JET JSH-275-10, JSH-550-10, JSH-275-15, JSH-275-20, JSH-550-15 Operating Instructions and Parts Manual

...

Operating Instructions and Parts Manual

JSH Series Electric Chain Hoists

Models JSH-275, JSH-550

Model JSH‐550 shown

WALTER MEIER (Manufacturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-110100

Ph.: 800-274-6848 Revision A1 06/2010

www.waltermeier.com Copyright © 2010 Walte r Meier (Man ufacturing) Inc.

Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

®

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECI AL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET® branded produc ts are not sold in Canada by Walter Meier.

tools. For the name of an Authorized Service Center in

2

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Introduction ............................................................................................................................................. 6

Desc ription .............................................................................................................................................. 6

Specifica tions .......................................................................................................................................... 7

Unpac king ............................................................................................................................................... 8

Contents of the Shipping Container.......................................................................................................... 8

Installation and Assembly ........................................................................................................................ 8

Electric al Connec tions ............................................................................................................................. 8

Grounding Instr uc tions ............................................................................................................................. 8

Extension Cords ...................................................................................................................................... 9

Installing Chain Container ........................................................................................................................ 9

Pre-Operation Inspection ....................................................................................................................... 10

Limit Sw itch In spectio n .......................................................................................................................... 1 0

Inspecting the Load Chain ..................................................................................................................... 10

Inspecting the Hooks ............................................................................................................................. 11

Operating the Hoist ................................................................................................................................ 12

Maintenance .......................................................................................................................................... 13

Brake Inspection .................................................................................................................................... 13

Lubrication............................................................................................................................................. 13

Replacing Load Chain ........................................................................................................................... 14

How to Cut Chains ................................................................................................................................. 1 4

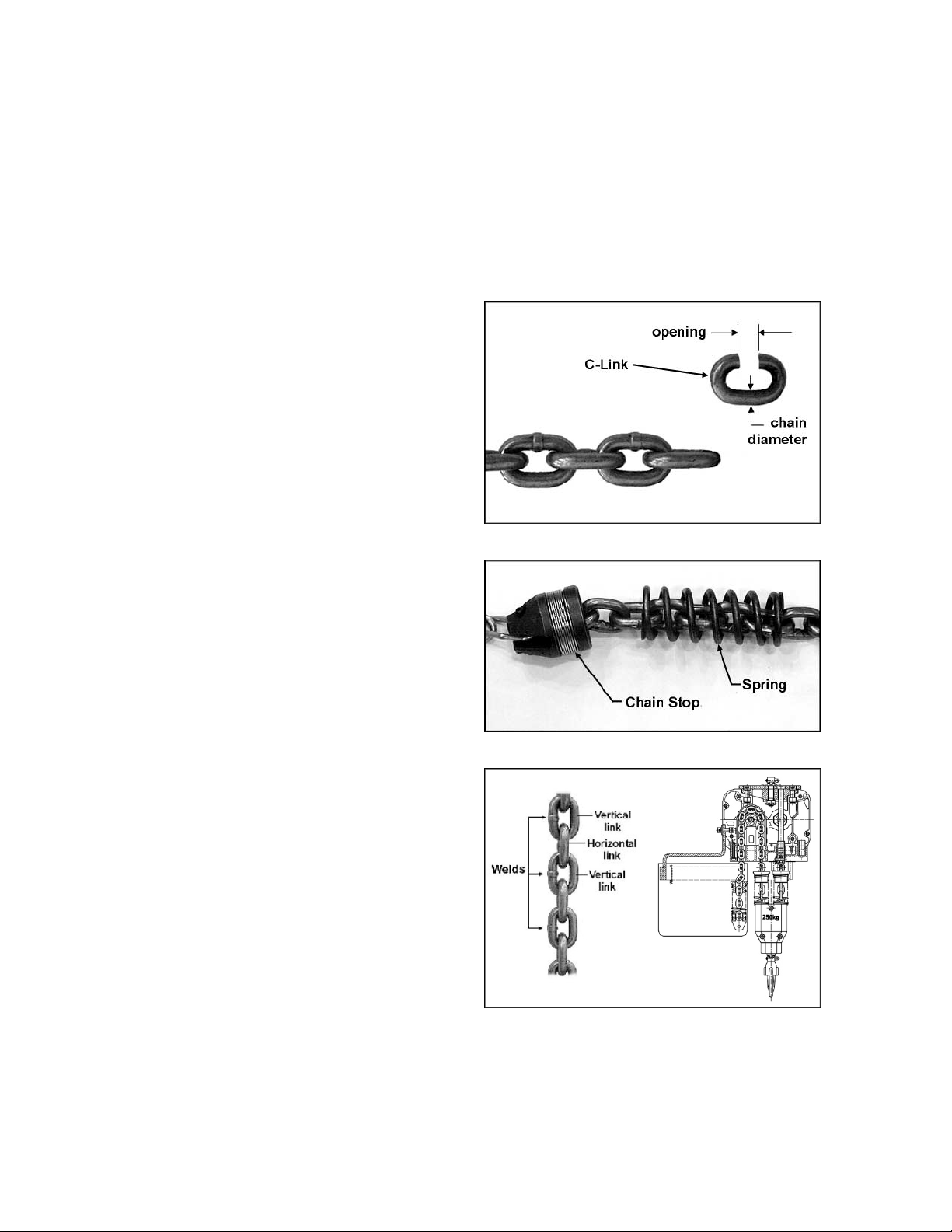

Making a C-Link .................................................................................................................................... 1 4

Single Fall Chain Hoist .......................................................................................................................... 14

Vertical and Hori z ontal Links.................................................................................................................. 15

Dual Fall Chain Hoists ........................................................................................................................... 15

Inspection and Maintenance .................................................................................................................. 16

Inspection Schedule A ........................................................................................................................... 16

Inspection Schedule B ........................................................................................................................... 16

Troubleshooting ..................................................................................................................................... 17

Replacement Parts ................................................................................................................................ 18

Parts Breakdown for JSH Series Electric Chain Hoists ........................................................................... 19

Parts List for JSH Series Electric Chain Hoists ....................................................................................... 20

Electric al Connec tions – JSH Series Hoists ........................................................................................... 23

3

1. Read and understand the entire owner’s manual befor e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This chain hoist is designed and intended for use by properl y trained and experienced personnel only.

