JENNAIR JIM1550ACX, JIM1550ARB, JIM1550ARS, JIM1550ARW Owner's Manual

I CE M AKER

OWNER’S

GUIDE

TABLE OF C O NTENTS

Introduction..............................................................................2

Safety ....................................................................................... 3

Installation............................................................................4-9

Operation................................................................................10

Care and Cleaning .......................................................11-12

Before Calling for Service .........................................13-18

Warranty..................................................................................20

Guide du Propriétaire ........................................................21

Guía del Propietario ...........................................................41

41007621

Introduction

Congratulations on the purchase of a Jenn-Air ice

maker.

We appreciate your purchase decision and feel

confident you will be happy with this appliance for

years to come. For best results, please read this guide

carefully. You will find instructions on the proper

operation and maintenance of your ice maker.

Should you ever need future assistance with your ice

maker, a complete model and serial number recorded

in the spaces below will be extremely helpful. These

numbers are found on the data plate inside on the

lower front of the ice maker cabinet.

Model Number ________________________

Serial Number ________________________

Purchase Date ________________________

Dealer Name _________________________

Dealer Address________________________

Dealer Phone _________________________

Before Calling for Service . . .

If something seems unusual, please check the “Before

Calling For Service” section, which is designed to help

you solve basic problems before calling a servicer.

What if These Features are Different

from Mine?

This book is intended to show the variety of features

that are available in the product line. If you have

questions, write us (include your model number and

phone number) or call:

Maytag Services

Attn: Jenn-Air CAIR®Center

P.O. Box 2370

Cleveland, TN 37320-2370

U.S.A. and Canada 1-800-JENNAIR

1-800-688-2080 (U.S.A. TTY for hearing

or speech impaired)

(Mon.-Fri., 8 a.m.-8 p.m. Eastern Time)

Internet: http://www.jennair.com

SM

(1-800-536-6247)

What You Need to Know About

Safety Instructions

Warning and Important Safety Instructions appearing in

this manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining or operating this appliance.

Always contact your dealer, distributor, service agent or

manufacturer about problems or conditions you do not

understand.

Recognize Safety Symbols, Words,

Labels

DANGER

DANGER – Immediate hazards which WILL result in

severe personal injury or death.

WARNING

WARNING – Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION

CAUTION – Hazards or unsafe practices which COULD

result in minor personal injury.

2

Important Safety Instructions

WARNING

•When using your appliance, always follow basic

precautions.

• Use the ice maker only for its intended purpose.

•To prevent possibility of hazard due to electrical

shock, never plug the ice maker into a receptacle

which has not been grounded adequately and in

accordance with the local and national electrical

codes. See warning and the grounding

instructions that follow.

• Disconnect power to the ice maker before cleaning,

servicing or replacing a light bulb.

• In case of power failure, minimize door openings.

• Any electrical service cord that becomes frayed or

damaged should be immediately repaired or

replaced. Never unplug your appliance by pulling on

the power cord.

•Your ice maker should not be operated in the

presence of gasoline or other flammable vapors and

liquids.

WARNING

•This appliance is designed to operate on a normal

115 volt, 15 amp, 60 cycle line. There should be a

separate, grounded circuit serving this appliance

only. Do not use an extension cord. Do not use

any device that will alter the electrical

performance of this appliance.

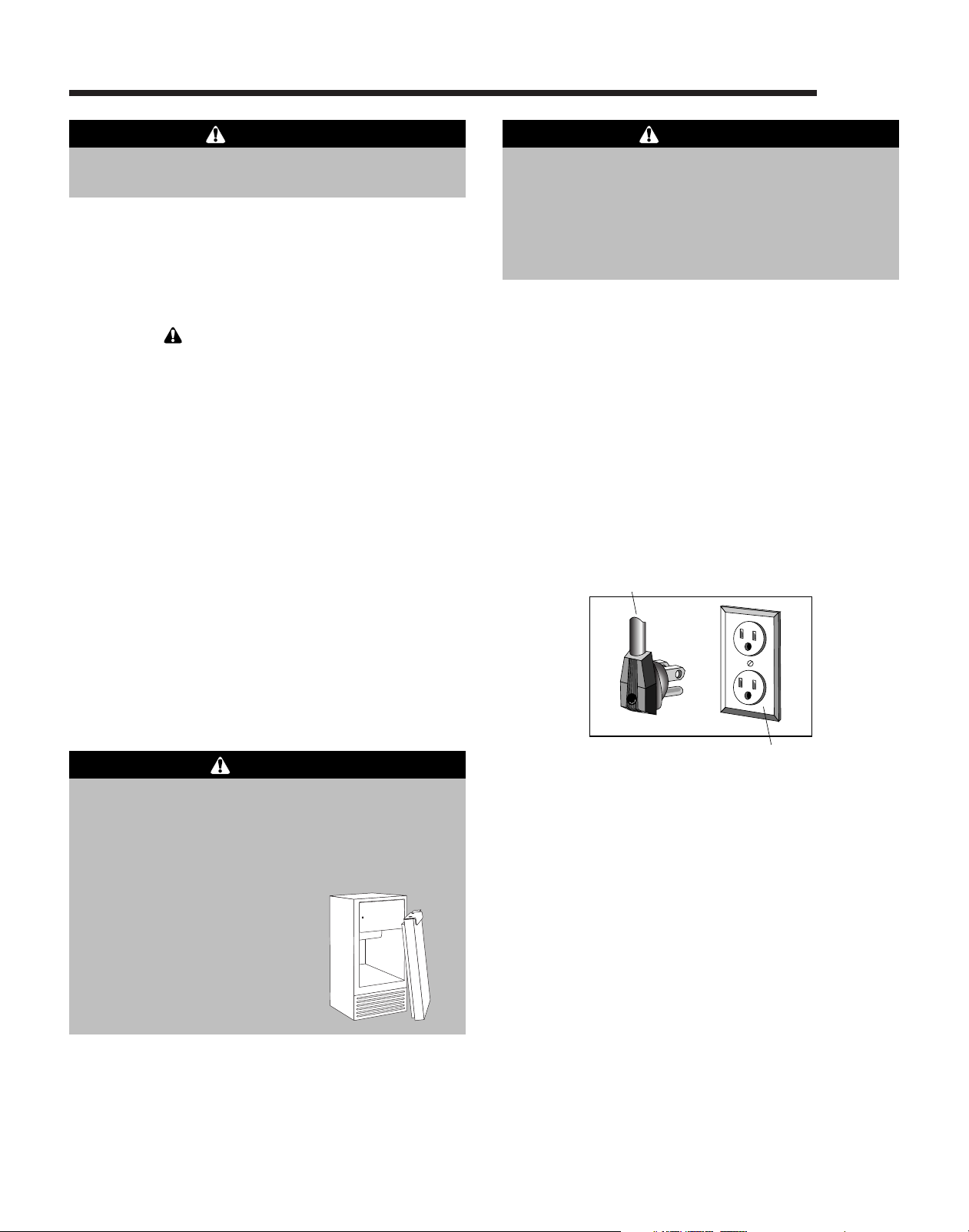

This appliance is equipped with a three-pronged

grounding plug for your protection against possible

electrical shock hazards. It must be plugged into a

grounding receptacle. Where a standard two-prong

wall receptacle is encountered, it is the personal

responsibility and obligation of the customer to have it

replaced with a properly grounded three-prong wall

receptacle. Do not under any circumstances, cut or

remove the third (ground) prong from the power cord.

Do not use an adapter plug.

Power Supply Cord With

3-prong Grounding Plug

• Children should not climb, hang or stand on or in

this refrigeration product.

• Read and follow manufacturer’s warnings on ice

machine cleaner products. Personal injury can result

when used improperly.

DANGER

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigeration

products are still dangerous…even if they will sit for

“just a few days.” If you are getting rid of your old

refrigeration products, please follow the instructions

below to help prevent

accidents.

•Take off the doors.

•Leave the shelves in place

so that children may not

easily climb inside.

