Page 1

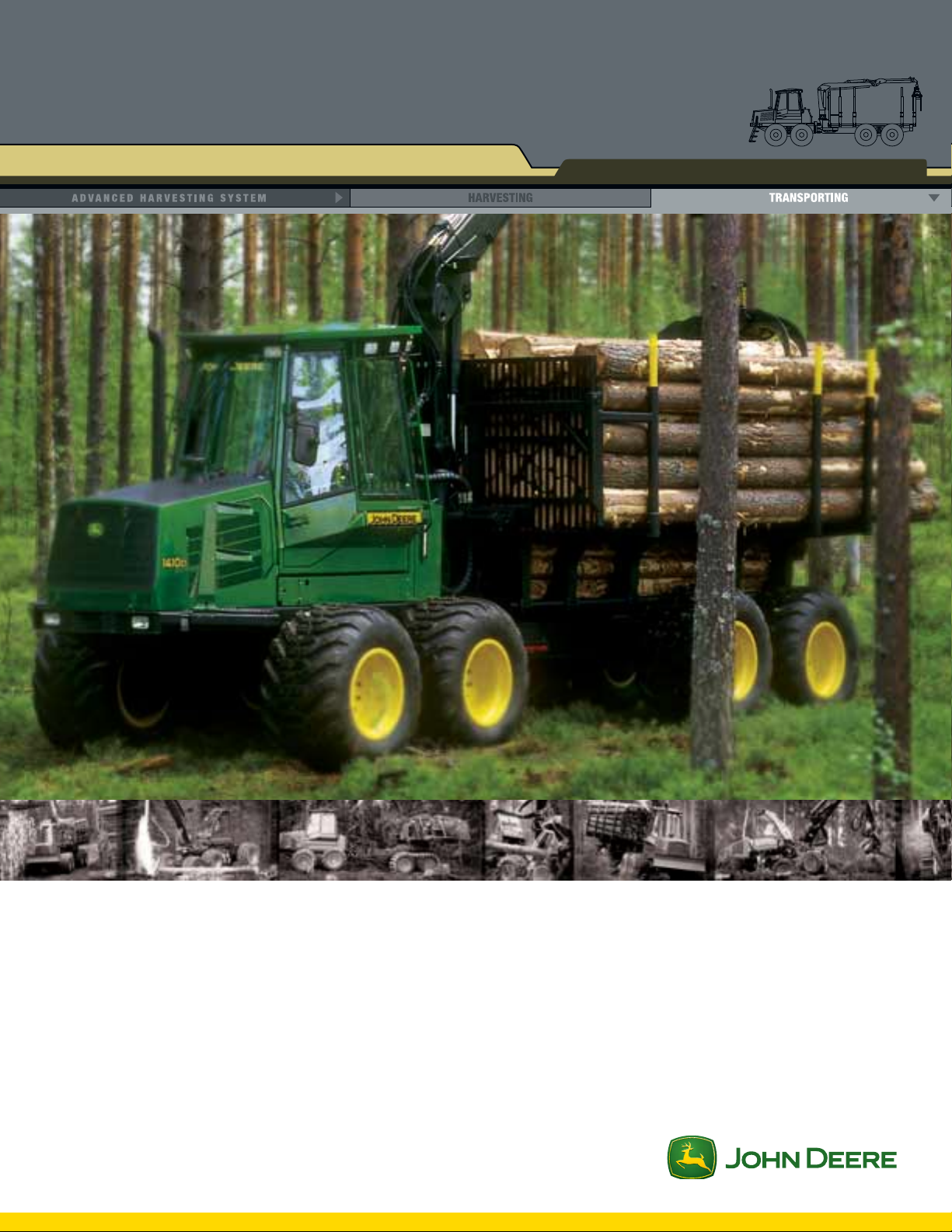

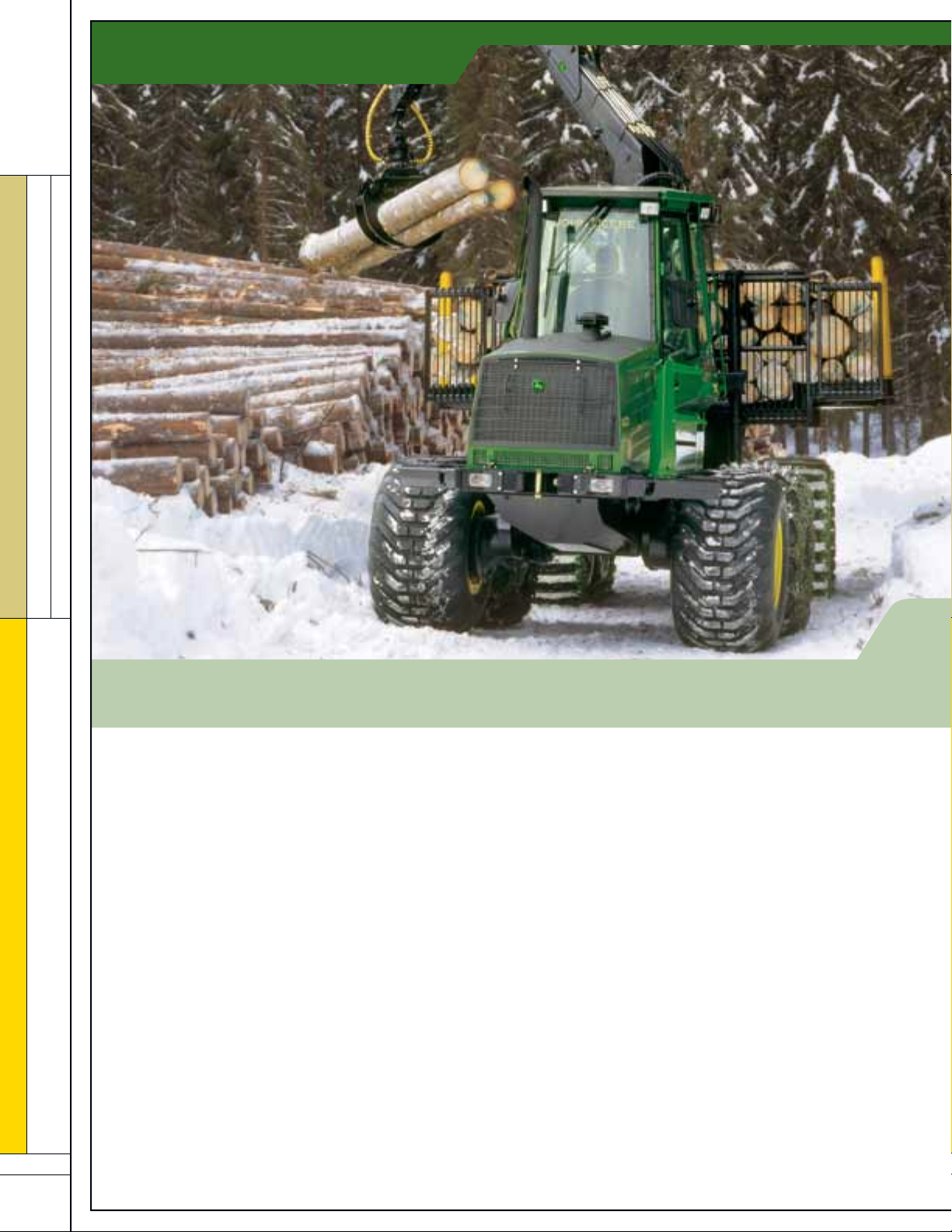

FORWARDERS

1010D 1110D 1410D 1710D

Page 2

THE PERFECT FIT.

No matter what kind of advanced harvesting system you run, there’s a

D-Series forwarder perfect for your operation.

FORWARDERS

1010D 1110D 1410D 1710D

PAGES

2–3

Advanced Harvesting System—No one

offers the extensive product line, dealer

network and tough, purpose-built

machines of John Deere.

Page 3

The 1010D, 1110D, 1410D and 1710D forwarders give you the

best performance in the woods, with features that boost your

productivity and uptime, all while keeping your daily operating

costs low.

The D-Series forwarders have earned a reputation worldwide as

hard-working, easy to operate and reliable machines that prove

themselves shift after shift. Powerful, fuel-effi cient John Deere

engines, telescopic booms that match operator preferences

automatically, a comfortable, air-suspension seat and easy

serviceability across the entire line assures you’re getting the

best whatever model you choose.

1010D 1110D 1410D 1710D

Rated Engine Power

Standard Operating Weight

(depending on equip.)

Max. Tractive Effort 31,473 lb-ft 140 kN 33,721 lb-ft 150 kN 39,342 lb-ft 175 kN 44,960 lb-ft 200 kN

4045H–115 SAE gross hp

86kW @ 2,000 rpm

26,450–27,560 lb

12 000–12 500 kg

6068H–161 SAE gross hp

121 kW @ 2,000 rpm

30,137–38,140 lb

13 670–17 300 kg

6068H–173 SAE gross hp

129 kW @ 2,000 rpm

36,375–38,580 lb

16 500–17 500 kg

6081H–215 SAE gross hp

160 kW @ 2,000 rpm

40,785–42,990 lb

18 500–19 500 kg

The added power from the high

torque rise gives you fast and easy

loading with numbers you’ll notice

at the end of the day.