If you are not f amiliar with t he proper and safe oper ation of a chain hoi st, do not use until proper

training and knowledge have been obtained.

5. Do not use this chai n hoist for other than it s intended use. If used for other purpo ses, Walt er Meier

(Manufactur ing) Inc., di sclaims any real or implied warranty and hol ds itself harmless from any injur y

that may result from that use.

6. Do not install this chai n hoist where explosive hazards may exist.

7. Give your work undivided attenti on. Looking around, carrying on a conversati on and “horse-play” are

careless acts that can result in serious injury.

8. Do not use to lift peopl e, or loads over people. Warn others in the vici nity when lifting or transporting a

load. Avoid swingi ng load and hook.

9. Make certain t he pathway for a moving load is free of all obstructions.

10. Do not leave a suspended load unattended.

11. Do not ex c eed the rated load limit of the chain hoist.

12. Make sure l imi t switches are operat i ng properl y. Do not use lim it switches as routi ne operat ing stop s;

they are emergency dev ic es onl y .

13. Do not use the loading limit device to measure a l oad.

14. Do not use the load chain to wrap around the load or as a sling.

15. Maintain firm footi ng when operating the hoist.

16. Before lifting a load, mak e sure chai n is seated i n c hain wheels or sprockets.

17. Always inspect the chai n hoi st f or dam age prior t o use. Do not use a chai n hoist wit h twisted, ki nked,

worn or other wise damaged chain. If the chain hoi st is damaged, do not use until it has been repaired

or replaced.

18. Do not use more than one c hain hoist to l ift or move a load. If this is unav oidable, each chai n hoist

must have the same capaci ty as the load to be moved.

19. Do not use when bi nding causes an unequal load distr ibut ion on the supporting chai ns.

20. Never allow the l oad chai n to “set” ov er sharp edges. A ll lif ts must be m ade wit h strai ght chain that is

free of obstacl es.

21. Do not use a chain hoist unless load is centered bet ween top and bottom hooks.

22. P rotect load c hain from weld spl atter and other contami nants. Do not all ow the hook or chai n to be

contacted by a live wel ding electrode.

23. Do not permit chain or hook to be used as a ground when welding.

24. Do not u se the hoist f or lif ting guided l oads, such as elev ators and dumbwait ers. The se appli cations

require additional protective devi c es which are not incorporated into this hoist.

25. Always take time to study the job to be performed and choose the safest method. Do not place

yourself or other people in an unsafe position.

26. Do not attempt to repair a damaged load chai n or l engthen t he c hain.

27. Replace the chain with factor y replacement chain only. Do not use any other t y pe of chain.

4

28. Use only r ec ommended lubricant when needed.

29. Never use the chai n hoist if either hook i s stretched, def ormed, or has a broken or mi ssing safety

latch. Always replace the safety latch and/or the hook before placing the chain hoist back int o servic e.

30. Leave all internal maintenance to a qualified Walter Meier service center.

31. Do not oper ate this hoist while tired or under the influence of drugs, alcohol or any medic ation.

32. Understand and follow all procedures as set forth in American National Standards (ANSI), titled

“Performanc e Standar d for Electric Chain Hoist, ” ANSI/ASM E HST- 1M.

Familiarize yourself with the following safety notice s used in this manual:

This means that if precautions are not heeded, it may result in minor injury

and/or possible machine damage.

fatal injury .

This means that if precautions are not heeded, it may result in serious or even

5

Introduction

This manual is provided by Walter Meier (Manufacturing) Inc., covering the safe operation and

maintenance procedures for the JET Model JSH Series Electric Chain Hoists. This manual contains

instructions on installation, safety precautions, general operating procedures, maintenance instructions

and parts breakdown. This hoist has been designed and constructed to provide years of trouble free

operation if used i n accordance with instructi ons set forth i n this manual. If there are any questions or

comments, pl ease contact either your local supplier or Walter Meier. Walt er M eier can also be reac hed at

our web site: www.waltermeier.com.

Description

The JSH Series Elect ric Hoists are portable, rugged hoists construct ed of sturdy but lightweight die cast

aluminum alloy housings. A transmission with heat-treated alloy steel gears provides reliable service.

Operation is activated with one hand using pushbutton controls on a pendant cord, keeping the other

hand free to gui de t he load. A m agnet ic di sc brake en sures rapi d stop and secure hol di ng of l oads. Thi s

hoist is designed and tested in accordance with the American Society of Mechanical Engineers Code

B30.16, “Saf ety Standar d for Overhead Hoists.”

Read and understand the entire contents of this manual before attempting set-up or operation!

Failure to compl y may cause seri ou s in ju ry.

