Page 1

.JET

EQUIPMENT & TOOLS

Operator's Manual

JWL-1236 Wood Lathe

, ~.

NRTL/C

LR108026

.JET EQUIPMENT a TOOLS, INC.

A WMH - Walter Meier Holding Company

P.O.BDX1349

AUBURN, WA98071-1349

5b

~

qOO

;v5!J

/cO

lVIv'

y& () <)

'3 ()(J'O

(253)351-6000

FAX(253)939-8001

No. M-708352 9/96

Page 2

Important Information.

2-YEAR

LIMITED WARRANTY

JET offers atwo-year limited

warranty on this product

Replacement parts for this tool are availabledirectly form JET Equipment& Tools.

To place an order, call 1-800-274-6848. Pleasehave the followinginformation ready:

1. Visa, MasterCard,or Discover Card number

2. Expiration date

3. Part number listedwithin this manual

4. Shipping address other than a Post Office box.

JET Equipment & Tools makes every effort to assure that parts meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our parts that each such part(s) to be free from

defects in materials and workmanship for a period of thirty (30) daysfrom the date of purchase.

Please retain your datedsales receiptas proof of purchaseto validate the warranty period.

--

JET makes every effort to assure that its products meet high quality and durability standards and warrants to the

original retail consumer/purchaser of our products that each product be free from defects in materials and

workmanship as follows: 2 YEAR LIMITED WARRANTY ON THIS JET PRODUCT. Warranty does not apply to

defects due directly or indirectly to misuse, abuse, negligence or accidents, repairs or alterations outside our

facilities or to a lack of maintenance. JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED

ABOVE FROM THE DATE THE PRODUCTWAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN, ANY

IMPLIED WARRANTIES OR MECHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY TO YOU. JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR

PROPERY OR FOR INCIDENTAL, CONTINGENT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING FROM

THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONOR EXCLUSION MAY NOT APPLY

TO yOU. To take advantage of this warranty,the product or part must be returned for examination, postage prepaid,

to an authorized service station designated by our Auburn office. Proof of purchase date and an explanation of the

complaint must accompany the merchandise. If our inspection discloses a defect, JET will either repair or replace

the product or refund the purchase price, if we cannot readily and quickly provide a repair or replacement, if you are

willing to accept such refund. JET will return repaired product or replacement at JET's expense, but if it is

determined there is no defect, or that the defect resulted from causes not within the scope of JET's warranty, then

the user must bear the cost of storing and returning the product. This warranty gives you specific legal rights, and

you have other rights, which vary, from state to state.

JET Equipment &Tools. P.O. Box 1349,Auburn, WA 98071-1349 . (253) 351-6000

--'<:

\

Page 3

Lt WARNING

For your own safety, read this instruction manual before operating the lathe.

Wear eye protection.

Do not wear glQves, necktie, or loose clothing.

Tighten all locks before operating.

Rotate the workpiece by hand before applying power.

Rough out the workpiece before installing on the faceplate.

Do not mount asplit workpiece or one containing a knot.

Usethe lowest speed when starting a new workpiece.

.

KEEP GUARDS IN PLACE and in workingorder.

.

REMOVEADJUSTING KEYSAND WRENCHES. Formthe habitof checking to see that keys and

adjusting wrenches are r.emovedfrom the tool beforeturningit on.

.

KEEP THE WORK AREA CLEAN. Cluttered,areas and benchesinviteaccidents.

.

DO NOT USE IN A DANGEROUS ENVIRONMENT. Don't use powertools in damp or wet locations,or

expose them to rain. Keepwork area well lighted.

.

KEEP CHILDREN AWAY. All visitors should be kept safe distancefrom the work area.

.

MAKE THE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

.

DON'T FORCE THE TOOL. It will do the job better and safer at the rate for which it was designed.

.

USETHE RIGHT TOOL. Don'tforce.a tool or attachmentto do ajob for which itwas not designed.

.

USETHE PROPER EXTENSIONCORD. Make sure you extensioncord is in good condition. When

usingan extension cord, be sure to use one heavyenough to carry the current yourproduct will draw.

An undersize cord will cause a drop in the line voltage resultingin loss of power and overheating. For

runs up to 25 feet, use a 18 AWG or larger gauge cord. For runs up to 50feet, use a 16AWG or

larger gauge cord. For runs up to 100feet, use a 14 AWG or larger gauge cord. For runs up to

150feet, use a 12 AWG or larger gauge cord. Runs over 150feet are not recommended. If in

doubt, usethe next heavier gauge. The smaller the gauge number,the heavier the cord.

