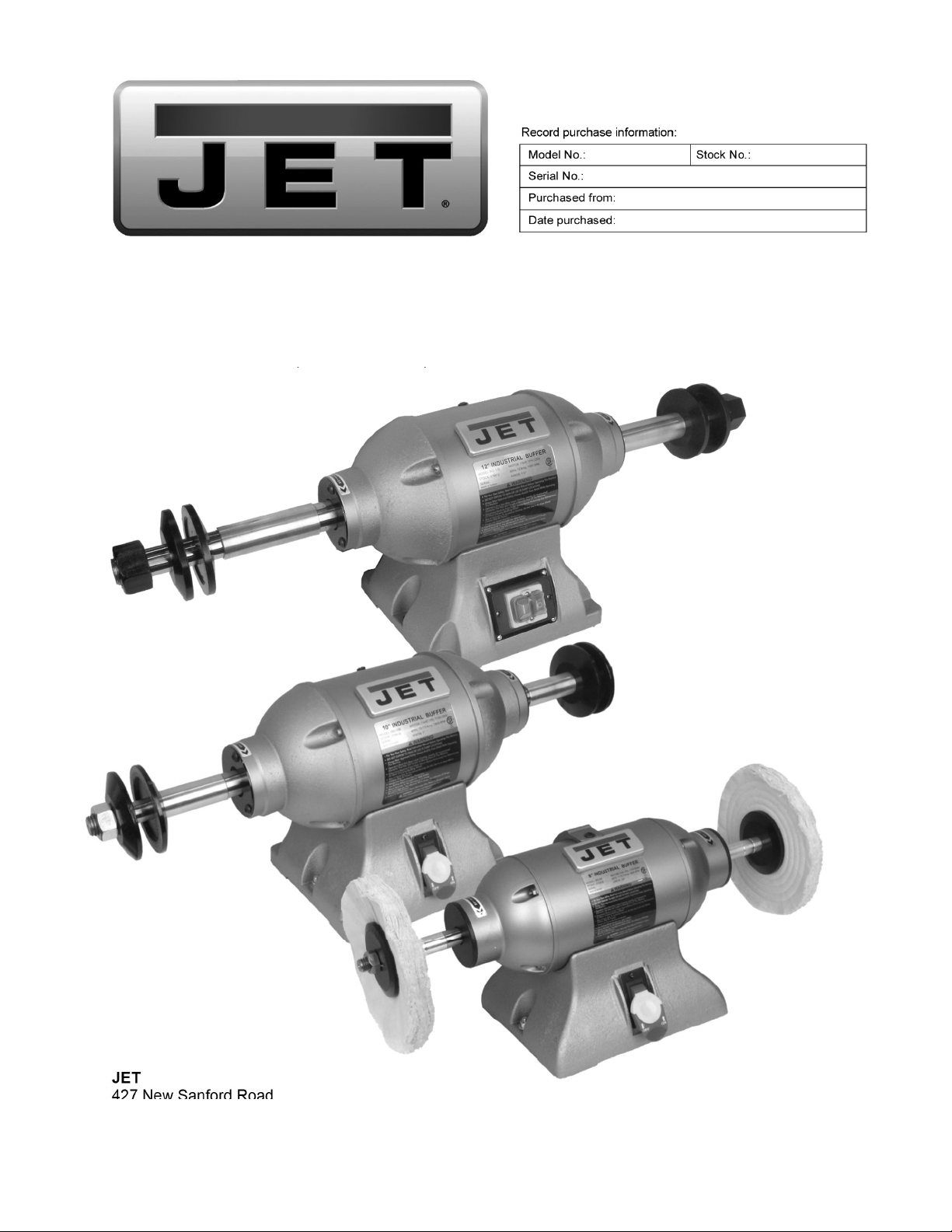

Page 1

Operating Instructions and Parts Manual

This .pdf document is bookmarked

Industrial Buffing Machines

Models IBG-8SSB, IBG-10SSB, IBG-12SSB

IBG-12SSB

JET

427 New Sanford Road

LaVergne, Tennessee 37086

Ph.: 800-274-6848

www.powermatic.com

IBG-10SSB

IBG-8SSB

(includes wheels)

Part No. M-577408

Edition 1 12/2019

Copyright © 2019 Powermatic

Page 2

1.0 IMPORTANT SAFETY

INSTRUCTIONS

WARNING – To reduce risk of injury:

1. Read and understand the entire owner's manual

before attempting assembly or operation.

2. Read and understand the warnings posted on the

machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

3. Replace warning labels if they become obscured

or removed.

4. This buffer is designed and intended for use by

properly trained and experienced personnel only.

If you are not familiar with the proper and safe

operation of a buffer, do not use until proper

training and knowledge have been obtained.

5. Do not use this buffer for other than its intended

use. If used for other purposes, JET disclaims any

real or implied warranty and holds itself harmless

from any injury that may result from that use.

6. Always wear protective eye wear when operating

machinery. Eye wear shall be impact resistant,

protective safety glasses with side shields which

comply with ANSI Z87.1 specifications. Use of eye

wear which does not comply with ANSI Z87.1

specifications could result in severe injury from

breakage of eye protection. (Everyday eyeglasses

only have impact resistant lenses; they are NOT

safety glasses.)

7. Wear proper respiratory protection.

8. Wear proper apparel. Do not wear loose clothing,

neckties, rings, bracelets, or other jewelry which

may get caught in moving parts. Non-slip footwear

is recommended. Wear protective hair covering to

contain long hair.

9. Wear protective clothing such as apron or safety

shoes, where the work activity presents a hazard

to the operator.

10. Wear ear protectors (plugs or muffs) if the

particular work requires it.

11. Do not operate this machine while tired or under

the influence of drugs, alcohol or any medication.

12. Make certain the switch is in the OFF position

before connecting the machine to the power

supply.

13. Make certain the machine is properly grounded.

14. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

15. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and adjusting

wrenches are removed from the machine before

turning it on.

16. Keep safety guards in place at all times when the

machine is in use. If removed for maintenance

purposes, use extreme caution and replace the

guards immediately after completion of

maintenance.

17. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may affect

its operation. A guard or other part that is damaged

should be properly repaired or replaced.

18. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free

of scrap material, oil and grease.

20. Keep visitors a safe distance from the work area.

Keep children away.

21. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

22. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in serious

injury.

23. Keep proper footing and balance at all times so

that you do not fall into or lean against the buffing

wheel or other moving parts. Do not overreach or

use excessive force to perform any machine

operation.

24. Disconnect buffer from power source before

servicing and when changing wheels.

25. Use recommended accessories. The use of

improper accessories may cause risk of injury to

persons.

26. Turn off the machine before cleaning. Use a brush

to remove chips or debris — do not use bare

hands.

27. Never leave the buffer running unattended. Turn

power off and do not leave machine until wheels

come to a complete stop.

28. Remove loose items and unnecessary work

pieces from the area before starting the buffer.

29. Don’t use in dangerous environment. Don’t use

power tools in damp or wet location, or expose

them to rain. Don’t use this buffer in a flammable

environment. Keep work area well lighted.

30. Keep work area clean. Cluttered areas and

benches invite accidents.

31. Use the right tool. Don't force tool or attachment to

do a job for which it was not designed.

2

Page 3

32. Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

Table 2 (see sect. 6.2) shows the correct size to

use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier

the cord.

33. Maintain tools with care. Keep tools sharp and

clean for best and safest performance. Follow

instructions for lubricating, and changing

accessories.

34. Only apply workpiece to lower half of buffing

wheel.

35. Do not overtighten wheel nut.

36. Use buffing wheel suitable for speed of machine.

37. Do not crowd the work so that the wheels slow.

38. Use only the flanges that are furnished with the

buffer.

