Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

20-inch Disc Grinder

Models J-4421-2 and J-4421-4

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-577010

Ph.: 800-274-6848 Revision B1 04/2014

www.jettools.com Copyright © 2014 JET

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Warnings ........................................................................................................................................................ 4

3.1 Machinery General Safety Warnings .......................................................................................................... 4

3.2 General Electrical Cautions ........................................................................................................................ 2

3.3 Wire Sizes .................................................................................................................................................. 2

3.4 Safety requirements for abrasive grinding machines ................................................................................. 2

4.0 General Specifications ................................................................................................................................... 6

5.0 Machine set-up ............................................................................................................................................... 7

5.1 Grinder set-up ............................................................................................................................................ 7

5.2 Spotting and anchoring the sander ............................................................................................................ 7

5.3 Checking table level ................................................................................................................................... 7

6.0 Electrical ......................................................................................................................................................... 7

6.1 Service wiring ............................................................................................................................................. 7

6.2 To correct disc rotation ............................................................................................................................... 8

6.3 Changing service voltage ........................................................................................................................... 8

6.4 Replacing the LVP switch cut-out coil ........................................................................................................ 8

6.5 Changing motor connections ...................................................................................................................... 8

7.0 Operating Instructions .................................................................................................................................... 9

7.1 Applying a workpiece to the disc face ........................................................................................................ 9

7.2 ON/OFF Switch .......................................................................................................................................... 9

7.3 Raising and lowering the table ................................................................................................................. 10

7.4 Adjusting the table angle .......................................................................................................................... 10

7.5 Using the miter system ............................................................................................................................. 11

8.0 Recomm en de d abra siv es

9.0 Maintenan ce pro ce dur es

9.1 Removing and replacing grinding discs .................................................................................................... 12

9.2 Removing and replacing motor and/or drive disc ........................................................................... .......... 13

10.0 Lubrication .................................................................................................................................................. 14

11.0 Replacement Parts ..................................................................................................................................... 14

11.1.1 Motor and Trunnion – Exploded View ................................................................................................. 15

11.1.2 Motor and Trunnion – Parts List .......................................................................................................... 16

................................................................................................................................. 11

................................................................................................................................. 12

3

Page 4

3.0 Warnings

- Misuse of this machine can cause serious injury.

- For safety, machine must be set up, used and serviced

properly.

- Read, understand and follow instructions in the

operator’s and parts manual which was shipped with

your machine.

When setting up machine:

- Always avoid using machine in damp or poorly lighted

work areas.

- Always be sure machine is securely anchored to the

floor.

- Al w ays k eep machine guards in place.

- Always put start switch in “OFF” position before

plugging in machine.

When using machine:

-Never operate with machine guards missing.

-Always wear safety glasses with side shields (See

ANSI Z87.1)

-Never wear loose clothing or jew elry.

-Never overreach — you may slip and fall into the

machine.

3.1 Machinery General Safety Warnings

1. Always wear protective eye wear when operating

machinery. Eye wear shall be impact resistant,

protective safety glasses with side shields which

comply with ANSI Z87.1 specifications. Use of eye

wear which does not comply with ANSI Z87.1

specifications could result in severe injury from

breakage of eye protection.

2. Wear proper apparel. No loose clothing or jewelry

which can get caught in moving parts. Contain long

hair. Rubber soled footwear is recommended for

best footing.

3. Do not overreach. Failure to maintain proper

working position can cause you to fall into the

machine or cause your clothing to get caught —

pulling you into the machine.

4. Keep guards in place and in proper working order.

Do not operate the machine with guards removed.

5. Avoid dangerous working environments. Do not use

stationary machine tools in wet or damp locations,

or in an explosive environment. Keep work areas

clean and well lit. Special electrics should be used

when working on flammable materials.

6. Avoid accidental starts by being sure the start

switch is “OFF” before plugging in the machine.

7. Machinery must be anchored to the floor.

8. Never leave the machine running while unattended.

Machine shall be shut off whenever it is not in

operation.

9. Disconnect electrical power before servicing.

Whenever changing accessories or general

maintenance is done on the machine, electrical

-Never leave machine running while you are away from

it.

-Always shut off the machine when not in use.

When ser vicing machin e:

-Always disconnect machine from electrical power while

servicing.

-Always follow instructions in operator’s and parts

manual when changing accessory tools or parts.

-Never modify the machine without consulting JET.

Read and follow these simple rules for best results and

full benefits from your machine. Used properly, JET

machinery is among the best in design and safety.

However, any machine used improperly can be

rendered inefficient and unsafe. It is mandatory that

those who use our products be properly trained in how

to use them correctly. They should read and understand

the Operating Instructions and Parts Manual as well as

all label s affi xed to t he machi ne. Fa ilur e to fol low al l of

these warnings can cause ser ious injuries.

power to the machine must be disconnected before

work is done.

10. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and the

changing of accessories. No attempt shall be made

to modify or have makeshift repairs done to the

machine. This not only voids the warranty but also

renders the machi ne unsafe.

11. Secure work. Use clamps or a vise to hold work,

when practical. It is safer than using your hands

and it frees both hands to operate the machine.

12. Never brush away chips while the machine is in

operation.

13. Keep work area clean. Cluttered areas invite

accidents.

14. Remove adjusting keys and wrenches before

turning mach in e on.

15. Use the right tool. Don’t force a tool or attachment

to do a job for which it was not designed.

16. Use only recommended accessories and follow

manufacturer’s instructions pertaining to them.

17. Keep hands in sight and clear of all moving parts

and cutting surfaces.

18. All visitors should be kept a safe distance from the

work area. Make workshop completely safe by

using padlocks, master switches, or by removing

starter keys.

19. Know the tool you are using; its application,

limitations, and potential hazards.

Page 5

3.2 General Electrical Cautions

This machine should be grounded in accordance

with the National Electrical Code and local codes

and ordinances. This work should be done by a

qualified electrician. The machine should be

grounded to protect the user from electrical shock.