Record your purchase information here for quic k ref er ence:

Model No.: Stock No.: Serial No.:

Purchased From : Date Purchased:

Date Installed: Installer:

6

Specifications

Figure 1

Model No. JSH-275-10 JSH-275-15 JSH-275-20 JSH-550-10 JSH-550-15 JSH-550-20

Stock No. 110100 110115 110120 110110 110515 110520

Rated Capacity (Ton) 1/8 1/8 1/8 1/4 1/4 1/4

Standard Lift (ft.) 10 15 20 10 15 20

Hoisting Speed (fpm) 16 16 16 8 8 8

Motor 1/6HP, 115V, 1PH, 60Hz

Rated Amps 3 3 3 3 3 3

Duty Cycle 25% 25% 25% 25% 25% 25%

Duty Cycle Rating H3 H3 H3 H3 H3 H3

No. of Falls 1 1 1 2 2 2

Load Chain ( mm) 4 Dia. x 12 4 Dia. x 12 4 Dia. x 12 4 Dia. x 12 4 Dia. x 12 4 Dia. x 12

Push Button Control

Cord Length (ft.)

Net Weight (lbs.) 30.62 32.38 33.92 34.6 37.22 40.09

Shipping Weight (lbs.) 33.48 35.02 36.78 37.22 40.09 42.95

A 12.09 12.09 12.09 12.09 12.09 12.09

B 6.46 6.46 6.46 6.46 6.46 6.46

C 3.58 3.58 3.58 3.58 3.58 3.58

D 6.81 6.81 6.81 6.81 6.81 6.81

E 2.99 2.99 2.99 3.74 3.74 3.74

F 5.47 5.47 5.47 5.47 5.47 5.47

G 4.72 4.72 4.72 4.72 4.72 4.72

Headroom - H (in.) 15.27 15.27 15.27 17.1 17.1 17.1

6 11 16 6 11 16

Table 1

The above specifications were current at the time this manual was publi shed, but bec ause of our policy of

continuous improvement, Walter Meier (Manufactur ing) Inc., reserves the right to c hange specifications at

any time and without pri or notice, without incurring obligat ions.

7

Unpacking

Lift the hoi st out of the carton by the top hook or

the center secti on. Do not ap ply ex cessiv e for ce

to the motor cover, as damage may result.

Carefully inspect t he hoist for shippi ng damage,

and for loose or missing parts. Report any

damage immediately to your distributor and

shipping agent. Do not discard any shipping

material until the Hoist is installed and running

properly.

Contents of the Shipping Container

1 Hoist

1 Chain Container with Bracket and Fasteners

1 Owner’s Manual

1 Warranty Card

Installation and Assembly

Support for the hoist may be hook, clevis pin,

trolley, or beam clamp. Supporting structures

(such as I-Beams, etc.) should be installed by

properly licensed professional installers.

Whatever method of

suspension is chosen, the support

components must be rated equal to, or

greater than th e capaci t y of the chain ho ist.

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

This machine’s power cable is installed with a

plug that has an equipm ent-grounding conductor

and a grounding pro ng, sim ilar to that shown in

Figure 3. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordanc e wit h al l loc al codes and

ordinances. Do not m odif y t he plug – if it will not

fit the outlet, have the proper outlet installed by

a qualified elec tric ian.

Grounding Instructions

This mac hine m ust be grounded. I n the event of

a malfuncti on or break down, groundi ng prov i des

a path of least resi stance f or electric current to

reduce the risk of el ect ri c shock.

Figure 2

Figure 3

8

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conductor . If repair or replac em ent of

the electric cord or plug is necessary, do not

connect the equi pm ent-grounding conductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Repair or replace a damaged or worn cord

immediately.

Make sure the voltage of your power supply

matches the specif ications on the nam e plat e of

the hoist.

Extens ion Cords

If an extension c or d is necessary, mak e sure t he

cord rating is suit able for the am perage listed on

the hoist’s nam e plate. An undersized cord will

cause a drop in line volt age resulting in loss of

power and overheating.

Use the chart in Fi gure 4 as a general guide in

choosing the cor rect size cord. If in doubt, use

the next heavi er gauge. The smaller the gauge

number, the heavier the cord.

Recomm end ed Ga ug es (A WG ) of Extensi on Co rd s

Extension Cord Length *

25

50

75

100

150

200

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

feet

feet

feet

feet

feet

feet

Installing Chain Container

Do not overfill chain

container. If chain should overfill and begin

to fall, th e entire chain container may empty

without warning, resulting in serious

personal injury or property damage.

To assemble the chai n c ontainer to the hoist:

1. Hang hoist in position on the I-Beam or

trolley. Do not install chain container yet.

Allow slack side and load side of chain to

hang freely from hoist.

2. Apply power to the hoist and press the

DOWN butt on until the l ower limit switch is

tripped.

3. Check the chain c ontainer to ensure that the

seam is inside the bag. The bag must not be

inside out. The forks of the bracket are

inserted into the slots in the bag, which is

then secured by closing the two selfadhesive flaps (see Figure 5).

*based on li mi ti ng th e lin e voltage drop to 5V at 150% of the

rated amp eres.

NR: Not Recommended.

Figure 4

Figure 5

9

4. Remove the screw and washer holding the

end chain to the hoist ( Figure 6). Mount the

bracket of the chain container in that

location as shown in Figur e 7.

5. Put the chai n stop into the container (Fi gure

7), and operate the hoist to bring the load

hook up until the upper limit switch is

tripped.

6. Check the chain to e nsure that all the nonloaded chain is completely in the container.

Do not put chain into the

chain container by hand! By not following

the above steps, the chain can become

twisted or kinked and can damage the hoist.

Pre-Operation Inspection

Limit Switch Inspection

1. Press UP button.

2. While the hook moves up, raise the limit

switch paddle where the chain enters the

hoist.

