JENNAIR JJW8627BAB, JJW8630AAW, JJW8630AAB, JJW9530AAW, JJW9530AAS Installation Instructions

...

INSTALLATION

Built-In 27²²²² &30²

²

²²

INSTRUCTIONS

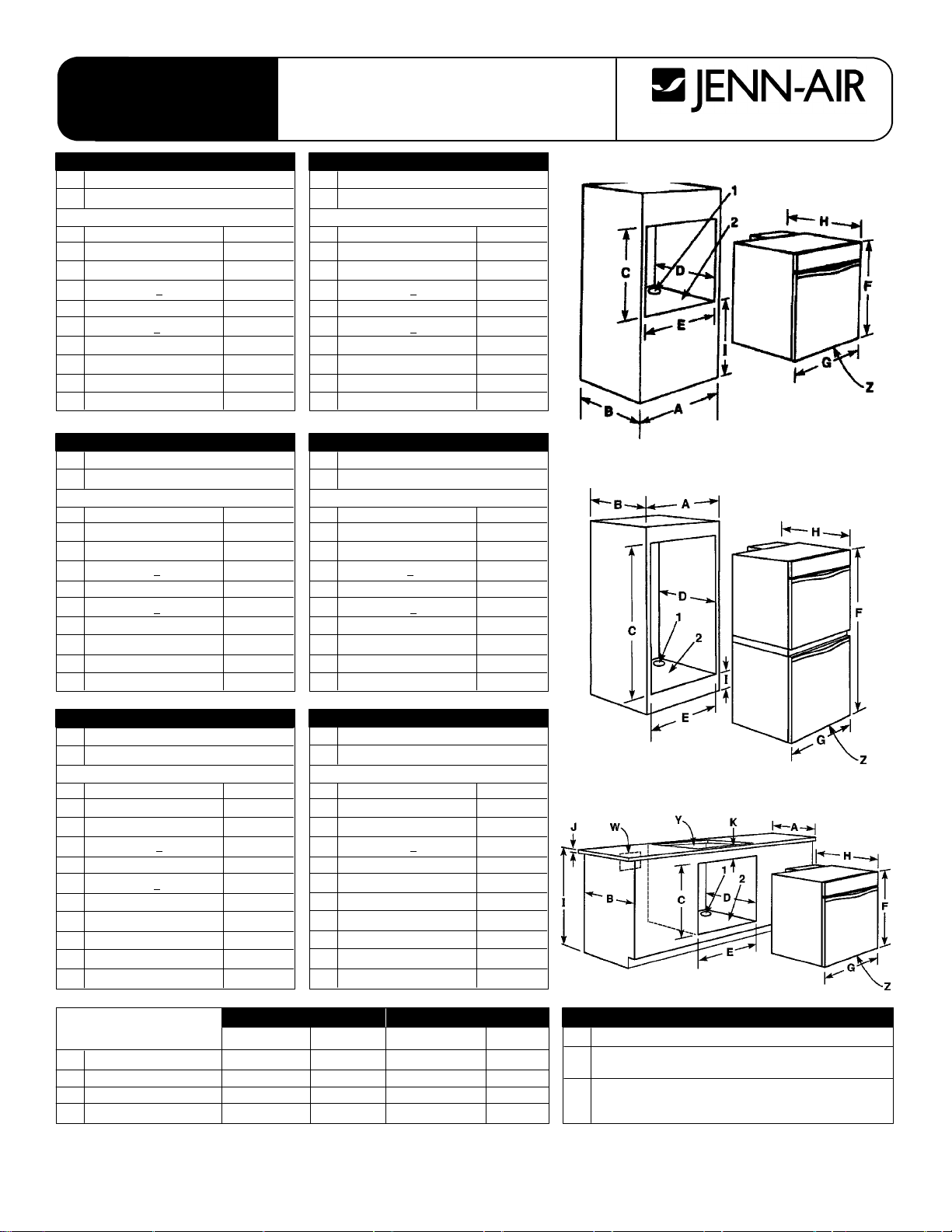

27²²²² SINGLE WALL OVEN

111/4² Dia. Conduit Access Hole*

25/8² Plywood Floor (Must Support 142 lbs.)

DIMENSIONS

inches cm

A 27 MIN 68.58

B 24 MIN 60.96

C 277/16+

D 23 1/2 MIN 59.69

E251/2+

F 27 3/4 70.49

G 26 3/4 67.95

H 24 7/16 62.07

I 4 to 33 10.2 to 83.8

27²²²² DOUBLE WALL OVEN

111/4² Dia. Conduit Access Hole*

25/8² Plywood Floor (Must Support 250 lbs.)

A 27 MIN 68.58

B 24 MIN 60.96

C495/8+

D 23 1/2 MIN 59.69

E251/2+

F 49 15/16 126.84

G 26 3/4 67.95

H 24 7/16 62.07

I 4 to 12 10.2 to 30.5

1/16 69.69

1/16 64.77

DIMENSIONS

inches cm

1/16 126.05

1/16 64.77

Electric Wall Ovens

30²²²² SINGLE WALL OVEN

111/4² Dia. Conduit Access Hole*

25/8² Plywood Floor (Must Support 142 lbs.)

DIMENSIONS

inches cm

A 30 MIN 76.20

B 24 MIN 60.96

C 277/16+

D 23 1/2 MIN 59.69

E 283/16+

F 27 3/4 70.49

G 29 3/4 75.57

H 24 7/16 62.07

I 4 to 33 10.2 to 83.8

30²²²² DOUBLE WALL OVEN

111/4² Dia. Conduit Access Hole*

25/8² Plywood Floor (Must Support 250 lbs.)

