Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Ferrous Manual Cold Saws

Models J- FK350-2, J-FK3 50 -4

WALTER M EIE R (Manufac turing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414214

Ph.: 800-274-6848 Revision B 02/2011

www.waltermeier.com Copyright © 2011 Walter Meier (Manufacturing) Inc.

J-FK350

Page 2

Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

®

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

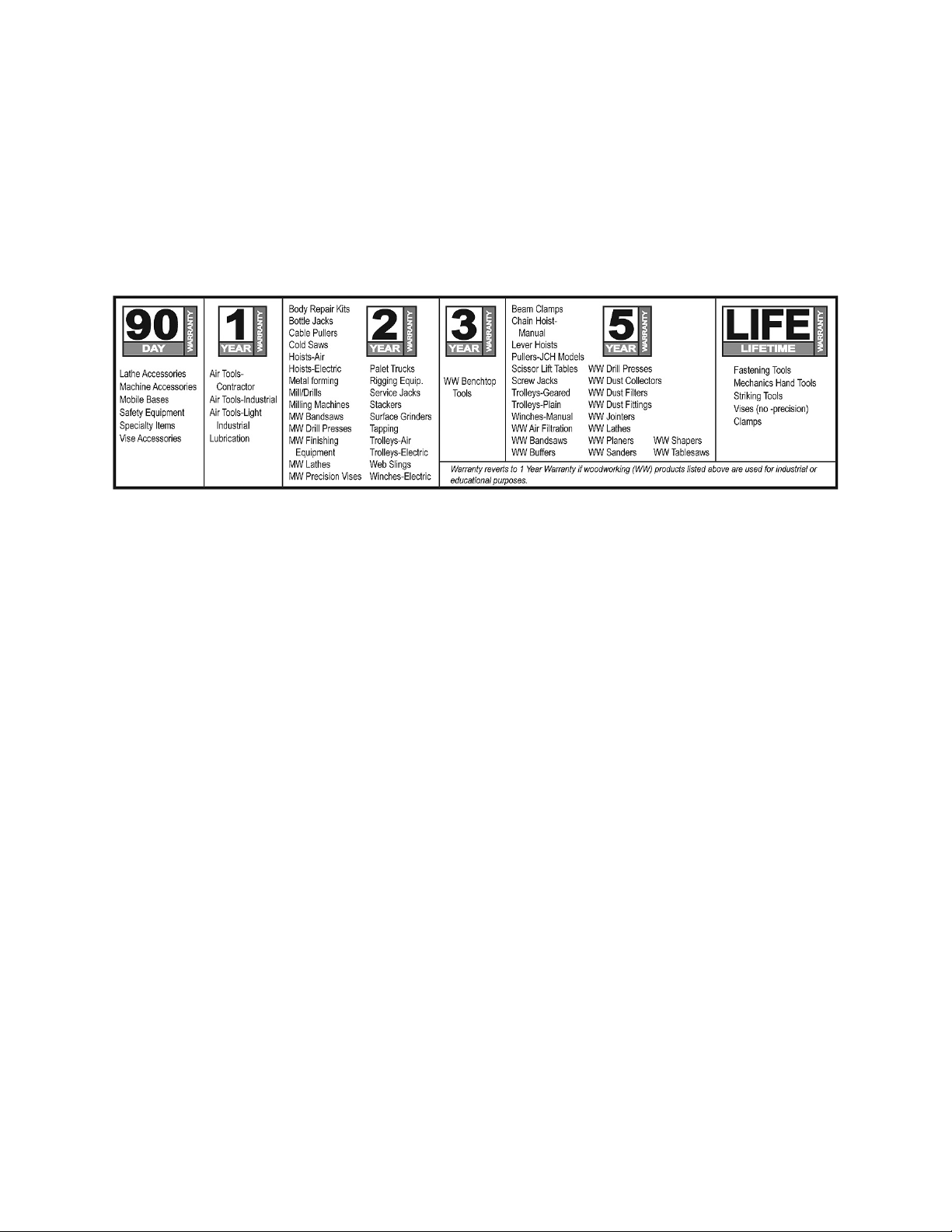

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

®

whatsoever. JET

branded products are not sold in Canada by Walter Meier.

tool s. F or th e nam e of an Aut hori zed Ser vic e Cent er in

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Introduction ............................................................................................................................................. 6

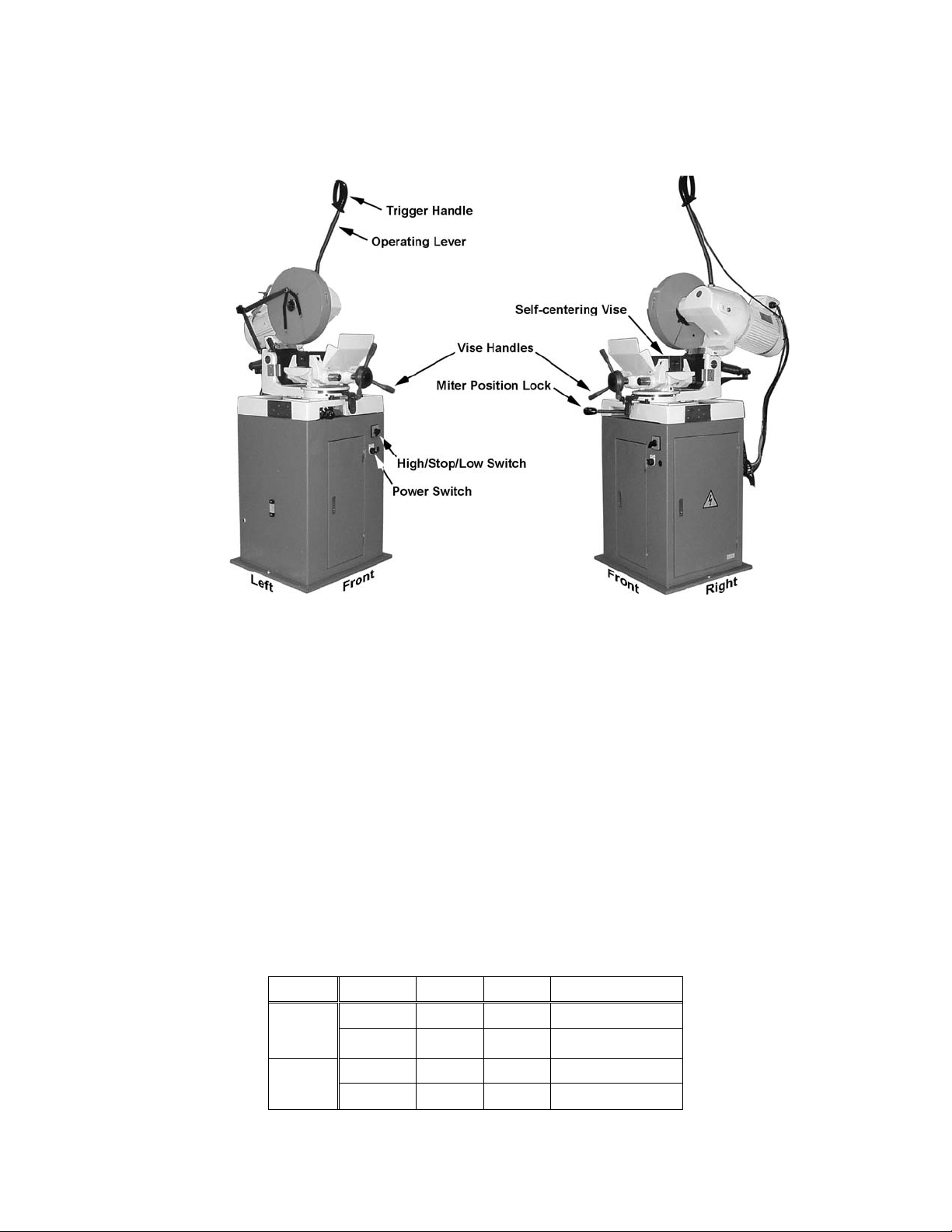

FK350 Featur es ................................................................................................................................... 6

