Page 1

Operating Instructions and Parts Manual

1/2- to 3-Ton Lever Hoists

Models: JPNX-50/75/150/300

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-225650

Ph.: 800-274-6848 Revision A1 4/05

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

This manual has been prepared for the owner and operators of a JET JPNX Series Lever Hoist. Its

purpose, aside f rom machine oper ation, is to promot e safety using acc epted operati ng and maint enance

procedures. To obtai n maximum life and effici ency from your puller and to aid in using i t safely, please

read this manual thoroughly and follow the instruc tions carefully.

Warranty and Service

WMH Tool Gr oup warrants ever y product it sell s. If one of our tools needs s ervice or repai r, one of our

Authorized Repair St ations located throughout the United States can provide quic k servi ce or information.

In most cases, a WM H Tool Group Repair Station can assist in authorizing repair work, obtaining part s, or

perform routi ne or m ajor maintenance repair on your JET produc t.

For the nam e of an A uthoriz ed Repair St ation in your area, pl ease call 1-800-274-6848, or v isit our web

site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group i s consistently adding new products to the li ne. For complete, up-to-dat e

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that it s products meet high quali ty and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from

defects in mat erials and workmanship as foll ows: 1 YEAR LI MITED WARRANTY ON ALL PRODUCTS

UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or i ndirectly to

misuse, abuse, negl igence or acc idents, norm al wear-and-tear , repair or alterati ons outside our f aciliti es,

or to a lack of maintenanc e.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP

BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanati on of the complaint m ust accompany the merchandi se. If our inspecti on discloses a defec t, we

will either repair or replace the produc t at our discret ion, or r efund t he purchase pri ce if we cannot readi l y

and quickly provide a repai r or replac ement. We will return the repai red product or replacem ent at WMH

Tool Group’s ex pense, but if it is determ ined there i s no defect, or that the def ect resulted f rom causes

not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and

returning t he product . This warranty gives you specif ic legal ri ghts; you m ay also hav e other ri ghts, whic h

vary from state t o state.

WMH Tool Group sells through distributor s only. Members of the WMH Tool Group reserve the right to

effect at any time, wit hout prior notice, alter ations to parts, fittings and accessory equi pment, which they

may deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty and Servic e ..............................................................................................................................2

Table of Contents....................................................................................................................................3

Warning...................................................................................................................................................4

Introduction.............................................................................................................................................. 5

Specifications..........................................................................................................................................5

Dimensions..............................................................................................................................................6

Prior to Ope r a t io n....................................................................................................................................7

Operation.................................................................................................................................................8

Precautions..........................................................................................................................................9

Allowable Limi ts for Load Chain and Hooks............................................................................................10

Load Chain.........................................................................................................................................10

Hooks (Top and Bottom ) ....................................................................................................................10

Replacement Parts................................................................................................................................11

JPNX-50 ............................................................................................................................................12

Parts List: JPNX-50............................................................................................................................13

JPNX-75/150/300...............................................................................................................................15

Parts List: JPNX-75............................................................................................................................16

Parts List: JPNX-150..........................................................................................................................18

Parts List: JPNX-300..........................................................................................................................20

Test Certificate ......................................................................................................................................23

3

Page 4

Warning

1. Read and understand t he entir e owners manual bef ore attempti ng operation. Fail ure to comply with

instructions and warnings may cause serious injury.

2. This lever hoist is designed and intended for use by properly trained and ex per ienced personnel only .

If you are not familiar with the proper and safe operation of a lever hoist, do not use until proper

training and knowledge have been obtained.

3. Do not use this lever hoist for other than its intended use. If used for other purposes, WMH Tool

Group discl aims any real or implied warranty and holds itself harm less from any injury that may result

from that use.

4. Do not use lever hoist to lift, support or transport people; or to lift or support loads over people.

5. Do not exceed the rated capacity of the hoist.

6. Do not use a “cheater pi pe” to extend the length of the handle.

7. Do not strike the handle with a hammer or any other object.

8. Do not use the chain as a sling. This may cause damage to the chain.

9. Always inspect t he lever hoist for damage prior to use. If hoi st is damaged, do not use until i t has

been repaired or replaced.

10. Do not use m ore than one lever hoi st to lift or move a load. If this is unavoi dable, each hoist must

have the same capacity as the load to be moved.

11. Never allow chain to “set” ov er sharp edges. All pull s or lifts must be made with strai ght chain that is

free of obstacles.

12. If the lev er is difficult to operate, then the l oad exceeds the capacit y of the hoist. Select a hoist of

larger capacit y.

13. Do not use a hoist if the chain is twisted, kinked or damaged.

14. Do not operate hoist unless load is centered between top and bottom hook s.

15. Always take time to study the job to be performed and choose the safest method. Do not place

yourself or ot her people in an unsafe position.

16. Leave all internal mai ntenance and inspections to a qualif ied WMH Tool Group repair stati on.

17. Replace chain wit h factor y r eplac em ent chain only. Do not use any other type of chain.

18. Never use the hoi st if either hook i s stretched, def ormed, or has a broken or mi ssing safety l atch.

Always replace the safety latch and/or the hook before placing the hoist back in servic e.

19. Be sure supporting structures and load-attaching devices used in conjunction with this lever hoist

provide an adequate safety factor to handle the rated load plus the weight of the equipment. If in

doubt, consult a qual ified structural engi neer .

20. Under stand and follow all pr oc edur es a s set forth in American National Standards ti tled “Performance

Standard for Manually Lever Operated Chain Hoists.” ANSI/ASME HST-3M. This standard is

available through the American Societ y of Mechanical Engineers, 345 East 47

th

St., NY, NY 10017.

21. K eep v isitors a safe distanc e from the work area. Keep children away.

- - SAVE THESE INSTRUCTIONS - -

4

Page 5

Introduction

This manual is provided by W MH Tool Group cov ering the safe oper ation and mai ntenance procedure s

for the JET Model JPNX Seri es Lever Hoists (also called “ Pullers”). This manual contai ns instructions on

safety precaut ions, general operati ng procedures, maintenanc e instructions, and part s breakdown. This

tool has been de signed and con structed t o provi de years of troubl e free operati on if used in accordance

with instruct ions set forth in this manual . If there are any questions or c omments, please contact ei ther

your local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web site:

www.wmhtoolgroup.com.

