Operating Instructions and Parts Manual

Hydraulic Pipe Bender

Models: JHPB-20 (2-inch), JHPB-30 (3-inch)

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-331900

Ph.: 800-274-6848 Revision C1 11/2018

www.jettools.com Copyright © 2015 JET

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

Accessories carry a limited warranty of one year from the date of receipt.

Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these machines in the processing of metal, plastics, or other materials may void the warranty. The exceptions

are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Table of contents

Section Page

Warranty and Service ............................................................................................................................................ 2

Table of contents ................................................................................................................................................... 3

Safety warnings ..................................................................................................................................................... 4

Specifications ........................................................................................................................................................ 5

Unpacking ............................................................................................................................................................. 6

Contents of Shipping Container ........................................................................................................................ 6

Contents of Hardware Bag ................................................................................................................................ 6

Assembly ............................................................................................................................................................... 7

Operation .............................................................................................................................................................. 8

Securing the Pipe Bender ................................................................................................................................. 8

Direction of the Pipe Bender ............................................................................................................................. 8

When Using for the First Time ........................................................................................................................... 8

To Bend a Pipe .................................................................................................................................................. 8

Lubrication ............................................................................................................................................................. 8

Troubleshooting the JHPB Pipe Benders .............................................................................................................. 9

Replacement Parts ................................................................................................................................................ 9

