Page 1

This manual is bookmarked

Operating Instructions and Parts Manual

Planer

Model: JWP-208

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-708528

Ph.: 800-274-6848 Revision G1 06/06

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of

these WMH Tool Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET® tools. For the name of an Authorized Service Center in

your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check

with your local WMH Tool Group distributor, or visit jettools.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product. (MW = Metalworking, WW =

Woodworking)

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option.

We will return the repaired product or replacement at our expense unless it is determined by us that there is no

defect, or that the defect resulted from causes not within the scope of our warranty in which case we will, at your

direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY,

OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE

OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information

and are not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

JET® branded products are not sold in Canada by WMH Tool Group.

2

Page 3

Table of Contents

Table of Contents.......................................................................................................................................... 3

Warnings .......................................................................................................................................................4

Features ........................................................................................................................................................6

Specifications ................................................................................................................................................6

Receiving....................................................................................................................................................... 7

Installation & Assembly ................................................................................................................................. 7

Starter Box................................................................................................................................................. 7

Handwheel................................................................................................................................................. 8

Table Extension Rollers.............................................................................................................................8

Dust Collection Hood................................................................................................................................. 8

Electrical Connections................................................................................................................................... 9

Extension Cords ........................................................................................................................................ 9

Adjustments ..................................................................................................................................................9

Belt and Pulleys......................................................................................................................................... 9

Table Rollers ...........................................................................................................................................10

Overview ..............................................................................................................................................10

Adjusting Table Extension Rollers ....................................................................................................... 11

Adjusting Depth of Cut.............................................................................................................................12

Cutterhead Adjustment............................................................................................................................ 12

Overview ..............................................................................................................................................12

Knife Adjustment..................................................................................................................................12

Replacing & Resetting Knives .................................................................................................................13

Adjusting Work Table Parallel to Cutterhead .......................................................................................... 14

Anti-Kickback Fingers..............................................................................................................................15

Adjusting Infeed & Outfeed Roller Spring Tension.................................................................................. 15

Height of Infeed Roller, Chipbreaker, Pressure Bar & Outfeed Roller ....................................................16

Feed Speed Control ................................................................................................................................ 17

Changing Accessories for Lowest Feed Speed ......................................................................................17

Return Rollers.......................................................................................................................................... 17

Maintenance................................................................................................................................................ 18

Lubrication................................................................................................................................................... 18

Troubleshooting ..........................................................................................................................................20

Operating Problems.................................................................................................................................20

Mechanical and Electrical Problems .......................................................................................................21

Optional Accessories ..................................................................................................................................22

Ordering Replacement Parts.......................................................................................................................22

Parts ............................................................................................................................................................ 22

Head Assembly – Parts List .................................................................................................................... 22

Head Assembly – Exploded View ...........................................................................................................25

Table and Roller – Parts and Assembly.................................................................................................. 26

Stand and Motor – Parts and Assembly.................................................................................................. 27

Base and Column – Parts List.................................................................................................................28

Base and Column – Assembly ................................................................................................................ 29

Gearbox – Parts List................................................................................................................................ 30

Gearbox – Assembly ...............................................................................................................................31

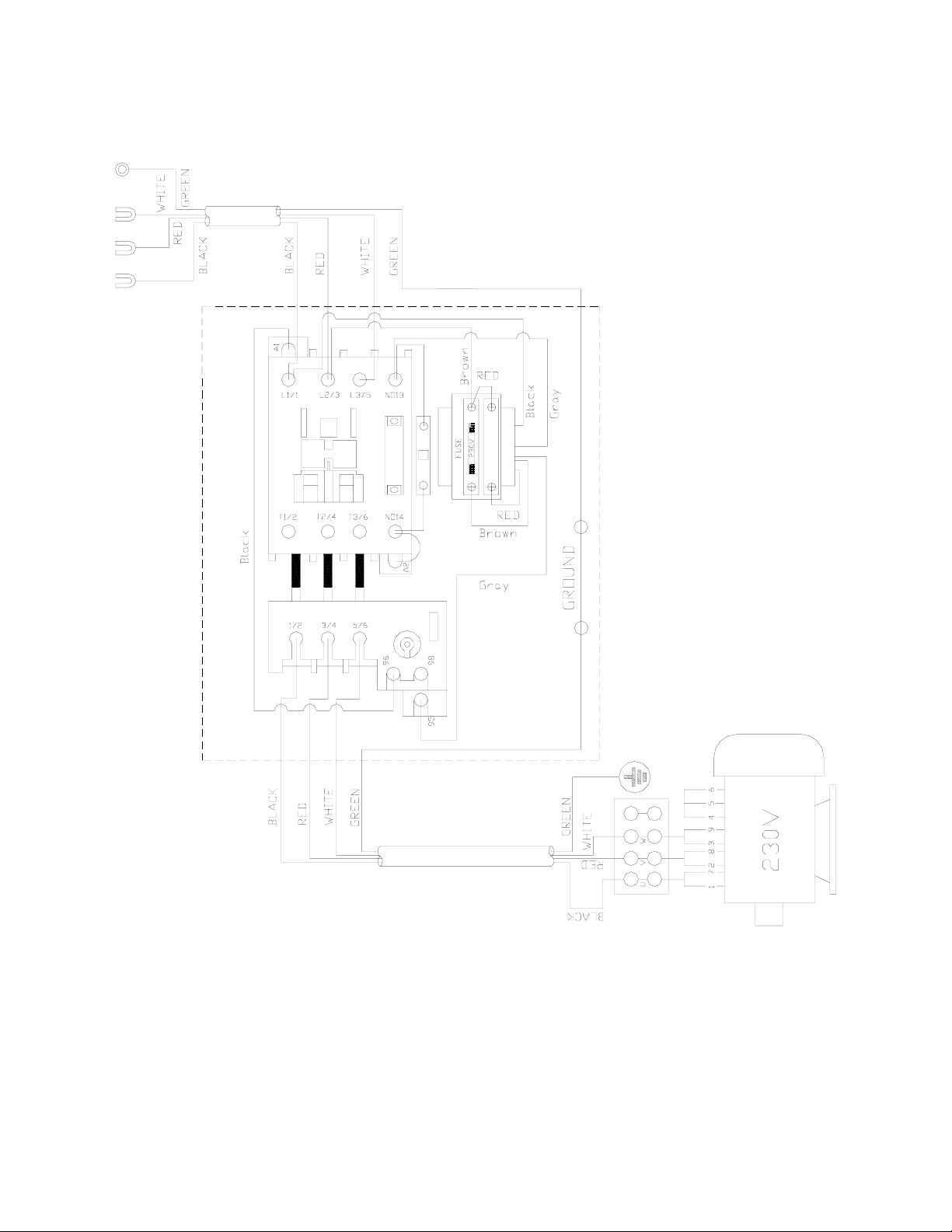

Wiring Diagrams.......................................................................................................................................... 32

230V 3HP Single Phase.......................................................................................................................... 32

230V 5HP Three Phase ..........................................................................................................................33

460V 5HP Three Phase ..........................................................................................................................34

3

Page 4

Warnings

Read the manual. Always read the owner’s manual carefully before attempting to use the machine.

Know the limitations and hazards associated with the use of this planer.

Installation. If mounting machine to the floor, use high quality anchor bolts through the mounting holes

on the base. If using a mobile base, be sure to lock the wheels.

Eye protection. Always wear approved safety goggles, glasses, or a face shield when operating this

machine. NOTE: Common eyeglasses are only impact resistant, they are not safety glasses. Also use

face or dust mask if the cutting operation is dusty.

Dress code. Do not wear loose clothing, neckties, jewelry, or gloves that can get caught in moving parts.

Confine long hair. Keep sleeves above the elbow.

Placement. Place machine so that potential kickback area is not in line with aisles, doorways, wash

stations or other work areas. Do not use machine in a damp or wet location, or expose to rain. Keep work

area well lighted.

Electrical grounding. Your machine must be electrically grounded. If a cord and plug are used, make

certain the grounding lug connects to a suitable ground. Follow the grounding procedure indicated by the

National Electrical Code.

Guards. Be sure machine guards are in place and in good working order. Do not operate while gear

cover is open. If a guard must be removed for adjustments or maintenance, it should be reinstalled

immediately upon completion of the procedure and before operating the machine.

Housekeeping. Before turning on machine, remove all extra equipment such as keys, wrenches, scrap,

stock, and cleaning rags from the machine. Keep the area around machine clean and free of scrap

material and sawdust to minimize the danger of slipping.

Power off. Make sure the machine is either unplugged or electrically disconnected and locked out when

performing maintenance or service work. Also, make sure switch is in OFF position before plugging in

power cord. Never leave the machine running unattended. Do not leave machine until it comes to a

complete stop.

Cutterhead. Keep knives sharp and free of all rust and pitch. Make sure gib screws are tightened

securely.

