Jenn-Air JGD8348CDP, JGC8645BDB/Q/S/W, JGCP430CDP, JGCP636CDP, JGCP648CDP Service Manual

...

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

Gas Cooktops

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

JGD8348CDP

JGC8430BDB/Q/S/W

JGC8645BDB/Q/S/W

JGCP430CDP

JGCP636CDP

JGCP648CDP

16023565

November 2004

©2004 Maytag Services

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

Important Notices for Servicers and Consumers

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

WARNING

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.JENNAIR.COM ............................................. 1-800-536-6247

CAIR Center in Canada ........................................... 1-800-688-2002

Recognize Safety Symbols, Words, and Labels

DANGER!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16023565 ©2004 Maytag Services

Table of Contents

Important Information .................................................. 2

Safety Information ....................................................... 4

Safety Practices for Servicer .................................. 5

Servicing ................................................................ 5

Before Installing ..................................................... 5

Receiving Cooktop ................................................. 5

Unpacking .............................................................. 5

Gas Connection ..................................................... 6

Electrical Requirements ......................................... 6

Electrical Connections ........................................... 6

Product Safety Devices .......................................... 7

General Information

Model Identification Rating Label and Ordering

Relacement Parts .................................................. 8

Cooking Nomenclature ................................................ 8

Specifications ........................................................ 9

Placement of the Cooktop ...................................... 9

Do Not Block Air Vents .......................................... 9

Location of Model Number ...................................... 9

Model Identification ................................................ 9

Service ................................................................... 9

Parts and Accessories ........................................... 9

Extended Service Plan ........................................... 9

Grounding .............................................................. 9

Cooktop Description ............................................. 10

Troubleshooting Procedures ..................................... 11

Component Testing Information ................................. 13

Disassembly Procedures

Disassembly Procedures for Models Listed ........... 16

JGC8430BDB/W/Q/S

JGC8645BDS

Main Top Removal ................................................ 16

Spark Module Removal Bottom Access ............... 16

Spark Module Removal ........................................ 16

Surface Ignitor Removal ........................................ 16

Burner Switch Removal ........................................ 16

Manifold Pipe Removal ......................................... 16

Orifice Holder Removal ......................................... 16

Burner Tubing Removal ........................................ 16

Disassembly Procedures for Models Listed ........... 18

JGD8348CDP

JGCP430ADP

JGCP636ADP

JGCP648ADP

Main Top Removal ................................................ 18

Spark Module Removal ........................................ 18

Surface Ignitor Removal ........................................ 18

Burner Switch Removal ........................................ 18

Manifold Pipe Removal ......................................... 18

Orifice Holder Removal ......................................... 18

Burner Tubing Removal ........................................ 18

E-Burner Removal ................................................ 18

Grease Filter Removal .......................................... 20

Blower Removal ................................................... 20

Appendix A: Installation Instructions

Models JGCP430ADP, JGCP636ADP,

JGCP648ADP .................................................... A–2

Model JGD8348CDP .... ...................................... A–4

Ducting Instructions, Model JGD8348CDP ......... A–6

Model JGC8430BD* ........................................... A–9

Model JGC8645BDS ........................................ A–10

Appendix B: Use and Care

Models JGCP430ADP, JGCP636ADP,

JGCP648ADP ....................................................

Model JGD8348CDP .... ...................................... B–4

Model JGC8430BD* ........................................... B–6

Model JGC8645BDS ...... .................................... B–8

Care and Cleaning ............................................ B–10

Appendix C: LP/Natural Gas Conversion

Models JGD8348CDP, JGCP430ADP,

JGCP636ADP, JGCP648ADP ............................ C–2

Models JGD8430BD*, JGD8645BDS .................. C–4

B–2

©2004 Maytag Services 16023565 3

Safety Information

As with all appliances, there are certain rules to follow for

safe operation. Verify everyone who operates the cooktop

is familiar with the operations and with these precautions.

Use appliance only for its intended purpose as described.

Pay close attention to the safety sections of this manual.

Recognize the safety section by looking for the following

symbol or the word safety.

Recognize this symbol as a safety precaution.

!

WARNI NG

!

This gas appliance contains or produces a chemical or

chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

To reduce the risk from substances in the fuel or from

fuel combustion make sure this appliance is installed,

operated, and maintained according to the instructions

in this manual.

Due to the nature of cooking, fires can occur as a

result of overcooking or excessive grease. Although a

fire is unlikely, if one occurs proceed as follows:

WARNI NG

!

If the information in this manual is not followed exactly,

a fire or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Extinguish any open flame.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call fire

department.

Installation and service must be performed by an

authorized installer, service agency or gas supplier.

Cooktop Fires

1. Do not turn on any ventilation system above the

cooktop.

2. Turn all controls to the OFF position.

3. As an added precaution turn off the electricity at

the main circuit breaker or fuse box and the gas

at the main supply valve.

4. Cover the food or grease to smother fire.

If smoke or fire persist call the local fire department.

To avoid the risk of property damage or personal injury

do not obstruct the flow of combustion or ventilation air.

To avoid the risk of electrical shock, serious personal

injury or death: Make sure your cooktop has been

properly grounded and always disconnect the electrical

supply before servicing the unit.

