JET JPS-10XL52SW, JPS-10XL50CW Operating Instructions and Parts Manual

This Manual is Bookmarked

Operating Instructions and Parts Manual

10-inch Table Saw

Model JPS-10TS

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60124 Part No. M-708480

Ph.: 800-274-6848 Revision A 9/06

www.wmhtoolgroup.com Copyright © WMH Tool Group

shown with optional mobile base #708118 (not provided)

WARRANTY AND SERVICE

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of

these WMH Tool Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check

with your local WMH Tool Group distributor, or visit jettools.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS C OVERE D ?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY,

OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE

OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMI TATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as ge neral information

and are not binding. Members of WMH Tool Group reserve the right to effect at any tim e, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

® branded products are not sold in Canada by WMH Tool Group.

JET

® t ools. For the name of an Authorized Service Center in

2

Table of Contents

Table of Contents....................................................................................................................................3

Warning...................................................................................................................................................4

Features....................................................................................................................... ...........................7

Specifications..........................................................................................................................................7

Assembly...............................................................................................................................................10

Unpacking and Cleanup ..................................................................................................................... 10

Installing Legs ....................................................................................................................................10

Blade Tilt Point er................................................................................................................................10

Handwheels .......................................................................................................................................10

Extens io n Wing s................................................................................................................................11

Extens io n Wing Adjustment................................................................................................................11

Rails and Fence .................................................................................................................................11

Switch Bracket................................................................................................................. ..................11

Dust Hood..........................................................................................................................................11

Blade Guard and Splitt er ....................................................................................................................12

Install ing /R e p la cing the B lad e .............................................................................................................12

Aligning the Blade Guard and Splitter.................................................................................................12

Table Insert........................................................................................................................................13

Miter Gauge .......................................................................................................................................13

Grounding Instructions...........................................................................................................................14

Electrical Connections........................................................................................................................14

Extension Cord Recommendations.....................................................................................................14

Adjustments........................................................................................................................................... 15

Blade Raising and Tilt Mechanism......................................................................................................15

Adjusting 45º and 90º Positive Stops..................................................................................................15

Table to Blade Alignment....................................................................................................................16

Operations.............................................................................................................................................17

Table Saws........................................................................................................................................17

Bevel and Miter Operat ions................................................................................................................20

Safety Devices.......................................................................................................................................21

Feather Board....................................................................................................................................21

Push Stick & Push Block....................................................................................................................21

Filler Piece.........................................................................................................................................21

Maintenance..........................................................................................................................................22

Cleaning.............................................................................................................................................22

Lubrication .........................................................................................................................................22

Miscellaneous ....................................................................................................................................22

Troubleshooting.....................................................................................................................................23

Replacement Parts................................................................................................................................23

Motor and Trunnion A ssembly............................................................................................................24

Parts List: Motor and Trunnion Assembly............................................................................................25

Table and Cabinet..............................................................................................................................27

Parts List: Table and Cabinet.............................................................................................................. 28

Parts List: Stand A ssembly .................................................................................................................30

Parts List: Cast Iron Wings.................................................................................................................31

Electrical Connections ...........................................................................................................................32

3

Warning

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. This Tabl e Saw is designed and intended f or use by properly trained and experienced personnel onl y .

If you are not familiar with the proper and safe operation of a Table Saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this Table Saw for other than its intended use. If used for other purposes, WMH Tool

Group discl aims any real or implied warranty and holds itself harmless from any injury t hat may result

from that use.

6. Always wear approved saf ety glasses/face shi elds whil e using thi s Table Saw. Ever yday eyeglasses

only have impact resi stant lenses; they are not safety glasses.

7. Bef ore operating thi s Table Saw, remove tie, rings, watches and other jewelry, and roll sleeves up

past the elbows. Rem ove all loose cl othing and confi ne long hair. Non-sl ip foot wear or anti-ski d floor

strips are recommended. Do not wear glov es.

8. Always use the blade guard on all '' through- sawing'' oper ati ons. A t hrough-sa wing operati on i s one in

which the blade cuts completely through the workpi ec e.

9. Kickback oc c ur s when the workpiece i s thr own towards t he oper ator at a high rate of speed. If y ou do

not have a clear understanding of kickback and how it occurs, DO NOT operate this table saw!

