Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Variab le Speed Tu rret Mill

Model JTM-4VS

Shown with optional accessori es X- Axis Tabl e Powerfeed and DRO

WALTER MEIER (Manuf acturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M- 690182

Ph.: 800-274-6848 Revision G 06/ 2010

www.walt er meier.c om Copyright © 2010 Walt er Meier (M anufacturi ng) Inc.

Page 2

W arranty and Service

W alter Meier (Manufacturin g) Inc ., warr ants every product it sel ls. If on e of our tools needs ser vice or r epair, one of our Authorized

Service Centers located throughout the United States can gi ve you quick ser vice. In mos t cases, any of these W alter Meier

Authorized Service Centers can authorize warranty repai r, assist you i n obtaining part s, or per for m r outin e maintenanc e and ma jor

repai r on your JET® tools. For the name of an Authorized Service Center in your area cal l 1- 800-274-6848.

MORE INFORMATION

W alter M eier is c onsi st en tly addi ng n e w products to th e li ne. For c o mplet e, up-to- da te pr oduc t i nf or mati on, c hec k wi th y our loc al

W alter Meier distribu tor , or vi sit wa lter meier.c om.

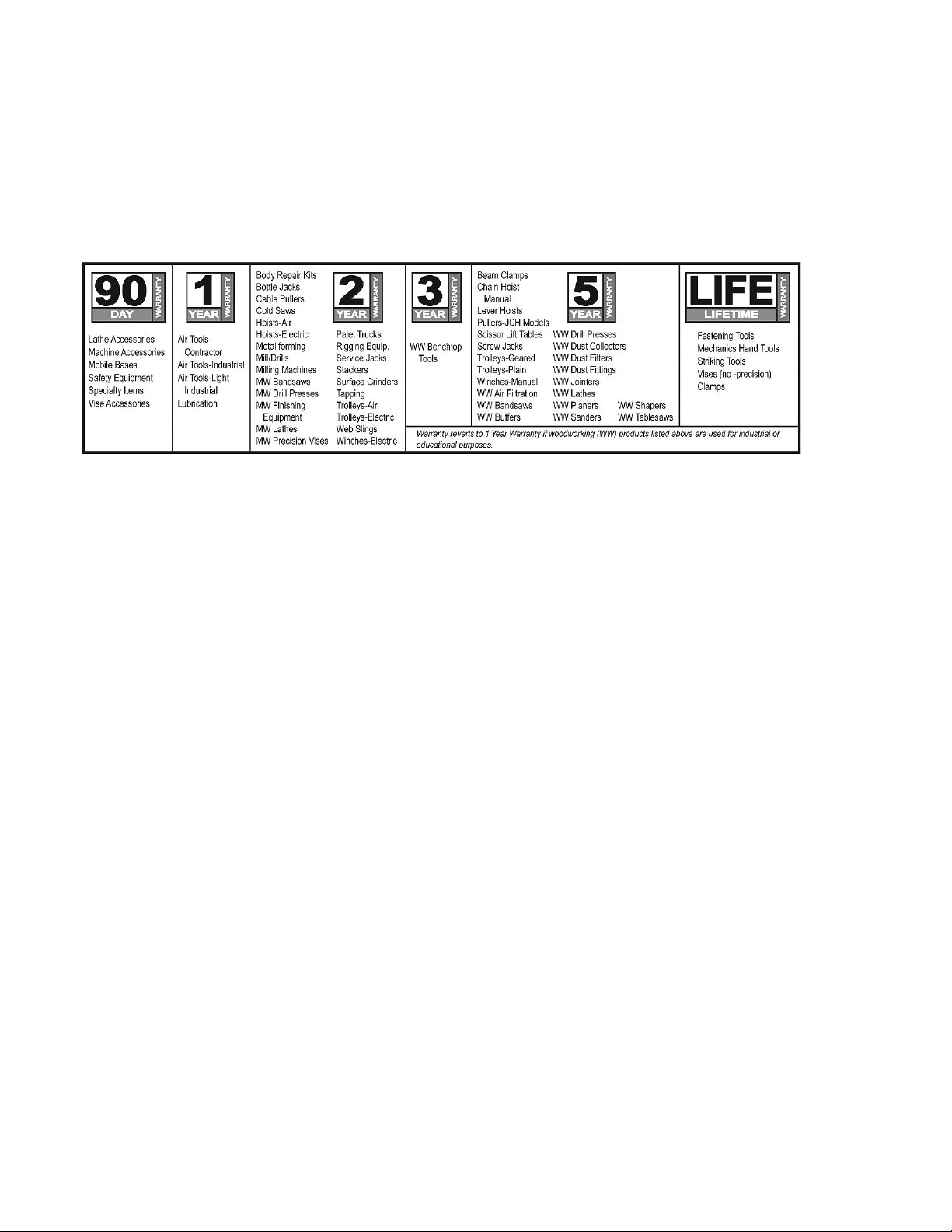

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COV ERED?

This warranty covers any defec ts in workmanship or materials subject to the exceptions stated below. Cutting tools, abrasives and

other consumables are e xcluded from warranty coverage.

WHO IS COVERED?

This w arranty covers only the initial purcha ser of t he product.

WHAT IS THE PERIOD O F COVERAGE?

The general JET warranty lasts for the time per iod specified in the product li terature of each pro duct.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational purposes.

W oodworking pr oduc t s wit h Fi ve Ye ar W arr anties th at ar e us ed for co mmer ci a l, indu str ia l or e duc a tion purp os es re ver t to a One

Year W ar r anty. This warra nty do es no t c over def ec ts d ue dir ec tly or i ndir ec tly to misu se, a buse, ne gli genc e or ac ci dents, nor mal

wear-and- tear, improper r epair or alteration s, or lack of mainten ance.

HOW TO G ET SERVICE

The pr oduc t or part must be re turned f or exami nation, po stage pre paid, to a loca tion d esigna ted by us. For the n ame of the

location neares t you, p lease call 1-800-2 74-6848.

You m ust pr ovide pr oof of ini tial p urchas e dat e and an e xpl anati on of th e co mp lain t must ac co mpany t he merc handi se. If our

insp ec tio n disc los es a defec t, we will r epai r or r eplace t he pr oduc t, or r efun d th e purc ha se pri c e, at o ur opti on. W e wil l retu rn the

repai red pr oduc t or r ep lace men t at our e xpen se un les s it i s d et er mine d by us th at t here is n o d efec t, or that the def ec t r esu lt ed

fr om cau ses no t withi n the sc op e of our warran ty i n which c ase we will, at y our di r ecti on, di spos e of or r eturn th e pro duc t. I n the

event you c hoose to have t he product returned, you will be responsib le for the shipping and handling costs of the ret urn.

HOW STATE LAW APPLIES

This warranty gi ves you specific legal ri ghts; y ou may a lso have other rights which vary from sta te to sta te.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED

WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY

AND FI TNESS ARE EXCL UDED. SOME STA TES DO NOT ALL OW LIMI TATIONS ON HOW LONG THE IMPLIE D WA RRANTY

LASTS, SO THE ABOVE LIMI TATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDE NTAL, CONTI NGENT, S PECIAL, OR CONSE QUENTIAL DA MAGES A RI SING FROM THE USE OF OUR PRODUC TS.

SOME STA TES DO NOT ALL OW THE EXCLUSI O N OR LIMITA TION OF I NCIDE NTAL OR CONS E QUENTIA L DAMAGES, S O

THE ABOVE LIMI TATI ON OR EXCLUSI ON MAY NOT AP PLY TO YOU.

W alter Meier se lls t hrou gh dis tr ibu tor s on ly. The s peci fi c ation s in W alt er Mei er c atalo gs are give n as gen er al inf or mati on a nd are

not bi nding. Me mb ers of Walter Meier reserve the right to effect at any time, withou t prior noti ce, th ose alt erations to part s, fittings,

and ac c essor y eq uip men t w hic h they may d ee m n ecess ar y f or any r e ason wh at so ever . J E T® br ande d pr oduc ts are no t so l d in

Canada by Walter Meier.

