JET 414450 User Manual

This .pdf document is bookmarked

Operating Instructions and Parts Manual

8-in x 13-in Hori zontal Cut-Off Bandsaw

Model: J-7015

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414450

Ph.: 800-274-6848 Revision C 02/2014

www.jettools.com Copyright © 2014 JET

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provid e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Introduction ............................................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 6

Machine Fe a tu r e s .................................................................................................................................... 7

Unpacking and Assembly ........................................................................................................................ 8

Electri c al Connec tion ............................................................................................................................... 8

Controls and Indicators ............................................................................................................................ 9

Blade Selecti on ..................................................................................................................................... 10

Operations............................................................................................................................................. 1 0

Adjustments ................................................................................................................... ....................... 1 4

Maintenance .......................................................................................................................................... 18

Cleaning ................................................................................................................................................ 20

Lubrication............................................................................................................................................. 20

Coolant.................................................................................................................................................. 20

Troubleshooting ..................................................................................................................................... 21

Parts ..................................................................................................................................................... 23

Saw Stand and Bed ........................................................................................................................... 23

Saw Stand and Bed – Parts Breakdown ............................................................................................. 25

Saw Head .......................................................................................................................................... 26

Saw Head – Parts Breakdown ............................................................................................................ 29

Electri c Assembly – Parts and Breakdown .......................................................................................... 30

Wiring Diagram ...................................................................................................................................... 31

Ordering Replacement Parts.................................................................................................................. 32

The specifications in this manual are given as general information and are not binding. Walter Meier

(Manufacturing) Inc., reserves the right to effect, at any time and without prior notice, changes or

alterati ons to par ts, fittings, and accessory equipment deemed necessary for any reason whatsoever.

3

Warnings

1. Read and understand the ent ire owner's manual bef or e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. The bandsaw is desi gned and intended f or use by properly t r ained and experienced personnel only. If

you are not familiar with the proper and saf e operation of a bandsaw, do not use until proper traini ng

and knowledge have been obtained.

5. Do not use this bandsaw for other than its intended use. If used for other purposes, JET disclaims

any real or implied warrant y and holds itself harmless from any injury that may result from that use.

6. Always wear approv ed safety glasses/face shiel ds wh ile using this bandsaw. Ev eryday eyeglasses

only have impact resi stant lenses; they are not saf ety glasses.

7. Before operating t he bandsaw, rem ov e ti e, ri ngs, watches and other jewelr y, and rol l sl eev es up past

the elbows. Remove all loose cl othing and c onfine long hair. Non- sli p footwear or anti- skid floor stri ps

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during ext ended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber.

10. Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

11. Do not operate this machi ne while tired or under the influence of drugs, alcohol or any medicati on.

12. M ak e c er tain the switch is in the OFF position before connecting the machine to the power supply.

13. M ak e c er tain the machine is properl y grounded.

14. M ak e all machine adjustments or maintenance with the machine unplugged from the power source.

15. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

16. Keep safety guards in place at all times when the machi ne is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

17. M ak e sure t he bandsa w i s firmly placed on a secure foundation.

18. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

19. P r ov ide for adequate space surrounding work area and non-glar e, overhead lighting.

20. K eep the floor around the machi ne clean and free of scrap material, oil and grease.

21. K eep v isitors a safe distanc e from the work area. Keep children away.

4

22. M ak e y our workshop child proof wit h padloc k s, m ast er switc hes or by r em oving starter keys.

23. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

24. M aintain a balanced stanc e at all times so that y ou do not fall into the blade or other moving parts. Do

not overreach or use excessive force to perform any machine operation.

25. Use the ri ght t ool at the cor rect speed and feed r ate. Do not for ce a tool or attachment to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

26. Use recom mended accessories; i mproper accessories m ay be hazar dous.

27. Maintain tools with care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions for lubricati ng and c hanging accessories.

28. Turn off the machine bef ore cleaning. Use a brush or compressed air t o remove chips or debris — do

not use your hands.

29. Do not stand on the machine. Seri ous injury could occur if the machine ti ps over.

30. Never leave the mac hine r unning unattended. Turn the power off and do not l eav e the mac hine until it

comes to a complete stop.