NOTE: The maximum gas supply pressure for these

models must not exceed 14 inches W.C.P.

!

WARNI NG

To avoid risk of electrical shock, property damage,

personal injury or death; verify wiring is correct, if

components were replaced. Verify proper and complete

operation of unit after servicing.

4 16023565 ©2004 Maytag Services

Safety Information

Safety Practices for Servicer

Safe and satisfactory operation of gas cooktops depend

upon its design and proper installation. However, there is

one more area of safety to be considered:

Servicing

Listed below are some general precautions and safety

practices which should be followed in order to protect the

service technician and consumer during service and after

service has been completed.

1. Gas smell—Extinguish any and all open flames and

open windows.

2. Turn gas off—Service cooktop with gas turned off

unless testing requires it.

3. Checking for gas leaks—Never check for leaks with

any kind of open flame. Soap and water solution

should be used for this purpose. Apply solution to

suspected area and watch for air bubbles which

indicates a leak. Correct leaks by tightening fittings,

screws, connections, applying approved compound,

or installing new parts.

4. Using lights—Use a hand flashlight when servicing

cooktops or checking for gas leaks. Electric

switches should not be operated where leaks are

suspected. This will avoid creating arcing or sparks

which could ignite the gas. If electric lights are

already turned on, they should not be turned off.

5. Do not smoke—Never smoke while servicing gas

cooktops, especially when working on piping that

contains or has contained gas.

6. Check cooktop when service is completed—After

servicing, make visual checks on electrical

connection, and check for gas leaks. Inform

consumer of the condition of cooktop before leaving.

7. Adhere to all local regulations and codes when

performing service.

Before Installing

Installing the gas cooktop in compliance with local

electrical and gas building codes results in proper

operation and consumer satisfaction with the cooktop.

Receiving Cooktop

Inspect cooktop thoroughly at time of delivery.

Immediately report any visible damage to carrier. Damage

not discovered until after accepting delivery can still be

claimed by using a concealed damage report form,

available from the carrier's agent.

All shipments, i.e., complete cooktop or parts, are

shipped at the buyer's risk. Maytag's responsibility ends

when the consignment is accepted by the carrier in

"good order." Maytag supports damage claims by

supplying invoices, bills of laden, and other

documentation as needed. providing this assistance,

however, does not imply any responsibility for settling

claims. Do not deduct claims for loss or damage from the

invoice and do not withhold payment pending adjustment

of claims. Do not return any units or parts for credit

without written consent.

Unpacking

• Open the carton and slide cooktop out of packing.

• Remove all literature packed with the cooktop and

place cooktop onto a protective flat surface.

• Avoid countertop damage by NOT sliding cooktop

across the countertop.

• Remove grates, burner caps, and pressure regulator

from the carton.

!

WARNI NG

Do not store items of interest to children in cabinets

above cooktop. Children may climb on cooktop to

reach these items and become seriously injured.

©2004 Maytag Services 16023565 5

Safety Information

Gas Connection

Verify the cooktop installation meets local codes or

current American Gas Association (CGA) requirements in

the absence of local codes. When installing CGA units,

verify that installation meets local codes or in absence of

local codes, current Natural Gas Installation Code CAN/

CGA-B149.1 or current Propane Installation Code, CAN/

CGA-B149.2 before connecting to the gas supply

system.

Installation in manufactured homes must conform with

the standard CAN/CSA-Z240 Mobile Homes,

Manufactured Home Construction and Safety Standards,

Title 24CFR, Part 3280, or with local codes is applicable.

WARNI NG

!

To avoid risk of personal injury or property damage.

Use only new flexible connectors design certified by

AGA or CGA. Do not reuse an old connector. Do not

reuse an old connector when moving the appliance.

Access to Gas Connection

Install manual shut-off valve in an accessible location

outside the cooktop. Be aware of the location of the

shut-off valve. Shut-off valve is not supplied with the

cooktop.

Use a pipe joint compound resistant to the action of

propane gas on all male threads.

Connect the gas supply line either using hard piping or a

properly-certified flexible connector. The pressure

regulator supplied with cooktops have a 1/2 inch NPT

female connection. Check local codes before choosing a

method.

Electrical Requirements

120-volt, 60 Hertz, 20 amp, individual circuit which is

properly grounded, polarized and protected by a circuit

breaker or fuse.

Electrical Connections

Models with automatic pilotless (spark) ignition require

an external electrical source that must be grounded and

polarized in accordance with local codes. use National

Electrical Code, ANSI/NFPA No. 70-Latest Edition in the

absence of local codes.

The wall receptacle must be placed within easy reach of

the power cord without interfering with the gas supply line

Cooktops must be properly grounded. Cooktop power

cords are equipped with a three-prong ground plug. They

fit standard three-prong wall receptacles.

WARNI NG

!

To avoid risk of electrical shock or property damage.

Do not cut or remove the third (ground) prong from the

power cord.

The consumer is responsible for replacing any standard

two-prong wall receptacle with a grounded and polarized

three-prong wall receptacle. A qualified electrician should

check any receptacle the customer doubts is properly

grounded. The wiring diagram is on the bottom of the

cooktop.

WARNI NG

!