2

Page 3

Ta ble of Contents

Warranty and Service .................................................................................................................................2

In trodu c tion ...............................................................................................................................................7

Spe ci fic ati ons ............................................................................................................................................7

Unpacking .................................................................................................................................................8

Contents of the Shipping Container..........................................................................................................8

Set-up and Installation................................................................................................................................9

Prepari ng the Milling Machine for Service.................................................................................................9

JTM-4VS Dimensions............................................................................................................................... 10

JTM-4VS Overview and Terminology ........................................................................................................ 11

Electrical Connect io ns .............................................................................................................................. 12

General Electrical Cautions ................................................................................................................ 12

Wire Sizes ........................................................................................................................................ 12

Lu bricati on ........................................................................................................................................... 12

Operating Instructions .............................................................................................................................. 12

Operating Controls ............................................................................................................................... 12

Motor Sw itch ........................................................................................................................................ 12

Variable Speed Control ......................................................................................................................... 13

Spindle Brake....................................................................................................................................... 14

High-Neutral-Low Shift Lever................................................................................................................. 14

Quill Power Feed Lever......................................................................................................................... 14

Feed Rate Lever................................................................................................................................... 14

Feed Trip Cam Lever ............................................................................................................................ 15

Feed Direction Control .......................................................................................................................... 15

Coarse Feed Handle ............................................................................................................................. 15

Quill Lock Lever.................................................................................................................................... 15

Micrometer Adjusting Nut ...................................................................................................................... 15

Fine Feed Handwhee l ........................................................................................................................... 15

Depth Scale and Stop ........................................................................................................................... 16

Power Feed O per at ion .......................................................................................................................... 16

Draw Bar Operation - Changing Tooling ................................................................................................. 17

Clamping Work Piece to the Table ......................................................................................................... 17

Adjustmen ts ............................................................................................................................................ 17

Mill Head – Left/Right Adjustment .......................................................................................................... 17

Mill Head – Fore/Aft Adjustment ............................................................................................................ 18

Positioning the Ram.............................................................................................................................. 19

Positioni ng the Ram Fore and Aft ....................................................................................................... 19

Positioning the Ram on its Turret........................................................................................................ 19

Gib Adjustment..................................................................................................................................... 19

Adjustment of Knee Gib ..................................................................................................................... 19

Adjustment of Saddle Gib .................................................................................................................. 19

Adjustment of Table Gib .................................................................................................................... 19

Power Feed Tr ip Lever Mechanism ........................................................................................................ 20

Table Lead Screw Backlas h Adjust me nt ................................................................................................ 20

Cross Feed Backlash Adjustment ....................................................................................................... 20

Longitudinal Backlash Adjustment ...................................................................................................... 20

Maintenance............................................................................................................................................ 22

Lu bricati on ........................................................................................................................................... 22

Periodic Maintenance Requirements .................................................................................................. 22

Replacement of Drive Motor .................................................................................................................. 23

Replacement of Vari- Speed Belt ............................................................................................................ 24

Replacement of Brake Shoes, Springs and/or Timing Belt ....................................................................... 24

Replacement of Q uill Feed Clock Spring ................................................................................................ 25

Replacement Parts .................................................................................................................................. 25

Head Assembly .................................................................................................................................... 26

Parts List for Head Assembly ................................................................................................................ 27

Spindle Assembly ................................................................................................................................. 30

Base Assembly .................................................................................................................................... 34

Parts List for Base Assembly ................................................................................................................. 35

3

Page 4

Lead Screw Assembly .......................................................................................................................... 37

One-Shot Lubrication System ................................................................................................................ 38

Electrical Connect io ns – Single Phase only ............................................................................................ 39

Electrical Connect io ns – 3 Phase only ................................................................................................... 40

4

Page 5

Warning

1. Read and understand t he entire owner’s manual befor e attempting assembly or operation.

2. Read and understand the war ni ngs posted on the machine and in this manual. Failure to c omp ly w ith all of

these warnings may cause serio us injury.

3. Replace the warning labels if they become obscured or removed.

4. This turret mill is designed and intended for use by properly trai ned and experi enced personnel only. If you

are not f amiliar with the pr oper and safe oper ation of a turret mill, do not use unt il proper tr aining and

knowledge have bee n obtai ned.

5. Do not use this turret mill for other t han its i ntended use. I f used for other purposes, W MH Tool Group

disclaims any r eal or implied war ra nty and holds itself harmless fr om any i njury that may result fr om that

use.

6. Always wear appr oved safet y glasses/fac e shields while using t his turret mill. ( Ever yda y ey eg lasse s o nly

have impact resistant lenses; t hey are not safety glasses.)

7. Before operating this turret mill, remove tie, rings, w at ches and ot her jew elry , and roll slee ves up pas t the

elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid floor strips are

recommended. Do not wear gloves.

8. Wear ear pr otect or s (plugs or muffs ) during extended periods of operation.

9. Some dust cr eated by power sandi ng, saw ing, grinding, drilli ng and ot her co nstr uction activities co ntai n

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of t hese

chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and ot her masonry products.

• Arsenic and chromium fr om chemically treated lumber.

Your risk of expos ure var ies, depe nding on how often you do t his type of wor k. To reduce your exposure

to these c hemicals, w or k i n a wel l-ventilated area and work with appr oved s af et y equipment, s uch as face

or dust masks that are specifically desig ned t o f ilter out microscopic particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medicat io n.

11. Make cer t ain the switch is in the OFF position before co nnecti ng the machine t o t he power s upply.

12. Make cer t ain the machine is properly grounded.

13. Make all machine adjustme nts or maintenance with the machine unplugged from the power source.

14. Remove ad justing keys a nd wrenches. For m a habit of c hec ki ng to see t hat key s and adj usti ng w r enc hes

are removed from the machine before t ur ning it on.

15. Keep safet y guards i n place at all times when the machine is in use. If r emoved for maintena nce purposes,

use extreme caution and replace the guards im mediately.

16 . S ome co ol a nts use d f or ma ch ini ng co nta i n c he mic al s t hat ma y b e ha za rd o us t o y our he a lth if not us ed

properly. Read and understand all inform at io n on the coolant contai ner a nd protect y ourself accor dingly.

17. Check damaged parts. Before f urt her use of t he machi ne, a g uard or ot her part t hat is da maged s hould be

carefully c hecked to det ermine that it w ill operate properly and perform its intended functio n. Chec k for

alignment of moving parts, binding of mo ving parts, br eakage of par ts, mounting and any ot her co ndit io ns

that may affect its operation. A guard or other part that is damaged should be properly repaired or

replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighti ng.

19. Keep the floor around t he machine clean and free of sc r ap material, oil and grease.

20. Keep visitors a saf e dist ance from the wor k ar ea. Keep children away.

5

Page 6

21. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

22. Maintain a balanced sta nce at all times so that you do not fall or lean against the cutters or ot her moving

parts. Do not overreach or use excessive for ce t o perfor m any machine operation.

23. Use the r ig ht tool at the correct s peed and feed rate. Do not for ce a tool or attac hme nt to do a job for

which it was not designed. The r ight t o ol will do t he job b e tter a nd mor e s a fely.

24. Use recommended accessor ies; improper acc essor ies may be ha zardo us.

25. Maintain tools with care. Keep cutters sharp and clean for the best and safest performance. Follow

instructions for lubricat ing and changi ng accessori es .

26. Turn off the machine and disconnect from power before cleaning. Use a brush or compressed air to

remove chips or debris — do not use your hands.

27. Do not stand on the machine. Serio us injury co uld occur if the machine tips over.

28. Never lea ve t he mac hine running unat tended. Turn the pow er off and do not lea ve the mac hine until it

comes to a complete stop.

29. Remove loose items a nd unnecessary w or k pieces f r om the area befor e starting the machine.

Familiarize yours elf with the f ollow ing saf et y not ices used in t his manual:

This mea ns t hat if precautio ns are not heeded, it may res ult in mi nor inj ury and/or poss ible

machine damage.

This means that if precautions are not heeded, it may result i n serio us or even fatal injury.

6

Page 7

Introduction

This manual is provided by Walter M eier (Manufact uring) Inc., coveri ng the safe operat ion and mainte nance

procedures for a JET M odel JTM- 4VS Turret M illing Machine. This manual contains inst r uctions on i nst a lla tion,

safety precautions, general operating procedures, maintenance instructions and parts breakdown. This

machine has bee n designed and constr ucted to provide year s of t rouble free operation if used i n accordance

with instr uctions set fort h in this m anual. If t here are any q uestions or com ments, please co ntact eit her your

local supplier or Walter M eier . Walter Meier can also be reached at our web site: www.w alter meier. com.

Specifications

Model Number ................................................................... JTM-4V S-1 ............................................JTM-4 VS-3

Stock Number.......................................................................... 690180 ................................................ 690182

Spindle Taper ................................................................................R -8 ....................................................... R -8

Diameter of Quill (in.) ..................................................................3.375 .................................................... 3. 375

Number of Spindle Speeds ...................................................... Vari ab le ................................................ Va ria bl e

Range of Spindle Speeds (RPM) ......................................... 60 to 4200 .............................................60 to 4200

Downfeeds per Revolution of Spindle ( i n.) ............ 0.0015, 0.003, 0.006 .............................. 0.0015, 0.003, 0.006

Spindle Travel (in.) ............................................................................ 5 ...........................................................5

Head Movement – Left and Right (deg.) ........................................... 90 ......................................................... 90

Head Movement – Fore and Aft (deg.).............................................. 4 5 ......................................................... 45

Maximum Distance Spindle to Table (in.) .................................... 17-1/2 ................................................... 17-1/2

Maximum Distance Spindle to Column (in.)....................................... 19 ......................................................... 19

Minimum Distance Spindle to Column (in.).................................... 4-1/2 ..................................................... 4-1/2

Collet Capacity (in.)................................................................ 1/8 – 7/8 ............................................... 1/8 – 7/8

Table Size (in.) .......................................................................... 9 x 49 ................................................... 9 x 49

Longitudinal Table Travel, maximum (in.) ......................................... 34 ......................................................... 34

Table Cross Travel, maximum (in.)................................................... 12 ......................................................... 12

Number of T-Slots ............................................................................. 3 ...........................................................3

T-Slot Size (WxD)(in.) ............................................................ 5/8 x 3/4 ................................................5/8 x 3/4

T-Slot Centers (in.)...................................................................... 2-1/2 ..................................................... 2-1/2

Table Load, maximum (lbs. ) .......................................................... 660 ...................................................... 660

Knee Travel, maxim um (in.) ....................................................... 14-1/2 ................................................... 14-1/2

Ram Travel, maximum (in.)........................................................ 13-3/8 ................................................... 13-3/8

Overall Dimensions (in.) ............................................ 66W x 63D x 85H .................................. 66W x 63D x 85H

Motor ............................................... TEFC 2HP, 1PH, 115/230V, 60Hz ......... TEFC 3 HP, 3PH, 230/460V, 60Hz

(prewired 230V) (prewired 230V)

Net Weight, approx. (lbs.) ............................................................2,420 .................................................... 2 ,420

The above spec ificat ions were c urrent at the t ime t his manual was p ub lis hed, but beca use of our policy of

continuo us improvement, W alt er M eier r eser ves the right to change specifications at any time and without prior

notice, without incurring obligations.