.

WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Nonslipfootwear is recommended. Wear protective hair

covering to contain longhair.

Page 4

.

ALWAYS USE SAFETY GLASSES. Also use face or dust masks if the cutting operation is dusty-

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

.

SECURE WORK. Use clamps ora viseto holdthework when its practical. It's safer than using your

hand and it frees bothhandsto operatethe tool.

.

DON'T OVERREACH. Keepproperfootingand balanceat alltimes.

.

MAINTAIN TOOLS WITH CARE. Keeptools sharp and cleanfor best and safest performance. Follow

instructions for lubricatingand changingaccessories.

.

DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits cutters, and

the like.

.

REDUCETHE RISK OF UNINTENTIONALSTARTING. Makesure the switch is in the off position

before plugging in the machine.

.

USE RECOMMENDEDACCESSORIES. Consultthe owner's manualfor recommendedaccessories.

The use of improperaccessoriesmaycause a risk of injury.

'-'-"

.

NEVER STAND ONA TOOL. Seriousinjurycould occurif the tool istipped or if the cutting tool is

unintentionallycontacted.

.

CHECK DAMAGED PARTS. Beforefurther useof the tool,a guard or other part that is damaged

should be carefully checkedto determinethat it will operate properlyand perform its intendedfunction.

Check for alignmentof movingparts, bindingof moving parts,breakageof parts, mounting, and any

other conditionsthat may affect its operation. A guard or other part that is damaged should be properly

repaired or replaced.

.

DIRECTIONOF FEED. Feedwork into a blade or cutter againstthe direction of rotation of the blade or

cutter only.

.

NEVER LEAVE THE TOOL RUNNINGUNATTENDED. TURNTHE POWEROFF. Don't leave the

tool until it comes to a completestop.

-

-----------.

- -- - - ~

- - - - - - -- ~ - - - ,.

'-

Page 5

Grounding Instructions

Caution: This tool must be grounded while in use to prevent electric shock.

Inthe event of a malfunctionor breakdown.groundingprovidesa path of least resistancefor electric

current to reduce the risk of electric shock Thistool is equippedwith an electric cord having an

equipment-groundingconductor and a grounding plug. The plug must be pluggedinto a matchingoutlet

that is properly installedand grounded in accordancewith all localcodes andordinances.

Do not modify the plug provided. If it will not fit the outlet. have the proper outlet installed by a qualified

electrician

Improper connection of the equipment-groundingconductorcan result ina risk of electric shock. The

conductor, with insulation having an outer surfacethat is greenwith or withoutyellow stripes, isthe

equipment-groundingconductor. If repairor replacementof the electriccord or plug is necessary, do not

connect the equipment-groundingconductorto a live terminal

Check with a qualifiedelectrician or service personnelif the groundinginstructionsare not completely

understood, or if in doubt asto whether the tool is properlygrounded.

Use only three wire extension cords that have three-prong grounding plugs and three-pole receptacles