Grounding Type

Wall Receptacle

Save These Instructions for Future Reference

3

Installation

Materials Needed

1

•

⁄8" Allen wrench

5

⁄16" socket

•

• Phillips screwdriver

•Putty knife

• Carpenter’s level

1

⁄4" O.D. copper tubing for water supply

•

5

•

⁄8" I.D. plastic tubing and hose clamp

(for gravity drain)

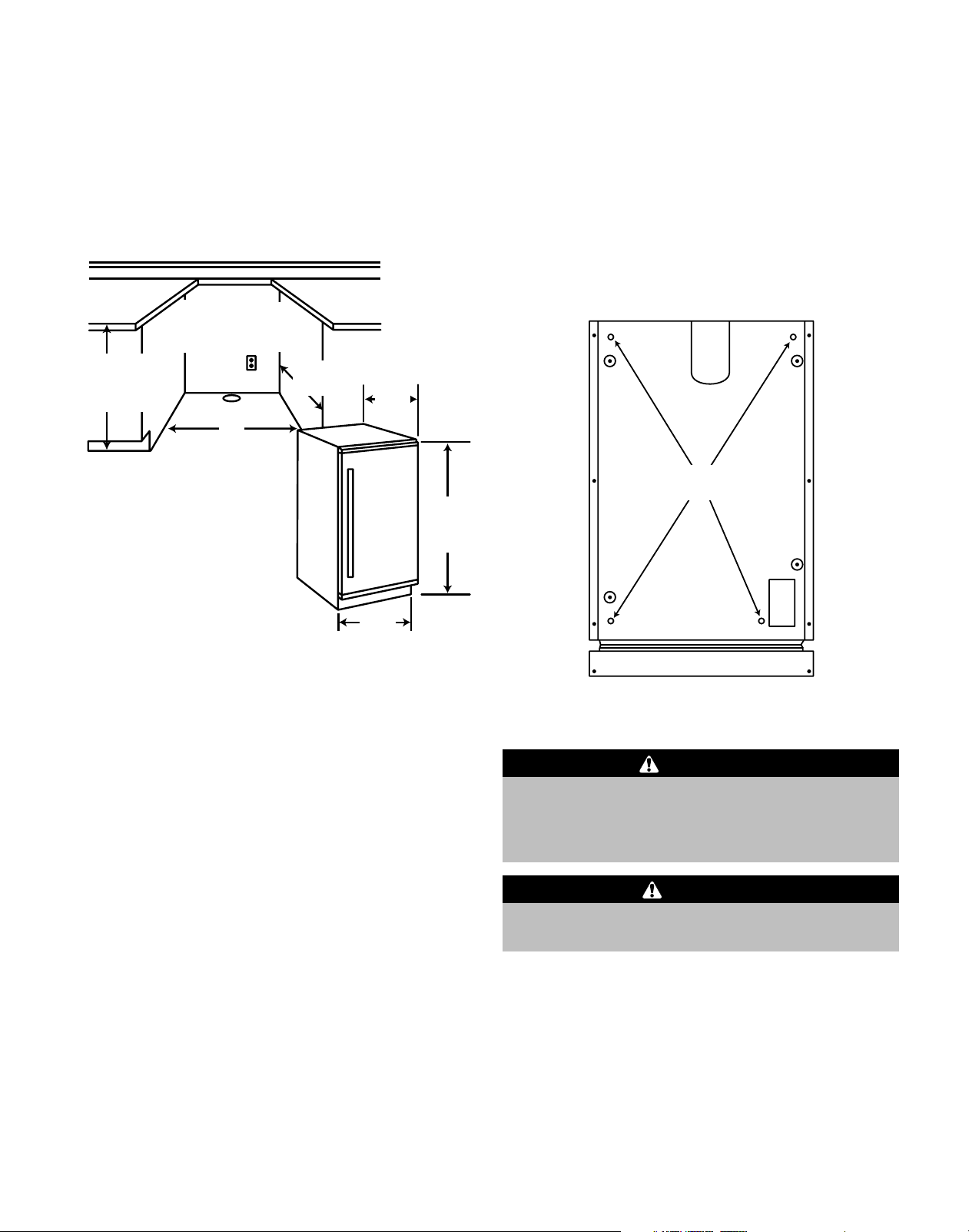

Select Location

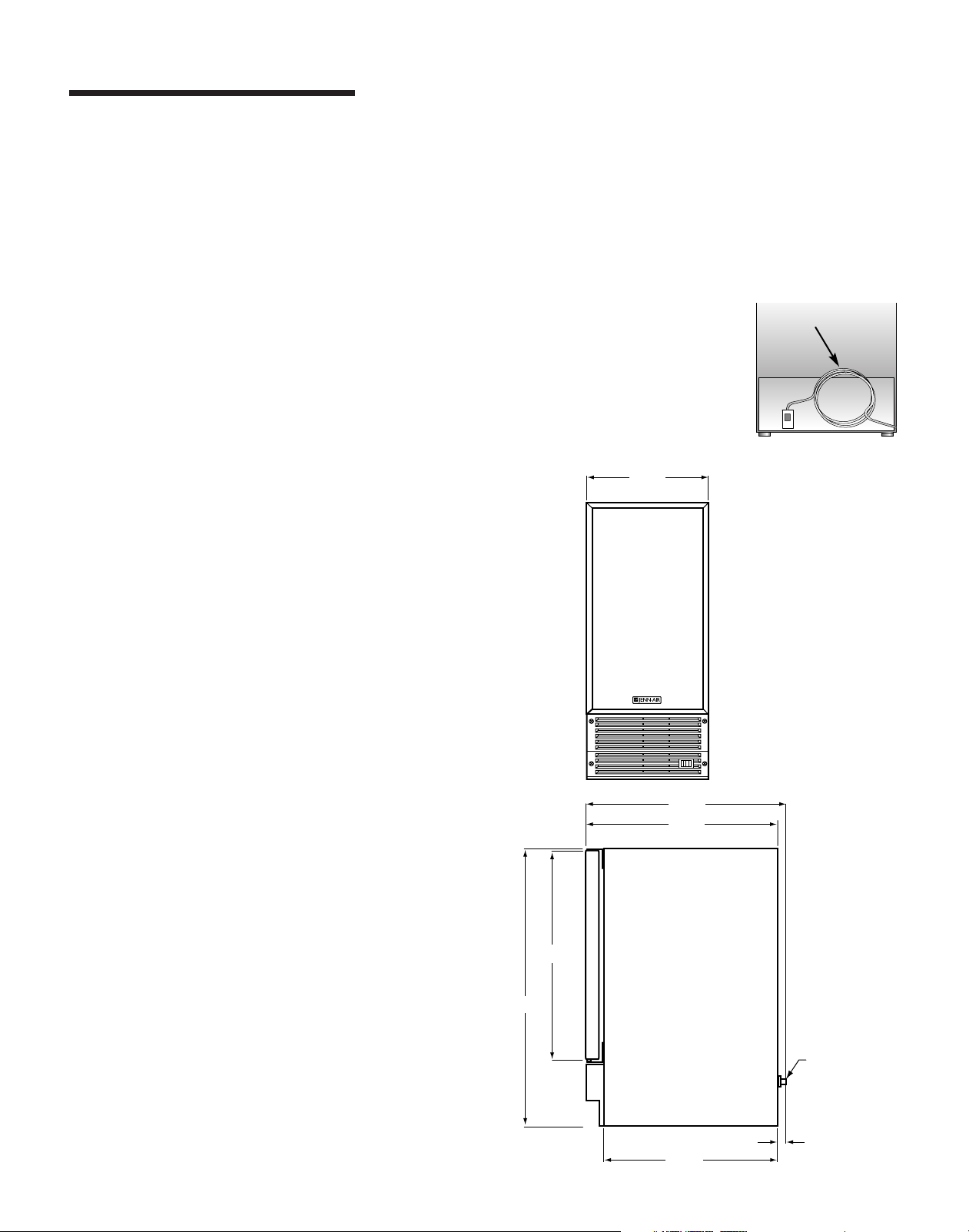

The ice maker was designed to be installed under the

counter. Its proper location will ensure peak

performance. Choose a location indoors, away from

heat and out of direct sunlight. Best performance will

be maintained when installed within the following

parameters:

Ideal Ambient

Temperature Range

Built-In..........................................................55-80° F

Cabinet Clearance

The ice maker may be enclosed on the sides, rear and

top. The front should be open and clear of any

obstructions.

