Jenn-Air JGC8645BDS Installation Guide

SEALED GAS COOKTOPS

JGC8645

403WEST FOURTHSTREET,NORTH• NEWTON,IA 5020

• JENN-AIR 81

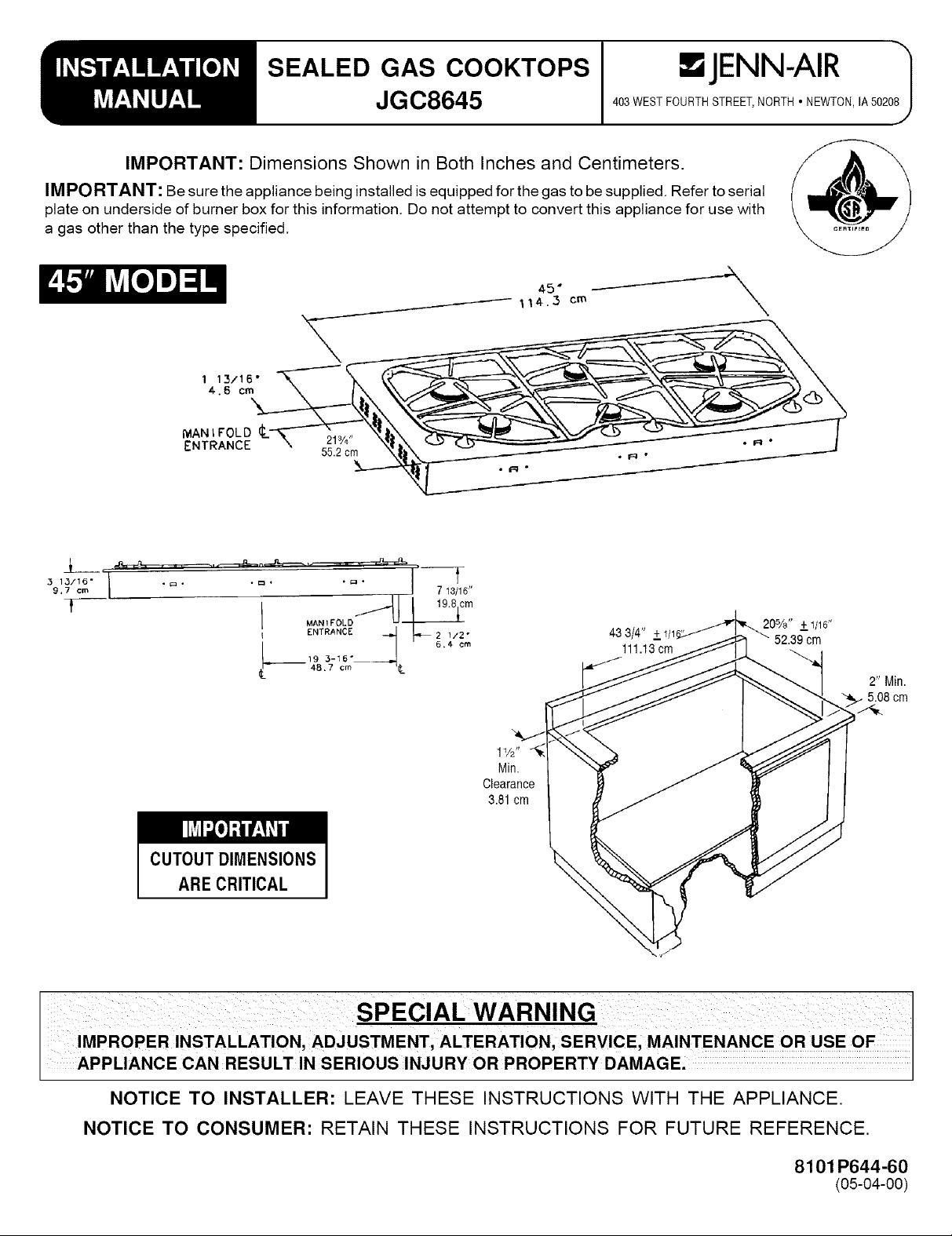

IMPORTANT: Dimensions Shown in Both Inches and Centimeters.