Specifica tions .......................................................................................................................................... 6

Cutting Capacity (All Models) ............................................................................................................... 6

Features .................................................................................................................................................. 7

Miter Cutting Head ............................................................................................................................... 7

Miter Position Lock ............................................................................................................................... 7

Self-ce n te rin g Vise ............................................................................................................................... 7

J-FK350 Contr ols ................................................................................................................................. 7

Trigger Handle ..................................................................................................................................... 7

Flood Coolant Sy stem .......................................................................................................................... 7

Installation ............................................................................................................................................... 8

Unpacking the machine ........................................................................................................................ 8

Anchoring and handli ng the machine .................................................................................................... 8

Electric al Connec tions ............................................................................................................................. 8

Controls ................................................................................................................................................... 8

Control Panel ....................................................................................................................................... 8

Trigger Handle ..................................................................................................................................... 8

Operation ................................................................................................................................................ 9

Miter Adjustment .................................................................................................................................. 9

Depth Stop ........................................................................................................................................... 9

Maintenance .......................................................................................................................................... 10

Maintenance Requirements ................................................................................................................ 10

Periodic Maintenance ......................................................................................................................... 10

Coolan t .............................................................................................................................................. 10

Changing the Saw Blade .................................................................................................................... 1 0

Lubrication ......................................................................................................................................... 10

Coolant System.................................................................................................................................. 10

Blade Selection ..................................................................................................................................... 11

Troubleshooting ..................................................................................................................................... 14

Parts ......................................................................................................................... ............................ 1 5

Ordering Replacement Parts .............................................................................................................. 15

Head Assembly .................................................................................................................................. 16

Stock Stop Assembly ......................................................................................................................... 18

Stand Assembly ................................................................................................................................. 19

Base Assembly .................................................................................................................................. 20

Manual Vise Assembly ....................................................................................................................... 22

Guard Assembly ................................................................................................................................ 24

In-Feed Table A ssembly .................................................................................................................... 26

Out-Feed Table .................................................................................................................................. 2 7

Wiring Diagram ...................................................................................................................................... 28

3

Page 4

Warnings

1. Read and understand the entire owner's manual before att empting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. The cold saw is designed and intended for use by properly trained and experienced personnel onl y. If

you are not familiar with t he proper and safe operation of a cold saw, do not use until proper training

and knowledge have been obtained.

5. Do not use this cold saw for other than its intended use. If used for other purposes, Walter Meier

(Manufactur ing) Inc., di sclaims any real or implied warranty and hol ds itself harmless from any injur y

that may result from that use.

6. Always wear approved safety glasses/face shields while using this cold saw. Everyday eyeglasses

only have impact resi stant lenses; they are not safety glasses.

7. Before operating the cold saw, remove tie, rings, watches and other jewelry, and roll sleev es up past

the elbows. Remove all loose cl othing and c onfine long hair. Non-sl ip foot wear or anti-ski d floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , birt h defects or other repr oductiv e harm. Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalline sil ic a from bricks, cement and other masonry produc ts.

• Arsenic and chromium from chemically treated lumber.

10. Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

11. Do not oper ate this machine while tired or under the influence of drugs, alcohol or any medication.

12. Make c er tain the switch is in the OFF position before connecting the machine to the power supply.

13. Make c er tain the machine is properly grounded.

14. Make all machine adjustments or mai ntenance with the machine unplugged from the power source.

15. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

16. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use ext r eme caution and replace the guards immediat ely .

17. Make sure t he c old saw is firmly placed on a secure foundation.

18. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, break age of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

19. Prov ide for adequate space surrounding work area and non-glare, overhead lighting.

20. Keep t he floor around the machine clean and free of scrap mater ial, oil and grease.

21. Keep visitors a safe distance from the work area. Keep ch il dren away.

22. Make y our workshop chi ld proof with padlocks, m aster switc hes or by r em ov ing starter keys.

4

Page 5

23. Giv e your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

24. Maintain a balanced stance at all times so that you do not fall into the blade or other m ov ing par ts. Do

not overreach or use excessive force to perform any machine operation.

25. Use the right tool at the correct speed and f eed rate. Do not for ce a tool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

26. Use recommended accessories; im pr oper accessories may be hazardous.

27. Maintain tools with care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

28. Turn off the machine bef ore cleaning. Use a brush or compr essed air to remove chips or debri s — do

not use your hands.

29. Do not stand on the machine. Serious injury c ould oc c ur if the mac hine tips over.

30. Never leave the machine runni ng unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

31. Remove loose items and unnecessary work pieces from the area before starting the mac hine.

Familiarize you rself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, i t may result in serious inj ury or possibly

even death.

The specifications in this manual are given as general information and are not binding. Walter Meier

(Manufacturing) Inc., reserves the right to effect, at any time and without prior notice, changes or

alterations to par ts, fittings, and accessory equipment deemed necessary for any reason whatsoever.

5

Page 6

Introduction

The J-FK350 circ ular saw is designed to provide a reliable solution to the needs of machine shops and

production envi ronments that work wit h steel or iron. The J-FK350 i s manually operated. Aft er clamping

the material in the vise, the operator presses the trigger handle starting the blade, and brings the

operating l ev er downward to cut the material. The saw can perf orm miter c uts up to 45º to the right or left.

FK350 Features

J-FK350 Cold Saw

Specifications

Model......................................................................... J-FK350-2............................................. J-FK350-4

Stock Number .............................................................. 414214.................................................. 414217

Disc Blade

Disc diameter ...................................................... 14" (350mm).......................................... 14" (350mm)

Hole diameter ........................................................1.3" (32mm)........................................... 1.3" (32mm)

Blade thickness .................................................... 0.1" (2.5mm).......................................... 0.1" (2.5mm)

Cutting Speed

Blade Speed (RPM) ......................................................... 44/88..................................................... 44/88

Motor

Motor ........................................................................ 2HP, 3PH............................................... 2HP, 3PH

Voltage ........................................................................ 220VAC................................................. 440VAC

Other

Coolant Capacity ............................................................. 3 gal.......................................................3 gal.