that accept the tool's plug *

Repair or replace a damaged or worn cord immediately

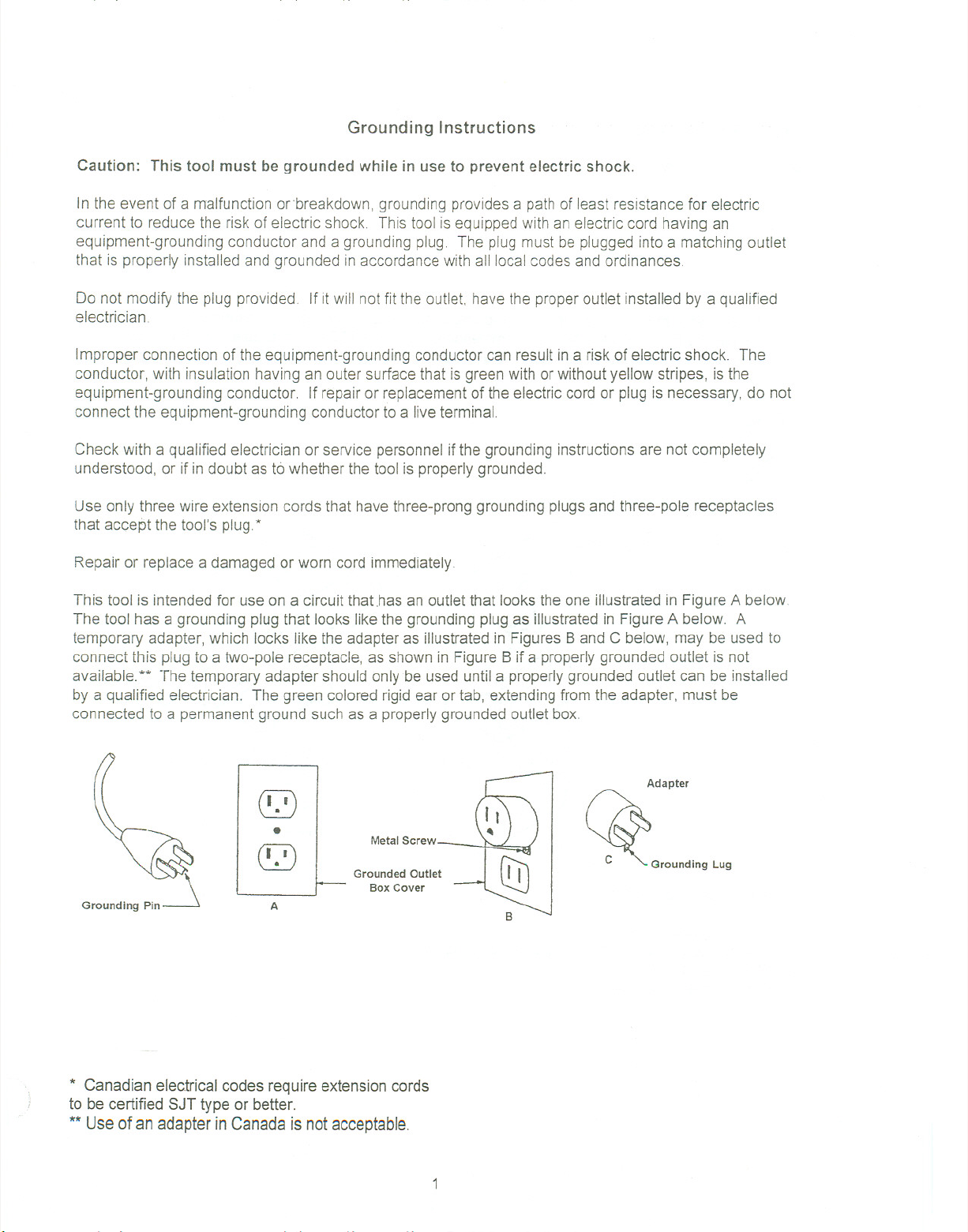

This tool is intended for use on a circuit that.hasan outletthat looks theone illustrated in FigureA below

The tool has a groundingplug that lookslike the grounding plugas illustratedin FigureA below. A

temporary adapter, which locks likethe adapter as illustrated in FiguresBand C below, may be usedto

connect this plugto a two-pole receptacle,as shownin Figure B if a properlygrounded outlet is not

available.** The temporaryadapter should only be used until a properlygrounded outlet can be installed

by a qualified electrician. The green colored rigidear ortab, extendingfrom the adapter, must be

connected to a permanentground such as a properlygroundedoutlet box.

Adapter

(!2)

.

~

A

Metal Screw

Grounded Outlet

Box Cover

~°'0"0';0' Lu,

* Canadian electrical codes requireextension cords

to be certified SJT type or better.

** Use of an adapter in Canada is not acceptable.

Page 6

On-Off Switch Padlock

Model No. BP-1, Stock No. 709736

To safeguard your machinefrom unauthorizedoperationand to avoid accidentalstarting byyoung

children, the use of a padlock is highlyrecommended. JET model BP-1 is availablefrom your local

authorized JET distributor or by callingJET Equipment& Tools at 800-274-6848.

To lock out an on-off switch

1. Open the padlock. See Fig. A

2. Insert through holes in the start button. See Fig. B

3. Close the padlock.

4. Place the key in a safe place.

-"--", ,,,,~-'--~-'--'--"--'"---'-'---'-'''-'''

....

'"

~ ~.~

2

Page 7

Specifications JWL-1236

Stock Number. """'" """""""""""" "'"'''' 708352

SwingOverBed """""""""""""""''''''''''''''''''''''''''''''''''''''''''''''' , 6"

Swing Over Tool Rest Base ... .,.,. , ,... .,..,.,. ...,..., , ", ,.,.,..., 4-3/8"

Distance Between Centers ""..,"""""",,, "'"'''''''''''''''''''''''''''''''''''''''''''' 35"

Speeds (RPM) '"'''''''' ... .. "''''''''''''''''''''''''''''''''''''''..'' '' 550-3000

Spindle Nose 1" x 8 T.P.I.