PRODUCTIVITY UPTIME LOW DAILY OPERATING COSTS

Page 4

FORWARDERS

1010D 1110D 1410D 1710D

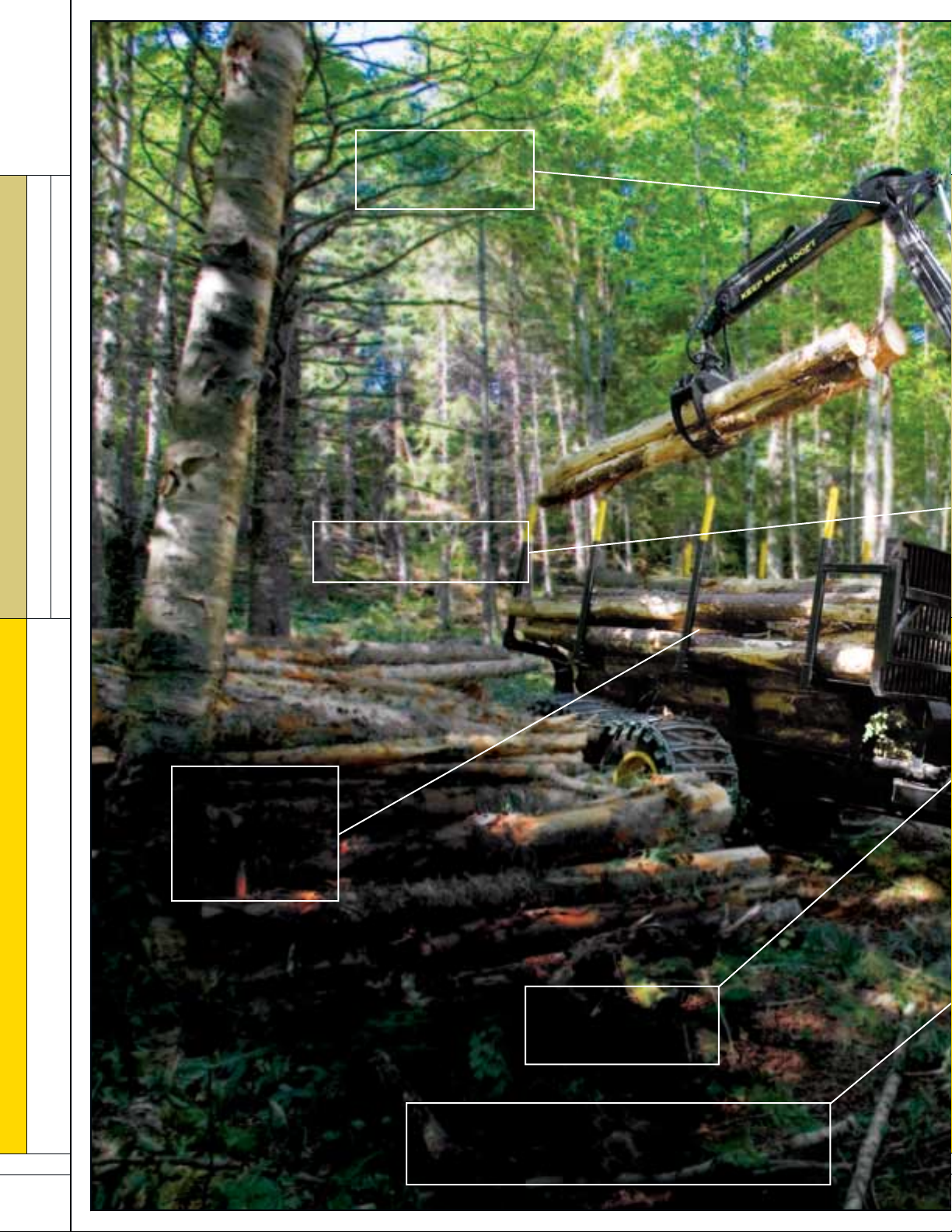

Powerful booms are easy to

control with smooth operation,

making loading and unloading

more effi cient.

Effi cient hydraulics make operation

effortless, while large diameter hoses

reduce pressure loss.

PAGES

4–5

Low center of gravity of

the load space keeps the

forwarder stable in all

conditions. There are two

different frame lengths

available to meet your

exact application.

The frame and middle joint

are built for reliability and a

well-balanced machine with a

powerful frame brake.

Patented balanced bogie system available on both the six-wheeled

and eight-wheeled versions signifi cantly reduces ground impact and

ensures a smooth ride over the toughest terrain. The six-wheeled

version features a rigid, dependable front axle.

Page 5

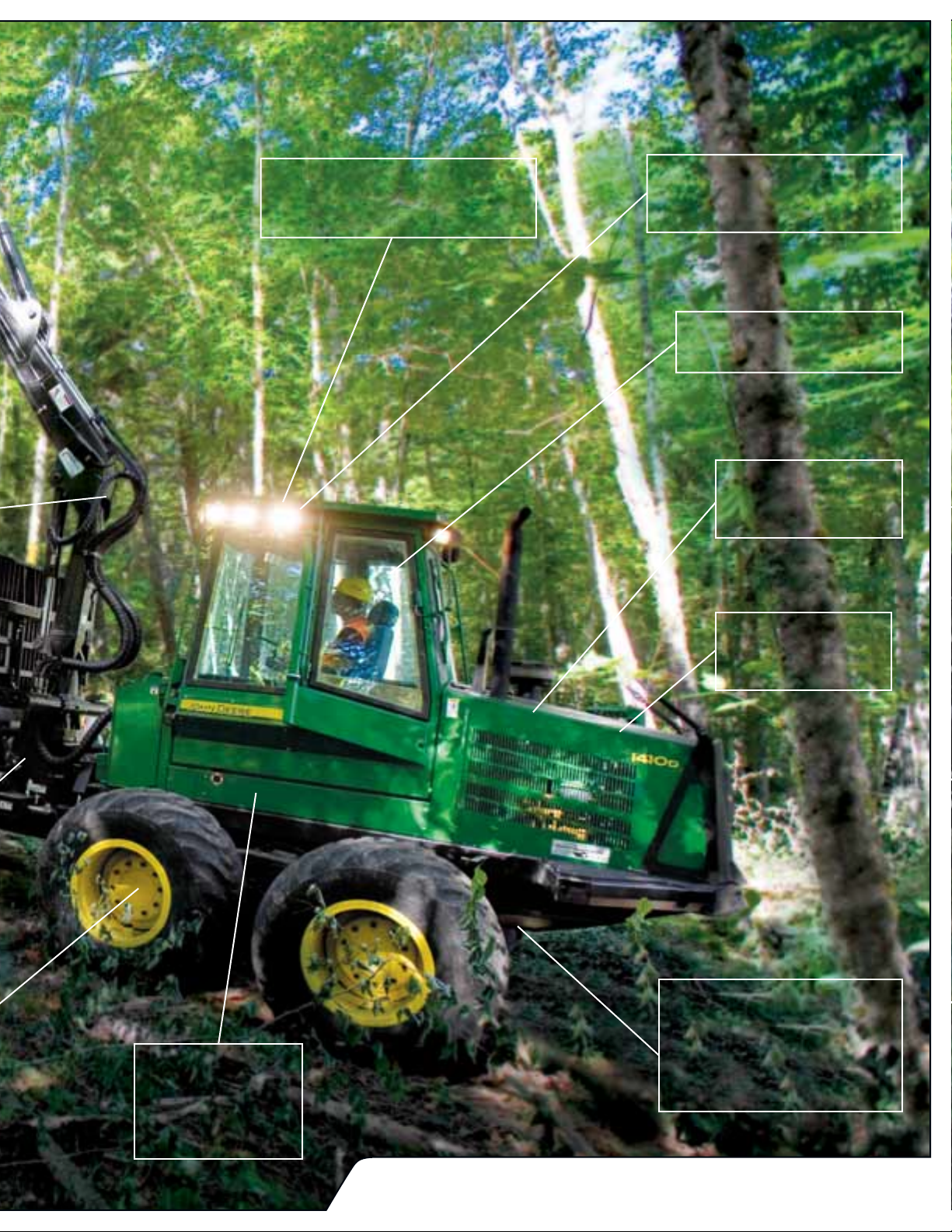

Total Machine Control (TMC™) governs all

machine functions for precise operator

control and increased productivity. Available

on 1110D, 1410D and 1710D.

Cab offers excellent visibility in all directions.

Effi cient air conditioning, sound insulation

and fully adjustable seat provides maximum

operator comfort.

Cab windows are made from a

durable polycarbonate glass that’s

tinted for operator comfort.

John Deere PowerTech™ diesel

engines deliver excellent fuel

economy with high torque at

low rpms.

Access to service points

under the cab is made

easy with hydraulic lift.

The belly pan can also be

lowered and raised with a

winch for easy access.

Engine components that

require daily servicing are

easily accessible under the

lightweight engine hood.

Excellent ground clearance and high

tractive effort enables you to move

over the toughest ground. Several tire

options, as well as compatible chains

and tracks, let you outfi t your forwarder

with the perfect combination to suit

your specifi c needs.

TAKE A LOOK AROUND.

Page 6

FORWARDERS

1010D 1110D 1410D 1710D

GET MORE OUT OF EACH SHIFT.