Dimensions................................................ 25"L x 43"W x 75"H................................ 25"L x 43"W x 75"H

Weight .......................................................................... 720 lbs................................................... 720 lbs

Cutting Capacity (All Models)

Degree Round Square Rectangle

Tubing

Solid

90° 4.5" 4.25" 5.5" x 3.75"

45° 3.5" 3.5" 3.5" x 3.5"

90° 2" 2" 2" x 2"

45° 1.75" 1.75" 1.75" x 1.75"

6

Page 7

Features

Flood Coolant System

Miter Cutting Head

The miter cutting head is the unit that cuts the

material and c onsists of a cast i ron base, blade

support unit and guard, transmission unit, and

motor. The depth of cut is set by adjusting the

depth cut stop. The miter cutting head swivels

and locks into -45º, 90º, and +45º by means of a

locking mechanism. Depressing the mechani sm

overrides the lock, permitti ng the head to adjust

to any position between -45º and +45°.

Miter Position Lock

The miter position lock secu res th e mit er cut tin g

head from movement. The miter is secured

when the lock is pushed all the way to the left

and can be positioned when the l oc k is moved to

the right.

Self-centering Vise

The self-centering vise holds the work piece in

place during c utting. The work piece is secur ed

in the vise by turning the vise handles.

The coolant pump must be

submerged before operating to prevent

damage to the pump.

Coolant is di spensed directl y onto t he saw blade

from a coolant fitting on the upper blade guard.

Coolant is provided through tubing from the

coolant pump (Figur e 2) in the mac hine base.

Adjust the coolant flow valve on coolant fitti ng to

achieve desired fl ow. When the coolant switch is

in the ON position, flow starts when the drive

motor is started. Turning off the coolant switch

stops coolant fl ow.

This coolant system can operate with either a

soluble oil base coolant or water-soluble

synthetic coolant. Coolant should be changed

regularly. Some r ecommended brands are DoAll

and Lenox. These coolants are availabl e at your

local industrial distributor.

J-FK350 Controls

The cont rol panel c onsist s of the Power (On/Off)

switch and High/Stop/Low switch, and an

integral coolant system. To operate the

machine, the Power switch must be set to on

and the High/Stop/Low swi tc h m ust be se t fo r Hi

or Low. Then depr ess the tr igger handle to start.

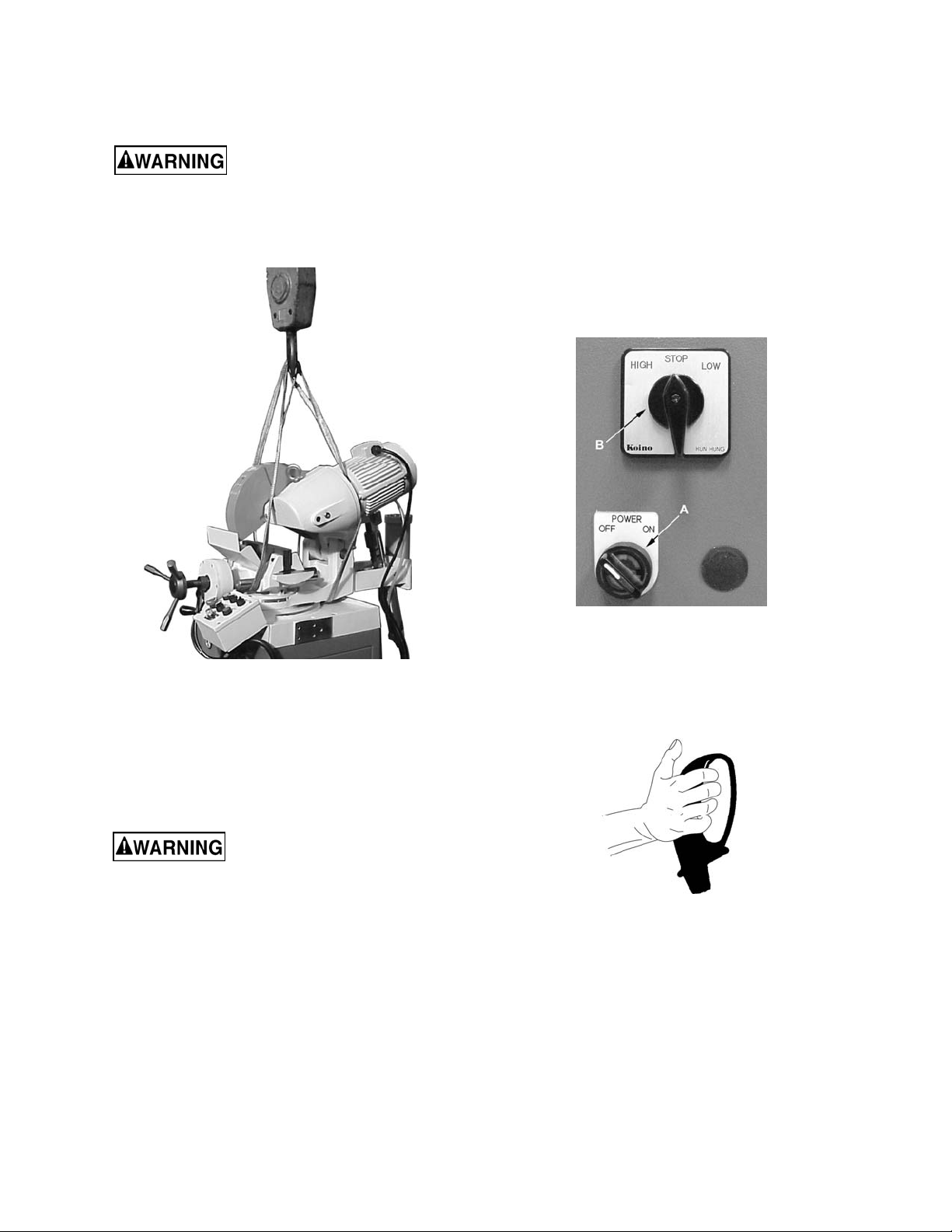

Trigger Handle

The trigger handle (Figure 1) is located on the

operating lever used to rai se and lower the saw.

It contains a micro-switch, which is activated

when the operator depres se s the r un trigger.

Figure 2

Figure 1

7

Page 8

Installation

Controls

Unpacking the machine

Do not handle the packed

machine using slings.

To install t he machine, fi rst rem ove the packing,

paying particular att ention not to cut any electric

wires or hydraulic hoses. Lift using straps

(Figure 3).