3.3 Wire Sizes

Caution: For circuits which are far away from the

electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire

3.4 Safety requirements for abrasive grinding machines

Abrasive grinding can be hazardous to operators and

bystanders. Grinding sparks, chips and dust particles

thrown off by the grinding disc can cause serious

injury by contact or inhalation. To avoid such injuries

you must comply with the following safety

requirements:

1. CAUTION: The gap between the abrasive

surface and table edge must not exceed 3/16". If

it does, loosen the four motor mount bolts and

move the motor forward to minimize gap.

2. Always wear protective eyewear when operating

machinery. Eye wear shall be impact resistant,

prot ecti ve saf ety g la sses w it h side shie lds w hic h

comply with ANSIZ87.1. Use of e ye wear which

does not comply with ANSIZ87.1 specifications

could result in severe injury from breakage of

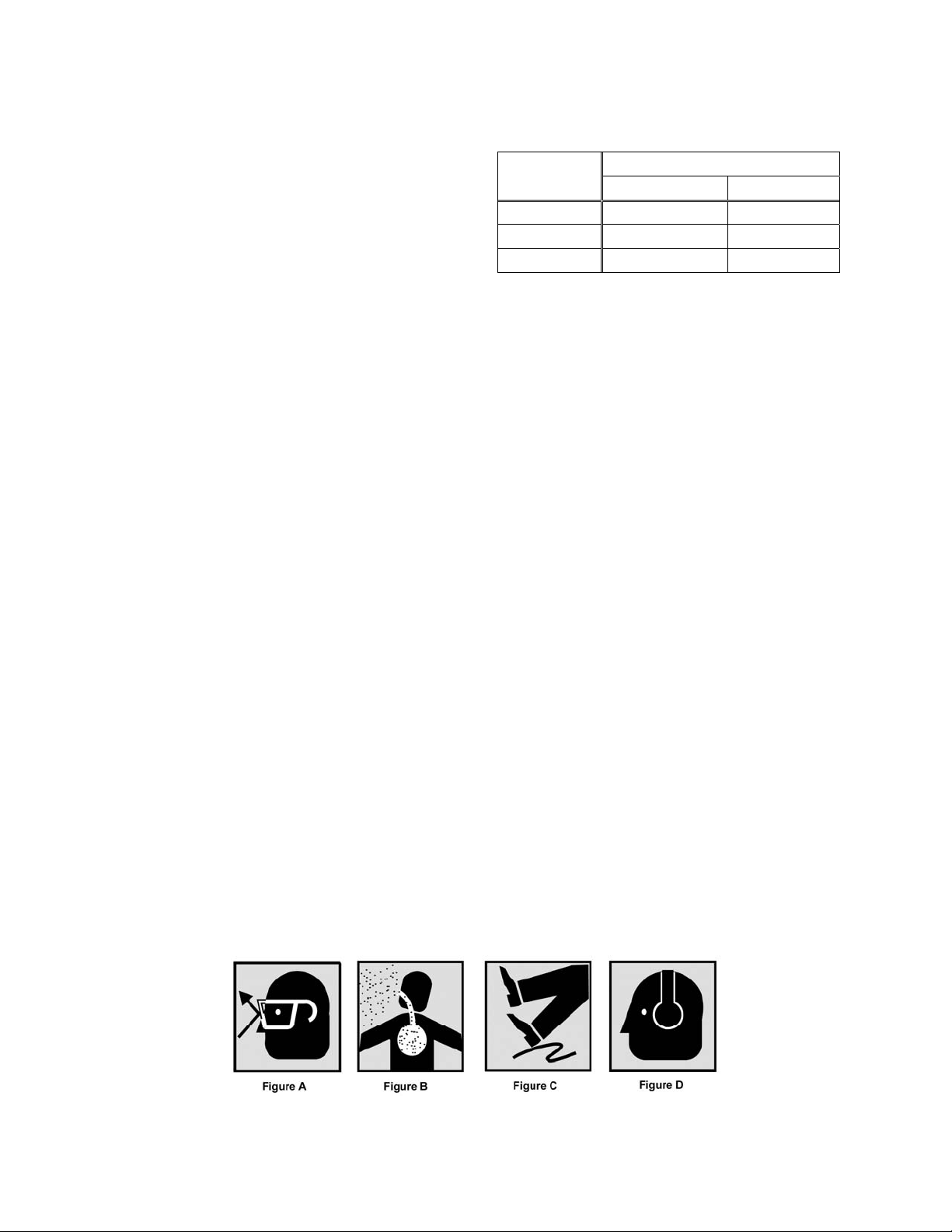

eye protection. See Figure A, below.

3. Wear leather safety gloves, arm guards, leather

aprons and safety shoes.

4. A dust collection system is recommended.

Operator shall also wear a dust mask at all

times. See Figure B, below.

5. Additional precautions may be necessary for

grinding materials which are flammable or have

other hazardous properties. You should always

consult the manufacturer of such materials for

instructions on grinding and handling.

6. Do not force or jamb the workpiece into the

gri nding disc.

7. Before grinding, always allow the motor to come

up to operating speed, then check the grinding

sizes for branch circuits or electrical extension

cords according to the following table is

recommended:

Conductor

Length

0 – 50 Ft. No. 14 No. 14

50 – 1 00 Ft. No. 14 No. 12

Over 100 Ft. No. 12 No. 8

disc for wobble, runout, or any unbalanced

condition. If the disc is not operating accurately

and smoothly, immediately stop the motor and

make repairs before attempting any grinding

operations.

8. Abrasive discs must be stored in a controlled

environment area. Relative humidity should be

35% to 50% and the temperature should be

between 60 and 80 degrees Fahrenheit. Failure

to do so could cause premature disc failure.

9. Examine the face of the grinding disc carefully.

Excessive grinding which wears down to the

backing material can result in tearing of the disc.

Never use a disc which shows backing, nicks or

cuts on the surface or edge or damage due to

creasing or poor handling.