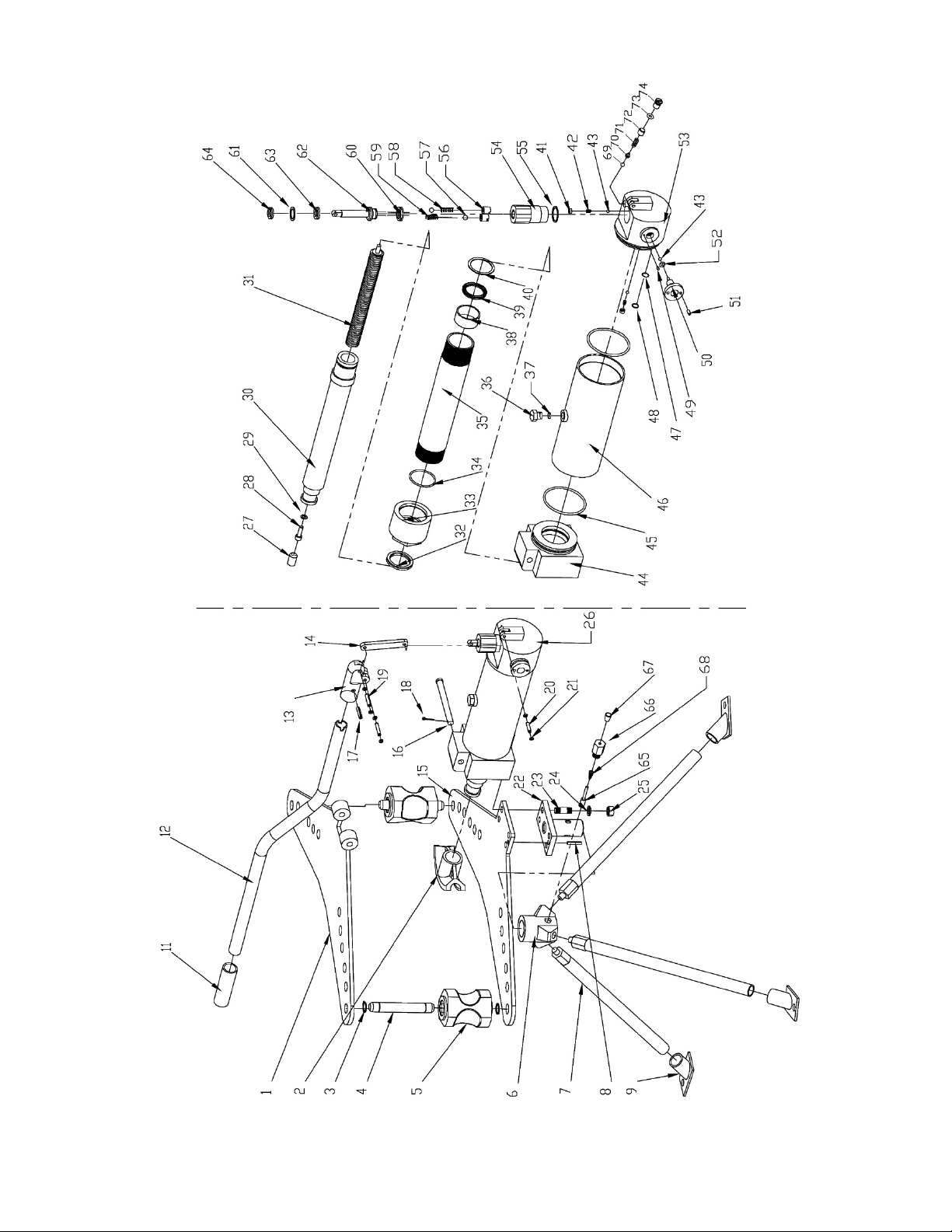

Parts Breakdown – JHPB-20 and JHPB-30 Pipe Benders .............................................................................. 10

Parts List – JHPB-20 and JHPB-30 Pipe Benders .......................................................................................... 11

3

Safety warnings

g

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with all of

these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This pipe bender is designed and intended for use by properly trained and experienced personnel only. If

you are not familiar with the proper and safe operation of a pipe bender, do not use until proper training

and knowledge have been obtained.

5. Do not use this machine for other than its intended use. If used for other purposes, JET disclaims any real

or implied warranty and holds itself harmless from any injury that may result from that use.

6. Always wear approved safety glasses/face shields while using this machine. Everyday eyeglasses only

have impact resistant lenses; they are not safety glasses.

7. Before operating this pipe bender, remove tie, rings, watches and other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid floor strips are

recommended. Do not wear gloves.

8. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

9. Check damaged parts. Before further use of the machine, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting and any other conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or

replaced.

10. Provide for adequate space surrounding work area and non-glare, overhead lighting.

11. Keep the floor around the machine clean and free of scrap material, oil and grease.

12. Keep visitors a safe distance from the work area. Keep children away.

13. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

14. Maintain a balanced stance and do not overreach or use excessive force to perform any machine

operation.

15. Use the right tool. Do not force a tool or attachment to do a job for which it was not designed. The right tool

will do the job better and safer.

16. Use recommended accessories; improper accessories may be hazardous.

17. Maintain tools with care and clean for the best and safest performance. Follow instructions for lubricating

and changing accessories.

WARNING: This product can expose you to chemicals including lead and cadmium which are known to

the State of California to cause cancer and birth defects or other reproductive harm. For more information

o to http://www.p65warnings.ca.gov.

WARNING: Some dust, fumes and gases created by power sanding, sawing, grinding, drilling, welding

and other construction activities contain chemicals known to the State of California to cause cancer and

birth defects or other reproductive harm. Some examples of these chemicals are:

lead from lead based paint

crystalline silica from bricks, cement and other masonry products

arsenic and chromium from chemically treated lumber

Your risk of exposure varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and work with approved safety equipment, such as dust

masks that are specifically designed to filter out microscopic particles. For more information go to

http://www.p65warnings.ca.gov/ and http://www.p65warnings.ca.gov/wood.

4

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

injury.

- - SAVE THESE INSTRUCTIONS - -

Specifications

Model ................................................................................... JHPB-20 .................................................... JHPB-30

Stock Number ......................................................................... 331900 ....................................................... 331910

Pipe Size Capacity (in.) ............................................................ 1/2 – 2 ........................................................ 1/2 – 3

Max. Pipe Wall Thickness (in.) ....................................................... 1/5 ............................................................ 6/25

Maximum Load (Tons) ...................................................................... 9 ............................................................... 20

Piston Stroke (in.) ...................................................................... 10-1/4 ......................................................... 12-5/8

Ram Diameter (in.) ...................................................................... 1-3/4 ........................................................... 2-1/3

Net Weight (lb) ............................................................................ 115 ............................................................. 260

Shipping Weight (lb) ...................................................................... 157 ............................................................. 272

Assembled Dimensions (LxWxH)(in.) ................. 38-3/4 x 26 x 28-3/4 ......................................... 40 x 35 x 28-3/4

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without

incurring obligations.

