Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

Heavy-Duty Mortiser

Model 720HD

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-1791309

Ph.: 800-274-6848 Revision A 7/05

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

This manual has been prepared f or the owner and operators of a P owermatic Model 720HD Morti ser. It s

purpose, aside f rom machine oper ation, is to promot e safety using acc epted operati ng and maint enance

procedures. To obtai n m axim um life and eff ici ency from your mortiser and t o aid i n usi ng it saf ely, please

read this manual thoroughly and follow the instructions carefully.

Warranty and Service

WMH Tool Gr oup warrants ever y product it sell s. If one of our tools needs s ervice or repai r, one of our

Authorized Repair St ations located throughout the United St ates can provide quick service or information.

In most cases, a WM H Tool Group Repair Station can as si st in authorizi ng r epair work, obtaini ng par ts, or

perform routi ne or m ajor maintenance repair on your Powermatic product.

For the nam e of an A uthoriz ed Repair St ation in your area, pl ease call 1-800-274-6848, or v isit our web

site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group i s consistently adding new products to the li ne. For complete, up-to-dat e

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that its produc ts meet high qualit y and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from

defects in mat erials and workmanship as foll ows: 1 YEA R LIMITED WARRANTY ON ALL PRODUCTS

UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or i ndirectly to

misuse, abuse, negl igence or acc idents, norm al wear-and-tear , repair or alterati ons outside our f aciliti es,

or to a lack of maintenanc e.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP

BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanati on of the complaint m ust accompany the merchandi se. If our inspecti on discloses a defec t, we

will either repair or replace the product at our discret i on, or refund t he purchase pri ce if we cannot readi l y

and quickly provide a repai r or replac ement. We will return the repai red product or replacem ent at WMH

Tool Group’s ex pense, but if it is determ ined there i s no defect, or that the def ect resulted f rom causes

not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and

returning t he product . This warranty gives you specifi c legal right s; you m ay also have ot her right s, which

vary from state t o state.

WMH Tool Group sells through distribut ors only. Members of the WMH Tool Group reserve the right to

effect at any time, wit hout prior notice, alter ations to parts, fittings and accessory equi pment, which they

may deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty and Servic e ..............................................................................................................................2

Table of Contents....................................................................................................................................3

Warning...................................................................................................................................................4

Introduction..............................................................................................................................................6

Specifications..........................................................................................................................................6

Unpacking ...............................................................................................................................................7

Contents of the Shipping Container......................................................................................................7

Assembly.................................................................................................................................................8

Installing Handle...................................................................................................................................8

Installing Wood Table...........................................................................................................................8

Installing B ushing, Chisel and Auger.....................................................................................................9

Grounding Instructions............................................................................................................................. 9

Extension cords.................................................................................................................................. 10

Adjustments...........................................................................................................................................11

Squaring Table To Chisel...................................................................................................................11

Setting Table to Vertical Position........................................................................................................11

Table Removal and Stor age............................................................................................................... 11

Chuck Extension A daptor...................................................................................................................12

Depth Setting Rod ..............................................................................................................................12

Head Movement.................................................................................................................................12

Clamp.......................................................................................................................... ......................13

Stock Stop..........................................................................................................................................13

Setting Lateral Stops ..........................................................................................................................13

Chisel Parallel to Workpiece...............................................................................................................14

Lower Work Support...........................................................................................................................14

Re-setting the Head...........................................................................................................................14

Gib Adjustment................................................................................................................................... 14

Tool Stora g e......................................................................................................................................15

Operating Controls.................................................................................................................................15

Operation...............................................................................................................................................16

Sharpening Chisel and Auger.............................................................................................................17

Lubrication .........................................................................................................................................17

Replacement Parts................................................................................................................................18

720HD Heavy Duty Mortiser...............................................................................................................19

Parts List: 720HD Heavy Duty Mortiser...............................................................................................20

Electrical Connections ...........................................................................................................................23

3

Page 4

Warning

1. Read and understand the entire owners manual befor e attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This mortiser is designed and i ntended f or use by properly trained and ex perienced per sonnel onl y. If

you are not f amiliar wit h the proper and safe operat ion of a mortiser, do not use unti l proper training

and knowledge have been obtained.

5. Do not use this mor tiser f or other t han i ts i ntended use. If used f or other purposes, W MH T ool Group

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Always wear approved safety glasses/face shields while using this mortiser. Everyday eyeglasses

only have impact resi stant lenses; they are not safet y glasses.

7. Before operating this morti ser, remove tie, ri ngs, watches and other jewelry , and roll sl eeves up past

the elbows. Rem ove all l oose clothing and confine long hair . Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tir ed or under the influence of drugs, alcohol or any m edic ation.

11. Make certain the machine is proper ly grounded.

12. Make all machine adjustm ents or maintenance with the machine unplugged f rom the power source.

13. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

14. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

15. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, br eakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged shoul d

be properly repaired or replaced.

16. Pr ovide for adequate space surrounding work area and non-glar e, overhead lighting.

17. Keep the floor around the machi ne cl ean and free of scrap material, oil and grease.

18. Keep v isitors a safe distance from the work area. Keep children away.

19. Make your workshop child proof wi th padlocks, master switches or by remov ing starter keys.

20. Giv e your work undivi ded attention. Looking ar ound, carryi ng on a conversation and “ horse-play” ar e

careless acts that can r esul t in serious injury.

4

Page 5

21. Mai ntain a bal anced stance at al l tim es so that y ou do not f all or l ean agai nst the auger and chi sel or

other movi ng parts. Do not overreach or use excessiv e force to perform any machine operation.

22. Use the ri ght t ool at the corr ect speed and f eed rat e. Do not forc e a tool or att achment to do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

23. Use recom mended accessories; improper accessories m ay be hazardous.

24. Maintain tools with care. Keep augers and chisels sharp and clean for the best and safest

performance. Follow instructions for lubricating and changing accessories.

25. Make sure t he work piece is securely clam ped against table and/or f ence. Never use your hand t o

hold the work piec e.

