Page 1

4630

SelfPropelled

Sprayer

(Serial No. N04630X000101 )

OPERATOR’S MANUAL

4630 SelfPropelled Sprayer

OMN300896 ISSUE L9 (ENGLISH)

DCYOMN300896

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

If this product contains a gasoline engine:

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

The State of California requires the above two warnings.

John Deere Des Moines Works

LITHO IN U.S.A.

Downloaded from manualsnet.com search engine

Page 2

Foreword

Introduction

READ THIS MANUAL carefully to learn how to operate

and service your machine correctly. Failure to do so

could result in personal injury or equipment damage.

This manual and safety signs on your machine may also

be available in other languages. (See your John Deere

dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your machine and should remain with the machine

when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and inch

fasteners may require a specific metric or inch wrench.

RIGHTHAND AND LEFTHAND sides are determined by

facing in the direction of forward travel.

WRITE PRODUCT IDENTIFICATION NUMBERS (P.I.N.)

in the Specification or Identification Numbers section.

Accurately record all the numbers to help in tracing the

machine should it be stolen. Your dealer also needs these

numbers when you order parts. File the identification

numbers in a secure place off the machine.

WARRANTY is provided as part of John Deere’s support

program for customers who operate and maintain their

equipment as described in this manual. The warranty is

explained on the warranty certificate or statement which

you should have received from your dealer.

This warranty provides you the assurance that John

Deere will back its products where defects appear within

the warranty period. In some circumstances, John Deere

also provides field improvements, often without charge

to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to change

its performance beyond the original factory specifications,

the warranty will become void and field improvements

may be denied. Setting fuel delivery above specifications

or otherwise overpowering machines will result in such

action.

THE TIRE MANUFACTURER’S warranty supplied with

your machine may not apply outside the U.S.

If you are not the original owner of this machine, it is in

your interest to contact your local John Deere dealer to

inform them of this unit’s serial number. This will help John

Deere notify you of any issues or product improvements.

DX,IFC1 1903APR091/1

Downloaded from manualsnet.com search engine

122309

PN=2

Page 3

Contents

Page

Safety.......................................................... 051

Safety Signs

Safety Signs .......................................................101

Safety Features

Safety Features ..................................................151

Operators Station

Front Console ..................................................... 201

Key Switch..........................................................202

Adjust Steering Wheel........................................202

Operate Turn Signals ......................................... 203

Operate the Hazard Warning Light Switch .........203

Operate Windshield Wiper..................................203

Operate Horn......................................................204

Operate Light Switch and High/Low

Beam Switch ..................................................204

Light Operation Table .........................................205

Side Console Switches.......................................206

Side Console Switches.......................................206

Operate Boom Section Switches........................207

Rate Select Switch .............................................207

Accessory Electrical Outlet................................. 208

CommandARM™ Controls ................................. 208

Multifunction Control Handle ..............................209

Foam Marker Switch—If Equipped...................2010

Speed Range Switch........................................2010

Spray System Master ON/OFF Switch .............2011

Boom Raise/Lower Switches............................ 2012

IBS Index Boom Section Buttons ..................... 2012

Solution Pump Switch.......................................2013

Agitation Switch ................................................ 2013

Lefthand and Righthand Fence Row

Nozzles Switches—If Equipped ...................2013

Ladder Switch...................................................2014

Tread Adjust Switches ......................................2014

Throttle .............................................................2014

Storage Rack....................................................2015

Load Center......................................................2015

Diagnostic Outlet ..............................................2015

Heater and Air Conditioning Controls ...............2016

Fan and Air Louvers .........................................2016

Heater............................................................... 2016

Air Conditioning System ................................... 2017

Operating Tips About Your Audio System ........2017

Page

DeereDelco AM/FM Stereo Radio, CD

Player, and Weatherband............................. 2018

Program Radio for Local Area Frequency ........2021

Weatherband....................................................2021

Dome Light and Console Light .........................2022

Switches at BPost ...........................................2022

Using Secondary Brake....................................2023

Traction Control (Optional) ...............................2023

Operate Beacon Light (If Equipped) .................2024

Operator’s Seat ................................................2024

Operator's Seat

Seat Belt....................................................... 2025

Instructional Seat—If Equipped........................2025

Adjust Rearview Mirrors ...................................2025

Breakin Period

Engine ................................................................251

Prestarting Checks

Check Engine Oil Level—Daily...........................301

Drain Water and Sediment from Fuel

Filter and Water Separator—Daily .................301

Check Coolant Level—Daily............................... 301

Check Hydrostatic and Hydraulic Oil

Level—Daily ...................................................302

Fill Fuel Tank ......................................................302

Check Tires For Damage And Correct

Inflation Pressure—Daily................................ 303

Check Air Springs—Daily (Machines

not Equipped with Auto Air Spring

Leveling System)............................................ 303

Lubricate Suspension Assemblies—Daily..........304

Drain Moisture from On Board Air Tank—Daily .. 305

Operating The Machine

Machine Informational Decals ............................ 351

Start the Engine..................................................351

Cold Weather Starting ........................................353

Warm The Engine...............................................353

Idle the Engine....................................................354

Operate the Engine ............................................354

Operate Warning Lights......................................354

Driving the Machine............................................355

Backup Alarm .....................................................356

Before Operating in the Field.............................. 356

Operate in the Field ............................................356

Operate Traction Control (Optional) ...................359

Original Instructions. All information, illustrations and specifications in this

manual are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

Downloaded from manualsnet.com search engine

Continued on next page

COPYRIGHT © 2009

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTION ® Manual

i

All rights reserved.

122309

PN=1

Page 4

Contents

Page

Operate IBS........................................................359

Operate Boom Return to Height .......................3511

Reduce Travel Speed .......................................3512

Verify Proper Operation Of Park Brakes........... 3513

Relieve Boom Pressure.................................... 3513

Transport Machine............................................3514

Mired Machine .................................................. 3515

Park the Machine..............................................3517

SprayStar System

Display Theory of Operation...............................401

Front of Display ..................................................402

Back of Display...................................................403

Display Secondary Navigation............................403

Data Card ...........................................................404

Screen Layout ....................................................405

Power Up............................................................406

Input Fields ......................................................... 407

ISO Standard Icons ............................................ 408

Message Center .................................................408

Display.............................................................. 4010

Display

Display Softkey (F)......................................4012

Application Menu .............................................. 4015

Settings Softkey (G)....................................4016

Diagnostics Softkey (I) ................................4017

Layout Manager................................................4017

Resetting Display..............................................4022

GS2 1800 Display Features .............................4023

Front of Display—GS2 1800 Display ................4024

Back of Display—GS2 1800 Display ................4025

Turn The Display On/Off—GS2 1800 Display ..4025

Navigate Your GS2 1800 Display .....................4026

Display Menu—GS2 1800 Display ...................4029

Adjust Volume And Brightness—GS2

1800 Display ................................................ 4030

Change Regional Settings—GS2 1800

Display .........................................................4031

Set The Time And Date—GS2 1800 Display ...4032

Set the Highlight Color—GS2 1800 Display .....4033

Choose Home Pages For Your

Display—GS2 1800 Display.........................4034

SprayStar System.............................................4034

Sprayer Main Page...........................................4035

Sprayer Main Page Information Drop

Down Lists.................................................... 4036

Spray Setup......................................................4037

Set Application Rates ....................................... 4038

Set Minimum Pressure ..................................... 4039

Set Spray Off Pressure.....................................4041

Set Tank Reset Volume .................................... 4042

Set Sprayer Response .....................................4043

Setup Boom Charge.........................................4044

Set Manual Pressure........................................4046

Foam Marker ....................................................4047

Enable Boom Pressure Relief ..........................4048

Turn Flow Rate Alarm On/Off ...........................4049

Turn Sections Off Alarm On/Off........................4050

Page

Set Number of Boom Sections,

Number of Nozzles and Spacing..................4051

Program SprayStar for Band Spraying .............4053

Setup Boom Return To Height..........................4055

Recording Engine Hours ..................................4056

Resetting Service Interval Counter...................4057

Setting Time and Date......................................4058

Setting Vehicle Speed Selection....................... 4059

Set Flowmeter Calibration Number ..................4060

Calibrate Pressure Sensor ...............................4061

Calibrate Solution Pump...................................4063

Reset Spray Calibrations to Factory

Default Settings ............................................4065

Calibrate Boom Return To Height..................... 4067

Calibrating Wheel Speed Sensor .....................4069

Calibrating Radar Sensor (Optional) ................4071

Controller Diagnostics ......................................4073

Diagnostic Readings.........................................4074

Diagnostic Tests ...............................................4075

Recent Problems .............................................. 4076

Job Summaries and Current Totals ..................4077

Operating Distance Counter.............................4080

Refill Tank .........................................................4081

Nozzle Flow Check Test ...................................4082

Fence Row Nozzles—If Equipped....................4083

Applying Low Application Rates .......................4084

Control Unit Info................................................4084

SprayStar Caution and Warning Statements....4085

Message Center Cautions and Warnings .........4085

Warning ............................................................4086

Chassis Caution Alarms ................................... 4086

Park Brake On..................................................4086

Secondary Brake On ........................................ 4086

Low Fuel ........................................................... 4086

Scheduled Maintenance/Service is Due...........4087

SprayStar: System Error—Data May

Be Lost .........................................................4087

SprayStar: Fuel Sensor Error—Out of

Range High .................................................. 4087

SprayStar: Fuel Sensor Error—Out of

Range Low ...................................................4087

Solution System Caution Alarms ...................... 4087

Solution Flow is Low.........................................4087

Solution Flow is High ........................................ 4087

SprayStar—Solution Pressure Sensor

Failure ..........................................................4088

Calibration in Progress—Please Wait... ...........4088

Pump Calibration Disabled!—Review

Calibrate Checklist ....................................... 4088

Boom Sections Are Off .....................................4088

Spraying is Disabled in Fourth Range ..............4088

Remote Load Disabled—Check

Remote Switch .............................................4088

Boom Sensors Are Out Of Calibration..............4088

SprayStar: Boom Return To Height

Sensor Failure ..............................................4089

Engine Caution Alarms.....................................4089

Engine System: 94.17 Fuel Pressure Low..... 4089

Downloaded from manualsnet.com search engine

Continued on next page

ii

122309

PN=2

Page 5

Contents

Page

Engine System: 97.16 – Water in Fuel

Detected.......................................................4089

Engine System: 105.16 – Engine Air

Temperature High.........................................4089

Engine System: 107.0 – Air Filter Restricted ... 4089

Engine System: 110.15 – Coolant

Temperature High.........................................4089

Engine System: 110.16 – Coolant

Temperature High.........................................4090

Engine System: 174.16 – Fuel

Temperature High.........................................4090

Engine System: 1638.16 – Hydraulic

Oil Hot .......................................................... 4090

Chassis Warning Alarms ..................................4090

Secondary Brake Is On ....................................4090

Solution System Warning Alarms ..................... 4090

Solution Pump is Dry Turn Off Pump

Immediately..................................................4090

Engine Warning Alarms ....................................4090

Engine System: 100.1 Engine Oil

Pressure Low ............................................... 4090

Engine System: 110.0 Coolant

Temperature High.........................................4091

Engine System: 190.0 Engine Speed

Too High .......................................................4091

Engine System: 1638.0 Hydraulic Oil Hot .......4091

Wet System

Solution System..................................................451

Avoid Contact with Chemicals,

Including Pesticides ....................................... 453

Solution Pump Maintenance and

Operation Recommendations ........................ 454

Replacing Nozzles..............................................456

Nozzle Types......................................................456

Flat Fan Nozzle ..................................................457

Even Spray Nozzle.............................................458

Hollow Cone Nozzle ........................................... 459

Flood Nozzle.....................................................4510

Flat Fan High Flow (Flood) Nozzle ...................4510

Using Nozzle Tip Calculator and Selector ........ 4511

Checking and Replacing Worn Nozzles ...........4512

24.4 M (80 ft) Boom Flow

Characteristics—Application

Rate vs. Speed ............................................ 4513

Boom Flow Characteristics (Standard

Flow)—Boom Flow Rate vs.