IMPORTANT: Be sure the appliance being installed is equipped for the gas to be supplied. Refer to serial

plate on underside of burner box for this information. Do not attempt to convert this appliance for use with

a gas other than the type specified.

114.3 cm

\

1 13116"

4,6 cm

I_AN I FOLD

ENTRANCE

391_J_"I "°"

CUTOUT DIMENSIONS

• = ° ' _ " J 7 13116"

, E.T._.CE1 t_LI'_;

( 4B.7 cm --_

ARE CRITICAL

MAN I It Ok D

!

20%" + 1/16"

2" Min.

5.08cm

11/2" _.

Min.

Clearance

3.81 cm

43 3/4" +_ 52.39 cm

111.13cm

NOTICE TO INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE.

NOTICE TO CONSUMER: RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE.

8101 P644-60

(o5-o4-oo)

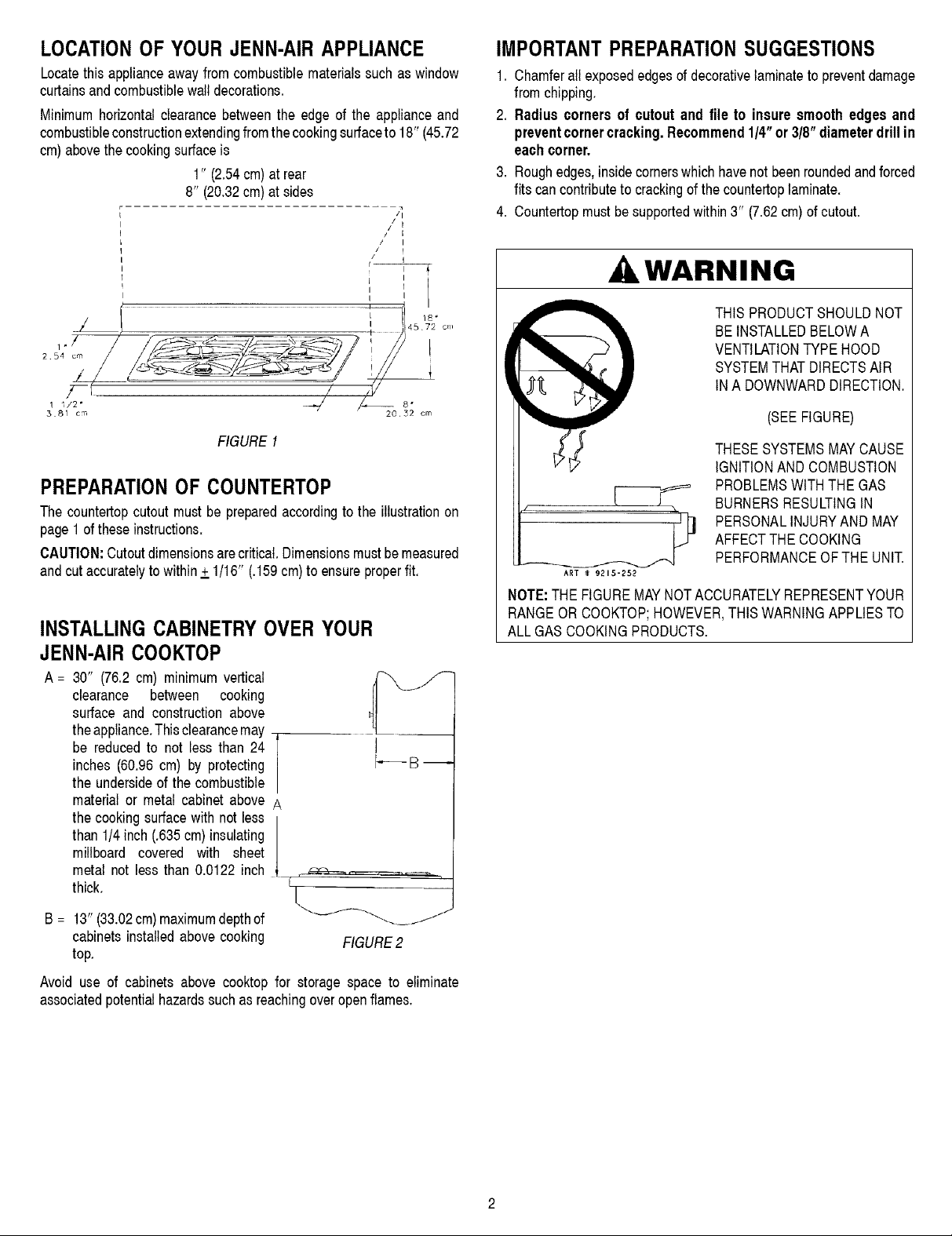

LOCATIONOF YOUR JENN-AIRAPPLIANCE

Locatethis applianceawayfromcombustiblematerialssuchas window

curtainsandcombustiblewalldecorations.

