Page 1

JET JWL-1220 Woodturning Lathe

The JET

JWL-1220

represents the

next step in

our hugely

popular mini

lathe series.

With 12”

swing and 20”

between

center

capacities

plus an array

of userfriendly

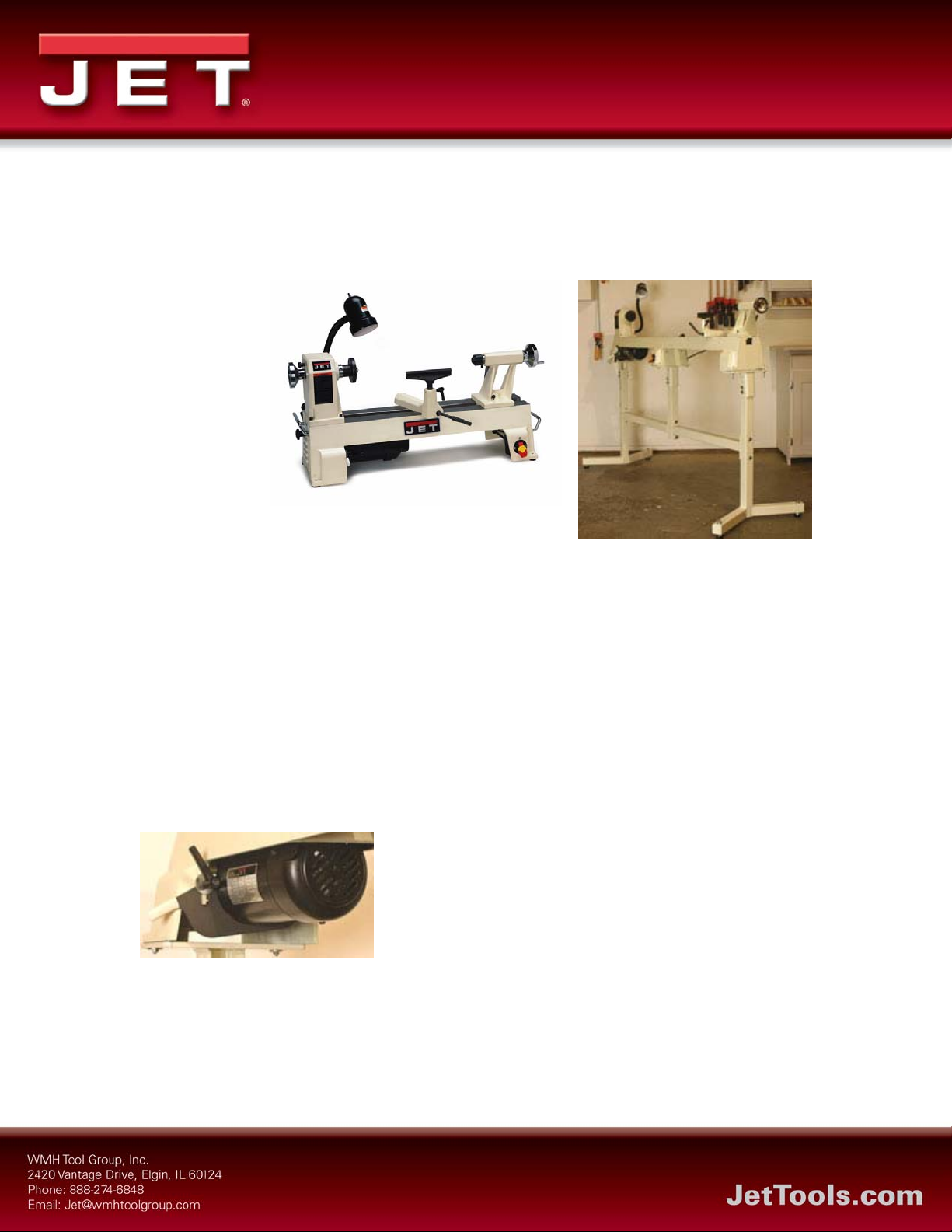

In its standard form, (left) the JWL-1220 is a very capable lathe. Add the bed (and

stand) extension (left) and its between centers capacity rivals that of many “full-sized”

lathes!

features, the

JET JWL-1220 more than fills the void between traditional mini and full-sized lathes.

Add the JWL-1220BE 28” bed extension and the JET JWL-1220 between centers

capacity expands to nearly 50”, rivaling that of much larger and substantially more

expensive woodturning lathes.

The JET JWL-1220 is based on the tried and true JET cast iron technology for maximum

accuracy, durability and long term stability. Precisely machined components and highend ball bearings are used throughout the JET JWL-1220, insuring long-term accuracy

and smooth running stability.

Power and Speed

The JET JWL-1220 features a 3/4HP TEFC (totally

enclosed fan cooled) motor (115V only) that handles

the increased capacities with ease. The additional

power also maintains consistent rpm through a much

The motor is mounted below the bed

with the belt tension handles up front

for quick speed changes.

wider range of turning situations.