39. Do not start the buffer while a workpiece is

contacting a buffing wheel.

WARNING: This product can expose you to

chemicals including lead which is known to the

State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to http://www.p65warnings.ca.gov.

WARNING: Some dust, fumes and gases

created by power sanding, sawing, grinding,

drilling, welding and other construction activities

contain chemicals known to the State of California

to cause cancer and birth defects or other

reproductive harm. Some examples of these

chemicals are:

lead from lead based paint

crystalline silica from bricks, cement and other

masonry products

arsenic and chromium from chemically treated

lumber

Your risk of exposure varies, depending on how

often you do this type of work. To reduce your

exposure to these chemicals, work in a wellventilated area and work with approved safety

equipment, such as dust masks that are specifically

designed to filter out microscopic particles. For

more information go to http://www.p65warnings.

ca.gov/ and http://www.p65warnings.ca.gov/wood.

SAVE THESE INSTRUCTIONS

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

injury.

3

Page 4

2.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 4

3.0 About this manual .......................................................................................................................................... 5

4.0 Specifications ................................................................................................................................................. 6

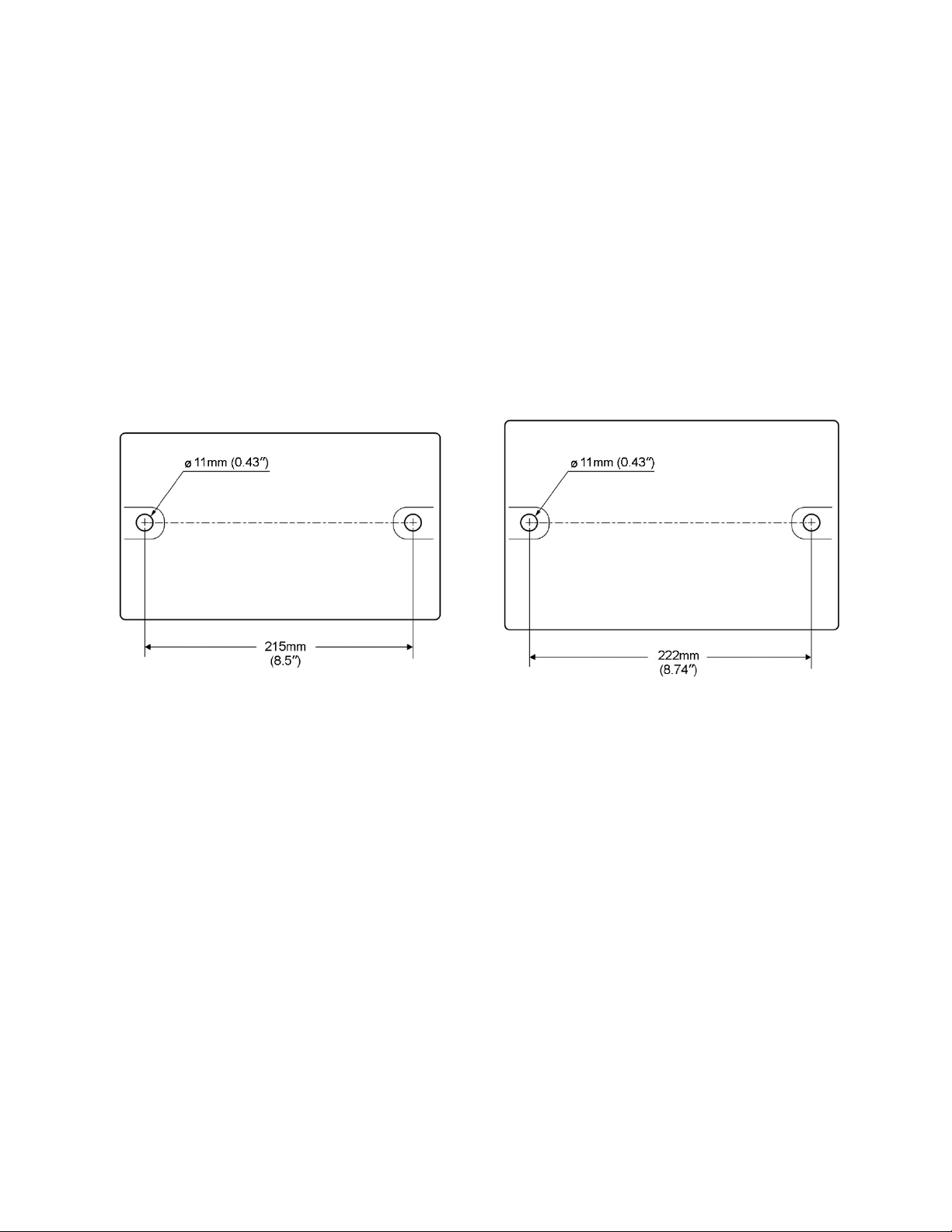

4.1 Mounting hole dimensions .......................................................................................................................... 7

5.0 Setup and assembly ....................................................................................................................................... 8

5.1 Unpacking .................................................................................................................................................. 8

5.2 Carton contents .......................................................................................................................................... 8

5.3 Tools required for assembly ....................................................................................................................... 8

5.4 Securing the buffer ..................................................................................................................................... 8

5.5 Buffing wheels ............................................................................................................................................ 8

6.0 Electrical connections .................................................................................................................................... 8

6.1 GROUNDING INSTRUCTIONS ................................................................................................................. 9

6.2 Extension cords .......................................................................................................................................... 9

6.3 Voltage conversion ..................................................................................................................................... 9

7.0 Operation ..................................................................................................................................................... 10

7.1 On/Off Switch ........................................................................................................................................... 10

7.2 General procedure ................................................................................................................................... 10

8.0 User-maintenance ........................................................................................................................................ 10

8.1 Changing Wheels ..................................................................................................................................... 10

8.2 Wheel balancing ....................................................................................................................................... 11

8.3 Buffer maintenance .................................................................................................................................. 11

8.4 Additional servicing .................................................................................................................................. 11

9.0 Troubleshooting IBG-SSB series Buffers ..................................................................................................... 12

10.0 Optional accessories .................................................................................................................................. 13

11.0 Replacement Parts ..................................................................................................................................... 13

11.1.1 IBG-8SSB Buffer – Exploded View ..................................................................................................... 14

11.1.2 IBG-8SSB Buffer – Parts List .............................................................................................................. 15

11.2.1 IBG-10SSB Buffer – Exploded View ................................................................................................... 16

11.2.2 IBG-10SSB Buffer – Parts List ............................................................................................................ 17

11.3.1 IBG-12SSB Buffer – Exploded View ................................................................................................... 18

11.3.2 IBG-12SSB Buffer – Parts List ............................................................................................................ 19

12.0 Electrical Connections ................................................................................................................................ 20

12.1 Wiring diagram for IBG-8SSB ................................................................................................................ 20

12.2 Wiring diagram for IBG-10SSB .............................................................................................................. 21

12.3 Wiring diagram for IBG-12SSB .............................................................................................................. 22

13.0 Warranty and Service ................................................................................................................................. 23

4

Page 5

3.0 About this manual

This manual is provided by JET, covering the safe operation and maintenance procedures for the JET IBG-SSB

series Buffing Machines. This manual contains instructions on installation, safety precautions, general operating

procedures, maintenance instructions and parts breakdown. Your buffer has been designed and constructed to

provide consistent, long-term operation if used in accordance with the instructions set forth in this document.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the buffer transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly or

operation! Failure to comply may cause serious injury!

