+ 999 kg) + 1,911 lb. (+ 867 kg)

Optional rear cast bumper/counterweight

(removed) . . . . . . . . . . . . . . . . . . . . . . . . . N/A N/A N/A

Operating Weight Tipping Load, Straight Degree Full Turn, SAE

*Equipped with one-piece rims.

**CaCl2not recommended with 600/65R25 tires.

Tipping Load, 40-

PAGES

24–25

Page 25

High-Lift Z-Bar Information with

5.00

(3.8)

4.00

(3.0)

3.00

(2.3)

2.00

(1.5)

2,000 2,500 3,000 3,500

2100

180015001200

lb./cu. yd.

kg/m

3

This guide, representing bucket sizes not necessarily manufactured by Deere, will help you in selecting proper bucket size for material density, loader configuration, and operating conditions. Optimum bucket size is determined

after adding or subtracting all tipping load changes due to optional equipment. The “conservative load” line on this guide is recommended when operating in conditions such as soft ground and unlevel surfaces. The “maximum

load” condition on this guide is sometimes utilized when operating on firm ground and level surfaces.

*

BUCKET SIZE cu. yd. (m

3

)

900

1,500

600

MATERIAL (Loose weight)

Caliche

Cinders

Clay and gravel, dry

Clay and gravel, wet

Clay, dry

Clay, natural bed

Clay, wet

Coal, anthracite, broken

Coal, bituminous, broken

Earth, dry, packed

Earth, loam

Earth, wet, excavated

Granite, broken or large crushed

Gravel, dry

Gravel, dry 1/2" to 2" (13 to 50 mm)

Gravel, pit run (graveled sand)

Gravel, wet 1/2" to 2" (13 to 50 mm)

Gypsum, crushed

Limestone, broken or crushed

Magnetite, iron ore

Phosphate rock

Pyrite, iron ore

Sand and gravel, dry

Sand and gravel, wet

Sand, dry

Sand, wet

Sandstone, broken

Shale

Slag, broken

Stone, crushed

Tops oi l

lb./cu. yd.

2,100

1,000

2,400

2,600

2,500

2,800

2,800

1,850

1,400

2,550

2,100

2,700

2,800

2,550

2,850

3,250

3,400

2,700

2,600

4,700

2,160

4,350

2,900

3,400

2,400

3,100

2,550

2,100

2,950

2,700

1,600

kg/m

3

1250

590

1420

1540

1480

1660

1660

1100

830

1510

1250

1600

1660

1510

1690

1930

2020

1600

1540

2790

1280

2580

1720

2020

1420

1840

1510

1250

1750

1600

950

M

a

x

i

m

u

m

L

o

a

d

N

o

r

m

a

l

L

o

a

d

C

o

n

s

e

r

v

a

t

i

v

e

L

o

a

d

Deere 3.0-cu.-yd. (2.3 m3)

General-Purpose Bucket

Deere 2.5-cu.-yd. (1.9 m3)

General-Purpose Bucket

Quick-Coupler and Bucket 544J

Bucket Type/Size

Capacity, Heaped SAE . . . . . . . . . . . . . . . . . . . 3.0 cu. yd. (2.3 m3) 2.5 cu. yd. (1.9 m3)

Capacity, Struck SAE . . . . . . . . . . . . . . . . . . . . 2.6 cu. yd. (2.0 m3) 2.1 cu. yd. (1.6 m3)

Bucket Weight with Coupler. . . . . . . . . . . . . . . 3,595 lb. (1631 kg) 2,879 lb. (1306 kg)

Bucket Width . . . . . . . . . . . . . . . . . . . . . . . . . . 105.9 in. (2690 mm) 100.4 in. (2550 mm)

Breakout Force, SAE J732C . . . . . . . . . . . . . . . 17,557 lb. (7964 kg) 18,104 lb. (8212 kg)

Tipping Load, Straight . . . . . . . . . . . . . . . . . . . 16,964 lb. (7695 kg) 17,687 lb. (8023 kg)

