Specifications and Main Features

- Devices Model numbers: W2451, W27100, W27200, W27400 W30100 W30400 W30400P WM27160 WM27260 WW2460 WW27110 WW27210 WW27430 WW30430 JJW8527 JJW8530 JJW8627 JJW8630 JJW9527 JJW9530 JJW9627 JMW8527 JMW8530 JMW9527 JMW9530

- Meat Probe: NTC Thermistor; Calibration 9938 ohms at 150 degrees Fahrenheit

- Oven Sensor: RTD 1000 ohm Platinum; Calibration 1654 ohms at 350 degrees Fahrenheit

- Membrane Switch: Installed with a 12 to 18 ounces push force

- Electronic Control: Provision for a program implementation, ovens will retain at set temperatures, circuitry self-monitoring with fault codes

- Touch Sensor Technology: Initiated by Electrostatic field

- Display Board: Indicates time, temperature and function status

- Power Relay Board: Relays operating functions of all the ovens

- Fault Codes: Codes issued for diagnosis of faults

- Safety Precautions: There is a danger of being injured. The appliance should only be operated by a competent person.

Frequently Asked Questions

- Q: What does a meat probe do?

- A: It is fitted in food probes to check the inner temperature of the food being baked and confirm it is done properly.

- Q: How can the fault codes of the oven be reset?

- A: void Error codes can be cleared to “FO” after repairs by entering the test mode and pressing in for a period of five seconds both the cook time as well as stop time keys.

- Q: What is the significance of the fault codes?

- A: Fault codes signify major malfunctions encountered by the electrical oven such as sensor fault, short keys, or temperature errors of the oven enabling the technicians to know which parts should be inspected.

- Q: Is it possible to get to all the internal components without much difficulty?

- A: Yes, the manual contains procedures for access, repair and replacement of parts which include removing the door of the oven and the control panel.

- Q: What kinds of safety measures are built in this particular oven?

- A: The oven has a control device which draws itself and other devices to attention during unsafe conditions engages alarms and disables any adverse acts.

User Manual

Page 1

Jenn-Air

ElectricWall Oven

ServiceManual

16009721

Issued7/99

Page 2

SAFETY PRECAUTIONS

This service information is intended to be used by a qualified service technician who is famil-

iar with proper and safe procedures to be followed when repairing any electrical appliance.

All tests and repairs should be performed by a qualified service technician who is equipped

with proper tools and measuring devices. All replacements should be made by a qualified

service technician using only Maytag Appliances Sales Company replacement parts.

Improper assembly or adjustment may occur if service or repair is attempted by persons

other than qualified service technicians or if parts other than Maytag Appliances Sales Com-

pany replacement parts are used. Improper assembly or adjustment can cause hazardous

conditions.

There can be risk of injury or electrical shock while performing services or repairs. Injury or

electric shock can be serious or even fatal.

16009721 _:_mety

O1999 Msytag Appliances Sales Company

Page 3

INTRODUCTION

The manual is printed in a loose format and is divided into sections relating to a general group

of components and/or service procedures. Each section is further subdivided to describe a

particular component or service procedure.

The subdividing of the subject matter, plus the loose leaf form, will facilitate the updating of

the manual as new or revised components are added or new models are introduced.

Each page of the manual will be identified in the lower, right-hand corner, and as new or

revised pages are published, the manual can easily be updated by following the filing

instructions on the cover letter of the supplement.

This service manual is a valuable tool and care should be taken to keep it up-to-date by prompt

and proper filing of subsequent pages as they are used.

MODELS COVERED IN THIS MANUAL:

W2451 WM27260

W27100 WM27460

W27200 WM30460

W27400 JJW8527

W30100 JJW8530

W30400 JJW8627

W3040OP JJW8630

WW2460 JJW9527

WW27110 JJW9530

WW27210 JJW9627

WW27430 JJW9630

WW27430P JMW8527

WW30110 JMW8530

WW30430 JMW9527

WW30430P JMW9530

WM27160

16009721 Introduction i

01999 Maytag Appliances Sales Company

Page 4

NOTES

16009721 Introduction ii

@1999 Maytag Appliances Sales Company

Page 5

CONTENTS

GENERAL SAFETY PRECAUTIONS ................................................................................................... i

INTRODUCTION ................................................................................................................................. ii

CONTENTS ........................................................................................................................................ iv

SECTION 1. COMPONENT DESCRIPTION ................................................................................... 1-1

MEAT PROBE ......................................................................................................................... 1-1

MEMBRANE SWITCH ........................................................................................................... 1-1

ELECTRIC CONTROL ............................................................................................................. 1-1

TOUCH SENSOR TECHNOLOGY ......................................................................................... 1-1

DISPLAY BOARD ................................................................................................................... 1-1

POWER RELAY BOARD ........................................................................................................ 1-1

OVEN SENSOR ...................................................................................................................... 1-1

FAULT CODES ........................................................................................................................ 1-2

SECTION 2. COMPONENT ACCESS .......................................................................................... 2-1

CONTROL PANEL ASSEMBLY .................................................................................................. 2-1

OVEN DOOR REMOVAL ............................................................................................................ 2-1

SERVICING OVEN DOOR ........................................................................................................... 2-1

OVEN DOOR-HINGE REPLACEMENT ...................................................................................... 2-2

COOLING FAN ACCESS ............................................................................................................. 2-2

OVEN CAVITY COMPONENTS .................................................................................................. 2-2

Oven Sensor Removal .......................................................................................................... 2-2

Bake Element Removal ......................................................................................................... 2-2

Broil Element Removal ......................................................................................................... 2-2

Oven Light .............................................................................................................................. 2-3

Convection Motor Assembly ............................................................................................... 2-3

OVEN VENT/SMOKE ELIMINATOR .......................................................................................... 2-3

OVEN CAVITY ............................................................................................................................. 2-3

OVEN HINGE POCKETS ............................................................................................................. 2-3

SECTION 3. TROUBLESHOOTING ............................................................................................. 3-1

ELECTRONIC OVEN CONTROL: ............................................................................................... 3-1

TROUBLESHOOTING ................................................................................................................. 3-5

MULTIPLEXING CIRCUITRY ....................................................................................................... '3-8

POWER RELAY BOARD CONNECTION ................................................................................... 3-9

DISPLAY BOARD CONNECTIONS .......................................................................................... 3-10

CIRCUIT BOARD CONNECTIONS ........................................................................................... 3-10

MEMBRANE CONNECTIONS .................................................................................................. 3-11

SECTION 4. WIRING DIAGRAM ................................................................................................. 4-1

W2451 .......................................................................................................................................... 4-I

W27100 ........................................................................................................................................ 4-3

W27200, W30100, WM27160, WM27260 .................................................................................. 4-4

W27400, W30400, W30400P, WM27460, WM30460 ................................................................. 4-6

WW2460 ....................................................................................................................................... 4-7

WW27110, WW30110 ................................................................................................................. 4-8

WW27210 ................................ _.................................................................................................... 4-9

WW27430, W27430P, WW30430, WW30430P ........................................................................ 4-11

16009721 Contents iii

©1999 Maytag Appliances Sales Company

Page 6

CONTENTS CONT.

JJW8527, JJW8530, JJW9527, JJW9530, ................................................................................. 4-13

JMW8530, JMW8527, JMW9527, JMW9530 ............................................................................ 4-13

JJW8627, JJW8630, JJW9627, JJW9630 .................................................................................. 4-15

JJW8530, JJW9530 - Canadian Models .................................................................................... 4-17

16009721 Contents iv

@1999M0,/tagAppliancesSalesCompany

Page 7

SECTION 1. COMPONENT DESCRIPTION

COMPONENTS

Meat Probe: Senses the internal tempera-

ture of products during a baking function.

