Page 1

Assembly Instructions and Parts Manual

XACTA® Commercial Fence & Rails (50” Rip)

for JTAS-12-DX Table Saw

WALTER MEIER (Manuf acturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M- 708955Z

Ph.: 800-274-6848 Revision A 08/2012

www.walt er meier.c om Copyright © 2012 Walt er Meier (M anufacturi ng) Inc.

Page 2

1.0 Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authori ze warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET® tools. For the name of an Authorized Service Center in

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

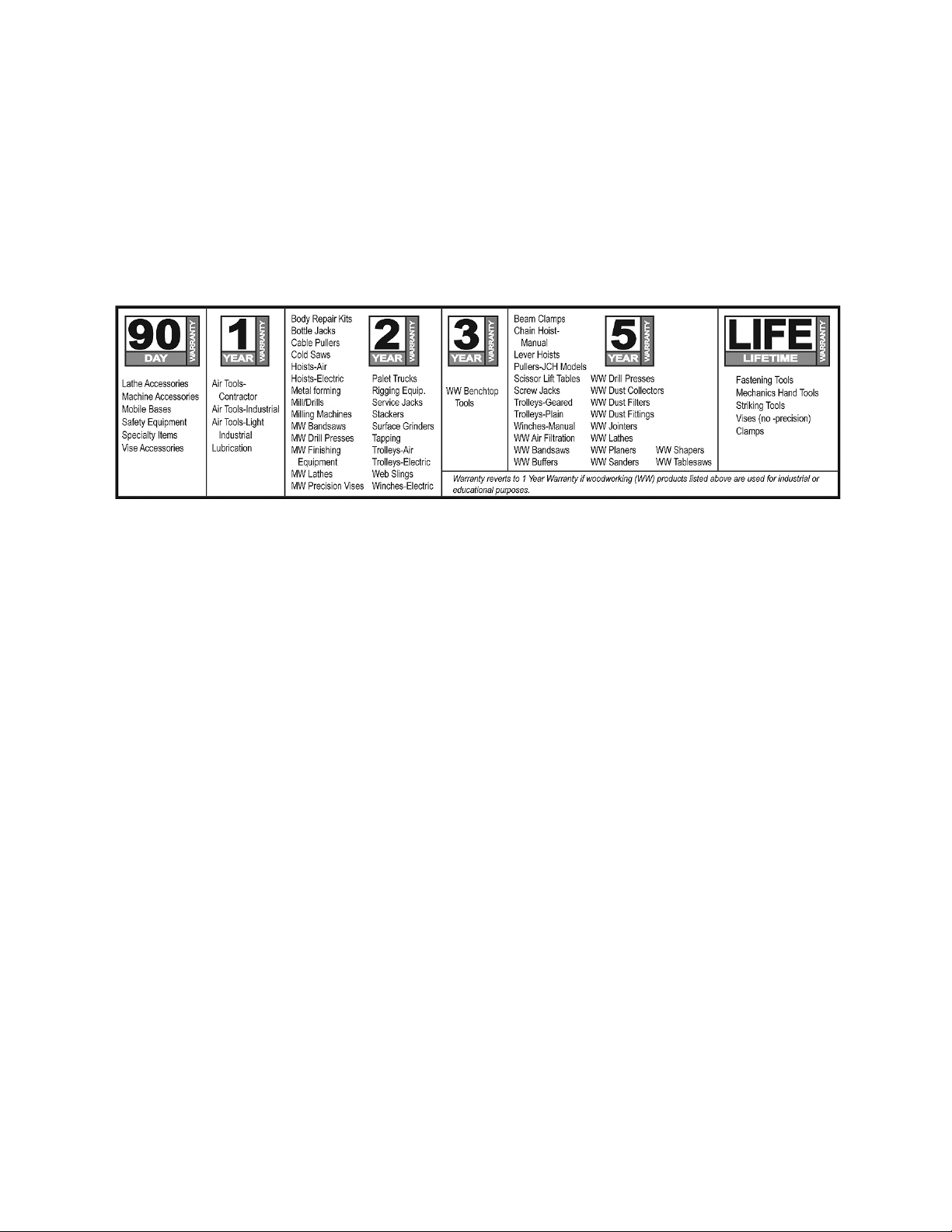

WARRANTY

JET products carry a limited warranty which varies in duratio n based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the e xceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. T his warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME ST ATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENT IAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET® branded products are not sold in Canada by Walter Meier.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ................................................................................................................... 2