Do not obstruct air flow through the lower front

grille area.

NOTE: Install the ice maker so that it can be

moved forward if service is

ever required. Do this by

adding enough copper tubing to

Service

Loop

create a service loop.

Use care to avoid kinks in tubing

when creating the service loop.

Dimensions

3

14

⁄4"

NOTE: Ice maker will not perform correctly in ambient

temperatures less than 55° F.

34

3

24

⁄4"

1

23

⁄2"

5

25

⁄8"

1

⁄4"

Supplied

Water Line

Fitting

1

1

⁄4"

21

1

8"

⁄

4

Cabinet Cut-Out Dimensions

and Specifications

Cut-out Height: 34

Cut-out Width: 15"

Cut-out Depth: 24" minimum

1

34

⁄2" Min.

to

1

35

⁄4" Max.

Water supply should enter

cutout from right rear wall.

1

⁄2" minimum

Locate outlet

on back wall

to local codes.

Floor Drain

15"

24"

Min.

24

3

⁄

4"

1

34

⁄4" Min.

Adjustable

to 35"

Leveling Legs

Install leveling legs (located in the literature pack):

•With at least 2 people, tip ice maker backwards

until there is approximately 12" of clearance

between the floor and the ice maker.

• Screw one front leveling leg into the screw

impression found in each corner. Leveling legs

should be screwed in until snug.

Screw

Impressions

14

3

⁄4"

of Unit

• Secure the door and repeat the above

procedures to install the rear leveling legs.

WARNING

Bottom

• One person should not attempt to tilt the ice maker

by themself. Have someone else assist to prevent

the ice maker from falling during leveling leg

installation.

CAUTION

• The ice maker should remain upright at least

30 minutes prior to plugging it in.

Level the Ice Maker

Using a carpenter’s level, check to be sure the ice

maker is level from side to side and from front to back.

Leveling adjustments can be made by turning the

leveling legs counter-clockwise to increase height and

clockwise to reduce height.

NOTE: The ice maker should not wobble. Use shims

to add stability when needed.

5

Installation, cont.

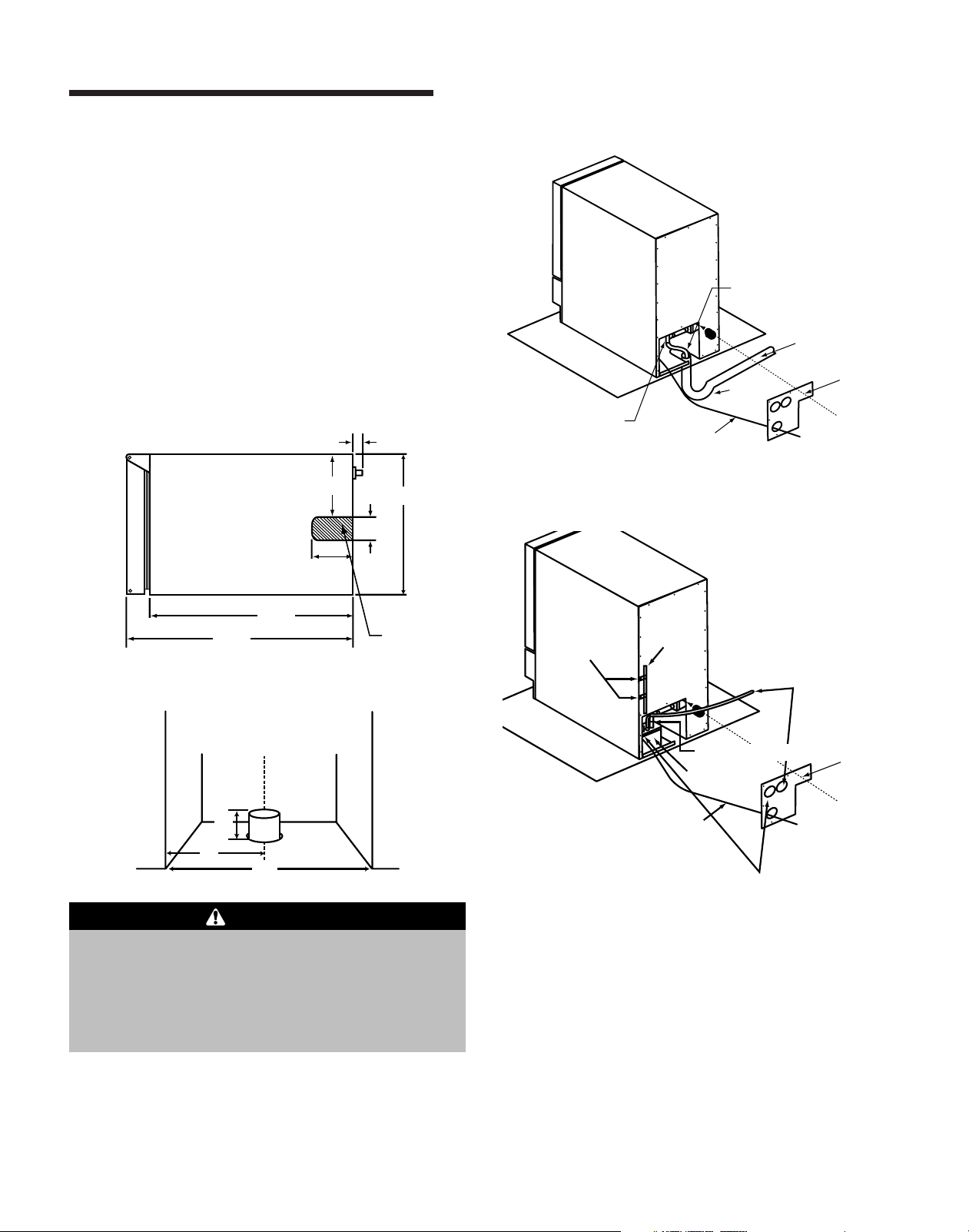

Drainage

Your ice maker uses a gravity drain that requires

tubing from the back of the ice maker to a plumbed

connection to a sanitary sewer (see illustration to the

below). Remove the access panel to plumb in drain

connection. Gravity drain location for built-in units can

be within the shaded area shown. An optional drain

pump can be purchased for your ice maker if a gravity

drain is not accessible.

NOTE: Avoid kinks and check for proper water

drainage after ice maker installation.

OBSERVE AND FOLLOW ALL LOCAL CODES

WHEN INSTALLING ICE MAKER.

3

6

⁄4"

Front

of Unit

Top

of Unit

3

2

⁄8"

1

4

⁄16"

5

⁄8" I.D.

1

1

⁄4"

3

14

⁄4"

Gravity Drain

5

⁄8" I.D. Drain

Tubing and

Hose Clamp

Drain

Drain from

Ice Maker

Ice Maker

Trap

Power Cord

Drain Pump (sold separately)

1

1

⁄2" Drain Pipe

Access

Panel

1

21

⁄8"

1

23

⁄2"

Gravity Drain Location

Baseplate

Opening for

Gravity Drain

Locate standpipe

as shown.

3"

8"

15"

WARNING

•Failure to use adequate drainage system will result

in surrounding water damage and/or poor ice

production.

•Water damage due to the use of an inadequate

drainage system may cause mold/mildew growth.

Tubing

Clamps

Vent

Tube

Drain from Ice Maker

Drain Pump

Drain Pump

Power Cord

Vent tube goes through this

opening in the access panel.

Discharge tube goes

through this opening

in the access panel.

