Jenn-Air JIM158XXRS0, JIM158XXCX0 Owner’s Manual

JENN-AIRTM ICEMAKER

F._,BRICADEHIELOJENN-AIR"

MACHINE.A.GLAqONS JENN-AIR_

USE& CAREGUIDE

For questions about features, operation/performance, parts, accessories, or service, call:

1-800-JENNAIR (1-800-536-6247) or visit our website at www.jennair.com.

In Canada, call: 1-800-807-6777, or visit our website at www.jennair.ca.

MANUAL DEUSOY CUIDADO

Si tiene preguntas respecto alas caracteristicas, funcionamiento, rendimiento, partes, accesorios o servicio tecnico, Ilame al:

1-800-JENNAIR (1-800-536-6247) o visite nuestro sitio de internet: www.jennair.com.

En CanadA, Ilame al: 1-800-807-6777, o visite nuestro sitio de internet: www.jennair.ca.

GUIDE D'UTILISATIONETD'ENTRETIEN

Au Canada, pour assistance, installation ou service, composez le 1-800-807-6777 ou visitez notre site Web www.jennair.ca.

Table of Contents/[ndice/Table des matieres ...................................................................................... 2

_T]ENN-AIRTo

W10206441 B

TABLEOF CONTENTS

ICE MAKER SAFETY ...................................................................... 3

INSTALLATION INSTRUCTIONS .................................................. 3

Tools and Parts ............................................................................ 3

Custom Panel Dimensions ........................................................... 3

Unpack the Ice Maker .................................................................. 5

Location Requirements ................................................................ 5

Electrical Requirements ............................................................... 6

Water Supply Requirements ........................................................ 6

Leveling ........................................................................................ 6

Connect Water Supply ................................................................. 7

Drain Connection ......................................................................... 8

Install Custom Overlay Panel ....................................................... 8

Ice Maker Door ............................................................................. 9

Normal Sounds .......................................................................... 10

[NDICE

SEGURIDAD DE LA FABRICA DE HIELO .................................. 20

INSTRUCCIONES DE INSTALACION ......................................... 20

Herramientas y piezas ................................................................ 20

Dimensiones del panel hecho a la medida ................................ 20

Desempaque la fabrica de hielo ................................................ 22

Requisitos de ubicacion ............................................................. 22

Requisitos electricos .................................................................. 23

Requisitos del suministro de agua ............................................. 23

Nivelacion ................................................................................... 24

Conexion del suministro de agua .............................................. 24

Conexion del desagOe ............................................................... 25

Instale el panel de revestimiento hecho a la medida ................ 26

Puerta de lafabrica de hielo ...................................................... 27

Sonidos normales ...................................................................... 29

ICE MAKER USE ........................................................................... 11

How Your Ice Maker Works ....................................................... 11

Using the Controls ...................................................................... 11

ICE MAKER CARE ........................................................................ 12

Cleaning ...................................................................................... 12

Vacation and Moving Care ......................................................... 14

TROUBLESHOOTING .................................................................. 15

Ice Maker Operation ................................................................... 15

Ice Production ............................................................................ 15

Ice Quality ................................................................................... 16

Plumbing Problems .................................................................... 16

ASSISTANCE OR SERVICE ......................................................... 17

In the U.S.A ................................................................................ 17

In Canada ................................................................................... 17

WAR RANTY .................................................................................. 18

USO DE LA FABRICA DE HIELO ................................................ 29

Como funciona su fabrica de hielo ............................................ 29

Uso de loscontroles .................................................................. 30

CUlDADO DE LA FABRICA DE HIELO ....................................... 31

Limpieza ..................................................................................... 31

Cuidado durante las vacaciones y mudanzas ........................... 34

SOLUCION DE PROBLEMAS ...................................................... 35

Funcionamiento de la fabrica de hielo ....................................... 35

Produccion de hielo ................................................................... 36

Calidad del hielo ......................................................................... 36

Problemas de plomeria .............................................................. 36

AYUDA O SERVICIO TI_CNICO ................................................... 37

En los EE.UU.............................................................................. 37

En Canada .................................................................................. 37

GARANTiA ..................................................................................... 38

TABLEDESMATIERES

SI_CURITI_ DE LA MACHINE ._,GLA(_,ONS................................ 39

INSTRUCTIONS D'INSTALLATION ............................................ 39

Outillage et pieces ...................................................................... 39

Dimensions du panneau personnalise ....................................... 39

Deballage de la machine &gla(;ons ........................................... 41

Exigences d'emplacement ......................................................... 41

Specifications electriques .......................................................... 42

Specifications de I'alimentation en eau ..................................... 42

Nivellement ................................................................................. 42

Raccordement &la canalisation d'eau ...................................... 43

Raccordement au drain de vidange ........................................... 44

Installation du panneau decoratif personnalise ......................... 45

Porte de la machine a gla(;ons .................................................. 45

Sons normaux ............................................................................ 47

2

UTILISATION DE LA MACHINE ,&GLA_ONS ............................ 47

Fonctionnement de la machine a gla(;ons ................................. 47

Utilisation des commandes ........................................................ 48

ENTRETIEN DE LA MACHINE ,&GLA_ONS .............................. 48

Nettoyage ................................................................................... 48

Precautions a prendre avant les vacances

ou un dem6nagement ................................................................ 51

DI_PAN NAG E................................................................................. 52

Fonctionnement de la machine & gla(_ons ................................. 52

Production de gla£_ons............................................................... 52

Qualite des gla£;ons.................................................................... 53

Problemes de plomberie ............................................................ 53

ASSISTANCE OU SERVICE ......................................................... 54

Aux #tats-Unis ............................................................................ 54

Au Canada .................................................................................. 54

GARANTIE ..................................................................................... 55

ICEMAKERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury when using your ice maker, follow these basic

precautions:

• Plug into a grounded 3 prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Do not use an extension cord.

• Disconnect power before cleaning.

• Disconnect power before servicing.

• Replace all parts and panels before operating.

• Use two or more people to move and install ice maker.

SAVE THESE INSTRUCTIONS

INSTALLATIONINSTRUCTIONS

TOOLS NEEDED:

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

• Cordless drill • Masking tape

• Phillips screwdriver • Tape measure

• Router or planer • Towel or piece of

• Pencil

PARTS NEEDED:

Custom Overlay Door Panel--See "Custom Panel Installation

Instructions," #8 x 1/2"pan head wood screws (8)

PARTS SUPPLIED:

• Adhesive pads (4)

cardboard

If you plan to install a custom overlay panel, you will need to

make the panel yourself or consult a qualified cabinetmaker or

carpenter.

IMPORTANT:

• The thickness of the overlay panel must be 3/4"(1.91 cm).

• Overlay panel must not weigh more than 8 Ibs (3.62 kg).

• Overlay panels weighing more than recommended may

cause damage to your ice maker.

• Match wood grain direction with that of adjacent

cabinets.

• Sand panel edges to provide a smooth finish.

• Use moisture sealer on both sides and all edges of the

panel to avoid damage from moisture.

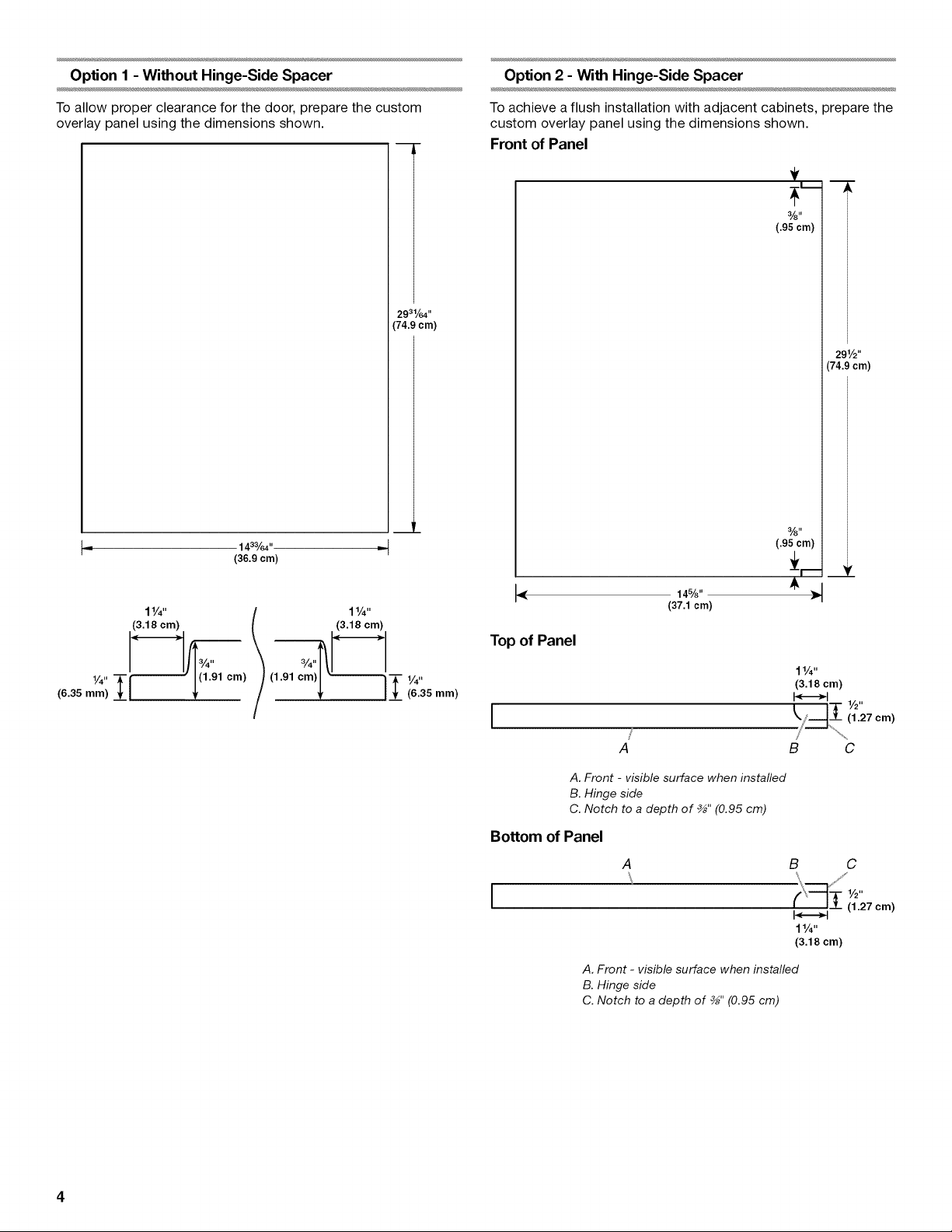

Option I - Without Hinge-Side Spacer

Option 2 - With Hinge-Side Spacer

To allow proper clearance for the door, prepare the custom

overlay panel using the dimensions shown.