Work piece. Check material for loose knots, nails and other defects that can damage knives and pose a

safety hazard for the operator.

Keep hands away from feed rollers and cutterhead while operating.

Use the proper extension cord. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersize cord will cause a drop in line voltage resulting in loss of power and overheating. For runs up to

25 feet, use an 18 AWG or larger gauge cord.

Do not operate this machine while under the influence of drugs, alcohol or any medication.

If you are not thoroughly familiar with the operation of wood planers, obtain advice from your supervisor,

instructor or other qualified person.

Health hazards. Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

x Lead from lead-based paint.

x Crystalline silica from bricks and cement and other masonry products.

x Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area, and work with approved safety equipment,

such as those dust masks that are specifically designed to filter out microscopic particles.

4

Page 5

Safety Decals

Familiarize yourself with the location and content of these decals on your planer.

!

1. Read instruction manua l before operating machine.

2. Do not operate without all guards properly installed.

3. Remove or fasten loose ar ticles of clothing such as neck ties, etc.

Contain long hair.

4. Remove jewelry such as fi nger rings, watches, bracel ets, etc.

5. Use approved safety glasses and/or face shield to pr otect eyes, and

use other personal safety equip ment as required. Do not wear

gloves.

DO NOT REMOVE OR OBSCURE THIS LABEL

Fig. 1

6. Disconnect machine f rom power source before maki ng any

adjustments or cleaning chips away from mach ine.

7. Keep the floor around m achine clean and free from scra ps,

sawdust, oil and grease to minimiz e the danger of slipping.

8. Do not operate this machine while under the influence of alcohol

or drugs .

9. Failure to comply with these warnings may result in serio us

personal injury.

5

Page 6

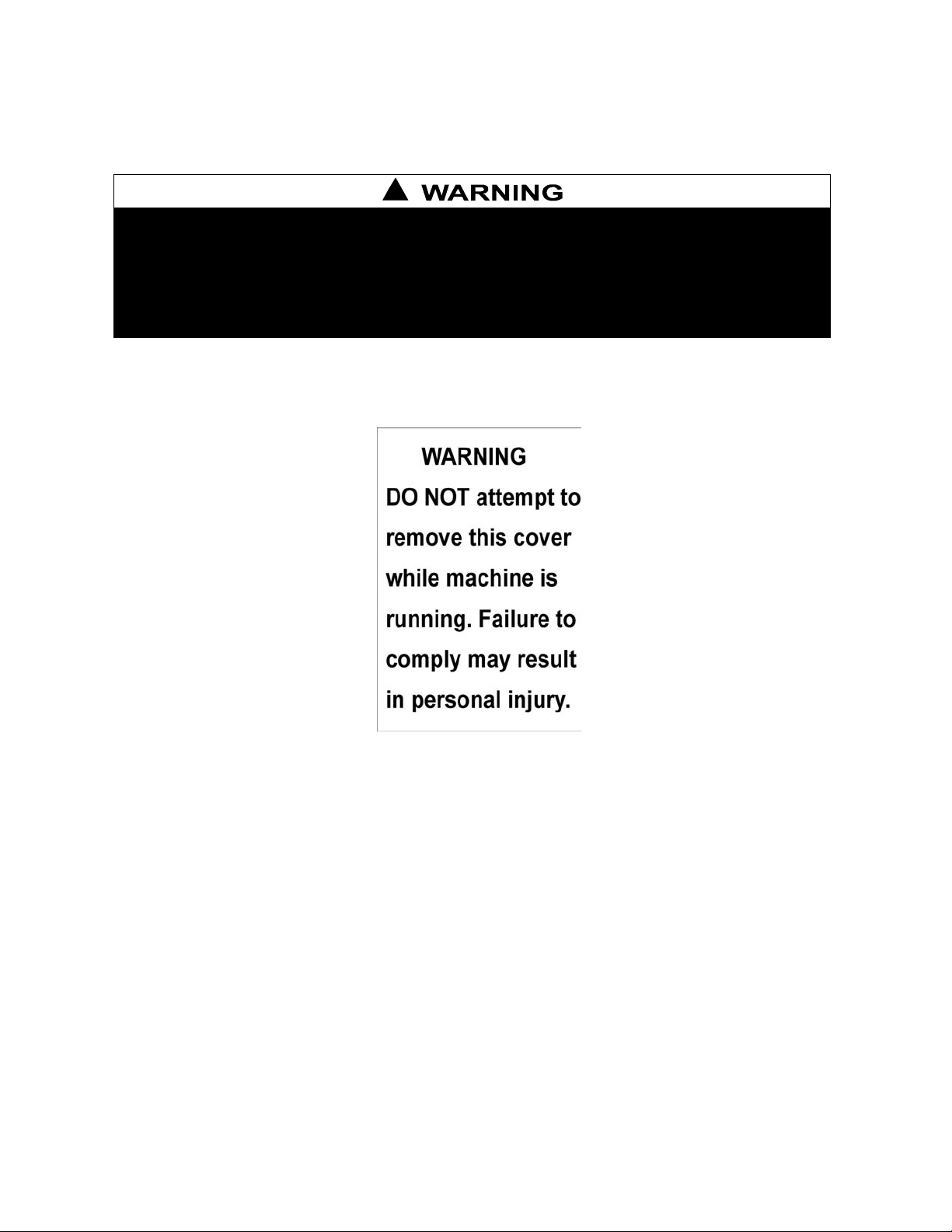

Features

Fig. 2

Specifications

Model No............................................................................ JWP-208-1........................................JWP-208-3

Stock No................................................................................... 708528.............................................. 708584

Table Area (D x W/in.)........................................................ 25-3/4 x 20........................................25-3/4 x 20

Maximum Planing (W/in.) ................................................................. 20...................................................... 20

Maximum Planing (T/in.) .................................................................... 6........................................................ 6

Full Width Cutting Depth (in.)........................................................ 3/32................................................... 3/32

Minimum Planing Depth (in.)........................................................ 6-3/4..................................................6-3/4

Knives................................................................................................. 4........................................................ 4

Blade Size (L x W x T/in.)...................................................20 x 1 x 1/8....................................... 20 x 1 x 1/8

Cutterhead Speed (RPM)............................................................ 5,000................................................. 5,000

Cuts per Minute......................................................................... 20,000............................................... 20,000

Cutterhead Diameter (dia/in.)..................................................... 3-3/16................................................3-3/16

Feed Rate (FPM) .....................................................................24 & 31..............................................24 & 31

Dust Chute Diameter (dia/in.)............................................................. 5........................................................ 5

Overall Dimensions (L x W x H/in.) ...................... 26 x 36-5/8 x 41-3/8.......................... 26 x 36-5/8 x 41-3/8

Motor ....................................................................3HP, 1Ph,230V only......................... 5HP, 3Ph, 230/460V

................... (prewired 230V)

Overall Dimensions (L x W x H/in.) ...................... 26 x 36-5/8 x 41-3/8.......................... 26 x 36-5/8 x 41-3/8

Net Weight (approx. lbs.) ............................................................... 640.................................................... 640

The specifications in this manual are given as general information and are not binding. WMH Tool Group

reserves the right to effect, at any time and without prior notice, alterations to parts, fittings, and

accessory equipment deemed necessary for any reason whatsoever.

6

Page 7

Receiving

Carefully unpack the planer and any loose items

from the wood crate and inspect for damage. Any

damage should be reported immediately to your

distributor and shipping agent. Before proceeding

further, read your manual thoroughly to familiarize

yourself with proper assembly, maintenance and

safety procedures.

Remove the screws that hold the planer to the

shipping skid. Remove the protective coating from

the table, bed rolls, feed rolls, cutterhead and

loose items packed with the machine, including

lifting handles and motor pulley. This coating may

be removed with a soft cloth moistened with

Kerosene. Do not use acetone, gasoline or

lacquer thinner for this purpose. Do not use

solvents on plastic parts.

Use care when cleaning the

cutterhead, the knives are very sharp.