Access

Panel

To purchase an optional drain pump, contact the dealer

where you purchased the ice maker or Jenn-Air

Customer Assistance: 1-800-JENNAIR (1-800-536-

6247). Drain pump model number: JIMPUMPAXX.

NOTE: Detailed installation instructions are provided

with the drain pump kit.

6

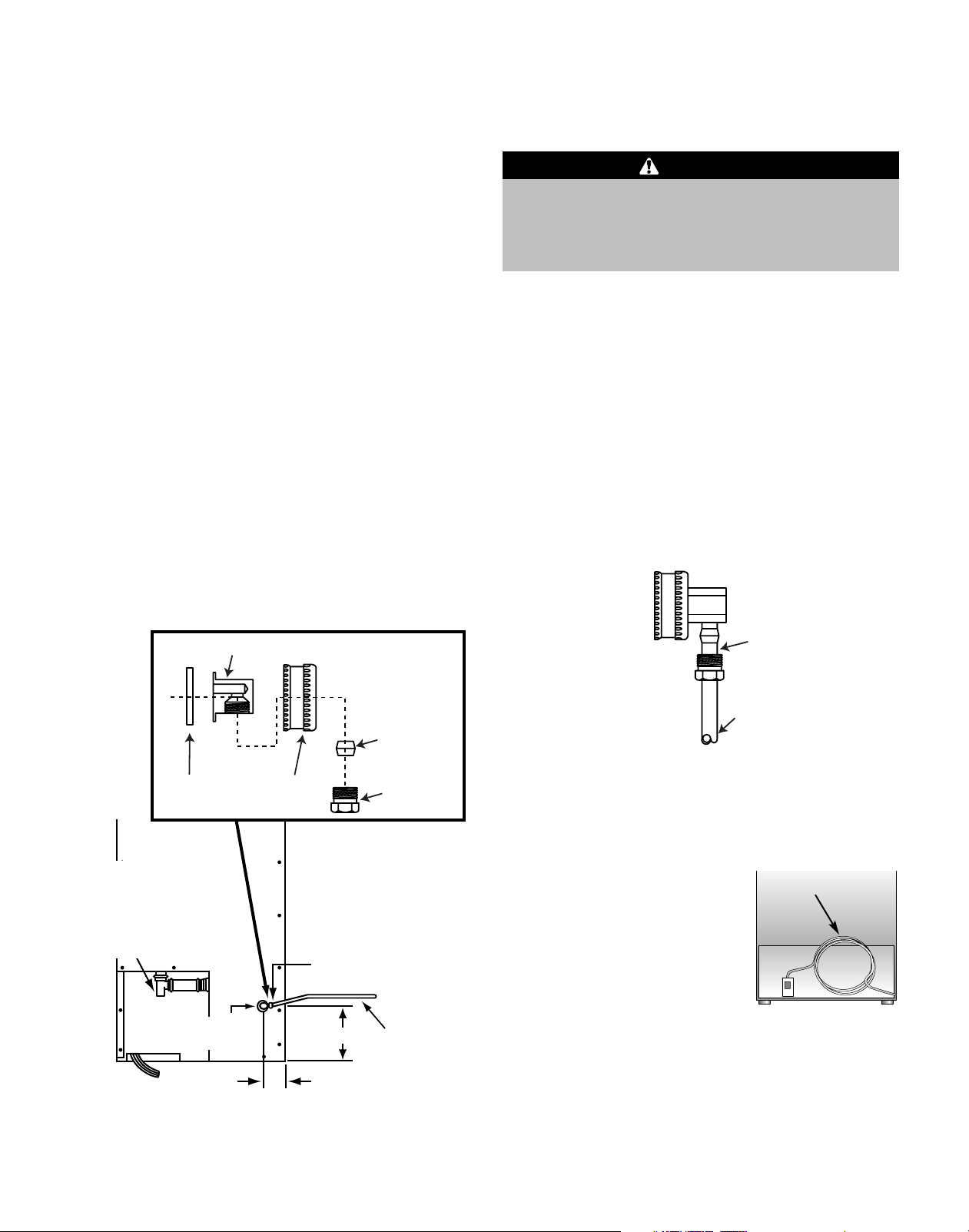

Water Supply

Connecting to the Water Supply

• This ice maker must be connected to a potable,

active cold water supply line delivering water

pressure at a minimum pressure of 20 psi and

maximum of 120 psi.

•A water filter is recommended for this unit. A quality

in-line filter can remove particles as well as remove

taste and odors from water.

To purchase an in-line water filter, call our parts

specialists at 1-877-232-6771 inside the U.S.A. from

7 a.m. to 7 p.m. central time Monday through Friday.

Outside the U.S.A., contact your local appliance

dealer or parts distributor. Ask for water filter part

number 18001010.

NOTES:

• Softened water is not recommended. This will

produce mushy, cloudy ice cubes that will stick

together.

• De-ionized water is not recommended. This water

will not form solid ice cubes.

•Do not use any type of thread sealer.

Adapter

WARNING

•The water line fitting supplied with your ice maker

is to be used on a

only. Do not attach a plastic supply line to your

unit using this fitting.

1. Shut off the main water supply.

2. Drain water from the nearest faucet by the ice maker.

3. Use a shut-off valve between the ice maker and

the water supply. The shut-off should be a drilled

saddle valve. Do not use a self-tapping valve. The

valve should be installed in a vertical water pipe.

NOTE: If the valve is installed in a horizontal water

pipe, make the connection at the top side of the

pipe.

4. Water connection is made through a

right angle garden hose fitting (fitting is packaged

in the literature kit).

1

⁄4" copper water supply line

1

⁄4" compression

1

⁄4" Copper Water

Supply Line*

Rubber

Washer

5

⁄8" I.D. Drain

Tubing Barb

Make certain

all hose clamps

are secure.

Hose Fitting

Rear View of Ice Maker

Garden

Compression

Fitting

Compression

Valve

Compression Fitting

1

5

⁄2"

1

2

⁄8"

Fitting

Nut

1

⁄4" Tubing

from Cold

Water Line

From water

supply to

ice maker

* Supplied by Customer

In compliance with local codes and ordinances,

1

use

⁄4" O.D. copper tubing from the cold water line

and the ice maker.

NOTE: Install the ice

maker so that it can be

Service

Loop

moved forward if service is

ever required. Do this by

adding enough copper tubing

to create a service loop.

Use care to avoid kinks in

tubing when creating the service loop.

5. Turn main water supply on.

6. Flush the water line for any foreign material and

check for leaks.

7. Make sure there are no sharp bends or kinks in the

water line.

7

Installation, cont.

Reversing the Door

WARNING

• Disconnect power to the ice maker before

reversing the door.

1. Turn OFF the ice maker

and disconnect the

power. Remove top

hinge pin with a

1

⁄8" Allen wrench.

Remove door by pulling

it out and upward off

bottom hinge pin. Set

aside, face down on

surface that will not

scratch the finish.

Remove the small plastic washer from bottom

hinge pin.

2. Remove the six small

plastic hole plugs from the

left hand hinge holes

using the putty knife.

Using a

wrench or nut-driver,

remove bottom hinge.

Reinstall hinge, moving it

to the top left hand side.

Using a

from the top left hinge, and install in top right

hinge. Now move top right hinge to left bottom.

Flip the door over and reinstall the small plastic

washer on the bottom hinge pin. Install hole plugs

in right side.

5

⁄16" socket,

1

⁄8" Allen wrench, remove the hinge pin

Top of

Unit

Out

Hinge

Bracket

Up

Hole Plugs

Move

Hinge

Pin

Realigning the door may be necessary. Using a

Allen wrench, loosen the two screws on the top

and bottom adjustable door hinge bracket. Adjust

the door to proper alignment. Make sure door

gasket seals fully against the cabinet front.

Retighten screws after making adjustments.

4. Plug the ice maker in and turn the control

back to the ON setting.