26. Do not turn on the power while the auger or chisel is cont ac ting a workpiece.

27. T urn off the machine before cleaning. Use a brush or compressed air to remov e c hips or debris — do

not use your hands.

28. Do not stand on the machine. Serious injur y c ould oc cur if the machine tips over.

29. Never leave t he machine runni ng unattended. Turn the power of f and do not leav e the mor tiser until

the auger comes to a complete stop.

30. Remove loose items and unnecessary work pieces from the area befor e start ing the machine.

Familiarize you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by W MH Tool Group cov ering the safe oper ation and mai ntenance procedure s

for a Model 720HD Heavy-Duty Mortiser. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordance wi th

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web site:

www.wmhtoolgroup.com.

Specifications

Model Number................................................................................................................................720HD

Stock Number.............................................................................................................................. 1791309

Chuck Capacity (in.)..............................................................................................................................1/2

Spindle Taper...................................................................................................................................JT33

Bushing Inside Diameter (in.)..........................................................................................3/4, 5/8 and 1-1/8

Chisel Stroke (in.)..............................................................................................................................6-1/8

Maximum Chisel Travel (in.):

Side to Side....................................................................................................................................9-1/8

Front to Back..................................................................................................................................3-3/8

Table Size (L x W)(in.).........................................................................................................14-5/8 x 7-1/ 8

Maximum Workpi ec e Height – wit hout Table (in.)...................................................................................46

Maximum Workpiece Height – with Table (in.)..................................................................................11-1/2

Clamp Surface (L x W)(in.)...........................................................................................................8 x 2-3/4

Table Tilt (deg.) ..................................................................................................................90 left, 45 right

Fence Size (L x W)(in.)...................................................................................................... 20-1/2 x 11-3/4

Base Size (L x W)(in.)........................................................................................................ 25-1/2 x 21-1/2

Overall Height (in.).................................................................................................................................80

Motor........................................................................................................... TEFC, 1.5HP, 1Ph, 230V only

Motor Speed (RPM)..........................................................................................................................1,720

Approximate Shipping Weight (lbs.).....................................................................................................575

Approximate Net Weight (lbs.) .............................................................................................................490

The above specifications were current at the time this manual was publi shed, but because of our policy of

continuous im provement, WMH Tool Group reserv es the right to change specif ications at any tim e and

without pri or notic e, without incurring obligations.

6

Page 7

Unpacking

Remove all c rating and pl astic from ar ound the

Mortiser. Check f or shipping dam age; report any

damage immediately to your distributor and

shipping agent. Do not discard any shipping

material until the Mortiser is assembled and

running properly.

Open the cabinet rear door and remove any

boxes and accessory items. Compar e these with

the following part s list to mak e sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

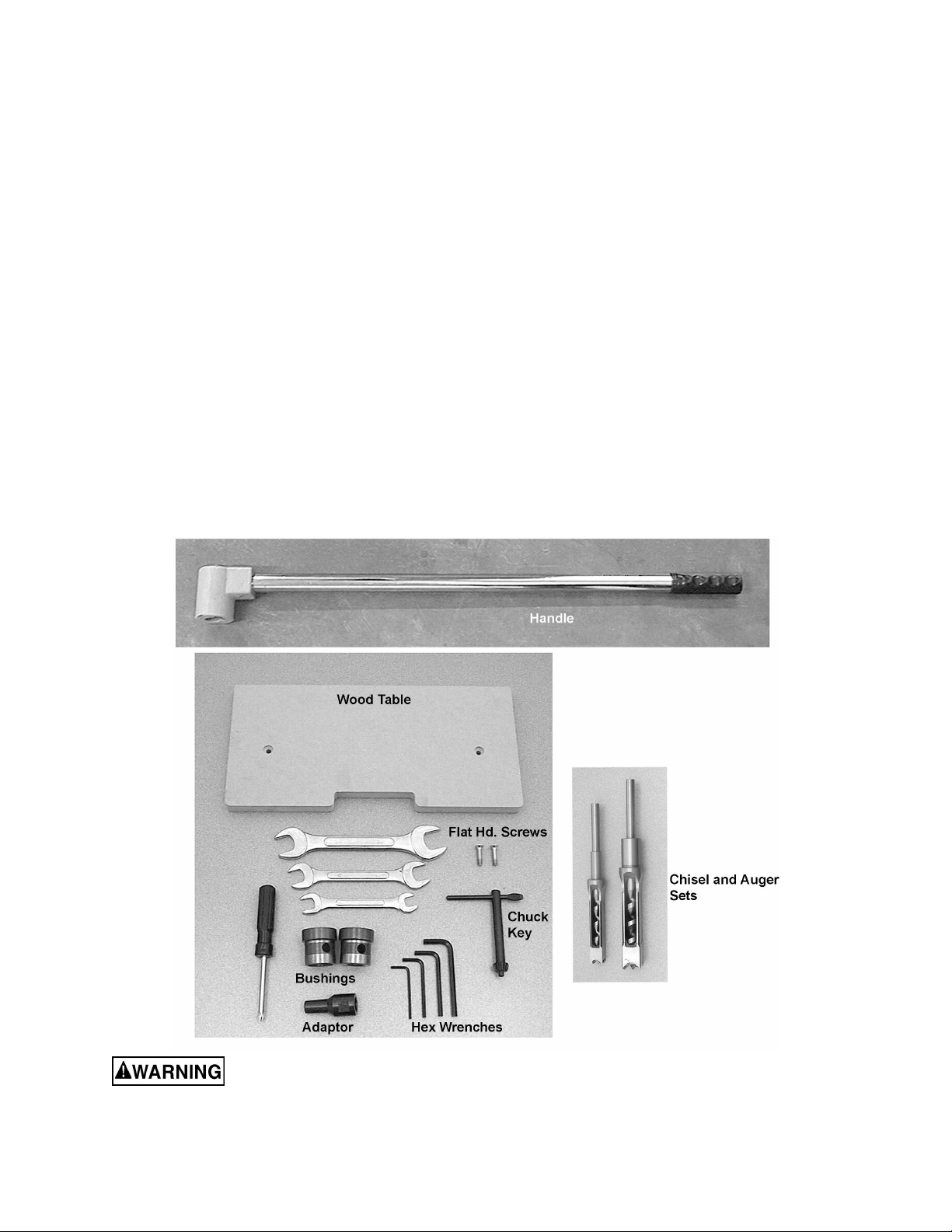

Contents of the Shipp ing Container

1 Mortiser

1 Handle

1 Chisel and Auger set – 3/ 4”

1 Chisel and Auger set - 1”

3 Bushings - 5/8”, 3/ 4” and 1- 1/8” I.D.

(NOTE: The 5/8” bushing i s al r eady installed

on the mortiser)