2931/64"

(74.9 cm)

I"" 143%4"

(36.9crn)

(3.18cm) (3.18 cm)

To achieve aflush installationwith adjacent cabinets, prepare the

custom overlay panel using the dimensions shown.

d

Front of Panel

(.95crn)

291/2"

(74.9 cm)

(.95crn)

_r

• 14%"

(37.1 cm)

Top of Panel

' 'il i

(6.35 mm) (6.35 mm)

11/4" / _ 11/4'__

I

A. Front - visible surface when installed

B. Hinge side

C. Notch to a depth of _" (0.95 cm)

Bottom of Panel

I

A. Front - visible surface when installed

B. Hinge side

C. Notch to a depth of _" (0.95 cm)

11/4"

(3.18 cm)

'_" 1/2"

/

A

A

_.t_(1.27cm)

B C

B C

_ J

I-_'4

11/4''

(3.18 cm)

(1.27cm)

Excessive Weight Hazard

Use two or more people to move and install ice maker.

Failure to do so can result in back or other injury.

Removing Packaging Materials

Remove tape and glue from your ice maker before using.

• To remove any remaining tape or glue from the exterior of the

ice maker, rub the area briskly with your thumb. Tape or glue

residue can also be easily removed by rubbing a small

amount of liquid dish soap over the adhesive with your

fingers. Wipe with warm water and dry.

• Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. Do not

use chlorine bleach on the stainless steel surfaces of the ice

maker. These products can damage the surface of your ice

maker.

Cleaning Before Use

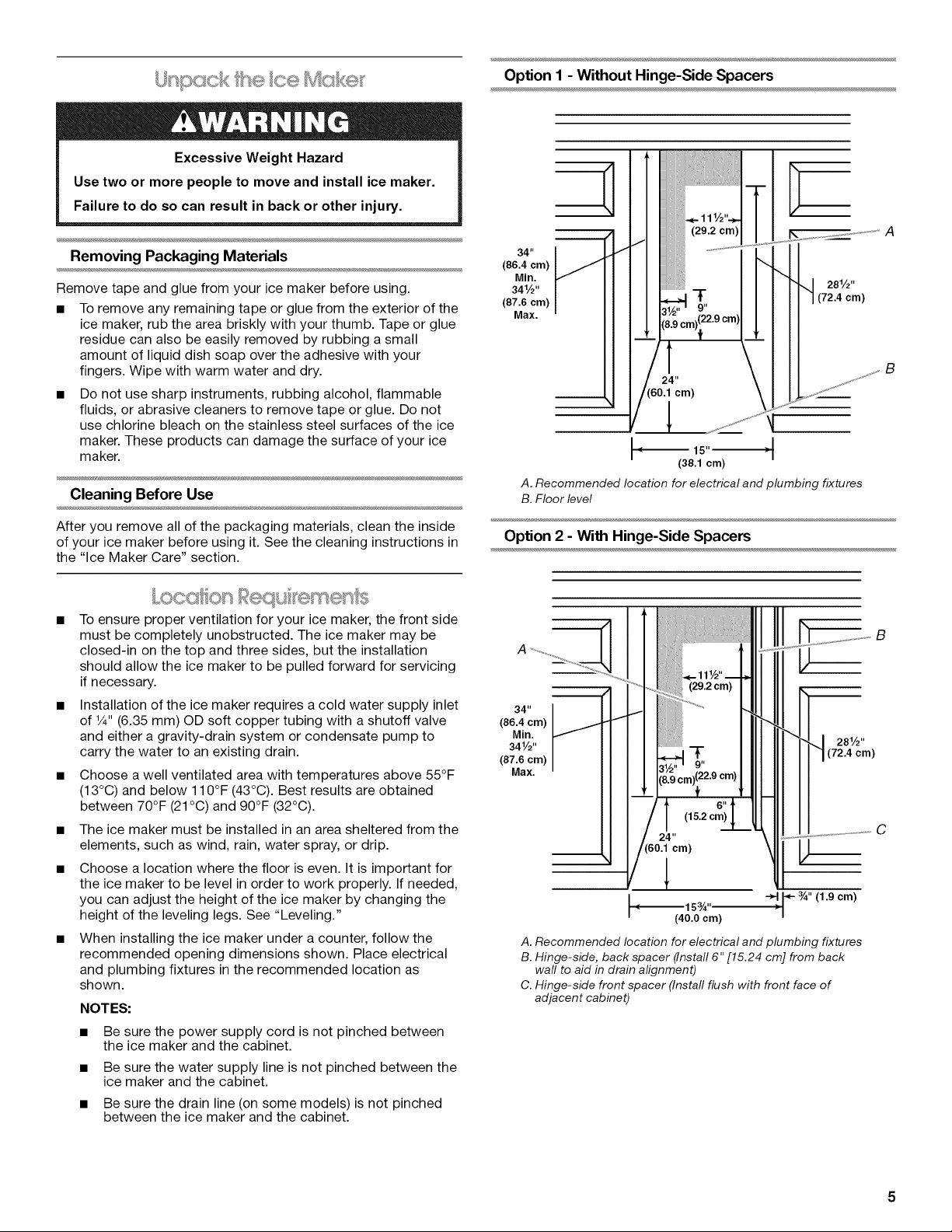

Option I - Without Hinge-Side Spacers

34 'l

(86.4 cm)

Min.

341/2,,

(87.6 cm)

Max.

cm)

I-'_ 15"

A. Recommended location for electrical and plumbing fixtures

B.Floor level

(38.1 cm)

A

281/2,,

(72.4 cm)

B

After you remove all of the packaging materials, clean the inside

of your ice maker before using it. See the cleaning instructions in

the "Ice Maker Care" section.

• To ensure proper ventilation for your ice maker, the front side

must be completely unobstructed. The ice maker may be

closed-in on the top and three sides, but the installation

should allow the ice maker to be pulled forward for servicing

if necessary.

• Installation of the ice maker requires acold water supply inlet

of 1/4"(6.35 mm) OD soft copper tubing with a shutoff valve

and either a gravity-drain system or condensate pump to

carry the water to an existing drain.

• Choose a well ventilated area with temperatures above 55°F

(13°C) and below 110°F (43°C). Best results are obtained

between 70°F (21°C) and 90°F (32°C).

• The ice maker must be installed in an area sheltered from the

elements, such as wind, rain, water spray, or drip.

• Choose a location where the floor is even. It is important for

the ice maker to be level in order to work properly. If needed,

you can adjust the height of the ice maker by changing the

height of the leveling legs. See "Leveling."

• When installing the ice maker under a counter, follow the

recommended opening dimensions shown. Place electrical

and plumbing fixtures in the recommended location as

shown.

NOTES:

• Be sure the power supply cord is not pinched between

the ice maker and the cabinet.

• Be sure the water supply line is not pinched between the

ice maker and the cabinet.

• Be sure the drain line (on some models) is not pinched

between the ice maker and the cabinet.

Option 2 - With Hinge-Side Spacers

34"

(86.4 cm)

Min.

341/2,,

(87.6 cm)

Max.

A. Recommended location for electrical and plumbing fixtures

B. Hinge-side, back spacer (Install 6" [15.24 cm] from back

wall to aid in drain alignment)

C. Hinge-side front spacer (Install flush with front face of

adjacent cabinet)

B

281/2,,

(72.4 cm)

C

E ¸ _ _:_,_,_ _ _E_/,,_ _£_

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Before you move your ice maker into its final location, it is

important to make sure you have the proper electrical

connection:

A 115 Volt, 60 Hz., AC only, 15- or 20-amp electrical supply,

properly grounded in accordance with the National Electrical

Code and local codes and ordinances, is required.

It is recommended that a separate circuit, serving only your ice

maker, be provided. Use a receptacle which cannot be turned off

by a switch or pull chain.

IMPORTANT: If this product is connected to a GFCI (Ground

Fault Circuit Interrupter) equipped outlet, nuisance tripping of the

power supply may occur, resulting in loss of cooling. Ice quality

may be affected. If nuisance tripping has occurred, and if the

condition of the ice appears poor, dispose of it.

Recommended grounding method

The ice maker must be grounded. The ice maker is equipped with

a power supply cord having a 3 prong grounding plug. The cord

must be plugged into a mating, 3 prong, grounding-type wall

receptacle, grounded in accordance with the National Electrical

Code and local codes and ordinances. If a mating wall receptacle

is not available, it is the personal responsibility of the customer to

have a properly grounded, 3 prong wall receptacle installed by a

qualified electrician.

A cold water supply with water pressure of between 30 and

120 psi (207 and 827 kPa) is required to operate the ice maker. If

you have questions about your water pressure, call a licensed,

qualified plumber.

Reverse Osmosis Water Supply

IM PORTANT:

• Reverse osmosis water filtration systems can be used only

with ice maker installations that have a gravity drain. A

reverse osmosis system is not recommended for ice makers

that have a drain pump installed.

• The pressure of the water supply coming out of a reverse

osmosis system going to the water inlet valve of the ice

maker needs to be between 30 and 120 psi (207 and

827 kPa).

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the reverse osmosis

system needs to be a minimum of 40 to 60 psi (276 to 414 kPa).

NOTE: The reverse osmosis system must provide 1 gal. (3.8 L) of

water per hour to the ice maker for proper ice maker operation. If

a reverse osmosis system is desired, only a whole-house

capacity reverse osmosis system, capable of maintaining the

steady water supply required by the ice maker, is recommended.

Faucet capacity reverse osmosis systems are not able to

maintain the steady water supply required by the ice maker.

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 to 414 kPa):

• Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

• Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

If you have questions about your water pressure, call a licensed,

qualified plumber.

