Page 1

Operating Instructions and Parts Manual

Drum Sander

Model: 10-20 PLUS

(shown with optional accessories)

WMH Tool Group

2420 Vantage Drive

Elgin, Illinois 60123 Part No.: M-628900

Phone: 800-274-6848

www.wmhtoolgroup.com Copyright © WMH Tool Group

Revision: B 11/03

Page 2

This manual has been prepared for the owner and operators of a Performax 10-20 Drum Sander. Its

purpose, aside from machine operation, is to promote safety using accepted operating and maintenance

procedures. To obtain maximum life and efficiency from your Drum Sander and to aid in using it safely,

please read this manual thoroughly and follow instructions carefully.

Warranty & Service

WMH Tool Group warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Repair Stations located throughout the United States can provide quick service or information.

In most cases, a WMH Tool Group Repair Station can assist in authorizing repair work, obtaining parts, or

perform routine or major maintenance repair on your Performax product.

For the name of an Authorized Repair Station in your area, please call 1-800-274-6848, or visit our web

site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group is consistently adding new products to the line. For complete, up-to-date

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that its products meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from

defects in materials and workmanship as follows: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS

UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or indirectly to

misuse, abuse, negligence or accidents, normal wear-and-tear, repair or alterations outside our facilities,

or to a lack of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP

BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanation of the complaint must accompany the merchandise. If our inspection discloses a defect, we

will either repair or replace the product at our discretion, or refund the purchase price if we cannot readily

and quickly provide a repair or replacement. We will return the repaired product or replacement at WMH

Tool Group’s expense, but if it is determined there is no defect, or that the defect resulted from causes

not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and

returning the product. This warranty gives you specific legal rights; you may also have other rights, which

vary from state to state.

WMH Tool Group sells through distributors only. Members of the WMH Tool Group reserve the right to

effect at any time, without prior notice, alterations to parts, fittings and accessory equipment, which they

may deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty & Service.................................................................................................................................... 2

More Information.................................................................................................................................... 2

WMH Tool Group Warranty ................................................................................................................... 2

Table of Contents ...................................................................................................................................... 3

Introduction................................................................................................................................................6

Specifications ............................................................................................................................................6

Grounding Instructions ..............................................................................................................................7

115 Volt Operation ................................................................................................................................. 7

Contents of the Shipping Carton ............................................................................................................... 8

Unpacking.................................................................................................................................................. 8

Assembly and Setup.................................................................................................................................. 8

Performax 10-20 Accessories................................................................................................................ 8

On/Off Switch......................................................................................................................................... 9

Switch Lock ........................................................................................................................................ 9

Circuit Breaker ....................................................................................................................................... 9

Conveyor Belt Tracking........................................................................................................................ 11

Conveyor Belt Tension.........................................................................................................................11

Drum Height Control ............................................................................................................................ 11

Checking Drum Alignment ................................................................................................................... 12

Aligning the Drum ................................................................................................................................12

Fine Tuning Drum Alignment ...............................................................................................................12

Wrapping Abrasive Strips ....................................................................................................................13

Using the TUF ToolTM.......................................................................................................................... 14

Connecting Sander to a Dust Collector ...............................................................................................15

Setting the Depth Gauge ..................................................................................................................... 15

Setting the Depth of Cut.......................................................................................................................15

Establishing the Proper Drum Height ..................................................................................................15

Abrasives................................................................................................................................................. 16

Selecting Drum Abrasives....................................................................................................................16

Selecting Abrasive Grits....................................................................................................................... 16

Cleaning Abrasive Strips......................................................................................................................16

Stretching Abrasive Life ....................................................................................................................... 16

Performax 10-20 Abrasives ................................................................................................................. 17

Ready-to-Wrap ................................................................................................................................. 17

Ready-to-Cut (Aluminum oxide).......................................................................................................17

Ready-to-Cut “Blue” (longer life) ...................................................................................................... 17

Stock Feeding Angle ...............................................................................................................................17

Multiple-Piece Sanding Runs .................................................................................................................. 17

Edge Sanding ..........................................................................................................................................17

Sanding Imperfect Stock .........................................................................................................................17

Face Frames and Raised Panel Doors ................................................................................................... 17

Monthly Maintenance ..............................................................................................................................17

Conveyor Belt Replacement ................................................................................................................ 18

Tension Roller Alignment..................................................................................................................... 18

Tension Roller Pressure Adjustment ................................................................................................... 18

Drum Height Control Adjustment .........................................................................................................18

Troubleshooting Guide ............................................................................................................................ 19

Exploded View – 10-20 PLUS Sander ....................................................................................................20

Parts List for the 10-20 PLUS Sander .................................................................................................21

Wiring Diagram........................................................................................................................................ 23

3

Page 4

Warnings

1. Read and understand the entire owners manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply

with all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This drum sander is designed and intended for use by properly trained and experienced

personnel only. If you are not familiar with the proper and safe operation of a drum sander, do not

use until proper training and knowledge have been obtained.

5. Do not use this machine for other than its intended use. If used for other purposes, WMH Tool

Group disclaims any real or implied warranty and holds itself harmless from any injury that may

result from that use.

6. Always wear approved safety glasses/face shields while using this machine. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses.

7. Before operating this machine, remove tie, rings, watches and other jewelry, and roll sleeves up

past the elbows. Remove all loose clothing and confine long hair. Non-slip footwear is

recommended.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. This drum sander is to be used with wood and wood products only. Use of this drum sander and

a dust collector with metal products is a potential fire hazard.

10. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

11. Do not operate this sander while tired or under the influence of drugs, alcohol or any medication.

12. Make certain the switch is in the OFF position before connecting the machine to the power

supply.

13. Always sand with the grain of the wood.

14. Always feed stock against the rotation of the drum.

15. Do not sand pieces of material that are too small to be safely supported.

16. When sanding a large piece, provide additional support at table height.

17. Always connect and use a dust collector to the drum sander while operating.

18. Make certain the machine is properly grounded.

19. Make all machine adjustments or maintenance with the machine unplugged from the power

source.

20. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

21. Keep machine guards in place at all times when the machine is in use. If removed for

maintenance purposes, use extreme caution and replace the guards immediately.