7

Page 8

Unpacking

Open shipping container and check for shipping

damage. Report any damage immediately to your

distributor and shipping agent. Do not discard any

shipping material until the Turret Mill is assembled

and running properly.

Compare the contents of your container with the

following parts list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distributor. Read the instruction manual thoroughly

for assembly, maintenance and safety instructions.

Contents of the Shipping Container

Note: Some parts may be pre-i nstalled on the mill.

1 Turre t Mill ( not shown)

1 Flat Way Cover

1 Pleated Way Cover

1 Draw Bar

3 Table Adjustment Handles

1 Tool Box, containing:

1 Hex Key Set (1.5-10mm) *

1 17/19mm Box Wrench *

1 Cross Point Screw Driver #2 *

1 Flat Blade Screw Driver #2 *

1 Plastic Oil Bottle *

1 Elevating Crank Handle

1 Handwheel

1 Coarse Feed Handle

1 C an Whi te Touch Up Paint

1 Eye Bolt

1 Operator ’s M anual (not shown)

1 Warranty Card (not shown)

* parts with an asterisk are also included in the

tool box service kit, p/n JTM4VS-TB.

Figure 1

Read and understand the entire contents of this manual before attempting set-up or

operation! Failur e t o comply may cause seri ous in jury.

If y o ur mill is suppl ie d with a n optio na l T ab le Po werfeed and/or DRO, be sure to consult the separate instr uction

materials that accompany them.

8

Page 9

Set-up a nd Installation

and-aft leveling. Be certain you get it level in

BOTH directions.

Preparing the Milling Machine for Servi ce

1. Remo ve a ny crating w hic h may be co vering the

machine on the pallet.

2. Remove accessory items from the pallet or

machine table. Compar e these items w ith the list

on the previous page.

3. C heck the tight ness of t he lifti ng ring on t he ram

to be certain it is tight.

4. Check the tightness of the lock handles on the

ram (see Figure 23) to be certain the ram is

locked tight.

5. Remove the nuts a nd/or bolts , which secure the

machine to the pallet.

6. Center an overhead crane or other suitable

overhead lifting device and sling arrangement

over the lifting ring.

Note: This machine weighs over 2400 pounds!

Be certain t he lifting arrangement is new or in

excellent condition and has a safety factor that

will account for age, difficulties in lifting, etc.

When lifting using the ring, the machine will tip

forward. If you wish, you can minimize this tipping

by rigging a support sling over the front of the

machine. Be caref ul when doing t his, to pr event

the sling from damaging any components on the

front of t he machi ne. Be s ure to st eady t he m il l to

prevent it fr om spinning.

7. Lift the machine off the pallet no higher than

necessary to clear the hold- down hardware, then

pull the pallet o ut of the way. Do NOT get hands

or feet underneath the machine when removing

the pallet!

8. Put the machi ne base over the ho ld-down system

where the machine will be spott ed. Anchor bolts

of sufficient size and le ngt h must be fast ened to

the floor accordi ng to the footprint of the mill. See

diagram on page 10.

Note: The accompa nying diagrams show you t he

maximum dimensions of the machines with the

table, ram, etc., fully extended in all possible

directio ns. When spotting the machine be cert ain

to leave room not o nly for t he machine itself, but

also for operator clearance and clearance for

worker s servicing the machine, a nd a ny unusual

sizes of workpieces that might extend off the

machine’s table.

9. When the mac hine is o ver its anchors, le vel t he

machine using shims under t he corner s needi ng

them. The machinist’s level used for leveling

should be placed on the table. The table is the

refer ence surfac e for both side-to- side and fore-

Mill must be supported equally

under a ll fo ur cor ners. Failure to comply may cause

the column to tw ist and put a bi nd in the table ways.

10. When the machine is level, secure the base to

the anchor system.

IMPORTANT: Before attempting to raise the mill

head, refer to Mill Head – Left/Right Adjustment in

the Adjustments section for procedures to safely

raise and set up the mill head.

11. Loose n the four he x head nuts (see A, Figure 22)

about 1/4 turn each (counterclockwise), just

enough to allow rot at ion of the head.

12. While assisting the worm mechanism by putting

upward press ure o n the motor by hand, use t he

wrench supplied with the machine to turn the

worm nut and raise the head to upright position.

13. Tighten the headbolts slightly — not torqued —

just snug.

14. Using mineral spirits or other cleaning solvent,

clean all of the rust proofing from where it may

have been applied. T his is important; mo ving the

table or any other components before removing

the r ust pr oof i ng will o nly p ut rust pro ofing w here

you don’t want it.

Some of the following steps may have already

been perfor m ed on the machine. If so, ignore the

instructions related to those particular steps.

Otherwise, perform them in the order listed,

refer ring to Fi gur e 11 for any clarifi cation.

15. Install the table traverse and cross-feed cranks

on their respective shafts using the nuts on the

shafts to secure the cranks.

16. Remove any r ust proof ing from the drawbar and

its washer, and put the drawbar with washer

installed i nto the spindle ce nter t hro ugh t he top of

the machine.

17. Slide the fine feed handwheel over the

handwheel hub and push it back until its rollpin

engages the hole in the hub and the wheel is

flush with the hub surface.

18. Put t he coar se f eed handle on the feed shaft and

tap it l ig htly unt il its r ol l pin engages a hole in the

hub and it is f l us h against the hub surface.

19. Unwrap and clean the k nee cr ank a nd i nstall it on

its shaft.

20. Install the r ubber way co vers at fr ont and behind

the table.