The meat probe is an NTC, or negative

temperature coefficient, which means the

resistance value decreases as the tempera-

ture increases. See meat probe chart below

for resistance values.

MEAT PROBE

Type: Calibration:

NTC Thermistor 9938 ohms (150°F.)

PROBE RESISTANCE VS. TEMR TABLE

Degrees E Resistance

122 18963 ohms

150 9938 ohms

156.2 8846 ohms

165.2 7456 ohms

210.1 3886 ohms

Membrane Switch: The means to make a

switch contact, thus instructing the elec-

tronic control system to perform a desired

function. The membrane switch is a simple

set of two contact surfaces containing

conductive material, one on the back layer

of MYLAR and the other on the front layer

of MYLAR. There is also a center section of

non-conductive MYLAR material that has a

hole punched out of it at each switch con-

tact position. The thickness of this spacer

MYLAR determines the push force required

to close the contacts between the front

contact strip and the rear contact strip.

Typically, the push force required to close a

contact is 12 to 18 ounces.

Electronic Control: A programmable soft-

ware component that controls oven, clock,

timer and various other functions. The

control maintains oven temperatures in

either bake, broil, or clean. It is adjustable to

maintain correct temperature offsets. It is

also programmed with self-monitoring

circuitry, which determines if a potential

unsafe condition is present, shuts the sys-

tem down and displays the appropriate fault

code. Fault codes are covered in product

specifications sections 3 and 4.

Touch Sensor Technology: With this new

technology a positive charge and negative

charge is present around each pad. This

creates an electrostatic field that emanates

around, below, and through the glass front.

When the consumer touches a key pad, this

disturbs the electrostatic field and draws

capacitance energy. This input is read by

the module, which in turn signals the con-

troller to respond, and the desired function

is performed. In order for a function to be

performed, a conductive material must

bridge the gap between the negative charge

present at each pad.

Display Board: Displays time-of-day clock,

oven temperatures, and any other function

programmed into the electronic control

system. The display board also acts as the

input means from the membrane switch

and sends those commands to the power

relay board to process, implement, and

monitor.

Power Relay Board: Contains the intelli-

gence in the electronic control system and

controls all oven functions, clock, timer, ,and

various other consumer programmable

inputs. The PRB has a relay mounted to it

for each function it provides.

Oven Sensor: A device to monitor internal

oven temperature. The sensor has a PTC or

positive temperature coefficient, or a resis-

tance value that increases with temperature.

Allows the electronic control to maintain a

temperature setting through means of

resistance matching with the control-se-

lected temperature. Example: The oven

control is set at 350°F, the oven sensor

resistance at room temperature is approxi-

mately 1060 ohms. As the oven heats, the

16009721 COMPONENT DESCRIPTION 1-1

_1999 Maytag Appliances Sales Company

Page 8

resistance of the sensor increases. The

resistance of the sensor at 350°F is approxi-

mately 1654 ohms. The electronic control

monitors the resistance value of the sensor

and cycles the oven heating elements off.

As the temperature in the oven decreases,

the resistance of the sensor decreases. At a

predetermined temperature setting, the

electronic control will initiate another heat-

ing cycle in the oven elements. See oven

sensor chart at right for resistance values.

OVEN SENSOR

Sensor Type: Calibration:

RTD 1000 ohm platinum 1654 ohms (350°E)

OVEN SENSOR RESISTANCE VS. TEMP. TABLE

Degrees E Resistance

100 1143 ohms

200 1350 ohms

300 1553 ohms

350 1654 ohms

400 1753 ohms

500 1949 ohms

600 2142 ohms

700 2331 ohms

800 "2516 ohms

900 2697 ohms

1000 2874 ohms

FAULT CODES

There are built-in fault codes to assist the technician in diagnosis of the control system. Any

time the control senses an error in the system, the control will beep at s 1 second interval

until the ON/OFF key is pressed.

_u_

CODES

F1

F3

F9

PROBLEM

Oven Temperature

Shorted Key, Keyboard

Disconnected

Sensor Failure or Sensor

Circuit Failure

Door Code

Ohm Test Sensor. Check connection at Sensor Wire

Harness

Check control. If keyboard is not disconnected (F1-4) or

key is not shorted (F1-3), replace control.

Ohm sensor. See chart,

Check Latch Assembly

COMPONENTS TO CHECK

For Models:

WW27110, WW30110, WM27160 (Oven Sensor Chart: Please refer to chart on 1-3)

16009721 COMPONENT DESCRIPTION 1-2

O199g Maytag Appliances Sales Company

Page 9

FAULT

CODES

PROBLEM COMPONENTS TO CHECK

F1

F2 Over temperature sensed Ohm TEST SENSOR. If checks ok, change control.

F3 Open sensor. Ohm sensor.

F4 Shorted sensor. Ohm sensor.

F5 Over temperature Ohm sensor. Check connection of sensor wire harness.

F7 Shorted key Stuck Function Key on control.

F9 Door Code Check LatchAssembly.

For Models:

W27100, W27200, W30100, WW27210, WM27260 (Oven Sensor Chart: Please refer to chart below)

MEAT PROBE:

TYPE:

CALIBRATION:

Power to element relay activated J1, J2 wire harness connection to control shorted. If

during time of day display, checks ok, change control.

OVEN SENSOR:

NTC thermistor

9938 ohms (150 F)

SENSOR TYPE:

CALIBRATION:

RTD 1000 ohm platinum

1654 ohms (350 F)

PROBE RESISTANCE VS TEMR TABLE

DEGREES F RESISTANCE

122 18963 ohms

150 9938

156.2 8846

165.2 7456

210.1 3886

For Models:

W27400, W30400, W30400RWW27430, WW27430RWW30430, WW30430RWM27460,

WM30460, JJW8527, JJW85300 JJW86270 JJW8630, JJW9527, JJW9530, JJW9627, JJW9630,

JMW8527, JMW8530, JMW9527, JMW9530

OVEN SENSOR RESISTANCE VS TEMR TABLE

DEGREES F RESISTANCE

100 1143 ohms

200 1350

300 1553

350 1654

400 1753

500 1949

600 2142

700 2331

800 2516

900 2697

1000 2874

16009721 COMPONENT DESCRIPTION 1-3

©1999 Maytag Appliances Sales Company

Page 10

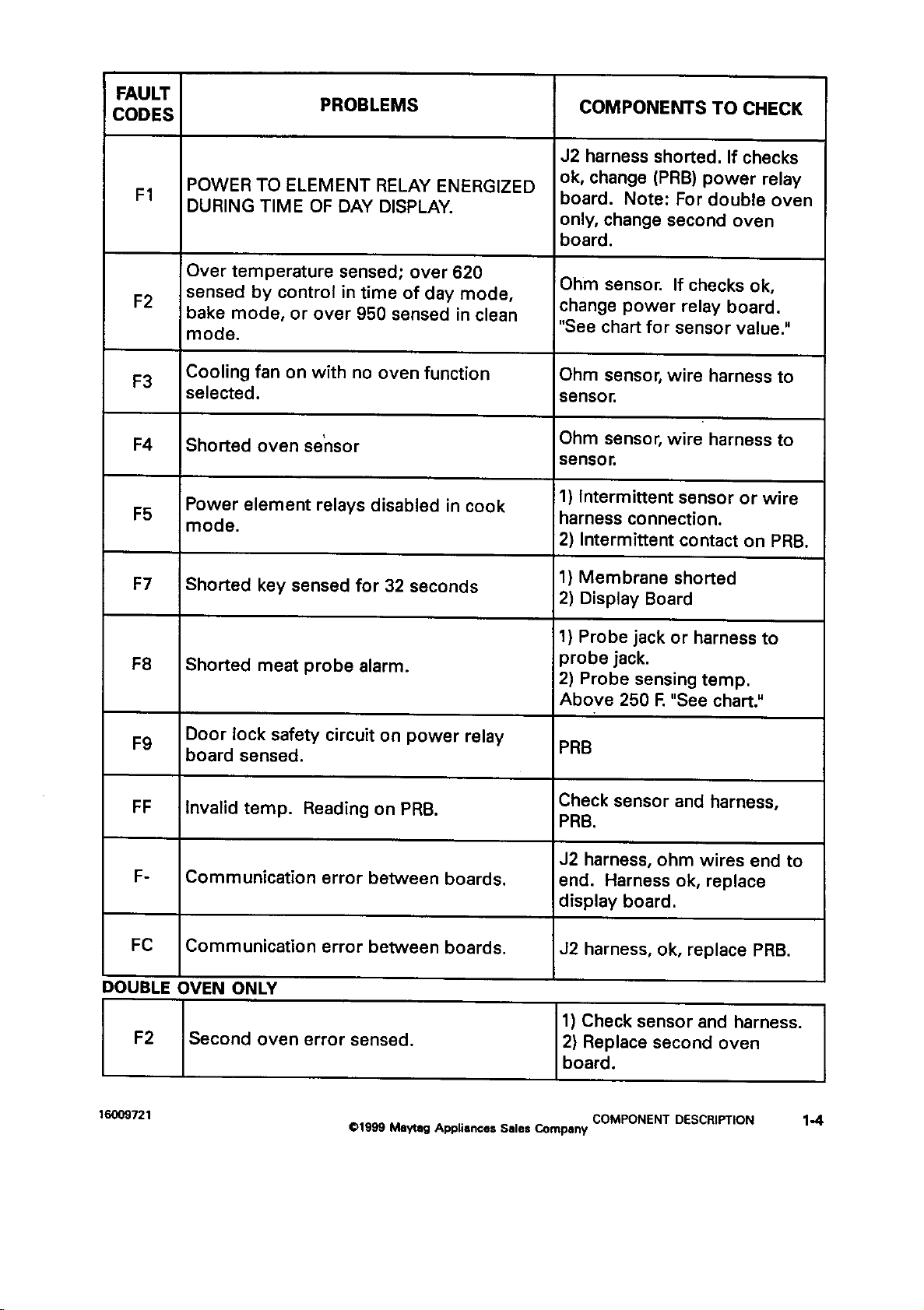

FAULT

CODES PROBLEMS COMPONENTS TO CHECK

J2 harness shorted. If checks

POWER TO ELEMENT RELAY ENERGIZED ok, change (PRB) power relay

F1 DURING TIME OF DAY DISPLAY. board. Note: For double oven

only, change second oven

board.

Over temperature sensed; over 620

F2 sensed by control in time of day mode, Ohm sensor. If checks ok,

bake mode, or over 950 sensed in clean change power relay board.

mode. "See chart for sensor value."

F3 Cooling fan on with no oven function Ohm sensor, wire harness to

selected, sensor.

F4 Shorted oven sensor Ohm sensor, wire harness to

sensor,

F5 Power element relays disabled in cook 1) Intermittent sensor or wire

mode. harness connection.

2) Intermittent contact on PRB.

F7 Shorted key sensed for 32 seconds 1) Membrane shorted

2) Display Board

1) Probe jack or harness to

F8 Shorted meat probe alarm, probe jack.

2) Probe sensing temp.

Above 250 F. "See chart."

F9 Door lock safety circuit on power relay

board sensed. PRB

FF Invalid temp. Reading on PRB. Check sensor and harness,

PRB.

J2 harness, ohm wires end to

F- Communication error between boards, end. Harness ok, replace

display board.

FC Communication error between boards. J2 harness, ok, replace PRB.

DOUBLE OVEN ONLY

1) Check sensor and harness.

I F2 I Second oven error sensed,

2) Replace second oven

board.

16009721 COMPONENT DESCRIPTION 1-4

01999 Maytag Appliances Sales Company

Page 11

SECTION 2. COMPONENT ACCESS

The following are instructions to access,

repair and replace components of the slide-in

range.

The unit is more accessible if it is removed

from the installed position before servicing

procedures begin.

-- IMPORTANT

DISCONNECT FROM POWER SOURCE [

BEFORE SERVICING APPLIANCE.

I

I

CONTROL PANEL ASSEMBLY

Electrical components can be accessed by

removing the control panel.

To remove the control panel, open the oven 4.

door as wide as possible. Remove the three

screws from the top of the control panel and

the three screws at the bottom of the con-

trol panel. Grasp the control panel by 5.

placing hands on the right and left sides of

the panel, pull out and down to disengage.

OVEN DOOR REMOVAL

.

Open the oven

door as wide as

possible.

,

Place an 1/8"

pin in the hole

on the right and

left door hinges,

see Figure 2-1,

.

Remove the

screws from

each side with a

PhiLlips screw-

driver. Remove

the lock plate

from each side,

Raise the oven door up to a broil stop

position. In this position, it will be

against the 1/8" pin.

Grasp the door toward the top on both

sides. Lift the door up and out to re-

move.

Figure 2-1

For JJW Models:

1. To remove the control panel, open the

door as wide as possible. Remove the

four screws from the bottom of the

control panel. Grasp the control panel

by placing hands on the right and left

sides of the panel, lift up and out to

disengage from upper flange.

2. Place the panel on the top oven rack

(cover with a cloth to prevent scratch-

ing) for component testing.

3. With the control panel pulled forward,

access is now available to the following

components: Control Assembly, Clock,

High Limit Thermostat, Cooling Fan,

Door Latch Mechanism and Motor.

16009721 COMPONENT ACCESS 2-1

©1999 Maytag Appliances Sales Company

SERVICING OVEN DOOR

1. Lay the oven door on a protected surface

with the inner door panel facing down.

2. Remove three screws from lower trim.

Remove trim piece.

3. Slide outer-door glass down to disen-

gage from top trim. Remove.

4. Remove three screws from top oven

door trim. Remove the two 3/8" nuts

from the door handle bracket.

5. Lift up and off. This will disengage the

side trim as well.

6. Remove the oven window pack by re-

moving the 3/8" nuts from the insulation

retainer.

Page 12

For JJW Models:

1. Lay oven door on a protected surface

with the inner door panel facing down.

2. Remove the three screws at the top and

the three at the bottom of the door, see

Figure 2-2,

3. Grasp the door assembly at the bottom

and lift the assembly off the front door

glass.

3. To reassemble the oven door, reverse the

procedures for disassembling.

COOLING FAN ACCESS

To access the cooling fan, remove two 1/4"

hex screws from the bracket which the fan is

mounted on. Tilt motor and bracket to

allow it to pass through main back panel.

OVEN CAVITY COMPONENTS

4. Remove the two center screws holding

the center bracket in position.

Figure 2-2

5. Once the center bracket is removed you

will see two screws securing the trim to

the glass. Remove these screws.

6. Remove the two screws holding the left

and right side brackets inposition.

7. Slide the front door glass out of the

frame.

