Page 1

Operating Instructions and Parts Manual

This Manual is Bookmarked

Wood Lathe

Models: JWL-1642EVS and JWL-1642EVS-2

WMH Tool Group

2420 Vantage Drive

Elgin, Illinois 60124

Phone: 800-274-6848 Revision B1 1/07

www.wmhtoolgroup.com

Copyright © WMH Tool Group

Part Number: M-708359

Page 2

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of

these WMH Tool Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check

with your local WMH Tool Group distributor, or visit jettools.com.

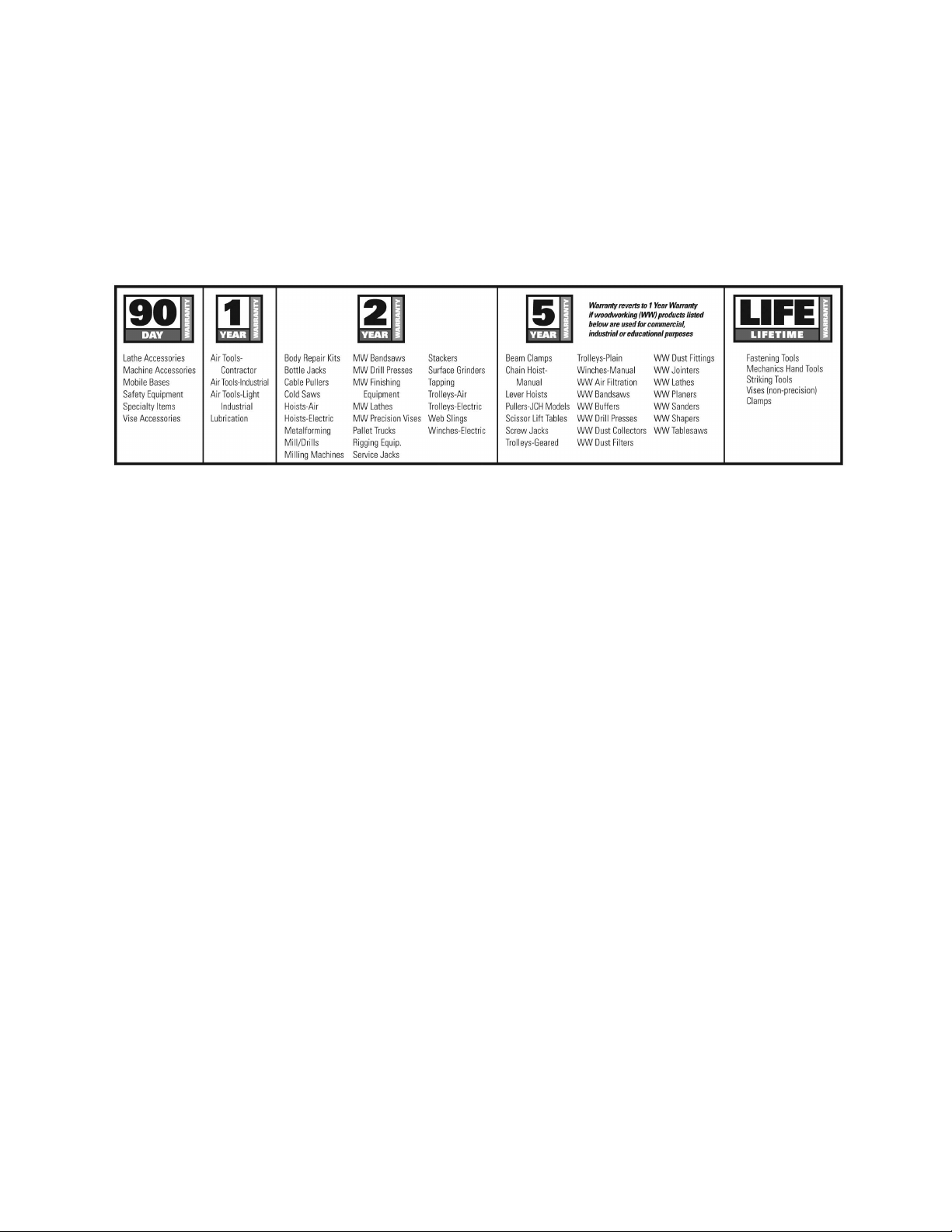

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY,

OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE

OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information

and are not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

® branded products are not sold in Canada by WMH Tool Group.

JET

® tools. For the name of an Authorized Service Center in

2

Page 3

1. Read and understand the entire owner’s manual before attempting assembly or operation.

2. This wood lathe is designed and intended for use by properly trained and experienced personnel

only. If you are not familiar with the proper and safe operation of a wood lathe, do not use it until

the proper training and knowledge have been obtained.

3. Always wear approved safety glasses/face shields while using this machine.

4. Make certain the machine is properly grounded.

5. Before operating the machine, remove tie, rings, watches, other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine long hair. Do not wear gloves.

6. Keep the floor around the machine clean and free of scrap material, oil and grease.

7. Keep machine guards in place at all times when the machine is in use. If removed for

maintenance purposes, use extreme caution and replace the guards immediately.

8. Do not over reach. Maintain a balanced stance at all times, so that you do not fall or lean against

blades or other moving parts.

9. Make all machine adjustments or maintenance with the machine unplugged from the power

source.

10. Use the right tool. Do not force a tool or attachment to do a job that it was not designed.

11. Replace warning labels if they become obscured or removed.

12. Make certain the switch is in the OFF position before connecting the machine to the power

supply.

13. Give your work undivided attention. Looking around, carrying on a conversation and "horse-play"

are careless acts that can result in serious injury.

14. Keep visitors a safe distance from the work area.

15. Use recommended accessories; improper accessories may be hazardous.

16. Read and understand warnings posted on the machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

17. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles

18. Do not operate this lathe while under the influence of drugs, alcohol or any medication.

19. Keep tools sharp and clean for safe and best performance. Dull tools can grab in the work and be

jerked from the operators hands causing serious injury.

20. Check the condition of the stock to be turned. Make sure it is free of knots, warpage, checked

ends, improperly made or cured glue joints and other conditions which can cause it to be thrown

out of the lathe.

21. Securely fasten spur/live centers to the material being used.

22. Check centers and center sockets in the headstock and tailstock to be sure they are free of dirt or

rust and oil lightly before inserting centers.

23. Test each set-up by revolving the work by hand to insure it clears the tool rest and bed. Check

the setup at the lowest speed before increasing it to the operating speed.

24. Use the correct cutting tool for the operation to be performed and keep all tools sharp.

25. Use low speeds for roughing and for long or large diameter work. If vibration occurs, stop the

machine and correct the cause. See the speed recommendation chart on the next page.

Warnings

3

Page 4

Warnings

SPEED RECOMMENDATIONS

Diameter of Work Roughing RPM General Cutting RPM Finishing RPM

Under 2" 1500 3000 3000

2 to 4" 600 1500 2300

4 to 6" 450 1100 1500

6 to 8" 450 600 1100

8 to 10" 450 600 850

10 to 12" 450 600 850

12 to 14" 450 450 600

26. When sanding, remove the tool rest from the machine, apply light pressure and use a slow speed

to avoid heat build up.

27. When turning large diameter pieces, such as bowls, always operate the lathe at low speeds. See

the speed recommendation chart.

28. Do not attempt to engage the spindle lock pin until the spindle has stopped. If leaving the

machine area, turn it off and wait until the spindle stops before departing.

29. Make no adjustments except speed changes with the spindle rotating and always disconnect the

machine from the power source when performing maintenance to avoid accidental starting or

electrical shock.

30. Provide for adequate space surrounding work area and non-glare, overhead lighting.

31. When stopping the lathe, never grab the part or faceplate to slow it down. Let the work coast to a

stop.

32. Use only JET factory authorized replacement parts and accessories; otherwise, the warranty and

guarantee are null and void.

33. Do not use this JET wood lathe for other than its intended purpose. If used for other purposes,

JET disclaims any real or implied warranty and holds itself harmless from any injury that may

result from that use.