Register your product using the mail-in card provided, or register online:

http://www.jettools.com/us/en/service-and-support/warranty/registration/

5

Page 6

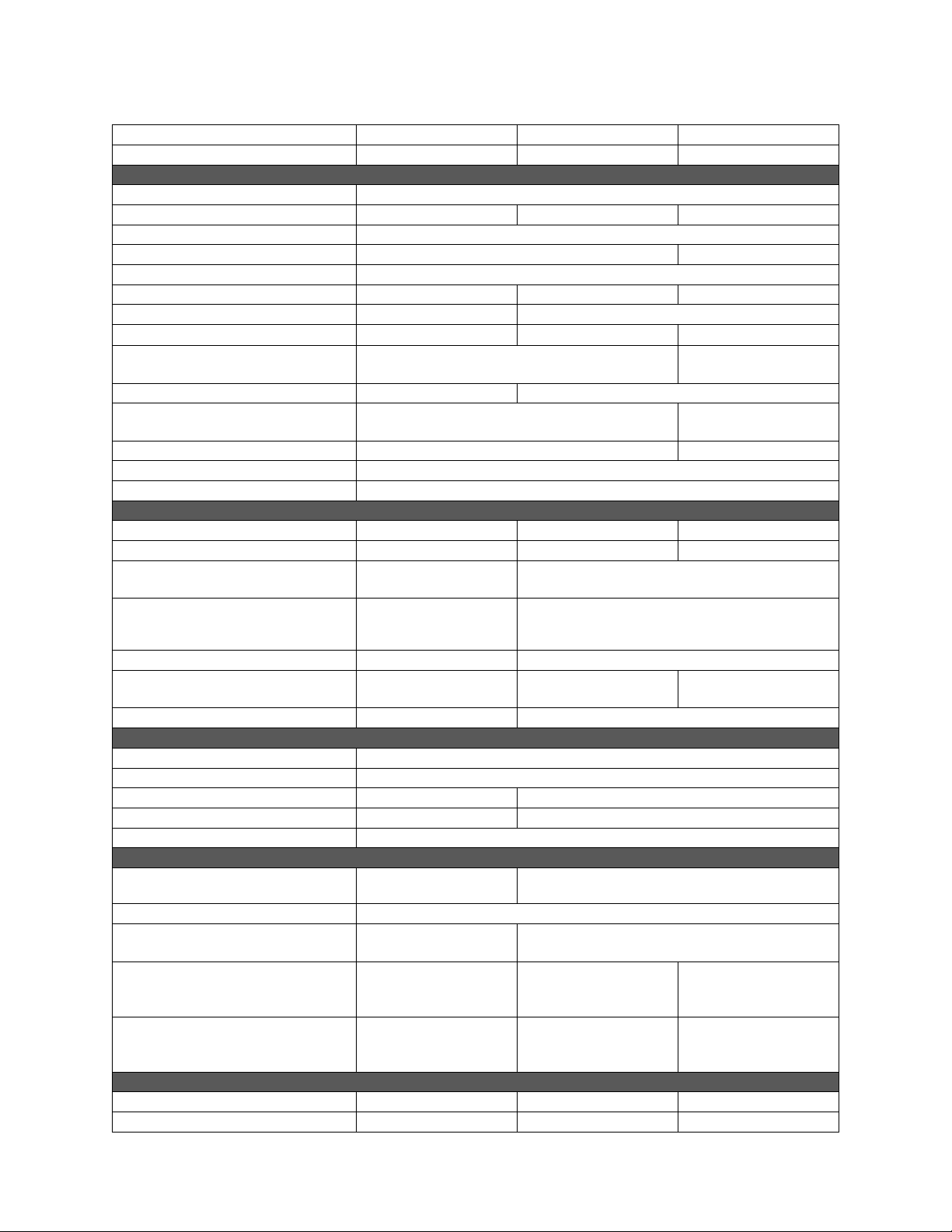

4.0 Specifications

Table 1

Model number

Stock number 577408 578410 578412

Motor and Electricals

Motor type Induction, capacitor start, centrifugal switch

Horsepower (true output) 1 HP 1-1/2 HP 2 HP

Motor phase single

Voltage 115/230V (prewired 115V) 230V only

Cycle 60 Hz

Listed FLA (full load amps) 11 / 5.5 A 15 / 7.5 A 12 A

Start capacitor 200MFD 125VAC 400MFD 125VAC

Run capacitor

On/off switch

Motor speed 3600 RPM 1800 RPM

Power cord

Power plug installed 5-15P, 125V/15A 6-15P, 250V/15A

Minimum recommended circuit size 1 15A

Sound emission without load 2 75 dB at 3 ft.

Arbor and buffing wheels

Arbor diameter 5/8 in. (16mm) 1 in. (25.4mm) 1-1/4 in. (31.75mm)

Arbor thread 5/8” – 11UNC 1” – 8UNC 1-1/4” – 7UNC

Buffing wheel size (OD x width x bore)

Wheel material Woven cotton: spiral

Wheel flange diameter 3-3/8 in. (85 mm) 4-1/8 in. (104.8 mm)

Spacers length 1/2, 5/8, 1 in.

Wheel speed 3600 RPM 1800 RPM

Main materials

Arbor Steel

Base Cast iron

Motor housing Sheet metal Cast iron

End cover Aluminum Cast iron

Flange washers Cast iron

Dimensions

Distance between mounting holes

(centers)

Mounting hole diameters 7/16 in. (11mm)

Base footprint (WxD) 9-1/2 x 8-1/16 in.

Assembled dimensions (LxWxH) 23-11/32 x 8-21/32 x

Shipping dimensions (LxWxH) 26-1/2 x 10-5/16 x

Weights

Net weight 38 lbs. (17.20 kg) 72 lbs. (32.75 kg) 86 lbs. (39.14 kg)

Shipping weight 44 lbs. (20.15 kg) 80 lbs. (36.53 kg) 97 lbs. (43.89 kg)

IBG-8SSB IBG-10SSB IBG-12SSB

35F 250V 45F 350V 20F 350V

Toggle switch with safety key

125/250V, 20A/12A

16AWG x 3C SJT, 6 ft. (182 cm) 14AWG x 3C SJT,

8 x 1/2 x 5/8 in.

(203.2 x 12.7 x 16 mm)

sewn and half-spiral

sewn

2, 1, 1/2 in.

(13, 16, 25mm)

8-15/32 in. (215mm) 8-3/4 in. (222.25 mm)

(241.6 x 205 mm)

9-17/32 in.

(593 x 220 x 242 mm)

11-25/32 in.

(680 x 260 x 330 mm)

(51, 25.5, 12.7 mm)

10 x 9-21/32 in. (254 x 245.3 mm)

30 x 9-11/16 x 11-7/8 in.

(762 x 246 x 302 mm)

33-27/32 x 12-19/32 x

15-11/32 in.

(860 x 320 x 390 mm)

not provided

not provided

Push button, magnetic

switch, 250V, 16A

6ft. (182 cm)

3-1/8, 2, 1, 1/2 in.

(79.5,51,25.5,12.7 mm)

35-29/32 x 9-11/16

x 11-7/8 in.

(912 x 246 x 302 mm)

40-5/32 x 12-19/32 x

15-11/32 in.

(1020 x 320 x 390 mm)

6

Page 7

1

subject to local/national electrical codes.

2

The specified values are emission levels and are not necessarily to be seen as safe operating levels. As workplace

conditions vary, this information is intended to allow the user to make a better estimation of the hazards and risks

involved only.

L = length, W = width, H = height, D = depth

n/a = not applicable

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

4.1 Mounting hole dimensions

Figure 4-1: IBG-8SSB

Figure 4-2: IBG-10SSB and IBG-12SSB

7

Page 8

5.0 Setup and assembly

5.1 Unpacking

Separate all parts from the packing material. Check

each part against sect. 5.2, Carton contents, and

make certain that all items are accounted for before

discarding any packing material. (Check buffer to

verify if any parts have been pre-mounted.)