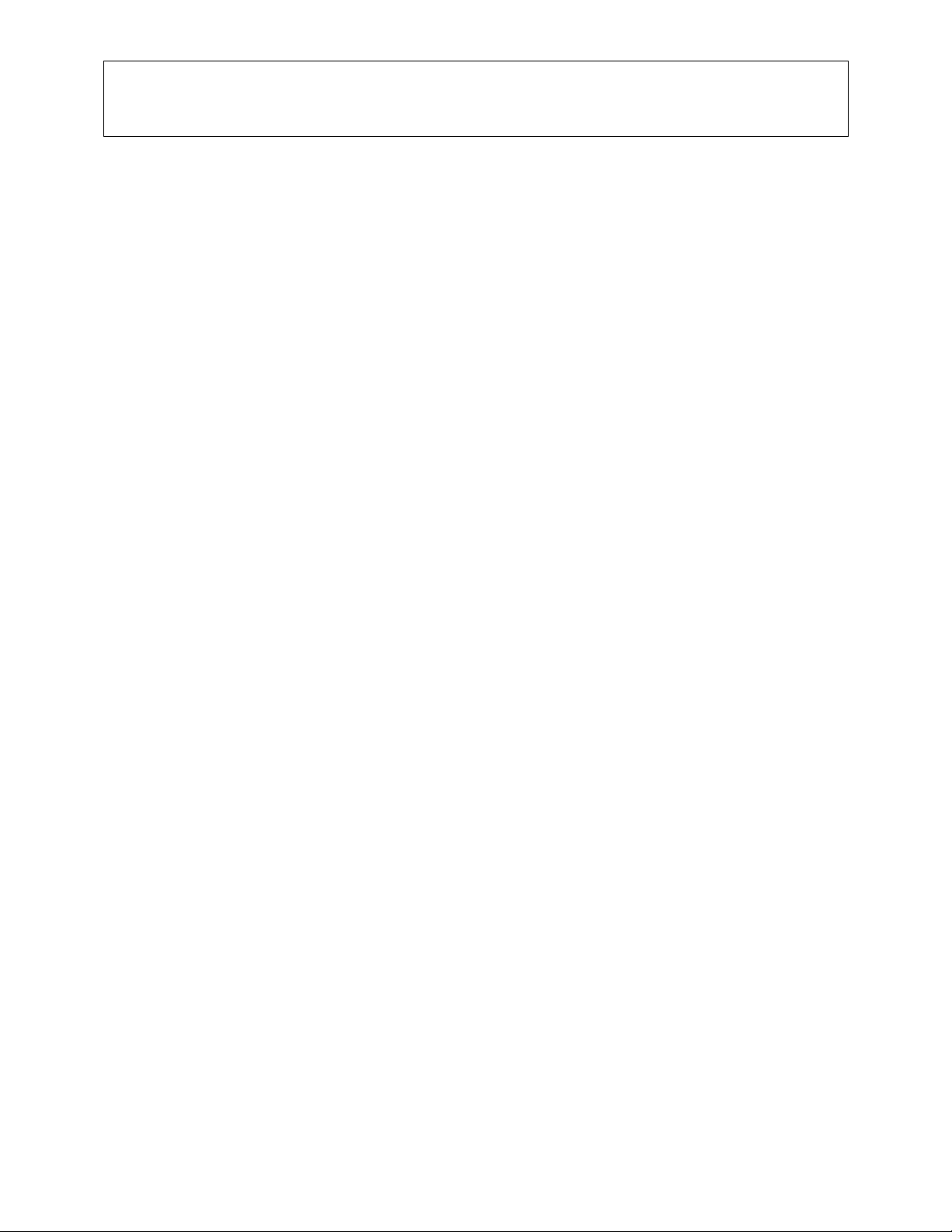

Specifications

Min.

Distance

Stock

Number*

225650 JPNX-50-5 1/2 5 12.00 1 5 3.77 82 10.03 13.4

225652 JPNX-50-15 1/2 15 12.00 1 5 3.77 82 10.03 17.2

225675 JPNX-75-5 3/4 5 12.40 1 6 0.8 40 10.03 18.9

225676 JPNX-75-15 3/4 15 12.40 1 6 0.8 40 10.03 24.2

225615 JPNX-150-5 1 1/2 5 14.37 1 8 0.86 48 14.17 31.7

225616 JPNX-150-15 1 1/2 15 14.37 1 8 0.86 48 14.17 41

225630 JPNX-300-5 3 5 19.29 1 10 0.68 84 14.17 52.4

225631 JPNX-300-15 3 15 19.29 1 10 0.68 84 14.17 67.2

Description

Rated

Capacity

(ton)

Standard

Lift

(ft.)

between

hooks

(in.)

Number

of falls

Load

Chain

Diameter

(mm)

Lift per

full turn

(in.)

* The above stock numb er s are repres ent at i v e; l oad chain is avai lable in ot h er lengths. Sp ec ify requir ed ch ain lengt h wh en or d ering.

Lbs Pull

to Lift

capacity

Lever

Length

(in.)

Shipping

Weight

(lbs)

The above specifications were current at the tim e this manual was publi shed, but because of our policy of

continuous im provement, WMH Tool Group reserv es the right to change specif ications at any tim e and

without pri or notic e, without incurring obligations.