Figure 6

3. Hook should immediately stop.

4. Check DOWN limit switch in similar manner.

Inspecting the Load Chain

Clean the chain with a solvent, and carefully

inspect the enti re load chain. The chain should

be visually checked before each day’s use.

Replace damaged c hain before using the chai n

hoist.

Replace the load chain if any of the following are

identified:

1. Seriously r usted or c r acked.

2. Marks on the chai n surfac e are deeper than

5% of the link’s diamet er.

3. Links are twisted or def ormed.

4. The link s are stretched too l ong or seriously

worn on the surf ace, especial l y at the poi nts

where links contact each other. To check

the links for str etch, pr oc eed as f ollows:

5. Select an unworn, un-stretched length of

chain (at t he slack end f or ex ampl e). Let t he

chain hang verti cally wit h a light load (about

20 pounds) on the chain to pull it taut .

Figure 7

10

6. Use a large caliper t o measure the outside

length of a convenient number of links.

Measure the same num ber of links in a used

section of chain and calculate the

percentage increase in length of the worn

chain.

7. If the l ength of the worn chai n is m ore than

1-1/2% longer than the unused chain, then

the chain should be repl aced. I f t he chain is

worn less than 1-1/2%, check it at several

more places along it s length. If any section

is worn more than 1-1/2%, the chain should

be replaced.

Never extend load chain by welding a second

piece to the origi nal.

Do not operate the hoi st wi t h

a twisted, kinked or damaged load chain. Do

not splice the load chain .

Check that the chain does not twist along its

length from hoist to hook. If twist is present on

units with multiple falls, the hook must be

passed back through the chain loop to remove

all twist in the chain.

The lo ad chain supplied with

your JET chain hoist is designed,

manufactured, and tested for proper fit and

durability. Over a period of time, the chain

may need to be replaced. For your own

safety, use factory replacement chain only.

Use of other th an factory replacement chain

may cause serious injury and/or damage to

the hoist.

Inspecting the Hooks

It is im por tant to check t op and bottom hooks for

proper opening and other signs of deformation

or damage. Repl ace a hook immediately if any

of the following problems are identified:

1. The safety latch no longer cont ac ts the hook

opening.

2. The vertical angle at the neck of the hook

reaches 10° (see Figure 8).

3. Chemical corr osi on or crack s on the hook .

4. Excessive wear on the inside surface.

5. The throat opening has enl arged wider than

the maxim um permissible 10% incr ease, as

shown in Figure 9.

Figure 8

HOIST CAPACITY TOP HOOK and BOTTOM HOOK

X-Normal X-Limit

1/8 Ton 0.906 inches 1 inch

1/4 Ton 0.906 inches 1 inch

NOTE: Maximum permissible throat opening of hook with

latch fully retracted.

Figure 9

11

NOTE: Excessive hook throat opening or twist

indicates abuse or overloading of the hoist. If

such deformation is discovered, inspect hoist,

chain and all supporting m embers very c arefully

for additional indications of excessive hoist

loading.

Do not attempt repair of a

hook by heat treating, bending or attaching

anything by welding. Such procedures will

weaken and may cause failu re of the hoo k.

Operating the Hoist

Before beginning a work

shift, an op erator should test t he pushbut ton

station, limit switches and brake control. If

not functioning properly, they should be

replaced or repaired before putting hoist in

service.

Allow the hoist to come to a full stop before

changing direction. Rapidly reversing or

catching a falling load can overload the hoist

system and cause a failure in the hoist and/or

chain, resulting in injury or property damage.

If the hoist is connected to a manual trolley,

move the hoist by pushing on the suspended

load. Move an unl oaded hoist by pull ing on the

empty hook. Do NOT move the hoist by pull ing

on the pendant cord.

The brake mechanism must be kept clean and

free from di rt, water, and oil. Never all ow oil to

penetrate the brake mechanism. Always keep

your hoist clean, and store in a clean, dry

location.

Follow this general procedure for hoisti ng loads:

1. Secure the upper hook to the supporting

structure.

2. Pl ace l oad sli ng or chai n in t he center of t he

bottom hook, m aking sure the saf et y latc h is

secure. Never load the hook in front of

the safety lat ch. See Fi gur e 10.

3. Avoid lifting one load with two hoists. I f this

is unavoidable, apply equal weight to both

hoists and use hoists with the proper lift

capacity. Capacity of each hoist mus t be

equal to the total load to be lifted.

4. Press UP button and remove all slack in

load chain. Increase tension in the load

chain until the hoist is about to raise the

load.

5. Check again that the load is properly slung,

directly under hoist, and will not suddenly

swing or twist.

Figure 10

12

6. Raise load an i nch or two abov e the ground

and stop. Observ e load for a f ew moments,

looking for signs that the load or hoist

system is unstabl e, or other i ndicati ons that

there is a problem.

7. Check that the chain is not twisted at the

bottom hook. All welds should face the

same direction (see Figure 13). For hoists

with two or more falls of chain, make sure

the bottom hook is not turned over. This

may cause the chain to t wist.

8. Raise load to the traveling height. Raise

only to the height necessary t o safely clear

all obstacles.

9. Lower load at destination. If both UP and

DOWN commands must be used during

lowering, pause f or a moment between each

reversal of load di r ect ion.

10. Slowly allow weight to shift from hoist to

ground or new support. Do not approach

load until all tension i s out of chai n and l oad

is stable.

Maintenance

Brake Inspection

Keep brake surface and

lining free of grease.

1. Remove load and disconnect hoist from

power source.