5.2 Carton contents

1 Buffing machine

2 Buffing wheels (IBG-8SSB only)

4 Flanges

1 Spacer kit (contains 3 spacers for IBG-8SSB

and IBG-10SSB; 4 spacers for IBG-12SSB)

2 Arbor nuts (1 left-hand, 1 right-hand)

1 Operating instructions & parts manual

1 Product registration card

5.3 Tools required for assembly

Adjustable wrenches, or tongue-and-groove

(“channel lock”) pliers

The Buffer requires only the installing of buffing

wheels and spacers. Additional fasteners and tools

may be needed for mounting the buffer to a

workbench or stand. For your safety, do not plug the

machine into a power source until all assembly and

adjustments are complete.

Do not plug in the buffer to

power until it is inspected for shipping damage,

fully assembled, and moved to its permanent

location.

5.4 Securing the buffer

To prevent the machine from moving during

operation, it should be securely mounted to a work

surface or stand. Fasteners for mounting are not

included with the buffer.

1. Align mounting holes on buffer with predrilled

holes in a bench or stand. Sect. 4.1 shows hole

centers for mounting.

2. Insert M10 (or 3/8”) bolts through the holes and

tighten, using washers and nuts.

An optional pedestal stand (not included) is

available from JET for your buffer. See sect. 10.0.

IMPORTANT: The buffer’s base plate contains

ventilation slots for heat dissipation. These slots

should not be obstructed. The rubber feet should be

left on the machine when mounting, as they allow air

circulation as well as vibration dampening.

5.5 Buffing wheels

1. Disconnect buffer from power source.

2. Install spacers onto each end of arbor as

needed for the width of the wheels used.

3. Check the flanges to make sure they are clean

and flat. Wheel flanges that are not flat will

cause the wheel to wobble.

4. Install inner flange, buffing wheel, and outer

flange.

5. Install the right-hand thread nut on right end of

arbor; turn clockwise to tighten. Install the lefthand thread nut on left end of arbor, turn

counterclockwise to tighten. Do not overtighten

the nuts. Place a wrench on the flats (next to the

housing) of the spindle to keep the spindle

stationary while tightening or loosening the

nuts.

Note: On the IBG-8SSB, the brass-colored nut

has left-hand threads; the silver-colored nut has

right-hand threads.

See sect. 8.0 for further information on inspecting

and changing wheels.

6.0 Electrical connections

Electrical connections should

be made by a qualified electrician in compliance

with all relevant codes. This tool must be

properly grounded. Failure to comply may result

in serious or fatal injury.

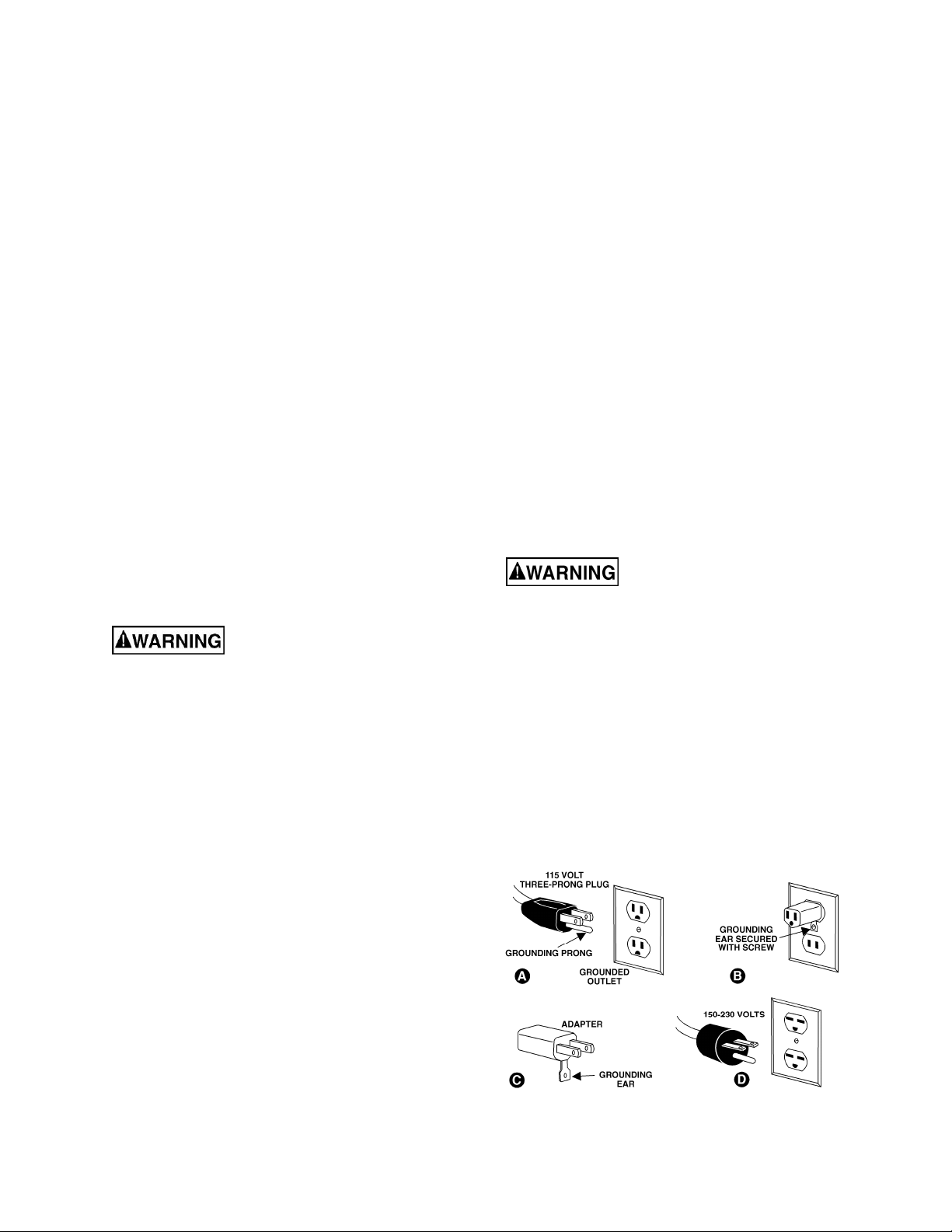

The IBG-8SSB and IBG-10SSB Buffers are

prewired for 115V single phase power, and are

supplied with a plug designed for use on a circuit

with a grounded outlet that looks like the one

pictured in A, Figure 6-1. These buffers may be

converted to 230V single phase power, see sect.

7.3.

The IBG-12SSB is prewired for 230V only and is

supplied with a plug designed for use on a circuit

with a grounded outlet that looks like the one

pictured in D, Figure 6-1.

8

Figure 6-1: plug configurations

Page 9

It is recommended that the buffer be connected to a

minimum 15-amp circuit with circuit breaker or fuse.

If using fuses, they should be time-delay fuses

marked “D”. Local codes take precedence over

recommen-dations.

6.1 GROUNDING INSTRUCTIONS

1. All Grounded, Cord-connected Tools:

This tool must be grounded. In the event of a

malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified

electrician or service personnel if the grounding

instructions are not completely understood, or if

in doubt as to whether the tool is properly

grounded. Failure to comply may cause serious

or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating less than

150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in A, Figure

6-1. An adapter, shown in B and C, may be used to

connect this plug to a 2-pole receptacle as shown in

B if a properly grounded outlet is not available. The

temporary adapter should be used only until a

properly grounded outlet can be installed by a

qualified electrician. This adapter is not permitted in

Canada. The green-colored rigid ear, lug, and the

like, extending from the adapter must be connected

to a permanent ground such as a properly grounded

outlet box.

3. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating between

150 - 250 volts, inclusive:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in D, Figure

6-1. A grounding plug may be installed, that looks

like the plug illustrated in D; or the grinder may be

“hard-wired” to a panel, provided there is a

disconnect for the operator.

Make sure the tool is connected to an outlet having

the same configuration as the plug. No adapter is

available or should be used with this tool. If the tool

must be reconnected for use on a different type of

electric circuit, the reconnection should be made by

qualified service personnel; and after reconnection,

the tool should comply with all local codes and

ordinances.

6.2 Extension cords

The use of extension cords is discouraged. Try to

position equipment near the power source. If an

extension cord becomes necessary, use only threewire extension cords that have three-prong

grounding type plugs and three-prong receptacles

that accept the tool's plug. Replace or repair

damaged or worn cord immediately.

Make sure your extension cord is good condition,

and is heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating.

Table 2 shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage

number (AWG), the heavier the cord.

Amp rating Volts Total length of cord in feet

120

25

50

More

Than

Not

More

Than

0 6 18 16 16

6 10 18 16 14

10 12 16 16 14

12 16 14 12

240

50

AWG

100

100

200

Not

Recommended

150

300

14

12

12

Extension Cord Recommendations

Table 2

6.3 Voltage conversion

To change voltage input to 230-volt on the IBG8SSB or IBG-10SSB:

1. Disconnect buffer from power source.

2. Turn buffer over and remove the base plate.

3. Rewire the leads according to the appropriate

diagram in sect. 12.0. Reinstall base plate.

4. Remove the existing plug from the power cord

and attach a UL/CSA listed plug designed for

230V power.

9

Page 10

7.0 Operation

Buffing wheels vary according to material and

structure, and range from aggressive wheels that

even out high spots and remove surface defects

(“cutting”), to finer wheels that bring out the brilliant

luster of the metal surface (“coloring”). The buffing

wheel surface may be straight or biased (cut at an

angle).

The IBG-8SSB only is provided with two buffing

wheels: full spiral-sewn wheel for general polishing

of metals, and a looser or half spiral-sewn wheel for

final polishing and coloring of metals.

A compound (not provided) should be selected for

the specific wheel and work to be done. Generally

for spiral-sewn cloth wheels, a brown (Tripoli),

compound will be used for basic cutting and

polishing, followed by a white compound for

coloring. Red (Jeweller’s Rouge) compound is often

used for further enhancement to gain a mirror-like

surface. Consult experienced metalworkers and

internet resources for specific recommendations on

buffing wheels and their application.

Always use approved safety

glasses or face shield while operating buffer.

Also use appropriate respiratory protection.

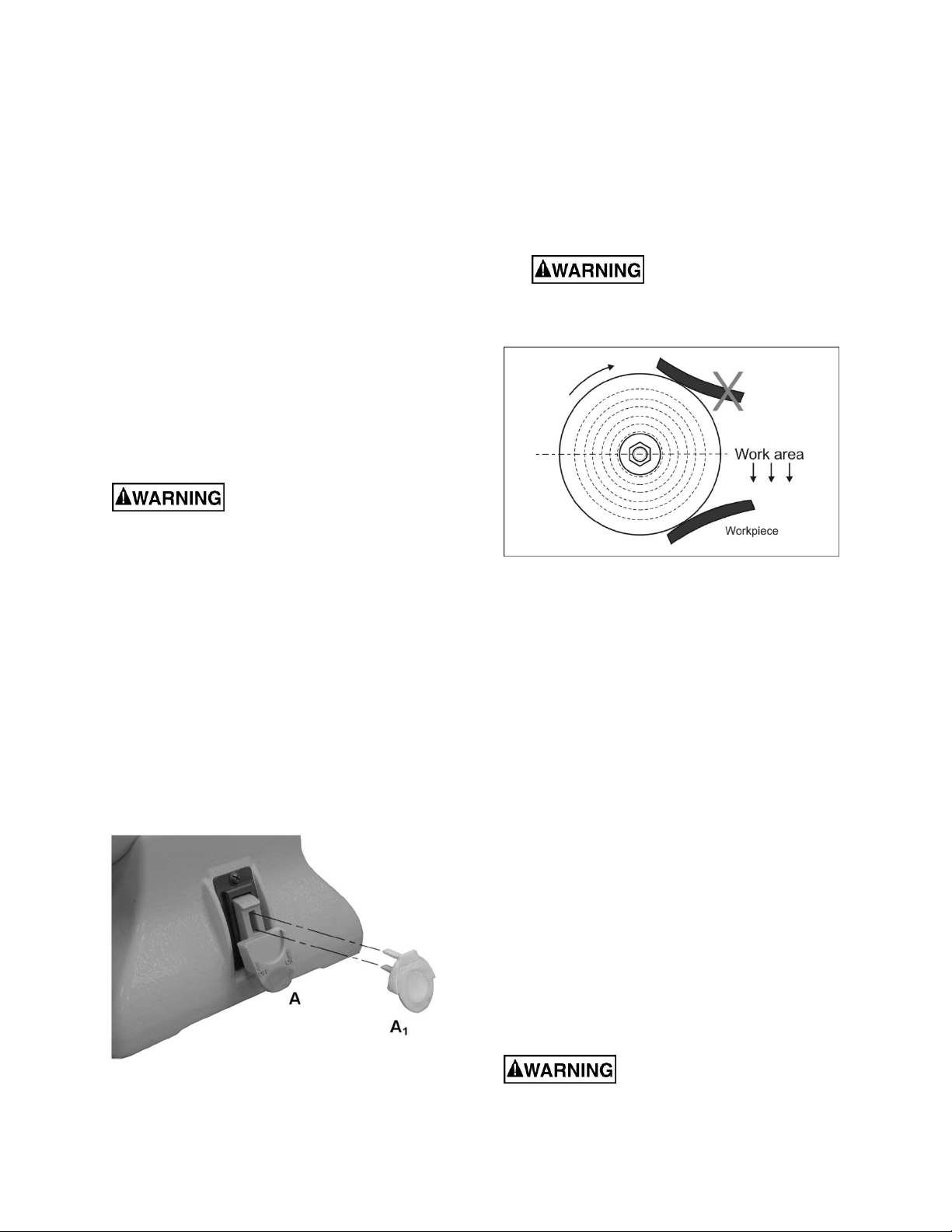

7.1 On/Off Switch

7.2 General procedure

1. Turn on buffer and apply compound to lower

part of spinning wheel (not the workpiece). Do

not apply excessive compound; press

compound stick lightly against wheel for only a

few seconds. Reapply later as needed.

2. Grip workpiece firmly and press it against

underside of wheel, that is, the area of wheel

that is rotating away from the workpiece. See

Figure 7-2.

Press workpiece to lower

half of buffing wheel only. Using upper half

of wheel may cause workpiece to catch and

could result in injury.

Figure 7-2

IBG-8SSB, IBG-10SSB: Pull up the paddle switch

(A, Figure 7-1) to start buffer, push to stop. The

safety key (A1) can be removed to prevent

unauthorized use of the machine. The safety key

must be inserted to restart the machine.

IBG-12SSB: Push green button to start. Push red

button to stop.

On all models, when the stop button is pushed, the

wheels may take a few moments to completely stop.

Note: After extended operation, the machine

housing may be warm to the touch. This is not

abnormal.

Figure 7-1: safety key (IBG-8SSB,10SSB only)

8.0 User-maintenance

For safety, unplug machine from power source

receptacle before adjusting or performing any

maintenance. If the power cord is worn, cut or

damaged in any way, have it replaced immediately.