5

Page 6

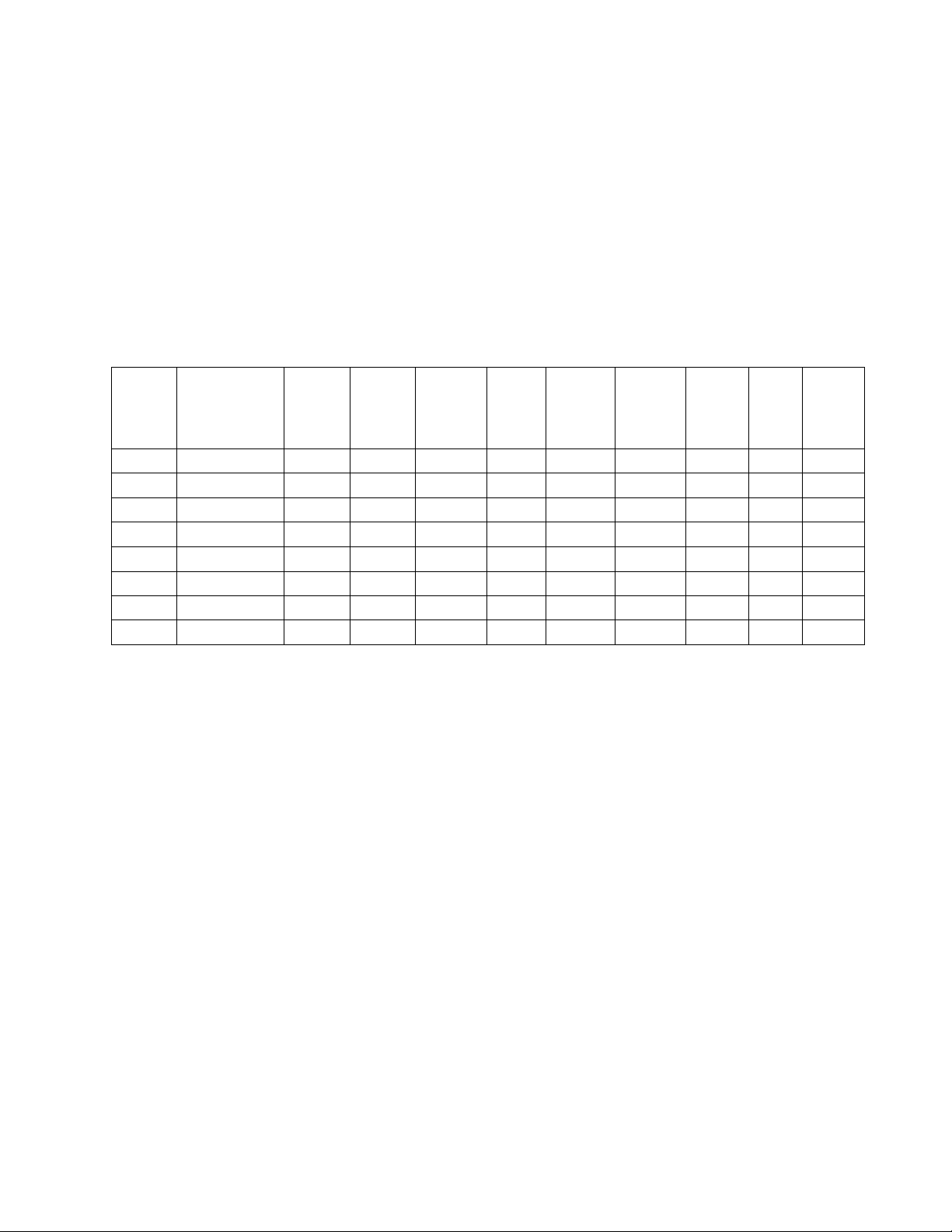

Dimensions

Stock

Number

225650 JPNX-50-5 4.8 2.55 2.79 2.55 7.91 4.32 1.18 3.14 0.59

225652 JPNX-50-15 4.8 2.55 2.79 2.55 7.91 4.32 1.18 3.14 0.59

225675 JPNX-75-5 4.96 2.75 3.3 2.67 8.74 5.86 2.44 3.42 0.62

225676 JPNX-75-15 4.96 2.75 3.3 2.67 8.74 5.86 2.44 3.42 0.62

225615 JPNX-150-5 5.74 3.5 3.62 3.03 10.15 7.08 2.95 4.13 0.82

225616 JPNX-150-15 5.74 3.5 3.62 3.03 10.15 7.08 2.95 4.13 0.82

225630 JPNX-300-5 7.59 4.13 4.33 4.01 12.48 7.49 3.66 4.33 1.1

225631 JPNX-300-15 7.59 4.13 4.33 4.01 12.48 7.49 3.66 4.33 1.1

Description A B C D E F G H I

Stock

Number

225650 JPNX-50-5 12 1.1 1.37 4.13 1.1 1.37 10.03 4.33 1.57

225652 JPNX-50-15 12 1.1 1.37 4.13 1.1 1.37 10.03 4.33 1.57

225675 JPNX-75-5 12.4 1.18 1.45 4.4 1.18 1.45 10.03 4.33 1.57

225676 JPNX-75-15 12.4 1.18 1.45 4.4 1.18 1.45 10.03 4.33 1.57

225615 JPNX-150-5 14.37 1.41 1.77 5.47 1.41 1.77 14.17 6.61 1.77

225616 JPNX-150-15 14.37 1.41 1.77 5.47 1.41 1.77 14.17 6.61 1.77

225630 JPNX-300-5 19.29 1.73 2.16 6.73 1.73 2.16 14.17 6.61 1.77

225631 JPNX-300-15 19.29 1.73 2.16 6.73 1.73 2.16 14.17 6.61 1.77

Description

J

(min.)

K L M N O P Q R

6

Page 7

Prior to Operation

1. Support for the hoist may be hook, clevis

pin, trolley, or beam clamp. Whatever

method of suspension is chosen, the

support component s must be rat ed equal to,

or greater than the capacity of the lever

hoist.

2. W ith the l ev er in the up posi ti on, c heck f or a

clicking sound when the ha ndle i s rotated in

a clockwise direction. If this sound is not

present, do not use the hoi st.

3. With the lever in the up position, check fr ee

play in handle rotation. Free play is

measured by the distance the handle travels

before resistance or gearing is felt. If free

play has reached 3/4 of a turn, the friction

discs are worn and shoul d be replaced by a

WMH Tool Group authori z ed r epair station.

4. If the lever hoist has not been used for an

extended period of time, check for proper

operation before putting into service.

5. The brake mechanism must be kept clean

and free from dirt, water, and oil. Never

allow oil to penetrate the braking

mechanism. Always keep your lever hoist

clean and store i n a clean, dr y l oc ation.

6. Periodi cally apply a light coat of 30W oil to

the chain. This will create easier operation

and prolong the lif e of t he c hain.

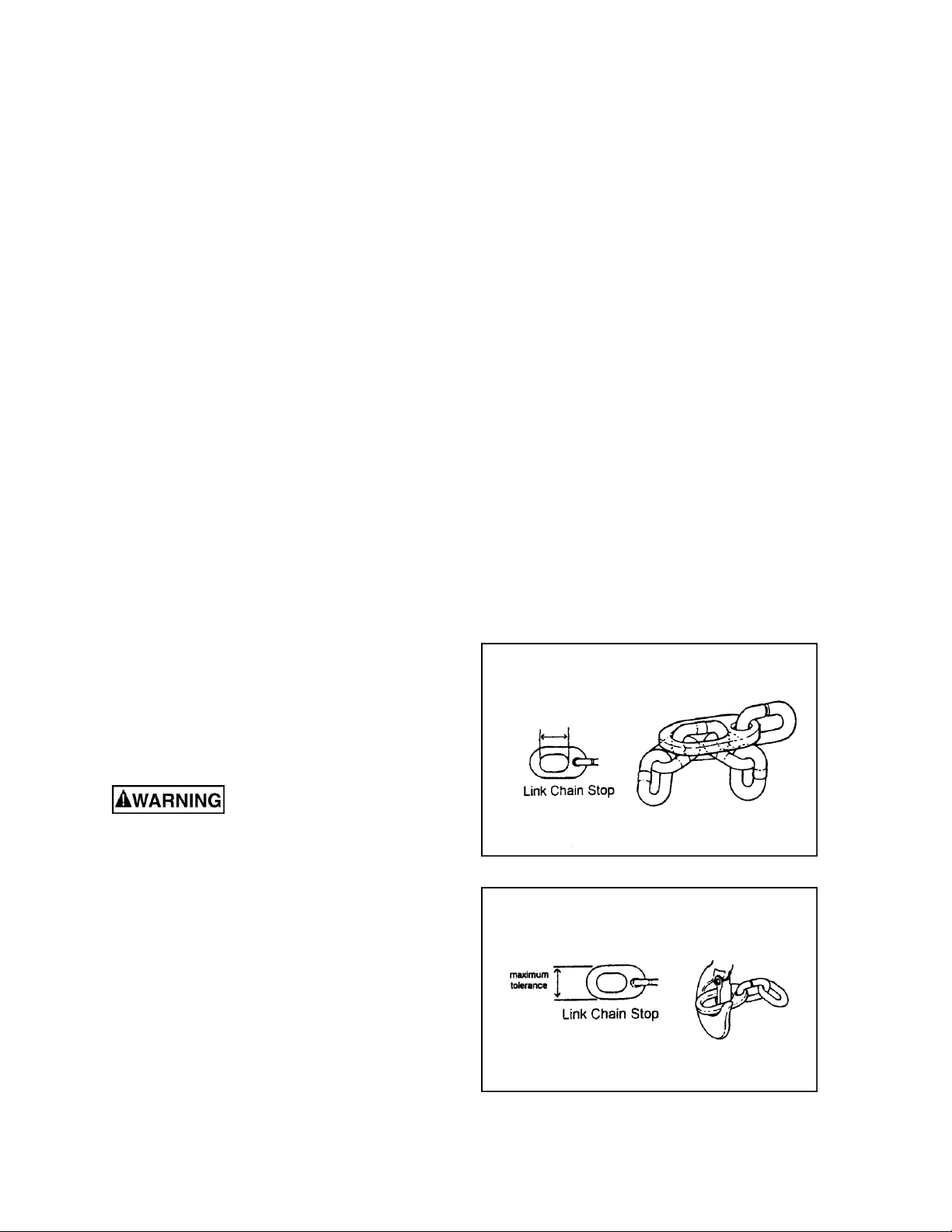

7. Check the chain for damage and elongation.

Use the chain gauge on the bottom end of

the chain as a guide. If the chain links do

not fit inside the chain gauge, as shown in

Figure 1, then the links have become

elongated and the chain must be replaced.

T h e lo ad c hai n su ppli ed wit h

your JET lever hoist is designed,

manufactured, and tested for proper fit and

durability. Over a period of time, the chain

may need to be replaced. For your own

safety, use factory replacement chain only.

Use of other th an factory replacement chain

may cause serious injury and/or damage to

the lever hoist.