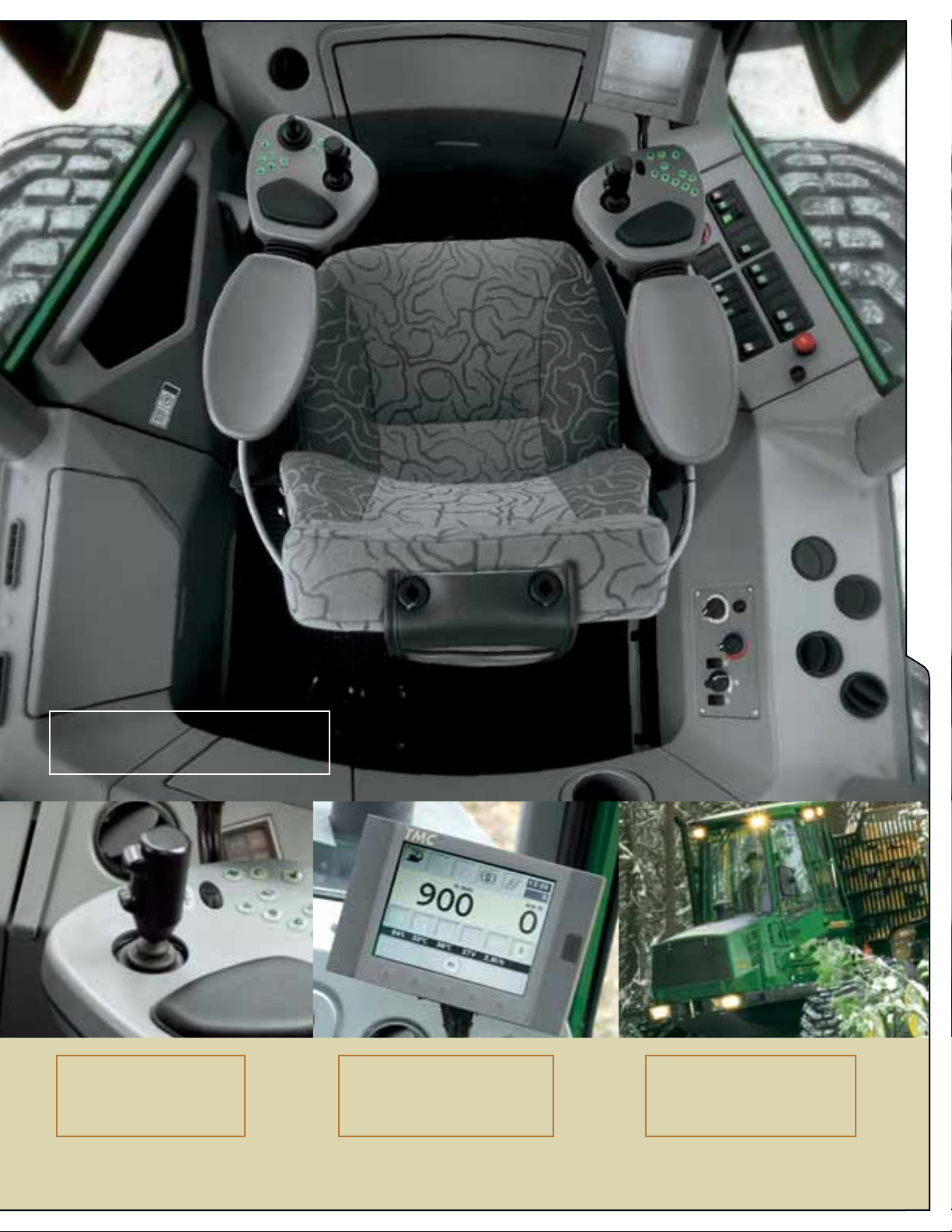

The D-Series forwarders feature highly effi cient John Deere diesel engines and

the most comfortable cab in the industry for unparalleled productivity.

The electronically controlled, fuel-injected common rail

fuel systems in John Deere engines give you the power you

need when you need it. The advanced Total Machine

Control (TMCTM) system (in the 1110D, 1410D and 1710D

models) automatically responds to the engine demands for

precise control. The TMC system optimizes performance by

effi ciently controlling the boom functions and power transmission.

The speed of the loader can be adjusted at the touch of a

button while loading.

The Timbermatic 700 system (available on the 1110D,

1410D and 1710D) is an alternative to TMC. T700 creates

a telecommunications link between the harvester and the

forwarder, keeping both up to date on vital information like

the location of logs produced by the harvester. The PC-based

T700 and large color monitor give the operator the tools to do

his job more effectively and effi ciently, from e-mail to maps.

The 1010D model is controlled by the exclusive Loader

Control System (LCS) to match operator preferences.

It runs at higher working pressure with lower hydraulic fl ow,

which allows you to load and unload faster with greater lift

capacity, on less fuel.

With the TMC speeds set, the operator is ready to work

tirelessly in the cab that sets the industry standard when it

comes to comfort and size. The fully adjustable, air suspension

seat is heated for maximum comfort and features air bag

lumbar support. The spacious interior is climate-controlled,

insulated and vibration-dampened to minimize operator

fatigue and keep him at his peak performance.

PAGES

6–7

Page 7

The sound-insulated and vibration-dampened cab

keeps noise levels below a quiet 72db(A). That

way you can hear the AM/FM cassette radio.

The mini-lever joystick controls

mounted on the armrest give

you precise control of all

loader functions.

TMC provides valuable information

on the different machine functions,

such as average or momentary

fuel consumption.

Powerful work lights have 30%

more power than before. You

have the option of Xenon lights

that turn night into day.

Page 8

1010D/1110D

FORWARDERS

1010D 1110D 1410D 1710D

PAGES

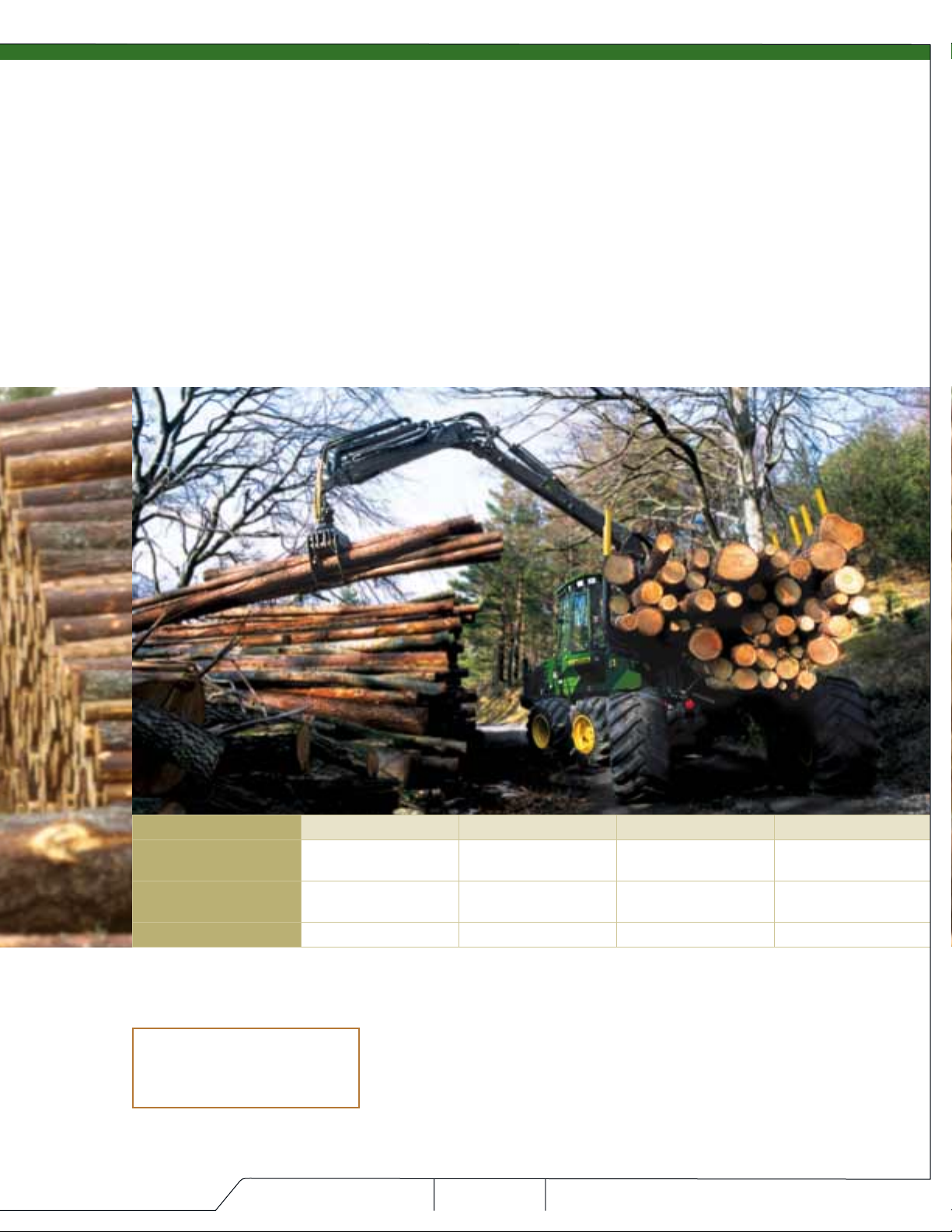

DON’T LET THEIR SIZE FOOL YOU.

When it comes to big-time productivity in short-haul forwarding, the 1010D

and 1110D forwarders are big on output.

The loader is crucial to quick cycle times in short-haul forwarding. Both the 1010D and 1110D forwarders feature the

powerful CF5 loader. It’s faster and stronger than previous models and it runs at higher working pressure with lower

hydraulic fl ow, so you can load and unload faster with greater lift capacity—on less fuel.

8–9

Page 9

The six-wheel 1010D rides on a

high-walker, full-gear bogie axle.

Mounted inside the rim, the axle

increases clearance from side to

side, further reducing the chance

for hang-ups.

The 1010D is available in either

four- or six-wheel drive. The 1110D

is available in either six- or eightwheel-drive confi gurations.

The eight-wheeled version of the

1110D features the patented balanced

bogie system for reduced ground

impact and a smooth ride even

when it’s fully loaded.

The 1010D and 1110D have the

power for regeneration harvesting

and the agility for thinnings.

Both models have the option of

three boom confi gurations and

two deck lengths to meet your lift

and reach needs.