Minimumhorizontalclearancebetweenthe edge of the applianceand

combustibleconstructionextendingfromthecookingsurfaceto 18" (45.72

cm)abovethecookingsurfaceis

1" (2.54cm)atrear

8" (20.32cm) atsides

t I

I I I

I I

r T

i i

/ 71_' !

I / I I V

20,32 cm

FIGURE1

PREPARATIONOF COUNTERTOP

Thecountertopcutoutmustbe preparedaccordingtothe illustrationon

page1 oftheseinstructions.

CAUTION:Cutoutdimensionsarecritical.Dimensionsmustbemeasured

andcutaccuratelytowithin_+1/16" (.159cm)to ensureproperfit.

INSTALLINGCABINETRYOVERYOUR

JENN-AIRCOOKTOP

A = 30" (76.2cm) minimum vertical

clearance between cooking

surface and constructionabove

theappliance.Thisclearancemay

be reducedto not less than 24

inches (60.96cm) by protecting

the undersideof the combustible

material or metalcabinetabove

thecookingsurfacewithnot less

than1!4inch (.635cm)insulating

millboard covered with sheet

metal not less than 0.0122 inch

thick.

B = 13"(33.02cm)maximumdepthof

cabinetsinstalledabovecooking

top.

A

f

L__vj/Ij

I

FIGURE2

IMPORTANTPREPARATIONSUGGESTIONS

1. Chamferallexposededgesof decorativelaminateto preventdamage

fromchipping.

2. Radius cornersof cutoutand file to insure smoothedges and

preventcornercracking.Recommend1/4"or 3/8"diameter drill in

each corner.

3. Roughedges,insidecornerswhichhavenot beenroundedandforced

fitscancontributeto crackingofthecountertoplaminate.

4. Countertopmustbesupportedwithin3" (7.62cm)of cutout.

WARNING

THISPRODUCTSHOULDNOT

BE INSTALLEDBELOWA

VENTILATIONTYPEHOOD

SYSTEMTHATDIRECTSAIR

INA DOWNWARDDIRECTION.

(SEEFIGURE)

THESESYSTEMSMAYCAUSE

IGNITIONAND COMBUSTION

PROBLEMSWITHTHEGAS

BURNERSRESULTINGtN

PERSONALINJURYANDMAY

AFFECTTHE COOKING

PERFORMANCEOFTHE UNIT.

NOTE:THEFIGUREMAYNOTACCURATELYREPRESENTYOUR

RANGEORCOOKTOP;HOWEVER,THISWARNINGAPPLIESTO

ALLGASCOOKINGPRODUCTS.

Avoid use of cabinets abovecooktop for storage space to eliminate

associatedpotentialhazardssuchas reachingoveropenflames.

INSTALLATIONOF APPLIANCE

Theinstallationof thisappliancemustconformwithlocalcodesor,inthe

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1-LatestEdition,or, inCanada,CAN!CGA-B149InstallationCode,

LatestEdition.

This appliance, when installed, must be electrically grounded in

accordancewith localcodesor,inthe absenceof local codes,with the

NationalElectricalCodeANSI!NFPANo.70-LatestEdition,or,inCanada,

currentCSAStandardC22.1CanadianElectricalCode,Part1.

In The CommonwealthOf Massachusetts

Thisproductmustbe installedbya licensedplumberorgasfitterwhe_

installedwithintheCommonwealthofMassachusetts.

A"F' handletypemanualgasvalvemust beinstalledinthegassupply

linetothisappliance.

A flexiblegasconnector,whenused,mustnotexceeda lengthof

three(3)feet136 inches.