10. When installing a new disc, be certain the disc is

accurately centered on the drive wheel. Failure

to do so could cause a serious unbalanced

condition.

11. Always present the workpiece to the wheel while

resting the workpiece firmly on the table. Failure

to do so could result i n dam age to t he workp iece

or throwing of the workpiece off the wheel.

12. Safety shoes which comply with ANSI Z41.1

shall be worn. See Figure C.

13. Personal hearing protection such as ear plugs or

earmuffs shall be used to protect against the

effect of noise exposure. See Figure D.

240 Volt Lines 120 Volt Lines

AWG Num ber

2

Page 6

4.0 General Specifications

The JET Model J-4421 20-inc h diameter disc grinder i s a high prod uction, rapid stock removal tool. The st ock

removal rate is controlled by t he amount of pressure t he operator applies to t he work piece and t he grit of the

abrasive sheet mounted on the drive disc. By using different grit values and materials, a wide range of

materials can be ground and an equally wide range of surface finishes achieved.

Because the Model J-4421 is of heavy-duty design throughout, large piece part s can be ground. The use of

either the miter system or the tilt table allows high production grinding of angles. When used in combination,

the miter/tilt design allows the grinding of compound angles.

The table tilt mechanism is a rigid, precision worm-and-sector gear controlled with a crank. Table angle is

shown on a protractor mechanism.

Table height with respect to the drive disc can be adjusted using a rack and pinion gear system controlled by a

crank. The table assembly is counterbalanced to make raising and lowering the table easier and to increase the

service life of the lifting components.

Model number ....................................................................... J-4421-2 ..................................................... J-4421-4

Stock numbers ........................................................................ 577010 ....................................................... 577011

.................................................................................. (prewired 220V) ......................................... (prewired 440V)

Motor ....................................................................................................... T EFC, 3HP, 3PH, 220/440V, 1725 RPM

Table size .................................................................................................... 27-1/2 x 10-1/2 in. (68.75 x 26.25 cm)

Disc speed ............................................................................................................................................. 1725 RPM

Disc diameter ................................................................................................................................. 20 in. (508 mm)

Table slot ....................................................................................................................... 3/8 x 3/4 in. (9.3 x 19 mm)

Table tilt ............................................................................................... 45 degrees downward; 15 degrees upwar d

Overall dimensions ............................................................................. 30 x 27-1/2 x 53 in. (75 x 68.75 x 132.5 cm)

Net weight ....................................................................................................................................... 397 lb (180 kg)

Shipping weight ............................................................................................................................... 452 lb (205 kg)

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

6

Page 7

5.0 Machine set-up

5.1 Grinder set-up

1. Uncrate the grinder and remove it from its

shipping skid.

2. Remove the table raiser crank which is taped

to the grinder and install the crank on the

raiser shaft, securing it with the set screw in

the crank.

3. Spot and anchor the grinder according to

instructions i n the ne xt se c t ion.

4. Remove the grinding disc (which is in a

protective sleeve) from the machine.

5. Clean the protective coating on the machine

surfaces with mineral spirits or other type of

non-flammable cleaning fluid.

6. Clean the surface of the drive disc using a filmfree cleaner such as naptha.

7. Remove the grinding disc from its protective

sleeve and install it on the drive disc accord ing

to instructions in sect. 9.1 Removing and

replacing grinding discs.

8. Tilt the table to level using the protractor on

the table, then raise the table assembly until it

is more-or-less in the middle of the drive disc.

5. Use the two leveling bolts on the rear of the

base to level the grinder. Shim under the

anchor positions as needed to level the

grinder.

6. Secure the grinder to the floor using the

anchors.

5.3 Checking table level

While the machine has been run at the factory and

checked before shipment, you may want to check

the table level before releasing the grinder for

service.

1. Disconnect the grinder from its electrical power

source to prevent accidental start-up (if you

have already connected it to power.)

2. Unlock the table tilt lock handle.

3. Place a machinist's square against the table

and disc face.

4. Using the table tilt adjustment handle, adjust

the table until it is at a right angle to the disc

face.

5. Check the protractor pointer. It should be on

the ZERO degree mark of the protractor. If not,

adjust the pointer by loosening its attachment

screw and moving it to the ZERO mark, then

retighten the screw.

9. Check table for level according to instructions

follo w i ng i n th is se c tion.

10. Establish power to the grinder using

instructions in sect. 6.0 Electrical w hich f ollow

in this section.

11. Grinder may be released for service.

Figure 1: Base hold-down diagram

5.2 Spotting and anchoring the

sander

1. Set 3/8 inch floor anchors in the pattern

indicated in Figure 1.

2. Set the grinder on its anchors.

3. Level the table using the protractor on the

table.

4. Put a machinist's level on the table.

6.0 Electrical

The Model J-4421 has a 220/440 Volt, 3-phase

motor. It is shipped wired to the specifica tions on

the customer order.

The machine uses a LVP or "low voltage

protection" ON/OFF switch which trips to the OFF

position when voltage drops below a predetermined safe level. This feature protects the

operator from a quick re-start when se rvice voltage

cuts out or varies excessively. After tripping, the

LVP switch must be positively reset by the operator

before the motor receives power.

The LVP switch has a coil inside its case which is

designed to work with a specific voltage level. If

you decide to change the voltage source to the

grinder from 220 to 440 (or the reverse) this coil

must be replaced (in addition to changing the

motor's internal wiring connections.)

6.1 Service wiring

1. Disconnect and lock out power to the service

branch you are going to use to power the

grinder.

2. Connect t he branch ground wire to the gro und

wire in the cable. The ground wire in the cable

will be either green, or green with a white

trace.

3. Connect the three power wires to the three

power wires in the cable.

7

Page 8

4. Reestablish power to the service branch for

the grinder.