2. Remove the back frame cover (index #31,

page 19).

3. Check for worn brake disc by m easuring t he

brake air gap with a feeler gauge (Figure

11). A brake gap larger than the allowable

wear limit – 0.039” - may cause chatter or

failure to rel ease.

4. If the brake is not operating properly, the

entire brake assembly must be replaced

by qualifi ed servic e per sonnel .

Lubrication

The gear housing has been f ill ed with 1/ 2 pound

of grease at the manufacturer and should not

require attention. If future lubrication becomes

necessary, use approxim ately 3/4 cup of a light

semi-fluid NLGI #1 gr ease.

Wipe the chain clean with a cloth periodically

and apply a light coat of SAE 90 gear oil.

Figure 11

13

Replacin g Loa d Ch ai n

Over time, the load chai n will wear or elongate.

This can cause damage t o the hoist, breakage,

or non-engagement of the load sheave. The

following procedur es descri be repl aci ng the load

chain for single and multiple fall hoists. These

procedures should be performed by

experienced personnel only.

How to Cut Chains

Use a bolt cutter with special cutter jaws for

cutting hardened chai n. Cut only one si de of the

link at a time. When making the second cut,

place a mat over the chain to catch the flying

chain section.

Making a C-Link

Replacing l oad chai n will requi re the use of a Clink (in some cases, two C-links), which you can

easily make as follows:

1. Cut a link from the old chain.

2. Cut the weld from the link leaving an

opening approximately 1.25 times the

diameter of the link mat eri al. See Figure 12.

3. Gr ind the cut areas smooth and remove all

burrs.

Figure 12

Single Fall Chain Hoist

1. Lower the l oad hook unti l onl y 1 to 2 f eet of

slack chain r em ains i n the chain c ontainer.

2. Remove chain cont ainer .

3. On t he slack side of the ol d chain, remove

the chain stop and the spring (Figure 12).

Keep these handy for later re-installing.

4. Using a C-l i nk, connect the new chain to t he

old chain. Be sure vertical link welds face

away from load sprocket ( see Figur e 14) .

5. Keep t ension on both sides of t he chai n and

lower the load hook to pull the new chain

through the hoist. Do not let the chain twist

or bind as it is being pulled through the

hoist.

6. Stop hoist when 1 to 2 feet of new chain

remains on the slack si de.

7. Install the spri ng and c hain stop on the slack

end of the new chain.

8. Remove C-link. Rem ove the load hook and

the spring from the old chain, and install

them on the new chain. Inspect condition of

both spring and hook.

Figure 13

Figure 14

(dual fall model show n)

14

9. Lower l oad hook until the limit switch stops

hoist movement. Inspect the chain for any

signs of twist.

10. Install chain container following the

instructi ons in this manual. Do not fill chai n

container by hand.

11. It is recommended that after installing new

chain, the fi rst f ew lifts be lim ited t o no more

than 25-50% of the rated load. Thoroughly

inspect chain for twist before placing hoist in

routine servi c e.

Vertical and Horizontal Links

Vertical and hor izontal are det ermined from the

relationship wit h the load sprocket. Vertical link s

will be guided by the center slit in the load

sprocket. Horizontal links will engage in the oval

pockets on the sprocket. See Figure 14.

Dual Fall Chain Hoists

T h e link o n t he lo a d si d e en d

must be a vertical link. If it is a horizontal

link, the chain will have a twist in it.

1. Lower hook until only 1 to 2 feet of slack

chain remains in the chain container.

2. Remove chain cont ainer .

3. On t he slack side of the chain, remove the

chain stop, and remove the spring(s). (see

Figure 13). Keep these handy for later reinstalling.

4. Using a C-link(s), c onnect the new chain to

the old chain. If the end li nk of the old chain

is horizontal , use t wo C-links. I f t he end link

of the old chain is vertical, use one C-link

See Figure 15. Using the correct number of

C-links will properly orient the chain, and

ensure that the first link on the load side end

is a horizontal link .

5. Install the spring(s) and chain stop on the

opposite end of the new chain.

6. Support the l oad hook so that t he load chain

can pass through the chain sheaves

smoothly.

7. Press the DOW N button to move the chain

through the hoist. Keep t ension on the chai n

as you pull i t through to the l oad side, until

the C-link(s) clears the hoist at the load

side.

8. Feed the new chain thr ough t he load hook .

Figure 15

9. Rem ove the clevis pin from t he suspension

block (#48, page 19), and remove the old

chain.

10. Remove C-link and connect the end of the

new chain to the su sp ension block, usi ng the

clevis pin and a new cott er pin to secure it.

Do not substitute any other pin or bolt in

this application.

NOTE: Be sure that there is no twisting of

chain between last chain sprocket in the

hoist and the suspension bloc k .

11. Install chain container following instructions

in this manual . Do not fill chai n container by

hand.

12. Lower hook until limit switch stops hoist

movement, t hen raise hook until lim it switch

stops hoist m ovement. Inspect chain for any

signs of twist and cor r ect before continuing.

13. It i s recomm ended that the fi rst few l ifts be

limited to no m ore than 25-50% of the rated

load. Inspect chain for twist before placing

hoist into routine serv ice.

15

Inspection and Maintenance

All repairs and adjustments are to be performed by trained and experienced

personnel using procedures that are approved for the hoist system being serviced. All safetyrelated defici encies discovered in the inspection are to be corrected b efore hoist is placed back

into service. Check f or internal damage whenever external d amage h as occu rred.