1

⁄8"

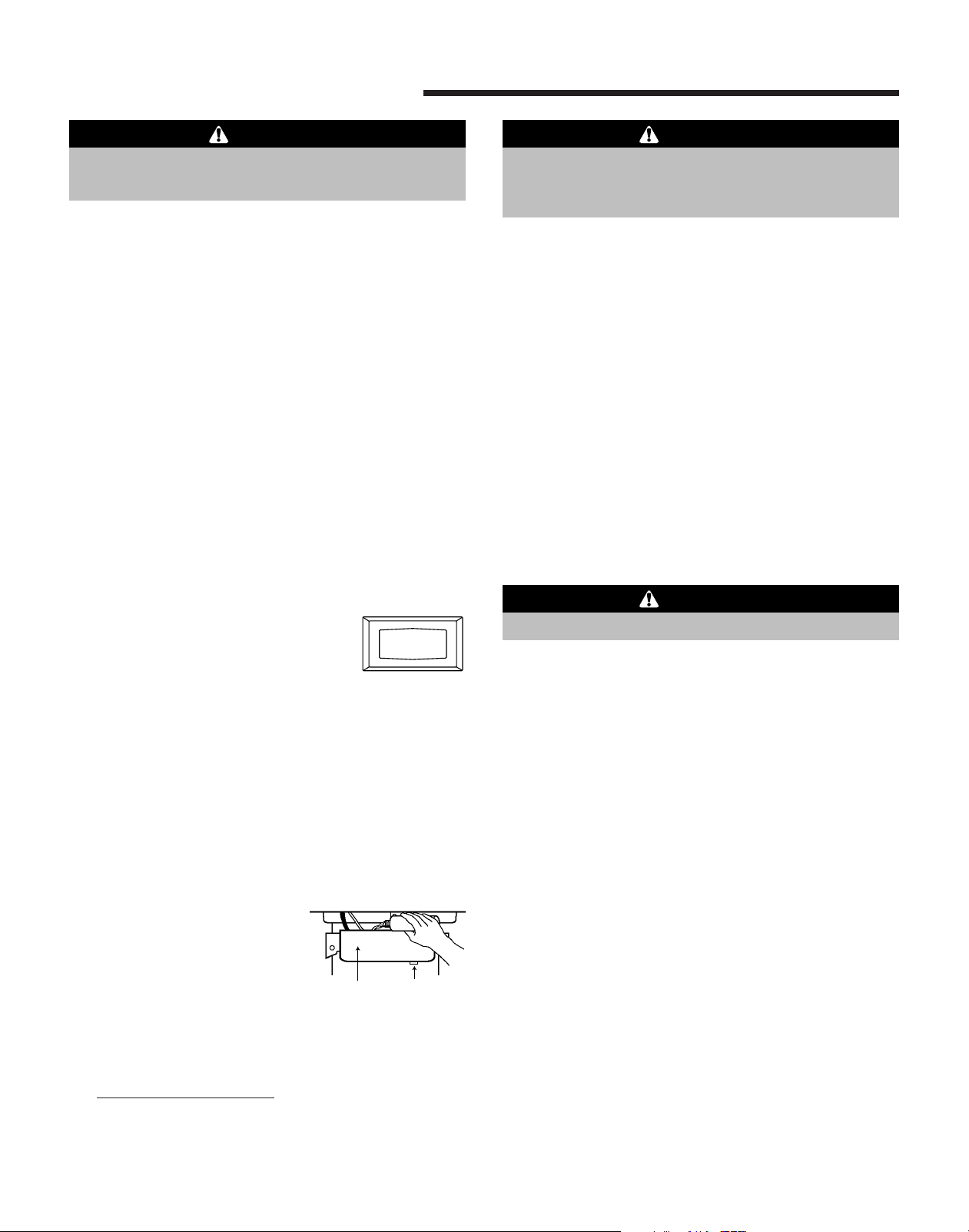

Installing the Custom Door

Panel (select models)

WARNING

• Disconnect power to ice maker before installing

the custom door panel.

The dimensions for a decorative custom door panel are:

3

⁄4" Width

14

5

25

⁄8" Height

3

⁄4" Thickness (maximum)

1. Turn off the ice maker and

disconnect the power.

1

2. Remove

screw (A) from the

top hinge. Remove

the door off of the

lower hinge, noting

washer location.

3. Remove the door

seal (B) to expose the screw

holes.

⁄8" set

A

B

3. Reinstall the door by

locating it over the

bottom hinge pin and

pushing down and in.

Reinstall the top

hinge pin. Check the

door for proper

alignment. The top

and sides of the door

should run parallel to

the top and side edges

of the cabinet. Some

misalignment is acceptable, but the door gasket

must seal fully against the cabinet.

8

Hinge

Bracket

In

Down

Hinge

Pin

Top of

Unit

Custom Handle

1. A custom handle (not supplied) must be installed.

2. Drill pilot holes through the custom panel to match

the handle. Countersink the holes on the back of

the panel.

3. Attach the custom handle to the front door panel

assembly.

NOTE: The custom handle screws should be installed

through custom panel and into the custom handle. The

screw heads should be countersunk so the inside panel

surface can be installed flush with the ice maker door.

Wood Screws

Attach the Wood Panel to the

1. #8 pan head wood screws are recommended to

properly secure the custom wood panel to the ice

maker door.

2. A total of 10 screws are needed.

3. Use only pan head screws.

4. Be sure the screw length is NOT longer than the

wood thickness at the screw locations.

5. Use the following pilot hole drill sizes.

Type of Pilot Hole Drill Size for

Wood #8 Pan Head Wood Screws

Hardwood

Softwood

3

⁄32" (.23 cm)

5

⁄64" (.20 cm)

Prepare the Wood Panel

3

14

⁄4"

5

25

⁄8"

(65.07 cm)

(37.47 cm)

10 Pilot Hole

Locations

Custom panel

thickness:

5

⁄8" to 3⁄4"

(1.57-1.91 cm)

Ice Maker Door

1. Place the custom wood panel on a non-abrasive

surface, protected by towels or rugs, to avoid

accidental damage to the door finish.

2. Place the ice maker door flush with the inside

surface of the custom wood panel. Clamp the

wood panel to the door, if necessary.

3. Mark the hole locations with a pencil.

4. Drill the pilot holes into the custom panel.

5. Insert the wood screws through the back of the

door and into the pilot holes in the custom wood

panel and tighten.

6. Reinstall the door seal by pressing it into the door

channel. Making certain the corners are fully

inserted.

7. Install the door back on to the ice maker using the

supplied plastic washers (as shown below).

8. Realigning the door may be necessary (see page 8).

CAUTION

• Door can become disengaged if washers are not

installed.

• Door may not swing properly if all nylon components

are not installed as shown.

Cabinet Hinge

Inside of Door

Top Hinge Corner

Bottom Hinge

Corner

Cabinet Hinge

Washer

(Optional)

Shoulder Bushing

Door Hinge

Door Hinge

Shoulder Bushing

Washer

9

Operation

O

N

O

F

F

C

L

E

A

N

Setting The Controls (see page 13)

1. To start the normal ice making cycle, select ON.

2. To stop ice maker operation, select OFF.

NOTE: The CLEAN setting is used whenever solutions

are circulated through the ice maker for cleaning. See

the Care and Cleaning section (page 11).

IMPORTANT: If the water supply to the ice maker is

turned off, be sure to set the ice maker control to OFF.

How Your Icemaker Works

The ice maker will keep producing ice until the ice

maker’s bin is full and will restart automatically when

ice needs to be replenished in the bin.

Due to variables in installation and use, individual

results may vary. Room and water supply

temperatures affect the output of ice. Ice will also melt

away, especially at the start of an empty bin, but this

will slow down as ice accumulates.

NOTE: When using the ice maker for the first time,

discard at least the first two harvests of ice cubes.

Your ice maker is unique in forming ice. It uses

fractional freezing to form a slab of ice that is clear and

has less mineral content than the water it is produced

from. This is accomplished

by running water over the

cold evaporator plate

which gradually freezes

the water to produce the

ice slab. Mineral deposits

are left in the reservoir.

