Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

14”x 40” Woodturning Lathe

Model JWL-1440VS

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-719400

Ph.: 800-274-6848 Revision C 11/2014

www.jettools.com Copyright © 2014 JET

Shown with optional20-inch extension bed (#719401)

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of thes e machines i n the pr ocess i ng of m etal, plastics, or other m aterials m ay void the warranty. The except ions

are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to pro vi d e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTI ES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

4.0 About this manual .......................................................................................................................................... 5

5.0 Specifications ................................................................................................................................................. 6

5.1 JWL-1440VS hole pattern .......................................................................................................................... 7

6.0 Setup and assembly ....................................................................................................................................... 8

6.1 Shipping contents ....................................................................................................................................... 8

6.2 Unpacking and cleanup .............................................................................................................................. 8

6.3 Mounting lathe to bench ............................................................................................................................. 8

6.4 Installing leg set .......................................................................................................................................... 8

6.5 Mounting bed extension (optional accessory) ............................................................................................ 9

6.6 User-made storage shelf ............................................................................................................................ 9

7.0 Electrical connections .................................................................................................................................. 10

7.1 Grounding instructions ................................................................................................... .......................... 10

7.2 Voltage conversion ................................................................................................................................... 10

7.3 Extension cords ........................................................................................................................................ 11

8.0 Adjustments ................................................................................................................................................. 11

8.1 Headstock sliding ..................................................................................................................................... 11

8.2 Headstock rotation ................................................................................................................................... 11

8.3 Tailstock movement ................................................................................................................................. 11

8.4 Cam tightness ............................................................................................................ .............................. 12

8.5 Tool rest ................................................................................................................................................... 12

8.6 Tool rest extension ................................................................................................................................... 12

8.7 Locking handles ....................................................................................................................................... 12

8.8 Spindle indexing ....................................................................................................................................... 12

8.9 Spur cen ter: Installing/removing ............................................................................................................... 13

8.10 Live center: Installing/removing .............................................................................................................. 13

8.11 Spindle lock ............................................................................................................................................ 13

8.12 Face plate: Installing/removing ............................................................................................................... 13

8.13 Checking center alignment ..................................................................................................................... 14

9.0 Operating controls ........................................................................................................................................ 14

10.0 Operation ................................................................................................................................................... 14

10.1 Inspection ............................................................................................................................................... 14

10.2 Turning Tools ........................................................................................................... .............................. 15

10.3 Spindle Turning ...................................................................................................................................... 15

10.4 Stock Selection ....................................................................................................................................... 16

10.5 Cutting Techniques ................................................................................................................................ 17

10.6 Face Plate and Bowl Turning ................................................................................................................. 18

10.7 Bowl Turning Techniques ....................................................................................................................... 19

11.0 Maintenance ............................................................................................................................................... 21

11.1 General procedures ................................................................................................................................ 21

11.2 Pulley lubrication .................................................................................................................................... 21

11.3 Belt and bearings replacement ............................................................................................................... 21

12.0 Optional accessory ..................................................................................................................................... 21

13.0 Troubleshooting the JWL-1440VS Lathe ................................................................................................... 22

14.0 Recommended Lathe Speeds (per diameter of workpiece) ....................................................................... 23

15.0 Indexer Positions ........................................................................................................................................ 24

16.0 Replacement Parts ..................................................................................................................................... 25

16.1.1 JWL-1440VS Headstock Assembly – Exploded View ......................................................................... 25

16.1.2 JWL-1440VS Headstock Assembly – Parts List .................................................................................. 26

16.2.1 JWL-1440VS Bed Assembly – Exploded View ................................................................................... 28

16.2.2 JWL-1440VS Bed Assembly – Parts List ............................................................................................ 29

16.3.1 JWL-1440VS Leg Set – Exploded View .............................................................................................. 30

16.3.2 JWL-1440VS Leg Set – Parts List ....................................................................................................... 30

16.4.1 JWL-1440VS Extension Bed Assembly (OPTIONAL) – Exploded View ............................................. 31

16.4.2 JWL-1440VS Extension Bed Assembly (OPTIONAL) – Parts List ...................................................... 31

17.0 Electrical Connections ................................................................................................................................ 32

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner’s

manual before attempting assembly or

operation.

2. This wood lathe is designed and intended for

use by properly trained and experienced

perso nnel on ly. If you are no t fam iliar w ith the

proper and safe operation of a wood lathe, do

not use it until the proper training and

knowledge have been obtained.

3. Always wear approved safety glasses/face

shields while using this machine.

4. Make certain the machine is properly

grounded.

5. Before operating the machine, remove tie,

rings, watches, other jewelry, and roll sleeves

up past the elbows. Remove all loose clothing

and confine long hair. Do not wear gloves.

6. Keep the floor around the machine clean and

free of scrap material, oil and grease.

7. Keep machine guards in place at all times

when the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately.

8. Do not over reach. Maintain a balanced

stanc e at all t imes, so that yo u do not fall o r

lean against rotating parts.

9. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

10. Use the right tool. Do not force a tool or

attachment to do a job that it was not designed

to do.

11. Replace warning labels if they become

obscured or removed.

12. Make certai n the switch is in the OFF position

before connecting the machine to the power

supply.

13. Give your work undivided attention. Looking

around, carrying on a conversation and "horseplay" are careless acts that can result in

serious injury.

14. Keep visitors a safe distance from the work

area.

15. Use recommended accessories; improper

accessories may be hazardous.

16. Read and understand warnings posted on the

machine and in this manual. Failure to comply

with all of these warnings may cause serious

injury.

17. Some dust created by power sanding, sawing,

grinding, drilling and other construction

activities contain chemicals known to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and

other masonry products.

• Arsenic and chromium from chemically

treated lumber.

Your risk of exposure varies, depending on

how often you do this type of work. To reduce

your exposure to these chemicals, work in a

well-ventilated area and work with approved

safety equipment, such as face or dust masks

that are specifically designed to filter out

microscopic particles.

18. Do not operate this lathe while under the

influence of drugs, alcohol or any medication.

19. Keep tools sharp and clean for safe and best

performance. Dull tools can grab in the

workpiece and be jerked from the operator's

hands, causing s e rious injury.

20. Check the condition of the stock to be turned.

Make sure it is free of knots, warpage,

checked ends, improperly made or cured glue

joint s and ot her c ondit ions w hich ca n cau se it

to be thrown out of the lathe.

21. Securely fasten spur and live centers to the

material being used.

22. Check centers and tapers in the headstock

and tailstock to be sure they are free of dirt or

rust, and oil li ghtly before inse rting centers.

23. Test each set-up by revolving the workpiece

by hand to ensure it clears the tool rest and

bed. Check the setup at the lowest speed

before increasing to operating speed.

24. Use the correct cutti ng tool f or the operation to

be performed and keep all tools sharp.

25. Use low speeds for roughing and for long or

large diameter work. If vibration occurs, stop

the machine and correct the cause.

26. When sanding, remove the tool rest from the

machine, apply light pressure and use a slow

speed to avoid heat buildup.

27. When turning large diameter pieces, such as

bowls, always operate the lathe at low speeds.

See the speed recommendation chart in sect.

14.

4

Page 5

28. Do not attempt to engage the spindle lock pin

until the spindle has stopped. If leaving the

machine area, turn lathe off and wait until the

spindle stops before departing.

29. Make no adjustments except speed changes

with the spindle rotating, and always

disconnect the machine from the power source

when performing maintenance to avoid

accidental starting or electrical shock.

30. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

Familiarize yourself with the following safety notices used in this manual:

This means that if preca utions are not heeded, it m ay result in minor injury a nd/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

injury.

31. When stopping the lathe, never grab the part

or faceplate to slow it down. Let the work coast

to a stop.

32. Use only JET factory authorized replacement

parts and accessories; otherwise, the warranty

and guarantee are null and void.

33. Do not use this JET wood lathe for other than

its intended purpose. If used for other

purposes, JET, disclaims any real or implied

warranty and holds itself harmless from any

injury that may result from that use.

4.0 About this manual

This manual is provided by JET, cover ing the safe operation and maintenance procedures for a J ET Model

JWL-1440VS Woodturning Lathe. This manual contains instruct ions on i nstallation, safety preca utions, ge neral

operating procedures, maintenance instructions and parts breakdown. Your machine has been designed and

constructed to provide consistent, long-term operation if used in accordance with the instructions as set forth in

this document.