Oven cavity components consist of: bake

and broil elements, oven light assembly,

convection motor, oven cavity, and oven

sensor,

Oven Sensor Removal

Remove two 1/4" hex screws, pull oven

sensor into oven cavity to gain access to the

electrical quick connector.

To reassemble, use a probe and attach the

probe to the quick connector, Guide it

through the insulation to ensure the connec-

tor does not contact the oven cavity. Contact

could damage the connector.

Return to the original position, reattaching

with the 1/4" hex screws.

Bake Element Removal

Remove the two 1/4" screws. Pull the bake

element into the oven cavity to access

electrical wiring.

8. Reverse the procedure to reassemble.

OVEN DOOR HINGE REPLACEMENT

Broil Element Removal

Remove the four 1/4" hex screws. Pull broil

element into oven cavity to gain access to

1. Remove two screws from oven inner

door panel that mount into the lower

portion of oven door hinge assembly.

the electric wiring. Reattach by returning to

the original position and fastening with four

hex screws.

2. Grasp and liftoven door hinge assembly

upward and slide down to disengage

upper tabs from the door panel.

16009721 COMPONENT ACCESS 2-2

©1999 Maytag Appliances Sales Company

Page 13

Oven Light

Bulb can be replaced or accessed by turning

the lens counterclockwise to remove the

entire oven light. The socket can be removed

by depressing the spring clips from the rear

of the light socket end pushing it into the

oven cavity.

3. Grasp the front flange of the oven liner

and gently pull forward to remove oven

liner from insulation and structure.

NOTE: When replacing oven cavity, use

pieces of sheet metal on sides and top of

oven liner to allow cavity installation

without tearing or removing insulation.

A new oven light socket can be inserted and

snapped into position by depressing the

spring clips and reattaching in the original

position.

Convection Motor Assembly

To access the motor assembly, remove the

three 1/4" hex screws from the convect

cover. Remove the cover. Remove three

additional 1/4" hex screws that secure the

convect motor assembly. Pull convect

motor assembly into the oven cavity, dis-

connecting the electricat quick-connect.

Reattach by returning to original position

using reverse procedures.

OVEN VENT/SMOKE ELIMINATOR

, Remove oven vent and smoke eliminator

by using tabs on bottom of smoke elimi-

nator, turning counterclockwise to disen-

gage the locking ears from the inner

insulation retainer.

When the cavity is within two inches of

being in place, remove the sheet metal.

OVEN HINGE POCKETS

,

Remove oven door following the steps

previously described in section on Oven

Door Removal.

.

Remove hex screws from the lower front

closure.

3. From each side of the range, remove two

1/4" hex screws.

4. Replace components and reassemble.

2. To remove the smoke eliminator, pull

down end align locking ears with notches

in oven cavity.

Reattach by reversing above procedures.

OVEN CAVITY

.

All internal oven cavity components

must be removed prior to oven cavity

removal.

.

Remove the five 1/4" hex screws from

the front flange of the oven liner. (Three

screws will be on the top and two on the

bottom.)

16009721 COMPONENT ACCESS 2-3

@1999 Maytag Appliances Sales Company

Page 14

160(;9721 COMPONENTACCESS 2-4

01999 Maytag Appliances Sales Company

Page 15

SECTION 3. TROUBLESHOOTING

Test Access The test mode can be accessed by holding the stop time key down at

power up or by holding the stop time key down for 10 seconds within 5

minutes of power up mode, No other key can be pressed before the

stop time key, that would block the test mode access.

Test Exit Exit the test mode by pushing the cancel key or test will self-terminate

after 16 seconds from the last key command chosen.

Test Function Test mode is perfomed by pushing a keypad and testing for an output

response. When the keypad is released, the output is terminated and

the display will return to the "-" display. The following is a list of key

actions and responses.

NOTE:

1. Each time a key is pressed a tone will sound.

2. If there is a red dot on the IC-chip and the display board when you touch the oven light key,

the oven light will come on and a beep will occur. The beep is to let you know that there is

a good circuit, in case the light is blown. Also, when you press the fan speed key on a dual

speed downdraft, it will beep each time you touch the key. The first beep will be the high

setting, the second beep will be the low setting, and the third beep will be off.

Bake Key

Broil Key

Convect Bake Key

Convect Roast Key

Oven Light Key

Probe Key

Timer Keys

Clean Key

Activates bake relay on the power relay board.

Activates broil relay on the power relay board.

Activates convect bake relay (CVBAK) on the power relay board.

Activates convect roast relay (CVRST) on the power relay board.

Activates oven light (OVLT) relay on the power relay board. (See note

2 above.)

Activates the display on the control to display the probe temperature.

Activates the display to show factory codes in the blue displayed digits

and oven temperature in red.

Activates blue display digits which shows the state of the door lock

switches and the status of the user selectable options. See charts on

page 1-2. NOTE: First (left) blue displayed digit is for user selectable

options code and the fourth (right) blue digit is for the door lock switch

status code.

16009721 TROUBLESHOOTING 3-1

O1999 Maytag Appliances Sales Company

Page 16

Stop Time Key Will activate the beeper 100% as long as the key is pressed. Also, it will

display the control I.D. # in the blue time digits and the power relay

board I.D. # in the red temperature digits.

Clock Key Activates all display segments to light.

Cook Time Key

Activates any fault codes stored in the memory. The time digits display

any fault codes for the membrane and control board. The temperature

digits display any fault codes for the power relay board. NOTE: If"FO"

is disDlaved, there has not been any fault codes sensed in that portion

of the svstem. Any stored fault code can be cleared to FO, after repairs

have been made, by entering the fast test and pressing both the cook

time and stop time keys for 5 seconds.

Digital Input Keys Activates the display to show the same digit (0-9) that is pressed.

Temperature Program bake above 500 °, repress bake pad and hold for 3-4 seconds,

Offset Change the pad must be re-pushed within 3 seconds. The digital keys can be

used to set the offset between positive and negative(-). Entered values

are rounded to the next 5° increment. (Example: pushing key 3 will

display a 5° increment).

Clock and

Temperature

Change

The clock can be set to be displayed in 24 hour form. Also,

temperature can be displayed in degree "C". To access, hold either

timer keys down on power up. The two left digits will display the

format for the clock, the right digit will display "F" or "C." The display

can be toggled by pushing the bake or upper bake key to toggle the

clock. The temperature display can be toggled from F to C by pushing

the broil key or upper broil key on a double oven control.

16009721 TROUBLESHOOTING 3-2

O1999 Maytag Appliances Sales Company

Page 17

Display

Code

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

User Selectable Options Display Codes

Deg. C

X

X

X

X

X

X

24 Hour

Clock

X

X

X

X

X

X

Continuous

EOC

X

X

X

X

x

X

X

x

X

x

X

X

60 Hz

Reference

X

X

X

X

X

X

X

X

Display Code

7

6

5

4

3

2

1

0

Door Lock Switch Codes

Unlocked Locked

Switch Switch

closed closed

open closed

closed open

open open

closed closed

open closed

closed open

open open

Door Closed

Switch

closed

closed

closed

open

open

open

open

open

16009721 TROUBLESHOOTING 3-3

@1999 Maytag Appliances Sales Company

Page 18

Fault Code Problem Components to Check

F1 Power to element relay energized J2 harness shorted; If checks ok,

during time of day display, change (PRB) power relay board.

NOTE: For double oven only, change

second oven board.

F2 Over temperature sensed; over 620 ° Ohm SENSOR. If checks ok, change

sensed by control in time of day mode, )ower relay board.

bake mode, or over 950 ° sensed in "See chart for sensor value."

clean mode.