When the ice slab reaches

the correct thickness

determined by the

temperature of the

evaporator plate, the

electronic control switches

to the harvest cycle to

harvest the ice slab.

During the harvest cycle,

the ice slab falls from the

evaporator to the ice grid

cutter. Here, the ice slab is

3

cut into

⁄4" squares by the

grid cutter’s low voltage

heated wires. During the harvest cycle, the drain valve

will remain open for 45 seconds to drain the reservoir

of remaining deposits. After that, the water valve will

open for 2 minutes providing 2 quarts of water to the

reservoir for the next ice production cycle.

10

Care and Cleaning

CAUTION

•Avoid leaning on the cabinet door, you may bend

the door hinge or tip the ice maker.

Both the ice making system and the condenser need to

be cleaned regularly.

Cleaning the Ice Maker

System

Some impurities and minerals will remain and build-up

in the ice maker and stick to the ice maker’s parts over

time. This build-up must be removed for proper ice

production, ice quality, and ice maker life. Your ice

maker is equipped with a cleaning mode that will help

in cleaning out these impurities.

Clean the ice and water system at least annually to

remove buildup. Frequency of cleaning depends on

water hardness. With very hard water ( >14 gpg),

cleaning may be required as frequently as every

6 months.

To clean the ice maker:

C

O

L

1. Switch the selector switch to the

OFF position (see page 13).

2. Wait approximately 10 minutes for the ice to fall

into the storage bin. Remove all ice from the

storage bin.

3. Remove the drain plug at the bottom of the

reservoir to drain any remaining water and then

reinstall.

O

E

F

N

A

F

N

WARNING

• Read and follow manufacturer’s warnings on ice

machine cleaner products. Personal injury can

result when used improperly.

6. Replace front cover panel and close door.

7. Switch selector switch on the grill of the machine

to the CLEAN position. Three quarts of water will

automatically be added to ice maker cleaner.

8. The total cleaning time will end in approximately

49 minutes. The cleaning cycle will automatically

rinse the evaporator plate and also drain the

cleaning solution and rinse water.

9. After the cleaning cycle has ended, remove the

front cover panel again and check that build up

has been removed. The evaporator plate should be

clean, shiny, and smooth to the touch. If not and

build up is still visible, repeat the cleaning cycle

above. If build up is removed, continue below.

10. Disconnect power to the ice maker.

CAUTION

• Disconnect power to the ice maker for steps 11-14.

11. Remove the distributor tube, hose clamp, hose and

its rubber ends.

12. Thoroughly clean the inside of the distributor tube

and the spray holes. You can use the same

cleaning solution as before and an old tooth brush

to reach the inside of the distributor tube, rinse

thoroughly.

4. Unscrew and remove interior stainless steel front

cover panel to gain access to the reservoir.

5. Determine the amount of ice maker cleaner

needed, based on 3 quarts

of water (refer to the cleaner

manufacturer’s directions).

Pour this amount of ice

maker cleaner into the

reservoir of the ice maker.

Reservoir

Drain

Plug

NOTE: “Ice Maker Cleaner Appliance” by Vapco

Products, a Division of Garman Co., Inc. is

recommended. It is available from

www.vapcoproduct

s.com (1-800-466-5150) or

many refrigeration supply and hardware stores.

13. Reinstall the rubber end, hose, and hose clamp to

the distributor and then reinstall the distributor

tube to the evaporator with the spray holes pointed

to the bottom of the evaporator plate. Reinstall the

front cover panel.

14. Clean the ice maker’s interior, ice scoop, interior

door panel, and door gasket with mild detergent

and water. Using two tablespoons of baking soda

in one quart of warm water while cleaning will help

remove odors. Rinse with fresh water. DO NOT

USE ANY ABRASIVE CLEANING PRODUCTS.

Your ice maker is now clean and may be put back into

operation by reconnecting the power and switching the

selector switch to the ON position.

NOTE: Discard the first harvest of ice cubes produced

after the clean cycle has been run.

11

Care and Cleaning, cont.

CAUTION

• Disconnect power to the ice maker before cleaning.

Condenser

For best performance, brush or vacuum lint and dirt

from the condenser at least once a year. Unscrew the

grille on the bottom front of the cabinet to access the

condenser.

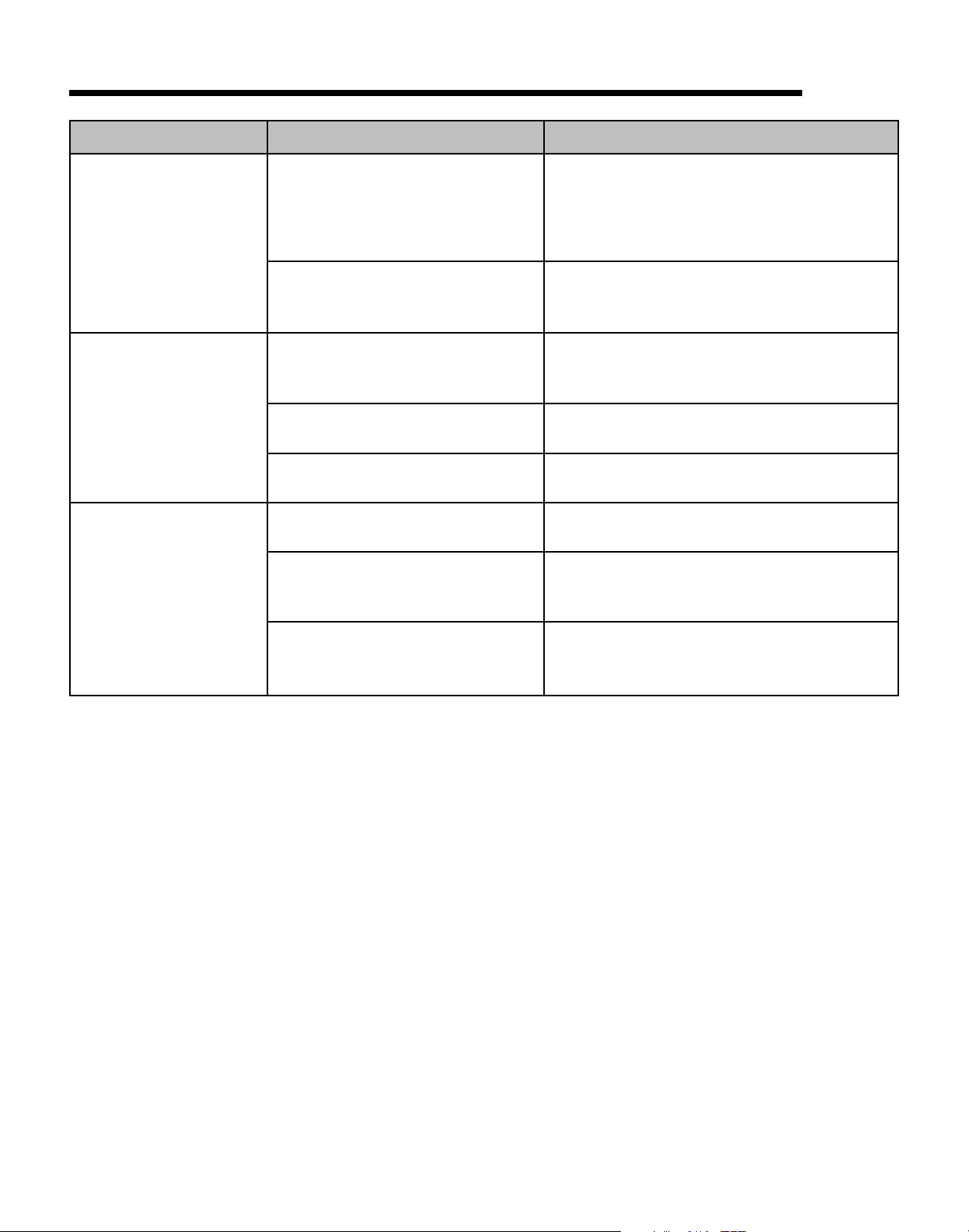

Ice Maker Cleaning Chart

EXTERIOR

Painted metal surfaces:

Cabinet, doors

Stainless steel doors

(certain models)

INTERIOR

Door gasket

Detergent and water

Mild liquid sprays

Light cleaning: mild

detergent and water

Moderate soil: Bon Ami*

Discoloration: Cameo

Stainless Steel Cleaner*

Baking soda and water

Detergent and water

Dry with a clean, soft cloth.