Installation & Assembly

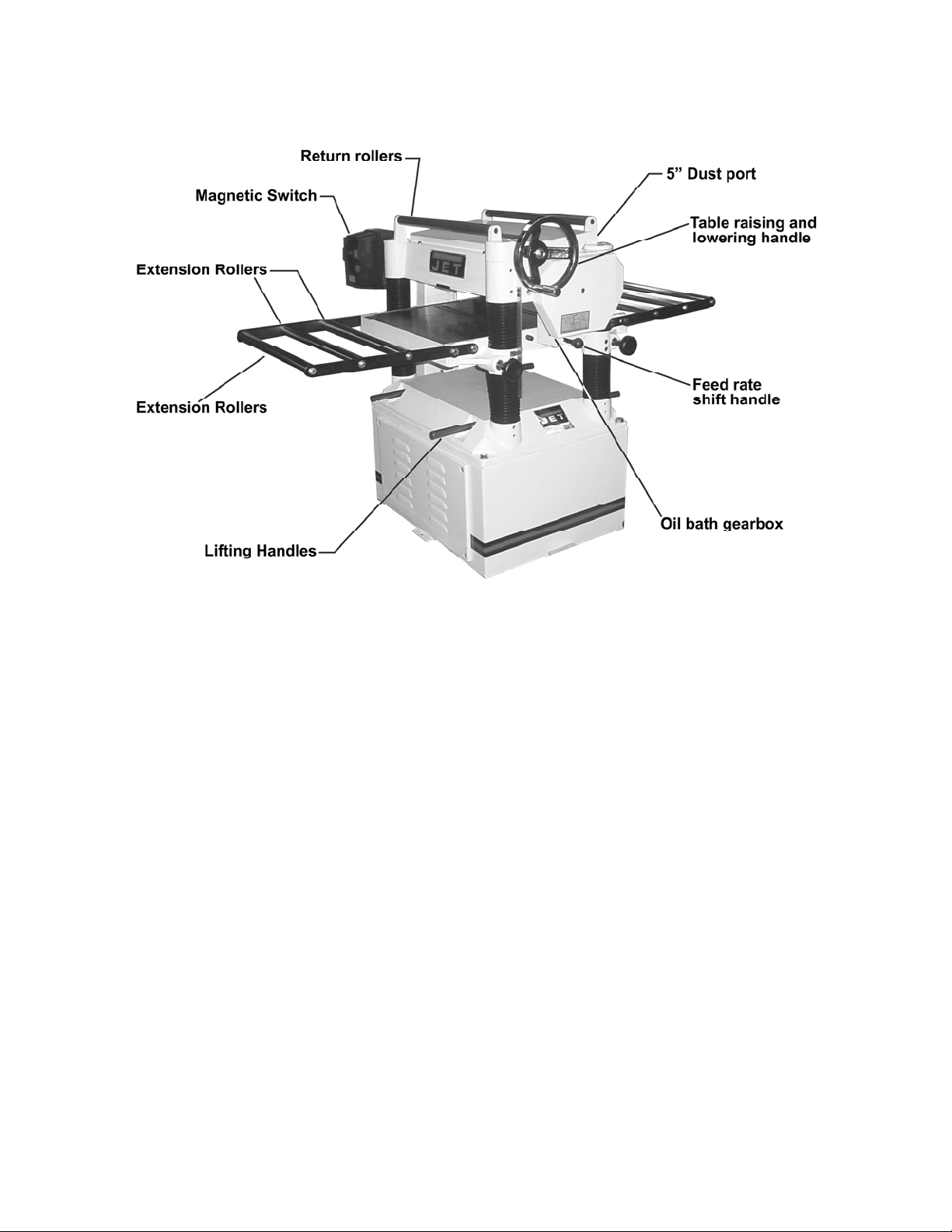

1. There are four lifting handles (Fig. 3) on the

machine. Pull the handles out for use, push in

when not in use.

2. If a sling or forklift is used to lift the machine,

be sure to lift by the handles only. See Fig. 3.

Make sure machine is kept in level position

while lifting.

3. For best planing performance, locate planer

on a solid, level foundation and anchor to the

floor with good quality lag screws. Do not

tighten screws completely yet.

4. With machine in position, test table surface

lengthwise and crosswise with machinist’s

level. Place metal shims under low corners.

5. Check that all four corners are supported,

then tighten lag screws.

6. Re-test level of table surface in both directions

and adjust if necessary.

Figure 3

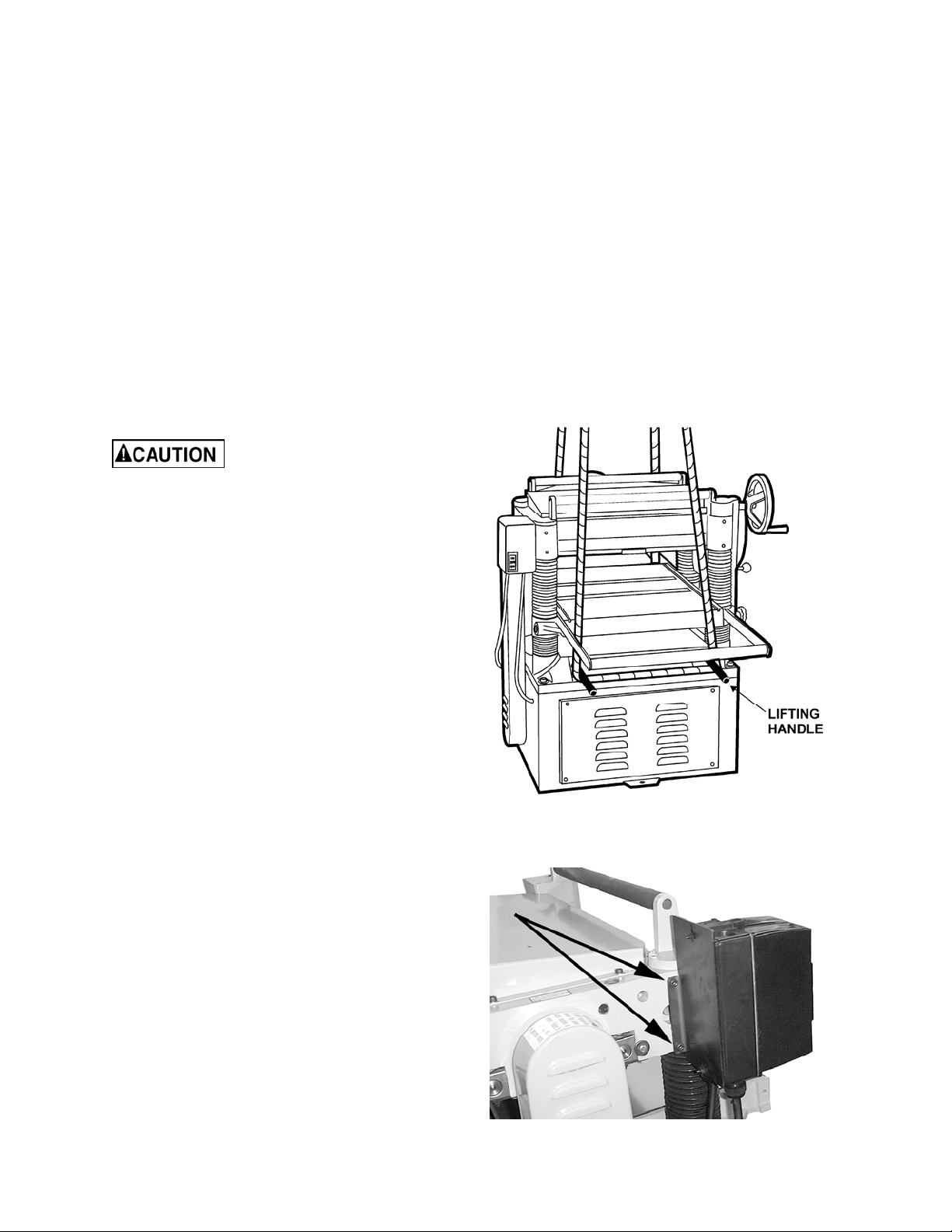

Starter Box

Mount the starter box at the left side of the

machine with two socket head cap screws (Fig. 4).