F3 Cooling fan on with no oven function Ohm SENSOR, wire harness to sensor.

selected.

F4 Shorted oven sensor Ohm sensor, wire harness to sensor.

F5 Power to element relays disabled in 1) Intermittent sensor or wire harness

cook mode. connection.

2) Intermittent contact on PRB.

F7 Shorted key sensed for 32 seconds. 1) Membrane shorted..

2) Display board.

F8 Shorted meat probe alarm. 1) Probe jack or harness to probe jack.

F9 Door lock safety circuit on power relay PRB.

board.

FF Invalid temperature reading on PRB. Check sensor and harness, PRB.

F- Communication error between boards. 1) J2 harness, ohm wires end to end.

Harness ok, replace display board.

FC Communication error between boards. J2 harness, ok, replace PRB.

Double Oven Only

FR Second oven error sensed. 1) Check sensor and harness.

2)

Replace second oven board,

MEAT PROBE

Type: Calibration:

NTC Thermistor 9938 ohms (150°R)

PROBE RESISTANCE VS. TEMR TABLE

Degrees E Resistance

122 18963 ohms

150 9938 ohms

156.2 8846 ohms

165.2 7456 ohms

210,1 3886 ohms

16009721 TROUBLESHOOTING 3-4

O1999 Maytag Appliances Sales Company

Page 19

TROUBLESHOOTING

Power Board Voltage Resistance Ref. Point Comments

J1-1 0.0 Vdc J1-1 Signal Ground

J1-2 13.0 Vdc J1-1 +12 Vdc Source

J1-3 21.2 VAC J1-4 T1 Secondary

J2-1 5.0 Vdc J1-1

J2-1 0.0 Vdc J1-1 Press Cancel 2

J2-2 5.0 Vdc J1-1

J2-2 0.0 Vdc J1-1 Press Cancel 1

J2-3 0,0 Vdc J1-1 Time of Day Mode

J2-3 2,8 Vdc J1-1 Cooking Mode Active Oven 1

J2-4 0.0 Vdc J1-1 Time of Day Mode

J2-4 2.8 Vdc J1-1 Cooking Mode Active Oven 2

J2-5 1.2 VAC J1-1 Serial Clock Line

J2-6 1.3 VAC J1-1 Transmit Line

J2-7 2.5 VAC J1-1 Receive Line

J2-8 Enable Line

J3-1 5.0 Vdc J1-1 Probe Out

J3-1 <3.5 Vdc J1-1 Probe In

J3-2 0.0 Vdc J1-1 Signal Ground

J4-1 12.0 Vdc J1-1 Down Draft OFF or High

J4-1 0.7 Vdc J1-1 Down Draft ON Low

J4-2 12.0 Vdc J1-1 +12 Vdc Source

J4-3 12.0 Vdc J1-1 Down Draft OFF or Low

J4-3 0,7 Vdc J1-1 Down Draft ON High

J5-1 12,0 Vdc J1-1 +12 Vdc Source

J5-2 Open Pin

J5-3 12.0 Vdc J1-1 Door 1 Closed

J5-3 0.0 Vdc J1-1 Door 1 Open

J5-4 0.0 Vdc J1-1 Door 1 Unlocked

J5-4 12,0 Vdc J1-1 Door 1 Locked

J5-5 12.0 Vdc J1-1 Door 1 Unlocked

J5-5 0.0 Vdc J1-1 Door 1 Locked

J7-1 Enable Line

J7-2 Open Pin

J7-3 2,5 VAC J1-1 Receive Line

16009721 TROUBLESHOOTING 3-5

O1999 Maytag Appliances Sales Company

Page 20

Power Board

J7-4

J7-5

Voltage

2.8 Vdc

0.0 Vdc

Resistance Ref. Point

J1-1

J1-1

Comments

Door Lock Limit

Time-of-Day Mode

J7-5

J7-6

J7-7

J7-7

J7-8

J8-1

J8-2

J8-2

J8-3

J8-3

J8-4

J8-5

J8-5

J9-1

J9-2

J9-3

J10-1

J10-2

J10-3

2.3 VAC

1.2

0.0 Vdc

2.8 Vdc

0.0 Vdc

12.0 Vdc

12.0 Vdc

0.0 Vdc

0.0 Vdc

12.0 Vdc

12.0 Vdc

0.0 Vdc

1.9 Vdc

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

<3.5 Vdc

<3.5 Vdc

1.9 Vdc J1-1

Cooking Mode Active

Oven 2

Serial Clock Line

Time-of-Day Mode

Cooking Mode Active

Oven 2

Signal Ground

+12 Vdc Source

Door 1 Closed

Door t Open

Door 1 Unlocked

Door 1 Locked

Open Pin

Door 1 Unlocked

Door 1 Locked

Oven Probe

Open Pin

Cool Oven

Open Pin

Cool Oven

Oven Probe

16009721 TROUBLESHOOTING 3-6

©1999 Maytag Appliances Sales Company

Page 21

Control Head

J1-1

J1-2

J1-3

J2-1

J2-1

J2-2

J2-2

J2-3

J2-3

J2-4

J2-4

J2-5

J2-6

J2-7

J2-8

Voltage

0.0 Vdc

13.0

21.2 VAC

5.0 Vdc

0.0 Vdc

5.0 Vdc

0.0 Vdc

0.0 Vdc

2.8 Vdc

0.0 Vdc

2.8 Vdc

1.2 VAC

,1.3 VAC

2.5 VAC

Resistance Ref. Point

J1-1

J1-1

J1-4

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

J1-1

Comments

Signal Ground

+12 Vdc Source

T1 Secondary

Press Cancel 2

Press Cancel 1

Time-0f-Day Mode

Cooking Mode Active Oven 1

Time-of-Day Mode

Cooking Mode Active Oven 2

Serial Clock Line

Transmit Line

Receive Line

Enable Line

2nd Oven Voltage Resistance Ref. Point Comments

J7-1 Enable Line

J7-2 Open Pin

J7-3 2.5 VAC J1-1 Receive Line

J7-4 2.8 Vdc J1-1 Door Lock Limit

J7-5 0.0 Vdc J1-1 Time of Day Mode

J7-5 2.3 VAC J1-1 Cooking Mode Active O_en 2

J7-6 1.2 VAC J1-1 Serial Clock Line

J7-7 0.0 Vdc J1-1 Time-of-Day Mode

J7-7 2.8 Vdc J1-1 Cooking Mode Active Oven 2

J7-8 0.0 Vdc J1-1 Signal Ground

16009721 TROUBLESHOOTING 3-7

O1999 Maytag Appliances Sales Company

Page 22

MULTIPLEXING CIRCUITRY-WALL OVENS

Imm|

TST

I DISPLAY ._

OVEN

POWER

BOARD

(DOUBLE

OVEN ONLY)

J1

MAIN

POWER BOARD

VCC REFERENCE -_

VCC REFERENCE -.'

i OVEN

J9

E-

KEY M

DOOR

LOCK ,b

UNLOCK m

DOOR M

LOCK

SENSOR

!r

LOWER

OVEN

SENSOR

_L

KEY ,a,

UNLOCK m

16009721 TROUBLESHOOTING 3-8

©1999 Maytag Appliances Sales Company

Page 23

POWER RELAY BOARD CONNECTIONS

TO

DISPLAy _ TO

TO L1

BOARD DOOR

N

NEU'm_

TO

OVEN

UGHT "--_OVLT

N

n.-..