5. Turn on the grinder using the ON/OFF switch

and observe the direction of rotation of the

drive disc. It should be turning CLOCKWISE

when viewed from the front. If it is turning

clockwise, the grinder is correctly connected

and can be placed in service. If t he di sc is not

turning clockwise, the electrical connections

are hooked up backward and need to be

corrected.

Figure 2: Service wiring diagram

6.2 To correct disc rotation

1. Disconnect and lock out power to the service

branch for the grinder.

2. S witch any two of the three power wires to the

machine service cable.

3. Re-establish power in the service b ranch and

turn the grinder ON, again. The drive disc

should now be rotating in a clockwise direction

and the machine can be released for service.

3. Locate the cut-out coil which is under the

switch. See Figure 3 for position and

removal/installati on motion.

Figure 3: Cut-out coil removal and replacement

4. The cut-out coil is a "snap fit" under the switch

mechanism, and is removed by pushing it to

the rear of its mount and snapping it o ut of its

retainer.

5. Remove the connectors which secure the coil

to the switch mechanism.

6. Connect the new cut-out coil to the switch at

the same connectors as the removed coil.

7. Insert the new coil by pushing it to the back of

its seat and snapping it i nto position under its

retainers.

8. Reinstall the switch cover to the switch base

using the two retainer screws.

9. P roceed to the next step – changing the motor

connections.

6.5 Changing motor connections

6.3 Changing service voltage

As indicated in the previous section, the grinder is

shipped wired for the voltage specified on the

customer order. If you decide to change the

voltage in the service branch to the grinder (f rom

220 to 440 volts, or 440 to 220 volts) the electrical

connections inside the motor must be changed to

reflect the change in voltage, and the LVP switch

cut-out coil must also be changed to reflect the

new voltage requirement.

6.4 Replacing the LVP switch cut-out

coil

1. Be certain the power in the service branch to

the machine is disconnected and locked out.

2. Open the switch case by removing the two

cover sc r e w s.

10. Again, be certain the power in the service

branch to the machine is disconnected and

locked ou t.

11. Open the electrical connection cover plate o n

the motor.

12. A wiring diagram for the motor is shown in

Figure 4, and will also be on a label

underneath the motor plate cover.

13. Switch the connectors inside the motor to meet

the voltage requirements for the service

branch supplying the motor.

14. Close the motor plate cover and secure it shut

with it s sc r e w s.

15. Reconnect power to the service branch and

turn ON the grinder to verify that it runs

correctly, and that the disc turns

counterclockwise.

8

Page 9

Figure 4: Motor wiring diagram

7.0 Operating Instructions

Use the nomenclature drawing in Figure 5 for

reference when various parts and components are

described in the operations and maintenance text.

To order service parts you will find an exploded

view of the grinder in sect. 11.1.1.

abraded from your workpiece will be hurled of f

the wheel if the wheel guard is not in position.

2. Always allow time for the disc to come fully up

to motor speed before contacting the

work p ie c e t o t he disc. Thi s gives you a chanc e

to check for possible wheel wobble (looseness

of the disc or motor, or damage from some

earlier operation) before working against the

disc.

3. This is a very powerful and aggressive

grinding device which operates at high surface

speeds. Therefore, you always want to support

the workpiece while using the work table.

"Freehand" presentation of workpiece to the

disc surfa ce is risk y to yo u, to t he work piece,

and to bystanders. It is not possible to

overemphasize the need to keep the

workpiece firmly on the table.

4. The safest position at which to do any grinding

is on the right hand side of the work table

where the disc is moving downward past the

work table. Whenever possible, keep the

workpiece in this area when grinding. In

addition to safety, keeping the workpiece in

this area greatly increases the effectiveness of

the dust control chute and any vacuum dust

cont ro l sy st em yo u m ig ht b e usi ng . S e e F ig ure

6.

Figure 5: General grinder nomenclature

7.1 Applying a workpiece to the disc

face

No matter what size, type or material workpiece

you will be grinding, there are several important

considerations you must understand if you are

going to use the Model J-4421 disc grinder

effectively.

1. Always be certain the wheel guard is

positioned over the disc edge. Materials

Figure 6: Correct table work area

5. The speed and aggressiveness of the machine

means that CONTROL of the workpiece, by

you, is absolutely essential. ALWAYS USE

TWO HANDS to control the workpiece.

6. Because of the speed with w hich the disc can

grind, heat build-up on work p ieces is usually

very rapid. To prevent burns and/or possible

loss of control of any workpiece:

a. Use heat resistant gloves to hold any

workpiece.

b. Where possible and appropriate, use

additional tooling or fixturing to hold the

workpiece when pressing against the grinding

disc.

7.2 ON/OFF Switch

The ON/OFF switch is located on a post on the left

hand side of the grinder. There are two push

9

Page 10

buttons on the switch: RED is for OFF and BLACK

is for ON. See Figure7.

The switch is a Low Voltage Protection or LVP

switch. When line voltage drops below a safe

working voltage (due to start-up of larger mac hines

on the electrical branch or other f luctuations in line

voltage) the switch automatically trips OFF.

The purpose of this feature is to pre vent acc idental

re-starts and damage to any workpieces you might

be grinding.

To restart the machine you should remove the

workpiece from the table and turn the switch ON,

again. Then wait for the motor to come up to full

speed before continuing your grinding.

the more disc you have exposed, the harder it is to

control dust when using a vacuum dust control

system.

Figure 8: Table ra iser system

7.4 Adjusting the table angle

The table can be adjusted downward to a

maximum angle of 45 degrees and upward to a

maximum angle of 15 degrees.

To adjust the table angle (Figure 9):

Figure 7: On/Off Switch

7.3 Raising and lowering the table

For grinding most workpieces, the table should be

positioned more-or-less in the middle of the disc.

This allows you to do most of your work on the

right-hand side of the disc where downward motion

of the disc provides the safest grinding torque.

To grind larger workpieces, a larger disc surface

area can be exposed by lowering the table. This is

done as follows:

1. Turn off the ON/OFF switch and disconnect

the machine from its electrical power source to

prevent the possibility of accidental start-up.

