Jet JPS2-115, JPS2-230, ProShop II JPS2-230, ProShop II JPS2-115 Operating Instructions And Parts Manual

Operating Instructions and Parts Manual

ProShop II™ 10-inch Table Saw

Model JPS2-115, JPS2-230

shown with cast wings, 52” rail set, and extension table

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-725000

Ph.: 800-274-6848 Edition 1 09/2017

www.jettools.com Copyright © 2017 JET

1.0 IMPORTANT SAFETY

INSTRUCTIONS

WARNING: Read all safety warnings, instructions,

illustrations and specifications provided with this

power tool. Failure to follow all instructions listed

below may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future

reference.

1.1 General Safety Warnings

Work area safety

•

Keep work area clean and well lit.

dark areas invite accidents.

•

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

create sparks which may ignite the dust or fumes.

•

Keep children and bystanders away while

operating a power tool.

you to lose control.

Distractions can cause

Electrical safety

•

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

Unmodified plugs and matching outlets will

tools.

reduce risk of electric shock.

•

Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

shock if your body is earthed or grounded.

•

Do not expose power tools to rain or wet

conditions.

increase the risk of electric shock.

•

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

increase the risk of electric shock.

•

When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

cord suitable for outdoor use reduces the risk of

electric shock.

•

If operating a power tool in a damp location is

unavoidable, use a GFCI (ground fault circuit

interruptor) protected supply.

reduces the risk of electric shock.

There is an increased risk of electric

Water entering a power tool will

Damaged or entangled cords

Cluttered or

Power tools

Use of a

Use of a GFCI

Personal safety

•

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while y ou are tired or under

the influence of drugs, alcohol or medication.

moment of inattention while operating power tools

may result in serious personal injury.

•

Use personal protective equipment. Always

wear eye protection.

dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

•

Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to

power source and/or battery pack, picking up or

carrying the tool.

finger on the switch or energising power tools that

have the switch on invites accidents.

•

Remove any adjusting key or wrench before

turning the powe r tool on.

attached to a rotating part of the power tool may

result in personal injury.

•

Do not overreach. Keep proper footing and

balance at all times.

the power tool in unexpected situations.

•

Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

away from moving parts.

long hair can be caught in moving parts.

•

If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

dust collection can reduce dust-related hazards.

•

Do not let familiarity gained from frequent use of

tools allow you to become complacent and

ignore tool safety principles.

can cause severe injury within a fraction of a

second.

Protective equipment such as

Carrying power tools with your

A wrench or a key left

This enables better control of

Loose clothes, jewelry or

A careless action

Power tool use and care

•

Do not force the power tool. Use the correct

power tool for your application.

power tool will do the job better and safer at the rate

for which it was designed.

•

Do not use the power tool if the switch does not

turn it on and off.

controlled with the switch is dangerous and must be

repaired.

•

Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any

adjustments, changing accessories, or storing

power tools.

reduce the risk of starting the power tool

accidentally.

Any power tool that cannot be

Such preventive safety measures

The correct

A

Use of

2

•

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

dangerous in the hands of untrained users.

•

Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool’s operation. If

damaged, have the power tool repaired before

Many accidents are caused by poorly

use.

maintained power tools.

•

Keep cutting tools sharp and clean.

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

•

Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into a ccount the worki ng conditions and

the work to be pe rformed.

for operations different from those intended could

result in a hazardous situation.

•

Keep handles and grasping surfaces dry, clean

and free from oil and grease.

and grasping surfaces do not allow for safe handling

and control of the tool in unexpected situations.

Service

•

Have your power tool serviced by a qualified

repair person using only identical replacement

This will ensure that the safety of the power

parts.

tool is maintained.

Power tools are

Properly

Use of the power tool

Slippery handles

1.2 Specific Safety Warnings for

Table Saws

Guarding related warnings

•

Keep guards in place. Guards must be in

working order an d be pro pe rl y mou nt ed.

that is loose, damaged, or is not functioning

correctly must be repaired or replaced.

•

Always use saw blade guard, riving knife and

anti-kickback pawls for every through-cutting

operation.

the saw blade cuts completely through the thickness

of the workpiece, the guard and other safety

devices help reduce the risk of injury.

•

Immediately reattach the guarding system after

completing an operation (such as rabbeting,

dadoing or resawing cuts) which requires

removal of the guard, riving knife and/or antikickback pawls.

kickback pawls help to reduce the risk of injury.

•

Make sure the saw blade is not contacting the

guard, riving knife or the workpiece before the

switch is turned on.

items with the saw blade could cause a hazardous

condition.

•

Adjust the riving knife as described in this

instruction manual.

For through-cutting operations where

The guard, riving knife, and anti-

Inadvertent contact of these

Incorrect spacing, positioning

A guard

and alignment can make the riving knife ineffective

in reducing the likelihood of kickback.

•

For the riving knife and anti-kickback pawls to

work, they must be engaged in the workpiece.

The riving knife and anti-kickback pawls are

ineffective when cutting workpieces that are too

short to be engaged with the riving knife and antikickback pawls. Under these conditions a kickback

cannot be prevented by the riving knife and antikickback pawls.

•

Use the appropriate saw blade for the riving

knife.

For the riving knife to function properly, the

saw blade diameter must match the appropriate

riving knife and the body of the saw blade must be

thinner than the thickness of the riving knife and the

cutting width of the saw blade must be wider than

the thickness of the riving knife.

Cutting proced ure s wa rni n gs

•

DANGER: Never place your fingers or hands in

the vicinity or in line with the saw blade.

moment of inattention or a slip could direct your

hand towards the saw blade and result in serious

personal injury.

•

Feed the workpiece into the saw blade or cutter

only against the direction of rotation.

the workpiece in the same direction that the saw

blade is rotating above the table may result in the

workpiece, and your hand, being pulled into the saw

blade.

•

Never use the miter gauge to feed the workpiece

when ripping and do not use the rip fe nce as a

length stop when cross cutting with the miter

Guiding the workpiece with the rip fence

gauge.

and the miter gauge at the same time increases the

likelihood of saw blade binding and kickback.

•

When ripping, always apply the workpiece

feeding force between the fence and the saw

blade. Use a push stick when the distance

between the fence and the saw blade is less

than 150 mm (6 in.), and use a push block when

this distance is less than 50 mm (2 in.).

helping” devices will keep your hand at a safe

distance from the saw blade.

•

Use only the push stick provided by the

manufacturer or constructed in accordance with

the instructions.

distance of the hand from the saw blade.

•

Never use a damaged or cut push stick.

damaged push stick may break causing your hand

to slip into the saw blade.

•

Do not perform any operation “freehand”.

Always use either the rip fence or the miter

gauge to position and guide the workpiece.

“Freehand” means using your hands to support or

guide the workpiece, in lieu of a rip fence or mitre

gauge. Freehand sawing leads to misalignment,

binding and kickback.

This push stick provides sufficient

Feeding

A

“Work

A

3

•

Never reach around or over a rotating saw

Reaching for a workpiece may lead to

blade.

accidental contact with the moving saw blade.

•

Provide auxiliary workpiece support to the rear

and/or sides of the saw table for long and/or

wide workpieces to keep them level.

and/or wide workpiece has a tendency to pivot on

the table’s edge, causing loss of control, saw blade

binding and kickback.

•

Feed workpiece at an even pace. Do not bend or

twist the workpiece. If jamming occurs, turn the

tool off imme diately, unplug the tool then clear

the jam.

can cause kickback or stall the motor.