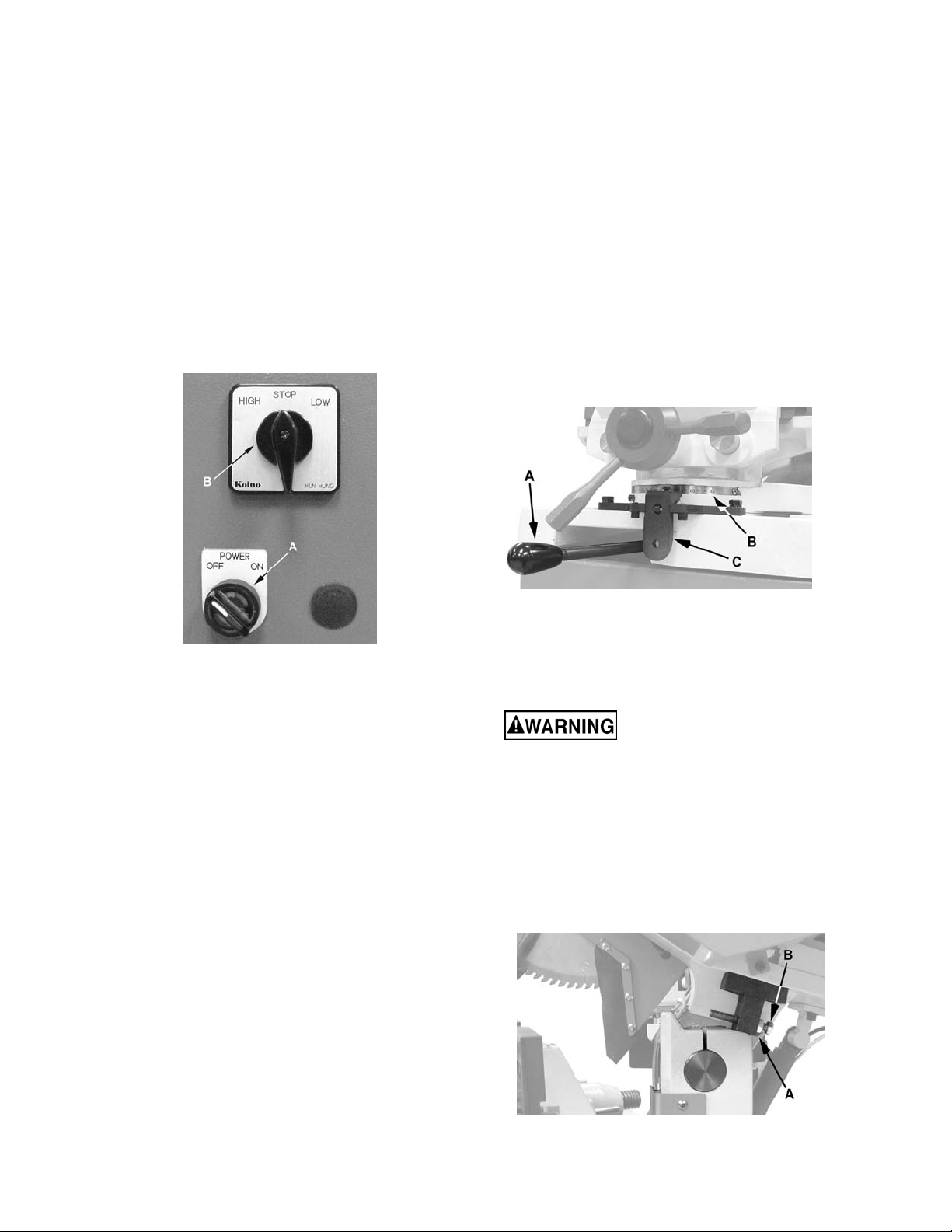

Control Panel

The Control Panel (Figure 4) is located on the

front of the cabinet stand and consists of the

Power and High/Stop/Low switches, described

below.

Power Switch – The Power switch has two

positions, Off and On.

High/Stop/Low Switch – This switch controls

the blade speed. To operat e the saw, the power

switch must set to on, High or Low must be

selected, and the Run Trigger depressed.

Figure 3

Anchoring and handling the machine

The base of the machine must be anchored to

the floor by two lag bolts or studs properly

anchored into conc r ete.

Electrical Connection s

All electrical connections

must be done by a qualified

electrician. All adjustments or repairs must

be done with the machine discon nect ed from

the power source, unplugged. Failure to

comply may result in seri ou s injury!

The J-FK350-2 is rated at 220V.

The J-FK350-4 is rated at 440V.

These machines not suppli ed with a plug. Use a

plug and outlet rated at least 20amps. The

circuit for the machi ne should al so be protected

by at least a 20 amp circuit break er or fuse.

Make sure that the blade turns in the correct

direction. If it does not, simply reverse two of

the phase wires on the supply input.

Figure 4

Trigger Handle

To operate, t he Power switch must b e set t o on

a Hi or Low speed selection made, and the

trigger handle depressed.

Figure 5

The sawing machi ne is now ready for use.

8

Page 9

Operation

Miter Adjustment

Before using the m ac hine:

Check that safety devices (e.g., blade

guards) are in position and work perfectly

and that personal safety requirements are

complied with.

Check the sharpness of the blade and verify

coolant flow.

Operation

1. Make sure the work piece is securely

clamped in the vise.

2. Turn the power on (A, Fig. 8).

3. Select the cutting speed (B , Fig. 8).

To adjust the miter position follow the steps

below while referring to Figure 10:

1. Mov e the miter position lock (A) to the right

to release.

2. Adj ust the head t o the desired angl e rangi ng

from –45º to +45º by pushing on the back of

the motor to the right or left. The miter

position is shown on the scale (B).

3. A detent mechanism locks the head in the -45º,

90º and +45º positions to pre vent the head from

rotating. For a miter position other than -45º,

90º and +45º, press the lever (C) to release

while rotating the head.

4. When the desir ed cutti ng angle is set, m ove

miter position loc k (A) to the left to secure.

Figure 8

4. Grip the trigger handle (Figure 5) on the

cont r o l lever.

5. Start the blade by pressing the micr o-switch

on the handgrip.

The down stroke speed of the head is controlled

manually by the operator. The coolant pump is

activated during t he time that the head is below

the upper limit positi on.

When the cut is complete:

6. Raise the head.

7. Rem ove the work piece from the vise using

the vise hand wheels.

Figure 10

Depth Stop

The depth cut stop ad justment limits the lower travel

of the saw blade du r ing a cutting operation.

Remove power when making

this adjustment. Failure to

comply may result in serious injury!

To adjust the depth of cut (refer to Figure 12):

1. Using t wo 13mm wrenches, loosen the lock

nut (A).

2. With the saw in the fully lowered position,

turn the screw (B) until the saw blade

bottoms out at the desir ed level.

3. Tighten the lock nut.

Figure 12

9

Page 10

Maintenance

Maintenance Requirements

All maintenance must be

carried out with the power switched off.

Failure to comply may result in serious

injury!

On completion of maintenance, ensure that

replaced parts and/or any tools used have been

removed from the machine before starting it up.

Periodic Maintenance

Remove chips from the m ac hine, preferably

with a cloth

Remove chips from the c oolant tank and

change coolant regularly (see Coolant

section)

Top up the coolant level ( see Coolant)

Check the wear of the blade and change if

necessary (see Changing the Saw Blade)

Empty the chips out of the base.

Clean the vi se and lubricate all the joints

and sliding surfac es, usi ng good quality oil.