8. The top and bottom hooks on your JET

lever hoist are designed to open to warn of

an overload. It i s im portant to c heck t op and

bottom hooks for proper opening. If the

safety latch no longer contacts the hook

opening, replace the hook. Another way to

check the opening is by using the chain

gauge. Position the gauge as in Figure 2.

Figure 1

Figure 2

7

Page 8

9. If the gauge does not contact both sides of

t

the hook, replace the hook. Never side

load the top or bottom hook; this

practice is dangerous and could lead to

serious injury.

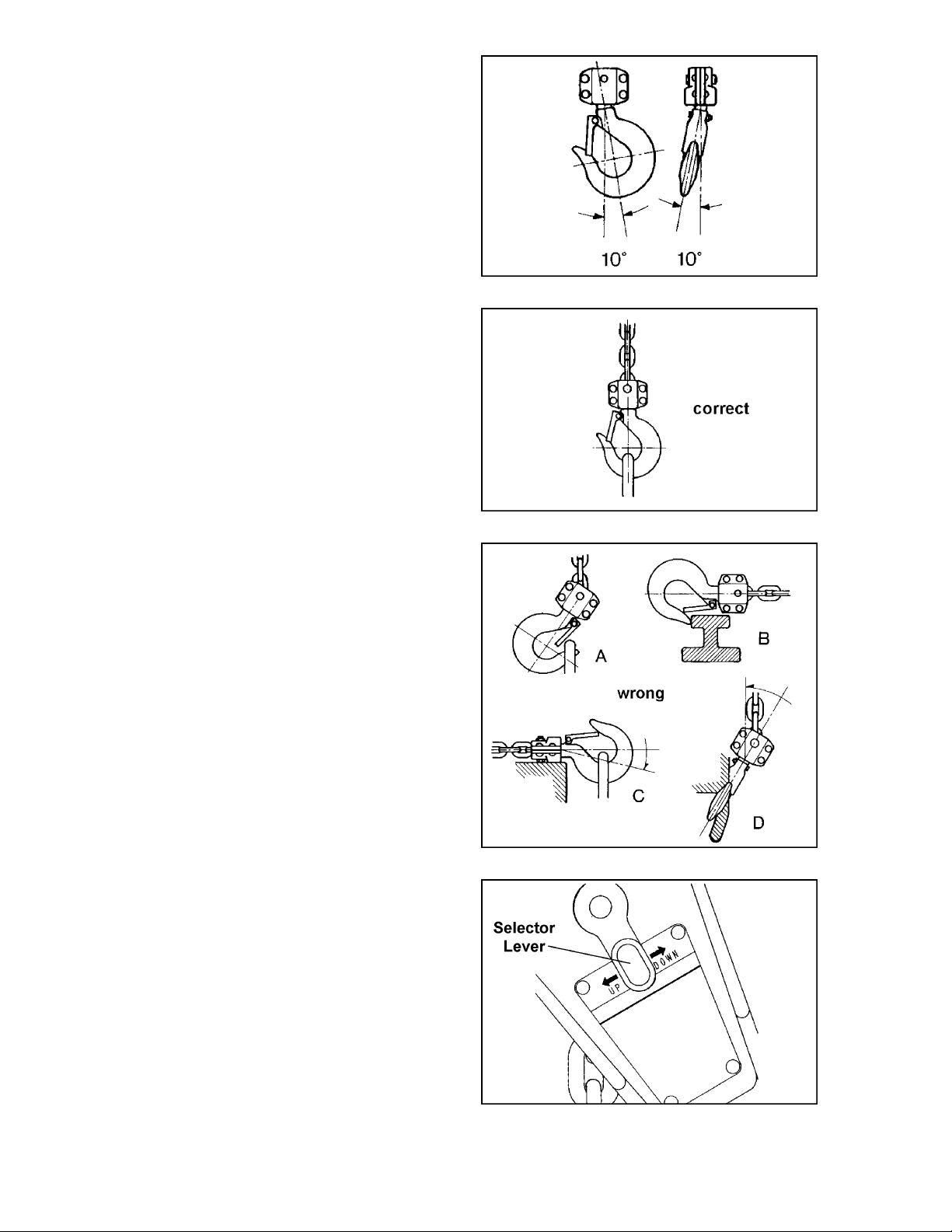

10. If the vertical angle at the neck of the bottom

or top hook reaches 10°, repl ace the hook

(see Figure 3).

Operation

1. Set the top hook securel y .

2. Center load on bottom hook correctly

(Figure 4). Incorrect loading is dangerous to

he operator, the lever hoist, and the load.

Never load the hook in front of the safety

latch (A, Figure 5). Never load the hook tip

(B, Figure 5). Never load the hook off the

centerline (C, Figure 5). Never load the

hook sideways (D, Figure 5).

3. Pl ace t he select or lever on the handl e i n the

center neutral posi tion (Figure 6) so that t he

chain free-wheels. Note: Chain will only

free-wheel when there i s no load. Take up

slack by pulli ng on loose or free end, or by

turning handwheel.

Figure 3

Figure 4

4. Move sel ector lever to the up positi on (see

Figure 6). Ratchet handle to raise or pull

load. Do not overload t he lev er hoist.

5. To release or lower load, turn selector lever

on handle to the down position ( see Figure

6) and ratchet the handle.

Figure 5

Figure 6

8

Page 9

Precautions

• During pulling operations, the operator

should stand near t he side of the top hook

on the opposite side of the lever. If the

hand should sli p off the l ever, the lever will

spring back away f rom the operator (Figure

7).

• During lif ting operati ons, do not stand under

the load.

• Do not use an extension on the lever (A,

Figure 8). Do not use a foot to apply

pressure to the l ev er (B, Fi gur e 8).

• Prev ent the chain from dragging over sharp

edges or corners. This will cause links to

weaken, bend, or break (Figure 9).

Figure 7

Figure 8

• W hen usi ng a wire rope sli ng, the lever hoist

must be applied al ong a strai ght line paral lel

to the surf ace on which it is resting (Figur e

10).