Hole through Spindle , , ,""""'''''''''''''''''''''''''''''''''''''''' , 3/8"

Headstock Taper , , , " MT-2

Tailstock Taper '"'' . """"' , MT-2

Ram Travel 2-1/4"

Spindle Center to Floor (approx.) """'"'''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''' 41"

Overall Dimensions

Motor " " 3/4 HP, 1Ph.

"""'''''' """"'''''''''''''''''''''''''''''''''' '"'''''''''' """""'''''''''''''''''''''''''''''''''''''''''' 115VOnly

Net Weight (approx.) '''''''''' " 183 Lbs.

Shipping Weight (approx.) '"'''''''''''''''''''''''''''''''''' 190Lbs.

The specifications in this manual are givenas general informationand are not binding. JET Equipment

and Tools reserves the rightto effect, at any timeand without prior notice,changes or alterations to parts,

fittings, and accessory equipment deemed necessaryfor any reasonwhatsoever.

"""""""""'''''''''''''''''''''''''''''''''''''''''''''' 44"H x 17"Wx 60"L

Table of Contents

Grounding Instructions ""'''''''' ""'"'''''''''' 1

On-Off Switch Padlock """'''''''''''''''''''''''''''' 2

Specifications 3

Table of Contents 3

Uncrating and Clean-Up ...4

ContentsofShippingCarton , 4

Tools Required for Assembly 4

Assembly .5-6

Controls 6-7

Nomenclature and Use """'..". 7

Adjusting Tool Rest 7

Operation ... ... ... 8-11

Parts Breakdown 12

Parts List 13-14

Electrical Schematic ...... .15

3

Page 8

Uncrating and Clean-Up

Note: Uncrating and assembly will require two

people due to the machines size and weight.

1.

Finish removing contents from the shipping

crate. Be sure to check crate thoroughly for

any parts not found on initial unpacking.

2.

Inspect contents for shipping damage and

report any damage to your distributor.

3.

Clean all protected parts with kerosene. Donot

use gasoline, paint thinner,or anyother

cellulose-basedsolvent. These will damage

paintedsurfaces and melt plastic.

Contents of Shipping Carton:

1 - Lathe bed wi motor and tailstock

1 - Tool rest wi extension

- Stand legs

4

2

- Long stand braces

-Short stand braces

2

-Stand tops

2

1 - Bed extension

1 - Face plate

1 - Drift rod

1 - Live center

1 - Spur center

2 - Index pins

1 - Face shield

1 - Hardware package (nuts, bolts, etc.)

1 - Operator's manual

1 - Warranty card

Tools Required for Assembly

NO.1 cross point screwdriver

NO.1 flat bladescrewdriver

Hex wrench set

Adjustablewrench or combinationwrench set

Use of sockets and a ratchet will speed stand

assembly but are not required.

- _.-_.'.

".- -- -'--"-- - --.,-- - - - .- 1

4

Page 9

Assembly

Note:

stand before tightening all nuts. Hand tighten only

during this part of the assembly'process

1

2.

3.

4.

Assemble stand completely and mount bed to

Attach a stand top (A, Fig. 1) to a stand leg (8,

Fig. 1) with three 5/16" x 1" carriage bolts (C,

Fig. 1), three 5/16" flat washers (D, Fig. 1),

three 5/16" lock washers (E, Fig. 1), and three

5/16" hex nuts (F, Fig. 1) Stand top must be

placed inside stand leg.

Attach second stand leg to previous assembly

in the same manner.

Repeat these steps with the remaining two

stand legs and stand top.

Join the two leg assemblies by attaching long

braces (G, Fig. 1) to each leg and fastening

with eight 5/16" x 1"carriage bolts (C, Fig. 1),

eight 5/16" flat washers (D, fig. 1), eight 5/16"

lock washers(E, Fig. 1) and eight 5/16" hex

nuts (F, Fig. 1). Remember

to hand tighten

only at this time.

A

FIG-1

5.

Attach short braces (H, Fig. 1)to each end of

the stand usingfour 5/16"x 1"carriage bolts

(C, Fig, 1),four 5/16" flat washers (D, Fig. 1),

four 5/16" lockwashers (E, Fig. 1), andfour

5/16" hex nuts (F, Fig. 1)

6.