4

Page 5

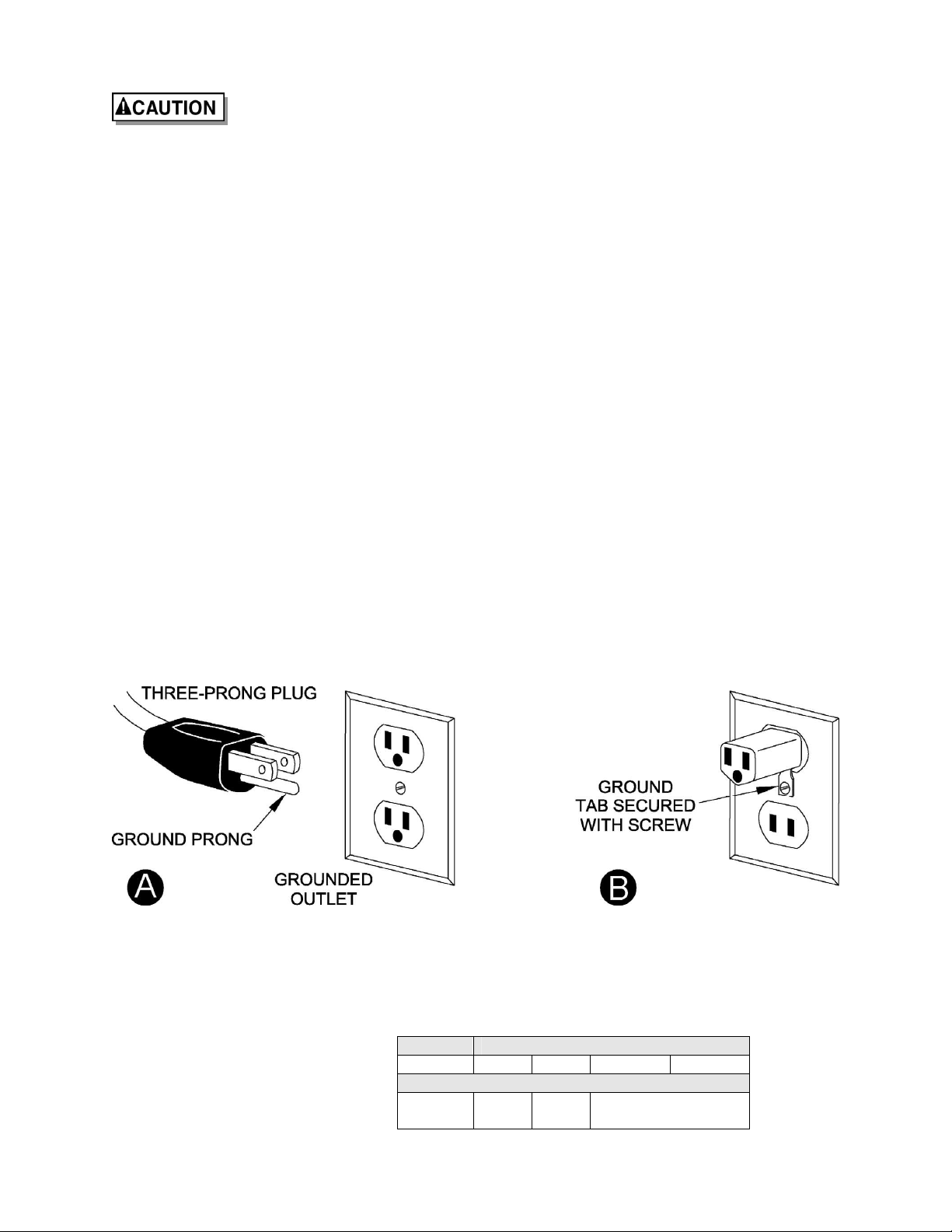

Grounding Instructions

This tool must be grounded while in use to protect the operator from electric

shock.

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The

conductor, with insulation having an outer surface that is green with or without yellow stripes, is the

equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is properly grounded. Use only three wire extension cords

that have three-prong grounding plugs and three-pole receptacles that accept the tool’s plug.

Repair or replace a damaged or worn cord immediately.

115 Volt Operation (Model JWL-1642EVS only)

As received from the factory, your JWL-1642EVS is ready to run at 115-volt operation. This lathe is

intended for use on a circuit that has an outlet and a plug that looks the one illustrated in Figure A. A

temporary adapter, which looks like the adapter as illustrated in Figure B, may be used to connect this

plug to a two-pole receptacle, as shown in Figure B if a properly grounded outlet is not available. The

temporary adapter should only be used until a properly grounded outlet can be installed by a qualified

electrician. This adapter is not applicable in Canada. The green colored rigid ear, lug, or tab, extending

from the adapter, must be connected to a permanent ground such as a properly grounded outlet box, as

shown in Figure B.

The use of an extension cord is not recommended. However, if you must use one make sure your

extension cord is in good condition. Be sure to use one heavy enough to carry the current your machine

will draw. An undersized cord will cause a drop in the line voltage resulting in power loss and overheating.

The following table shows the correct size to use depending on the cord length needed and the

nameplate ampere rating. If in doubt, use the next heavier gauge. Remember, the smaller the gauge

number, the heavier the cord.

Volts7 Total Length of Cord in Feet

120V 25 50 100 150

AWG

12-16

Amps

14 12 Not Recommended

5

Page 6

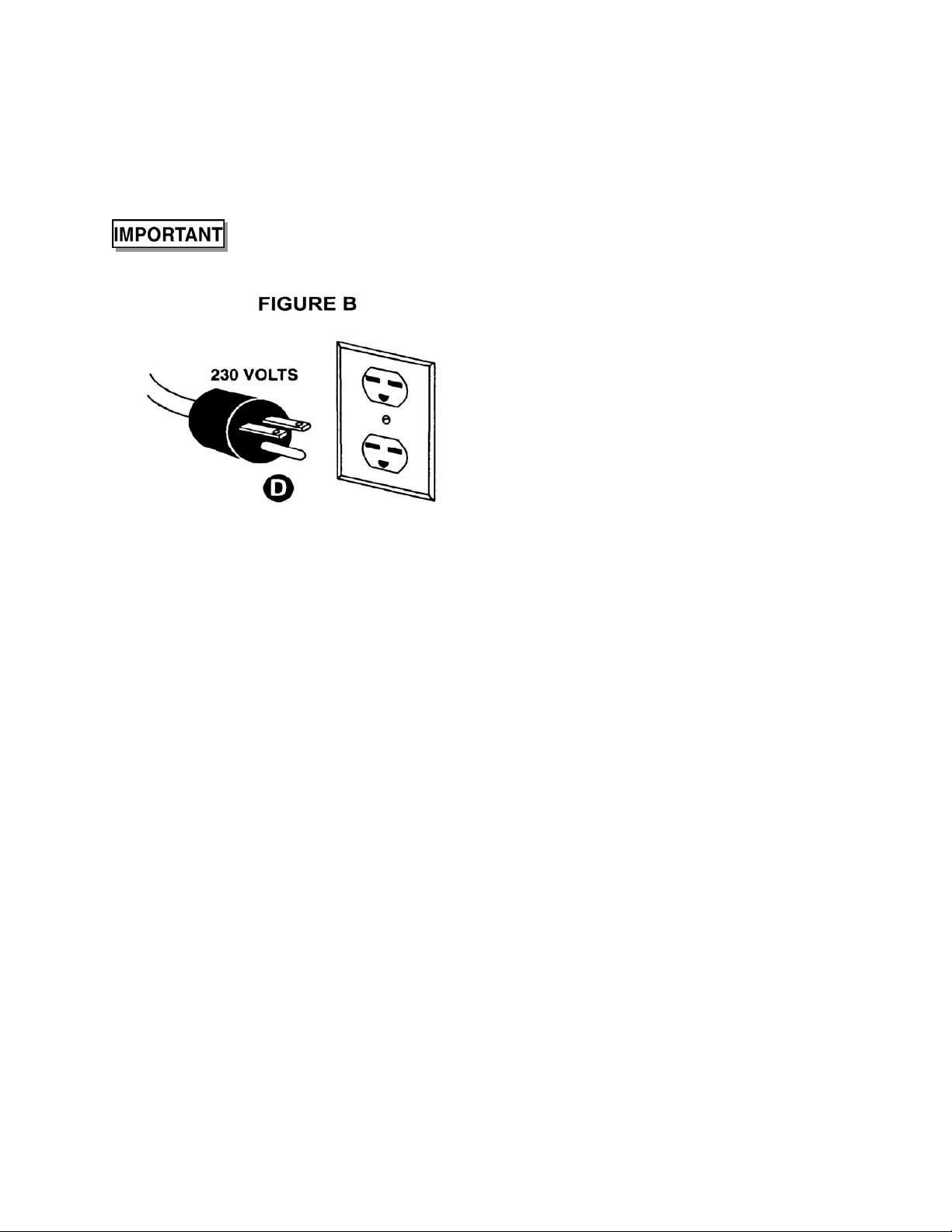

230-Volt Operation (Model JWL-1642EVS-2 only)

1. A plug with a UL/CSA listing suitable for 230V operation (Figure D) must be connected to the

power cord. Contact your local authorized WMH Tool Group service center or qualified electrician

for proper procedures to install the plug. The lathe must comply with all local and national codes

after the 230V plug is installed.