Read and follow the ANSI Inspection and Maintenance instructions. Know the meaning of Frequent

Inspection, P eriodic Inspecti on, Normal Servic e, Heavy Service, and Severe Service. It is the customer’s

responsibili ty to understand and follow all ANSI and J ET inspect ion and maintenance instr uc tions.

The following i tems are to be i nspected by appoi nted personnel at the tim e interval noted bel ow. Dated

inspection and repair reports must be maintained. Copies of all reports must be available to service

personnel.

Inspection Schedule A

Service Interval:

Normal Service – Monthl y

Heavy Service – Weekly to Monthl y

Severe Service – Daily to Weekl y

1. Check brake for slippage.

2. Check that pushbutton controls operate

properly.

3. Check that limit switches function properly.

Without load, oper ate up button control whil e

observing stopper spring. If stopper spring

becomes compressed and motor does not

stop, STOP operation immediately. Limit

switch is not oper ating proper ly. Repeat t est

with down button control.

4. Check top hook and load hook for

deformati on, chemical damage, and cracks.

5. Check that load chain is clean and lightly

lubricated, free of excessive wear or

deformation at the contact points between

links and link and hook. This hoist uses

special alloy hoisting chain and does not

interchange wit h any other manufacturer . All

replacement chain must be purchased f rom

your JET distributor or from Walter Meier

directly by calling 800-274-6848.

6. Check that the chain is untwisted, and

passes through all sprockets sm oothly whil e

under load.

7. Check entire hoist system for signs of

damage and loss of integr it y .

Inspection Schedule B

Service Interval:

Normal Service – Yearly

Heavy Service – Semi-Annually

Severe Service – Qu art erl y

1. Do all of the Schedule A items.

2. Check entire unit for loose screws, bolts,

nuts and pins.

3. Check for evidence of excessive wear,

corrosion, cracks, or distortion in the

following parts: hook parts, chain

attachments, suspension bolts and shafts,

gears, bearings, pins, rollers, and locking

and clamping devi c es.

4. Check f or evidenc e of dam age to hook parts

including hook r etaining nuts and collars and

pins and hook holding f rame and parts used

to secure the frame.

5. Check f or evidenc e of dam age or excessiv e

wear of load gear, sheave and sprocket

wheel. If the pockets are too deep, the chai n

may jam with corresponding failure of

engagement betwee n chain an d sprocket or

sheave.

6. Check for ev idence of excessiv e load brake

wear. Inspect clearance between brake

components, and adjust if needed.

7. Check for evidence of pitting or other

deteriorati on of visible controller c ontacts.

8. Check for evidence of deterioration of

supporting struc tures and trolleys.

9. Check for vi sible deform ation of limit switc h

coil springs.

10. Check that all warning labels are present

and readable.

16

Troubleshooting

Trouble Probable Cause Remedy

Motor will not run.

Hoist lifts very slowly.

Hoist lifts but will not

lower.

Hoist lowers but will

not lift.

Check circuit br eak er s, switc hes and

No incoming power, or low voltage.

Rectifier damaged so that the brake

won’t release.

Motor damaged.

Overloaded. Reduce load.

Low voltage.

Broken conductor in pendant cord.

Up/down switch malfunctioning. Repair or replace switc h.

Overloaded. Reduce load to within hoist capacity.

Up/down switch malfunctioning. Repair or replace switc h.

Brake malfunction.

connections in power supply lines. If

low voltage, hav e certif ied electrician

test incoming power.

Have rectifier replaced by qualified

service per sonnel .

Have motor replaced by a qualif ied

service technician.

Determine cause of low voltage and

bring up to withi n +/- 10% of t he

voltage listed on the hoist nameplate.

Test continuity of each conductor.

Replace cable if needed.

Have brake inspected by qualified

personnel. Replace if needed.

Load continues

drifting down

excessiv ely when

hoist is stopped.

Motor overheat s.

Poor engagement of

chain with

sprocket/sheave.

Brake chatters.

Hoist overloaded. Reduce load to within r ated capacity.

Have a qualifi ed technic ian dis-

Grease or oil on the lining.

Brake disc is worn. Replace brake assembly.

Brake springs are dam aged.

Excessive load or too frequent use.

Brake drags.

Load chain seriously worn. Replace load chain.

Sprocket wheel, sheave or the chain

guide is seriously worn.

Check for greater t han allowable air

gap.

If brake still chat ters after being

replaced check r ectifier for proper

operation.

assemble the brake and cl ean the

lining.

Replace brake spri ngs (qualified

personnel).

Operate within r at ed load and

according to duty cycle rating.

Adjust brake clear anc e ( qualified

personnel).

Replace parts as needed.

Replace brake assembly.

Have rectifier replaced by qualified

service per sonnel .

17

Trouble Probable Cause Remedy

Limit switch failure.

Bad connection of lim it swit c h leads.

Limit switch dam aged. Replace limit switc h.

Inspect the contac ts of the leads and

limit switches.

Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order par ts or reach our serv i ce departm ent, call

1-800-274-6848, Monday through Friday (see our website for business hours, www.waltermeier.com).

Having the Model Number and Serial Number of your mac hine available when you call will allow us to

serve you quickly and accurately.