2.0 Table of contents.......................................................................................................................... 3

3.0 Safety warnings ........................................................................................................................... 4

4.0 About this manual ........................................................................................................................ 5

5.0 Specifications............................................................................................................................... 6

6.0 Setup and assembly ..................................................................................................................... 7

6.1 Tool s required .................................................................................................................................................... 7

6.2 Shipping contents .............................................................................................................................................. 7

6.3 Front rail installation .................................................................................................. ........................................ 7

6.4 Switch installation ...................................................................................................... ........................................ 8

6.5 Back rail installation ........................................................................................................................................... 8

6.6 Guide tube .......................................................................................................................................................... 8

6.7 XACTA Fence .................................................................................................................................................... 9

6.8 Leveling fence to saw table............................................................................................................................... 9

6.9 Adjusting fence parallel to miter slot ................................................................................... ............................. 9

6.10 Clamping Pressure ........................................................................................................................................ 10

6.11 Checking 90° to Table ................................................................................................................................... 10

6.12 Cursor Adjustment ......................................................................................................................................... 10

7.0 Replaceme nt Parts ..................................................................................................................... 11

7.1.1 XACTA Fence Rail Assembly – Exploded View .............................................................................. .......... 11

7.1.2 XACTA Fence Rail Assembly – Parts List .................................................................................................. 11

7.2.1 XACTA Fence Assembly – Exploded View ................................................................................................ 12

7.2.2 XACTA Fence Assembly – Parts List ......................................................................................................... 12

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner's

manual before attempting assembly or

operation.

2. Read and understand warni ngs posted on the

machine and in this manual. Failure to comply

with all of these warnings may cause serious

injury.

3. Replace warning labels if they become

obscured or rem oved.

4. The table saw on which this fence is used, is

designed and intended for use by properly

trained and experienced personnel only. If you

are not familiar with the proper and safe

operation of a table saw, do not use until

proper training and knowledge have been

obtained.

5. Do not use the table saw for other than its

intended use. If used for other purposes,

Walter Meier (Manufacturing) Inc., disclaims

any real or implied warranty and holds itself

harm les s from any injur y that may res ult fro m

that use.

6. Always wear approved safety glasses/face

shields while using the table saw. Everyday

eyeglasses only have impact resistant lenses;

they a re not safety glasses.

7. Before operating the table saw, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Remove all loose

clothing and confine long hair. Non-slip

footwear or anti-skid floor strips are

recommended. Do n o t w ear gloves.

8. Always use the blade guard on all ''throughsawing'' operations. A through-sawing

operation is one in which the blade cuts

completely throu gh the workpi ece.

9. Kickback occurs when the workpiece is thrown

towards the operator at a high rate of speed. If

you do not have a clear understanding of

kickback and how it occurs, DO NOT operate

the table sa w!

10. Wear ear protectors (plugs or muffs) during

extended periods o f operation.

11. Some dust created by power sanding, sawing,

grinding, drilling and other construction

activities contain chemicals known to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

•

Lead fr om lead based pain t.

Crystalline silica from bricks, cement and

•

other m asonry products.

•

Arsenic and chromium from chemically

tr eated lu m ber.

Your risk of exposure varies, depending on

how often you do this type of work. To reduce

your exposure to these chemicals, work in a

well-ventilated area and work with approved

safety equipment, such as f ace or dust masks

that are specifically designed to filter out

microscopic particles.

12. Do not operate this machine while tired or

under the influence of drugs, alcohol or any

medication.

13. Make certain switch is in OFF position before

connecting the machin e to the power supply.