2. The lathe with a 230V plug should only be connected to an outlet having the same configuration

(Figure D). There is no adapter available nor should one be used with the 230V plug.

In all cases (115 or 230 volts), make certain the receptacle in question is properly

grounded. If you are not sure, have a registered electrician check the receptacle.

Note: The JWL-1642EVS-2 lathe requires a 230-volt single-phase input. It is equipped with a power

inverter, located between the power cord and the drive motor. The inverter takes the 230V 1-phase input

from the power cord and converts it to the 230V 3-phase output required by the drive motor.

6

Page 7

Introduction

This manual is provided by JET covering the safe operation and maintenance procedures for Models

JWL-16423EVS and JWL-1642EVS-2 Wood Lathes. This manual contains instructions on installation, safety

precautions, general operating procedures, maintenance instructions and parts breakdown. These machines

have been designed and constructed to provide years of trouble free operation if used in accordance to the

instructions set forth in this manual. If there are any questions or comments, please contact either your local

supplier or WMH Tool Group. WMH Tool Group can also be reached at our web site:

www.wmhtoolgroup.com.

Table of Contents

Warranty ................................................................................................................................................. 2

Warnings................................................................................................................................................. 3

Grounding Instructions............................................................................................................................. 5

115V Operation ....................................................................................................................................... 5

230V Operation ....................................................................................................................................... 6

Introduction .............................................................................................................................................7

Table of Contents.................................................................................................................................... 7

Specifications.......................................................................................................................................... 8

Contents of the Shipping Container.......................................................................................................... 9

Unpacking and Cleanup .......................................................................................................................... 9

Assembly ................................................................................................................................................ 9

Stand Shelf............................................................................................................................................ 10

Tool Basket ........................................................................................................................................... 10

Guard.................................................................................................................................................... 11

Controls and Features ........................................................................................................................... 11

Speed Change ...................................................................................................................................... 13

Lathe Tools ........................................................................................................................................... 13

Mounting the Workpiece Between Centers............................................................................................. 14

Stock Selection...................................................................................................................................... 15

Roughing Out ........................................................................................................................................ 15

Coves, “V” Cuts, Parting and Beads....................................................................................................... 16

Sanding and Finishing ........................................................................................................................... 17

Face Plate or Bowl Turning.................................................................................................................... 17

Mounting Stock...................................................................................................................................... 17

Face Plate or Chuck .............................................................................................................................. 18

Wood Selection ..................................................................................................................................... 18

Checks and Cracks ............................................................................................................................... 18

Distortion............................................................................................................................................... 18

Tools for Bowl Turning........................................................................................................................... 18

To Shape the Outside of a Bowl............................................................................................................. 19

To Shape the Interior of a Bowl .............................................................................................................. 20

Sanding and Finishing a Bowl................................................................................................................ 20

Adjusting the Clamping Mechanism ....................................................................................................... 21

Changing the Belt and Bearings............................................................................................................. 21

Troubleshooting..................................................................................................................................... 22

Part Breakdowns and Parts List ............................................................................................................. 23

Wiring Diagram for JWL-1642EVS......................................................................................................... 28

Wiring Diagram for JWL-1642EVS-2...................................................................................................... 29

Indexer Positions ................................................................................................................................... 30

Page 8

Specifications JWL-1642EVS JWL-1642EVS-2

Stock Number.....................................................708359 ................................................................708360

Over Bed............................................................16”.............................................................................16”

Swing Over Tool Rest Base................................12”.............................................................................12”

Distance Between Centers .................................42”............................................................................. 42”

Speeds (RPM)....................................................50-1200 and 120-3200 ................50-1200 and 120-3200

Spindle Nose......................................................1-1/4" x 8 T.P.I. ......................................1-1/4” x 8T.P.I.

Drive Spindle Through Hole................................3/8”........................................................................... 3/8”

Tailstock Spindle Through Hole ..........................3/8”...........................................................................3/8”

Tailstock Spindle Travel......................................4” ................................................................................4”

Tool Rest............................................................14”.............................................................................14”

Face Plate..........................................................6” ................................................................................6”

Headstock Taper ................................................MT-2 ......................................................................MT-2

Tailstock Taper...................................................MT-2 ...................................................................... MT-2

Spindle Center to Floor (approx.) ........................44-1/2”.................................................................44-1/2”

Motor..................................................................1-1/2 HP, 3Ph, 230V..............................2HP, 3PH, 230V

...........................................................................Input Power 115V Only

Net Weight (approx.)...........................................440 Lbs ..............................................................440Lbs.

Shipping Weight (approx.) ..................................475 Lbs ..............................................................475Lbs.

.......... Input Power 230V Only

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, WMH Tool Group reserves the right to change specifications at any time and

without prior notice, without incurring obligations.

8

Page 9

WARNING

Read and understand the entire contents of

this manual before attempting assembly or

operation!

Failure to comply may cause serious injury!

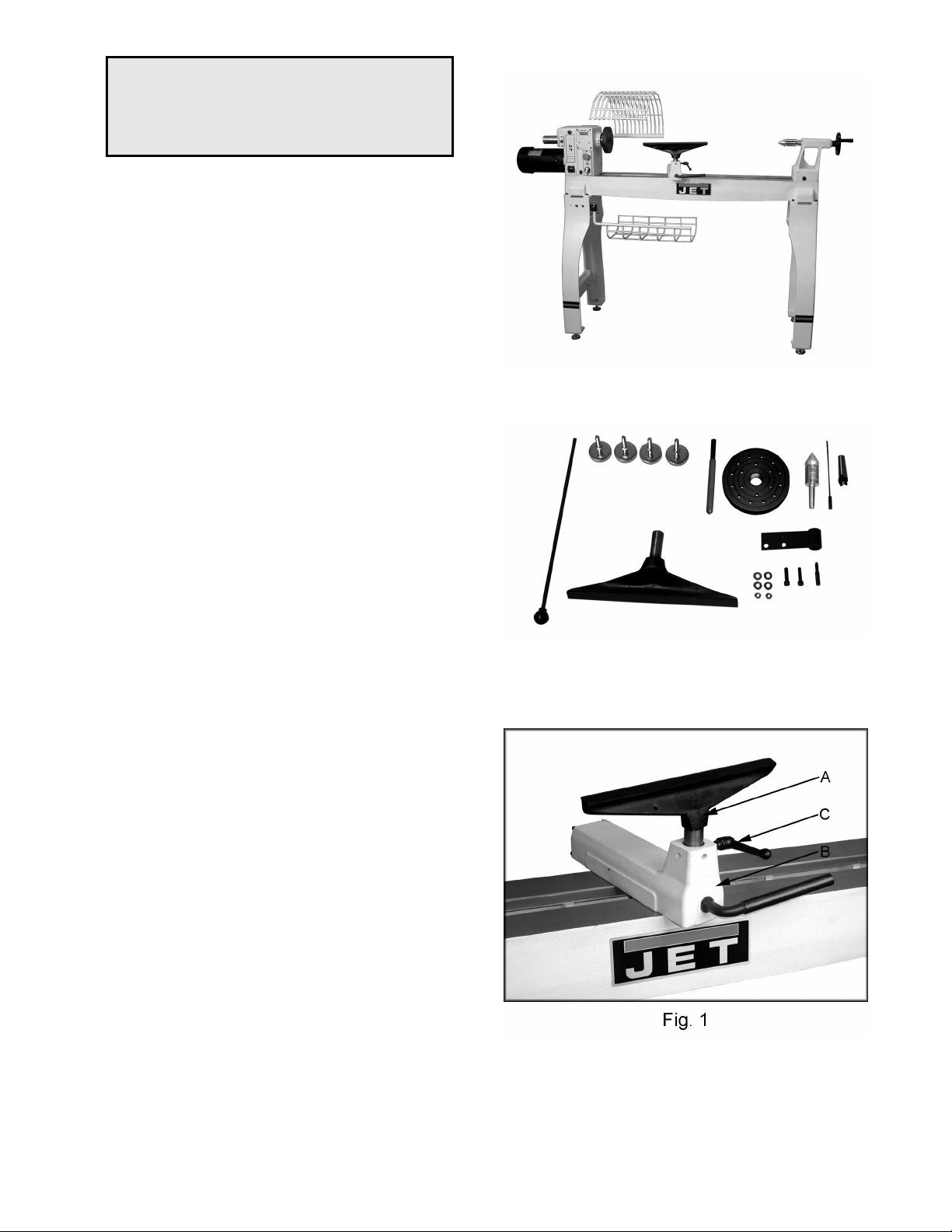

Contents of the Shipping Containers

1. Lathe

2. Cast Legs

1. Tailstock

1. Headstock

1. Tool Rest Body

1. Tool Basket

1. Guard Assembly

1. Accessory Package

1. Owner’s Manual & Warranty Card

Accessory Package Box

1. Live Center

1. Rod for Live Center

1. Spur Center

1. Index Pin

1. Face Plate

1. Rod for Face Plate

1. Knockout Rod Headstock

1. Tool Rest

4. Adjustable Feet

Tool Basket Bracket Hardware

2. Hex Sckt Cp Screws 5/16”-18 x 1-1/2”

4. Flat Washers 5/16”

2. Set Screws 1/4”-20 x 1/4”

3. Hex Nuts 5/16”

1. Set Screw 5/16”-18 x 5/8”

Unpacking and Clean-Up

1. Remove the shipping container. Do not

discard any shipping material until the lathe

is set up and running properly.

