Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Belt (2x42”) and Disc (8”) Sander

Model J-41002

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-577004

Ph.: 800-274-6848 Revision B1 03/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provi d e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTI ES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 4

Introduction ............................................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 6

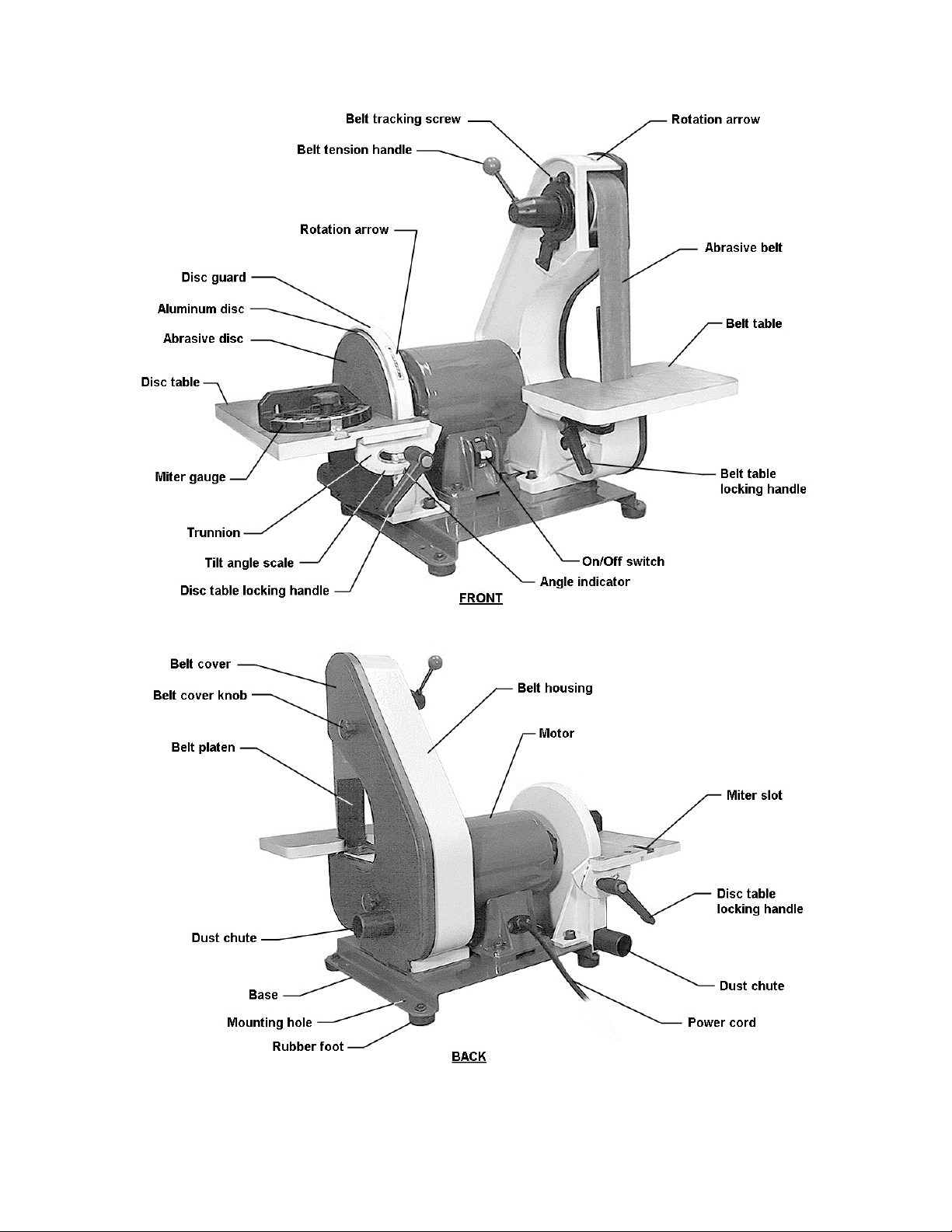

Features and Terminology ....................................................................................................................... 7