5

Unpacking

Contents of Shipping Container

1 Bending Die (A) – see also Table 1

1 Hardware Bag (B)

1 Hydraulic Pump Unit (C)

1 Tripod Seat (D)

1 Swage Block (E)

1 Support Assembly (F)

1 Hinge Pin (G)

1 Upper Wing Plate (H)

1 Lower Wing Plate (J)

1 Handle (K)

3 Tripod Leg (L)

3 Tripod Pole Base (M)

Bending

Die Size

JHPB-20 (2-in) JHPB-30 (3-in)

Model

01/2" x x

03/4" x x

01" x x

01-1/4" x x

01-1/2" x x

02" x x

02-1/2" x

03" x

Table 1 lists the bending die sizes that are included

with each hydraulic pipe bender model.

Table 1

Contents of Hardware Bag

Figure 1: Shipping Contents

4 Double-Ended Threaded Stud (M)

4 M12 Lock Washer (N)

4 M12 Hex Nut (O)

1 Vented Oil Plug (P)

1 O-Ring (Q)

1 Cotter Pin (R)

6

Figure 2: Contents of Hardware Bag

Assembly

Referring to Figure 3:

1. Screw three tripod pole bases (M) onto three

tripod poles (L).

2. Screw tripod poles (M) into the tripod seat (D).

For steps 3 – 13 refer to Figure 4.

3. Pull the knob (D

4. Insert the support assembly (F) onto the tripod

seat (D) by first pulling out the knob (D

on the tripod seat (D). When the knob is

released, the support assembly will be secured

to the tripod seat.

5. Screw four double-ended threaded studs (M)

(short-threaded end) into bottom of the

housing base (C

6. Place the hydraulic pump unit (C) onto the

lower wing plate such that the studs protrude

through the bottom of the wing plate.

Note: The alignment holes in the wing plate

and pump unit must line up. If not, flip the wing

plate over.

7. With the assistance of a second person, lift the

hydraulic pump unit (C) and lower wing plate

(J) as a unit and place it on top of the support

assembly (F).

8. The studs (M) should protrude through the

bottom of the support assembly plate (F) and

the spring pin should fit into the alignment

holes of the wing plate (J) and pump unit (C).

9. Secure the pump unit (C) and wing plate (J) to

the support assembly (F) with four each M12

lock washers (N) and M12 hex nuts (O).

Tighten with a 7/8" wrench.

10. Mount swage blocks (E) onto the end-holes of

the wing plate (J). These will be adjusted as

required later.

11. Place the upper wing plate (H) onto the pump

unit (C) and swage blocks (E).

12. Insert hinge pin (G) though the upper wing

plate and pump unit hinge holes and secure

the hinge pin with cotter pin (R).

13. Insert the handle (K) into the handle cap (C

on the pump unit.

14. Remove the factory installed oil plug (P) and

replace with the vented oil plug (P) and rubber

O-ring (Q) from the hardware bag.

Important: Failure to replace the oil plug will

cause improper operation.

Assembly is complete and the pipe bender is ready

for use.

, Fig. 3) on the tripod seat and

1

, Fig. 3)

1

) of the hydraulic pump unit.

1

2

D

D

1

L

M

Figure 3

)

Figure 4

7

Operation

Securing the Pipe Bender

The JHPB-20 and JHPB-30 Hydraulic Pipe Bender

can be secured to the floor with three bolts through

the holes on the tripod pole bases if desired for

increased stability.

Direction of the Pipe Bender

The direction of the pipe bender can be adjusted

by pulling out the knob on the tripod seat (D

Fig. 3) and rotating the pump unit. When the knob

is released, the pipe bender can still be adjusted.

The machine can only be fixed in one position by

rotating the pipe bender until the position rod

resets into the indent in the base of the tripod seat.

When Using for the First Time

If the pipe bender is being used for the first time,

be sure to change the shipping plug on the top of

the pump unit (see Assembly Step 14) with the oil

plug in the hardware bag, which contains a vent

hole on the top. Failure to remove the shipping

plug will cause improper operation. The shipping

plug comes without the vent hole to prevent oil

leakage during the shipment.

, D,

1

To Bend a Pipe

Referring to Figure 5:

1. Raise the handle (A).

2. Raise the upper wing plate (B).

3. Select the suitable bending die (C) for the pipe

to be bent and slip it on the end of the cylinder

ram (D).

4. Select the positions of the swage blocks (E) for

the pipe. For shorter pipes, position the swage

blocks closer together to account for the pipe

shortening during the bending process.

5. Turn the swage blocks (E) so the notch that

best fits the diameter of the pipe to be bent

faces in the direction of the bending die.