2. Remove hex cap bolts from skid bottom and

move the lathe off the skid and into position.

3. Clean all rust protected surfaces with a

cleaner degreaser. Clean thoroughly under

the headstock, tailstock and tool rest body.

Assembly

1. Secure tool rest (A, Fig. 1) to tool rest body

(B, Fig. 1) by tightening handle (C, Fig. 1).

2. Slide the tailstock and tool rest to the

headstock end of the lathe bed. See

“Controls and Features” section of this

manual on how to move the tailstock and

tool rest.

Contents of Accessory Package

9

Page 10

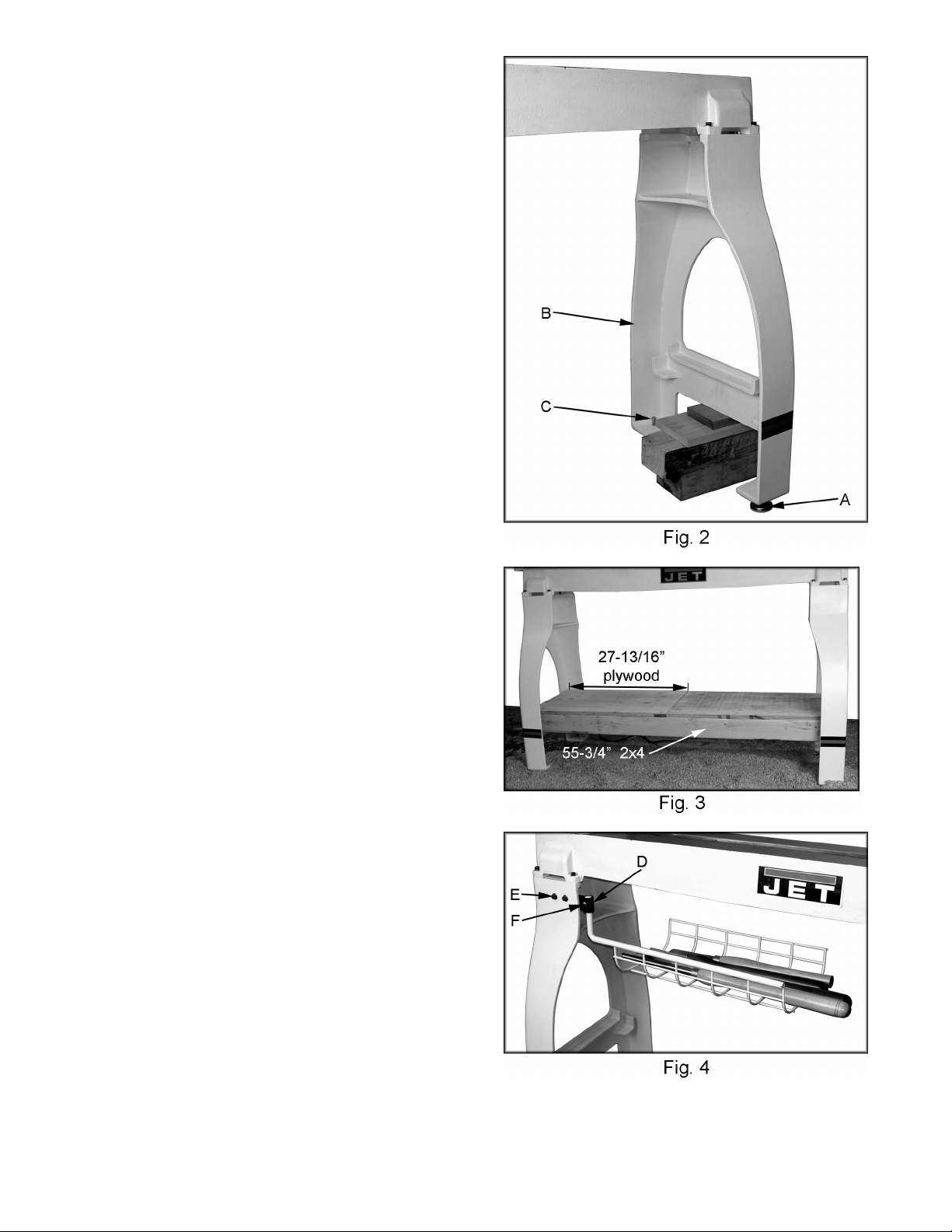

3. Lift the tailstock end of the lathe up far

enough to slide a few pieces of scrap wood

under the leg, see Figure 2.

4. Thread adjustable feet (A, Fig. 2) into stand

leg (B, Fig. 2). There is a flat spot on the

shaft near the foot that will accommodate a

wrench. Thread a hex nut (C, Fig. 2) onto

shaft and leave loose for now.

5. Remove the scrap pieces of wood and slide

the tailstock, tool rest and headstock down

to the tailstock end of the late bed.

6. Mount the two adjustable feet in the same

manner as above and move the headstock,

tool rest and tailstock into their normal

positions.

7. Adjust the feet so that the lathe rests evenly

on the floor, and tighten the nuts.

Stand Shelf

You can make an extra shelf that rests between

the legs if you wish, see Figure 3. It will be

useful for storing lathe accessories, or adding

sand bags for some extra weight. The two 2x4’s

should be 55-3/4” long. The plywood should be

ripped into two equal pieces 27-13/16”L x 17”W

so that it can be assembled between the legs.

Use screws to attach the plywood to the 2x4

supports.

Tool Basket

1. Mount the bracket (D, Fig. 4) to the inside of

the lathe leg with two 5/16”-18 x 1-1/2” hex

socket cap screws, four 5/16” flat washers

and two 5/16” hex nuts (E, Fig. 4).

2. The two setscrews, on the bracket should be

below the bolts and accessible from the

backside for adjustment.

3. Place the arm of the tool basket into the

bracket and secure with a 5/16”-18 x 5/8” set

screw and tighten the 5/16” hex nut (F, Fig.

4). Line up the notch in the arm with the

setscrew so the tool basket can pivot.

4. Adjust the setscrews on the bracket so that

the tool basket swings in a level manner.

Tighten the two hex socket cap screws.

10

Page 11

Guard

1. Attach guard to the bracket by inserting the

rod and lifting up on the plunger (A, Fig. 5).

2. There are two detents that will hold the

guard in place. One is for turning and the

other is for when you need the guard up and

out of the way.

3. Tighten the bushings (B, Fig. 5) against the

bracket with two setscrews (C, Fig. 5).

Controls and Features

1. Headstock Lock Handle: (D, Fig. 6) Locks

head in position. Unlock handle to position

the head along lathe bed. Tighten handle

when properly positioned.

2. Headstock Spindle Lock: (E, Fig. 6) Push

pin in to keep the spindle from turning.

CAUTION! Never press the headstock

spindle lock while the spindle is turning!

3. Headstock On/Off Button: (F, Fig.6) Pull

the button out to turn “ON” the lathe. Push

the button in to turn the lathe “OFF”.

4. Headstock RPM Knob: (G, Fig. 6) Turn

knob to desired RPM. There are two speed

ranges offering “speed” (0-3200) and

“torque” (0-1,200).

5. Headstock For/Rev Switch: (H, Fig. 6) Use

the toggle switch to change the direction the

spindle turns. Only change direction when

the spindle has stopped.

6. Headstock RPM Readout: (I, Fig. 6)

Displays the spindles RPM, see Figure 7.

7. Headstock Spur Center: (J, Fig. 8) Used

for turning between centers. Spindle taper is

MT-2. Remove spur center by inserting drift

rod through the opposite end of the spindle

and knocking spur center out.

11

Page 12

8. Headstock Faceplate: (K, Fig. 8) Used for

turning bowls and plates. There are a

number of screw holes for mounting the

workpiece. Thread the faceplate onto the

spindle in a clockwise direction, and tighten

two setscrews. Remove the faceplate by

loosening two setscrews. Push in headstock

spindle lock and use the provided rod in

faceplate holes to unthread the faceplate.