31. Remove loose items and unnecessary work pieces from the area bef or e start ing the machine.

32. Always wear leather gloves when handling saw blade. The operator shall not wear gloves when

operating the machine.

33. A ll doors shall be closed, all panel s replaced, and other saf ety guards in pl ace prior to t he machine

being started or oper ated.

34. Be sure that the bl ade is not i n contact with the workpi ece when the m otor is start ed. T he mot or shall

be started and you shoul d allow the saw to com e up to f ull speed before bri nging the saw blade int o

contact wit h the workpi ec e.

35. K eep hands a way from the blade area.

36. Remove any cut off piece carefully while keeping your hands free of the blade area.

37. Saw must be stopped and electrical supply must be cut off before any blade replacement or

adjustment of blade support mechanism is done, or befor e any attempt is made to change the drive

belts or before any peri odic service or maintenance is performed on the saw.

38. Remove loose items and unnecessary workpieces from area before starting machine.

39. B r ing adjustable saw guides and guards as cl ose a s po s si ble to the workpiece.

40. A lways wear protective eye wear when operating, servic ing, or adjusting machinery. Eyewear shall be

impact resistant , protective safety glasses with side shi elds complyi ng with ANSI Z87.1 specific ations.

Use of eye wear which does not com ply with ANSI Z87.1 specif ications could resul t in severe injury

from breakage of ey e protec tion.

41. Nonsl ip footwear and safet y shoes are recom mended.

42. The workpiece, or part being sawed, must be securely clamped before the saw blade enters the

workpiece.

43. Saw must be stopped an d elec tr ic al supply cut off or m achine unpl ugged bef ore reac hing int o cut ting

area.

44. Avoid contact wit h cool ant, especially guarding y our eyes.

5

Familiariz e you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, i t may result in serious i njury or possibly

even death.

Introduction

The JET Model J-7015 Horizontal Cut-off Bandsaw is designed for high production cut-off work. Four

cutting speeds and a hydraulic feed control allow the efficient cutting of vir tually any material.

The Model J-7015 Horizont al Cut-off Bandsaw is equipped wit h a coolant system t hat can greatly extend

blade life and speed the cut ting of a variety of materials t hat are best cut with cutting fluids and coolants.

Specifications

Model Number ............................................................................................................................... J-7015

Stock Num ber................................................................................................................................ 414450

Capacity:

Rectangular Stock at 90° (in.) ...................................................................................................... 9 x 13

Rectangular Stock at 45° (in.) .......................................................................................................9 x 8

Round Stock at 90° (in.) ...................................................................................................................... 9

Round Stock at 45° (in.) ...................................................................................................................... 9

Flat Stock (in.) .............................................................................................................................8 x 10

Speeds (FPM) ................................................................................................................ 82, 132, 170, 235

Motor ........................................ TEFC, 1-1/2 Horsepower, Capacitor Start, 1725 RPM, 1 Phase, 115/230V

Blade Size (in.) ............................................................................................................... 1 x 0.035 x 114.5

Blade Guides ............................................................... Tungsten carbide tip & ball bearing, ecc entric shaft

Material ........................................................................................................... Tungsten carbide inserts

Sides ........................................................................................................ Eccentric shaft, ball bearings

Blade Wheel (in.) ................................................................................................ 11-5/8 diameter, cast iron

Dimensions (LxWxH)(in.) ....................................................................... 62.5 x 22.4 x 48.4 (cutoff position)

Net Weight, approx. (lbs.) .................................................................................................................... 551

Vise ..................................................................................................... Rapid acting, screw tightening vise

Coolant Pump..................................................................................... 1/8 Horsepower, 1Phase, 115/230V