22. Make sure the drum sander is firmly secured to the stand or bench before use.

23. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function – check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

24. Provide for adequate space surrounding work area and non-glare, overhead lighting.

25. Keep the floor around the machine clean and free of scrap material, oil and grease.

26. Keep visitors a safe distance from the work area. Keep children away.

27. Make your workshop child proof with padlocks, master switches or by removing starter keys.

28. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play”

are careless acts that can result in serious injury.

4

Page 5

29. Stand to one side of the conveyor and make sure no one else is standing in line with the

conveyor while feeding into the machine. The drum sander operates at high speed and should a

part slip, it will exit the machine at a high rate of speed and may result in injuries to anyone

standing directly in front of the infeed. (Keep the conveyor belt clean and check pin-roll

adjustments). Maintain a balanced stance at all times so that you do not fall or lean against the

sanding drum or other moving parts. Do not overreach or use excessive force to perform any

machine operation.

30. Use the right tool. Don’t force a tool or attachment to do a job for which it was not designed. The

right tool will do the job better and safer at the rate for which it was designed.

31. Use recommended accessories; improper accessories may be hazardous.

32. Maintain tools with care. Keep tools sharp and clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

33. Never brush away sawdust while the machine is running. Use the correct speed and feed for the

tool. Be sure that the tool is the correct one for your operation.

34. Never stand on a machine. Serious injury could occur if the machine tipped or if the sanding drum

is unintentionally contacted.

35. Never leave the machine running unattended. Turn the power off and don’t leave the machine

until it comes to a complete stop.

36. All doors should be closed, all panels replaced and other safety guards should be in place before

the machine is started or operated.

37. Keep your hands clear when feeding parts onto the conveyor. The part will be forced down as it

begins to feed into the machine, causing a pinching action between the part and the table. Use

caution! Hands should be clear of the stock and the table to avoid pinching. Never reach into a

running machine. Turn off the electrical power and stop the machine before attempting to retrieve

parts from within it. Keep your hands away from the sanding area. Contact with internal moving

parts can result in the loss or injury to fingers, hands and arms.

38. Remove loose items and unnecessary work pieces from the area before starting the machine.

• ADDITIONAL INFORMATION regarding the safe and proper operation of this product is available

from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201, in the Accident

Prevention Manual for Industrial Operations and in the safety Data Sheets provided by the NSC.

Please also refer to the American National Standards Institute ANSI 01.1 Safety Requirements for

Woodworking Machinery and the U.S. Department of Labor OSHA 1910.213 Regulations.

Warnings

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by Performax covering the safe operation and maintenance procedures for a Model

10-20 Plus Drum Sander. This manual contains instructions on installation, safety precautions, general

operating procedures, maintenance instructions and parts breakdown. This machine has been designed and

constructed to provide years of trouble free operation if used in accordance to instructions set forth in this

manual. If there are any questions or comments, please contact either your local supplier or WMH Tool

Group. WMH Tool Group can also be reached at our web site: www.wmhtoolgroup.com.

Specifications

Stock Number ..................................................................................................................................... 628900

Max. Width (in) .....................................................................................................................20 (Two Passes)

Min. Length (in) ....................................................................................................................................... 2-1/4

Max. Thickness (in) ....................................................................................................................................... 3

Min. Thickness (in) ................................................................................................................................... 1/32

Drum (in) ...............................................................................................................5 x 10 Extruded Aluminum

Drum Speed (RPM)................................................................................................................................. 1700

Dust Chute (in) .............................................................................................................................................. 4

Conveyor Motor.....................................................................................43 inch-lb Torque, Direct Drive, D.C.

Conveyor Variable Feed Rate (FPM)....................................................................................................... 0-12

Motor (TEFC) ................................................................................................................1 HP, 1Ph, 115V only

Net Weight (lbs) .......................................................................................................................................... 74

The specifications in this manual are given as general information only, and they are not binding. WMH

Tool Group reserves the right to effect, at any time and without prior notice, changes or alterations to

parts, fittings and accessory equipment deemed necessary for any reason whatsoever.

6

Page 7

Grounding Instructions

This tool must be grounded while in use to protect the operator from electric

shock.

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The

conductor, with insulation having an outer surface that is green with or without yellow stripes, is the

equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is properly grounded. Use only three wire extension cords

that have three-prong grounding plugs and three-pole receptacles that accept the tool’s plug.

Repair or replace a damaged or worn cord immediately.