14. Make certain the machine is properly

grounded.

15 . Make all m ac hine ad just m e nt s o r m ain t e nance

with the machine unplugged from the power

source.

16. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and

adjusting wrenches are removed from the

machine before turning i t on.

17. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

completion of maintenance.

18. Check damaged parts. Before further use of

the machine, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving par ts, binding of moving

parts, breakage of parts, mounting and any

othe r co nditio ns th at may aff ect i ts ope ration.

A guard or other part that is damaged should

be properly repaired or replaced.

19. Provide for adequate space surrounding work

area and non- g lare , over he ad lig hting .

20. Keep the floor around the machine clean and

free o f scr ap material, oil a nd grease.

21. Keep visitors a safe distance from the work

area . Keep children away.

22. Make your workshop child proof with padlocks,

master swi tches or by rem oving starter keys.

23. Give your work undivided attention. Looking

aroun d, ca rrying on a conver sation an d “horseplay” are careless acts that can result in

seri ous inj ury.

4

Page 5

24. Maint ain a balanced stance at all times so that

you do not fall into the blade or other moving

parts. Do not overreach or use excessive force

to per form any machine operation.

25. Use the right tool at the correct speed and

fee d rate. D o not forc e a tool or attachme nt to

do a job for which it was not designed. The

ri ght tool will do th e job better and more safel y.

26. Use recommended accessories; improper

accessories m ay be hazardous.

27. Maintain tools with care. Keep saw blades

sharp and clean for the best and safest

pe rform ance . F o llow instruc tions f o r lubric ating

and changing a ccessories.

28. Turn off the machine before cleaning. Use a

brush or compressed air to remove chips or

debri s — do not use your ha nds.

29. Do not stand on the machine. Serious injury

could occur if the machine tips over.

30. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a com plete stop.

31. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

32. Keep hands out of the line of saw blade.

33. Use a push-stick w hen requi red.

34. Pay particular attention to instructions on

reducing risk of kickba ck.

35. Do not perform any operation freehand.

36. Never rea ch arou nd or over sa w blade.

37. Don’t use in dangerous environment. Don’t

use power tools in damp or wet location, or

expose them to rain. Keep work area well

lighted.

4.0 About t hi s manual

This manual is provided by Walter Meier (Manufacturing) Inc. covering the assembly and adjustment

procedu res for a JET X ACTA

on installation, safety precautions, and parts breakdown. Your fence has been designed and constructed to

provide years of trou ble-free operation if used in accordan ce with the instruction s as set forth in this document.

If there are questions or comments, please contact your local supplier or W alter Meier. W alter Meier can also

be reached at our web site: ww w.walt ermei er.com .

Retain this manual for future reference. If the fence transfers ownership, the manual should accompany it.

Read and understand the entire contents of the table saw manual before attempting

operat ion of the rip fence. Failure to compl y m ay cause serious injur y.

®

Fence syste m for the JTAS-12-D X Table Saw. This ma nual cont ains instru ction s

5

Page 6

5.0 Specifications

XACTA Fence :

Stock number...................................................................................................................................................... 708955Z

Fence body length ............................................................................................................................... 40-1/2” (1029 mm)

Side plate length ........................................................................................................................................ 42” (1067 mm)

Side plate thickness .................................................................................................................................. 19/32” (15 mm)

Side plate material ........................................................................................................................................ polyethylene

Fence width ............................................................................................................................................. 4-1/4” (108 mm)

Fence height .............................................................................................................................................. 2-1/2” (64 mm)

Head length ................................................................................................................................................. 16” (406 mm)

Net weight (fence only) ...............................................................................................................................23 lb (10.4 kg)

Paint finish ..................................................................................................................................................... powder coat

Rail Assembly:

Stock number ....................................................................................................................................................708956Z

Maximum rip to right of blade .................................................................................................................50” (1270 mm)

Maximum rip to left of blade ..................................................................................................................... 14” (356 mm)

Guide tube dimensions ............................................................................ 84-3/8”L x 3”W x 2”H (2143 x 76 x 51 mm)

Front rail dimensions.......................................................................... 72”L x 2-1/2”W x 2-1/2”H (1830 x 64 x 64 mm)

Rear rail dimensions ............................................................................ 72” x 1-1/2”W x 1-1/2”H (1830 x 38 x 38 mm)

Paint finish ..................................................................................................................................................... powder coat

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Walter M eier (Manufacturing) Inc., reserves the ri ght to change speci fications at any time and wi thout

prior notice, without incurring obligations.