Pressure 24.4 M (80 ft.) Boom.....................4514

Calibrating Nozzles...........................................4515

Calibration Procedure.......................................4515

Conversion Factors (Calibrating for

Carriers Other Than Water)..........................4516

Installing and Positioning Nozzle Tips

and Strainers ................................................4516

Clean SprayMaster Triplet Nozzle Bodies........4518

Cleaning SprayMaster 5Position

Nozzle Bodies .............................................. 4519

Wet System Valves...........................................4520

Page

Solution Strainers .............................................4523

Filling Solution Tank Without Using

QuikFill ........................................................4524

Filling Rinse Tank Using LeftHand

Rinse Fill ...................................................... 4524

Filling Solution Tank with Sprayer Pump ..........4524

Priming Solution Pump with Rinse

Tank to Fill When Nurse Tank Fluid

Level Even or Below Sprayer Pump ............4526

Fill Solution Tank with Sprayer Pump

Through Eductor .......................................... 4527

Filling Solution Tank with Nurse Tank Pump.....4530

Fill Solution Tank with Nurse Tank

Pump and Sprayer Pump Through

Eductor.........................................................4531

Mixing Solution in Tank (Using Agitation) .........4534

Preparing to Spray............................................4535

Applying Low Application Rates .......................4536

Using Rinse System (Rinsing Solution

Tank and Boom) ...........................................4537

Use Rinse System (Rinsing Solution

Pump, Boom, and Flowmeter Only) .............4541

Recommendations For Eliminating Air

from Solution System ...................................4541

Relieve Boom Pressure.................................... 4542

Relieve Boom Pressure.................................... 4543

Clean Fill Strainer.............................................4544

Draining Solution Tank......................................4545

Cleaning Boom Supply Line

Strainer(s)—Daily.........................................4545

Clean Flowmeter—Daily...................................4546

Clean Water Tank.............................................4547

24.4 m (80 ft) Booms

Unfold Boom.......................................................501

Unfold Boom In Limited Height Area ..................503

Fold Boom ..........................................................506

Fold Boom In Limited Height Area......................508

Spray with Boom at 18.3 m (60 ft) ....................5010

Adjust Breakaway Section Springs...................5010

Adjust Roll Suspension Springs .......................5010

Adjust Boom Stop Bolts.................................... 5011

Adjusting Inner Fold Cylinder ........................... 5011

Foam Marker

On Board Air (OBA) Foam Marker

Schematic and Operation...............................551

Foam Marker System (With Internal

12volt Compressor) Schematic and

Operation .......................................................553

Operate Foam Marker System ...........................554

Use John Deere Foam and Marking

Chemicals ......................................................557

Electrical System Service

Basic Electrical Component Handling /

Precautions For Vehicles Equipped

With Computer Controlled Systems ...............601

Downloaded from manualsnet.com search engine

iii

Continued on next page

122309

PN=3

Page 6

Contents

Page

Welding Near Electronic Control Units ...............601

Keep Electronic Control Unit

Connectors Clean .......................................... 602

Prevent Acid Burns.............................................602

Service Batteries ................................................603

Prevent Battery Damage .................................... 603

Connection To A Booster Battery or Charger .....604

Charge Batteries (Removed From Machine) ......604

Safety Rules When Replacing Halogen Bulbs ...605

Replace Hood Grille Work Light Bulb .................606

Replace High and Low Beam Light Bulbs .......... 606

Adjust the Headlights..........................................608

Replace Fill Station Light Halogen Bulb ...........6010

Replace Platform Light Halogen Bulb...............6010

Replace Roof Flood Light Halogen Bulb .......... 6011

Replace Extremity Front Warning Light Bulb....6012

Replace Rear Warning Light Bulbs ..................6013

Replace Dome Light Bulb.................................6014

Safeguard Alternator and Regulator.................6015

Load Center Fuses...........................................6015

Load Center Relays and Diodes.......................6016

Fuses and Relays in the Engine

Compartment ...............................................6017

Cab and Air Conditioning

Avoid Exposure to Chemicals.............................651

Cab Pressure Indicator.......................................651

Cab Air Filters.....................................................651

Change Cab Air Filters .......................................652

Service Air Conditioner....................................... 658

Engine and Drive Train

Replace Fan Belt................................................701

Replace Alternator Belt.......................................702

Fan Belt Routing.................................................703

Inspecting Fan Belt Tensioner ............................704

Do Not Modify Fuel System ................................706

Do Not Open HighPressure Fuel System..........706

Relieve Fuel System Pressure ...........................707

Drain Water and Sediment from Fuel

Filter and Water Separator—Daily ................. 707

Replace Fuel Filters—500 Hours .......................708

Bleeding Fuel System.........................................708

Engine Air Filter..................................................709

Clean Primary Engine Air Filter Element ............709

Service Engine Air Intake and

PreCleaner—750 Hours.............................. 7010

Replace Primary and Secondary

Engine Air Filters—1500 Hours or

Two Years.....................................................7010

Secondary (Safety) Element............................. 7011

Clean Cooling Package.................................... 7011

Wheels and Tires

Use Proper Lifting Equipment.............................751

Check Tires For Damage And Correct

Inflation Pressure—Daily................................ 751

Attach Lift Bracket ..............................................752

Page

Tighten Wheel Hardware ....................................753

Install Optional Tires...........................................753

Check Front Axle ToeIn—Annually....................754

Adjust Front Axle ToeIn (Wide Machine) ........... 756

Adjust Front Axle ToeIn (Narrow Machine)........757

Discarded Tires ..................................................757

Chassis

Additional Service Information............................ 801

Set Tread Width Narrow Machine ...................... 801

Set Tread Width Wide Machine—With

out Hydraulic Tread Adjust Option .................806

Set Tread Width—With Hydraulic

Tread Adjust Option ..................................... 8011

Check Air Springs—Daily (Machines

not Equipped with Auto Air Spring

Leveling System).......................................... 8012

Auto Air Spring Leveling System ......................8013

Follow Safe Transport Procedures ................... 8013

Towing The Sprayer..........................................8013

Bleed Service Brakes ....................................... 8014

Prepare Machine For Transport on

SemiTractor Trailer .....................................8014

Checking Engine Compartment for

Accumulated Trash and Debris....................8016

Determining When to Adjust Shim Gap

on Axle Tread Adjust ....................................8016

Adjust Shim Gap with Wheel Off

Ground (Preferred) .......................................8017

Adjust Shim Gap with Wheel on Ground ..........8019

Install Fire Extinguisher (If Equipped)...............8021

Fuels, Lubricants and Coolants

Diesel Fuel..........................................................851

Handling and Storing Diesel Fuel .......................851

Biodiesel Fuel ..................................................... 852

Lubricity of Diesel Fuel .......................................853

Heavy Duty Diesel Engine Coolant .................... 853

Drain Intervals for Diesel Engine Coolant...........854

John Deere COOLGARD™ II

COOLANT EXTENDER .................................854

Supplemental Coolant Additives.........................855

Operating in Warm Temperature Climates .........855

Additional Information About Diesel

Engine Coolants and John Deere

COOLGARD™ II COOLANT EXTENDER ....856

Testing Diesel Engine Coolant............................857

Diesel Engine BreakIn Oil .................................857

BreakIn Oil Recommendations for

4630 Sprayers ................................................858

Diesel Engine Oil................................................859

Diesel Engine Oil and Filter Service Intervals ..8510

Diesel Engine Oil and Filter Service

Intervals For 4630 Sprayers......................... 8511

Extended Diesel Engine Oil Service Intervals ..8512

Hydrostatic/Hydraulic Drive Oil......................... 8512

Planetary Hub Oil .............................................8513

Grease.............................................................. 8513

Downloaded from manualsnet.com search engine

iv

Continued on next page

122309

PN=4

Page 7

Contents

Page

Suspension and Steering Grease.....................8513

Lubricant Storage .............................................8514

Alternative and Synthetic Lubricants ................8514

Lubrication and Maintenance

Lubrication Symbols ...........................................901

Prevent Hydraulic System Contamination .......... 901

Dispose of Waste Properly ................................. 901

Service Intervals—4630 (Excluding Boom) ........ 902

Tighten Lug Nuts—After First Hour ....................903

Check Solution Tank Straps—After

First Ten Hours...............................................903

Change Planetary Hub Oil—After First

50 Hours......................................................... 904

Visually Inspect Suspension

Bushings—After First 50 and

First 100 Hours...............................................904

Check Suspension Rod

Hardware—After First 100 Hours...................904

Check Shim Gap on Axle Tread

Adjust—After First 100 Hours ........................905

Change Engine Oil and Filter—After

First 100 Hours...............................................906

Check Engine Oil Level—Daily...........................907

Check Coolant Level—Daily............................... 907

Check Hydrostatic and Hydraulic Oil

Level—Daily ...................................................908

Drain Water and Sediment from Fuel

Filter and Water Separator—Daily ................. 908

Lubricate Suspension Assemblies—Daily..........909

Rinse Solution Pump, Boom, and

Flowmeter—Daily.........................................9010

Drain Moisture from On Board Air

Tank—Daily .................................................. 9010

Check Tires For Damage And Correct

Inflation Pressure—Daily.............................. 9011

Check Air Springs—Daily (Machines

not Equipped with Auto Air Spring

Leveling System).......................................... 9011

Clean Flowmeter—Daily...................................9012

Clean Screens and Cooling

Package—As Required ................................9013

Clean Fill Strainer—As Required......................9013

Replace Engine Air Filters—As Required.........9013

Inspect and Replace Fan Belt—As Required ...9013

Check and Replace Cab Air Filters—As

Required.......................................................9013

Lubricate Steering Cylinder Ball

Joints—100 Hours........................................ 9014

Visually Inspect Service Brake

Components—100 Hours............................. 9014

Tighten Wheel Hardware—100 Hours..............9015

Check Shim Gap on Axle Tread

Adjust—250 Hours .......................................9015

Change Engine Oil and Filter—250 Hours .......9016

Check Solution Tank Straps—250 Hours ......... 9017

Lubricate Drive Shaft UJoints—Every

250 Hours..................................................... 9017

Page

Service Batteries—250 Hours .......................... 9018

Rotate Tires—250 Hours ..................................9018

Check and Replace Cab Air

Filters—250 Hours or Annually .................... 9019

Replace Hydrostatic and Hydraulic

Filters—500 Hours ....................................... 9019

Change Hydraulic Oil—500 Hours ...................9020

Change Planetary Hub Oil—500 Hours............9020

Replace Fuel Filters—500 Hours .....................9021

Visually Inspect Suspension

Bushings—500 Hours .................................. 9022

Check Suspension Rod

Hardware—500 Hours ................................. 9022

Inspect Seat Belt—Annually.............................9022

Replace Air Drier Cartridge—Annually ............. 9023

Clean Engine Vent Tube—Annually ................. 9023

Inspect Service Brake Compo

nents—Annually ...........................................9024

Inspect Hydro Isolators—Annually ................... 9025

Check Front Axle ToeIn—Annually..................9026

Clean Sprayer and Coat Exposed Surfaces.....9027

Test Coolant—Annually .................................... 9028

Service Engine Air Intake and

PreCleaner—750 Hours.............................. 9028

Check Engine Speeds—750 Hours..................9028

Check Belt Tensioner1500 Hours....................9028

Adjust Engine Valve Clearance—2000 Hours ..9028

Replace Engine Crankshaft

Damper—5000 Hours or Five

Years ............................................................9028

Drain, Flush and Refill Cooling

System—Every 6000 Hours or Six Years..... 9029

Test or Replace Thermostats and

Radiator Cap—Every 6000 Hours or

Six Years ......................................................9030

Lubrication—Booms

Boom Lubrication Locations ............................... 951

Service Intervals—24.4, m (80 ft) .......................951

Tighten Boom Assembly—After First

Ten Hours and Every 50 Hours ......................951

Lubricate Center Boom Section..........................951

Lubricate Boom Lift Arm Pivots—10 Hours ........953

Lubricate Outer Boom Hinge—50 Hours ............953

Lubricate Breakaway Chain Pivot and

Hinge—50 Hours............................................ 953

Maintenance—Foam Marker

Drain Moisture from On Board Air Tank

(If Equipped)—Daily .....................................1001

Clean Foamer Control Box filters ..................... 1001

Replace Foam Compressor Fuse.....................1002

Troubleshooting

Engine .............................................................. 1051

Hydrostatic Drive ..............................................1056

Hydraulic System..............................................1059

SprayStar Solution Control System ................ 10510

Downloaded from manualsnet.com search engine

Continued on next page

v

122309

PN=5

Page 8

Page

Eductor ...........................................................10518

Suspension System........................................10520

Tread Adjust System ......................................10521

Operator’s Cab ...............................................10522

Foam Marker System—If Equipped ...............10525

24.4 m (80 ft) Boom Operation .......................10527

Storage

Clean Vehicle of Hazardous Chemicals,

Including Pesticides ..................................... 1101

Recommended Cleaners And Coatings ........... 1101

Clean Solution System ..................................... 1101

Prepare Machine To Ship During Cold

Weather Months ........................................... 1102

Prepare Machine for Storage ........................... 1103

Prepare Foam Marker System for Cold

Weather Storage .......................................... 1105

Remove Machine from Storage........................ 1108

Specifications

Machine Specifications..................................... 1151

Dimensions....................................................... 1155

Dimensions—All Machines............................... 1156

Metric Bolt and Screw Torque Values............... 1157

Unified Inch Bolt and Screw Torque Values...... 1158

High Pressure Face Seal Torque Chart ............ 1159

SAE Face Seal Fitting Torque

Chart—Standard Pressure Applications .... 11510

Limited Battery Warranty................................ 11511

Identification Numbers.................................... 11512

Keep Proof of Ownership ............................... 11514

Keep Machines Secure .................................. 11514

Contents

Downloaded from manualsnet.com search engine

vi

122309

PN=6

Page 9

Safety

Recognize Safety Information

This is a safetyalert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is

used with the safetyalert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

T81389 —UN—07DEC88

DX,ALERT 1929SEP981/1

Follow Safety Instructions

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

There can be additional safety information contained on

parts and components sourced from suppliers that is not

reproduced in this operator’s manual.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

TS187 —19—30SEP88

DX,SIGNAL 1903MAR931/1

TS201 —UN—23AUG88

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

DX,READ 1916JUN091/1

Downloaded from manualsnet.com search engine

051

122309

PN=9

Page 10

Park Machine Safely

Before working on the machine:

Lower all equipment to the ground.

•

Stop the engine and remove the key.

•

Disconnect the battery ground strap.

•

Hang a "DO NOT OPERATE" tag in operator station.

•

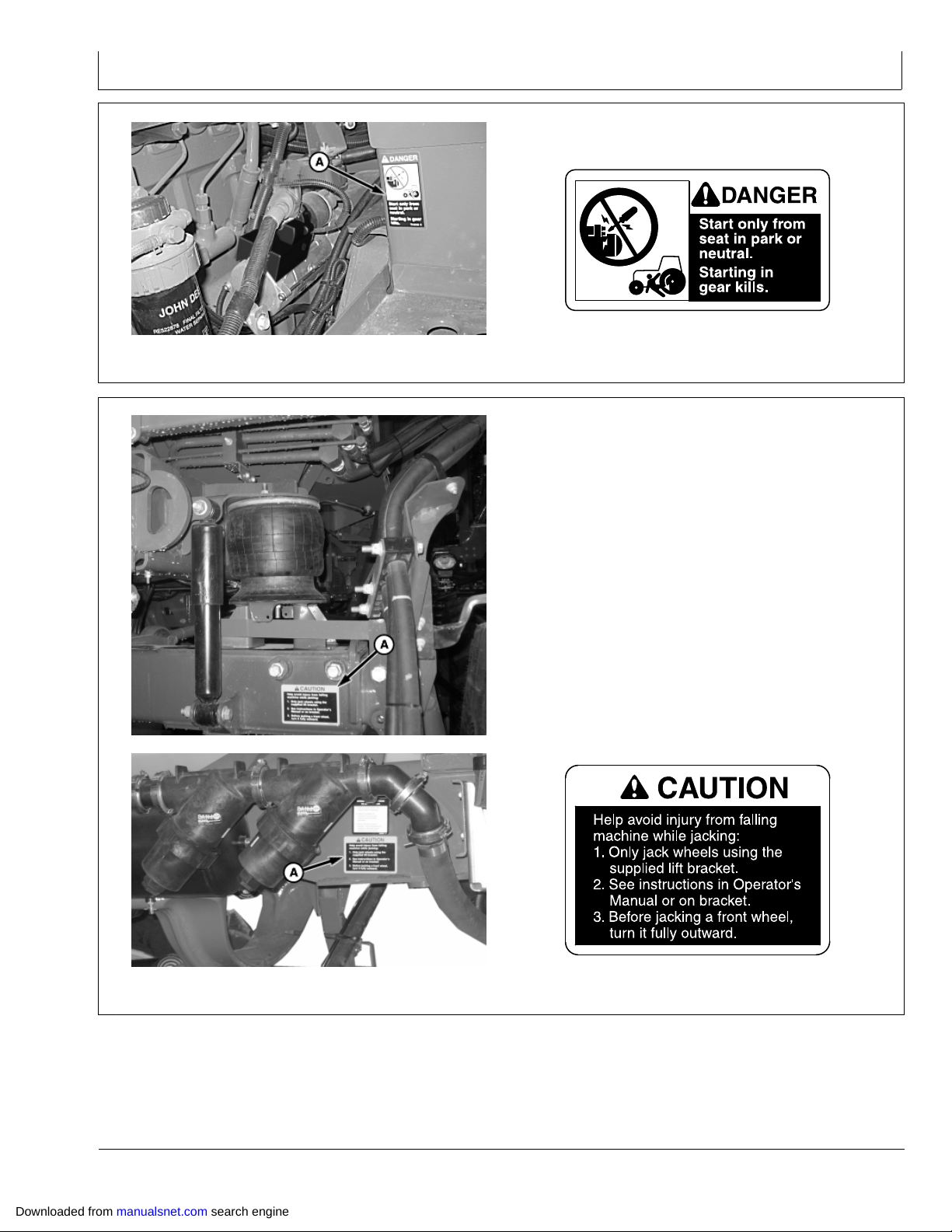

Prevent Machine Runaway

Avoid possible injury or death from machinery runaway.