3 Combinati on Wr enc hes: 12- 14, 17-19, 22-24

4 Hex (Allen) Wrenc hes: 3, 4, 5 and 6mm

1 Chuck Key

1 Chuck Extension A daptor

1 Wood Table

2 Phillips Flat Head Scr ews, M6 x 20L

1 Reversibl e (Cross Point/Flat Head)

Screwdriver

1 Owner's Manual

1 Warranty Card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mpl y may cause seri ou s injury.

7

Page 8

Assembly

Tools required for assembly

forklift or hoist with straps/slings

14mm wrench (provided)

4 and 6mm hex wrenches (provided)

1. Remove the four screws that secure the

Mortiser to the wood pallet, using a 14mm

wrench.

2. With a forklift or hoist, lift the machine off the

pallet and into its desired location.

3. The Mortiser should be located in a dry

area, on a sturdy, level floor, and with

sufficient lighting. Leave plenty of space

around the machine for operations and

routine maintenance work.

4. If desired, the Mortiser can be further

stabilized by securing it to the floor, using

lag screws through the four holes in the

base.

The mortiser should be

disconnected f rom the power source during

assembly procedures.

5. Unpai nted areas of the machine have been

treated with a r ust prev entative. This should

be removed with a soft cloth and a mild

solvent. Do not use paint thinner, lacquer

thinner, gasoline or miner al spirits; these will

damage paint ed surfaces and pl astic par ts.

Do not use an abrasive pad.

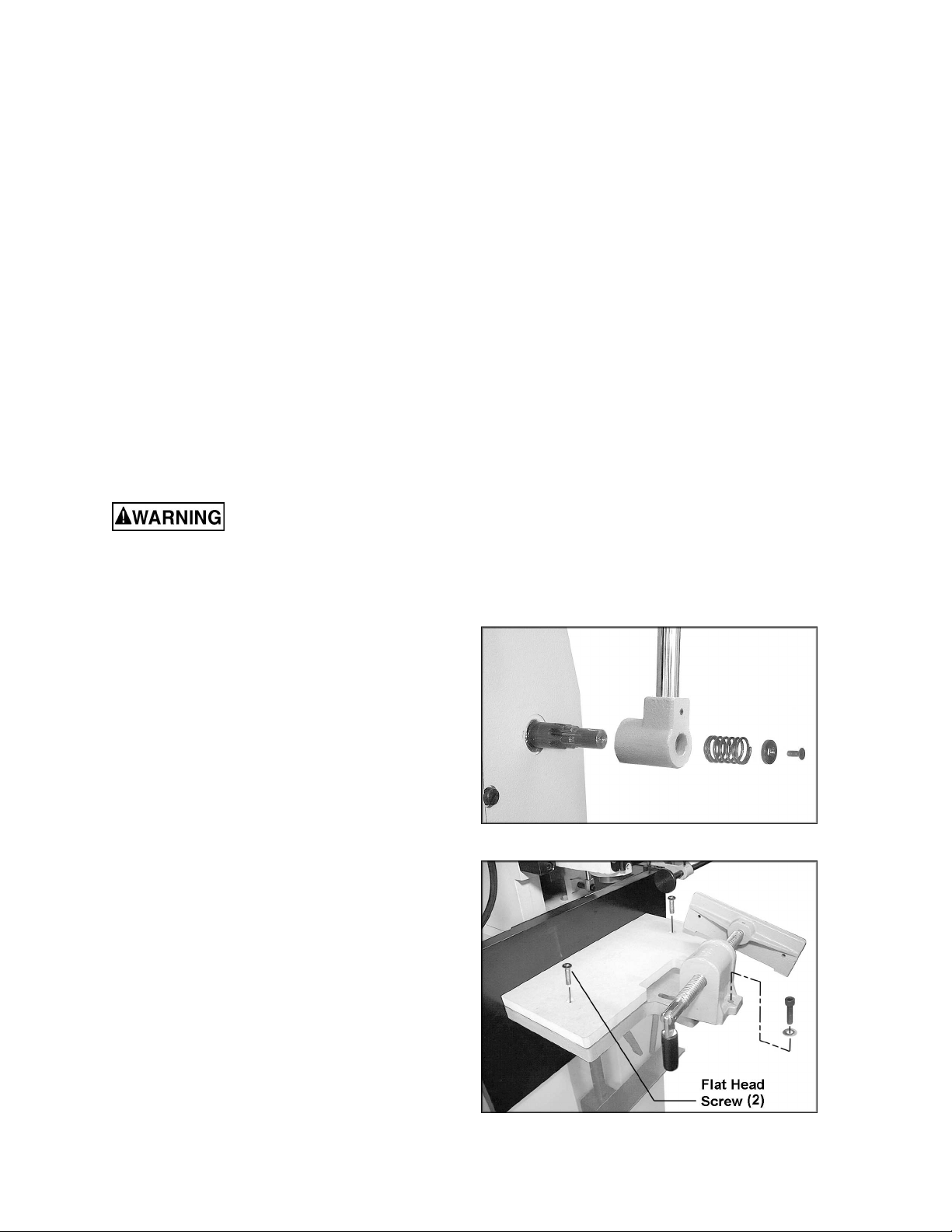

Installing Handle

1. Use a 4mm hex wrench to remove the

screw, washer and spring from the shaft

(Figure 1).