DO NOT wipe the ice maker with a soiled

dishwashing cloth or wet towel. These may leave

residue that can scratch and weaken the paint. Do

not use scouring pads, powdered cleansers, bleach

or cleaners containing bleach. These products can

scratch and erode the paint finish.

DO NOT wax plastic or vinyl parts.

Use a soft cloth or sponge.

Always wipe with the grain of the stainless steel.

DO NOT use chlorine bleach or any cleaning product

that contains chlorine bleach.

After cleaning, rinse and dry.

To restore luster and remove streaks follow with

Stainless Steel Magic Spray* (Jenn-Air model A912,

Part No. 20000008).

Use 1–2 tablespoons baking soda per quart of

water. Be sure to wring out excess water from

sponge or cloth when cleaning around controls,

lights or electrical parts.

Interior and door liner

* Brand names are the trademarks of the respective manufacturer.

12

Detergent and water

Baking soda and water

See above for baking soda solution.

DO NOT use abrasive cleaners, concentrated

detergents, bleaches, cleaning waxes, solvents or

polish cleaners to clean the ice maker interior.

Before Calling for Service

Things to Remember

1. Allow your ice maker to run for at least 48 hours to

accumulate ice in ice maker’s bin.

2. The ice maker will cycle often between ice

production and ice harvest cycles.

3. Your ice maker will automatically shut down when

the ice bin is full.

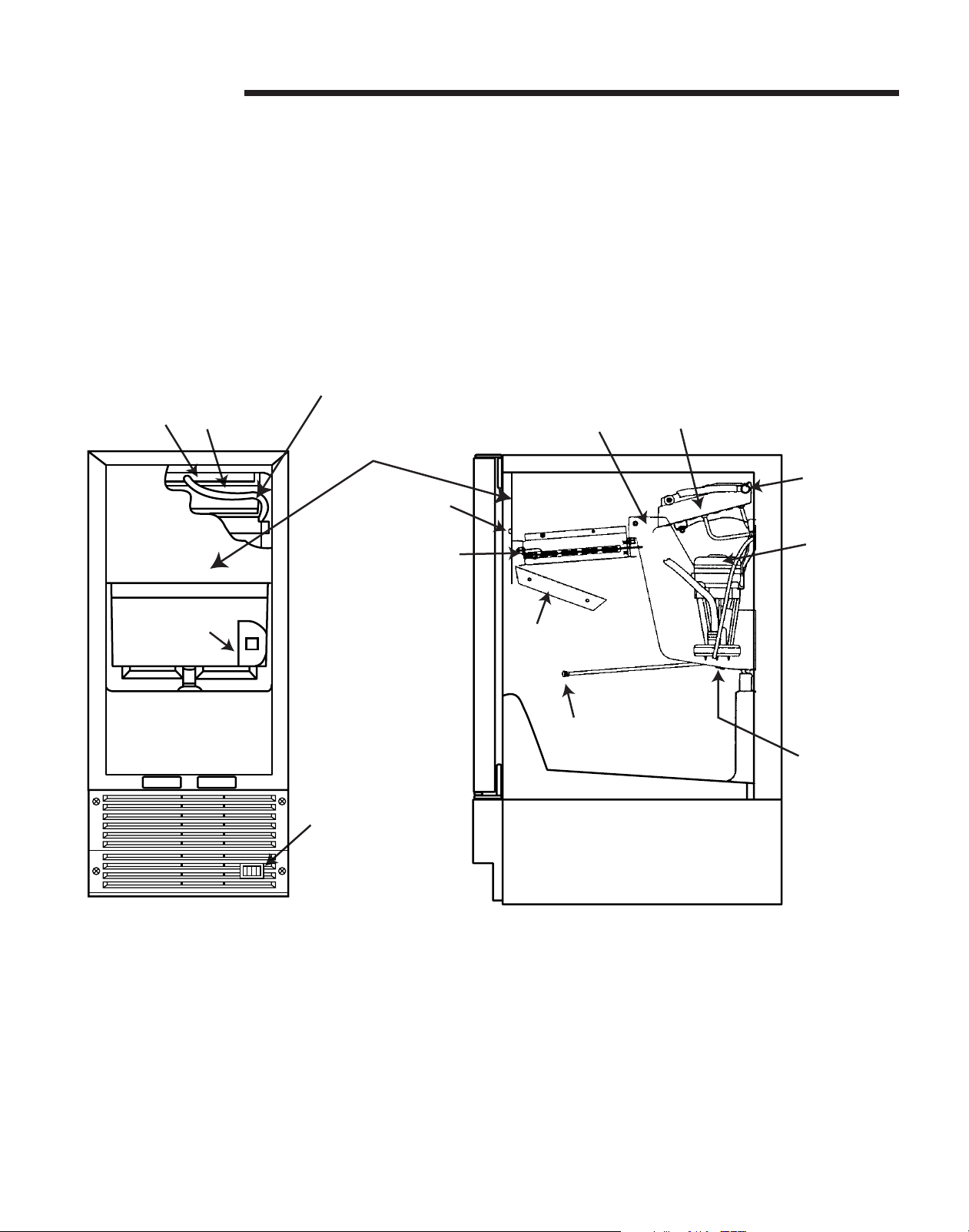

Make sure that distributor

tubing is not in the path

of the ice slab.

Distributor Evaporator

Front Cover

Panel

Phillips

Screw

Grid Cutter

4. Disconnect power to the ice maker before working

on it.

5. Keep your ice maker clean for proper ice quality,

production, and unit life.

6. If ice maker is to be left unattended for a month or

longer, turn off its water supply, switch the control

to OFF and disconnect the power supply. Remove

any ice that remains in the bin.

EvaporatorReservoir

Distributor

Circulation

Pump

Ice Scoop

ON/OFF/CLEAN

Selector Switch

Front View Side View

Ice

Deflector

Bin

Thermostat

Reservoir

Drain

Plug

13

Before Calling for Service, cont.

Check the following items:

1. Make sure the ice maker is plugged into outlet.

2. Check the outlet for power. Test outlet with a lamp

to make certain outlet has power.

3. Make sure the ice maker’s selector switch is in the

ON position (see page 13).

4. Make sure that there is cold water supplied to the

ice maker.

5. Make sure drain plug on bottom of reservoir is

inserted.

PROBLEM

Ice maker does

not operate.

POSSIBLE CAUSE

The ice maker is unplugged.

Breaker is tripped or fuse is blown.

Ice machine selector switch is in

the OFF position.

Water supply is turned off.

6. Make certain unit is level from front to back and

side to side.

7. Make certain that the drain line to the ice maker is

not restricted or kinked.

If you are not able to correct the problem, contact your

dealer or the manufacturer. Be sure to have the model

number and the serial number handy before you call.

The model and the serial number are located on the

data plate inside on the lower front of the ice maker

cabinet.

SOLUTION

Plug in the ice maker.

Reset the breaker or replace fuse.

Set the rocker switch on the grille of the ice

machine to the ON position.

Turn on water supply to the ice maker.

Ice maker operates

but does not produce

any ice.

The ice maker has just been started

and it has been less than 6 hours.

Typical ice production cycle can

take up to 1

cycles can be longer.

The selector switch is in the OFF or

CLEAN position.

No water in the reservoir.

Distributor tube is restricted.

Build up of deposits on evaporator

plate.

Condenser fan air flow is restricted.

1

⁄2 hours. Initial startup

Ice produced when the unit is initially started

will melt off in the bin. In 6 hours there can be

a few cubes in the bin. This is normal

operation.