10. Wear ear protectors (plugs or muffs) during extended periods of operation.

11. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

12. Do not operate this machine while tired or under the influence of drugs, alcohol or any medic ation.

13. Make certain the switch is in the OFF position before connecting the m achi ne to t he power supply .

14. Make certain the machine is properly grounded.

15. Make all machine adjustments or maintenance with t he machine unplugged from the power source.

16. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

17. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guar ds immediately.

18. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, br eakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged shoul d

be properly repaired or replaced.

4

blahblahblah

19. Provide for adequate space surrounding work area and non- glare, overhead lighting.

20. Keep the floor around t he m achi ne clean and free of scrap material, oil and grease.

21. Keep visitor s a safe di st anc e from the work area. Keep children away.

22. Make your workshop chil d pr oof with padlocks, master switc hes or by r emoving starter keys.

23. Giv e your work undivi ded attention. Looking ar ound, carryi ng on a conversation and “ horse-play” ar e

careless acts that can r esul t in serious injury.

24. Maintain a bal anc ed stanc e at all times so that y ou do not fall int o the blade or other moving par ts. Do

not overreach or use excessive force to perf orm any machine operation.

25. Use the ri ght t ool at the cor rect speed and feed r ate. Do not for ce a tool or attachment to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

26. Use rec om mended accessories; i mproper accessories may be hazardous.

27. Maintain tools with care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

28. Turn off the machine befor e c leaning. Use a bru sh or com pr essed air to remove chips or debris — do

not use your hands.

29. Do not stand on the machine. S eri ous i njury could occur if the machine tips over.

30. Never leave the m ac hine r unning unattended. Turn the power off and do not leav e the mac hine until it

comes to a complete stop.

31. Remove loose item s and unnecessary work pieces from the area before starting the machine.

Familiarize you rself with the following safet y no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

The most common accidents among table saw users, according to statistics, can be

linked to kickback, the high-speed expulsion of material from the table that can strike the operator.

Kickback can also result in operator’s hands being pul led into the blade.

Kickback Prevention

Tips to avoid the most common causes of

kickback:

• Make sure the blade splitter is always

aligned wit h the blade. A workpiece can bind

or stop the flow of the cut if the blade spl itt er

is misaligned and resul t in kickback.

• Use the blade spli tter during every cut. The

blade splitter maintains the kerf in the

workpiece, which will reduce the chance of

kickback.

• Never attempt fr eehand cut s. The workpiece

must be f ed perf ectly parall el with t he blade,

otherwise kickback will likely occur. Always

use the rip fence or crosscut fence to

support the workpi ec e.

• Make sure that the r ip fence is parallel with

the blade. If not, the c hanc es of ki c k bac k ar e

very high. Tak e the time t o check and adjust

the rip fence.

• Feed cuts through to completion. Anytime

you stop feeding a workpiece that is in the

middle of a cut, the chance of binding,

resulting in kickback, is greatly increased.

Pro tection Tips from

Kickback

Kickback can happen even if precautions are

taken to prevent it. Listed below are som e tips to

protect you if kickback DOES occur:

• Stand to the side of the blade when cutting.

An ejected workpiece usual ly travel s directly

in front of the blade.

• Wear safety glasses or a face shield. Your

eyes and face are the most vul nerable part

of your body.

• Never plac e your hand behind the blade. If

kickback occurs, your hand will be pulled

into the blade.

• Use a push stic k to keep your hands far ther

away from the moving blade. If a kickback

occurs, the push stick will most likely take

the damage that your hand would have

received.

