Jenn-air JID4436ES Installation

INSTALLATION INSTRUCTIONS

36" (91.4 CM) DOWNDRAFT TOUCH-ACTIVATED

ELECTRONIC INDUCTION COOKTOP

INSTRUCTIONS D’INSTALLATION

TABLE DE CUISSON PAR INDUCTION AVEC

COMMANDES ÉLECTRONIQUES TACTILES À

ASPIRATION VERS LE BAS DE 36" (91,4 CM)

Table of Contents/Table des matières

COOKTOP SAFETY ........................................................................1

INSTALLATION REQUIREMENTS .................................................3

Tools and Parts .............................................................................3

Location Requirements ................................................................3

Venting Requirements ..................................................................7

Electrical Requirements ...............................................................9

INSTALLATION INSTRUCTIONS ...................................................9

Prepare Cooktop ..........................................................................9

Cooktop Mounting Brackets Installation ...................................10

Install Cooktop and Blower Motor Assembly ............................11

Make Electrical Connection .......................................................16

Complete Installation .................................................................19

WIRE DIAGRAM ...........................................................................20

SÉCURITÉ DE LA TABLE DE CUISSON .....................................21

EXIGENCES D'INSTALLATION ...................................................23

Outillage et pièces ......................................................................23

Exigences d’emplacement .........................................................23

Exigences concernant l’évacuation ...........................................27

Spécifications électriques ..........................................................29

INSTRUCTIONS D’INSTALLATION .............................................29

Préparation de la table de cuisson ............................................29

Installation des supports de fixation

de la table de cuisson ................................................................30

Installation de la table de cuisson

et du moteur du ventilateur ........................................................31

Raccordement électrique ...........................................................36

Achever l’installation ..................................................................39

SCHÉMA DE CÂBLAGE ...............................................................40

COOKTOP SAFETY

IMPORTANT:

Save for local electrical inspector’s use.

IMPORTANT :

À conserver pour consultation par l’inspecteur local

des installations électriques.

3595/W10793589B

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

2

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools Needed

■ Tape measure ■ Marker or pencil

■ Phillips screwdriver ■ Pliers

■ Flat-blade screwdriver ■ Jigsaw

■ Level ■ Caulking

■ Drill ■ Aluminum duct tape

®†

■ T20

Parts Supplied

Check that all parts are included.

■ Cooktop assembly

■ Blower housing assembly with electronic box assemblies

■ (4) Cooktop mounting brackets (corners)

■ Grease filter

■ (11) M4 x 9.5 mm screws (ducting and electrical box

■ (16) M4 x 12 mm screws (cooktop mounting brackets

■ (4) M6 x 16 mm screws (blower motor assembly to

■ (4) M5 x 10 mm flat-head screws (mounting feet to

■ (4) M5 x 50 mm cap head screws (cooktop-to-cooktop

■ (4) M5 lock washers

■ (4) M5 flat washers

■ (2) UL listed or CSA approved M\," (2.2 cm) strain relief

■ Rectangular duct 2-piece telescoping (blower assembly

■ Foam strip

Parts Needed

■ A UL listed or CSA approved strain relief for M\," (2.2 cm)

■ (4) UL listed wire connectors for 8-gauge wires

For vented installations:

■ 3Z\v" x 10" (8.3 cm x 25.4 cm) metal ducting

■ Jenn-Air

For non-vented installations:

■ Recirculation Kit part number W10807915 (See the

†

®TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC.

TORX®† drivers

strain reliefs)

to cabinet)

cabinet floor)

blower motor assembly bottom)

mounting brackets)

to cooktop)

knockout

®

wall cap:

Jenn-Air® 3¼" x 10" (8.3 cm x 25.4 cm) Surface Wall Cap

Damper part number A403.

See the “Assistance or Service” section in your Use and

Care manual to order.

“Assistance or Service” section in your Use and Care

manual to order.)

a. Recirculation duct housing

b. (4) Mounting screws

c. (2) Charcoal filters

d. Recirculation housing cover

e. (2) Mounting screws – cover

f. Duct extension

g. (4) Mounting screws – duct extension

For non-vented installations side recirculation only:

■ 3Z\v" x 10" (8.3 cm x 25.4 cm) metal duct – length required

is determined by the distance from the exhaust outlet to the

back flat surface of the Recirculation Kit housing.

Check local codes. Check existing electrical supply. See the

“Electrical Requirements” section.

It is recommended that all electrical connections be made by

a licensed, qualified electrical installer.

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

When installing the cooktop, use the minimum dimensions given.

■ To eliminate the risk of burns or fire by reaching over the

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage is to

be provided, the risk can be reduced by installing a range

hood that projects horizontally a minimum of 5" (12.7 cm)

beyond the bottom of the cabinets.

■ Use the countertop opening dimensions that are given

with these Installation Instructions. Given dimensions are

minimum clearances and provide 0" (0 cm) clearance.

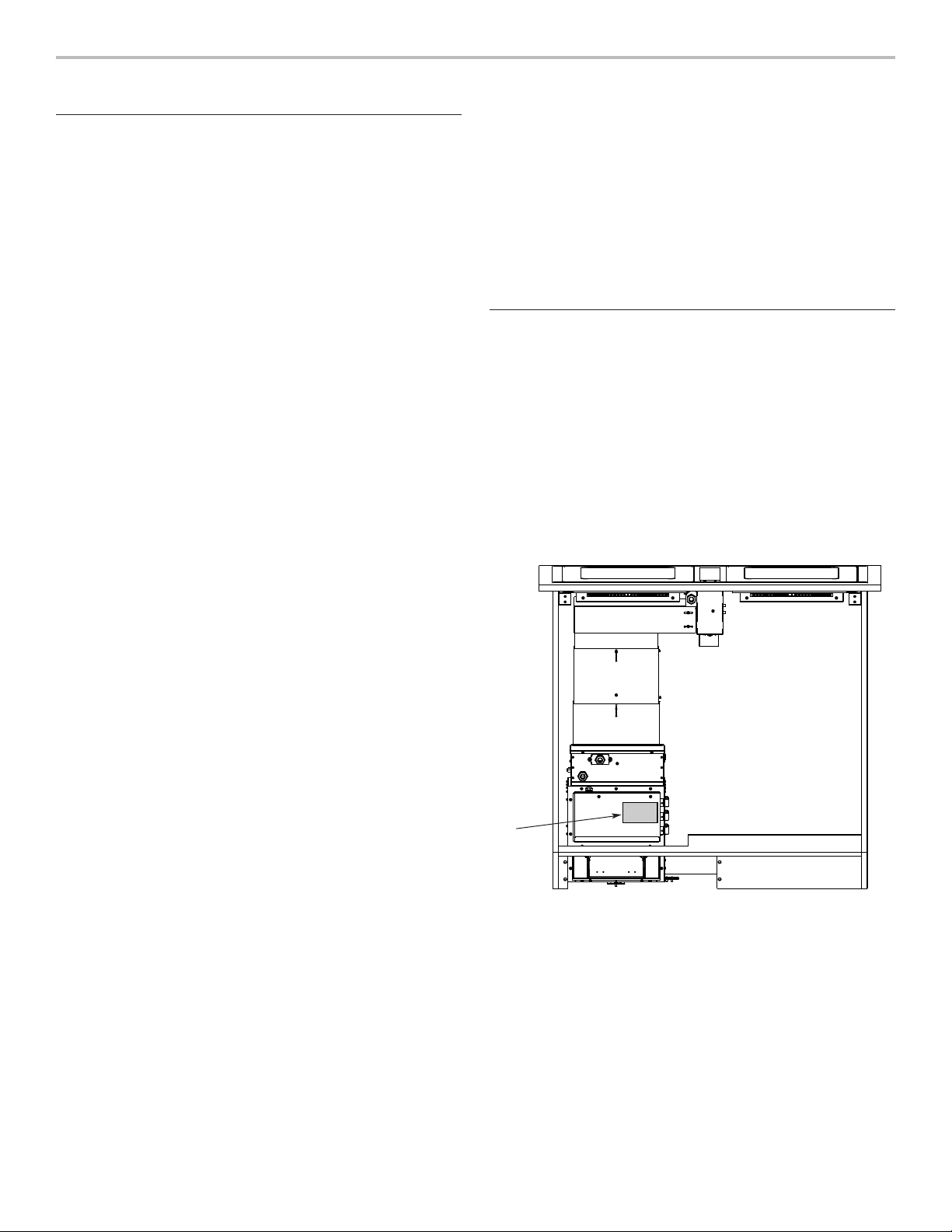

■ The model/serial/rating label is located on the front face of

the electrical junction box cover.