Check the unit in 24 hours for ice

accumulation in the bin.

Set the rocker switch on the grille of the ice

machine to the ON position.

Make sure that the reservoir drain plug is

installed. Check the water line to make sure it

is on and that there are no restrictions or

kinks. Check all filters to make sure they are

not restricted or plugged.

See Cleaning the Ice Maker System (page 11).

See Cleaning the Ice Maker System (page 11).

Make certain the grille in the front of the unit

is free and open for proper air circulation.

Check and clean the condenser coil by

removing the grille in the front of the unit.

Clean the condenser with a vacuum and brush

attachment.

14

PROBLEM

POSSIBLE CAUSE

SOLUTION

Ice maker operates

but does not produce

any ice, cont.

Ice cubes are too

small (less than

1

⁄2" thick).

Room and/or water temperature is

too warm.

Leaking drain valve.

Inadequate drain system.

Grid cutter is unplugged.

Low ice consumption.

Move the ice maker to an area where ambient

temperature is below 80° F. The ice maker

should not be placed next to a heat source such

as an oven. Check for cold water connection.

See Cleaning the Ice Maker System (page 11).

This will also dissolve and flush out foreign

material in the drain valve which may be causing

it to leak.

Restriction in drain lines will cause ice in the

bin to melt. If using a gravity drain, make

certain there are no kinks or restrictions in the

drain lines. If using a drain pump, check the

inlet screen, discharge line, and vent line for

any buildup or restrictions.

Remove the front cover panel and plug the

grid cutter into the receptacle on the side of

the liner.

Ice is slowly melting on the ice bin and will

affect the size of the ice cube. This is normal

operation. When the ice bin needs to be

replenished, cubes will return to regular size.

Not enough water in reservoir.

Distributor tube is restricted.

Build up of deposits on evaporator

plate.

Inadequate drain system.

Leaking drain valve.

Room temperature is too warm.

Make sure that the reservoir drain plug is

installed properly. Check the water line to the

ice maker to make sure there are no

restrictions or kinks. Check all filters to make

sure they are not restricted or plugged.

See Cleaning the Ice Maker System (page 11).

See Cleaning the Ice Maker System (page 11).

Restriction in drain lines will cause ice in the

bin to melt to a thinner cube. If using a gravity

drain, make certain there are no kinks or

restrictions in the drain lines. If using a drain

pump, check the inlet screen, discharge line,

and vent line for any build or restrictions.

See Cleaning the Ice Maker System (page 11).

This will also dissolve and flush out foreign

material in the drain valve which may be

causing it to leak.

Move to an area where temperature is below

80° F.

15

Before Calling for Service, cont.

PROBLEM

Ice cubes are too big

(greater than

Hollow ice slab.

Ice is not clear.

3

⁄4" thick).

POSSIBLE CAUSE

Ice slab not releasing.

Condenser fan air flow is restricted.

Room temperature is too warm.

Distributor tube is restricted.

Build up of deposits on evaporator

plate.

Low water level in reservoir.

Low water level in reservoir.

SOLUTION

See Cleaning the Ice Maker System (page 11).

Make certain the grille in the front of the unit is

free and open for proper air circulation. Check

and clean the condenser coil by removing the

grille in the front of the unit. Clean the condenser

with a vacuum and brush attachment.

Move to an area where temperature is below 80° F.

See Cleaning the Ice Maker System (page 11).

See Cleaning the Ice Maker System (page 11).

Make sure that the reservoir drain plug is

installed properly. Check the water line to the

unit to make sure there are no restrictions or

kinks in the line. Check all filters to make sure

they are not restricted or plugged.

Make sure that the reservoir drain plug is

installed properly. Check the water line to the

ice maker to make sure there are no restrictions

or kinks in the line. Check all filters to make

sure they are not restricted or plugged.

Low ice production.

Unit is running, has

run over a 48 hour

period, and there is

little ice in bin.

Softened water supply.

Room temperature is too cold.

Low water level in reservoir.

Distributor tube is restricted.

Build up of deposits on evaporator

plate.

Inadequate drain system.

Condenser fan air flow is restricted.

Make certain that water line is not connected

to the water softener.

Move the ice maker to an area where room

temperature is above 55° F.

Make sure that the reservoir drain plug is

installed properly. Check the water line to the

ice maker to make sure there are no

restrictions or kinks. Check all filters to make

sure they are not restricted or plugged.

See Cleaning the Ice Maker System (page 11).

See Cleaning the Ice Maker System (page 11).

Restriction in drain lines will cause ice in the

bin to melt. If using a gravity drain, make

certain there are no kinks or restrictions in the

drain lines. If using a drain pump, check the

inlet screen, discharge line, and vent line for

any buildup or restrictions.

Make certain the grille in the front is free and

open for proper air circulation. Check and

clean the condenser coil by removing the grille

in the front. Clean the condenser with a

vacuum and brush attachment.

16

PROBLEM

POSSIBLE CAUSE

SOLUTION

Unit continues to run

and produce ice.

Grid cutter is not

cutting the ice slab.

Ice cubes are sticking

together.

Ice level is too high.

Ice bin is not full.

Room temperature is too warm.

Ice maker is not level.

The selector switch is not in the ON

position.

The grid cutter is not plugged into

the receptacle.

Time to cut through the slab.

Ice consumption is low.

Room temperature is too warm.

The ice machine is not level.

The ice maker will automatically shut down

when ice reaches the thermostat.

Move the ice maker to an area where room

temperature is below 80° F.

Use a level to check the unit for level from

side to side and front to rear.

Set the rocker switch on the grille of the ice

machine to the ON position.

Remove the front cover panel and plug the

grid cutter into the receptacle on the side of

the liner.

It can take up to 35 minutes to cut through a

harvested ice slab. This is normal operation.

Use the ice in the bin frequently. Ice will stick

together if left in insulated bin over long

periods of time.

Move the ice maker to an area where

temperature is below 80° F.

Use a level to check the ice maker for level

from side to side and front to rear.

Ice level is too low.

Room temperature is too warm.

Ice deflector is not in place or

secured properly.

Bin level thermostat needs

adjusted.

The ice machine is not level.

Room temperature is too cold.

The selector switch is not in the ON

position.

Move the ice maker to an area where

temperature is below 80° F.

Check to see that the ice deflector is in place

and secured below the grid cutter.

You can adjust the bin thermostat tube by

simply pressing directly down on the tube 5"

from the front of the tube to get a desired bin

level.

Use a level to check the unit for level from

side to side and front to rear.

Move the unit to an area where temperature is

above 55° F.

Set the rocker switch on the grille of the ice

machine to the ON position (see page 13).

17

Before Calling for Service, cont.

PROBLEM

Water keeps backing

up into the ice bin

(gravity drain).

Water keeps backing

up into the ice bin

(drain pump).

The drain pump cycles

on and off erratically.

POSSIBLE CAUSE

Inadequate drain system.

Foreign material in ice bin drain.

Drain pump tubing kinked or

restricted.

Inlet screen to the drain pump is

restricted or blocked.

Drain pump and/or the ice machine

are not level.

Vent line to the drain pump is

restricted or kinked.

Discharge line is restricted or

kinked.

SOLUTION

Restriction or improperly installed drain lines

will cause water to back up into the ice bin.

Make certain there are no kinks or restrictions

in the drain lines. If necessary, consult a

qualified plumber.

Foreign material is restricting or blocking the

ice bin drain located at the right rear corner of

the ice bin. The drain will need to be cleared.

Check inlet, discharge, and vent line tubing for

any kinks or restrictions and repair as

necessary.

Clean the inlet screen to the drain pump.

Check and level is necessary the drain pump

as well as the ice machine.

Check the vent line for any restrictions or

kinks and repair as necessary.

Check the discharge line and connection to

the desired drain for any restrictions or kinks

and repair as necessary.

The drain pump is not level.

The drain pump must be level. Check for level

on the top of the drain pump case and adjust

the tubing or use shims to level.

18

Loading...

Loading...