Do not start engine by shorting across starter terminals.

Machine will start in gear if normal circuitry is bypassed.

NEVER start engine while standing on ground. Start

engine only from operator’s seat, with transmission in

neutral or park.

Safety

TS230 —UN—24MAY89

DX,PARK 1904JUN901/1

Use Seat Belt Properly

Use a seat belt when you operate with a rollover

protective structure (ROPS) or cab to minimize chance of

injury from an accident such as an overturn.

Do not use a seat belt if operating without a ROPS or cab.

Replace entire seat belt if mounting hardware, buckle,

belt, or retractor show signs of damage.

Inspect seat belt and mounting hardware at least

once a year. Look for signs of loose hardware or belt

damage, such as cuts, fraying, extreme or unusual wear,

discoloration, or abrasion. Replace only with replacement

parts approved for your machine. See your John Deere

dealer.

TS177 —UN—11JAN89

DX,BYPAS1 1929SEP981/1

TS205 —UN—23AUG88

DX,ROPS1 1929OCT071/1

Downloaded from manualsnet.com search engine

052

122309

PN=10

Page 11

Operate Safely

Safety

DO NOT start engine with multifunction control handle

engaged.

DO NOT operate close to a ditch or creek.

DO NOT fold or unfold boom near overhead wires.

Always come to a complete stop before reversing

directions.

Drive slowly over rough ground.

Slow down when turning.

Use Caution On Hillsides

Avoid holes, ditches, and obstructions which may cause

sprayer rollover, especially on hillsides. Avoid sharp

turns on hills.

Never drive near the edge of a gully or steep embankment.

Stay off slopes that are too steep for operation.

Always shut off engine when leaving machine. Remove

key when leaving machine unattended. Park brake

will engage when engine is turned off regardless of

multifunction control handle position.

Keep hands, feet and clothing away from moving parts.

Wear relatively tight and belted clothing to prevent from

being caught on some part of the machine.

OUO6092,000068F 1910AUG041/1

RW13093 —UN—07DEC88

Remove Paint Before Welding or Heating

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated

by welding, soldering, or using a torch.

Remove paint before heating:

Remove paint a minimum of 100 mm (4 in.) from area

•

to be affected by heating. If paint cannot be removed,

wear an approved respirator before heating or welding.

If you sand or grind paint, avoid breathing the dust.

•

Wear an approved respirator.

If you use solvent or paint stripper, remove stripper with

•

soap and water before welding. Remove solvent or

paint stripper containers and other flammable material

from area. Allow fumes to disperse at least 15 minutes

before welding or heating.

Do not use a chlorinated solvent in areas where welding

will take place.

OUO6092,0000F99 1928JUN071/1

TS220 —UN—23AUG88

Do all work in an area that is well ventilated to carry toxic

fumes and dust away.

Dispose of paint and solvent properly.

DX,PAINT 1924JUL021/1

Downloaded from manualsnet.com search engine

053

122309

PN=11

Page 12

Safety

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near

pressurized fluid lines, resulting in severe burns to yourself

and bystanders. Do not heat by welding, soldering,

or using a torch near pressurized fluid lines or other

flammable materials. Pressurized lines can accidentally

burst when heat goes beyond the immediate flame area.

Work In Ventilated Area

Engine exhaust fumes can cause sickness or death. If

it is necessary to run an engine in an enclosed area,

remove the exhaust fumes from the area with an exhaust

pipe extension.

If you do not have an exhaust pipe extension, open the

doors and get outside air into the area.

TS953 —UN—15MAY90

DX,TORCH 1910DEC041/1

Keep Riders Off Machine

Only allow the operator on the machine. Keep riders off.

Riders on machine are subject to injury such as being

struck by foreign objects and being thrown off of the

machine. Riders also obstruct the operator’s view

resulting in the machine being operated in an unsafe

manner.

TS220 —UN—23AUG88

DX,AIR 1917FEB991/1

TS290 —UN—23AUG88

DX,RIDER 1903MAR931/1

Downloaded from manualsnet.com search engine

054

122309

PN=12

Page 13

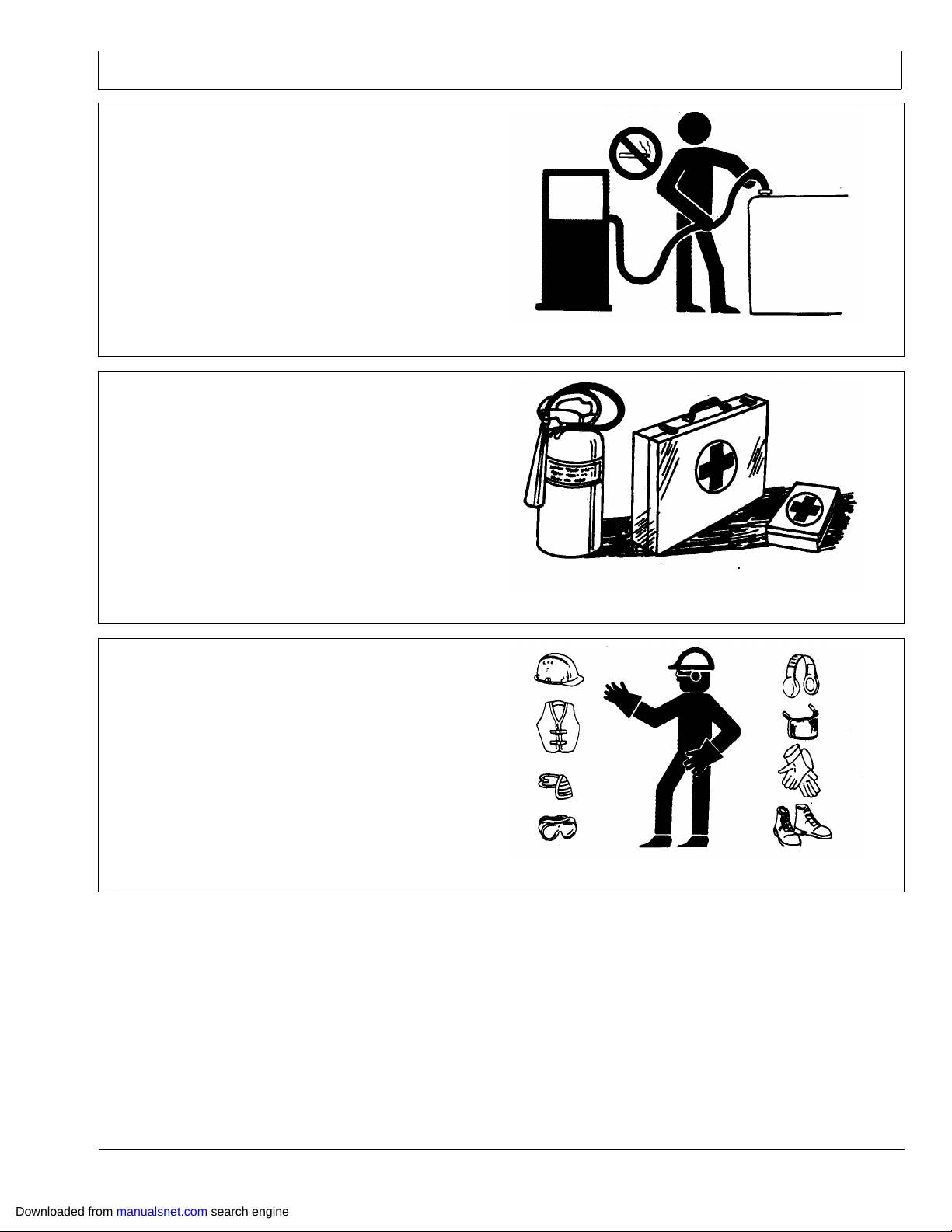

Handle Fuel Safely—Avoid Fires

Handle fuel with care: it is highly flammable. Do not refuel

the machine while smoking or when near open flame or

sparks.

Always stop engine before refueling machine. Fill fuel

tank outdoors.

Prevent fires by keeping machine clean of accumulated

trash, grease, and debris. Always clean up spilled fuel.

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance

service, hospital, and fire department near your telephone.

Safety

TS202 —UN—23AUG88

DX,FIRE1 1903MAR931/1

Wear Protective Clothing

Wear close fitting clothing and safety equipment

appropriate to the job.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones

while operating machine.

TS291 —UN—23AUG88

DX,FIRE2 1903MAR931/1

TS206 —UN—23AUG88

DX,WEAR2 1903MAR931/1

Downloaded from manualsnet.com search engine

055

122309

PN=13

Page 14

Safety

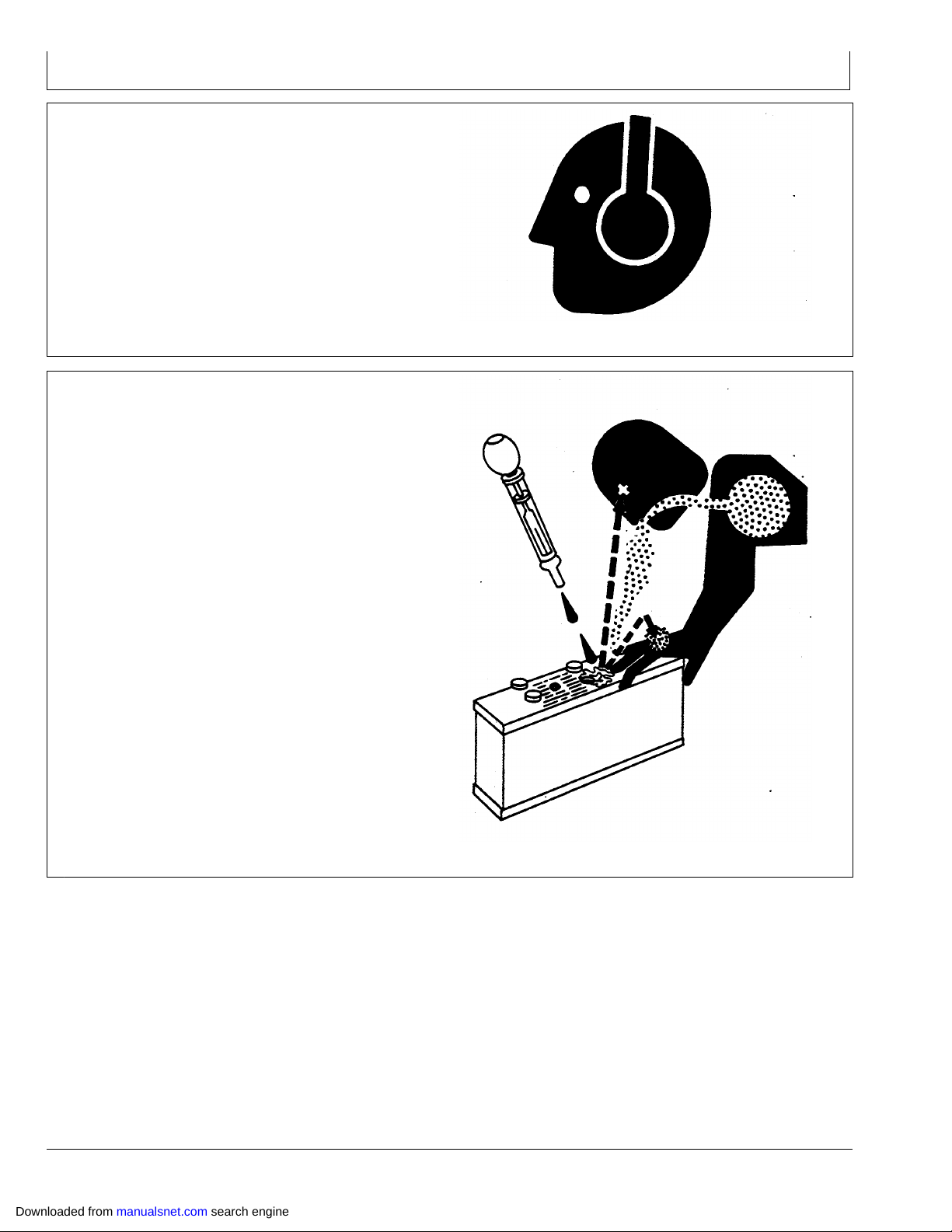

Protect Against Noise

Prolonged exposure to loud noise can cause impairment

or loss of hearing.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Prevent Acid Burns

Sulfuric acid in battery electrolyte is poisonous. It is strong

enough to burn skin, eat holes in clothing, and cause

blindness if splashed into eyes.

Avoid the hazard by:

1. Filling batteries in a wellventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is added.

4. Avoiding spilling or dripping electrolyte.

5. Use proper jump start procedure.

TS207 —UN—23AUG88

DX,NOISE 1903MAR931/1

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize the acid.

3. Flush your eyes with water for 15—30 minutes. Get

medical attention immediately.

If acid is swallowed:

1. Do not induce vomiting.

2. Drink large amounts of water or milk, but do not

exceed 2 L (2 quarts).