Page 10

1410D/1710D

FORWARDERS

1010D 1110D 1410D 1710D

PAGES

10–11

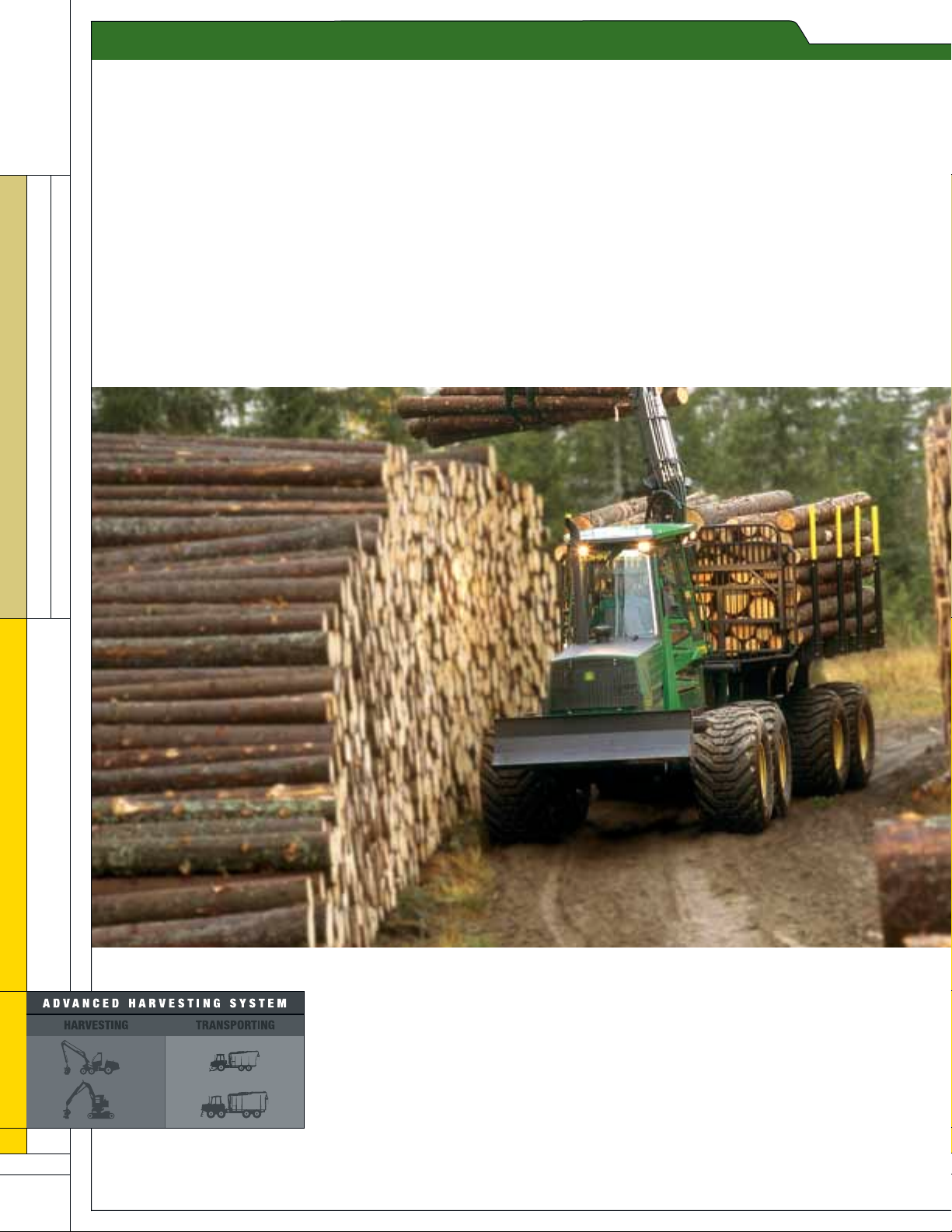

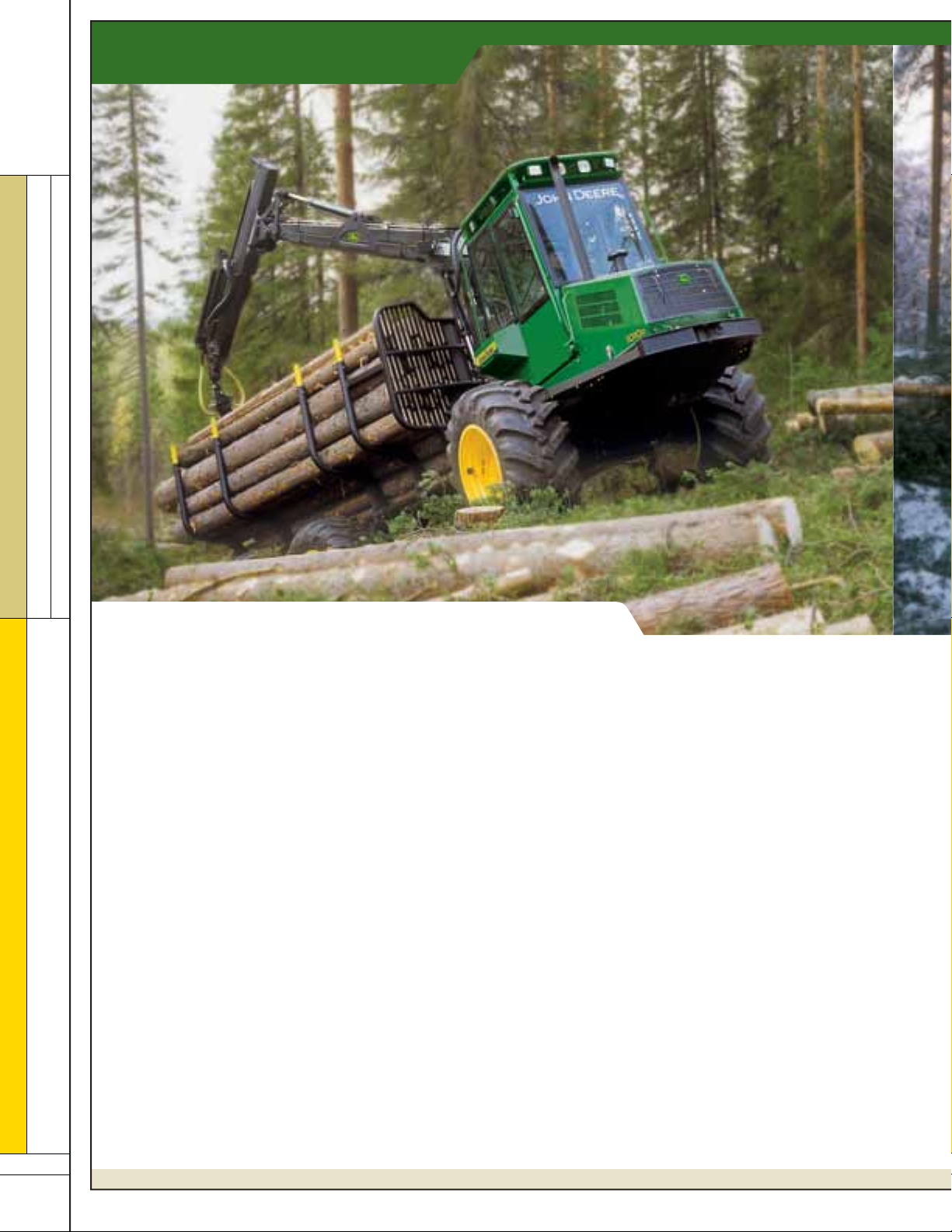

STAMINA FOR THE LONG HAUL.

Riding on a balanced bogie system, the 1410D and 1710D forwarders are the

perfect choice for reliable, double-shift production.

The 1410D is the ideal forwarder for average- to longdistance hauls. While the 1710D is the choice for longdistance forwarding in large-scale, demanding operations

like regeneration harvesting of large trees.

Va riable Load Space (VLS) is optional equipment (also

available on the 1110D model) that allows the size of the

load space to be adjusted hydraulically, without steps.

As much as an additional 25 inches (64 cm), depending on

conditions, is available for forwarding and sorting short

pulpwood and energy wood. At its narrowest, the load space

is ideal for operating in narrow spaces and transporting on

public roads.

Both models feature quick-response, high-torque John Deere

engines. The 1410D is powered by the 6.8L 6068H, and the

1710D features the 6081H turbocharged 8.1L.

Page 11

The patented balanced bogie system signifi cantly increases the environmental friendliness of the machine.

Evenly distributing the weight between all the wheels reduces the ground impact and provides a smooth

ride, even when the forwarder is fully loaded.

The steep approach angle and

high ground clearance make travel

easier on rough ground. Insidethe-rim mounting increases the

width of clearance as well.

The new loaders are more powerful

yet lighter. The single telescopic

boom extension is standard.

Longer reach options are available

with double extensions.

Page 12

FORWARDERS

1010D 1110D 1410D 1710D

PAGES

12–13

Page 13

AROUND-THE-CLOCK RELIABILITY.

A full line of forwarders that are built to keep working long

after the sun has gone down.

The D-Series forwarders are designed to operate reliably and

effi ciently. They are powered by industry-leading John Deere

diesel engines, which run at lower rpms and match power output

to the heaviest demands. Working well within the engine’s rated

capacity extends the life of the engine and its components.

The effi cient hydraulic system features large diameter hoses and

pipes that reduce pressure loss, while the high-grade fi lter system

lengthens the life of the components. And when the sun goes

down, bright halogen lights keep you working. An optional

Xenon light package turns night into day, allowing you to work

around the clock.

Service intervals have been extended.

The engine oil and fi lter change has

been increased from 250 hours to 500

hours, which means less downtime

and more time working.

Page 14

KEEP YOUR DAILY OPERATING COSTS

LOW AND YOUR PROFITS HIGH.

The less money you spend on fuel and less time you spend performing daily

maintenance chores means more money for your bottom line.

FORWARDERS

1010D 1110D 1410D 1710D

PAGES

14–15

For preventative maintenance, the

cab on the 1110D, 1410D and 1710D

models can be hydraulically lifted and

shifted to one side, and the belly pan

is lowered and raised by a winch for

easy access.