2. Unlock the table lock handle.

3. Turn the table height handle until the table is at

a height appropriate to your workpiece size.

1. Be sure the ON/OFF switch is in the off

position.

2. Disconnect the machine from its electrical

power source to prevent any chance of an

accidental start-up.

3. Unlock the table lock handle.

4. Turn the table tilt handle until the pointer on

the angleprotractor is on the angle you want to

achieve.

5. Lock the table lock handle.

6. Reconnect the machine to its electrical power

source.

4. Lock the table lock handle.

5. Rec onnect the machine to the electrical power

source.

Note: Never expose more of the grinding disc than

necessary to do an effective job of grinding the

workpiece. The more disc you have exposed, the

more hazardous any operation may become. And,

Figure 9: Table tilt system

Note: The table protractor, while accurate, may not

give you the precision required for highly accurate

grinding. For these cases requiring high precision

angles, use a machinist's protractor to establish the

required angle between table and disc a s show n in

Figure 10.

10

Page 11

Figure 10: Achieving accurate angles using a

machinist’s prot ractor

7.5 Using the miter system

Figure 11: Use of the miter system

The miter slot in the table allows you to use a miter

gauge to grind angles on workpieces. Use the

following procedure:

1. Put the table in a level position. Use the table

tilt mechanism to adjust it, if necessary .

2. Loosen the lock knob on the miter gauge.

3. Adjust the miter gauge to the angle you want

to cut.

4. Lock the lock knob on the miter gauge.

5. Put the miter gauge in its miter slot on the

table.

6. Turn the grinder ON and allow the motor and

disc to come up to full speed.

7. Hold the reference edge of the workpiece

against the miter gauge face and move the

workpiece into contact with the abrasive disc.

8. A llow the workpiece to slide forward, along the

face of the miter gauge, until the required

depth of cut has been achieved.

Figure 11 shows how to set and use the miter

gauge to grind a simple angle on a workpiece. To

grind a compound angle you can set the miter

gauge to one required angle and set the table tilt to

a second required angle, thus achieving the

compound angle desired. Remember: When

grinding complex compound angles, always test

your table and miter set-up on scrap material

before attempting a finish machining task on the

actual part you will be grinding.

8.0

Recommended abrasives

By using different abrasive types and different

weights of grit it is possible to produce a very wide

variety of cutting speeds and surface finishes on a

very wide range of materials – from metals, to

plastics, to wood.

The following information is provided as a general

guide to the types of discs appropriate to many

materials. Your industrial distributor may be able to

prov ide yo u wit h spec ial ab rasi ve di scs f or sp ecif ic

production applications. And of course, your

workpiece supplier should be consulted for

recommendations, as well.

Aluminum Oxide

Aluminum oxide is available in cloth backed discs

in a very wide range of grits – typically from 24

(extremely aggressive) to 400 (almost a polishing

grade.) Aluminum oxide is suitable for use on

virtually all materials – ferrous and non-ferrous.

The list of materials appropriate for aluminum oxide

cutting includes low, medium and high carbon/alloy

steels, brass, aluminum, bronze, copper and

titanium.

Garnet

Garnet is available in a c loth backed disc, t ypically

in a range of grits from 80 to 220. Garnet is a

material used almost exclusively on wood. This

makes it appropriate to shops such as pattern

shops. It has the beneficial property of grit

fracturing at low pressure levels. This quick

renewal of the cutting surface results in more rapid

wear-out of the disc, of course. But it also allows

very low temperature sanding of wood – thus

permitting rapid sanding without burns. This is

particularly beneficial when doing sanding on end

grains.

Silicon carbide

While discs may be available for 20 inc h grinding,

this material is not recommended for use on the

11

Page 12

ModelJ-4421 because a water coolant/lubricant is

typically required for effective use of this material.

Application tip

While the 20 inch grinder can mount the full range

of grits available – from 24 to 400 – the most

efficient production and the longest abrasive disc

life can be achieved when the production manager

is aware of the capabilities of the grits of fered. If

you start with a workpiece which has been rough

cut with an 80 grit wheel of some type, and you

eventually want to achieve a finish at t he 400 grit

level – don't go directly from the 80 to the 400 disc

machine. The 400 grit wheel will eventually do the

job, but it will take an excessive amount of time

and the disc will have a short servi c e life. Plan your

surface finishing to take advantage of the full range

of grits available to the shop.

Figure 12: Replacing a grinding disc

9.0

Maint e na nc e procedure s

9.1 Removing and replacing grinding

discs

CAUTION: The gap between the abras ive surface

and table edge must not exceed 3/16". If it does,

loosen the four motor mount bolts and move the

motor forward to minimize gap.

Grinding discs are secured to the aluminum drive

disc using an adhesive on the grinding disc

backing. To remove an abrasive disc:

1. Turn the ON/OFF switch OFF.

2. D isconnect the machine from its power source

to prevent accidental start-up of the motor.

3. Move the table to the bottom of its travel using

the table raiser mechanism. (See sect. 7.3,

Raising and lowering the table)

4. Tilt the disc guard to the rear to expose the top

of the drive disc.

5. Pull at the edge of the mounted grinding disc

to pull it away from the drive disc, then pull it

completely off of the drive disc.

6. Be certain the drive disc surface is clean. If

necessary, use a cleaner which dries film-free

(such as naptha) to remove any old adhesive

(or dust) which might adhere to the drive disc.

7. Remove a small portion of the protective co ver

from the back side of the new grinding disc

you are mounting on the drive disc. A typical

amount to remove is about a third of the

protective cover. See Figure 12.

8. P ut the exposed edge of the new grinding disc

against the drive disc and center t he grinding

disc carefully on the drive disc. When you are

certain it is accurately centered, press on

grinding disc so the exposed portion of the

adhesive anchors the grinding disc to the drive

disc.

9. Rotate the drive disc 180 degrees. See Figure

13. The part of the grinding disc which is

attached to the drive disc will now be at the

bottom of the drive disc, and will be slightly

hidden behind the table.