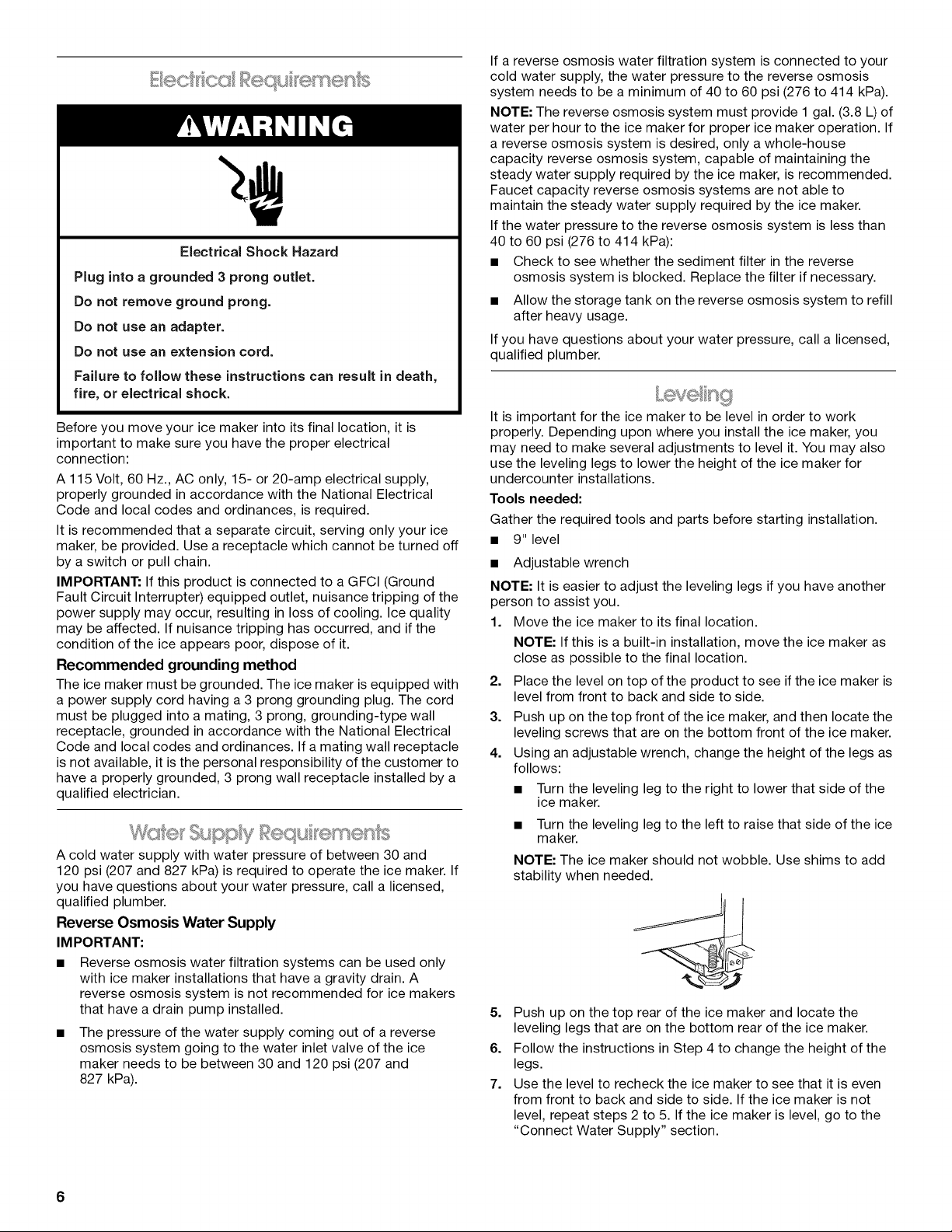

It is important for the ice maker to be level in order to work

properly. Depending upon where you install the ice maker, you

may need to make several adjustments to level it. You may also

use the leveling legs to lower the height of the ice maker for

undercounter installations.

Tools needed:

Gather the required tools and parts before starting installation.

• 9" level

• Adjustable wrench

NOTE: It is easier to adjust the leveling legs if you have another

person to assist you.

1. Move the ice maker to its final location.

NOTE: If this is a built-in installation, move the ice maker as

close as possible to the final location.

2. Place the level on top of the product to see if the ice maker is

level from front to back and side to side.

3. Push up on the top front of the ice maker, and then locate the

leveling screws that are on the bottom front of the ice maker.

4. Using an adjustable wrench, change the height of the legs as

follows:

• Turn the leveling leg to the right to lower that side of the

ice maker.

• Turn the leveling leg to the left to raise that side of the ice

maker.

NOTE: The ice maker should not wobble. Use shims to add

stability when needed.

5. Push up on the top rear of the ice maker and locate the

leveling legs that are on the bottom rear of the ice maker.

6. Follow the instructions in Step 4 to change the height of the

legs.

7. Use the level to recheck the ice maker to see that it is even

from front to back and side to side. If the ice maker is not

level, repeat steps 2 to 5. If the ice maker is level, go to the

"Connect Water Supply" section.

6

Read all directions before you begin.

IMPORTANT:

• Plumbing shall be installed in accordance with the

International Plumbing Code and any local codes and

ordinances.

• Use copper tubing or Whirlpool supply line, Part Number

8212547RP, and check for leaks.

• Install tubing only in areas where temperatures will remain

above freezing.

Tools needed:

Gather the required tools and parts before starting installation.

• Flat-blade screwdriver

• 7Ae"and 1/2"open-end wrenches or two adjustable wrenches

• 1/4"nut driver

NOTE: Do not use a piercing-type or 3Ae"(4.76 mm) saddle valve

which reduces water flow and clogs more easily.

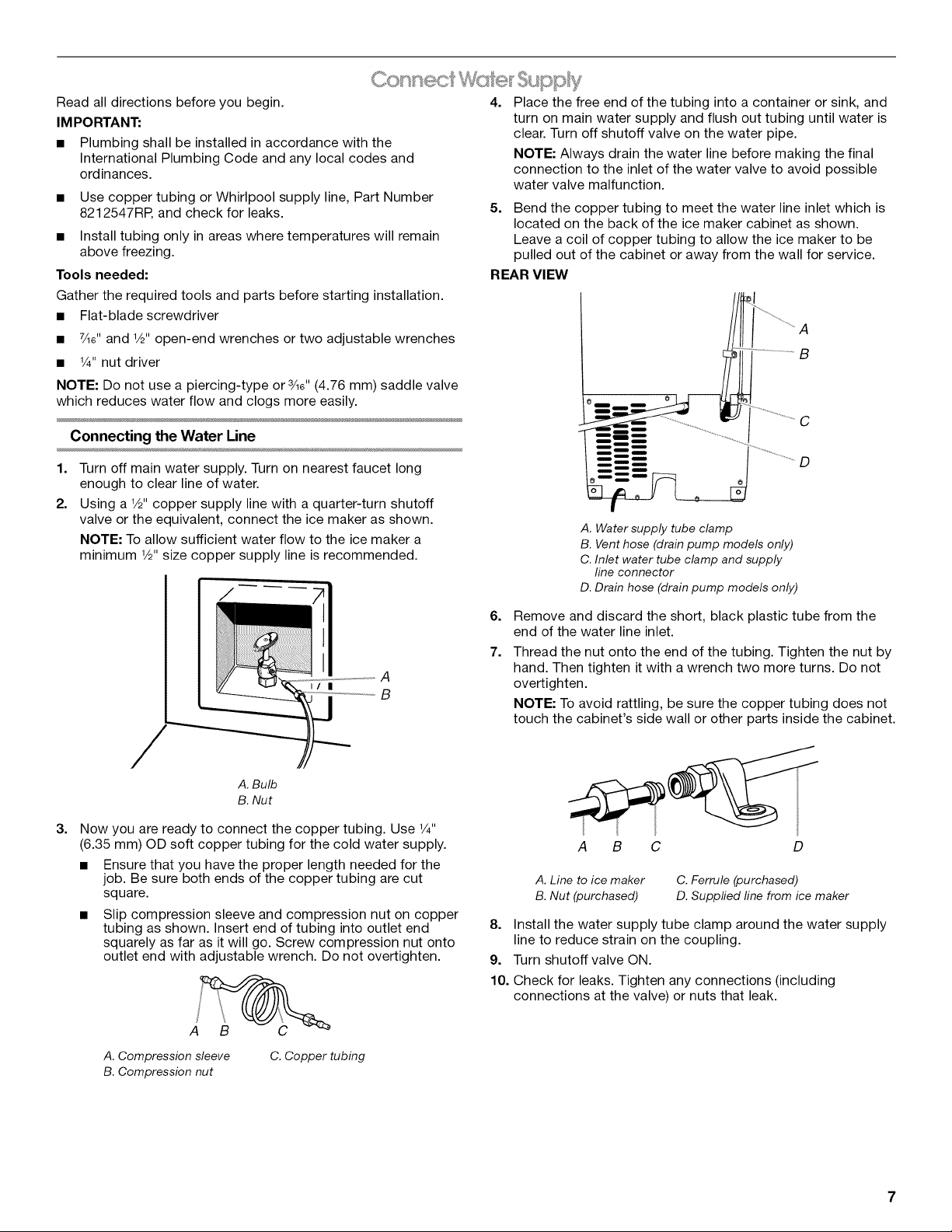

Connecting the Water Line

1,

Turn off main water supply. Turn on nearest faucet long

enough to clear line of water.

2.

Using a 1/2"copper supply line with a quarter-turn shutoff

valve or the equivalent, connect the ice maker as shown.

NOTE: To allow sufficient water flow to the ice maker a

minimum 1/2"size copper supply line is recommended.

I/ II

A

B

4,

Place the free end of the tubing into a container or sink, and

turn on main water supply and flush out tubing until water is

clear. Turn off shutoff valve on the water pipe.

NOTE: Always drain the water line before making the final

connection to the inlet of the water valve to avoid possible

water valve malfunction.

5. Bend the copper tubing to meet the water line inlet which is

located on the back of the ice maker cabinet as shown.

Leave a coil of copper tubing to allow the ice maker to be

pulled out of the cabinet or away from the wall for service.

REAR VIEW

B

C

D

A. Water supply tube clamp

B. Vent hose (drain pump models only)

C. Inlet water tube clamp and supply

line connector

D. Drain hose (drain pump models only)

6,

Remove and discard the short, black plastic tube from the

end of the water line inlet.

7.