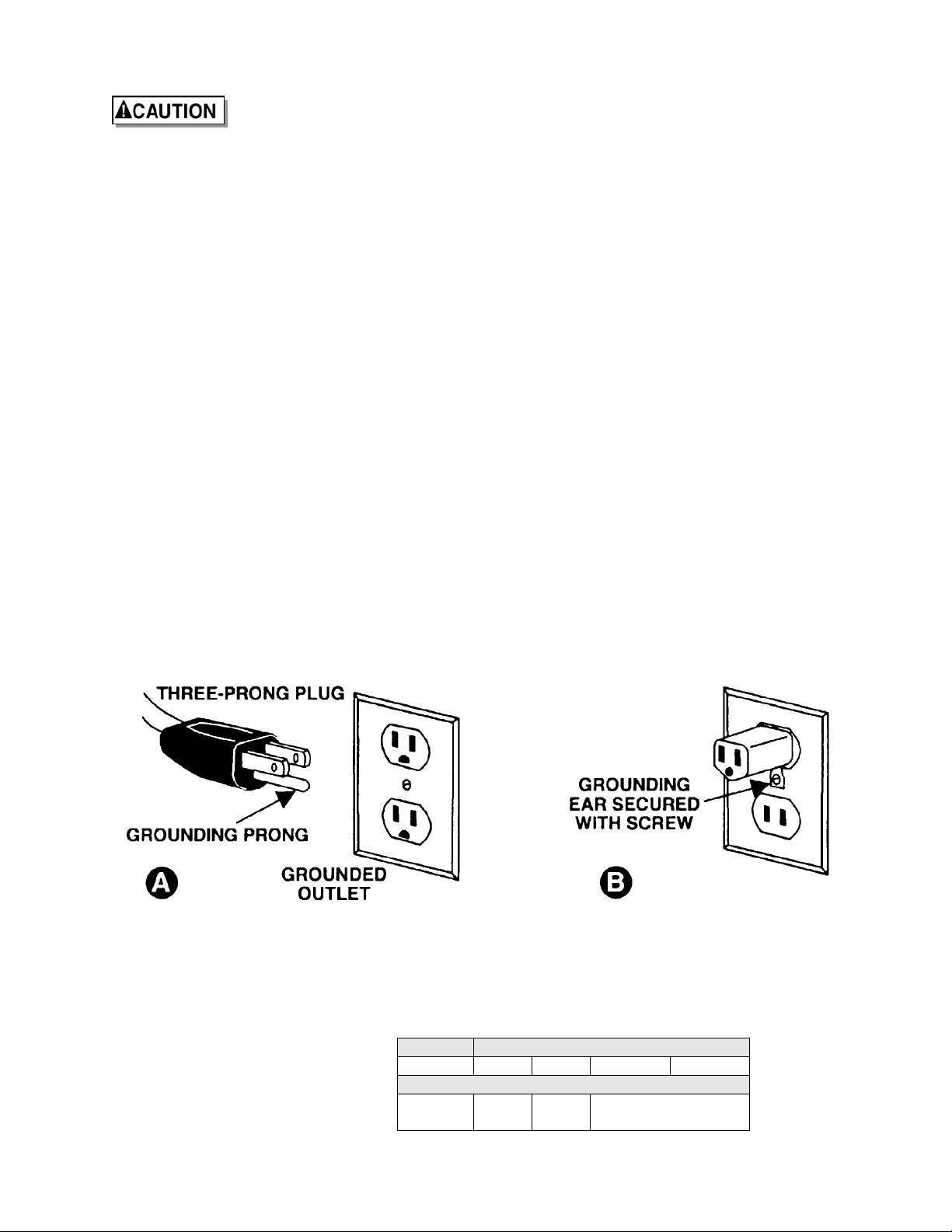

115 Volt Operation

As received from the factory, your sander is ready to run at 115-volt operation. This sander, when wired

for 115 volts, is intended for use on a circuit that has an outlet and a plug that looks the one illustrated in

Figure A. A temporary adapter, which looks like the adapter as illustrated in Figure B, may be used to

connect this plug to a two-pole receptacle, as shown in Figure B if a properly grounded outlet is not

available. The temporary adapter should only be used until a properly grounded outlet can be installed by

a qualified electrician. This adapter is not applicable in Canada. The green colored rigid ear, lug, or

tab, extending from the adapter, must be connected to a permanent ground such as a properly grounded

outlet box, as shown in Figure B.

The use of an extension cord is not recommended. However, if you must use one make sure your

extension cord is in good condition. Be sure to use one heavy enough to carry the current your machine

will draw. An undersized cord will cause a drop in the line voltage resulting in power loss and overheating.

The following table shows the correct size to use depending on the cord length needed and the

nameplate ampere rating. If in doubt, use the next heavier gauge. Remember, the smaller the gauge

number, the heavier the cord.