2. Mount the hub of the handl e onto the shaf t

as shown. Make sure the hub slides all the

way onto the shaft.

3. Re-install spring, washer and screw. T ighten

screw.

Installing Wood Table

1. To install the wood table, first remove the

right hand screw at the right of the clamp

(Figure 2), with a 6mm hex wrench, and

loosen the left hand screw from beneath.

Pivot the clam p out of the way.

2. Mount the wood table with two flat head

screws as shown.

3. Re-position t he clamp and install the screw.

Figure 1

Figure 2

8

Page 9

Installing Bushing, Chisel and Auger

4

1. The mortiser should be disconnected from

power source.

2. Open the chuck access cover ( A, Figure 3).

3. Insert a bu shing (B, Fi gure 3) into the hole

with the bushing’s hole facing the front

toward the set screw (C, Figur e 3) .

NOTE: The Morti ser i s shipped with t he 5/8”

bushing pre-installed.)

4. Tighten the set screw (C, Figure 3) with a

mm hex wrench just enough to hold

bushing in plac e.

5. Place the chisel (D, Figure 3) and auger ( E,

Figure 3) beneat h the bushi ng and all ow the

auger to rest upon the table while pushing

the chisel up through the bushing.

6. The cutti ng portion of the auger m ust clear

the chisel by about 1/16” to 3/16”,

depending upon the type of wood to be

worked. Place a “spacer” of 1/8” to 3/16”

diameter (a hex wrench works well)

between bushing and chisel, and push

chisel up until it contacts the spacer.

7. Tight en the set screw (C, Figure 3) t o hold

the chisel in plac e, and rem ov e spacer.

8. Push the auger up through the chisel

opening and into t he chuck as far as it wil l

go. Tight en the auger i n the chuc k using t he

chuck key.

9. Loosen the set screw (C, Figure 3) and

push the chisel all the way up until it

contacts the bushing. This should provide

the proper distance so that the cutting

portion of the auger clears the chisel.

Tighten the set screw (C, Fi gur e 3) .

NOTE: Set the slot in the side of the chisel

to the left or right, if the cut is to be done

laterall y; and fr ont or back if the cut is to be

done front to back. The chisel slot should

always be positioned so chips are being

released into the already-cut part of the

workpiece.

10. Close the c huck access cover (A, Figure 3)

before operating.

Figure 3

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

9

Page 10

This mac hine m ust be grounded. I n the event of

a malfuncti on or break down, groundi ng prov i des

a path of least resi stance f or electri c current to

reduce the ri sk of el ectri c shock.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conductor. If r epair or replac em ent of

the electric cord or plug is necessary, do not

connect the equi pment-grounding conduc tor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool i s properly grounded. Us e only

three wire extensi on c or ds that have three-prong

grounding plugs and three- pole recept acles that

accept the tool’s plug.

The Mortiser is factory wired for 230 volt. You

may either install a plug or “hard-wire” the

machine directly to a control panel.

If you are connecting a plug, use a proper

UL/CSA listed grounding plug suitable for 230

volt operation, similar to that shown in Figure 4.

The Morti ser with a 230 volt plug should onl y be

connected to an outlet having the same

configurati on. No adapter is av ailable or should

be used with the 230 volt pl ug.

If the Mortiser is to be hard-wired to a panel,

make sure a disconnect is available for the

operator. During hard-wiring of the Mortiser,

make sure the fuses hav e been removed or the

breakers have been tripped in the circuit to

which the Mortiser will be connected. Place a

warning placard on the fuse holder or circuit

breaker to prevent it being turned on while the

machine is being wired.

Make sure the voltage of your power supply

matches the specif ications on the m otor plate of

the Mortiser.

Figure 4

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

25

50

75

100

150

Amps

feet

feet

feet

feet

feet

200

feet

Extens ion cords

If an extension cord is necessary, make sure the

cord rating i s suitable for the am perage listed on

the machine’s motor plate. An undersized cord

will cause a drop in line voltage resulting in loss

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

of power and overheating.

Use the chart in Fi gure 5 as a general guide in

choosing the cor rect size cord. If in doubt, use

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

the next heavi er gauge. The smaller the gauge

number, the heavier the cord.

*based on li miting the l in e vol tage drop t o 5V at 150% of the

rated amp eres.

NR: Not Recommended.

Figure 5

10

Page 11

Adjustments

Squaring Table To Chisel

1. Place a sq uare upon the table and against

the chisel, as shown in Figur e 6.

2. If the table and c hisel are not perpendic ular

to each other, loosen the table’s stud with

the attached hex wrench ( A , Fi gur e 6) .

3. Loosen the l ocking handle (B, Figur e 6) and

adjust the tabl e until the table and chi sel are

square.

4. Re-tighten the stud (A, Figure 6) and locking

handle (B, Figure 6) .

5. Make sure the pointer aligns with zero on

the scale. Loosening the screw on the

pointer will allow slight adjustment of the

pointer if necessary.

NOTE: The l ocking handle (B, Figure 6) can be

rotated out of the way. Simply lift up on the

handle, rotate it on the pin, then release the

handle, making sure it seats itself properly on

the pin.

Setting Table to Vertical Position

For table angl es fr om 45° to 90°:

1. Loosen the stud (A, Figure 7).

2. Unscrew and rem ov e the locki ng handle (B,

Figure 7).

3. Rotate the table to vertical position and

install the locking handle (B, Figure 7) into

the other hole as shown.

Figure 6

4. Adjust the table to the desired angle and

tighten bot h stud and l oc ki ng handle.

Figure 7

Table Removal and Storage

The table can be removed for mortising large

workpieces using the lower work support.

First remove the locking handle (B, Figure 7),

then unscrew and remov e the stud (A, Figure 7).

The table can be stored in the rack at the side of

the cabinet. See Figur e 8.

Figure 8

11

Page 12

Chuck Extension Adaptor

The provided Chuc k Extension Adaptor is used

to lower the chuck for use with after-market

chisels (chisels other than those supplied with

your machine) that may r equire a spacer due to

varying lengt hs i n shanks.