Figure 4

7

Page 8

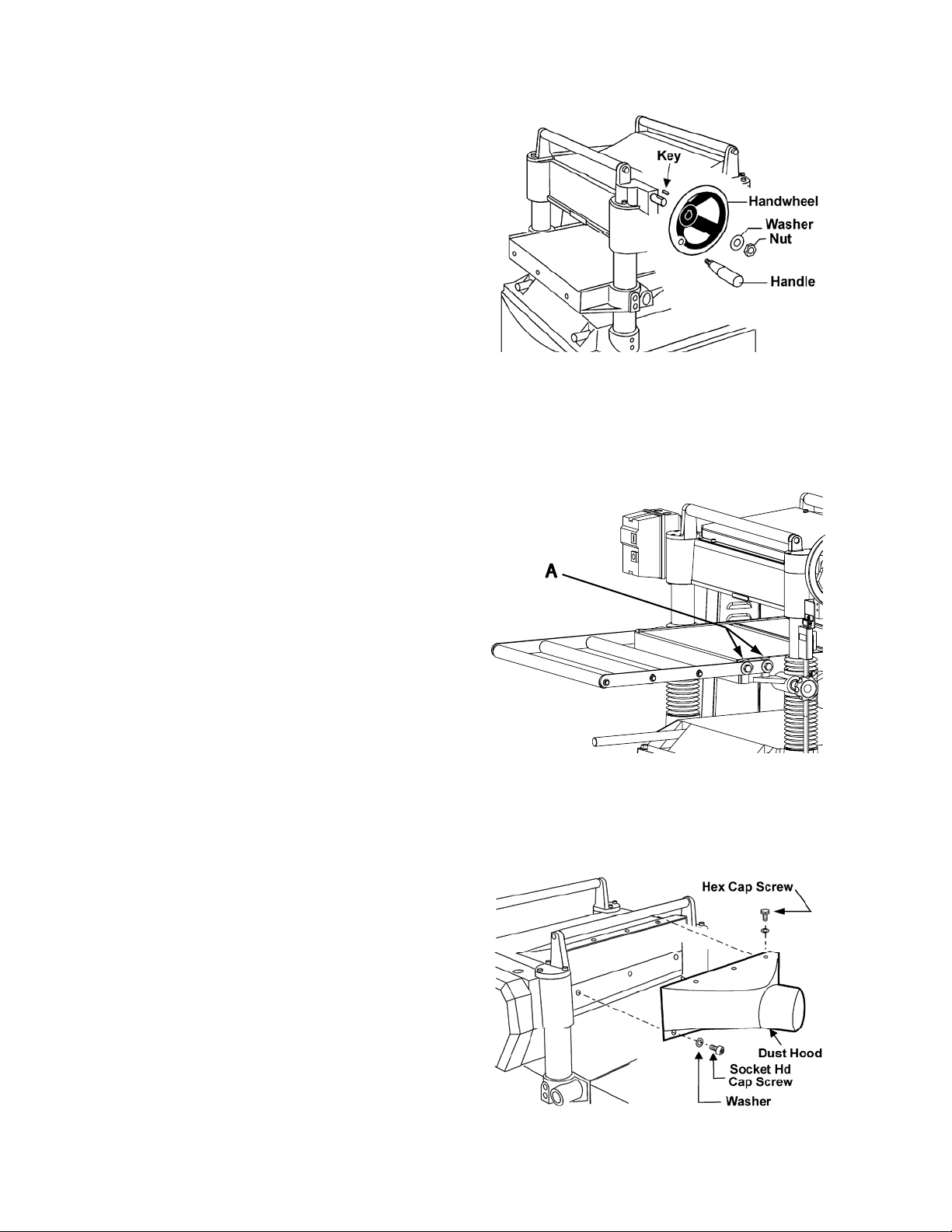

Handwheel

1. Remove the nut and washer from the gearbox

shaft, and place the handwheel onto the shaft

(Fig. 5), making sure it is oriented so the

handwheel slips over the key.

2. Place flat washer and hex nut on shaft and

tighten with wrench.

3. Mount the handle in the threaded hole in the

handwheel, and tighten with a wrench placed

over the flat on the handle.

Figure 5

Table Extension Rollers

Mount the table extension rollers to the table using

the provided hex cap screws and washers

(A, Fig. 6). The rollers should be adjusted before

operating the planer; see Adjusting Table

Extension Rollers on page 11.

Dust Collection Hood

The dust collection hood (Fig. 6a) comes standard

with the model JWP-208 planer, and helps

maintain a clean and safe work area. It is

assembled to the planer with the screws and

washers as shown.

Figure 6

Figure 6a

8

Page 9

Electrical Connections

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. The machine must be

properly grounded to help prevent electrical

shock and possible fatal injury.

A power plug is not provided with the 208 planer.

You may either connect one or "hard-wire" the

machine directly to your electrical panel provided

there is a disconnect near the machine. Consult

the wiring diagrams on pages 32-33 for further

clarification of wiring setup.

This machine must be grounded. Grounding

provides a path of least resistance to help divert

current away from the operator in case of

electrical malfunction.

Make sure the voltage of your power supply

matches the specifications on the motor plate of

the machine.

Extension Cords

The use of an extension cord is not recommended

for this machine, but if one is necessary make

sure the cord rating is suitable for the amperage

listed on the machine's motor plate. An undersize

cord will cause a drop in line voltage resulting in

loss of power and overheating.

Figure 7

The chart in Figure 7 shows the correct size cord

to use based on cord length and motor plate amp

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number the heavier the cord.

Adjustments

Belt and Pulleys

1. Using a straight edge, align the motor pulley

(A, Fig. 8 ) and cutterhead pulley (B, Fig. 8).

The motor plate can be moved for alignment

by loosening the set screws (C, Fig. 9) in the

motor plate.

Figure 8

Figure 9

9

Page 10

2. Check belt tension. Proper tension is obtained

when there is approximately 1/4” deflection of

the center span of the pulleys using light

finger pressure (Fig. 10).

3. If adjustment of belt tension is necessary,

loosen one pair of hex nuts (E & F, Fig. 11)

and turn the other pair to raise or lower the

motor plate. Re-tighten nuts.

Figure 10

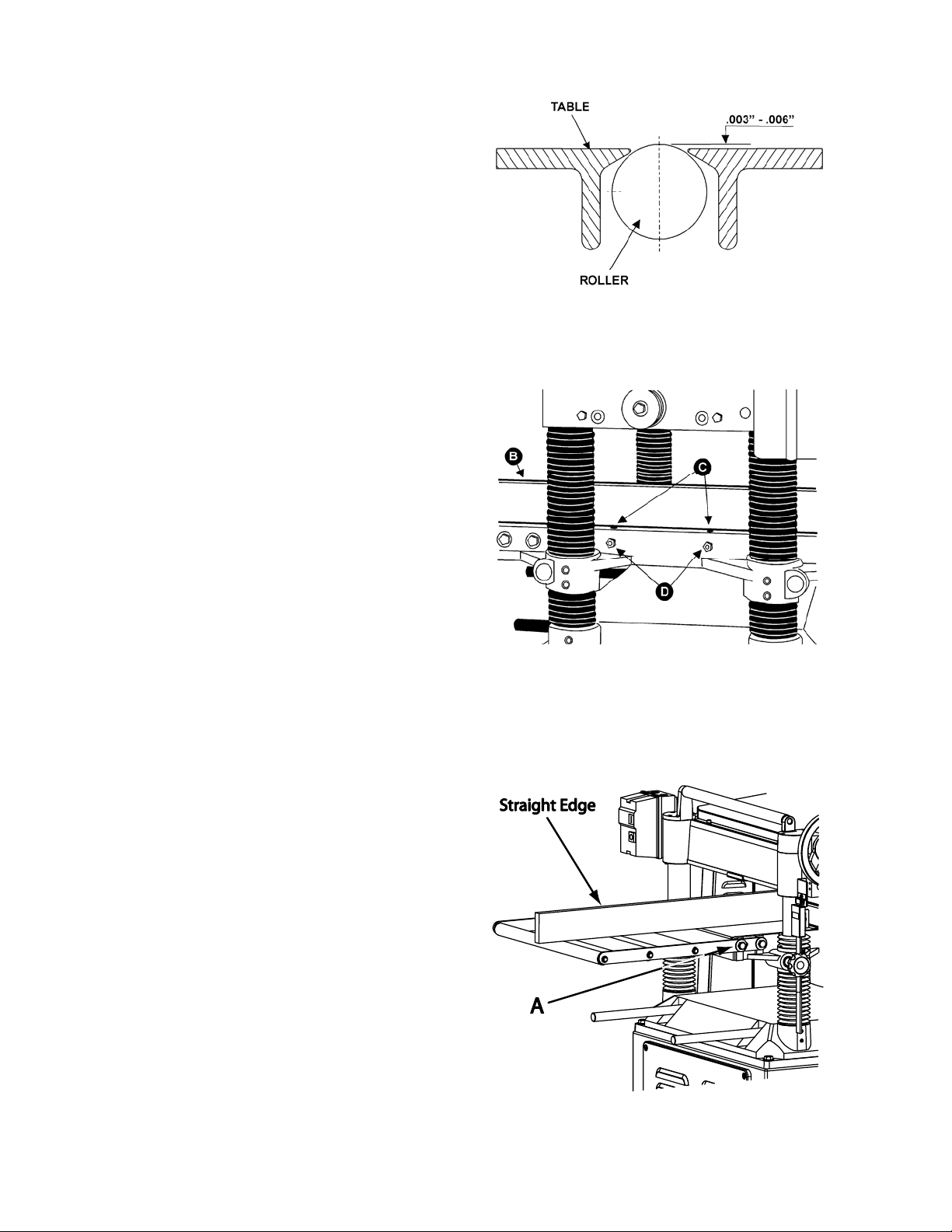

Table Rollers

Overview

Your planer is supplied with two table rollers

(A, Fig. 12) which turn as the stock is fed into the

planer, thus reducing friction. It is not possible to

give exact dimensions on the proper height setting

of the table rollers because each type of wood

behaves differently.

As a general rule, however, when planing rough

stock, the table rollers should be set at high

position. When planing smooth stock the rollers

should be set at low position.

Note: When raising the roller higher above the

table, the available range is from .003” to .006”

See Fig. 13.

Figure 11

Figure 12

10

Page 11

The table rollers are factory set for average

planing and are parallel to the table surface. If you

desire to adjust the table rollers higher or lower,

proceed as follows:

1. Disconnect machine from power source.

2. Lay a straight edge (B, Fig. 14) across both

rollers.