Thread the nut onto the end of the tubing. Tighten the nut by

hand. Then tighten it with a wrench two more turns. Do not

overtighten.

NOTE: To avoid rattling, be sure the copper tubing does not

touch the cabinet's side wall or other parts inside the cabinet.

A. Bulb

B. Nut

3,

Now you are ready to connect the copper tubing. Use 1/4"

(6.35 mm) OD soft copper tubing for the cold water supply.

• Ensure that you have the proper length needed for the

job. Be sure both ends of the copper tubing are cut

square.

Slip compression sleeve and compression nut on copper

tubing as shown. Insert end of tubing into outlet end

squarely as far as it will go. Screw compression nut onto

outlet end with adjustable wrench. Do not overtighten.

A. Compression sleeve

B. Compression nut

C. Copper tubing

A B C D

A. Line to ice maker

B. Nut (purchased)

C. Ferrule (purchased)

D. Suppfied fine from ice maker

8. Install the water supply tube clamp around the water supply

line to reduce strain on the coupling.

9. Turn shutoff valve ON.

10. Check for leaks. Tighten any connections (including

connections at the valve) or nuts that leak.

Connecting the Drain

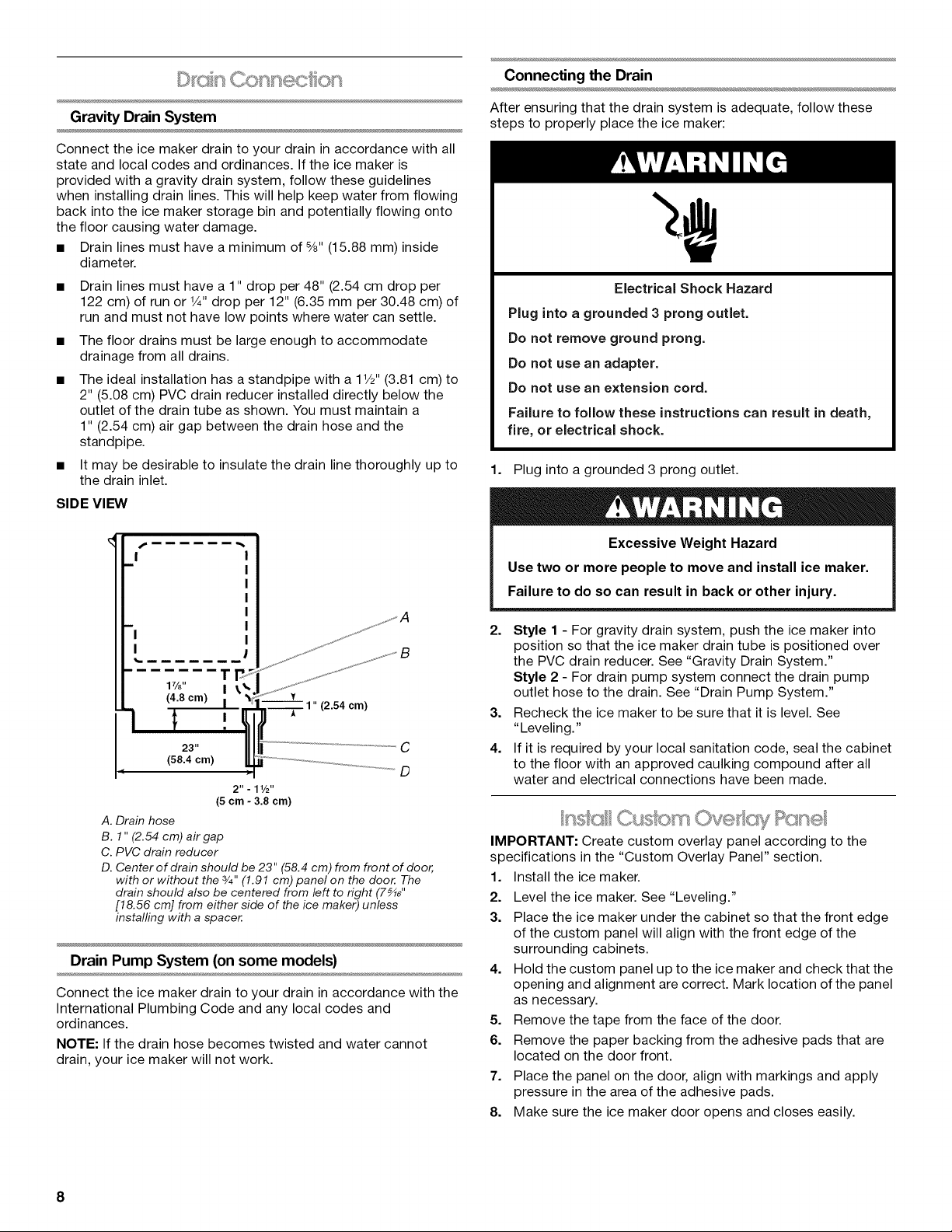

Gravity Drain System

Connect the ice maker drain to your drain in accordance with all

state and local codes and ordinances. If the ice maker is

provided with a gravity drain system, follow these guidelines

when installing drain lines. This will help keep water from flowing

back into the ice maker storage bin and potentially flowing onto

the floor causing water damage.

• Drain lines must have a minimum of 5/8"(15.88 mm) inside

diameter.

• Drain lines must have a 1" drop per 48" (2.54 cm drop per

122 cm) of run or V4"drop per 12" (6.35 mm per 30.48 cm) of

run and must not have low points where water can settle.

• The floor drains must be large enough to accommodate

drainage from all drains.

• The ideal installation has a standpipe with a 1W' (3.81 cm) to

2" (5.08 cm) PVC drain reducer installed directly below the

outlet of the drain tube as shown. You must maintain a

1" (2.54 cm) air gap between the drain hose and the

standpipe.

• It may be desirable to insulate the drain line thoroughly up to

the drain inlet.

SIDE VIEW

After ensuring that the drain system is adequate, follow these

steps to properly place the ice maker:

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Plug into a grounded 3 prong outlet.

Excessive Weight Hazard

Use two or more people to move and install ice maker.

Failure to do so can result in back or other injury.

I

I

T

(4.8 cm)

23 II

(58.4 cm)

2,,. 11/d,

(5 cm - 3.8 cm)

A. Drain hose

B. 1" (2.54 cm) air gap

C. PVC drain reducer

D. Center of drain should be 23" (58.4 cm) from front of door,

with or without the 3/4"(1.91 cm) panel on the door. The

drain should also be centered from left to right (7_/'

[18.56 cm] from either side of the ice maker) unless

instalfing with a spacer.

(2.54 cm)

C

D

Drain Pump System (on some models)

Connect the ice maker drain to your drain in accordance with the

International Plumbing Code and any local codes and

ordinances.

NOTE: If the drain hose becomes twisted and water cannot

drain, your ice maker will not work.

2. Style 1 - For gravity drain system, push the ice maker into

position so that the ice maker drain tube is positioned over

the PVC drain reducer. See "Gravity Drain System."

Style 2 - For drain pump system connect the drain pump

outlet hose to the drain. See "Drain Pump System."

3. Recheck the ice maker to be sure that it is level. See

"Leveling."

4. If it is required by your local sanitation code, seal the cabinet

to the floor with an approved caulking compound after all

water and electrical connections have been made.

IMPORTANT: Create custom overlay panel according to the

specifications in the "Custom Overlay Panel" section.

1. Install the ice maker.

2. Level the ice maker. See "Leveling."

3. Place the ice maker under the cabinet so that the front edge

of the custom panel will align with the front edge of the

surrounding cabinets.

4. Hold the custom panel up to the ice maker and check that the

opening and alignment are correct. Mark location of the panel

as necessary.

5. Remove the tape from the face of the door.

6. Remove the paper backing from the adhesive pads that are

located on the door front.

7. Place the panel on the door, align with markings and apply

pressure in the area of the adhesive pads.

8. Make sure the ice maker door opens and closes easily.

8

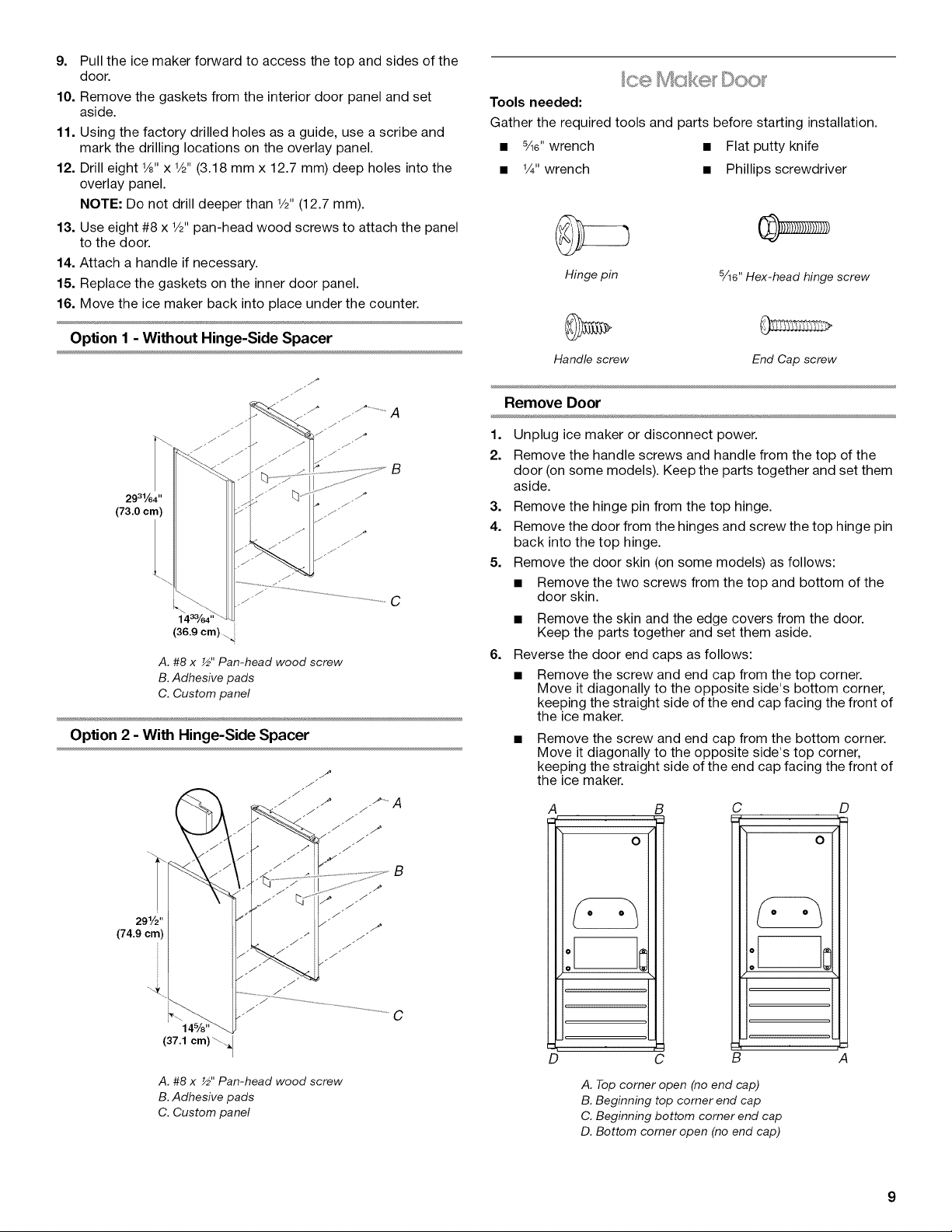

9. Pull the ice maker forward to access the top and sides of the

door.