Figure 13: Replacing a grinding disc

With the components in this posit ion you ca n keep

the grinding disc accurately centered while

reaching behind the grinding disc to remove the

rest of the protective backing and progressively

pressing the grinding disc against the face of the

drive disc. The reason for this care is that a

grinding disc, once firmly pressed into position, is

often extremely difficult to remove. In other words:

Once it is down... it is down to stay.

12

Page 13

10. Press firmly against the full surface of the disc.

The idea here is to be sure the grinding disc

makes full contact with the drive disc and is

laying absolutely flat on the disc surface.

11. Move the wheel guard forward so it covers the

edge of the grinding and drive disc.

12. Adjust the table height to working height.

13. Reconnect power to the machine.

14. Turn the machine "ON" and observe the action

of the disc for possible imbalance. When you

are certain all systems are operating correctly,

grinding operations may resume.

6. Loosen the four bolts which hold the motor to

the stand.

7. Slide the motor toward the rear of the stand

while pulling the drive disc and hub toward the

front of the stand. This is a combined effort.

The disc and hub can be separated from the

motor shaft only if you perform these two

operations at the same time.

8. Slide the drive disc and hub off of the motor

shaft.

To replace the drive disc:

9. Remove the three bolts and washers which

hold the disc to the hub.

10. Position the new disc on the hub and secure it

with the bolts and washers.

11. Align the support plate keyway with the key on

the motor shaft and slide the hub plate onto

the motor shaft as you also pull the motor

forward on its plate. Do this until the assembly

bottoms out against the shaft.

12. Reinstall and tighten the retaining screw and

washer which screws into the center of the

motor shaft.

13. Tighten the two set screws which secure the

hub to the motor shaft.

Figure 13 (repeated)

9.2 Removing and replacing motor

and/or drive disc

In the rare event that damage to the drive disc

might require its replacement, or electrical failure

might require motor replacement, the following

procedure can be used. Since motor replacement

requires removal of the drive disc, these

procedures are treated as a single procedure.

Ignore the motor replacement instructions if you

are only servicing the drive disc.

To remove drive disc from motor shaft:

1. Disconnect the grinder from its electrical power

source to prevent accidental start-up and to

allow motor replacement without danger of

electrical shocks.

2. Lower the table to its lowest position. (See

sect. 7.3, Raising and lowering the table.)

3. If you are replacing the metal drive disc,

remove the abrasive disc before proceeding.

(See sect. 9.1)

4. Remove the socket head screw and washer

from the center of the drive disc.

5. Loosen the two socket head set screws which

secure the drive disc hub to the motor shaft.

To replace the motor:

Note: be certain you have performed all of the

step s above – thro ugh ste p 8 – wh ich rem ove t he

drive disc assembly from the motor. And, BE

CERTAIN YOU HAVE TURNED OFF POWER TO

THE MOTOR AND HAVE LOCKED OUT POWER

TO THE BRANCH ON WHICH YOU WILL BE

WORKING. JET recommends that a licensed

electrician perform all electrical service work for

this grin der.

14. Open the plate on the m otor frame where the

electrical service cable enters the motor.

15. Remove the wires from their connectors to free

the cable from the motor. Note and label the

positions of the wires.

16. Remove the four bolts and washers which

secure the motor to the stand.

17. Place the replacement motor on the frame and

secure it loosely with the four bolts and

washers.

18. Open the motor plate to expose the electrical

connections.

19. Connect the switch-to-motor cable to the wire

positions noted in step 15, above, then close

the motor electrical cover plate and tighten the

cover plate screws.

20. Install the drive disc and hub plate as outlined

in steps 11-13, above.

21. Raise the table to its highest position.

13

Page 14

22. If the drive disc does not have a grinding disc

installed on it – install a disc now, using the

instructions in sect. 9.1 Removing and

replacing grinding discs.

23. Slide the motor forw ard on the frame until the

disc is 1/8-inch from the table. Be certain that

both the right and left hand gaps between the

table and disc are equal.

24. Tighten the motor mounting bolts securely.

25. Reconnect the machine to its electrical power

source.

26. Verify the motor and disc rotation. If you have

connected everything correctly, the disc will

rotate clockwise when viewed from the front. If

the disc rotates counterclockwise, correct the

electrical connections according to instructions

in sect. 6, Electrical.

27. The machine is ready to return to service.

10.0 Lubrication

Since the grinder operates in an environment of

high amounts of dust and grit, most lubrication

would simply pick up the grit and cause increased

wear to the machine and its parts. Therefore, the

primary method of keeping the machine working

surfaces in good order is KEEPING THE

MACHINE AS CLEAN AS POSSIBLE. Before

using the tilt table or table raisi ng mechanism the

operator should use a stiff brush to remove

excessive dust and grit from the tilt worm-andsector and/or table raising rack. The single

exception to this "no-lubrication" recommendation

is the right angle drive used for the table raising

rack-and-pinion system. This gearbox is prelubricated at the factory and should require no

additional lubrication unless it is disassembled. If

this is done, use Shell Retinax A or a similar

grease to refill the gearbox.

11.0 Replacement Parts

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday (see our website for business hours, www.jettools.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to serve you quickly

and accurately.