6

Features

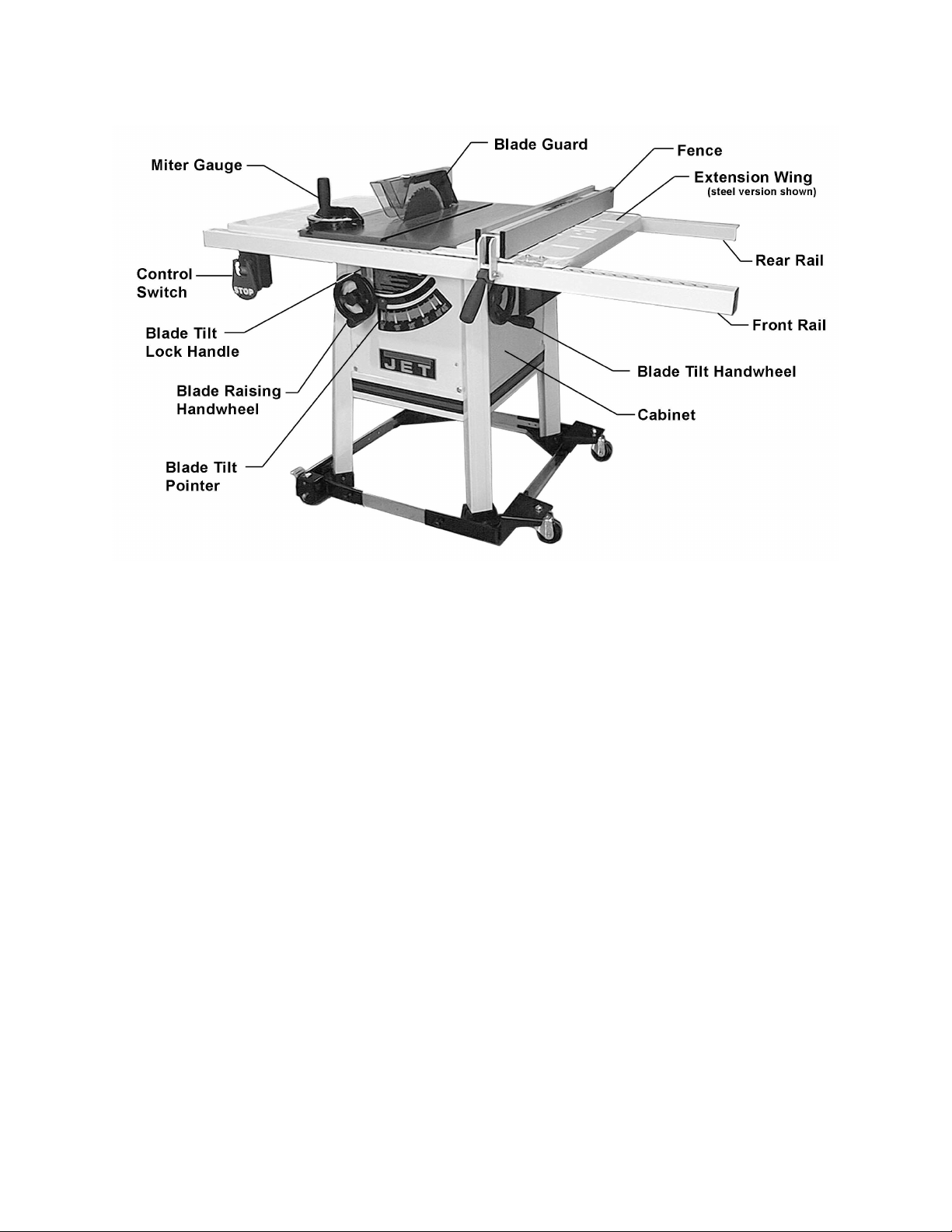

Figure 1

(mobile base purchased separ ately)

Specifications

Model Number............................................................ JPS-10TS..............................................JPS-10TS

Stock Num ber ..................................................................708480..................................................708481

Blade Diameter (i n.)................................................................ 10..........................................................10

Arbor Diameter (in.)...............................................................5/8.........................................................5/8

Maximum Depth of Cut (in.)................................................3-1/8......................................................3-1/8

Maximum Rip to Right of Bl ade (i n.)........................................ 30..........................................................30

Maximum Rip to Left of Blade (i n.).......................................... 12 ..........................................................12

Maximum Depth of Cut at 45° (in.)...................................... 2-1/8......................................................2-1/8

Table in Front of Blade at Maximum Cut (in) ..................... 10-1/2....................................................10-1/2

Maximum Width of Dado (i n.)..............................................13/16.....................................................13/16

Maximum Diameter of Dado (in.)............................................... 8............................................................8

Table Height (in.).............................................................. 34-3/4....................................................34-3/4

Extens io n Wing s..................................................................s te e l.................................................cast iron

Table Size without Ext ensi ons (in.)...................................20 x 27.................................................. 20 x 27

Table Size with Extensions (in.).......................................44 x 27.................................................. 44 x 27

Overall Dimensions (L x W x H)(in.)......................... 60 x 27 x 40...........................................60 x 27 x 40

Arbor Speed (RPM) .............................................................3600......................................................3600

Motor........................................ TEFC, 1-1/2HP, 1Ph, 115/230V*............TEFC, 1-3/4HP, 1Ph, 115/230V*

Net Weigh t (lb s.)................................................................... 205........................................................270

Gross Weight (lbs .)............................................................... 215........................................................280

*pre-wired 115 volt

The specifications in this manual are given as general information and are not binding. WMH Tool Gr oup

reserves the r ight to effect, at any time and without prior notice, changes or alterati ons to parts, fi ttings,

and accessory equipment deemed necessary for any reason what soever.