Tipping Load, 40-Degree Full Turn, SAE. . . . . . 14,202 lb. (6442 kg) 14,905 lb. (6761 kg)

Reach, 45-Degree Dump, 7-ft. (2.13 m)

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 70.5 in. (1790 mm) 72.7 in. (1846 mm)

Reach, 45-Degree Dump, Full Height. . . . . . . . 43.0 in. (1092 mm) 43.4 in. (1102 mm)

Dump Clearance, 45 Degree, Full Height . . . . . 117.2 in. (2977 mm) 120.6 in. (3063 mm)

Overall Length, Bucket on Ground . . . . . . . . . . 25 ft. 11 in. (7905 mm) 25 ft. 7 in. (7807 mm)

Loader Clearance Circle, Bucket In Carry

Position . . . . . . . . . . . . . . . . . . . . . . . . . . 39 ft. 10 in. (12 151 mm) 39 ft. 4 in. (12 002 mm)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 28,836 lb. (13 080 kg) 28,122 lb. (12 756 kg)

Loader operating information is based on machine with standard equipment; cab; rear cast bumper/counterweight; 20.5R25 tires; ROPS cab; 175-lb. (79 kg) operator; and full fuel tank. This

information is affected by tire size, ballast, and different attachments.

General Purpose General Purpose

w/Bolt-On Edge w/Bolt-On Edge

High-Lift Z-Bar Information with Quick-Coupler and Construction Fork

Tine Length

Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . 26 ft. 8 in. (8139 mm) 27 ft. 8 in. (8442 mm)

Tipping Load, Straight (fork level, load

centered forward 24 in. [610 mm]

on 48-in. [1220 mm] tine and 30 in.

[762 mm] on 60-in. [1525 mm] tine) . . . . . 13,379 lb. (6069 kg) 12,651 lb. (5739 kg)

Tipping Load, 40-Degree Full Turn (fork

level, load centered forward 24 in.

[610 mm] on 48-in. [1220 mm]

tine and 30 in. [762 mm] on 60-in.

[1525 mm] tine) . . . . . . . . . . . . . . . . . . . . 11,345 lb. (5146 kg) 10,711 lb. (4858 kg)

Operating Weight. . . . . . . . . . . . . . . . . . . . . . . 27,249 lb. (12 358 kg) 27,351 lb. (12 404 kg)

48 in. (1220 mm) 60 in. (1525 mm)

Standard Z-Bar Pin-On Bucket Selection Guide*

Page 26

Specifications

Specifications

Specifications

Engine 624J

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . John Deere PowerTech 6068H; certified to EPA Tier 2 emissions

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valves Per Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . 4

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414 cu. in. (6.8 L)

Net Peak Power . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 hp (129 kW) @ 1,800 rpm

Net Rated Power . . . . . . . . . . . . . . . . . . . . . . . . . . 165 hp (119 kW) @ 2,200 rpm

Net Peak Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . 605 lb.-ft. (810 Nm) @ 1,000 rpm

Net Torque Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . 54%

Net Power Bulge. . . . . . . . . . . . . . . . . . . . . . . . . . . 9%

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . high-pressure common rail

Lube System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . full-flow spin-on filter and integral cooler

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . turbocharged, charge air cooled

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dual element dry type, restriction indicator in cab monitor for service

Fan Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulically driven, proportionally controlled, fan aft of coolers

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . 24 volt with 80-amp alternator

Batteries (two 12 volt) . . . . . . . . . . . . . . . . . . . . . . 950 CCA

Transmission

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . countershaft-type power shift

Torque Converter . . . . . . . . . . . . . . . . . . . . . . . . . . single stage, single phase

Shift Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electronically modulated, adaptive, load and speed dependent

Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . steering-column or joystick-mounted F-N-R and gear-select lever, kick-down button on hydraulic lever

Shift Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . auto/manual, auto to 1st or 2nd, kick down or kick up/down, three clutch cutoff settings adjustable on switch pad

Tra vel Speeds*

Gear 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 mph (7.2 km/h) 4.7 mph (7.5 km/h)

Gear 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.7 mph (12.4 km/h) 8.1 mph (13.1 km/h)

Gear 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15.2 mph (24.5 km/h) 16.0 mph (25.8 km/h)

Gear 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.6 mph (39.5 km/h)

*Equipped with 20.5-25 tires.