Attend to daily, weekl y and annual

lubrication recommendations (see the

Lubrication secti on)

Coolant

The c oolant tank access door is located on the

back of the cabinet stand. Remove four hex cap

screws with a 5mm hex wrench. Check coolant

level in t he c oolant tank periodically and top off if

necessary. Coolant can also be added by

pouring directly on the table, which will drain int o

the tank through the c hip s trainer .

Lubrication

For long life and trouble-free operation, it is

essential that this machine be kept well

lubricated. The vise and leadscrew should be

oiled daily. Pivot joints and bearings should be

greased weekly. Check the gearbox oil level

weekly; full level is top of sight gl ass with head

in full up position. The gearbox oil should be

changed annually.

Recommended Lubricants:

Gearbox

Use Texaco Meropa 460 or equivalent.

Grease fittings

Texaco Star plex 2 or equivalent

Vise and Leadscrew

Regal R & O 68

Coolant System

This coolant system can operate with either a

soluble oil base coolant or water-soluble

synthetic coolant. Coolant should be changed

regularly. Some r ecommended brands are DoAll

and Lenox. These coolants are availabl e at your

local industrial distributor.

Coolant Type:

Soluble Oil Base

Water-Soluble Synthetic Coolant

Remove excess chips periodically from the tank.

Use the coolant l evel gauge to check the c oolant

level.

Changing the Saw Blade

The cold saw must not be

connected to the power source when

changing saw blad es. Failure to comply may

result in serious injury!

To change the saw blade:

1. Switch off the m achi ne.

2. Release the lower disc guard.

3. Move the lower guard upwards.

4. Remove the bl ade and replace it wit h a new

one.

5. To secure the saw blade, reverse the

preceding steps.

10

Page 11

Blade Selection

When using the J-FK350 cold saw, it is

important to sel ect the correct type of blade for

the material to be cut. Thi s section explains the

limitations and specific applications of the

different t y pes of blades.

General Characteristics:

Fine Tooth Pitch – used for thin wall materials

such as sheet steel, tubes and prof iles

Coarse Tooth Pitch – used for large crosssections – for soft materials (aluminum alloys

and soft alloys in general).

Determining Proper Tooth Pitch

Proper tooth pit c h depends on:

a) the size of the section;

b) the hardness of the m aterial;

c) wall thickness.

Solid sections call for

discs with a coarse

tooth pitch, while

small cross-sections

require blades with

finer teeth. This is

because when cutting

walls of small crosssection (1–7 mm)

profiles, it is im portant that the number of teeth

actually m aking the cut should not be too small,

otherwise the effect obtained will be one of

tearing rat her than of chip remov al, leading to a

large increase in shearing stress. On the other

hand, when cutting thick materials or solid

sections using an excessively fine tooth pitch,

the chip collects as a spiral inside the gull et, and

since fine tooth pitches have small gullets, the

accumulat ed chip will exceed the gullet capacity

and press against the walls of the workpieces,

resulting in poor cutting (same situati on with soft

materials), greater shearing stress and hence

breakage of the bl ade.

Table 1

A larger pitch should be chosen when, as a

result of the shape of the piece to be cut, the

cross-section at any given point exceeds the

average cross-sect ion given above.

Cutting and Feeding Speed

The cutting speed, in m/min, and the head

feeding speed, in cm

amount of heat generated near t he points of the

teeth. If t he head feeding speed is too hi gh, the

cut will not be straight i n either the vertic al or the

horizontal plane. As we have already said, the

cutting speed depends on the strengt h (kg/mm

and hardness (HRC) of the material and the

dimensions of the thickest section. The feeding

speed depends on the cross-section of the

material. Solid or thick-walled materials

(thickness>5mm) can therefore be cut at high

speed providi ng there is sufficient swarf rem oval

by the blade, while t hin-wall ed mat erials such as

tubes or thin profiles must be cut with a low

feeding speed.

break-in p eriod, du ring which time abou t half

the normal feeding sp eed shoul d be used.

2

/min, are limited by the

2

)

A new blade requires a

Coolant

The cooling fluid ensures that the blade teeth

and material in the area of the cut do not

overheat. The fluid must be an excellent

lubricant so as to prev ent abrasion of the teet h

and welding of t he chips to t he teet h themselv es

(seizing).

11

Page 12

Blade Structure

For non-ferrous metals, it is common to use

circular saws wit h brazed hard m etal HM cutting

edge, consisting of a disc made of alloy tool

steel (71Cr1) on which the shape of the teeth

and the seats for the cutti ng edges are made of

Widia K10. These saws have shown excellent

wear resistance but low resistance to impact,

which is in any case a minor pr oblem with nonfe rrous materials.

Table 2

Types of Blades

Figure 14

”BW” TYPE SHARPENING DIN 1838--UNI 4014

Coarse toothing with teeth alternately raked to

the right and left.

Toothing generally used on cutti ng-off machines

for cutting ferrous and alloy materials with

tubular and profil ed sect ions.

The blades fitted to the J-FK350 have

dimensions 350 x 32 x 2.5 mm and are of HM

hard steel type sinc e the machi ne is to be used

for cutting non-ferrous materials. In addition to

the size and pitch of the teeth, however, the

blades also have different geometric

characteri stic s i n accordance with thei r partic ular

use:

tooth cutting angle – may be negative or

positive

tooth sharpening –may be BW with an

alternate raked tooth or C with a roughing tooth

raked on both sides and a non--raked finishing

tooth

tooth pi tch – the distance between the crest of

one tooth and the crest of t he next toot h (tooth

pitch = T)

Teeth Shape

”C” TYPE SHARPENING (HZ)

Coarse toothing with roughing tooth raked on

both sides and non--raked finishing tooth. The

roughing tooth is about 0.3 mm higher.

Coarse toothing with roughing tooth and

finishing tooth. Used in saws with pitch greater

than or equal to 5 mm for cutting ferrous and

non-ferrous m ateri als with soli d or solid-profiled

sections.

Figure 15

POSITIVE AND NEGATIVE CUTTING ANGLES

The cutting angle may vary from positive to

negative depending on the cutting speed, the

profile and the type of m at eri al to be cut.

Figure 16

A positive angle determines bett er penetrati on of

the tool and hence lower shear stress and

greater ease of sliding for the swarf over the

cutting edge. On the other hand, the cutting

edge has lower mechanical resistance, so as the

breaking load of the material to be cut increases,

the cutting angl e decreases from positiv e until it

becomes negativ e so as to offer a cutting edge

with a larger resistant sect ion.

12

Page 13

Figure 17

Short swarf material such as brass, bronze,

aluminum and hard cast iron require smaller

cutting angles because the swarf becomes

crushed immediately and the rake angle has

little effec t during the cutting stage.

Figure 18

The J-FK350 uses discs with positive cutting

angles for cutting solid materials and with

negative cutting angles for cutting hollow

profiles. Thi s is because, as a result of the hi gh

cutting speeds (3400 rpm), even with

non-ferrous materials the tool ”strikes” against

the wall of the profile to be cut several times,

thus requiring a cutting edge with a larger

resistant section.