3. Get medical attention immediately.

TS203 —UN—23AUG88

DX,POISON 1921APR931/1

Downloaded from manualsnet.com search engine

056

122309

PN=14

Page 15

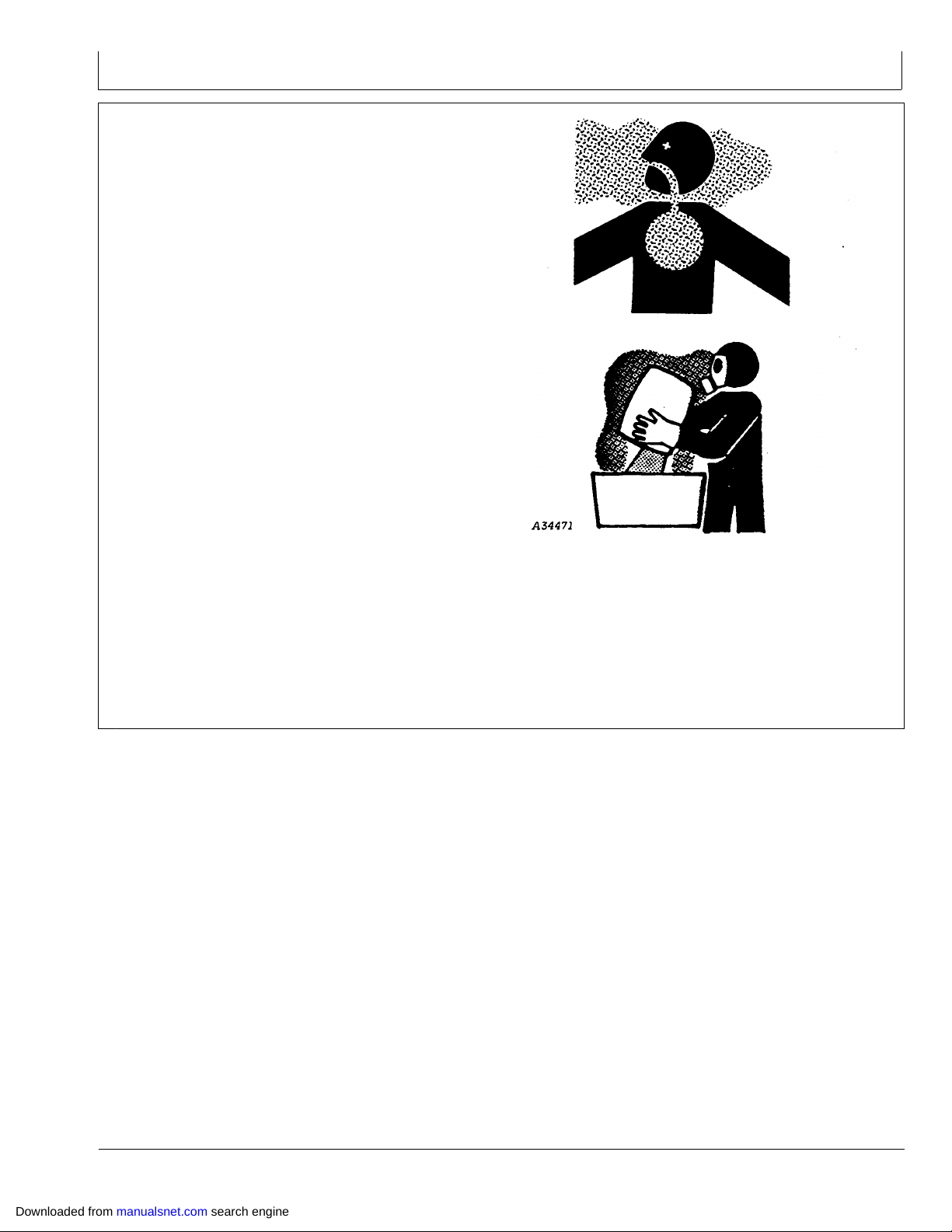

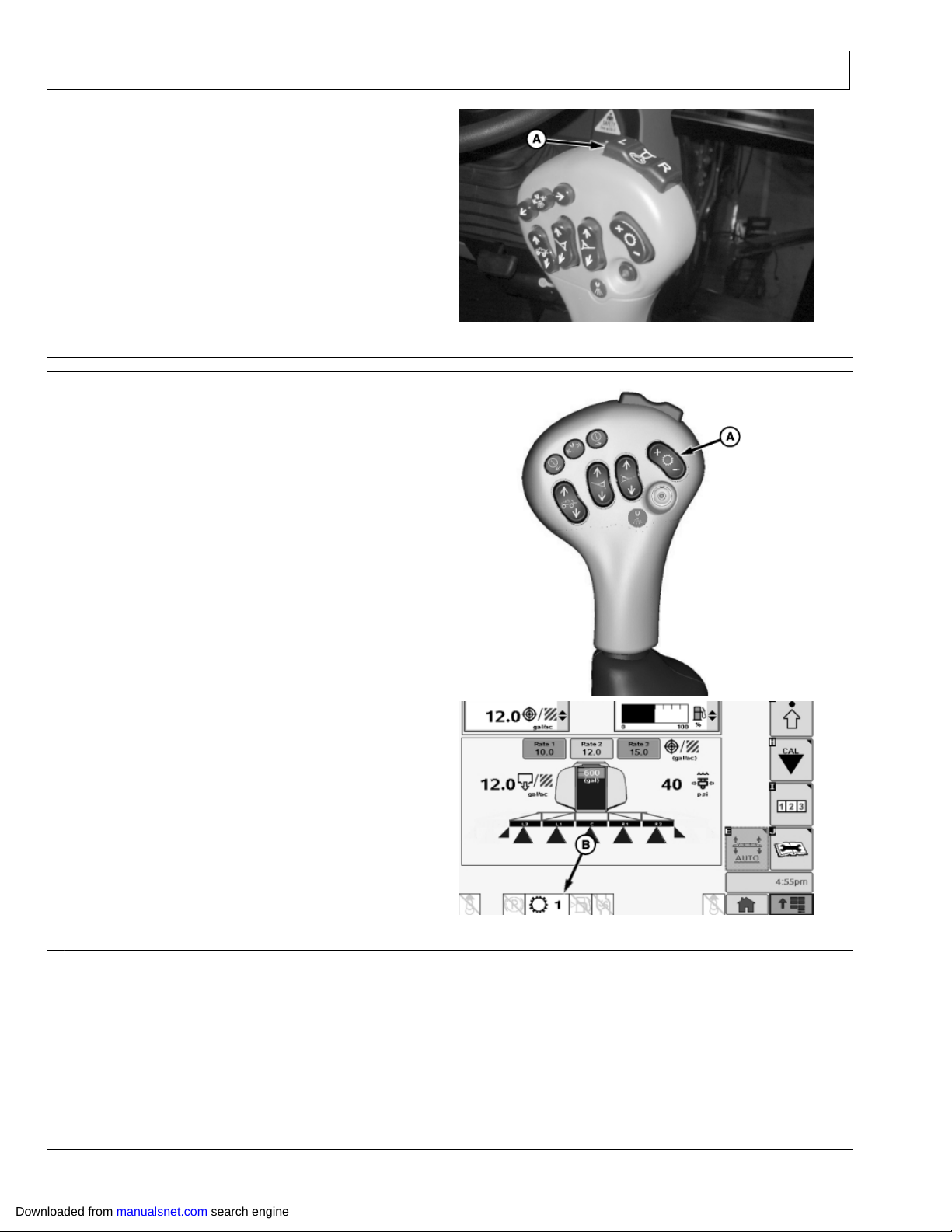

Handle Agricultural Chemicals Safely

Chemicals used in agricultural applications such

as fungicides, herbicides, insecticides, pesticides,

rodenticides, and fertilizers can be harmful to your health

or the environment if not used carefully.

Always follow all label directions for effective, safe, and

legal use of agricultural chemicals.

Reduce risk of exposure and injury:

Wear appropriate personal protective equipment as

•

recommended by the manufacturer. In the absence

of manufacturer’s instructions, follow these general

guidelines:

Chemicals labeled ’Danger’: Most toxic. Generally

require use of goggles, respirator, gloves, and skin

protection.

Chemicals labeled ’Warning’: Less toxic. Generally

require use of goggles, gloves, and skin protections.

Chemicals labeled ’Caution’: Least toxic. Generally

require use of gloves and skin protection.

Avoid inhaling spray or dusts.

•

Always have soap, water, and towel available when

•

working with chemicals. If chemical contacts skin,

hands, or face, wash immediately with soap and water.

If chemical gets into eyes, flush immediately with water.

Wash hands and face after using chemicals and before

•

eating, drinking, smoking, or urination.

Do not smoke or eat while applying chemicals.

•

After handling chemicals, always bathe or shower and

•

change clothes. Wash clothing before wearing again.

Seek medical attention immediately if illness occurs

•

during or shortly after use of checmials.

Keep chemicals in original containers. Do not transfer

•

chemicals to unmarked containers or to containers used

for food or drink.

Safety

Store chemicals in a secure, locked area way from

•

human or livestock food. Keep children away.

Always dispose of containers properly. Triple rinse

•

empty containers and puncture or crush containers and

dispose of properly.

DX,WW,CHEM01 1905APR041/1

TS220 —UN—23AUG88A34471 —UN—11OCT88

Downloaded from manualsnet.com search engine

057

122309

PN=15

Page 16

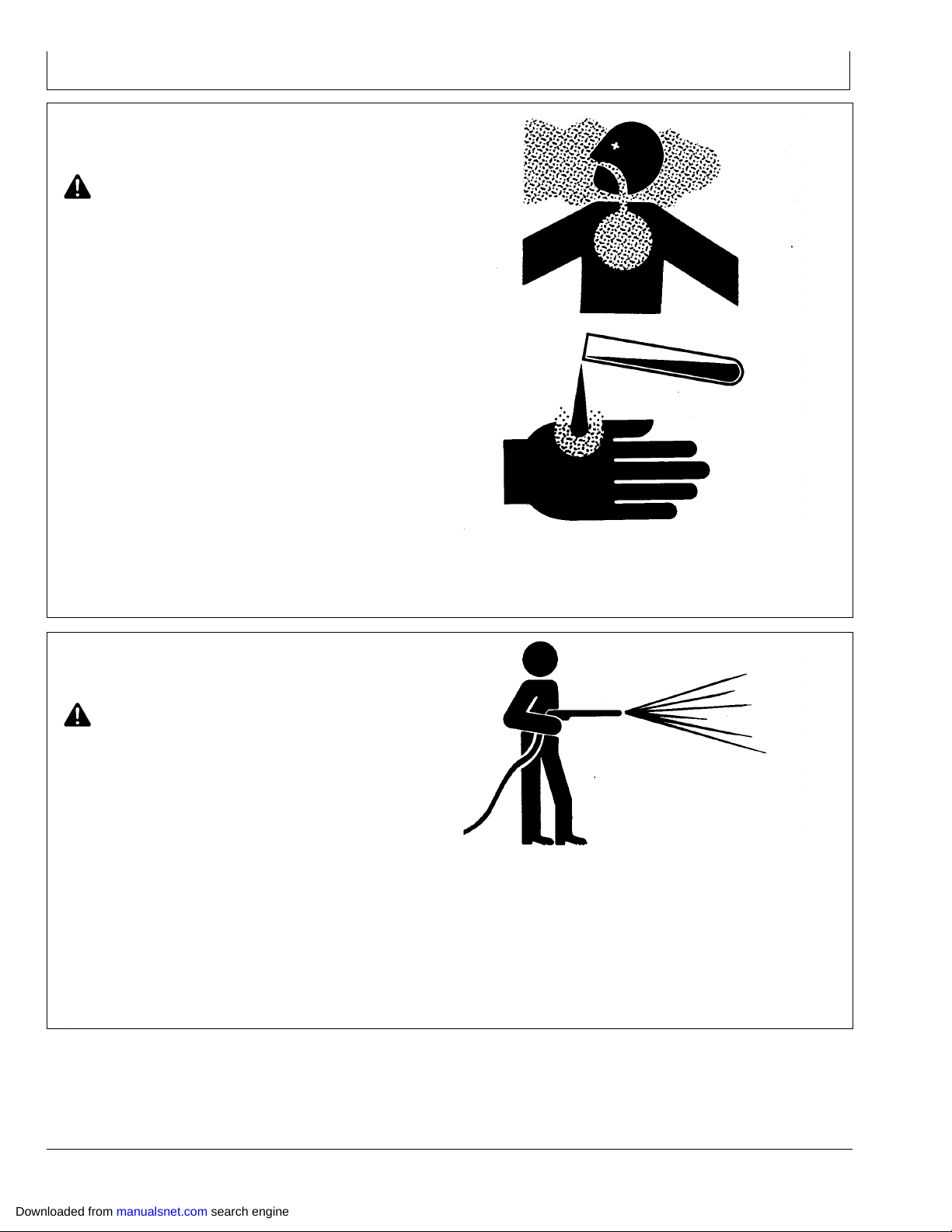

Avoid Contact with Chemicals,

Including Pesticides

CAUTION: This enclosed cab does not

protect against chemical exposure, including

exposure to pesticides.

1. When operating in an environment where harmful

chemicals are present, wear a longsleeved shirt,

longlegged pants, shoes, and socks.

Safety

2. If chemical label requires respiratory protection, wear

an appropriate respirator in the cab.

3. Wear personal protective equipment as required by

the chemical label when leaving the enclosed cab:

into a treated area,

•

to work with contaminated application equipment,

•

such as nozzles, which must be cleaned, changed,

or redirected,

to become involved with mixing and loading

•

activities.

4. Before reentering the cab, remove personal protective

equipment and store either outside the cab in a closed

box or some other type of sealable container or inside

the cab in a pesticide resistant container.

5. Clean or remove contaminated shoes or clothing

before entering the cab.

Clean Vehicle of Hazardous Chemicals, Including Pesticides

CAUTION: During application of hazardous

chemicals, including pesticides, residue

can build up on the inside or outside of

the vehicle. Clean vehicle according to use

instructions of hazardous chemical.

TS220 —UN—23AUG88TS272 —UN—23AUG88

OUO6092,0000337 1904MAR021/1

When exposed to hazardous chemicals, clean exterior and

interior of vehicle daily to keep free of the accumulation of

visible dirt and contamination.

1. Sweep or vacuum the floor of cab.

2. Clean headliners and inside cowlings of cab.

IMPORTANT: Directing pressurized water at

electronic/electrical components or connectors,

bearings and hydraulic seals, fuel injection

pumps or other sensitive parts and components

may cause product malfunctions. Reduce

pressure, and spray at a 45 to 90 degree angle.

Downloaded from manualsnet.com search engine

3. Wash entire exterior of vehicle.

4. Dispose of any wash water with hazardous

concentrations of active or nonactive ingredients

according to published regulations or directives.

058

T6642EJ —UN—18OCT88

OUO6092,000081B 1923JUN051/1

122309

PN=16

Page 17

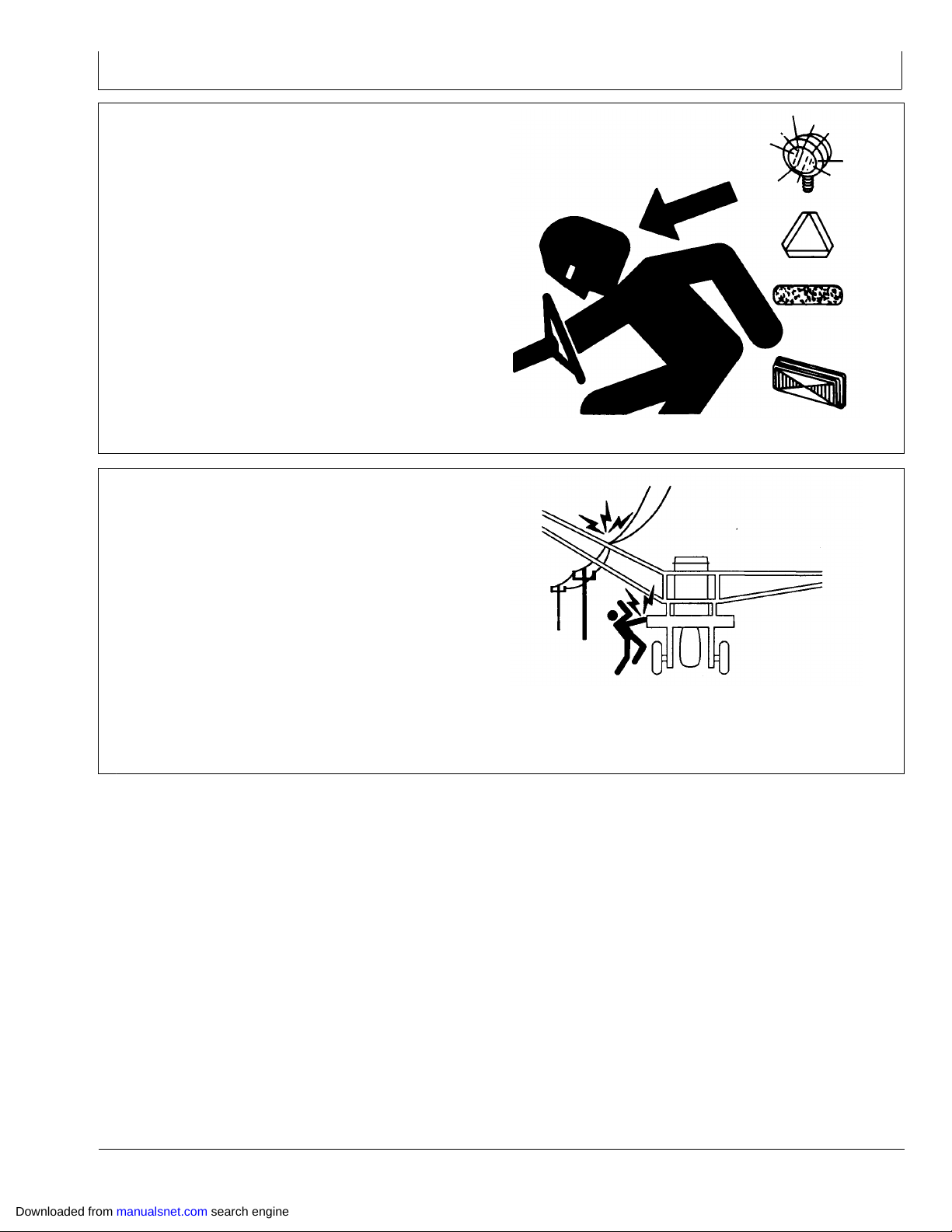

Use Safety Lights and Devices

Prevent collisions between other road users, slow moving

tractors with attachments or towed equipment, and

selfpropelled machines on public roads. Frequently

check for traffic from the rear, especially in turns, and use

turn signal lights.

