Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

Table Saw

Model: JW TS -10

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60124 Part No. M-708100

Ph.: 800-274-6848 Revision B2 9/06

www.wmhtoolgroup.com Copyright © WMH Tool Group

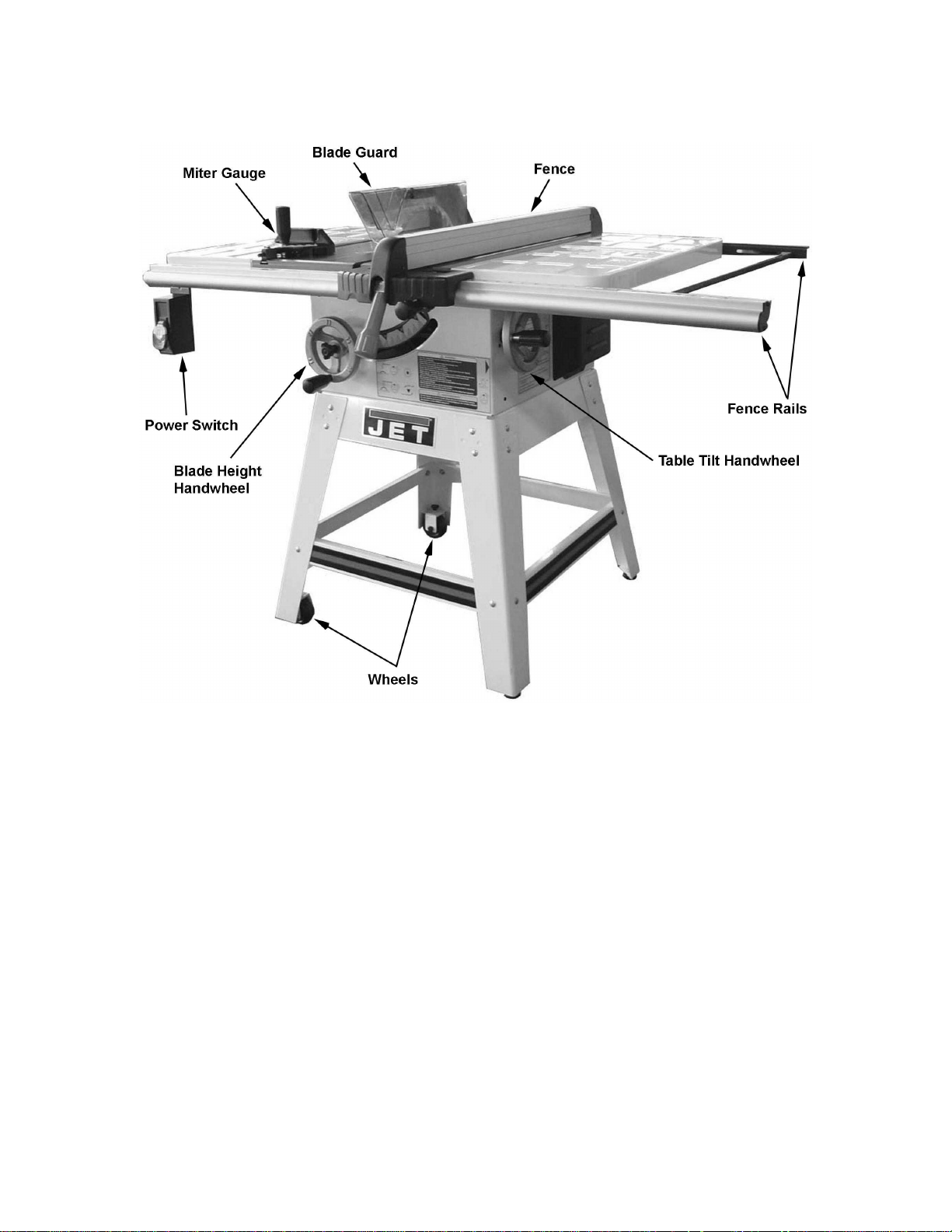

Page 2

WARRANTY AND SERVICE

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of

these WMH Tool Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check

with your local WMH Tool Group distributor, or visit jettools.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS C OVERE D?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY,

OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE

OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMI TATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as ge neral information

and are not binding. Members of WMH Tool Group reserve the right to effect at any tim e, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

® branded products are not sold in Canada by WMH Tool Group.

JET

® t ools. For the name of an Authorized Service Center in

2

Page 3

Table of Contents

Table of Contents....................................................................................................................................3

Warnings ....................................................................................................................... ..........................4

Assembly...............................................................................................................................................11

Unpacking and Cleanup ..................................................................................................................... 11

Stand Assembly .................................................................................................................................11

Assembling the Saw to the Stand.......................................................................................................12

Blade Tilt Point er................................................................................................................................12

Handwheels .......................................................................................................................................13

Extens io n Wing s................................................................................................................................13

Rear Guide Rail..................................................................................................................................13

Front Guide Rail.................................................................................................................................14

Support Rod.......................................................................................................................................14

Switch Bracket...................................................................................................................................15

Extens io n Wing Adjustment................................................................................................................15

Blade Guard and Splitt er ....................................................................................................................15

Install ing /R e p la cing the B lad e .............................................................................................................16

Aligning the Blade Guard and Splitter.................................................................................................16

Table Insert........................................................................................................................................17

Rip Fence..........................................................................................................................................17

Miter Gauge...........................................................................................................................................18

Grounding Instructions...........................................................................................................................19

Electrical Connections........................................................................................................................19

Extension Cord Recommendations.....................................................................................................19

Blade Raising and Tilt Mechanism......................................................................................................20

Adjusting 45º and 90º Positive Stops..................................................................................................20

Operations.............................................................................................................................................21

Table Saws........................................................................................................................................21

Kickbacks.......................................................................................................................................21

Rip Sawi ng .....................................................................................................................................22

Resawing........................................................................................................................................23

Crosscutting....................................................................................................................................23

Align-a-rip ..........................................................................................................................................24

Bevel and Miter Operat ions................................................................................................................24

Safety Devices.......................................................................................................................................25

Feather Board....................................................................................................................................25

Filler Piece.........................................................................................................................................26

Push Stick & Push Bl ock ....................................................................................................................26

Maintenance..........................................................................................................................................27

Cleaning.............................................................................................................................................27

Lubrication .........................................................................................................................................27

Miscellaneous ....................................................................................................................................27

Troubleshooting.....................................................................................................................................28

Parts......................................................................................................................................................29

Wiring Di agram ................................................................................................................. .....................37

Ordering Replacement Parts..................................................................................................................38

3

Page 4

Warnings

1. Read and understand the entire owners manual bef or e attempti ng assem bly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This Tabl e Saw is designed and intended f or use by properly trained and ex peri enc ed per sonnel only.

If you are not familiar with the proper and safe operation of a Table Saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this Table Saw for other than its intended use. If used for other purposes, WMH Tool

Group discl aims any real or implied warranty and holds itself harmless from any injury t hat may result

from that use.

6. Always wear approved saf ety glasses/face shi elds whil e using thi s Table Saw. Ever yday eyeglasses

only have impact resi stant lenses; they are not safety glasses.

7. Bef ore operating this Tabl e Saw, remove tie, rings, watches and other j ewelry, and roll sleeves up

past the elbows. Rem ove all loose cl othing and confi ne long hair. Non-sl ip foot wear or anti-ski d floor

strips are recommended. Do not wear gloves.

8. Always use the blade guard on all '' through- sawing'' oper ati ons. A t hrough-sa wing operati on i s one in

which the blade cuts completely through the workpiece.

9. Kickback oc c ur s when the workpiece is thrown towards the operator at a high rate of speed. If you do

not have a clear understanding of kickback and how it occurs, DO NOT operate this table saw!

10. Wear ear protectors (plugs or muffs) during ext ended peri ods of oper ation.

11. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oducts.

• Arsenic and chromium from chemically treated lumber.

12. Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

13. Do not operate this machine while tired or under the influence of drugs, alcohol or any medicati on.

14. M ak e c ertain the switch is in the OFF position before connecting the machine to the power supply.

15. M ak e c ertain the machine is properly grounded.

16. M ak e all machine adjustm ents or maintenance with the machine unplugged from the power source.

17. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

18. Keep safety guards in place at all times when the machi ne is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

19. M ak e sure the Table Saw is firmly secured to the floor or bench before use.

20. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, br eakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged shoul d

be properly repaired or replaced.

4

Page 5

Error! Objects canno t be created from editing field codes.