Do not over tighten the fitting on the pressure regulator.

Overtightening may crack the regulator.

6 16023565 ©2004 Maytag Services

Safety Information

Product Safety Devices

Safety devices and features have been engineered into the product to protect consumer and servicer. Safety devices

must never be removed, bypassed, or altered in such a manner as to defeat the purpose for which they were intended.

Listed below are various safety devices together with the reason each device is incorporated in the gas ranges.

Pressure Regulator Maintains proper and steady gas pressure for operation of oven controls. Regulator

must be set for the type of gas being used Natural or LP. After servicing regulator,

make certain it is set properly before completing service.

Gas Burner Orifices Universal orifices are used on most valves. They must be adjusted or set for the type

of gas being used Natural

After servicing a valve or orifice verify it is adjusted properly before completing service.

Grounded Cooktop Frame Ground prong on power cord is connected to the frame, usually a green lead fastened

by a screw. In addition, any part or component capable of conducting an electric

current is grounded by its mounting.

If any ground wire, screw, strap, nut, etc. is removed for service, or any reason, it

must be reconnected to its original position with original fastener before the appliance

is put into operation again.

Failure to do so can create a possible shock hazard.

or LP.

©2004 Maytag Services 16023565 7

General Information

This manual provides basic instructions and suggestions

for handling, installing and servicing gas cooktops.

The directions, information, and warnings in this manual

are developed from experience with, and careful testing of

the product. If the unit is installed according to this

manual, it will operate properly and will require minimal

servicing. A unit in proper operating order ensures the

consumer all the benefits provided by clean, modern gas

Model Identification Rating Label and

Ordering Replacement Parts

Model numbers are recorded on the rating label. Rating

label is located on the bottom of the burner box. Before

ordering parts, write down the correct model and serial

number from rating label. This avoids incorrect

shipments and delays. Please refer to parts reference

material when ordering replacement parts.

cooking.

This manual contains information needed by authorized

service technicians to install and service gas cooktops.

There may be, however, some parts which need further

explanation. Refer to the Technical Sheets or toll-free

technical support line to recieve technical assistance

from authorized service technicians.

Cooking Nomenclature

J G C 8 4 3 0 B D W

A Almond on Almond

Brand

A Amana

C Magic Chef

G Graffer &

Sattler

H Hardwick

J Jenn-Air

M Maytag

N Norge

U Universal

Y Cro sley

Fuel

B Butane

D Dual Fuel

E/J Electric

G Gas, Natural

L Liquid Propane

M Microwave

P Standing Pilot

X No Fuel

W Warming Drawer

Product Type

A Accessory/Cartridge

C Cooktop Updraft/Countertop

D Downdraft Cooktop or Warming Drawer

E Eyelevel Range

G Grill

L Range (20")

M Range (36")

P Drop In (24")

Q Wall Oven (27")

R Range, Free-Standing (30")

S Slide-In (30")

T Range Hood

V OTR

W Wall Oven

Y RV Range

Z RV Top

B Black

C Brushed Chrome

H Traditional White

L Traditional Almond

P Prostyle

Q Monochromatic Bisque

S Stainless

T Traditional Bisque

W White on White

F Frost White (True Color White)

N Natural Bisque (True Color Bisque)

A UL/AGA

C CSA/CGA/CUL

D Dual Listed

G 220-240 V / 50-60 Hz

M Military Model

P PSB Approved

X Export 120 V / 60 Hz

Production Code

This identifies the

production version.

Feature Content

1000-3999 Brands

4000-6999 Maytag/Amana

7000-9999 Jenn Air

8 16023565 ©2004 Maytag Services

Color

Listing

(Singapore)

General Information

Specifications

Refer to individual Technical Sheet for specification

information.

Placement of the Cooktop

This cooktop must be placed in the kitchen or

comparable room. All safety guidelines must be followed

and free air flow around the cooktop is essential.

Do Not Block Air Vents

All air vents must be kept clear during cooking. If air

vents are covered during operation, the oven may

overheat. If this occurs, a sensitive, thermal safety

device automatically removes power to the oven,

rendering the oven inoperable. The oven will remain in

this state until it has sufficiently cooled.

Location of Model Number

To request service information or replacement parts, the

service center will require the complete model, serial, and

manufacturing number of your cooktop. The number can

be found in the burner box. Lift the cooktop surface to

view the data.

Model Identification

Complete enclosed registration card and promptly return.

If registration card is missing:

• For Jenn-Air product call 1-800-536-6247 or visit the

Web Site at www.jennair.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.jennair.com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an authorized

servicer:

• For Jenn-Air product call 1-800-688-1100 or visit the

Web Site at www.jennair.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.jennair.com

Warranty service must be performed by an authorized

servicer. We also recommend contacting an authorized

servicer, if service is required after warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. To order accessories for your product call:

• For Jenn-Air product call 1-800-688-1100 or visit the

Web Site at www.jennair.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.jennair.com

Extended Service Plan

We offer long-term service protection for this new oven.

• Dependability Plus

specially designed to supplement Jenn-Air’s strong

warranty. This plan covers parts, labor, and travel

charges.

Call 1-800-925-2020 for information.