Use headlights, flashing warning lights, and turn signals

day and night. Follow local regulations for equipment

lighting and marking. Keep lighting and marking visible,

clean, and in good working order. Replace or repair

lighting and marking that has been damaged or lost. An

implement safety lighting kit is available from your John

Deere dealer.

Transport and Operate Safely

Keep away from overhead power lines. Serious injury

or death to you or others can result should machine

contact electrical wires. Know the transport height, boom

operating height and boom folding height of your machine.

Safety

TS951 —UN—12APR90

DX,FLASH 1907JUL991/1

Stop slowly to avoid “nose diving”.

Keep SMV emblem and reflectors clean and in place.

Do not exceed maximum transport speed specified in the

operator manual.

Reduce speeds for icy, wet, graveled or soft roadway

surfaces.

Check and follow local regulations for equipment size,

lighting and marking before driving on public roadways.

N44191 —UN—27APR92

OUO6092,00002ED 1923DEC091/1

Downloaded from manualsnet.com search engine

059

122309

PN=17

Page 18

Safety

Practice Safe Maintenance

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from powerdriven

parts. Disengage all power and operate controls to relieve

pressure. Lower equipment to the ground. Stop the

engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be

raised for service work.

Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On selfpropelled equipment, disconnect battery ground

cable () before making adjustments on electrical systems

or welding on machine.

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

Using Compressed Air For Cleaning

CAUTION: Reduce compressed air to 210 kPa

(2 bar) (30 psi) or less when using for cleaning

purposes. Clear area of bystanders, guard

against flying debris, and wear personnel

protective equipment, including eye protection.

TS218 —UN—23AUG88

DX,SERV 1917FEB991/1

TS266 —UN—23AUG88

AG,OUO6043,83 1928JUL991/1

Downloaded from manualsnet.com search engine

0510

122309

PN=18

Page 19

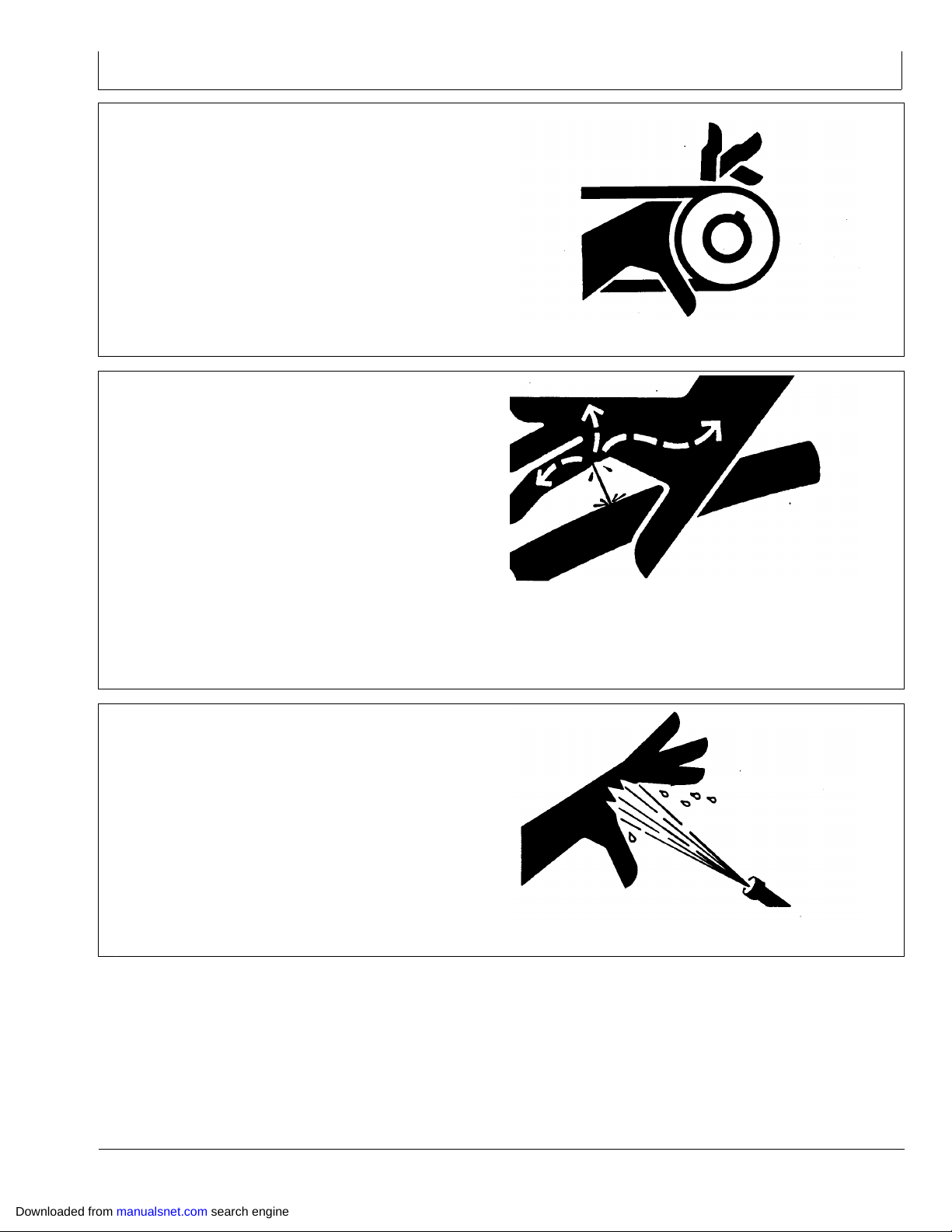

Service Drive Belts Safely

When servicing drive belts always observe these

precautions:

Avoid serious injury from hand or arm entanglement.

•

Never attempt to clean, check or adjust belts while the

machine is running. Always shut off the engine, set the

parking brake and remove the key.

Do not attempt to clean belts with flammable cleaning

•

solvents.

Avoid HighPressure Fluids

Escaping fluid under pressure can penetrate the skin

causing serious injury.

Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines. Tighten all

connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands

and body from highpressure fluids.

Safety

TS285 —UN—23AUG88

OUO6043,00015E3 1924MAY041/1

If an accident occurs, see a doctor immediately. Any fluid

injected into the skin must be surgically removed within

a few hours or gangrene may result. Doctors unfamiliar

with this type of injury should reference a knowledgeable

medical source. Such information is available from Deere

& Company Medical Department in Moline, Illinois, U.S.A.,

by calling 18008228262 or +1 3097485636.

Do Not Open HighPressure Fuel System

Highpressure fluid remaining in fuel lines can cause

serious injury. Do not disconnect or attempt repair of fuel

lines, sensors, or any other components between the

highpressure fuel pump and nozzles on engines with

High Pressure Common Rail (HPCR) fuel system.

Only technicians familiar with this type of system can

perform repairs. (See your John Deere dealer.)

X9811 —UN—23AUG88

DX,FLUID,NA 1929JUL091/1

TS1343 —UN—18MAR92

DX,WW,HPCR1 1907JAN031/1

Downloaded from manualsnet.com search engine

0511

122309

PN=19

Page 20

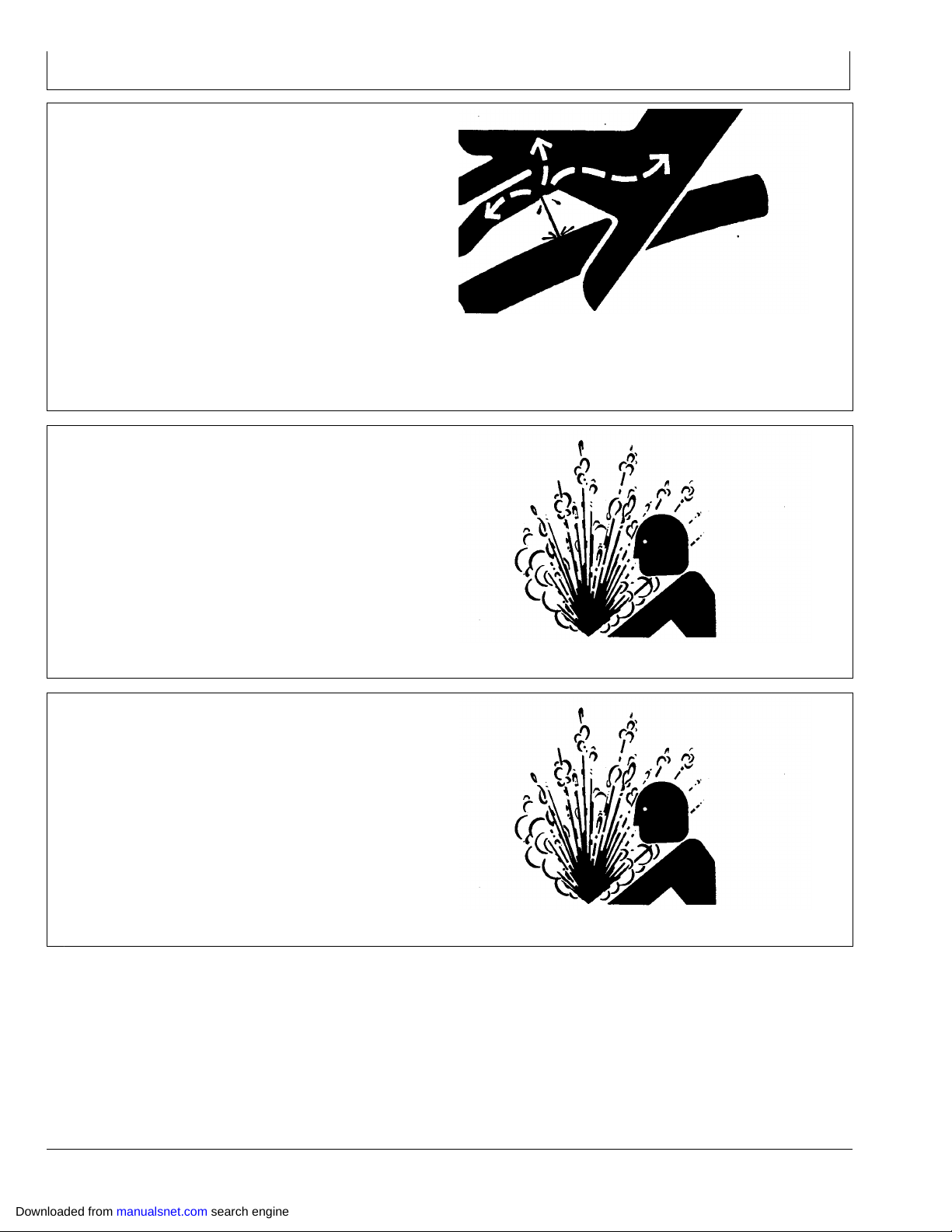

Check Hydraulic Hoses

Hydraulic hoses can fail due to physical damage, kinks,

age, and exposure. Check hoses regularly. Replace

damaged hoses.

Escaping fluid under pressure can penetrate the skin

causing serious injury to you or others. Search for leaks

with a piece of cardboard. Protect hands and body from

high pressure fluids.

If an accident occurs see a doctor immediately. Any fluid

injected into the skin must be surgically removed within

a few hours or gangrene can result. Doctors unfamiliar

with this type of injury should reference a knowledgeable

medical source. Such information is available from Deere

and Company Medical Department in Moline, Illinois,

U.S.A.

Service Cooling System Safely

Explosive release of fluids from pressurized cooling

system can cause serious burns.

Shut off engine. Only remove filler cap when cool enough

to touch with bare hands. Slowly loosen cap to relieve

pressure before removing completely.

Safety

X9811 —UN—23AUG88

NXN,9930,HYD 1902DEC971/1

Add coolant only when engine is shut off.

Service Accumulator Systems Safely

Escaping fluid or gas from pressurized hydraulic

accumulator systems can cause serious injury. Extreme

heat can cause the accumulator to burst, and pressurized

lines can be accidentally cut. Do not weld or use a torch

near a pressurized accumulator or pressurized line.

Relieve pressure from the hydraulic system before

removing accumulator. Never attempt to relieve hydraulic

system or accumulator pressure by loosening a fitting.

Accumulators cannot be repaired.