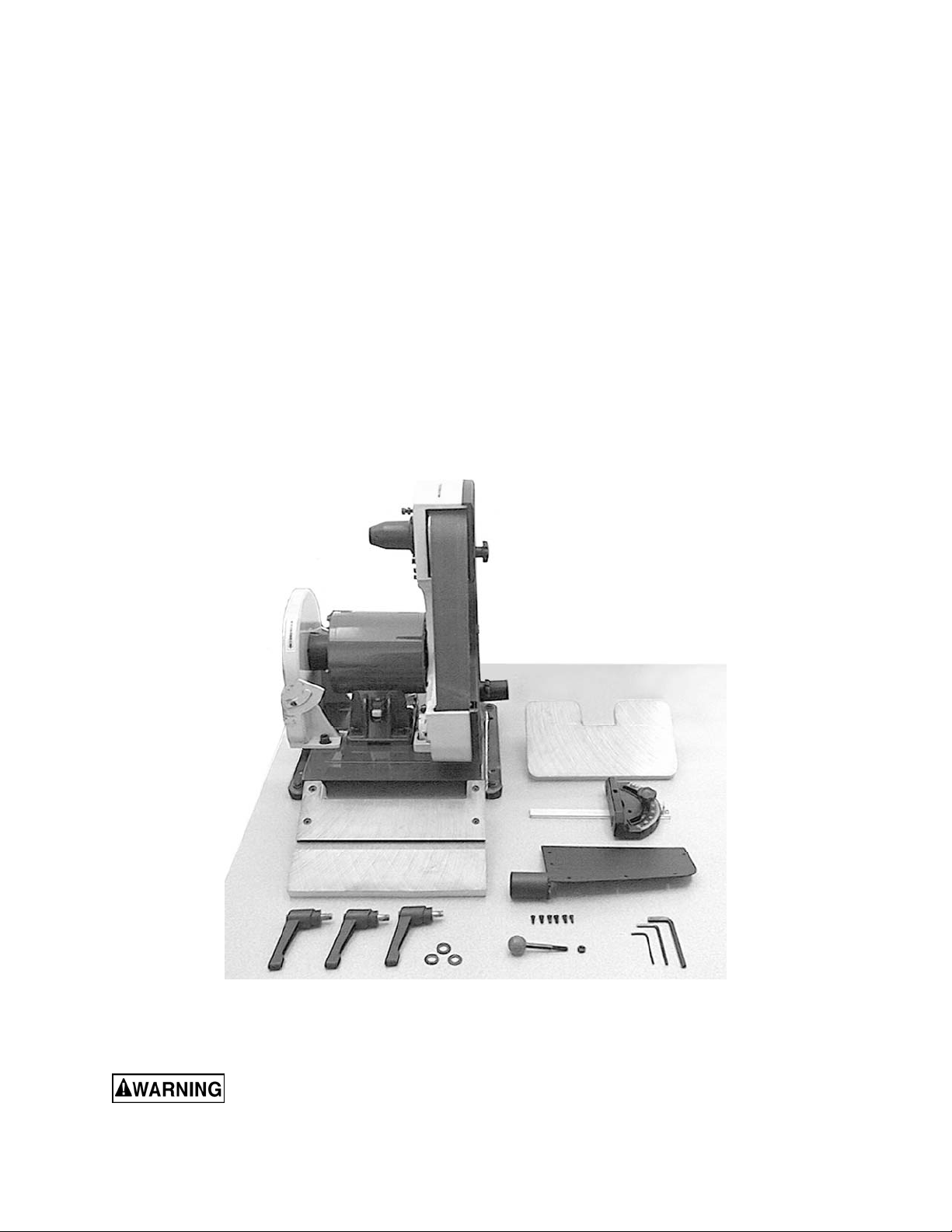

Unpac king ............................................................................................................................................... 8

Contents of the Shipping Container ...................................................................................................... 8

Assembly ................................................................................................................................................ 9

Installing Belt Table .............................................................................................................................. 9

Installing Dust Chute ............................................................................................................................ 9

Installing Disc Table ........................................................................................................................... 10

Installing Miter Gauge ........................................................................................................................ 10

Installing Tension Handle ................................................................................................................... 10

Grounding Inst r uc tions ........................................................................................................................... 11

115 Volt Operati on ............................................................................................................................. 11

Adjustments ................................................................................................................... ....................... 1 2

Tilting th e Be lt Ta b le .......................................................................................................................... 12

Tilting the Disc Table .......................................................................................................................... 12

Use of the Miter Gauge ...................................................................................................................... 13

Belt Platen ......................................................................................................................................... 13

Abras i ve Bel t Re p la cement ................................................................................................................ 14

Tracking the Abrasive Belt.................................................................................................................. 14

Abrasive Disc Replacement ............................................................................................................... 15

Aluminum Disc Removal .................................................................................................................... 15

Operation .............................................................................................................................................. 1 6

Starting and Stopping the Sander ....................................................................................................... 16

Belt and Disc Movem ent .................................................................................................................... 16

Typical Op e ra tions ............................................................................................................................. 16

Extension Cords................................................................................................................................. 11

Maintenance .......................................................................................................................................... 18

Replacement Parts ................................................................................................................................ 18

Troubleshooting ..................................................................................................................................... 19

Assembly Drawing ............................................................................................................................. 20

Parts List............................................................................................................................................ 21

3

Page 4

Warning

1. Read and understand the ent ire owner’s manual befor e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. This sander is designed and int ended for use by proper ly t rained and experi enced personnel onl y. If

you are not f amiliar wit h the proper and safe operati on of a sander, do not use unt il proper training

and knowledge have been obtained.

5. Do not use this sander for other than it s intended use. If used for other pur poses, JET disclaim s any

real or implied warranty and holds itself harmless from any injury that may result from that use.

6. Always wear appr oved saf ety glasses/face shields while u si ng this sander. Everyday ey eglasses only

have impact resistant lenses; they are not safety glasses.

7. Before operati ng this sander, rem ove tie, rings, watches and other j ewelry, and r oll sleeves up past

the elbows. Remove all loose clothi ng and c onfine long hair. Non-sli p footwear or anti-skid fl oor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during ext ended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi c als known to the S tate of California to cause cancer, birth defects or ot her reproductiv e

harm. Some exampl es of these chemicals are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oducts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machi ne whil e tired or under the influence of drugs, al cohol or any medication.