21. P r ov ide for adequate space surrounding work area and non-glare, overhead lighting.

22. K eep the floor around the m achi ne cl ean and free of scrap material, oil and grease.

23. K eep v isitors a safe distanc e from the work area. Keep children away.

24. M ak e y our workshop child proof with padlocks, master switches or by removing starter keys.

25. Giv e your work undivi ded attention. Looking ar ound, carryi ng on a conversation and “ horse-play” ar e

careless acts that can r esul t in serious injury.

26. M aintain a balanced st anc e at all times so that you do not fall into the blade or other moving par ts. Do

not overreach or use excessive force to perform any machine operation.

27. Use the ri ght t ool at the cor rect speed and feed r ate. Do not forc e a tool or attachment to do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

28. Use recom mended accessories; i mproper accessories may be hazardous.

29. Maintain tools with care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions for lubricati ng and changing accessories.

30. Turn off the mac hine before cleaning. Use a brush or compressed air to remove chips or debri s — do

not use your hands.

31. Do not stand on the machine. Seri ous injury could occur if the machine ti ps over.

32. Never leave the mac hine running unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

33. Remove loose item s and unnecessary work pieces from the area before starting the machine.

Familiarize you rself with the following safety no ti ces used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in serious injury or possibly

even death.

5

Page 6

The most common accident s among table saw users, acco rding to statist ics, can

be linked to kickback, the high-speed expulsion of material from the table that can strike the

operator. Kickback can also result in operator’s hands being pull ed into the blade.

Kickback Prevention

Tips to avoid the most common causes of

kickback:

• Make sure the blade splitter is always

aligned wit h the blade. A workpiece can bind

or stop the flow of the cut if the blade spl itt er

is misaligned and resul t in kickback.

• Use the blade spli tter during every cut. The

blade splitter maintains the kerf in the

workpiece, which will reduce the chance of

kickback.

• Never attempt fr eehand cut s. The workpiece

must be f ed perf ectly parall el with t he blade,

otherwise kickback will likely occur. Always

use the rip fence or crosscut fence to

support the workpi ec e.

• Make sure that the r ip fence is parallel with

the blade. If not, the c hanc es of ki c k bac k ar e

very high. Tak e the time t o check and adjust

the rip fence.

• Feed cuts through to completion. Anytime

you stop feeding a workpiece that is in the

middle of a cut, the chance of binding,

resulting in kickback, is greatly increased.

Pro tection Ti ps from

Kickback

Kickback can happen even if precautions are

taken to prevent it. Listed below are some tips to

protect you if kickback DOES occur:

• Stand to the side of the blade when cutting.

An ejected workpiece usual ly travel s directly

in front of the blade.

• Wear safety glasses or a face shield. Your

eyes and face are the most vul nerable part

of your body.

• Never plac e your hand behind the blade. If

kickback occurs, your hand will be pulled

into the blade.

• Use a push stic k to keep your hands far ther

away from the moving blade. If a kickback

occurs, the push stick will most likely take

the damage that your hand would have

received.

6

Page 7

Features

Specifications

Model Number............................................................................................................................JWTS-10

Stock Num ber ................................................................................................................................ 708100

Blade Diameter.....................................................................................................................................10"

Arbor Diameter....................................................................................................................................5/8"

Maximum Depth of Cut.....................................................................................................................3-1/8"

Maximum Rip to Right of Blade .............................................................................................................30"

Maximum Rip to Left of Blade...............................................................................................................12"

Maximum Depth of Cut at 45° ...........................................................................................................2-1/8"

Table in Front of Blade at Maximum Cut (in) ....................................................................................10-1/2

Maximum Width of Dado..................................................................................................................13/16"

Maximum Diameter of Dado....................................................................................................................8"

Table Height...................................................................................................................................36-1/2"

Table Size (Cast Iron) with Extensions.........................................................................................27" x 44"

Table Size (Cast Ir on) without Extensions....................................................................................27" x 20"

Overall Dimensions (D x W x H)....................................................................................40" x 55-1/2" x 42"

Arbor Speed ............................................................................................................................. 3600 RPM

Motor................................................................................ 115/230V, 60Hz , 1Ph, 1-1/2HP, Prewired 115V

Net Weigh t......................................................................................................................................205 lbs

Gross Weight..................................................................................................................................214 l bs

The specifications in this manual are given as general inform ation and are not binding. WM H Tool Group

reserves the r ight to effect, at any time and without prior notice, changes or alterati ons to parts, fi ttings,

and accessory equipment deemed necessary for any reason whatsoever.

7

Page 8

Definitions And Terminology

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanism mounted over the

saw blade to prev ent accidental c ontact with the

cutting edge.

Crosscut: Sawing oper ation in which the mi ter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Blade(s) used f or cutting grooves

and rabbets.

Dado Cut: Fl at bottomed groov e in the face of

the workpiece made wit h a dado blade.

Featherboard: Device used to keep a board

against the rip fence or table that allows the

operator to keep hands away from the saw

blade.

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is

lifted up and thrown back toward an operator,

caused when a work piece binds on the saw

blade or between the sa w blade and rip f ence

(or other fixed object). To minimize or prevent

injury from kickbacks, see the Operating

Instructions section.

Miter Gauge: A component that controls the

workpiece movement while performing a

crosscut of vari ous angl es.

Non-Through Cut: A sawing operation that

requires the rem oval of the blade guard spl itter,

resulting in a c ut that does not protrude through

the top of the workpiece (includes Dado and

rabbet cuts).

The blade guard and split ter must be re-installed

after performing a non-through cut to avoid

accidental contact with the saw blade during

operation.

Parallel: Position of the rip fence equal in

distance at every point to the side face of the

saw blade.

Perpendicular: 90° (right angl e) intersection or

position of the vertical and horizontal planes

such as the posi tion of the saw blade (v ertical)

to the table surfac e ( hori z ontal).

Push Board/Push St ick: A n instr ument used to

safely push the workpiece through the cutting

operation.

Rabbet: A cutting operation that creates an

L-shaped channel along the edge of the board.

Rip Cut: A cut made along the grain of the

workpiece.

Splitter: Metal pl ate to which t he blade guard i s

attached that maintains the kerf opening in the

workpiece when performing a cutting operation.

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool used to check that a

surface is flat or parallel.

Through Sawing: A sawing operation in which

the workpiece thickness is completely sawn

through. Proper blade height usually allows a

1/8" of the top of the blade t o extend above the

wood stock.

Read and understand the entire contents of this manual before attempting

assembly or operat io n! Failure to comply may cause serious injury!