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

6

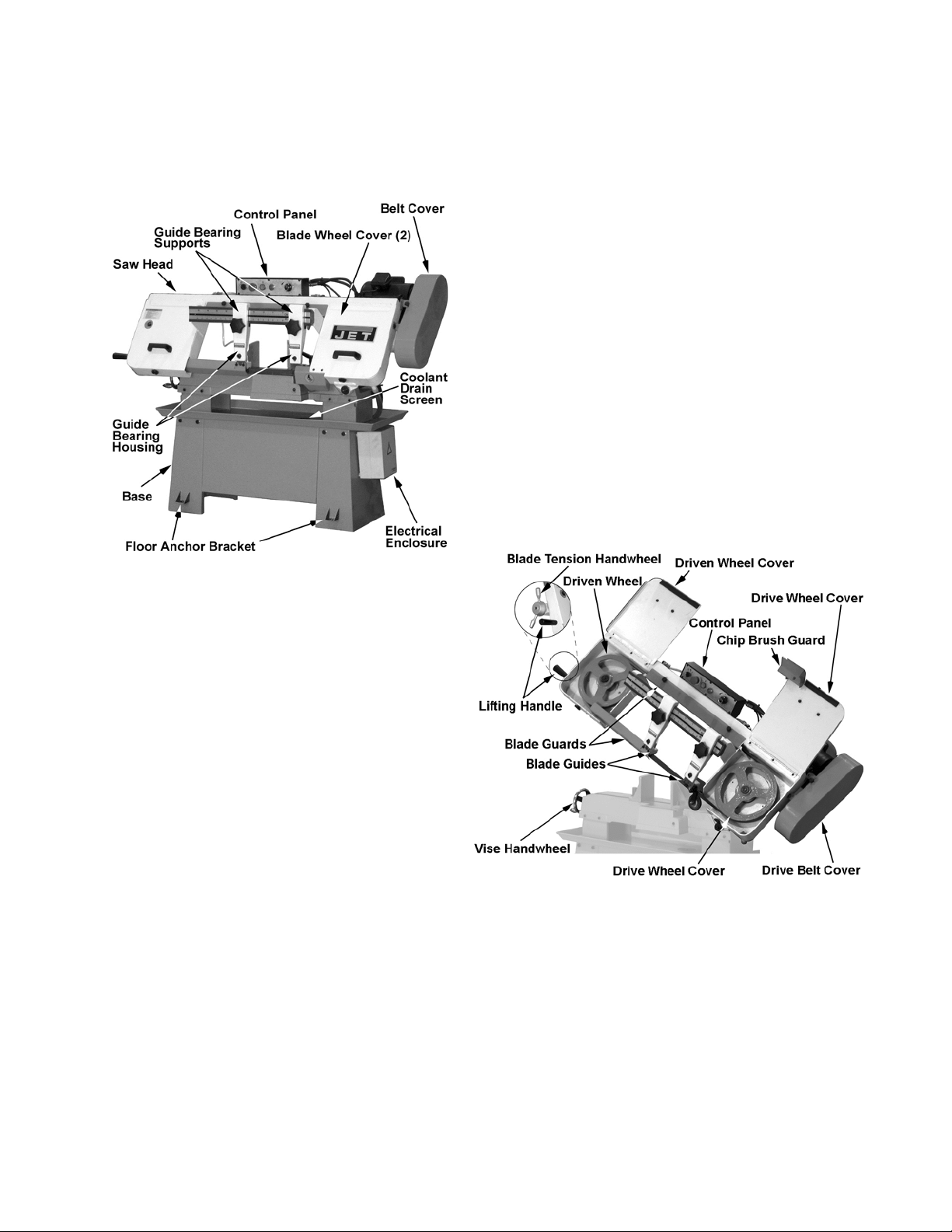

Machine Features

Saw Head

Figures 1 and 2 depic t the main features of the

Model J-7015 Horiz ontal Cut-Off Bandsaw. T he

machine consists of a machine base onto which

is installed a saw head.