Place assembled stand in approximate final

location that is solid and level.

7.

With the helpof a second person, carefully lift

bed up and onto stand.

Note: Be sure to place headstockend on the

stand end with the switch.

Note: Beforesetting bed assembly down on the

stand top, run motor cord through the hole in

the stand top.

5

Page 10

8.

Align holes on bed with those in the stand top

and fasten with eight hex socket cap screws

(5/16"x1") , eight lock washers (5/16"), and

eight nuts (5/16") supplied. Note: Two larger

hex socket cap screws and washers will be

used later to attach the bed extension to the

bed.

9.

Tighten eight hex socket cap screws with a hex

wrench.

1O. Tightenall stand hardware making sure it is

stable on the shop floor.

11. Attach bed extensionto bed usingtwo hex

socket cap screws (3/8"x1") andtwo lock

washers (3/8") supplied.

...-.-----------------------

12. Insert index plunger(A, Fig.2) intothe base of

the headstock (B, Fig.2) and tighten.

13. \ttach the headstocklock handle (A, Fig.3) to

the head stock lock shaft (B, Fig.3) with one

spring (C, Fig. 3) andone hex socket cap

screw (0, Fig.3).

14. Attach the tailstock handleto theto the tailstock

handwheelandtighten.

15. Connect the motorcord plugto the switch plug.

Controls

Speed Selector (A, Fig. 4) - selects one of six

available speeds. Select desired speed by pulling

handle out from headstock and turning to left or right.

Release handle and it will engage detent for that

speed. Caution: Never change speeds without

motor running. Damage to the variable speed

pulleys may result.

Headstock Lock (B, Fig.4)-locks headstockin a

fixed position. Tighten clockwiseto lock. Loosen

counterclockwiseto unlock. Caution: always

operate lathewith the headstockin the locked

position.

FIG-2

~A

B -~c --'

~D--

FIG-3

Detent Release(C, Fig.4) - pullout and holdto

swivel headstock. Releaseto engagedetentsat 90

or 180 degrees.

,- ._~- .--.

..- _. ..~- - ~_. -- ,,-

FIG-4

6

Page 11

-------

./

Tailstock Handwheel (A, Fig. 5) - turn clockwise to

move tailstock spindle forward. Turn counter-

clockwise to retract tailstock spindle.

Tailstock Spindle Lock (B, Fig: 5) - locks tailstock

spindle. Release to adjust handwheel.

Tailstock Lock (C, Fig. 5) - locks tailstock in

position on the bed. Release to move tailstock

assembly closer to or farther from the headstock.

Nomenclature and Use

Spur Center (A, Fig. 6) - locks into headstock and

holds the workpiece during spindle turning.

Index Pins (B, Fig. 6) - used to install and remove

spur center and face plate.

FIG-5

B

c

I

fl

Face plate (C, Fig. 6) - attaches to headstock and is

used in face plate turning operations.

"-- Drift Rod (D, Fig. 6) - fits into the tailstocktO,remove

\ I the livecenter and into the headstockto removethe

' / livecenter..

Tool Rest (Fig. 7) - attaches to any locationon the

bed or bed extension. Usedto steady cuttingtool

during spindleturning or face plate operations.

Adjusting Tool Rest

Position the tool rest as close to the work piece as

possible. It should be 1/8" above the centerline.

Position the tool rest base on the bed or bed

extension by releasing the lock handle (A, Fig. 7)

and sliding onto the desired position. Tighten handle

(A, Fig. 7) to lock. Adjust the height of the tool rest

by loosening handle (B, Fig. 7) and raising ,arm (C,

Fig. 7).

Shouldadjustment of the tool rest clampingdevice

become necessary, simply turn base over and adjust

~-, largenut(A,Fig.8).

.- .--'--' _w- ---

d-

fA

FIG-6

B

FIG-?

-,...,---

7

FIG.8

Page 12

Operation

Lt,WARNING!

Use supplied face shield or similar protection

during all operations! Failure to comply may

cause serious injury!

Befere attempting work on regular stock, use scrap

material to get a feel for the machine.

Lathe Tools

Most turning is accomplished with special

woodworking chisels. They are available individually

or in sets. JET's wood turning chisel set ( optional

accessory - stock No. 709008) contains eight of the

most popular types of chisels:

5/16", 1/2", and 1" Gouge - a round nose,hollow

chisel for roughingand cove cutting

1/2" and 1" Skew -a double ground, flat, andend

ground to an angle used for smoothingcylindersand

cutting shoulders, beads, v-grooves, etc.