8

Page 9

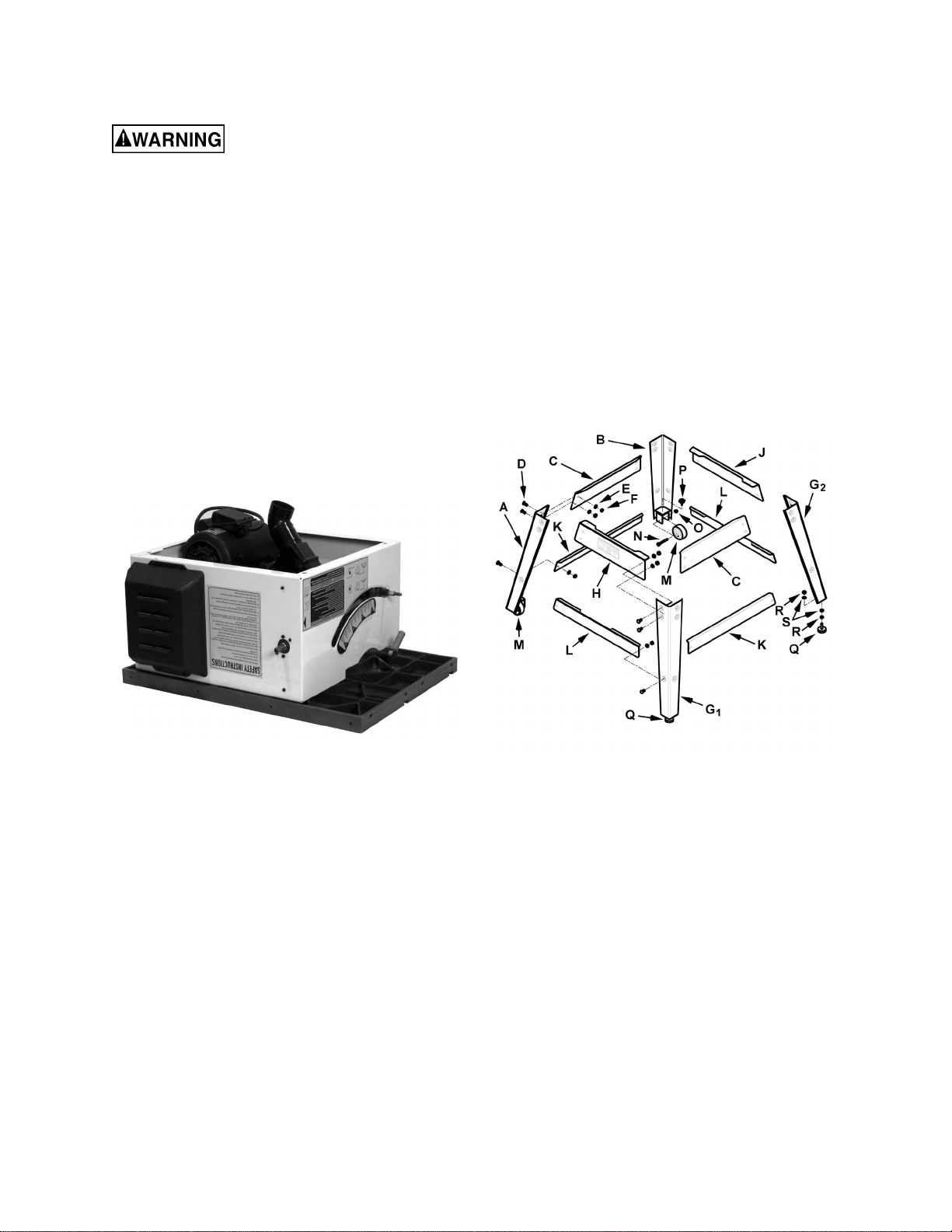

Shipping Contents

Carton Contents

1 ea Table Saw (not shown)

1 ea Front Rail – Long (A)

1 ea Front Rail – Short (B )

1 ea Extension Wing – Left ( C)

1 ea Extension Wing – Right (D)

1 ea Support Rod with mounting screw

and washer (E)

1 ea Rear Rail – Short (F)

1 ea Rear Rail – Long (G)

1 ea Left Leg – Rear (H)

1 ea Left Leg – Front (J)

1 ea Handwheel – Large Mounting Hole (K)

1 ea Handwheel – Small Mount ing Hole (L)

2 ea Right Leg (M)

2 ea Top Plate – Short (N)

2 ea Top Plate – Long (O)

2 ea Support Plate – Short ( P)

2 ea Support Plate – Long (Q)

1 ea Saw Blade (R)

1 ea Fence (S)

1 ea Table Insert (T )

1 ea Blade Guard Assembl y ( U)

1 ea Miter (V)

Carton Contents

9

Page 10

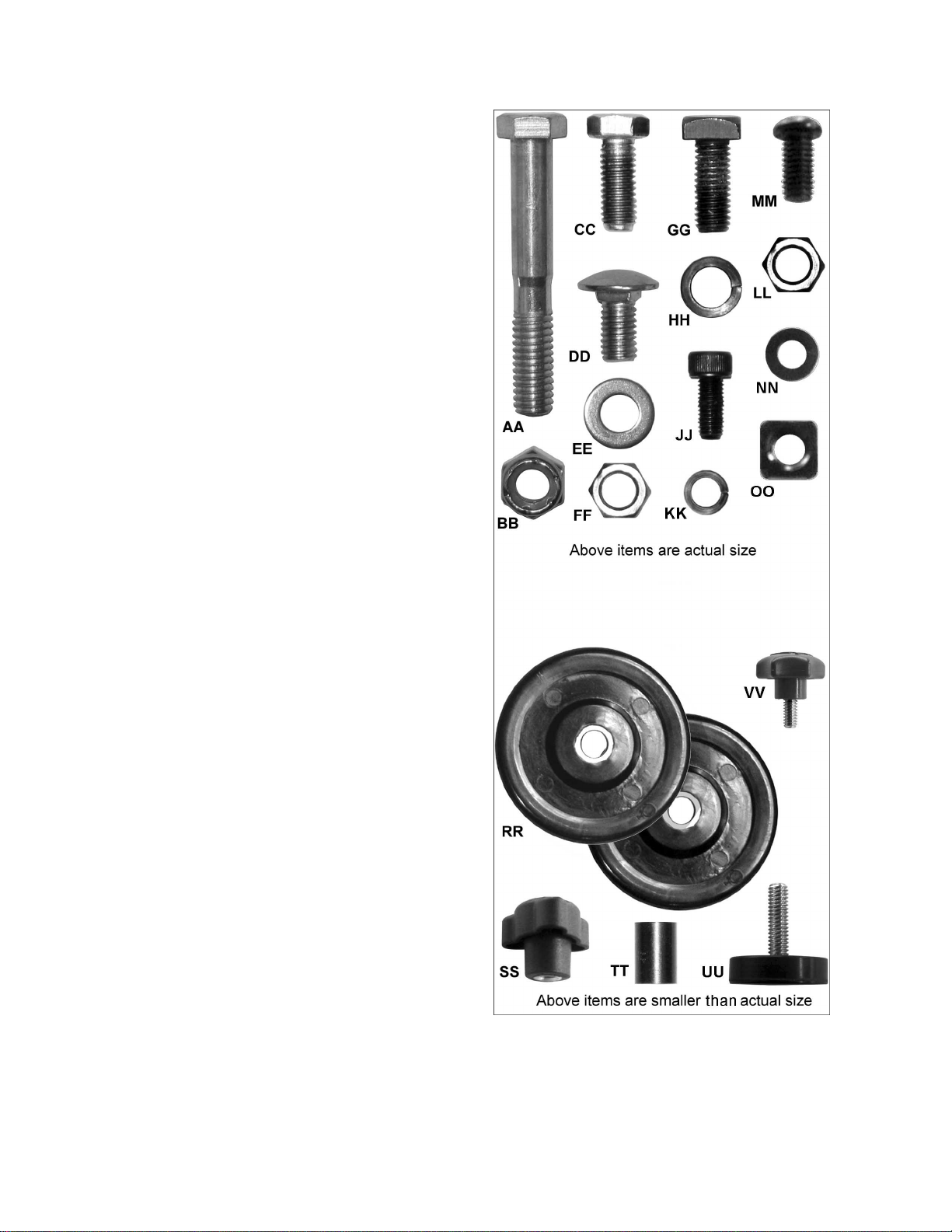

Hardware

The shipping carton includes two hardware bags

with parts f or assembli ng the JWTS-10 Tabl e Saw.

Hardware bag JWT S10-HP cont ains six packets of

parts and JWT S10-SHP contains three packets of

parts. If eit her bag is mi ssing the proper num ber of

packets, contact customer service (phone number

on cover and back pages).

Remove contents from all packets and sort.

Hardware contents can be identified by the

illustration to the right and quantities can be v erified

from the list below.

02 3/8”-16 x 2.5” Hex Cap Screw (AA)

02 3/8” Nylon Insert Lock Nut (B B )

18 M8x20 Hex Cap Screw (CC)

24 M8x12 Carriage Bolt (DD)

36 M8 Flat Washer (EE)

40 M8 Hex Nut (FF)

06 M8 Square Head Bolt (GG)

20 M8 Lock Washer (HH)

01 M5x12 Socket Head Cap Screw (JJ)

01 M5 Lock Washer ( K K)

04 5/16" Hex Nut (LL)

02 M6x10 Pan Head Screw (MM)

02 M6 Washer (NN)

02 M6 Square Nut (OO)

02 Wheel (RR)

01 Lock Knob for Front Handwheel (SS)

01 Bushing (TT)

02 Foot Pad (UU)

02 Lock Knob for Wheels (VV)

Tools Included for Assembly

2 Arbor/Blade G uar d B r acket Wrenc h

1 Hex Wrench (2.5mm)

1 12-14mm Open End Wrench

Addition al Tools Required

1 No. 1 and No. 2 Cross Point Screwdrivers

1 6"– 8" Adjustable W r enc h

1 Accurate Straight Edge (approximately 2 ft )

1 4mm Hex Wrench

1 13mm Box Wrench

Note: Use of sockets and ratchets will speed

assembly time but are not required.

Hardware Content s

10

Page 11

Assembly

Read and understand all

assembly instructions before attempting

assembly! Failure to comply may cause

serious injury!

Unpacking and Cleanup

1. Remove all contents from the shipping carton.

Keep the saw tabl e upside down (Figure 1) and

place on a two-by-f our or similar piec e of wood

under the rear of the saw. This will help when

picking up the t able again. Do not discard t he

carton of packing material until the saw is

assembled and is runni ng satisfactoril y.