Page 15

Fuel prices are taking a bite out of your profi ts. The D-Series

forwarders will help take control of your daily operating costs

with fuel-effi cient engines. The electronically controlled, fuelinjected common rail system gives you the power you need,

when you need it. And makes the most of every gallon of fuel.

Ground-level access to daily servicing points quickens the process

of checking fl uid and fuel levels. That way your operator can

spend more time working and less time fi ddling with dipsticks.

Rest assured that your purpose-built

John Deere Forestry equipment is

supported by the most extensive

dealer network in the industry and

unsurpassed parts availability.

That’s our promise.

Page 16

TECHNICAL DATA 1010D 1110D

OPERATOR’S STATION

Air conditioner (R134A refrigerant)/heater, with fi lters

AM-FM stereo radio/cassette with two (2)

remote-mounted speakers

Parallel cab lift/shift with onboard hydraulic pump

Cab with integral forestry guarding, FOPS, OPS,

and ROPS protective structure

Secondary exit (right side window)

Tinted polycarbonate windows

Sun blinds, all windows

Sun curtain on front window

Windshield wiper/washer, front and rear windows

FORWARDERS

1010D 1110D 1410D 1710D

Storage compartment with spare parts catalog and

operator’s manual

Floor mat

Coat hook

TMC display

Horn

Rearview mirror, interior mounted

Seat, fabric covered, heated, air suspension: lumbar adjustment / weight

adjustment / seat armrest height adjustment / high back / seat backrest angle

adjustment / 230-degree seat rotation with three-position lock pedestal.

Seat belt, 2-in 51 mm wide with retractor (conforms to SAE J386)

TOTAL MACHINE

CONTROL SYSTEM (TMC

Controls engine, transmission and loader

Driver-specifi c parameters for seven operator and two factory settings

Operator chooses speed and sensitivity of functions to personal preference.

Gauge and indicator light information displayed on graphic screen: engine coolant

temperature, hydraulic oil temperature, voltage, etc. Monitoring and visual and

audible alarm system with a built-in diagnostic program to reduce downtime.

STANDARD EQUIPMENT

1010D 1110D

LCS (Loader Control System) ....................TMC (Total Machine Control) system

Fire extinguisher ABE III 10 lb 5 kg ............Fire extinguisher ABE III 10 lb 5 kg

Engine hood and cab protection ................Engine hood and cab protection

Back-up alarm ..........................................Back-up alarm

Frame oscillation brake.............................Frame oscillation brake

Hydraulic oil refi ll pump, electric ...............Hydraulic oil refi ll pump, electric

Parts manual ............................................Parts manual

Operator’s manual ....................................Operator’s manual

OPTIONAL EQUIPMENT

700 series tires in lieu of 600 series

Xenon working and boom lights

CF5 85 loader, 27-ft 11-in reach 8,5 m

CF5 10 loader, 32-ft 10-in reach 10 m

Hultdins SG260 or SG360 grapple

Grapple swing damp link

Decking blade, with manual control

Eco-tracks, spare wheel assemblies

TM

)

Tool box

To w pin

PAGES

16 –17

Specifi cations and design subject to change without notice and without incurring any obligation to make such changes on machines manufactured previously. Wherever

possible, specifi cations are in accordance with SAE standards. Except where otherwise noted, these specifi cations are based on the machines with standard equipment.

Some items shown are optional and may not be available in all markets. Errors and omissions excepted.

Photos may show features or options not available in all markets.

Page 17

ENGINE 1010D 1110D

Type . . . . . . . . . . John Deere 4045H, . . . . . . . . . . . . .John Deere JD6068 HTJ75

water-cooled turbocharged turbo-charged, 6-cylinder

and inter-cooled 4-cylinder diesel engine, CAC

diesel engine (charge air cooled)

Rated Power . . . 115 SAE gross hp 86 kW . . . . . . . . .161 SAE gross hp 121 kW

@ 2,000 rpm @ 2,000 rpm

Cylinders . . . . . . 4 . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Displacement . . . 276 cu-in 4,5 L . . . . . . . . . . . . . . . .414 cu-in 6,8 L

Maximum

Net Torque . . . . . 367 lb-ft 498 Nm . . . . . . . . . . . . . . .530 lb-ft 719 Nm

@ 1,400 rpm @ 1,400 rpm

Air Cleaner . . . . . Two-stage with safety element . . . . .Two-stage with safety element

and dust unloader valve and dust unloader valve

Cooling System . Heavy-duty radiator with . . . . . . . . .Heavy-duty radiator with

coolant level indicator and coolant level indicator and

coolant recovery reservoir, coolant recovery reservoir,

oil to water engine cooler oil to water engine cooler

Cooling Fan . . . . Suction-type, enclosed . . . . . . . . . . .Suction-type, enclosed

with guard with guard

Service interval for engine ................Service interval for engine

oil and fi lter is 500 hours oil and fi lter is 500 hours

Oil drain hose for spill-free ...............Oil drain hose for spill-free

oil changes oil changes

Antifreeze . . . . . -34°F -37°C . . . . . . . . . . . . . . . . . . .-34°F -37°C

Fuel Line . . . . . . Quick release fuel fi lter, . . . . . . . . . .Quick release fuel fi lter,

electric fuel shut-off with electric fuel shut-off with

start switch key, electronically start switch key, electronically

controlled, rotary-type controlled, rotary-type

injection pump injection pump

ELECTRICAL

Type . . . . . . . . . . 24 volt with 100-amp alternator . . . .24 volt with 100-amp alternator

Batteries . . . . . . 2 heavy-duty 12 volt, 870 . . . . . . . . .2 heavy-duty 12 volt,

cold cranking amps (115 Ah) cold cranking amps (145 Ah)

Work Lights . . . . 8 high-intensity Halogen style . . . . .8 high-intensity Halogen style

Twin-Power (2 x 70 watt) work Twin-Power (2 x 70 watt) work

lights, 2 single 70-watt head lights, 2 single 70-watt head

lights, 1,260 watts in the lights, 1,260 watts in the

working area of the loader, working area of the loader,

2 optional 70-watt working 2 optional 70-watt working

lights to the boom are available lights to the boom are available

TRANSMISSION

1010D 1110D

Type . . . . . . . . . . Hydrostatic-mechanical . . . . . . . . . .Hydrostatic-mechanical

transmission with low and transmission with low and

high range high range

Travel Speeds Forward and Reverse

High . . . . . . . . 0–13.7 mph 0–22 km/h . . . . . . . . . .0–13.7 mph 0–22 km/h

Low . . . . . . . . . 0–5 mph 0–8 km/h . . . . . . . . . . . . .0–5 mph 0–8 km/h

Max. Tractive

Effort . . . . . . . . . 31,473 lb-ft 140 kN . . . . . . . . . . . . .33,721 lb-ft 150 kN

STEERING

Type . . . . . . . . . . Articulated frame steering . . . . . . . .Articulated frame steering

with two hydraulic cylinders with two hydraulic cylinders

Frame

Articulation . . . . ± 44 degrees, stop to stop . . . . . . . .± 44 degrees, stop to stop

Steering Control . . Proportional, electric . . . . . . . . . . . .Proportional, electric

mini-joystick over hydraulic, mini-joystick over hydraulic,

armrest mounted armrest mounted

CAPACITIES 1010D 1110D

Fuel Reservoir . . . . . . . . . 30 US gal 113 L . . . . . . . . . . . 39.6 US gal 150 L

Cooling System . . . . . . . . 5.5 US gal 21 L . . . . . . . . . . . 7.1 US gal 27 L

Hydraulic System. . . . . . . 50.2 US gal 190 L . . . . . . . . . 39.6 US gal 150 L

OPERATING WEIGHT

Depending On . . . . . . . . . 26,450–27,560 lb . . . . . . . . . 30,137–38,140 lb

Confi guration 12 000 kg–12 500 kg 13 670 kg–17 300 kg

HYDRAULIC SYSTEM

Type . . . . . . . . . . Load-sensing hydraulic system . . . .Load-sensing hydraulic system

with power control and with power control and

Loader Control System (LCS) Total Control System (TCS)

Working

Hydraulics . . . . . Variable displacement pump . . . . . .Variable displacement pump

Rated Flow . . . 39.6 US gpm 150 L/min . . . . . . . . . .49.5 US gpm 187,5 L/min

@ 1,500 rpm @ 1,500 rpm

Pressure . . . . . 3,480 psi 24 MPa . . . . . . . . . . . . . . .3,480 psi 24 MPa

Powertrain

Hydraulics . . . . . Variable displacement pump . . . . . .Variable displacement pump

BRAKE SYSTEM

Service Brakes . . Foot pedal operated,

hydraulically actuated,

oil immersed, multiple

disc brakes, inboard

Working Brake . . Automatically operated, . . . . . . . . . .Service and working brakes are

spring applied, hydraulically hydraulically actuated, oil-immersed

released, oil immersed, inboard multi-disc brakes

Parking Brake . . Automatically or manually . . . . . . . .Spring-actuated parking and

operated, spring applied, emergency brakes. ISO 11169

hydraulically released,

oil immersed, inboard

Frame oscillation brake,

automatic

WOOD BUNK 1010D

4-Wheel Long 4-Wheel Short

and 6-Wheel

Length . . . . . . . . . . . . . 16-ft 4,90 m . . . . . . . . . . . . . .9-ft 8-in 2,95 m

Width . . . . . . . . . . . . . . 8-ft 8.7-in 2,66 m . . . . . . . . . .8-ft 5.6-in 2,58 m