9

Page 10

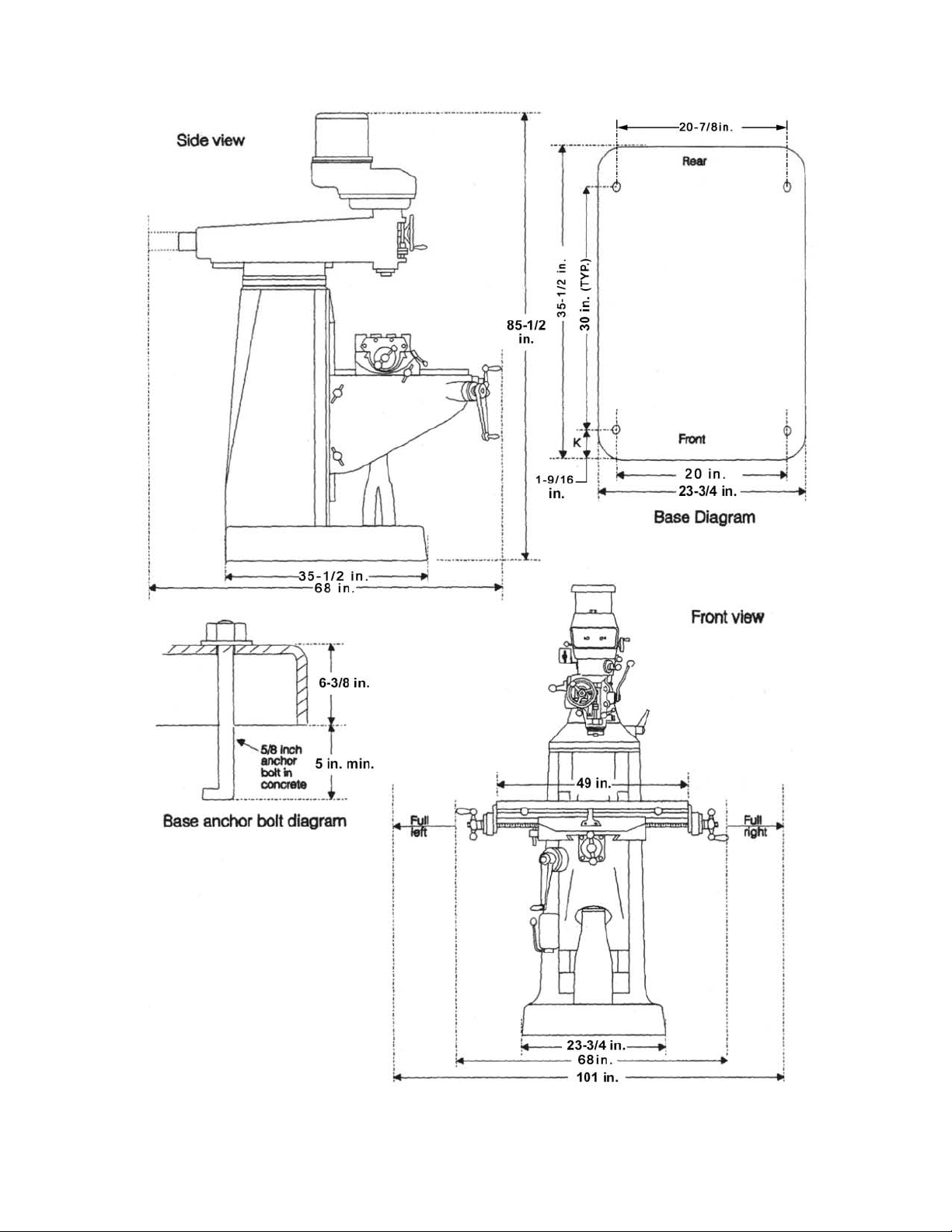

JTM-4VS Dimensions

Figure 2: Install ation Di agr am

10

Page 11

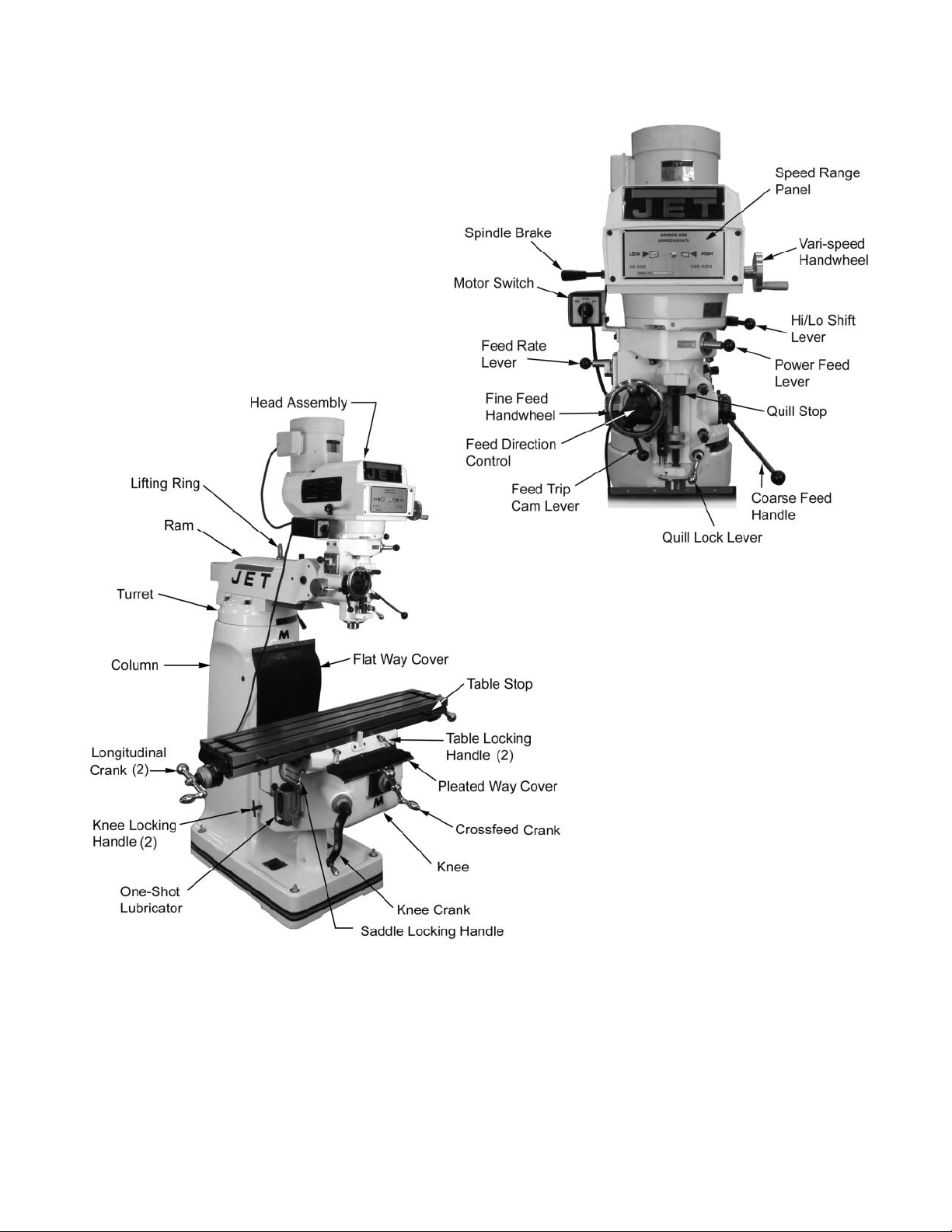

JTM-4V S Over view and Terminology

Figure 3: Ov er view

11

Page 12

Electrical Connections

Operating Instructions

All electrical connections must

be made by a qualified electrician! Failure to

comply may cause serious injur y!

General Electrica l Cautions

This mac hine must be grounded i n accorda nce with

the National Electrical Code and local codes and

ordinances. T his work should be done by a q ualified

electrician. T he machine must be grounded to prot ect

the us er f r om electr ical shock.

Wire Sizes

For circuits which are far aw ay from

the electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and bur nout, the use of wir e sizes

for branch circuits or electrical extension cords

accordi ng to the following table is recommended:

Conductor

Length

0 – 50 Ft. No. 14 No. 14

50 – 100 Ft. No. 14 No. 12

Over 100 Ft. No. 12 No. 8

Confirm that power at the site matches power

requirements of the mill before connecting to the

power source.

The JTM-4VS has been pre-wired for 230 volt

operation. To c hange from 230 V to the ot her voltage

offer ed, remove the junction box co ver o n the motor

and change t he wires acc or di ng to the diagram found

on the inside of the cover.

Before connecting to the power source, make sure

that the switch is in the off position.

The mill must be properly grounded.

Check for pr oper spindle rotat ion in the high-speed

range. The spindle should rotate clockwise when

viewed from the top of the machine. If the spindle

rotates counter-clockwise, disconnect from power

and switch two of t he three power leads.

230/ 460 Vol t Lines 120 V olt Lines

AWG Number

Figure 4

Operati ng Con t rols

The lubricatio n system is a ma nually operated, oneshot system requiring operator intervention. The

operator must lower the one-shot lever to lubricate

the machine ways and ball screws. The one-shot

lubrication system reservoir is located o n t he left side

of the machine.

The positio n of t he milli ng machi ne mill head can be

set up to accommodate the work piece being

machined. T he mill head ca n be set up for a ngles to

the left or rig ht a nd for fore and aft angles. T he mill

head can also be r otated on it s turret. The ram ca n

be moved back and forth to reach work piece

locations at the fore and aft extremes of worktable

travel. Refer to the Adjustments section.