Page 2

Finely machined and balanced step pulleys on the motor and spindle provide six rpm

settings to handle

virtually any turning or sanding task you may

encounter. Changing from one speed to another among

the available 500, 840, 1240, 1800, 2630 and 3975 rpm

settings is fast and tool free.

Release the belt tension using the front-mounted levers

and then slip the drive belt onto the new pulley

positions through the two spring-loaded access doors.

Re-tension the belt and the JET JWL-1220 is ready for

use.

Indexing

Another new feature on the JET JWL-1220 is 24position indexing that makes it possible to do many

Moving the belt between the five

available pulley positions is fast,

tool-free and easy through the

spring-loaded access doors.

fluting or drilling operations with exceptional accuracy. A specially designed, springloaded button above the hand wheel can be depressed to temporarily lock the spindle for

removing thread-on accessories such as a chuck. That same button can be screwed in to

lock the spindle in any of the 24 positions, freeing your hands for other operations.

Standardized Versatility

The JET JWL-1220 is designed to be compatible with a

huge range of commonly used accessories. The spindle and

tailstock both accept tooling with the popular #2 Morse

taper. The spindle has equally popular 1 X 8 threads. Using

these popular sizes mean you can use tooling and

accessories you already have. They also mean finding

specialized accessories in the future will be easy and

The 1X8 spindle thread and #2

Morse taper make the JWL-

1220 compatible with a huge

range of accessories.

economical.

Page 3

Included Accessories

The JET JWL-1220 comes with a full set of popular accessories and a few that are not so

common. A four-wing spur drive, quality ball bearing live center, knockout rod, 6”- tool

rest and 3”-diameter faceplate are included with the JET JWL-1220.

Not so common is the 10”-long tool rest included and

handy tool caddy that are standard equipment with the

JET JWL-1220. We also include a pair of quality safety

glasses in

place of the more common “science class” goggles. A pair

of cord wrap brackets is factory installed to provide

handy storage for the power cord when not in use.

The basic JWL-1220 package

includes all these accessories as

standard equipment!

Because many users will store the JET JWL-1220 when

not in use, we added a pair of retractable carry handles.

Located on either end, the large-diameter handles provide comfort and control when

moving the JET JWL-1220 is necessary.

Let There Be Light

Woodturners have added task lighting to their lathes for ages. That

often meant another cord and a less than optimum mounting that

frequently hindered work (and safety) on the lathe.

We added a built-on task light, mounted on a positionable flexible

arm to the JET JWL-1220 to eliminate these problems. The task

light draws its current from the JET JWL-1220 wiring so there is

no extra cord or socket required. The task light also has its own

on/off switch so it can be used only when needed.

The built-in task light

on a flexible arm

makes it easy to see

fine detail work.

Page 4

Accessories

Bed Extension

Adding the JWL1220BE 28” bed

The 28” bed extension (left) bolts up easily to the JWL-1220 bed. The

mating end of the extension bed (right) has adjuster screws that make

aligning the surfaces easy and accurate.

extension expands the

JET JWL-1220

between center

capacity to nearly

50”, exceeding that of

many full-sized 12” lathes! The 3/4hp motor allows turning long pieces without concern.

The JWL-1220BE 28” bed extension comes with the necessary hardware for installation

but goes a step further to make this process easy. A hanging plate on the mating end of

the extension makes aligning it to the JET JWL-1220 bed much easier when a second set

of hands are not available. The mating face also has hex head socket screws pre-installed

that make aligning the JWL-1220BE 28” bed extension perfectly much easier. Even the

rubber-cushioned feet on the bed extension are adjustable to be sure your newly

configured JET JWL-1220 remains stable on irregular surfaces.

Stand

We offer the JWL-1220S stand that makes your JET JWL-1220

a rock-solid, stand-alone machine when bench space is not

available. Built from heavy walled square steel tubing with fully

welded plate steel joining plates, the JWL-1220S is beautifully

finished to retain its good looks while resisting corrosion for

many years to come.

The JWL-1220S comes with rubber tipped adjustable leveling

feet to dampen vibrations and resist moving. The lathe mounting

plates are adjustable so spindle height can be set to between 43

and 45” above the floor for maximum comfort.

Shown with the

extension kit installed,

the JWL-1220S stand

makes a very stable

platform for the JWL-

1220 lathe.

Page 5

Stand Extension

The stand extension kit

includes the center post,

adjustable mount plate and

crossbar. All of the parts bolt

up to the JWL-1220S stand.

A specially designed extension kit JWL1220SE enlarges the

JWL-1220S stand to accommodate the JET JWL-1220 when

equipped with the JWL-1220E bed extension. Made from

the same materials as the JWL-1220S stand, all of the

required parts and fasteners are included to make this

conversion easy without sacrificing stability.

Loading...

Loading...