9. Headstock Indexing Hole: (L, Fig. 8)

Thread indexing pin into the indexing hole

making sure that it locates in the spindle

hole. There are 12 holes in the spindle 30°

apart. Three holes in the headstock casting

accept the indexing pin. These holes are 20°

apart. The combination of holes will allow

you to mark your workpiece for evenly

spaced features. See chart on page 30.

CAUTION! Never start the lathe with the

index pin engaged in the spindle!

10. Tool Rest Body Lock Handle: (M, Fig. 9)

Locks the tool rest body in position. Unlock

handle to position the tool rest in any

location along lathe bed. Tighten handle

when properly positioned.

11. Tool Rest Lock Handle: (N, Fig. 9) Locks

the tool rest in position. Unlock the handle to

position tool rest at a specific angle, or

height. Tighten handle when properly

positioned.

12. Tailstock Lock Handle: (O, Fig. 10) Locks

the tailstock in position. Unlock handle to

position the tool rest in any location along

lathe bed. Tighten handle when properly

positioned.

13. Tailstock Quill Lock Handle: (P, Fig. 10)

Locks the tailstock quill in position. Unlock

handle to position the quill. Tighten handle

when properly positioned.

14. Tailstock Quill Handwheel: (Q, Fig. 10)

Turn the handwheel to position the quill. The

tailstock quill lock handle must be loose to

position quill.

15. Tailstock Live Center: (R, Fig. 10) Used for

turning between centers. Quill taper is MT-2.

Remove live center by retracting the quill

until live center loosens. Remove, or add

different tips to the live center by inserting

the provided rod through the holes in the

center’s shaft. Unscrew the tip and change

as needed.

12

Page 13

Speed Change

1. Disconnect the machine from the power

source!

2. Loosen the locking handle (A, Fig. 11).

3. Lift up on the tensioning handle (B, Fig. 11)

to remove tension from the poly v-belt. You

can now position the belt in the desired

speed range. It is pictured in the low speed

pulley range. Note: The “High” speed range

(120-3200) provides maximum speed,

where as the “Low” speed range (50-1200)

will provide maximum torque.

4. Lower the tensioning handle so that the

weight of the motor provides the needed

tension and tighten the locking handle.

AC Inverter does not require any programming.

It is pre-programmed from the factory. The

buttons and knob on the face of inverter should

not be changed. Use only controls on the front of

headstock. Refer to Inverter manual.

Lathe Tools

If possible, select only high quality, high-speed

steel turning tools with long handles. As one

becomes proficient in turning, a variety of

specialty tools for specific applications can be

acquired. The following tools provide the basics

for most woodturning projects. See your JET

distributor for a wide variety of JET woodturning

tools.

Roughing Gouge — used for rapidly cutting

raw wood into round stock, see Figure 12.

Deep Fluted Bowl Gouge — used for turning

bowls and plates, see Figure 12.

Spindle Gouge — used for turning beads,

coves and other details, see Figure 12.

Spear — fine scraping and delicate operations,

such as the forming of beads, parallel grooves

and shallow vees, etc, see Figure 12.

Skew — used to make vees, beads, etc., see

Figure 12.

Square Scraper — used for diameter scraping

and featureless scraping, etc, see Figure 12.

Large Domed Scraper — used to reduce ridges

on the interior of bowls, round edges of bowls,

etc, see Figure 12.

Parting Tool — used to cut directly into the

material, or to make a cut off. Also used for

scraping and to set diameters, see Figure 12.

For safety and best performance, keep tools

sharp. If a tool stops cutting, or requires

excessive pressure to make a cut, it needs to be

sharpened. A number of brand name sharpening

jigs and fixtures are available, however, a

woodturner should learn to sharpen tools

freehand.

13

Page 14

Mounting Workpiece Between Centers

Spindle turning takes place between the centers

of the lathe. It requires a spur center in the

headstock and a live center in the tailstock.

1. With a ruler locate and mark the center on

each end by going corner to corner, see

Figure 13. Accuracy is not critical on full

rounds but extremely important on stock

where square sections are to remain. Put a

dimple in each end of the stock with an awl,

or nail.

2. Extremely hard woods may require kerfs cut

into the spur drive end of stock, see Figure

13. You may need to drive the spur center

into the stock with a wood mallet. Note:

Never drive stock onto spur while it is

mounted in the lathe spindle.

3. Install workpiece by inserting the attached

spur center into the spindle taper on the

headstock.

4. Bring tailstock into position, lock it to the

bed, and advance quill with the handwheel

in order to seat the live center into the

workpiece. Lock the quill in place. Make

sure the live center point is centered on your

mark.

5. Move tool rest into position. It should be

parallel to workpiece, approximately at the

centerline and approximately 1/8" from the

closest part of the workpiece. Lock tool rest

body and tool rest in place.

6. Rotate workpiece by hand to check for

proper clearance from tool rest. Note: You

may want to trim off the corners of a square

workpiece to make turning a little easier, see

Figure 14.

7. Start lathe at the lowest

up to the appropriate RPM for the size of

stock, see Figure 7 page 10.

The position of the tool rest can be varied to suit

the work and operator. After you become

experienced with setting the tool rest changing

the position will become second nature for the

workpiece and comfort of the user.

speed and bring it

14

Page 15

Stock Selection

Stock for spindles should be straight grained

and free of checks, cracks, knots and other

defects. It should be cut 1/8" to 1/4" larger than

the finished diameter and may require additional

length to remove ends if required. Larger stock

should have the corners removed to produce an

octagon making the piece easier to rough down

to a cylinder, see Figure 14.

Roughing Out

1. Use a large roughing gouge and begin

cutting about 2” from the tailstock end of the

workpiece. Place the tool on tool rest with

heel of the tool on surface to be cut.

2. Slowly and gently, raise tool handle until

cutting edge comes into contact with the

workpiece. Work to the right towards the end

of the workpiece. You never want to start at

the end of a workpiece.

3. Now continue to work the rest of the

workpiece. Roll the flute (hollowed-out

portion) of the tool in the direction of the cut;

see Figure 15. Make long sweeping cuts in a

continuous motion to rough the piece down

to a cylinder. Keep as much of the bevel of

tool as possible in contact with workpiece to

ensure control and avoid catches. Note:

Always cut downhill, or from large diameter

to small diameter. Always work toward the

end of a workpiece, never start cutting at the

end.

4. Once the workpiece is roughed down to a

cylinder, smooth it with a large skew. Place

the cutting point near the center of the chisel

and high on the workpiece, see Figure 16.

Touching one of the points of the skew to

the spinning workpiece may cause a catch

and ruin the workpiece.

5. Add details to the workpiece with the skew,

spindle gouge, etc.

15

Page 16

Coves

1. Use a spindle gouge. With the flute of the

tool at 90 degrees to the workpiece, touch

the center of the cutting edge to the

workpiece and roll in towards the bottom of

the cove. Stop at the bottom; attempting to

go up the opposite side may cause the tool

to catch.

2. Move tool over the desired width of cove.

3. With the flute facing the opposite direction,

repeat step 1 for other side of cove. Stop at

the bottom of the cut; see Figure 18.

“V” Cuts

1. Use the long point of the skew. Note: Do not

press the long point of the skew directly into

the workpiece to create the "V"; this will

result in a burned or burnished "V" with

fibers being rolled up at both sides.

2. Lightly mark the center of the "V" with the tip

of the skew.

3. Move the point of skew to the right half of

the desired width of your cut, see Figure 19.

4. With the bevel parallel to the right side of the

cut, raise the handle and push the tool in to

the desired depth.

5. Repeat from the left side. The two cuts

should meet at the bottom and leave a clean

"V" cut.

6. Additional cuts may be taken to add to either

the depth or width of the cut.

Parting

1. Place the parting tool on the tool rest and

raise the handle until it starts to cut and

continue to cut to the desired depth.

2. If the cut is deep a clearance cut should be

made along side the first cut to prevent the

tool tip from burning.

Beads

1. Place the parting tool on the tool rest and

move it forward to allow the full bevel of the

tool to contact the workpiece. Gently raise

the handle to make the cut to the

appropriate depth.

2. Repeat for the other side of the bead.

3. Using a small skew or spindle gouge, start in

the center between the two cuts and cut

down each side to form the bead. Roll the

tool in the direction of the cut.

16

Page 17

Sanding and Finishing

Leaving clean cuts will reduce the amount of

sanding required. Adjust the lathe to a finishing

speed, and begin with fine sandpaper (120 grit

or finer). Coarser sandpaper will leave deep

scratches that are difficult to remove, and dull

crisp details. Fold the sandpaper into a pad; do

not wrap sandpaper around your fingers or the

workpiece.