Figure 9

Figure 10

9

Page 10

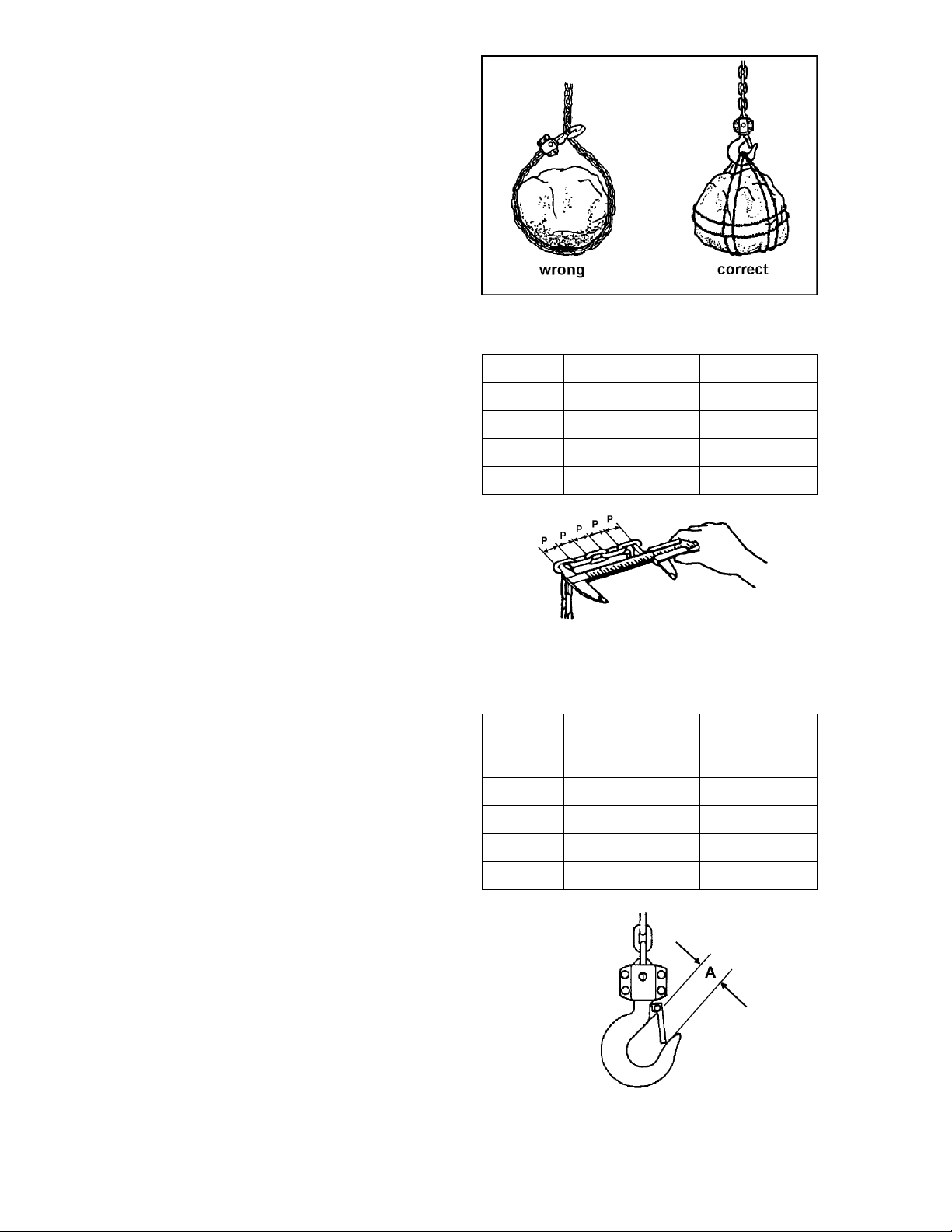

•

W

hen lifting loads, hook the load wit h sl ings.

Do not use the lever hoist chain as a

sling (Figure 11).

• Both ends of a sling or rope must be

completely on the inside of t he safety latch

before pulli ng or lifting the load. Do not put

one end on the i nside of the l atc h and leav e

the other end on the hook end out side the

latch.

Allowable Limits for Load

Chain and Hooks

Load Chain

Carefully inspect the entire load chain. As

illustrated in Figure 12, measure five

consecutiv e li nks with cali pers to f ind t he length,

Compare the resul ts with t he table i n Figure 12.

Check every three feet and especially where

excessiv e wear is indicated. Any load c hain that

shows noticeabl e deformation or heat influence

must be replaced wit h a new one.

Never extend load chain by welding a second

piece to the original.

Hooks (Top and Bottom)

Replace the hook when “A” i n Fi gure 13 is wider

than Limit A in the table. Never heat treat the

hook or attach anything to the hook by welding.

Figure 11

Capacity 5 Links Normal 5 L in ks Li mit

1/2 ton 2.95” 3.04”

3/4 ton 3.54” 3.65”

1-1/2 ton 4.72” 4.87”

3 ton 5.91” 6.08”

Figure 12

Standard

Capacity

1/2 ton 1.1” 1.21”

3/4 ton 1.18” 1.3”

1-1/2 ton 1.42” 1.56”

Throat Opening

(A)

Throat

Opening

Limit (A)

3 ton 1.73” 1.91”

Figure 13

10

Page 11

Replacement Parts

Replacement part s are li sted on the f ollowing page s. To order par ts or reac h our servi ce depar tment, call

1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve y ou quickly and

accurately.

11

Page 12

JPNX-50

12

Page 13

Parts List: JPNX-50

Note: Parts listed under eac h as sembly are parts that make up that assembly .

Index No. Part No. Description Size Qty

1...............JPNX50-1 ............... Cover........................................................... ......................................... 1

5...............JLP50-5..................Cover Side P late Ass e mbly.......................... .........................................1

................. ...............................Cover Side Plate.......................................... .........................................1

................. ...............................Stay Bolt...................................................... .........................................3

................. ...............................Race............................................................ .........................................1

7...............JLP50-7..................Load Shaft................................................... .........................................1

9...............JLP50-9..................Guide Block................................................. .........................................2

10.............JLP50-10 ................ Stripper........................................................ .........................................1

13.............JLP75-13 ................ Pawl Spring (1/2, 3/4 Ton) ........................... .........................................2

14.............JLP50-14 ................ Pawl ............................................................ .........................................2

15.............JLP75-15 ................ Snap Ring (1/2, 3/4 Ton) ..............................8 mm ................................2

16.............JLP50-16 ................ Lever Side Plate Assembly.......................... .........................................1

................. ...............................Lever Side Plate.......................................... .........................................1

................. ...............................Race............................................................ .........................................1

................. ...............................Pawl Pin...................................................... .........................................2

17.............JLP50-17 ................ Disc Hub...................................................... .........................................1

18.............JLP75-18 ................ Spring (1/2, 3/4, 1-1/2 Ton).......................... .........................................1

19.............JLP50-19 ................ Friction Disc................................................. .........................................2

20.............JLP50-20 ................ Ratchet Disc................................................ .........................................1

22.............JPNX50-22..............Brake Cover Assembly ................................ .........................................1

................. ...............................Brake Cover ................................................ .........................................1

................. ...............................Handle Case................................................ .........................................1

................. ...............................Nut .............................................................. .........................................2

................. ...............................Bushing....................................................... .........................................1

23.............JLP50-23 ................ Change Over Gear ...................................... .........................................1

24.............JPNX75-24..............Lever Handle Assembly (1/2, 3/ 4 Ton) ......... .........................................1

................. ...............................Lever Handle............................................... .........................................1

................. ...............................Selector Lever............................................. ......................................... 1

................. ...............................Change Over Shaft...................................... .........................................1

................. ...............................Cover........................................................... .........................................1

................. ...............................Rivet............................................................3 x 12 mm.........................1

................. ...............................Bolt.............................................................. .........................................2

................. ...............................Spring Seat.................................................. .........................................1

25.............JLP75-25 ................ Change Over Pawl (1/2, 3/4 Ton)................. .........................................1

26.............JLP75-26 ................ Spring Shaft (1/2, 3/4 Ton)........................... .........................................1

27.............JLP75-27 ................ Spring (1/2, 3/4 Ton).................................... .........................................1

28.............JPNX75-28..............Handwheel (1/2, 3/ 4 Ton) ............................. .........................................1

29.............JPNX50-29..............Warning Label............................................. ......................................... 1

29A...........JPNX50-29A........... ID Label....................................................... .........................................1

30.............JLP75-30 ................ Chain Stop (1/2, 3/4 Ton)............................. .........................................1

31.............JLP75-31 ................ Hex Nut (1/2, 3/4 Ton).................................M8....................................6

32.............JLP75-32 ................ Lock Washer (1/2, 3/4 Ton)..........................M8....................................6

32A...........JLP75-32A.............. Fl at Washer (1/2, 3/4 Ton)...........................M8 ....................................6

33.............JLP75-33 ................ Hex Nut (1/2, 3/4 Ton).................................M6....................................2

34.............JLP75-34 ................ Lock Washer (1/2, 3/4 Ton)..........................M8....................................2

34A...........JLP75-34A.............. Fl at Washer (1/2, 3/4 Ton)...........................M6 ....................................4