SM

Extended Service Plan is

Grounding

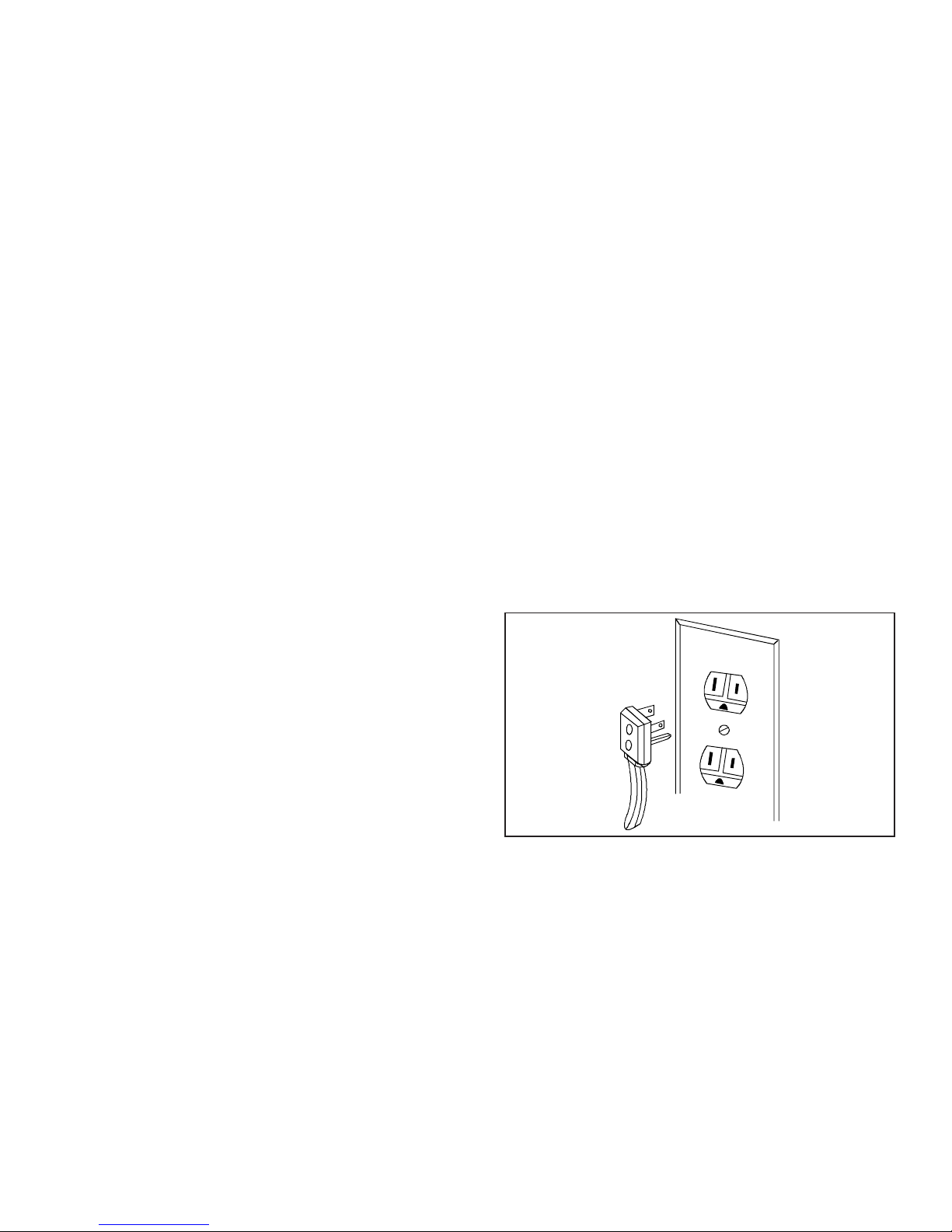

NOTE: This appliance must be properly grounded, for

personal safety.

Power cord on this appliance is equipped with a threeprong grounding plug. This matches standard three-prong

grounding wall receptacle to prevent possibility of electric

shock from this appliance.

Consumer should have wall receptacle and circuit

checked by qualified electrician to verify receptacle is

properly grounded.

Where standard two-prong wall receptacle is

encountered, it is consumers responsibility and

obligation to have it replaced with a properly grounded

three-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

POWER CORD.