A

A. Model/serial/rating label location

■ Grounded electrical supply is required. See the “Electrical

Requirements” section.

■ If cabinet has drawers, drawers will need to be removed

and drawer fronts installed on front of cabinet.

NOTE: The exhaust system is for outside venting. For

non-vented (recirculating) installation, see “For non-vented

(recirculating) installations only” in the “Connect Vent System”

section. Recirculating Kit part number W10807915 is available

from your dealer or an authorized parts distributor.

IMPORTANT: An undercounter built-in oven cannot be installed

under this product.

3

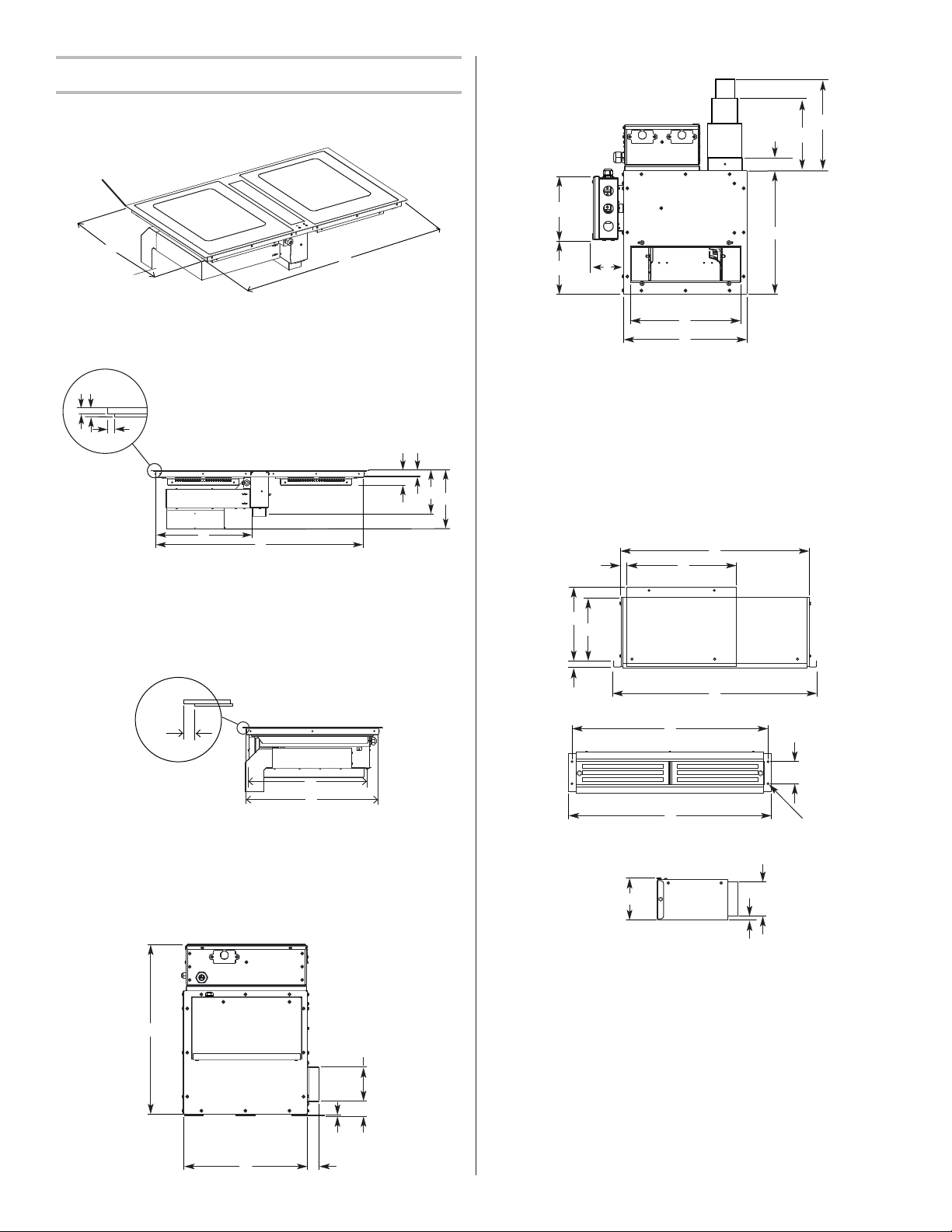

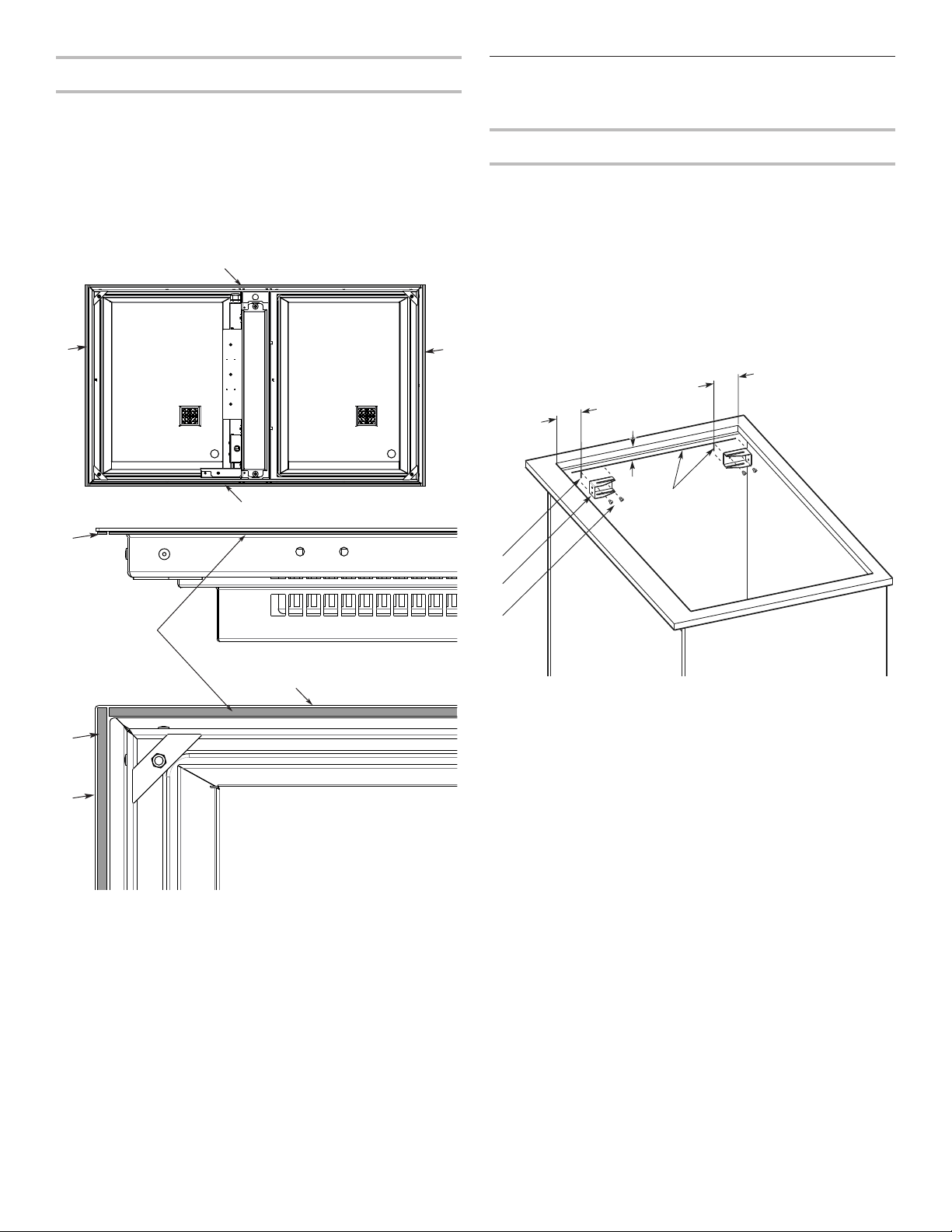

Product Dimensions

Right Side

Cooktop

C

B

HI

A. 29/32" (6.5 cm)

B. 13/32" (2.8 cm)

C. 73/8" (18.7 cm)

D. 95/8" (24.5 cm)

E. 1525/32" (40.1 cm)

Top View

A. 36" (91.4 cm)

B. 2111/32" (54.2 cm)

C. 5/64" (2.0 mm) radius (4-corner radius)

Front View

G

E

F

F. 349/16" (87.8 cm)

G. 11/32" (8.45 mm) typical sides

H. 1/8" (3.25 mm)

I. 5/64" (2.0 mm)

Side View – Left

M

K

C

A

A. 111/8" (28.2 cm)

B. 111/32" (28.0 cm)

C. 111/8" (28.3 cm)

D. 151/4" (38.7 cm)

E. 15/16" (2.4 cm) typical right,

A B

C

D

F. 7/16" (1.1 cm) typical right,

G. 31/8" (7.9 cm) typical right,

J

left, or front position

left, or front position

left, or front position

L

H

B

H. 97/8" (25.0 cm) typical right,

left, or front position

J. 415/16" (12.5 cm)