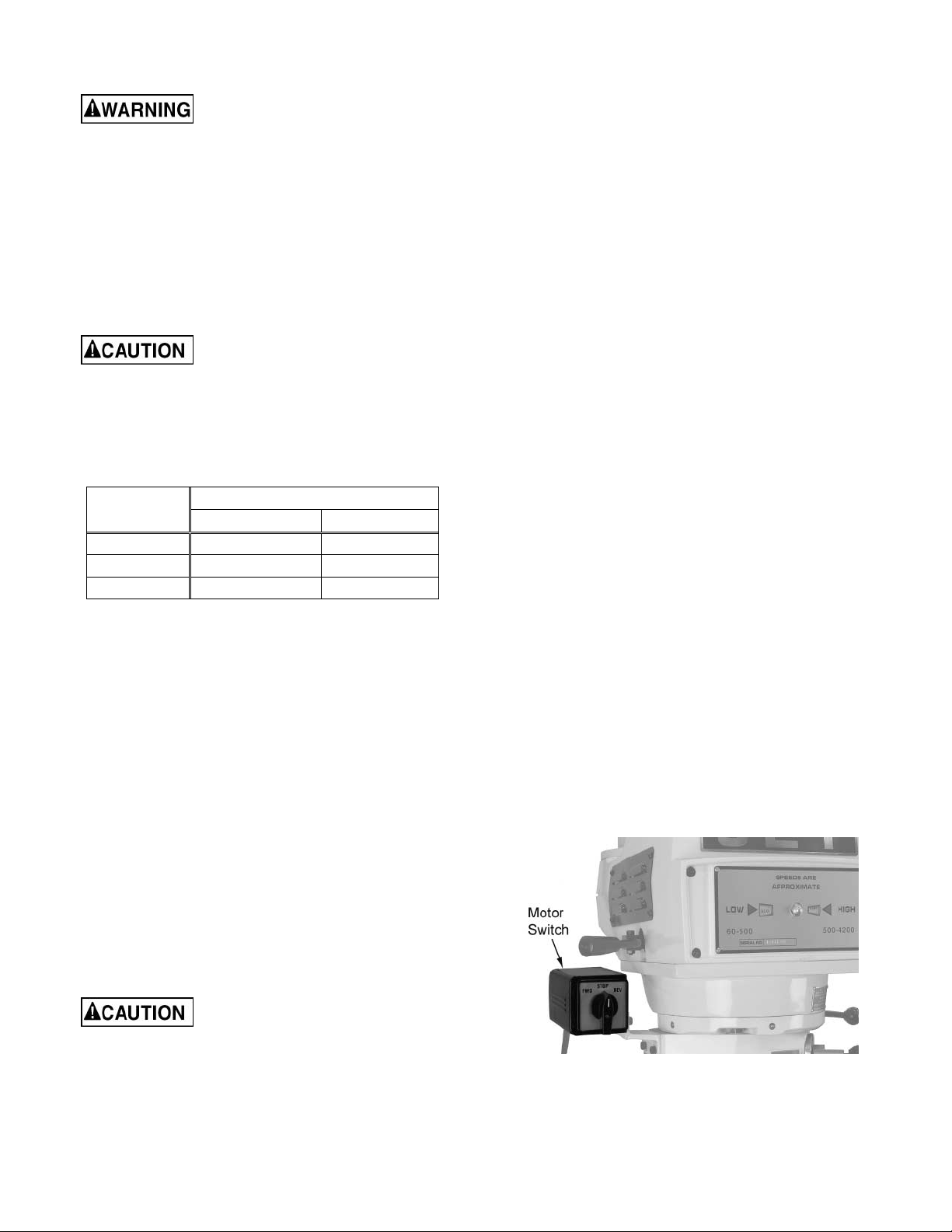

M otor Swi t ch

The Motor Switch is on the upper left-hand side of t he

mill head (Figure 5). The switc h has three posit ions:

FWD (forward), STOP, and REV (reverse).

Setting the switch to FWD will provide clockwise

spindle rotation. Use FWD for normal, right-hand

tooling.

FWD (clockwise) operation occurs only when the

gearbox is in the low speed position. When the

gearbox is in high-speed position, the motor switch

must be i n the REV posit io n to provide r ight- hand or

clockwise rotation. Refer to Figure 6 for a chart of

required switc h positions.

The motor sw itch co ntrols a t hree-p hase motor. The

motor can be sw itched from FWD t o REV a nd back

with the motor running, and will reverse direction

when the switch setting is changed. At higher

speeds, this may put strain on the timing belt but

there will be no damage to the motor or gear

mechanism.

Lubrication

Do not operate the mill before

lubricating the machine fully. Failure to comply

may cause damage to the machine.

Refer to the Maintenance/Lubrication section and

make sure the machine has been fully lubricated

before oper at ing.

Figure 5

12

Page 13

Figure 6

Variable Speed Cont rol

Change speed only while the

spindle is turn ing.

The vari-speed handwheel (A, Figure 7) is used to

control the spindle speed. The speeds for high and

low speed ra nges are disp layed on t he pa nel on t he

front of the mill head (B, Figure 7).

All speed changes must be made while the motor is

running. Att empting speed changes without the motor

running can result in damage to the drive

mechanism.

Figure 7

13

Page 14

Spindle Brake

The spindle brake lever is located on the upper left

side of the m ill head ( Figure 8). P ull lever dow nward

to apply the brake. The spindle brake lever is used

only after the motor switch has been set to OFF. The

spindle will not st op with the motor running.

Figure 8

High-Neutral-Low Shift Lever

The mill head can be dri ven directly ( High Speed) or

through t he back gear (Low Speed) in t he mill head.

The selection is m ade by changing t he posit io n of t he

shift lever.

The shift lever is locat ed at the lower r ight side of the

mill head (Figure 9). The le ver position closest to the

operator is the High set ting. T he lever pos ition aw ay

from the operator is the Low setting. The middle

position is the Neutral setting.

Do not shift the High-Low Gear

Lever while the motor is

running. Rotate the spindle by hand to facilitate

changing lever pos it ion s.

Do not move the Quill Power

Feed Lever unless the motor is

at a complete stop. When changing the lever

position, do it gent l y. If the gear does not engage,

jog the motor and allow it to stop before

attempting to change.

The quill pow er feed le ver is locat ed on t he right s ide

of the mill head (Figure 10). I t is used to engage and

disengage t he quill power f eed mechanism.

The power feed is engaged by pulling out the knob

and rotating the handle to a new locked position.

When engaged, the power f eed mechanism w ill dr i ve

the spindle upward or downward. The power feed

mechanism will not dri ve the spi ndle w hen t he handle

is in the disengage position.

Figure 10

Feed Rat e Lever

The Feed Rate Lever (Figure 11) is used to set the

per-revolution rate of the power feed mechanism.

Three feed rates are available: 0.0015-inch, 0.003inch, a nd 0.006-i nch per r evo l utio n. T he positions are

shown on an indicator plate under t he feed rat e lever.

The rate is selected by pulling out the knob on the

feed rat e lever and moving the handle to the detent of

the desired feed rat e.

Note: The knob is spring loaded – pull out t o r ot at e to

new po s ition.

Figure 9

Quill Power Feed Lever

Do not use power feed at speeds

above 3000 R.P.M.

It is reco mmende d to disengage

the power feed worm gear

whenever the power feed is not required. This

avoids unnecessary we ar on t he worm gear.

Unlike other controls o n the machi ne, the lever s hifts

into engageme nt more easily with t he motor running,

and the quill feed lever engaged.

Figure 11

14

Page 15

Feed Trip Cam L ever

The Feed Trip Cam Lever (A, Figure 12) is located on

the left side of the head behind t he Manual Fine Feed

Handwheel (B, Figure 12). It engages t he o verload

clutch on the pinio n shaft when positioned to the left .

The Feed Trip Cam L ever stays e ngaged until Quill

Stop (C, Figure 15) comes in contact with Micrometer

Adjusting Nut (A, Figure 15) forcing it to drop out

automatically, or until it is released manually by

engaging the lever to t he right.

Figure 12

Coarse F eed Handl e

The Coarse Feed Handl e (A, Figure 14) is located on

the right side of head. The Coarse Feed Handle is

used for non-precision drilling operations and for

moving the quill to a specific depth. A return spring

will r et rac t t he s pi ndle a uto mat ica lly o nce the hand le

is released.

Quill Lock Lever

The Quill Lock Lever (B, Figure 14) is locat ed o n the

right side of the head. Rotate the handle clockw ise to

lock the quill in a desir ed positio n. Rotate t he handle

counter-clockwise t o r elease.

Feed Direction Cont rol

The Feed Dir ecti on Co ntrol (B, Fig ure 13) det er mines

whether the power feed will move up, down, or not

move at all. The posit ion of the knob depe nds upon

the direction of spindle rotation (see the Motor Switch

section). T he position of the control may b e changed

with the system stopped or running. If the control

does not engage easily, move the fine feed

handwheel (A, Figure 13) back and forth to aid

engagement.

If the spindle is rotating clockwise, in is downfeed; out

is upfeed. If the spindle rotat ion is counterclockw ise,

out is downfeed; in is upfeed. Neutral position is

between the in and out position.

It is recommended t hat the Feed

Direction Knob be left in the

neutral posit ion whe n not in use.

Figure 14

M i crometer Adj ustin g Nu t

The Micrometer Adjusting Nut (A, Figure 15) is

located on the front of the head. Use for setting

specific spindle depth. Secure with the lock nut (B,

Figure 15).

Fine Feed Handwheel

When the controls are set for the Fine feed using

Handwheel position (see Figure 6), the Fine Feed

Handwheel (A, Figure 13) can be used for manual

fine feed control in either upward or downward

directio n of the quill.

Remove the Manual Fine Feed

Handwheel when not in use.

Failure to comply may cause ser ious injury.

Figure 13

15

Page 16

Depth Scale and Stop

Referring to Figure 15:

The Depth Scale and Stop are used in drilling

operations t o set the dept h of t he dril led hole. T he

depth scale is located o n the front of the mill he ad.

The scale consists of a Micrometer Adjusting Nu t (A),

Lock Nut (B), Quill Stop (C), Quill Stop Screw (D),

and Scale (E).

The Micrometer Adjusting Nut is set to the desired

dimension and locked in place using the Lock Nut.

The quill stop provides a positive stop f or quill travel.

The graduations on the micrometer nut are in

0.001-inch increments. Adjustment of q uill travel is

made by rotating the micrometer nut.

9. Select f eed r at e with the Variable Speed Control

Handwheel (E).

10. Set the Feed Rate Lever (B) to the feed rate

required for the tooling and material requir ed.

11. Place the Quill Feed Engagement Lever (F) in

the Engaged position.

12. Select feed direction by setting t he Feed

Direction Knob ( C) posit ion per the table:

Spindle Dir. Feed Dir. Knob Pos.

Down In

CW

Up Out

Down Out

CCW

Up In

Figure 16

13. Engage the Feed Trip Cam Lever (D) by pulling

away from head assembly.

Note: Due to variables in tool diameter, coatings,

coolant, and materials, no specific spindle speed or

feed rate recommendations are provided. Use

general shop manuals that have data applicable to

the milling and drilling operations being performed.