©2004 Maytag Services 16023565 9

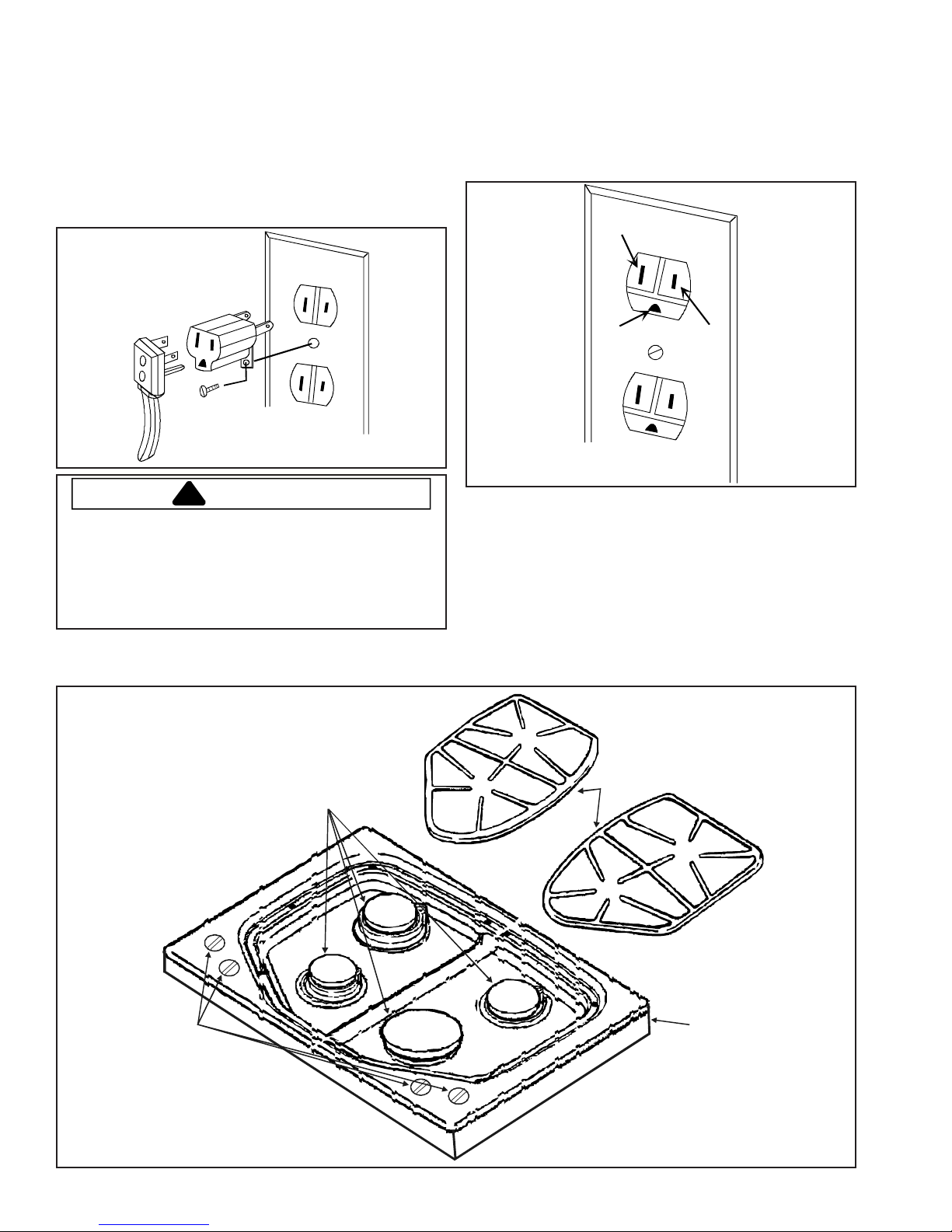

General Information

For 15 amp circuits only. Do not use an adapter on 20

amp. circuit. Where local codes permit, a TEMPORARY

CONNECTION may be made to properly grounded twoprong wall receptacle by the use of a UL listed adapter

available at most hardware stores.

Larger slot on adapter must be aligned with larger slot in

the wall receptacle to provide proper polarity.

WARNI NG

!

Attaching adapter ground terminal to wall receptacle

cover screw does not ground appliance unless the

cover screw is metal and not insulated, and wall

receptacle is grounded through the house wiring.

Consumer should have circuit checked by a qualified

electrician to verify receptacle is properly grounded.

When disconnecting power cord from adapter, always

hold adapter with one hand. If this is not done, adapter

ground terminal is very likely to break with repeated use.

Should this happen, DO NOT USE appliance until a

proper ground has been established.

Neutral Wire

Ground

NOTE: Circuit tester can be use to verify voltage is

present at the outlet, connect one lead to hot

line and the other lead to ground, circuit tester

should light.