7

Definitions And Terminology

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanism mounted over the

saw blade to prev ent accidental c ontact with the

cutting edge.

Crosscut: Sawing operat ion in which the mi ter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Blade(s) used f or cutting grooves

and rabbets.

Dado Cut: Fl at bottomed gr oov e in the face of

the workpiece made wit h a dado blade.

Featherboard: Device used to keep a board

against the rip fence or table that allows the

operator to keep hands away from the saw

blade.

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is

lifted up and thrown back toward an operator,

caused when a work piece binds on the saw

blade or between the sa w blade and rip f ence

(or other fixed object). To minimize or prevent

injury from kickbacks, see the Operating

Instructions section.

Miter Gauge: A component that controls the

workpiece movement while performing a

crosscut of vari ous angl es.

Non-Through Cut: A sawing operation that

requires the rem oval of the blade guard spl itter,

resulting in a c ut that does not protrude through

the top of the workpiece (includes Dado and

rabbet cuts).

The blade guard and split ter must be re-i nstalled

after performing a non-through cut to avoid

accidental contact with the saw blade during

operation.

Parallel: Position of the rip fence equal in

distance at every point to the side face of the

saw blade.

Perpendicular: 90° (right angl e) intersection or

position of the vertical and horizontal planes

such as the posi tion of the saw blade (v ertical)

to the table surfac e ( hori z ontal).

Push Board/Push St ick: A n instr ument used to

safely push the workpiece through the cutting

operation.

Rabbet: A cutting operation that creates an

L-shaped channel along the edge of the board.

Rip Cut: A cut made along the grain of the

workpiece.

Splitter: Metal pl ate to which t he blade guard i s

attached that maintains the kerf opening in the

workpiece when performing a cutting operati on.

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool used to check that a

surface is flat or parallel.

Through Sawing: A sawing operat ion in which

the workpiece thickness is completely sawn

through. Proper blade height usually allows 1/8"

of the top of blade to extend above the wood

stock.

Read and understand the entire contents of this manual before attempting

assembly or operat io n! Failure to comply may cause serious inju ry!