Motor bearings are permanently lubricated and

sealed at the factory and require no additional

attention.

Periodically clean accumulated dust or debris away

from areas such as the on/off switch. Do not allow

dust and debris to build up beneath the machine.

Periodically wipe the shafts clean with a soft rag,

and wipe on a light application of SAE 20, or basic

machine tool oil, to inhibit rust.

8.1 Changing Wheels

When replacing a buffing wheel, obtain one with a

safe rated speed at least as high as the maximum

RPM of the buffing machine. See sect. 4.0 for the

RPM specification for your model.

The spacers on the shaft allow for different

configurations and widths of buffing wheel.

The use of any other accessory

is not recommended and may result in serious

injury.

10

Page 11

8.2 Wheel balancing

With the buffer unplugged from the power

source, and arbor nuts snugged down, rotate

wheels by hand and observe their motion.

A buffing wheel has proper balance when:

1. The wheel’s outside face spins true and round;

that is, its circumference rotates concentric to

the arbor.

2. There is no side-to-side wobble.

8.2.1 Adjusting concentricity

If the outside face is not rotating concentric to arbor,

try shifting the wheel closer to arbor centerline

before tightening the nut.

A wheel rake (not provided) may also be used to

shape the buffing wheel for better concentric

rotation.

8.2.2 Correcting side-to-side wobble

The IBG-SSB series Buffers have large, machined

flanges, making wobble unlikely if a good quality

buffing wheel is used. Should a wheel exhibit need

for adjustment:

1. Loosen nut and rotate the outer flange a little.

Snug the nut and spin the wheel by hand to

check.

2. If wobble still exists, continue repeating step 1,

rotating outer flange incrementally in the same

direction. Make sure to keep the wheel in the

same position each time.

3. If complete rotation of outer flange has proved

ineffective, remove nut, outer flange, and wheel

(keep wheel in same orientation by placing a

pencil mark on it somewhere for reference).

Then rotate inner flange about 90° and repeat

the above steps for the outer flange.

4. Continue this combination of flange movements

until the wobble is eliminated.

If required, a shim made of paper or card stock may

be placed between flange and wheel side.

NOTE: Slight wobble may still exist at spin-up and

spin-down, but will not affect normal speed

operation.

8.3 Buffer maintenance

Periodically use a wheel rake (not provided) to clean

and shape the buffing wheels.

8.4 Additional servicing

Any additional servicing on the buffer machine

should be performed by an authorized service

representative.

11

Page 12

9.0 Troubleshooting IBG-SSB series Buffers

Table 3

* WARNING: Some corrections may require a qualified electrician.

Symptom Possible Cause Correction *

Motor will not start. Not connected to power source. Verify that plug is properly inserted into

receptacle.

Motor cord cut or abraded. Replace with new cord.

Motor will not start;

fuses blow or circuit

breaker trips.

Motor fails to develop

full power.

Wheels cannot rotate because of

obstruction.

Plug on cord is faulty. Replace with new plug.

Low line voltage. Check power line for proper voltage.

Fuse blown or circuit breaker open. Re-set fuses/breaker.

Faulty switch. Replace switch.

Start capacitor faulty. Replace start capacitor.

Motor fault. Contact JET technical service.

Too many electrical machines

running on same circuit.

Incorrect fuse. Use time-delay fuse, or go to circuit with

Wheels cannot rotate because of

obstruction.

Undersized extension cord. Use correct size extension cord.

Short circuit in line cord or plug. Inspect cord or plug for damaged

Short circuit in motor or loose

connections.

Low line voltage. Check power line for proper voltage.

Run capacitor faulty. Replace capacitor.

Unplug and turn wheel by hand to ensure

free movement. Restart.

Turn off other machines and try again.

higher rated fuse or breaker.

Unplug and turn wheel by hand to ensure

free movement. Clear any obstructions

and restart.

insulation and shorted wires.

Inspect all connections on motor for loose

or shorted terminals or worn insulation.

Faulty motor. Contact JET technical service.

Motor overheats. Motor overloaded. Reduce pressure against wheel. Make

sure wheel is appropriate for the job.

Motor stalls, resulting

in blown fuses or

tripped circuit.

Motor slows. Motor overloaded. Reduce load to motor; do not press so

Frequent fuse or circuit

breaker failure.

Motor overloaded. Reduce load on motor; do not press so

hard.

Capacitor failure. Contact JET technical service.

Short circuit in motor or loose

connections.

Low voltage. Correct the low voltage conditions.

Incorrect fuses or circuit breaker in

power line.

Low line voltage. Check power line for proper voltage.

Loose electrical connections. Inspect connections.

Motor overload. Reduce load to motor; do not press so

Electrical circuit overload; too many

machines running on same circuit.

Incorrect fuse or circuit breaker. Have electrician upgrade service to outlet.

12

Inspect connections on motor for loose or

shorted terminals or worn insulation.

Install correct fuse or breaker.

hard.

hard.

Turn off other machines and try again.

Page 13

Symptom Possible Cause Correction *

Excessive vibration. Wheel(s) out of balance; wobbling or

not rotating concentric to arbor.

Improper mounting. Secure machine firmly to bench or stand.

Rake the wheel or replace it. Adjust

wobble by rotating flange as needed.

10.0 Optional accessories

These accessory items, purchased separately, are available for your JET buffer. Contact your dealer to order, or

call JET at the phone number on the cover.

Flexible 3W LED

Lamp

IBG Stand

#578172

(includes two

Deluxe IBG

Stand

#578173

1/4 x 3/8 mounting

screws)

#578100

JDCS-505 Dust

Collection Stand

#414800

Dust Shroud

#578400 (for 8” Buffer)

#578405 (for 10” and 12” Buffers)

11.0 Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-800274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial Number of

your machine available when you call will allow us to serve you quickly and accurately.

Non-proprietary parts, such as fasteners, can be found at local hardware stores, or may be ordered from JET.

Some parts are shown for reference only, and may not be available individually.