11. M ak e c er tain the switch is in the OFF position before connecting the machine to the power supply.

12. M ak e c er tain the machine is properl y grounded.

13. M ak e all machine adjustm ents or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machi ne is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. If there is a tendency f or the machine to ti p over or move dur ing operation, such as when sanding

long or heavy boards, the machine must be securely fastened to a supporting surface.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. P r ov ide for adequate space surrounding work area and non-glar e, overhead lighting.

19. K eep the floor around the machi ne clean and free of scrap material, oil and grease.

20. K eep v isitors a safe distanc e from the work area. Keep children away.

4

Page 5

21. M ak e y our workshop child proof wit h padloc k s, m ast er switc hes or by r emoving starter keys.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. Maint ain a balanced stanc e at all tim es so that you do not fall or lean against t he abrasiv es or other

moving part s. Do not over r eac h or use excessive force to perform any mac hi ne oper ation.

24. Use the ri ght t ool at the cor rect speed and feed r ate. Do not for ce a tool or attachment to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

25. Make sure the abrasive belt is running in the proper direction. When disc sanding, place the

workpiece against t he downward rot ating part of the abrasive disc.

26. Thi s machine can be used f or sanding wood or m etal products. Ho wever , combini ng wood dust an d

metal fil ings can create a fire haz ard. Make sure your dust col lector is fr ee of wood du st deposit s

before processing m etal products.

27. Use recom mended accessories; i mproper accessories may be hazardous.

28. M aintain tools with care. F ol low instructions for lubric ating t he m ac hine and changing accessories.

29. Abrasiv e discs m ust be stored in a cont roll ed environm ent. Relativ e humidity should be 35% t o 50%

and the temperature should be between 60° and 80° Fahrenheit. Failure to do this could cause

prematur e disc f ailur e.

30. Examine t he face of the abrasive disc or belt c arefully. Excessiv e sanding that wears down to the

backing materi al can t ear the disc/ belt. Never use an abrasiv e whic h shows backi ng, ni cks or cuts on

the surface or edge, or dam age due to creasing or poor handling.

31. Turn off the mac hine before cl eaning. Use a brush or compressed air to rem ov e c hips or debris — do

not use your hands.

32. Never leave the mac hine r unning unattended. Tur n the power off and do not leav e the mac hine until it

comes to a complete stop.

33. Do not use the sander in wet or damp loc ations.

34. Remove loose items and unnecessary work pieces from the area bef ore starting the machine.

Familiariz e you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result i n minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by JET covering the safe operation and maintenance procedures for a JET

2x42x8 Belt and Disc Sander. This manual contains instructions on installation, safety precautions,

general operating procedures, maintenance instructions and parts breakdown. This machine has been

designed and constructed to provide years of trouble free operation if used in accordance with

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local suppli er or JET. JET can also be reached at our web site: www.jettools.com.

Specifications

Model Number .............................................................................................................................. J-41002

Stock Num ber................................................................................................................................ 577004

Belt Size (in .)( LxW) ........................................................................................................................... 42 x 2

Belt Speed (SFPM) ............................................................................................................................ 3100

Disc Size (in.) ............................................................................................................................ 8 diameter

Disc Speed (RPM) ............................................................................................................................. 3 450

Motor .................................................................................................................... 3/4HP, 1Ph, 115V, 6.2A

Belt Table Size (in.)(LxW) ................................................................................................................. 10 x 6

Disc Table Size (in.)(LxW) .................................................................................................... 10-3/4 x 7-1/2

Disc Table Tilt (deg. )....................................................................................................................... 0 to 45

Dust Chutes (in.) ...................................................................................................... two @ 1-1/2 diameter

Overall Size (in.)(WxDxH) ........................................................................................... 20-1/2 x 22-3/4 x 20

Approximate Net Weight (lbs.) ............................................................................................................... 58

Approximate Shipping Weight (lbs.) ....................................................................................................... 64

The above specifications were current at the tim e this manual was publi shed, but because of our policy of

continuous impr ovement, JET reserves the ri ght to change specifications at any tim e and without prior

notice, without incurring obligati ons.

6

Page 7

Features and Terminology

7

Page 8

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shippi ng material until t he sander is

assembled and running properly.

Compare the c ontent s of y our cont ainer wit h t he

following parts list to make sure all parts are

intact. Mi ssing parts, i f any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

1 Belt and Disc Sander

1 Belt Table

1 Disc Table with trunnions

1 Miter Gauge

1 Dust Chute

6 Phillips Pan Hd. Machine Screws, 3/16x3/8”

3 Handles

3 Flat Washers, 3/8”

1 Tension Handle

1 Hex Nut, 1/4”

3 Hex Wrenches, 3, 4 and 6mm

1 Owner's Manual

1 Warranty Card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mply may cause serious injury.

8

Page 9

Assembly

Tools needed for assembly:

• 10mm open-end wrench

• Cross-point (P hillips) screwdriver

• Combination square, or similar angle

measuring devic e.

Sander must be unplugged

from power source during assembl y.

Remove the pr otective coating from the surf ac es

of the sander and from any loose parts. This

coating may be removed with a soft cloth

moistened with kerosene (do not use acetone,

gasoline or lacquer thinner for this purpose).

After cleaning, cover the table surfaces with a

good quality paste wax.

Leave enough space aroun d the sander f or l ong

workpieces and for gener al maintenance.