•

Do not remove pieces of cut-off material while

the saw is running.

trapped between the fence or inside the saw blade

guard and the saw blade pulling your fingers into

the saw blade. Turn the saw off and wait until the

saw blade stops before removing material.

•

Use an auxiliary fence in contact with the table

top when ripping workpieces less than 2 mm

thick.

fence and create a kickback.

Jamming the saw blade by the workpiece

The material may become

A thin workpiece may wedge under the rip

A long

Kickback causes and related warnings

Kickback is a sudden reaction of the workpiece due to a

pinched, jammed saw blade or misaligned line of cut in

the workpiece with respect to the saw blade or when a

part of the workpiece binds between the saw blade and

the rip fence or other fixed object.

Most frequently during kickback, the workpiece is lifted

from the table by the rear portion of the saw blade and is

propelled towards the operator.

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be avoided

by taking proper precautions as given below.

•

Never stand directly in line with the saw blade.

Always position your body on the same side of

the saw blade as the fence.

the workpiece at high velocity towards anyone

standing in front and in line with the saw blade.

•

Never reach over or in back of the saw blade to

pull or to support the workpiece.

contact with the saw blade may occur or kickback

may drag your fingers into the saw blade.

•

Never hold and press the workpiece that is

being cut off against the rotating saw blade.

Pressing the workpiece being cut off against the

saw blade will create a binding condition and

kickback.

•

Align the fence to be parallel with the saw blade.

A misaligned fence will pinch the workpiece against

the saw blade and create kickback.

•

Use a featherboard to guide the workpiece

against the table and fence when making nonthrough cuts such as rabbeting, dadoing or

Kickback may propel

Accidental

resawing cuts

workpiece in the event of a kickback.

•

Use extra caution when making a cut into blind

areas of assembled workpieces.

saw blade may cut objects that can cause kickback.

•

Support lar ge pa nels t o minimiz e the risk of saw

blade pinching and kickback.

to sag under their own weight. Support(s) must be

placed under all portions of the panel overhanging

the table top.

•

Use extra caution when cutting a workpiece that

is twisted, knotted, warped or does not have a

straight edge to guide it with a miter gauge or

along the fence.

workpiece is unstable and causes misalignment of

the kerf with the saw blade, binding and kickback.

•

Never cut more than one workpiece, stacked

vertically or horizontally.

pick up one or more pieces and cause kickback.

•

When restarting the saw with the saw blade in

the workpiece, center the saw blade in the kerf

so that the saw teeth are not engaged in the

material.

workpiece and cause kickback when the saw is

restarted.

•

Keep saw blades clean, sharp, and with

sufficient set. Never use warped saw blades or

saw blades with cracked or broken teeth.

and properly set saw blades minimize binding,

stalling and kickback.

. A featherboard helps to control the

The protruding

Large panels tend

A warped, knotted, or twisted

The saw blade could

If the saw blade binds, it may lift up the

Sharp

Table saw operating procedure warnings

•

Turn off the ta ble sa w and dis connec t the power

cord when removing the table insert, changing

the saw blade or making adjustments to the

riving knife, anti-kickback pawls or saw blade

guard, and when the machine is left unatte nded.

Precautionary measures will avoid accidents.

•

Never leave the table saw running unattended.

Turn it off and don’t leave the tool until it comes

to a complete stop.

an uncontrolled hazard.

•

Locate the table saw in a well-lit and level area

where you can maintain good footing and

balance. It should be installed in an area that

provides enou gh room to easi ly handle the s ize

of your workpiece.

uneven slippery floors invite accidents.

•

Frequently clean and remove sawdust from

under the saw table and/or the dust collection

Accumulated sawdust is combustible and

device.

may self-ignite.

•

The table saw must be secured.

is not properly secured may move or tip over.

•

Remove tools, wood scraps, etc. from the table

before the table saw is turned on.

potential jam can be dangerous.

An unattended running saw is

Cramped, dark areas, and

A table saw that

Distraction or a

4

•

Always use saw blades with correct size and

shape (diamond versus round) of arbor holes.

Saw blades that do not match the mounting

hardware of the saw will run off-center, causing loss

of control.

•

Never use damaged or incorrect saw blade

mounting means such as flanges, saw blade

washers, bolts or nuts.

were specially designed for your saw, for safe

operation and optimum performance.

•

Never stand on the table saw, do not use it as a

stepping stool.

tool is tipped or if the cutting tool is accidentally

contacted.

•

Make sure that the saw blade is installed to

rotate in the proper direction. Do not use

grinding wheels, wire brushes, or abrasive

wheels on a table saw.

installation or use of accessories not recommended

may cause serious injury.

Serious injury could occur if the

These mounting means

Improper saw blade

Additional safety rules

•

This table saw is designed and intended for use by

properly trained and experienced personnel only. If

you are not familiar with the proper and safe

operation of a table saw, do not use until proper

training and knowledge have been obtained.

•

Do not use this table saw for other than its intended

use. If used for other purposes, JET disclaims any

real or implied warranty and holds itself harmless

from any injury that may result from that use.

•

Do not wear gloves when operating a table saw.

•

WARNING: Drilling, sawing, sanding or machining

wood products generates wood dust and other

substances known to the State of California to

cause cancer. Avoid inhaling dust generated from

wood products or use a dust mask or other

safeguards to avoid inhaling dust generated from

wood products.

•

Wood products emit chemicals known to the State

of California to cause birth defects or other

reproductive harm. (California Health and Safety

Code Section 25249.6)

•

Blade should have minimum exposure during cuts.

Adjust blade to approximately 1/8” inch above

surface of workpiece.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious or possibly fatal injury.

5

2.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ............................................................................................... 2

1.1 General Safety Warnings ................................................................................................................... 2

1.2 Specific Safety Warnings for Table Saws .......................................................................................... 3

2.0 Table of contents .................................................................................................................................... 6

3.0 About this manual .................................................................................................................................. 7

4.0 Table Saw terminology........................................................................................................................... 8

5.0 Specifications ......................................................................................................................................... 9

5.1 Kit configuratio ns .............................................................................................................................. 10

6.0 Setup and assembly ............................................................................................................................. 11

6.1 Shipping contents ............................................................................................................................. 11

6.2 Tools required for assembly ............................................................................................................. 12

6.3 Unpacking and cleanup .................................................................................................................... 12

6.4 Installing legs and levelers ............................................................................................................... 12

6.5 Extension wings ................................................................................................................................ 12

6.6 Handwheels ...................................................................................................................................... 13

6.7 Motor cover ....................................................................................................................................... 13

6.8 Rails and fence ................................................................................................................................. 13

6.9 Wood extension table ....................................................................................................................... 14

6.10 Switch bracket ................................................................................................................................ 14

6.11 Dust collection ................................................................................................................................ 14

6.12 Riving knife ..................................................................................................................................... 14

6.13 Anti-kickback pawls ........................................................................................................................ 14

6.14 Blade guard .................................................................................................................................... 15

6.15 Blade installation/replacement ....................................................................................................... 15

6.16 Low profile riving knife .................................................................................................................... 15

6.17 Table insert ..................................................................................................................................... 16

6.18 Miter gauge ..................................................................................................................................... 16

6.19 Tool storage .................................................................................................................................... 16

7.0 Electrical connections .......................................................................................................................... 16

7.1 GROUNDING INSTRUCTIONS ....................................................................................................... 16

7.2 Overload reset button ....................................................................................................................... 17