Hot Line

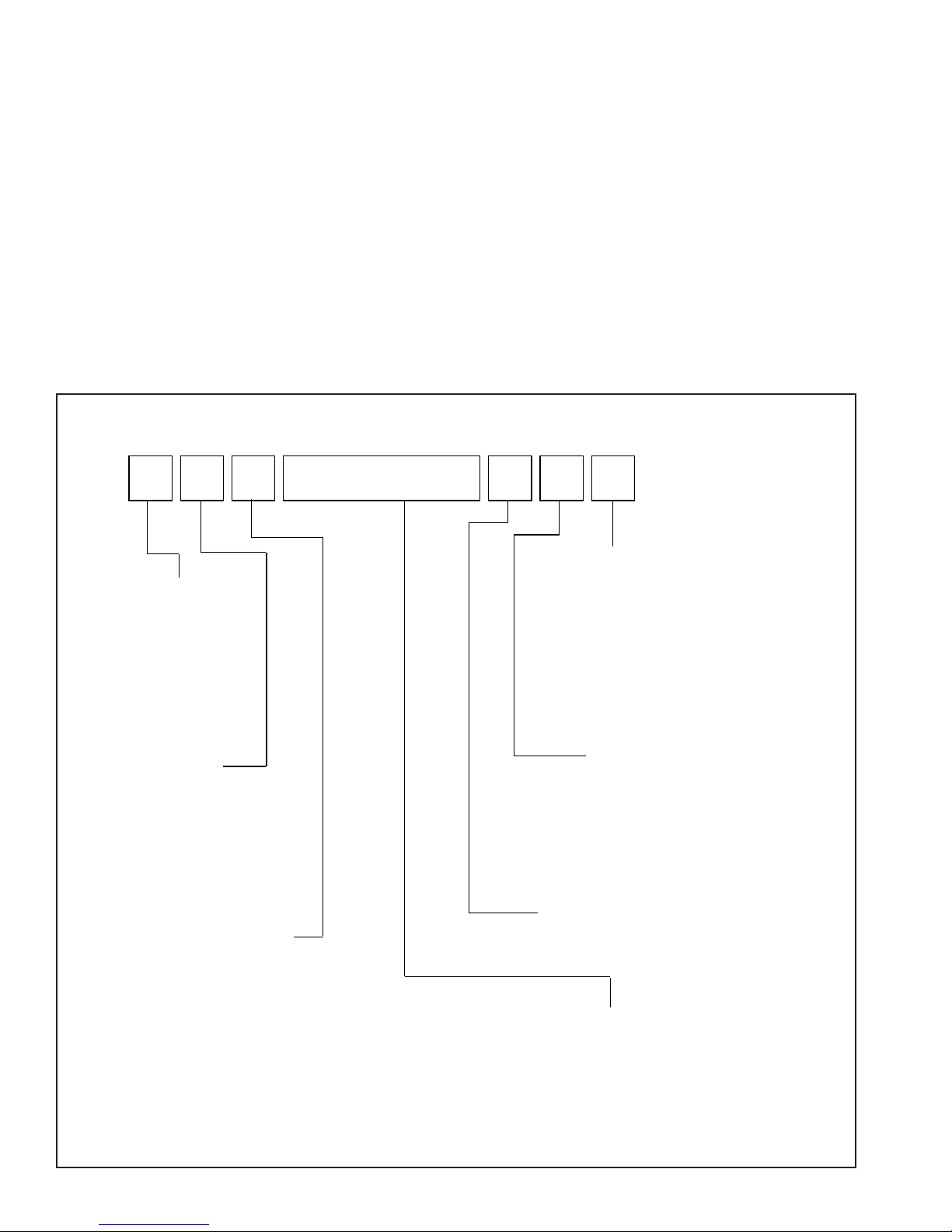

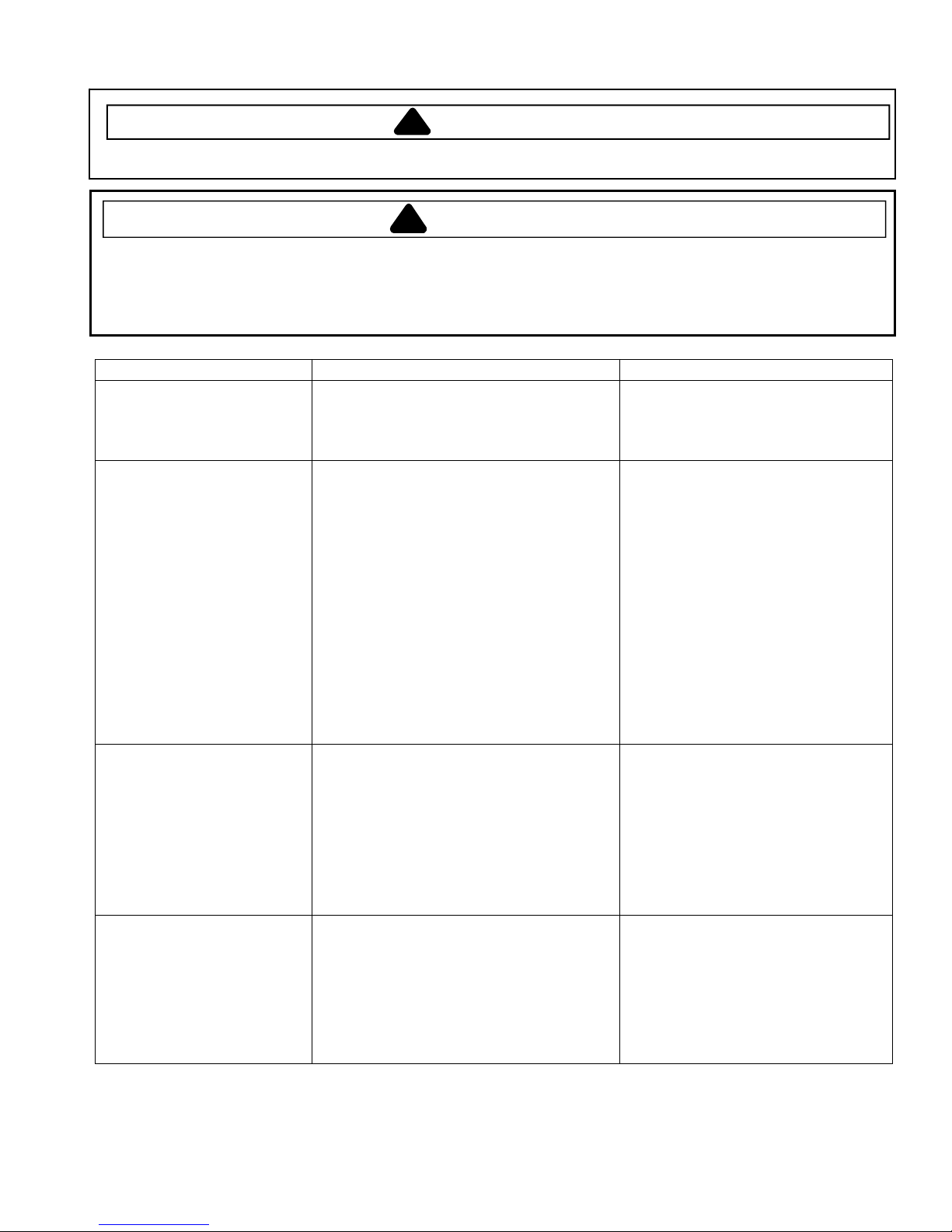

Cooktop Description

Burner

Knobs

Burner Caps

and

Assemblies

Grates

Main

To p

10 16023565 ©2004 Maytag Services

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to cooktop before servicing,

unless testing requires power and/or gas.

!

• Verify proper grounding before checking for trouble.

• Be careful of any high voltage circuit.

• Do not touch any part of the circuit on the printed circuit board, since static electric discharge may damage the

control panel. Always touch ground while working on this panel to discharge the static electricity, which may be

resting on your body.

WARNING

CAUTION

Problem Possible Cause Correction

Burners will not ignite; no

spark at top burner.

Burner will not ignite. No

spark to burner ignitors when

burner knob is rotated to

“LITE” position.

No spark or only random

spark at one ignitor.

Unit continues to spark after

knob is turned to OFF

position.

Poor ground on burner cap .........................

Weak or failed spark module ......................

Low gas pressure ........................................

No 120 VAC to range ..................................

Micro switch contacts not closing ................

Faulty wiring. Bad connection at burner

electrode and electrode socket ...................

Inoperative spark module ............................

Electrode dirty. Burner cap dirty ..................

Cracked or broken electrode, electrode

wire or electrode socket ..............................

Check for cracked ignitor or pinched

ignitor wire ..................................................

Poor continuity to burner cap.......................

Bad ground connection or lack of

continuity to ground or ignitor ......................

Cracked or broken ignitor extension lead....

Shorted valve switch/harness......................

Switch has slipped off the valve ..................

• Clean burner cap.

• Replace spark module.

• Verify pressure 5” WCP for

natural, 10” WCP for LP.