1/2" Diamond Point and 1/2" Round Nose - used

where their shape fits the contour of the work.

1/2" Parting Tool - double-groundchisel usedfor

cutting-off, straight incisions, and sizingcuts to any

diameter.

Spindle Turning

The majorityof turning on a wood lathewill be

betweencenters, or spindle turning.

Centering the Work

Preparation of the stock for spindle turning starts

with finding the center of the work piece. The most

common method is the diagonal method. Draw two

lines to attach opposite corners on each end of the

workpiece (Fig. 9). The intersection of these two

lines is the center. Mark both ends of the stock.

Mark the center of each end with a punch awl for

softer wood or drill each end approximately 1/8"

depth for harder woods. Place the spur center on

one end and seat it by striking with a mallet. Hold

the center and work piece together and prepare to

mount between the spindles.

FIG-9

8

Page 13

Mounting the Work

Move the tailstockto approximately 1 to 1-1/2" from

the end of the work pieceand lock in position. Turn

the tailstock handwheel untilthe center makes

contact with the work piece. Continueto turn the

hand wheel and slowly rotatethe work pieceby

hand. After the work piecebecomes difficult to turn

by hand, reverse the handwheel approximatelyone

quarter turn and lockthe tailstock spindle (Fig. 10)

Adjusting the Tool Rest

-'" -

Position the tool rest approximately 1/8" away from

the work piece and 1/8" above the work centerline.

After some experience has been gained, this position

can be varied slightly to suit the operation.

Position of Hands

/-"

There is no "proper" positionfor the handswhen

using chisels. Most beginners begin by usingthe

) palm-down grip (Fig. 11)for bettercontrol and switch

later to the palm-up position(Fig. 12) for better

manipulation. Inthe palm-downposition,the little

finger or heel of the hand acts as a guide alongthe

tool rest. The first finger acts as a guidewhen using

the palm-up method.

Roughing a Cylinder

Use a large gouge and run the lathe at a slow speed

to rough-off the sharp corners of the work. Beginthe

cut 2 to 3 inches from the tailstock and work toward

and off the tailstock end. Continue by cuttingthe

next 2 to 3 inches left of the first cut, preferably

working toward the tailstock end. This method of

always working toward the tailstock is preferred

because it throws the chips clear of the operator. Do

not rough cut by taking one long pass at the work

piece and do not start cuts at either end ofthe work

piece. This has a tendency to tear long sliversfrom

the work piece. Rollthe gouge over slightly in the

direction of the cut for best results. Once a

cylindrical form has started to take shape, step up

the speed one or two stops.

FIG -10

FIG -11

FIG -12

,-.- ,-- -- ..-- ._--

9

Page 14

Smoothing a Cylinder

Use a largeskew chisel with the cutting point near

the center of the chisel and high up on the work

piece. Support the chisel on the tool rest at all times.

To locate the proper cutting position, placethe chisel

flat against the work piece with the skewwell over

the area to be cut. Pull back slowly on thechisel

until it bites into the wood. Raising the handlewill

increase the depth of cut; lowering the handlewill

decrease the depth of cut.

Using the Parting Tool

The parting tool is a scraping tool and is simply

pushed into the work piece.. A better cutting action is

obtained by starting the cut with the handle low and

gradually raising it as the cut gets deeper. If the cut

is over 3/8" deep, a clearance cut should be made

along side the first cut to avoid burning the chisel

point.

Face Plate Turning

Work that cannot be turned between centersmustbe

attached to and turned on a face plate. All work

should be cut slightly oversized prior to mountingon

the face plate to prevent heavy roughingcuts during

turning.

Mount the work piece directly to the face plate using

four wood screws from the back. Be careful to use

screws short enough not to interfere with the cutting

process but long enough to hold the work piece

securely to the face plate. If screws will interfere

with the cutting process, the work piece can be

screwed to a backing block and the backing block

screwed to the face plate. If screw mounting is not

allowed at all, the work may be glued to a backing

block and the backing block screwed to the face

plate. A piece of paper in the glue joint will prevent

damaging the wood when separated later.

Remove the spur center from the headstock spindle

by inserting the drift pin into the opening in the

headstock and pushing the spur center out. Mount

the face plate with the workpiece already attached

onto the threaded portion of the spindle and hand

tighten.

the headstock spindle facing the tailstock (Fig. 13).