Note: Lubricating the swage blocks will

promote ease of movement.

6. Place the pipe you are going to bend.

Note: Keeping the bending die (C) lubricated

will promote easy removal of pipe after the

bend is made.

7. Lower the upper wing plate (B).

8. Close the release valve (G) by turning clockwise.

9. Pump the handle (A) to bend the pipe.

Note: Applying heat to the pipe will promote

ease in bending.

To Bend Pipe

When applying heat to the

pipe, the pipe must be free of oil and other

flammable material.

10. When the bend has been made, release the

pressure by opening the release valve (G).

The ram will automatically retreat.

Lubrication

Check the oil level regularly by removing the

vented oil plug found on the top of the pump

housing. When changing or adding oil, fill the tank

through the Cap Screw. Normally about 820 ml of

ISO VG of 22 or ISO VG of 32 hydraulic oil is

recommended for model JHPB-20 Hydraulic Pipe

Bender and 1700 ml for model JHPB-30. Lightly

grease all moving parts if necessary.

Figure 5

8

Troubleshooting the JHPB Pipe Benders

Symptom Possible Cause Correction

Hydraulic unit does not

lift, Pipe Bender does not

work

Piston does not advance

or retract smoothly

Oil low in tank. Make sure there is no oil leakage. Check

that the oil level is full.

Air in pump. Pump the handle repeatedly until the ram

piston stops to lift. Tilt the pump housing to

about 45 degrees. Loose the release valve

to allow any trapped air to escape from the

oil tank.

Worn UN-Ring in ram cylinder. Change the UN-Ring (Parts List Item 39).

Function Fail. Check if the steel ball (Parts List Item 43)

touching the release valve (Parts List Item

50) fell off. If so, tighten the release valve

clockwise.

Air inside the oil tank. Pump the handle repeatedly until the ram

piston stops to lift. Tilt the pump housing to

about 45 degrees. Loose the release valve

to allow any trapped air to escape from the

oil tank.

Low oil in the oil tank. Fill oil.

Incorrect oil type. Change to ISO VG of 22 or ISO VG of 32

hydraulic oil.

Debris or dirt in the oil flow. Flush the oil from inside the pump unit with

gasoline.

Leakage from the Ram

piston or Plunger Piston

Worn Seals Change the seal kits in the seal kits bag.

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1800-274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial

Number of your machine available when you call will allow us to serve you quickly and accurately.

9

Parts Breakdown – JHPB-20 and JHPB-30 Pipe Benders

10

Parts List – JHPB-20 and JHPB-30 Pipe Benders

Index No. Part No. Description Size Qty

1 ................ JHPB20-1 .................. Upper Wing Plate .................................................... ...................................... 1

.................. JHPB30-1 .................. Upper Wing Plate * .................................................. ...................................... 1

2 ................ JHPB20-2-1 ............... 1/2” Bending Die ...................................................... 1/2" ................................ 1

.................. JHPB20-2-2 ............... 3/4" Bending Die ...................................................... 3/4" ................................ 1

.................. JHPB20-2-3 ............... 1” Bending Die ......................................................... 1” ................................... 1

.................. JHPB20-2-4 ............... 1-1/4” Bending Die ................................................... 1-1/4” ............................ 1

.................. JHPB20-2-5 ............... 1-1/2” Bending Die ................................................... 1-1/2” ............................ 1

.................. JHPB20-2-6 ............... 2” Bending Die ......................................................... 2” ................................... 1

.................. JHPB30-2-7 ............... 2-1/2” Bending Die * ................................................ 2-1/2” ............................ 1

.................. JHPB30-2-8 ............... 3” Bending Die * ...................................................... 3” ................................... 1

3 ................ JHPB20-3 .................. Snap Ring ................................................................ ...................................... 4

4 ................ JHPB20-4 .................. Shaft ........................................................................ ...................................... 2

.................. JHPB30-4 .................. Shaft * ...................................................................... ...................................... 2

5 ................ JHPB20-5 .................. Swage Block ............................................................ ...................................... 2

.................. JHPB30-5 .................. Swage Block * ......................................................... ...................................... 2

6 ................ JHPB20-6 .................. Tripod Seat .............................................................. ...................................... 1

7 ................ JHPB20-7G ............... Tripod Leg ............................................................... ...................................... 3

8 ................ JHPB20-8 .................. Spring Pin ................................................................ 6x30 mm ....................... 1