Volts Total Length of Cord in Feet

120V 25 50 100 150

AWG

12-16

Amps

14 12 Not Recommended

7

Page 8

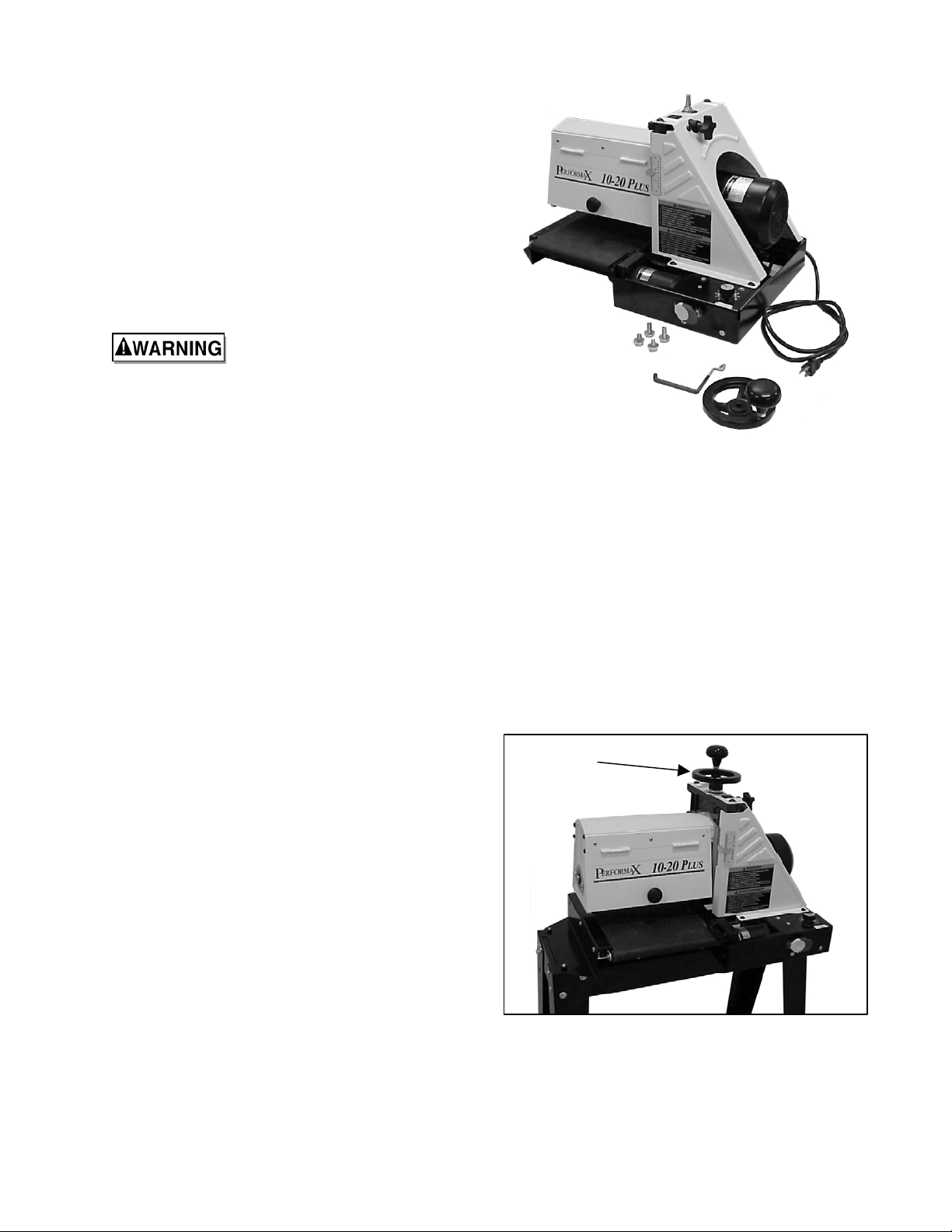

Contents of the Shipping Carton

A

1. Sander Assembly

1. Handwheel with Handle

1. TUF Tool

1. Abrasive Strip (wrapped on the drum)

1. Conveyor Belt (attached to the base)

1. Owner's Manual

1. Warranty Card

1. Hardware Bag (for attaching the Sander

to the Optional Open Stand) —

containing:

4. 3/8”-16x5/8” Hex Cap Screws

4. 3/8” Flat Washers

Read and understand the

entire contents of this manual

before attempting assembly or

operation of this drum sander.

Failure to comply may cause

serious injury.

Unpacking

1. Remove all the contents from the

shipping carton.

2. Report any damage to your distributor.

3. Do not discard any shipping material

until the sander has been assembled

and is running properly.

Assembly and Setup

If you purchased the optional Performax 10-20

Stand, refer to its assembly instructions before

proceeding with the drum and conveyor

assembly. Note: The figures shown in this

manual may display the Performax 10-20-Plus

Drum Sander with several optional accessories.

To purchase any of these accessories contact

your dealer.

1. Attach the handwheel (Figure 1, Item A)

to the height adjustment screw and

tighten.

Performax 10-20 Accessories

Stock # Description

638004 Open Stand with Shelf

608005 Infeed/Outfeed Tables

98-0130 Caster Set (4) for Open Stand

60-0505 Abrasive cleaning stick

Figure 1

8

Page 9

A

On/Off Switch

Before powering up the unit,

make sure all of the tools

used to assemble and adjust

the unit are removed and

accounted for. Make sure

your hands, loose clothing

and any other items that may

get caught are safely away

from the unit.

The On/Off Switch (Figure 2, Item A) is located

on the front of the sander. To turn the sander on,

pull the switch to the on position. To turn the

sander off, push the switch to the off position.

Switch Lock

The sander can be locked from unauthorized

use by locking the switch. To lock the switch:

1. Turn the switch to the off position and

disconnect the sander from the power

source.

2. Pull the key (Figure 2, Item B) out. The

switch cannot be turned on with the key

removed.

Should the key be removed

from the switch in the on

position, the switch can be

turned off but cannot be

turned back on.

3. To replace the key, slide the key into the

slot on the switch until it snaps.

Circuit Breaker

The sander is equipped with a motor protective

device (circuit breaker). The breaker will

automatically shut the sander off when

excessive current is consumed.

If the breaker is tripped, turn the sander off and

reset the circuit breaker by pressing the button

(Figure 2, Item C).

Be sure to turn the sander off

before resetting the circuit

breaker to avoid

unintentionally starting the

sander

B C

Figure 2

9

Page 10

This Page Intentionally Left Blank

10

Page 11

A

Conveyor Belt Tracking

Belt tracking adjustment may be necessary

during the break-in period and normal operation

to compensate for belt stretching.

Abrasive belt tension must be properly adjusted

before adjusting the tracking. Adjust the belt

tracking while the conveyor belt is running at its

fastest speed.

Tighten the hex nut (Figure 5, Item B) on the

side the belt is drifting towards, and loosen the

hex nut on the opposite side. Use the attached

wrenches (Figure 5, Item C) to adjust the hex

nuts.

Note: Adjustment should be made in 1/4 turns of

the hex nut. Allow time for the belt to react to the

adjustment. Do not over adjust.

Conveyor Belt Tension

Conveyor belt tension adjustment may be

necessary during the break in period to

compensate for belt stretching.

If the conveyor belt can be stopped by hand

pressure applied directly to the top of the

conveyor bed, the belt is too loose. Insufficient

belt tension will cause slippage of the conveyor

belt on the drive roller during sanding

operations.

Excessive belt tension can cause tracking

problems and result in bent rollers, bent take-up

brackets and premature conveyor belt wear.

Adjust the hex nuts (Figure 5, Item B) on both

sides of the conveyor to obtain a tight, and

equally tensioned, conveyor belt. Use the

attached wrenches (Figure 5, Item C) to adjust

the hex nuts.

Drum Height Control

Drum height is controlled by the height

adjustment handle (Figure 5, Item A). Turning

the handwheel in a counterclockwise direction

lowers the drum.

Turning the height adjustment handwheel one

revolution lowers the drum approximately 1/16”.

C

B

Figure 5

11

Page 12

Checking Drum Alignment

The sanding drum comes preset from the

factory. If a problem with the drum alignment

occurs, follow the instructions listed below.

1. Lift the knob (Figure 6, Item A) to open the

dust cover and remove the abrasive strip. If

you are unsure how to do this, see the

“Wrapping Abrasive Strips” section in this

manual.

2. Using a metal straight edge, or ruler, as a

thickness gauge (Figure 6, Item B), insert

the gauge between the drum and the

conveyor bed on the outer end of the drum.

3. Open the dust cover and lower the sanding

drum while slowly rotating the drum by hand

until the drum lightly contacts the thickness

gauge.

4. Remove the thickness gauge and place it

under the drum at the opposite end. If the

drum does not contact the thickness gauge

to the same degree as the other end of the

drum, alignment is necessary.

Aligning the Drum

1. Loosen the two hex cap bolts (Figure 7, Item

C).

2. Lay the thickness gauge under the drum

lengthwise.

3. Adjust the knob, (Figure 7, Item D) until the

drum contacts the gauge equally along its

entire surface. Turn the adjusting knob

clockwise to lower the outboard end of the

drum, and counterclockwise to raise the

outboard end of the drum.