10. Remove the gaskets from the interior door panel and set

aside.

11. Using the factory drilled holes as a guide, use a scribe and

mark the drilling locations on the overlay panel.

12. Drill eight 1/8"x 1/2"(3.18 mm x 12.7 mm) deep holes into the

overlay panel.

NOTE: Do not drill deeper than 1/2"(12.7 mm).

13. Use eight #8 x 1/2"pan-head wood screws to attach the panel

to the door.

14. Attach a handle if necessary.

15. Replace the gaskets on the inner door panel.

16. Move the ice maker back into place under the counter.

Option I - Without Hinge-Side Spacer

L

1433/64'

(36.9 cm)

A. #8 x ½" Pan-head wood screw

B.Adhesive pads

C. Custom panel

Option 2 - With Hinge-Side Spacer

C

Tools needed:

Gather the required tools and parts before starting installation.

• 5/le" wrench • Flat putty knife

• 1/4"wrench • Phillips screwdriver

Hinge pin 5_6" Hex-head hinge screw

Handlescrew

End Cap screw

Remove Door

1. Unplug ice maker or disconnect power.

2. Remove the handle screws and handle from the top of the

door (on some models). Keep the parts together and set them

aside.

3. Remove the hinge pin from the top hinge.

4. Remove the door from the hinges and screw the top hinge pin

back into the top hinge.

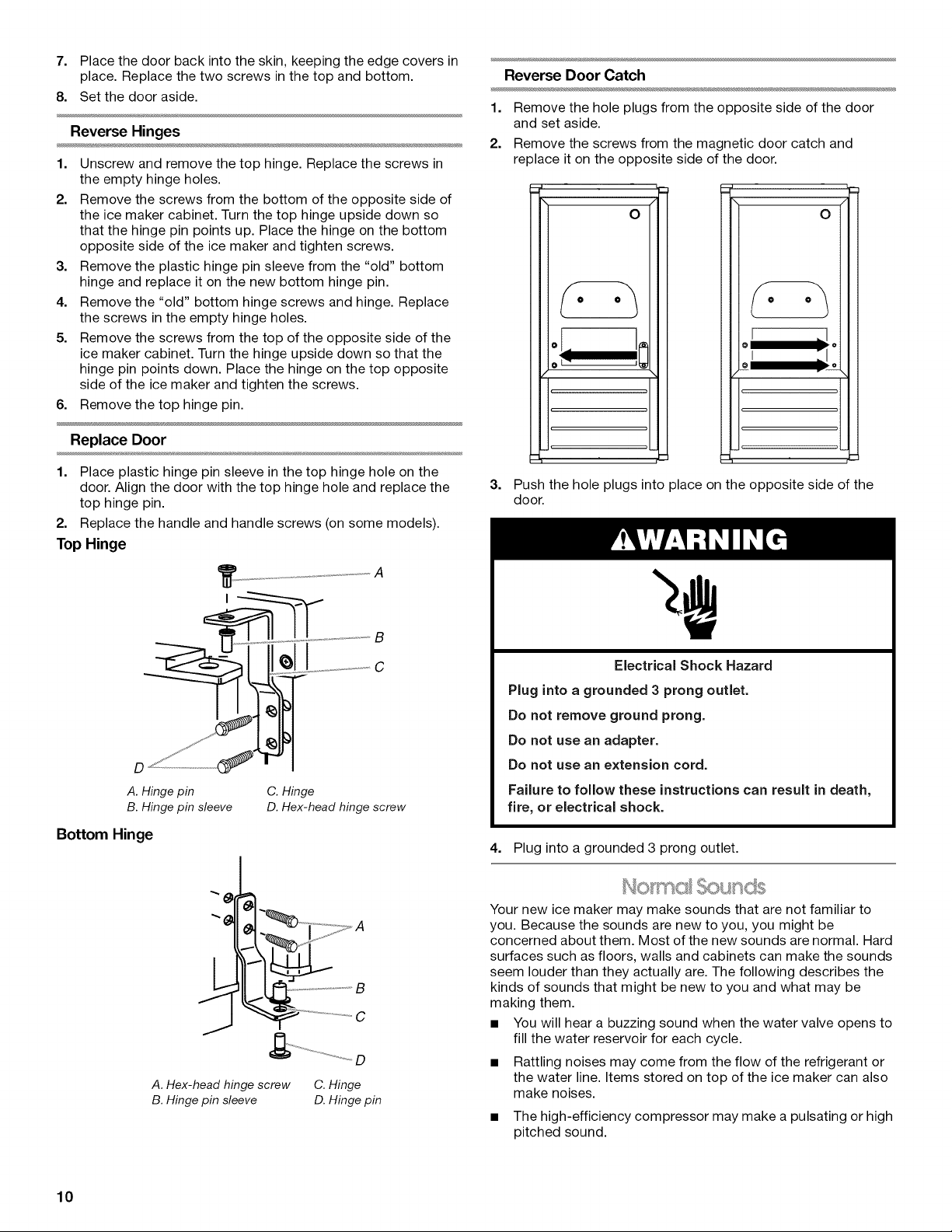

5. Remove the door skin (on some models) as follows:

• Remove the two screws from the top and bottom of the

door skin.

• Remove the skin and the edge covers from the door.

Keep the parts together and set them aside.

6.

Reverse the door end caps as follows:

• Remove the screw and end cap from the top corner.

Move it diagonally to the opposite side's bottom corner,

keeping the straight side of the end cap facing the front of

the ice maker.

Remove the screw and end cap from the bottom corner.

Move it diagonally to the opposite side's top corner,

keeping the straight side of the end cap facing the front of

the ice maker.

291/2"

(74.9 cm)

(37.1 cm) _._

A. #8x ½" Pan-head wood screw

B.Adhesive pads

C. Custom panel

A B C D

o

B

° 0

o

C

D C B A

A. Top corner open (no end cap)

B. Beginning top corner end cap

C. Beginning bottom corner end cap

D. Bottom corner open (no end cap)

7. Place the door back into the skin, keeping the edge covers in

place. Replace the two screws in the top and bottom.

8. Set the door aside.

Reverse Hinges

1. Unscrew and remove the top hinge. Replace the screws in

the empty hinge holes.

2. Remove the screws from the bottom of the opposite side of

the ice maker cabinet. Turn the top hinge upside down so

that the hinge pin points up. Place the hinge on the bottom

opposite side of the ice maker and tighten screws.

3. Remove the plastic hinge pin sleeve from the "old" bottom

hinge and replace it on the new bottom hinge pin.

4. Remove the "old" bottom hinge screws and hinge. Replace

the screws in the empty hinge holes.

5. Remove the screws from the top of the opposite side of the

ice maker cabinet. Turn the hinge upside down so that the

hinge pin points down. Place the hinge on the top opposite

side of the ice maker and tighten the screws.

6. Remove the top hinge pin.

Replace Door

Reverse Door Catch

1. Remove the hole plugs from the opposite side of the door

and set aside.

2. Remove the screws from the magnetic door catch and

replace it on the opposite side of the door.

1. Place plastic hinge pin sleeve in the top hinge hole on the

door. Align the door with the top hinge hole and replace the

top hinge pin.

2. Replace the handle and handle screws (on some models).

Top Hinge

I

B

C

D

A. Hinge pin C. Hinge

B. Hinge pin sleeve D. Hex-head hinge screw

Bottom Hinge

J

A. Hex-head hinge screw

B. Hinge pin sleeve

C.Hinge

D.Hingepin

3.

Push the hole plugs into place on the opposite side of the

door.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

4. Plug into a grounded 3 prong outlet.

Hos"mc un@

Your new ice maker may make sounds that are not familiar to

you. Because the sounds are new to you, you might be

concerned about them. Most of the new sounds are normal. Hard

surfaces such as floors, walls and cabinets can make the sounds

seem louder than they actually are. The following describes the

kinds of sounds that might be new to you and what may be

making them.

• You will hear a buzzing sound when the water valve opens to

fill the water reservoir for each cycle.

• Rattling noises may come from the flow of the refrigerant or

the water line. Items stored on top of the ice maker can also

make noises.

• The high-efficiency compressor may make a pulsating or high

pitched sound.

10

Water running over the evaporator plate may make a

splashing sound.

Water running from the evaporator plate to the water reservoir

may make a splashing sound.

As each cycle ends, you may hear a gurgling sound due to

the refrigerant flowing in your ice maker.

You may hear air being forced over the condenser by the

condenser fan.

During the harvest cycle, you may hear a "thud" when the ice

sheet slides from the evaporator onto the cutter grid.

When you first start the ice maker, you may hear water

running continuously. The ice maker is programmed to run a

rinse cycle before it begins to make ice.

ICE MAKERUSE

5.

Cubes fall into the storage bin. When the bin is full, the ice

maker shuts off automatically and restarts when more ice is

needed. The ice bin is not refrigerated, and some melting will

occur. The amount of melting varies with room temperature.

NOTE: As the room and water temperatures vary, so will the

amount of ice produced and stored. This means that higher

operating temperatures result in reduced ice production.