This manual is not intended to be an exhaustive guide to lathe operational methods, use of after-market

accessories, choice of stock, and such. Additional knowledge may be obtained from experienced users or

trade articles. Whatever accepted methods are used, always make personal safety a priority.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attem pting assembly

or operation! Failure to comply may cause serious injury!

5

Page 6

5.0 Specifications

Model number ...................................................................................................................................... JWL-1440VS

Stock numbers:

Lathe with Leg Set ................................................................................................................................. 719400K

Lathe only ................................................................................................................................................ 719400

Leg Set only ............................................................................................................................................. 719402

Bed Extension 20”, with tool post (optional accessory) ............................................................................... 719401

Mot or and electr ical s:

Motor type ............................................................................ totally enclosed fan cooled, induction, capacitor start

Horsepower ................................................................................................................................. 1HP (0.746 kW)

Phase......................................................................................................................................................... sing le

Voltage ........................................................................................................................ 115/230V (prewired 115V)

Cycle ........................................................................................................................................................... 60Hz

Listed FLA (full load amps 115V/230V) .................................................................................................... 11/5.5 A

Starting amps ............................................................................................................................................... 10 A

Running amps (no load) ............................................................................................................................... 6.6 A

Start capacitor ......................................................................................................................... 200MFD, 125VAC

Run capacitor ................................................................................................................................ 30μF, 250VAC

Power transfer ............................................................................................................................................ V-be lt

Variable drive ............................................................. Reeves Drive, with variable speed within established range

On/off switch ........................................................................................... toggle switch with removable safety key

Motor speed ........................................................................................................................................ 1720 RPM

Power cord ............................................................................................................................ 3/C 16 AWG (300V)

Power cord length ............................................................................................................................. 6 ft. (183cm)

Power plug installed (115V) ................................................................................................................... 5-15P UL

Power requirements .......................................................................................................................... single phase

Recommended circu it and fuse /breaker size

1

subject to local/national electrical codes.

Capacities:

Working distance between centers .................................................................................................. 40” (1016mm)

Working distance between centers, optional 20” bed ext. mounted ............................................. 60-3/4” (1543mm)

Maximum distance between spindle face and tailstock quill, optional 20” bed ext. mounted ......... 62-1/2” (1587mm)

Swing over bed ........................................................................................................................... 14-1/2” (370mm)

Swing over to ol rest b a s e ..................................................................................................................11” (280m m)

Number of indexing positions ..................................................................... positive locking, 10 degree increments

Swing over 20” bed extension in low position (optional accessory) .............................................. 32-1/2” (826 m m)

Headstock and Spindle:

Spindle taper ......................................................................................................................................... #2 Morse

Spindle thread size ............................................................................................................................... 1” x 8 TPI

Spindle speed (RPM) ...................................................................................................variable within 400 to 3000

Headstock spindle bore......................................................................................................................3/8” (10mm)

Spindle direction ....................................................................................................................................... forward

Headstock movement ............................................................................................... sliding and 360 deg. rotation

Headstock rotation positive lock positions ............................................................ 0, 30, 60, 90, 120, 180, 270 deg.

Tailstock:

Tailstock quill taper ................................................................................................................................ #2 Morse

Tailstock bore ....................................................................................................................................5/16 ” (9mm)

Tailstock quill travel ...................................................................................................................... 4-1/4” (108mm)

Tailstock quill thread ......................................................................................................... acme, 5/8-11UNC (LH)

Materials:

Legs ....................................................................................................................................................... cast iron

Bed ........................................................................................................................................................ cast iron

Headstock .............................................................................................................................................. cast iron

Tailstock ................................................................................................................................................. cast iron

Tailstock quill ................................................................................ hardened HRC20 steel, with laser etched scale

Tool support and base ............................................................................................................................ ca st iron

1

............................................................... 20A (115V), or 15A (230V)

6

Page 7

Dimensions:

Tool rest ...........................................................................................................................................12” (305m m )

Leg footprint ........................................................................................................... 54” x 20” (1372mm x 508mm)

Bed length ...................................................................................................................................... 53” (1346mm)

Bed width .......................................................................................................................................... 8” (203mm)

Overall height, floor to top of headstock, without levelers ................................................................. 47” (1194mm)

Distance floor to spindle centerline (approximate) ............................................................................ 44” (1117mm)

Tool rest post diameter ......................................................................................................................1” (2 5.4mm)

Shipping dimensions (Lathe only) ........................................ 56”L x 21”W x 21.65”H (1420mm x 530mm x 550mm)

Shipping dimensions (Leg Set only)...................................33”L x 22.83”W x 17.71”H (840mm x 580mm x 450mm)

Overall dimensions, assembled with Legs ............................. 74”L x 18”W x 49”H (1880 mm x 458mm x 1244mm)

Overall dimensions, assembled without Legs ...................... 74”L x 18”W x 18.26”H (1880 mm x 458mm x 464mm)

Bed Extension length (optional accessory).........................................................................................2 0 ” (5 0 8mm)

Weights:

Net Shipping

Lathe only ............................................................................................. 220 lb (100 kg) ............... 270 lb (123 kg)

Leg Set only ............................................................................................ 132 lb (60 kg) ................. 143 lb (65 kg)

Optional Bed Extension only ................................................................ 49.5 lb (22.5 kg) ................... 56 lb (2 5 kg)