Figure 1

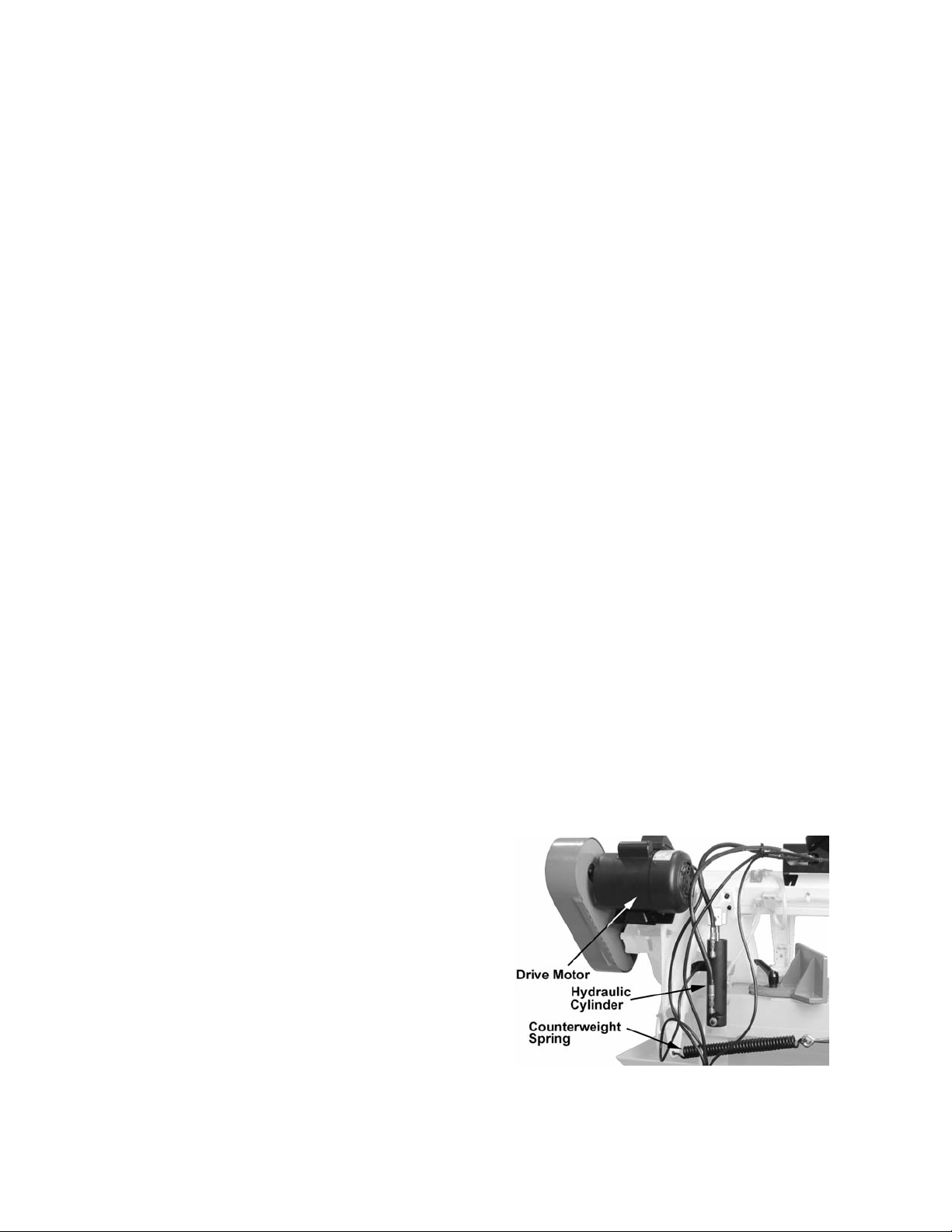

The saw head (Figure 2) consists of a drive

motor, drive pulleys, gearbox, blade wheels,

blade guides and support s, control panel, blade

tension/blade tracking mechanism, wire brush,

and the saw blade.

The drive m otor is mounted on a piv oting plate

that swings outward to provide V-belt tension.

The motor is fitted with a step pulley; the V- belt

connects to a second step pulley that is

mounted on the input shaft of the gearbox.

A speed-reducing gearbox is mounted on the

back side of the blade wheel box on the right

side of the machine. The blade wheel (drive

wheel) is installed on the output shaft of the

gearbox.

A second blade wheel is located in a blade

wheel box on the left of the machine. The blade

wheel (driv en wheel) is mounted on a shaft that

is part of the blade tensi on/tracking mechani sm.

The blade tension mechanism is used to tighten

the saw blade on the blade wheels.

Machine Base

The machine base consists of a coolant

collection pan m ounted on two panels that form

the legs of the machine. A shelf is provided

under the coll ection pan that support s a coolant

tank.

The machine bed mounts on the top of the

collection pan. The bed supports the vise and

the vise-tightening lead screw.