Forward Reverse

Axles/Brakes

Final Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . heavy-duty inboard planetary

Differentials* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic locking front, conventional rear — standard; dual locking front and rear — optional

Rear Axle Oscillation, Stop to Stop* . . . . . . . . . . . . 24 deg.

Brakes (conform to SAE J1473, ISO3450)

Service Brakes . . . . . . . . . . . . . . . . . . . . . . . . hydraulically actuated, inboard, carrier mounted, pressure oil cooled, self adjusting, multi-disc

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . automatic spring applied, hydraulically released, oil cooled, multi-disc

*Equipped with 20.5-25 tires.

Tires

Choice of (with three-piece rims)

20.5R25 L-3 . . . . . . . . . . . . . . . . . . . . . . . . . . 80.7 in. (2050 mm) 101.6 in. (2582 mm) 0 in. (0 mm)

20.5R25 L-2 . . . . . . . . . . . . . . . . . . . . . . . . . . 80.7 in. (2050 mm) 101.6 in. (2582 mm) – 0.83 in. (– 21 mm)

20.5-25 L-2. . . . . . . . . . . . . . . . . . . . . . . . . . . 80.7 in. (2050 mm) 101.7 in. (2583 mm) – 0.27 in. (– 7 mm)

20.5-25 L-3. . . . . . . . . . . . . . . . . . . . . . . . . . . 80.7 in. (2050 mm) 101.9 in. (2588 mm) – 0.27 in. (– 7 mm)

600/65R25 L-3 . . . . . . . . . . . . . . . . . . . . . . . . 80.7 in. (2050 mm) 104.1 in. (2644 mm) – 0.83 in. (– 21 mm)

28L-26 Logger* . . . . . . . . . . . . . . . . . . . . . . . . 89.4 in. (2272 mm) 117.6 in. (2986 mm) + 3.1 in. (+ 79 mm)

*Equipped with one-piece rims.

Refill Capacities (U.S.)

Fuel Tank (with ground-level fueling) . . . . . . . . . . . 92 gal. (348 L)

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 qt. (22 L)

Engine Lubrication, Including Full-Flow Spin-

On Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 qt. (24 L)

Powershift Transmission, Including Filter . . . . . . . . 24 qt. (23 L)

Tread Width Width Over Tires Change In Vertical Height

PAGES

26–27

Page 27

Refill Capacities (U.S.)

A

B

C

J

E

45˚

I

Cab and Canopy

F

H

G

D

K

L

M

Differential (each axle)

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 qt. (24.5 L)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 qt. (20 L)

Loader Hydraulic Reservoir and Filters . . . . . . . . . . 31.5 gal. (119 L)

Wet-Disc Parking Brake . . . . . . . . . . . . . . . . . . . . . 10 oz. (0.3 L)

(continued)

624J

Hydraulic System/Steering

Pump (loader and steering). . . . . . . . . . . . . . . . . . . variable-displacement, axial-piston pump; closed-center, pressure-compensating system

Maximum Flow @ 2,350 rpm . . . . . . . . . . . . . 58 gpm (220 L/m) @ 1,000 psi (6895 kPa)

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . loader and steering relief 3,600 psi (24 850 kPa)

Loader Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . two-function valve; single- or dual-lever controls; control lever lockout feature; optional third- and fourth-function valve with auxiliary lever

Steering (conforms to SAE J1511)

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . power, fully hydraulic

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,600 psi (24 850 kPa) relief

Articulation Angle . . . . . . . . . . . . . . . . . . . . . . 80-degree arc (40 degrees each direction)

Hydraulic Cycle Times

Raise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.9 sec. 5.9 sec.

Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 sec. 1.3 sec.

Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7 sec. (float down) / 3.3 sec. (power down) 2.7 sec. (float down) / 3.3 sec. (power down)

Total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.9 sec. 9.9 sec.

Maximum Lift Capacity (with 3.0-cu.-yd.

[2.3 m3] bucket with bolt-on edge)

Lift at Ground Level . . . . . . . . . . . . . . . . . . . . . 30,958 lb. (14 040 kg) 29,190 lb. (12 238 kg)

Lift at Maximum Height . . . . . . . . . . . . . . . . . . 17,305 lb. (7848 kg) 15,812 lb. (7171 kg)

Turning Radius (measured to centerline of

outside tire) . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 ft. 0 in. (5187 mm) 17 ft. 0 in. (5187 mm)

Standard Z-Bar High-Lift Z-Bar

Dimensions with Pin-On Bucket

Standard Z-Bar High-Lift Z-Bar

A Height to Top of Cab and Canopy. . . . . . . . . . . . 10 ft. 10.6 in. (3317 mm) 10 ft. 10.6 in. (3317 mm)

B Height to Top of Exhaust . . . . . . . . . . . . . . . . . . 10 ft. 10 in. (3303 mm) 10 ft. 10 in. (3303 mm)

C Ground Clearance . . . . . . . . . . . . . . . . . . . . . . . 17.1 in. (435.6 mm) 17.1 in. (435.6 mm)

D Length from Centerline to Front Axle . . . . . . . . . 59.65 in. (1515 mm) 59.65 in. (1515 mm)

E Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119.3 in. (3030 mm) 119.3 in. (3030 mm)

F Dump Clearance . . . . . . . . . . . . . . . . . . . . . . . . (see page 29) (see page 30)

G Height to Hinge Pin, Fully Raised. . . . . . . . . . . . 13 ft. 0 in. (3966 mm) 14 ft. 3 in. (4332 mm)

H Dump Reach . . . . . . . . . . . . . . . . . . . . . . . . . . . (see page 29) (see page 30)

I Maximum Digging Depth . . . . . . . . . . . . . . . . . . 3.5 in. (88 mm) 7.4 in. (188 mm)

J Overall Length. . . . . . . . . . . . . . . . . . . . . . . . . . (see page 29) (see page 30)

K Maximum Rollback at Ground Level . . . . . . . . . 40 deg. 40 deg.

L Maximum Rollback, Boom Fully Raised . . . . . . . 55 deg. 55 deg.

M Maximum Bucket Angle, Fully Raised . . . . . . . . 50 deg. 50 deg.

Page 28

Dimensions with Quick-

E

45˚

C

A

B

H

D

F

G

H

A

C

E

D

B

G

F

Coupler and Bucket 624J

Standard Z-Bar High-Lift Z-Bar

A Dump Clearance . . . . . . . . . . . . . . . . . . . . . . . . (see page 29) (see page 31)

B Dump Reach . . . . . . . . . . . . . . . . . . . . . . . . . . . (see page 29) (see page 31)

C Maximum Digging Depth . . . . . . . . . . . . . . . . . . 6.5 in. (164 mm) 10.5 in. (266 mm)

D Height to Hinge Pin, Fully Raised . . . . . . . . . . . . 13 ft. 0 in. (3966 mm) 14 ft. 3 in. (4332 mm)

E Overall Length. . . . . . . . . . . . . . . . . . . . . . . . . . (see page 29) (see page 31)

F Maximum Rollback, Boom Fully Raised . . . . . . . 55 deg. 49 deg.

G Maximum Bucket Discharge Angle, Fully

Raised. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 deg. 46 deg.

H Maximum Rollback at Ground Level . . . . . . . . . 42 deg. 42 deg.

624J LOADER WITH QUICK-COUPLER AND BUCKET

Dimensions with Quick-Coupler

and Construction Fork 624J

Standard Z-Bar High-Lift Z-Bar