2. Inspect the contents for shipping damage.

Report damage, if any, to your distributor.

3. Compare the contents of the shipping carton

with the contents list in this manual. Report

shortages, if any, to y our distr ibutor.

2. Assemble the right legs (G

, G2) to the

1

remaining long top plate (C) in the same

manner.

3. Assemble the short top plate wit h the JET logo

(H) to the front stand legs (A, G

) using the

1

same combination of hardware as used to

attach the long top plates. Hand-tighten the

hardware only at this time.

4. Assemble the remaining short top plate (J) to

the rear stand legs (B, G

) in the same manner.

2

5. Assemble two long support plates (K) to the

inside of the left stand legs (A, B) and right

stand legs (G

, G2) respectively with the same

1

hardware. Hand-tighten only at this time.

Note: The long support plates have no cutouts.

Figure 1

Stand Assembly

Refer to Figure 2.

Tool required – 12mm wrench

Mounting Hardware – the stand (ex cluding wheels)

is assembled usi ng 24 eac h of t he following: M8x16

carriage bolts (D), M8 flat washers (E), and M8

hex nuts (F).

The legs consi st of one lef t front leg, one l eft rear

leg and two right legs. The left legs contain the

wheel mounti ng brackets and are not inter changeable. The ri ght legs are interchangeable. Refer to

Figure 2 for identification and orientation.

1. Assemble the front l eft and rear lef t legs (A, B )

to a long top plate (C) using the mounting

hardware listed above. Hand-tighten only at

this time. The long t op plates hav e no cutouts.

Note: For entire assembly place plates inside legs.

Figure 2

6. Assemble two short support plates (L) to the

inside of the front stand legs (A, G

stand legs (B, G

) respectively with the same

2

) and rear

1

hardware. Hand-tighten only at this time.

Note: The short support pl ates have cutouts.

7. Assemble two wheels (M) t o the left legs with

two 3/8”-16 x 2.5” hex cap screws (N) and two

3/8”-16 nylon insert lock nuts (O) and tighten

with two 13mm wrenches.

8. Place two wheel loc k k nobs ( P ) on the brackets

above the wheels.

9. Attach wheel pad ass emblies to the right l egs

(no wheels), each assembly consisting of one

threaded wheel pad (Q), two 5/16" hex nuts (R)

and two M8 flat washers (S).

11

Page 12

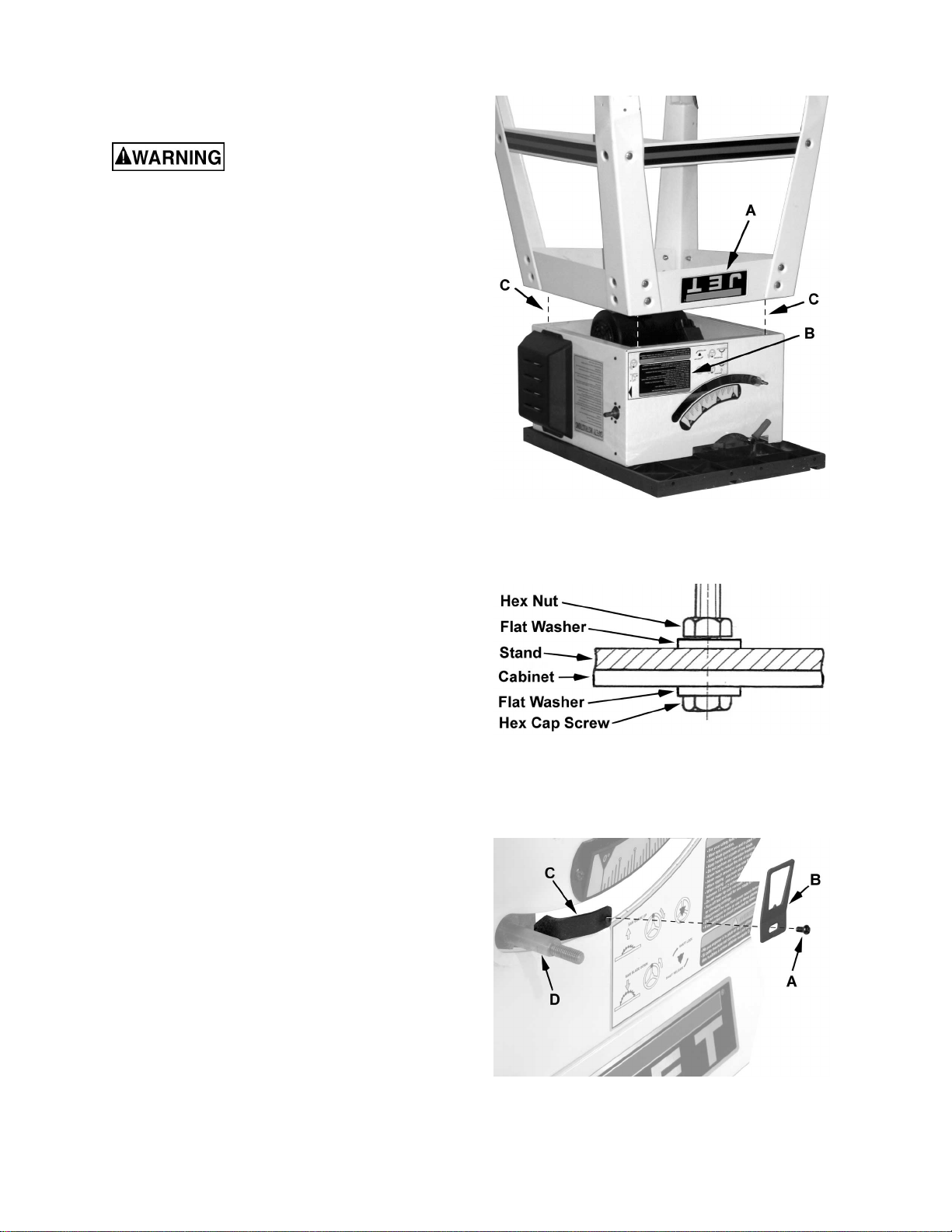

Assembling the Saw to the Stand

Do not plug the table saw into

the power source until all assembly has been

completed! Failure to comply may cause

serious injury!

1. Turn the stand upside down and place ont o the

table saw (Figure 3)

Note: The side with the JET logo (A) is the

front side of the stand and will be on the same

side as the Warning label ( B ) on the table saw.

Line up the holes i n the top pl ates of t he stand

with the holes i n the table saw (C) so t hat the

front of t he stand is f lush with the front of the

saw. The sides of the stand should also be

flush with the si des of the saw.

2. Attach the saw to the stand with four M8x20

hex cap screws, eight M8 flat washers and four

M8 hex nuts using Figure 4 as a guide. Ti ghten

the saw to the stand hardware f irmly.

3. Turn the table saw right side up. Make sure t he

saw is sitting level and with a 12mm wrench

tighten all stand har dware.

Blade Tilt Pointer

Figure 3

Figure 4

Referring to Fi gur e 5:

Secure the blade tilt pointer (B) on the front of the

saw onto the bracket (C) next to the shaft (D) with

an M4 screw (A) and tighten with a cross-point

screwdriver.

Figure 5

12

Page 13

Handwheels

Referring to Fi gur e 6:

The JWTS-10 Tabl e Saw comes equipped with t wo

handwheels which look identical except for the

mounting hol es as follows:

1. On the front of t he table saw slide the bushing

(C) onto shaft (D) followed by the handwheel

(A) with the larger mounting hole, m aking sure

to line up the fl at side in the hole wit h the flat

side on the shaft.

2. Fasten in place wit h lock knob (B).

3. Slide the remaining handwheel (D) with the

smaller mounting h ole onto the shaft (F) on the

right side of the table saw, lining up the fl at side

in the hole with the fl at side on the shaft.

4. Secure wit h an M5 lock washer (E) and M5x12

socket head cap sc r ew (F).

Extension Wings

Referring to Fi gur e 7:

1. Attach the right extension wing (A) to the table

(B) on the right side using four M8 hex cap

screws (C) and four M8 lock washers (D).

Hand-tighten only at this time.

2. Repeat for the left side.

Rear Guide Rail

Referring to Fi gur e 8:

Required Fastening Hardware:

A – 1 ea – Rear Rail (Long)

H – 1 ea – Rear Rail (Short)

E – 6 ea – Hex Cap Screws (M8x20)

F – 6 ea – Lock Washers (M8)

G – 6 ea – Hex Nuts (M8)

Required Tool s:

Two 12mm wrenches

1. Place the long rail (A) agai nst the back of the

right extension (B) and table (C). Line up the

mounting hol es.