3. On one side of the table, loosen the screws

(C, Fig. 14) with a hex wrench, and turn the

eccentric shafts (D, Fig. 14) to raise or lower

the rollers.

4. When the proper height is achieved, tighten

screws (C, Fig. 14).

5. Adjust the rollers from the opposite side of the

table in the same manner.

Important: Be sure that the height of front and

rear rollers are the same. The table rollers must

always be set parallel to the table.

Figure 13

Figure 14

Adjusting Table Extension Rollers

1. Place a straight edge over the extension roller

and the table, as shown in Fig. 15, to make

sure the extension roller and table are at the

same height. If necessary, adjust the table

extension rollers as follows:

2. Loosen the screws and washers (A, Fig. 15)

to move the extension roller to the proper

position, then retighten the screws.

3. Adjust both front and rear extension rollers in

the same manner.

Figure 15

11

Page 12

Adjusting Depth of Cut

The cutting depth scale (A, Fig. 16) is a

combination inch/metric scale with a cutting range

from 0 to 8” (204mm). The distance of upward or

downward movement is controlled by the

handwheel (B, Fig. 16). One revolution of the

handwheel is .059” (1.5mm). Before moving the

table up or down, loosen the lock nuts (C, Fig. 16).

After obtaining the proper table position, tighten

the lock nuts (C, Fig. 16).

Always tighten the lock nuts

before operating the planer.

Cutterhead Adjustment

Overview

Although your planer was carefully adjusted at the

factory, it should be checked before being put into

operation. Any inaccuracies due to rough handling

in transit can easily be corrected by following

these directions.

To check the adjustments you will need a straight

edge, feeler gauge, and a home made gauge

block made of hardwood. This gauge block can be

made by following the dimensions shown in

Figure 17.

Knife Adjustment

When checking or adjusting the cutterhead knives,

proceed as follows:

1. Disconnect machine from power source.

2. Remove the six screws (A, Fig. 18) and

remove upper cover (B, Fig. 18).

3. To check and adjust knives, use the provided

knife gauge (Fig. 19 & 20) and check all four

knives. Knives should just contact the bottom

of the center protrusion (D, Fig. 19) of the

knife gauge.

Figure 16

Figure 17

4. If an adjustment to one or more of the knives

is necessary, slightly loosen the knife gib

(E, Fig. 19) by turning the six locking screws

(F, Fig. 19) into the gib. Turn the screws just

enough to relieve stress in the cutterhead

without disturbing the setting of the knives. Do

this for all four knives at the same time.

5. With the gauge in place over a knife

(G, Fig. 19) continue to loosen the locking

screws (F, Fig. 19) until the springs

(H, Fig. 19) begin raising the knife. When knife

comes into contact with the center protrusion

(D, Fig. 19) of the gauge, snug up the gib by

Figure 18

12

Page 13

lightly backing out the six locking screws (F,

Fig. 19) against the slot. NOTE: At this time,

only tighten the knife in the slot just enough to

hold knife in position.

6. If additional knives must be reset, repeat

step 5.

7. After all four knives are set with screws just

snug, back out and tighten the six locking

screws (F, Fig. 19 & 20), against the slot

starting with the end screws first, then the

center screws, until the knife is securely held

in the cutterhead. Tighten remaining three

knives in the same manner.

Important: Double check all screws for tightness.

Replacing & Resetting Knives

If the knives are removed for sharpening, care

must be exercise in replacing and resetting them.

Proceed as follows:

1. Disconnect machine from power source.

2. Remove six screws and upper cover (see

Fig. 18).

3. To remove knife, loosen the gib (E, Fig. 19) by

turning the six locking screws (F, Fig. 19) into

the gib. Remove gib (E, Fig. 19), knife (G, Fig.

16) and springs (H, Fig. 19). NOTE: The inner

two springs may pop out when the knife and

gib are removed.

4. Remove the remaining three knives in the

same manner.

5. Thoroughly clean the knife slots, gibs, springs

and locking screws. Check the locking screws;

if the threads appear worn or stripped or if the

heads are becoming rounded, replace them.

6. Inspect the cutting edge of the knives for nicks

or wire edge. Hone the knives slightly using a

stone, or if the knives are to be sharpened,

maintain a cutting angle of 35 degrees.

7. Insert springs, knives and gib into slot of

cutterhead. Back out locking screws just

enough to hold the knife in the cutterhead.

8. Place knife gauge (C, Fig. 19) over knife.

9. While holding down on the knife gauge,

loosen all six locking screws (F) by turning

them into the gib (E) until cutting edge of knife

comes into contact with the protrusion (D) of

the gauge. Snug up the gib by slightly backing

out the six locking screws against the slot.

Figure 19

Figure 20

Note: At this time, only tighten the knife into the

slot just enough to hold the knife in position.

10. Replace and reset the other three knives in

13

Page 14

the same manner.

11. After all four knives are set with the screws

just snug, back out and tighten the six screws

(F) against the slot starting with the end

screws first and then the center screws until

the knife is securely held in the cutterhead.

Tighten the remaining three knives in the

same manner.

After replacing and checking

knives, CHECK AGAIN carefully. Make certain

the direction of knives is correct and all

twenty-four locking screws are tightened

securely.

Checking Work Table Parallel to Cutterhead

The work table is set parallel to the cutterhead at

the factory and no further adjustment should be

needed. If your machine is planing a taper, first

check to see if the knives are set properly in the

cutterhead. Then check to see if the work table is

set parallel to the cutterhead. Proceed as follows:

1. Disconnect machine from power source.

2. Place the gauge block (A, Fig. 21) on the work

table directly under front edge of head casting

(B, Fig. 21). Make slight contact by gently

raising table.

Figure 21

3. Move the gauge block to opposite end of

working table. NOTE: Distance from the

working table to edge of the head casting

should be the same.

4. Check the back of the work table in the same

manner.

Adjusting Work Table Parallel to Cutterhead

If the work table is not parallel to the cutterhead,

perform the adjustment procedure as follows:

1. Disconnect the machine from power source.

2. Tilt planer on its side to expose underside of

base, as shown in Fig. 22.

3. Remove bolt (A, Fig. 22) and loosen bolt (B,

Fig. 22) which will allow you to move the idler

sprocket assembly (C, Fig. 22) far enough to

release tension on the chain.

4. Remove chain from the particular sprocket on

corner of base that must be adjusted.

5. Turn the sprocket by hand to bring that corner

into adjustment with the other three corners.

NOTE: Turning sprocket clockwise will

increase the distance between the working

table and headcasting; counter-clockwise will

Figure 22

decrease the distance. This adjustment is very

sensitive and it should not be necessary to turn

the sprocket more than one or two teeth.

6. When adjustments are correct, replace chain

around corner sprocket, slide sprocket (C, Fig.

22) back to re-tension chain, tighten bolt (B, Fig.

22) and replace and tighten bolt (A, Fig. 22).

14

Page 15

Know the Transmitting Rollers of Your Planer

A – Anti-Kickback Fingers

B – Infeed Roller

C – Chipbreaker

D – Cutterhead

D – Pressure Bar

E – Outfeed Roller

The infeed roller (B, Fig. 23) and outfeed roller

(F, Fig. 23) are those parts of your planer that feed

the stock while it is being planed. The infeed and

outfeed rollers are under spring tension and this

tension must be sufficient to feed the stock

uniformly through the planer without slipping but

should not be so tight that it causes damage to the

board. The tension should be equal at both ends

of each roller.

Anti-Kickback Fingers

The anti-kickback fingers (A, Fig 23) help prevent

kickback of stock. They operate by gravity and it is

necessary to inspect them occasionally to make

sure they are free of gum and pitch, so that they

move independently and operate correctly.

Figure 23

Adjusting Infeed & Outfeed Roller Spring Tension

To adjust the spring tension of the infeed and

outfeed rollers, turn screws (G & H, Fig. 24) with a

hex wrench. Turn screws on opposite end of

infeed/outfeed rollers in the same manner.

Figure 24

15

Page 16

Figure 25

Height of Infeed Roller, Chipbreaker, Pressure Bar & Outfeed Roller

The infeed roller, chipbreaker, pressure bar and

outfeed roller are adjusted at the factory. The

infeed roller and the chipbreaker should be set

at 0.004” (0.1mm) below the cutting circle; and

the outfeed roller should be set at 0.02” (0.5mm)

below the cutting circle. See Fig. 25.

If an adjustment to the infeed roller, chipbreaker,

pressure bar or outfeed roller is necessary, use

the following steps as an example of procedure.

To check and adjust the outfeed roller below the

cutting circle, proceed as follows:

1. Disconnect machine from power source.

2. Make sure the knives are adjusted properly

as previously explained under “Checking &

Adjusting of Knives.”