6

Page 7

6.0 Setup and assembly

Open shipping cartons and check that all parts are

intact. Report any damage immediately to your

distributor. Read the instruction manual thoroughly

for assembly, alignment, and maintenance

instructions.

6.1 Tools required

1 #3 cross p oin t screwdr iver

1 7/16” wrench

1 1/2" wrench

1 Combinati on square & straight edge

1 1/4” h ex key

1 3/16” hex key

6.2 Shipping contents

1 XACT A Fence II

1 Front rail

1 Back rail

1 Guide tube

3 Black plastic end covers

1 Owner’s manual

1 Warranty registration card

1 Hardware package (p/n XF12DX-H P )*

contains:

7 Flat head screws, 1/4 x 1-1/2 (HP-1)

5 Hex cap screws, 1/4 x 1-1/2 (HP-2)

7 Hex cap screws, 1/4 x 3/4 (HP-3)

2 Hex cap screws, 5/16 x 3/4 (HP-4)

2 Flat washers, 5/16 (HP-5)

24 Flat washers, 1/ 4 (HP-6)

19 Lock washers 1/4 (HP-7)

12 H ex nuts 1/4 (HP-8)

* Hard ware package is shipped inside guide tube.

Contents a re shown full scale in Figure 1.

6.3 Front rail installation

1. Identify the front rail (A, Figure 2), which is

2-1/2" x 2-1/2" with notches on one side and

countersu nk mounting holes on th e other side.

Figur e 1

2. Lightly secure front rail (A) to table with seven

1/4 x 1-1/2 screws, flat washers, lock washers

and he x nuts (HP-1/6/7/8). Tighten just enough

to hold rail next to table but loose enough to

allow height adjustment.

Figur e 2

7

Page 8

The front rail must be low enough to clear the miter

gauge slot, and para llel to the table top:

1. Place an adjustable square on the table as

shown in Figure 3.

2. Check height of front rail at several locations

along the surface of the saw table. The front

rail must be parallel with table top.

3. When front rail has been correctly positioned,

use a screwdriver and 7/16" wrench to tighten

nuts securely. However, do not tighten

hardware for the farthest left hole; it should

remain loose to accommodate switch

installation (below).

Figur e 4

Figur e 5

Figur e 3

6.4 Switch installation

At this time refer to your JTAS-12DX Table Saw

man ual and mount the switc h as d escr ibed in the

Installing Switch section. The switch should be

mounted before the guide tube installation

described later in this manual.

6.5 Back rai l instal latio n

1. Locate the back rail which is 2" x 2" with holes

runn ing along one side on ly. Height of ba ck rail

when atta ched to the saw is not criti cal.

2. Align holes in back rail to holes in table top.

3. Secure back rail to pre-tapped holes in saw

table with two 5/16 screws and flat washers

(HP-4/5), as sh own in Figu re 4. Tighten screws

securely with 1/2" wrench.

4. Secure remainder of back rail with 1/4 screws,

flat washers, lock washers, and hex nuts (H P-

2/6/7/8) as shown in Figure 5.

5. Tighten all nuts.

6.6 Guide tube

Important: Before proceeding with guide tube

instal lation, the table saw switch should already be

installed. If not, refer to the Switch Installation

secti on in your JTAS -12-DX Saw manual.

Referring to Figure 6:

The guide tube (A) is placed on top of front rail (B)

and is mount ed with scale facing towar d operator .

1. Align holes in bottom of guide tube with holes

in front rail. When properly positioned, the

guide tube should extend beyond the front rail

about 6" in both directi ons.