4. When the drum is parallel to the conveyor,

tighten the two hex cap bolts.

Fine Tuning Drum Alignment

When sanding boards wider than the drum,

drum alignment is critical and must be adjusted

slightly higher on the outboard end. This will

prevent any ridges from developing in the stock.

Always check it on a piece of scrap wood, as

follows, before sanding the work piece.

Run a piece of scrap wood approximately 6”

wide by 16” to 18“ long through the sander

sideways so that the end of the board extends

past the end of the drum.

Turn the board 180 degrees and sand the same

side without changing the sanding height.

If a ridge is visible where the drum overlaps,

loosen the two hex cap bolts (Figure 7, Item C)

and turn the adjusting knob (Figure 7, Item D)

slightly. Turn the adjusting knob clockwise to

lower the outboard end of the drum and

counterclockwise to raise it. Tighten the two hex

cap bolts. Repeat this process until the ridge is

gone and the entire board is sanded.

A

B

Figure 6

D

C

Figure 7

12

Page 13

Wrapping Abrasive Strips

Note: When using Performax “Ready to Wrap”

and “Ready to Cut” abrasives, not all of the

steps below are necessary. You can use the

original abrasive belt that came with the sander

as a template for cutting your own strips.

1. Mark and cut a taper at one end of the

roll, as shown in Figure 8.

2. Square off the end of the taper, as

shown in Figure 8.

3. Squeeze the fastener lever (Figure 9,

Item A) on the outboard end of drum,

and insert the tapered end of the

abrasive (Figure 9, Item B) so that it

uses most of the width of the slot.

Release the fastener lever to securely

hold the strip end to the fastener.

4. The square edge of the abrasive strip

should follow the edge of the drum, as

shown in Figure 9.

5. Wrap the abrasive strip around the

drum, being careful not to overlap the

windings, as shown in Figure 10.

6. Mark the trailing end of the strip where it

crosses the inboard end of drum (Figure

11, Item C).

7. Remove the abrasive strip and cut a

taper as was done with the starting

edge, (See Figure 8). Note: The taper

on the remaining roll can be used as the

taper for the starting edge of the next

strip to be cut.

8. Rewrap the drum starting at the left side

as described in steps 3-5.

9. Squeeze the fastener lever on the

inboard end of the drum, and insert the

tapered end of the abrasive strip

through the slot into the take-up

fastener.

Position the abrasive strip

with sufficient room between

the inside of the slot and the

tapered end of the strip to

allow it to be pulled into the

drum as needed, (See Figure

12).

Figure 8

A

B

Figure 9

Figure 10

C

13

Figure 11

Page 14

Using the TUF ToolTM

The Tuf Tool (Figure 13)

can also be used to hold

the take-up fastener in

place while you feed the

sandpaper through the

slot.

Figure 13

1. Clip the sandpaper into the outboard

fastener. Wrap the drum, being careful

not to overlap the windings. Hold the

sandpaper over the inboard slot with the

left hand.

2. Hold the TUF Tool with the red end of

the tool pointing away from you (Figure

14). Insert the hook into the hole in the

end of the take-up lever of the fastener

(Figure 14).

3. Lift the lever with the TUF Tool, pulling

the lever up until it touches the inside of

the drum. Turn the TUF Tool

counterclockwise and lower it onto the

sandpaper, making sure it is holding the

sandpaper tight and opening the throat

of the fastener (Figure 15).

4. Insert the tapered end of the paper into

the slot and the fastener. It may be

necessary to trim the tapered end of the

paper so it does not “bottom out” against

the inside of the drum. Be sure to leave

a gap of at least 1/8” between the

tapered strip and the closed end of the

slot to allow the strip to be pulled into

the fastener as needed (Figure 15). If

necessary trim the outside edge of the

paper.

5. Hold the sandpaper in place with your

left hand. Rotate the drum toward you

slightly. Pull up on the TUF Tool and

turn the handle clockwise while

maintaining upward pressure. Slowly

move the TUF Tool away from you

slightly, then down, while easing it out of

the hole. This releases the lever into its

proper position. (Figure 16).

All abrasive strips will stretch with use and may

stretch enough to allow the take-up lever to

reach its lowest position so it cannot maintain

tension on the strip. If this occurs, follow the

above procedures to reset the take-up lever.

Figure 12

Figure 14

Figure 15

14

Figure 16

Page 15

Connecting Sander to a Dust Collector

Dust collection is necessary for all drum

sanders. The Performax 10-20 is equipped with

a 4” dust collection port in the back of the dust

cover, and is designed to be used with a

standard dust collector as shown in Figure 17.

JET offers a variety of Dust Collectors and Air

Filtration Units that will work nicely with your

new sander. Contact your local distributor for

more information.

Setting the Depth Gauge

The depth gauge indicates the distance from the

bottom of the drum to the top of the conveyor.

1. Lower the drum, with the sandpaper

installed, until it touches the conveyor.

2. Loosen the screw (Figure 18, Item B).

3. Adjust the pointer (Figure 18, Item C) to

read zero and tighten the screw.

Note: depending on the desired accuracy, you

may need to repeat this process when installing

different sandpaper grits.

Setting the Depth of Cut

Adjusting the Performax 10-20 for proper

contact between the abrasive and the stock is

the most important set-up procedure before

operating the sander. It may take some

experimentation to determine the proper depth

of cut, given the variables of abrasive grit and

types of wood. For best results, use scrap wood

to practice sanding and to develop your skills

and familiarity with the machine before doing

any finish work.

A good rule of thumb when sanding with grits

finer than 80 is lower the drum so that it contacts

the work piece but can still be rotated by hand.

When using grits coarser than 80 grit, you can

lower the drum slightly more. However, a

combination of several variables will determine

the proper depth of cut to use, including the

following:

• Abrasive type and grit size.

• Width of the piece being sanded.

• Hardness of the piece being sanded.

• Feed rate of the piece being sanded.

Establishing the Proper Drum Height

To establish the proper drum height, place the

board to be sanded under the drum and lower

the drum until it just touches the board. Note:

The sanding drum should still rotate by hand.