K. 55/8" (14.4 cm)

L. 23/4" (7.0 cm)

M. 11/8" (2.9 cm)

N. 5/64" (0.2 cm)

O. 9" (22.9 cm) min.

P. 151/4" (38.7 cm) max.

P

O

Recirculation Assembly (accessory)

N

GF

D

C

C

B

A. 209/32" (51.5 cm)

B. 181/2" (47.0 cm)

C. 9/32" (7.2 mm) typical front and back

A

Blower Housing Assembly

NOTE: Vent exhaust – shown for right exhaust. It can also be

positioned for left or front exhaust.

Front Side

D

G

F

N

A E

E

B

A. 183/8" (46.6 cm)

B. 33/4" (9.5 cm)

C. 53/4" (14.7 cm)

D. 63/4" (17.1 cm)

E. 9/16" (14 mm)

F. 9/16” (14 mm)

G. 97/8" (25.0 cm)

A

H

A

J

M

H. 175/8" (44.8 cm)

J. 33/32" (7.8 cm)

K. 2" (5.0 cm)

L. 3/16" (4.8 mm) diameter (4)

M. 5/16" (7.9 mm)

N. 17" (43.2 cm)

K

L

4

Recirculation Cover (part of Recirculation Kit)

A

B

A. 181/2" (47.0 cm)

B. 331/32" (10.1 cm)

C. 11/16" (1.7 cm)

C

Cabinet Dimensions

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

NOTES:

■ Cabinet opening dimensions shown are for 25" (64 cm)

countertop depth, 24" (61 cm) base cabinet depth, and 36"

(91 cm) countertop height. Dimensions must be met in order

to ensure a flush fit to the back wall.

■ For clarification, all cabinet illustrations are shown with the

door and front panel removed.

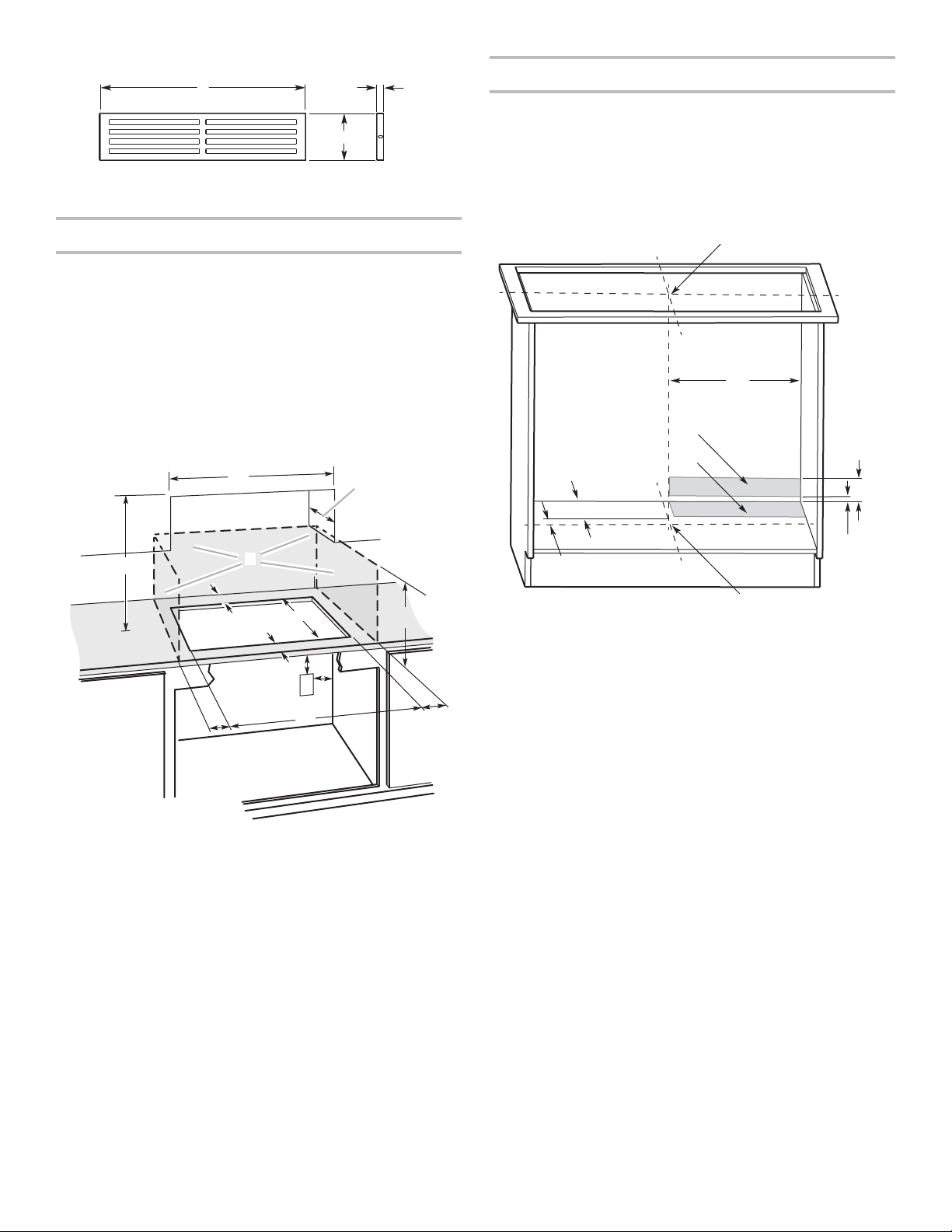

Countertop Cutout and Clearances

A

D

Cutout Dimensions

NOTE: All dimensions for cabinet cutouts are to be located

from the centerline/center point of the countertop cutout.