3. Place the gauge block (J, Fig. 26) on the

table directly underneath the cutterhead (D,

Fig. 26). Using a 0.02” (0.5mm) feeler

gauge (K, Fig. 26) placed on top of the

gauge block, raise the working table until

the knife just touches the feeler gauge

when the knife is at its lowest point. Do not

move the working table any further until the

outfeed roller is adjusted.

Figure 26

4. Move the gauge block (J, Fig. 27) under

one end of the outfeed roller (F, Fig. 27).

The bottom of the outfeed roller should just

touch the top of the gauge block. If an

adjustment to the outfeed roller is

necessary, loosen the lock nut (L, Fig 27)

and turn screw (M, Fig. 27) until the outfeed

roller just touches the gauge block. Then

tighten lock nut (L, Fig. 27).

5. Check and adjust opposite end of the

outfeed roller in the same manner.

16

Figure 27

Page 17

Feed Speed Control

Your machine is equipped with a spiral, serrated

infeed roller and a solid outfeed roller. When the

feed rollers are engaged, they turn to feed the

stock. The feed rollers slow automatically when

the machine is under heavy load for best planing

in all conditions. The feed rollers are driven by

chains (A, Fig. 28) and sprockets (B, Fig. 28)

which take power directly from the cutterhead

through the oil bath gear box (C, Fig. 28).

The gear box has two feed speeds. These are

set by pulling out or pushing in the shift lever (D,

Fig. 28) while the machine is running. The feed

speed range is shown in Fig. 29.

Changing Accessories for Lowest Feed Speed

The lowest feed speed for your planer (16.2 fpm

& 20.7 fpm) can be obtained by replacing the

lower (gear shaft) sprocket and the chain. See

Fig. 29. To change the sprocket and the chain

on your machine, proceed as follows:

Figure 28

1. Disconnect machine from power source.

2. Remove the three hex cap screws and

washers (E, Fig. 28).

3. Remove the three sprockets (B, Fig. 28)

from the infeed roller, outfeed roller and the

gear shaft at the same time.

4. When the sprockets (B, Fig. 28) are

removed, replace the lower sprocket which

will be assembled on the gear shaft.

5. Assemble the three sprockets and chains to

the shafts, and tighten the hex cap screws

(E, Fig. 28).

Return Rollers

The two return rollers on the top of the machine

serve as a convenient rest for stock. They save

time and motion for the operator as the stock is

returned to the infeed side.

Figure 29

17

Page 18

Maintenance

Lubrication

Periodic or regular inspections are required to

ensure that the machine is in proper adjustment,

that all screws are tight, that belts are in good

condition, that dust has not accumulated in the

electrical enclosures, and that there are no worn

or loose electrical connections.

Buildup of sawdust and other debris can cause

your machine to plane inaccurately. Periodic

cleaning is not only recommended but mandatory

for accurate planing.

Close-fitting parts, such as the cutterhead slot

and gibs, should be cleaned with a cloth or brush

and non-flammable solvent, and freed from

clinging foreign matter.

Remove resin and other accumulations from feed

rollers and table with a soft rag and nonflammable solvent.

Periodically check all the chains for proper

tension and adjust accordingly if required.

Tip: If a foreign object nicks the knives, instead of

throwing them away or trying to grind out the

deep nick, simply stagger the knives in the head,

moving one knife no more than 1/4" to the right

and another knife no more than 1/4" to the left.

The nick should no longer be noticeable.

The bearings on the cutterhead are factory

lubricated and sealed for life – no lubrication

required.

The lubricant in the gearbox must be replaced

every 2,500 hours. Multi-purpose gearbox

lubricant will be suitable.

To replace the gearbox lubricant:

Remove the drain plug (A, Fig. 30), and filler cap

(B, Fig. 30). Drain dirty oil thoroughly.

Tighten the drain plug (A, Fig. 30).

Fill with clean lubricant through hole (B, Fig.

30).

Tighten filler cap (B, Fig. 30).

The table should be kept clean and free of rust.

Some users prefer a paste wax coating. Another

option is talcum powder applied with a

blackboard eraser rubbed in vigorously once a

week; this will fill casting pores and form a

moisture barrier. This method provides a table

top that is slick and allows rust rings to be easily

wiped from the surface. Important also is the fact

that talcum powder will not stain wood or mar

finishes as wax pickup does.

[The item numbers on this chart are referenced with the accompanying illustrations.]

No. Position Interval Suitable Types of Lubricant Fig. No.

1 Drive Chain Frequently Grease 30

2 Gear Box When operated more

than 2,500 hours

3 Return Rollers Frequently SAE-30 32

4 Worm Gear Frequently Grease 33

5 Lead Screw Frequently Grease 33

6 Column Frequently Clean and SAE-30 33

7 Table Chain Frequently Grease 34

8 Feed Rollers Frequently SAE-30 35

HD-100, Mobil Gear 627, Shell

Omala 100, ESSO Spartan EP-100

2

Fig. 31

30

18

Page 19

Figure 32

Figure 34

Figure 33

Figure 35

19

Page 20

Troubleshooting

Operating Problems

Problem Possible Cause Solution

Snipe.

Note: Snipe can

be minimized but

not eliminated.

Fuzzy Grain Planing wood with a high

Torn Grain Too heavy a cut.

Rough/Raised

Grain

Table rollers not set properly.

Inadequate support of long

boards.

Uneven feed roller pressure

front to back.

Dull Knives

Lumber not butter properly.

moisture content.

Dull knives.

Knives cutting against grain.

Dull knives.

Dull knives.

Too heavy a cut.

Moisture content too high.

Adjust rollers to proper height.

Support long boards with extension rollers.

Adjust feed roller tension.

Sharpen knives.

Butt end to end each piece of stock as they

pass through.

Remove high moisture content from wood by

drying.

Sharpen or replace.

Adjust proper depth of cut.

Cut along the grain.

Sharpen knives.

Sharpen knives.

Adjust proper depth.

Remove high moisture content from wood by

drying.

Rounded, glossy

surface

Poor feeding of

lumber

Dull knives.

Feed speed too slow.

Cutting depth too shallow.

Inadequate feed roller

pressure.

Planer bed rough or dry.

Transmission v-belt slipping.

Surface of feed rollers too

smooth.

Sharpen or replace knives.

Increase speed.

Increase depth.

Adjust feed roller tension. If proper tension

cannot be achieved, replace feed rollers.

Clean pitch and residue, and wax planer table.

Tighten transmission v-belt.

Lightly roughen the feed roller surface with

sandpaper.

20

Page 21

Mechanical and Electrical Problems

Problem Possible Cause Solution

Uneven depth of

cut side to side.

Board thickness

does not match

depth of cut scale.

Chain jumping. Inadequate tension.

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blows fuses.

Knife projection.

Cutterhead not level with bed.

Depth of cut scale incorrect. Adjust depth of cut scale.

Sprockets misaligned.

Sprockets worn.

No incoming power.

Overload automatic reset has

not reset.

Planer frequently trips.

Adjust knife projection.

Level bed.

Adjust chain tension.

Align sprockets.

Replace sprockets.

Verify unit is connected to power.

When planer overloads on the circuit breaker

built into the motor starter, it takes time for the

machine to cool sown before restart. Allow unit

to adequately cool before attempting restart. If

problem persists, check amp setting on the

motor starter inside the electrical box.

One cause of overloading trips which are not

electrical in nature is too heavy a cut. If too

deep a cut is not the problem, then check the

amp setting on the overload relays. Match the

full load amps on the motor as noted on the

motor plate. If amp setting is correct then there

is probably a loose electrical lead. Check amp

setting on motor starter.

Building circuit breaker trips

of fuse blows.

Loose electrical connections.

Motor starter failure.

Motor starter failure.

Verify that planer is on a circuit of correct size.

If circuit size is correct, there is probably a

loose electrical lead. Check amp setting on

motor starter.

Go through all the electrical connections on

the planer including motor connections,

verifying the tightness of each. Look for any

signs of electrical arcing which is a sure

indicator of loose connections or circuit

overload.

Examine motor starter for burned or failed

components. If damage is found, replace

motor starter. If motor starter looks okay but is

still suspect, you have two options: have a

qualified electrician test the motor starter for

function, or purchase a new starter and

establish if that was the problem on

changeout.

If you have access to a voltmeter, you can

separate a starter failure from a motor failure

by first, verifying incoming voltage are 220 +/20 and second, checking the voltage between

starter and motor at 220 +/- 20. If incoming

voltage is incorrect, you have a power supply

problem, If voltage between starter and motor

21

Page 22

Problem Possible Cause Solution

is correct, you have a motor problem.

Motor failure.

Miswiring of the unit.

On/off switch failure.

Optional Accessories

(for the JWP-208 Planer)

Stock No Description

If electrical motor is suspect, you have two

options: Have a qualified electrician test the

motor for function or remove the motor and

take it to a quality electric motor repair shop

and have it tested.