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

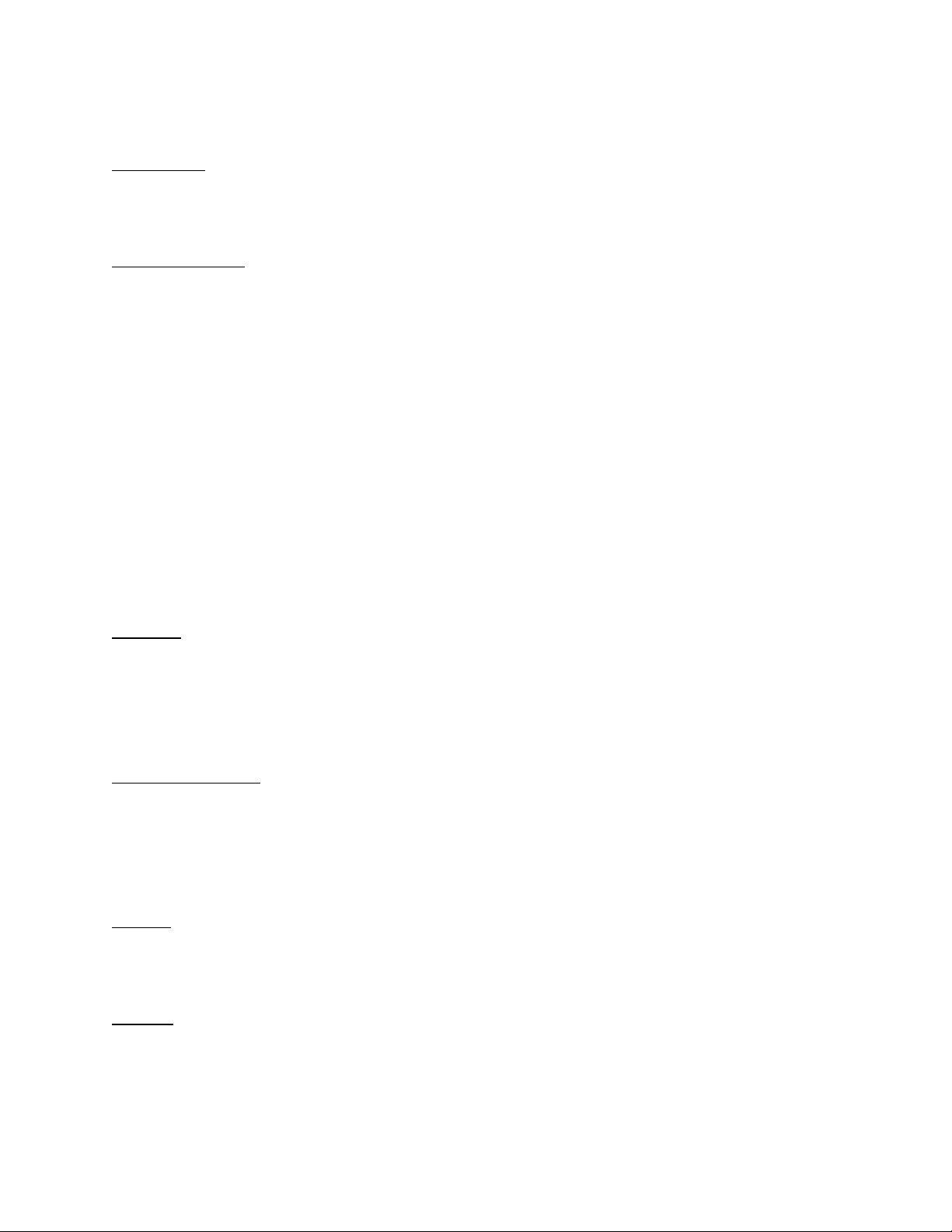

5.1 JWL-1440VS hole pattern

Figure 1

7

Page 8

6.0 Setup and assembly

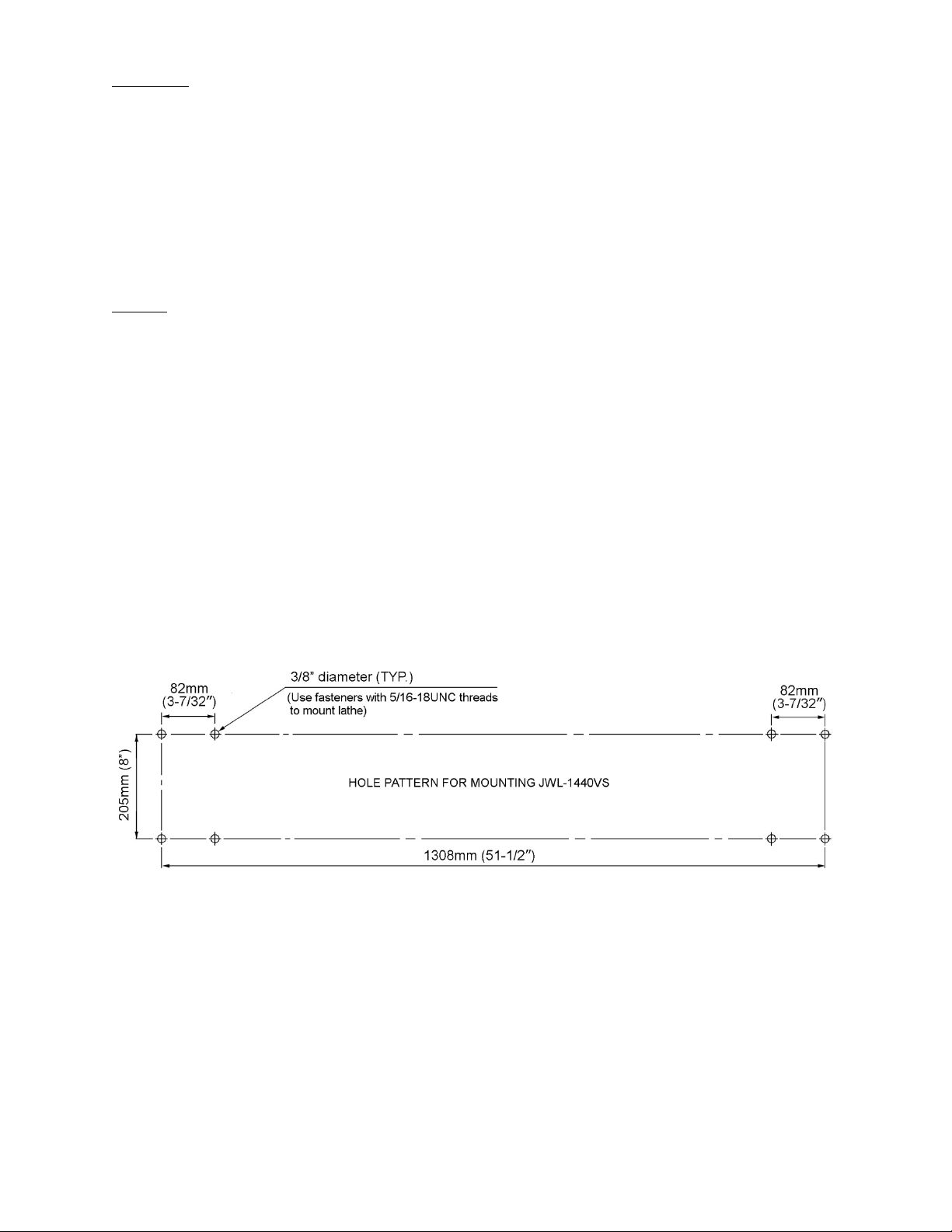

6.1 Shipping contents

Carton contents for # 719400K (see Figure 2)

1 Lathe bed with headstock, tool support and

tailstock – A

2 Legs – B

1 Spindle index pin – C

1 Spur center – D

1 Live cone center – E

1 Knockout rod – F

1 Faceplate – G

1 Tool rest – H

1 Faceplate wrench – J

1 Tool rest extension – K

4 Levelers – L

1 Operating Instructions & Parts Manual

1 Warranty Card

1 Hardware Package (JWL1440-HP1) – M

8 Socket Head Cap Screws, 5/16 X 1-1/4

8 Lock Washers, 5/16

8 Flat Washers, 5/16

6.2 Unpacking and cleanup

1. Remove all smaller items from main carton. Do

not discard carton or packing material until

lathe is assembled and running satisfactorily.

2. Inspect contents for shipping damage; if any is

found, report it to your distributor.

3. Compare contents of shipping carton with the

contents list in this manual. Report shortages,

if any, to your distributor. Note: Check lathe

first – some parts may have been pre-installed.

If you did not purchase the leg set and are

mounting the lathe to a bench or table, continue

with sect ion 6 .3. If yo u purc hase d t he leg set , sk ip

to section 6.4.

6.3 Mounting lathe to bench

1. Unscrew the stud (N, Figure 3) from each end

of the bed.

2. Loosen the locking handles on headstock, tool

rest and tailstock, and slide these items off the

bed. (Refer to section 8.0 for detailed

instructions on adjusting or removing these

items.)

The headstock is heavy.

Use an assistant to help remove.

3. Ref er to Figure 1 for mounting hole sizes and

spacing in the lathe bed. The bed has four

5/16”-18UNC threaded holes. Use appropriate

fast eners (bo lts and wa shers) to secure lathe

to bench or table from underneath.