7.3 Extension cords ................................................................................................................................ 17

7.4 On/off switch lock-out ....................................................................................................................... 17

8.0 Adjustments ......................................................................................................................................... 18

8.1 Blade raising/tilt mechanism ............................................................................................................. 18

8.2 Adjusting blade tilt stops ................................................................................................................... 18

8.3 Riving knife alignment ...................................................................................................................... 19

8.4 Table to blade alignment .................................................................................................................. 20

8.5

Belt adjustment/replacement

9.0 Operations ............................................................................................................................................ 21

9.1 Kickbacks ......................................................................................................................................... 21

9.2 Rip sawing ........................................................................................................................................ 22

9.3 Resawing .......................................................................................................................................... 23

9.4 Crosscutting ...................................................................................................................................... 23

9.5 Bevel and miter operations ............................................................................................................... 24

10.0 Safety devices .................................................................................................................................... 25

11.0 User-maintenance .............................................................................................................................. 26

11.1 Cleaning ......................................................................................................................................... 26

11.2 Lubrication ...................................................................................................................................... 26

11.3 Additional servicing ........................................................................................................................ 26

12.0 Optional accessories .......................................................................................................................... 26

13.0 Troubleshooting JPS2 ProShop II ...................................................................................................... 27

14.0 Replacement Parts ............................................................................................................................. 27

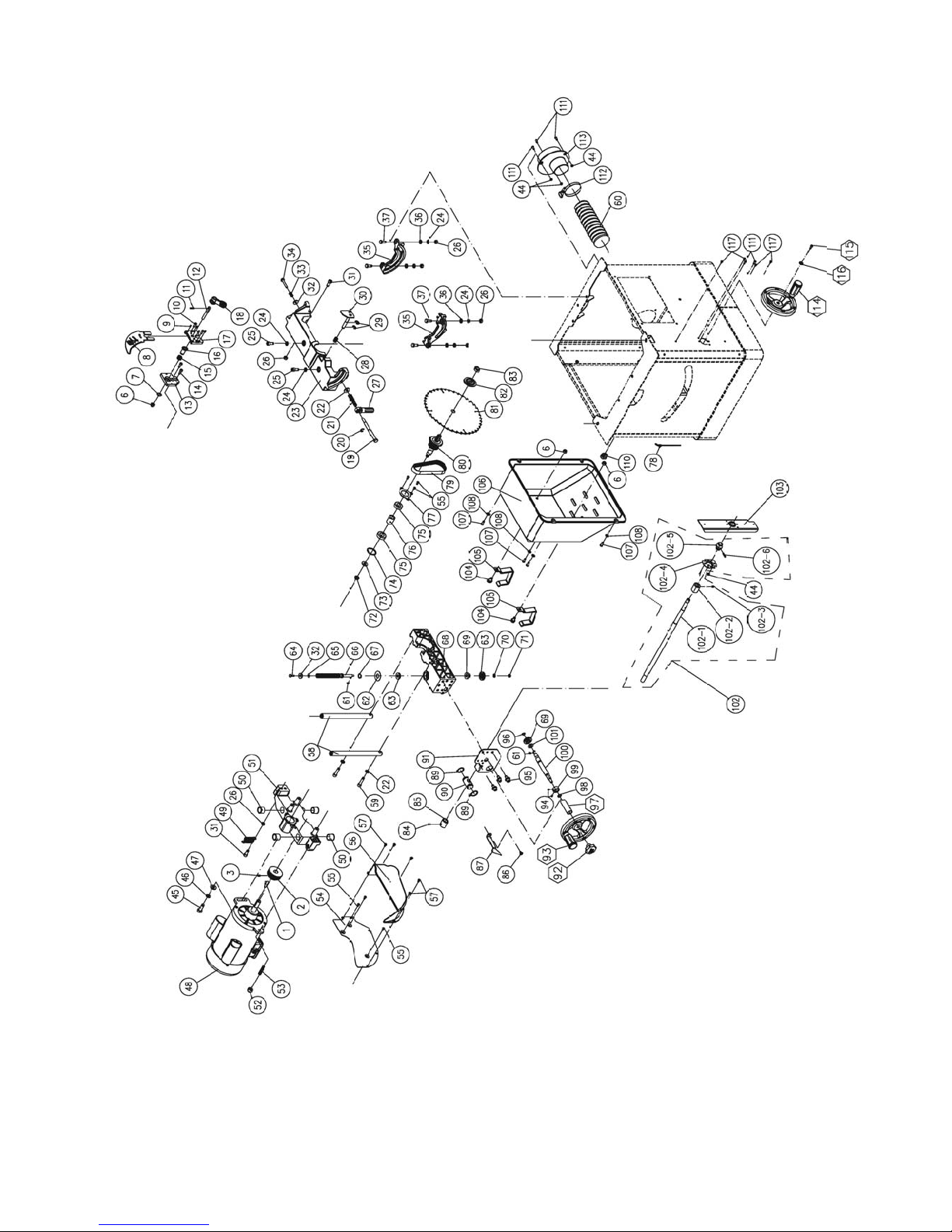

14.1.1 Motor and Trunnion – Exploded View ......................................................................................... 28

............................................................................................................. 20

6

14.1.2 Motor and Trunnion – Parts List .................................................................................................. 29

14.2.1 Table and Cabinet– Exploded View ............................................................................................ 32

14.2.2 Table and Cabinet– Parts List ..................................................................................................... 33

14.3.1 Stand Assembly – Exploded View............................................................................................... 34

14.3.2 Stand Assembly – Parts List ....................................................................................................... 34

14.4.1 Switch Assembly – Exploded View ............................................................................................. 35

14.4.2 Switch Assembly – Parts List ...................................................................................................... 35

14.5.1 Blade Guard Assembly – Exploded View .................................................................................... 36

14.5.2 Blade Guard Assembly – Parts List............................................................................................. 37

14.6.1 Miter Gauge Assembly – Exploded View .................................................................................... 38

14.6.2 Miter Gauge Assembly – Parts List ............................................................................................. 38

15.0 Electrical Connections for JPS2 ......................................................................................................... 39

16.0 Warranty and Service......................................................................................................................... 40

3.0 About this manual

This manual is provided by JET covering the safe operation and maintenance procedures for a JET Model

JPS2 ProShop II™ Table Saw. This manual contains instructions on installation, safety precautions, general

operating procedures, maintenance instructions and parts breakdown. Your machine has been designed and

constructed to provide consistent, long-term operation if used in accordance with the instructions as set forth in

this document.

This manual is not intended to be an exhaustive guide to table saw operational methods, use of jigs or aftermarket accessories, choice of stock, etc. Additional knowledge can be obtained from experienced users, trade

articles, or website forums. Whatever accepted methods are used, always make personal safety a priority.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand th e entire contents of this manual before attempting a ssembly

or operation. Failure to comply may cause serious injury.

Register your product using the mail-in card provided, or register online:

http://www.jettools.com/us/en/service-and-support/product-registration/

7

4.0 Table Saw terminology

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanism mounted over the saw

blade to prevent accidental contact with the cutting

edge.

Crosscut: Sawing operation in which the miter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Blade(s) used for cutting grooves and

rabbets. A stacked dado set can be used for wider

grooves.

Dado Cut: Flat bottomed groove in the face of the

workpiece made with a dado blade.

Featherboard: Device used to keep a board

against the rip fence or table, allowing the operator

to keep hands away from saw blade.