TS281 —UN—23AUG88

OUO6092,000026F 1913OCT091/1

TS281 —UN—23AUG88

DX,WW,ACCLA 1915APR031/1

Downloaded from manualsnet.com search engine

0512

122309

PN=20

Page 21

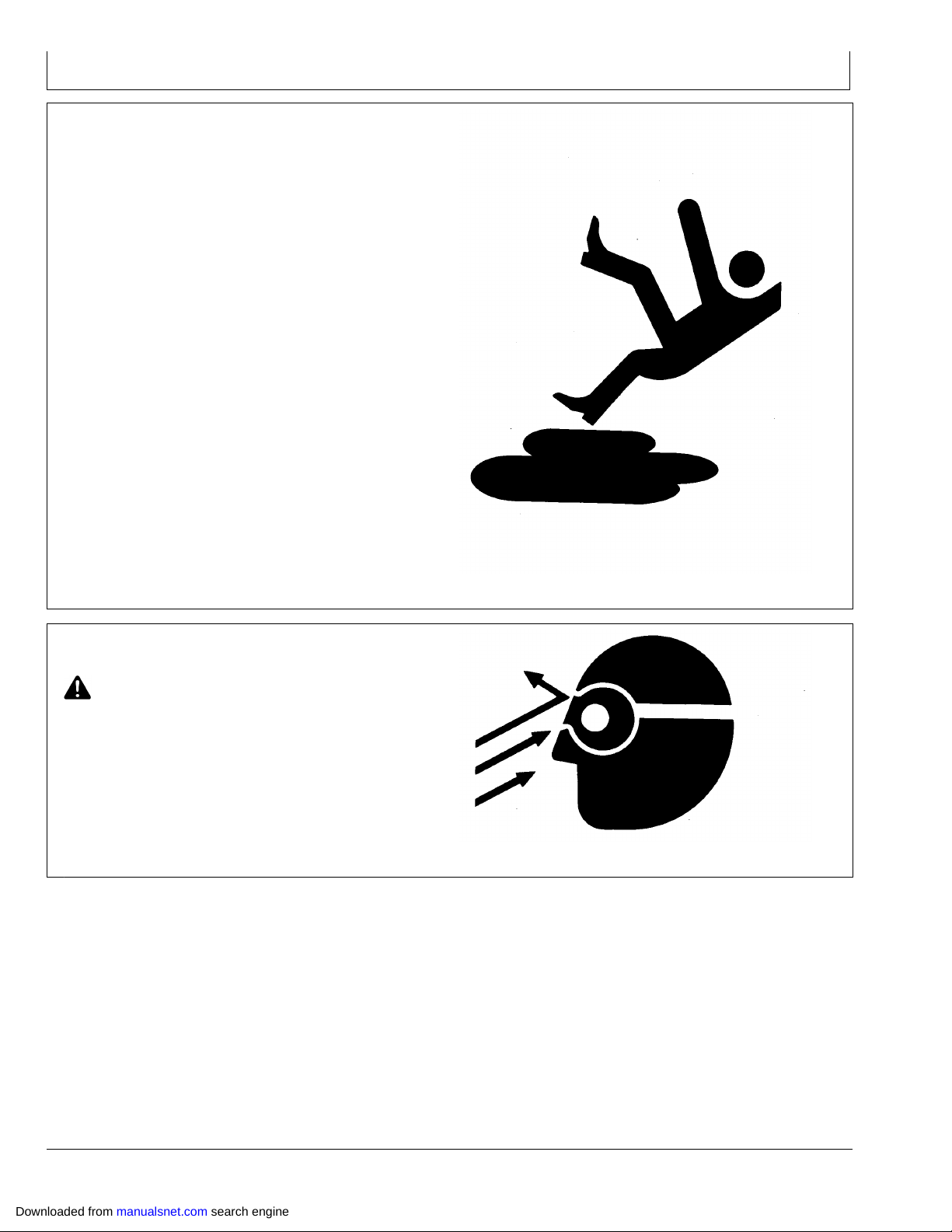

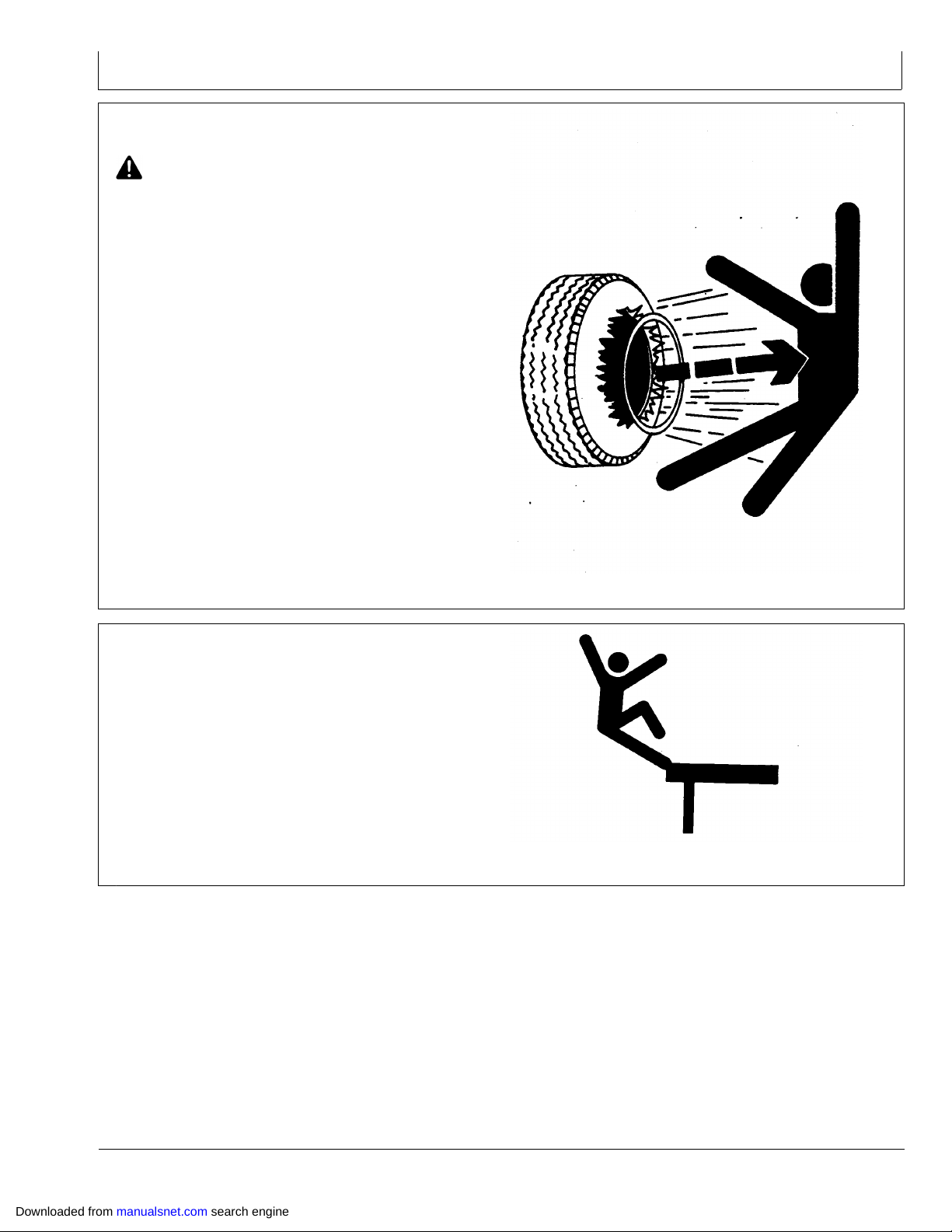

Service Tires Safely

CAUTION: Explosive separation of a tire and rim

parts can cause serious injury or death.

Do not attempt to mount a tire unless you

have the proper equipment and experience

to perform the job.

Always maintain the correct tire pressure. Do not inflate

the tires above the recommended pressure.

Never weld or heat a wheel and tire assembly. The heat

can cause an increase in air pressure resulting in a tire

explosion. Welding can structurally weaken or deform

the wheel.

When inflating tires, use a clipon chuck and extension

hose long enough to allow you to stand to one side and

NOT in front of or over the tire assembly. Use a safety

cage if available.

Check wheels for low pressure, cuts, bubbles, damaged

rims or missing lug bolts and nuts.

Safety

Handle Global Positioning Receivers and Brackets Safely

Falling while installing or removing a global positioning

receiver can cause serious injury. Use a ladder or platform

to easily reach a mounting location.

Use sturdy and secure footholds and handholds. Do not

install or remove the receiver in wet or icy conditions.

The receiver mast used on implements is heavy and can

be awkward to handle. Two people are required when

mounting locations are not accessible from the ground or

from a service platform. Use proper lifting techniques and

wear proper protective equipment.

TS211 —UN—23AUG88

DX,RIM1 1927OCT081/1

TS249 —UN—23AUG88

DX,WW,RECEIVER 1908JAN081/1

Downloaded from manualsnet.com search engine

0513

122309

PN=21

Page 22

Safety

Dispose of Waste Properly

Improperly disposing of waste can threaten the

environment and ecology. Potentially harmful waste used

with John Deere equipment include such items as oil, fuel,

coolant, brake fluid, filters, and batteries.

Use leakproof containers when draining fluids. Do not use

food or beverage containers that may mislead someone

into drinking from them.

Do not pour waste onto the ground, down a drain, or into

any water source.

Air conditioning refrigerants escaping into the air can

damage the Earth’s atmosphere. Government regulations

may require a certified air conditioning service center to

recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste

from your local environmental or recycling center, or from

your John Deere dealer.

Replace Safety Signs

Replace missing or damaged safety signs. See the

machine operator’s manual for correct safety sign

placement.

TS1133 —UN—26NOV90

DX,DRAIN 1903MAR931/1

Emergency Exit

Remove pin (A). The window can now be pushed out of

retaining clips and allowed to fall free.

(See your John Deere dealer for window replacement.)

A—Pin

TS201 —UN—23AUG88

DX,SIGNS1 1904JUN901/1

N84876 —UN—04JUN09

OUO6092,0000101 1908JUL091/1

Downloaded from manualsnet.com search engine

0514

122309

PN=22

Page 23

Safety

Empty Tank and Boom

Plumbing—Decontaminate Spray Equipment

CAUTION: Empty tank. When removing hoses,

be aware of residual spray material that

needs to be drained carefully.

Decontaminate work area before servicing.

Decontamination should be done in a safe area

by washing with water or neutralizing agent,

or by means recommended by manufacturer

of chemical last used.

Spray solutions or vapors may be extremely

dangerous. Treat all spray chemicals, solutions,

or solution residues with great caution. DO

NOT take chances. When in doubt, proceed

as though contamination is present.

Keep spray material from contacting skin.

If spray material contacts skin, wash off

immediately with clean water and detergent

or follow manufacturer’s instructions for

chemical last used.

KB78086,000051A 1907MAY081/1

Downloaded from manualsnet.com search engine

0515

122309

PN=23

Page 24

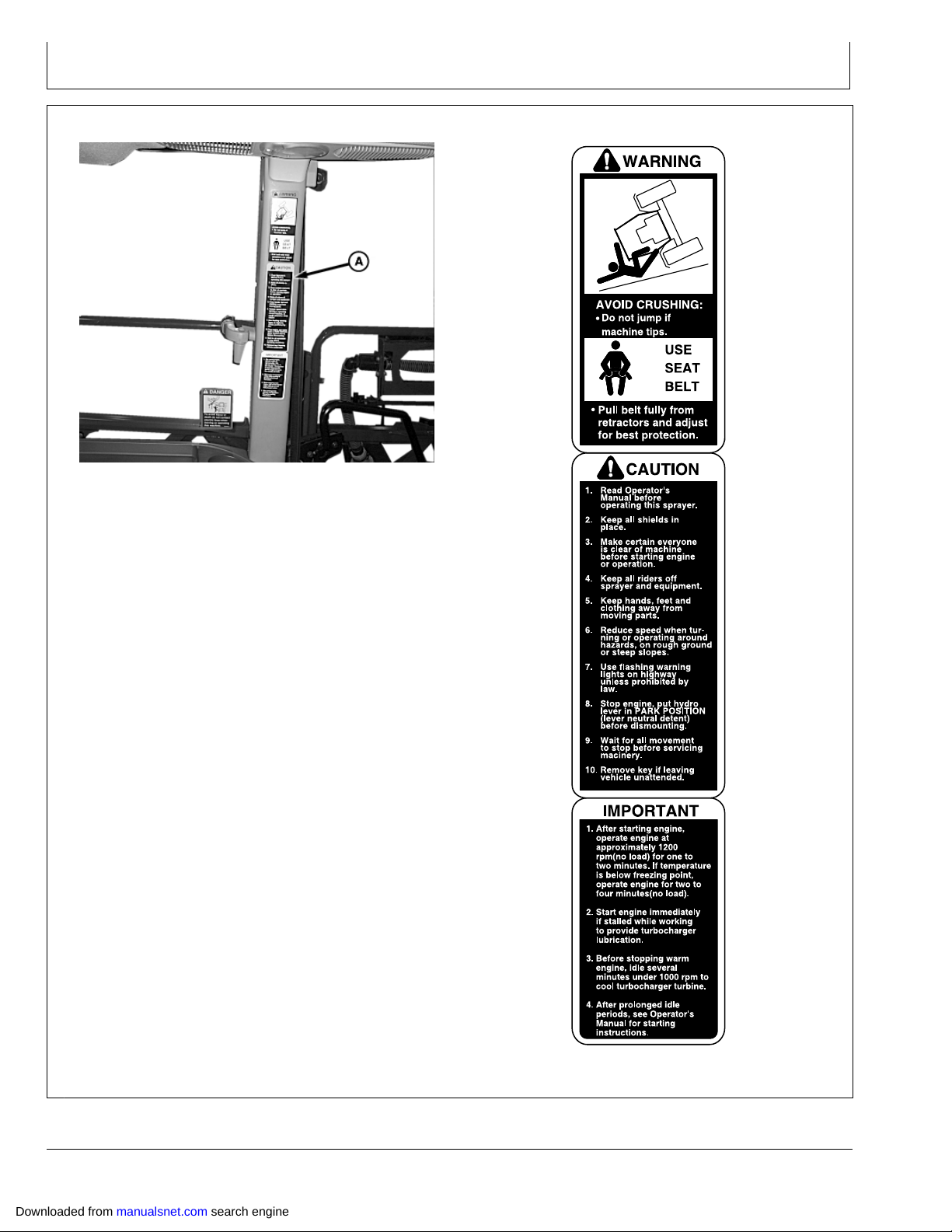

Safety Signs

Safety Signs

N83546 —UN—11MAR09

Downloaded from manualsnet.com search engine

Decal A

Continued on next page OUO6092,00000E1 1911MAY091/13

101

SSN204681 —19—09AUG05

122309

PN=24

Page 25

Safety Signs

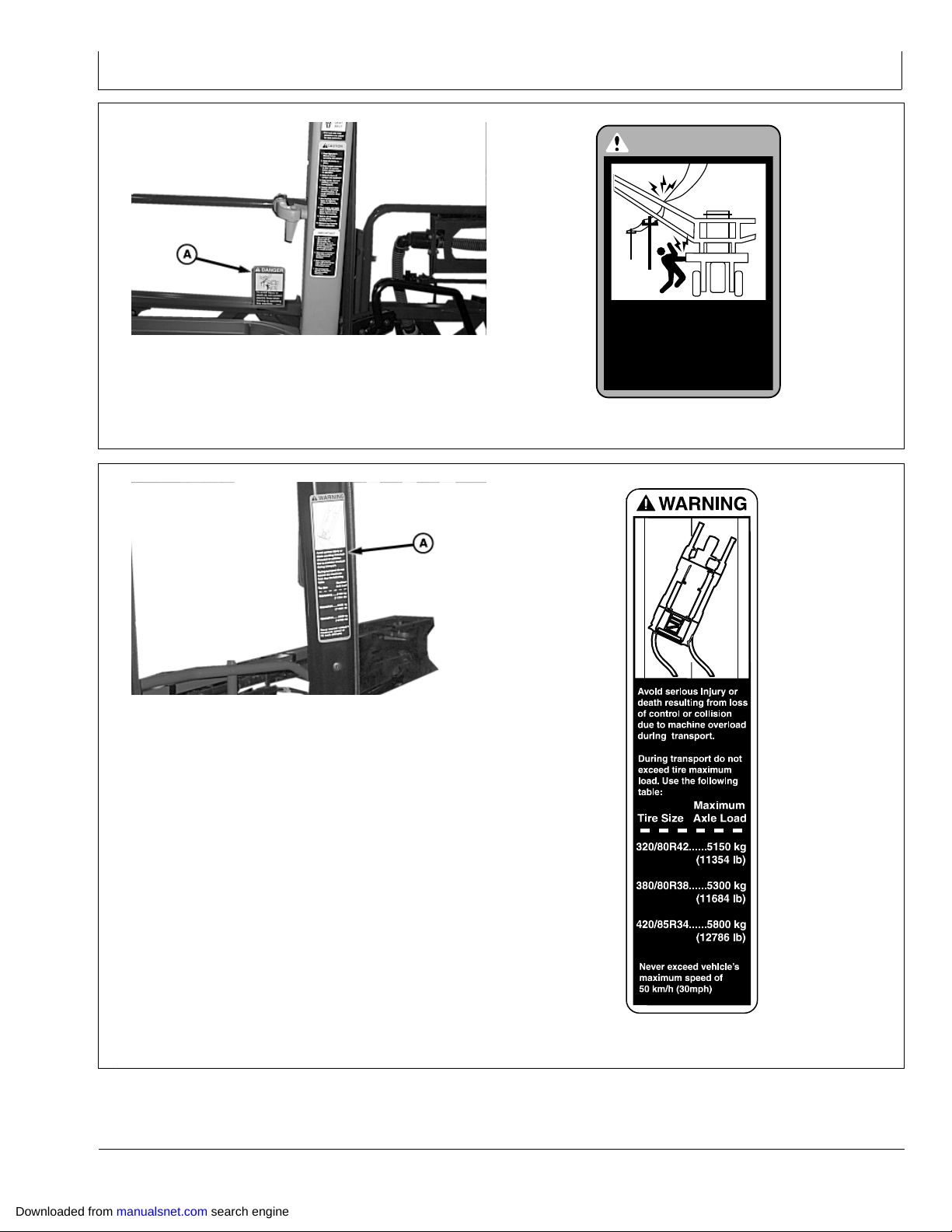

To avoid injury or

death do not contact

electric lines when

moving or operating

this machine.