13

Page 14

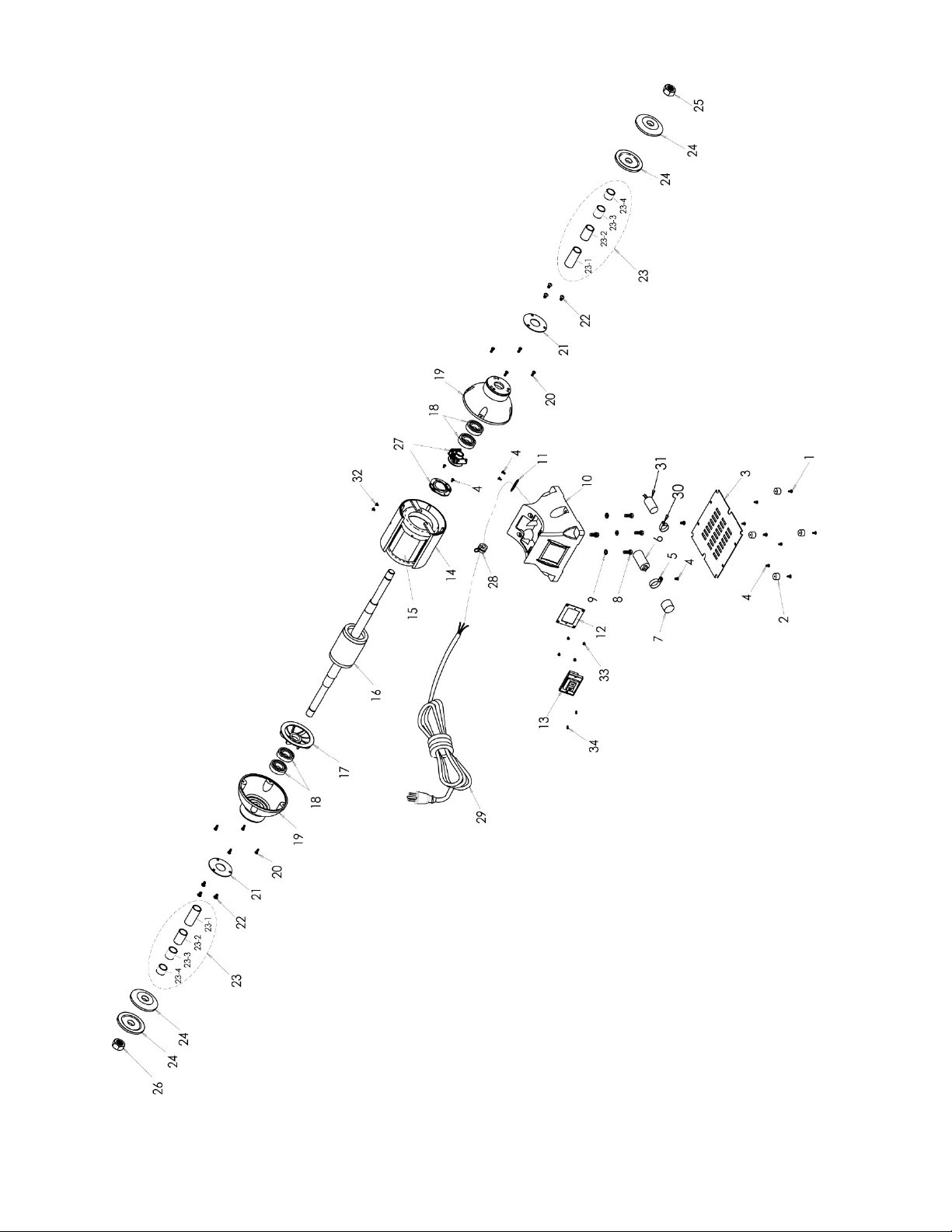

11.1.1 IBG-8SSB Buffer – Exploded View

14

Page 15

11.1.2 IBG-8SSB Buffer – Parts List

Index No. Part No. Description Size Qty

1 ................ IBG8-01 ..................... Truss Head Screw ................................................... 3/16”-24 x 1/4” .............. 4

2 ................ IBG8-02 ..................... Rubber Pad ............................................................. ...................................... 4

3 ................ IBG8-03 ..................... Base Plate ............................................................... ...................................... 1

4 ................ IBG8-04 ..................... Truss Head Screw ................................................... 3/16”-24 x 3/8” ............ 10

5 ................ IBG8-05 ..................... Capacitor Bra cket .................................................... ...................................... 1

6 ................ IBG8-06 ..................... Start Capacitor ......................................................... 200MFD, 125VAC ......... 1

7 ................ IBG8-07 ..................... Capacitor Cov er ....................................................... ...................................... 1

8 ................ TS-0050021 .............. Hex Cap Screw ........................................................ 1/4”-20 x 5/8” ................ 2

9 ................ TS-0720071 .............. Lock Washer ............................................................ 1/4” ................................ 2

10 .............. IBG8-10 ..................... Base ........................................................................ ...................................... 1

11 .............. IBG8-11 ..................... Cord Plate ................................................................ ...................................... 1

12 .............. IBG8-12 ..................... Switch Plate ............................................................. ...................................... 1

13 .............. IBG8-13 ..................... Switch with Safety Key ............................................ ...................................... 1

.................. IBG8-13-1 .................. Safety Key ............................................................... ...................................... 1

14 .............. IBG8-41 ..................... Centrifugal Switch Assembly ................................... ...................................... 1

15 .............. IBG8-14 ..................... Motor Housin g ......................................................... ...................................... 1

16 .............. IBG8-15 ..................... Stator ....................................................................... ...................................... 1

17 .............. IBG8SSB-17 .............. Rotor with Shaft ....................................................... ...................................... 1

18 .............. IBG8-17 ..................... Motor Fan ................................................................ ...................................... 1

19 .............. BB-6204ZZ ................ Ball Bearing ............................................................. 6204ZZ ......................... 2

20 .............. IBG8-19 ..................... End Be ll ................................................................... ...................................... 2

21 .............. TS-1540031 .............. Hex Nut .................................................................... M5 ................................. 4

22 .............. IBG8VSB-22 .............. End Cap ................................................................... ...................................... 2

23 .............. IBG8VSB-23 .............. Spacer ..................................................................... L 25mm ......................... 2

24 .............. IBG8VSB-24 .............. Spacer ..................................................................... L 16mm ......................... 2

25 .............. IBG8VSB-25 .............. Spacer ..................................................................... L 13mm ......................... 2

26 .............. IBG8-22 ..................... Wheel Flange .......................................................... 4-1/8” OD, 5/8” ID ......... 4

27 .............. IBG8VSB-27 .............. Buffing Wheel (full spiral sewn) ............................... Ø8” x W 1/2” x B 5/8” .... 1

28 .............. IBG8-24 ..................... Hex Nut (LH Thread) ............................................... 5/8”-11UNC LH ............. 1

29 .............. IBG8-42 ..................... Screw ....................................................................... M5 x 0.8 x 205 .............. 4

30 .............. IBG8VSB-30 .............. Buffing Wheel (half spiral sewn) .............................. Ø8” x W 1/2” x B 5/8” .... 1

31 .............. IBG8-44 ..................... Hex Nut (RH Thread) ............................................... 5/8”-11UNC ................... 1

32 .............. IBG8-50 ..................... Lamp Fixed Bracket ................................................. ...................................... 1

33 .............. F000297 .................... Phillips Pan Hd Machine Screw ............................... 1/4”-20 x 3/8” ................ 2

34 .............. IBG8-47 ..................... Strain Relief ............................................................. ...................................... 1

35 .............. IBG8-46 ..................... Power Cord with 15A Plug ....................................... 16AWG x 3C SJT ......... 1

36 .............. IBG8-48 ..................... Capacitor Bra cket .................................................... ...................................... 1

37 .............. IBG8-49 ..................... Running Capacitor ................................................... 35µF, 250V ................... 1

.................. LM000410 ................. ID/Warning Label, IBG-8SSB (not shown) .............. ...................................... 1

.................. JET-92-73R ............... JET Logo (not shown).............................................. 92x38mm ...................... 1

15

Page 16

11.2.1 IBG-10SSB Buffer – Exploded View

16

Page 17

11.2.2 IBG-10SSB Buffer – Parts List

Index No. Part No. Description Size Qty

1 ................ IBG8-01 ..................... Truss Head Screw ................................................... 3/16”-24 x 1/4” .............. 4

2 ................ IBG10-02 ................... Rubber Pad ............................................................. ...................................... 4

3 ................ IBG10-03 ................... Base Plate ............................................................... ...................................... 1

4 ................ IBG8-04 ..................... Truss Head Screw ................................................... 3/16”-24 x 3/8” ............ 12

5 ................ IBG10-05 ................... Capacitor Bra cket .................................................... ...................................... 1

6 ................ IBG10-06 ................... Start Capacitor ......................................................... 400MFD, 125VAC ......... 1

7 ................ IBG10-07 ................... Capacitor Cover ....................................................... ...................................... 1

8 ................ TS-0060051 .............. Hex Cap Screw ........................................................ 3/8”-16 x 1” ................... 4

9 ................ TS-0720091 .............. Lock Washer ............................................................ 3/8” ................................ 4

10 .............. IBG10-10 ................... Base ........................................................................ ...................................... 1

11 .............. IBG8-11 ..................... Cord Plate ................................................................ ...................................... 1