Figure 3

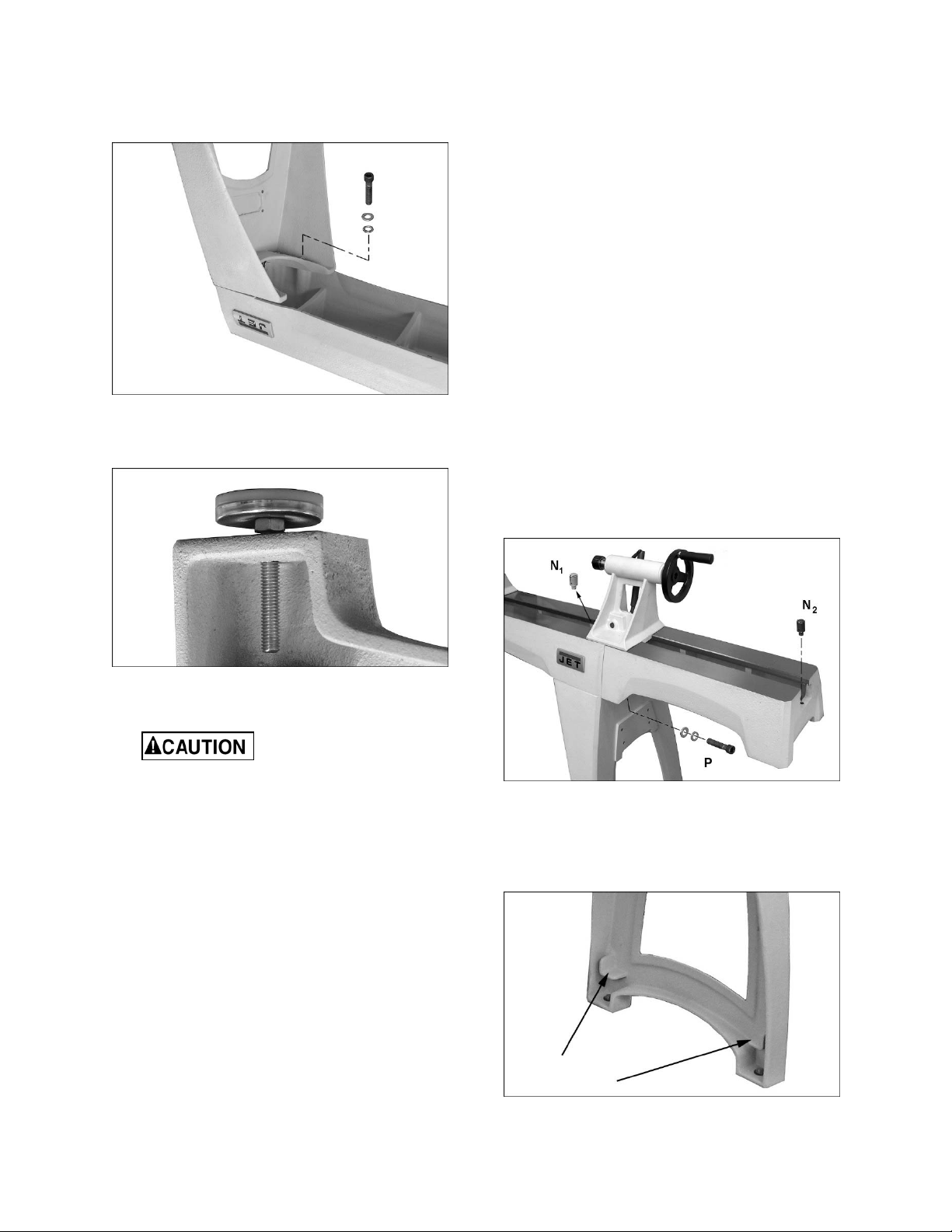

6.4 Installing leg set

Refer to Figure 4.

6mm hex key required

Figure 2

(not to scale)

1. Unscrew the stud (N, Figure 3) from each end

of bed.

2. Remove headstock, tailstock and tool rest

support from bed. (Refer to sect. 8.0 for

detailed instructions on adjusting and

removing these items.)

3. Carefully turn bed upside down. Place a mat or

cardboard beneath it to prevent scratching the

bed ways.

8

Page 9

4. Install legs with eight 5/16” screws, lock

washers and flat washers (Figure 4), and 6mm

hex key.

5. Tighten screws firmly.

Figure 4

6. Install the four levelers (Figure 5). These can

be adjusted later.

1. Slide tailstock away from edge of bed.

2. Have an assistant hold bed extension flush to

end of lathe bed, and insert four 3/8” socket

head cap screws with lock washers and flat

washers, provided with the bed extension (P,

Figure 6). Snug screws just enough to hold

bed extension to lathe bed.

3. Unscrew stud from lathe bed (N1), and insert it

into hole at end of bed extension (N2).

4. Adjust bed extension to lathe bed, aligning the

surface and the inside ways as closely as

possible.

IMPORTANT: Top surface of bed extension

must be flush with surface of lathe bed, and

inside ways must be aligned, to allow smooth

movement of tailstock across joint.

5. Slide tailstock over joint where beds meet, so

that clamping nut is centered over joint (Figure

14). Lock tailstock clamping handle; this will

align the beds.

6. Securely tighten screws (P) in bed extension.

7. Unlock tailstock and slide it back and forth to

test smoothness of the joint. Make further

adjustments if needed.

Figure 5

7. With help from an assistant, raise bed and leg

assembly right-side up.

Bed and leg assembly is

heavy. Use care when lifting.

8. Rotate the levelers (Figure 5) as needed to

establish level for the lathe. Tighten the hex

nut on each leveler against the leg casting.

9. Install headstock, tool support and tailstock,

and both studs (N, Figure 3).

6.5 Mounting bed extension (optional

accessory)

8mm hex key required.

The 20” bed extension (p/n 719401) is optional and

purchased separately. See your JET dealer for

information. If you did not purchase the bed

extension, proceed to section 6.6.

The bed extension can be mounted to the upper or

lower holes of the lathe. Mounting in upper holes

increases the spindle length capacity of the lathe.

Mounting the extension to the lower holes allows

use of the tool support during outboard turning.

Figure 6

6.6 User-made storage shelf

A shelf may be constructed below the bed, using

the ledges inside the lathe legs (Figure 7).

Figure 7

9

Page 10

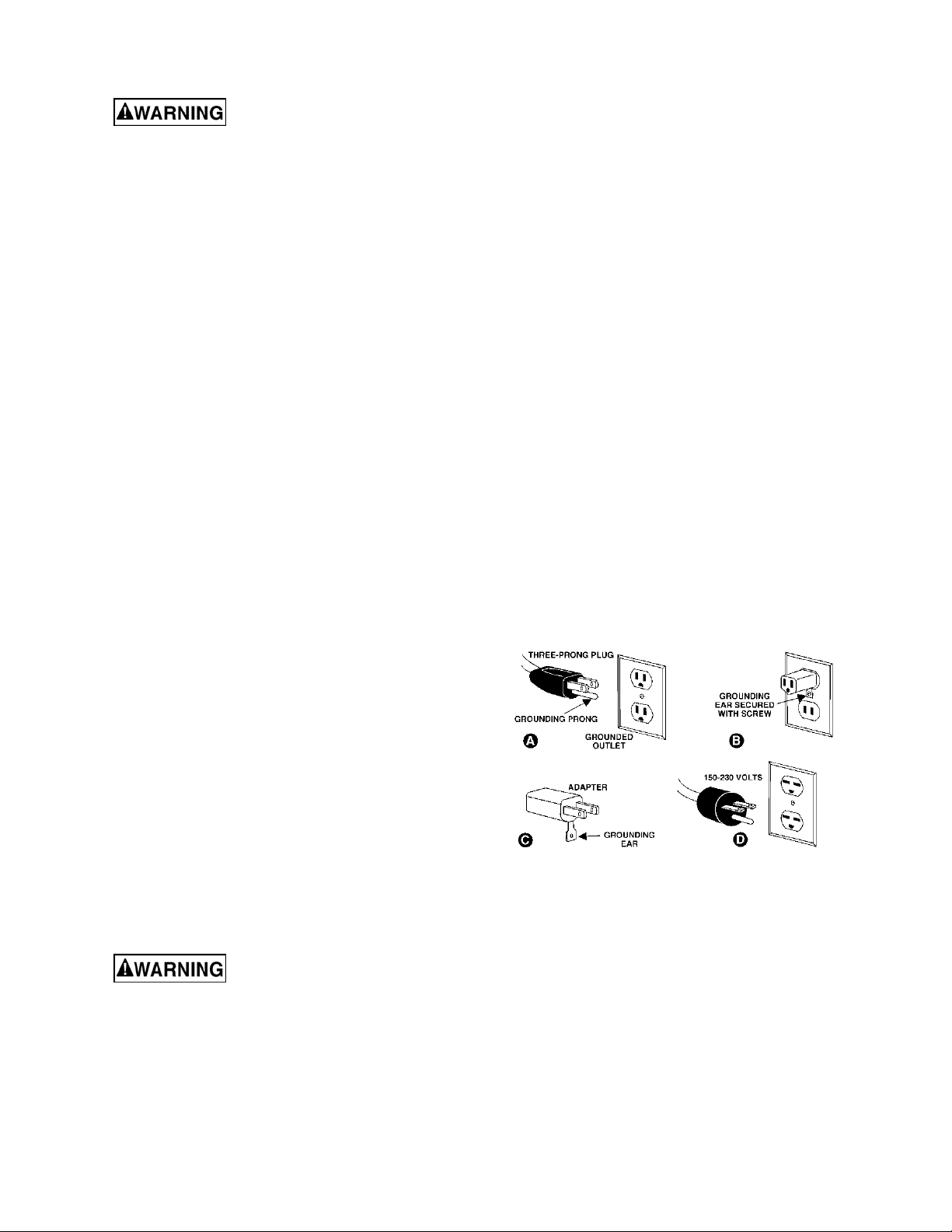

7.0 Electrical connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

The JWL-1440VS Lathe is rated at 115/230V

power, and is pre-wired for 115 volt. The lathe

comes with a plug designed for use on a circuit

with a grounded outlet that looks similar to the one

pictured in A, Figure 8.