DANGER

N83547 —UN—11MAR09

SSN204628 —19—08JUL05

Decal A

OUO6092,00000E1 1911MAY092/13

Transport Decal

Downloaded from manualsnet.com search engine

N83548 —UN—11MAR09

Decal A

Continued on next page OUO6092,00000E1 1911MAY093/13

102

SSN317099 —19—15JUL09

122309

PN=25

Page 26

Safety Signs

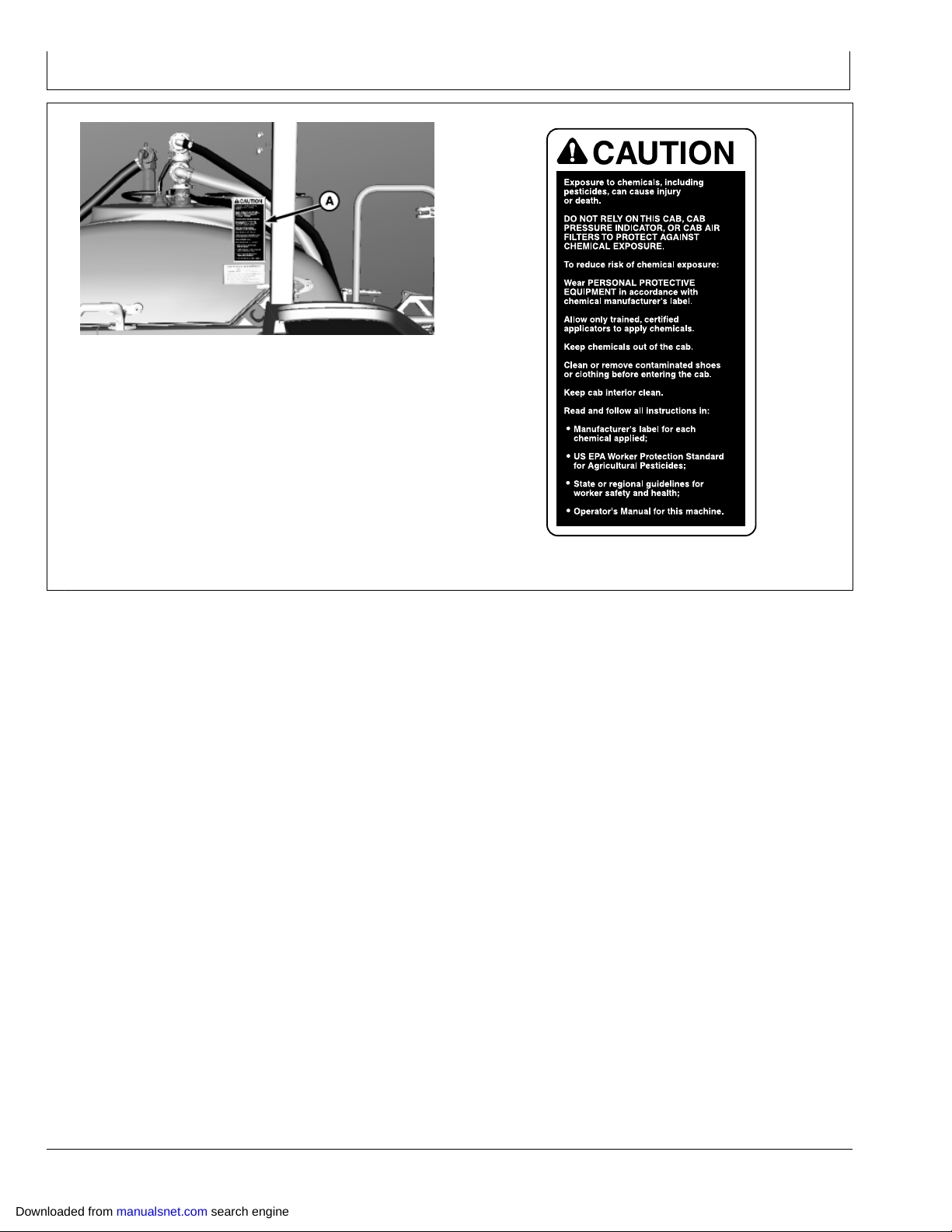

N81649 —UN—22SEP08

SSN303688 —19—09AUG05

Decal A

Continued on next page OUO6092,00000E1 1911MAY094/13

Downloaded from manualsnet.com search engine

103

122309

PN=26

Page 27

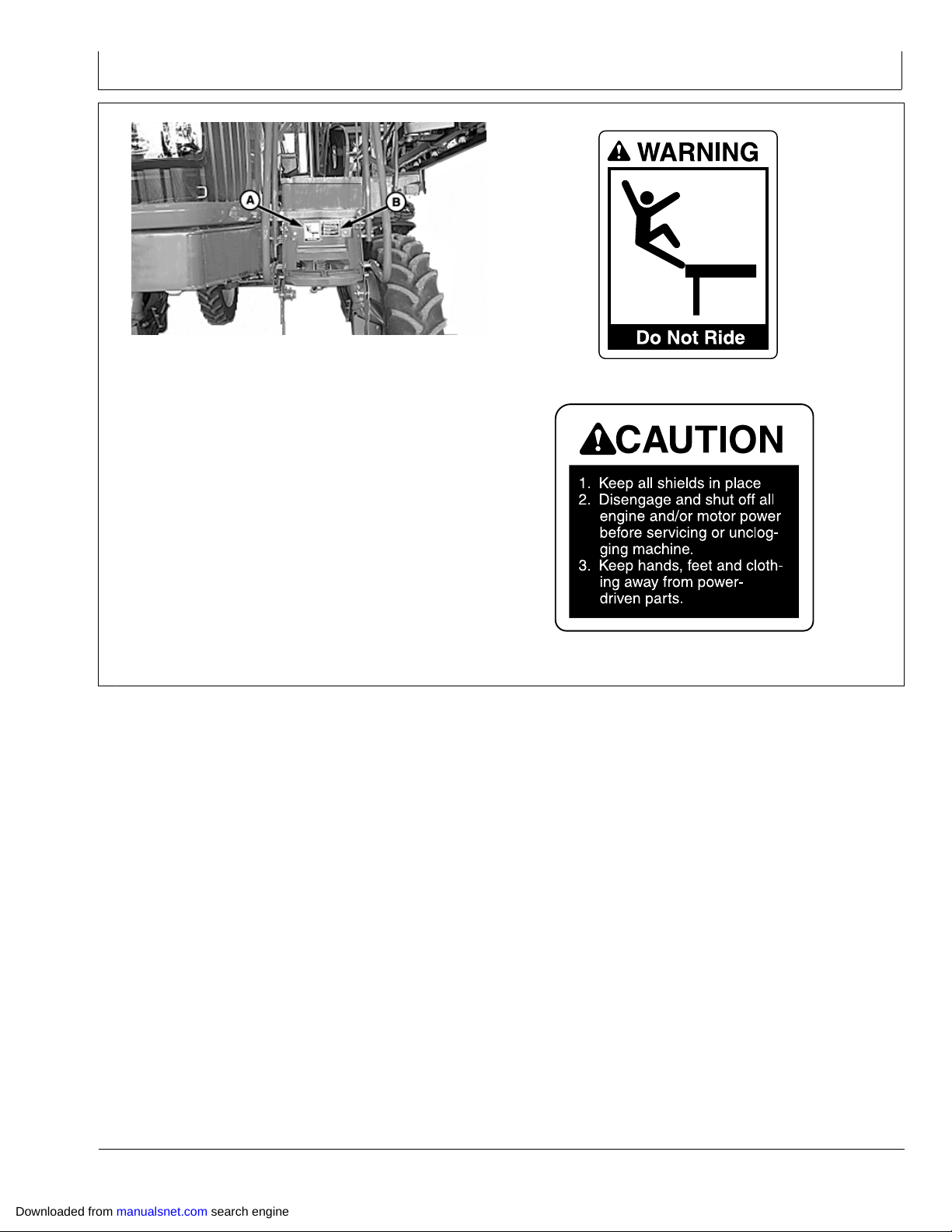

Safety Signs

N81654 —UN—22SEP08

SSN272929 —19—09AUG05

Decal A

SSN82510 —19—09AUG05

Decal B

Continued on next page OUO6092,00000E1 1911MAY095/13

Downloaded from manualsnet.com search engine

104

122309

PN=27

Page 28

Safety Signs

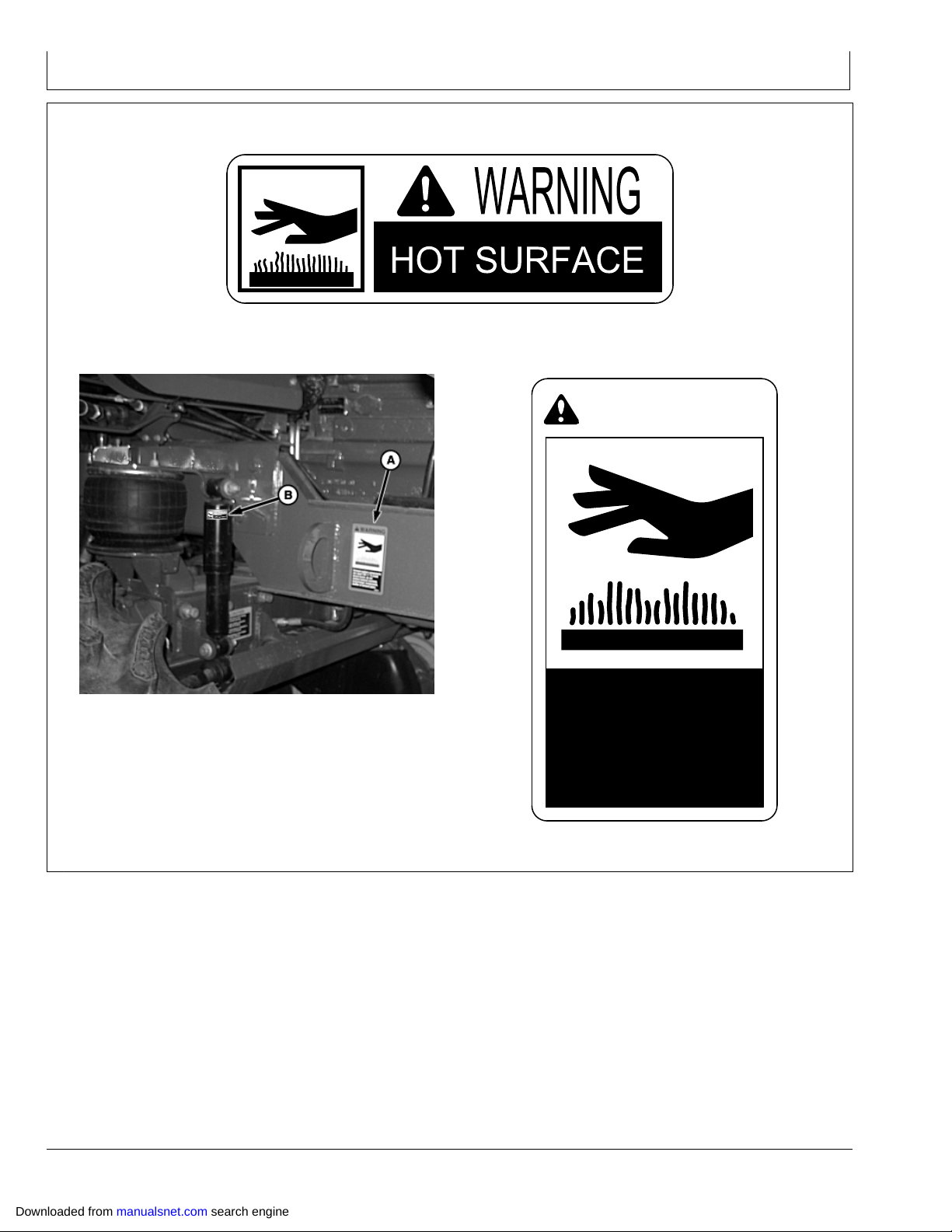

WARNING

Exhaust system components

can reach 700˚ F. To avoid

severe burns, do not

contact exhaust manifold,

turbocharger components,

muffler, or exhaust pipes.

Decal B

SSM117554 —19—27MAR09

N84206 —UN—17APR09

Decal A

Continued on next page OUO6092,00000E1 1911MAY096/13

105

SSN203310 —19—09AUG05

122309

PN=28

Downloaded from manualsnet.com search engine

Page 29

Safety Signs

N83549 —UN—14APR09

N83815 —UN—23MAR09N81657 —UN—22SEP08

SST146102 —19—09AUG05

Decal A

OUO6092,00000E1 1911MAY097/13

Downloaded from manualsnet.com search engine

Decal A

Continued on next page OUO6092,00000E1 1911MAY098/13

106

SSN209455 —19—09AUG05

122309

PN=29

Page 30

Safety Signs

WARNING

Water for rinse/wash

purpose only. Do not

drink from this container.

Container may become

contaminated by sprayer

chemicals. Fill with clean

rinse water only.