Style 1 – Cabinet Cutouts for Vented Installations

Cabinet cutout areas are for venting out of the right-hand side of

the blower motor assembly to the back or through the floor. All

cutouts are to be located from the centerline/center point of the

countertop cutout.

Centerline/center point

of countertop cutout

17"

(439 mm)

11"

(280 mm)

A

B

4" min.

(101 mm)

C

B

L

F

E

G

H

I

K

A. 36" (91.4 cm)

B. Combustible area above countertop (shown by dashed box above)

C. 30" (76.2 cm) minimum clearance between top of cooktop platform

and bottom of uncovered wood or metal cabinet (24" [61 cm]

minimum clearance if bottom of wood or metal cabinet is covered by

not less than 1/4" [0.6 cm] flame-retardant millboard covered with not

less than No. 28 MSG sheet steel, 0.015" [0.04 cm] stainless steel, or

0.024" [0.06 cm] aluminum or 0.020" [0.05 cm] copper)

D. 13" (33 cm) recommended upper-cabinet depth

E. 211/16" (6.8 cm)

F. 207/8" (53.0 cm)

G. 18" (45.7 cm) minimum clearance from upper cabinet to countertop

within minimum horizontal clearances to cooktop

H. Junction box or outlet; 12" (30.5 cm) minimum from bottom

of countertop

I. Junction box or outlet; maximum 24" (61 cm) from centerline

of cabinet

J. 357/16" (90.0 cm)

K. 21/2" (6.4 cm) minimum distance to nearest left- and right-side

combustible surface above cooktop

L. 115/32" (3.7 cm) minimum clearance between back wall and countertop

J

K

NOTE: After making the countertop cutout, some installations

may require notching down the base cabinet sidewalls to clear

the cooktop base. To avoid this modification, use a base cabinet

with sidewalls wider than the cutout.

5

/16" min.

3

/8"

(10 mm)

Centerline/center point

of countertop cutout

A. The vent supply area in back of the cabinet is for venting out of the

back of the cabinet, using a 31/4" x 10" (8.3 cm x 25.4 cm) vent duct

and a flat 90° elbow.

B. The vent supply area in the cabinet floor is for venting through the

bottom of the cabinet using 31/4" x 10" (8.3 cm x 25.4 cm) vent duct

and a 90° elbow.

(8 mm)

NOTE: Gray areas are references for ducting locations.

5

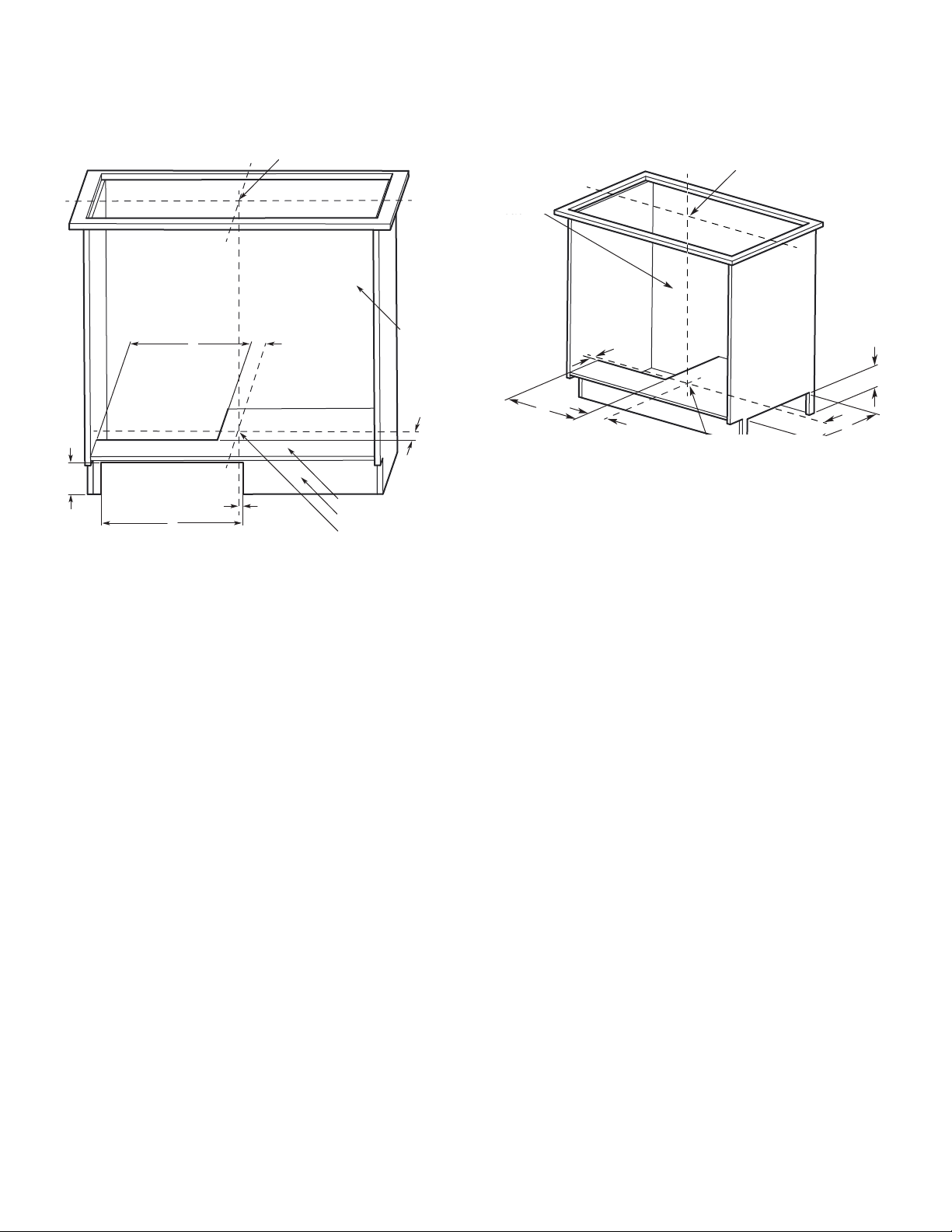

Style 2 – Cabinet Cutouts for Recirculation Front

Kick Plate Installations

Cabinet cutout areas for recirculation venting out of the front of

the blower motor assembly to the front kick plate of the cabinet.

Centerline/center point

Center line/center point

of countertop cutout

of countertop cutout

Inside

Inside

cabinet

C

B

cabinet

back

back

Style 3 – Cabinet Cutouts for Side Recirculation

Installations

Cabinet cutout areas for recirculation venting out of the right-side

of the blower motor assembly to the right side of the cabinet.

Center line/center point

Centerline/center point

of countertop cutout

of countertop cutout

Inside

Inside

cabinet

cabinet

back

back

D

A

H

A

H

E

F

G

Centerline/center point

Center line/center point

of countertop cutout

of countertop cutout

A. Cutout in cabinet floor for blower motor housing –

recirculation position

B. 21/2" (6.4 cm)

C. 143/4" (37.5 cm)

D. 33/4" (9.5 cm)

E. Cutout in cabinet kick plate for recirculation duct assembly

F. 13/16" (2.0 cm)

G. 173/64" (43.3 cm)

H. 331/32" (10.1 cm)

Cabinet floor

Cabinet oor

Cabinet kick plate

Cabinet kick-plate

D

C

B

Center line/center point

of countertop cutout

A. Cutout in cabinet floor for blower motor

housing – recirculation position

B. 21/2" (6.4 cm)

C. 143/4" (37.5 cm)

D. 33/4" (9.5 cm)

E. Cutout in cabinet right-end panel

for recirculation duct assembly

F. 63/16" (16.0 cm)

G. 173/64" (43.3 cm)

H. 331/32" (10.1 cm)

E

G

Use the same cabinet cutout dimensions E, F, G, and H for

recirculation out the left side of the cabinet.