Freehand: Moving the workpiece into the blade

using only the hands, without a fixed positioning

device. (This is a dangerous, unacceptable

procedure on a table saw – always use appropriate

devices to feed the workpiece through the saw

blade during cutting operations.)

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is lifted

up and thrown back toward an operator, caused

when a workpiece binds on the saw blade or

between the blade and rip fence (or other fixed

object). To minimize or prevent injury from

kickbacks, see the Operations section.

Miter Gauge: A component that controls the

workpiece movement while performing a crosscut

of various angles.

Non-Through Cut: A sawing operation that

requires the removal of the blade guard and

standard riving knife, resulting in a cut that does

not protrude through the top of the workpiece

(includes dado and rabbet cuts).

The blade guard and riving knife must be reinstalled after performing a non-through cut to

avoid accidental contact with the saw blade during

operation.

Parallel: Position of the rip fence equal in distance

at every point to the side face of the saw blade.

Perpendicular: 90° (right angle) intersection or

position of the vertical and horizontal planes such

as the position of the saw blade (vertical) to the

table surface (horizontal).

Push Board/Push Stick: An instrument, usually of

wood or plastic, used to safely push the workpiece

through the cutting operation by keeping the

operator’s hands at a distance.

Rabbet: A cutting operation that creates an

L-shaped channel along the edge of the board.

Rip Cut: A cut made along the grain of the

workpiece.

Riving Knife: A metal plate fixed relative to the

blade, which moves with the blade as cutting depth

is adjusted. Thus, it maintains not only the kerf

opening in the workpiece, but also the knife-to-

blade distance. A low-profile riving knife sits lower

than the top edge of the blade, for making a nonthrough cut.

Splitter (Spreader): A stationary metal plate to

which the blade guard is attached that maintains

the kerf opening in the workpiece during a cutting

operation. (JET table saws use the superior Riving

Knife system instead.)

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool used to check that a surface

is flat or parallel.

Through Sawing: A sawing operation in which the

workpiece thickness is completely sawn through.

Proper blade height usually allows 1/8" of the top

of blade to extend above the wood stock. Keep the

blade guard down, the anti-kickback pawls down,

and the riving knife in place over the blade.

8

5.0 Specifications

Table 1

Model number

Stock number – saw only

(see Table 2 below for kit configurations)

Motor and Electricals

Motor type Totally enclosed, fan cooled, induction

Horsepower 1.75 HP

Motor phase 1 PH

Motor voltage 120 V 230 V

Cycle 60Hz

Listed FLA (full load amps) 7.4 A 14.8 A

Motor speed 3450 RPM

Starting amps 36 A 18 A

Running amps (no load) 3.7 A 1.8 A

Start capacitor 200MFD 125VAC

Run capacitor

Power transfer belt

On/off switch Magnetic switch KJD17B (NVR type)

Power cord 14AWG x 3, 6 ft (183cm)

Plug provided 5-15P 6-15P

Recommended circuit size 1 15 A

Sound emission without load 2 80 dB at 30 in. (762mm) from blade

Arbor and blade

Arbor diameter 5/8 in. (15.88 mm)

Arbor speed 4000 RPM

Arbor lock included

Arbor wrench included

Blade included 10 in. (254 mm), 40 tooth

Maximum depth of cut at 90 degrees 3-1/8 in. (79 mm)

Maximum depth of cut at 45 degrees 2-1/8 in. (54 mm)

Maximum rip to right of blade 30 in. or 52 in.

Maximum rip to left of blade 13.5 in. (343 mm)

Blade height per one revolution of handwheel 5/32 in. (4 mm) at 90°; 7/64 in. (2.83 mm) at 45°

Dado maximum width 13/16 in. (20.6 mm)

Dado maximum diameter 8 in.

Blade tilt 45° left tilt

Table

Main table dimensions, L x W 20 x 27 in. (508 x 686 mm)

Table dimensions with wings, L x W 44 x 27 in. (1118 x 686 mm)

Table area in front of blade at maximum height 8.81 in. (223.83 mm)

Table height from floor, approximate 34-3/4 in. (883 mm)

Miter T-slot, W x D 3/4 x 3/8 in. (19 x 10 mm)

Edge bevel Front

Main materials

Main table Cast iron

Table insert Aluminum

Extension wings Cast iron or stamped steel

Base and legs Steel

Center trunnion Aluminum

Pulleys Steel

JPS2-115 JPS2-230

725000 725001

40μF 300VAC

9

Dust collection

Dust port outside diameter 4 in. (102 mm)

Recommended minimum extraction volume 400 CFM (0.5 CMM)

General Dimensions

Base footprint 23-1/2 x 24-1/2 in. (597 x 623 mm)

Assembled, with 30-in. rail set, L x W x H 60 x 40 x 43 in. (1524 x 1016 x 1090 mm)

Assembled, with 52-in. rail set, L x W x H 82 x 40 x 43 in. (2083 x 1016 x 1090 mm)

Shipping dimensions, saw only, L x W x H 30 x 29-3/4 x 29 in. (76 x 75.5 x 74.5 cm)

Weights

Saw only without wings – net weight 178 lbs (81 kg)

Saw only without wings – shipping weight 191.5 lbs (87 kg)

1

subject to local/national electrical codes.

2

The specified values are emission levels and are not necessarily to be seen as safe operating levels. As workplace

conditions vary, this information is intended to allow the user to make a better estimation of the hazards and risks

involved only.

L = length, W = width, H = height, D = depth

n/a = not applicable

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

5.1 Kit configurations

Stock numbers

120V model 230V model

Proshop II saw only

Proshop II saw, 30” rip, cast wings 725000K 725002K

Proshop II saw, 30” rip, steel wings

Proshop II saw, 52” rip, cast wings, wood extension table

Proshop II saw, 52” rip, steel wings, wood extension table

Table 2

725000 725001

725004K 725006K

725001K 725003K

725005K 725007K

10

Read and understand all

assembly instructions before attempting

assembly. Failure to comply may cause serious

injury.

6.0 Setup and assembly

6.1 Shipping contents

See Figures 6-1 and 6-2.

NOTE: Some parts may have come pre-assembled

to the table saw.

1 Table saw with on/off switch (not shown)

1 Blade (preinstalled on saw)

1 Table insert (preinstalled on saw)

1 Arbor wrench (preinstalled on tool holder)

1 Miter gauge – A

1 Push stick – B

1 Handwheel, large mounting hole – C

1 Handwheel, small mounting hole – D

1 Guard assembly – E

1 Anti-kickback pawl assembly – F

1 Riving knife – G

1 Low profile riving knife – H

1 Motor cover – J

4 Legs – K

2 Extension wings – L

1 Operator’s manual (not shown)

1 Product registration card (not shown)

1 Hardware package

6.1.2 Hardware package

1 Storage hook – HP1

1 Open end wrench 11-13mm – HP2

1 Knob – HP3

1 Spacer – HP4

3 Hex wrenches, 2.5, 4, 5 mm – HP5

4 Levelers – HP6

8 Socket hd cap screws M8x20 – HP7

8 Socket hd cap screws M6x16 – HP8

1 Soc hd cap screw w/lock wshr M5x12 – HP9

2 Tapping screws M5x12 – HP10

2 Hex cap screws w/flat wshr M8x10 – HP11

4 Pan hd machine screws M6x16 – HP12

8 Flat washers M8 – HP13

12 Flat washers M6 – HP14

4 Hex nuts M8 – HP15

NOTE: Fence and rail assemblies with fasteners,

and wood extension tables and legs with fasteners,

are shipped in separate boxes.