Figure 19

Circular saws can also be characterized by other

parameter s such as the whine r educti on f eature,

which cuts down noise at high speeds, or

expansion, which compensates for the pushing

of chips inside the cutting edge, thus reducing

the thrust on the walls of t he material to be cut.

Figure 20

13

Page 14

Troubleshooting

Troubleshooting – Blade and Cutting Problems

Problem Probable Cause Solution

Incorrect lubricant/coolant fluid Ensure proper coolant flow.

Check the cutting speed, feed speed and air pressure

parameters and the type of blade you are u sing.

With a new blade it is necessary to start cutting at half

feeding speed. After t he wear ing- - in period (a cutting

surface of about 300 cm2 for hard materials and about

1000 cm

speeds can be brought up to normal values

The s warf w edges into t he bott om of the teeth caus ing

excessive pressure on the teeth themselves

The surface of the cut may have undergone work

hardening. When starting work again, use a lower

cutting speed and head feed speed. A tooth from the

old blade may be left in the cut: check and remove

before starting work again.

Any movement of the work piece during cutting can

cause broken teeth: check the vise, jaws and clamping

pressure.

The blade runs over the material without removing it:

increase feed sp eed.

The teeth slid e over t he mater ial withou t cutting it :

reduce the blad e speed.

Check the coolant level and clean coolant lines and

nozzles.

The materials may pres ent al tered zones either on the

surface, such as oxides or sand, or in section, such as

under-cooled inclusions. These zones, which are

much harder than the blade, caus e t he teet h to br eak:

discard or clean these materials.

Always check the position of the blade before starting

a new job.

Check the coolant level and clean coolant lines and

nozzles.

Teeth breaking

Rapid to oth wear

Broken blade

Material too hard

Disc not worn-in correctly

Disc with excessively fine

tooth pitch

New blade inserted in a

partially completed cut

Work piec e not cl amped firmly

in place

Feed speed t oo slow

Cutting pressure too high Reduce cutting pressure.

Blade speed too high

Insufficient coolant

Incorrect fluid concentration Check and use the correct concentration.

Material defective

Feed speed too high Reduce blade speed.

Teeth in contact with material

before starting the cut

Insufficient coolant

2

for soft materials) the cutting and feed

14

Page 15

Troubleshooting

Troubleshooting – Machine Fault & Operating Problems

Problem Probable Cause Solution

Electrical power supply

Transformer

Contactor

Spindle motor will not

turn

Thermal relay

Motor

Check: the phases; the cables; the plug; the socket.

Also check that the motor connections are in place.

Chec k that the voltag es are present both on the input

and output. Otherwise replace.

Chec k that the phases in it are present both on the

input and output, that it is not jammed, that it closes

when powered and that it is not causing short circuits.

Change if any of these problems are found.

Make sure it is closed, i.e. check that the phases are

present in input and output, that it is not causing short

circuits and responds when the reset coil is closed. If it

has tripped to protect the motor, check the amperage

setting, reset, and check the motor. Change if

necessary.

Check that it has not burnt out, that it turns freely and

that there is no moisture in the connection terminal

board box. The winding can be rewound or replaced.

Parts

Ordering Replacement Parts

To order parts or reach our service department, call 1-800-274-6848 Monday through Friday (see our

website for business hours, www.walt ermei er.com). Hav ing the Model Number and Serial Number of your

machine avail able when you call will allow us to serve you quickly and acc ur ately.

15

Page 16

Head Assembly

Index No. Part No. Description Size Qty

1 ............... J-FK350-201 ............Head Body ............................................................................................ 1

2 ............... FK350-202A.............Spindle .................................................................................................. 1

3 ............... FK350-203 ...............Spindle Housing .................................................................................... 1

4 ............... FK350-204 ...............Cutter Cap ............................................................................................. 1

5 ............... FK350-205 ...............Cutter Cap Pin ....................................................................................... 2

6 ............... FK350-206 ...............Stopper Ring ......................................................................................... 1

7 ............... FK350-207 ...............Spring Block .......................................................................................... 1

8 ............... FK350-208 ...............Tension Bolt .......................................................................................... 1

9 ............... FK350-209 ...............Belleville Spring ..................................................................................... 4

10 ............. FK350-210 ...............Taper S haft ........................................................................................... 1

11 ............. FK350-211 ...............Wor m Wheel ......................................................................................... 1

12 ............. FK350-212 ...............Wor m Shaft ........................................................................................... 1

13 ............. FK350-213 ...............36NTGear ............................................................................................. 1

14 ............. FK350-214 ...............21NTGear ............................................................................................. 1

15 ............. FK350-215 ...............Collar A ................................................................................................. 1

16 ............. FK350-216 ...............Collar B ................................................................................................. 1

17 ............. FK350-217 ...............Bearing Cover ....................................................................................... 1

18 ............. FK350-218 ...............Handle................................................................................................... 1

19 ............. FK350-219 ...............Handl e S witch ....................................................................................... 1

21 ............. BB-32007 .................Tapered Roller Bearing .......................................#32007 ....................... 1

22 ............. BB-32008 .................Tapered Roller Bearing .......................................#32008 ....................... 1

23 ............. FK350-223 ...............Retainer ................................................................................................ 1

24 ............. FK350-224 ...............Tooth Washer ........................................................................................ 1

25 ............. FK350-225

26 ............. FK350-226 ...............Retainer Nut .......................................................................................... 1

27 ............. FK350-227 ...............Tooth Washer ........................................................................................ 1

28 ............. FK350-228 ...............Tooth Washer ........................................................................................ 1

29 ............. FK350-229 ...............Retainer Nut .......................................................................................... 1

30 ............. FK350-230 ...............Fl at Key ..............................................................8x7x42mm.................. 1

31 ............. FK350-231 ...............Fl at Key ..............................................................8x7x27mm.................. 1

32 ............. FK350-232 ...............O-Ring................................................................................................... 1

33 ............. FK350-233 ...............O-Ring................................................................P8 .............................. 1

34 ............. FK350-234 ...............Pin......................................................................5mm Dia. x 28 ............ 2

35 ............. TS-1540071 .............Hex Nut ..............................................................M10 ............................ 2

36 ............. FK350-236 ...............Needl e Roller Bearing.........................................BK3026 ...................... 1

37 ............. BB-51206 .................Thrust Bearing ....................................................#51206 ....................... 1

38 ............. BB-6206...................Deep Groove Ball Bearing ..................................#6206 ......................... 1

39 ............. J-FK350-239 ............Motor 220V ............................................................................................ 1

................. J-FK350-239-4 .........Motor 440V ............................................................................................ 1

40 ............. ................................Saw Blade ............................................................................................. 1

41 ............. FK350-241 ...............Stopper ................................................................................................. 1

42 ............. FK350-242 ...............Oil Sight Glass....................................................................................... 1

43 ............. TS-1504051 .............Socket Head Cap Screw .....................................M8x25 ........................ 2