Before connecting to power source, be sure switch

is in off position.

It is recommended that the lathe, when operated

on 115 volt power, be connected to a ded icated

20 amp circuit with a 20 amp circuit breaker or

time-delay fuse marked “D”. When operated on

230 volt power, it is recommended that the lathe

be connected to a dedicated 15 am p circuit with a

15 amp circuit breaker or time-delay fuse marked

“D”. Local codes take precedence over

recommendations.

7.1 Grounding instructions

1. All Grounded, Cord-connected Tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce t he risk of electr ic shock.

This tool is equipped with an electric cord having

an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating less

than 150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in A, Figure

8. An adapter, shown in B and C, may be used to

connect this plug to a 2-pole receptacle as shown

in B if a properly grounded outlet is not available.

The temporary adapter should be used only unt il a

properly grounded outlet can be installed by a

qualified electrician. This adapter is not permitted

in Canada. The green-colored rigid ear, lug, and

the like, extending from the adapter must be

connected to a permanent ground such as a

properly grounded outlet box.

3. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between 150 - 250 volts, inclusive:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in D, Figure

8. The tool has a grounding plug that looks like the

plug illustrated in D. Make sure the tool is

connected to an outlet having the same

configuration as the plug. No adapter is available

or should be used with this tool. If the tool must be

reconnected for use on a diff erent type of electric

circuit, the reconnection should be made by

qualified service personnel; and after reconnection,

the tool should comply with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

cond uctor with insulatio n having an o uter surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualified

electrician or service personnel if the

grounding instructions are not completely

understood, or if in doubt as to whether the

tool is properly grounded. Failure to comply

may cause serious or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Figure 8

7.2 Voltage conversion

To switch the incoming power leads for 230 volt

operation:

1. Remove the junction box cover on the motor

and reconnect the leads according to the

diagram inside the cover. A similar diagram is

found at the back of this manual. (Note: In the

event of discrepancies, the diagram inside

junction box takes precedence.)

2. Remove the 120V plu g on the end of the motor

cord and replace it with a UL/CSA listed plug

rated for 240V.

10

Page 11

Alternatively, the lathe m ay be “hard-wired” to

the power source. If you are hard-wiring the

lathe to a panel, make sure a disconnect is

available for the operator. During hard-wiring

of the Lathe, make sure the fuses have been

removed or the breakers have bee n tripped in

the circuit to which the Lathe will be

connected. Place a warning placard on the

fuse holder or circuit breaker to prevent it

being turned on while the machine is being

wired.

7.3 Extension cords

The use of extension cords is discouraged; try to

position equipment within reach of the power

source. If an extension cord becomes necessary,

be sur e it is heav y e no ugh to ca r ry the c ur rent your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating.

Table 1 shows recommended size to use

depending on cord length and nameplate ampere

rat ing . If in d o ubt , use t he ne xt hea v ie r g a uge . T he

smaller the gauge number, the heavier the cord.

4. Release knob (B) and it will seat itself with an

audible click when the headstock reaches a

positive lock position.

5. Tighten handle (A) by pulling it away f rom the

motor.

6. Rotate knob (B) clockwise until it e ngages the

threads.

Always tighten handle (A)

firmly before operatin g lath e.

Ampere

Rating

More

Than

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

More

Than

Extension Cord Recommendations

Volts

120

240

AWG

Total length of

cord in feet

25

50

50

100

Table 1

100

200

Not

Recommended

150

300

8.0 Adjustments

8.1 Headstock sliding

Push handle (A, Figure 9) tow ard motor to unlock.

Headstock will slide freely alo ng the length of the

bed. Retighten handle before operating lathe.

8.2 Headstock rotation

1. Loosen handle (A, Figure 9).

2. Unscrew the knurled knob (B) counterclockwise until it can be pulled outward.

3. Pull knob outward and rotate headstock to

desired position. The headstock has seven

positive locking positions. NOTE: Be careful

not to pinch your fingers against the bed as

you rotate the headstock.

Figure 9

8.3 Tailstock movement

To slide tailstock, push locking handle (C, Figure

10) down toward the bed. Push locking handle

upright to lock tailstock in position.

To mo ve the q uil l, loo sen the lock handle (D) a nd

rotate the handwheel (E).

Make sure tailstock is locked

to bed (C, Figure 10) a nd quill is tightened (E)

before turning a spindle on the lathe.

Figure 10

To remove headstock, tailstock or toolrest base

from bed, unscrew and remove either of the studs

(see N, Figure 3). A fter rem ounting these item s on

the lathe, reinstall studs.

For most turning operations, except outboard

turning, the headstock is positioned at the left end

of bed, and the tailstock moved to accommodate

the workpiece.

11

Page 12

8.4 Cam tightness

8.6 Tool rest extension

The clamping mechanisms of headstock, tailstock

and tool rest base are pre-set by the manufact urer,

and should not require adjustment.

If one of them does not tighten properly against the

bed when the locking handle is tightened, adjust it

as follows. (Figure 11 uses the tailstock as the

example.)

Figure 11

1. Remove stud from end of lathe bed, and slide

tailstock off.

2. Turn tailstock on its side, and tighten lock nut

(F, Figure 11) to increase cam pressure, or

loosen the nut to relieve cam pressure.

3. Mount tailstock on bed and lock it to verify

adjustment. Repeat as needed.

4. Reinstall stud.

8.5 Tool rest

A 12-inch tool rest is provided with your lathe. It is

designed to allow adjustment for height, position on

the bed, and angle to the work.

Loosen locking handle on tool rest base (G, Figure

12) to slide base forward or back, and to angle it to

the bed. Tighten locking handle firmly before

operating lathe.

The extension (J, Figure 13) mounts to the tool rest

base and offers greater reach for the tool rest when

turning off the bed using the headstock at an

angle, as shown.

Make sure the clamp bushings (K, Figure 13) are

pulled apart sufficiently to accept the post of the

extension.

Figure 13

8.7 Locking handles

Locking handles, such as H, Figure 12, are

adjustable. Simply lift out on handle, rotate it on the

pin, t hen relea se it, making sure it seats itself o n

the pin.

8.8 Spindle indexing

Indexing is used to create evenly spaced features

in a work piece, while keeping the lathe spindle

locked; for example, when cutting flutes on a

spindle blank with a hand-held router, while the

spindle blank is secured between lathe centers.

The JWL-1440VS lathe provides 36 indexing

positions. These are identified in the chart in

section 15.0.

Loosen handle (H, Figure 12) to raise or lower tool

rest and angle it to the work. Tighten handle before

operating lathe.

Figure 12

Figure 14

1. Rotate spindle using the handwheel until the

index pin (L, Figure 14) aligns with the desired

hole .

2. Screw the index pin into the hole until it

engages the spindle.

12

Page 13

3. Perform the desired procedure.

4. Unscrew the index pin until the spindle is

released. Rotate spindle to next desired hole,

and repeat.

Remove spindle index pin

before starting lathe.

IMPORTANT: Do no t use index p i n t o l o c k spindle ,

which will cause unnecessary wear to the pin. U se

spindle lock for this purpose.

8.9 Spur center: Installing/removing

The live center is installed into the headstock

spindle. The live center should first be mounted to

your workpiece, and then installed into the spindle.

See section 10.4.

1. Disconnect lathe from power source.

2. Clean the tapered end of the center, and the

inside of the headstock spindle, then push the

center into the headstock spindle.

3. To remove a live center, first remove

workpiece from lathe. Insert knockout rod

(Fig ur e 1 5) t hro ugh ho le i n ha ndw hee l a nd t ap

the tapered end of the spur center.

IMPORTANT: Hold the center by either

placing your thumb and forefinger on outside

diameter of spur center, or wrapping the center

with a rag. The center can be damaged if

allowed to fall.

sure the keyway (N, Figure 16) in the quill is

aligned with the locking handle.

To remove the live center:

4. Back off the tailstock and remove workpiece

from lathe.