Figure 6-1: Contents (not to scale)

11

Figure 6-2: Hardware (not to scale)

6.2 Tools required for assembly

Hex (Allen) wrenches: 4, 5, 6mm

Open end wrenches: 10, 13mm

Cross point (Phillips) screwdriver

Straight edge

Rubber mallet (or hammer with block of wood)

Level

Note: A ratchet wrench with sockets will speed

assembly time. Additional tools may be needed for

adjustments and/or assembly of fence and rails.

The main saw unit is heavy;

use an assistant or a hoist mechanism when

moving or turning it right side up.

6.3 Unpacking and cleanup

1. Remove all contents from shipping carton and

from inside of saw body. Do not discard carton

or packing material until saw is assembled and

running satisfactorily.

2. Inspect contents for shipping damage. Report

damage, if any, to your distributor.

3. Compare contents of shipping carton with the

contents list in this manual. Report shortages,

if any, to your distributor. Check machine first

to see if parts have been pre-installed.

4. Slide table saw off pallet onto cardboard or

pad to prevent scratching table surface. Keep

saw upside down.

Install both screws first, then tighten with 5mm

hex wrench. (Note: If more clearance is

needed to insert a screw, see sect. 6.6 to

temporarily mount a handwheel and tilt the

trunnion out of the way.)

2. Install four levelers with hex nuts (HP6/14).

3. Turn saw right-side up and allow the feet to

adjust to floor surface. Place a level on table,

and adjust the levelers as needed. Tighten hex

nuts up against leg with 10mm wrench to

secure setting.

6.5 Extension wings

See Figure 6-4.

Wings are available in cast iron or stamped steel.

Make sure mating surfaces are clean and free of

burrs.

Attach each extension wing to saw table using four

screws and washers (HP7/13). Do not fully tighten

yet.

Assembly Tip: If you are doing this without an

assistant, lift extension wing perpendicular to table

edge. Install a center screw and washer, and make

snug. Then pivot wing parallel to saw table to insert

remaining three screws.

Figure 6-3

6.4 Installing legs and levelers

See Figure 6-3.

1. Mount legs (K) to cabinet using two M8 screws

with washers (HP8/13) into each leg as shown.

Figure 6-4

6.5.1 Leveling extension wings

Note: The following instructions show assembly of

the cast wings. The stamped steel wings may have

a tendency to sag until rails are installed, and may

need further leveling adjustments during rail

installation.

Level extension wings to saw table using a straight

edge. A metal straight edge is ideal, though a

carefully jointed board may also be used.

Two methods are described below: one using a

rubber mallet, the other using clamps on the table

edges.

12

Method 1 (Figure 6-5):

1. Shift extension wing so it is slightly above saw

table surface.

2. Begin by tightening the screws beneath

extension wing that secure it to saw table.

Tighten these just enough to hold wing in

place but loose enough to change wing height

by tapping on it. (Tap with rubber mallet, or

hammer over a flat block of wood. Never use a

steel-faced hammer directly on the tables.)

3. Lay straight edge across saw table and

extension wing, extending it out past edge of

wing as shown in Figure 6-5.

4. Move straight edge to several places along

wing, as you continue to nudge wing level with

saw table. Also brush your fingertips over the

seam to ensure the transition feels smooth. As

each area of wing becomes flush with table,

tighten screw under that area. Continue until

all screws are fully tightened. NOTE: Make

sure front edge of wing remains flush with front

edge of saw table.

5. Repeat above steps for opposite extension

wing.

Figure 6-6: leveling extension wings, method 2

6.6 Handwheels

See Figure 6-4.

Note: The two handwheels look identical but have

different sized mounting holes.

1. On front of table saw, slide spacer (HP4,

Figure 6-4) onto shaft followed by handwheel

with large mounting hole (C). The flat side of

handwheel hole aligns with flat side on shaft.

2. Fasten in place by screwing in lock knob

(HP3).

Figure 6-5: leveling extension wings, method 1

Method 2 (Figure 6-6):

1. Follow steps 1 through 3 from Method 1.

2. Position clamps over seam, one at front, one

at back of table. Use a pad or flat block

beneath clamp jaw to prevent damage to table

surface. See Figure 6-6.

3. Tighten both clamps to align front and back

edges of tables. Make sure front edge of wing

remains flush with front edge of saw table.

4. Tighten screws incrementally, and position

straight edge at various places across seam,

especially checking at the center. Make further

adjustments as needed.

5. Fully tighten screws.

3. Slide handwheel with small mounting hole (D)

onto shaft on right side of table saw, aligning

flat side of hole with flat side on shaft.

4. Secure handwheel with lock washer and screw

(HP9), using 4mm hex wrench.

6.7 Motor cover

See Figure 6-7.

Install motor cover (J) with four pan head screws

and washers (HP12/14).

Figure 6-7

6.8 Rails and fence

To install front and rear rails and fence, consult

manual M-725005 which accompanies your fence

assembly, then proceed to sect. 6.11.

13

6.9 Wood extension table

To install the optional wood table, consult manual

M-725005, which accompanies your fence

assembly, then proceed to sect. 6.11.

6.10 Switch bracket

See Figure 6-8.

Use two screws with washers (HP-11) to secure

switch bracket to front rail.

Figure 6-8

6.11 Dust collection

Use of a dust collection system (not provided) is

strongly recommended during table saw operation.

It will help keep the shop clean, as well as prevent

potential health issues due to dust inhalation.

A dust collection system, with minimum capacity of

400 CFM (cubic feet per minute) should be

connected to the port via a 4-inch diameter hose

(not included) and secured with a hose clamp.

Note: Dryer vent hose is not acceptable for this

purpose.

An extensive line of JET dust collectors is

available; contact your dealer or visit our website

for information.

Figure 6-9

5. Slide tabs of riving knife (D) into slot between

the two blocks, all the way down onto

mounting stud.

6. Push down lever (A) to secure riving knife.

The clamping block (Figure 6-9) is adjusted at the

factory and no further adjustment of blade guard

and riving knife assembly should be necessary.

However, proper alignment is very important.

Before operating table saw, read sect. 8.3, Riving

knife alignment, to verify and follow the adjustment

procedure if necessary.

6.13 Anti-kickback pawls

See Figures 6-10 and 6-11.

1. Push and hold button (D) on opposite side of

the head to release the catch pin. Mount pawl

assembly straight down, in the location shown

in Figure 10.

2. Pivot head and push it downward (Figure 6-11)

until there is an audible click. Make sure you

hear the click to verify that pawl assembly is

secure.

6.12 Riving knife

See Figure 6-9.

1. Disconnect machine from power source.

2. Set saw blade to 90° (vertical) position and

raise it all the way (refer to sect. 8.1).

3. Remove table insert by rotating locking knob

(shown at M, Figure 6-14) and lift up insert

using finger hole.

Use care when working around

an installed blade.

4. Through the saw table opening, pull up lever

(A, Figure 6-9). The floating clamp block (B)

will move away from the fixed block (C),

leaving a gap.

14

Figure 6-10

Figure 6-11

6.14 Blade guard

See Figure 6-12.

1. Push up guard leaves (E, Figure 6-12) until

they catch and hold on the peg (F).

2. Lower blade guard assembly onto riving knife

and push it backward to seat it.