44 ............. TS-1504041 .............Socket Head Cap Screw .....................................M8x20 ........................ 4

45 ............. TS-1504131 .............Socket Head Cap Screw .....................................M8x70 ........................ 1

46 ............. FK350-246 ...............Oil Plug ................................................................................................. 1

47 ............. FK350-247A.............Socket Head Cap Screw (left-hand thread) .........M20x45 (LH) .............. 1

48 ............. FK350-248

49 ............. FK350-249 ...............Oil Plug ................................................................................................. 1

50 ............. TS-1504061 .............Socket Head Cap Screw .....................................M8x30 ........................ 2

51 ............. TS-1492051 .............Hex Cap Screw ..................................................M1 2x50 ...................... 4

52 ............. TS-154012 ...............Hex Nut ..............................................................M20 ............................ 1

53 ............. TS-1540061 .............Hex Nut ..............................................................M8 .............................. 1

54 ............. TS-2361201 .............Lock Was h e r ......................................................M20 ............................ 1

55 ............. TS-2361121 .............Lock Was h e r ......................................................M12 ............................ 4

...............Retainer Nut .......................................................................................... 1

...............Oil Plug ................................................................................................. 1

16

Page 17

Head Assembly

17

Page 18

Stock Stop Assembly

Index No. Part No. Description Size Qty

1 ............... FK350-501 ...............Block ..................................................................................................... 1

2 ............... FK350-502 ...............Shaft ..................................................................................................... 1

3 ............... FK350-503 ...............Stop Rod ............................................................................................... 1

4 ............... FK350-504 ...............Scale (Inch) ........................................................................................... 1

6 ............... FK350-506 ...............Handle................................................................M8x30 ........................ 2

7 ............... FK350-505 ...............Rivet ...................................................................................................... 2

18

Page 19

Stand Assembly

Index No. Part No. Description Size Qty

1 ............... J-FK350-601 ............Cabinet Stand........................................................................................ 1

2 ............... FK350-602 ...............Coolant Pump........................................................................................ 1

3 ............... FK350-603 ...............Cam Switch ........................................................................................... 1

4 ............... FK350-604 ...............Magnetic Switch .................................................................................... 1

5 ............... FK350-605 ...............Overload Relay ...................................................................................... 1

6 ............... FK350-606 ...............Lighted Selector Switch ......................................................................... 1

7 ............... TS-1502051 .............Socket Head Cap Screw .....................................M5x20 ........................ 4

8 ............... TS-1551031 .............Lock Washer ......................................................M5 .............................. 4

9 ............... FK350-609 ...............Cable Lock ............................................................................................ 3

10 ............. J-FK350-610 ............Rear Cover ............................................................................................ 1

11 ............. TS-1503021 .............Socket Head Cap Screw .....................................M6x10 ........................ 4

12 ............. FK350-612 ...............Taper ed P lug ......................................................PT1/4 ......................... 1

13 ............. FK350-613 ...............Coolant Gauge ...................................................................................... 1

14 ............. TS-1502051 .............Socket Head Cap Screw .....................................M5x20 ........................ 2

15 ............. FK350-615 ...............Transformer (440V only) .....................................AU-20DW(50/60Hz) .... 1

................. FK350-615-2 ............Transformer (220V only) ........................................................................ 1

19

Page 20

Base Assembly

Index No. Part No. Description Size Qty

1 ............... J-FK350-101 ............Base ...................................................................................................... 1

2 ............... J-FK350-102 ............Hinge Body ............................................................................................ 1

3 ............... FK350-103 ...............Locking Mount ....................................................................................... 1

4 ............... FK350-104 ...............Release Handle ..................................................................................... 1

5 ............... FK350-105 ...............Pin......................................................................................................... 1

6 ............... FK350-106 ...............Coil Spring............................................................................................. 1

7 ............... FK350-107 ...............Scale ..................................................................................................... 1

8 ............... FK350-108 ...............Pivot Shaft ............................................................................................. 1

9 ............... J-FK350-109A ..........Spring Bracket A ................................................................................... 1

10 ............. J-FK350-110A ..........Spring Bracket B ................................................................................... 1

11 ............. FK350-111A.............Retur n Spring ........................................................................................ 1

12 ............. FK350-112 ...............Chip Screen .......................................................................................... 1

13 ............. TS-1505031 .............Socket Head Cap Screw .....................................M10x25 ...................... 2

14 ............. TS-1551071 .............Lock Was h e r ......................................................M10 ............................ 2

15 ............. TS-1504041 .............Socket Head Cap Screw .....................................M8x20 ........................ 2

16 ............. TS-1504101 .............Socket Head Cap Screw .....................................M8x50 ........................ 2

17 ............. TS-1491041 .............Hex Cap Screw ..................................................M1 0x30 ...................... 2

18 ............. TS-2361101 .............Lock Was h e r ......................................................M10 ............................ 2

19 ............. TS-1504021 .............Socket Head Cap Screw .....................................M8x12 ........................ 2

20 ............. TS-1490041 .............Hex Cap Screw ..................................................M8 x25 ........................ 1

21 ............. TS-223A911.............Socket Head Cap Screw .....................................M12x100 .................... 2

22 ............. FK

23 ............. FK350-123 ...............Pin......................................................................10mm Dia. x 22 .......... 3

24 ............. FK350-124 ...............Grease Fitting .....................................................PT 1/8 ........................ 2

350-122 ...............Pipe ....................................................................................................... 1

20

Page 21

Base Assembly

10

15

17

8

16

24

7

23

1

11

9

2

12

21

14

13

18

3

20

22

19

6

5

4

FK-350-BASE ASS'Y

21

Page 22

Manual Vise Assembly

Index No. Part No. Description Size Qty

................. FK350-300 ...............Complete Vise Assembly (includes index #1-32) ......................................

1 ............... J-FK350-301 ............Base ...................................................................................................... 1

2 ............... J-FK350-302 ............Front Vise Jaw....................................................................................... 1

3 ............... FK350-303 ...............Tip ......................................................................................................... 1

4 ............... FK350-304 ...............Vi se Screw ............................................................................................ 1

5 ............... FK350-305 ...............Jaw Insert A (Steel, Smooth) ................................................................. 2

FK350-305ST ..........Jaw Insert A (Steel, Serrated) ................................................................ 2

6 ............... FK350-306 ...............Jaw Insert B (Steel, Smooth) ................................................................. 2

................. FK350-306ST ..........Jaw Insert B (Steel, Serrated) ................................................................ 2

7 ............... FK350-307 ...............Guide Rod ............................................................................................. 2

8 ............... FK350-308 ...............Handle Hub ........................................................................................... 1

9 ............... FK350-309 ...............Handle................................................................................................... 3

10 ............. FK350-310 ...............Filling Block ........................................................................................... 1

12 ............. FK350-312 ...............Cap ....................................................................................................... 1

13 ............. FK350-313 ...............Setting Screw ........................................................................................ 1

14 ............. FK350-314 ...............Hex Nut ..............................................................M20x1.5P ................... 1