1. To install the adaptor, first remove the chisel

and auger.

2. It may be necessary to remov e the bushing

to provide enough cl earance when installing

the chuck and adaptor. If so, loosen the set

screw and remove t he bushing.

3. Hold the spindle stationary by placing a

wrench on the flats of the spindle (see

Figure 9). With your other hand, insert the

chuck key into the chuck and use it to twist

the entire chuck, until the chuck releases

from the tapered spindle. Do not allow the

chuck to drop, as it can be damaged.

4. Push the a daptor into the c huck (Figure 9).

Then push this assembly onto the spindle.

5. Re-instal l the bushing and secure it loosely

with the set screw.

Figure 9

6. Re-install the chisel and auger. See

“Installing Bushing, Chisel and Auger”.

Depth Setting Rod

The depth setting rod (Figure 10) limits the

depth of the stroke.

1. Lower the m ortising head until the chisel is

at the desired depth.

2. Loosen the locking handle and slide the

depth rod down until the collar contacts the

block.

3. Tighten the locking handle.

Head Movement

The three handles for head movement

(explained bel ow) are spring l oaded, and can be

adjusted to different positions for the

convenience of the operator. Pull up on the

handle close to it s hub and rotate it, allowing it

to drop back down onto t he pin. See Fi gure 11.

Make sure the handl e re-seats itsel f proper ly on

the pin.

Figure 10

Figure 11

12

Page 13

Lateral (X Axis)

Use the handl e (A, Fi gure 12) to m ove t he head

right or left. The lateral stops should be set in

accordance with the length of the mortise cut

(see “Setti ng Lateral Stops”).

Up/Down (Z Axis)

Handle B, Figure 12.

Forward/Backward (Y Axis)

Loosen the Y-Axis locking handle (shown in

Figure 18) and move t he handle ( C, Fi gur e 12) .

NOTE: When making lateral cuts the Y-Axis

locking handl e (Figure 18) should be tightened.

Figure 12

Clamp

The clamp (Figure 13) has a quick release

feature; push the handle forward to move the

jaw against the workpiece, then further tighten

the clamp by r otati ng the handl e. The clam p jaw

can also be retracted by loosening the handle

about a half turn, and then pulling it outward.

The clamp can be swiveled for tapered

workpieces. Loosen bot h screws (one is shown

in Figur e 13) and swivel the cl am p as needed.

Re-tighten both screws.

If you do not wish to mar a soft workpiec e, you

can mount a board t o the face of the cl amp j aw,

using screws (not provided) through the two

holes in the jaw.

Stock Stop

The stock stop, shown i n Fi gure 13, i s useful for

repetitive cuts of the same length, and can be

mounted to either end of the fence. Loosen the

wing screws to adjust.

Figure 13

Setting Lateral Stops

Loosen the locki ng handles and sli de the lat eral

stops (Figure 14) to the desired position. Retighten the locking handles.

Figure 14

13

Page 14

Chisel Parallel to Wo rkpiece

For accurate mortise cuts, the chisel must be

parallel t o the workpiece. The workpiec e should

be cut square for this adjustment to be accurate.

Check and adjust this parallelism as follows:

1. Move the head f orward far enough that t he

workpiece can be inserted between fence

and chisel.

2. Slightly loosen the set screw to allow the

chisel to be rotated.

3. Mov e the head back caref ully until the face

of the chisel rests against the workpiece, but

do not force. See Fi gur e 15.

4. If needed, further adjust the chisel by hand.

5. Tighten set screw, making sure the chisel

maintains contac t with the bushing.

Lower Work Support

To use the lower work support, r emove the table

(see “Table Rem oval and Storage” ). Loosen the

locking handle (Figure 16) and slide the lower

work support into position. Re-tighten the handle

securely.

Figure 15

Re-setting the Head

The head can be adjusted in order to achieve

the maximum workpi ec e height.

1. Place a bloc k of wood for support between

the head and fence (Figure 17). Lower the

head until it rests upon t he block.

2. Loosen only slightly the hex nut (A, Figure

17).

3. Pull down the handl e ( B, Fi gure 17) unt il the

cylinder (C, Fi gur e 17) bott om s out .

4. Tighten the hex nut (A, Figure 17).

Gib Adjustment

The tightness of the gibs has been set at the

factory and should not require adjustment. As

parts wear through long-term use, or “play”

develops in the gib, adjustments can be made

as foll ows. NOTE: Gi b tightness should be just

enough to allow smooth movement without

binding.

Gib for Vertical Movemen t

Figure 16

Figure 17

1. Sli ghtly l oosen the three hex c ap screws (D,

Figure 17) which hol d the gib.

2. Turn the gib screws (E, F igure 17) until any

play is remov ed.

3. Re-tighten the hex cap screws (D, Figure

17) securely.

14

Page 15

Gib for Front-to - Back Movement

1. Remove the t wo screws on the pleated dust

cover (F, Figure 18) and move the dust

cover out of the way.

2. Loosen the three hex nuts (G, Figure 18)

with a 10mm wrench.

3. Turn the three set screws (H, Figure 18)

with a 3mm hex wrench, until play is

eliminat ed on the gib ( J, Figure 18).

4. Re-ti ghten the three hex nuts (G, Fi gure 18)

NOTE: Hold t he set scre ws so they do not

turn during the ti ghtening process.

5. Re-instal l the pleated dust cov er (F, Figure

18) before operating.

Gib for Lateral Movement

1. Remove the t wo screws on the pleated dust

cover (F, Figure 19) and move the dust

cover out of the away.

2. Loosen the three hex nuts (K, Figure 19)

with a 10mm wrench.

3. Turn the three set scr ews (L, Figure 19) until

all play is eliminated on the gib (M, Figure

19).

4. Re-t ight en the thr ee hex nuts (K, Figure 19).

NOTE: Hold t he set scre ws so they do not

turn during the ti ghtening process.

5. Re-instal l the pleated dust cov er (F, Figure

19) before operating.