If needed, the sander c an be bolt ed to a t abl e or

workbench using the holes in the base. If the

sander has a tendency to walk or slide during

operation, it must be bolted to a supporting

surface.

Installing Belt Table

1. Unscrew the stud. See Figur e 1.

2. Position the brac k et of the belt table over the

holes in the ca sting as sh own, and re-i nstal l

the stud into its hole.

3. Place a flat washer onto a handle, and insert

the handle through the table bracket and

into the hol e. Screw the handle all the way

into the hole.

NOTE: The handle i s spring loaded; screw

the handle in by rot ating cloc kwise, then pul l

outward on the handle. Rotate the handle

back to position, then release it, making sure

it seats itself upon the pin. Continue the

process until the handle is tightened in the

hole.

Installing Dust Chute

The sander has two 1- 1/2” diam eter dust chutes.

The dust chute for the belt is locat ed on the belt

cover. The dust chute for the disc should be

install ed as shown in Figure 2, using the six (6)

pan head machine screws that ar e pr ov ided.

Figure 1

The dust chutes can be connect ed to a vacuum

system to collect dust particles.

Figure 2

9

Page 10

Installing Disc Table

1. Position the disc table at an angle, as shown

in Figure 3, and sli de the table on so that the

trunnion slots fit over the raised tracks on

the disc guard.

2. Install a flat washer onto each of the two

remaini ng handles. Insert the handle into the

holes through the left and right trunnions.

See Figure 4.

3. The gap between the sanding di sc and the

disc table sho uld be a m aximum of 1/ 16”. If

it is larger than this, loosen the two socket

head cap screws on the disc guard (one is

shown in Fi gure 4) and sli de the disc guard

to achieve this gap m easurement.

4. When finished, tighten the two socket head

cap scre ws securely.

Figure 3

Installing Miter Gauge

Insert the miter gauge bar into one end of the

miter slot in the disc table. See Figure 5.

The mit er gauge can be used in eit her directi on

in the slot to achieve the most effective

positioning of the workpiece against the abrasive

disc.

Installing Tension Handle

1. Place the 1/4” hex nut onto the threads of

the tension handl e.

2. Screw the tension handle into the hole on

the hub, then ti ght en the hex nut against the

hub. See Figure 6.

Figure 4

Figure 5

Figure 6

10

Page 11

Grounding Instructions

This machine must be

grounde d while in use to protect the ope r a t or

from electri c sho ck.

In the event of a malfunction or breakdown,

grounding prov i des a path of least resistanc e f or

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a

grounding plug. The plug must be inserted into a

matching receptacle that is properly installed

and grounded in acc orda nce with al l l ocal codes

and ordinances.

Do not modify the pl ug pr ovided. If it will not fit

the outlet , have the proper outlet i nstalled by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-gr ounding conductor t o a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properl y grounded. Use onl y

three wire ex tension cords that have three-pr ong

grounding plugs and t hree-pole recept acles that

accept the tool ’s pl ug.

115 Volt Operation

As received from the factory, your sander is

ready to run at 115 volt oper ation. This sander is

intended for use on a circuit that has an outlet

and a plug that looks like the one illustrated in

Figure 7.

A temporary adapt er, like the adapter i n Figure

8, may be used to connect this plug to a twopole receptacle, as shown in Figure 8, if a

properly grounded outlet is not available. The

temporary adapter should only be used until a

properly grounded outlet can be installed by a

qualified electrician. This adapter is not

applicable in Canada. The green colored rigi d

ear, lug, or tab, extending from the adapter,

must be connect ed to a permanent ground such

as a properly gr ounded outlet box, as shown in

Figure 8.

Figure 8

Extens ion Cords

Use proper ext ension cor ds. Make sur e the cor d

rating is suitable for the amperage of the

machine’s mot or. An undersized cord will cause

a drop in line voltage r esulting i n loss of power

and overheating.

Use the chart in F igure 9 as a general gui de in

choosing the correc t size cord. The smaller the

gauge number, the heavier the cord.

Recommended Gauges (AWG ) of Extension Cords

Extension Cord Length *

25

50

75

100

150

200

feet

feet

feet

feet

feet

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

feet

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on li miting th e lin e vol tage drop to 5V at 15 0% of t h e

rated amp eres.

NR: Not Recommended.

Figure 7

Figure 9

11

Page 12

Adjustments

Tilting the Belt Table

The belt table til ts from zero ( horizont al) down to

45°.

1. Loosen the handle and adjust t he table into

desired positi on.

2. Check the angle with a machinist’s

protractor or similar measuring device that

has the required angle. Figure 10 shows a

square being used to confirm the zero, or

horizontal, positi on. Place the square flat on

the table and agai nst the bel t. Push against

the belt until the square is against the

platen.

3. Make any adjustment s to the table angle as

necessary until it is square with the belt.

4. Tighten the handle securely.

To avoid trapping the

workpiece or fingers between the table and

abrasive belt, the table edge should be

positioned a maximum of 1/16” from the

abrasive bel t.

Tilting the Disc Table

The disc table tilts from zero (horiz ontal) down to

45°.

1. Loosen both handles and adjust the table

until the indicator lines up with the desired

angle on the scale. It is a good idea to

confirm this angle using your angle

measuring devi ce placed flat upon the table

and against the abrasive disc.

2. Figure 11 shows a square being used to

confirm the zer o, or horizontal posi tion of the

disc table.