2. Insert three hex cap screws (E) through the

rail, extension and table.

3. Place lock washers (F) and hex nuts (G ) on the

threaded ends of the scr ews and hand-t ighten

only at this time.

4. Place the short rail (H) against the back of the

table (C) and left extension (D). Line up the

mounting hol es.

Figure 6

Figure 7

Figure 8

5. Insert three socket head cap screws (E)

through the rail; extension and table.

6. Place lock washers (F) and hex nuts (G ) on the

threaded ends of the scr ews and hand-t ighten

only at this time.

13

Page 14

Front Guide Rail

Referring to Fi gur e 9:

Required Fastening Hardware (see also inset):

A – 6 ea – Square Head Bolt (M8)

B – 6 ea – Lock Washer (M8)

C – 6 ea – Hex Nuts (M8)

Required Tool s:

– 12mm wrench

1. Place six square head bolts (A) through the

mounting holes on the front of the left

extension (F), table (G) and right extension (H).

2. Place lock washers (B) and hex nuts (C) on the

threaded ends of the bolts protruding through

the extensions and table. Just start the hex

nuts but do not tighten.

3. Position all six bolts so that approximat ely 1/4"

of thread is vi sible bet ween the bolt head s and

extensions/table (J).

4. Slide the short rail (D) onto the front edge of

the extension and table from left to right (K).

The back edge of the r ail should make contact

with the f ront edge of the extension and t able

and the square head bolts shoul d slide into the

groove on the back side of t he r ail.

5. In t he same manner described i n step 4, slide

the long rail (E) onto the front edge of the

extension and t abl e from ri ght t o left ( L).

6. Slide the short and long rail sections together

so they become one pi ece. The protrudi ng pins

from the short rail should insert into the

corresponding openings in the long rail.

7. Positi on the entire rail assembl y so the left end

of the rail is about 0.75” i n from the edge of the

left extensi on.

8. Hand-tighten onl y the hex nuts (C) that secure

the front rail to the table.

Support Rod

Referring to Fi gur e 10:

1. Place the tenon end (A ) of the suppor t rod into

the slot (B) of the front rail.

2. Secure the t apped and threaded end (C) of t he

support rod to the rear rail (D) with the M6 flat

washer (E) and M6 hex cap screw (F)

provided.

Figure 9

Figure 10

14

Page 15

Switch Bracket

Referring to Fi gur e 11:

1. Insert two M6x 12 pan head screws (A) through

the back of the switch bracket m ounting holes

(B). Place M6 washers (C) and s quare nuts (D)

on the threaded ends of the screws.

2. Mount the switchbox (C) onto the rail (F) such

that the square nuts (A) slide into the

groove (E) on the lower back si de of t he r ail .

Tighten screws with a c r oss point scr ewdriver.

Extension Wing Adjustment

Referring to Fi gur e 12:

1. Level the left extension wing (B) to the saw

table (C) by using a st raight edge (A). Start by

tightening the three screws (12mm wrench

required) under the extension wing (B) that

secures it to the table (C). Tighten these just

enough to hold the wing in place but loose

enough to change the wing hei ght by tapping

on it.

2. Use the straight edge (A) to level the inside

edge of the ex tension w ing (B) to the table (C).

Tighten the three screws that hold the wings

(B) to the table (C).

Figure 11

3. Nex t bring the straight edge out t o the highest

point on the outside edge of the wing at the

front (A) of the saw. You may have to gr ab the

outside edge of t he ext ension wing and pull up

or push down to lev el. Once the highest point

at the f ront of the saw is locat ed and leveled,

tighten the hardware holding the extension

wing to the front rail.

4. Move the straight edge (D) to the rear of the

same extension wing and repeat this process.

5. Repeat steps 1 – 4 for the right extensi on wing.

Blade Guard and Splitter

Referring to Fi gur e 13:

1. Through the saw table opening on top, locate

two hex nuts (A

plates (B) and loosen with a 10mm wrench.

2. Slide the tab of the blade guard splitter (C)

between the two ret aining plates (B) and onto

the threaded mounting studs (D).

Note: The anti-kickback pawls (E) should be

held back when perf orming this step.

) that secure two retaining

1

Figure 12

3. Tighten the hex nuts (A

) enough to hold the

1

tab (C) in place but l oose enough to allow for

adjustment. You will need to install the blade

before the final adjustment.

Figure 13

15

Page 16

Installing/Replacing the Blade

When inst alling or ch anging the

saw blade, al ways di sconnect the saw f rom the

power source! Failure to comply cay cause

serious injury!

1. Using the handwheels, raise the blade arbor

fully and lock the saw at zero degrees by

tightening the lock knob in the middle of the

hand wheel.

Referring to Fi gur e 14:

2. Using the tools provided, remove the arbor

nut (A) and outer flange ( B). If replacing blade,

remove the old bl ade.

3. Place the blade (C) on the arbor shaft (E)

making sure that the teeth point down at the

front of the saw (note the blade ori entation in

Figure 14). Replace the flange (B) and arbor

nut (A).

4. Tighten the arbor nut (A ).

Aligning the Blade Guard and Splitter

Referring to Fi gur e 15:

1. Raise the blade guard ( A) away fr om the table

and hold the anti-kick pawls (B) away from the

table surface.

2. Pl ace an accurat e strai ght edge (C) against t he

saw blade (D) and splitter (E). For proper

alignment, the blade and splitter should be

perfectly in line with the straight-edge.

If alignment is required:

3. Move the straight-edge aside and through the

opening (see inset ) locate four hex nuts (F, G)

and two retaining plates (H) that secure the

splitter tab (J).

4. Slightly loosen the hex nuts (F, G).

5. To move the splitter (E) right or left, adjust all

four nuts evenly to move the retaining plate

and tab accordingly. To tilt the angle of the

splitter to achieve alignment, adjust the two

front hex nuts (F) or two rear hex nuts (G) only.

6. When adj ustment is complete, tight en the hex

nuts (F, G).

Figure 14

7. Check t he alignment by repeating steps 1 an d

two. If necessary repeat steps 3–8 until proper

alignment is achieved.

Figure 15

16

Page 17

Table Insert

Referring to Fi gur e 16:

1. Raise the blade guard assembly.

2. Lower the blade com pletely.

3. Place the table insert ( A) into the opening wit h

the notched end (B) towards the splitter (C).

A clip underneath t he notch secures the insert

to the tabl e at the rear; a n M5 flat head screw

(E) secures the insert at the front.

4. Adjust the insert (A) flush with the table by

turning f our lev eling setscrews (D) and using a

straight edge (F). A 2.5mm hex wrench is

required to adjust the setscrews.

Rip Fence

Attaching the Rip Fence

Referring to Fi gur e 17:

1. Raise the rip fence handle (A) as shown.

2. Position the rip fence ( B) over the table (C) a s

shown, holding up t he front end while engagi ng

the holding clam p (D) t o the r ear, then loweri ng

the front end (E ) onto the rail (F).

Figure 16

3. Lower the handle (A) t o clamp t he fence to t he

table.

Note: If the rip fence does not hol d onto the rail

tight enough when the handle is lowered,

adjust the hex nut (G) with a 10mm socket.

Calibrating the Rip Fence S c ale

1. Attach the rip fence to the table (as de scribed

in the previ ous section) to the right of t he saw

blade, but do not l ower the handle to cl am p the

fence to the table.

2. Slide the fence against the saw blade.

You will need to raise the blade guar d and the

anti-kick pawl to provide clearance for the

fence.

With the fenc e snug against the saw blade, cl amp

the fence in position by lowering the handle. The

hairline on t he indicator (A) should line up wit h 0"

on the rail (C). If they do not line up:

3. With a 12mm wrench, slightly loosen the six

hex nuts that secure the front rail (F) to the

table (C) and extension wings.

4. Adjust the position of the front rail so the red

hairline indicator (A, Fig. 17) on the fence scale

lines up with 0" (B, Fig. 18) on the rail.

Remember to keep t he fence snug against the

saw blade.

Figure 17

Figure 18

5. When alignment is complete, tighten the six

hex nuts securing the front rail.

17

Page 18

This fence is positioned by lifting up the lock handle

(A, Fig. 19) and sliding to the desired location.

"Fine-tuning" is accomplished by pushing the

micro-adjust k nob in (B, Fig. 19) and at the same

time turning it (C, Fig. 19) until t he ex act positi on i s

read on the scale.

Miter Gauge

Operation

Referring to Fi gur e 20:

Operate the miter gauge by loosening the lock

knob (A) and turning the miter body (B) to the

desired angle.