Tool Storage

The cabinet shelf contains a perf orated cushion

for the accessories, as shown in Figure 20.

Figure 18

Figure 19

Operating Controls

The magnetic starter with control buttons is

mounted to the motor. P ress the “start” button to

begin rotation of the auger. Press the “stop”

button to stop rotation of t he auger. The auger

will quickly coast to a stop after the “stop” button

is pressed.

The magnetic starter is a valuable safety feature

of the Mortiser. Should electrical power

suddenly be cut off while the mortiser is being

operated, the magnetic starter will prevent the

machine from immediately re-starting when

power is restored. To re-start the Mortiser you

must press the “on” button.

Figure 20

15

Page 16

Operation

General operating procedure:

1. Posit i on workpiec e on t abl e and secure wit h

clamp.

2. Set depth stop.

3. For lateral cuts, adjust positive stops

according to l ength of cut.

4. Positi on head front-to-back and l aterally for

the first cut. If making a lateral cut, make

sure the Y-axis l oc ki ng handle is tightened.

5. Turn on the machine and feed the chisel

and bit steadily into the workpiece.

IMPORTANT: The rate of feed must be fast

enough to prevent burning at the tip of the bit,

but not so fast as to cause the m achine to slow

or stall. The different rates of feed for different

woods must be learned by ex peri enc e.

6. After the first cut, the head is mov ed using

one of the handl es for each successiv e cut.

The direction of movement must allow the

chips to clear freel y. Move the workpiece so

that the slot in the chisel is releasing chi ps

into the already-cut part of the workpiece

(Figure 21).

Do not have the chisel slot

against the blind end of the mortise, as the

chips will not be able to cl ear t he chisel. Thi s

can cause overheating and possible

breakage of chi sel o r bit.

When cutting deep mortises, make the cut in

several stages of approximately 1” each, to

allow chips to clear. When cutting throughmortises, to pr event breakout at the back of the

workpiece and damage t o the work table, use a

piece of scrap mat erial under the workpi ece as

support.

Maintenance

Before doing maintenance

on the mortiser, disconnect it from the

electrical supply by pulling out the plug or

switching off the main switch. Failure to

comply may cause serious inj ury.

The Mortiser requires only minor maintenance,

such as cleaning and lubrication and routine

adjustment and sharpeni ng of the chisel and bit.

Wipe down the Mort iser after each use and, as

necessary, use l ight appli cations of oil or gr ease

to lubricat e li nk ages, m ov ing par ts, etc.

If the power cord is worn, cut, or damaged in

any way, have it repl ac ed immediately.

Figure 21

16

Page 17

Sharpening Chisel and Auger

The chisel and auger should be kept sharp for

best performance. If cutting operations require

excessive force, the chisel and/or auger are

probably dull and should be sharpened. Blunt

edges will give inaccurate mortises and can lead

to overheati ng and breakage of chi sel or auger.

If chisel and auger are badl y worn and becom e

difficult to sharpen, they should be replaced.

Chisel

Sharpen the chisel with a mortise chisel cutter

with the correct size pilot. (Pilot size will differ

depending on the size of your chisel.) Two or

three turns of the cutter in a carpenter’s brace

chuck should be enough t o sharpen the c hisel,

as shown in Figure 22.

Use a small, triangul ar, smoot h file to relieve t he

inner corners of the chisel ( Figure 23). Remove

any burrs from the outside of the chisel with a

fine oilstone.

Figure 22

Auger

Sharpen the auger by using a small, smooth file,

following the original shape of the auger. Fil e the

inside edge of the spur, the sides of the brad

point, and the cutting edge inwards toward the

flute of the auger. See Figure 24.

Do not file the outside edge of the spur, as thi s

will affect the diameter of the auger.

Lubrication

All ball bearings are sealed. They require no

further lubrication.

Periodically grease the gears, racks, and table

pivot points wit h a #2 tube grease.

Periodic ally cl ean and appl y grea se or oil t o any

exposed machi ne surfaces, such a s dove-t ailed

ways and slides.

Figure 23

Figure 24

17

Page 18

Troubleshooting

Trouble Probable Cause Remedy

No incoming power. Check all plug connections.

Mortiser will not star t.

Drill bit does not

come up to speed.

Mortiser vibrates

excessively.

Noisy Operation. Auger contacti ng c hisel .

Workpiec e Burns.

Fuse blown, or cir c uit break er tr ipped. Replace f use, or r eset circuit breaker.

Cord damaged. Replace cord.

Motor bad. Contact WMH techni c al service.

Extension cord too light or too long.

Low current. Contact a qualified electrician.

Stand on uneven surface.

Chips not cleari ng from hole or auger.

Dull auger. Resharpen, or replace auger.

Feeding auger into workpiece too

slowly.

Auger sharpened inc or r ec tly. Resharpen auger correctly (page 17).

Replace with adequat e si z e and

length cord.

Machine should be placed on level

floor; use shim s if nec essary.

Increase off set of auger in relation to

chisel. See page 9.

Retract auger frequently to remove

chips. Make sure chisel slot opens

toward area already cut.

Increase feed r ate.

Chuck jaws not tight. Tighten chuck jaws.

Drill bit wanders.

Bent auger. Replace auger.

Auger or chuck not i nstalled properly. Reinstall the chuck, or auger properly.

Wood splint er s on the

underside.

Drill bit binds in

workpiece.

No backing board used.

Workpiec e not clam ped pr oper ly ,

pinching the auger.

Excessive f eed r ate. Decrease feed rat e.

Chuck jaws not tight. Tighten chuck jaws.

Place a scrap board underneath the

workpiece to prevent splintering.

Support or clamp workpiece firmly.

Replacement Parts

Replacement part s are li sted on the f ollowing page s. To order par ts or reac h our servi ce depar tment, call

1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve you qui c kl y and

accurately.