3. Make any necessary adjustments to the

table angle. If the table is square with the

disc but the angle indicator needs slight

adjustment, loosen the screw on the

indicator and shift the indicator as needed.

Re-tighten the screw.

4. Tighten both handles securely.

To avoid trapping the

workpiece or fingers between the table and

abrasive disc, the table edge should be

positioned a maximum of 1/16” from the

abrasive di sc.

Figure 10

Figure 11

12

Page 13

Use of the Miter Gauge

The miter gauge is used to sand accurate

angles on workpieces. When using the miter

gauge on the hori zontal table position, you c an

sand a single angl e. By tilt ing the disc t able and

using the miter gauge in combination with the

table tilted, it is possible to sand compound

angles as well.

The miter gauge rotates to 30° for bevel

sanding. Loosen t he knob and rot ate the gauge

body until the pointer li nes up with the d esired

angle on the scale.

Use a square to c onfirm that the miter gauge i s

set at 90° (perpendi c ular to the disc). See Figure

12. If slight adjustment is needed:

1. Loosen the knob.

2. Adj ust the miter gauge body unti l it is flush

with the square, and t he square i s f lush with

the disc.

3. Tighten the knob.

4. Loosen the screw on the pointer and adjust

the pointer until it aligns with 90° on the

scale.

5. Tighten the screw on the poi nter.

Belt Platen

The belt platen (Figure 13) is used to properly

support the workpi ece whi le sandi ng. T he plat en

is constructed of heavy steel to provide

adequate support.

The platen should be adjusted so it is almost

touching the back of the abrasive belt. Loosen

the socket head cap screw and adju st the pl aten

to the desired position. Tighten the screw to

secure the platen.

Figure 12

The platen can be r emoved f or operations such

as stripping, c ontour sanding, polishing or ot her

special operations. To remove the platen,

remove the socket head c ap screw and washer.

Be sure to re-install the platen to perform

operations where support of the belt is required.

Figure 13

13

Page 14

Abrasive Belt Replacement

1. Unplug the Sander from the power source.

2. Unscre w and remov e the two knobs on the

belt cover.

3. Remove the belt cover.

4. Rotate the tension handle (Figure 6) to

loosen the belt , and rem ov e the old belt from

around the wheels.

5. Install the new belt around the wheels.

IMPORTANT: Some sanding belts have a

directional arrow printed on the i nsi de of t he belt.

In these cases, t he belt m ust be install ed so the

directional arrow is in the same direction that the

machine is running. Refer to the rotation arrow

on top of the belt cover.

6. Install the belt cover and the two knobs.

7. Start the sander and check t he belt tracking

before sanding operations (See “Tracking

the Abrasive Belt”).

Tracking the Abrasive Belt

“Tracking” refers to the manner in which the

abrasive bel t is positioned on the wheel s during

operation. The belt should remain in vertical

position wit hout shifti ng to one side or the other

of the wheel. If any shifting occurs, the belt

needs to be track ed pr operl y , as follows:

1. Disconnect sander from power source.

2. Remove the side cover , and make sure the

belt is pl aced ev enly over t he center of the

wheels. Loosen the tension and re-position

the belt if necessary. Re-install the side

cover.

3. Move the belt by r otating the disc with your

hand (do not turn on the power yet).

Observe the movement of the belt on the top

wheel.

4. If the belt slips to one side or the other,

loosen the hex nut (Fi gure 14) with a 10m m

open-end wrench.

5. Rotate t he tracki ng screw (Fi gure 14) with a

5mm hex wrench. If the belt is sliding toward

the right, rotate the screw clockwise. If the

belt is sliding toward the left, rotate the

screw countercl oc k wise.

6. Continue t his procedure in sm all inc rements

until the belt is tracking properly when

moved by hand.

7. Re-connect t he sander to po wer, and cycle

the on/off switc h quic kly t o double c heck t he

tracking.

Figure 14

8. Re-connect t he sander to po wer, and cycle

the on/off switc h quic kly t o double c heck t he

tracking.

9. Make further adj ustm ents as needed.

10. Tighten the hex nut to secure the setting.

14

Page 15

Abrasive Disc Replacement

1. Unplug the sander from the power source.

2. Remove the dust cover and the disc table.

To remove the disc table, remove the

handles then til t the disc table upward while

pulling it away f r om the disc.

3. Peel off the old abr asive disc.

4. Thoroughl y clean the aluminum disc surface

using naptha or a similar non-flammable

solvent that will dr y film -free.

5. Pull the protective backing half-way off the

new abrasive disc.

6. Carefully posi tion the new abrasive disc so i t

is centered accur ately on the aluminum disc.

7. W hen accurately centered, r emove the r est

of the protective backing and press the

abrasive disc firmly against the aluminum

disc so complete adhesive contact is made.

8. Re-install dust c over and table.

9. Reconnect sander to power source.

Aluminum D isc Removal

The aluminum disc can be easily removed if

needed; for example, to facilitate cleaning the

aluminum di sc when replac ing abrasive discs.

1. Unplug sander fr om the power source.

2. Remove the disc tabl e and the dust chute.

3. Rotate the disc until the set screw is

accessible through the opening behind the

disc guard. See Fi gure 15. Y ou may need t o

loosen the socket head cap screws (see

Figure 4) on t he gu ard an d shi ft it for ward in

order to clear t he set screw.