When you first start your ice maker, the water pan will fill and the

system will rinse itself before starting to make ice. The rinsing

process takes about 5 minutes.

Under normal operating conditions, the ice maker will cycle at

preset temperatures. The ice level sensor located in the ice

storage bin will monitor the ice levels.

IMPORTANT:

• If the water supply to the ice maker is turned off, be sure to

set the ice maker control to OFR

• The ice maker is designed to make clear ice from the majority

of water sources on a daily basis. If your results are

unsatisfactory, your water may need to be filtered or treated.

The Ice Making Process

1. Water is constantly circulated over a freezing plate. As the

water freezes into ice, the minerals in the water are rejected.

This produces a sheet of ice with a low mineral content.

1. To start the normal ice making cycle, press ON.

2. To stop ice maker operation, press OFF.

On Control Clean

Off Lock Service Re set

O-Q-O-Q

NOTES:

• Pressing the ON/OFF switch does not shut off power to

the ice maker.

• Allow 24 hours to produce the first batch of ice. Discard

the first batch produced.

Control Lock

The control panel can be turned off for easy cleaning or to avoid

unintentional activation by children or small pets.

NOTE: The control lock feature does not shut off power to the ice

maker or to the ice maker bin light. It simply deactivates the

control panel.

1. To lock the control panel, press and hold the Control Lock

button until the indicator appears.

2. To unlock the control panel, press and hold the Control Lock

button until the indicator disappears.

2. When the desired thickness is reached, the ice sheet is

released and slides onto a cutter grid. The grid divides the

sheet into individual cubes.

3.

The water containing the rejected minerals is drained after

each freezing cycle.

4.

Fresh water enters the machine for the next ice making cycle.

Service

The service light indicates when service is needed. If the service

light turns on, turn the ice maker off and back on. If the service

light turns on again, call for service.

Clean/Reset

The Clean/Reset Status light will help you know when it is time to

clean your ice maker. The light will change to yellow. This tells

you it is almost time to clean your ice maker. It is recommended

that you clean the ice maker when the status light changes to red

OR ice production decreases significantly. To clean your ice

maker, see "Ice Maker System" in the "Cleaning" section.

11

ICEMAKERCARE

The ice making system and the air cooled condenser need to be

cleaned regularly for the ice maker to operate at peak efficiency

and to avoid premature failure of system components. See the

"Ice Maker System" and the "Condenser" sections.

Exterior Surfaces

Wash the exterior enamel surfaces and gaskets with warm water

and mild soap or detergent. Wipe and dry. Regular use of a good

household appliance cleaner and wax will help maintain the

finish. Do not use abrasive cleaners on enamel surfaces as they

may scratch the finish.

For products with a stainless steel exterior, use a clean sponge or

soft cloth and a mild detergent in warm water. Do not use

abrasive or harsh cleaners. Do not use chlorine bleach on the

stainless steel surfaces.

Ice Maker System

Minerals that are removed from water during the freezing cycle

will eventually form a hard scaly deposit in the water system.

Cleaning the system regularly helps remove the mineral scale

buildup. How often you need to clean the system depends upon

how hard your water is. With hard water of 15 to 20 grains/gal.

(4 to 5 grains/liter), you may need to clean the system as often

as every 6 months.

NOTE: Use one 16 oz (473 mL) bottle of approved ice maker

cleaner. To order, call 1-800-JENNAIR and ask for Part Number

4396808. In Canada, call 1-800-807-6777.

1. Press the selector switch to OFE

2. Wait 5 to 10 minutes for the ice to fall into the storage bin.

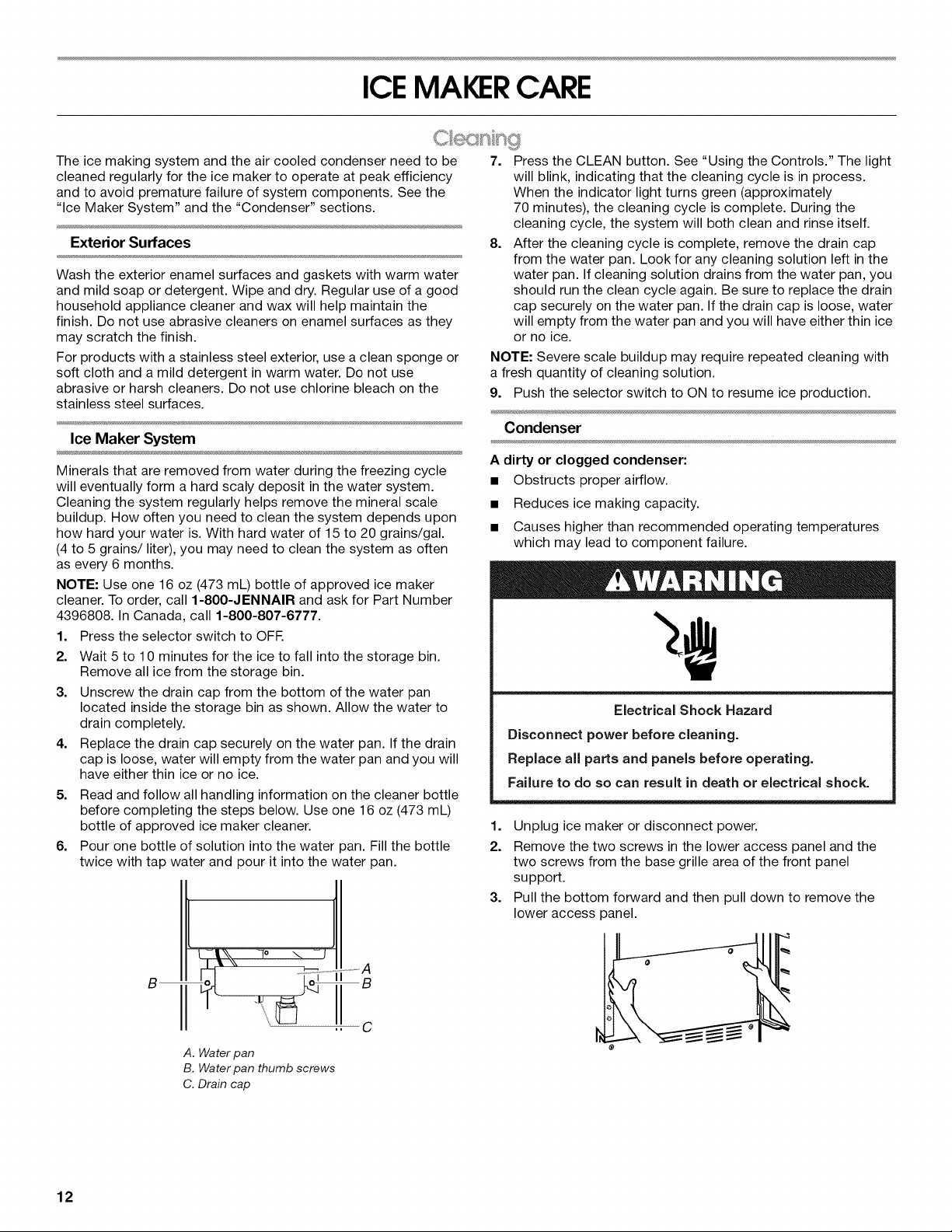

Remove all ice from the storage bin.

3. Unscrew the drain cap from the bottom of the water pan

located inside the storage bin as shown. Allow the water to

drain completely.

4. Replace the drain cap securely on the water pan. If the drain

cap is loose, water will empty from the water pan and you will

have either thin ice or no ice.

5. Read and follow all handling information on the cleaner bottle

before completing the steps below. Use one 16 oz (473 mL)

bottle of approved ice maker cleaner.

6. Pour one bottle of solution into the water pan. Fill the bottle

twice with tap water and pour it into the water pan.

7. Press the CLEAN button. See "Using the Controls." The light

will blink, indicating that the cleaning cycle is in process.

When the indicator light turns green (approximately

70 minutes), the cleaning cycle is complete. During the

cleaning cycle, the system will both clean and rinse itself.

8. After the cleaning cycle is complete, remove the drain cap

from the water pan. Look for any cleaning solution left in the

water pan. If cleaning solution drains from the water pan, you

should run the clean cycle again. Be sure to replace the drain

cap securely on the water pan. If the drain cap is loose, water

will empty from the water pan and you will have either thin ice

or no ice.

NOTE: Severe scale buildup may require repeated cleaning with

a fresh quantity of cleaning solution.

9. Push the selector switch to ON to resume ice production.

Condenser

A dirty or clogged condenser:

• Obstructs proper airflow.

• Reduces ice making capacity.

• Causes higher than recommended operating temperatures

which may lead to component failure.

Electrical Shock Hazard

Disconnect power before cleaning.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Unplug ice maker or disconnect power.

2. Remove the two screws in the lower access panel and the

two screws from the base grille area of the front panel

support.

3. Pull the bottom forward and then pull down to remove the

lower access panel.