5. Loosen quill lock handle (M, Figure 16).

6. Rotate the handwheel counterclockwise to

retract quill all the way, until the live center

comes out. Hold the center while doing this to

prevent it from falling.

Figure 16

8.11 Spindle lock

Push spindle lock pin (P, Figure 17), and rotate the

spindle slightly until the pin goes entirely into the

recess. Continue to hold spindle lock pin in the

recess.

Figure 15

8.10 Live center: Installing/removing

The live center is installed into the tailstock quill.

1. Disconnect lathe from power source.

2. Clean the tapered end of the center and the

inside of the tailstock quill, then push the

center into the quill. Test the insertion by

attempting to pull the center out of the quill by

hand. It should remain secure within the quill.

3. Always tighten the quill locking handle (M,

Figure 16), once the live center has been

properly positioned in the workpiece. Make

Figure 17

8.12 Face plate: Installing/removing

1. Disconnect lathe from power source.

2. Mount the face plate to your workpiece.

3. Engage spindle lock pin.

4. Install face plate onto threads of headstock

spindle and rotate clockwise as far as it will go.

5. Face plate is now ready for turning.

6. To remove the face plate, engage spindle lock,

and turn face plate counterclockwise with face

plate wrench.

13

Page 14

8.13 Checking center alignment

When the headstock is returned from outboard

position, the alignment between centers should be

checked.

1. Lock the headstock in normal spindle turning

position.

2. Slide the tailstock toward the headstock until

the centers almost touch (see Figure 18). Lock

the tailstock in position.

3. View the center points from top and side to

make sure they align.

4. If the centers do not align, unlock the

headstock and pivot it slightly. There should be

enough “play” in the headstock to adjust for

this alignment. Lock the headstock when

finished.

Figure 18

9.0 Operating controls

Refer to Figure 19.

Speed control handle: Rotate handle (B, Figure

20) to set speed, which is displayed as RPM

(revolutions per minute) in the adjoining window

(C).

Do not start lathe at maximum

speed when a workpiece is mounted in the

lathe. Start at lower speed and gradually

increase to desired speed.

Figure 20

The JWL-1440VS contains a Reeves or “splitpulley” system.

As speed is increased, via the speed change

handle, the spindle pulley widens and the belt

drops down to the smaller diameter between the

pulley halves. Conversely, the motor pulley, which

is spring-loaded so that it adj usts automatically to

the movement of the spindle pulley, gets narrower,

drawing the belt outward toward the larger

diameter. When the speed is decreased, the

pulleys act in opposite fashion.

On/off switch (A): Pull to start lathe, push to stop.

The safety key (A1) can be removed to prevent

unauthorized use of lathe. The safety key must be

inserted to restart the lathe.

Figure 19

If a power outage should

occur during operation, the lathe will

immediately restart when power is resumed if

the start switch is still engaged. Push switch

immediately to OFF position in the event of a

power outage.

Change speed while the lathe

spindle is turning to avoid overstressing the

belt.

10.0 Operation

The information which follows is general in nature

and not intended to be a complete course in

woodturning. Nothing can replace the knowledge

gained by talking with experienced woodturners or

consulting books or trade magazines. Above all,

simple trial and error will aid in developing

proficiency in the craft.

10.1 Inspection

Before operating the lathe, check that everything is

in proper working order:

1. Level your machine; use the leveling feet to

help reduce vibration.

2. Check bearings; adjust only if endplay exists.

3. Check belt; it should be snug but not overly

tight.

14

Page 15

4. Bed ways; keep clean, use steel wool to

remove any rust spots, and apply paste wax to

prevent buildup of rust and finishes.

5. Tool rest; use a mill file to remove nicks and

dings.

6. Spindle tapers; should be clean and free of

dust and chips for proper seating of tapers.

7. Tailstock; clean and lubricate quill and locking

device.

8. Lighting; proper lighting is essential to

eliminate shadows and reduce eye strain.

10.2 Turning Tools

If possible, select only quality, high-speed steel

turning tools. High-speed steel tools hold a n edge

and last longer than ordinary carbo n steel. As one

becomes proficient in turning, a variety of specialty

tools for specific applications can be acquired. The

following tools provide the basics for most

woodturning projects (see Figure 21):

Skews – 1-1/2" and 1" or 1-1/4", used to make

finishing cuts and details.

Large Roughing Gouge – 1" to 1-1/4", used to

eliminate waste wood.

Spindle Gouges – 1/4", 3/8", 1/2", used to turn

beads, coves and other details.

Deep Fluted Bowl Gouge – 1/4", 3/8" and 1/2",

used for turning bowls & plates.

Square Scraper (Bedan) – 3/8” or 1/2", used to

create square shoulders.

Large Round Nose (Domed) Scraper – 1-1/2",

used to reduce ridges on interior of bowls, round

edges of bowls, etc.

Parting Tool - 1/8", used for scraping, making a

cut-off, or to set diameters for sizing.

For safety and best performance, keep tools sharp.

If a tool stops cutting or requires excessive

pressure to make a cut, it needs to be sharpened.

A number of brand name sharpening jigs and

fixtures are available; however, a woodturner

should learn to sharpen tools freehand.

For best results, use a slow speed grinder (1800

rpm) fitted with a 60-grit a l uminum oxide wheel (f or

shaping) and a 100-grit alum. o xide wheel (f or f inal

sharpening and touchup). The grinder should be

located near your lathe and at a comfortable

height. A diamond dresser will keep the wheels

true and eliminate glazing.

Figure 21

Basic Turning To ols

Carbon steel tools can over heat easily and should

be cooled frequently. If the edge turns blue, it has

lost its temper and should be ground past t he blue

area. High-speed steel tools are not as likely to

overheat, but can be damaged if allowed to get red

hot. High-speed steel tools should not be

quenched for cooling. Honing with a diamond lap

or slipstone will save trips to the grinder and keep

the edge fresh.

10.3 Spindle Turning

Spindle turning takes place between the centers of

the lathe. It requires a spur or drive center in the

headstock and a live or dead center in the tailstock.

A cup center rather than a cone center in the

tailstock will often reduce the risk of splitting the

stock.

Figure 22 shows the basic profile shapes in spindle

turning.

Never allow the tool to rest in one place on the

wheel, keep it moving and use a light touch.

Figure 22

15

Page 16

10.4 Stock Selection

Stock for spindles should be straight grained and

free of checks, cracks, knots and other defects. It

should be cut 1/8" to 1/4" larger than the fini shed

diameter and may require additional length so the

ends can be removed later. Larger stock should

have the corners removed to produce an octagon

making the piece easier to rough down to a

cylinder.

1. With a combination square, or plastic center

finder for round stock, locate and mark center

on each end of the workpiece. Accuracy is not

critical on full rounds but extremely important

on stock where square sections are to remai n.

Put a dimple in the stock with an awl or nail, or

use a spring-loaded automatic center punch.

2. Extremely hard woods may require kerfs cut

into the ends of the stock (Figure 23) using a

band saw, so the wood will accept the spur

center and the live center.

Never use a steel face

hammer and never drive the workpiece

onto the spur center while it is mounted in

the Lathe spindle.

4. Make sure headstock is locked to lathe bed.

5. Clean tapered end of spur center a nd i nside of

headstock spindle.

6. Insert tapered end of spur center (with the

attached workpiece) into headstock spindle.

7. Support the workpiece while bringing the

tailstock into position about 1-inch away from

end of workpiece. Lock tailstock to bed.

8. Advance tailstock quill with the handwheel in

order to seat the live center into the workpiece.

Use enough pressure to secure the workpiece

between the centers so that it won’t f ly off, but

do not use excessive pressure.

9. T ig ht en quill loc king ha ndle .

The tailstock quill is capable

of exerting excessive pressure against the

workpiece and the headstock. Apply only

sufficient force with tailstock to hold workpiece

securely in place. Excessive pressure can

overheat center bearings and damage both

workpiece and lathe.

Figure 23

3. Drive the spur center about 1/4” into the

workpiece, using a wood mallet or dead b low

hammer as shown in Figure 24. Be careful that

you do not split the workpiece.

10. Move tool rest into position. It should be

parallel to workpiece, just below the centerline

and approximately 1/8" to 1/4" from the

corners of the workpiece to be turned, as in

Figure 25. Tighten tool rest base to Lathe bed.