Or, contact the supplier of the tooling, coolant, and

material for specific recommendations.

IMPORTANT: The pow er feed ca n be used for drills

up to 3/8” in diameter (mild steel). Use manual feed

for drills la r g e r than 3/8” .

Figure 15

Power Feed Op erat ion

The Feed Trip Adjustment sets t he point at which the

quil l will res e t duri ng Po wer Feed.

Referring to Figure 17:

Be sure that the Manual Fine

Feed Handwheel is removed.

Failure to comply may cause ser ious injury.

1. Loos en the Lock nut (I ) .

2. With the Quill Feed Handle (J ), advance the quill

to the point where the feed should stop.

3. Engage the Feed Trip Cam Lever ( D) by pulling

away from head assembly.

4. Adjust Mi cr om eter Adjusting Nut (H) against

Quill Stop (G).

5. Continue turning the Micrometer Adjusting Nut

(H) until the Feed Tr ip Cam Lever (D) tri p s .

6. Tighten the Locknut (I).

7. Ensure Quill Lock (K) is disengaged by rotating

counter-clockwise.

8. St ar t the spindle (A):

T he overload clutch is f act ory set

to hold up to 200 lbs. downfeed pressure on t he

quill (accommodates drills up to 3/8”). Do not

attempt t o adjust clutch pr essure.

Figure 17

16

Page 17

Draw Bar Operatio n - Chan ging Tooling

1. Using the wrench provided with the machine,

loosen the draw bar two or three turns (turn

counterclockwise) using the draw bar hex

(Figure 18).

Figure 18

2. Tap the top of the draw bar with a soft-faced

hammer to loosen the collet fr om the taper.

Adjustments

Mill Head – Left/Right Adjustment

Make sure the machine base is

secured to t he floor before repositioning t he mill

head. The center of gra vity can shift enough to

cause the machine to tip over, resulting in

serious in jury to the o perator and da mage t o the

machine.

1. Loosen four large hex nuts that secure the mill

head to the ram adapter (ref er to Figure 20).

1/4 turn should be sufficient to allow the head to

move.

NOTE: For angles greater than 10 degrees, use your

free hand to support the mill head, taking some

weight off t he brass w or m gears. Doi ng so will great ly

lengthen the life of t he wor m gears.

3. Remove the tool from the collet.

4. Insert the tool you are going to use into the collet.

5. Tighten the draw bar firmly using the wrench

provided with the machine. Turn the draw bar.

The tool is now ready for use.

Clamp i ng Work Piece to the Table

1. The worktable has 5/8-inch T-slots for clamping

the work piece to the table.

2. Set motor switch to STOP position.

3. Place the work piece on the table.

4. Clamp the work piece using the T-slot clamps,

studs, and step blocks as required (Figure 19).

Figure 20

2. Turn the worm nut (B, Figure 20) to tilt the head

left or r ight as required. Use the scale on the ram

adapter t o set the desired angle.

Note: The scales on the ram adapter and for

head rotation are guides only. Close tolerance

work will require the use of a dial indicator to

make sure t he head is 90° to the t able in the X

and Y a xis. P lease note the t able is fitted t o be

slightly higher in front, usually about 0. 0005” .

Figure 19

Be sure to apply torque in two

steps using a crossing pattern. Failure to do so

could distort t he f ace of the r am adapter.

3. Tighten the four hex nuts. Tighten in two steps

using a calibrated torque wr ench. Use a crossi ng

pattern to tighten the nuts. Tighten i nitially to 25

foot-pounds.

17

Page 18

4. Bef ore applying f inal torque, c heck to make s ure

the mill head is perpendicular to the wor kt able.

5. Set up a dial indicator in a collet and secure

using the draw bar (ref er to Figure 22).

2. Returning to upright position:

a. When retur ning the mill head to its full upright

position, be sure to support t he head by upward

pressure on the spindle as you turn the worm nut.

6. Put the spindle drive in neutral.

7. Set the dial indicator plunger on the worktable.

Zero the indicator.

8. Rotate the spindle 180 degrees (when rotating,

raise the dial indicator plunger by hand to prevent

it from dropping into the table T-slots) .

9. Read the dial indicat or . The indicator should read

zero. If not, loosen the four hex nuts and

repositio n the mill head.

10. Recheck p er pendic ular ity using t he dia l i ndicat or .

Repeat the procedure above until the dial

indicator reads zero in both positions.

Be sure to apply torque in two

steps using a crossing pattern. Failure to do so

could distort t he f ace of the r am adapter.

11. Tighten the four hex nuts. Tighten in two steps

using a calibrated torque wr ench. Use a crossi ng

pattern to tighten the nuts. Tighten i nitially to 25

foot-pounds, then tighten to a final torque of 50

foot-pounds.

M il l Head – Fore/Aft Adjust ment

1. Setting the angle:

a. Loosen the t hree ram adapter clamp bolts on

the ram (A, Figure 21). There is no need to

loosen the bolts more than 1/2 turn to allow

tilting.

b. Check to make sure t he mill head is p erpendicular to the worktable.

c. Set up a dial indicator in a collet and secure

using the draw bar (ref er to Figure 22).

Figure 22

d. Put the spindle drive in neutral.

e. Set t he dial i ndicat or pl unger on the workt able.

Zero the indicator.

Figure 21

b. Support the mill head with your free hand.

Press upward on the spindle when changing the

angle.

c. Turn t he ram adapter worm nut (B, Fig ure 21)

to tilt the head forward and backward. Use the

scale on the ram adapter to locate the desired

angle.

f. Rot ate the spindle 180 degrees ( when rotating,

raise the dial indicator plunger by hand to prevent

it from dropping into the table T-slots) .

g. Read the dial indicator. The indicator should

read zero. If not, loosen the four hex nuts and

repositio n the mill head.

h. Recheck perpendicularity using the dial

indicator. Repeat the proced ure abo ve until t he

dial indicator reads zero in both positions.

i. When the i ndicator r eads zero, tig hten the ram

adapter clamp bolts.

18

Page 19

Positioning the Ram

Positioning t he Ram Fore and Aft

1. Loose n the tw o bolts (A, Fig ure 23) t hat lock t he

ram to its ways.

Figure 23

2. Turn the lever (B, Figure 23) to move the ram on

its ways.

Figure 24

Adjustment of Knee G ib

The knee gib adjustment screw (A, Figure 24) is

located under the chip w iper at the rear of the knee

where it co ntacts the colum n. Remove the way cover

and the wiper to expose t he gib adjustment screw.

Tighten the screw until a slight drag is felt when

turning the knee crank.

3. When the desired position is reached, lock the

bolts (A, Figure 23) securely.

Positioning t he Ram on its T ur re t

Make sure the machine base is

secured to t he floor bef or e r eposition ing the ra m.

The center of gravity can shift enough to cause

the machine to tip over, resulting in serious injury

to the operat or and damage to t he machine.

1. Loosen four turret lock bolts (C, Figure 23) that

clamp the ram to the top of the base. 1/2 turn

should be sufficient to allow the turret to move.

Note: Use gentle hand pressure to avoid rapid

movement.

2. Turn the ram until the spindle is in the desired

position. Use the scale on the turret for degree

measurement.

3. Tighten the four turret lock bolts (C. Figure 23).

Gib Adjustment

The table, saddle and knee are equipped with

adjustable gibs. The gibs may require adjustment if

unusual vibration is noted when the locking

mechanisms are off, or if you experience unusual

vibratio n when spindle speed, toot h pitch or dept h of

cut do not account for the vibration.

Adjustment of Saddl e G ib

The saddle gib adjustme nt screw is on the left front of

the saddle (B, Figure 24). Tighten the screw until a

slight drag is felt w hen turning the cross-f eed cr ank.

Adjustment of Table Gib

The table gib adj ustm ent screw ( C, Figure 24) is o n

the left-hand side, beneath the table. Tighten the

screw until a slight drag is felt when turning the

longitudi nal table cra nks.

NOTE: When adjusting gibs, always start with the

knee first; adjust the saddle second, and adjust the

table last.

19

Page 20

Power Feed T rip Lever M echanism

Refer to Figure 25.

The power f eed trip lever mec hanism will need to be

adjusted if worn or whenever any trip lever

mechanism compo nents are r eplaced.

1. Loosen the feed trip adjusting screw lock nut.

2. Loose n the adjusting screw until it is loose in the

lever and no longer contacts the bottom of the

feed tr ip plunger.

3. Using the coar se feed ha ndle, mo ve t he q uill to

the bottom of its travel so the quill stop contacts

the micrometer nut. Hold the quill on the stop.

4. Pull the feed handle out to engage the power

feed system.

5. Tur n the feed t rip adjusti ng screw unti l the power

feed disengages.

power f eed. I f not, readjust t he mechanism until

positive dise ngage me nt occ urs when the q uill is

at the top of its stroke.

10. Check for cor r ect operat ion using the coarse f eed

handle. If operating correctly, start the drive

motor and engage the power feed mechanism.

Verify that the power feed lever correctly

engages and disengages when driven by the

drive motor.

Tab le Lead Screw Backlash Adjust ment

Refer to Figure 26.