9 ................ JHPB20-9 .................. Tripod Leg Base Foot .............................................. ...................................... 3

10 .............. JHPB20-10 ................ Handle End Cap ...................................................... ...................................... 1

11 .............. JHPB20-11 ................ Handle Grip ............................................................. ...................................... 1

12 .............. JHPB20-12 ................ Handle ..................................................................... ...................................... 1

13 .............. JHPB20-13 ................ Handle Cap .............................................................. ...................................... 1

14 .............. JHPB20-14 ................ Rod .......................................................................... ...................................... 1

15 .............. JHPB20-15 ................ Lower Wing Plate .................................................... ...................................... 1

.................. JHPB30-15 ................ Lower Wing Plate * .................................................. ...................................... 1

16 .............. JHPB20-16 ................ Hinge Pin ................................................................. ...................................... 1

.................. JHPB30-16 ................ Hinge Pin * ............................................................... ...................................... 1

17 .............. ESR1650-81 .............. Spring Pin ................................................................ 6x35 mm ....................... 1

18 .............. JHPB20-18 ................ Cotter Pin ................................................................. ...................................... 1

19 .............. JHPB20-19 ................ Joint Shaft ................................................................ ...................................... 2

20 .............. JHPB20-20 ................ Joint Pin ................................................................... ...................................... 1

21 .............. JHPB20-21 ................ E-Ring ...................................................................... ...................................... 6

22 .............. JHPB20-22 ................ Support Assembly ................................................... ...................................... 1

.................. JHPB30-22 ................ Support Assembly * ................................................. ...................................... 1

23 .............. JHPB20-23 ................ Double-Ended Threaded Stud ................................. ...................................... 4

.................. JHPB30-23 ................ Double-Ended Threaded Stud * .............................. ...................................... 4

24 .............. TS-2361121 .............. Lock Washer ............................................................ M12 ............................... 4

.................. TS-2361141 .............. Lock Washer * ......................................................... M14 ............................... 4

25 .............. TS-1540081 .............. Hex Nut .................................................................... M12 ............................... 4

.................. TS-154009 ................ Hex Nut * ................................................................. M14 ............................... 4

26 .............. JHPB20-26 ................ Hydraulic Pump Unit ................................................ ...................................... 1

.................. JHPB30-26 ................ Hydraulic Pump Unit * ............................................. ...................................... 1

27 .............. JHPB20-27 ................ Socket Set Screw .................................................... M16x25 ......................... 1

28 .............. TS-2238911 .............. Socket Head Cap Screw ......................................... M8x100 ......................... 1

29 .............. JHPB20-29 ................ Copper Washer ....................................................... ...................................... 1

30 .............. JHPB20-30 ................ Ram Piston .............................................................. ...................................... 1

.................. JHPB30-30 ................ Ram Piston * ............................................................ ...................................... 1

31 .............. JHPB20-31 ................ Spring ...................................................................... ...................................... 1

.................. JHPB30-31 ................ Spring * .................................................................... ...................................... 1

32 .............. JHPB20-32 ................ Dust Seal ................................................................. ...................................... 1

.................. JHPB30-32 ................ Dust Seal * ............................................................... ...................................... 1

33 .............. JHPB20-33 ................ Pump Housing Cap.................................................. ...................................... 1

.................. JHPB30-33 ................ Pump Housing Cap * ............................................... ...................................... 1

34 .............. JHPB20-34 ................ O-Ring ..................................................................... 59x3 mm ....................... 1

.................. JHPB30-34 ................ O-Ring * ................................................................... 78.97x3.53 mm ............. 1

35 .............. JHPB20-35 ................ Ram Piston Housing ................................................ ...................................... 1

.................. JHPB30-35 ................ Ram Piston Housing * ............................................. ...................................... 1

36 .............. JHPB20-36-1 ............. Solid Shipping Oil Plug (for shipping use only) ........ ...................................... 1

.................. JHPB20-36-2 ............. Vented Oil Plug ........................................................ ...................................... 1

11

Index No. Part No. Description Size Qty

37 .............. JHPB20-37A ............. O-Ring ..................................................................... 13.2x2.65 mm ............... 1

38 .............. JHPB20-38 ................ Piston Slipcover ....................................................... ...................................... 1

.................. JHPB30-38 ................ Piston Slipcover *..................................................... ...................................... 1