2. Fasten guide tube (A) to front rail (B) from

beneath, with seven 1/4" screws, lock

washers, and flat washers (H P-3/6/7). Fingerti ghten onl y until all scr ews are inserted.

3. Tighten all screws with a 7/16" wrench.

8

Page 9

6.8 L eveling fence to saw t able

Place fence on ta ble and lock it.

1. View the fence from left side of saw (Figure 9).

Look for the space between the table and the

fence bottom to be equal along entire length of

fence (A, B, Figure 9).

Figur e 6

6.7 XACT A Fence

Screw knob into threaded handle on fence, as

shown in Figure 7.

Figur e 7

The lock lever has three functional positions as

shown in Figure 8:

Figur e 9

If adjustment is necessary:

2. Unlock fence.

3. Raise or lower two nylon adjustment screws

(D, Figure 10) the same number of turns until

the space between bottom of fence and table

is the same. Care must be taken to raise or

lower fence on each side equally or the fence

may not be 90° to the table after the height

adjustment i s perfor m ed.

Figur e 10

Figur e 8

1. Upright position permits mounting and removal

of fence from saw .

2. Unlock position permits ea sy fence positioning.

3. Lower position locks f ence to guide tube. The

cam handle should be pushed down firmly

against the pin.

6.9 Adjusting fence parallel to miter

slot

1. Place fence next to outside edge of right miter

slot and lock it.

2. Fence should be ev en with m iter slot from front

to back.

3. If fence is not even along length of miter slot,

unlock fence, remove it and turn it upside

down.

4. Adjust one of two setscrews (A, Figure 11)

unt il fence is even with miter slot edge along

its entire length when locked.

Note: You may need to re-adjust the clamping

pressure after aligning the fence.

9

Page 10

6.12 Cu rsor Adjustment

1. Disconnect sa w from power source.

2. Raise blade above t able top.

3. Unlock fence and slide it to approximately four

inches from blade.

4. Lock the fence.

5. Measure distance between saw blade and

inside of fence.

Figur e 11

6.10 Clampin g P ressure

The XACTA Fence has been adjusted by the

manufacturer to lock securely when lock handle is

pushed down. If adj ustment is needed:

1. Unlock fence.

2. Remove fence from guide tube and turn it

over.

3. Adjust each of two setscrews (A, Figure 11)

exactly the same number of rotations until the

fence is held securely when lock handle is

pushed down.

6.11 Ch ecki ng 90° to T able

1. Place fence on saw ta ble and lock it.

2. Place a square (A, Figure 12) on table next to

fence. The fen ce should be 90° to the table.

3. If adjustment is necessary, unlock fence and

turn one of two nylon adjustment screws (B,

Figure 12) until fence i s 90° to table.

4. Lock fence and check the adjustment again.

6. Adjust cursor (C, Figure 12) to read the

distance just measured, and tighten cursor

assembly to fence.

7. Make a tes t c ut and c onf irm the adjus tme nt is

correct.

Note: If the cursor does not have enough travel to

give the correct measurement, loosen guide rail

and adjust as needed. If you still do not get the

correct measurement, loosen front rail and adjust

as needed. If you have to adjust front rail you will

need to go through the front rail assembly

instructions again.

Cursor accuracy should be checked whenever a

dif ferent blade is installed.

Af ter installing the XA CTA Fence, pre ss the black

plastic end covers into the openings of the guide

rail . There is also an end co ver fo r the fe nce that

may already be inst alled.

Figure 12

10

Page 11

7.0 Repl acement Parts

Replacement parts are listed on the f ollowing pages. To order parts or reach our service department, call 1800-274-6848 Monday through Friday (see our website for business hours, www.jettools.com). Having the

Model Number and Serial Number of your machine available when you call will allo w us to s erve yo u quickly

and accur ate ly.