18

Page 19

720HD Heavy Duty Mortiser

19

Page 20

Parts List: 720HD Heavy Duty Mortiser

Index No. Part No. Description Size Qty

1............... 720HD-101..............Stand................................................................. ...................................1

1............... 720HD-101..............Stand................................................................. ...................................1

2............... 720HD-102..............X Axis Slide Base.............................................. ...................................1

3............... 720HD-103..............Socket Head Cap Screw.................................... M10x65......................4

4............... 720HD-104..............Set Screw.......................................................... M10x55......................6

5............... 720HD-105..............X Axis Gear Rack.............................................. ...................................1

6............... TS-1503041 ............ Socket Head Cap Screw.................................... M6x16........................7

7............... 720HD-107..............Rod Support ...................................................... ...................................2

8............... TS-1503071 ............ Socket Head Cap Screw.................................... M6x30........................4

9............... TS-1523011 ............ Set Screw .......................................................... M6x6..........................4

10.............6294144.................. Setting Rod........................................................ ...................................1

11.............6294143.................. Setting Collar ..................................................... ...................................3

12.............720HD-112..............Locking Handle..................................................M6x10........................ 2

13.............720HD-113..............X Axis Slide ...................................................... ...................................1

14.............720HD - 1 1 4..............Dovetail Gib....................................................... ...................................1

15.............720HD-115..............Wooden Table Top ............................................ ...................................1

16.............720HD-116..............Gear Housing .................................................... ...................................1

17.............TS-1506031............Socket Head Cap Screw.................................... M12x30 ......................2

18.............TS-1540081............Hex Nut ............................................................. M12............................1

19.............TS-1492041............Hex Cap Screw..................................................M12x40 ......................1

20.............BB-6004ZZ..............Bearing.............................................................. #6004ZZ.....................2

21.............720HD-121..............X Axis Shaft....................................................... ...................................1

22.............720HD-122..............Key.................................................................... 5x5x30........................ 3

23.............720HD-123..............Feed Gear......................................................... ...................................1

24.............TS-1523041............Set Screw.......................................................... M6x12........................4

25.............720HD-125..............Spacer............................................................... ...................................1

26.............TS-1514021............Flat Head Socket Screw.....................................M6x16........................5

27.............720HD-127..............X Axis Handle.................................................... ...................................1

28.............720HD-128..............Plastic Handle Grip............................................ ...................................3

29.............6294166.................. Spring................................................................ ...................................3

30.............6294167.................. Washer.............................................................. ...................................3

31.............720HD-131..............Y Axis Shaft....................................................... ...................................1

32.............TS-1525011............Set Screw.......................................................... M10x10......................1

33.............720HD-133..............Y Axis Feed Gear .............................................. ...................................1

34.............720HD-134..............Retaining Ring................................................... STW-20......................2

35.............720HD-135..............Y Axis Handle.................................................... ...................................1

36.............720HD-136..............Y Axis Slide....................................................... ...................................1

37.............720HD-137..............Y Axis Gear Rack.............................................. ...................................1

38.............720HD - 1 3 8..............Dovetail Gib....................................................... ...................................1

39.............720HD-139..............Set Screw..........................................................M6x40........................6

40.............TS-1540041............Hex Nut ............................................................. M6 ..............................6

41.............720HD-141..............Locking Handle..................................................M6x38........................ 1

42.............720HD-142..............Column.............................................................. ...................................1

43.............TS-2360121............Flat Washe r....................................................... M12............................3

44.............TS-1506051............Socket Head Cap Screw.................................... M12x40 ......................3

45.............720HD-145..............Z Axis Shaft....................................................... ...................................1

46.............720HD-146..............Washer .............................................................. D34.5xd20x0.4t ..........1

47.............720HD-147..............Pleated Dust Cover............................................ ...................................1

48.............720HD-148..............Z Axis Handle.................................................... ...................................1

49.............720HD-149..............Spring................................................................ ...................................1

50.............720HD - 1 5 0..............Stee l Ba l l........................................................... D8 ..............................1

51.............720HD-151..............Gib.................................................................... ................................... 1

52.............TS-1504031............Socket Head Cap Screw.................................... M8x16 ........................3

53.............720HD-153..............Screw................................................................ ...................................3

54.............720HD-154..............Z Axis Slide Base............................................... ...................................1

55.............720HD-155..............Z Axis Gear Rack............................................... ...................................1

56.............720HD-156..............Cylinder Fitting Shaft (Short).............................. ...................................1

20

Page 21

57.............720HD-157..............Cylinder Head.................................................... ...................................2

58.............720HD-158..............Cylinder............................................................. ...................................1

59.............720HD-159..............Cylinder Fitting Shaft (Long)............................... ...................................1

60.............720HD-160..............E-Ring............................................................... ETW-7........................2

61.............720HD-161..............Stopper Block.................................................... ...................................1

62.............TS-1504061............Socket Head Cap Screw.................................... M8x30 ........................2

63.............720HD-163..............Shelf Cushion.................................................... ...................................1

64.............720HD-164..............Rubber Collar .................................................... 5x50 ...........................1

65.............TS-1550031............Flat Washe r....................................................... M5..............................3

66.............TS-1481021............Hex Cap Screw..................................................M5x10........................3

67.............720HD-167..............Handle Bracket.................................................. ...................................1

68.............720HD-168..............Headstock ......................................................... ...................................1

69.............720HD-169..............Square Head Screw........................................... ...................................1

70.............TS-155010..............Fla t Washer....................................................... M16............................1

71.............TS-2310162............Hex Nut ............................................................. M16x1.5P...................1

72.............720HD-172..............Motor................................................................. 1-1/2HP, 230V, 1Ph ....1

73.............TS-1551041............Lock Was h e r ......................................................M6..............................4

74.............TS-1482061............Hex Cap Screw..................................................M6x30........................4

75.............6294171.................. Chuck................................................................ JT33-13mm................1

76.............6294198.................. Bushing.............................................................1-1/8”..........................1

................. 6294221..................Bushing (not shown) .......................................... 3/4”.............................1

................. 6294222..................Bushing (not shown) .......................................... 5/8”.............................1

77.............TS-1524041............Set Screw.......................................................... M8x16........................2

78.............720HD-178..............Chuck Access Cover.......................................... ...................................1