NOTE: Left-side recirculation recommendation: There must be a

minimum of 7B\," (19.4 cm) between the face panel of the blower

motor housing assembly and the left outside of the cabinet.

6

Venting Requirements

IMPORTANT: This appliance must be exhausted outdoors

unless you are using the Recirculation Accessory Kit. See the

“Venting Methods” section and the “Accessories” section in

your Use and Care manual to order.

■ Do not terminate the vent system in an attic or other

enclosed area.

■ Vent system must terminate to the outside.

■ Use only a 3Z\v" x 10" (8.3 cm x 25.4 cm) rectangular metal

vent or 6" (15.2 cm) round metal vent. Rigid metal vent is

recommended. Do not use plastic or metal foil vent.

■ Before making cutouts, make sure there is proper clearance

within the wall or floor for the exhaust vent.

■ Do not cut a joist or stud unless absolutely necessary.

If a joist or stud must be cut, then a supporting frame must

be constructed.

■ The size of the vent should be uniform.

■ The vent system must have a damper.

■ Use vent clamps and metal duct tape to seal all joints in the

vent system.

■ Use caulking to seal exterior wall or roof opening around

the cap.

■ Determine which venting method is best for your application.

For Best Performance:

■ Use 26-gauge minimum galvanized or 25-gauge minimum

aluminum metal vent. Poor quality pipe fittings can reduce

airflow. For external venting, flexible metal vent is not

recommended.

NOTE: Local codes may require a heavier gauge material.

■ Metal duct may be reduced to 30-gauge galvanized steel

or 26-gauge aluminized steel if allowed by local codes.

This reduction is based on information in the International

Residential Codes Section M1601.1 (2006 edition).

■ Avoid installing 2 elbows together.

■ Use no more than three 90° elbows.

■ If an elbow is used, install it as far away as possible from

the hood’s vent motor exhaust opening.

■ Make sure there is a minimum of 18" (45.7 cm) of straight

vent between the elbows if more than one elbow is used.

Elbows too close together can cause excess turbulence

that reduces airflow.

■ Do not use a 5" (12.7 cm) elbow in a 6" (15.2 cm) or

3¼" x 10" (8.3 cm x 25.4 cm) system.

■ Do not reduce to a 5" (12.7 cm) system after using a

6" (15.2 cm) or 3¼" x 10" (8.3 cm x 25.4 cm) fittings.

■ Avoid forming handmade crimps. Handmade crimps may

restrict airflow.

■ Use a Jenn-Air

®

vent cap for proper performance. If an

alternate wall or roof cap is used, be certain the cap size

is not reduced and that it has a backdraft damper.

■ Use vent clamps and metal duct tape to seal all joints

in the vent system.

■ Use caulking to seal exterior wall or roof opening around

the cap.

The length of vent system and number of elbows should be

kept to a minimum to provide efficient performance.

The maximum equivalent length of the vent system is 35 ft

(10.7 m). For altitudes above 4,500 ft (1272 m), reduce

recommended vent run by 20% for best performance.

Cold Weather Installations

An additional backdraft damper should be installed to minimize

backward cold air flow and a thermal break installed to minimize

conduction of outside temperatures as part of the vent system.

The damper should be on the cold air side of the thermal break.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements

in your area.

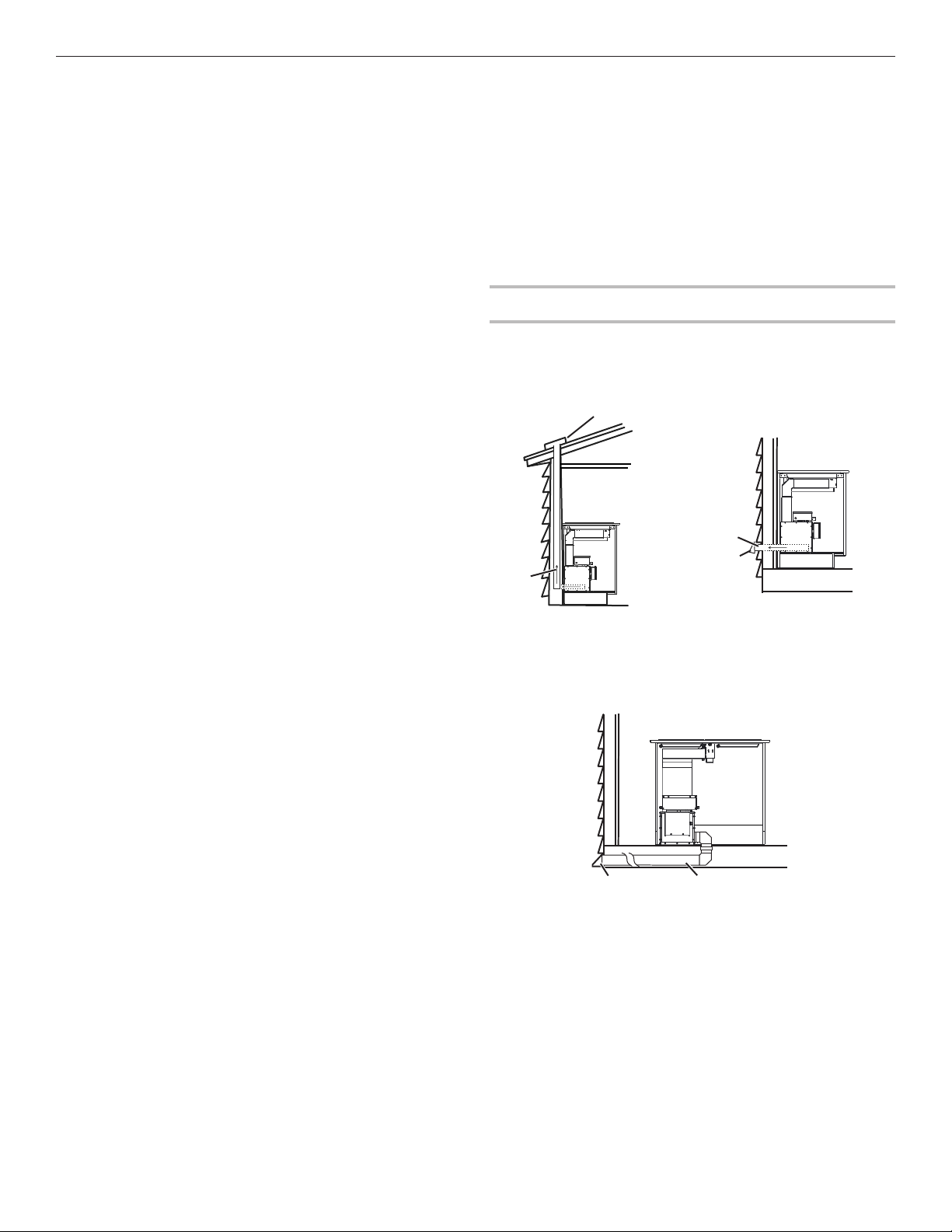

Venting Methods

Common venting methods are shown for a counter-mounted

downdraft cooktop. The cooktop may be vented through the

wall or floor.