The milling machi ne table is moved by a lead screw

and nut for each mac hine a xis. For pr oper operat ion,

there m ust be clearance between the lead screw and

the nut, which results in backlash. A second lead

screw nut is provided to eliminate most of the

backlash. The following procedures provide

instructions for obtaining acceptable backlash.

6. Tighten the feed tr ip adjusting scr ew .

7. Release the quill stop so you can engage the

power f eed mechanis m using the power f eed trip

lever.

8. Using the coarse feed handle, pull the quill s top

back into firm contact with the micrometer nut.

Cross Feed Backlash Adjust ment

1. Use the cross feed crank to move the table to t he

extreme rear of its travel.

2. Remove the pleated way cover.

3. O pen the two c hip guards e nough to e xpose the

cross-f eed adjustment nut (the nut t hat is towar d

the rear of t he nut bracket is not adjustable – only

the front nut is adjustable).

4. Loosen the two nut locking screw s.

5. Turn the nut slightly to tighten it against the

opposing nut.

6. Tighten the two nut locki ng screw s.

7. Using the cross-feed crank, move the tab le t o t he

midd le po s ition.

8. Set up a dial indicator to check cross-feed

backlash. Gently mo ve t he cross f eed c r ank back

and forth while watching the dial indicator.

Backlash should be between 0.003 inch and

0.005 inch.

9. If necessary, repeat the steps above to set

backlash.

Figure 25

Note: The power feed should disengage when the

quill stop pushes on the micrometer nut. If it does not

disengage, repeat t he adjustment steps above.

9. Engage t he power f eed and move the q uill stop

to the top of its travel. Make sure that the

reverse trip mechanism also disengages the

10. Install the pleated w ay cover.

Longitudina l Back lash Adjustment

Refer to Figure 26.

1. Only one of t he longitudi nal lead screw nuts can

be adjusted. The other nut is fixed. The left hand

nut is typically adjustable. This can be

determined by looking at the nut from the

underside of t he table.

2. Loosen the two nut locking screw s.

3. Turn the nut slightly to tighten it against the

opposing nut.

20

Page 21

4. Tighten the two nut locki ng screw s.

5. Using the longitudina l table cr ank, move the table

to the middle position.

6. Set up a dial indicator to check longitudinal

backlash. Gently mo ve t he cra nk back a nd fort h

while watching the dial indicator. The backlash

should be between 0.003 inc h and 0.005 inch.

If necessary, r epeat the steps above to set backlash.

Figure 26

21

Page 22

Maintenance

Before any intervention on the machine, disconnect it from the electrical supply by

pulling out t he plug or switchi ng of f t he main switch! Failure to com ply may cause seri ous in jury.

Lubrication

The milling machine is eq uipped wit h a “one-s hot” lubricat io n system. T he system l ubricates the lead screw s

and ways. An oil c up and grease nipple on the mi ll head provide lubrication for t he spindle beari ngs a nd back

gear mechanism. Refer t o Figures 28 and 29 for lubrication require me nts and access points.

Key Description Recommended Lubricant Action

A Spindle bearing oil cup Mobil DTE Oil Lig ht, or equivalent Service daily.

Check oil daily – add if required.

B One-shot lube system Mobil Vactra Oil #2, or equivalent

Knee leadscrew grease

C

nipple

Mob ilith AW2, or e qui valent Serv ic e o nce each week .

Pull lube handle every hour

during operations.

D Back gear gr ease nipple Mobilith AW1, o r equiva lent

Figure 27: Lubri cation Points

Periodic Maintenance Requirements

During operation, periodically vacuum and brush

chips and debris from machine.

Periodically operate knee and table lead screws

t hro ug h f ull r a ng e of mo ve me nt to eve nl y d is tr ib ut e

lubricant (particularly when applied using the “oneshot” system).

Periodically apply light machine oil to w or k t able and

other exposed metal surfaces to prevent rust or

corrosion.

Figure 28

Periodically remove vent panels to check pulleys

and belts for unusual wear or grooving. NOTE:

Operators should vary speed occasional l y to prevent

form ation of groov es on the pulley surfaces .

Service weekly when operating

in back gear mode.

Figure 29

22

Page 23

Repl acement o f Drive Motor

Refer t o Figure 30 and Head Assembly in the Parts

section.

Figure 30

1. Operat e spindle at its highest speed.

Disconnect electrical power to

the machine before per f or ming any ma intenance.

2. Disconnect electrical power. Remove junction

box cover and disconnect wiring. Tag wires to

identify leads for r einstallation.

3. Remove vent covers on both sides of head to

provide access to the vari-speed belt a nd pulleys.

4. Remove the lower cover plate under the motor

pulley (at the rear of t he cover) by removing three

cap screws.

5. Remove the four screws that attach the motor.

6. Connect a lifting sling to support and lift t he motor

during removal. Ease the motor up and forward

on the ho using.

7. Tilt the motor sl ightly toward t he rear t o slacken

the vari-speed belt. Remove the vari-speed belt

from the motor pulley.

10. Slowly release pressure on hydraulic ram until

the spring (ref. 8) is fully extended.

11. Remove the lengthening shaft (ref. 106), spring

stop w asher (r ef . 9), spr ing (ref . 8) and outermost

pulley (ref. 5) from the motor shaft.

12. Loosen set screw (ref. 3) on innermost pulley

(ref . 2). Remove t he pulley (ref. 2) and dri ve key

(ref. 7) from the motor shaft.

13. Install drive key (ref. 7) and pulley (ref. 2) on

shaft of replacement motor. Tighten set screw

(ref. 3) on pulley.

14. Support the drive motor in a hydraulic press.

Place the outerm ost pulley (ref . 5) on the motor

shaft.

15. Install the spri ng (ref. 8), spr ing stop washer (ref.

9), and le ngtheni ng shaft (ref . 106) o n t he motor

shaft.

16. Move the hydraulic ram into contact with the

spring stop washer (ref. 9) . Compress the spring

(ref . 8) and insta ll the lengtheni ng s haf t ( r ef . 106)

on the motor shaft. Install and tighten the

attaching scr ew (ref. 107) in t he end of the motor

shaft.

17. Using an overhead hoist, lift the replacement

moto r int o po s ition.

18. Tilt the motor slightly towar d the rear and i nstall

the vari-speed belt on the motor pulleys.

19. Install the four motor at t ac hing screws.

20. Install lower cover plate.

21. Connect electr ical wir i ng to motor junction box.

22. Start the drive motor. Operate the spindle

throughout its speed r ange to check operatio n.

23. Install vent cover s on mill head.

8. Remove the belt; lift the motor clear of the

housing.

Do not attempt to remove the

screw from the end of the motor shaft without

use of a hydraulic press. Failure to comply may

cause serious injury .

The screw ret ains the underlying spring stop w asher,

which is under spring tension. Serious injury can

result if the spring tension is not gradually released

using the hydraulic press. Pr oceed as f ollow s.

9. Support the drive motor in a hydraulic press.

Move the hydraulic ram into contact with the

spring stop washer (ref. 9). Remove the screw

(ref . 107) from the end of the motor shaft.

Figure 31

23

Page 24

Repl acement o f V ari-Speed Belt

Refer t o Fig ures 31 and 32, and Head Assembly in

the Parts sectio n.

Disconnect electrical power to

the machine before per f or ming any ma intenance.

1. Remove drive motor (refer to the Replacement of

Dri v e Motor sect ion).

2. Remove Quill Top Cover by removing three cap

screws (Figu re 31).

3. Remove six cap screws and remove the upper

housing (Figure 32).

4. Remove the vari-speed belt ( r ef . 4).

5. Install the new vari-speed belt (ref. 4) on the

driven hub (ref. 44) .

6. Install drive motor (refer to the Replacement of

Dri v e Motor section).

Figure 33

6. Pull the pi vot f inger stud (ref . 58) out of the lower

housing cover (ref. 50) and the brake pivot

fingers (ref. 59).

7. Before removing, note the orientation of the

brake pivot f ingers ( r ef. 59) for corr ec t posit ioning

for re-assembly. Remove t he pivot fingers.

If replac ing the brake components onl y, ski p Steps 8

and 9 and go to Step 10.

To replace the tim i ng belt:

8. Remove lower housing cover a nd pulley.

Figure 32

Repl acement o f Brake S hoes, S prings and/or Timing Belt

Disconnect electrical power to

the machine before per f or ming any ma intenance.

1. Remove drive motor (refer to the Replacement of

Dri v e Motor section).

2. Remove vari-speed belt and upper housing (r efer

to the Replacement of Vari-Speed Belt section).

3. Remove screws from lower housing cover

(ref. 50).

4. Loosen the setscrew (ref. 3) securing the brake

pivot finger stud (ref. 58) in the lower housing

cover (ref. 50).

5. Move the pivot finger stud (ref. 58) inward

enough to remove the snap ring (ref. 60).

9. Replace belt (r ef 63).

To replace the brak e com ponents:

10. Using a soft- f ac ed mallet, tap upward to separ at e

the lower housing cover (ref. 50) and the brake

assembly (ref. 47) from the bearing (ref. 43).

11. Remove the brake shoes (ref. 47) and springs

(ref . 49). I nstall the replacem ent brake shoes and

springs.