12 .............. IBG10-12 ................... Switch Plate ............................................................. ...................................... 1

13 .............. IBG8-13 ..................... Switch with Safety Key ............................................ ...................................... 1

.................. IBG8-13-1 .................. Safety Key ............................................................... ...................................... 1

14 .............. IBG10-14 ................... Motor Housin g ......................................................... ...................................... 1

15 .............. IBG10-15 ................... Stator ....................................................................... ...................................... 1

16 .............. IBG10SSB-16 ............ Rotor with Shaft ....................................................... ...................................... 1

17 .............. IBG10-17 ................... Motor Fan ................................................................ ...................................... 1

18 .............. BB-6206ZZ ................ Ball Bearing ............................................................. 6206ZZ ......................... 2

19 .............. IBG10-19B ................ End Bell ................................................................... ...................................... 2

20 .............. IBG8-26 ..................... Truss Head Screw ................................................... 1/4”-20 x 3/4” ................ 8

21 .............. IBG10SSB-21 ............ End Cap ................................................................... ...................................... 2

22 .............. TS-0255011 .............. Socket HD Button Screw ......................................... 5/16” x 3/8” .................... 6

23 .............. IBG10SSB-23 ............ Spacer Kit (includes #23-1 thru 23-3) ...................... ...................................... 1

23-1 ........... IBG10SSB-23-1 ........ Spacer ..................................................................... L 2” ................................ 2

23-2 ........... IBG10SSB-23-2 ........ Spacer ..................................................................... L 1” ................................ 2

23-3 ........... IBG10SSB-23-3 ........ Spacer ..................................................................... L 1/2” ............................. 2

24 .............. IBG10-24 ................... Wheel Flange .......................................................... 4-1/8” OD, 1” ID ............ 4

25 .............. IBG10-45 ................... Hex Nut (Right Hand Thread) .................................. 1”-8UNC ........................ 1

26 .............. IBG10-26 ................... Hex Nut (Left Hand Thread) .................................... 1”-8UNC LH .................. 1

27 .............. IBG10-43 ................... Centrifugal Switch Assembly ................................... ...................................... 1

28 .............. IBG10-48 ................... Strain Relief ............................................................. ...................................... 1

29 .............. IBG10-47 ................... Power Cord .............................................................. ...................................... 1

30 .............. IBG10-50 ................... Capacitor Bra cket .................................................... ...................................... 1

31 .............. IBG10-51 ................... Running Capacitor ................................................... 45F, 350VAC .............. 1

32 .............. F000297 .................... Phillips Pan HD Machine Screw .............................. 1/4”-20 x 3/8” ................ 2

.................. LM000411 ................. ID/Warning Label, IBG-10SSB (not shown) ............ ...................................... 1

.................. JET-113-93R ............. JET Logo (not shown).............................................. 113x47mm .................... 1

17

Page 18

11.3.1 IBG-12SSB Buffer – Exploded View

18

Page 19

11.3.2 IBG-12SSB Buffer – Parts List

Index No. Part No. Description Size Qty

1 ................ IBG8-04 ..................... Truss Head Screw ................................................... 3/16”-24 x 1/4” .............. 4

2 ................ IBG10-02 ................... Rubber Pad ............................................................. ...................................... 1

3 ................ IBG10-03 ................... Base Plate ............................................................... ...................................... 1

4 ................ IBG8-04 ..................... Truss Head Screw ................................................... 3/16”-24 x 3/8” ............ 10

5 ................ IBG10-05 ................... Capacitor Bra cket .................................................... ...................................... 1

6 ................ IBG10-06 ................... Start Capacitor ......................................................... 400MFD, 125VAC ......... 1

7 ................ IBG10-07 ................... Capacitor Cover ....................................................... ...................................... 1

8 ................ TS-0060051 .............. Hex Cap Screw ........................................................ 3/8”-16 x 1” ................... 4

9 ................ TS-0720091 .............. Lock Washer ............................................................ 3/8” ................................ 4

10 .............. IBG12SSB-10 ............ Base ........................................................................ ...................................... 1

11 .............. IBG12-09 ................... Cord Plate ................................................................ ...................................... 1

12 .............. IBG12SSB-12 ............ Switch Plate ............................................................. ...................................... 1

13 .............. IBG12-45 ................... Magnetic Swit ch ...................................................... ...................................... 1

14 .............. IBG10-14 ................... Motor Housin g ......................................................... ...................................... 1

15 .............. IBG12-11 ................... Stator ....................................................................... ...................................... 1

16 .............. IBG12SSB-16 ............ Rotor with Shaft ....................................................... ...................................... 1

17 .............. IBG12-13 ................... Motor Fan ................................................................ ...................................... 1

18 .............. BB-6007ZZ ................ Ball Bearing ............................................................. 6007ZZ ......................... 4

19 .............. IBG10-19B ................ End Bell ................................................................... ...................................... 2

20 .............. IBG8-26 ..................... Truss Head Screw ................................................... 1/4”-20 x 3/4” ................ 8

21 .............. IBG10SSB-21 ............ End Cap ................................................................... ...................................... 2

22 .............. TS-0255011 .............. Socket HD Button Screw ......................................... 5/16” x 3/8” .................... 6

23 .............. IBG12SSB-23 ............ Spacer Kit (includes #23-1 thru 23-4) ...................... ...................................... 1

23-1 ........... IBG12SSB-23-1 ........ Spacer ..................................................................... L 3-1/8” ......................... 2

23-2 ........... IBG12SSB-23-2 ........ Spacer ..................................................................... L 2” ................................ 2

23-3 ........... IBG12SSB-23-3 ........ Spacer ..................................................................... L 1” ................................ 2

23-4 ........... IBG12SSB-23-4 ........ Spacer ..................................................................... L 1/2” ............................. 2

24 .............. IBG12-20 ................... Wheel Flange .......................................................... 4-1/8” OD, 1-1/4” ID ...... 4

25 .............. IBG12SSB-25 ............ Hex Nut (Right Hand Thread) .................................. 1-1/4”-7UNC ................. 1

26 .............. IBG12SSB-26 ............ Hex Nut (Left Hand Thread) .................................... 1-1/4”-7UNC LH ............ 1

27 .............. IBG12-40 ................... Centrifugal Switch Assembly ................................... ...................................... 1

28 .............. IBG12-49 ................... Strain Relief ............................................................. ...................................... 1

29 .............. IBG12-48 ................... Power Cord .............................................................. ...................................... 1

30 .............. IBG12-50 ................... Capacitor Bra cket .................................................... ...................................... 1

31 .............. IBG12-51 ................... Running Capacitor ................................................... 20F, 350VAC .............. 1

32 .............. F000297 .................... Phillips Pan Hd Machine Screw ............................... 1/4”-20 x 3/8” ................ 2

33 .............. TS-2284082 .............. Pan Head Screw ...................................................... M4 x 8 ........................... 4

34 .............. 6293330 .................... Pan Head Screw ...................................................... 5/32” x 1/2” .................... 2

.................. LM000412 ................. ID/Warning Label, IBG-12SSB (not shown) ............ ...................................... 1

.................. JET-113-93R ............. JET Logo (not shown).............................................. 113x47mm .................... 1

19

Page 20

12.0 Electrical Connections

12.1 Wiring diagram for IBG-8SSB

20

Page 21

12.2 Wiring diagram for IBG-10SSB

21

Page 22

12.3 Wiring diagram for IBG-12SSB

22

Page 23

13.0 Warranty and Service

JET® warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

Accessories carry a limited warranty of one year from the date of receipt.

Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these machines in the processing of metal, plastics, or other materials outside recommended guidelines may

void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

23

Page 24

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

24

Loading...

Loading...