Option 1 – Roof Venting Option 2 – Wall Venting

B

B

A

A

A. 31/4" x 10" (8.3 cm x 25.4 cm)

rectangular floor venting

B. Roof cap

Option 3 – Venting Between Floor Joist

Front view of cabinet with doors removed

B A

A. 31/4" x 10" (8.3 cm x 25.4 cm)

rectangular wall venting

B. Wall cap

A. 31/4" x 10" (8.3 cm x 25.4 cm)

rectangular wall venting

B. Wall cap

7

Concrete Slab Installations – Exhaust Through Wall

K

(0.6 m)

wall cap

BA

E

F

D

O

C

Vent Piece 6" (15.2 cm) Round

6" (15.2 cm)

5.0 ft (1.5 m)

to 3Z\v" x 10"

(8.3 cm x 25.4 cm)

90° elbow transition

3Z\v" x 10"

5.0 ft (1.5 m)

(8.3 cm x 25.4 cm)

90° elbow

G

N

M

A. Wall cap

B. 6" (15.2 cm) round metal vent

C. 16" (40.6 cm) maximum

D. 6" (15.2 cm) round PVC sewer pipe

E. 31/4" x 10" (8.3 cm x 25.4 cm) rectangular 90° metal vent elbow

F. 31/4" x 10" (8.3 cm x 25.4 cm) rectangular to 6" (15.2 cm)

round metal vent transition

G. 6" (15.2 cm) round PVC coupling

H. Concrete slab

I. 6" (15.2 cm) round PVC sewer pipe

J. 6" (15.2 cm) round 90° PVC sewer pipe elbow

K. Tightly pack gravel or sand completely around pipe.

L. 30 ft (9.1 m) maximum

M. 6" (15.2 cm) round 90° PVC sewer pipe elbow

N. 6" (15.2 cm) round PVC coupling

O. 12" (30.5 cm) minimum

L

H

I

J

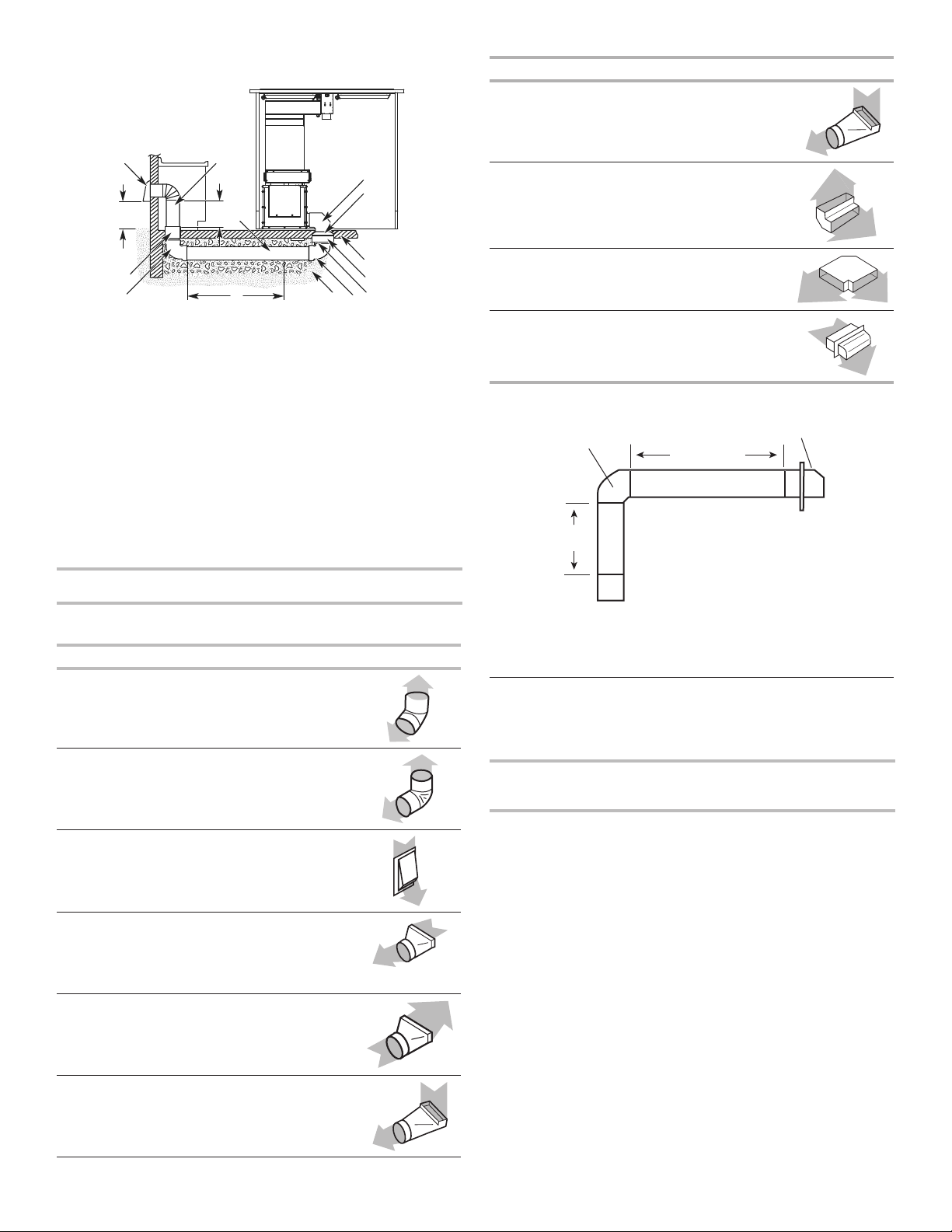

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

Vent Piece 6" (15.2 cm) Round

45° elbow 2.5 ft (0.8 m)

3Z\v" x 10"

5.0 ft (1.5 m)

(8.3 cm x 25.4 cm)

flat elbow

3Z\v" x 10"

0.0 ft (0.0 m)

(8.3 cm x 25.4 cm)

wall cap

Example vent system

90˚ elbow

6 ft (1.8 m)

2 ft

1 - 90° elbow = 5 ft (1.5 m)

8 ft (2.4 m) straight = 8 ft (2.4 m)

1 - wall cap = 0 ft (0 m)

System length = 13 ft (3.9 m)

90° elbow 5.0 ft (1.5 m)

6" (15.2 cm) wall cap 0.0 ft (0.0 m)

3Z\v" x 10"

4.5 ft (1.4 m)

(8.3 cm x 25.4 cm)

to 6" (15.2 cm)

transition

6" (15.2 cm)

1 ft (0.3 m)

to 3Z\v" x 10"

(8.3 cm x 25.4 cm)

transition

3Z\v" x 10"

5.0 ft (1.5 m)

(8.3 cm x 25.4 cm)

to 6" (15.2 cm)

90° elbow transition

NOTE: A flexible vent is not recommended. Flexible vents

create back pressure and air turbulence that greatly reduce

performance.

Recirculation: Non-Vented (Recirculating)

Installations Only

You will need to order:

■ Recirculation Kit part number W10807915 (See the

“Assistance or Service” section in your Use and Care

manual to order.)

■ You may also need a section of 3Z\v" x 10" (8.3 cm x 25.4 cm)

metal duct – length required is determined by the distance

from the exhaust outlet to the back flat surface of the

Recirculation Kit housing.

8

Electrical Requirements

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire.

Electrically ground cooktop.

Failure to follow these instructions can result in death,

fire, or electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine

that the ground path and wire gauge are in accordance with

local codes.

Check with a qualified electrical installer if you are not sure the

cooktop is properly grounded.

Make sure that the electrical connection and wire size are

adequate and in conformance with the National Electrical Code,

ANSI/NFPA 70 - latest edition or CSA Standards C22.1-94,

Canadian Electrical Code, Part 1 and C22.2 No. O-M91 - latest

edition, and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

Before You Make the Electrical Connection:

To properly install your cooktop, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ A 3-wire or 4-wire, single phase, 120-/240-volt, 60 Hz,

AC-only electrical supply on a separate, 40-amp circuit

breaker is required. If a fused system is used, fuse both

sides of the line.