18

Parts Breakdown for JSH Series Electric Chain Hoists

19

Parts List for JSH Series Electric Chain Hoists

Index No. Part No. Description Size Qty

1 ............... JSH275-1 .................Capacity Label for JSH-275 ................................................................... 1

................. JSH550-1 .................Capacity Label for JSH- 550 ................................................................... 1

................. TS-1531012 .............Phillips Pan Head Machine Screw ......................M3x6 .......................... 2

................. TS-1550011 .............Plain Washe r ......................................................3mm ........................... 2

2 ............... JHS275-2 .................Socket Head Cap Screw .....................................M6x40 ........................ 2

................. TS-2361061 .............Spring Wash er....................................................6mm ........................... 2

................. TS-1550041 .............Plain Washe r ......................................................6mm ........................... 2

3 ............... JSH275-3 .................Motor Side Cover................................................................................... 1

4 ............... JSH275-4 .................Motor Case Gasket ................................................................................ 1

5 ............... JSH275-5 .................Grooved Ball Bearing..........................................6201 ........................... 1

6 ............... JSH275-6 .................Rotor Assembly ..................................................................................... 1

7 ............... JSH275-7 .................Grooved Ball Bearing..........................................6202 ........................... 1

8 ............... JSH275-8 .................Motor Case Assembly ............................................................................ 1

9 ............... JSH275-9 .................Round Pin ............................................................................................. 4

10 ............. JSH275-10 ...............Self Locking Hex Nut ..........................................M6 .............................. 1

11 ............. JSH275-11 ...............Grooved Ball Bearing..........................................6004 ........................... 2

12 ............. JSH275-12 ...............Chain Guard .......................................................................................... 2

13 ............. JSH275-13 ...............Lift Wheel .............................................................................................. 1

14 ............. JSH275-14 ...............Self Locking Hex Nut ..........................................M8 .............................. 2

15 ............. JSH275-15 ...............Gear Case ............................................................................................. 1

16 ............. JSH275-16 ...............Lift Gear ................................................................................................ 1

17 ............. JSH275-17 ...............Snap Ring ..........................................................18mm ......................... 1

18 ............. JSH275-18 ...............First Gear Shaft ..................................................................................... 1

19 ............. JSH275-19 ...............Grooved Ball Bearing..........................................6000 ........................... 1

20 ............. JSH275-20 ...............Brake Nut .............................................................................................. 1

21 ............. JSH275-21 ...............Snap Ring ..........................................................10mm ......................... 1

22 ............. JSH275-22 ...............Grooved Ball Bearing..........................................6201 ........................... 2

23 ............. JSH275-23 ...............Second Gear Assembly ......................................................................... 1

24 ............. TS-1503061 .............Socket Head Cap Screw .....................................M6x25 ........................ 4

................. TS-2361061 .............Spring Wash er....................................................6mm ........................... 4

................. TS-1550041 .............Plain Washe r ......................................................6mm ........................... 4

25 ............. JSH275-25 ...............Gear Side Gasket .................................................................................. 1

26 ............. JSH275-26 ...............Back Frame ........................................................................................... 1

27 ............. TS-1503061 .............Socket Head Cap Screw .....................................M6x25 ........................ 3

................. TS-2361061 .............Spring Wash er....................................................6mm ........................... 3

................. TS-1550041 .............Plain Washe r ......................................................6mm ........................... 3

28 ............. JSH275-28 ...............Back Frame Gasket ............................................................................... 1

29 ............. JSH275-29 ...............Brake .................................................................................................... 1

30 ............. JSH275-30 ...............Cross Head Pan Screw ......................................M5x65 ........................ 2

................. TS-2361051 .............Spring Wash er....................................................5mm ........................... 2

................. TS-1550031 .............Plain Washe r ......................................................5mm ........................... 2

31 ............. JSH275-31 ...............Back Frame Cover ................................................................................. 1

32 ............. TS-1502091 .............Socket Head Cap Screw .....................................M5x40 ........................ 3

................. TS-2361051 .............Spring Wash er....................................................5mm ........................... 3

................. TS-1550031 .............Plain Washe r ......................................................5mm ........................... 3

................. JSH275-32-3 ............O-Ring................................................................4 x1.8mm .................... 3

33 ............. JSH275-33-10 ..........ID Label for JSH-275-10 ........................................................................ 1

................. JSH275-33-15 ..........ID Label for JSH-275-15 ........................................................................ 1

................. JSH275-33-20 ..........ID Label for JSH-275-20 ........................................................................ 1

................. JSH550-33-10 ..........ID Label for JSH-550-10 ........................................................................ 1

................. JSH550-33-15 ..........ID Label for JSH-550-15 ........................................................................ 1

................. JSH550-33-20 ..........ID Label for JSH-550-20 ........................................................................ 1

................. TS-1531012 .............Phillips Pan Head Machine Screw ......................M3x6 .......................... 4

................. TS-1550011 .............Plain Washe r ......................................................3mm ........................... 4

34 ............. JSH275-34 ...............Load Chain .........................................................Ø4x12m m............ per ft.

35 ............. JSH275-35 ...............Touch Block A ....................................................................................... 2

20

Index No. Part No. Description Size Qty

36 ............. JSH275-36 ...............Limit Spring ........................................................................................... 2

37 ............. JSH275-37 ...............Retainer Ring ........................................................................................ 1

38 ............. JSH275-38 ...............Chain Stop ............................................................................................ 1

39 ............. JSH275-39 ...............Chain Container .................................................................................... 1

40 ............. JSH275-40 ...............Spring Pin.............................................................................................. 2

41 ............. TS-1503061 .............Socket Head Cap Screw .....................................M6x25 ........................ 1

................. TS-2361061 .............Spring Wash er....................................................6mm ........................... 1

................. TS-1550041 .............Plain Washe r ......................................................6mm ........................... 1

42 ............. JSH275-42 ...............Chain Container Bracket ........................................................................ 1

43 ............. JSH275-43 ...............Limit Switch ........................................................................................... 2

................. JSH275-43-1 ............Phillips Pan Head Machine Screw ......................M3x16 ........................ 4