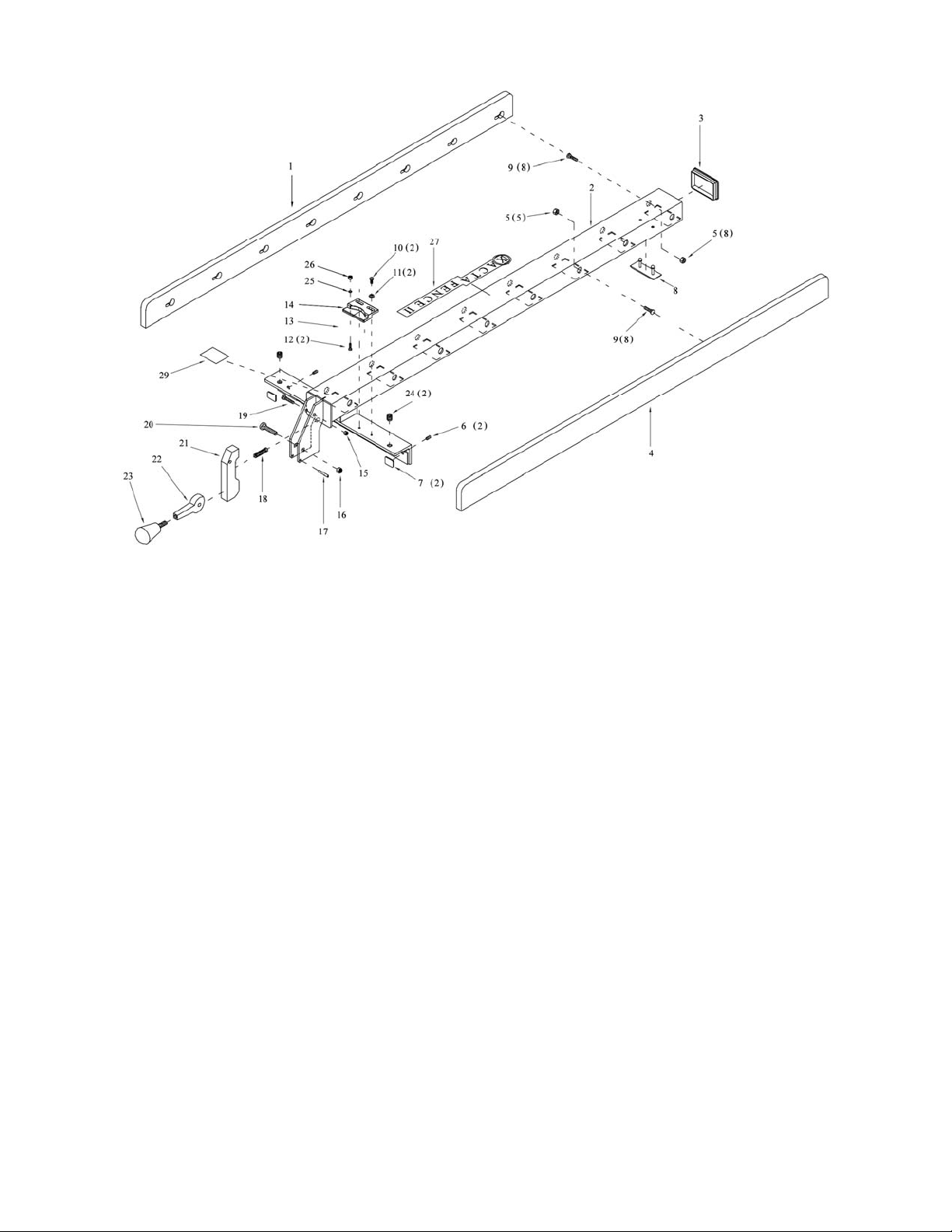

7.1.1 XACTA Fence Rail Assemb ly – Expl oded V iew

7.1.2 XACTA Fence Rail Assemb ly – Part s List

Index No Part No Description Size Qty

....................708956Z...................... XACTA Rail Assembly 50” (index # 1-13) ................ ........................................ 1

1..................XF12DX-201............... Front Rail ..................................................................... ........................................ 1

2..................TS-081F081 ............... Flat Head Screw ......................................................... 1/4”-20 × 1-1/2”.............. 7