12

-1\\ 3o \ - j

_l _ .............._ .................A

A. Water pan

B. Water pan thumb screws

C. Drain cap

J_ B

h

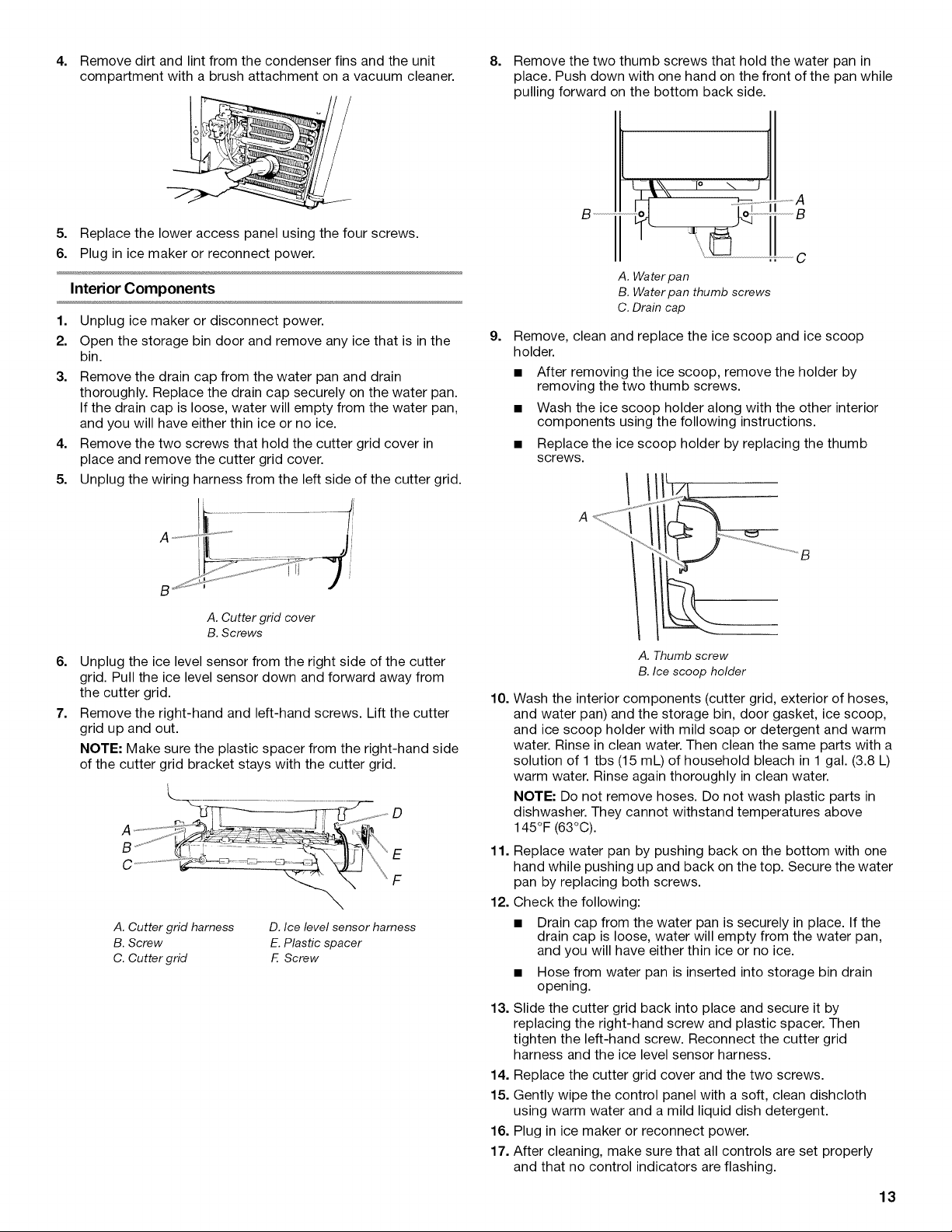

4. Remove dirt and lint from the condenser fins and the unit

compartment with a brush attachment on a vacuum cleaner.

8. Remove the two thumb screws that hold the water pan in

place. Push down with one hand on the front of the pan while

pulling forward on the bottom back side.

[ I\\ p \ -j

5. Replace the lower access panel using the four screws.

6. Plug in ice maker or reconnect power.

Interior Components

1. Unplug ice maker or disconnect power.

2. Open the storage bin door and remove any ice that is in the

bin.

3. Remove the drain cap from the water pan and drain

thoroughly. Replace the drain cap securely on the water pan.

If the drain cap is loose, water will empty from the water pan,

and you will have either thin ice or no ice.

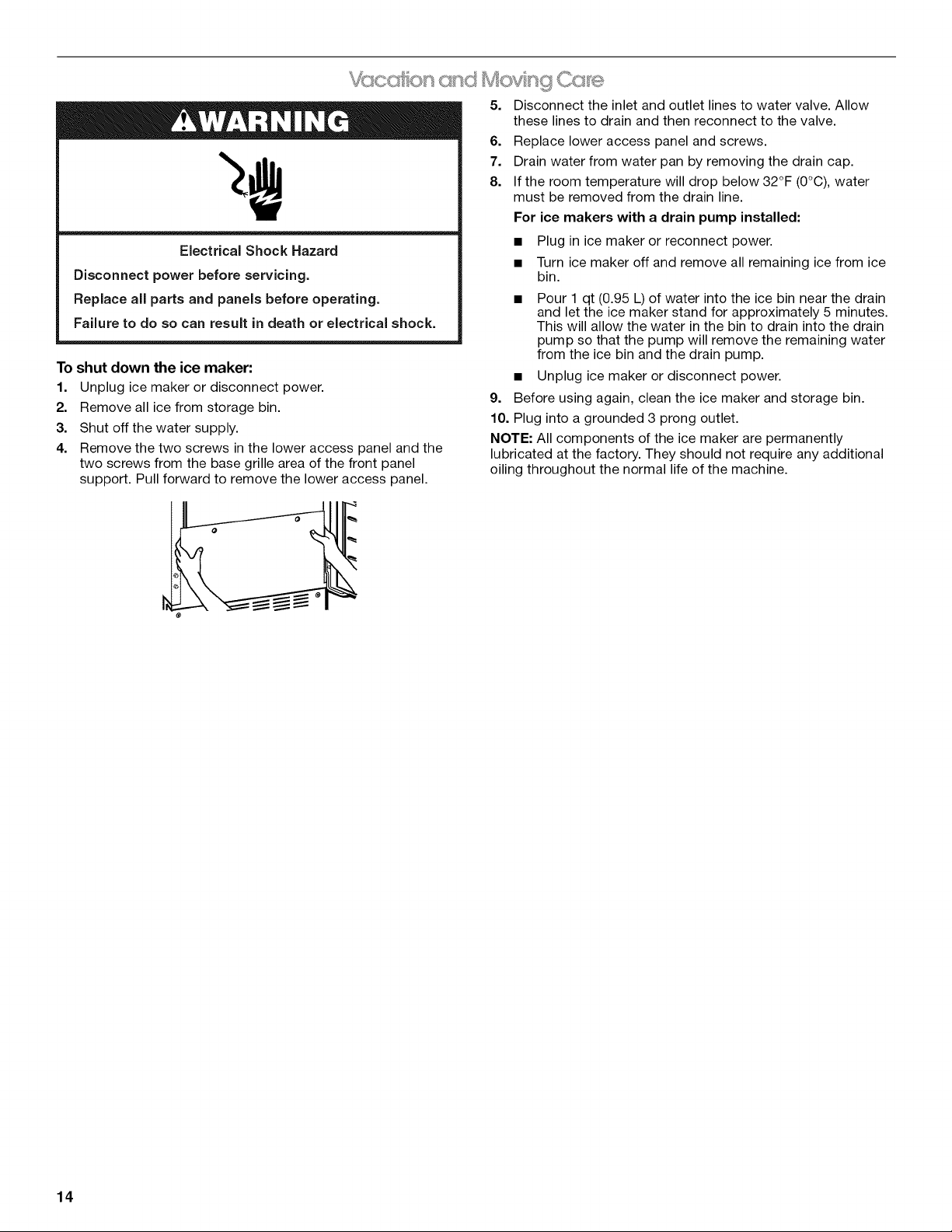

4. Remove the two screws that hold the cutter grid cover in

place and remove the cutter grid cover.

5. Unplug the wiring harness from the left side of the cutter grid.

A. Cutter grid cover

B. Screws

6. Unplug the ice level sensor from the right side of the cutter

grid. Pull the ice level sensor down and forward away from

the cutter grid.

7. Remove the right-hand and left-hand screws. Lift the cutter

grid up and out.

NOTE: Make sure the plastic spacer from the right-hand side

of the cutter grid bracket stays with the cutter grid.

Ag_ ........... _ ......... J .................. gE

A. Cutter grid harness

B. Screw

C. Cutter grid

D. Ice level sensor harness

E. Plastic spacer

F. Screw

g--

9=

Remove, clean and replace the ice scoop and ice scoop

_l_ ............._ ......................A

A. Waterpan

B. Water pan thumb screws

C. Drain cap

holder.

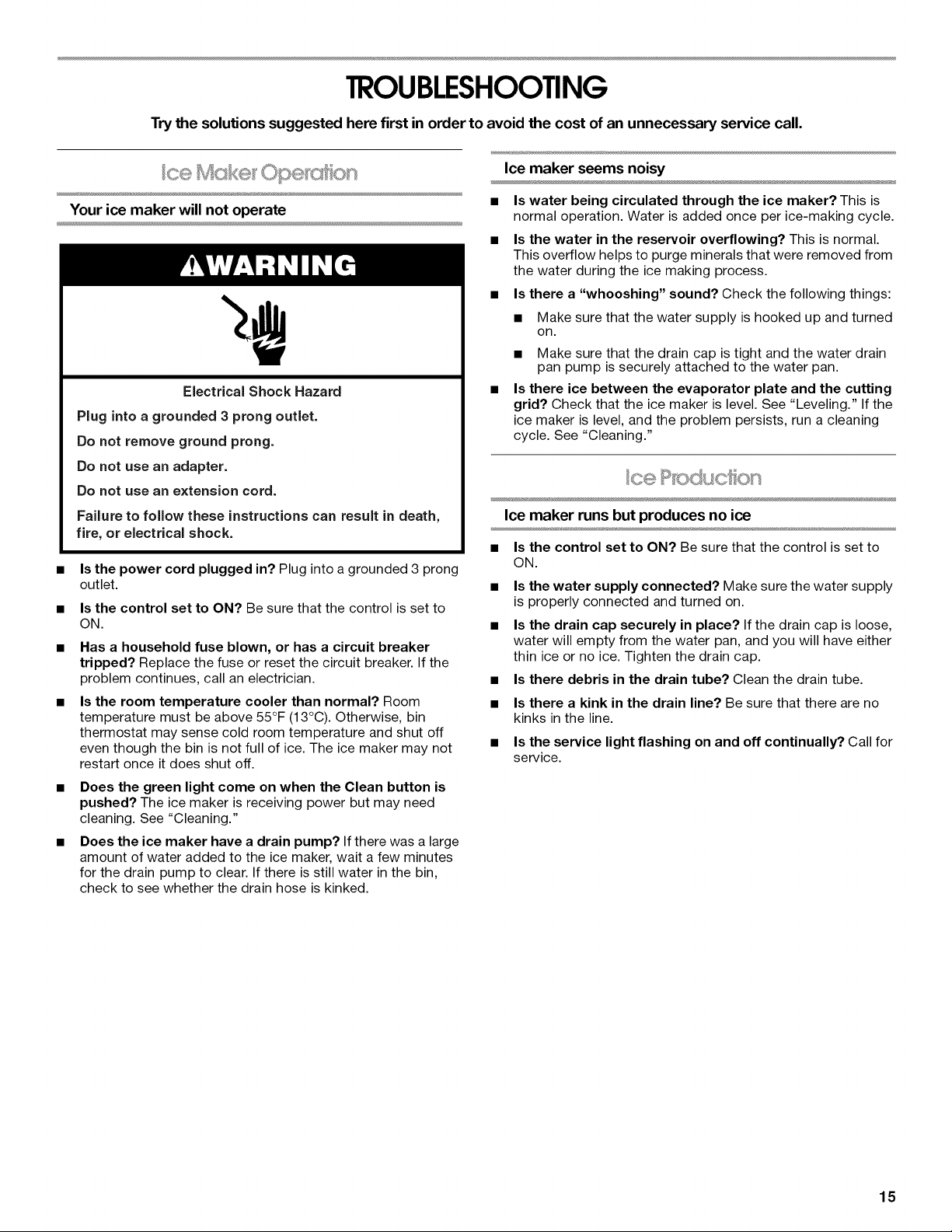

• After removing the ice scoop, remove the holder by

removing the two thumb screws.