................. TS-2361031 .............Spring Wash er....................................................3mm ........................... 4

................. TS-1550011 .............Plain Washe r ......................................................3mm ........................... 4

44 ............. JSH275-44 ...............Limit Switch As sembly ........................................................................... 1

................. JSH275-44-1 ............Gasket................................................................................................... 1

................. JSH275-44-2 ............Cover .................................................................................................... 1

................. JSH275-44-3 ............Countersunk Cross Head Screw .........................M3x8 .......................... 2

................. JSH275-44-4 ............Insulation Sheet ..................................................................................... 2

................. JSH275-43 ...............Limit Switch ........................................................................................... 2

................. JSH275-43-1 ............Phillips Pan Head Machine Screw ......................M3x16 ........................ 4

................. TS-2361031 .............Spring Wash er....................................................3mm ........................... 4

................. TS-1550011 .............Plain Washe r ......................................................3mm ........................... 4

45 ............. TS-1501081 .............Socket Head Cap Screw .....................................M4x30 ........................ 4

................. TS-2361041 .............Spring Wash er....................................................4mm ........................... 4

................. TS-1550021 .............Plain Washe r ......................................................4mm ........................... 4

46 ............. JSH275-46 ...............Bottom Hook Assembly for JSH-275 ...................................................... 1

46-1 .......... JSH275-46-1 ............Bottom Hook ......................................................................................... 1

46-2 .......... JSH275-46-2 ............Thrust Ball Bearing .............................................8100 ........................... 1

46-3 .......... JSH275-46-3 ............Slotted Hex Nut ..................................................M10 ............................ 1

46-4 .......... JSH275-46-4 ............Spring Pin...........................................................Ø2.5x8mm.................. 1

46-5 .......... JSH275-45-5 ............Socket Head Cap Screw .....................................M5x20 ........................ 2

46-6 .......... JSH275-45-6 ............Bottom Hook Housing ............................................................................ 2

46-7 .......... JSH275-45-7 ............Self Locking Hex Nut ..........................................M5 .............................. 2

46-8 .......... JSH275-46-8 ............Safety Latch Assembly .......................................................................... 1

................. ................................Safety Latch .......................................................................................... 1

................. ................................Double Spring........................................................................................ 1

................. ................................Phillips Pan Head Machine Screw ......................M4x20 ........................ 1

................. ................................Self Locking Hex Nut ..........................................M4 .............................. 1

47 ............. JSH275-47 ...............Top Hook Assembly for JSH-275 ........................................................... 1

47-1 .......... JSH275-47-1 ............Top Hook .............................................................................................. 1

47-2 .......... TS-1504051 .............Socket Head Cap Screw .....................................M8x25 ........................ 2

47-3 .......... JSH275-47-3 ............Countersunk Cross Head Screw .........................M5 x10 ........................ 4

47-4 .......... JSH275-47-4 ............Fixing Board .......................................................................................... 1

47-5 .......... JSH275-47-5 ............Connection Bar for JSH-275 .................................................................. 1

47-6 .......... JSH275-47-6 ............Washe r.................................................................................................. 1

48 ............. JSH550-48 ...............Suspension Chain Block ........................................................................ 1

49 ............. JSH550-49 ...............Clevis Pin .............................................................................................. 1

50 ............. JSH550-50 ...............Cotter Pin ...........................................................Ø2x16mm................... 1

51 ............. JSH550-51 ...............Touch Block B ....................................................................................... 1

52 ............. JSH550-52 ...............Bottom Hook Assembly for JSH-550 ...................................................... 1

52-1 .......... JSH275-32 ...............Socket Head Cap Screw .....................................M5x40 ........................ 1

52-2 .......... JSH275-45-5 ............Socket Head Cap Screw .....................................M5x20 ........................ 2

52-3 .......... JSH275-7 .................Grooved Ball Bearing..........................................6202 ........................... 2

52-4 .......... JSH550-52-4 ............Sheave .................................................................................................. 1

52-5 .......... JSH550-52-5 ............Bottom Hook Housing ............................................................................ 2

52-6 .......... JSH275-45-7 ............Self Locking Hex Nut ..........................................M5 .............................. 3

53 ............. JSH550-53 ...............Top Hook Assembly for JSH-550 ........................................................... 1

21

Index No. Part No. Description Size Qty

53-1 .......... JSH550-53-1 ............Suspension Bolt .................................................................................... 1

53-2 .......... JSH550-53-2 ............Connection Bar for JSH-550 .................................................................. 1

54 ............. JSH275-54 ...............Cable Gland .......................................................................................... 2

55 ............. JSH275-55 ...............Warning Card ........................................................................................ 1

56 ............. JSH275-56 ...............Pushb u tto n Co rd ................................................1 6 AWGx3C ......... per ft.

57 ............. JSH275-57 ...............Pushbutton ............................................................................................ 1

58 ............. JSH275-58 ...............Rectifier ..............................................................50A ............................ 1

59 ............. TS-2284202 .............Phillips Pan Head Machine Screw ......................M4x20 ........................ 1

................. TS-1550021 .............Plain Washe r ......................................................4mm ........................... 1

60 ............. JSH275-60 ...............Housing for Capacitor ............................................................................ 1

61 ............. JSH275-61 ...............Capacitor ............................................................................................... 1

62 ............. JSH275-62 ...............Power Cable Assembly .......................................16AWGx3C ................ 1

22

Electrical Connection s –

JSH Series Hoists

23

WALTER M EIE R (Manufa c turing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.waltermeier.com

24

Loading...

Loading...