The pin (C) functions as an index stop. When

pushed in, the body will stop at -45º, 90º or +45º

when turned as one of three screws (D) located

underneath the mit er hits the pin.

Calibration

If a miter angle at the -45º, 90º or +45º is not

correct, the index stops can be adju sted by turni ng

one of three adjustment screws (D), then locking

the hex nut.

Note: Always make test cuts. Do not rely solely on

miter gauge indic ator marks.

Figure 19

Figure 20

18

Page 19

Grounding Instructions

1. All Grounded, Cord-c onnec ted Tools:

In the event of a malfunction or breakdown,

grounding prov i des a path of least resistanc e f or

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a

grounding plug. The plug m ust be plugged into a

matching outlet that is properly installed and

grounded in accord ance wit h all l ocal codes and

ordinances.

Do not modify the plug provided - if it will not fi t

the outlet , have the proper outlet i nstalled by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes is the equipmentgrounding conductor . If repair or replacement of

the electric cord or plug is necessary, do not

connect the equi pment-grounding conductor t o a

live terminal.

3. Grounded, cor d-connected tools intended f or

use on a supply circuit having a nomi nal rati ng

between 150 - 250 volt s, incl usive:

This tool i s intended for use on a ci rcuit t hat

has an outlet t hat l ooks li ke the one i llustr ated i n

Sketch D. The tool has a grounding plug that

looks lik e the plug illustr ated in Sketc h D. Make

sure the tool is connected to an outlet having t he

same configuration as the plug. No adapter is

available or should be used with this tool. If the

tool must be rec onnected for use on a different

type of electric circuit, the reconnection should

be made by qualified service personnel; and

after reconnection, the tool should comply with

all local codes and ordinanc es.

Check with a qualified

electrician or service personnel if the

grounding instructions are not completely

understood, or if in doubt as to whether the

tool is properly grounded. Failure to comply

may cause serious injury or death!

Use only 3-wire extension cords that have 3prong grounding plugs and 3-pole receptacles

that accept the tool's plug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cor d-connected tools intended f or

use on a supply circuit having a nomi nal rati ng

less than 150 volts:

This tool i s i ntended f or use on a ci rcui t that has

an outlet that looks like the one illustrated in

Sketch A. B and C, may be used to connect thi s

plug to a 2-pol e receptacle as shown in Sketch

B if a properly grounded outl et is not available.

The tempor ary adapter should be used only unt il

a properly grounded outl et can be instal led by a

qualified electrician. (This adapter is not

permitted in Canada) The green-colored rigid

ear, lug, and the like, extending from the adapter

must be connected t o a permanent ground such

as a properly grounded outlet box.

Figure 21

Electrical Connections

The JWTS-10 table saw is rated at 115/230V

and comes from the factory prewired at 115V.

The table saw comes with a pl ug designed for

use on a cir cuit with a gr ounded outlet that looks

like the one pictured in A.

To switch the motor for 230V operation, follow

the wiring di agram found on the inside cov er of

the motor j unction box. The plug on the end of

the motor cord will have to be replaced with a

plug that is rat ed 230V.

Before hooki ng up to t he power source, be sure

the switch is in the off position.

Extension Cord Recommendations

12 Gauge Cord 0 – 25 feet

10 Gauge Cord 0 – 50 feet

8 Gauge Cord 0 – 100 feet

19

Page 20

Adjustments

Blade Raising and Tilt Mechanism

Never try to force the tilting

mechanism past the 45º or 90º stops! This may

cause the blade to go out of alignment!

Referring to Fi gur e 22:

To raise or lower the saw blade, loosen the lock

knob (A) and tur n the handwheel (B) on the front of

the saw until the desir ed height i s reached. T i ghten

the lock knob. The blade should be adjusted

between 1/8" to 1/ 4" above the top surf ace of the

material being c ut.

To tilt the saw blade, turn the lock handle (C)

countercloc kwise to l oosen, tur n the handwheel (D)

on the right si de of the saw until the desired angle

is obtained, then tighten the lock handle (C) by

turning cloc k wise.

Adjusting 45º and 90º Positive Stops

1. Disconnect the saw fr om the power source.

2. Raise the table saw blade to its maximum

height using the handwheel .

Figure 22

3. Set the blade at 90º to the tabl e by turning the

blade tilting handwheel counterclockwise

(D, Fig. 22) as far as it will go. Do not force

beyond stop.

4. Place a square (A, Fig. 23) on the table and

check to see that t he blade (B, F ig. 23) is at a

90º angle to the table. Make sure that the

square is not touchi ng a blade tooth.

If adjustment is required:

5. Back out the 90º adjust setscrew (turn

countercloc kwise) one or t wo turn s wi th a 4mm

hex wrench (C, Fig. 23) .

6. Turn the bl ade tilti ng handwheel until the blade

is exactly 90º.

7. Tighten the 90º adjust setscrew until it stops,

but do not force.

8. Set the blade at 45º to the tabl e by turning the

blade tilting handwheel clockwise (D, Fig. 22)

as far as it will go. Do not force beyond stop.

9. Place a square (D, Fig. 24) on the table and

check to see that t he blade (E, F ig. 24) is at a

45º angle to the table. Make sure that the

square is not touchi ng a blade tooth.

If adjustment is required:

10. Back out the 45º adjust setscrew (turn

counterclockwise) one or two turns with a 4mm

Figure 23

Figure 24

hex wrench (F, Fig. 24).

11. Turn t he blade tilti ng handwheel until the blade

is exactly 45º.

12. Tighten the 45º adjust setscrew until it stops,

but do not force.

Check to make sure that the point er on the fr ont of

the saw properly indicates 45º or 0º (90º). If not,

loosen screw and adj ust until the pointer indicates

properly

20

Page 21

Operations

Table Saws

Familiarize yourself with the location and

operation of all controls and adjustm ents and the

use of accessories such a s the miter gauge and

rip fence.

Kickbacks

Serious injury can result from kickbacks which

occur when a work pi ec e binds on the saw blade

or binds between the saw blade an d ri p fenc e or

other fixed object. This binding can cause the

work piece to lift up and be thrown toward the

operator.

Listed below are conditions, which can cause

kickbacks:

• Confining the cut off piece when crosscutti ng

or ripping.

• Releasing the work pi ece before compl eting

the operation or not pushing the work piece

all the way past the saw blade.

• Not using the splitter when ripping or not

maintaining alignment of the splitter with the

saw blade.

• Using a dull saw blade.

• Not maintaining alignment of the rip fence so

that it tends to angle toward rather than

away from the saw blade fr ont t o bac k.

• Applying feed force when ripping to the

cutoff (free) section of the work piece

instead of the section between the saw

blade and fence.

• Ripping wood that is twisted (not flat), or

does not have a strai ght edge, or a twisted

grain.

To minimize or prev ent injury from kickbacks:

Figure 25

Dull, badly set, improper, or improperly filed

cutting tool s and cutting tools with gum or resin

adhering to them can cause accidents. Never

use a cracked saw blade. The use of a sharp,

well maint ained, and correc t cutting tool for the

operation will help to avoid injuries.

Support the work properly and hold it firmly

against the gauge or f ence. Use a push stick or

push block when ri pping short, narrow (6" widt h

or less), or thin work. Use a push block or miter

gauge holddown when dadoing or molding.

For increased safety in crosscutting, use an

auxiliar y wood faci ng (Figur e 26) att ached t o the

miter gauge using the holes provided in the

gauge.

• Avoid conditions listed above.

• Wear a safety face shield, goggles, or

glasses.

• Do not use the m it er gauge and ri p fence i n

the same operation unless provision is made

by use of a f acing board on the f ence so a s

to allow the cutoff section of the workpiece

to come free before the next cut is started

(See Figure 33).

• As the machine rec eives use, the operation

of the anti-kickback pawls should be

checked periodically (Figure 24). If the pawls

do not stop the reverse motion of a

workpiece, resharpen al l the points.

• Where possible, keep your face and body

out of line wit h potential kickbacks includi ng

when starting or stopping the machine.

Figure 26

Never use the fence as a length stop when

crosscutti ng. Do not hold or touch the f ree end

or cutoff section of a workpiece. On throughsawing operations, t he cutoff section must NOT

be confined.

Always keep your hands out of the line of the

saw blade and never reach back of the cutti ng

blade with either hand to hold the workpiece.

Bevel rippi ng cuts should always be made with

the fence on the right si de of the saw blade so

that the blade tilts away from the fence and

minimizes the possi bili t y of the work bi ndi ng and

the resulting kickback.