79.............720HD-179..............Retaining Ring................................................... ISTW-10.....................1

80.............720HD-180..............Depth Setting Rod............................................. ...................................1

81.............720HD-181..............Locking Handle..................................................M8x15........................ 1

82.............TS-1533032............Pan Head Screw................................................ M5x10........................2

83.............720HD-183..............Fence................................................................ ...................................1

84.............TS-1505031............Socket Head Cap Screw.................................... M10x25 ......................7

85.............720HD-185..............Guide Bracket (Upper)....................................... ...................................1

86.............TS-1505061............Socket Head Cap Screw.................................... M10x40 ......................2

87.............TS-1525021............Set Screw.......................................................... M10x12......................2

88.............720HD-188..............Guide Rod......................................................... ...................................1

89.............720HD-189..............Guide Bracket.................................................... ...................................1

90.............720HD-190..............Support Bracket................................................. ...................................1

91.............720HD-191..............Locking Handle..................................................M12x60......................2

92.............720HD-192..............Guide Bracket (Lower)....................................... ...................................1

93.............TS-1505131............Socket Head Cap Screw.................................... M10x80 ......................2

94.............720HD-194..............Bracket.............................................................. ...................................2

95.............720HD-195..............Table................................................................. ...................................1

96.............TS-1504061............Socket Head Cap Screw.................................... M8x30 ........................1

97.............720HD-197..............Pointer............................................................... ...................................1

98.............TS-2171012............Pan Head Screw................................................ M4x6..........................1

99.............720HD-199..............Scale................................................................. ...................................1

100...........6294187.................. Clamping Bloc k.................................................. ...................................1

101...........6294192.................. Locking Screw................................................... ...................................1

102...........6294223.................. Plastic Handle Sleeve........................................ ...................................1

103...........6294188.................. Rapid Nut.......................................................... ...................................1

104...........6294186.................. Clamping Jaw.................................................... ...................................1

105...........6294189.................. Friction Toe....................................................... ...................................1

106...........6294190.................. Spring................................................................ ...................................1

107...........6294191.................. Rivet.................................................................. ...................................5

108...........TS-1502051............Socket Head Cap Screw.................................... M5x20 ........................4

109...........6294193.................. Stop Disc........................................................... ...................................1

110...........6294148.................. Length Setting Rod (Rear) ................................. ...................................1

111...........6294150.................. Length Setting Rod (Front)................................. ...................................1

112...........TS-1550061............Flat Washe r....................................................... M8..............................2

113...........TS-1540021............Hex Nut.............................................................M4 .............................2

114...........TS-1550041............Flat Washe r....................................................... M6..............................5

115...........720HD-1115............ Specia l Was h e r................................................. ...................................1

21

Page 22

116...........720HD-1116............ Allen Wren c h..................................................... ...................................1

117...........TS-1514031............Flat Head Socket Screw.....................................M6x20........................2

118...........720HD-1118............ Cover................................................................. ...................................1

119...........TS-1534032............Pan Head Screw................................................ M6x10........................5

120...........720HD-1120............ Switch Board..................................................... ...................................1

121...........TS-2245081............Flat Head Socket Screw.....................................M5x8..........................8

122...........720HD-1122............ Stud................................................................... ...................................1

123...........720HD-1123............ Pleated Dust Cover............................................ ...................................1

124...........720HD-1124............ Magnetic Switch................................................. ...................................1

125...........TS-1532042............Pan Head Screw................................................ M4x12........................2

126...........720HD-1126............ Sleeve............................................................... ...................................1

127...........720HD-1127............ Power Cord .......................................................1.25/3Cx3M................1

128...........720HD-1128............ Motor Cord........................................................1.25/3Cx0.8M.............1

129...........720HD-1129............ 90º Scale........................................................... ...................................1

130...........6294149.................. Length Setting Block.......................................... ...................................1

131...........720HD-1131............ Hook.................................................................. ...................................2

132...........TS-0152011............Carriage Bolt......................................................5/16”-18x1”.................2

133...........TS-0680031............Flat Washe r....................................................... 5/16”...........................2

134...........TS-0561021............Hex Nut.............................................................5/16”-18......................2

135...........6294145.................. Wing Screw....................................................... M6x16 ........................4

136...........720HD-1136............ Table Holder...................................................... ...................................1

137...........TS-1550061............Flat Washe r....................................................... M8..............................2

138...........720HD-1138............ Gear.................................................................. ...................................1

139...........720HD-1139............ Washer .............................................................. ...................................1

140...........720HD-1140............ Pad....................................................................26L.............................2

141...........TS-1504031............Socket Head Cap Screw.................................... M8x16 ........................2

142...........TS-0267051............Set Screw.......................................................... 1/4”-20x1/2”................2

143...........TS-1504061............Socket Head Cap Screw.................................... M8x30 ........................1

144...........720HD-1144............ Roll Pi n.............................................................. M6x36 ........................1

145...........6294204.................. Chuck Key......................................................... ...................................1

146...........720HD-1146............ Door.................................................................. ...................................1

147...........6294227.................. Pin ..................................................................... ...................................2

148...........6294228.................. Door Latch......................................................... ...................................1

149...........TS-2171012............Pan Head Screw................................................ M4x6..........................2

150...........TS-1503051............Socket Head Cap Screw.................................... M6x20 ........................3

151...........TS-0680011............Flat Washe r....................................................... 3/16”...........................2

152...........TS-0680021............Flat Washe r....................................................... 1/4”.............................4

153...........720HD-1153............ Cord Strain Relief.............................................. ...................................2

154...........720HD-1154............ Cord Strain Relief.............................................. ...................................1

155...........720HD-1155............ Cord Strain Relief.............................................. ...................................1

156...........3005069.................. Chuck Extension Adaptor............................. .........................................1

22

Page 23

Electrical Connections

23

Page 24

WMH Tool Gr ou p

2420 Vantage Drive

Elgin, Illinois 60123

Phone: 800-274-6848

www.wmhtoolgroup.com

24

Loading...

Loading...