To apply a finish, the workpiece can be left on

the lathe. Turn the lathe off and use a brush, or

cloth to apply the finish. Remove excess finish

before restarting lathe. Allow it to dry and sand

again with 320 or 400 grit sandpaper. Apply

additional coats of finish and buff.

Face Plate and Bowl Turning

Faceplate turning is normally done on the

inboard side of the headstock over the bed; see

Figure 20.You must move the headstock to the

end of the lathe bed for larger workpieces.

Mounting Stock

Use of a faceplate is the most common method

for holding a block of wood for turning bowls,

and plates, see Figure 21.

1. Select stock at least 1/8" to 1/4" larger than

the dimension on the desired finished

workpiece.

2. True one surface of workpiece for mounting

against the faceplate. It is best to leave extra

stock against the faceplate that can be cut

off when the workpiece is finished.

3. Using the faceplate as a template, mark the

location of the mounting holes, and drill pilot

holes of the appropriate size. If the mounting

screws on the faceplate interfere with the

workpiece, a waste block can be mounted to

the faceplate and then the waste block

mounted to the workpiece by gluing or

screwing, see Figure 21.

4. Both waste block and workpiece should

have good flat surfaces.

5. Push in the spindle lock and thread

faceplate and workpiece onto spindle.

Tighten setscrews in faceplate when secure.

17

Page 18

Face Plate or Chuck

While faceplates are the simplest, most reliable

method of holding a block of wood for turning,

chucks can also be used. A chuck is not a

requirement but is handy when working on more

than one piece at a time. Rather than removing

screws, you simply open the chuck and change

workpieces. The most popular ones are four jaw

scroll chucks with a variety of jaws to

accommodate different size tenons. Most also

come with a screw chuck as well.

Wood Selection

Firewood is the cheapest, most widely available

stock to use while learning to turn bowls.

Develop skill with each tool before attempting to

make a finished piece. It is best to start with dry

wood, without worrying about drying or

distortion. Once turning becomes comfortable,

try green wood, which cuts very easily. As the

turner gains experience, he or she will find

extraordinary grain and figure in the form of

burls, crotches and bark inclusions.

Checks and Cracks

Green wood will check and crack. For best

results, leave logs in as long lengths as you can

handle. As the material starts to dry, surface

cracks will develop on the ends of the log. Cut

off two to three inches and you should find good,

sound wood. Also, cut the log in half along the

pith to avoid having it in the finished piece. Most

checks radiate from the pith. As you turn bowls

from green wood, make sure you maintain a

consistent wall thickness throughout the piece.

Leaving a piece thick in some areas and thin in

others will cause the wood to dry unevenly and

promote checks and cracks.

Distortion

Distortion is a problem associated with turning

green wood. It will vary from one type of wood to

the next. Typically, fruitwoods tend to distort

more than others do. It also varies with the time

of year the tree was cut and how the logs are

stored.

Tools for Bowl Turning

The deep fluted bowl gouge is the most

essential and versatile tool for most bowl and

faceplate style turning. The bowl gouge is

heavier and easier to control than other types of

18

gouges. It also allows removal of wood much

faster and with less vibration than other gouges.

Most average sized bowl work can be

accomplished with a 3/8" or 1/2" bowl gouge. A

1/4" bowl gouge is best suited for smaller bowls

and light finishing cuts. Larger 3/4" and 1" bowl

gouges are only used for extremely large pieces.

Large domed scrapers can also be used to help

clean up the interior surfaces of bowls. A light

touch with the scraper slightly tilted will eliminate

some of the ridges left by a bowl gouge.

Page 19

To Shape the Outside of a Bowl

1. Odd shaped burls, crotches and other

irregular shaped blanks require special

preparation before mounting in a chuck, or

onto a faceplate. Remove the bark, if there

is any, from what appears to be the center of

the top of workpiece.

2. Drive the spur center into the top of

workpiece with a wood mallet.

3. Slip the spur center into the headstock taper

and bring the tailstock, with a live center,

into position. Lock the tailstock to the bed

and advance the spindle in order to seat the

cup center into the workpiece, see Figure

22. Tighten the quill lock.

4. Position the tool support just below the

centerline and about 1/4" from the

workpiece. Note: For larger outboard

turning, an optional outboard turning stand is

used to place the tool support, see your JET

distributor.

5. Turn the workpiece by hand to ensure

proper clearance.

6. Start the lathe at the lowest speed and bring

it up to the maximum safe speed for the size

of work to be turned, see Figure 7 on page

10. If the machine starts to vibrate, lower the

speed until the vibration stops.

7. Rough out the outside of the bowl with the

1/2" deep fluted bowl gouge, holding the tool

firmly against your hip. For best control, use

your whole body to move the gouge through

the workpiece.

8. As the bowl takes shape, work on the

bottom (tailstock end) to accommodate

attaching a faceplate, see Figure 22.

9. Turn a short tenon (about 1/8" long) the size

of the hole in the faceplate, see Figure

22.This will allow centering the workpiece

when the faceplate is attached. Note: If you

plan to use a chuck, turn a tenon of

appropriate length and diameter to fit your

chuck.

10. Stop the lathe, remove the workpiece and

attach the faceplate, or chuck.

11. Finish turning the outside of the bowl with a

1/2" or 3/8" bowl gouge. Leave additional

material at the base of the bowl for support

while turning the interior. This will be

removed later.

19

Page 20

To Shape the Interior of a Bowl

1. Stop the lathe and move the tailstock away.

Remove the center from the tailstock to

prevent bumping it with your elbow.

2. Adjust the tool support in front of the bowl

just below the centerline, at a right angle to

the lathe bed.

3. Rotate the workpiece by hand to check the

clearance.

4. Face off the top of the bowl by making a

light shearing cut across the workpiece, from

rim to center.

5. Place the 1/2" bowl gouge on the tool rest at

the center of the workpiece with the flute

facing the top of the bowl. The tool handle

should be level and pointed toward four

o'clock, see Figure 23.

6. Use left hand to control the cutting edge of

the gouge, while the right hand swings the

tool handle around toward your body, see

Figure 23. The flute should start out facing

the top of the workpiece, and rotate upward

as it moves deeper into the bowl to maintain

a clean even curve. As the tool goes deeper

into the bowl, progressively work out toward

the rim. It may be necessary to turn the tool

rest into the workpiece as you get deeper

into the bowl. Note: Try to make one, very

light continuous movement from the rim to

the bottom of the bowl to ensure a clean,

sweeping curve through the workpiece.

Should there be a few small ridges left, a

light cut with a large domed scraper can

even out the surface.

7. Develop the wall thickness at the rim and

maintain it as you work deeper into the bowl.

When the interior is finished, move the tool

support to the exterior to re-define the

bottom of the bowl. A general rule of thumb:

the base should be approximately 1/3 the

overall diameter of the bowl.

8. Work the tight area around the faceplate or

chuck with 1/4" bowl gouge.

Sanding and Finishing a Bowl

1. Remove the tool rest and adjust the lathe

speed to the appropriate finishing speed.

High speed can build friction while sanding

and cause heat check in some woods.

2. Begin with fine sandpaper 120 grit and

progress through each grit, using only light

pressure. Coarser sandpaper tends to leave

deep scratches that are hard to eliminate.

Use power-sanding techniques to avoid

concentric sanding marks around your

finished piece. Avoid rounding over the rim

and foot with sandpaper. Try to keep details

crisp. Finish sanding with 220 grit.

3. Remove the sanding dust with tack rags, or

compressed air and, with the lathe turned

off, apply the first coat of finish. Let it stand

for several minutes then wipe off the excess.

Allow it to dry before sanding again with 320

or 400 grit sandpaper.

4. Turn lathe back on and make a separation

cut through the base. Stop at about 3" and

use a small fine tooth saw to separate the

bowl from the waste.

5. Apply additional finish coats and allow them

to dry before buffing.

20

Page 21

Adjusting the Clamping Mechanism

The clamps are pre-set at the factory and should

not need any adjustment. However, if

adjustment is needed remove the stud (A, Fig.

24). Loosen the locking handle and slide the

headstock, tailstock or tool rest to the edge of

the bed and slightly turn the hex nut (B, Fig. 24).

Slide back into position and test the handle to

make sure it securely locks.

Changing the Belt and Bearings

Changing the belt and bearings can be a difficult

task, and should be performed by a JET

authorized repair station. Remove the headstock

and take it into a repair station for servicing.

1. Disconnect the machine from the power

source!

2. Loosen the locking handle (C, Fig. 25), and

lift up on the tensioning handle (D, Fig. 25)

to remove tension from the poly v-belt.

3. Open the door (E, Fig. 25), and remove the

belt (F, Fig. 25) from the lower pulley.