3..................TS-0680021................ Flat Washer ................................................................. 1/4” ............................... 24

4..................TS-0720071................ Lock Washer ............................................................... 1/4” ............................... 19

5..................TS-0561011................ Hex Nut ....................................................................... 1/4”-20 .......................... 12

6..................TS-0050031................ Hex Cap Screw ........................................................... 1/4”-20 × 3/4” ................. 7

7..................XF2-207 ...................... Scale............................................................................ 50” .................................. 1

8..................XF2-208 ...................... Guide Rail ................................................................... 50” .................................. 1

9..................XF12DX-209............... Rear Rail ..................................................................... 50” .................................. 1

10................XF2-210 ...................... Guide Cover ................................................................ ........................................ 2

11................TS-0081031................ Hex Cap Screw ........................................................... 5/16”-18 × 3/4” ............... 2

12................TS-0050071................ Hex Cap Screw ........................................................... 1/4”-20 × 1-1/2”.............. 5

13................TS-0680031................ Flat Washer ................................................................. 5/16” ............................... 2

....................XF12DX-HP................ Hardware Package (index # 2-6 and 11-13) ............ ...........................................

11

Page 12

7.2.1 XACTA Fence Assembly – Exploded View

7.2.2 XACTA Fence Assemb l y – P art s List

Index No Part No Description Size Qty

....................708955Z...................... XACTA Commercial Fence 40” (index # 1-29)......... ........................................ 1

1..................XF12DX-101............... Left Side Plate ............................................................ ........................................ 1

2..................XF12DX-102............... Fence Body Assembly ............................................... ........................................ 1

3..................XF2-103 ...................... Tube Cover ................................................................. ........................................ 1

4..................XF12DX-104............... Right Side Plate .......................................................... ........................................ 1

5..................TS-0640071................ Lock Nut ...................................................................... 1/4” × 20....................... 16

6..................TS-0271031................ Socket Set Screw ....................................................... 3/8”-16 × 3/8” ................. 2

7..................3575081 ...................... Fluoroway Pad ............................................................ ........................................ 2

8..................XF-8A .......................... Pad .............................................................................. ........................................ 1

9..................TS-0151011................ Carriage Bolt ............................................................... 1/4”-20 × 3/4” ............... 16

10................TS-081D022 ............... Pan Head Machine Screw ......................................... 10-32 × 3/8” ................... 2

11................TS-0680021................ Flat Washer ................................................................. 1/4” ................................. 2

12................TS-081D021 ............... Flat Head Machine Screw.......................................... 10-32 × 3/8” ................... 2

13................800708950D ............... Cursor .......................................................................... ........................................ 1

14................800708950C ............... Cursor Bracket ............................................................ ........................................ 1

15................TS-0640071................ Lock Nut ...................................................................... 1/4” × 20......................... 1

16................TS-0640081................ Lock Nut ...................................................................... 5/16”-18.......................... 1

17................XF2-117 ...................... Spring Pin.................................................................... 4 × 28mm ....................... 1

18................6813042 ...................... Compression Spring ................................................... ........................................ 1

19................TS-0151041................ Carriage Bolt ............................................................... 1/4”-20×1-1/2”................ 1

20................TS-0152031................ Carriage Bolt ............................................................... 5/16”-18 × 1-1/2” ........... 1

21................3215301 ...................... Foot Cam..................................................................... ........................................ 1

22................3076232 ...................... Lock Cam .................................................................... ........................................ 1

23................6430055 ...................... Knob w/stud ................................................................ ........................................ 1

24................XF-5 ............................ Nylon Adjustment Screw ............................................ 1/2” × W12 ..................... 2

25................TS-0680021................ Flat Washer ................................................................. 1/4” ................................. 2

26................TS-0560081................ H ex Nut ....................................................................... 10-32 .............................. 2

27................XF-27 .......................... XACTA Fence II Label ............................................... ........................................ 1

29................XF-29 .......................... JET Label .................................................................... ........................................ 1

12

Loading...

Loading...