r,i

TO

UNIT

BROIL B_

:..i

L2

TO BAKE

BAKE T

UNIT

l

CVBAK _

CONVECTION

MOTOR SLOW

SPEED

1.2

NCor--

USED

USED L.-.J

TO L2

D

DRLK _]_

COOL

CVRST []_

J9

--DOOR LOCK

C_DUNG

FAN

TO

CONVECTION

MOTOR HIGH

SPEED

OVEN

I SENSOR

T°

TO

DISPLAY

BOARD

TO

MOTOR

16009721 01999 Maytag Appliances Sales Company TROUBLESHOOTING 3-9

Page 24

DISPLAY BOARD CONNECTIONS

TO POWER

RELAY J

BOARD J1

CIRCUIT BOARD CONNECTIONS

I

ITO

DOOR

LOCK

CIRCUIT

DISPLAY BOARD

J2

)

MEMBRANE

SWITCH TAIL

TO POWER

RELAY

BOARO J2

l_l o,sPLAv.oA.oIJ

MEMBRANE

SWITCH TAlL

N BOARD J10_

0OVLT

2

J'E

1 OR_I}

SClll_IIF

160G9721 TROUBLESHOOTING 3-10

@1999 Maytag Appliances Sales Company

Page 25

MEMBRANE CONNECTIONS

PAD

1

2

3

4

5

5

7

8

9

0

LO BAKE

LOBROIL

LO CLEAN

TIMER ONE

STOP TIME

CLOCK

PROBE

OVEN LIGHT

TIMER TWO

COOK TIM E

UPPER BAKE

UPPER BROIL

UPPER CLEAN

UPPER CONVECTION BAKE

UPPER CONVECTION ROAST

UPPER CANCEL

LOWER CANCEL

CIRCUIT

15to 4

14to 4

13to4

12to4

11to4

10to 4

9to4

8to 4

7to 4

6to4

15 to 16

14 to 16

13 to 16

14to 5

13to5

12to 5

11to5

10to5

9to 5

8to5

10to3

9to 3

8to 3

7to3

6to3

1 to2

1 to 17

Membrane Switch: The means to make a

switch contact, instructing the electronic

control system to perform a desired function.

The membrane switch is a simple set of two

contact surfaces containing conductive

material, one on the back layer of MYLAR

and the other on the front layer of MYLAR.

There is also a center section of non-conduc-

16009721 TROUBLESHOOTING 3-11

O1999 Maytag Appliances Sales Company

tive MYLAR material that has a hole

punched out of it at each switch contact

position. The thickness of the MYLAR

spacer determines the push force required

to close the contacts between the front

contact strip and the rear contact strip.

Typically, the push force required to close a

contact is 12 to 18 ounces.

Page 26

POWER RELAY BOARD-DOUBLE WALL OVEN

TO

TO UPPER

DISPLAY OOOR

BOARD LOCI<

TO L1

TO

LOWER

DOOR

LOCK

IpRTOBE

JACK

TO

NEUTRAL

TO

OVEN

LIGHTS

TO

UPPER

BROIL

UNIT

N

L2

J1 J5

J8 J3

J9

J10

J2

DRLK _--

COOL D

TO

/

| LOWER OVEN

.J

SENSOR

TO

"m--_IuPPER OVEN

]SENSER

DITOsPLAY

JBOARD

TOuxILLARy

RELAY

BOARD

TO

UPPER

DOOR

LOCK

MOTOR

1.2

TO

UPPER

BAKE

UNIT

SC116"nF

16009721 TROUBLESHOOTING 3-12

BAKE T T

CVBAK

•_ TO L2

TO

CONVECTION

MOTOR

SLOW SPEED

O1999 Mayteg Appliances Sales Company

CVRST _--

-1

TO

CONVECTION

MOTOR

HIGH SPEED

TO

COOLING

FAN

Page 27

AUXILLARY RELAY BOARD-DOUBLE WALL OVEN

TO L1

L1 L1

TO N

NEUTRAL

To D

LOWER

DOOR N

LOCK

MOTOR

DRLK

RELAY

TO

BOARD

TO

LOWER

BAKE

UNIT

L2

L2

-2

TO L2

BROIL

T.°

OWER

BROIL

UNIT

SC11TrlF

16009721 TROUBLESHOOTING 3-13

01999 Maytag Appliances Sales Company

Page 28

CIRCUIT BOARD CONNECTIONS-DOUBLE WALL OVEN

TO

UPPER

DOOR

LOCK

TO

LOWER

TO

L1

J1 J5 J8 J3

TO

NEUTRAl

TO

OVEN

OVLT JlC

J9

TO

UPPER.,dI.

BROIL--

UNIT

8C111rNF

TO

UPPER

BAKE

UNIT

BROIL

NOT J2

USED

CVBAKI CWSTIR I MOTOR

L.TO Oo.NG

t _ FAN

TO

CONVECTION

MOTOR

SLOW SPEED

TO

CONVECTION

MOTOR

HIGH SPEED

TO NEUTRAL _ n_

TO LOWER DOOR

LOCK MOTOR

TO

LOWER

BAKE "91

UNIT

N_I

TO

L1

u

N

DRLK

L2 BROIL

R:P =;=

t LOWER

TO

BROIL

TO UNIT

L2

\

/

16009721 TROUBLESHOOTING 3-14

@1999 Msytag Appliances Sales Company

Page 29

ELECTRONIC CONTROL PROGRAMMABLE CHANGES

TEMPERATURE OFFSET CHANGE:

1) Program bake above 500 degrees F

2) Repress bake pad and hold for 3 to 4 seconds

3) The digital keys can be used to offset between 0 to 35 degrees in increments of 5

degrees.

4) The broil key is used to toggle between positive and negative offsets.

CLOCK AND TEMPERATURE CHANGE:

1)

2)

3)

4)

5)

Hold either timer pad down during power up

The two left digits will display the format of the clock

The right digit will display F or C

Pushing the bake key will toggle the clock

Pushing the broil key will toggle the temperature from F to C

ELECTRONIC CONTROL FAST TEST PROCEDURE

1) Test Function:

Depressing a key pad allows for testing for an output

When the key is released, the output is terminated

2) Test Access:

Hold the stop time key down at power up or for 10 seconds

within 5 minutes of power up.

3) Test Exit:

Push the cancel key

Test will self terminate after 16 seconds from the last key

command chosen.

16009721 TROUBLESHOOTING 3-15

O1999 Maytag Appliances Sales Company

Page 30

While in the test mode the following outputs may be checked:

Bake Pad-

Broil Pad-

Press the pad in the test mode and the bake relay will be activated.

Press the pad in the test mode and the broil relay will be activated.

Convect Bake Pad- Press the pad in the test mode and the convect bake relay will be

activated.

Convect Roast Pad-Press the pad in the test mode and the convect roast relay will be

activated.

Oven Light Pad- Press the pad in the test mode and the oven light relay will be

activated.

Probe Pad-

Press the probe pad in the test mode and the probe temperature will

be displayed.

Timer-

Press the timer pad in the test mode and the factory codes will

appear and the oven temp will appear in red.

Stop Time Pad- Press the stop time pad in the test mode and the beeper will be

activated and the control ID will be displayed in the blue digits

and the power relay board ID will be displayed in the red

temperature digits.

Clock Pad-

Press the clock pad in the test mode and all display segments will be

activated.

Clock Time Pad-

Press the clock time pad in the test mode and the last fault code

sensed in the system will be displayed.