4. Loosen the two setscrews in the handwheel

(G, Fig. 25) and remove.

5. Loosen the socket head cap screw enough

to unthread the clamping nut (H, Fig. 25).

6. Loosen the two setscrews in the right hand

pulley (I, Fig. 25).

7. Loosen the setscrew in the collar (J, Fig. 26)

8. Use a wood dowel, or aluminum stock to

knock the spindle towards the tailstock. Use

a material that is softer than the spindle so

you do not mushroom the end of the spindle.

Only go far enough to remove the belt from

the spindle; see Figure 26.

9. Now you can replace the belt or bearings.

There are two bearings, #5 and 10, that can

be seen in “Headstock Assembly” on page

24.

10. To reassemble, reverse the procedure.

Note: When reinstalling the clamping nut,

thread it onto the spindle until its snug. Then

back it off slightly and tighten the socket

head cap screw.

21

Page 22

Problem Possible Cause Solution

Excessive vibration.

Motor or spindle stalls or will not

start

Motor fails to develop full power.

Tools tend to grab or dig in.

Tailstock moves when applying

pressure

Digital readout does not work

Troubleshooting

1. Workpiece warped, out of

round, has major flaw, or was

improperly prepared for

turning

2. Worn spindle bearings

3. Worn belt

4. Motor mount bolt or handle

loose

5. Lathe on uneven surface

1. Excessive cut

2. Worn motor

3. Broken belt

4. Worn spindle bearings

5. Improper cooling on motor

1. Power line overloaded

2. Undersize wires in supply

system

3. Low voltage

4. Worn motor

1. Dull tools

2. Tool support set too low

3. Tool support set too far from

workpiece

4. Improper tool being used

1. Excessive pressure being

applied by tailstock. Note:

The screw action of the

tailstock is capable of

applying excessive pressure

to workpiece and headstock.

Apply only sufficient force by

tailstock to hold workpiece

securely in place. Excessive

pressure can cause damage

to machine.

2. Lathe bed and tailstock

mating surfaces are greasy

or oily.

1. Digital readout sensor out of

position

1. Correct problem by planing,

bandsawing, or scrap the

workpiece all together

2. Replace bearings

3. Replace belt

4. Tighten bolt or handle

5. Shim lathe bed, or adjust feet

on stand

1. Reduce cut depth

2. Replace motor

3. Replace belt

4. Replace bearings

5. Clean sawdust from motor

fan

1. Correct overload condition

2. Increase supply wire size

3. Request voltage check from

power company and correct

low voltage condition

4. Replace motor

1. Sharpen tools

2. Reposition tool support

height

3. Reposition tool support

closer to workpiece

4. Use correct tool for operation

1. Slide tailstock down to the

right side of the lathe against

the stop. Move headstock

into position and apply

pressure to workpiece with

tailstock.

2. Remove and clean surfaces

with a cleaner degreaser

1. Open the belt access and

position the sensor so that it

reads the bolts

22

Page 23

Stand and Bed Assembly

23

Page 24

Stand and Bed Assembly

Index Part

No. No. Description Size Qty.

1.......... JWL1642-201 ...............I.D. Label............................................... JWL-1642EVS ........................ 1

............ JWL-1642-201A ............I.D. Label............................................... JWL-1642EVS-2..................... 1

2.......... JWL1642-202 ...............Live Center............................................ MT2 ........................................ 1

3.......... JWL1642-203 ...............Stand .................................................... ............................................... 2

4.......... JWL1442-219 ...............JET Label.............................................. ............................................... 1

5.......... JWL1642-205 ...............JET Stripe ............................................. ............................................... 1

6.......... JWL1642-206 ...............Adjustable Foot ..................................... 3/8”......................................... 4

7.......... TS-0561031..................Hex Nut................................................. 3/8” ......................................... 4

8.......... JWL1442-201 ...............Bed ....................................................... ............................................... 1

9.......... TS-0208081..................Hex Socket Cap Screw.......................... 5/16”-18 x 1-1/2” ................... 10

10........ TS-0680032..................Flat Washer........................................... 5/16”..................................... 12

11........ JWL1642-211 ...............Tool Rest............................................... ............................................... 1

12........ JWL1442-207 ...............Tool Rest Base...................................... ............................................... 1

13........ JWL1442-208 ...............End Cover............................................. ............................................... 1

14........ TS-0267021..................Set Screw..............................................1/4”-20 x 1/4” .......................... 6

15........ JWL1442-129 ...............Support Bracket..................................... ............................................... 1

16........ JWL1442-210A .............Tool Support Rod .................................. ............................................... 1

17........ JWL1442-211 ...............Handle................................................... ............................................... 1

18........ JWL1442-212 ...............Handwheel ............................................ ............................................... 1

19........ JWL1442-202 ...............Stud ...................................................... ............................................... 3

20........ JWL1442-206 ...............Tool Support Handle.............................. 3/8”......................................... 1

21........ JWL1442-124 ...............C-Ring...................................................S19......................................... 3

22........ JWL1642-222 ...............Tailstock................................................ ............................................... 1

23........ JWL1442-218 ...............Tailstock Quill Handle............................ 5/16” ....................................... 1

24........ JWL1442-214 ...............Lead Screw ........................................... ............................................... 1

25........ JWL1442-215 ...............Quill....................................................... ...............................................1

26........ JWL1642-226 ...............Bracket.................................................. ............................................... 1

27........ JWL1442-217 ...............Tailstock Rod......................................... ............................................... 1

28........ JWL1642-228 ...............Storage Basket...................................... ............................................... 1

29........ TS-0570021..................Hex Nut................................................. 5/16” ....................................... 3

30........ TS-0270061..................Set Screw..............................................5/16”-18 x 5/8” ........................ 1

31........ JWL1442-128 ...............Clamp Bolt............................................. ...............................................2

32........ JWL1442-127 ...............Bushing................................................. ............................................... 1

33........ JWL1442-126 ...............Key........................................................5 x 5 x 30................................ 1

34........ JWL1442-154 ...............Clamp.................................................... ............................................... 2

35........ TS-0561081..................Hex Nut................................................. 3/4”-10.................................... 2

36........ TS-0206011..................Hex Socket Cap Screw.......................... #10-24 x 3/8”........................... 4

37........ JWL1642-237 ...............Tip......................................................... ............................................... 1

38........ JWL1642-238 ...............Cap ....................................................... ............................................... 1

39........ JWL1642-239 ...............Knockout Rod........................................ ............................................... 1

40........ JWL1442-228 ...............C-Ring...................................................S25......................................... 1

............ JWL1642-TCA ..............Tailstock Complete Assembly (not shown)............................................. 1

............ JWL1642-TRCA............Tool Rest Complete Assembly (not shown)............................................ 1

24

Page 25

Headstock Assembly

25

Page 26

Headstock Assembly

Index Part

No. No. Description Size Qty.

1.......... JWL1642-101 ...............Headstock ............................................. ............................................... 1

2.......... JWL1642-102 ...............Spur Center........................................... MT2 ........................................ 1

3.......... JWL1642-103 ...............Face Plate ............................................. 6”............................................ 1

4.......... JWL1642-104 ...............Spindle.................................................. ............................................... 1

5.......... BB-6207ZZ ...................Ball Bearing........................................... 6207ZZ ................................... 1

6.......... VB-180J........................Poly-V Belt ............................................180J........................................ 1

7.......... TS-0270011..................Set Screw..............................................5/16”-18 x 1/4” ........................ 4

8.......... JWL1642-108 ...............Spindle Pulley........................................ ............................................... 1

9.......... JWL1642-109 ...............Wave Washer........................................ ø49......................................... 1

10........ BB-6205ZZ ...................Ball Bearing........................................... 6205ZZ ................................... 1

11........ TS-0207041..................Hex Socket Cap Screw.......................... 1/4”-20 x 3/4” .......................... 1

12........ JWL1642-112 ...............Lock Nut ................................................ M22 ........................................ 1

13........ TS-0207021..................Hex Socket Cap Screw.......................... 1/4”-20 x 5/8” .......................... 4

14........ JWL1642-114 ...............Hand Wheel .......................................... ............................................... 1

15........ JWL1442-164 ...............Knockout Rod........................................ ............................................... 1

16........ JWL1642-116 ...............Motor.....................................................1.5 HP .................................... 1

............ JWL1642-116A .............Motor..................................................... 2 HP ....................................... 1

............ JWL1642-MFC..............Motor Fan Cover (not shown) ................ ............................................... 1

............ JWL1642-MF ................Motor Fan (not shown)........................... ............................................... 1

17........ JWL1642-117 ...............Handle................................................... 3/8”-16 x 1” ............................. 1

18........ TS-0680042..................Flat Washer........................................... 3/8”......................................... 1