15 ............. J-FK350-315 ............Cover .................................................................................................... 1

16 ............. FK350-316 ...............Tension Handle ..................................................................................... 1

17 ............. FK350-317 ...............Tension Nut ........................................................................................... 1

18 ............. FK350-318 ...............Pressure Plate ....................................................................................... 1

19 ............. FK350-319 ...............Scale Centering ..................................................................................... 1

20 ............. FK350-320 ...............Pin......................................................................10mm Dia. x 30 .......... 2

21 ............. FK350-321 ...............Retainer ................................................................................................ 2

22 ............. TS-1505051 .............Socket Head Cap Screw .....................................M10x35 ...................... 4

23 ............. TS-1540071 .............Hex Nut ..............................................................M10 ............................ 4

25 ............. TS-1502031 .............Socket Head Cap Screw .....................................M5x12 ........................ 2

26 ............. TS-1550031 .............Flat Washe r ........................................................M5 .............................. 2

27 ............. TS-1490091 .............Hex Cap Screw ..................................................M8 x50 ........................ 3

28 ............. TS-1540061 .............Hex Nut ..............................................................M8 .............................. 3

29 ............. TS-1505041 .............Socket Head Cap Screw .....................................M10x30 ...................... 2

30 ............. TS-1505011 .............Socket Head Cap Screw .....................................M10x16 ...................... 2

31 ............. FK350-331 ...............Rivet ...................................................................2mm Dia. x 4 .............. 2

32 ............. J-FK350-332 ............Rear Vise Jaw ....................................................................................... 1

22

Page 23

Manual Vise Assembly

23

Page 24

Guard Assembly

Index No. Part No. Description Size Qty

1 ............... J-FK350-401 ............Guard A ................................................................................................. 1

2 ............... J-FK350-402 ............Guard B ................................................................................................. 1

3 ............... J-FK350-403 ............Guard C ................................................................................................ 1

4 ............... FK350-404 ...............Link A .................................................................................................... 1

5 ............... FK350-405 ...............Nylon Spacer A ..................................................................................... 6

6 ............... FK350-406 ...............Nylon Spacer B ..................................................................................... 3

7 ............... FK350-407 ...............Nylon Spacer C ..................................................................................... 2

8 ............... FK350-408 ...............Link B .................................................................................................... 1

9 ............... FK350-409 ...............Link C .................................................................................................... 1

10 ............. FK350-410 ...............Link Ring ............................................................................................... 1

11 ............. FK350-411 ...............Link Pin ................................................................................................ 1

12 ............. FK350-412 ...............Link Bracket .......................................................................................... 1

13 ............. FK350-413 ...............Link D .................................................................................................... 1

14 ............. FK350-414 ...............Link D Ring ............................................................................................ 1

15 ............. TS-1504031 .............Socket Head Cap Screw .....................................M8x16 ........................ 3

16 ............. TS-1550061 .............Flat Washe r ........................................................M8 .............................. 3

17 ............. TS-1504061 .............Socket Head Cap Screw .....................................M8x30 ........................ 2

18 ............. TS-1551061 .............Lock Was h e r ......................................................M8 .............................. 2

19 ............. TS-1521021 .............Set Screw ...........................................................M4x6 .......................... 1

20 ............. FK350-420 ...............Snap Ring ..........................................................S48 ............................ 1

21 ............. FK350-421 ...............Snap Ring ..........................................................S10 ............................ 2

22 ............. FK350-422 ...............Bushing ................................................................................................. 1

23 ............. FK350-423 ...............Knob ..................................................................M8x30 ........................ 1

24 ............. FK350-424 ...............Shut off Valve ........................................................................................ 1

25 ............. FK350-425

26 ............. FK350-426 ...............Hose ..................................................................................................... 1

...............Hose Band ............................................................................................ 1

24

Page 25

Guard Assembly

25

Page 26

In-Feed Table Assembly

Index No. Part No. Description Size Qty

1 ............... J-FK350-701 ............Bracke t ................................................................................................. 1

2 ............... J-FK350-702 ............Stand .................................................................................................... 1

3 ............... FK350-703 ...............Leveling Foot ......................................................................................... 2

4 ............... TS-154010 ...............Hex Nut M16 ......................................................................................... 2

5 ............... FK350-705 ...............Angle Rail .............................................................................................. 2

6 ............... J-FK350-706 ............Base A .................................................................................................. 1

7 ............... J-FK350-707 ............Base B .................................................................................................. 1

8 ............... TS-1491041 .............Hex Cap Screw ..................................................M10x30 ...................... 8

9 ............... TS-1491061 .............Hex Cap Screw ..................................................M10x40 ...................... 2

10 ............. TS-1491121 .............Hex Cap Screw ..................................................M1 0x70 ...................... 2

11 ............. TS-2361101 .............Lock Was h e r ......................................................M10 .......................... 1 2

12 ............. TS-1540071 .............Hex Nut ..............................................................M10 .......................... 16

13 ............. FK350-713 ...............Roller .................................................................................................... 6

14 ............. FK350-714 ...............Roller Bracket ...................................................................................... 12

15 ............. TS-1502021 .............Socket Head Cap Screw .....................................M5x10 ...................... 12

16 ............. J-FK350-716 ............Cover A ................................................................................................. 2

17 ............. J-FK350-717 ............Cover B ................................................................................................. 5

18 ............. TS-1533032 .............Pan Head Screw ................................................M5x10 ........................ 7

26

Page 27

Out-Feed Ta ble

1 ............... FK350-801 ...............Guide Block ........................................................................................ EA

2 ............... FK350-802 ...............Guide Rail .......................................................................................... EA

3 ............... TS-1502051 .............Socket Head Cap Screw .....................................M5x20 ..................... EA

4 ............... FK350-804 ...............Stopper Base...................................................................................... EA

5 ............... TS-1502051 .............Socket Head Cap Screw .....................................M5x20 ..................... EA

6 ............... FK350-806 ...............Connecting Plate ................................................................................ EA

7 ............... TS-1502071 .............Socket Head Cap Screw .....................................M5x30 ..................... EA

8 ............... FK350-808 ...............Lock Block A ...................................................................................... EA

9 ............... FK350-809 ...............Lock Block B ...................................................................................... EA

10 ............. FK350-818 ...............Spring................................................................................................. EA

11 ............. FK350-811 ...............Stopper .............................................................................................. EA

12 ............. TS-1503051 .............Socket Head Cap Screw .....................................M6x20 ..................... EA

13 ............. FK350-813 ...............Stopper P ad ....................................................................................... EA

14 ............. TS-1502041 .............Socket Head Cap Screw .....................................M5x16 ..................... EA

15 ............. FK350-815 ...............Scale Indicator .................................................................................... E A

16 ............. FK350-816 ...............Rivet ................................................................................................... EA

17 ............. FK350-817 ...............Inch Scale .......................................................................................... EA

18 ............. FK350-810 ...............Handle................................................................................................ EA

27

Page 28

Wiring Diagram

WALTER M EIE R (Manufac turing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.waltermeier.com

28

Loading...

Loading...