4. Loosen the set screw with a 3mm hex

wrench, and pull the aluminum disc off the

motor shaft.

5. When re-m ounting the aluminum disc, make

sure the key is properly seated in the

keyway on the m otor shaft. Tighten t he set

screw firmly when the disc has been

mounted.

Figure 15

15

Page 16

Operation

This sander is intended for dry sanding of

metals. Do not use lubrica nts.

Do not sand or polish

magnesium; i t may creat e a fire hazard. Also,

do not sand very small or very thin

workpieces th at canno t be safely controlled.

Starting and Stopping the Sander

The on/off switch is located on the side of the

motor housing. Move the switch upward to the

ON positi on to start the sander. Move the switch

downward to the OFF position to stop the

sander.

When the sander is not being used, the switch

can be locked in OFF position to prevent

unauthorized use. Pull out the locking tab and

store in a safe pl ace. See Figure 16. The switch

will not operat e with the locking tab removed.

To use the sander, re-i nsert the locking tab.

Belt and Disc Movement

When the machine is turned on, the abrasive

belt should be moving downward and the disc

rotating clockwise. The motor is wired at the

factory for correct rotation.

The workpiece should not contact the disc or

belt during start-up. Before sanding, always

allow the motor to come up to operati ng speed,

then observe t he disc for wobble, runout, or any

unbalanced condit i on. If the disc i s not operat i ng

accurately and smoothly, stop the motor and

make repairs before attempting any sanding

operations.

Always sand on the side of the abrasive disc

that rotates downward. Sanding on the up ward

rotation side can cause the workpiece to catch

and fly out of your hands.

The table must be a maximum of 1/16” away

from the abrasive disc or belt.

Typical Operations

Figure 16

When sanding a compound angle you should

check the accur acy of your setup by sanding a

piece of scrap material before doing any finish

sanding on the actual workpiece.

Figure 17 demonstrates a basic method of

operation using the miter gauge and disc table:

1. Set the angle you wish to sand using the

scale on the miter gauge.

Figure 17

16

Page 17

2. Tighten the miter gauge securely so the

miter r eference angl e will not shif t while y ou

are sanding.

3. Place the workpiece against the miter

referenc e surf ac e and sl ide it along t he mi ter

referenc e surf ac e and into the sanding disc.

The following are just some of the many

operations that can be performed with your JET

Sander.

• Sharpening a wood chisel on the sanding

belt using a bl ock of wood. Use the bloc k of

wood to support the chisel and provide

clearance f or the chisel handle. See Figure

18. Sand a bevel in the block of wood in

order to position the block as close as

possible to the sanding belt and clamp the

block to the table.

• A cold chi sel can also be sharpened on the

belt table with the table tilted.

• Sanding alumi num on the disc unit wit h the

table tilted and using the miter gauge as a

guide. See Figure 19.

Figure 18

• Sanding outsi de curves on the belt unit wit h

the platen removed. See Figure 20.

• Polishing using a felt belt (not provided) in

place of the sanding belt.

Note: Most polishing operations are

perform ed with t he platen removed.

• Sandi ng in ti ght areas with t he sanding bel t.

See Figure 21.

Figure 19

Figure 20

Figure 21

17

Page 18

Maintenance

Before performing any

maintenance on the machine, disconnect it

from the electrical supply by pulling out the

plug or switching off the main switch.

Failure to compl y may cause seri ou s injury.

Keep the table surfaces clean and f r ee of rust. If

rust appears on the tables, use 000 steel wool

with a paste mixt ure of household amm onia and

good commercial detergent (or use a

commercial rust remover available from most

hardware stores.)

A light coat of paste wax on the tables will help

protect them from tarnish and reduce friction

between table and workpiece.

Note: Do not get pa ste wax on t he abra siv e bel t

or disc.

Check all fastener s for tightness.

Inspect the power cord; if worn, cut , or damaged

in any way, have it repl ac ed immediately.

Inspect the abrasive belt and disc. If either is

worn, replace it.

Occasionally remove the belt cover and brush

out any shavings or debris from around the

wheels.

Lubrication

All of the ball bearings are packed with grease

and sealed at the factory. They require no

further lubrication.

Replacement Parts

To order parts or reac h our service departm ent, call 1-800-274-6848, Monday throug h Friday (see our

website for business hour s: j ett ools.c om). Having t he Model Num ber and Seri al Num ber of your machine

available when you call wi ll allow us to serve you quickly and accur ately.

18

Page 19

Troubleshooting

Trouble Probable Cause Remedy

Not connected t o power source. Connect to power source.

Determine r eason for blown fuse/

Branch circuit fuse is blown or the

circuit breaker is tr ipped.

Sander will not star t.

tripped break er ( such as short circuit

or motor overload) . Correct reason for

fault. Repl ac e fuse/ r eset ci r c uit

breaker.

Voltage is too low.

Switch is defective. Replace switch.

Motor failure. Replace motor.

Motor stalls easily. Low voltage.

Abrasive disc

separates fr om

al uminum disc.

Abrasive belt will not

track correctly.

Improper bond.

Belt not cent er ed on wheels. Readjust track ing. See page 14.

Belt stretched unevenly. Replace abrasive belt.