The coolant tank is equipped wit h a pump/motor

assembly. The pump/motor circulates coolant

through tubing to cool and lubricate the saw

blade, the blade guides, and the workpiece.

A drainpipe is provided to connect the collecti on

pan to the coolant tank. A screen is provided in

the collecti on pan to screen-out c utting debri s as

the coolant drai ns into the coolant tank. Coolant

is added to the tank by pouring c oolant into the

collection pan. The tank is easily r emoved from

its shelf f or cleaning and maintenance.

Figure 2

7

The mechanism also has adjustment screws

that enable the saw blade to “track” evenly on

the blade wheels. The adjustment screws

change the angle of the driv en bl ade wheel s haft

so the wheels are al igned. Tr acking adj ustment s

are generally made after the saw blade is

changed but may be required periodically due to

wear over time.

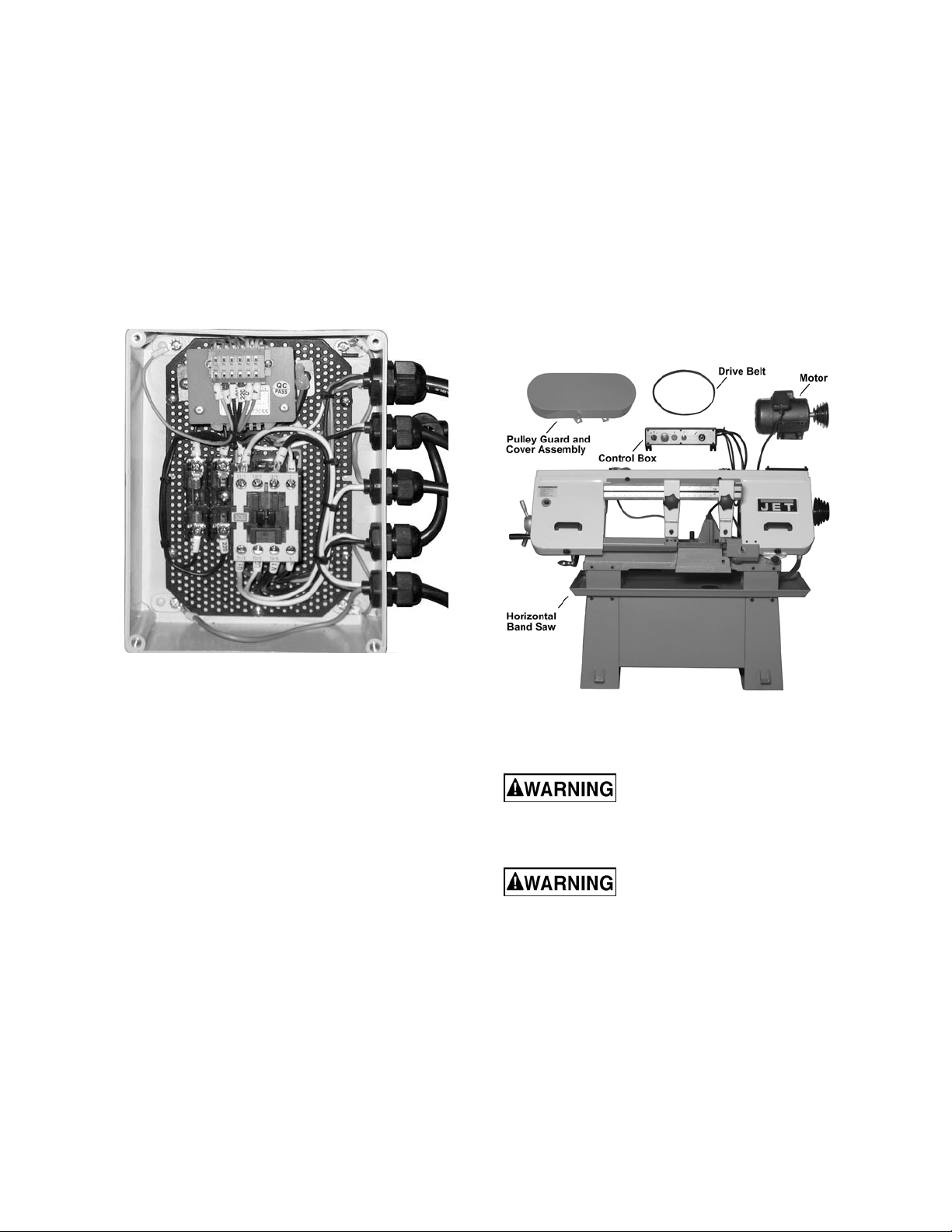

An electrical enclosure is attached to the leg

panel on the right side of the machine. The

enclosure contains the switches and fuses

required for operation and pr otecti on of the dr iv e

motor (Figur e 3).