3. Tighten knob (G).

4. Pull down guard leaves (E) and allow them to

drop to the table.

5. Reverse procedure to remove guard.

IMPORTANT: Knob (G) must be tightened before

operating saw with guard in place.

6.15 Blade installation/replacement

When installing or changing

blades, always disconnect saw from power

source. Failure to comply may cause serious

injury.

1. Disconnect machine from power source.

2. Using the handwheels, raise blade arbor fully

and lock saw at zero-degrees by tightening

lock knob at center of handwheel.

See Figure 6-13:

3. Press arbor lock paddle (H) and rotate arbor

until you feel arbor lock engage. Continue

pressing arbor lock paddle.

4. Using the provided wrench, remove arbor

nut (J) and outer flange (K). If replacing blade,

remove old blade.

5. Place new blade on arbor shaft making sure

that the teeth point down toward front of saw.

Replace flange and arbor nut (K/J).

6. Tighten arbor nut (J). Do not overtighten.

Figure 6-12

Figure 6-13

6.16 Low profile riving knife

A low profile riving knife is included with your saw.

It mounts and adjusts in the same manner as the

standard riving knife. The low profile riving knife

sits just below top of blade and is used for making

non-through cuts. The blade guard is not used with

this knife, so extra precautions should be taken

during operation.

15

6.17 Table insert

See Figure 6-14.

1. Remove blade guard and riving knife.

2. Lower blade completely.

3. Place table insert into opening with notched

end towards rear of table, as shown.

4. Adjust insert flush with table by turning four

leveling setscrews (L) and using a straight

edge at different points over the insert. A

2.5mm hex key is required to adjust the

setscrews.

5. Turn lock knob (M) so that it catches insert and

holds it against table. If lock knob will not catch

properly, remove insert and adjust spring

tension by turning the nut on the knobs’ shaft.

Figure 6-14

6.18 Miter gauge

See Figure 6-15.

Calibration

If a miter angle at the -45º, 90º or +45º is not

correct, the index stops can be adjusted by turning

one of three adjustment screws (D), then tightening

the hex nut.

Note: Always make test cuts. Do not rely solely on

miter gauge indicator marks.

6.19 Tool storage

The fence assembly can be stored on the motor

cover hooks. Arbor wrench and low profile riving

knife are stored on tool holder on right side of saw.

Below tool holder is a hook for accessory storage.

Install the additional hook (HP1) to any surface of

saw stand with the tapping screws (HP10). Drill

pilot holes before inserting screws.

7.0 Electrical connections

The JPS2-115 table saw is wired for 120-volt only.

The JPS2-230 is wired for 230-volt only. The table

saw comes with a plug designed for use on a

circuit with a grounded outlet that looks like the one

pictured in either A or D, Figure 7-1.

Before connecting to power source, be sure switch

is in off position.

It is recommended that the JPS2 table saw be

connected to a dedicated 15 amp circuit with circuit

breaker or fuse. If fuses are used, they should be

time-delay fuse marked “D”.

NOTE: Local codes take precedence over

recommendations.

7.1 GROUNDING INSTRUCTIONS

Figure 6-15

Operate miter gauge by loosening lock knob (A)

and turning miter body (B) to desired angle.

The pin (C) functions as an index stop. When

pushed in, the body will stop at -45º, 90º or +45º

when turned, as one of three screws (D) located

underneath the miter body hits the pin.

You can adjust any play of the miter gauge in the

table slot by tightening set screws (E).

1. All Grounded, Cord-connected Tools:

This machine must be grounded. In the event of a

malfunction or breakdown, grounding provides a

path of least resistance for electric current to

reduce the risk of electric shock. This tool is

equipped with an electric cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipmentgrounding conductor to a live terminal.

16

Check with a qualified

electrician or service personnel if the

grounding instructions are not completely

understood, or if in doubt as to whether the

tool is properly grounded. Failure to comply

may cause serious or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating less

than 150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in A, Figure

7-1. An adapter, shown in B and C, may be used to

connect this plug to a 2-pole receptacle as shown

in B if a properly grounded outlet is not available.

The temporary adapter should be used only until a

properly grounded outlet can be installed by a

qualified electrician. The green-colored rigid ear,

lug, and the like, extending from the adapter must

be connected to a permanent ground such as a

properly grounded outlet box.

In Canada, the use of a temporary adaptor is not

permitted by the Canadian Electrical Code, C22.1.

3. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between 150 - 250 volts, inclusive:

7.2 Overload reset button

If saw becomes overloaded and the motor shuts

off, push re-set button above switch (Figure 7-2) to

restart. If overloading happens frequently, consult

the Troubleshooting section in this manual.

Figure 7-2

7.3 Extension cords

The use of extension cords is discouraged. Try to

position machines within reach of the power

source. If an extension cord must be used, make

sure it is heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating. Table 3 shows correct size to use

depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in D, Figure

7-1. The tool has a grounding plug that looks like

the plug illustrated in D. Make sure the tool is

connected to an outlet having the same

configuration as the plug. No adapter is available

or should be used with this tool. If the tool must be

reconnected for use on a different type of electric

circuit, the reconnection should be made by

qualified service personnel; and after reconnection,

the tool should comply with all local codes and

ordinances.

Figure 7-1

Ampere

Rating

More

Than

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

More

Than

Volts Total length of cord in feet

120

240

AWG

25

50

50

100

100

200

Not

Recommended

150

300

Extension Cord Recommendations

Table 3

7.4 On/off switch lock-out

The Table Saw is equipped with a push-button

switch that will accept a safety padlock, as shown

in Figure 7-3. To safeguard your machine from

unauthorized operation and accidental starting by

young children, the use of a padlock (not included)

is highly recommended. Place the key in a location

that is inaccessible to children and others not

qualified to use the tool.

17

Figure 7-3

8.0 Adjustments

8.1 Blade raising/tilt mechanism

Never try to force the tilting

mechanism past the 45º or 90º stops. This may

cause blade misalignment.

See Figure 8-1.

To raise or lower blade, loosen lock knob (A) and

turn handwheel (B) on front of saw until desired

height is reached. Tighten lock knob. The blade

should be adjusted about 1/8" above the top

surface of the material being cut.

To tilt blade, turn lock handle (C) counterclockwise

to loosen, turn handwheel (D) until desired angle is

obtained, then tighten lock handle (C) clockwise.

Figure 8-1

8.2 Adjusting blade tilt stops

The 45° and 90° blade tilt stops have been set by

the manufacturer, but should be verified by the

operator.

1. Disconnect machine from power source.

2. Raise blade to maximum height.

Figure 8-2

If adjustment is required:

5. Remove motor cover on left side.

6. Back out the setscrew in the 90° stop collar (E,

Figure 8-3), and position collar to allow further

movement of shaft bracket.

7. Turn blade tilting handwheel until blade is

exactly 90º.

8. Turn stop collar until it contacts shaft bracket,

and tighten set screw (E).

Figure 8-3

9. Tilt blade to 45° and verify setting in the same

manner as above. See Figure 8-4. Adjust 45°

stop collar as needed (F, Figure 8-3).

3. Set blade 90º to table by turning blade tilting

handwheel (D, Figure 8-1) counterclockwise

as far as it will go. Do not force beyond stop.

4. Place a square on the table and verify that

blade is at 90º to table. See Figure 8-2. Make

sure square is flat against blade surface and

not touching a blade tooth.