39 .............. JHPB20-39 ................ UN-Ring ................................................................... 40x50x6 mm ................. 1

.................. JHPB30-39 ................ UN-Ring * ................................................................ 55x65x6 mm ................. 1

40 .............. JHPB20-40 ................ Washer .................................................................... ...................................... 1

.................. JHPB30-40 ................ Washer * .................................................................. ...................................... 1

41 .............. JHPB20-41 ................ Bolt .......................................................................... ...................................... 2

42 .............. JHPB20-42 ................ Spring ...................................................................... ...................................... 2

43 .............. SB-6MM .................... Steel Ball ................................................................. 6mm .............................. 3

44 .............. JHPB20-44 ................ Housing Base .......................................................... ...................................... 1

.................. JHPB30-44 ................ Housing Base * ........................................................ ...................................... 1

45 .............. JHPB20-45 ................ O-Ring ..................................................................... 88x4 mm ....................... 2

.................. JHPB30-45 ................ O-Ring * ................................................................... 101.19x3.53 mm ........... 2

46 .............. JHPB20-46G ............. Oil Tank ................................................................... ...................................... 1

.................. JHPB30-46G ............. Oil Tank * ................................................................. ...................................... 1

47 .............. JHPB20-47 ................ Filter ......................................................................... ...................................... 1

48 .............. JHPB20-48 ................ Steel Wire ................................................................ ...................................... 1

49 .............. JHPB20-49 ................ Bolt .......................................................................... ...................................... 1

50 .............. JHPB20-50 ................ Release Knob .......................................................... ...................................... 1

51 .............. JHPB20-51 ................ E-Bolt ....................................................................... ...................................... 1

52 .............. JHPB20-52 ................ O-Ring ..................................................................... 13.2x2.65 mm ............... 1

53 .............. JHPB20-53 ................ Pump Housing ......................................................... ...................................... 1

.................. JHPB30-53 ................ Pump Housing * ....................................................... ...................................... 1

54 .............. JHPB20-54 ................ Plunger Piston Housing ........................................... ...................................... 1

55 .............. JHPB20-55 ................ Copper Washer ....................................................... ...................................... 1

56 .............. JHPB20-56 ................ Bolt .......................................................................... ...................................... 2

57 .............. SB-4MM .................... Steel Ball ................................................................. Ø4mm ........................... 2

58 .............. JHPB20-58 ................ Reposition Spring .................................................... ...................................... 1

59 .............. JHPB20-59 ................ Adjustable Spring .................................................... ...................................... 1

60 .............. JHPB20-60A ............. UN-Ring ................................................................... 20x28x6 mm ................. 1

61 .............. JHPB20-61 ................ U-Packing ................................................................ ...................................... 1

62 .............. JHPB20-62 ................ Plunger Piston ......................................................... ...................................... 1

63 .............. JHPB20-63 ................ UN-Ring ................................................................... 14x22

64 .............. JHPB20-64 ................ Dust Seal ................................................................. ...................................... 1

65 .............. JHPB20-65 ................ Position Rod ............................................................ ...................................... 1

66 .............. JHPB20-66 ................ Stop Bolt .................................................................. ...................................... 1

67 .............. JHPB20-67 ................ Knob ........................................................................ ...................................... 1

68 .............. JHPB20-68 ................ Spring ...................................................................... ...................................... 1

69 .............. SB-4MM .................... Steel Ball ................................................................. Ø4mm ........................... 1

70 .............. JHPB20-70 ................ Ball Seat .................................................................. ...................................... 1

71 .............. JHPB20-71 ................ Spring ...................................................................... ...................................... 1

72 .............. JHPB20-72 ................ Screw ....................................................................... ...................................... 1

73 .............. JHPB20-73 ................ Sealing Washer ....................................................... ...................................... 1

74 .............. JHPB20-74 ................ Bolt .......................................................................... ...................................... 1

.................. LM000166 ................. Warning Label (not shown) ...................................... ...................................... 1

.................. JHPB20-ID ................ ID Label (not shown) ............................................... ...................................... 1

.................. JHPB30-ID ................ ID Label (not shown) * ............................................. ...................................... 1

.................. JET-138 ..................... JET Logo (not shown).............................................. 138 x 57mm .................. 1

x5 mm ................. 1

NOTE: * denotes for use on Model JHPB-30 only.

12

Loading...

Loading...