8

Shipping Contents

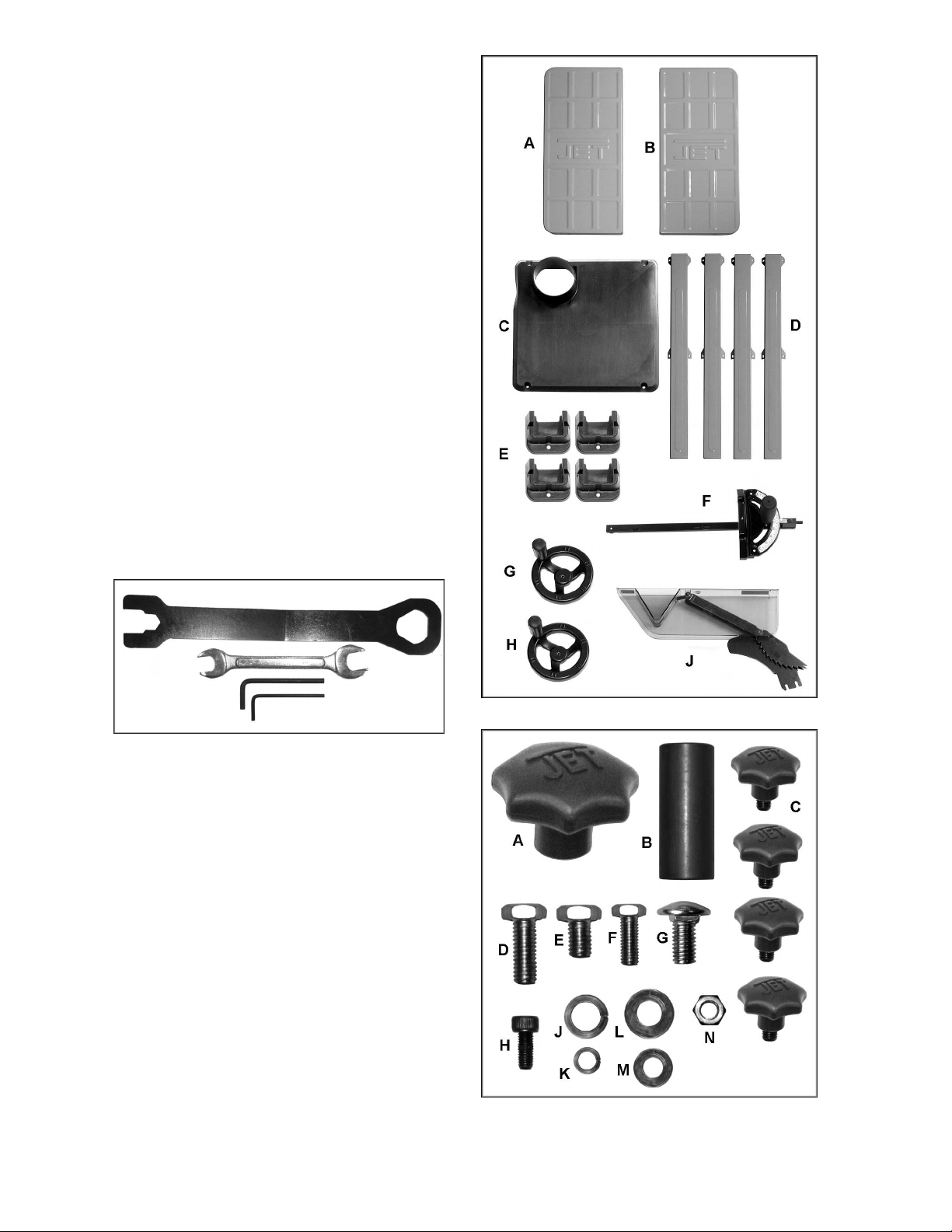

Carton Contents (see Figur e 2)

1 ea Table Saw (not shown)

1 ea Blade (not shown)

1 ea Extension Wing – Left (A)

1 ea Extension Wing – Right (B)

1 ea Dust Hood (C)

4 ea Legs (D)

4 ea Feet (E)

1 ea Mi ter Gauge (F)

1 ea Handwheel – Lar ge M ounting Hole (G)

1 ea Handwheel – Small Mounting Hole (H)

1 ea Blade Guard Assembly (J)

Tools Included for Assembly

(see Figure 3)

1 Blade Locking Wrench

1 10-12mm Open End Wrench

1 4mm Hex Wrench

1 2.5mm Hex Wrench

Note: other tools not provided may be required

for assembly.

Figure 3

Hardware

Remove content s from all pac kets and sort. Use

Figure 4 to help identify hardware.

1 ea Lock Knob for Handwheel (A)

1 ea Bushing (B )

4 ea Knobs for Dust Hood ( C)

8 ea M8x 20 Hex Cap Sc r ews (D)

2 ea M8x10 hex Cap Screw (E)

8 ea M6x 16 Hex Cap Sc r ews (F)

16 ea M6x12 Button Head Socket Scr ews (G)

1 ea M5x 12 Sock et Head Cap Screw (H)

8 ea M8 Lock Washers (J)

1 ea M5 Lock Washer (K)

2 ea M8 Flat W ashers (L)

8 ea M6 Flat Washers (M)

8 ea M6 Hex Nuts (N)

Figure 2

Figure 4

9

Assembly

Read and understand all

assembly instructions before attempting

assembly! Failure to comply may cause

serious injury!

Unpacking and Cleanup

1. Remove all contents from the shipping

carton. Keep the saw table upside down

(see Figure 5) and pl ace on a two-by-f our or

similar pi ece of wood under the rear of the

saw. This will help when picki ng up the table

again. Do not di scard the carton of packing

material until the saw is assembled and is

running satisfactorily.

2. Inspect the contents for shipping damage.

Report damage, if any, to your distributor.

3. Compare the contents of the shipping carton

with the content s list in this manual. Report

shortages, if any, to y our distr ibutor.