All supplypiping,exceptas noted, shoulduse commonNational Pipe

Thread (N.P.T.).For all pipe connectionsuse an approvedpipe joint

compoundresistantto theactionof LPgas.

CAUTION:Warrantyisvoid onJenn-Airequipmentinstalledotherthanas

recommendedby manufacturer.

This applianceis designedfor use with the appliance gas pressure

regulatorsuppliedwiththis appliance.Itmustbeinstalledinthe gasway

aheadofthe gasmanifoldentrance.Itis presetfor usewithnaturalgasand

mustbeconverted,asdescribedon pages6&7, forusewithLPgas.(See

figures8 and9).

This applianceisdesignedto operateat apressureof 5 inchesofwater

columnon naturalgasor, if convertedfor usewith LPgas (propaneor

butane),10incheswatercolumn.Makesurethisapplianceis suppliedwith

andadjustedfor thetype ofgas forwhich itisdesigned.

Thisappliancewasadjustedatthefactoryforusewithnaturalgas.If,at any

time,this applianceis to be usedwitha differenttype of gas, all ofthe

conversionadjustmentsdescribedon pages6 and7 mustbe madebya

qualifiedservicetechnicianbeforeattemptingto operatethe cooktopon

thatgas.Naturalgasshouldbesuppliedtotheappliancepressureregulator

atalinepressurebetween6and14inchesofwatercolumnor,ifconverted

for LPgas,between11and 14inches.