Remove the saw fr om the shipping skid; discard

any hold-down devices. Place the saw on the

shop floor; secure the saw to the floor using

mounting anchor s secured through four holes in

the machine base. If the saw will be used to cut

long pieces of stoc k, allow plent y of room for t he

length of the stock .

Minimal assembly is required (see to Fig. 4),

consisting of mounting the control box, motor,

pulley guard/cover assembly and motor drive

belt. The mounting hardware is already in place

on the saw head. Loosen or remove the

hardware, plac ing the components (listed above)

in place and secure. For the drive belt, refer to

the Drive Belt section on page 19.

Figure 3

Work Stop

A work stop is provided with the machine to

allow cutting multiple pieces of identical length

(refer to Figure 12). The stop consists of a rod

onto which is installed a stop bracket , a tapered

stop, a clamping knob and a locking handle. T he

rod is installed in a bore in the front of the saw

bed. The stop bracket is positioned on the rod

with the tapered stop toward the end of the

workpiece. The br ac k et is moved in or out on the

rod to establish the length of the workpiece.

Control Panel

The control panel is mounted on the top of the

saw head. Refer to the Controls and Indicators

section (page 9) f or a description of the controls.

Unpacking and Assembl y

Machine Setup

The cut-off saw has been pre-adjusted at the

factory and sev eral test pieces hav e been cut to

verify cutting accuracy.

Figure 4

Electrical Connection

Electrical connection must

be made by a licensed electri cian. The wirin g

methods and practices must comply with

local electri cal codes.

The machine uses high

voltage electrical power that poses a

significant risk of serious injury or death if

proper precaut ions are no t ob served

Connect the machine to the electrical power

branch circuit (refer to the Wiring section on

page 31). Observ e the following guideli nes when

connecting the saw to the power source.

1. Make sure the saw is disconnected from the

electrical power branch circuit (trip the

required circuit breakers or remove the

required fuses).

8

2. Place a warning placard or tag on the

service panel to prevent accidental

electric al shock.

3. W hen installing the mot or power cord into a

receptacle, make sure the plug is

compatible with the receptacle.

4. When using hard-wired connections,

connect the wires as shown i n the Wiring

Data section.

5. Install the f uses or reset t he br eak er s.

Check operati on of t he saw.