• Verify voltage at wall outlet.

• Check wiring against appropriate

wiring diagram. Verify all terminals

and connections are correct and

tight. Check micro switch

contacts.

• Check wiring against appropriate

wiring diagram. Verify all terminals

and connections are correct and

tight.

• Check module according to testing

procedures information.

• Clean electrode or burner cap.

• Replace electrode.

• Replace ignitor lead or electrode.

• Clean burner cap and lead.

• Tighten ground connection and

correct any breaks in ground path

from ignitor path to unit ground

path.

• Replace ignitor lead.

• Replace switch/harness. If

sparking is caused by excessive

spillovers, customer education is

advised.

• Carefully reposition switch on valve

and rotate from OFF to high,

several times to verify switch is not

broken.

©2004 Maytag Services 16023565 11

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to cooktop before servicing,

unless testing requires power and/or gas.

Problem Possible Cause Correction

Gas pressure too high ..............................

No gas flows to burner.

Fan motor does not operate.

Failed gas valve........................................

Loose wire connection or broken wire ......

No power to fan motor ..............................

Failed fan motor or winding/frozen shaft ..

WARNING

• Check for correct gas pressure.

Natural gas pressure should be 5"

WCP and LP gas pressure should

be 10" WCP.

• Check gas valve for continuity.

• Verify all connections are clean and

tight, replace broken wire.

• Check for 120 VAC supplied at fan

motor. If no voltage is present, check

for broken or loose wiring between

fan motor and relay board. If voltage

is present at fan motor, go to the

next step.

• Check motor winding for continuity.

Check for a frozen motor shaft.

Check for broken wiring between

motor and neutral terminal block.

12 16023565 ©2004 Maytag Services

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to cooktop before servicing,

unless testing requires power.