Digital Input Pads- Press the digital input pads in the test mode and the digit that has

been pressed will be displayed.

Clean Key- Press the clean key pad in the test mode and the state of the door

lock switches and the status of the user selectable options will be

displayed.

16009721 TROUBLESHOOTING 3-16

01999 Mayteg Appliances Sales Company

Page 31

USER SELECt'ABLE OPTION DISPLAY CODES

DISPLAY CONTINUOUS 60 HZ

CODE EOC REFERENCE

DEG C 24 HR CLOCK

F X X X X

E X X X

D X X X

C X ×

B X X X

A X X

9 X X

8 X

7 X X X

J1, J2 wire

harness

connection to

co ntro I

shorted, If

checks ok,

change control.

X X

5 X X

4 X

3 X X

2 X

_1 X

0

16009721 TROUBLESHOOTING 3-17

€1999 Maytag Appliances Sales Company

Page 32

DOOR LOCK SWITCH CODES

UNLOCKED DOOR CLOSED

DISPLAY CODES SWITCH LOCKED SWITCH SWITCH

7 CLOSED CLOSED CLOSED

6 OPEN CLOSED CLOSED

5 CLOSED OPEN CLOSED

i

!4 OPEN OPEN OPEN

3 CLOSED CLOSED OPEN

2 OPEN CLOSED OPEN

1 CLOSED OPEN OPEN

0 OPEN OPEN OPEN

For JJW Models

To test the control the following should be performed:

Bake Pad-

Touch the bake pad then touch the auto set pad within 4 seconds of

each other. The bake relay should engage and the element start to

heat. Listen for the relay and then check for heat from the element.

Broil Pad-

Touch the broil pad and then touch the auto set pad within 4 seconds

of each other. The broil relay should engage and the element start to

heat. Listen for the relay and then check for heat from the element.

Convect Bake Pad-

Touch the convect broil pad and then touch the auto set pad within

four seconds of each other. The convect bake relay should engage,

the fan should come run on low speed, end the element start to heat.

Listen for the relay, the fan, and then check for heat from the element. ,

Convect Roast Pad-Touch the convect roast pad and then touch the auto set pad within

four seconds of each other. The relay should engage, the fan should

start on high speed, and the element should start to heat. Listen for

the relay, the fan, and then check for heat from the element.

Drying Pad-

Touch the drying pad and then the auto set pad within four seconds

of each other. The fan should start and the element should start to

heat. Listen for the fan and check for heat from the element.

Clean Pad-

Touch the clean pad and then the auto set pad within four seconds of

each other. The relay should engage, the door lock motor energize,

and the door lock. Listen for the relay, the motor to energize, and

check the door to make sure it locks.

16009721 "[ROUBLESHOO'nNG 3-18

@1999 Maytag Appliances Sales Company

Page 33

SECTION 4. WIRING DIAGRAM

W2451

L1 N L2

I BK W R

16009721 WtRtNG DtAGRAM 4-1

O1999 Maytag Appliances Sales Company

Page 34

W2451

L1

L2

LIS'II

"rIMER

RELAY

p_kl SW.

W/R

TIM£R >

3L

_lItt _, inT.)

r

V/R THERMOSTAT _ S£L5W

i llP(ATOq "

THERMOS;TAT LAT[H_# ITOPI

N

KSSTORrSXl

N_UTRAL- i;.l_,r A!

_1LNT CY_

S[L $W,

511.SW R

"I" _AI_ SE'LECTOR

I O

OF L_ I 6_

OVZN

• _IERATIOH CV BAT

OFF

8AI_

CLEAN X

(_hIEC1 X

BROL

[ONVECT X

SETTINGS

OFF

BA_E

T(t'IP, OR

CL[AN

ZDMPONENTSYHBOLSDO NOTREFLECTTRUE

TH_RMO_AT

CONTA(:TPI_

AT OVeN

T[tIP "F

1 S

w--

2 6

O_K OP_t4

I

B[L_ I _J.OW

i

CONFIGURATIONALLFEEDLINECOLORSARE

,,'-SCISSORLATCHSW. HAKES W_TH DOOR CLOSED

NOTED(BLACK.WVdTEAND RED).ALL[OMPONENIS

_H_WNtN"nFF"POSITION

16009721 WiRiNG DIAGRAM 4"2

@1999 Maytag Appliances Sales Company

Page 35

W27100

DOOR

ACTUAT[O

SWI TCH[S

L1

O00R ACTUAT[D

_-_ HI

LIMIT

OCOR ACTUAT (O

SWITCH

I

'--i i

OVE_N __J

LIGHT

SWITCH --

:-_:] i

C(_IV_CT J ON _-_

" (_.

BAK£

EL [I_IENT ,____.

BROIL

[LEI/4E)IT

,:I'_A_V'-I=

• .... d

Ml _O_qAV[ _I1

I_JTLET

®

NOTI C(:

I. DIS_kt[CT RAN(_ _ FOAER

II_FI_( REMOVING Wll_ ¢OV(R.

2, IRFER ONLy TO F[AI_A[$ (_A_IpplEI_,

,_:_l_: """_ _ °"_" TM "_'

ALL liES PIIIQR TO OI_[CTION

S_RVlCING CQI_TR_LS. II_IN_ PII_eLDA$

CAM _ IMP_O_R AND _ CPIE_ATION.

$, VERIFY _ I_PI[ILA'_IGN AFT[.R SERVICING,

L2

__1

m2_

9gA

J,..

16009721 WIRING DIAGRAM 4-3

@1999 Maytag Appliances Sales Company

Page 36

W27200, W30100, WM27160, WM27260

L.i N L_

JLUG_

//9 *e

..... _- _--'-_''I r................

I

tw

I I

1_ nr_o o

N[UlI_

€_cl L_._L CC_S

€0C_OR r_/_ KS /QAV

_U_

ROt _ IRJ*AIT

[LU4_T

Ik_ F_ I[LMy

[L[MU4T

IRLA5

_l- ImIL, MmLIWLLAT

C0141110-|_ lqtlN51_ ¢T_-JTT _ lL1ff_t)

mlt_

16009721 WIRING DIAGRAM 4-4

@1999 Meytag Appliances Sales Company

Page 37

W272000 W30100, WM27160, WM27260

L1

RELCiY BOleRO

0

OlA_AHP/N 208S_F

16009721 WIRING DIAGRAM 4*5

©1999 Maytag Appliances Sales Company

Page 38

W27400, W30400, W30400R WM27460, WM30460

.t

;i_I,°,''_,,"

9

I

xt,..i, _.

, I

ti_r-'-L-I

t -._ !l

fill__ / I i >!

•" i ill ill

_l I _k I

'" _,7_i._

,T,,it

• ai I

!

f

i

!

mT[l!

i 2I"

i

i

o, -'I '

'i

!i,0!°

ll!

ili

i{

I

16009721 WIRING DIAGRAM 4-6

€1999 Maytag Appliances Sales Compnny

Page 39

WW2460

II

E

\

e

il

s

i i

!

16009721 WIRING DIAGRAM 4-7

©1999 Maytag Appliances Sales Company

Page 40

WW27110, WW30110

L1

,,-----_; ,_A%.