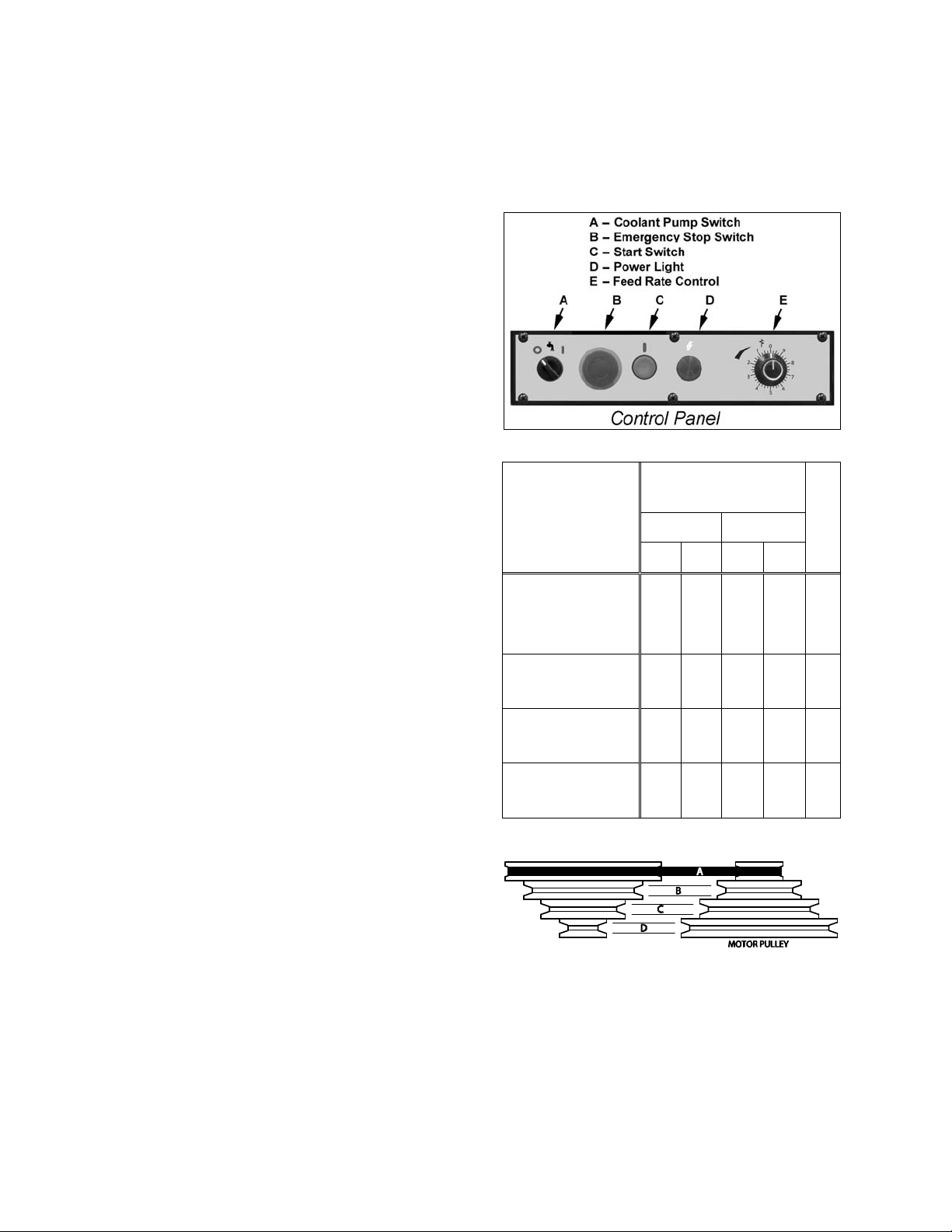

Controls and Indicators

Control Panel

The operating controls for the cut-off saw are

located on the control panel (Figure 5) and

consist of the f ollowing c ontrols and indicat or s:

Coolant Pump Swit ch – turns the coolant pum p

on and off.

Emergency St op Sw itch – pr ess to stop the dr ive

motor. Note: A micro switch also stops the

motor when the workpiece is cut and the saw

head is complet ely down.

4. Loosen the drive motor locking handl e. Pivot

the motor inward to slac k en the belt.

5. Select the speed using the placard on the

cover. Put the V-belt in the pulley grooves

of the pulley f or the desir ed speed. Refer to

Figure 6 for belt locations and the speeds

available.

Figure 5

Belt Speed

Material to Be Cut

60Hz 50Hz

fpm mpm fpm mpm

Belt Position

Start Switch – press to start the drive motor. The

saw head must be in the raised position.

Power Light – indicates that machine is plugged

in and the outlet circuit breaker is turned on. T he

machine does not need to be running for the

power light to be on.

Feed Rate Control –

thi s knob i s used to set t he

amount of downward f orce that is applied to the

saw blade. The feed rate is proportional to the

opening of t he valve. When set t o zero, the sa w

head is locked i n the raised posit ion. Increasing

the valve opening (countercloc k wise adj ustment)

increases the feed rate; decreasing the valve

opening (clockwise adjustment) reduces the

feed rate.

Blade Speeds

The Model J-7015 horizontal cut-off bandsaw

has four blade speeds. The dif fer ent speeds are

obtained by changing the position of the motor

drive V-belt on step pulleys. Change blade

speeds as foll ows:

1. Disconnect the electrical power from the cutoff saw branch circuit to prevent accidental

motor start-up

2. Set the saw head at the fully down position.

3. Remove the knob f rom the drive belt cover.

Swing cover out and downward to expose

the V-belt and pull eys.