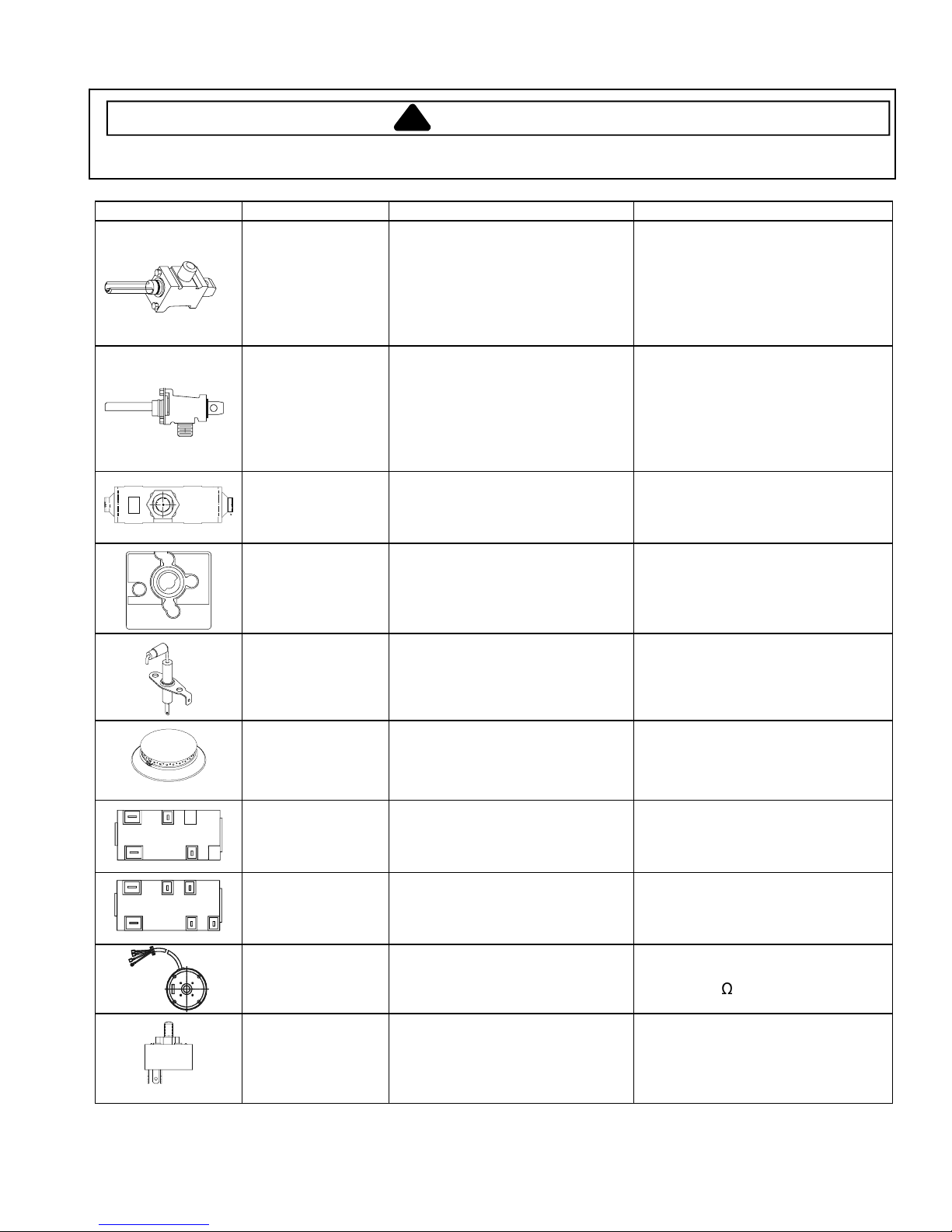

Illustration Component Test Procedure Results

Burner valve,

top, 360°

JGD8348CDP

Burner valve,

left and right, 360°

JGD8348CDP

Snap switch

JGD8348CDP

Dreefs spark

switch

JGD8348CDP

Burner ignition

electrode

JGD8348CDP

Verify gas is supplied.

Orifice adjusted for

Natural or LP.

Adjust set screw for simmer

control............................................

Verify gas is supplied.

Orifice adjusted for

Natural or LP.

Adjust set screw for simmer

control............................................

Test for voltage at terminals ..........

Disconnect wiring and check for

continuity in LITE position..............

Test for voltage at terminals ..........

Disconnect wiring and check for

continuity in LITE position..............

Test for resistance of spark lead ...

Test ignitor to chassis....................

To replace burner valve(s),

complete assembly must be

replaced (manifold and valves).

1650 BTU per hour minimum.

See conversion section.

To replace burner valve(s),

complete assembly must be

replaced (manifold and valves).

See conversion section.

120 VAC

Continuity in LITE position.

120 VAC

Continuity in LITE position.

Continuity

No continuity from ignitor to

chassis.

Sealed surface

burner

JGD8348CDP,

JGC8430BD*,

L

AB

JGC8645BDS

Spark module

2 + 0

B1N

A1

L

AB

JGD8348CDP

Spark module

4 + 0

B1N

A1

JGD8348CDP

Blower motor

assembly

JGD8348CDP

Rotary switch

JGD8348CDP

Verify gas is supplied..................... Check for obstructions in burner

ports.

Test for voltage at terminals

L and N ..........................................

Check polarity and ground.............

Test for voltage at terminals

L and N ..........................................

Check polarity and ground.............

Verify resistance between white

and black wires..............................

Test for voltage at terminals ..........

Disconnect wiring, reference

wiring diagram and check for

continuity in Lo and Hi positions ....

120 VAC

See wiring diagram

120 VAC

See wiring diagram

115 VAC, 60 Hz, 2.4 amps

1550 RPM, 1/10 HP, CWLE

Ω

Approx. 48

120 VAC

Continuity in Lo and Hi positions.

©2004 Maytag Services 16023565 13

Loading...

Loading...