35.............JLP75-35 ................ Castl e Nut (1/2, 3/4 Ton)..............................M10..................................1

36.............JLP75-3 6................ Split Pin (1/2, 3/4 Ton).................................2.5 x 20 mm......................1

37.............JLP75-3 7................ Rivet (1/2 to 6 To n )......................................2.5 x 6 mm........................4

38.............JPNX50-38..............Rivet (1/2 Ton).............................................2 x 5 mm...........................4

40.............JLP50-40 ................ Top Hook Assembly..................................... .........................................1

................. ...............................Top Hook..................................................... .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................3 x 16 mm.........................1

13

Page 14

Index No. Part No. Description Size Qty

................. ...............................Top Hook Block........................................... .........................................2

................. ...............................Rivet............................................................5 x 20 mm.........................2

41.............JLP50-41 ................ Top Hook Shaft............................................ ......................................... 1

43.............JLP50-43 ................ Bottom Hook Assembly................................ .........................................1

................. ...............................Bottom Hook................................................ .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................3 x 16 mm.........................1

................. ...............................Bottom Hook Block...................................... .........................................2

................. ...............................Rivet............................................................5 x 20 mm.........................4

43A...........JLP50-43A.............. Bottom Hook Shaft....................................... .................................. .......1

43C ..........JLP50-43C.............. Castle Nut....................................................M6....................................1

43D ..........JLP50-43 D.............. Spl it Pin.......................................................1.6 x 14 mm......................1

50.............JLP75-50 ................ Hex Cap Screw (1/2, 3/4 Ton)......................M6 x 12.............................2

51.............JLP75-51 ................ Lock Washer (1/2, 3/4 Ton)..........................M6....................................2

52.............JLP50-52 ................ Special Pin.................................................. ......................................... 1

100...........JLP50-100 ..............Safety Latch Kit ........................................... .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................3 x 16 mm.........................1

104...........121006.................... Load Chai n* ( 1/2 Ton)..................................Ø 5 mm.............................1

* Specify required chain length when ordering.

Note: Top and bottom hooks are sold as an assem bly only.

14

Page 15

JPNX-75/150/300

15

Page 16

Parts List: JPNX-75

Note: Parts listed under eac h as sembly are parts that make up that assembly.

Index No. Part No. Description Size Qty

1...............JPNX75-1 ............... Gear Case Assembly................................... .........................................1

................. ...............................Gear Case................................................... .........................................1

................. ...............................Bushing....................................................... .........................................1

2...............JLP75-2..................Spur Gear Assembly .................................... .........................................2

................. ...............................Spur Gear.................................................... .........................................2

................. ...............................Pinion Gear ................................................. .........................................2

3...............JLP75-3..................Driving Shaft................................................ .........................................1

4...............JLP75-4..................Load Gear ................................................... .........................................1

5...............JLP75-5..................Gear Side Plate Assembly........................... .........................................1

................. ...............................Gear Side Plate........................................... .........................................1

................. ...............................Gear Side Plate........................................... .........................................1

................. ...............................Stay Bolt...................................................... .........................................3

................. ...............................Bushing....................................................... .........................................2

................. ...............................Race “A”...................................................... .........................................1

6...............JLP75-6..................Load Sheave ............................................... .........................................1

8...............JLP75-8..................Guide Block................................................. .........................................1

9...............JLP75-9..................Guide Roll er ................................................ ......................................... 1

10.............JLP75-10 ................ Stripper........................................................ .........................................1

11.............JLP75-11 ................ Roller Kit (34 Rollers)...................................3 x 5 mm...........................1

12.............JLP75-12 ................ Bearing Race............................................... .........................................1

13.............JLP75-13 ................ Pawl Spring (1/2, 3/4 Ton) ........................... .........................................2

14.............JLP75-14 ................ Pawl ............................................................ .........................................2

15.............JLP75-15 ................ Snap Ring (1/2, 3/4 Ton) ..............................8mm.................................2

16.............JLP75-16 ................ Lever Side Plate Assembly.......................... .........................................1

................. ...............................Lever Side Plate.......................................... .........................................1

................. ...............................Race “B”...................................................... .........................................1

................. ...............................Pawl Pin...................................................... .........................................2

17.............JLP75-17 ................ Disc Hub...................................................... .........................................1

18.............JLP75-18 ................ Spring (1/2, 3/4, 1-1/2 Ton).......................... .........................................1

19.............JLP75-19 ................ Friction Disc................................................. .........................................2

20.............JLP75-20 ................ Ratchet Disc................................................ .........................................1

21.............JLP75-21 ................ Feed Gear................................................... .........................................1

22.............JPNX75-22..............Brake Cover Assembly ................................ .........................................1

................. ...............................Brake Cover ................................................ .........................................1

................. ...............................Handle Case................................................ .........................................1

................. ...............................Nut .............................................................. .........................................2

................. ...............................Bushing....................................................... .........................................1

23.............JLP75-23 ................ Change Over Gear ...................................... .........................................1

24.............JPNX75-24..............Lever Handle Assembly (1/2, 3/ 4 Ton) ......... .........................................1

................. ...............................Lever Handle............................................... .........................................1

................. ...............................Selector Lever............................................. ......................................... 1

................. ...............................Change Over Shaft...................................... .........................................1

................. ...............................Cover........................................................... .........................................1

................. ...............................Rivet............................................................3 x 12 mm.........................1

................. ...............................Bolt.............................................................. .........................................2

................. ...............................Spring Seat.................................................. .........................................1

25.............JLP75-25 ................ Change Over Pawl (1/2, 3/4 Ton)................. .........................................1

26.............JLP75-26 ................ Spring Shaft (1/2, 3/4 Ton)........................... .........................................1

27.............JLP75-27 ................ Spring (1/2, 3/4 Ton).................................... .........................................1

28.............JPNX75-28..............Handwheel (1/2, 3/ 4 Ton) ............................. .........................................1

29.............JPNX75-29..............Warning Label............................................. ......................................... 1

29A...........JPNX75-29A........... ID Label....................................................... .........................................1

30.............JLP75-30 ................ Chain Stop (1/2, 3/4 Ton)............................. .........................................1

31.............JLP75-31 ................ Hex Nut (1/2, 3/4 Ton).................................M8....................................6

32.............JLP75-32 ................ Lock Washer (1/2, 3/4 Ton)..........................M8....................................6

32A...........JLP75-32A.............. Fl at Washer (1/2, 3/4 Ton)...........................M8 ....................................6

16

Page 17

Index No. Part No. Description Size Qty

33.............JLP75-33 ................ Hex Nut (1/2, 3/4 Ton).................................M6....................................2

34.............JLP75-34 ................ Lock Washer (1/2, 3/4 Ton)..........................M6....................................2

34A...........JLP75-34A.............. Fl at Washer (1/2, 3/4 Ton)...........................M6 ....................................4

35.............JLP75-35 ................ Castl e Nut (1/2, 3/4 Ton)..............................M10..................................1

36.............JLP75-3 6................ Split Pin (1/2, 3/4 Ton).................................2.5 x 20 mm......................1

37.............JLP75-3 7................ Rivet (1/2 to 6 To n )......................................2.5 x 6 mm........................6

40.............JLP75-40 ................ Top Hook Assembly..................................... .........................................1

................. ...............................Top Hook..................................................... .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................3 x 16 mm.........................1

................. ...............................Top Hook Block........................................... .........................................2

................. ...............................Rivet............................................................5 x 20 mm.........................2

41.............JLP75-41 ................ Top Hook Shaft............................................ ......................................... 1

43.............JLP75-43 ................ Bottom Hook Assembly................................ .........................................1

................. ...............................Bottom Hook................................................ .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................3 x 16 mm.........................1

................. ...............................Bottom Hook Block...................................... .........................................2

................. ...............................Rivet............................................................5 x 20 mm.........................4

43A...........JLP75-43A.............. Bottom Hook Shaft....................................... .................................. .......1

43C ..........JLP75-43C.............. Castle Nut....................................................M6....................................1

43D ..........JLP75-43 D.............. Spl it Pin.......................................................1.6 x 14 mm......................1

50.............JLP75-5 0................ Hex Cap Screw............................................M6 x 12.............................2

51.............JLP75-5 1................ Lock Washe r ................................................M6....................................2

58.............JLP75-58 ................ Snap Ring....................................................28 mm ..............................1

100...........JLP75-100 ..............Safety Latch Kit ........................................... .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................3 x 16 mm.........................1

104...........121007.................... Load Chai n* ( 3/4 Ton)..................................Ø 6 mm.............................1

* Specify required chain length when ordering.