A 30 MIN 76.20

B 24 MIN 60.96

C495/8+

D 23 1/2 MIN 59.69

E 283/16+

F 49 15/16 126.84

G 29 3/4 75.57

H 24 7/16 62.07

I 4 to 12 10.2 to 30.5

1/16 69.69

1/16 71.60

DIMENSIONS

inches cm

1/16 126.05

1/16 71.60

403 WEST FOURTH STREET, NORTH D NEWTON, IA 50208

SINGLE WALL OVEN

DOUBLE WALL OVEN

27²²²² WALL OVEN UNDER COUNTER

111/4² Dia. Conduit Access Hole*

25/8² Plywood Floor (Must Support 142 lbs.)

DIMENSIONS

inches cm

A 25 63.50

B 24 MIN 60.96

C 277/16+

D 23 1/2 MIN 59.69

E251/2+

F 27 3/4 70.49

G 26 3/4 67.95

H 24 7/16 62.07

I 36 91.44

J11/2 3.81

1/16 69.69

1/16 64.77

30²²²² WALL OVEN UNDER COUNTER

111/4² Dia. Conduit Access Hole*

25/8² Plywood Floor (Must Support 142 lbs.)

DIMENSIONS

inches cm

A 25 63.50

B 24 MIN 60.96

C 277/16+

D 23 1/2 MIN 59.69

E 28 3/16 71.60

F 27 3/4 70.49

G 29 3/4 75.57

H 24 7/16 62.07

I 36 91.44

J11/2 3.81

1/16 69.69

27²²²² WALL OVEN 30²²²² WALL OVEN

* * COOKTOPS inches cm inches cm

K 4 Burner Gas Glass Top 2 1/8 MIN 5.4 MIN 2 1/8 MIN 5.4 MIN

K Electric 3 1/8 MIN 7.9 MIN 3 1/8 MIN 7.9 MIN

K Induction 3 1/8 MIN 7.9 MIN 3 1/8 MIN 7.9 MIN

K 4 Burner Gas Stamped Top 4 13/16 MIN 12.2 MIN 4 13/16 MIN 12.2 MIN

NOTE:

* Hole must becut as close to corner of cabinet as possible.

** See dealer for approved cooktops.

UNDER COUNTER WALL OVEN

NOTES

Z Do not block air intake slots along bottom of oven.

Y Gas or electric cooktops may be installed over ovens.

See cooktop installation instructions for cutout size.

W Electrical connection for electric cooktop must in adjacent

accessible location. Cooktop and walloven must be on separate

120/240 or 120/208 volt 60 Hz AC circuits.

8101P423-60

(10-01-00)

When installing a 27² wall oven under a 30² cooktop

some interference may occur. The following cutout

notching of the side trims will eliminate the interference of

the side trim to the burner box. After cutting, file the side

trim edges to eliminate burrs.

Installing Bottom Trim Piece

Electrical Connections

Unit to be properly circuit protected and wired according

to local electrical code and National Electrical Code.

It is advisable that the electrical wiring and hookup be

accomplished by a competent electrician.

120/240 VAC or 120/208 VAC 60 Hz. See serial plate on

front of unit for power requirements.

CAUTION

For European style cabinets (flush front) the required

clearance for operation of the oven door is minimum

spacing of 7/8² betweenthecutoutand the door, hinge

or drawer of the cabinet.

Some built-incabinetsmay not be wide enough, due to

their construction, to allow this installation.

1. Cut hole in cabinet to mount oven. Cutout in cabinet

should be level and straight.

NOTE: There are no provisions to level the unit after it

is installed. An oven that is not level could cause poor

baking results.

2. Install plywood floor as shown.

3. Attach unit to the cabinet with four No. 8 x 1² screws

supplied with unit inside of envelope containing these

instructions. Pre-drill holes in cabinet for attachment

screws using 1/8² drill. Oven mounting holes are

provided in side trim.

4. See instructions at right for electrical hook-up.

5. See Use and Care Manual for operating instructions.

The neutral of this unit is grounded to the frame through

the green or solid grounding wire. (The green and the

white wires are twisted together at the termination of the

conduit.) If used on new branch-circuit installations (1996

NEC), mobile homes, recreational vehicles, or in an area

where local codes prohibit grounding through the neutral

conductor, untwist or disconnect the green wire and

connect the green wire to ground in accordance with local

code. Connect the white neutral to the service neutral.

Connect all wires to the branch circuit with approved

connectors. Use copper or aluminum wire. If aluminum

wire is used, use connectors recognized for joining

aluminum to copper.

The chart below recommends the minimum circuit

protection and wire size if the appliance is the only unit on

the circuit.

K.W.RATING

ON SERIAL PLATE

0-- 4.8

4.9 -- 6.9

7.0 -- 9.9

10.0 -- 11.9

12.0 -- 14.9

RECOMMENDED MINIMUM

CIRCUIT PROTECTION

IN AMPERS

20

30

40

50

60

WIRE SIZE

(AWG)

12

10

8

8

6

Service

Interrupt the source of electricity to the unit when

attempting to repair or service the oven. Failure to do this

could result in a dangerous or even fatal shock.

IMPORTANT - SAVE FOR LOCAL ELECTRICAL INSPECTOR’S USE

Loading...

Loading...