Belt is jointed impr oper ly.

Wheel is worn. Replace affect ed wheel.

Worn bearings.

Check power source f or pr oper

voltage.

Check power source f or pr oper

voltage and correct if necessary.

Clean residual adhesive from

aluminum di sc, and re-apply

adhesive- bac ked abrasive disc.

Check the belt for an irr egular seam

or shape. Replace if needed.

Check all the beari ngs for ex c essive

heat or loose shafts. Replace if

necessary.

Abrasive belt slips or

stalls when pressure

is applied.

Frequent

replacement of

abrasive belt or disc.

Abrasive belt t ensi on inadequate;

spring in tensi on m ec hanism is worn.

Excessive pressure being applied to

platen.

Too much pressure being appl ied to

workpiece.

Full width of belt or di sc not bei ng

used.

Incorrect abr asive material or grit

size.

Replace spring.

Reduce pressure on abrasive belt

(and platen).

Allow the belt to do the cutti ng.

Excessive pressure only dulls the grit

and removes it from the cloth.

Stroke across abrasive belt using full

width of belt surfac e.

Check with your abrasives supplier for

recommendations on the type and

coarseness of the abrasive required

for your parti c ular workpieces.

19

Page 20

Assembly Drawing

20

Page 21

Parts List

Index No. Part No. Description Size Qty

1 ............... J-41002-01 ..............Base ...................................................................................................... 1

2 ............... TS-0680042 .............Flat Washe r ........................................................3/8”............................. 2

3 ............... TS-1551031 .............Lock Washer ......................................................M5 .............................. 4

4 ............... TS-1515041 .............Socket Head Cap Screw .....................................M8x30 ........................ 4

5 ............... TS-0050021 .............Hex Cap Sc re w ..................................................1/4-20x5/8” ................. 4

6 ............... TS-0720081 .............Lock Washer ......................................................5/16 ” ........................... 4

7 ............... 41002-07 .................Rubber Foot .......................................................................................... 4

8 ............... TS-0680021 .............Flat Washe r ........................................................1/4”............................. 4

9 ............... TS-0570011 .............Hex Nut ..............................................................1/4”-20........................ 4

10 ............. TS-1525021 .............Socket Set Screw ...............................................M10x12 ...................... 1

11 ............. 41002-11 .................Capacitor Cap ....................................................................................... 1

12 ............. 41002-12A ...............Capacitor ............................................................30uF, 300V ................. 1

13 ............. HBS814GH-166-5 ....Cross Head Flat Screw .......................................10-24x3/8” .................. 6

14 ............. 41002-14 .................Capacitor Clamp ................................................................................... 1

15 ............. TS-0570011 .............Hex Nut ..............................................................1/4”-20........................ 4

16 ............. TS-0720071 .............Lock Washer ......................................................1/4”............................. 4

17 ............. TS-1504051 .............Socket Head Cap Screw .....................................M8x25 ........................ 4

18 ............. 41002-18 .................Strain Relief Plate .................................................................................. 1

19 ............. 41002-19 .................Strain Relief ........................................................6N-4 ........................... 1

20 ............. 41002-20 .................Line Cord .............................................................................................. 1

22 ............. 41002-22 .................Strain Relief Bushing ............................................................................. 1

23 ............. 41002-23 .................Self Tapping Screw ............................................10-24 X3/8 ” ................. 2

24 ............. J-41002-24 ..............Motor Housing Base .............................................................................. 1

24A .......... J-41002-24A1

25 ............. 41002-25 .................Switch with Key ..................................................................................... 1

26 ............. 41002-26 .................Copper Washer ..................................................................................... 1

27 ............. TS-081C022 ............Phillips Pan Head Machine Screw ......................10-24x3/8” .................. 1

28 ............. TS-1540031 .............Hex Nut ..............................................................M5 .............................. 4

29 ............. J-41002-29 ..............End Shield ............................................................................................. 2

30 ............. BB-6203ZZ ..............Bearing...............................................................6203ZZ....................... 2

31 ............. 41002-31 .................Motor Fan .............................................................................................. 1

32 ............. 41002-32 .................Armatu re ............................................................................................... 1

33 ............. 41002-33 .................Stator .................................................................................................... 1

34 ............. 41002-34 .................Pan Head Screw ................................................1/4-20x7/8” ................. 4

35 ............. J-41002-35 ..............Motor Housing ....................................................................................... 1

36 ............. 41002-36 .................Pan Head Screw ................................................M5x0.8x163 ................ 4

37 ............. 41002-37 .................Bar ........................................................................................................ 1

38 ............. 41002-38 .................Pointer ................................................................................................... 1

39 ............. HBS814GH-200 .......Phillips Pan Head Machine Screw ......................1/4x3/8” ...................... 1

40 ............. 41002-40 .................Miter Body ............................................................................................. 1

41 ............. 41002-41 .................Knob ..................................................................................................... 1

42 ............. TS-2361081 .............Lock Washer ......................................................M8 .............................. 2

43 ............. 41002-43 .................Miter Gauge Assembly (includes index 37 thru 41, 99, 100) ................... 1

44 ............. TS-1534052 .............Phillips Pan Head Machine Screw ......................M6x15 ........................ 4

45 ............. J-41002-45 ..............Disc Table ............................................................................................. 1