Max. Cross Section . . . 37.7 sq-ft 3,5 m2 . . . . . . . . . .36.6 sq-ft 3,4 m

Fixed headboard with Fixed headboard with

4 bunks, 8 stakes 3 bunks, 6 stakes

Max. Load Rating . . . . . 22,000 lb 10 000 kg . . . . . . . .19,810 lb 9 000 kg

Payload . . . . . . . . . . . . 4.7 cords 17,1 m3 . . . . . . . . . .2.3 cords 8,3 m

stacked stacked

2

3

WOOD BUNK 1110D

6- and 8-Wheel

Length . . . . . . . . . . . . . 15-ft 11-in 4,85 m/15-ft 4,58 m/17-ft 11-in 5,47 m

Width . . . . . . . . . . . . . . 8-ft 5-in 2,56 m

Max. Cross Section . . . 4,0 m2/3,5 m2/4,5 m

Fixed headboard with

4 bunks, 8 stakes

Max. Load Rating . . . . . 26,455 lb 12 000 kg

Payload . . . . . . . . . . . . 5.6 cords 20,3 m

stacked

2

3

LOADER CF5

Type . . . . . . . . . . Telescopic knuckleboom with

telescopic outer boom and

mini-joystick control with LCS in 1010D and TMC in 1110D

Gross Lifting

Tor que . . . . . . . . 75,230 lb-ft 102 kNm

Slewing Torque . 18,000 lb-ft 24,4 kNm

Slewing Angle . . 380 degrees

Grapple . . . . . . . SG260 2.8 sq-ft 0,26 m

Optional . . . . . SG360 3.9 sq-ft 0,36 m

SG260S 2.8 sq-ft 0,26 m

Model CF5 72 CF5 85 CF5 10

Reach, . . . . . . . . . . . . . 23-ft 7-in . . . . . . . .27-ft 11-in . . . . . . . 32-ft 10-in

Maximum 7,2 m 8,5 m 10,0 m

Length of . . . . . . . . . . . 4-ft 7-in . . . . . . . . .8-ft 2-in . . . . . . . . . 13-ft 9-in

Extension 1,39 m 2,5 m 4,2 m

Max. Load . . . . . . . . . . 2,381 lb . . . . . . . . . 1,764 lb . . . . . . . . . 1,280 lb

at Max. Reach 1 080 kg 800 kg 580 kg

(Without grapple, link and rotator)

2

2

2

Page 18

TECHNICAL DATA 1010D 1110D

TIRES 1010D 1110D

Front 6-Wheel 4-Wheel Long 4-Wheel Short 6-Wheel 8-Wheel

Standard . . . . . . . .600x34/14. . . . . . 600x34/14 . . . . . . . 600x34/14 ....................600x34/14 ....................600x26.5/20

Optional . . . . . . . .700x34/14. . . . . . 700x34/14 . . . . . . . 700x34/14 ....................700x34/14 ....................710x26.5/16

66/43-26

Rear

Standard . . . . . . . .600x26.5/20 . . . . 600x34/14 . . . . . . . 600x34/14 ....................600x26.5/20 .................600x26.5/20

Optional . . . . . . . .700x26.5/20 . . . . 700x34/14 . . . . . . . 700x34/14 ....................710x26.5/16 .................710x26.5/16

66/43-26

AXLES 1010D 1110D

Type ....................4W: Single, rigid axle .........................Six wheel ........................................ Eight wheel

front and rear

6W: Single, rigid front axle .................Rigid axles at the front; ................... Balanced gear bogie axles;

and high-walker, full gear Balanced gear bogie Hydro-mechanical differential

bogie axle with portal type axles at the rear; hydro-lock lock at the front and rear

bogie beams on the rear at the front and rear

FORWARDERS

1010D 1110D 1410D 1710D

Final Drives ......... 4W: Heavy-duty planetary, ................Heavy-duty planetary, ..................... Balanced gear bogie axles;

mounted outboard in front mounted outboard in front Hydro-mechanical differential

and rear and inboard in rear lock at the front and rear

6W: Heavy-duty planetary, ....................................................................... Optional HD axles also available

mounted outboard in front

and inboard in rear

Differentials ........ Hypoid-type, hydraulically .................Hypoid-type hydraulically................ Hypoid-type hydraulically

operated mechanical operated mechanical operated mechanical

differential locks front differential locks front differential locks front

and rear and rear and rear

Disconnection of the rear- .................Disconnection of the rear- .............. Disconnection of the rear-

wheel drive in high range wheel drive in high range wheel drive in high range

GROUND PRESSURE DATA

1010D 1110D

Front Empty ........6-Wheel .............4-Wheel Long ...... 4-Wheel Short .........6-Wheel .............. 8-Wheel

600x34 ................. 7.8 psi 54 kPa ............ 7.8 psi 54 kPa ...........7.8 psi 54 kPa ........10.3 psi 71 kPa ........7.8 psi 54 kPa

700x34 ................. 7.5 psi 52 kPa ............ 7.5 psi 52 kPa ...........7.5 psi 52 kPa .........9.0 psi 62 kPa .........6.8 psi 47 kPa

66x34-26 .....................N/A ................... 4.8 psi 33 kPa ................... N/A .........................N/A ......................... N/A

Front Loaded

600x34 ................. 7.8 psi 54 kPa ............ 8.3 psi 57 kPa ...........8.3 psi 57 kPa ........10.3 psi 71 kPa ........7.8 psi 54 kPa

700x34 ................. 7.5 psi 52 kPa ............ 7.8 psi 54 kPa ...........7.8 psi 54 kPa .........9.0 psi 62 kPa .........6.8 psi 47 kPa

66x34-26 .....................N/A ................... 5.1 psi 35 kPa .................. N/A.......................... N/A .........................N/A

Rear Empty .........6-Wheel .............4-Wheel Long ...... 4-Wheel Short .........6-Wheel .............. 8-Wheel

600x34 ......................... N/A .................... 6.1 psi 42 kPa ...........6.1 psi 42 kPa ................. N/A .........................N/A

Different Tire Size .....................................................................................................5.3 psi 37 kPa .........5.3 psi 37 kPa

600x26.5 .............. 4.2 psi 29 kPa .................... N/A ........................... N/A..................5.4 psi 37 kPa ......... 5.4 psi 37 kPa

With Tracks ..........2.5 psi 17 kPa .................... N/A ..........................N/A.......................... N/A ......................... N/A

700x26.5 ............. 3.6 psi 25 kPa.................... N/A ........................... N/A..................4.6 psi 32 kPa .........4.6 psi 32 kPa

With Tracks ..........2.2 psi 15 kPa .................... N/A ........................... N/A.......................... N/A ......................... N/A

66x34-26 .....................N/A .....................3.8psi 26 kPa ...................N/A..........................N/A ......................... N/A

Rear Loaded

600x34 ......................... N/A .................. 18.4 psi 127 kPa .......17.1 psi 118 kPa ...............N/A ......................... N/A

600x26.5 ............. 11.5 psi 79 kPa ................... N/A ........................... N/A................14.5 psi 100 kPa ..... 14.5 psi 100 kPa

With Tracks ..........6.7 psi 46 kPa .................... N/A ........................... N/A.......................... N/A ......................... N/A

700x34 ......................... N/A .................. 17.5 psi 121 kPa .......16.4 psi 113 kPa ...............N/A ......................... N/A

700x26.5 ............. 10.0 psi 69 kPa ................... N/A ........................... N/A.................13.1 psi 90 kPa ....... 13.1 psi 90 kPa

With Tracks ..........5.8 psi 40 kPa .................... N/A ........................... N/A.......................... N/A ......................... N/A

66x34-26 .....................N/A ................... 11.3 psi 78 kPa .................. N/A.......................... N/A .........................N/A

PAGES

18 –19

DIMENSIONS 1010D 1110D

4-Wheel Long 4-Wheel Short 6-Wheel 8-Wheel

and 6-Wheel

A Length ................................. 30-ft 6-in 9,30 m ........... 24-ft 5-in 7,44 m ................30-ft 11-in 9,42 m or ...........31-ft 10-in 9,70 m or

32-ft 2-in 9,82 m 33-ft 10-in 10,31 m

B Width

With 600 series tires ........8-ft 9.6-in 2,68 m ..........8-ft 6-in 2,59 m ..................8-ft 11-in 2,70 m .................8-ft 11-in 2,70 m

With 700 series tires ........ 9-ft 4.6-in 2,86 m .......... 9-ft 4.6-in 2,86 m ...............9-ft 6-in 2,88 m ...................9-ft 6-in 2,88 m

With 66/43-26 tires

(4W long only) ..................11-ft 5-in 3,48 m ........... N / A ..................................N / A .....................................N / A

C Transport Height .................12-ft 2-in 3,70 m ...........12-ft 2-in 3,70 m ................12-ft 2-in 3,70 m .................12-ft 2-in 3,70 m

D Ground Clearance ...............1-ft 11.8-in 60,5 cm ...... 1-ft 11.8-in 60,5 cm ........... 1-ft 11.8-in 60,5 cm ............1-ft 11.8-in 60,5 cm

E Wheelbase ..........................15-ft 9-in 4,80 m ........... 12-ft 3-in 3,72 m ................16-ft 5-in 5,00 m or .............16-ft 5-in 5,00 m or

17-ft 8-in 5,40 m 17-ft 8-in 5,40 m

F Load Stake Width ................ 8-ft 8.7-in 2,66 m .......... 8-ft 5.6-in 2,58 m ..............8-ft 5-in 2,56 m or ...............8-ft 5-in 2,56 m or

9-ft 1-in 2,76 m 9-ft 1-in 2,76 m

G Length of Wood Bunk .......... 16-ft 4,9 m .................... 9-ft 8-in 2,95 m ..................15-ft 11-in 4,85 m ...............15-ft 11-in 4,85 m

............................................................................................................................ 15-ft 4,58 m ........................15-ft 4,58 m

............................................................................................................................ 17-ft 11-in 5,47 m ...............17-ft 11-in 5,47 m

H Reach .................................. 23-ft 7-in 7,2 m ............. 23-ft 7-in 7,2 m ................. 23-ft 8-in 7,2 m ...................23-ft 8-in 7,2 m