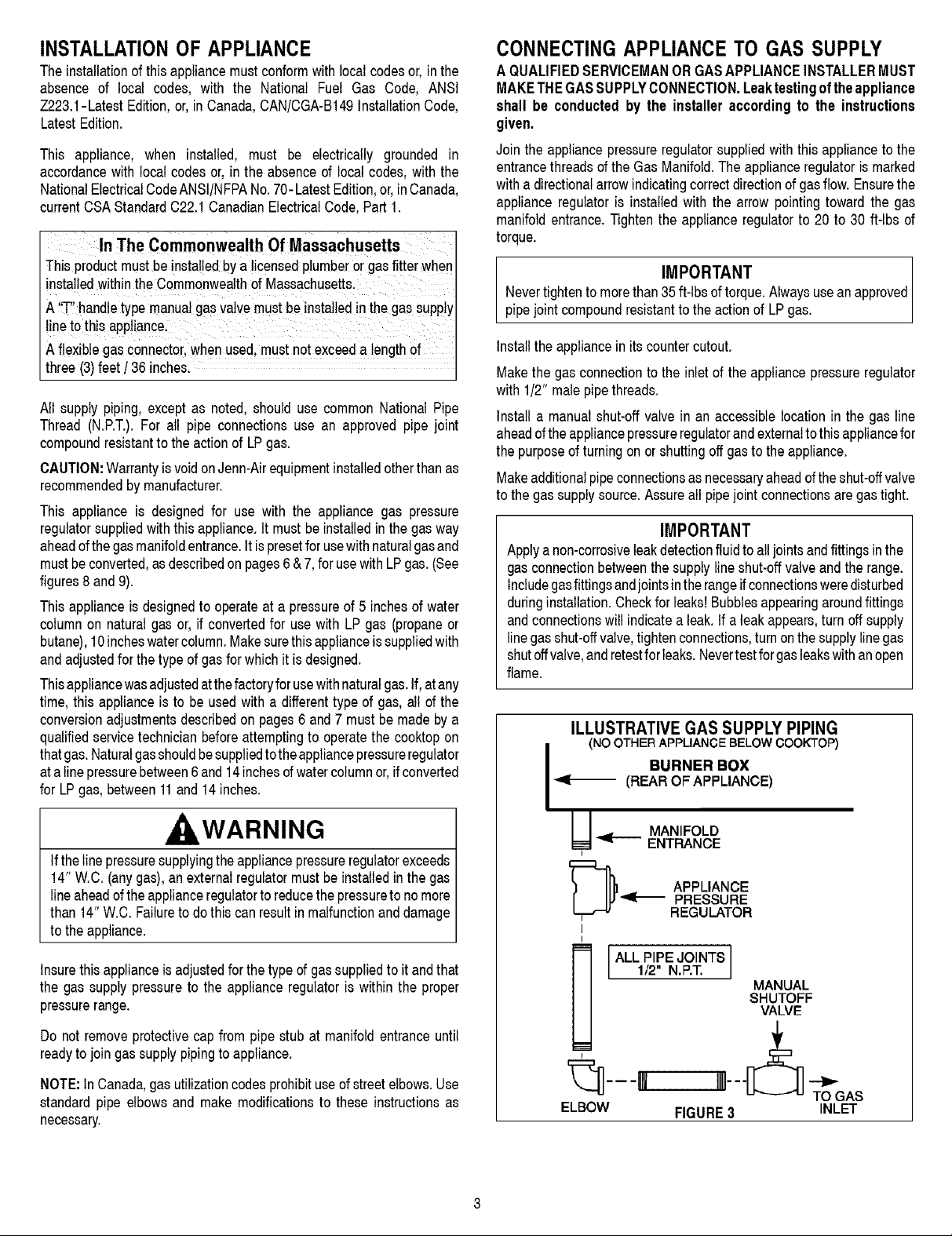

CONNECTINGAPPLIANCETO GAS SUPPLY

AQUALIFIEDSERVICEMANORGASAPPLIANCEINSTALLERMUST

MAKETHEGASSUPPLYCONNECTION.Leaktestingoftheappliance

shall be conductedby the installer accordingto the instructions

given.

Join theappliancepressureregulatorsuppliedwith this applianceto the

entrancethreadsof theGasManifold.Theapplianceregulatorismarked

with adirectionalarrowindicatingcorrectdirectionof gasflow.Ensurethe

applianceregulatoris installedwith the arrow pointingtoward the gas

manifoldentrance.Tightenthe applianceregulatorto 20 to 30 ft-tbs of

torque.

IMPORTANT

Nevertightento morethan35ft-tbsoftorque.Alwaysuseanapproved

pipejointcompoundresistantto theactionof LPgas.

Installthe appliancein itscountercutout.

Makethe gasconnectionto the inletof the appliancepressureregulator

with 1/2"malepipethreads.

Installa manualshut-offvalve in an accessiblelocationin the gas line

aheadof theappliancepressureregulatorandexternaltothisappliancefor

the purposeofturningonor shuttingoff gastotheappliance.

Makeadditionalpipeconnectionsasnecessaryaheadoftheshut-offvalve

to thegassupplysource.Assureallpipejoint connectionsaregastight.

IMPORTANT

Applya non-corrosiveleakdetectionfluidto alljointsandfittingsinthe

gasconnectionbetweenthe supplylineshut-offvalveandthe range.

Includegasfittingsandjointsintherangeifconnectionsweredisturbed

duringinstallation.Checkforleaks!Bubblesappearingaroundfittings

andconnectionswill indicatea leak.Ifa leak appears,turn offsupply

linegasshut-offvalve,tightenconnections,turnonthe supplylinegas

shutoffvalve,andretestforleaks.Nevertestforgasleakswithanopen

flame.

ILLUSTRATIVEGAS SUPPLYPIPING

(NO OTHER APPLIANCE BELOW COOKTOP)

BURNER BOX

I

(REAROF APPLIANCE)

WARNING

Ifthelinepressuresupplyingtheappliancepressureregulatorexceeds

14"W.C.(anygas),anexternalregulatormustbeinstalledin thegas

lineaheadoftheapplianceregulatortoreducethepressureto nomore

than 14"W.C,Failuretodothiscan resultin malfunctionanddamage

to theappliance.

Insurethisapplianceisadjustedforthetypeof gassuppliedto itandthat

the gas supplypressureto the applianceregulatoris withinthe proper

pressurerange.

Do not removeprotectivecapfrom pipestub at manifoldentranceuntil

readyto joingassupplypipingtoappliance.

NOTE:In Canada,gas utilizationcodesprohibituseofstreetelbows.Use

standardpipeelbowsand make modificationsto these instructionsas

necessary.

U MANIFOLDENTRANCE

PRESSURE

APPLIANCE

REGULATOR

I

I

1/2" N.P.T.

ALL PIPEJOINTS

I

ELBOW

FIGURE3 INLET

MANUAL

SHUTOFF

VALVE

TOGAS

Loading...

Loading...