Note: Top and bottom hooks are sold as an assem bly only.

17

Page 18

Parts List: JPNX-150

Note: Parts listed under eac h as sembly are parts that make up that assembly.

Index No. Part No. Description Size Qty

1...............JPNX150-1..............Gear Case Assembly................................... .........................................1

................. ...............................Gear Case................................................... .........................................1

................. ...............................Bushing....................................................... .........................................2

2...............JLP150-2 ................ Spur Gear Assembly.................................... .........................................2

................. ...............................Spur Gear.................................................... .........................................2

................. ...............................Pinion Gear ................................................. .........................................2

3...............JLP150-3 ................ Driving Shaft................................................ .........................................1

4...............JLP150-4 ................ Load Gear ................................................... .........................................1

5...............JLP150-5 ................ Gear Side Plate Assembly........................... .........................................1

................. ...............................Gear Side Plate........................................... .........................................1

................. ...............................Stay Bolt...................................................... .........................................3

................. ...............................Bushing....................................................... .........................................2

................. ...............................Race “A”...................................................... .........................................1

6...............JLP150-6 ................ Load Sheave ............................................... .........................................1

8...............JLP150-8 ................ Guide Block................................................. .........................................1

9...............JLP150-9 ................ Guide Roller................................................ .........................................1

10.............JLP150-10 ..............Stripper........................................................ .........................................1

11.............JLP150-11 ..............Roller Kit (37 Rollers)...................................3 x 6 mm........................... 1

12.............JLP150-12 ..............Bearing Race............................................... .........................................1

13.............JLP150-13 ..............Pawl Spring (1-1/2, 3, 6 Ton) ....................... .........................................2

14.............JLP150-14 ..............Pawl (1-1/2, 3, 6 Ton) .................................. .........................................2

15.............JLP150-15 .............. Snap Ring (1-1/2, 3, 6 Ton)......................... .........................................2

16.............JLP150-16 ..............Lever Side Plate Assembly.......................... .........................................1

................. ...............................Lever Side Plate.......................................... .........................................1

................. ...............................Race “B”...................................................... .........................................1

................. ...............................Pawl Pin...................................................... .........................................2

17.............JLP150-17 ..............Disc Hub...................................................... .........................................1

18.............JLP75-18 ................ Spring (1/2, 3/4, 1-1/2 Ton).......................... .........................................1

19.............JLP150-19 ..............Friction Disc................................................. .........................................2

20.............JLP150-20 ..............Ratchet Disc................................................ .........................................1

21.............JLP150-21 ..............Feed Gear................................................... .........................................1

22.............JPNX150-22............ Brake Cover Assembly................................ .........................................1

................. ...............................Brake Cover ................................................ .........................................1

................. ...............................Handle Case................................................ .........................................1

................. ...............................Nut .............................................................. .........................................2

................. ...............................Bushing....................................................... .........................................1

23.............JLP150-23 ..............Change Over Gear (1-1/2, 3, 6 Ton)............. .........................................1

24.............JPNX150-24............ Lever Handle Assembly (1-1/2, 3 Ton)......... .........................................1

................. ...............................Lever Handle............................................... .........................................1

................. ...............................Selector Lever............................................. ......................................... 1

................. ...............................Change Over Shaft...................................... .........................................1

................. ...............................Cover........................................................... .........................................1

................. ...............................Rivet............................................................3 x 12 mm.........................1

................. ...............................Screw.......................................................... .........................................2

................. ...............................Spring Seat.................................................. .........................................1

25.............JLP150-25 ..............Change Over Pawl (1-1/ 2, 3, 6 Ton)............. .........................................1

26.............JLP150-26 ..............Spring Shaft (1-1/2, 3, 6 Ton)....................... .........................................1

27.............JLP150-27 ..............Spring (1-1/2, 3, 6 Ton)................................ .........................................1

28.............JPNX150-28............ Handwheel (1-1/2, 3 Ton) ............................ .........................................1

29.............JPNX150-29............ Warning Label............................................. .........................................1

29A...........JPNX150-29A ......... ID Label....................................................... .........................................1

30.............JLP150-30 ..............Chain Stop................................................... ......................................... 1

31.............JLP150-31 ..............Hex Nut.......................................................M10..................................6

32.............JLP150-32 ..............Lock Wash e r ................................................M10..................................6

32A...........JLP150-32A ............ Fla t Washer.................................................M1 0..................................6

33.............JLP150-33 ..............Hex Nut (1-1/2, 3, 6 Ton).............................M8 ....................................2

18

Page 19

Index No. Part No. Description Size Qty

34.............JLP150-34 ..............Lock Washer (1-1/2, 3, 6 Ton)......................M8....................................2

34A...........JLP150-34A ............ Flat Washer (1-1/2, 3, 6 Ton).......................M8....................................4

35.............JLP150-35 ..............Castle Nut (1-1/2, 3, 6 Ton)..........................M12..................................1

36.............JLP150-36 ..............Split Pin (1-1/2, 3, 6 Ton).............................2.5 x 25 mm......................1

37.............JLP75-3 7................ Rivet (1/2 to 6 To n )......................................2.5 x 6 mm........................6

40.............JLP150-40 ..............Top Hook Assembly..................................... .........................................1

................. ...............................Top Hook..................................................... .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................4 x 18 mm.........................1

................. ...............................Top Hook Block........................................... .........................................2

................. ...............................Rivet............................................................6 x 24 mm.........................2

41.............JLP150-41 ..............Top Hook Shaft............................................ .........................................1

43.............JLP150-43 ..............Bottom Hook Assembly................................ .........................................1

................. ...............................Bottom Hook................................................ .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................4 x 18 mm.........................1

................. ...............................Bottom Hook Block...................................... .........................................2

................. ...............................Rivet............................................................6 x 24 mm.........................4

43A...........JLP150-43A ............ Bottom Hook Shaft....................................... .........................................1

43C ..........JLP150-43C............Castle Nut....................................................M8....................................1

43D ..........JLP150-43D............Split Pin.......................................................2 x 16 mm.........................1

50.............JLP150-50 ..............Hex Cap Screw (1-1/2, 3, 6 Ton)..................M8 x 16.............................2

51.............JLP150-51 ..............Lock Washer (1-1/2, 3, 6 Ton)......................M8....................................2

58.............JLP150-58 ..............Snap Ring....................................................34 mm..............................1

100...........JLP150-100............. Safety Latch Kit........................................... .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................4 x 18 mm.........................1

104...........121002.................... Load Chai n* ( 1- 1/2 Ton)...............................Ø 8 mm.............................1

* Specify required chain length when ordering.

Note: Top and bottom hooks are sold as an assem bly only.