Tool Steel, Stainless

Steel, Alloy Steel,

Phosphor Bronze, Hard

Bonze, Hard Cast Iron,

Malleable Iron

Mild Steel, Soft Cast Iron,

Medium Hard Brass,

Medium Hard Bronze

Soft Brasses and

Bronzes, Hard Aluminum,

Plastics

Plastics, Soft and Medium

Aluminum, Wood, Other

Light Materials

82 25 68 21

132 40 110 33

170 51 142 43

235 71 196 60 D

A

B

C

Note: Belt position A shown below

Figure 6

6. Pivot the motor outward to tighten the V-belt.

Tighten the locking handle.

7. Check V-belt tension by pushing the V-belt

firmly downward; press down about m idway

between the pulleys. When properly tightened, the V-belt should depress no more

than the width of the belt.

9

Blade Selection

The cut-off saw is delivered with a saw blade

that is adequate f or a variety of cut-off jobs on a

variety of common materials. A 10-tooth,

general-purpose blade is provided as standard

equipment with the machine.

Refer to Figure 6 for the speeds recommended

for various materials. These speeds, while

appropriate for many common shop cutting

needs, do not encompass the wide variety of

special bl ade configur ations (toot h pitc h and set)

and special alloys for cutting unusual or exotic

materials.

A coarse blade could be used for a solid steel

bar, but a finer toot h blade would be used on a

thin-wall steel tube. In general, the blade choice

is determined by the thickness of the material;

the thinner the materials; the finer the tooth

pitch.

A minimum of three teeth should be on the

workpiece at all times for proper cutting. The

blade and workpiece can be damaged if the

teeth are so far apart that they straddle the

workpiece.

For very high production on cutting of special

materials, or to cut hard-to-cut materials such as

stainless steel, tool steel, or titanium, you can

ask your industrial distributor for more specific

blade recommendations. The supplier that

provides the workpiec e material should be able

to provide you with very specific instructions

regarding the best blade ( and coolant or cutting

fluid, if needed) for the material or shape

supplied.

4. Keep the hydraulic cylinder needle valve in

the same position and begin a second cut

on the same or similar workpiec e.

5. W hen the blade has completed about 1/3 of

the cut, increase the f eed r ate.

Watch the chi p form ation until cutting is at its

most efficient rate and allow the saw to

complete the cut (refer to Evaluating Blade

Efficiency on page 10). The blade is now

considered ready for use.

Operations

Hydraulic Feed Control

The weight of the saw head provides the force

needed to cut through the workpiece. The cut-off

saw has a hydraulic cylinder that controls the

feed rate of the saw.

The hydraulic feed control circuit consists of a

single acting hy draulic cylinder (Figure 7) and a

feed rate control (Figure 5). The feed control

cylinder resi sts motion in the downward directi on

to control the feed rate. The control cylinder

offers no resistance when raised upward.

The feed rate control knob (Figure 5) controls

the rate at which the saw head is lowered. The

control knob (needle valve) controls the rate at

which the hydraulic fluid is released from the

hydraulic cylinder. When the needle valve is

closed, the cylinder is locked. With the needle

valve slightl y open, the cylinder permits slow, or

light, downward for ce. Opening the needle valve

further incr eases the feed rate and applies mor e

weight to the saw blade and workpiece.

Blade Break-in Procedures

New blades are very sharp and, theref ore, have

a tooth geometry that is easily damaged if a

careful break-in procedure is not followed.

Consult the blade manufacturer’s literature for

break-in of specifi c blades on specific materi als.

However, the following procedure will be

adequate for break-i n of JET-supplied blades on

lower alloy ferrous materials.

1. Clamp a secti on of round stock in t he vise.

The stock should be 2 inches or larger in

diameter.

2. Oper ate the saw at low speed. Start the cut

with a very light feed rate.

3. When the saw has compl eted 1/3 of the cut,

increase the feed rate sli ghtly and allow the

saw to complete the cut.

The needle valve is adjusted until the saw is

operating efficiently. The efficiency of operation

is usually evaluated by observing c hip formati on.

Blade efficiency is further described below.

Figure 7

10

Loading...

Loading...