Without changing the drum height, finish feeding

the stock under the sander. Start the sanding

drum and sand the board at that same position.

Figure 17

B

C

Figure 18

15

Page 16

Abrasives

The abrasive material you choose will have a

substantial effect on the performance of your

sander. Variations in paper type, weight, coating

and durability all contribute to achieving your

desired finish. For the best sanding results,

Performax offers premium abrasives that have

been tested and certified for lowest overall cost

and maximum performance. Genuine Performax

abrasives are available in pre-cut “Ready- toWrap” lengths or in the convenient pre-marked

“Ready-to-Cut” box.

Selecting Drum Abrasives

To achieve maximum sanding results, it is

important to select the proper grit of abrasive for

the type of sanding being performed. As with

any sanding operation, first begin sanding with a

coarser grit, depending on the roughness of the

stock, or the amount of stock to be removed.

Then progressively work toward finer grits. The

chart below shows the general uses for the

various grits. Performax offers strip rolls in the

nine different abrasive grits shown.

Grit Common Application

Abrasive planing, surfacing rough-

24 Grit

36 Grit

60 Grit

80 Grit

100 Grit

120 Grit Light surfacing, minimal stock removal.

150 Grit Finish sanding, minimal stock removal.

180 Grit

220 Grit

Selecting Abrasive Grits

The amount of stock to be removed is a major

consideration when choosing the grit grade to

start with. Grits of 24, 36, 50, 60 and 80 are

primarily designed for stock removal. Grits of 24

and 36 will remove the most material in one

sawn boards, maximum stock

removal, glue removal.

Abrasive planing, surfacing rough

sawn boards, maximum stock

removal, glue removal.

Surfacing and dimensioning boards,

truing warped boards

Surfacing, light dimensioning,

removing planer ripples.

Light surfacing, removing light planer

ripples.

Finish sanding only, not for stock

removal.

Finish sanding only, not for stock

removal.

pass, whether you are doing abrasive planing,

cleaning up glued panels or flattening stock.

Grits from 100 through 220 are primarily

finishing grits designed to remove the scratch

pattern from the previous grit used. For best

results, never skip more than one grit grade

when progressing through a sanding sequence.

For fine work, such as furniture, try not to skip

any grit grades during the sanding process. In

general, premium quality abrasives such as

genuine Performax abrasives will produce a

better finish with a less noticeable scratch

pattern. Note: Grits that are too fine can

sometimes burnish the wood and leave a glossy

surface that will not accept stains evenly. This

will vary by the type of wood. Oak, for example,

is susceptible to burnishing because of its open

pores.

Cleaning Abrasive Strips

A sandpaper cleaning stick may be used to

remove deposits and help extend sandpaper life.

To use, operate the sanding drum with the dust

cover open.

For your own safety, always

wear eye protection while

performing sandpaper

cleaning, and take all

precautions to avoid any

contact of hands or clothing

with uncovered drums. Hold

the cleaning stick against the

rotating drum and move it

along the drum surface. It is a

good idea to use a shop brush

or air nozzle to remove any

cleaning stick crumbs from

the drums before resuming

sanding operations.

Cloth-backed abrasives can be cleaned by

soaking in paint thinner or mineral spirits for 20

minutes to one hour. Then use a nylon brush to

remove any buildup.

Stretching Abrasive Life

Abrasive life can also be increased by removing

the abrasive strip from the drum and reversing it.

To do this, remove the strip and use what was

the trailing end as the starting end on the left

(outboard) side of the drum. Reversing the strip

will provide a fresh set of cutting edges on the

drum.

16

Page 17

Performax 10-20 Abrasives

“Ready-to-Wrap” 24-220 Grit contains six precut wraps.

Ready-to-Wrap

60-1024 ............24 Grit 60-1120 ............120 Grit

60-1036 ............36 Grit 60-1150 ............150 Grit

60-1060 ............60 Grit 60-1180 ............180 Grit

60-1080 ............80 Grit 60-1000 ............220 Grit

60-1100 ............100 Grit

Ready-to-Cut (Aluminum oxide)

60-9036 ............36 Grit 60-9120 ............120 Grit

60-9060 ............60 Grit 60-9150 ............150 Grit

60-9080 ............80 Grit 60-9180 ............180 Grit

60-9100 ............100 Grit 60-9220 ............220 Grit

Ready-to-Cut “Blue” (longer life)

60-8024 ............24 Grit 60-8080 ............80 Grit

60-8036 ............36 Grit 60-8100 ............100 Grit

60-8050 ............50 Grit 60-8120 ............120 Grit

60-8060 ............60 Grit

Stock Feeding Angle

The optimum stock feeding angle, when

sanding, is at a 60-degree angle. However, even

a slight stock feeding angle will provide more

effective stock removal, less loading of

abrasives, longer abrasive life, potentially faster

feed rates and reduced motor loads.

When finish sanding, the work piece should be

fed through in line with the grain on the final one

or two passes for the optimum finish.

Multiple-Piece Sanding Runs

When abrasive planing (or thickness sanding) a

run of similar pieces that you want to have the

same thickness, it is best to sand all the pieces

at the same time. This way you will be able to

determine the thickness of the thinnest piece

and process all pieces to that same thickness.

Be aware that the sander will remove cups and

crowns in the work piece; consider this when

measuring the processing stock to the same

thickness.

Edge Sanding

When edge sanding, the Performax sander will

mimic the opposite edge of the stock which is

lying on the conveyor belt. Because of this, it is

important for the stock edge to have been ripped

at the proper angle to the face before the

sanding process. When edge sanding stock that

is less than 3/4” wide, or more than 2” high, it is

good procedure to stack and clamp several

pieces together to prevent them from slipping, or

tipping.

Sanding Imperfect Stock

When sanding stock with a cup or crown, place

the crown up. This will stabilize the stock to help

prevent tipping or rocking during sanding. (After

the crown has been removed and the top is flat,

turn the stock over and sand the opposite side.)

To avoid personal injury, take special care when

sanding stock that is twisted, bowed or

otherwise varies in thickness from end to end. If

possible, support such stock as it is being

sanded to keep it from slipping, or tipping. Use

extra roller stands, help from another person, or

hand pressure on the stock to minimize

potentially hazardous situations.