For larger work pieces, the head stock will have to

Note: pieces up to 12" may be turned with

FIG -13

10

Page 15

~ be turned 90 degrees,the tool rest extensionadded

, to the tool rest, and the tool rest moved out to the

bed extension (Fig. 14).

For face plate turning, the tool rest is set

approximately 1/8" from the work piece and slightly

lower than centerline. The chisel must be held on

the left half of the tool rest so that the rotation of the

work piece keeps the chisel against the tool rest.

Attempts at cutting from the right side of the rest may

cause the chisel to be ripped from the operator's

hand.

FIG-14

~

",--

J

~~

~ ~"' - .---.-

--- --

11

--

-- -- --- '--'--

Page 16

--

N

57-\

~

Page 17

~-

Parts List for the JWL-1236 Woodworking Lathe

Index Part

No. No.

Description

1 .JWL1236-01W Headstock 1

2 JWL1236-02 SpurCenter 1

3 JWL1236-03 Face Plate. 1

4 . .JWL1236-04 ""'" Spindle """'"'''''''''' 1

5... ..JWL 1236-05... Key 4x4x85 """""""""'''' 1

6. ...BB-6205ZZ BallBearing 1

7 BB-6205ZZ Ball Bearing ... 1

8 .JWL1236-08 Spring 1

9 JWL1236-09 ShiftingLeverBracket 1

10 BB-6006Z"""""""'''''''''''' BallBearing 1

11 JWL1236-11 C-Clip S-25 1

12 JWL1236-12 SpindlePulley(right) 1

13 VB-M23 V-Belt 1

14 JWL1236-14 Spindle Pulley(left)"'''''''''''''''''''''''''''''''''''''''' 1

15.. JWL1236-15 C-Clip S-24 1

16 JWL1236-16 Drift Rod 1

17 .JWL1236-17 Lock NuL 1/2 2

.~-

,~

18 JWL1236-18 Clamp (left) 1

19 TS-0011031 Hex.HeadBoiL 5/16x3/4 2

19-1 TS-0720081 LockWasher..... 5/16 2

20 JWL1236-20 Rack 1

21 JWL1236-21 SpeedSelectorAssembly 1

21-1 JWL1236-21-1 PanHeadScrew 2

21-2 JWL1236-21-2 SetScrew 5/16 1

22 JWL1236-22 Clamp(right) : 1

23 JWL1236-23 Hex Head Screw 1

24 JWL1236-24 HeadstockLock 1

24-1 JWL1236-24-1 HeadstockLock Handle 1

24-2 JWL1236-24-2 Spring 1

24-3 JWL1236-24-3 Screw 1

25 JWL1236-25A lndex Tool 1

25-1 JWL1236-25-1 IndexTool 1

26 JWL 1236-26 C-Clip : S-16 1

27 JWL1236-27 Sleeve 1

28 JWL1236-28 Spring 1

29 JWL1236-29 Motor Pulley(right) 1

30 JWL1236-30 , MotorPulley(left) 1

31 JWL1236-31 PanHeadScrew 3/16x3/8 4

32 JWL1236-32 Key 4x4x85 1

33.. JWL1236-33 MotorwI Motor Cord 1

JWL1236-33A MotorwI Motor Cord (afterserial#305000) 1

33-1 JWL1236-33-1 Nameplate 1

34 JWL1236-34W MotorCover 1

JWL1236-34A MotorCover (after serial#305000) 1

35 JWl1236-35 Index Plunger 1

36,:::-; JWL1236-36=.,;,:,,:,,;, "C.'".. . Tool Rest-:~,,:,:~.=,,,,,,,,=..,.,.,.,.=..,,,,,,=:-;,=...,,n-,.,.,.~.-,.,.,,~.,,,,,",,..,,,",..,...""..=."",.,',,,,,-...~..- - - ..- -

JWL1236-36A Tool Rest (afterserial #205000) 1" 1

Size

Qty.

13

Page 18

- --

37. . ..JWL 1236-37 Handle "" ,... .""'"'' . .. ... 3

38. . ..JWL 1236-38 Tool Rest Extension '''''''''' 1

...JWL1236-38A Tool RestExtension(afterserial #205000) ""' ".. 1

39 JWL1236-39 Tool RestBody : 1

JWL 1236-39A Tool Rest Body (after serial #205000) 1" 1

40 JWL 1236-40 Eccentric Rod 1

41 JWL 1236-26 C-Clip . . .. S-16 """"'"'''''' 2

42.. JWL 1236-42 BoiL . """''''''''''''''''' " .'.. 1

42-1 JWL 1236-42-1 ..""'" ... .. Bol1 . "" , '''''''''''''''''' """'"'''''''''''''''''''''''' 1

43 JWL 1236-43 ... ... Clamp ... ".. 2

44 .TS-0640141 Nut 3/4 2

45 .JWL 1236-45 Live Center """''''''''''''''''''''''' ""'''''' ,..