Figure 8-4

Verify that blade tilt pointer (Figure 8-5) accurately

indicates 45º or 90º (0°) on scale. If not, loosen

screw and adjust pointer. Retighten screw.

18

Figure 8-5

8.3 Riving knife alignment

8.3.1 Lateral alignment

Saw blade and riving knife must be as closely

aligned as possible (lateral alignment) for

prevention of kickback. This should be checked

upon initial blade guard and riving knife installation.

Alignment should also be reaffirmed after each

blade change.

1. Disconnect machine from power source.

2. Remove blade guard and anti-kickback pawls.

3. Place a straight edge on table so it rests

against blade and riving knife. See Figure 8-6.

Rotate blade so that top of blade tooth touches

straight edge.

Figure 8-6

The saw blade and riving knife must be in line. If

adjustment is needed:

4. Pull up lever (A, Figure 8-7) and remove riving

knife, making note as to which direction riving

knife needs to be moved to align it with saw

blade.

5. Use 3mm hex key to make adjustments to four

set screws (B, Figure 8-7). Adjust any of the

set screws required to bring riving knife in

alignment with saw blade.

6. Reinsert riving knife, secure by tightening lever

(A) and check alignment per step 2.

7. Repeat steps 3–5 until alignment is correct.

Figure 8-7

8.3.2 Blade proximity alignment

The gap between saw blade and riving knife must

be between 3mm (0.12in.) and 8mm (0.32in.). See

Figure 8-8.

If adjustment is needed, note whether blade-toknife gap needs to be increased or decreased.

Then adjust as follows:

1. Disconnect machine from power source.

2. Remove blade guard, pawl assembly, table

insert and riving knife.

3. Use 3mm hex key to loosen two socket head

button screws (C, Figure 8-7). This will allow

the clamp plate (D) to slide back and forth on

the fixed base.

Slide clamp plate (D) toward or away from saw

blade as required. Attempt to make the gaps

as even as possible.

4. Tighten screws (C).

5. Reinsert riving knife; engage lever (A) and

check that saw blade/knife gap is between 3 to

8mm (Figure 8-8).

Figure 8-8

19

8.4 Table to blade alignment

Refer to Figures 8-9 and 8-10.

The table has been set square with the blade by

the manufacturer and no adjustment is necessary

now. As the saw receives extensive use, however,

table/blade squareness should be checked and

corrected if necessary. Use the miter slot to do this:

1. Disconnect machine from power source.

2. Raise blade to maximum height.

3. Mark one tooth (A) with a grease pencil and

position the tooth slightly above top edge of

table at the front.

8. Retighten mounting screws firmly.

9. Verify the alignment, angle pointer setting,

fence setting, etc. Make any further

adjustments as needed.

8.5

Belt adjustment/replacement

To adjust tension of drive belt:

1. Disconnect machine from power source.

2. Loosen bolt (C, Figure 8-11) in motor bracket

slot. If needed, also slightly loosen hex nut on

opposite side of motor bracket.

3. Shift motor as needed, downward to tighten

belt, upward to loosen.

4. Retighten bolt (and hex nut).

To replace belt, loosen bolt (C) and shift motor

upward to create sufficient slack in belt. Remove

old belt from pulleys and install new one. Tension

new belt and retighten bolt.

Figure 8-9

4. Raise the miter gauge slightly out of its slot to

serve as a shoulder. Place a sliding square (B)

against side of miter bar, slide the scale over

until it touches the tip of blade, and lock the

scale in position. See Figure 8-9.

5. Rotate marked tooth (A) so that it is slightly

above table top at the rear and, using the

square as before, verify that the distance to

the blade is the same. See Figure 8-10. If the

distances are not the same, make a careful

note of the difference.

Figure 8-10

6. Slightly loosen the three mounting screws

(#10, sect. 14.2.1) that hold the table to the

stand; two in front, one in back.

7. Nudge table to bring miter slot in line with

blade.

Figure 8-11

20

9.0 Operations

NOTE: The following Figures are general in nature

and may not show your particular saw model.

Familiarize yourself with the location and operation

of all controls and adjustments and the use of

accessories such as miter gauge and rip fence.

9.1 Kickbacks

Serious injury can result from kickbacks which

occur when a workpiece binds on the saw blade or

binds between the blade and rip fence or other

fixed object. This binding can cause work piece to

lift up and be thrown toward the operator.

Listed below are conditions which can cause

kickbacks:

• Confining the cutoff piece when crosscutting or

ripping.

• Releasing the workpiece before completing

operation or not pushing work piece all the

way past the saw blade.

• Not using the splitter/riving knife when ripping

or not maintaining alignment of the

splitter/riving knife with the saw blade.

• Using a dull saw blade.

• Not maintaining alignment of the rip fence so

that it tends to angle toward rather than away

from the saw blade front to back.

• Applying feed force when ripping to the cutoff

(free) section of the workpiece instead of the

section between saw blade and fence.

Figure 9-1

Dull, badly set, improper, or improperly filed cutting

tools and cutting tools with gum or resin adhering

to them can cause accidents. Never use a cracked

saw blade. The use of a sharp, well maintained,

and correct cutting tool for the operation will help

avoid injuries.

Support the work properly and hold it firmly against

gauge or fence. Use a push stick or push block

when ripping short, narrow (6" width or less), or

thin work. Use a push block or miter gauge holddown when dadoing or molding.

For increased safety in crosscutting, use an

auxiliary wood facing (Figure 9-2) attached to the

miter gauge, using the slots or holes provided in

the gauge.

• Ripping wood that is twisted (not flat), or does

not have a straight edge, or a twisted grain.

To minimize or prevent injury from kickbacks:

• Avoid conditions listed above.

• Wear a safety face shield, goggles, or glasses.

• Do not use the miter gauge and rip fence in

the same operation unless provision is made

by use of a facing board on the fence so as to

allow the cutoff section of the workpiece to

come free before the next cut is started (See

Figure 9-9).

• As the machine receives use, the operation of

the anti-kickback pawls should be checked

periodically (Figure 9-1). If the pawls do not

stop the reverse motion of a workpiece,

resharpen all the points.

• Where possible, keep your face and body out

of line with potential kickbacks including when

starting or stopping the machine.

Figure 9-2

Never use the fence as a length stop when

crosscutting. Do not hold or touch the free end or

cutoff section of a workpiece. On through-sawing

operations, the cutoff section must NOT be

confined.

Always keep your hands out of line of the saw

blade and never reach back of the cutting blade

with either hand to hold the workpiece.

Bevel ripping cuts should always be made with the

fence on the right side of saw blade so that the

blade tilts away from the fence and minimizes the

possibility of the work binding and the resulting

kickback.

21

9.2 Rip sawing

Ripping is where the workpiece is fed with the grain

into the saw blade using the fence as a guide and

a positioning device to ensure the desired width of

cut (Figure 9-3).

Figure 9-3

Before starting a ripping cut,

verify that fence is clamped securely and

aligned properly.

• Never rip freehand or use miter gauge in

combination with the fence.

• Never rip workpieces shorter than the saw

blade diameter.

Figure 9-4

In ripping, use one hand to hold the board down

against the fence or fixture, and the other to push it

into the blade between blade and fence. If

workpiece is narrower than 6" or shorter than 12",

use a push stick or push block to push it through

between fence and blade (Figure 9-5). Never push

in a location such that the pushing hand is in line

with the blade. Move the hand serving as a holddown a safe distance from blade as cut nears

completion. For very narrow ripping where a push

stick cannot be used, use a push block or auxiliary

fence. Always push the workpiece completely past

the blade at the end of a cut to minimize the

possibility of a kickback.