11. Rotate workpiece by hand to check for proper

clearance.

12. Start lathe at lowest speed and bring it up to

the appropriate RPM for the size of work piece

used. Consult digital readout on the

headstock.

Figure 25

Figure 24

16

Page 17

10.5 Cutting Techniques

10.5.3 Coves

10.5.1 Roughing Out

1. Begin with a large ro ughing gouge. Place the

tool on the tool rest with the heel of the tool on

the surface to be cut.

2. Slowly and gently raise tool handle until cutting

edge comes into contact with the workpiece.

3. Beginning about 2” from the tailstock end of

the workpiece, roll the flute (hollowed-out

portion) of the tool in the direction of the cut.

See Figure 26. Make lo ng sweeping cuts in a

cont in uous m otio n to r oug h the p iece down t o

a cylinder.

4. Keep as much of the bevel of the tool as

possible in contact with the workpiece to

ensure control and avoid catches. NOTE:

Always cut down-hill, or from large diameter to

small diameter. Always work toward the end of

a work-piece, never start cutting at the end.

1. Use a spindle gouge. W ith the flute of the tool

at 90 degrees to the workpiece, touch the point

of the tool to the workpiece and roll in toward s

the bottom of the cove. See Figure 27. Stop at

the bottom; attempting to go up the

opposite side may cause the tool to catch.

Figure 27

2. Move the tool over the desired width of the

cove.

3. With the flute facing the opposite direction,

repeat step 1 for other side of cove. Stop at

bottom of cut.

Figure 26

5. Once the workpiece is roughed down to a

cylinder, smooth it with a large skew. Keep t he

skew handle perpendicular to the spindle and

use only the center third of the cutting edge for

a long smoothing cut (touching one of the

points of the skew to the spinning workpiece

may cause a catch and ruin the workpiece).

6. Add details to the workpiece with skew, parting

tool, scraper or spindle gouge.

10.5.2 Beads

1. Make a parting cut for what is to be a bead to

the desired depth. Place the parting tool on the

tool support and move tool forward to make

the full bevel of the tool come into contact with

the workpiece. Gently raise handle to make cut

to the appropriate depth.

2. Repeat for other side of the bead.

3. Using a small skew or spi ndle gouge, start in

the center between the two cuts a nd cut down

each side to form the bead. Roll the tool in

direction of cut.

10.5.4 "V" Cuts

1. Use the long point of the skew. (NOTE : Do not

press the long point of the skew directly into

the workpiece to create the "V"; this will result

in a burned or burnished "V" with fibers being

rolled up at both sides.)

2. Lightly mark the center of the "V" with the tip of

the skew.

3. Move the point of the skew to the right half of

the desired width of your cut.

4. With the bevel parallel to the right side of the

cut, raise the handle and push the tool in to the

desired depth, as shown in Figure 28.

Figure 28

5. Repeat from the left side. T he two cuts should

meet at the bottom and leave a clean "V" cut.

17

Page 18

6. Additional cuts may be take n to add to e ither

the depth or width of the cut.

10.5.5 Parting Off

1. Use parting tool.

2. Adjust lathe speed to lower RPM for parting

through a workpiece.

3. Place tool on tool support and raise the handle

until it starts to cut and continue to cut toward

center of workpiece.

4. Loosely hold on to the piece in one hand as it

separates from the waste wood.

10.5.6 Sanding and Finishing

Leaving clean cuts will reduce the amount of

sanding required. Move the tool support out of the

way, adjust the lathe to a low speed, and begin

with fine sandpaper (120 grit or finer). Coarser

sandpaper will leave deep scratches that are

difficult to remove, and dull crisp details on the

spindle. Progress through each grit without

skipping grits (for e xample, do not jump from 120

grit to 220 grit). Fold the sandpaper i nto a pad; do

not wrap sandpaper around your fingers or the

workpiece.To apply a finish, the workpiece can be

left on the lathe.

metal screws are case hardened with deeper

and sharper threads than wood screws.)

If the mounting screws on the face plate interfere

with the workpiece, a glue or waste block can be

used:

5. Make a block the same diameter as the face

plate, Figure 29. Both waste block and

workpiece should have flat surfaces for gluing.

6. Glue the block to the workpiece. Avoid using

brown paper or newspaper between the waste

block and workpiece. It may work fine if you

are using scrapers, but a slight catch with a

bowl gouge can separate the two.

NOTE: When using a waste block, be careful with

the adhesive you select. Dry workpieces can be

bonded with ordinary white or yellow glue but must

be clamped to ensure a good bond. Green

workpieces require cyanoacrylate type glue.

Turn off lathe and use a brush or paper towel to

apply the finish. Remove excess finish before

restarting lathe. Allow to dry and sand again with

320 or 400 grit sandpaper. Apply second coat of

fin ish and buff.

10.6 Face Plate and Bowl Turning

Face plate turning is normally done o n the inboard

side of the headstock over the bed. Larger

workpieces must be turned on the outboard side

(remove tailstock and tool support base, and slide

headstock to opposite end of bed).

10.6.1 Mounting Stock

Use of a face plate is the most common method for

holding a block of wood for turning bowls and

plates:

1. Select stock at least 1/8" to 1/4" larger than

each dimension on the finished workpiece.

2. Always select the largest diameter face plate

that can be used for the workpiece to be

turned.

3. True one surface of the workpiece for

mounting against the face plate.

4. Using the face plate as a template, mark the

location of the mounting holes on the

workpiece, and drill pilot holes of the

appropriate size. Face plates are drilled for No.

12 screws. (Phillips and square drive screws

will hold up better than slotted screws. Sheel

Figure 29

10.6.2 Faceplate or Chuck?

While faceplates are the simplest, most reliable

method of holding a block of wood for turning,

chucks can also be used. As there are dozens of

chucks to choose from, the woodturner should first

consider all the different t ypes of turning that will be

done, and read reports or discuss with other

turners who own chucks before making a decision.

A chuck i s not a requirement, but is hand y whe n

working on more than one piece at a time. Rather

than re mov ing scre ws, yo u simp ly ope n the ch uck

and change workpieces.

The most popular ones are four jaw scroll chucks

with a variety of jaws to accommodate different

size tenons. Most also come with a screw chuck as

well.

18

Page 19

10.6.3 Wood Selection

Firewood is the cheapest, most widely available

stock to use while learning to turn bowls. Simply

waste wood for a while practicing turning

techniques. Develop skill with each tool before

attempting to make a finished piece. It is best to

start with dry wood, without worrying about drying

or distortion. Once turning becomes comfortable,

try green wood which cuts very easily. As the

turner gains experience, he or she will find

extraordinary grain and figure in the f orm of burls,

crotches and bark inclusions.

10.6.4 Checks and Cracks

Green wood will check and crack. For best results,

lea ve log s in as lo ng a le ngth a s you c an hand le.

As the material starts to dry, surface cracks will

develop on the ends of the log. Cut off two to three

inches and you should find good, sound wood.

Also cut the log in half along the pith to avoid

having it in the finished piece. Most checks radiate

from the pith.

As you turn bowls from green wood, make sure

you maintain a consistent wall thickness

throughout the piece. Leaving a piece thick in

some areas and thin in others will cause the wood

to dry unevenly and promote checks and cracks.

10.6.5 Distortion

Distortion is a problem associated with turning

green wood. It will vary from one type of wood to

the next. Typically, fruitwoods tend to distort more

than others. It also varies with the time of year the

tree was cut and how the logs are stored.

10.6.6 Tools for Bowl Turning

The deep fluted bowl gouge is the m ost essential

and versatile tool for most bowl and plate turning.

The bowl gouge is heavier and easier to control

than other types of gouges. It also allows removal

of wood much faster and with less vibration than

other gouges. Most average sized bowl work can

be accomplished with a 3/8" or 1/2" bowl gouge.

A 1/4" bowl gouge is best suited f or smaller bowls

and light finishing cuts. Larger 3/4" and 1" bowl

gouges are only used for extremely large pieces.

from what appears to be the center of the top

of the workpiece.

2. Drive spur center into the top of t he workpiece

with a mallet or dead blow hammer.

3. Slip the spur center into the headstock taper

and bring the tailstock with a live or ball

bearing center into position. Lock the tailstock

to the bed and advance the tailstock spindle in

order to seat the cup center into the

workpiece. Tighten the ram locking handle.