14

Page 15

11.1.1 Motor and Trunnion – Expl oded Vi ew

15

Page 16

11.1.2 Motor and Trunnion – Parts List

Index No Part No Description Size Qty

1 ................ J-5644311 ................. Base ........................................................................ ...................................... 1

2 ................ 5644321 .................... Column .................................................................... ...................................... 1

3 ................ J-5644331 ................. Support Bracket ....................................................... ...................................... 1

4 ................ 5644341 .................... Hex Cap Bolt............................................................ 3/8"-16 × 1-3/4" ............. 4

5 ................ 5644351 .................... Lock Washer ............................................................ 3/8" ................................ 8

6 ................ 5644361 .................... Flat Washer ............................................................. 3/8" ................................ 4

7 ................ J-5644371 ................. Support .................................................................... ...................................... 1

8 ................ 5644381 .................... Spring Pin ................................................................ Ø5 x 20 mm .................. 1

9 ................ 5644391 .................... Stud Bolt .................................................................. . ..................................... 1

10 .............. 5644411 .................... Hex Nut .................................................................... 1/2"-12 .......................... 1

11 .............. 5644421 .................... Lock Washer ............................................................ 1/2" ................................ 1

12 .............. 5644431 .................... Flat Washer ............................................................. 1/2" ................................ 1

13 .............. 5644441 .................... Spring Stud Bolt ....................................................... ...................................... 1

14 .............. 5644451 .................... Flat Washer ............................................................. 1/2" ................................ 1

15 .............. 5644461 .................... Bracket..................................................................... ...................................... 1

16 .............. 5644471 .................... Spring ...................................................................... ...................................... 2

17 .............. 5644481 .................... Keeper ..................................................................... ...................................... 2

18 .............. 5644491 .................... Sheave..................................................................... ... ................................... 2

19 .............. 5644511 .................... Hex Cap Bolt............................................................ 1/4"-20 x 5/8" ............... 2

20 .............. 5644521 .................... Washer .................................................................... 1/4" ................................ 2

21 .............. 5644531 .................... Hex Nut .................................................................... 1/4" ................................ 4

22 .............. 5644541 .................... Shaft (Pin) ................................................................ ...................................... 1

23 .............. 5644551 .................... Hex Cap Bolt............................................................ 1/4"-20 x 1-1/2" ............. 1

24 .............. 5644561 .................... Hex Nut .................................................................... 1/4" ................................ 1

25 .............. 5644571 .................... Wire Rope ................................................................ ...................................... 1

26 .............. 5644581 .................... Hex Cap Bolt............................................................ 5/16"-18 x 1-3/4" ........... 1

26-1 ........... 5644581A .................. Hex Nut .................................................................... 5/16" .............................. 2

27 .............. 5644591 .................... Handle ..................................................................... ...................................... 1

28 .............. 5644611 .................... Crank Wheel ............................................................ ...................................... 1

29 .............. 5644621 .................... Hex Socket Set Screw ............................................. 5/16"-18 x 3/4" .............. 6

30 .............. J-5644631 ................. Shaft Guide .............................................................. ...................................... 1

31 .............. 5644641 .................... Hex Cap Bolt............................................................ 1/4"-20 x 1" ................... 4

32 .............. 5644651 .................... Lock Washer ............................................................ 1/4" ................................ 6

33 .............. 5644661 .................... Shaft ........................................................................ ...................................... 1

34 .............. 5644671 .................... Special Washer........................................................ ...................................... 2

35 .............. 5644681 .................... Spring Pin ................................................................ Ø4 x 20 mm .................. 1

36 .............. 5644691 .................... Worm, Pinion ........................................................... ...................................... 1

37 .............. 5644711 .................... Worm Gear .............................................................. ...... ................................ 1

38 .............. 5644721 .................... Special Washer........................................................ ...................................... 1

39 .............. 5644731 .................... Flat Washer ............................................................. ...................................... 1

40 .............. 5644741 .................... Sheave Stand .......................................................... ...................................... 1

41 .............. 5644751 .................... Lock Handle ............................................................. ...................................... 1

42 .............. 5644761 .................... Knob ........................................................................ ...................................... 1

43 .............. 5644771 .................... Rack......................................................................... . ..................................... 1

44 .............. 5644781 .................... Socket Hex Cap Screw ............................................ 5/16"-18 x 1/2" .............. 2

45 .............. J-5644791 ................. Solid Segment ......................................................... ...................................... 1

46 .............. J-5644811 ................. Table ........................................................................ ...................................... 1

48 .............. 5644831 .................... Table Pivot Shaft ..................................................... ...................................... 1

49 .............. J-5644841 ................. Trunnion................................................................... ...................................... 1

50 .............. 5644851 .................... Hex Cap Bolt............................................................ 3/8"-16 x 1" ................... 4

51 .............. 5644861 .................... Flat Washer ............................................................. 3/8" ................................ 8

52 .............. 5644871 .................... Trunnion Shoe ......................................................... ...................................... 1

53 .............. 5644881 .................... FH Screw ................................................................. 1/4"-20 x 1/2" ................ 4

54 .............. 5644891 .................... Spring Pin ................................................................ Ø5 x 20 mm .................. 4

55 .............. 5644911 .................... Trunnion Shoe ......................................................... ...................................... 1

56 .............. J-5644921 ................. Sector Gear ............................................................. ...................................... 1

57 .............. 5644931 .................... Table Lock Handle ................................................... ...................................... 1

58 .............. 5644941 .................... Pointer ..................................................................... ...................................... 1

59 .............. 5644951 .................... Round HD Screw ..................................................... M4 x 0.7p x 6 ................ 1

16

Page 17

Index No Part No Description Size Qty

60 .............. 5644961 .................... Worm Gear .............................................................. ...... ................................ 1

61 .............. 5644971 .................... Spring Pin ................................................................ Ø4 x 20 mm .................. 1

62 .............. 5644981 .................... Shaft ........................................................................ ...................................... 1

63 .............. 5644991 .................... Hex Socket Set Screw ............................................. 5/16"-18 x 3/4" .............. 2

64 .............. 5645011 .................... Crank Wheel ............................................................ ...................................... 1

65 .............. 5645021 .................... Knob ........................................................................ ...................................... 1

66 .............. J-5645031 ................. Bracket..................................................................... ...................................... 1

67 .............. 5645041 .................... Protractor ................................................................. ...................................... 1

68 .............. 5645051 .................... Drive Rivet ............................................................... ...................................... 3

69 .............. 5645061 .................... Hex Cap Bolt............................................................ 3/16"-24 x 3/4" .............. 1