19

Page 20

Parts List: JPNX-300

Note: Parts listed under eac h as sembly are parts that make up that assembly.

Index No. Part No. Description Size Qty

1...............JPNX300-1..............Gear Case Assembly (3 Ton)....................... .........................................1

................. ...............................Gear Case................................................... .........................................1

................. ...............................Bushing....................................................... .........................................2

2...............JLP300-2 ................ Spur Gear Assembly (3, 6 Ton).................... .........................................2

................. ...............................Spur Gear.................................................... .........................................2

................. ...............................Pinion Gear ................................................. .........................................2

3...............JLP300-3 ................ Driving Shaft (3, 6 Ton)................................ .........................................1

4...............JLP300-4 ................ Load Gear (3, 6 Ton) ................................... .........................................1

5...............JLP300-5 ................ Gear Side Plate Assembly (3, 6 Ton)........... .........................................1

................. ...............................Gear Side Plate........................................... .........................................1

................. ...............................Stay Bolt...................................................... .........................................3

................. ...............................Bushing....................................................... .........................................2

................. ...............................Race “A”...................................................... .........................................1

6...............JLP300-6 ................ Load Sheave (3, 6 Ton) ............................... .........................................1

8...............JLP300-8 ................ Guide Block (3, 6 Ton)................................. .........................................1

9...............JLP300-9 ................ Guide Roller (3, 6 Ton)................................ .........................................1

10.............JLP300-10 ..............Stripper (3, 6 Ton)........................................ .........................................1

11.............JLP300-11 ..............Roller Kit (3, 6 Ton) (24 Rollers)...................5 x 6 mm...........................1

12.............JLP300-12 ..............Bearing Race (3, 6 Ton)............................... .........................................1

13.............JLP150-13 ..............Pawl Spring (1-1/2, 3, 6 Ton) ....................... .........................................2

14.............JLP150-14 ..............Pawl (1-1/2, 3, 6 Ton) .................................. .........................................2

15.............JLP150-15 ..............Snap Ring (1-1/2, 3, 6 Ton).......................... .........................................2

16.............JLP300-16 ..............Lever Side Plate Assembly (3, 6 Ton).......... ......................................... 1

................. ...............................Lever Side Plate.......................................... .........................................1

................. ...............................Race “B”...................................................... .........................................1

................. ...............................Pawl Pin...................................................... .........................................2

17.............JLP300-17 ..............Disc Hub (3, 6 Ton)...................................... .........................................1

18.............JLP300-18 ..............Spring (3, 6 Ton).......................................... .........................................1

19.............JLP300-19 ..............Friction Disc (3, 6 Ton)................................. .........................................2

20.............JLP300-20 ..............Ratchet Disc (3, 6 Ton)................................ .........................................1

21.............JLP300-21 ..............Feed Gear (3, 6 Ton)................................... .........................................1

22.............JPNX300-22............ Brake Cover Assembly (3 Ton).................... .........................................1

................. ...............................Brake Cover ................................................ .........................................1

................. ...............................Handle Case................................................ .........................................1

................. ...............................Nut .............................................................. .........................................2

................. ...............................Bushing....................................................... .........................................1

23.............JLP150-23 ..............Change Over Gear (1-1/2, 3, 6 Ton)............. .........................................1

24.............JPNX150-24............ Lever Handle Assembly (1-1/2, 3 Ton)......... .........................................1

................. ...............................Lever Handle............................................... .........................................1

................. ...............................Selector Lever............................................. ......................................... 1

................. ...............................Change Over Shaft...................................... .........................................1

................. ...............................Cover........................................................... .........................................1

................. ...............................Rivet............................................................3 x 12 mm.........................1

................. ...............................Bolt.............................................................. .........................................2

................. ...............................Spring Seat.................................................. .........................................1

25.............JLP150-25 ..............Change Over Pawl (1-1/ 2, 3, 6 Ton)............. .........................................1

26.............JLP150-26 ..............Spring Shaft (1-1/2, 3, 6 Ton)....................... .........................................1

27.............JLP150-27 ..............Spring (1-1/2, 3, 6 Ton)................................ .........................................1

28.............JPNX150-28............ Handwheel (1-1/2, 3 Ton) ............................ .........................................1

29.............JPNX300-29............ Warning Label............................................. .........................................1

29A...........JPNX300-29A ......... ID Label....................................................... .........................................1

30.............JLP300-30 ..............Chain Stop (3, 6 Ton)................................... .........................................1

31.............JLP300-31 ..............Hex Nut (3, 6 Ton).......................................M12..................................6

32.............JLP300-32 ..............Lock Washer (3, 6 Ton)................................M12 ..................................6

32A...........JLP300-32A ............ Flat Washer (3, 6 Ton) .................................M12..................................6

33.............JLP150-33 ..............Hex Nut (1-1/2, 3, 6 Ton).............................M8 ....................................2

20

Page 21

Index No. Part No. Description Size Qty

34.............JLP150-34 ..............Lock Washer (1-1/2, 3, 6 Ton)......................M8....................................2

34A...........JLP150-34A ............ Flat Washer (1-1/2, 3, 6 Ton).......................M8....................................4

35.............JLP150-35 ..............Castle Nut (1-1/2, 3, 6 Ton)..........................M12..................................1

36.............JLP150-36 ..............Split Pin (1-1/2, 3, 6 Ton).............................2.5 x 25 mm......................1

37.............JLP75-3 7................ Rivet (1/2 to 6 To n )......................................2.5 x 6 mm........................6

40.............JLP300-40 ..............Top Hook Assembly..................................... .........................................1

................. ...............................Top Hook..................................................... .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................4 x 22 mm.........................1

................. ...............................Top Hook Block........................................... .........................................2

................. ...............................Rivet............................................................8 x 28 mm.........................2

41.............JLP300-41 ..............Top Hook Shaft (3, 6 Ton)............................ .........................................1

43.............JLP300-43 ..............Bottom Hook Assembly................................ .........................................1

................. ...............................Bottom Hook................................................ .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................4 x 22 mm.........................1

................. ...............................Bottom Hook Block...................................... .........................................2

................. ...............................Rivet............................................................8 x 28 mm.........................4

43A...........JLP300-43A ............ Bottom Hook Shaft....................................... .........................................1

43C ..........JLP300-43C............Castle Nut....................................................M12..................................1

43D ..........JLP300-43D............Split Pin.......................................................2.5 x 2.5 mm.....................1

50.............JLP150-50 ..............Hex Cap Screw (1-1/2, 3, 6 Ton)..................M8 x 16.............................2

51.............JLP150-51 ..............Lock Washer (1-1/2, 3, 6 Ton)......................M8....................................2

58.............JLP300-58 ..............Snap Ring (3, 6 Ton)....................................45 mm..............................1

100...........JLP300-100............. Safety Latch Kit........................................... .........................................1

................. ...............................Safety Latch ................................................ .........................................1

................. ...............................Double Spri ng.............................................. .........................................1

................. ...............................Rivet............................................................4 x 22 mm.........................1

104...........121008.................... Load Chai n* ( 3 Ton).....................................Ø 10 mm...........................1

* Specify required chain length when ordering.

Note: Top and bottom hooks are sold as an assem bly only.

21

Page 22

NOTES

22

Page 23

Test Certificate

Model No. JPNX-

Serial No.

Rated Load Ton

Test Load Ton

Lift (ft.)

Judgment Passed

Inspected by

Date

23

Page 24

WMH Tool Gr ou p

2420 Vantage Drive

Elgin, Illinois 60123

Phone: 800-274-6848

www.wmhtoolgroup.com

24

Loading...

Loading...