■ The cooktop should be connected directly to the junction

box through the flexible metal conduit. The flexible, armored

cable extending from the fuse box or circuit breaker box

should be connected directly to the junction box.

■ Locate the junction box to allow as much slack as possible

between the junction box and the cooktop so that the

cooktop can be moved if servicing becomes necessary

in the future.

■ A UL listed or CSA approved conduit connector must

be provided at each end of the power supply cable

(at the cooktop and at the junction box).

■ If the house has aluminum wiring, follow the procedure

below:

1. Connect a section of solid copper wire to the

pigtail leads.

2. Connect the aluminum wiring to the added section

of copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer’s recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

INSTALLATION INSTRUCTIONS

Prepare Cooktop

WARNING

Excessive Weight Hazard

Use two or more people to move and install cooktop.

Failure to do so can result in back or other injury.

1. Open product as instructed on product packaging.

2. Remove shipping materials and tape from cooktop.

3. Using 2 or more people, remove the cooktop from

the carton.

NOTE: Always handle the cooktop from the underside of

the cooktop chassis, not from the stainless steel frame or

the metal covers on the bottom of the cooktop.

4. Using 2 or more people, place the cooktop upside

down on a protected surface.

9

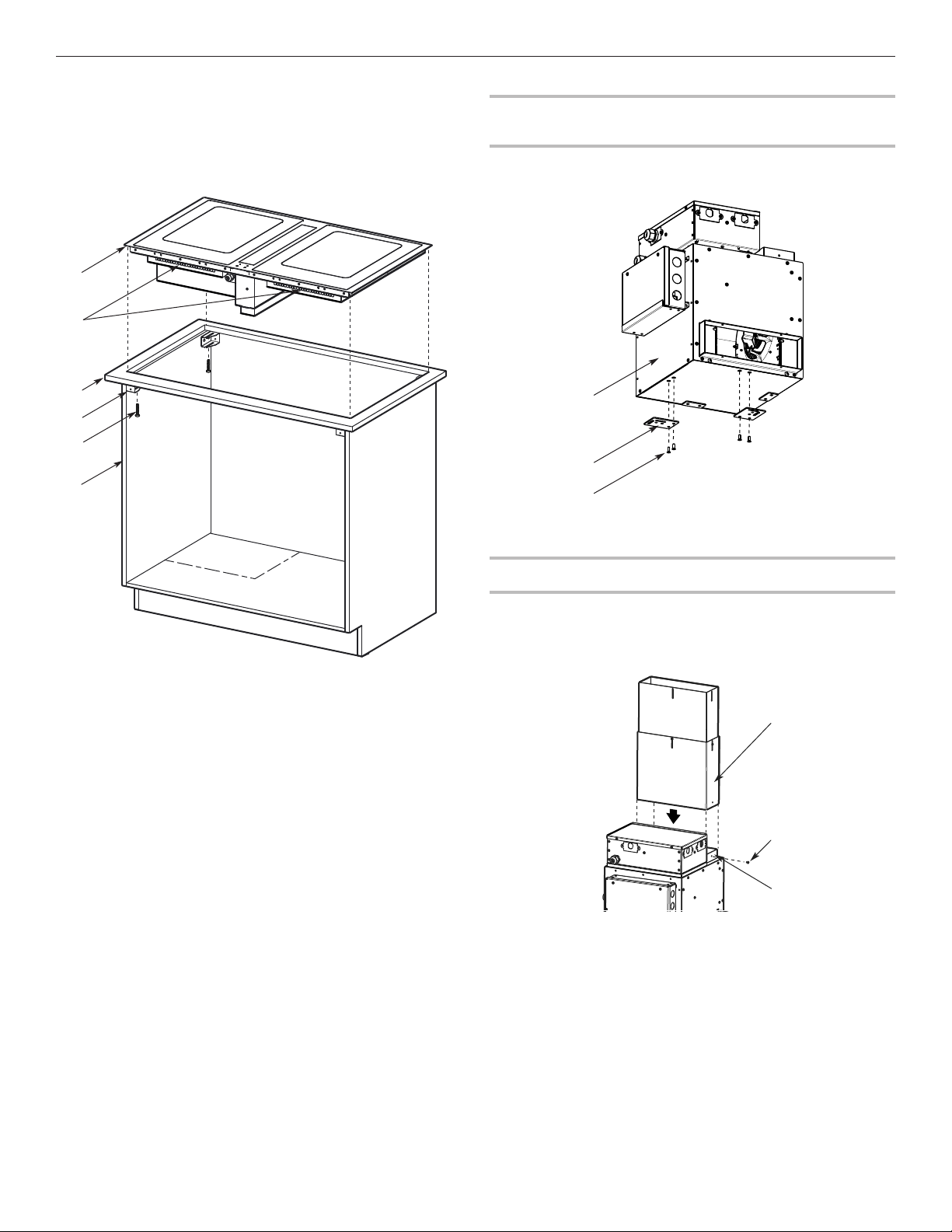

Install Foam Strips

1. Remove foam strip from literature and hardware package.

2. Measure and cut 4 pieces: 2 pieces 211/4" (54.0 cm) long

and 2 pieces 35" (88.9 cm) long.

3. Remove backing from the 211/4" (54.0 cm) foam strips and

apply the foam strips, adhesive-side down, to each end of

the outer flange on the underside of the cooktop trim.

4. Remove backing from the 35" (88.9 cm) foam strips and

apply the foam strips, adhesive-side down, to the front and

rear outer flanges on the underside of the cooktop trim.

Do not overlap the foam strips.

B

A

Cooktop Mounting Brackets Installation

NOTE: For ease of installation, install cooktop mounting

brackets to cabinet before installing cooktop into cabinet.

Installing Mounting Brackets to Cabinet Sides

NOTE: Cabinets wider than 36" (91.4 cm) may require additional

sides (Z\x" [1.3 cm] thick wood, minimum) to be constructed

inside of the cabinet at a width of 34>\zn" (87.8 cm). The inside

of each sidewall should be located 17>\cx" (43.9 cm) from the

center line of the cooktop cutout and parallel to the sides of the

cooktop cutout.

1. Draw a horizontal line on the inside of both cabinet sides or

added sidewall 1C\zn" (30 mm) down from the top surface of

the countertop.

2. Align the 4 brackets 1M\," (47 mm) from the front and back

cutout surface of the countertop on the marked horizontal

A

lines and orient as shown with 1 front bracket and 1 rear

bracket on each side.

17/8"

(47 mm)

3

1

17/8"

(47 mm)

/16"

(30 mm)

B

A

B

D

A

C

A. Foam strip - 211/4" (54.0 cm) long (2 pieces)

B. Foam strip - 35" (88.9 cm) long (2 pieces)

C. Cooktop trim - edge flange (right and left sides)

D. Cooktop trim - edge flange (front and rear)

NOTE: The foam strip (optional) keeps the underside of the

cooktop frame from debris and helps the cooktop sit flat on

uneven counters.

A

A

B

C

A. Marked location lines on inside of

cabinet sidewalls (typical both ends)

B. Cooktop mounting brackets (4)

C. M4 x 12 mm screws (8)

3. Mark and pre-drill the mounting holes using a Z\," (3 mm)

drill bit. (Do not drill through the cabinet sidewalls.)

4. Using 2 M4 x 12 mm mounting screws (supplied) for each

mounting bracket, attach the 4 mounting brackets to the

cabinet sides. A shorter screw length (not supplied) may

be required if the cabinet sidewall thickness is less than

Z\x" (12.7 mm).