Double check to confirm all electrical

connections are correct and properly tight. The

electrical connections other than the motor are

pre-assembled and tested at the factory.

Therefore, the motor connections should be

double checked as the highest probability for

error, If problems persist, double check the

factory wiring.

If the on/off switch is suspect you have two

options: Have a qualified electrician test the

switch for function, or purchase a new on/off

switch and establish if that was the problem on

changeout.

708808 Knives, Single Sided (set of 4)

708583 Low Speed Gear Kit

Ordering Replacement Parts

To order parts or reach our service department, call 1-800-274-6848 between 7:30am and 5:31pm (CST),

Monday through Friday. Having the Model Number and Serial Number of your machine available when

you call will allow us to serve you quickly and accurately.

Parts

Head Assembly – Parts List

Index Part No. Description Size Qty

1 ...............JWP208-001 ............Head Casting ....................................................... .................................... 1

2 ...............TS-1525021 .............Set Screw............................................................. M10 x 12 ..................... 8

3 ...............JWP208-003 ............Cutterhead ........................................................... .................................... 1

4 ...............6292620 ...................Spring ................................................................... .................................... 8

5 ...............708808 .....................Knife ..................................................................... .................................... 4

6 ...............JWP208-006 ............Knife Gib .............................................................. .................................... 4

7 ...............6292623 ...................Hex Cap Bolt ........................................................ M8 x 10 ..................... 24

8 ...............JWP208-008 ............Knife Gauge Bar .................................................. .................................... 1

9 ...............JWP208-009 ............Knife Gauge ......................................................... .................................... 2

10 .............JWP208-010 ............Washer................................................................. 3/8 ............................... 2

11 .............JWP208-011 ............Nut........................................................................ M10 ............................. 2

22

Page 23

Head Assembly – Parts List

Index Part No. Description Size Qty

12 .............BB-6206ZZ...............Ball Bearing.......................................................... 6206ZZ........................ 1

13 .............JWP208-013 ............Key ....................................................................... 8 x 8 x 36 .................... 1

14 .............6292630 ...................Pulley ................................................................... .................................... 1

15 .............6292631 ...................Washer................................................................. .................................... 2

16 .............TS-1523071 .............Set Screw ............................................................. M6 x 25 ....................... 2

17 .............JWP208-017 ............Motor Pulley ......................................................... .................................... 1

18 .............JWP208-018 ............Infeed Roller......................................................... .................................... 1

19 .............JWP208-019 ............Bushing ................................................................ .................................... 4

20 .............JWP208-020 ............Spring................................................................... .................................... 4

21 .............JWP208-021 ............Screw ...................................................................M22 x 20 ..................... 4

22 .............JWP208-022 ............Plate ..................................................................... .................................... 4

23 .............TS-1490031 .............Hex Cap Screw .................................................... M8 x 20 ....................... 8

25 .............TS-1540041 .............Hex Nut ................................................................M6 ............................... 8

26 .............JWP208-026A..........Key ....................................................................... 5 x 5 x 24 .................... 2

27 .............6292643 ...................Sprocket ............................................................... .................................... 1

28 .............TS-1550041 .............Washer ................................................................. M6 ............................... 2

29 .............JWP208-029A ..........Hex Washer Head Screw..................................... M6 x 16 ....................... 5

30 .............JWP208-030 ............Outfeed Roller ...................................................... .................................... 1

31 .............6292647 ...................Sprocket ............................................................... .................................... 1

32 .............JWP208-032 ............Locking Bolt.......................................................... .................................... 1

33 .............JWP208-033 ............Retaining Ring ..................................................... .................................... 1

34 .............JWP208-034 ............Chip Breaker ........................................................ .................................... 1

35 .............TS-1540081 .............Nut........................................................................ M12............................. 2

36 .............JWP208-036 ............Plate Springs........................................................ .................................... 3

37 .............JWP208-037 ............Washer................................................................. 1/4 ............................. 12

38 .............JWP208-038A ..........Hex Washer Head Screw..................................... M6 x 12 ..................... 14

39 .............JWP208-039 ............Shaft..................................................................... .................................... 1

40 .............JWP208-040 ............Bracket ................................................................. .................................... 2

41 .............JWP208-041 ............Pressure Plate ..................................................... .................................... 1

42 .............TS-2361081 .............Lock Washer ........................................................M8 ............................... 2

43 .............JWP208-043 ............Shaft..................................................................... .................................... 1

44 .............TS-1523051 .............Set Screw ............................................................. M6 x 16 ....................... 9

45 .............TS-1523061 .............Set Screw ............................................................. M6 x 20 ....................... 2

46 .............JWP208-046 ............Plate Spring.......................................................... .................................... 3

47 .............JWP208-047 ............Chip Deflector Plate ............................................. .................................... 1

48 .............6292664 ...................Anti-Kickback Finger ............................................ .................................. 87

49 .............6292665 ...................Collar .................................................................... .................................. 88

50 .............JWP208-050 ............Shaft..................................................................... .................................... 1

51 .............JWP208-051 ............Retaining Ring ..................................................... .................................... 2

52 .............6292668 ...................Cut Limit Plate...................................................... .................................... 1

53 .............JWP208-053A ..........Flat Head Machine Screw.................................... M5 x 8 ......................... 2

54 .............JWP208-054 ............Upper Cover......................................................... .................................... 1

55 .............JWP208-055 ............Gasket.................................................................. .................................... 1

56 .............JWP208-056 ............Collector Tube...................................................... .................................... 1

57 .............JWP208-057 ............Roller Stand ......................................................... ....................................3

58 .............JWP208-058 ............Roller.................................................................... .................................... 3

59 .............TS-1503041 .............Socket Head Cap Screw ...................................... M6 x 16 ....................... 9

60 .............JWP208-060 ............Worm Gear Box ................................................... .................................... 1

61 .............TS-1503111 .............Socket Head Cap Screw ...................................... M6 x 50 ....................... 3

62 .............JWP208-062 ............Worm.................................................................... .................................... 1

63 .............BB-6201Z .................Ball Bearing.......................................................... .................................... 1

64 .............JWP208-064 ............Retaining Ring ..................................................... 6201Z.......................... 1

65 .............JWP208-065 ............Key ....................................................................... 4 x 4 x 10 .................... 1

66 .............JWP208-066 ............Hand Wheel ......................................................... .................................... 1

67 .............JWP208-067 ............Washer................................................................. 1/2 ............................... 1

23

Page 24

Head Assembly – Parts List

Index Part No. Description Size Qty

68 .............6292684 ...................Handle.................................................................. .................................... 1

69 .............JWP208-069 ............Scale .................................................................... ....................................1

70 .............JWP208-070 ............Machine Screw .................................................... M5 x 10 ....................... 2

71 .............JWP208-071 ............Pointer.................................................................. .................................... 1

72 .............6292814 ...................Special Washer .................................................... M6 ............................... 3

73 .............JWP208-073 ............Cover.................................................................... .................................... 1

74 .............JWP208-074 ............Spring Pin............................................................. 6 x 20 .......................... 1

75 .............JWP208-075 ............Safety Plate.......................................................... .................................... 1

76 .............JWP208-076 ............Machine Screw .................................................... M6 x 8 ......................... 4

77 .............JWP208-077 ............Safety Latch ......................................................... .................................... 1

78 .............TS-1504081 .............Socket Head Cap Screw ...................................... M8 x 40 ....................... 1

79 .............JWP208-079 ............Pulley Guard ........................................................ .................................... 1

80 .............6292696 ...................Bolt ....................................................................... .................................... 2

81 .............TS-0680041 .............Washer ................................................................. 5/16 ............................. 2

82 .............TS-0561021 .............Nut........................................................................ 5/16-18........................ 2

83 .............VB-M60 ....................V-Belt ................................................................... .................................... 3

84 .............JWP208-084 ............Pulley Cover......................................................... .................................... 1

85 .............6292710 ...................Knob..................................................................... 5/16 ............................. 2

86 .............JWP208-086A..........Switch Mounting Plate ......................................... .................................... 1

87 .............JWP208-087D..........Switch (3HP, 1Ph)................................................ .................................... 1

.................JWP208-087E.......... Switch (5HP, 3Ph)................................................ .................................... 1

88 .............TS-1540031 .............Nut........................................................................ M5............................... 2

91 .............JWP208-091 ............Chain.................................................................... .................................... 1

92 .............JWP208-092 ............Relief Bushing ...................................................... .................................... 2

93 .............JWP208-093 ............Power Cord .......................................................... .................................... 1

94 .............JWP208-094 ............Tooth Washer....................................................... .................................... 4

95 .............TS-1503021 .............Socket Head Cap Screw ...................................... M6 x 10 ..................... 12

96 .............TS-1524011 .............Set Screw ............................................................. M8 x 8 ......................... 1

98 .............JWP208-098 ............Collar.................................................................... .................................... 1