46

., JWL1236-46 Tail Spindle ,.. 1

47 JWL 1236-47 Tailstock Screw "'"'''''''''''''''''''''''' 1

48 .., JWL 1236-48W ""'"'''' Tailstock """""""'"'''''''''''''''''''''''''''' ..'"'' 1

48-1 JWL1236-48-1 C-Ring ...S-16 1

48-2 JWL1236-48-2 Set Screw"""""'''''''''''''''''''''''''''''''''''''''''''''' 1

49 ..JWL 1236-49 "'" """""" Handwheel .""""""" 1

50 JWl1236-50 Tailstock Lock Handle 1

51' JWL 1236-51 Handle Stop "".., 1

52 JWL 1236-52W... ',""" Bed Extension """'''''''''''''''''''''''''''' 1

53... TS-0209051 .. Hex Socket Cap Screw ...""" 3/8x1 2

53-1 TS-0720091 Lock Washer 3/8 2

54 ...JWL 1236-54W... Stand Leg (left rear) """""" ... ..., 1

54-1 .....JWL 1236-54-1 W Stand Leg (right front)... 1

54-2 JWL 1236-54-2W Stand Leg (left front

-switch) 1

54-2A ..JWL 1236-54-2AW.. Stand Leg (right rear) 1

54-3 JWL 1236-54-3W. Stand Top '''''''''''''''''''''''''''''''''''''''''''''''''''''''' . 2

54-4. ...JWL 1236-54-4W. ... Long Brace """""'" .. 2

54-5... .JWL 1236-54-5W .."" Short Brace ' '"'''''''' """'''''''''''''''''''''' ... """"""'''''''''''''''''' 2

55 JWL1236-55W... """" Bed """ " 1

56 TS-0208061 ""'" . Hex Socket Cap Screw 5/16 x 11/4" 8

57 .JWL 1236-57. ... """ Switch (serial

#6105922andlower) 1

.JWL 1236-57 A """'" Switch (serial #6115923 and higher) 1

JWL 1236-57B... Switch Assembly CP (serial #6105922 and lower) 1

... JWL1236-57C. '" SwitchAssemblyCP (serial#6115923 and higher) 1

57-1 JWL 1236-57-1 Switch Box .."'''''''''''''' ,. 1

58 .JWL 1236-58. " Screw M4x24 2

59 ..."'" JWL 1236-59 "" Screw """'"'''''''''''''''''''''''' 3/16x3/8 2

59-1 JWL 1236-59-1 Key Washer " '''''''''''''''''''''''''''''''''' 2

59-2 JWL 1236-59-2 Nut """""'"'''''''''''''''''''''''''''''''''''''''''''''''''''''' 3/16 2

60 TS-0152011 Carriage Bolt... 5/16x1 24

61 ... .. TS-0680031 Washer "".." 5/16 24

62 ..."... TS-0561 021 '"'''''''''''' Nut 5/16 24

63 ... . ..JWL 1236-63 Power Cord... .." "'"'''''''''''''''''''''' 1

63-1 . ..JWL 1236-63-1 Power Cord (switch to motor - serial #6105922 and lower) 1

'" ...JWL 1236-63-1A """'''''''''' Power Cord (switch to motor - serial #6115923 and higher) 1

63-2 JWL 1236-63-2 : Motor Cord (serial #6105922 and lower) 1

JWL 1236-63-2A Motor Cord (serial #6115923 and higher) 1

64 J\iVL1236-64 ,... , Label 1

65 JWL 1236-65" """, Warning Label. 1

66 ..JWL 1236~66 ,,, Speed Label

67 ... TS-OnOO81 LockWasher 5/16 32

JWL 1236-C '''''''' Capacitor (not shown-100MFD, 125VAC) 1

1

1

14

Page 19

Electrical Schematic

~

BLACK

'w'HITE

GREEN

'..

T

GROUND

BLACK

GREEN

--

--- ---------.

_.e__-

15

----

-----

---

Page 20

Loading...

Loading...