I L 1_'4T

L...... d

TH[RIdO5 TAT ,._-_,

LIMIT

O00fl ACTUATED

s_2T._C"_.o

[X_R ACTUATE{}

SW_ TCH

HI-LIMIT

SWITCIt

BROIL

ELI_IEt_I

.... J

ELE NT

r ....... •

BLOCK

I_ L_O_ SNIT_[5 R_LAy CONTACTS I

L_ UI_,OCKE0 LIHI[ I LIH( 1

I OFF OPEN I CLO3ED _ I _N

I _'_L i OF_H I CLO_ED I SEE NOT[ I I SEE NOTE 1

CLEAN L N S[ _ _F _TE 3

_-Ir_Tc_(c_Es so S_C_OS, s S_CO_DS _01L ONLy. 54 S_C_OS

B_K[ ONLY,

2-HI Ek_OIL-FU_.L gATE, LO BROIL-CY_.[_; AT 80s RAT_.

3-FI_ST 40 MIN. I*ll_ I/BROIL OPEI_ATINC ONLY CYCLIN_.

AFTER 443 _41N. LINE I/_AK[ CYCLING Ot_-y AT F'UL__ RATE.

NO_ NO/COU r_R9 I_ .*I_A_ £ ,

16009721 WIRING DIAGRAM 4-8

(_1999 Maytag Appliances Sales Company

Page 41

WW27210

LI N L2

REUIY BOgRD

_AH P/N 2106938

16009721 WIRING DIAGRAM 4-9

©1999 Maytag AppliancesSalesCompany

Page 42

WW27210

LI N

ILa_( !

Nt.MI

_qLUI .J

L2

IBI

@

SP£CF[(Y(]£UT[SFOR(_

Wt_G_A_H PIN 21O6938

160C9721 WIRING DIAGRAM 4-10

©1999 Maytag Appliances Sales Company

Page 43

WW27430, W27430R WW30430, WW30430P

|

0

16009721 WIRING DIAGRAM 4-11

@1999 Maytag Appliances Sales Company

Page 44

WW27430, W27430P, WW30430, WW30430P

tm_mwlmml mw_ m _

LI

m

I,_lf

PlD_V V.B,jt

to ¢m,111_

N=_O°

n_v

w

L P_ KLAV

_m

_ _q_ Ay

_,,_ ._.l_ _u =_,._ _J- =_.

m. _,",_'° ._ I_,,._-

WIRtFIGDfAG_AHP/N 20851_B

16009721 WIRING DIAGRAM 4-12

_1999 Maytag Appliances Sales Company

S_CFI(CYCLERATESFOR[A_U

&S_OKO[H[_IIS

Page 45

JJW8527, JJW8530, JJW9527, JJW9530, JMW8530, JMW8527, JMW9527, JMW9530

i

i

ii

16009721 WIRING DIAGRAM 4-13

€1999 Maytag Appliances Sales Company

Page 46

JJW8527, JJW8530, JJW9527, JJW9530, JMW8530, JMW8527, JMW9527, JMW9530

.m

PPP

L1

_w

..L

"_N$FORF4ER

TO CO_d1ROL

B_UI'_YPLuG J3 BK

RELAY

OBJEEN PLU_ JlO

N 1.2

IW__MGN

LI_LOO_O

MICRQWA'_ _KI AMp

RE_PTACU[

I I

t._.--r--_ J

I

RNSO

..... O..i

OROL_UGDNEUIRAL

CHECI(LGP.,ALCOOES

REO

..L--

o_

-_G3

_0_0

o_

o_o

O"

m LIMIT

8K :.F'_ Q

CI_AL_;_ENT SYMBOLS00 NOT REFLECTI_U_ CONtqOURATION.

NJ. f_r_EDt._lE COLORSN_E ttOTEO_ W_ttTEIi _E_,

_4J_COMPONENTSSHOWNIM "l_P O_t REt.NCEDFO_TION.

'X" INOIC, ATI_5 R_L_y

CON'm0LS MAg_

WtRIE COLORS' OFF

R-REO M Zl0 •

IIKdBLA_K _UU(I: [_ff at 21_'

w_._ _p_E _ _:

G-GREEN

V-_IOt.ET Ggfl k_'_r IL_xF o1_,_

mL'_LU_ TIME D CONNECT BAKE Cdf at

_aamovm o.,, _;

O*OR/_IGE C_V_CT ROAST _ff at

y-Y_OW

u.,i _:

MOTO R f .. _ _-_

O_fN LI_tT

P_IF-.D CI_RUIT BO_R D _t4h D°m CAM SVIRT CH

C_du €_du x I_ _.d x x

C_dm Otd_ X _ _d X X

cydm _,_*, x _ _r_.. d x X

Cyd_ Cyci_ X X

ikq OiL PCB RELAY

0 ELEMENT

_J

_',,,,, x x

x I¢;_'_-_-d X X

Z

SPECIFIC CYCLE RATES FOR EACH

MODE b SPECIFIC ELEMENT IS

AVAILABLE FROM SERVICE.

16009721 WIRING DIAGRAM 4-14

_1999 Maytag Appliances Sales Company

Page 47

JJW8627, JJW8630, JJW9627, JJW9630

i

I

I

I

I

I

i

I

I

j _

i

Z

m

a

I

I

o................ J

16009721 WIRING DIAGRAM 4-15

©1999 Maytag Appliances Sales Company

Page 48

JJW8627, JJW8630, JJW9627, JJW9630

NO_lm:

i, E_llm UNB mmum_r _ iqum_t,

L1 N

V4UTE

NED

L2

m

To _ern_.

..........

mtmA_(D mUllt_

CHECKL_r_. C_

4=OaLINGr._q

may

UAIL_XI_

mcAa_w ION _

l_w... _a.._..ji_.. M r,' R

w R

_- mm_11mw

c_ncL_ MA_(

w_

Om

N

_'_L

m C_CU_ N

x •

x •

x •

x

x

SPECIFIC CYCLE RATES FOR EACH

WIRING DIAGRAM P/N 208512F MODEbSPECIFICELEMENTIS

AVAILABLE FROM SERVICE.

16009721 WIRING DIAGRAM 4-16

01999 Maytag Appliances Sales Company

Page 49

JJW8530, JJW9530 - CANADA MODELS

!

!

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

0

16009721 WIRING DIAGRAM 4-17

@1999 Maytag Appliances Sales Company

Page 50

JJW8530, JJW9530 - CANADA MODELS

_ ca_ m Rv.opP oq W po_

•X, IN0_GATES RELAy

CONTROLS M_

M_SO_ = m I L1 U

OPIER_.TI_N DL6 ! Ot_ OOORL_

OFF X

BAKE X

TIMED B/_JE X

COt_'vlECT BAKE X

T_MED COI¢_CT BAKE X

CON_IECT ROAST X

CLEAN X k

BRGtL X

[_,d ng LO_

L2 LIE LZ LZ L2RS LZ

_'_: Cv,_,, c_. L_,_ x x

_;_: c_*,. cyd. ,_' _,.,._"_ x x

O_ _t _10" _j_ _ padO1_*t _' cyd_ Cyd_ _ L_DO_ X X

Q_ at Zl0" XK_or L_DO_

I Off *t L_0' CYd_ _ _1 ll_t¢h _ P_d X X

O_ _ POWER t_

I Oil *t ;NO* Cy_u Cyd_ x X X

O_ _t POM_ER _ X L _k D_

Off |t aO0" r.v_4t_h _ _d X X

SPECIFIC CYCLE RATES FOR EACI"

MODE 6 SPECIFIC ELEMENT IS

AVAILABLE FROM SER_

BR_L B_(E C/WE 1 OVUGHT LOCI .q/L_

Lee= Door X X

Ewhd_ _ p_d

swk_h m"PH

16009721 WIRING DIAGRAM 4-18

@1999 Maytag Appliances Sales Company

Page 51

Loading...

Loading...