99 .............6292714 ...................Shaft ..................................................................... .................................... 1

100 ...........PA-C59 ....................Idler Pulley ........................................................... .................................... 1

101 ...........PA-C58 ....................Bracket ................................................................. .................................... 1

.................JWP208-106 ............Chain Tensioning Assy ........................................ ....................................1

102 ...........PA-C59 ....................Shaft ..................................................................... .................................... 1

103 ...........PA-C60 ....................Hanger ................................................................. .................................... 1

104 ...........PA-C61 ....................Spring................................................................... .................................... 1

105 ...........PA-C62 ....................Collar .................................................................... .................................... 1

106 ...........TS-1534042 .............Pan Head Screw .................................................. M6X12......................... 1

107 ...........TS-1503021 .............Socket Head Cap Screw...................................... M6x10 ......................... 2

108 ...........JWP208-108 ............Hex Head Screw .................................................. M8x18 ......................... 4

.................MS-SA20-24V ..........Magnetic Contactor for 3HP Motor (not shown) .. .................................... 1

.................MS-SA20-24VA........ Magnetic Contactor for 5HP Motor (not shown) .. .................................... 1

.................JWP208-087DTR.....Thermal Relay for 3HP Motor (not shown) .......... ....................................1

.................JWP208-087ETR .....Thermal Relay for 5HP Motor (not shown) .......... .................................... 1

.................PG-M02....................JET Plaque........................................................... .................................... 1

.................6012192 ...................Warning Label (not shown) .................................. .................................... 1

.................6292819 ...................Lubrication Label (not shown).............................. .................................... 1

.................6292820 ...................Guard Label (not shown) ..................................... .................................... 1

24

Page 25

Head Assembly – Exploded View

25

Page 26

Table and Roller – Parts and Assembly

Index Part No. Description Size Qty

1 ...............JWP208-201 ............Middle Table......................................................... .................................... 1

2 ...............6292722 ...................Roller .................................................................... .................................... 2

3 ...............BB-6201ZZ...............Ball Bearing.......................................................... 6201ZZ........................ 4

4 ...............6292724 ...................Eccentric Shaft ..................................................... .................................... 1

5 ...............TS-1523041 .............Set Screw............................................................. M6x12 ......................... 4

6 ...............6292725 ...................Lock Bar ............................................................... .................................... 2

7 ...............6292726 ...................Lock Bolt .............................................................. .................................... 2

8 ...............6292727 ...................Lock Bushing (no thread)..................................... .................................... 2

9 ...............6292728 ...................Knob ..................................................................... .................................... 2

10 .............TS-1504041 .............Socket Head Cap Screw ...................................... M8x20 ......................... 8

11 .............6292730 ...................Roller Frame ........................................................ .................................... 4

12 .............6292731 ...................Roller .................................................................... .................................... 6

13 .............TS-1491031 .............Hex Cap Screw .................................................... M10x25 ....................... 8

14 .............TS-0680041 .............Washer ................................................................. 3/8 ............................... 8

15 .............6292808 ...................Shaft ..................................................................... .................................... 6

16 .............6292809 ...................Bushing ................................................................ .................................. 12

17 .............TS-1482021 .............Hex Head Screw .................................................. M6x12 ....................... 12

18 .............TS-1550041 .............Flat Washer.......................................................... M6 ............................. 12

26

Page 27

Stand and Motor – Parts and Assembly

Index Part No. Description Size Qty

1 ...............JWP208-401 ............Stand.................................................................... .................................... 1

2 ...............JWP208-402 ............Cover.................................................................... .................................... 2

3 ...............TS-2286201 .............Flat Head Machine Screw.................................... M6 x 20 .......................8

4 ...............6292796 ...................Bar........................................................................ .................................... 2

5 ...............JWP208-405 ............Motor Mount ......................................................... .................................... 1

6 ...............TS-1524011 .............Set Screw............................................................. M8 x 8 ......................... 4

7 ...............JWP208-407 ............Collar.................................................................... .................................... 1

8 ...............JWP208-408 ............Adjust Bolt ............................................................ .................................... 2

9 ...............TS-1540081 .............Nut........................................................................ M12 ............................. 8

10 .............TS-0680061 .............Washer ................................................................. 1/2 ............................... 4

11 .............TS-1490041 .............Hex Cap Screw .................................................... M8 x 35 ....................... 4

12 .............TS-0680031 .............Washer ................................................................. 5/16 ............................. 4

13 .............TS-1540061 .............Nut........................................................................ M8............................... 4

14 .............JWP208-414 ............Motor (3HP, 1Ph, 230V)....................................... .................................... 1

.................JWP208-414A..........Motor (5HP, 3Ph, 230/460V)................................ .................................... 1

15 .............JWP208-415 ............Key ....................................................................... .................................... 1

16 .............TS-1492051 .............Hex Cap Screw .................................................... M12 x 50 ..................... 4

17 .............JWP208-417 ............Power Cord .......................................................... .................................... 1

18 .............JWP208-418 ............Strain Relief.......................................................... .................................... 1

19 .............TS-0680031 .............Washer ................................................................. 5/16 ............................. 4

27

Page 28

Base and Column – Parts List

Index Part No. Description Size Qty

1 ...............JWP208-301 ............Base ..................................................................... .................................... 1

2 ...............TS-1525021 .............Set Screw............................................................. M10 x 12 ..................... 8

3 ...............JWP208-303 ............Column................................................................. .................................... 3

4 ...............JWP208-304 ............Column................................................................. .................................... 1

5 ...............JWP208-305 ............Lead Screw .......................................................... .................................... 3

6 ...............JWP208-306 ............Lead Screw .......................................................... .................................... 1

7 ...............JWP208-307 ............Nut........................................................................ .................................... 4

8 ...............JWP208-308 ............Bushing ................................................................ .................................... 1

9 ...............JWP208-309 ............Retaining Ring ..................................................... .................................... 1

10 .............JWP208-310 ............Key ....................................................................... 4 x 4 x 10 .................... 1

11 .............JWP208-311 ............Gear .....................................................................24T.............................. 1

12 .............JWP208-312 ............Retaining Ring ..................................................... .................................... 1

13 .............BB-6202ZZ...............Ball Bearing.......................................................... 6202ZZ........................ 4

14 .............JWP208-314 ............Retaining Ring ..................................................... .................................... 4

15 .............JWP208-315 ............Key ....................................................................... 5 x 5 x 16 .................... 4

16 .............JWP208-316 ............Sprocket ............................................................... 10T .............................. 4

17 .............JWP208-317 ............Washer................................................................. 3/8 ............................... 4

18 .............JWP208-318 ............Nut........................................................................ M10 ............................. 4

19 .............JWP208-319 ............Washer................................................................. .................................... 2

20 .............TS-1490041 .............Hex Cap Screw .................................................... M8 x 25 ....................... 2

21 .............6292749 ...................Idler Bracket ......................................................... .................................... 1

22 .............JWP208-322 ............Shaft..................................................................... .................................... 1

23 .............6292751 ...................Sprocket ............................................................... 10T.............................. 1

24 .............JWP208-324 ............Retaining Ring ..................................................... STW-15....................... 1

25 .............JWP208-325 ............Chain.................................................................... .................................... 1

26 .............JWP208-326 ............Carry Handle ........................................................ .................................... 4

27 .............JWP208-327 ............Retaining Ring ..................................................... ETW-19....................... 4

28 .............JWP208-328 ............Pipe Band............................................................. .................................. 16

29 .............TS-1533032 .............Pan Head Screw .................................................. M5 x 10 ..................... 32

30 .............JWP208-330 ............Expansion Band ................................................... .................................... 8

28

Page 29

Base and Column – Assembly

29

Page 30

Gearbox – Parts List

Index Part No. Description Size Qty

1 ...............JWP208-501 ............Gear Box .............................................................. .................................... 1

2 ...............OS-28408.................Oil Seal................................................................. .................................... 1

3 ...............BB-6204ZZ...............Ball Bearing.......................................................... 6204ZZ........................ 1

4 ...............6292762 ...................Gear .....................................................................16T.............................. 1

5 ...............TS-1503061 .............Socket Head Cap Screw...................................... M6 x 25 .......................1

6 ...............TS-1550041 .............Washer................................................................. M6 ............................... 2

7 ...............TS-1503041 .............Socket Head Cap Screw...................................... M6 x 16 .......................1

8 ...............BB-6201 ...................Ball Bearing.......................................................... 6201 ............................ 2

9 ...............6292766 ...................Gear .....................................................................47T.............................. 1

10 .............6292767 ...................Shaft ..................................................................... 18T.............................. 1

11 .............JWP208-511 ............Key ....................................................................... 5 x 5 x 12 .................... 1

12 .............6292769 ...................Gear .....................................................................71T.............................. 1

13 .............JWP208-513 ............Key ....................................................................... 5 x 5 x 10 .................... 1