Optional ............................27-ft 11-in 8,5 m .......................................................27-ft 11-in 8,5 m .................27-ft 11-in 8,5 m

......................................... 32-ft 10-in 10 m ........................................................32-ft 10-in 10 m ..................32-ft 10-in 10 m

I Approach Angle ................... 30 degrees .................... 30 degrees .........................27 degrees ...........................39 degrees

Page 19

H

F

G

B

C

30

I

D

E

A

H

F

G

B

C

30

I

D

E

A

Page 20

TECHNICAL DATA 1410D 1710D

OPERATOR’S STATION

Air conditioner (R134A refrigerant)/heater, with fi lters

AM-FM stereo radio/cassette with two (2)

remote-mounted speakers

Parallel cab lift/shift with onboard hydraulic pump

Cab with integral forestry guarding, FOPS, OPS,

and ROPS protective structure

Secondary exit (right side window)

FORWARDERS

1010D 1110D 1410D 1710D

Tinted polycarbonate windows

Sun blinds, all windows

Sun curtain on front window

Windshield wiper/washer, front and rear windows

Storage compartment with spare parts catalog

and operator’s manual

Floor mat

Coat hook

TMC display

Horn

Rearview mirror, interior mounted

Seat, fabric covered, heated, air suspension: lumbar

adjustment / weight adjustment / seat armrest height

adjustment / high back / seat backrest angle adjustment / 230-degree seat rotation with three-position

lock pedestal. Seat belt, 2-in 51 mm wide with

retractor (conforms to SAE J386)

STANDARD FEATURES

Timberjack TMC™ (Total Machine Control) system

Preheater, 10 kW, for engine, cab and hydraulic

reservoir

Extra working lights on the boom (two 70 watt)

Extra working lights on the cab rear (two 70 watt)

Fire extinguisher, 10 lb 5 kg

Hydraulically actuated steps

Hand grips

Vacuum pump for the hydraulic system, electrical

Refi ll pump for hydraulic fl uid, electrical

Quick coupling for fuel refi lling

Cable-type cab and engine hood guards

Back-up alarm

Frame oscillation brake

Articulation lock bar and pins

To w pin

Toolbox with tool kit

Hose carrier

Spare parts catalogue

Operator’s manual

OPTIONAL EQUIPMENT

Nokian 650 mm tires (8), in lieu of 750 mm

(1710D only)

Nokian 600 mm tires (8), in lieu of 700 mm

(1410D only)

Rear window sun curtain

Washer and wiper for rear side windows

CD changer with 5 CD capacity

Environmental spill kit

Hultdins SG360S grapple (1710D only)

Hultdins SG260 or SG260S grapple (1410D only)

Decking blade, with proportional control

Fuel refi ll pump, electrical

Extra pre-cleaners for engine and cab air intake

EcoTrack bogie tracks and tire chains,

consult your dealer

Spare wheel assemblies

French decals and operator’s and spare

parts manuals

Xenon work lights

TOTAL MACHINE

CONTROL SYSTEM (TMC

Controls engine, transmission and loader

Driver-specifi c parameters for seven

operator and two factory settings

Operator chooses speed and sensitivity of functions

to personal preference. Gauge and indicator light

information displayed on graphic screen: engine

coolant temperature, hydraulic oil temperature,

voltage, etc. Monitoring and visual and audible alarm

system with a built-in diagnostic program to reduce

downtime.

™

)

PAGES

20–21

Page 21

ENGINE 1410D 1710D

Type . . . . . . . . . . . . . . . . . John Deere 6068H, . . . . . . . . . . John Deere 6081H,

charge air cooled, charge air cooled,

6-cylinder turbocharged 6-cylinder turbocharged

isolation-mounted diesel isolation-mounted diesel

with TMCTM with TMC

Rated Power . . . . . . . . . . 173 SAE gross hp 129 kW . . . . . 215 SAE gross hp 160 kW

@ 2,000 rpm @ 2,000 rpm

Cylinders . . . . . . . . . . . . . 6 . . . . . . . . . . . . . . . . . . . . . . . . 6

Displacement . . . . . . . . . . 414 cu-in 6,8 L . . . . . . . . . . . . . 494 cu-in 8,1 L

Maximum Net Torque. . . . 575 lb-ft 780 Nm . . . . . . . . . . . . 811 lb-ft 1100 Nm

@ 1,300–1,400 rpm @ 1,200–1,300 rpm

Air Cleaner . . . . . . . . . . . Two-stage with safety element and dust unloader valve

Cooling System . . . . . . . . Heavy-duty radiator with coolant level indicator and coolant

recovery reservoir, oil to water engine cooler

Cooling Fan . . . . . . . . . . . Suction-type, enclosed with guard

Service interval for engine oil and fi lter is 500 hours

Oil drain hose for spill-free oil changes

Antifreeze . . . . . . . . . . . . -34°F -37°C

Fuel Line . . . . . . . . . . . . . Quick release fuel fi lter, . . . . . . . Quick release fuel fi lter,

electric fuel shut-off with electric fuel shut-off with

start switch key, electron- start switch key, electron ically controlled, rotary- ically controlled, high type injection system pressure common rail

fuel injection system

TM

ELECTRICAL

Type . . . . . . . . . . . . . . . . . 24 volt with 140-amp alternator

Batteries . . . . . . . . . . . . . Heavy duty, low maintenance, 1,050 (1710D), 850 (1410D)

cold cranking amps, (two 12 volt) 145 Ah

Work Lights . . . . . . . . . . . 10 high-intensity halogen-style Twin-Power (2 x 70 watt)

work lights, 2 single 70-watt head lights, 2 x 70-watt boom

lights, 2 x 70-watt cab rear lights and 1 x 70-watt rear light

– 1,750 watts in the working area of the loader

TRANSMISSION

Type . . . . . . . . . . . . . . . . . Hydrostatic mechanical with protected electric/hydraulic

range shift of two-speed gearbox and TMC. Off-road driving

with smooth no-surge starts without dropping engine speed,

disconnection of rear axle drive with high range

Travel Speeds, Forward and Reverse

High . . . . . . . . . . . . . . . 0–13.7 mph 0–22,0 km/h . . . . . 0–14.3 mph 0–23,0 km/h

Low . . . . . . . . . . . . . . . . 0–5.0 mph 0–8,0 km/h . . . . . . . 0–5.0 mph 0–8,0 km/h

Maximum tractive effort . 39,342 lb-ft 175 kN . . . . . . . . . . 44,960 lb-ft 200 kN

AXLES

Type . . . . . . . . . . . . . . . . . High-walker, patented, full gear balanced heavy-duty bogie

axle with portal-type bogie beams in front and rear

Final Drives . . . . . . . . . . . Heavy-duty planetary, mounted inboard in front and rear

Differentials . . . . . . . . . . . Hypoid-type, hydraulically operated mechanical differential

locks front and rear

Disconnection of the front wheel drive in high range

STEERING 1410D 1710D

Type . . . . . . . . . . . . . . . . . Articulated frame steering with two hydraulic cylinders

Frame Articulation . . . . . . ± 42 degrees, stop to stop

Lever Steering . . . . . . . . . Proportional, electrical mini-joystick over hydraulics,

armrest mounted

HYDRAULIC SYSTEM

Type Load sensing, power control and TMC, vacuum pump for the

hydraulic system, electrical

Working Hydraulics . . . . . Variable-displacement . . . . . . . . Variable-displacement

pump pump

Rated Flow . . . . . . . . . . 55.5 US gpm 210 L/min . . . . . . . 55.5 US gpm 210 L/min

@ 1,500 rpm @ 1,500 rpm

Pressure . . . . . . . . . . . . 3,480 psi 24,0 MPa . . . . . . . . . . 3,480 psi 24,0 MPa

Powertrain Hydraulics . . . Variable-displacement-pump and motor

Rated Flow . . . . . . . . . . 50 US gpm 189 L/min . . . . . . . . 71.3 US gpm 270 L/min

@ 1,500 rpm @ 1,500 rpm

Fluid . . . . . . . . . . . . . . . . . Heavy-duty oil cooler, side by side with radiator, oil

fi lter, return, 10 micron with bypass, quick-disconnect

diagnostic ports

TIRES

Front and Rear

Standard . . . . . . . . . . . 700x26.5, 20 PR ELS NK . . . . . . 750x26.5, 20 PR ELS NK

Optional . . . . . . . . . . . . 600x26.5, 20 PR ELS NK . . . . . . 650x26.5, 20 PR ELS NK

WOOD BUNK

Deck Length. . . . . . . . . . . 17-ft 10-in 5,4 m or . . . . . . . . . . 18-ft 3-in 5,56 m

Optional . . . . . . . . . . . . 13-ft 10-in 4,2 m

Load Stake Width . . . . . . . 9-ft 1-in 2,76 m . . . . . . . . . . . . . 9-ft 8-in 2,95 m

Optional . . . . . . . . . . . . 9-ft 10-in 3,0 m

for 13-ft 10-in deck

Maximum Cross

Section. . . . . . . . . . . . . . . 49.5 sq-ft 4,6 m2 . . . . . . . . . . . . 58 sq-ft 5,4 m

Optional . . . . . . . . . . . . 53.5 sq-ft 5,0 m

for 13-ft 10-in deck

Headboard . . . . . . . . . . . Fixed with hydraulic . . . . . . . . . . Fixed with hydraulic

extension extension

Log Bunks . . . . . . . . . . . . 4 pair with 8 stakes, . . . . . . . . . 4 pair with 8 stakes,

moveable moveable

Payload . . . . . . . . . . . . . . 6.2 cords 22,4 m3 . . . . . . . . . . . 7.3 cords 26,3 m

stacked stacked

Optional . . . . . . . . . . . . 6.7 cords 24,4 m

stacked for 13-ft 10-in deck

Max. Load Rating . . . . . . . 30,865 lb 14 000 kg . . . . . . . . . 37,480 lb 17 000 kg