Face Frames and Raised Panel Doors

It is very important to have the proper abrasive

contact when doing this type of sanding. If the

sander is set to take an excessive depth of cut,

the result can be a gouge, or dip as the drum

goes from sanding the rails at full width to

sanding just a few inches of width on the stiles.

To prevent this problem, make sure that when

using abrasives finer then 80 grit, the drum is in

contact with the wood but can still be spun by

hand.

Monthly Maintenance

For best results, perform the following

recommended maintenance procedures on a

monthly basis:

• Lubricate the conveyor bushings and

check for wear.

• Lubricate all moving parts, such as

threaded rods, washers and bushings.

• Clean the sawdust from the conveyor

belt and sanding drum.

• Blow the dust from the motors and

switches. Blow the dust from the inside

of the sanding drum to prevent vibration.

Be careful not to disturb the drum

balancing weights.

• Check all the setscrews for tightness on

parts such as bearings, the conveyor

and couplings.

17

Page 18

Conveyor Belt Replacement

A

To replace the conveyor belt:

1. Disconnect the machine from the power

source.

2. Raise the drum to its highest position using

the handwheel (Figure 19, Item A).

3. Remove the belt tension by loosening both

take-up nuts (Figure 19, Item B).

4. Unscrew the three screws (Figure 19, Item

C) that attach the conveyor to the bracket.

5. Unbolt the two hex head bolts (Figure 19,

Item D) that hold the bracket to the bench or

stand.

6. Slide the conveyor belt off the conveyor and

replace it with a new belt.

7. Reverse the procedure for installation.

Tension Roller Alignment

1. Remove the abrasive strip (Figure 20 Item

E) from the drum.

2. Loosen the two bearing hex nuts (Figure 20,

Item F) on the outboard side of the drum

and two cap screws on the inboard side

(Figure 20, Item G).

3. This will allow the tension rollers to drop to

their lowest position.

4. Lower the sanding drum so that it just

touches the conveyor bed.

5. Turn the drum height handle one complete

revolution to raise the drum.

6. Retighten the bearing hex nuts and the cap

screws.

Tension Roller Pressure Adjustment

You can also adjust the spring-loaded screws

(Figure 20, Item H) found on the pressure roller

brackets, to increase or decrease roller

pressure. If you are getting snipe marks at the

leading end of the board adjust the outfeed roller

pressure. If the snipe marks occur on the trailing

end of the board, adjust the infeed roller

pressure.

Drum Height Control Adjustment

If the height control mechanism does not

operate easily or smoothly, or there is excessive

vertical movement of the drum carriage, perform

the following adjustments.

1. To reduce the handwheel backlash, tighten

the locknut on the height adjustment screw

(Figure 21, Item J).

2. Thoroughly lubricate all mating surfaces and

height adjustment screw (Figure 21, Item K).

B

C

D

Figure 19

F F

E

E

H

Figure 20

K

H

J

K

18

Figure 21

Page 19

Troubleshooting Guide

Problem Possible Cause Solution

Conveyor belt does not

move.

Conveyor rollers run

intermittently.

Abrasive strip comes off

drum.

Abrasive strip is loose.

Abrasive loads up

prematurely.

Line or groove in stock.

Wood burns.

Board slips on conveyor

belt.

Sander motor slows or

stalls

Rippled sanded surface

A. Non-uniformly

spaced ripples.

B. Uniformly spaced

ripples.

Gouging of the wood.

Snipes 1. Improper tension on rollers 1. See tension roller adjustment.

Motor overload

protector trips or shop

wiring breaker trips.

Shaft coupler is not attached. Attach the shaft coupler.

Shaft coupling is loose. Align the shaft flats of the gear motor

and the drive roller and tighten the

shaft-coupling setscrews.

1. Slack in abrasive strip on drum.

2. Abrasive improperly wrapped.

1. Strip caught on inside edge of

slot, or on inboard side of drum.

2. Strip not cut properly.

1. Excessive depth of cut.

2. Excessive feed rate.

3. Inadequate dust collection.

4. Inadequate abrasive.

1. Inconsistent feed rate. 1. Do not stop or change the feed

1. Abrasive strip is overlapped.

2. Excessive depth of cut.

3. Excessive depth of cut for fine

grit.

4. Feed rate is too slow.

5. Abrasive is loaded.

6. Worn abrasives.

1. Tension rollers are too high.

2. Excessive feed rate.

3. Dirty or worn conveyor belt.

1. Improper conveyor belt tension.

2. Excessive depth of cut.

3. Excessive feed rate.

A. Uneven feed rate.

B. Conveyor bed flexing or

vibration.

1. Inconsistent feed rate.

2. Stock slipping on conveyor.

3. Work piece not properly

supported.

1. Excessive load on sanding drum

and motor.

2. Too many tools on circuit.

3. Excessive length or inadequate

size extension cord.

1. Remove the slack in the strip.

2. Read the section on wrapping

abrasive strips.

1. Re-adjust the strip end in the slot

and/or trim the abrasive edge.

2. Re-cut and re-install the abrasive

strip.

1. Reduce the depth of cut.

2. Use a slower feed rate.

3. Increase airflow at the dust ports.

4. Use an open-coat abrasive.

rate.

1. Re-wrap the abrasive strip.

2. Reduce the depth of cut.

3. Use a coarser grit or reduce the

depth of cut.

4. Increase the feed rate.

5. Clean the abrasives.

6. Replace the abrasives.

1. Lower the tension rollers.

2. Reduce the feed rate.

3. Replace the conveyor belt.

1. Adjust the belt tension.

2. Reduce the depth of cut.

3. Reduce the feed rate.

A1. Conveyor belt slipping, see

above.

A2. Board slips on conveyor, see

above.

A3. Power feed gear motor stalls,

see above.

B1. Reduce the depth of cut.

B2. Reduce the feed rate.

B3. Check for loose bolts, shaft coupling setscrews or out of

balance drum.

1. Maintain constant feed rate (by

hand).

2. Excessive depth of cut

(PowerFeed) or inadequate hold

down pressure.

3. Add work supports for long work

pieces.

1. Allow motor to cool and reset

overload button.