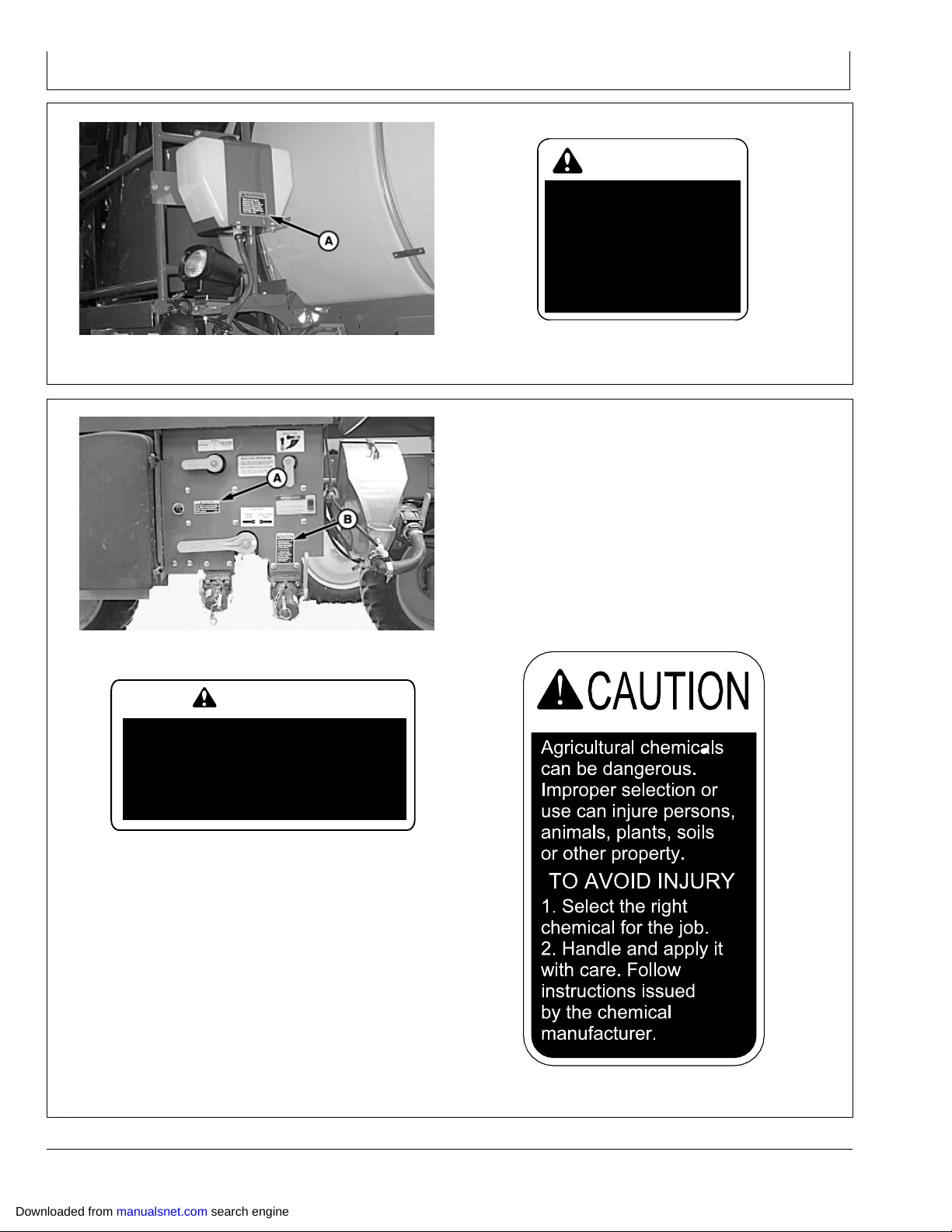

CAUTION

Avoid injury from impact with sprayer

frame. Chassis moves during inflation

and deflation of air bag suspension

system. Stand clear of machine when

operating system.

N81652 —UN—05JUN09

N81651 —UN—25NOV08

SSN302108 —19—09AUG05

Decal A

OUO6092,00000E1 1911MAY099/13

Decal A

Downloaded from manualsnet.com search engine

SSN307233 —19—14JUL05

Decal B

Continued on next page OUO6092,00000E1 1911MAY0910/13

107

SSN203265 —19—04NOV09

122309

PN=30

Page 31

Safety Signs

DANGER

N83814 —UN—26JUN09

SSN209177 —19—09AUG05

Decal A

OUO6092,00000E1 1911MAY0911/13

Decal A

N81659 —UN—22SEP08

Continued on next page OUO6092,00000E1 1911MAY0912/13

108

SSE82514 —19—25JUL05

122309

PN=31

Downloaded from manualsnet.com search engine

Page 32

Safety Signs

N83550 —UN—11MAR09

Decal A

SSN302717 —19—09AUG05

OUO6092,00000E1 1911MAY0913/13

Downloaded from manualsnet.com search engine

109

122309

PN=32

Page 33

Safety Signs

Downloaded from manualsnet.com search engine

1010

122309

PN=33

Page 34

Safety Features

L

A

A

I

K

H

J

G

F

B

M

N

O

C

E

D

Safety Features

A—FRONT AND REAR HAZARD

LIGHTS—Alerts oncoming

and following traffic of your

presence on roads.

B—HOSES ON TOP OF

TANK—Helps prevent tank

drainage if a hose breaks.

C—SMV EMBLEM—Alerts

following traffic of your

presence on roads.

D—REFLECTORS ON

BOOM—Alerts following

traffic of your presence on

roads.

E—SLIP RESISTANT

SURFACES—Helps prevent

slippage when walking on

platform.

F— CLEAN WATER

TANK—Provides a supply

of clean water for infield

cleaning and emergency

situations when working with

chemicals.

G—GROUND LEVEL

FILLING—Allows operator to

add chemicals at ground level

which helps prevent spilling

or splattering.

H—DIVOTTED STEPS AND

PLATFORMS—Helps prevent

slipping when on platform or

ladders, also diminishes dirt

and mud build up.

In addition to the safety features described here, other

components and systems, safety signs on the machine,

safety messages in the Operator’s Manual and elsewhere,

I— HAND RAILS—Gives support

when climbing onto machine

or walking on platforms.

J— STARTER SOLENOID

SHIELDING—For bypass

start prevention.

K—FAN GUARDING—Protection

from Engine Fan.

L— EMERGENCY EXIT—Exit from

right side of cab if required.

M—TRACTOR STYLE CAB WITH

SEAT BELT— For operator

comfort.

N—LARGE REARVIEW

MIRRORS AND WINDSHIELD

WIPER—For clear view of

surroundings.

O—AUTOMATIC PARK—Shifts

automatically into park when

machine stops.

as well as the care and concern of a capable operator,

contribute to the safety of operators and others nearby.

OUO6092,0000130 1929APR091/1

N82359 —UN—29APR09

Downloaded from manualsnet.com search engine

151

122309

PN=34

Page 35

Front Console

Operators Station

A—Stop Warning Light

B—Engine Preheating

Indicator

C—Caution Indicator Light

D—Windshield Wiper Switch

E—Light Switch

F— Low Beam And High Beam

Switch

G—Hazard Warning Light

Switch

H—Turn Signal Switch

I— Horn

J— Steering Wheel Tilt Release

K—Key Switch

L— Brake Pedal

M—Boom Fold Mode Switch

N—Steering Wheel Telescoping

Release

N81790 —UN—03NOV08N83816 —UN—23MAR09N81792 —UN—04MAY09

Downloaded from manualsnet.com search engine

201

OUO6092,0000102 1915APR091/1

122309

PN=35

Page 36

Key Switch

CAUTION: Sound horn before starting engine to

clear people away from the machine.

To avoid the possibility of personnel injury

or death, start ONLY from the operator seat.

Do not start engine by shorting across

starter terminals. Machine will start in gear

if normal circuit is bypassed.

Operators Station

Key switch (A) is located on the righthand side of the

steering column and has four positions:

Accessory position (top of key turned counterclockwise

•

from Off position) allows accessories such as radio and

windshield wiper to operate.

Off position (B) shuts off engine and all accessory

•

functions.

Accessory/Run position (top of key turned clockwise

•

from Off position to first detent) allows all accessories to

operate and engine to run once it has been started.

Start position (top of key turned clockwise from Off

•

position past the detent position and held there) is a

Adjust Steering Wheel

Telescope

Rotate knob (A) counterclockwise to release lock. Extend

or retract steering wheel to desired position. Rotate knob

clockwise to lock.

Tilt

Pull up on lever (B) and move the steering column to the

desired position. Release lever to lock.

A—Knob B—Lever

A—Accessories Position

B—Off Position

momentary switch position that cranks the engine.

Once the engine starts and the switch is released, it

will return to accessory/run position. (See Starting The

Engine in this section for important details on starting

your machine.)

OUO6092,0000103 1927OCT081/1

N81793 —UN—23MAR09

Downloaded from manualsnet.com search engine

202

N83817 —UN—31MAR09

OUO6092,00001A9 1925MAR091/1

122309

PN=36

Page 37

Operators Station

Operate Turn Signals

Turn lever (A) right for a right turn, or left for a left turn.

Return lever to center position after completing turn.

A—Turn signal lever

Operate the Hazard Warning Light Switch

Push top of switch (A) to activate warning lights.

Turn signals operate as hazard lights regardless of key

position.

NOTE: Always turn hazard lights off when spraying.

A—Hazard warning light switch

N82178 —UN—03NOV08

OUO6092,0000106 1928OCT081/1

Operate Windshield Wiper

Rotate knob (A) to operate wiper at desired speed:

Off

•

Slow

•

Fast

•

A—Knob

N82180 —UN—03NOV08

OUO6092,0000107 1928OCT081/1

N82344 —UN—13NOV08

OUO6092,0000110 1908JUL091/1

Downloaded from manualsnet.com search engine

203

122309

PN=37

Page 38

Operators Station

Operate Horn

Press switch (A) to sound the horn.

A—Horn switch

Operate Light Switch and High/Low Beam Switch

CAUTION: Accidental collision with another

vehicle can cause serious injury or death to you

or others. Always comply with traffic regulations

when driving machine on a road. Dim headlights

to lowbeam for oncoming vehicles.

To avoid motorist confusion, do not operate work

lights when transporting on public roadways.

N82179 —UN—23MAR09

OUO6092,0000105 1925MAR091/1

Light switch (F) has five positions—OFF (B), Road (C),

Field 1 (D), Field 2 (E), Exit Lighting (G) and operates

regardless of the key position.

Off Position

Turns off all exterior lighting with exception of warning

lights if hazard light switch is on.

Exit Lighting

Exit lighting is activated by turning the light switch counter

clockwise

Each time the exit lighting position (G) is activated on

the light switch the cab roof lights and fill station light will

turn on for 30 seconds. The operator can bump the exit

lighting switch up to three times. Each bump increases the

time that the lights stay on by 30 seconds for a maximum

time of 90 seconds.

High/Low Beam

A—High/Low Beam Switch

B—OFF Position

C—Road Position

D—Field Position 1

E—Field Position 2

F— Light Switch

G—Exit Lighting

Push upper portion of switch (A) forward to activate high

beam head lights. Push lower portion of switch forward

to operate low beam.

Dim headlights for oncoming vehicles. Adjust headlights

correctly. (See Aiming Headlights in the Electrical System

Service section.)

NOTE: (See Light Operation Table in this section.)

OUO6092,0000109 1908JUL091/1

N83818 —UN—31MAR09

Downloaded from manualsnet.com search engine

204

122309

PN=38

Page 39

Light Operation Table

E

B

H

A

C

G

D

F

Operators Station

N82196 —UN—06NOV08

A—Hood / Grill Work Lights

B—High / Low Beams

ROAD LIGHT SWITCH

OFF LOW OFF OFF OFF OFF OFF OFF

OFF HIGH OFF OFF OFF OFF OFF OFF

ROAD LOW ON OFF OFF OFF OFF OFF

ROAD HIGH OFF ON OFF OFF OFF OFF

FIELD 1

FIELD 1

FIELD 2

FIELD 2

DELAY

DELAY

ROAD LIGHT SWITCH WARN SWITCH TURN SIGNAL REAR TAIL (RED)

OFF OFF OFF OFF OFF

OFF OFF ON OFF ON T

OFF ON OFF OFF ON W

OFF ON ON OFF ON T

ROAD OFF OFF ON ON W

ROAD OFF ON ON ON T

ROAD ON OFF ON ON W

ROAD ON ON ON ON T

FIELD 1

FIELD 1

FIELD 1

FIELD 1

FIELD 2

FIELD 2

FIELD 2

FIELD 2

DELAY

DELAY

C—Front Caution (Yellow)

D—Roof Floods

HIGH / LOW

SWITCH

LOW ON OFF OFF OFF ON ON

HIGH OFF ON OFF OFF ON ON

LOW ON OFF ON ON ON ON

HIGH OFF ON ON ON ON ON

LOW OFF OFF ON ON OFF OFF

HIGH OFF OFF ON ON OFF OFF

LOW BEAM HIGH BEAM

OFF OFF OFF OFF

OFF ON OFF ON T

ON OFF OFF ON W

ON ON OFF ON T

OFF OFF OFF OFF

OFF ON OFF ON T

ON OFF OFF ON W

ON ON OFF ON T

OFF OFF OFF OFF

OFF ON OFF ON T

E—Rear Caution (Yellow)

F— Tail / Stop (Red)

FILL

STATION

Continued on next page OUO6092,0000271 1913OCT091/2

G—Fill Station

H—Platform Floods

ROOF

FLOODS

HOOD

WORK

LIGHTS

FRONT / REAR

205

PLATFORM

FLOODS

CAUTION

122309

PN=39

Downloaded from manualsnet.com search engine

Page 40

Operators Station

DELAY

DELAY

ON OFF OFF ON W

ON ON OFF ON T

ON T—Indicates that light is on when turn signal switch

is on.

ON W—Indicates that light is on when hazard switch is on

or when light switch is in road position.

Side Console Switches

NOTE: Boom sections numbered 1 closest to center on

designated side, 2 being farthest to outside.

A—Rate Select Switch

B—R2 Spray Control Switch

C—R1 Spray Control Switch

D—Center Spray Control

Switch

E—L1 Spray Control Switch

F— L2 Spray Control Switch

G—Cigarette Lighter

H—Accessory Electrical Outlet

Side Console Switches

Brake lights are independent of turn or light switches. With

key in “Run” position, brake lights will illuminate when the

service brake is pressed or the machine decelerates at a

rate of 2 mph per second or greater.

OUO6092,0000271 1913OCT092/2

N82182 —UN—16APR09

OUO6092,0000272 1913OCT091/1

NOTE: Boom sections numbered 1 closest to center on

designated side, 3 being farthest to outside.

A—Rate Select Switch

B—R2 Spray Control Switch

C—R1 Spray Control Switch

D—Center Spray Control

Switch

E—L1 Spray Control Switch

F— L2 Spray Control Switch

G—Cigarette Lighter

H—Accessory Electrical Outlet

N82182 —UN—16APR09

OUO6092,000010C 1916APR091/1

Downloaded from manualsnet.com search engine

206

122309

PN=40

Page 41

Operate Boom Section Switches