• Wash the ice scoop holder along with the other interior

components using the following instructions.

• Replace the ice scoop holder by replacing the thumb

screws.

A. Thumb screw

B. Ice scoop holder

10. Wash the interior components (cutter grid, exterior of hoses,

and water pan) and the storage bin, door gasket, ice scoop,

and ice scoop holder with mild soap or detergent and warm

water. Rinse in clean water. Then clean the same parts with a

solution of 1 tbs (15 mL) of household bleach in 1 gal. (3.8 L)

warm water. Rinse again thoroughly in clean water.

NOTE: Do not remove hoses. Do not wash plastic parts in

dishwasher. They cannot withstand temperatures above

145°F (63°C).

11. Replace water pan by pushing back on the bottom with one

hand while pushing up and back on the top. Secure the water

pan by replacing both screws.

12. Check the following:

• Drain cap from the water pan is securely in place. If the

drain cap is loose, water will empty from the water pan,

and you will have either thin ice or no ice.

• Hose from water pan is inserted into storage bin drain

opening.

13. Slide the cutter grid back into place and secure it by

replacing the right-hand screw and plastic spacer. Then

tighten the left-hand screw. Reconnect the cutter grid

harness and the ice level sensor harness.

14. Replace the cutter grid cover and the two screws.

15. Gently wipe the control panel with a soft, clean dishcloth

using warm water and a mild liquid dish detergent.

16. Plug in ice maker or reconnect power.

17. After cleaning, make sure that all controls are set properly

and that no control indicators are flashing.

13

_, w_,_ __ _- •,4MC_ _i_ _

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

To shut down the ice maker:

1. Unplug ice maker or disconnect power.

2. Remove all ice from storage bin.

3. Shut off the water supply.

4. Remove the two screws in the lower access panel and the

two screws from the base grille area of the front panel

support. Pull forward to remove the lower access panel.

5. Disconnect the inlet and outlet lines to water valve. Allow

these lines to drain and then reconnect to the valve.

6. Replace lower access panel and screws.

7. Drain water from water pan by removing the drain cap.

8. If the room temperature will drop below 32°F (0°C), water

must be removed from the drain line.

For ice makers with a drain pump installed:

• Plug in ice maker or reconnect power.

• Turn ice maker off and remove all remaining ice from ice

bin.

• Pour 1 qt (0.95 L) of water into the ice bin near the drain

and let the ice maker stand for approximately 5 minutes.

This will allow the water in the bin to drain into the drain

pump so that the pump will remove the remaining water

from the ice bin and the drain pump.

• Unplug ice maker or disconnect power.

9. Before using again, clean the ice maker and storage bin.

10. Plug into a grounded 3 prong outlet.

NOTE: All components of the ice maker are permanently

lubricated at the factory. They should not require any additional

oiling throughout the normal life of the machine.

@

14

TROUBLESHOOTING

Try the solutions suggested here first in order to avoid the cost of an unnecessary service call.

Ice maker seems noisy

Your ice maker will not operate

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Is the power cord plugged in? Plug into a grounded 3 prong

outlet.

is the control set to ON? Be sure that the control isset to

ON.

Has a household fuse blown, or has a circuit breaker

tripped? Replace the fuse or reset the circuit breaker. If the

problem continues, call an electrician.

Is the room temperature cooler than normal? Room

temperature must be above 55°F (13°C). Otherwise, bin

thermostat may sense cold room temperature and shut off

even though the bin is not full of ice. The ice maker may not

restart once it does shut off.

• Does the green light come on when the Clean button is

pushed? The ice maker is receiving power but may need

cleaning. See "Cleaning."

• Does the ice maker have a drain pump? If there was a large

amount of water added to the ice maker, wait a few minutes

for the drain pump to clear. If there is still water in the bin,

check to see whether the drain hose is kinked.

• Is water being circulated through the ice maker? This is

normal operation. Water is added once per ice-making cycle.

• Is the water in the reservoir overflowing? This is normal.

This overflow helps to purge minerals that were removed from

the water during the ice making process.

• Is there a "whooshing" sound? Check the following things:

• Make sure that the water supply is hooked up and turned

on.

• Make sure that the drain cap is tight and the water drain

pan pump is securely attached to the water pan.

Is there ice between the evaporator plate and the cutting

grid? Check that the ice maker is level. See "Leveling." If the

ice maker is level, and the problem persists, run a cleaning

cycle. See "Cleaning."

Ice maker runs but produces no ice

Is the control set to ON? Be sure that the control is set to

ON.

Is the water supply connected? Make sure the water supply

is properly connected and turned on.

Is the drain cap securely in place? If the drain cap is loose,

water will empty from the water pan, and you will have either

thin ice or no ice. Tighten the drain cap.

Is there debris in the drain tube? Clean the drain tube.

Is there a kink in the drain line? Be sure that there are no

kinks in the line.

Is the service light flashing on and off continually? Call for

service.

15

Ice maker runs but produces very little ice

• Is the room temperature hotter than normal? Room

temperatures of more than 90°F (32°C) will normally reduce

ice production.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

• Is the condenser dirty? Dirt or lint may be blocking the

airflow through the condenser. See "Condenser" in the

"Cleaning" section.

• Is there scale buildup in the ice maker? If there is white

scale buildup in the ice maker's water or freezing system, you

should clean the ice maker. See "Interior Components" in the

"Cleaning" section.

• Is the drain cap securely in place? If the drain cap is loose,

water will empty from the water pan, and you will have either

thin ice or no ice. Tighten the drain cap if it is loose.

Grid is not cutting ice sheets

Is the cutter grid securely in place? Check the cutter grid

harness plug to make sure the connection is intact. See

"Interior Components" section of "Cleaning" for instructions

on cutter grid removal.

Off taste, odor or gray color in the ice

• Is there unusually high mineral content in the water

supply? The water may need to be filtered or treated.

• Is there mineral scale buildup? Clean your ice maker. See

"Ice Maker System" in the "Cleaning" section.

• Are there food items stored in the ice bin? Do not store any

foods in the ice bin.

• Were all the packaging materials removed? Make sure that

all packaging materials were removed at the time of

installation.

Thin, soft or clumps of ice

• Is there unusually high mineral content in the water

supply? The water may need to be filtered or treated.

• Is there mineral scale buildup? Clean your ice maker. See

"Ice Maker System" in the "Cleaning" section.

• Are there clumps of ice in the bin? If ice isnot used

regularly it will melt and form clumps. Break the clumps with

the ice scoop provided.

i,I_III,_ _)ii_!i:;l,,,,,,, 1_ l?)i]l%lli!,l=i,,l_:,I_................,....

Excessive Weight Hazard I

Use two or more people to move and install ice maker.

Failure to do so can result in back or other injury.

• Is the drain hose aligned over the drain? Move the ice

maker to align the drain. See "Connect Water Supply."

NOTE: Service technicians cannot repair plumbing problems

outside of the ice maker. Call a licensed, qualified plumber.

|

|

16

ASSISTANCEORSERVICE

Before calling for assistance or service, please check

"Troubleshooting." It may save you the cost of a service call. If

you still need help, follow the instructions below.

When calling, please know the purchase date and the complete

model and serial number of your appliance. This information will

help us to better respond to your request.

S A

If the problem is not due to one of the items listed in the

"Troubleshooting" section...

Call the dealer from whom your appliance was purchased, or call

Jenn-Air at 1-800-JENNAIR (1-800-536-6247) to locate an

authorized service company. When calling, please know the

purchase date and the complete model and serial number of your

appliance. Be sure to retain proof of purchase to verify warranty

status.

If the dealer or service company cannot resolve your problem,

write to:

Jenn-Air Brand Home Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

Web address: www.jennair.com

Or call: 1-800-JENNAIR (1-800-536-6247).

U.S. customers using -FrY for deaf, hearing impaired or speech

impaired, call: 1-800-688-2080 (Monday - Friday, 8:00 a.m. -

8:00 p.m. Eastern Time).

NOTE: When writing or calling about a service problem, please

include the following information:

1. Your name, address and daytime telephone number.

2. Appliance model number and serial number.

3. Name and address of your dealer or servicer.

4. A clear description of the problem you are having.

5. Proof of purchase (sales receipt).

User's guides, service manuals and parts information are

available from Jenn-Air Brand Home Appliances, Customer

eXperience Center.

If the problem is not due to one of the items listed in the

"Troubleshooting" section...

Call the dealer from whom your appliance was purchased, or call

Jenn-Air at 1-800-807-6777 to locate an authorized service

company. When calling, please know the purchase date and the

complete model and serial number of your appliance. Be sure to

retain proof of purchase to verify warranty status.

If the dealer or service company cannot resolve your problem,

write to:

Jenn-Air Brand Home Appliances

Customer eXperience Centre

1901 Minnesota Court

Mississauga, ON LSN 3A7

Web address: www.jennair.ca

Or call: 1-800-807-6777.

NOTE: When writing or calling about a service problem, please

include the following information:

1. Your name, address and daytime telephone number.

2. Appliance model number and serial number.

3. Name and address of your dealer or servicer.

4. A clear description of the problem you are having.

5. Proof of purchase (sales receipt).

User's guides, service manuals and parts information are

available from Jenn-Air Brand Home Appliances, Customer

eXperience Centre.

17

Loading...

Loading...