2. Have a certified electrician

correct the shop-wiring problem.

3. Use a shorter, heavier gauge

extension cord.

19

Page 20

Exploded View – 10-20 PLUS Sander

20

Page 21

Parts List for the 10-20 PLUS Sander

Item

No.

1 1020-101 Handwheel, Height Adjustment 1

2 1020-102 Socket Head Button Screw 5/16-18UNCx3/4 2

3 TS-0680031 Flat Washer 5/16 8

4 1020-104 Main Support 1

5 1020-105 Lock Nut 1/2-20UNF 1

6 TS-0680061 Flat Washer 1/2 1

7 1020-107 Nylon Washer 1

8 1020-108 Washer, Oilite 1

9 TS-0267051 Set Screw 1/4-20UNCx1/2 2

10 1020-110 Bracket, Drum Height Control 1

11 1020-111 Height Adjusting Screw 1

12 1020-112 Bushing, Oilite 2

13 1020-113 Slide Plate, Motor Mount 1

14 1020-114 Arm 1

15 TS-081B03 Pan Head Machine Screw #8-32UNCx1/2 7

16 1020-116 Dust Cover 1

17 1020-117 Plate, Outboard 1

18 1020-118 Hex Socket Round Head Screw 1/4-20UNCx3/4 4

19 TS-0720071 Lock Washer 1/4 4

20 50-3089 Bearing Assembly, Drum 1

21 TS-0152011 Bolt, Carriage Head 5/16-18UNCx1 2

22 TS-0561021 Hex Nut 5/16-18UNC 2

23 60-0310-P Conveyor Belt 1

24 20-0778 Retaining Ring STW25 1

25 1020-125 Drum 1

26 1020-126 Main Coupler 1

27 1020-127 Socket Head Cap Screw #8-32UNCx3/8 2

28 TS-0208041 Socket Head Cap Screw 5/16-18UNCx3/4 4

29 TS-0720081 Lock Washer 5/16 6

30 10-4008-16 Screw, Fillister Head-Phillip #8-32UNCx1 4

31 20-3211 Spring, Tension Rollers 4

32 40-0304 Bracket, Tension Rollers 1

33 40-0308-01 Bracket, Right Tension Roller Suspension 2

34 40-0308-02 Bracket, Left Tension Roller Suspension 2

35 80-1060 Pad, Bracket-Tension Roller 2

36 1020-136 Roller, Tension 2

37 TS-0208021 Socket Head Cap Screw 5/16-18UNCx1/2 2

38 1020-138 Motor Cord 1

39 1020-139 Bracket, Inboard Tension Roller 1

40 1020-140 Rod, Side Plate 1

41 1020-141 Rod, Square-Slide Plate 1

42 1020-142 Conveyor adjusting screw 2

43 1020-143 Bracket, Right Take-Up 1

44 50-3105 Bushing, Oilite ... 7

45 1020-145 Driven Roller 1

46 1020-146 Bracket, Left Take-Up 1

47 TS-0733041 Lock Washer, External Tooth 1/4 4

48 TS-0561011 Hex Nut 1/4-20UNC 6

49 TS-0813021 Screw 1/4-20UNCx3/8 3

50 1020-150 Foot Plate 1

51 1020-151 Drive Roller Support 1

52 1020-152 Drive Roller 1

Part No. Description Size Qty

21

Page 22

Parts List for the 10-20 PLUS Sander

Item

No.

53 10-4010-04 Set Screw #10-32UNFx1/4 1

54 1020-154 Guide Plate 1

55 10-4010-08 Socket Head Cap Screw #10-32UNFx1/2 4

56 3237359 Conveyer Gear Motor 1

57 1020-157 Cover, Base-Control Housing 1

58 72-2004 Switch, On/Off-Drum 1

59 1020-159 Overload 1

60 1020-160 Pan Head Machine Screw #10-32UNFx1/2 5

61 12-9001 Lock Nut #6-32UNC 2

62 72-6101 Strain Relief, DC-Motor Cord 6N-4 1

63 1020-163 Base Assembly 1

64 73-1255 Controller, Conveyer-Variable Speed 1

65 80-3137 Knob, Dust Cover 1

66 1020-166 Dust Hood, Door 1

67 20-0775 Hinge Pin 2

68 1020-168 Dust Hood, Hinge 1

69 1020-169 Needle, Depth Gauge 1

70 1020-170 Round Head Machine Screw #10-24UNCx3/8 1

71 20-0762-02 Key 3/16SQx3/4” 2

72 1020-172 Main Drum Motor 1

73 1020-173 Spring 1

74 1020-174 Adjustment Bracket 1

75 1020-175 Socket Head Button Screw 5/16-24UNFx1/2 4

76 1020-176 Power Cord 1

77 1020-177 Strain Relief, Power Cord and Motor Cord 6N3-4 2

78 94-1670 Label, Depth Gauge 1

79 1020-179 Socket Head Button Screw 5/16-18UNCx1/2 2

80 21-1173 Fastener, Abrasive-Outboard 1

81 1020-181 Knob, Adjusting 1

82 TS-0207041 Socket Head Cap Screw 1/4-20UNCx3/4 4

83 1020-183 Label, Height-Direction 1

84 1020-184 Set Screw 1/4-20UNCx1/4 2

85 80-3131 Knob, 2 pc Swivel Handle 1

86 40-0260 Wrench 2

88 1020-188 Shoulder Screw 2

89 TS-0733061 Lock Washer, External Tooth 3/8 2

90 10-4009-06 Flat Head-Machine Screw #6-32UNCx3/8 2

91 1020-191 Strain Relief 6P3-4 1

92 21-1172 Fastener, Abrasive-Inboard 1

93 TS-0680042 Flat Washer 3/8 6

94 1020-194 Machine Screw 1/4-20UNCx5/8 1

95 TS-0680011 Flat Washer 3/16 4

96 1020-196 Hex Head Screw 3/8-16UNCx5/8 4

Part No. Description Size Qty

22

Page 23

Wiring Diagram

23

Page 24

WMH Tool Group

2420 Vantage Drive

Elgin, Illinois 60123

Phone: 800-274-6848

www.wmhtoolgroup.com.

24

Loading...

Loading...