• Never reach behind the blade with either hand

to hold down or remove the cutoff piece with

the saw blade rotating.

Always use blade guard, splitter/riving knife and

anti-kickback pawls. Make sure splitter/riving knife

is properly aligned. When wood is cut along the

grain, the kerf tends to close and bind on the blade

and kickbacks can occur.

The rip fence (A, Figure 9-4) should be set for the

width of the cut (C) by using the scale on the front

rail, or by measuring the distance between blade

(B) and fence (A). Stand out of line with saw blade

and workpiece to avoid sawdust and splinters

coming off the blade or a kickback, if one should

occur.

If the work piece does not have a straight edge,

nail an auxiliary straight edged board on it to

provide one against the fence. To cut properly, the

board must make good contact with the table. If it

is warped, turn the hollow side down. Do not

attempt to cut boards with significant warp.

Figure 9-5

22

Figure 9-6

When ripping long boards, use a support at front of

table (A, Figure 9-6), such as a roller stand, and a

support or "tailman" (B) at the rear.

Never use the rip fence beyond the point where the

carriage is flush with the end of the rails.

Have the blade extend about 1/8" above the top of

the workpiece. Exposing the blade above this point

can be hazardous.

9.3 Resawing

Resawing is a ripping operation in which thick

boards are cut into thinner ones. Narrow boards up

to 3" can be resawn in one pass. Wider boards up

to 6" must be resawn in two passes.

In resawing wider boards, adjust the blade height

so as to overlap the two cuts by 1/2" as shown in

Figure 9-7. Too deep a first cut can result in

binding and possible kickbacks on the second cut.

Always use the same side of the board against the

fence for both cuts.

Figure 9-8

Crosscutting should never be done freehand nor

should the fence be used as an end stop unless an

auxiliary block (A, Figure 9-9) is clamped to the

front of the blade area such that the cutoff piece

comes free of the block before cutting starts.

Figure 9-9

Length stops should not be used on the free end of

the workpiece in the cutoff area.

Do not crosscut workpieces shorter than 6". Before

starting a cut, be sure the miter gauge is securely

clamped at the desired angle. Hold the workpiece

firmly against the table and back against the miter

gauge. Always use the saw guard and riving knife

and make sure the riving knife is properly aligned.

Figure 9-7

9.4 Crosscutting

Crosscutting is where the workpiece is fed cross

grain into the saw blade using the miter gauge to

support and position the workpiece (Figure 9-8).

For 90-degree crosscutting, most operators prefer

to use the left-hand miter gauge slot. When using it

in this position, hold the workpiece against the

gauge with the left hand and use the right hand to

advance the workpiece. When using the right hand

slot for miter and compound crosscutting so that

the blade tilts away from the gauge, the hand

positions are reversed.

When using the miter gauge, the workpiece must

be held firmly and advanced smoothly at a slow

rate. If the workpiece is not held firmly, it can

vibrate causing it to bind on the blade and dull the

saw teeth.

23

To improve the effectiveness of the miter gauge in

crosscutting, some users mount an auxiliary

wooden extension face (A, Figure 9-10) with a

glued-on strip of sandpaper (B) to the miter gauge.

Provide auxiliary support for any workpiece

extending beyond the table top with a tendency to

sag and lift up off the table.

Have the blade extend about 1/8" above the top of

the workpiece. Exposing the blade above this point

can be hazardous.

Figure 9-10

Note: When making compound miters (with blade

tilted) use the miter gauge in the right hand slot to

provide more hand clearance and safety.

Have the blade extend only 1/8" above the top of

the workpiece. Exposing the blade above this point

can be hazardous.

Figure 9-12

Dado cutting – Dadoing is cutting a wide groove

into a workpiece or cutting a rabbet along the edge

of a workpiece. A dado insert (optional accessory,

not provided) shown in Figure 9-13, is necessary

for this type of operation.

9.5 Bevel and miter operations

Bevel cut – A bevel cut is a special type of

operation where the saw blade is tilted at an angle

less than 90 degrees to the table top (Figure 9-11).

Operations are performed in the same manner as

ripping or crosscutting, except the fence or miter

gauge should be used on the right-hand side of the

blade to provide added safety in avoiding a binding

action between blade and table top. When beveling

with the miter gauge, the workpiece must be held

firmly to prevent creeping.

Figure 9-11

Mitering – Crosscuts made at an angle to the edge

of the workpiece are called miters (Figure 9-12).

Set the miter gauge at the required angle, lock the

miter gauge, and make the cut the same as a

normal crosscut except the workpiece must be held

extra firmly to prevent creeping.

Do not use the standard table

insert for dadoing operations.

Figure 9-13

The process of cutting 1/8" to 13/16" grooves in

workpieces is accomplished by the use of a

stacked dado blade set or an adjustable type blade

mounted on the saw arbor. By using various

combinations of stacked dado blades, or properly

setting the dial on an adjustable blade, an accurate

width dado can be made. This is very useful for

shelving, making joints, tenoning, etc. The guard,

riving knife, and anti-kickback pawls supplied with

the saw should be used for all cutting operations

where they can be used. When performing

operations where the guard cannot be used, as in

some dadoing operations, alternative safety

precautions should be taken.

These include push sticks, feather boards, filler

pieces, fixtures, jigs and any other appropriate

device that can be utilized to keep operators’

hands away from the blade. Upon completion of

the operation requiring removal of the guard, the

entire guard assembly must be placed back on the

machine in its proper working order.

24

Never use a dado head in a

tilted position. Never operate the saw without

the blade guard, riving knife and anti-kickback

pawls for operations where they can be used.

10.0 Safety devices

Feather board

The feather board (Figure 10-1) should be made of

straight grain hardwood approximately 1" thick and

4" to 8" wide depending on the size of the machine.

The length is developed in accordance with

intended use. Feather boards can be fastened to

the table or rip fence by use of C-clamps.

Alternatively, drilled and tapped holes in the table

top allow the use of wing nuts and washers as a

method of clamping. If this method of fastening is

used, provide slots in the feather board for

adjustment. (The illustration shows a method of

attaching and use of the feather board as a vertical

comb. The horizontal application is essentially the

same except that the attachment is to the table

top.)

Figure 10-2 – Push Block Template

Figure 10-1

Push stick & push block

The use of a push block or push stick provides an

added level of safety for the operator. A push stick

is included with your table saw, but you may wish

to make others personalized for different cutting

procedures. The templates in Figures 10-2 and 103 offer construction details.

Figure 10-3 – Push stick template

25

11.0 User-maintenance

12.0 Optional accessories

Always disconnect power to

the machine before performing maintenance.

Failure to do this may result in serious

personal injury.

11.1 Cleaning

Clean the JPS2 according to the schedule below to

ensure maximum performance. The schedule

assumes the saw is being used every day.

Daily:

• Use a brush or compressed air to remove

chips or debris – do not use bare hands.

• Wipe down the table surface and T-slots

with a rust preventive.

• Clean pitch and resin from the saw blade.

Weekly:

• Clean motor housing with compressed air.

• Wipe down fence rails with a dry silicon

lubricant.

These accessory items, purchased separately, can

enhance the functionality of your table saw.

Contact your dealer to order, or call JET at the

phone number on the cover.

# 725004 – Dado Insert for ProShop II

11.2 Lubrication

Lubricate the areas indicated below every 12

months.