4. Turn workpiece by hand to ensure proper

clearance.

5. Start lathe at lowest speed and bring it up to

the maximum safe speed for the size of work

to be turned. If the machine starts to vibrate,

lower the speed until vibration stops.

6. Rough out the outside of the bowl with the 1/2"

deep fluted bowl gouge, holding the handle of

the tool firmly against your hip. For best

control, use your whole body to move the

gouge through the workpiece.

7. As the bowl takes shape, work on the bottom

(tailstock end) to accommodate attaching a

face plate.

8. Turn a short tenon (about 1/8" long) the size of

the hole in the faceplate. See Figure 30. This

will allow centering the workpiece when the

faceplate is attached.

(NOTE: If you plan to use a chuck, turn a

tenon of the appropriate length and diameter

to fit your chuck.)

9. Stop the lathe, remove workpiece and attach

face plate or chuck (see section 10.6.1

"Mounting Stock").

The surfaces of faceplate

and workpiece should mount flush to each

other.

10. Finish turning the outside of bowl with 1/2" or

3/8" bowl gouge. Leave additional material at

base of bowl for support while turning interior.

This will be removed later.

Large domed scrapers can also be used to help

clean up the interior surfaces of bowls. A light

touch with the scraper slightly tilted will eliminate

some of the ridges occasionally left by an

inexperienced bowl gouge.

10.7 Bowl Turning Techniques

10.7.1 To Shap e Out s ide of Bowl

1. Odd shaped burls, crotches and other irreg ular

shaped blanks require special preparation

before mounting in a chuck or onto a

faceplate. Remove the bark, if there is any,

Figure 30

19

Page 20

10.7.2 To Shape Interior of Bowl

1. Stop lathe and move tailstock away. (You may

want to remove the center from the tailstock to

avoid bumping it with your elbow.)

2. Adjust tool support in front of the bowl just

below centerline, at a right angle to the lathe

ways.

9. Begin the separation with a parting tool, b ut do

not cut all the way through yet.

10.7.3 Sanding and Finishing

1. Remove the tool support and adjust lathe

speed to approximately 500 RPM. Higher

speeds can build friction while sanding and

cause heat check in some woods.

3. Rotate workpiece by hand to check clearance.

4. Face off top of bowl by making a light shearing

cut across the top of workpiece, from rim to

center.

5. Place 1/2" bowl gouge on tool support at

center of the workpiece with the flute facing

top of bowl. The tool handle should be level

and pointed toward the four o'clock position, as

shown in Figure 31.

Figure 31

6. Use the left hand to control cutting edge of

gouge, while right hand swings tool handle

toward your body (Figure 31). The flute should

start out facing top of workpiece, and rotate

upward as it moves deeper into the bowl to

maintain a clean even curve. As the tool goes

deeper into the bowl, progressively work out

toward the rim. It may be necessary to turn the

tool support into the piece as you get deeper

into the bowl.

2. Begin with fine sandpaper (120 grit) and

progress through each grit, using only light

pressure. Coarser sandpaper tends to leave

deep scratches that are hard to eliminate. Use

power-sanding techniques to avoid concentric

sanding marks around your finished piece.

Avoid rounding over the rim and foot with

sandpaper; try to keep details crisp. Finish

sanding with 220 grit.

3. Remove sanding dust with tack rags or

compressed air and, with lathe turned off,

apply first coat of finish. Let sta nd for several

minutes, wipe off excess. Allow to dry before

sanding again with 320 or 400 grit sandpaper.

4. Turn lathe back on and continue the

separation cut almost all the way through the

base. Stop at about 3" and use a small fine

tooth saw to separate the bowl from the waste.

5. Apply second finish coat and allow to dry

before buffing.

(NOTE: Try to make one, very light continuous

movement from the rim to the bottom of the

bowl to ensure a clean, sweeping curve

through the piece.

Should there be a few small ridges left, a light

cut with a large domed scraper can even out

the surface.)

7. Develop wall thickness at the rim and maintain

it as you work deeper i nto the bowl (Once the

piece is thin toward the bottom, you cannot

make it thinner at the rim). When the interior is

finished, move the tool support to exterior to

re-define bottom of bowl. (General rule of

thumb: the base should be approximately 1/3

the overall diameter of the bowl).

8. Work the tight area around faceplate or chuck

with 1/4" bowl gouge.

20

Page 21

11.0 Maintenance

Before doing mainte nance o n

the lathe, disconnect it from the electrical

supply by pulling out the plug or switching off

the main switch. Failure to comply may cause

serious injur y.

11.1 General procedures

Maintenance on the lathe should be perf ormed at

periodic intervals to ensure that the machine i s in

proper working order, that all fasteners are tight,

and all necessary adjustments have been made.

Inspection and maintenance should be performed

at least twice a year, but more frequently if the

lathe receives constant use.

Clean and oil the lathe bed so that headstock,

tailstock and tool rest base will slide easily. Clean

any rust spots that may develop on the bed with a

commercial rust remover.

Use compressed air to blow out the interior of the

headstock, in order to keep sawdust and chips

from accumulating on belts and sheaves. Also blow

off debris that accumulates in the motor fan.

Frequently clean out the morse tapers on both

headstock and tailstock. Commercially available

taper cleaners may be acquired from tool stores.

purpose grease into the zerk fitting on the motor

shaft (Figure 32) and the groove of the main

spindle (Figure 33).

Figure 32

Figure 33

Bearings are permanently lubricated and sealed,

and do not require further lubrication.

11.2 Pulley lubrication

After every 200 working hours, or every 30 days,

use a grease gun to insert a good quality, all-

11.3 Belt and bearings replacement

Changing belt and bearings can be a difficult task,

and should be performed by a JET authorized

service center. Remove headstock and take it to a

service center for servicing.

12.0 Optional accessory

This accessory item, purchased separately, can enhance the functionality of your lathe. Contact your dealer to

order, or call JET at the phone number on the cover.

719401 ...... 20" Extension Bed w/ Post

21

Page 22

13.0 Troubleshooting the JWL-1440VS Lathe

Table 3

Symptom Possible Cause Correction

Motor fails to develop

full power.

Motor or spindle stalls

or will not start.

Excessive vibration. Workpiece warped, out of round, has

Tools tend to grab or

dig in.

Headstock moves

when applying

pressure with

Tailstock.

Tailstock moves when

applying pressure.

Power line overloaded. Correct overload condition.

Undersized wires in supply system, or

extension cord is too long.

Running capacitor is bad. Replace running capacitor.

Worn motor. Replace motor.

Excessive cut. Reduce depth of cut.

Worn or broken belt. Replace belt.

Improper cooling of motor.

Starting or Running capacitor is bad. Replace capacitor.

Centrifugal switch is bad. Replace centrifugal switch.

Worn spindle bearings. Replace bearings.

Worn motor. Replace motor.

major flaw, was improperly prepared for

turning, or RPM is set too high.

Worn spindle bearings. Replace spindle bearings.

Worn drive belt. Replace drive belt.

Motor mount bolts are loose. Tighten bolts.

Lathe on uneven surface. Adjust leveling feet.

Dull tools. Keep tools sharp.

Tool rest set too low. Reposition tool rest height.

Tool rest set too far from workpiece. Reposition tool rest closer to workpiece.

Improper tool being used. Us e correct tool for operation.

Loc k i ng handl e no t t i ght. Tig ht en handle.

Excessive pressure being applied by

tailstock.

Cam lock nut needs adjusting. Tighten cam lock nut.

Excessive pressure being applied by

tailstock.

Lathe bed and tailstock mating surfac es

are greasy or oily.

Increase supply wire size.

Blow out sawdust from motor housing

fan.

Correct problem by planing or sawing

workpiece, or discard entirely and use

new workpiece. Reduce RPM.

Slide headstock to left end, lock firmly,

then apply pressure to workpiece with

tailstock. Apply only sufficient force with

tailstock to hold workpiece securely in

place.

Slide tailstock to right side of lathe

against the stop. Move headstock into

position and apply pressure to

workpiece with tailstock.

Remove tailstock and clean surfaces

with a cleaner/degreaser. Re-apply light

coat of oil to lathe bed surface.

22