2

3

2

3

CAPACITIES

Fuel Reservoir . . . . . . . . . 43.6 US gal 165 L . . . . . . . . . . . 48 US gal 180 L

Cooling System . . . . . . . . 8.2 US gal 31 L . . . . . . . . . . . . . 7.7 US gal 29 L

Hydraulic Oil System . . . . 37 US gal 140 L . . . . . . . . . . . . . 50 US gal 190 L

BRAKES

Service Brake . . . . . . . . . Foot-pedal operated, hydraulically activated, oil immersed,

multiple disc, inboard

Working Brake . . . . . . . . . Automatically operated, spring applied, hydraulically

released, oil immersed, inboard

Parking Brake . . . . . . . . . Automatically or manually operated, spring applied,

hydraulically released, oil immersed, inboard

Frame oscillation brake, automatic

OPERATING WEIGHT

Depending on Equipment . 36,375–38,580 lb . . . . . . . . . . . 40,785–42,990 lb

16 500–17 500 kg . . . . . . . . . . . 18 500–19 500 kg

Page 22

TECHNICAL DATA 1410D 1710D

LOADER 1410D 1710D

Type . . . . . . . . . . . . CF7 knuckleboom. . . . . . . . . . CF8 knuckleboom

with telescopic outer with telescopic outer

boom and TMC™ with boom and TMC™ with

mini-joystick controls mini-joystick controls

Gross Lifting

Tor que. . . . . . . . . . . 92,195 lb-ft 125 kNm. . . . . . .111,370 lb-ft 151 kNm

FORWARDERS

1010D 1110D 1410D 1710D

Gross Swing

Tor que. . . . . . . . . . . 23,600 lb-ft 32 kNm. . . . . . . .30,235 lb-ft 41 kNm

Slewing Angle. . . . . 380 degrees . . . . . . . . . . . . . .380 degrees

Grapple . . . . . . . . . SG360 3.9 sq-ft 0,36 m2. . . . .SG420 4.5 sq-ft 0,42 m

Optional . . . . . . . . SG260 2.8 sq-ft 0,26 m2. . . . .SG360S 3.9 sq-ft 0,36 m

SG260S 2.8 sq-ft 0,26 m

Link. . . . . . . . . . . . . Single, dampened, steel . . . . . Single, dampened, steel

1410D 1710D

Model . . . . . . . . .CF772 . . . . . . CF785 . . . . . . CF710 . . . . . . . . CF885

Reach,. . . . . . . 23-ft 7-in . . . .27-ft 11-in . . 32-ft 10-in . . . . . 27-ft 11-in

Maximum 7,2 m 8,5 m 10 m 8,5 m

Length of . . . . . .54.7-in . . . . . 103.5-in . . . . . 165.4-in . . . . . . . .85.4-in

Extension 1,39 m 2,6 3 m 4,2 m 2,17 m

Max. Load at . . 2,756 lb . . . . . 2,172 lb . . . . . 1,786 lb . . . . . . . 2,613 lb

Max. Reach 1 250 kg 985 kg 810 kg 1 185 kg

(Without grapple, rotator and link)

GROUND PRESSURE

1410D With Rated Payload

700 Front empty Front Loaded

Standard Tires . . . . . . . 7.4 psi 51 kPa . . . . . . . . . . . .8.0 psi 55 kPa

With Bogie Tracks . . . . 5.1 psi 35 kPa . . . . . . . . . . . .5.4 psi 37 kPa

600

Optional Tires . . . . . . . . 8.6 psi 59 kPa . . . . . . . . . . . .9.4 psi 65 kPa

With Bogie Tracks . . . . 5.7 psi 39 kPa . . . . . . . . . . . .5.9 psi 41 kPa

700 Rear empty Rear Loaded

Standard Tires . . . . . . . 5.1 psi 35 kPa . . . . . . . . . . .14.6 psi 101 kPa

With Bogie Tracks . . . . 3.8 psi 26 kPa . . . . . . . . . . . .8.7 psi 60 kPa

600

Optional Tires . . . . . . . . 5.8 psi 40 kPa . . . . . . . . . . .17.1 psi 118 kPa

With Bogie Tracks . . . . 4.2 psi 29 kPa . . . . . . . . . . . .9.9 psi 68 kPa

1710D With Rated Payload

750 Front empty Front Loaded

Standard Tires . . . . . . . 7.1 psi 49 kPa . . . . . . . . . . . .7.7 psi 53 kPa

With Bogie Tracks . . . . 4.8 psi 33 kPa . . . . . . . . . . . .5.1 psi 35 kPa

650

Optional Tires . . . . . . . . 8.1 psi 56 kPa . . . . . . . . . . . .8.7 psi 60 kPa

With Bogie Tracks . . . . 5.2 psi 36 kPa . . . . . . . . . . . .5.5 psi 38 kPa

750 Rear empty Rear Loaded

Standard Tires . . . . . . . 5.1 psi 35 kPa . . . . . . . . . . .15.2 psi 105 kPa

With Bogie Tracks . . . . 3.8 psi 26 kPa . . . . . . . . . . . .8.8 psi 61 kPa

650

Optional Tires . . . . . . . . 5.8 psi 40 kPa . . . . . . . . . . .17.4 psi 120 kPa

With Bogie Tracks . . . . 4.1 psi 28 kPa . . . . . . . . . . . .9.7 psi 67 kPa

WOOD BUNK 1410D 1710D

Deck Length. . . . . . . . . . . 17-ft 10-in 5,4 m or . . . . . . . . . . 18-ft 3-in 5,56 m

Optional 13-ft 10-in 4,2 m

Load Stake Width . . . . . . . 9-ft 1-in 2,76 m . . . . . . . . . . . . . 9-ft 8-in 2,95 m

Optional . . . . . . . . . . . . 9-ft 10-in 3,0 m

for 13-ft 10-in deck

Maximum Cross

Section. . . . . . . . . . . . . . . 49.5 sq-ft 4,6 m

Optional . . . . . . . . . . . . 53.5 sq-ft 5,0 m

for 13-ft 10-in deck

2

2

Headboard . . . . . . . . . . . Fixed with hydraulic . . . . . . . . . . Fixed with hydraulic

extension extension

2

Log Bunks . . . . . . . . . . . . 4 pair with 8 stakes, . . . . . . . . . . 4 pair with 8 stakes,

moveable moveable

Payload . . . . . . . . . . . . . . 6.2 cords 22,4 m

stacked stacked

Optional . . . . . . . . . . . . 6.7 cords 24,4 m

stacked for 13-ft 10-in deck

Max. Load Rating . . . . . . . 30,865 lb 14 000 kg . . . . . . . . . 37,480 lb 17 000 kg

2 . . . . . . . . . . . . . . . . . . . . .

2

3 . . . . . . . . . . . . . . . . . . . .

3

58 sq-ft 5,4 m

7.3 cords 26,3 m

2

3

DIMENSIONS 1410D 1710D

A Length . . . . . . . . . . . . 34-ft 1-in 10,40 m . . . . . . 35-ft 7-in 10,85 m

Optional . . . . . . . . . 30-ft 2-in 9,20 m

B Width . . . . . . . . . . . . . 700x26.5 tires . . . . . . . . . 750x26.5 tires

10-ft 0.8-in 3,07 m 10-ft 5.6-in 3,19 m

600x26.5 tires 650x26.5 tires

9-ft 5.8-in 2,89 m 10-ft 4-in 3,15 m

C Transport Height . . . . 12-ft 1-in 3,7 m . . . . . . . . 12-ft 10-in 3,9 m

D Ground Clearance . . . 1-ft 11.8-in 60 cm . . . . . . 2-ft 4.7-in 73 cm

E Wheelbase . . . . . . . . 19-ft 2-in 5,85 m . . . . . . . 19-ft 4-in 5,9 m

Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-ft 2.7-in 5,25 m

F Load Stake Width . . . 9-ft 1-in 2,76 m . . . . . . . . 9-ft 8-in 2,95 m

Optional . . . . . . . . . 9-ft 10-in 3,0 m

G Length of

Wood Bunk . . . . . . . . 17-ft 10-in 5,4 m . . . . . . . 18-ft 3-in 5,56 m

Optional . . . . . . . . . . . 13-ft 10-in 4,2 m

H Reach, Maximum . . . 23-ft 7-in 7,2 m . . . . . . . . 27-ft 11-in 8,5 m

Optional . . . . . . . . . 27-ft 11-in 8,5 m

32-ft 10-in 10 m

I Approach Angle . . . . . 40 degrees . . . . . . . . . . . . 42 degrees

PAGES

22–23

Page 23

Page 24

FORWARDERS

1010D 1110D 1410D 1710D

NOTHING RUNS LIKE A DEERE.

NOTHING RUNS LIKE A DEERE.

Maybe those words are the reason why almost every

other professional logger is a John Deere customer.

™

They’re just fi ve simple words. Yet they have profound

impact on your company. Because at their heart they

mean equipment that is built forest tough, with greater

productivity, more uptime and lower daily operating

costs. They mean a dealer network over 380 locations

strong, with immediate access to parts and experts that

understand your industry. They mean a dedicated lender

Your world is logging. So is ours. John Deere Forestry. Leading the way, worldwide.

in John Deere Credit, committed to helping loggers succeed

with competitive fi nancing to enhance cash fl ow. And they

mean a global forestry equipment leader that invests more

in R & D than any other manufacturer.

But most of all, these words represent the confi dence that

comes with over 168 years of heavy equipment experience.

www.JohnDeere.com

DKA1010DF Litho in U.S.A. (05-10)

Loading...

Loading...