21

Page 22

Rip Sawing

Ripping is where the work piece i s fed with the

grain into the saw blade using the fence as a

guide and a positioning device to ensure the

desired width of cut (Figure 27).

Figure 27

Before startin g a ripping cu t,

be sure the fence is clamped securely and

aligned properly.

• Never rip freehand or use the mi ter gauge in

combination with the fence.

• Never rip workpi ec es shorter than the saw

blade diamet er.

• Never reach behind the blade with either

hand to hold down or remove the cutoff

piece with the saw blade rotat ing.

Always use the blade guard, splitter and antikickback pawls. Make sure the splitter is

properly aligned. When wood is cut along the

grain, the kerf tends to close and bind on the

blade and kickback s can occ ur .

on the front rail, or by measuring the distance

between the blade (B ) and fence (A ). Stand out

of line with the saw blade and workpiece to

avoid sawdust and splinters coming off the blade

or a kickback, if one shoul d oc c ur .

If the work pi ece does not hav e a straight edge,

nail an auxiliary straight edged board on it to

provide one again st the fence. To c ut properly,

the board must make good contact with the

table. If it is warped, tur n the hollow side down.

In ripping, use one hand to hol d the board down

against the fence or fixture, and the other to

push it into t he bl ade between the bl ade and the

fence. If the workpiece is narrower than 6" or

shorter than 12", u se a push stick or push block

to push it through between the fence and saw

blade (Fi gure 29). Nev er push in a loc ati on such

that the pushing hand is in line with the blade.

Move the hand serving as a hold-down a safe

distance from the blade as the cut nears

completion. For very narrow ripping where a

push stick cannot be used, u se a push block or

auxiliary fence. Always push the workpiece

completely past the blade at the end of a cut to

minimize the possibility of a kickback.

Note: A caution decal is installed on the guard

and splitter assembly warning of the hazard of

misalignment.

Figure 28

The rip fence (A, Fig. 28) should be set for the

width of t he cut (C, Fig. 28) by using the scale

Figure 29

Figure 30

22

Page 23

When ripping l ong boards, use a support at the

front of the tabl e, such as a roller stand, and a

support or "tailman" at the rear as shown in

Figure 30.

Never use the rip f ence beyond the point where

the carriage i s flush with the end of the rails.

Have the blade ext end about 1/8" abov e the t op

of the workpiece. Exposi ng the blade abov e this

point can be hazardous.

Resawing

Resawing is a ripping operation in which thick

boards are cut i nto thi nner ones. Narrow board s

up to 3" can be resawed in one pass. Wider

boards up to 6" must be resawed in two passes.

In resawing wider boards, adjust the blade

height so as to overl ap the two cuts by 1/2" as

shown in Figure 31. Too deep a first cut can

result in binding and possible kickbacks on the

second cut. Always use the same side of the

board against the fence for both cuts.

Crosscutting should never be done freehand nor

should the fence be used as an end stop unless

an auxili ary block is clamped t o the front of the

blade area such that t he cut off piece comes f ree

of the block before cutting starts (Figure 33).

Figure 33

Length stops should not be used on the free end

of the workpiece in the cutoff area.

Do not crosscut workpieces shorter than 6".

Before starti ng a cut, be sure the mit er gauge is

securely cl amped at the de sired angle. Hold the

workpiece firmly against the table and back

against the miter gauge. Always use the saw

guard and spli tter and make sure the spli tter is

properly aligned.

Figure 31

Crosscutting

Crosscutting i s where the workpi ece i s f ed cross

grain into the saw blade using the miter gauge to

support and position the workpiece (Figure 31) .

For 90 degree crosscutting, most operators

prefer to use the left-hand miter gauge slot.

When using it i n this position, hold the workpiece

against the gauge wi th t he lef t hand and use the

right hand to advance the workpiece. When

using the right hand slot for miter and c ompound

crosscutting so that the blade tilt s away f rom th e

gauge, the hand positions are reversed.

When using the miter gauge, the workpiece

must be held firml y and advanced smoot hly at a

slow rate. If the workpiece is not held firmly, it

can vibrate c ausing it to bind on the blade and

dull the saw teeth.

Figure 32

Figure 34

23

Page 24

To improve t he effec tiveness of the mit er gauge

in crosscutting, some users mount an auxiliary

wooden extension f ace (with a glued-on strip of

sandpaper) to the miter gauge as shown in

Figure 34.

Provide auxiliary support for any workpiece

extending beyond t he table top with a tendency

to sag and lift up off the table.

Stop rods can be used in the hol es provided in

the miter gauge for repetitive work of equal

length. Do not use a stop rod on the f ree end of

a workpiece. It should be used on the side of the

miter gauge opposite the saw blade.

Have the blade ext end about 1/8" abov e the t op

of the workpiece. Exposi ng the blade abov e this

point can be hazardous.

Align-a-rip

same manner as ripping or crosscutting except

the fence or miter gauge shoul d be used on the

right-hand side of the saw blade to provide

added safety in avoiding a binding action

between the saw bl ade and the tabl e top. W hen

beveling with the miter gauge, the workpiece

must be held firml y to prevent creeping.

The yellow align-a-rip pad on the saw table is

used for creating a mark that lines up the

workpiece with the saw blade. After the first

workpiece is cut with the miter gauge, turn the

saw off and pull the miter gauge together with

the workpiece back. The workpiece must be

unmoved and still against the miter fence. The

cut edge of the workpiece is pul led over the pad

and the pad can be marked with a pencil

(A, Fig. 35). Now, when cutting the next marked

workpiece, the workpiece can be lined up with

the line on the pad and cut.

Figure 36

Crosscut – Crosscut s made at an angl e to the

edge of the workpiece are called miters

(Figure 37). Set the miter gauge at the required

angle, lock the miter gauge, and make the cut

the same as a normal crosscut except the

workpiece must be held extra firmly to prevent

creeping.

Note: When making compound miters (with

blade tilted) use the miter gauge in the right

hand slot to provide more hand clearance and

safety.

Have the blade extend only 1/8" above the top of

the workpiece. Exposing the blade above this

point can be hazardous.

Figure 35

Bevel and Miter Operations

Bevel Cut – A bevel cut is a special type of

operation where the saw blade is tilted at an

angle less than 90 degrees to the table top

(Figure 36). Operations are performed in the

Figure 37

24

Page 25

Dado Cutting – Dadoing is cutting a wide

groove into a workpiece or cutting a rabbet

along the edge of a workpiece. A dado insert,

shown in Figure 38, is necessary for this type of

operation.

A dado insert (stock # 708098) designed to fit

the JWTS-10 Table Saw can be ordered from

your dealer or WMH Tool Group.

Do not use the standard table

insert for dadoing operations.

Safety Devices

Feather Board

The feather board (Figure 39) should be made

of straight grain hardwood approximately 1" thick

and 4" to 8" wide depending on t he size of the

machine. The length i s developed i n ac c or danc e

with intended use. Feather boards can be

fastened to the table or rip fence by use of

C-clamps. Alt ernat iv ely, drill ed and tapped h ol es

in the tabl e top allow the use of wing nut s and

washers as a m ethod of clamping. If this method

of fasteni ng is used, provi de slots in the f eather

board for adjustment. (The illustration shows a

method of attaching and use of the feather

board as a vertical comb. The horizontal

application is essentially the same except that

the attachment is to the table top.)

Figure 38

The process of cut ting 1/8" to 13/16" groov es in

workpieces is accomplished by the use of a

stacked dado blade set or an adjustable type

blade mounted on the saw arbor. By using

various combinations of the stacked dado

blades, or properly setting the dial on an

adjustable blade, an accurate width dado can be

made. This is very useful for shelving, making

joints, tenoning, etc. The guard, splitter, and

anti-kickback pawls supplied with the saw

should be used f or all cutting operations where

they can be used. W hen performing operati ons

where the guard can not be used, as in some

dadoing operations, alternative safety

precautions should be taken. These include

push sticks, f eather boards, filler pieces, fixtures,

jigs and any other appropriate device that can

be utiliz ed to keep operator's hands away f rom

the blade. Upon completion of the operation

requiri ng removal of the guard, the entire guard

assembly m ust be placed back on the m achine

in its proper working or der .

Figure 39

Never use a dado head in a

tilted posi tion . Never operate the saw wi thou t

the blade guard, splitter and anti-kickback

pawls for operations where they can be

used.

25

Page 26

Filler Piece

Push Stick & Push Block

A filler piec e (Figure 40) is necessary for nar row

ripping and permits the blade guard to remain on

the machine. It also provides space f or the safe

use of a push stick.