10

Install Cooktop and Blower Motor Assembly

1. Using 2 or more people, place cooktop into the cutout.

2. Align cooktop to sit flat onto the countertop.

3. Install 4 M5 x 50 mm cap screws, lock washers, and flat

washers (1 each corner) to secure the cooktop to the

mounting brackets. Tighten screws to pull cooktop tight

to the countertop.

A

A

B

C

D

C

D

B

C

E

F

E

G

F

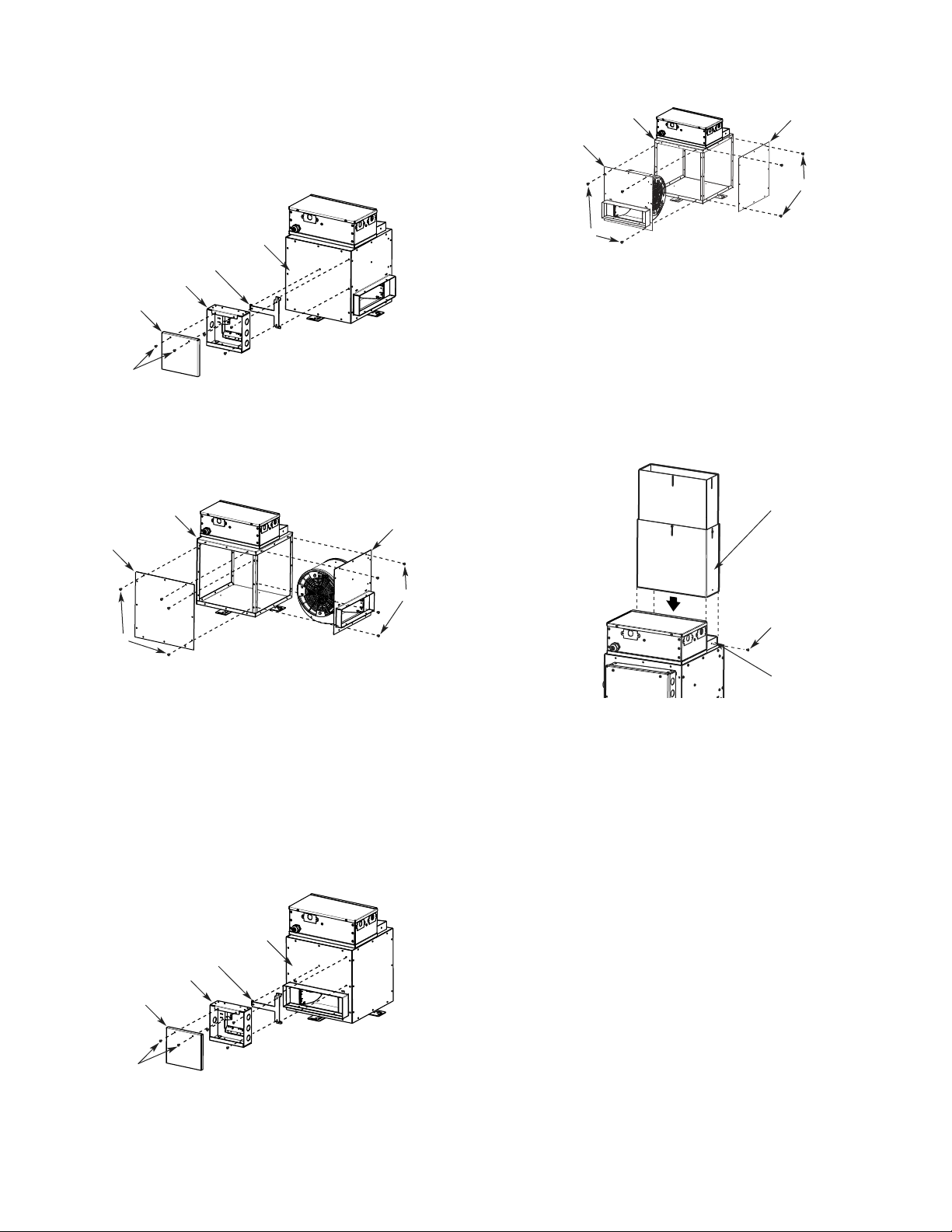

Install Mounting Feet/Spacers to Blower

Motor Assembly

1. Install the mounting feet (2) to the bottom of the blower

motor assembly, using 2 M5 x 10 mm flat-head screws

per foot, and tighten.

A

B

C

A. Blower motor assembly front side

B. Mounting feet (2)

C. M5 x 10 mm screws - flat head (4)

Prepare Blower Motor Assembly

A. Cooktop

B. Cooktop vent slots

C. Countertop

D. Mounting brackets (4)

E. M5 x 50 mm cap screws, lock

washers, and flat washers (4 each)

F. Cabinet (shown with front removed)

G. Cutout location in cabinet floor

(for recirculation installations only)

NOTES:

■ Make sure that the front edge of the cooktop is parallel to

the front edge of the countertop. If repositioning is needed,

lift entire cooktop up from the cutout to avoid scratching

the countertop.

■ Do not block vent slots on the front of the cooktop.

Style 1 – Vented or Recirculation to the Right

1. Assemble the 2-piece telescoping rectangular vertical duct

to the blower motor assembly top duct extension. Secure

with screw and metal duct tape.

A

B

C

A. Telescoping rectangular duct (2 pieces)

B. M4 x 9.5 mm screw

C. Blower motor assembly top duct extension

11

Style 2 – Recirculation to the Front

1. Using a T20® TORX® driver, remove the 2 screws and cover

from the electrical junction box on the front panel of the

blower motor assembly housing and set aside.

2. Using a T20® TORX® driver, remove the 4 screws and the

electrical junction box from the mounting bracket and

set aside.

NOTE: Do not remove any electrical connections.

8. Reassemble the panel and motor assembly into the front of

the blower motor assembly housing. Install the 11 screws

and tighten.

A

B

D

C

D

C

B

A

E

A. Cover – electrical junction box

B. Electrical junction box

C. Mounting bracket – electrical junction box

D. Blower motor assembly housing

E. Screws (6)

3. Using a T20® TORX® driver, remove the 11 screws and cover

panel from the front blower motor assembly housing.

A

D

B

C

C

A. Blower motor assembly housing

B. Cover panel

C. Screws (11 for each plate)

D. Panel and motor assembly

4. Using a T20® TORX® driver, remove the 3 screws and the

electrical junction box mounting bracket from panel and

set aside.

5. Disconnect the 9-pin blower motor electrical connector.

6. Using a T20® TORX® driver, remove the 11 screws that attach

the panel and motor assembly to the right side of the blower

motor assembly housing. Remove the panel and motor

assembly from the blower motor assembly housing.

7. Assemble the electrical box bracket to the front panel using

the 3 screws and tighten.

C

A. Blower motor assembly housing

B. Panel and blower motor assembly

C. Screws (22)

D. Front panel

9. Reconnect the 9-pin blower motor electrical connector.

10. Reassemble the panel to the right side of the blower motor

assembly housing. Install the 11 screws and tighten.

11. Reassemble the electrical box to the bracket using the

4 screws and tighten.

12. Assemble the 2-piece telescoping rectangular vertical duct

to the blower motor assembly top duct extension. Secure

with screw and metal duct tape.

A

B

C

A. Telescoping rectangular duct (2 pieces)

B. M4 x 9.5 mm screw

C. Blower motor assembly top duct extension

Style 3 - Vented or Recirculation to the Left

1. Using a T20® TORX® driver, remove the 11 screws and panel

from the left side of the blower motor assembly housing and

set aside.

2. Disconnect the 9-pin blower motor electrical connector.

12

D

C

B

A

E

A. Blower motor assembly housing

B. Mounting bracket – electrical junction box

C. Electrical junction box

D. Cover – electrical junction box

E. Screws (6)

Loading...

Loading...