46 ............. 41002-46 .................Armatu re Gu a r d ..................................................................................... 1

47 ............. 41002-47 .................Handle................................................................................................... 3

48 ............. J-41002-48 ..............Right Trunnion

49 ............. J-41002-49 ..............Disc Guard ............................................................................................ 1

50 ............. TS-1540061 .............Hex Nut ..............................................................M8 .............................. 4

51 ............. 41002-51 .................Alumin u m Disc ...................................................8" ............................... 1

52 ............. 6291479...................Key.....................................................................5x5x30 mm.................. 1

53 ............. 5640211...................Abrasive Disc, 100 grit ........................................8” ............................... 1

54 ............. 41002-54 .................Dust Chute. ........................................................................................... 1

55 ............. J-41002-55 ..............Left Trunnion ......................................................................................... 1

56 ............. TS-1523011 .............Socket Set Screw ...............................................M6x6 .......................... 1

..........Motor Assembly ..................................................115V, 1P h .................. 1

....................................................................................... 1

21

Page 22

Parts List

57 ............. TS-1505021 .............Socket Head Cap Screw .....................................M10x20 ...................... 2

58 ............. J-41002-58 ..............Belt Housing .......................................................................................... 1

59 ............. TS-0680031 .............Flat Washer ........................................................5/16” ........................... 4

60 ............. TS-0570011 .............Hex Nut ..............................................................1/4”-20........................ 1

61 ............. TS-1490021 .............Hex Cap Screw .................................................M8x16 ........................ 2

62 ............. TS-0680031 .............Flat Washer ........................................................5/16” ........................... 3

63 ............. 41002-63 .................Belt Table Bracket ................................................................................. 1

64 ............. J-41002-64 ..............Belt Table .............................................................................................. 1

65 ............. TS-1524031 .............Socket Set Screw ...............................................M8 x12 ........................ 1

66 ............. 41002-66 .................Shaft ..................................................................................................... 1

67 ............. BB-6202ZZ ..............Bearing...............................................................6202ZZ....................... 4

68 ............. 41002-68 .................Idler Wheel ............................................................................................ 2

69 ............. 5640491...................Retaining Ring ....................................................S-15 ........................... 2

70 ............. 41002-70 .................Abrasive Belt ......................................................100 Grit 2”x42” ........... 1

71 ............. 41002-71 .................Stand Off ............................................................................................... 2

72 ............. 41002-72 .................Drive Wheel ........................................................................................... 1

73 ............. TS-1523031 .............Socket Set Screw ...............................................M6 x10 ........................ 1

74 ............. 41002-74 .................Belt Cover ............................................................................................. 1

75 ............. 41002-75 .................Knob ..................................................................................................... 2

76 ............. 41002-76 .................Track in g Wheel Cam Shaft .................................................................... 1

77 ............. 5513018...................Retaining Ring ....................................................S-17 ........................... 1

78 ............. 41002-78 .................Tension Spring ...................................................................................... 1

79 ............. 41002-79 .................Spring Cap ............................................................................................ 1

80 ............. 41002-80 .................Handle with Knob .................................................................................. 1

81 ............. 41002-81 .................Tracking Bracket ................................................................................... 1

82 ............. TS-1540041 .............Hex Nut ..............................................................M6 .............................. 1

83 ............. TS-1503051 .............Socket Head Cap Screw .....................................M6x20 ........................ 1

84 ............. 41002-84 .................Spring Plate ........................................................................................... 2

85 ............. TS-1502021 .............Socket Head Cap Screw .....................................M5x10 ........................ 2

86 ............. TS-1502031 .............Socket Head Cap Screw .....................................M5x12 ........................ 2

87 ............. 41002-87 .................Belt Platen ............................................................................................. 1

88 ............. TS-1504031 .............Socket Head Cap Screw .....................................M8x16 ........................ 1

89 ............. TS-152707 ...............Hex Wrench .......................................................M6 .............................. 1

90 ............. TS-152705 ...............Hex Wrench .......................................................M4 .............................. 1

91 ............. TS-152704 ...............Hex Wrench .......................................................3mm x140L ................. 1

92 ............. TS-0680031 .............Flat Washer ........................................................5/16” ........................... 4

93 ............. 41002-93 .................Pan Head Screw ................................................10-24x1/4” .................. 3

94 ............. 41002-94 .................Serra te d Was h e r ...............................................M 5 .............................. 1

95 ............. 41002-95 .................Cable ................................................................. 18# 100m/m ............... 1

96 ............. 41002-96 .................Term inal .............................................................A-3 ............................. 1

97 ............. 41002-97 .................Cable ................................................................. 22# 200m/m ............... 1

98 ............. TS-0267041 .............Socket Set Screw ...............................................1/4-20x3/8” ................. 1

99 ............. TS-1550031 .............Flat Washer ........................................................M5 .............................. 1

100 ........... TS-0680022 .............Flat Wash er ........................................................1/4”............................. 1

101 ........... 41002-101 ...............Indicator ................................................................................................ 1

102 ........... 41002-93 .................Pan Head Screw ................................................10-24x1/4” .................. 1

22

Page 23

Notes

23

Page 24

427 New Sanford Road

LaVergne, Tennessee 37086

Ph.: 800-274-6848

www.jettools.com

24

Loading...

Loading...