Figure 40 – Filler Piec e

The use of a pus h block or push stick provides

an added level of safet y for the operator.

See the templates in Figures 41 and 42 for

construction details, or purchase one from the

JET, Performax and Powermatic Woodworking

Machinery and Acces s or ies catalog.

Figure 41 – Push Block Tem plate

Figure 42 – Push Stick Template

26

Page 27

Maintenance

Always disconnect power to the machine before performing maintenance. Failure

to do this may result in serious personal injury.

Cleaning

Clean the JWTS-10 according to the schedule

below to ensure maximum performance.

Note—The following maintenance schedule

assumes the saw is being used ever y day .

Daily:

• Wipe down the table surface and grooves

with a rust preventive.

• Clean the pitch and resin from the saw

blade.

Weekly:

• Clean the motor housing with compressed

air.

• Wipe down the fence rails with a dry silicon

lubricant.

Lubrication

Lubricate the areas indicated below every 12

months.

• Lubricate blade angling trunnions with 6 or 7

drops of light machine oil.

• Lubricate t he bl ade height trunnion with 6 or

7 drops of light mac hine oil.

• Worm gears and threads should be

lubricated with an automotive wheel bearing

grease.

Check all adjustments after lubricating.

Miscellaneous

Always be aware of the condition of your

machine. Routinely check the condition of the

following items and repair or replace as

necessary:

• Mounting bolts

• Power switch

• Saw blade

• Blade guard

27

Page 28

Troubleshooting

Symptom Possible Cause Correction

Low voltage. Check power line for proper voltage. Motor will not st art

Motor will not st art: fuses

or circuit breakers blow.

Motor stalls resulting in

blown fuses or tripped

circuit.

operating.

Loud, repetitious noise

coming from machine.

Open circuit in motor or loose

connection.

Short circuit in line cord or plug. Inspect cord or plug for damaged insulation

Short circuit in motor or loose

connections.

Incorrect fuses of circuit breakers in

power line.

Motor overloaded. Reduce load on motor. Motor overheats.

Air circulation through the motor

restricted.

Short circuit in motor or loose

connections.

Low voltage. Correct the low voltage conditions.

Incorrect fuses of circuit breakers in

power line.

Motor overloaded. Reduce load on motor.

Applying too much pressure to

workpiece.

Belts lo ose. Tighten belts.

Pulley setscrews or keys are missing

or loose.

Motor fan is hitting the cover. Tighten fan or shim cover.

Inspect all lead connections on motor for

loose or open connections.

and shorted wires.

Inspect all connections on motor for loose or

shorted terminals or worn insulation.

Install correct fuses or circuit breakers.

Clean out motor to provide normal air

circulation.

Inspect connections on motor for loose or

shorted terminals or worn insulation.

Install correct fuses or circuit breakers.

Feed workpiece slower. Machine slows when

Inspect keys and setscrews. Replace or

tighten if necessary.

Blade is not square with

the miter slot or fence is

not square to the blade.

when sliding on the table.

degrees.

V-belt is defective. Replace V-belt.

Blade is warped. Replace saw blade.

Table top is not parallel to the blade. Adjust table parallel to the blade.

Fence is not parallel to the blade. Adjust fence parallel to the blade.

Front rail is bolted too low to the table. Raise the front rail. Fence hits the table top

Rear rail is bolted too low on the table. Raise the rear rail.

90 degree stop bolt is out of

adjustment.

Pointer bracket is hitting before the

blade reaches 90 degrees.

Adjust the 90 degree stop bolt. Blade does not reach 90

File down the right side of the pointer

bracket until the blade can reach 90

degrees.

28

Page 29

Parts

JWTS-10 Table and Cabinet Parts List

Index No. Part No. Description Size Qty

1...............JWTS10-301........... Table................................................................. ...................................1

2...............JWTS10- 3 0 2........... Extension Wing , Left.......................................... ...................................1

3...............JWTS10- 3 0 3........... Extension Wing , R ig h t........................................ ...................................1

4...............JWTS10-304........... Guide Line Pl ate................................................ ...................................1

5...............TS-2285121............Flat Head Screw................................................M5x12........................1

6...............TS-1524051............Set Screw.......................................................... M8x20........................2

7...............TS-1522011............Set Screw.......................................................... M5x5..........................4

8...............JWTS10- 3 0 8........... Table Inse r t....................................................... ...................................1

9...............TS-1490031............Hex Cap Screw

10.............TS-2361081............ Lock Washe r *...................................................M8..............................8

11.............JWTS10-311........... Cover................................................................. ...................................1

12.............TS-1532032............ Pan Head Screw................................................ M4x10........................4

13.............JWTS10-313........... Cabinet.............................................................. ................................... 1

14.............JWTS10-172........... External Tooth Lock Washer.............................. M8..............................3

15.............TS-1490021............ Hex Cap Screw..................................................M8x16........................3

................. JWTS10-BG............ Blade G uar d Assembly (#16 thru #26)................ ...................................1

16.............JWTS10-316........... Warning Label ................................................... ...................................1

17.............JWTS10-317........... Push Nut............................................................ ...................................4

18.............JWTS10-318........... Blade G uard...................................................... ...................................1

19.............JWTS10-319........... Pin..................................................................... ...................................1

20.............JWTS10-320........... Support Arm...................................................... ...................................1

21.............JWTS10-321........... Anti-Kickback Pawl............................................ ...................................2

22.............JWTS10-322........... Bushing............................................................. ...................................2

23.............JWTS10-323........... Spring Pin.......................................................... Ø4x20.........................1

24.............JWTS10-324........... Pin..................................................................... ...................................1

25.............JWTS10-325........... Splitter............................................................... ...................................1

26.............JWTS10-326........... Spring................................................................ ...................................1

................. JWTS10-MG...........Miter Gauge Assembly (#27 thru #40)................ ...................................1

27.............JWTS10-327........... Handle............................................................... ...................................1

28.............TS-0680041............ Flat Washer....................................................... 3/8”.............................1

29.............JWTS10-329........... Miter Gauge Body.............................................. ...................................1

30.............TS-2284202............ Pan Head Screw................................................ M4x20........................3

31.............TS-1540021............ Hex Nut.............................................................M4..............................3

32.............TS-1533032............ Pan Head Screw................................................ M5x10........................1

33.............JWTS10-333........... Pointer............................................................... ...................................1

34.............JWTS10-334........... Bracket.............................................................. ...................................1

35.............JWTS10-335........... Stop Pin............................................................. ...................................1

36.............JWTS10-336........... Screw................................................................ ...................................1

37.............JWTS10-337........... Miter Bar............................................................ ...................................1

38.............JWTS10-3 38........... Guide Washe r.................................................... ...................................1

39.............JWTS10-339........... Flat Head Screw................................................M6x8..........................1

40.............JWTS10-340........... Scale................................................................. ...................................1

41.............JWL1442-118.......... Switch................................................................ ...................................1

42.............JWTS10-342........... Switch Box......................................................... ...................................1

43.............JWTS10-217........... Self Tapping Screw ............................................ M4x8..........................3

44.............JWTS10-344........... Power Cord ....................................................... ...................................1

45.............JWTS10-242........... Square Nut *...................................................... ...................................2

46.............TS-1550041............ Flat Washer *..................................................... M6..............................2

47.............JWTS10-347........... Switch Box Plate................................................ ...................................1

48.............TS-1534032............ Pan Head Screw * ............................................. M6x10........................2

49.............JWTS10-349........... Cord Strain Relief .............................................. SB8R-3.......................2

*

* ............................................... M8x20........................8

*

* Refer to Note on page 32

29

Page 30

JWTS-10 Table and Cabinet Exploded View

30

Page 31

Motor and Trunnion Assembly Parts List

Index No. Part No. Description Size Qty

1...............VB-A31...................Belt.................................................................... A-31 ...........................1

2...............JWTS10-102........... Belt.................................................................... 125J ...........................1

3...............TS-2342102............Nylon Insert Lock Nut......................................... M10-1.25P..................1

4...............TS-1550071............Flat Washer....................................................... M10............................1

5...............JWTS10-105........... Pulley................................................................ ...................................1

6...............JWTS10-106........... W asher.............................................................. ...................................1

7...............BB-6202VV.............Ball Bearing.......................................................6202-2NSE.................2

8...............JWTS10- 108........... Wave Washer.................................................... BWW-6202.................1

9...............JWTS10-109........... Retaining Ring, External. ................................... STW-15......................2

10.............JWTS10-110........... Pulley ................................................................ ...................................1