For all:

12. Position the brake pivot fi ngers (ref. 59) as noted

during removal. Install the pivot finger stud (ref.

58) thro ugh t he low er housing cover (ref. 50) and

into the brake pivot fingers (ref. 59). Install the

snap ring (ref. 60) on the pivot finger stud (ref.

58).

13. Tighte n t he sets crew (ref . 3) to secure the pi vot

finger stud (ref. 58).

14. Install t he brake assemb ly (ref. 47) on the lower

housing cover (ref. 50).

15. Secure the lower housing cover (ref. 50) with four

screws.

16. Install timi ng belt and upper housi ng.

17. Install vari-speed belt (refer to the Replacement

of Vari-Speed Belt section).

18. Install drive motor (refer to the Replacement of

Dri v e Motor section).

24

Page 25

Repl acement o f Qu ill Feed Clock Sp rin g

Refer to the Spindle Assem bly in the Parts sectio n.

Disconnect electrical power to

the machine before per f or ming any ma intenance.

1. Remove the coarse feed handle.

2. Remove the screw, hub, and key from the coarse

feed shaft (r ef. 172, 175, and 171).

3. Remove six screw s (Ref. 1) and allow t he clock

spring (ref. 178) to slowly unwind.

4. Remove feed handle hub sleeve (ref. 176).

5. Lift t he end of the s pring (ref. 178) from the pin

(ref . 168) on the pinion shaft (ref. 166).

6. Remove the spring (ref. 178) from the spring

cover (ref. 177).

7. Install the replacement spring (ref. 178) in the

spring cover (ref 177) .

8. Install end of spring (ref. 178) over the pin

(ref . 168) on pinion shaft (r ef. 166).

9. Install pin (ref. 168) in feed handle hub sleeve

(ref . 176) on other end of spring (ref. 178).

10. Turn the spring cover (ref. 177) t o wind the spring

(ref. 178). Turn the spring cover (ref. 177) until

the desired t ension is ac hieved. Hold t he spring

cover (ref. 177) in position and secure with six

screws (ref . 1).

11. Install t he key, hub, a nd screw ( r ef. 171, 175, and

172) onto the feed shaft (ref. 166) .

Replacement Parts

Replacement p arts ar e listed o n t he follow ing pages. To or der part s or reac h o ur ser vice departme nt, call 1-800274-6848, M onday through Fr iday (see o ur website for business hours, www.waltermeier.com). Having t he Model

Number and Serial Number of your machine available when you call will allow us to serve you quickly and

accurately.

25

Page 26

Head Ass embly

26

Page 27

Parts L ist for Head Assembl y

Index No. Part No. Description Size Qty

................ JTM4 V S-HA ............Head Assembly w/ M ot or................................................................................. 1

1 .............. VS-001....................Upper Housing ............................................................................................... 1

2 .............. VS-002....................Motor Pulley ................................................................................................... 1

................ VS -044A .................Motor Pulley Bushing (not shown) .................................................................... 1

3 .............. TS-1503011 ............Set Screw ........................................................M6 x 6.................................... 4

4 .............. VS-004....................Belt ..................................................................900VC3830 ............................ 1

5 .............. VS-005....................Motor Pulley Disk............................................................................................ 1

6 .............. VS-006....................Motor Pulley Shaft .......................................................................................... 1

7 .............. KEY7725.................Key ..................................................................7 x 7 x 25 mm......................... 1

8 .............. VS-008....................Motor Pulley Spring ........................................................................................ 1

9 .............. VS-009....................Spring Stop Washer ........................................................................................ 1

11 ............ VS-011A .................Motor Pulley Cover ......................................................................................... 1

12 ............ TS-1502051 ............Hex Socket Cap Screw .....................................M5 x 20 .................................. 8

13 ............ VS-013....................Cover ............................................................................................................. 1

14 ............ TS-1503041 ............Hex Socket Cap Screw .....................................M6 x 16 ................................ 10

15 ............ BB-6007ZZ ..............Ball Bearing.................................................................................................... 1

16 ............ VS-016....................Dial Cover ...................................................................................................... 1

17 ............ TS-1503071 ............Hex Socket Cap Screw .....................................M6 x 30 .................................. 4

18 ............ TS-1503041 ............Hex Socket Cap Screw .....................................M6 x 16 .................................. 2

19 ............ VS-019....................Bushin g.......................................................................................................... 1

20 ............ VS-020....................Bushin g.......................................................................................................... 1

21 ............ VS-021....................Worm ............................................................................................................. 1

22 ............ VS -0 2 2....................Wo rm Gear .................................................................................................... 1

23 ............ VS-023....................Spring Pin ........................................................5 x 10 mm .............................. 2

24 ............ VS-024....................Bushin g.......................................................................................................... 2

25 ............ VS-025....................Dial Control Shaft ........................................................................................... 1

26 ............ VS-026....................Spring Pin ........................................................3 x 12 mm .............................. 1

27 ............ VS -0 2 7....................D i a l Wheel ..................................................................................................... 1

28 ............ VS-028....................Wh eel Handle................................................................................................. 1

29 ............ VS-029....................Shaft .............................................................................................................. 1

30 ............ VS-030....................Spring Pin ........................................................4 x 16 mm .............................. 2

31 ............ VS-031....................Spring Pin ........................................................3 x 25 mm .............................. 1

32 ............ VS-032....................Speed Change Chai n ...................................................................................... 1

33 ............ VS-033....................Adjustment Stud ............................................................................................. 1

34 ............ VS-034....................Sleeve Nut ..................................................................................................... 1

35 ............ VS-035....................Adjustment Stud ............................................................................................. 1

36 ............ VS-036....................Tilter .............................................................................................................. 1

37 ............ VS-037....................Bushin g.......................................................................................................... 2

38 ............ KEY6645.................Key ..................................................................6 x 6 x 45 mm......................... 1

39 ............ VS -0 3 9....................R e gula tin g Scre w .................................................................... ....................... 1

40 ............ VS-040....................Spring Pin ........................................................3/32” x 3/4"............................. 1

41 ............ VS-041....................Washer .......................................................................................................... 1

42 ............ VS-042....................Support .......................................................................................................... 1

43 ............ BB-6010VV .............Ball Bearing.................................................................................................... 2

44 ............ VS-044....................Driven Pulley Assembly (s/n:xxx1944 & lower ) .................................................. 1

................ VS-044N .................Driven Pulley Assembly (s/n:xxx1945 & higher) ................................................ 1

45 ............ VS-045....................Steady Pulley (s/n: xx x1944 & lower) ................................................................ 1

................ VS -0 4 5N .................Steady Pulley (s/ n: xx x1945 & higher) ............................................................... 1

46 ............ VS-046....................Bearing Cover ............................................................................................... 1

47 ............ VS-047....................Brake Linin g ................................................................................................... 1

48 ............ VS -0 4 8....................Lo c k Scre w .................................................................................................... 1

49 ............ VS-049....................Brake Spring .................................................................................................. 2

50 ............ VS-050....................Lower Housing Cover...................................................................................... 1

51 ............ TS-1504031 ............Hex Socket Cap Screw .....................................M8 x 20 .................................. 4

52 ............ VS-052....................Brake Shaft Sleeve ......................................................................................... 1

53 ............ VS-053....................Brake Lock Shaft ............................................................................................ 1

54 ............ VS-054....................Brake Lock Block ............................................................................................ 1

27

Page 28

55 ............ TS-1503061 ............Hex Socket Cap Screw .....................................M6 x 25 .................................. 1

56 ............ VS-056....................Brake Lock Ha ndle ......................................................................................... 1

57 ............ VS-057....................Plastic Ball ..................................................................................................... 2

58 ............ VS-058....................Brake Finger Pivot Stud .................................................................................. 1

59 ............ VS-059....................Brake Stud ..................................................................................................... 2

60 ............ VS-060....................Snap Ring ........................................................S-8 ........................................ 2

61 ............ TS-0561072 ............Nu t ..................................................................5/8” -1 8 UNF ........................... 1

62 ............ VS-062....................Timing Belt Pulley ........................................................................................... 1

63 ............ VB-225L100 ............Timing Belt .......................................................225L100................................. 1

64 ............ VS-064....................Bearing Retainer............................................................................................. 1

65 ............ BB-6203ZZ ..............Ball Bearing.................................................................................................... 2

66 ............ VS-066....................Bull Gear ........................................................................................................ 1

67 ............ VS-067....................Counter Shaft ................................................................................................. 1

68 ............ VS-068....................Key ..................................................................5 x 5 x 15 mm......................... 1

69 ............ VS-069....................Key ..................................................................5 x 5 x 18 mm......................... 1

70 ............ VS -0 7 0....................S p indle Pu ll ey H ub ......................................................................................... 1

71 ............ VS-071....................Key ..................................................................8 x 7 x 24 mm......................... 1

72 ............ VS-072....................Key ..................................................................8 x 7 x 12 mm......................... 1

73 ............ VS-073....................Spindle Gear Hub ........................................................................................... 1

74 ............ VS-074....................Spindle Gear Assembly ................................................................................... 1

75 ............ VS-075....................Rack Cup ....................................................................................................... 1