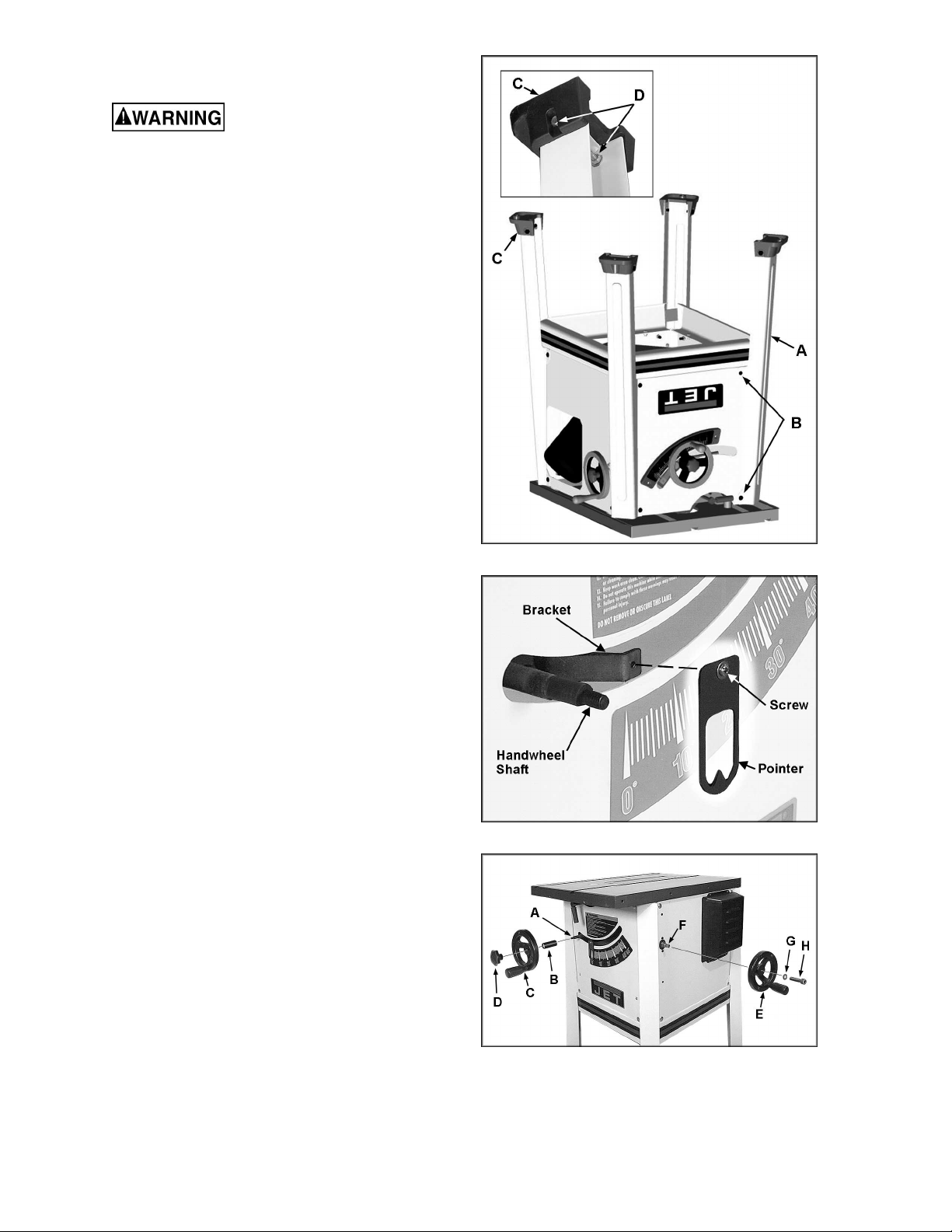

Installing Legs

Referring to Fi gur e 5:

1. Mount the four steel legs ( A) to the cabinet

using M6x12 button head socket screws (B).

2. Install a foot (C) on the bottom of each l eg,

using two M6x16 hex cap screws, M6 flat

washers and M6 hex nuts ( D) for each foot .

Hand tighten only.

3. Turn saw right side up and al low the feet to

adjust to the floor surface. Tighten hex nuts.

Blade Tilt Pointer

Referring to Fi gur e 6:

Secure the blade t ilt pointer on the f ront of the

saw onto the bracket with an M4 screw and

tighten with a cross-point screwdriver .

Handwheels

Referring to Fi gur e 7:

The JPS-10TS Tabl e Saw comes equipped with

two handwheels whi ch look identical except for

the mounting holes as follows:

Figure 5

Figure 6

1. On the front of the table saw slide the

bushing (B) onto shaft (A) followed by the

handwheel (C) with the larger mounting

hole, maki ng sure to line up the flat side in

the hole with the fl at side on the shaft.

2. Fasten in place wit h lock knob (D).

Figure 7

10

Loading...

Loading...