70 .............. 5645071 .................... Hex Nut .................................................................... 3/16" .............................. 1

74 .............. 5645121 .................... Flat Washer ............................................................. 3/8" ................................ 4

75 .............. 5645131 .................... Hex Nut .................................................................... 3/8" ................................ 4

76 .............. 5645141 .................... Hex Cap Bolt............................................................ 3/8"-16 × 1-1/2" ............. 4

77 .............. 5645151 .................... Flat Washer ............................................................. 3/8" ................................ 8

78 .............. J-5645161 ................. Motor........................................................................ ...................................... 1

80 .............. 5645181A .................. Electric Cord…………………… ............................... 14AWGx4C, 600V, ST .. 1

81 .............. 5645191 .................... Key........................................................................... 7 x 7 x 30 ...................... 1

82 .............. 5645211 .................... Socket Hex Cap Screw ............................................ 3/8"-16 x 7/8" ................ 3

83 .............. 5645221 .................... Lock Washer ............................................................ 3/8" ................................ 3

84 .............. J-5645231 ................. Hub .......................................................................... ...................................... 1

85 .............. 5645241 .................... Drive Disc ................................................................ ... ................................... 1

86 .............. 5645251 .................... Clamp Washer ......................................................... ...................................... 1

87 .............. 5645261 .................... Socket Hex Cap Screw ............................................ 1/4"-20 x 3/4" ................ 1

88 .............. 5645271 .................... Sanding Paper ......................................................... 36 grit ............................ 1

.................. 5645281 .................... Sand ing Paper ......................................................... 50 grit ............................ 1

.................. 5645291 .................... Sand ing Paper ......................................................... 80 grit ............................ 1

.................. 5645311 .................... Sand ing Paper ......................................................... 120 grit .......................... 1

89 .............. J-5645321 ................. Disc Guard ............................................................... ...................................... 1

90 .............. J-5645331 ................. LH Guard Arm.......................................................... ...................................... 1

91 .............. J-5645341 ................. RH Guard Arm ......................................................... ...................................... 1

92 .............. 5645351 .................... Hex Cap Bolt............................................................ 1/4"-20 × 5/8" ................ 4

93 .............. 5645361 .................... Lock Washer ............................................................ 1/4" ................................ 4

94 .............. J-5645371 ................. Bracket..................................................................... ...................................... 2

95 .............. 5645381 .................... Hex Cap Bolt............................................................ 1/4"-20 x 1" ................... 2

96 .............. 5645391 .................... Flat Washer ............................................................. 1/4" ................................ 4

97 .............. 5645411 .................... Hex Cap Bolt............................................................ 1/4"-20 x 1-1/2" ............. 2

99 .............. 5645431 .................... Hex Nut .................................................................... 1/4" ................................ 2

100 ............ 5645441 .................... Hex Cap Bolt............................................................ 1/4"-20 x 1” ................... 2

101 ............ J-5645451 ................. Magnetic Switch Arm ............................................... ...................................... 1

102 ............ 5645461 .................... Hex Cap Bolt............................................................ 1/4"-20 x 1" ................... 2

103 ............ 5645471 .................... LVP Switch .............................................................. ...................................... 1

104 ............ 5645481 .................... Switch Screw ........................................................... 3/16"-24 x 3/4" .............. 2

105 ............ 9139071 .................... Motor Cable ............................................................. 440V cut coil ................. 2

106 ............ J-5514646 ................. Dust Chute ............................................................... ...................................... 1

107 ............ 5507491 .................... Hose Adapter ........................................................... 1.5 to 3 inch .................. 1

108 ............ 5507546 .................... Cooling fan and cove r (not shown) .......................... ...................................... 1

109 ............ J-5507545 ................. Junction Box ............................................................ ...................................... 1

110 ............ 5514789 .................... Hex Cap Bolt............................................................ 1/4"-20 x 1" ................... 2

111 ............ 5514796 .................... Spring Pin ................................................................ Ø5 x 20 mm .................. 1

112 ............ 5514797 .................... Sleeve ...................................................................... 1/2" ................................ 1

113 ............ 5514800A .................. Strain Relief ............................................................. MG25A-16B .................. 1

114 ............ 5514801 .................... 90° Connector .......................................................... 1/2" ................................ 1

115 ............ 5514802 .................... Connector ................................................................ S-FZS21-21-1/2" ........... 1

116 ............ 5645500 .................... Spring Pin ................................................................ Ø3 x 16 mm .................. 1

117 ............ 5514808 .................... Spring ...................................................................... ...................................... 2

118 ............ 5645501 .................... Brass Pin ................................................................. ...................................... 2

119 ............ 5646000 .................... Miter Gauge Complete Assembly (item #119-1 to #119-11) .......................... 1

119-1 ......... 5646001 .................... Knob ........................................................................ ...................................... 1

119-2 ......... TS-2205201 .............. Hex Cap Screw ........................................................ M5-0.8p x 20 ................. 3

119-3 ......... TS-1540031 .............. Hex Nut .................................................................... M5 ................................. 3

119-4 ......... 5646002 .................... Miter Gauge ............................................................. ...................................... 1

17

Page 18

Index No Part No Description Size Qty

119-5 ......... 5646003 .................... Pointer ..................................................................... ...................................... 1

119-6 ......... 5646004 .................... Roll Pin .................................................................... Ø3 x 6 mm .................... 1

119-7 ......... 5646005 .................... Stop Link .................................................................. ...................................... 1

119-8 ......... TS-0267021 .............. Socket Set Screw .................................................... 1/4"-20 x 1/4" ................ 1

119-9 ......... 5646006 .................... Guide Bar................................................................. ...................................... 1

119-10 ....... 5646007 .................... Flat Head Screw ...................................................... 1/4"-20 x 5/16" .............. 1

119-11 ....... 5646008 .................... Guide Disc ............................................................... ...................................... 1

Note: When ordering parts, please use your grinder serial number as a reference number.

18

Page 19

19

Page 20

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

20

Loading...

Loading...