19........ TS-228820....................Flat Head Screw.................................... M8 x 20................................... 4

20........ TS-0209051..................Hex Socket Cap Screw.......................... 3/8”-16 x 1” ............................. 1

21........ TS-0720091..................Lock Washer ......................................... 3/8”......................................... 1

22........ JWL1642-122 ...............Motor Assembly Plate............................ ............................................... 1

23........ JWL1642-123 ...............Knob ..................................................... ............................................... 1

24........ JWL1642-124 ...............Motor Pulley .......................................... ............................................... 1

25........ TS-0267021..................Set Screw..............................................1/4”-20 x 1/4” .......................... 4

26........ TS-0206031..................Socket Head Cap Screw........................ #10-24 x 5/8”........................... 4

27........ JWL1642-127 ...............Tap Screw............................................. M3x10..................................... 4

28........ JWL1642-128 ...............DRO Cover............................................ ............................................... 1

29........ JWL1642-129 ...............Plate...................................................... ............................................... 1

30........ JWL1642-130 ...............Digital Readout...................................... JWL-1642EVS ........................ 1

............ JWL1642-130A .............Digital Readout...................................... JWL-1642EVS-2 ..................... 1

31........ TS-1540011..................Nut ........................................................ M3 .......................................... 2

32........ TS-236103....................Lock Washer ......................................... M3 ..........................................2

33........ TS-2283202..................Round Head Screw ............................... M3 x 20................................... 2

34........ JWL1642-134 ...............Tapping Screw ......................................1/4” x 1/2” ...............................2

35........ JWL1642-135 ...............Bracket.................................................. ............................................... 1

36........ JWL1642-136 ...............Label Control Panel ............................... ............................................... 1

37........ JWL1642-137 ...............Push/Pull Switch.................................... ............................................... 1

38........ TS-0206011..................Socket Head Cap Screw........................ #10-24 x 3/8”........................... 8

39........ JWL1642-139 ...............Panel Cover .......................................... ............................................... 1

40........ JWL1442-116 ...............Spring.................................................... ............................................... 1

41........ JWL1642-141 ...............Fwd/Rev Switch..................................... ............................................... 1

42........ JWL1642-142 ...............Variable Speed Control.......................... ............................................... 1

43........ JWL1642-143 ...............Variable Speed Knob............................. ............................................... 1

44........ JWL1642-144 ...............Speed Label .......................................... ............................................... 1

45........ JWL1642-145 ...............Belt Door............................................... ............................................... 1

46........ JWL1642-146 ...............Knob ..................................................... ............................................... 1

26

Page 27

Headstock Assembly (continued)

Index Part

No. No. Description Size Qty.

47........ JWL1642-147 ...............O-Ring................................................... ............................................... 1

48........ JWL1442-122 ...............Spindle Lock Pin.................................... ............................................... 1

49........ JWL1642-149 ...............Retaining Washer.................................. ............................................... 1

50........ JWL1442-121 ...............Bracket.................................................. ............................................... 1

51........ JWL1442-153 ...............Plate...................................................... ............................................... 1

52........ TS-0720041..................Lock Washer ......................................... #8 ........................................... 2

53........ JWL1642-155 ...............Pad ....................................................... ............................................... 1

54........ JWL1642-154 ...............Door Hinge............................................ ............................................... 1

55........ TS-056006....................Hex Nut ................................................. #8-32...................................... 2

56........ JWL1442-127 ...............Bushing................................................. ............................................... 1

57........ JWL1442-128 ...............Clamp Bolt............................................. ...............................................1

58........ JWL1442-154 ...............Clamp.................................................... ............................................... 1

59........ TS-0561081..................Hex Nut................................................. 3/4”-10.................................... 1

60........ JWL1442-124 ...............C-Ring...................................................S19......................................... 2

61........ JWL1642-161 ...............Lever..................................................... ............................................... 1

62........ JWL1642-162 ...............Handle................................................... ............................................... 1

63........ JWL1642-163 ...............Key........................................................5 x 5 x 40................................ 1

64........ JWL1642-164 ...............Inverter.................................................. JWL-1642EVS ........................ 1

............ JWL1642-164A .............Inverter.................................................. JWL-1642EVS-2..................... 1

65........ JWL1642-165 ...............Strain Relief........................................... ............................................... 3

66........ JWL1642-166 ...............Bracket.................................................. ............................................... 1

67........ TS-0270011..................Set Screw..............................................5/16”-18 x 1/4” ........................ 1

68........ JWL1642-168 ...............Plunger.................................................. ............................................... 1

69........ JWL1642-169 ...............Braking Resistor.................................... JWL-1642EVS ........................ 1

............ JWL-1642169A .............Braking Resistor .................................... JWL-1642EVS-2..................... 1

70........ JWL1642-170 ...............Signal Cord ........................................... ...............................................1

71........ JWL1642-171 ...............Power Cord ........................................... JWL-1642EVS ........................ 1

............ JWL1642-171A .............Power Cord ........................................... JWL-1642EVS-2 ..................... 1

72........ JWL1642-172 ...............Motor Cord............................................ ............................................... 1

73........ JWL1642-173 ...............Motor Label ........................................... JWL-1642EVS ........................ 1

............ JWL1642-173A .............Motor Label ........................................... JWL-1642EVS-2..................... 1

74........ JWL1642-174 ...............Collar .................................................... ............................................... 1

75........ JWL1442-169 ...............Index Pin ............................................... ............................................... 1

76........ JWL1642-176 ...............Key........................................................8 x 8 x 90................................ 1

77........ TS-0051021..................Hex Head Bolt ....................................... 5/16”-18 x 5/8” ........................ 4

78........ JWL1442-126 ...............Key........................................................5 x 5 x 30................................ 1

79........ JWL1642-179 ...............Guard.................................................... ............................................... 1

80........ JWL1642-180 ...............Guard Bracket ....................................... ............................................... 1

81........ TS-0209071..................Hex Socket Cap Screw ........................ 3/8”-16 x 1-1/2” ....................... 2

82........ TS-0720091..................Lock Washer ......................................... 3/8”......................................... 2

83........ JWL1642-183 ...............Cable Clamp ......................................... ............................................... 1

84........ TS-056007....................Hex Nut ................................................. #10 ......................................... 1

85........ JWL1642-185 ...............Cable Clamp ......................................... ............................................... 1

86........ TS-0206021..................Hex Socket Cap Screw.......................... #10-24 x 1/2”........................... 1

87........ JWL1642-187 ...............Collar .................................................... ............................................... 2

88........ JWL1642-188 ...............Hex Nut ................................................. ............................................... 2

89........ TS-1524031..................Set Screw..............................................M8x12..................................... 2

27

Page 28

Wiring Diagram for JWL-1642EVS

28

Page 29

Wiring Diagram for JWL-1642EVS-2

29

Page 30

Indexer Positions

How to use the chart

A diagram of the indexer is shown at right, as viewed

from the tailstock end of the Lathe. Points A, B and C

are the holes in the head casting. The holes in the

spindle collar may be considered as numbered 1

through 12.

Example: You wish to rout 9 flutes on your spindle

blank. Locate the “9” in the “No. of Flutes” column;

each flute angle will be 40°. The index pin should first

be inserted into hole combination “A-1”. Make your

first flute at this position. Back off the index pin and

rotate the spindle until the index pin can be inserted

into hole combination “A-5”; this will be followed by

“A-9”. Succeeding flutes will be made with the index

pin in the B position: “B-3”, “B-7” and so on.

No. of Flutes

360° divided by... Angle Letter # Letter # Letter #

1 360.00 A 1

2 180.00 A 1,7

3 120.00 A 1,5,9

4 90.00 A 1,4,7,10

5 72.00 -----------------------

6 60.00 A 1,3,5,7,9,11

8 45.00 A 1,4,7,10

9 40.00 A 1,5,9 B 3,7,11 C 1,5,9

10 36.00 -----------------------

12 30.00 A 1 to 12

15 24.00 -----------------------

16 22.50 -----------------------

18 20.00 A 1,3,5,7,9,11 B 1,3,5,7,9,11 C 1,3,5,7,9,11

20 18.00 -----------------------

24 15.00 A 1 to 12

30 12.00 -----------------------

36 10.00 A 1 to 12 B 1 to 12 C 1 to 12

other interesting patterns....

9 ------ A 1,5,9 B 1,5,9 C 1,5,9

NOTE: A dashed line indicates that particular set of angles is not possible with the indexer.

30

Page 31

Notes:

31

Page 32

WMH Tool Group

2420 Vantage Drive

Elgin, Illinois 60124

Phone: 800-274-6848

www.wmhtoolgroup.com

32

Loading...

Loading...